SERVICE MANUAL

MODEL: PT-MT (P-touch mini' tech)

PREFACE

This publication is a service manual covering the specifications, outline of operating

principles, disassembly/reassembly procedure, and troubleshooting of t he Brother PTMT. It is intended for service personnel and other concerned persons to accurately and

quickly provide after-sale service f or our PT-MT.

To perform appropriat e maintenance so that the machine is always in best condition

for the customer, the service personnel must adequately understand and apply this

manual.

This manual is made up of four chapt ers and appendix.

CHAPTER I SPECIFICATIONS

CHAPTER II THEORY OF OPERATION

CHAPTER III DISASSEMBLY/REASSEMBLY

CHAPTER IV TROUBLESHOOTING

APPENDIX MAIN PCB CIRCUIT DIAGRAM

© Copyright Brother 2002

All rights reserved.

No part of this publication may be reproduced in any

form or by any means without permission in writing

from the publisher.

Specifications are subject to change without notice.

CONTENTS

CHAPTER I SPECIFICATIONS

1.1 Mechanical Specifications................................................................................................I - 1

1.1.1 External Appearance.................................................................................................I - 1

1.1.2 Entry system..............................................................................................................I - 1

1.1.3 Display.......................................................................................................................I - 1

1.1.4 Printing Mechanism ...................................................................................................I - 2

1.1.5 Tape Cassette...........................................................................................................I - 2

1.1.6 Tape Cutter................................................................................................................I - 2

1.2 Electronics Specifications................................................................................................I - 4

1.2.1 Character Generator..................................................................................................I - 4

1.2.2 Power Supply.............................................................................................................I - 4

CHAPTER II THEORY OF OPERATION

2.1 Outline of Mechanisms.................................................................................................. II - 1

2.1.1 Print Mechanism...................................................................................................... II - 1

2.1.2 Platen Setting & Retracting Mechanism................................................................... II - 2

2.1.3 Tape Feed Mechanism............................................................................................ II - 3

2.1.4 Tape Cutter Mechanism........................................................................................... II - 4

2.1.5 Cutter Safety Lock Mechanism................................................................................ II - 5

2.2 Outline of Control Electronics ........................................................................................ II - 6

2.2.1 Configuration ........................................................................................................... II - 6

2.2.2 Main PCB................................................................................................................. II - 7

CHAPTER III DISASSEMBLY & REASSEMBLY

3.1 Disassembly Procedure................................................................................................ III - 2

[ 1 ] Removing the Cassette Cover, Dry Cells, Tape Cassette, and Cutter Unit .............. III - 2

[ 2 ] Removing the Chassis ASSY ................................................................................... III - 3

[ 3 ] Removing the Main PCB.......................................................................................... III - 6

[ 4 ] Removing Battery Terminals P1 and P2................................................................... III - 8

[ 5 ] Removing the Rubber 4 Key, Lens, Dial Sheet, Select Dial, Select Dial Claw,

and Enter Key.......................................................................................................... III - 9

3.2 Reassembly Procedure...............................................................................................III - 10

[ 1 ] Installing the Ent e r Key, Select Dial Claw, Select Dial, Dial Sheet, Lens, and

Rubber 4 Key......................................................................................................... III - 10

[ 2 ] Installing Battery Terminals P2 and P1................................................................... III - 12

[ 3 ] Installing the Main PCB.......................................................................................... III - 13

[ 4 ] Installing the Chassis ASSY................................................................................... III - 14

[ 5 ] Setting the Cutter Unit, Tape Cassette, Dry Cells, and Cassette Cover................. III - 17

[ 6 ] Final Operation Check............................................................................................III - 18

[ 7 ] Inspection Mode..................................................................................................... III - 19

CHAPTER IV TROUBLESHOOTING

4.1 Troubleshooting............................................................................................................IV - 1

4.1.1 Precautions.............................................................................................................IV - 1

4.1.2 After Repairing........................................................................................................IV - 1

4.1.3 Troubleshooting Flows............................................................................................IV - 2

[ 1 ] Tape feeding failure................................................................................................IV - 2

[ 2 ] Printing failure.........................................................................................................IV - 3

[ 3 ] Powering failure (Nothing appears on the LCD.) .....................................................IV - 4

[ 4 ] Abnormal LCD indication........................................................................................IV - 5

[ 5 ] No key entry possible..............................................................................................IV - 5

APPENDIX MAIN PCB CIRCUIT DIAGRAM

CHAPTER I SPECIFICATIONS

1.1 Mechanical Specifications

1.1.1 External Appearance

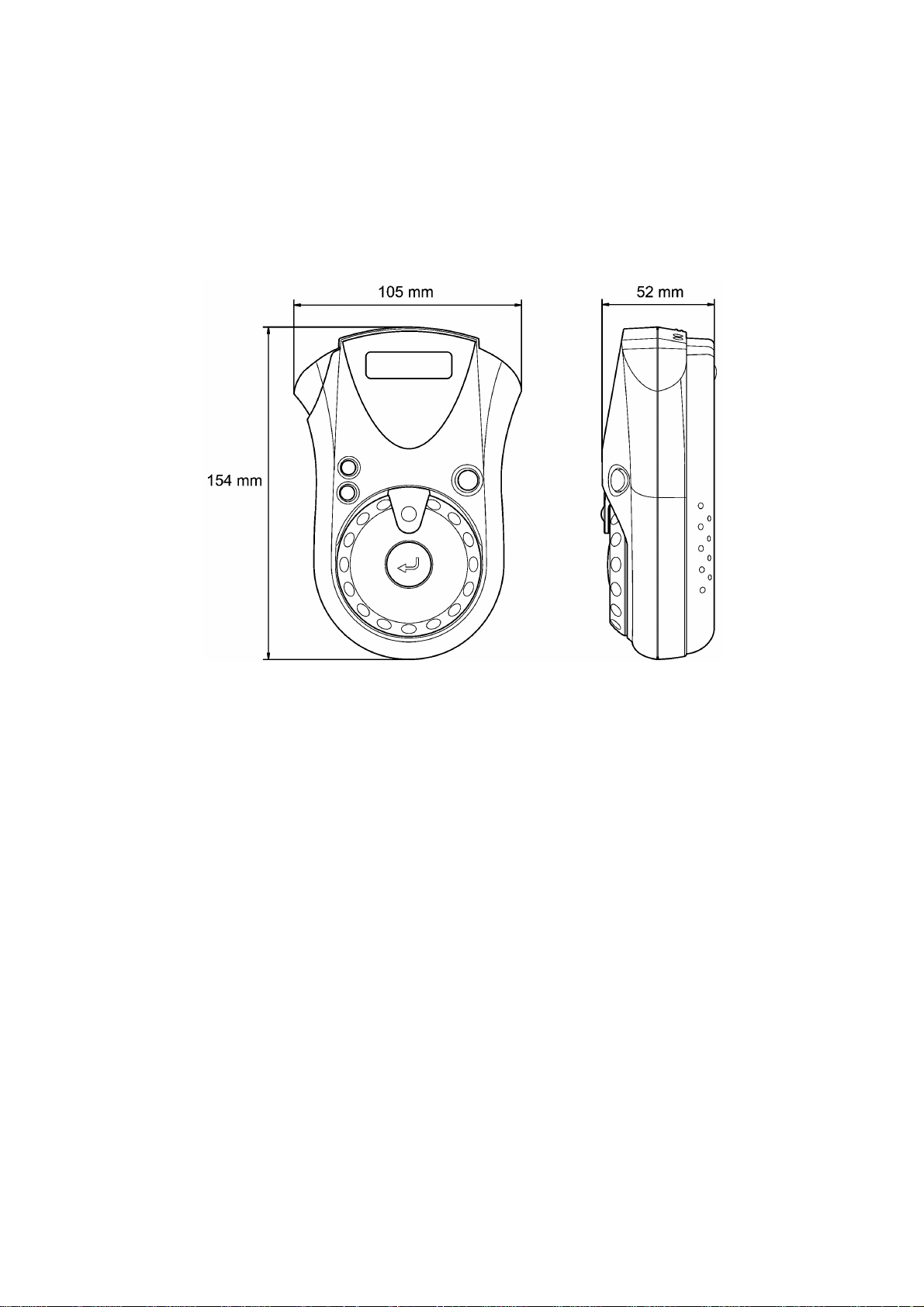

(1) Dimensions (W x D x H) 105 mm x 154 mm x 52 mm

(2) Weight

Machine proper Approx. 250 g

In package Approx. 500 g (incl. a tape cassette, excl. dry cells)

1.1.2 Entry system

(1) Rubber keypad 4 keys

(2) Dial 32 positions

1.1.3 Display

(1) Display type Liquid crystal display (LCD)

(2) Number of columns 8 columns x 1 row

(3) Number of indicators 7 (See Figure 1.1-2.)

Figure 1.1-1 External Appearance

(See Figure 1.1-2.)

I - 1

1.1.4 Printing Mechanism

(1) Print system Direct thermal printing

(2) Print speed 7.5 mm/second (Typical)

(3) Print head

Type Thermal print head

Heat generator Consists of 64 heating elements vert ically alig ned

Size of a heating element 0.136 mm wide by 0.106 mm high

1.1.5 Tape Cassette

(1) Cassette Cartridge type

(2) Tape type Direct thermal print tape

(3) Tape size Width: 9, 12 mm

(4) Tape cassette packed with the machine Char act er color: Black

(Fixed print head and tape feeding mechanism)

Length: 8 m

Tape color: White

Tape width: 12 mm or 9 mm (EU)

Tape length: 4 m

1.1.6 Tape Cutter

(1) Tape cutting Manual cutting with the cutter lever

(2) Cutter unit User-replaceable

I - 2

8 columns x 1 row

Figure 1.1-2 Key Arrangement

I - 3

1.2 Electronics Specifications

1.2.1 Character Generator

(1) International character German version 190 character s

Other versions 182 characters

(2) Internal fonts HELSINKI

(3) Text buffer capacity 55 characters

(4) Phrase memory capacity None

1.2.2 Power Supply

(1) Power supply Driven by 6 dry cells

(2) Battery type Alkaline dry cells (AM3/LR6)

(3) Service life of batter ies Will last t hr ough one tape cassette, and then some

(at room temperature and normal humidity).

(4) Automatic powering-off Yes (If the machine remains unused for approx. 5

minutes, it automatically turns it self off.)

(5) Low voltage indication

If the voltage drops below the following level:

On standby in the entry

mode

approx. 6.96V approx. 5.35V Turn the power off.

---- approx. 5.86V

During printing

Then, the machine will:

Display the "BATTERY" message

on the LCD.

I - 4

CHAPTER II THEORY OF OPERATION

2.1 Outline of Mechanisms

2.1.1 Print Mechanism

Structure of Thermal Head

This machine uses direct thermal printing. The thermal print head has a heat generator

consisting of 64 heating elements which are vertically aligned as shown in Figure 2.1-1.

Each heating element is 0.136 mm wide by 0.106 mm high.

0.106 mm

6.784 mm

0.136 mm

Figure 2.1-1 Heat Generator of Thermal Head

Printing Process

When the cylindrical rubber platen is pressed against the thermal print head with the

thermal tape sandwiched inbetween, the CPU applies electric power to the selected ones

of those 64 heating elements.

The selected heating element(s) generates heat that dissolves the metal deposit layer of

the thermal tape so as to reveal the substrate layer, producing a dot on the tape. The tape

is advanced and the next heating cycle is repeated, thus forming a character on the tape.

Character Formation

While the drive motor (DC mot or) feeds the tape by 0.106 mm for 13.8 ms, the thermal

head generates heat once. The feed amount of 0.106 mm is smaller than the width (0.136

mm) of the heating elements so that the heat generated at one heating cycle will o verlap

with the next heating cycle. This forms a character having no gap between adjacent

printed dots.

II - 1

2.1.2 Platen Setting & Retracting Mechanism

This mechanism consists of the roller holder ASSY and the roller holder setting lever

(wedged lever) provided on the inside of the cassette cover.

The roller holder ASSY supports the platen so that the platen can move perpendicularly to

the thermal head and rotate freely.

Closing the cassette cover fits its roller holder setting lever into the slot between the roller

holder ASSY and the chassis's bent section. This pivots the roller holder ASSY around the

shaft provided on the chassis so as to press the roller holder ASSY against the thermal

head.

The platen is pressed perpendicularly against the thermal head with the tape sandwiched

inbetween under a uniform load by the platen spring. At the same time, the platen gear

becomes engaged with the drive gear of the gear train on the chassis (see Figure 2.1-3).

Opening the cassette cover pulls out its roller holder setting lever so that the roller holder

spring retracts the roller holder ASSY from the thermal head, providing you with enough

space to replace the tape cassette.

Figure 2.1-2 Platen Setting & Retracting Mechanism

II - 2

2.1.3 Tape Feed Mechanism

This mechanism consists of a DC motor, gear train and roller holder ASSY.

When you load a tape cassette and close the cassette cover, the platen and the thermal

head sandwich the tape inbetween and the platen gear becomes engaged with the gear

train, as described in Subsection 2.1.2.

As the DC motor rotates, the rotation is transmitted via the gear train to the platen gear.

Accordingly, the sandwiched tape will be advanced.

Figure 2.1-3 Tape Feed Mechanism

II - 3

2.1.4 Tape Cutter Mechanism

The cutter mechanism consists of a cutter lever and a cutter unit in which a blade is

retracted by a spring.

Pressing the cutter lever pushes out the blade from the cutter unit. The blade presses the

printed tape against the cutter board of the tape cassette, cutting the tape coming through

the cutter unit and the cutter board.

When the cassette cover is opened and no tape cassette is loaded, the cutter safety

mechanism works to lock the cutter lever as described in Subsection 2.1.5.

Figure 2.1-4 Tape Cutter Mechanism

II - 4

2.1.5 Cutter Safety Lock Mechanism

When the cassette cover is opened and no tape cassette is loaded, the roller holder ASSY

is retracted from the thermal head with the roller holder spring (as described in Subsection

2.1.2). In this retracted position, the cutter lever stopper of the roller holder ASSY blocks

the end of the cutter lever, preventing the cutter lever from pushing the cutter blade out of

the cutter unit for safety, as shown below.

Closing the cassette cover or loading a tape cassette releases the cutter safety lock

mechanism. If you close the cassette cover, the roller holder ASSY pivots towards the

thermal head so that the cutter lever stopper does not interfere with the cutter lever.

When a tape cassette is loaded, its outer edge pushes the tab of the roller holder ASSY to

pivot the roller holder ASSY towards the thermal head so that the cutter lever stopper

does not interfere with the cutter lever.

Figure 2.1-5 Cutter Safety Lock Mechanism

Figure 2.1-6 Releasing the Cutter Safety Lock Mechanism

II - 5

2.2 Outline of Control Electronics

2.2.1 Configuration

Figure 2.2-1 shows a block diagram of the control electronics of this machine. T he control

electronics consists of a main PCB, DC motor, and thermal print head ASSY.

Figure 2.2-1 Configuration of the Electronic Part

Main PCB

This manages all the components including an LCD, DC motor, keypad, and thermal print

head ASSY.

Motor

The DC motor is a power source to advance tape.

Thermal Print Head

This is a thick-film thermal print head which integrates a heat generator (consisting of 64

heating elements vertically aligned) and driver circuitry.

II - 6

Loading...

Loading...