Burkert 6517 User Manual [en, de, fr]

Operating Instructions

Voltage 12V or 24V

UL / UR valid with

class 2 power supply only

Bedienungsanleitung

Instructions de Service

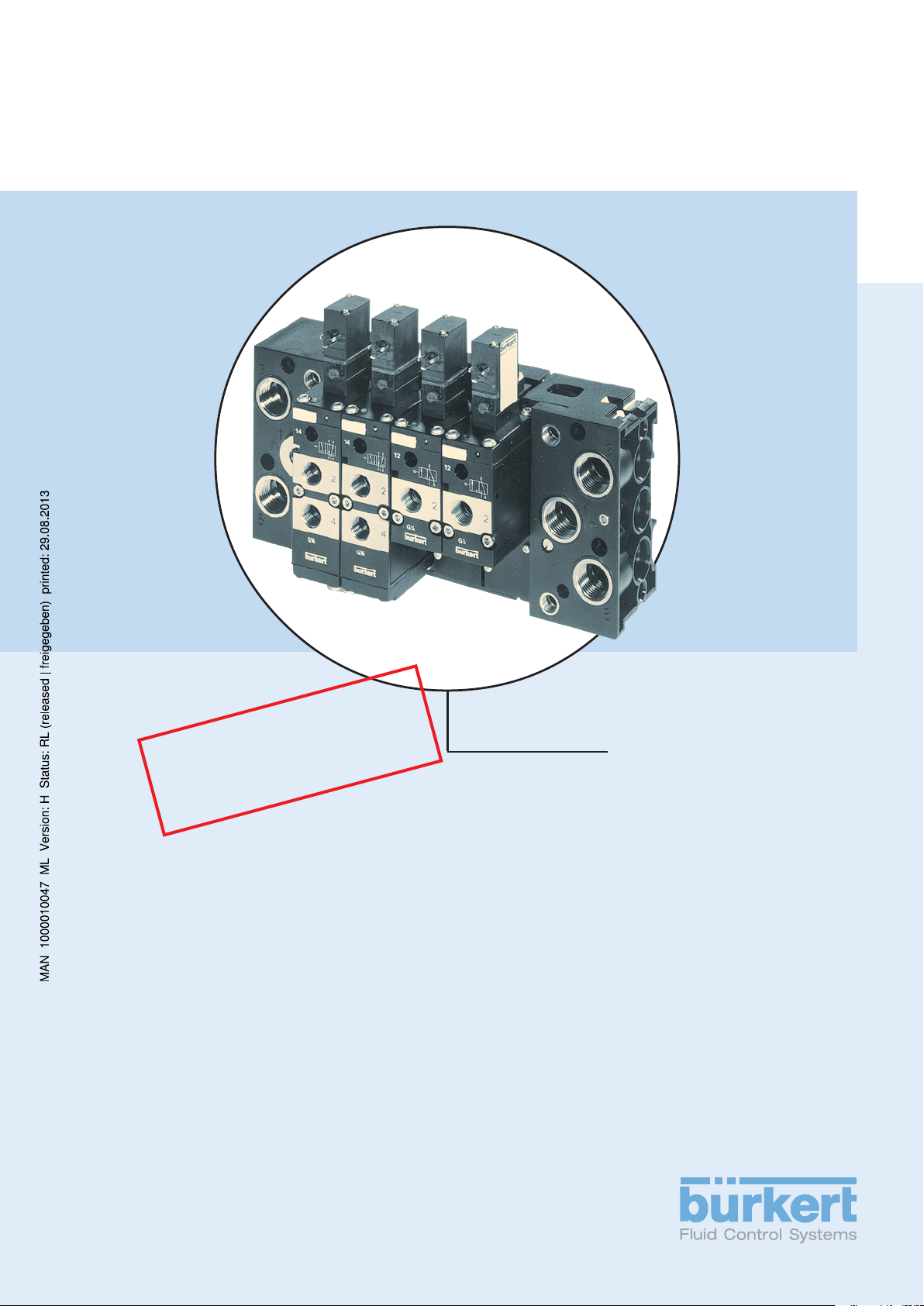

Block Assemblies and Modular Pneumatic

pneumatische Grundschiene Typ MP07

Blocs multiples et Profil pneumatique

Type 6516 / 6517

Basic Rail Type MP07

Mehrfachblöcke und modulare,

modulaire Type MP07

We reserve the right to make technical changes without notice.

Technische Änderungen vorbehalten.

Sous resérve de modification techniques.

© 2000 Bürkert Werke GmbH & Co. KG

Operating Instructions 0512/11_EU-ML_00803141

Contents of the

Voltage 12V or 24V

UL / UR valid with

class 2 power supply only

Operating Instructions for the

Block Assemblies

Type 6516/6517

and Modular Pneumatic

Basic Rail Type

Typ MP07

GENERAL NOTES.................................................................................................................................................................................................................................. 3

Symbols ..................................................................................................................................................................................................................................................... 4

Safety notes

Warranty conditions

.......................................................................................................................................................................................................................................... 4

.................................................................................................................................................................................................................... 5

TECHNICAL DESCRIPTION ................................................................................................................................................................................................ 7

Valve Construction....................................................................................................................................................................................................................... 8

Valve operations of the Type 6516 / 6517

Media

Electrical connections

Example of a block assembly

............................................................................................................................................................................................................................................................ 9

.............................................................................................................................................................................................................. 9

.................................................................................................................................................................................... 10

...................................................................................................................................................... 8

INSTALLATION, INITIALISATION AND SERVICE........................................................................................................................... 11

General notes................................................................................................................................................................................................................................. 12

Setting up block assemblies using the modular pneumatic rail

type MP07

Dismantling the module

Other possible uses of the connecting module, - right-hand -

Mounting the valve block

........................................................................................................................................................................................................................................... 12

..................................................................................................................................................................................................... 13

......................................................................................... 13

.................................................................................................................................................................................................. 13

Mounting single valves

Measures to be taken before putting into service

Faults

......................................................................................................................................................................................................................................................... 16

....................................................................................................................................................................................................... 15

............................................................................................................................ 16

6516 / 6517 - 1

C

ONTENTS

english

2 - 6516 / 6517

Symbols ..................................................................................................................................................................................................................................................... 4

Safety notes

.......................................................................................................................................................................................................................................... 4

Warranty conditions

.................................................................................................................................................................................................................... 5

6516 / 6517 - 3

G

ENERAL NOTES

In these Operating Instructions, the following symbols are used:

indicates a working step that you will have to carry out

english

ATTENTION!

NOTE

To ensure that the device will function correctly, and have a long service life, please comply with the

information in these Operating Instructions, as well as with the application conditions and additional

data given in the Type 6516 and 6517 data sheets:

• When planning the application of the device, and during its operation, observe the general technical

rules!

• Note that lines and valves must not be unscrewed from systems that are under pressure!

• Observe the relevant accident prevention and safety regulations applicable for electrical equipment

throughout the operation, maintenance and repair of the device!

indicates information which must be followed. Failure to do this could endanger your

health or the functionality of the device.

indicates important additional information, tips and recommendations.

• Always switch off the voltage supply before working on the system!

• Take suitable measures to prevent unintentional operation or impermissible impairment!

• If these instructions are ignored, no liability will be accepted from our side, and the guarantee on the

device and on accessories will become invalid!

NOTE

If there are discrepancies, please contact immediately your Bürkert subsidiary or our customer service.

Approvals such as Ex, UL, UR, CSA, DVGW etc., will be indicated on the rating plate,

or by a special label.

Bürkert Steuer- und Regelungstechnik, Service-Abteilung

Chr.-Bürkert-Str. 13-17, D-76453 Ingelfingen

Tel.: (07940) 10-111

Fax: (07940) 10-448

eMail: info@de.buerkert.com

4 - 6516 / 6517

Warranty conditions

This document contains no warranty statements. In this connection we refer to our general sales and

business conditions. A prerequisite for validity of the warranty ist unse of the device as intended with

observance of the specified conditions of use.

G

ENERAL NOTES

ATTENTION!

The warranty covers only faultless condition of the Block Assemblies Type 6516,

6517 and Modular Pneumatic Basic Rails Type MP07. No liability will be accepted

for consequent damage of any kind that max arise form failure or malfunctioning of

the device.

english

6516 / 6517 - 5

G

ENERAL NOTES

english

6 - 6516 / 6517

T

ECHNICAL DESCRIPTION

TECHNICAL

DESCRIPTION

Valve Construction....................................................................................................................................................................................................................... 8

Valve operations of the Type 6516 / 6517

Media

Electrical connections

Example of a block assembly

............................................................................................................................................................................................................................................................ 9

.............................................................................................................................................................................................................. 9

.................................................................................................................................................................................... 10

.................................................................................................................................................. 8

english

6516 / 6517 - 7

T

ECHNICAL DESCRIPTION

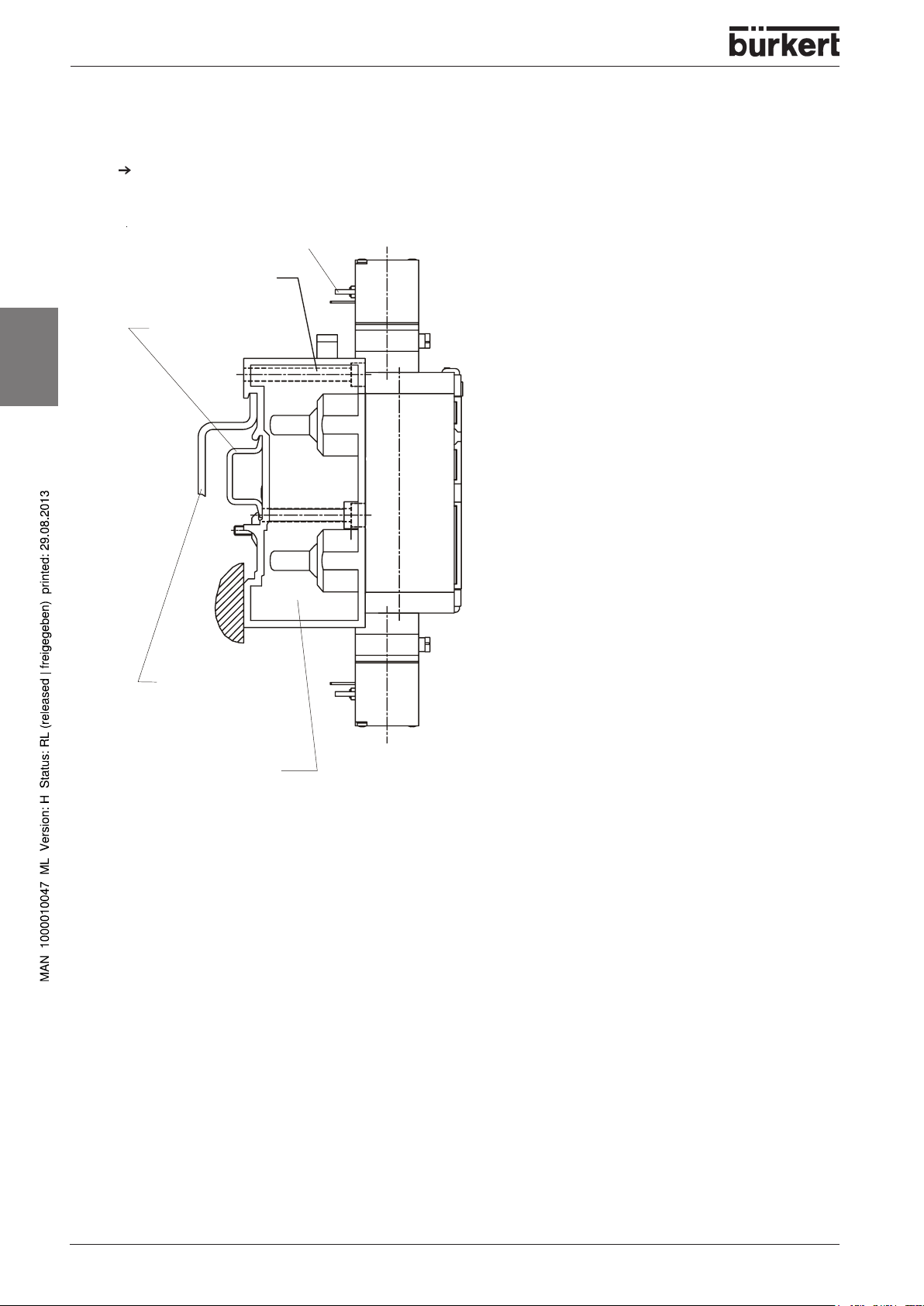

Valve Construction

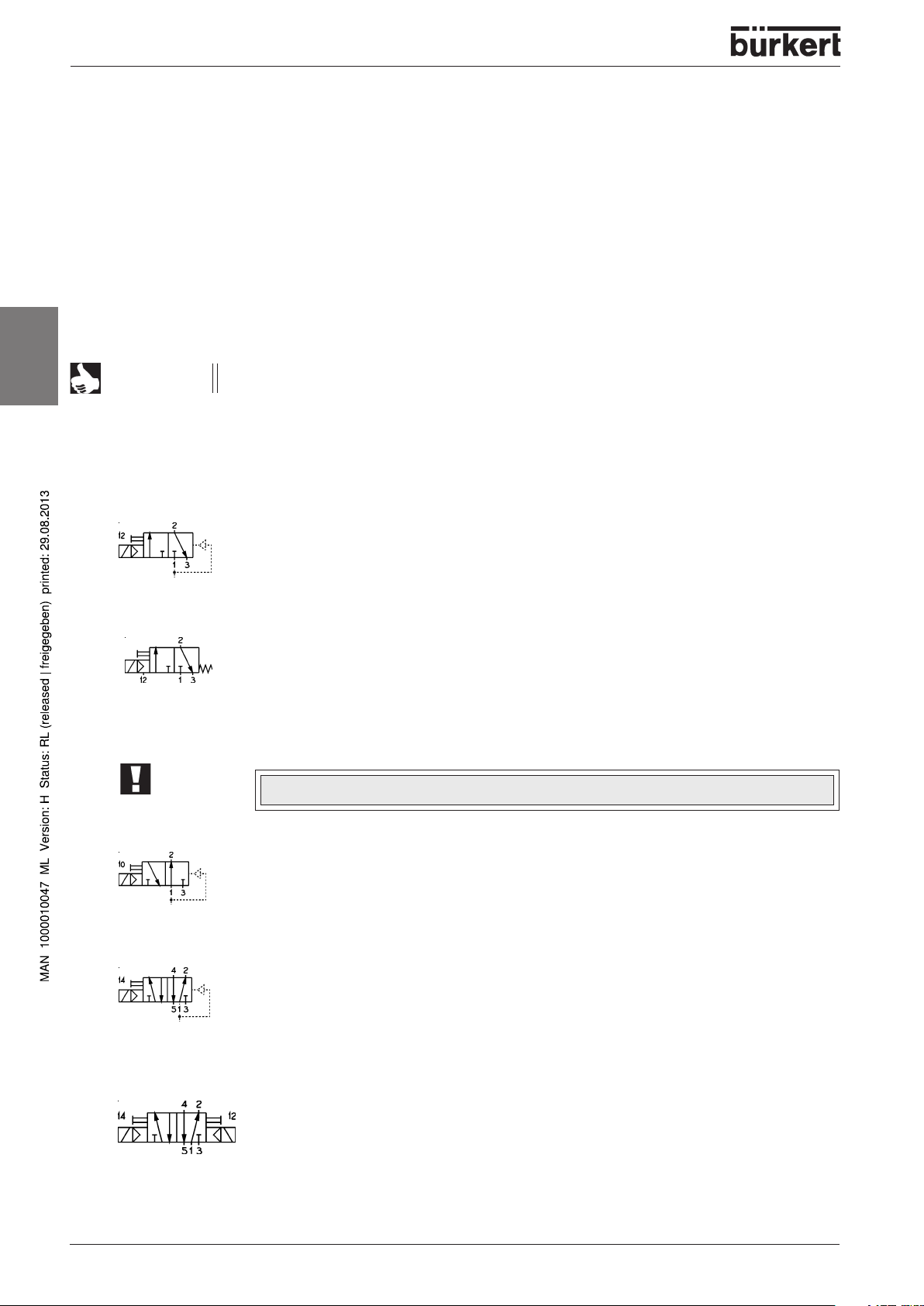

• 3/2 way pilot valve with various electrical connection possibilities

• valve body with diaphragm and seat seals (3/2 and 5/2), or with gate valve (5/3)

• 2(B) / 4 (A) service ports plus supply and venting ports 1 (P) / 3 (R) / 5 (S) with

internal G 1/4 thread

• as option, plug-in connectors for external 8 mm hose diameters for the service ports

• the valves can be mounted on the modular pneumatic basic rail Type MP07

• can be mounted in any position, preferably with the magnetic system at the top

NOTE

english

Plug-in connections only for the service ports 2 (B) and 4 (A).

The valves require no maintenance.

Valve operations of the Type 6516 / 6517

3/2 way valve:

In de-energised position, Pressure Inlet 1 closed, Outlet Port 2 exhausted

3/2 way valve for vacuum, with auxiliary pilot air:

In de-energised position, Pressure Inlet 1 closed, Outlet Port 2 exhausted

ATTENTION!

The vacuum generator must be connected to port 1!

3/2 way valve:

In de-energised position, Pressure Inlet 1 connected to Outlet Port 2

5/2 way valve:

In de-energised position, Pressure Inlet 1 connected to Outlet Port 2, Outlet Port 4 exhausted.

5/2 way valve:

Impulse drive model

8 - 6516 / 6517

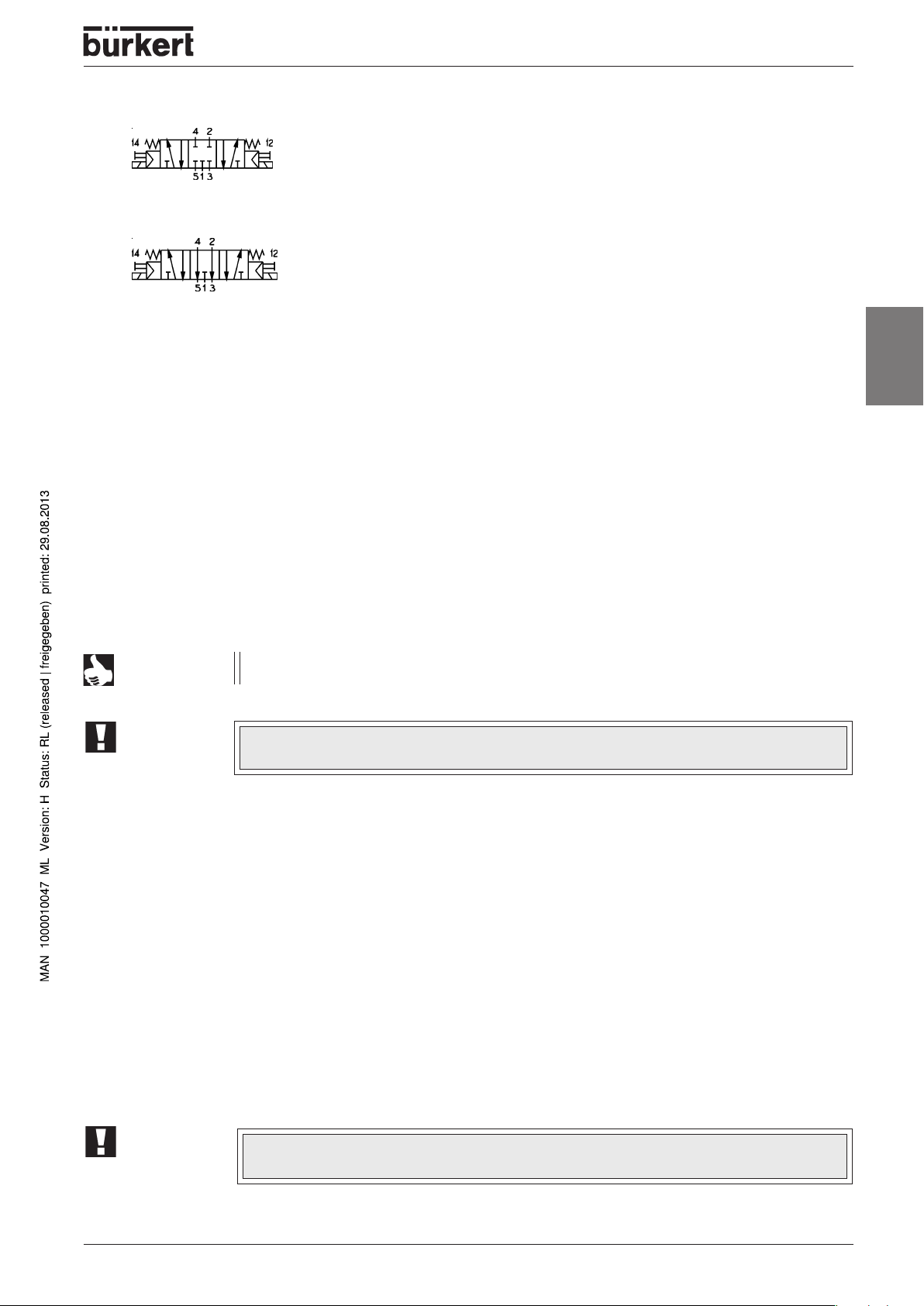

5/3 way valve:

in middle position, all outlet ports closed

5/3 way valve:

in middle position, Outlet Ports 2 and 4 vented, Pressure Inlet 1 closed

T

ECHNICAL DESCRIPTION

Media

• filtered compressed air (max. particle size 10 µm), preferably non-oiled

• operation is possible with oiled air

• seal materials: BP = NBR and polyurethane for 3/2 and 5/2 valves

• permissible medium temperature: max. +50° C

• permissible ambient temperature: max. +55° C

• operational pressure range: 2 - 8 bar

NOTE

ATTENTION!

BB = NBR and POM for 5/2 pulse and 5/3 valves

The pilot pressure of the pneumatic controller is dependent on the pressure of the flow

of medium: it must not exceed a maximum of 8 bar!

Observe the permissible pressure range given on the rating plate!

Pressure difference between Ports 1 and 3/5

≥ ≥

≥ 2 bar

≥ ≥

english

Electrical connections

• read the voltage, electrical power, type of protection and current from the rating plate!

• voltage tolerance ±10%

• electrical connection: Instrument socket type 2506 to the tag connection on the coil (tightening

torque: 1 Nm)

• protection level IP 65 (only in combination with appliance socket type 2506)

• to match the cable run, the instrument socket can be mounted rotated by 180°

• refer to types 6106 or 8640 for other connection possibilities

ATTENTION!

When screwing down the instrument socket onto the coil,

ensure that the flat seal is well seated!

6516 / 6517 - 9

T

ECHNICAL DESCRIPTION

english

r

o

t

a

c

i

t

h

g

i

r

,

e

l

u

d

o

m

on

i

-

e

l

b

u

o

d

e

l

u

d

o

m

e

s

a

B

-

t

h

g

i

r

,

e

l

u

d

o

m

n

o

i

t

c

e

n

e

l

p

i

r

t

e

l

u

d

o

m

e

s

a

B

h

c

t

a

c

g

n

i

k

c

o

L

-

t

f

e

l

,

e

l

u

d

o

m

n

o

i

t

c

e

n

n

o

C

n

o

C

k

o

o

h

g

n

i

k

c

o

L

l

e

n

n

a

h

c

y

l

p

p

u

S

t

c

e

n

n

o

C

g

n

i

R

O

t

e

k

s

a

g

e

l

i

f

o

r

P

d

n

i

e

r

u

s

s

e

r

P

t

n

e

v

e

v

l

a

v

t

o

l

i

P

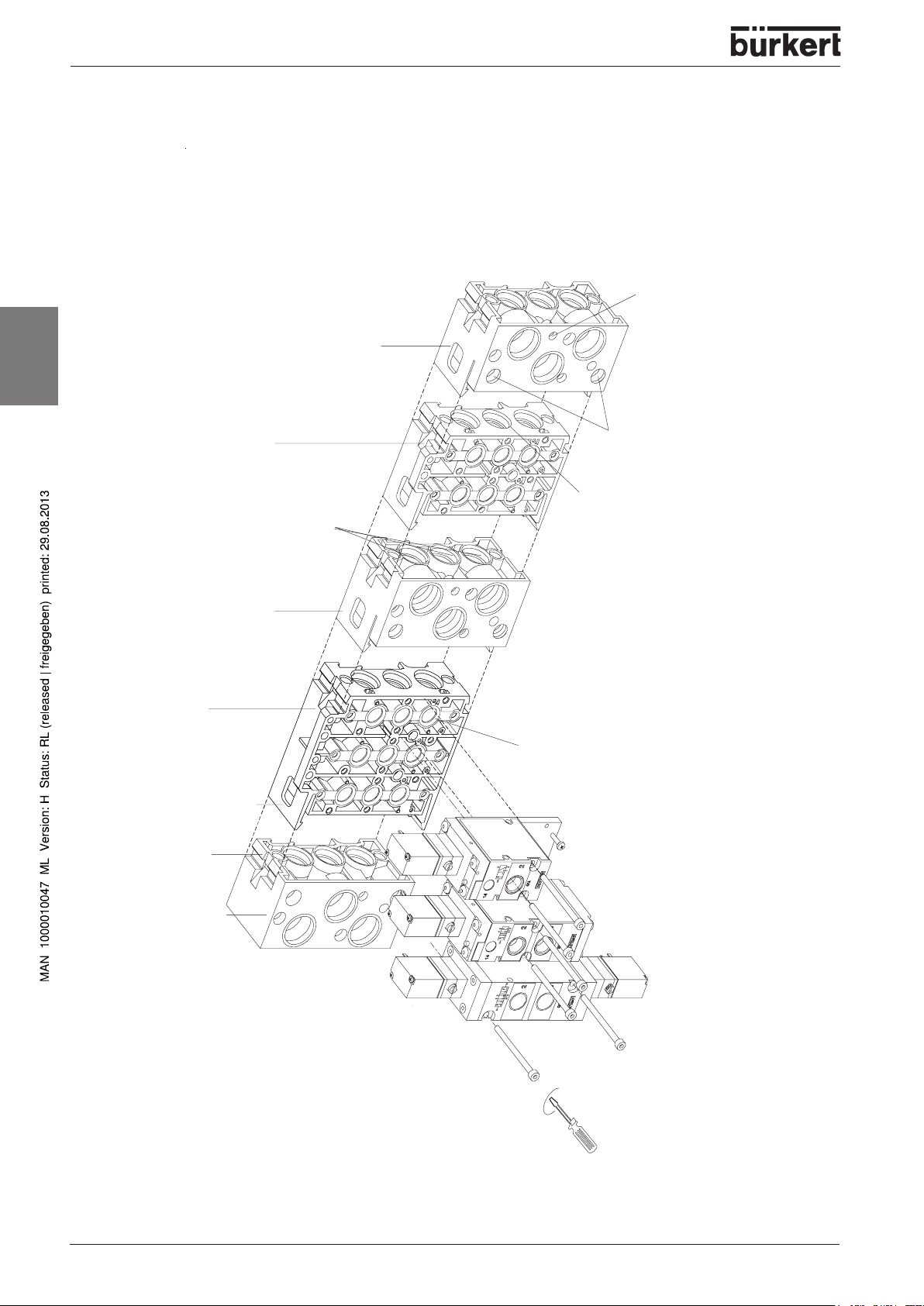

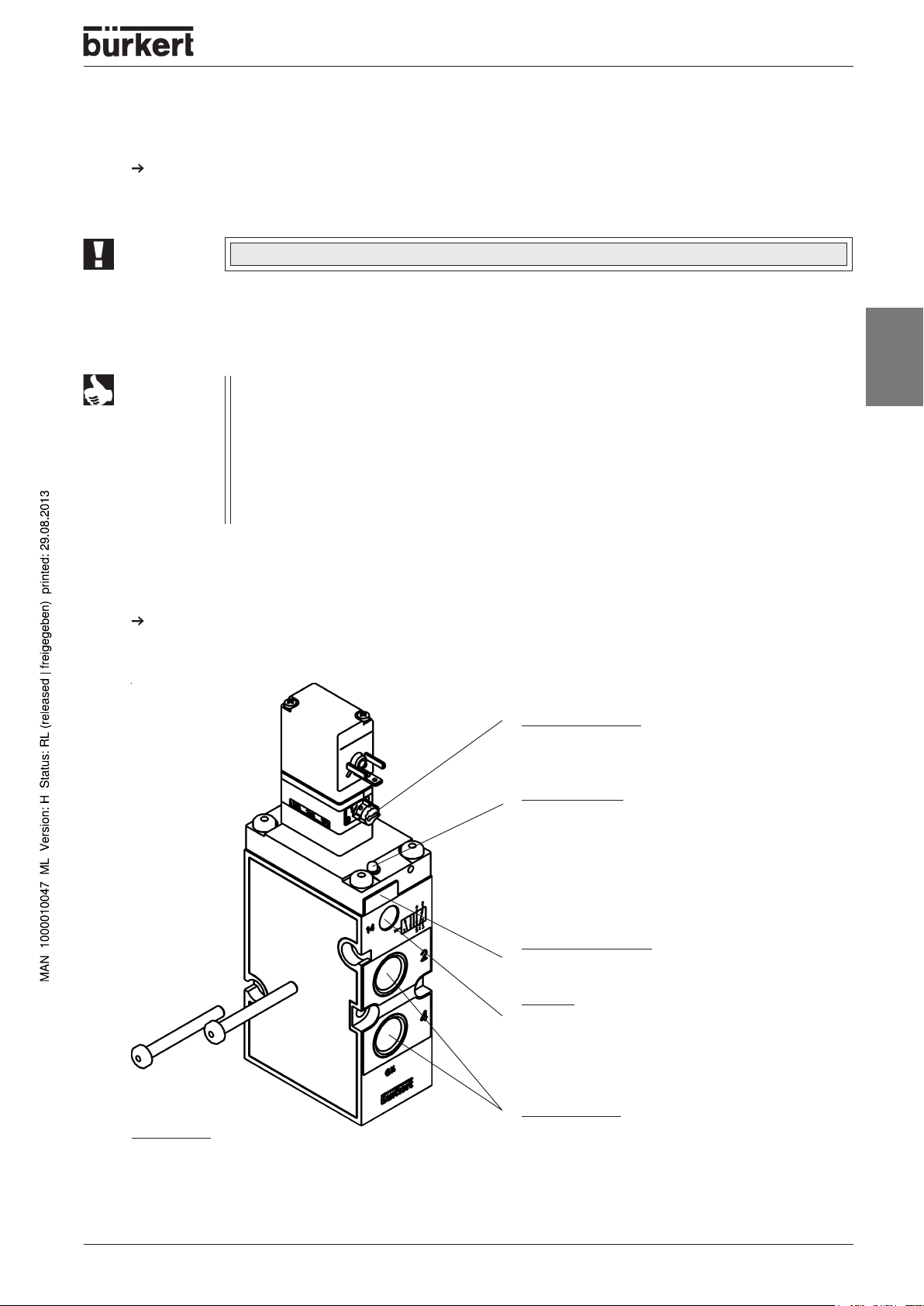

Example of a block assembly

10 - 6516 / 6517

m

x

N

a

5

m

,

1

I

NSTALLATION

, I

NITIALISATION AND SERVICE

INSTALLATION,

INITIALISATION

AND SERVICE

General notes................................................................................................................................................................................................................................. 12

Setting up block assemblies using the modular pneumatic rail

type MP07

Dismantling the module

Other possible uses of the connecting module, - right hand -

Mounting the valve block

Mounting single valves

Measures to be taken before putting into service

........................................................................................................................................................................................................................................... 12

..................................................................................................................................................................................................... 13

......................................................................................... 13

.................................................................................................................................................................................................. 13

....................................................................................................................................................................................................... 15

............................................................................................................................ 16

english

Faults

......................................................................................................................................................................................................................................................... 16

6516 / 6517 - 11

I

NSTALLATION

, I

NITIALISATION AND SERVICE

General notes

Work on the valve should only be carried out by specialist staff and with the correct tools!

Before working on the system, always turn off the supply voltage!

Clean the piping system before installing the valve!

Where necessary, connect a strainer upstream to protect against faults.

When tightening the connections, never use the coil as a lever!

Ensure that the operational conditions agree with the performance data of the unit!

Ensure that the operational conditions agree with the performance data of the unit!

english

ATTENTION!

Pressure indicator with indicating pin on the connecting module - right -

- Indicating pin can be pressed in: pressure in valve block < 1 bar

- Indicating pin cannot be pressed in: there is pressure in the valve block

- Indicating pin springs back: there is pressure in the valve block

Lines or valves must never be loosened while the system is under pressure!

Observe the pressure indicator on the right-hand connecting module!

(vent the system before dismantling

lines or devices)

Setting up block assemblies using the modular pneumatic rail

type MP07

With combination of two-way and three-way base modules, you can assemble valve blocks of any size.

NOTE

Check that each module is completely pre-fitted with O-rings!

Before locking together, lightly grease or oil the fitted O-rings.

Insert the hooks of the module being added into the slot on the previous module, ensuring that the O-

rings are correctly seated!

Press the modules together until both hooks latch.

Ensure that the profile gaskets are correctly seated on the base module!

ATTENTION!

12 - 6516 / 6517

It is advisable to start the assembly with the left-most connector module. (Fig. 1).

Squashed O-rings and profile gaskets sause leackages in the block!

I

NSTALLATION

Secure the valves to the base module using 2 M4 screws each.

(Tightening torque max. 1.5 Nm).

Mount the complete valve block onto the wall or the standard rail.

Connect the supply and working lines.

Make the electrical connections to the pilot valves: in doing this, observe the values given on the rating

plate!

, I

NITIALISATION AND SERVICE

Dismantling the module

Unlatch both locking hooks by using a screwdriver on the end dismantling-grooves.

Remove the block part / module sideways.

Other possible uses of the connecting module, - right-hand -

• As a separation module for special applications when building up several pressure levels in a single

block

english

• Additional supply lines for larger valve blocks.

Mounting the valve block

Standard rails

• Standard rail 35 x 15 DIN 50022 (Standard)

• Standard rail 75 x 25 DIN 50023

NOTE

Installation

Hang the valve block onto the upper groove of the standard rail.

Latch the lower clamp into the standard rail.

Firmly tighten the screws on the clamp.

When using the 75 x 25 DIN 50023 standard rail, change over the pre-assembled

screws with clamps and springs as necessary.

Dismounting

Loosen the clamping screws (by about 4 revolutions).

Remove the block upwards from the standard rail.

6516 / 6517 - 13

I

NSTALLATION

english

, I

NITIALISATION AND SERVICE

Wall mounting

Fix the module system directly to the wall using M5 screws.

Electrical connection

can be rotated by 180°

Wall mounting

Standard rail 35 x 15

DIN 50022

Standard rail 75 x 25

DIN 50023

Connecting module

Figure: Mounting the valve block

14 - 6516 / 6517

Mounting single valves

I

NSTALLATION

, I

NITIALISATION AND SERVICE

Fix the single valve directly to the wall using M4 screws.(Figure:

Mounting single valves, Manual override, Pneumatic position indicator

ATTENTION!

When mounting, do not distort the valve body!

Installation, Initialisation and Service -

Plug-in connections

NOTE

For plug-in connections, the hose lines must meet the following requirements:

• Minimum rigidity of 40 Shore D (to DIN 53505 or ISO 868);

• External diameter corresponding to DIN 73378 (max. permissible deviation ± 0.1 mm

from nominal dimension);

• Without burr, cut at right-angles and with undamaged circumference;

• The hose lines must be pushed into the plug-in connectors up to the stop.

Dismantling the plug-in connections

)

english

To release the line, press in the pressure ring and pull out the hose line.

Manual override

to operate the valve manually, turn the manual

override by 90° in the direction of the arrow

Indicating pin for indicating the pneumatic

position

With the valve not switched, the red indicating

pin can be pressed in. If the valve has been

switched, the indicating pin moves outwards,

and remains in this position. The indicating pin

must be pushed in again for every functional

test.

Designation plate (can be removed for

marking / engraving)

Port 14

• not used in the standard model

• used as an auxiliary pilot air connection

and as the connection for pneumatic

controls

Service ports

M4 screws

for wall mounting

the single valve

Figure: Mounting single valve, Manual override, Pneumatic position indicator

2 (B) and 4 (A)

6516 / 6517 - 15

Loading...

Loading...