Briggs & Stratton 71021, 71018, 71019, 71020 User Manual 2

Installation & Operator’s

Manual

Questions? Help is just a moment away!

Call: Transfer Switch Helpline

1-800-743-4115 M-F 8-5 CT

BRIGGSandSTRATTON.COM

100 AMP/200 AMP

Automatic Transfer Switch

with AC Power Control Module™

Models 071018, 071019, 071020 & 071021

201705GS Rev. - (12/14/06)

Thank you for your purchase of this Briggs & Stratton Power Products Automatic Transfer Switch. This product is intended for use with Briggs & Stratton Home Standby Generator sets ONLY. This is an optional home standby system which provides an alternate source of electric power and to serve loads such as a gas furnace, refrigeration and communication systems that, when stopped during any power outage, could cause discomfort or the like. This product DOES NOT qualify for emergency standby as defined by NFPA 70 (NEC).

This manual contains safety information to make you aware of the hazards and risks associated with transfer switches and how to avoid them. Briggs & Stratton has made every effort to provide for a safe, streamlined and cost-effective installation. Each installation is unique, it is impossible to know of and advise of all conceivable procedures and methods by which installation might be achieved. We do not know all possible hazards and/or the results of each method or procedure. Save these instructions for future reference.

This transfer switch requires installation before use. Refer to the Installation section of this manual for instructions on installation procedures. Only licensed electrical contractors should install transfer switches. Installations must strictly comply with all applicable federal, state and local codes, standards and regulations.

Where to Find Us

You never have to look far to find Briggs & Stratton support and service for your transfer switch. Consult your Yellow Pages. There are over 30,000 Briggs & Stratton authorized service dealers worldwide who provide quality service. You can also contact Briggs & Stratton Customer Service by phone at (800) 743-4115, or on the Internet at BRIGGSandSTRATTON.COM.

Transfer Switch

Model Number

Revision

Serial Number

Date Purchased

Briggs & Stratton Power Products Group, LLC

900 North Parkway

Jefferson, WI 53549

Copyright © 2006 Briggs & Stratton Power Products Group, LLC. All rights reserved. No part of this material may be reproduced or transmitted in any form by any means without the express written permission of Briggs & Stratton Power Products Group, LLC.

Table of Contents

Important Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Owner Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Installer Responsibilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Equipment Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Mounting Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Power Wiring Interconnections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Supervisory Control Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

System Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Testing the Automatic Transfer Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Schematic and Wiring Diagram, Models 071018 and 071019. . . . . . . . . . 11 Schematic and Wiring Diagram, Models 071020 and 071021. . . . . . . . . . 12 Illustrated Parts List, Model 071018 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 Illustrated Parts List, Model 071019 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 Illustrated Parts List, Model 071020 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 Illustrated Parts List, Model 071021 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Español |

Français |

1

Save These Instructions

Important Safety Instructions

This is the safety alert symbol. It is used to alert you to potential personal injury hazards. Obey all safety messages that follow this symbol to avoid possible injury or death.

The safety alert symbol ( ) is used with a signal word (DANGER, CAUTION, WARNING), a pictorial and/or a safety message to alert you to hazards. DANGER indicates a hazard which, if not avoided, will result in death or serious injury. WARNING indicates a hazard which, if not avoided, could result in death or serious injury. CAUTION indicates a hazard which, if not avoided, might result in minor or moderate injury. NOTICE indicates a situation that could result in equipment damage. Follow safety messages to avoid or reduce the risk of injury or death.

) is used with a signal word (DANGER, CAUTION, WARNING), a pictorial and/or a safety message to alert you to hazards. DANGER indicates a hazard which, if not avoided, will result in death or serious injury. WARNING indicates a hazard which, if not avoided, could result in death or serious injury. CAUTION indicates a hazard which, if not avoided, might result in minor or moderate injury. NOTICE indicates a situation that could result in equipment damage. Follow safety messages to avoid or reduce the risk of injury or death.

The manufacturer cannot possibly anticipate every possible circumstance that might involve a hazard. The warnings in this manual, and the tags and decals affixed to the unit are, therefore, not all-inclusive. If you use a procedure, work method or operating technique that the manufacturer does not specifically recommend, you must satisfy yourself that it is safe for you and others. You must also make sure that the procedure, work method or operating technique that you choose does not render the transfer switch unsafe.

WARNING

WARNING

Failure to properly ground transfer switch can result in electrocution.

•DO NOT touch bare wires or receptacles.

•DO NOT use transfer switch with worn, frayed, bare or otherwise damaged wiring.

•DO NOT handle electrical cords while standing in water, while barefoot, or while hands or feet are wet.

•If you must work around a unit while it is operating, stand on an insulated dry surface to reduce shock hazard.

•DO NOT allow unqualified persons or children to operate or service transfer switch.

•In case of an accident caused by electrical shock, immediately shut down the source of electrical power and contact local authorities. Avoid direct contact with the victim.

WARNING

WARNING

Transfer Switch contains hazardous voltage that can cause personal injury or death.

•Despite the safe design of the transfer switch, operating this equipment imprudently, neglecting its maintenance or being careless can cause possible injury or death.

WARNING

WARNING

Only qualified electricians should attempt installation of this system, which must strictly comply with applicable codes, standards and regulations.

WARNING

WARNING

Low voltage wire cannot be installed in same conduit as power voltage wiring.

•Failure to follow above warning could cause personal injury, damage and/or malfunction of equipment.

NOTICE

Improper treatment of transfer switch can damage it and shorten its life.

•Use transfer switch only for intended uses.

•If you have questions about intended use, ask dealer or contact Briggs and Stratton Power Products.

•Do not expose transfer switch to excessive moisture, dust, dirt, or corrosive vapors.

•Remain alert at all times while working on this equipment. Never work on the equipment when you are physically or mentally fatigued.

•If connected devices overheat, turn them off and turn off their circuit breaker/fuse.

2 |

BRIGGSandSTRATTON.COM |

Introduction

Your Briggs & Stratton Transfer Switch is supplied with this combined “Installation and Operator’s Manual”. This is an important document and should be retained by the owner after the installation has been completed.

Every effort has been expended to make sure that the information in this manual is both accurate and current. However, the manufacturer reserves the right to change, alter or otherwise improve the system at any time without prior notice.

For the Home Owner

To help you make informed choices and communicate effectively with your installation contractor(s),

Read and understand the Owner Orientation Section of this manual BEFORE contracting or starting your transfer switch installation.

To arrange for proper installation, contact the store at which you purchased your Briggs & Stratton Transfer Switch, your dealer, or your utility power provider.

The Transfer Switch Warranty is VOID unless the system is installed by a licensed electrical professional.

Owner Orientation

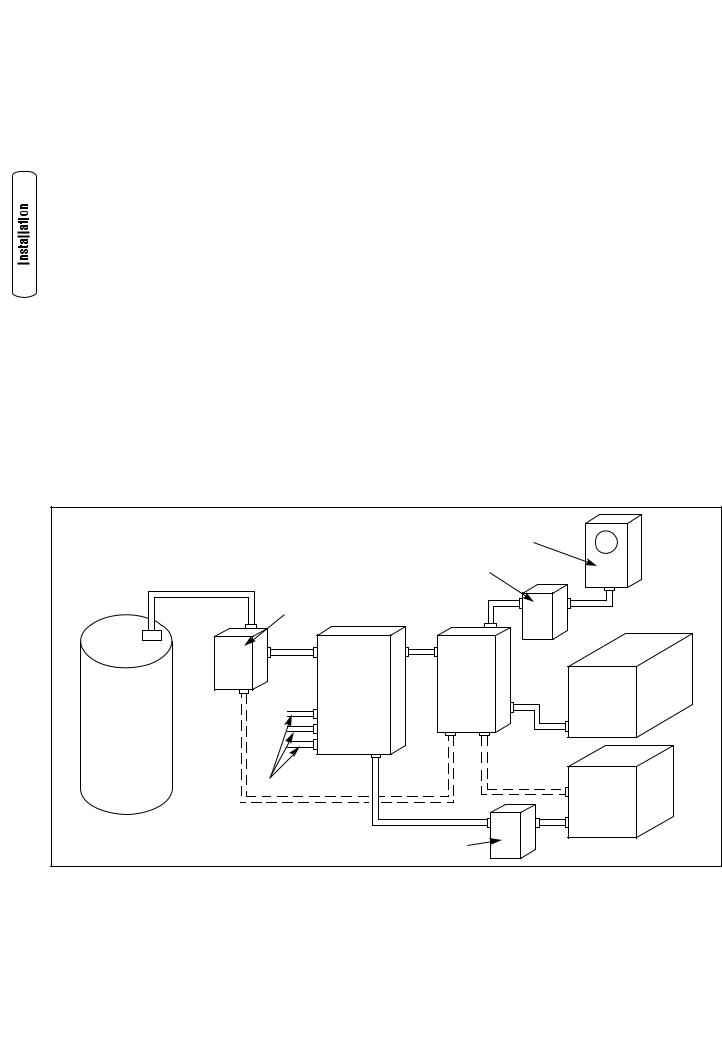

The illustrations are for typical circumstances and are meant to familiarize you with the installation options available with your transfer switch.

Local codes, appearance, and distances are the factors that must be considered when negotiating with an installation professional. As the distance from the existing electrical service increases, compensation in wiring materials must be allowed for. This is necessary to comply with local codes and overcome electrical voltage drops.

The factors mentioned above will have a direct effect on the overall price of your transfer switch installation.

NOTE: Your installer must check local codes AND obtain permits before installing the system.

•Read and follow the instructions given in this manual.

•Follow a regular schedule in caring for and using your transfer switch, as specified in the manual.

Installer Responsibilities

•Read and observe the safety rules.

•Read and follow the instructions given in this manual.

•Check federal, state and local codes and authority having jurisdiction, for questions on installation.

•Ensure generator is not overloaded with selected loads.

If you need more information about the transfer switch, call (800) 743-4115, between 8:00 AM and 5:00 PM CT.

Equipment Description

These transfer switches are intended to transfer the entire electrical load of normal residential installations when used with the supervisory contacts provided. The load is connected either to utility power (normal) or home standby power (generator). The transfer switch monitors utility and generator voltages and will automatically connect to the appropriate source of power.

Major components of the transfer switch are a 2 pole utility disconnect circuit breaker (models 071020 & 071021 only), a 2 pole double throw transfer switch, control circuit board, fused utility terminals and interconnecting wiring. The control board also has two inputs for current tranformers used to sense generator current.

The transfer switch is solenoid-operated from utility or generator inputs and contains suitable mechanical and electrical interlock switches to eliminate the possibility of connecting the utility service to the generator output. It has ratings capable of switching full utility power into the residence. In addition, a manual override lever is provided for the transfer function.

The control circuit board has active circuits sensing utility and generator voltages. It creates a signal for the generator start-up, switch transfer, and retransfer when utility is restored. The control board also contains red and green LED’s indicating the power sources available and two relay operated contacts that provide supervisory control of external loads.

3

Installation

Unpacking

Delivery Inspection

After removing the carton, carefully inspect the transfer switch components for any damage that may have occurred during shipment.

IMPORTANT: If loss or damage is noted at time of delivery, have the person(s) making delivery note all damage on the freight bill and affix his signature under the consignor's memo of loss or damage. If loss or damage is noted after delivery, contact the carrier for claim procedures. Missing or damaged parts are not warranted.

Shipment Contents

•Automatic Power Transfer Switch

•Two Current Transformers

•Installation and Operator’s Manual

Mounting Guidelines

The Automatic Transfer Switch is enclosed in NEMA Type 3R enclosures suitable for indoor or indoor/outdoor use.

Guidelines for mounting the Automatic Transfer Switch include:

•Install the switch on a firm, sturdy supporting structure.

•The switch must be installed with minimum NEMA 3R hardware for conduit connections.

•To prevent switch contact distortion, level and plumb the enclosure. This can be done by placing washers between the switch enclosure and the mounting surface.

•Never install the switch where any corrosive substance might drip onto the enclosure.

•Protect the switch at all times against excessive moisture, dust, dirt, lint, construction grit and corrosive vapors.

A typical installation of the Automatic Power Transfer Switch for Models 071018 and 071019 is depicted in Figure 1. An alternative installation of the Automatic Power Transfer Switch is depicted in Figure 2.

It is best if the transfer switch is mounted near the utility watt-hour meter, either inside or outside. Discuss layout suggestions/changes with the owner before beginning the system installation process.

— — — — — — Control Wiring |

Watt - |

|

|

Hourmeter |

|

|

Service |

|

|

Disconnect |

|

Contactor |

|

|

Main |

Transfer |

|

Circuit |

||

Breaker |

Switch |

|

Panel |

Generator |

|

Hot Water |

||

|

||

Heater |

|

|

Branch Circuits |

Air |

|

|

||

|

Conditioner |

|

|

Disconnect Switch |

Figure 1 - Typical Transfer Switch Mounting for Models 071018 and 071019

4 |

BRIGGSandSTRATTON.COM |

— — — — — — Control Wiring |

|

Watt - |

|

|

Hourmeter |

||

|

|

||

Contactor |

|

|

|

|

|

Branch |

|

|

|

Circuits |

|

Emergency |

Transfer |

Main |

|

Circuit |

|||

Load Center |

Switch |

||

Breaker |

|||

Hot Water |

|

||

|

Panel |

||

Heater |

|

|

|

|

|

Generator |

|

Emergency |

|

Air |

|

Branch Circuits |

|

||

|

Conditioner |

||

|

Disconnect Switch |

||

|

|

Figure 2 - Alternate Transfer Switch Mounting

|

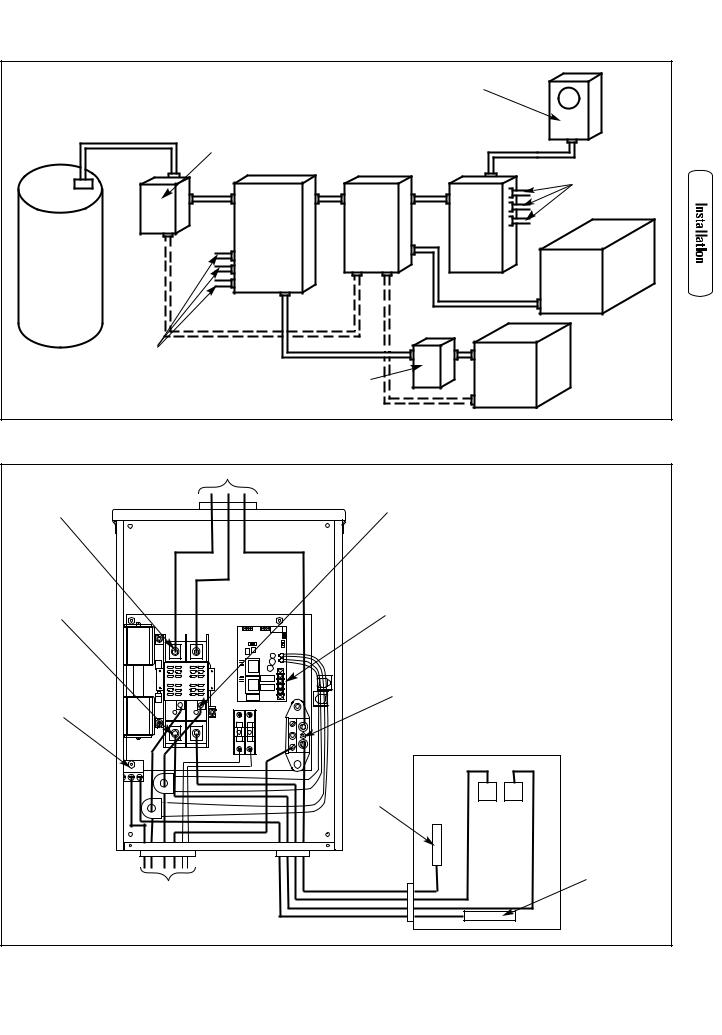

To Utility Meter |

|

Utility |

Generator |

|

Connection |

||

Connection |

||

|

||

Load |

Supervisory |

|

Contacts |

||

Connection |

||

|

||

|

Neutral |

|

|

Terminal |

|

Ground Lug |

|

|

|

Main Breaker Panel |

|

|

Neutral |

|

|

Bus |

|

|

Main |

|

|

Ground Bus |

|

|

To Generator |

Figure 3 - Typical Installation Diagram for Model 071018 & 071019 Transfer Switches

5

Power Wiring Interconnections

All wiring must be the proper size, properly supported and protected by conduit.

Complete the following connections between the transfer switch, main distribution panel, utility power and generator, as shown in Figures 3 and 4.

WARNING

WARNING

Low voltage wire cannot be installed in same conduit as power voltage wiring.

•Failure to follow above warning could cause personal injury, damage and/or malfunction of equipment.

1.Ensure utility power is turned OFF. Connect utility feeder conductors to transfer switch terminals marked “UTILITY CONNNECTION”.

2.Connect utility Neutral conductor to the transfer switch “NEUTRAL” terminal.

3.Connect main breaker panel feeder conductors to transfer switch terminals marked “LOAD CONNECTION”.

4.Connect main breaker panel Neutral conductor to transfer switch “NEUTRAL” terminal.

5.Connect main breaker panel Ground conductor to the transfer switch “GND” terminal.

NOTE: Assure grounding electrode conductor is connected and bonded per applicable federal, state and local codes, standards and regulations.

6.Connect generator feeder conductors from the generator control panel to transfer switch terminals marked “GENERATOR CONNECTION” Each conductor should pass through hole of current transformer before making connection.

7.Plug in current transformer leads into “CT1” and “CT2” on control module.

|

To Utility Meter |

|

Load |

Utility |

Connection |

Connection |

|

|

Supervisory |

|

Contacts |

Generator |

|

Connection |

|

|

Neutral |

|

Terminal |

Ground Lug |

|

|

Main Breaker Panel |

|

Neutral |

|

Bus |

CT2 |

Main |

|

|

CT1 |

Ground Bus |

|

|

|

To Generator |

Figure 4 - Typical Installation Diagram for Model 071020 and 071021 Transfer Switches

6 |

BRIGGSandSTRATTON.COM |

8.Connect Neutral conductor from the generator control panel to the transfer switch “NEUTRAL” terminal.

9.Connect generator Ground conductor from the control panel to the transfer switch “GND” terminal.

NOTE: Assure generator equipment grounding conductor is connected per applicable federal, state and local codes, standards and regulations.

10.Connect generator “UTILITY 240 VAC” terminals to transfer switch “UTILITY 240 VAC” terminals. Use minimum #14 AWG conductors.

11.Tighten all wire connections/fasteners to proper torque. See inside transfer switch enclosure for proper torque values.

Supervisory Control Wiring

1.Terminal strip on control module in transfer switch has four connections for customer use. There are two sets of “Normally Closed” contacts available. They will be activated when generator power is required. These can be used for supervisory control of large connected loads on generator. Loads will be allowed to operate if there is enough generator power available.

NOTE: There are two wireways provided to keep the supervisory loads separated from each other.

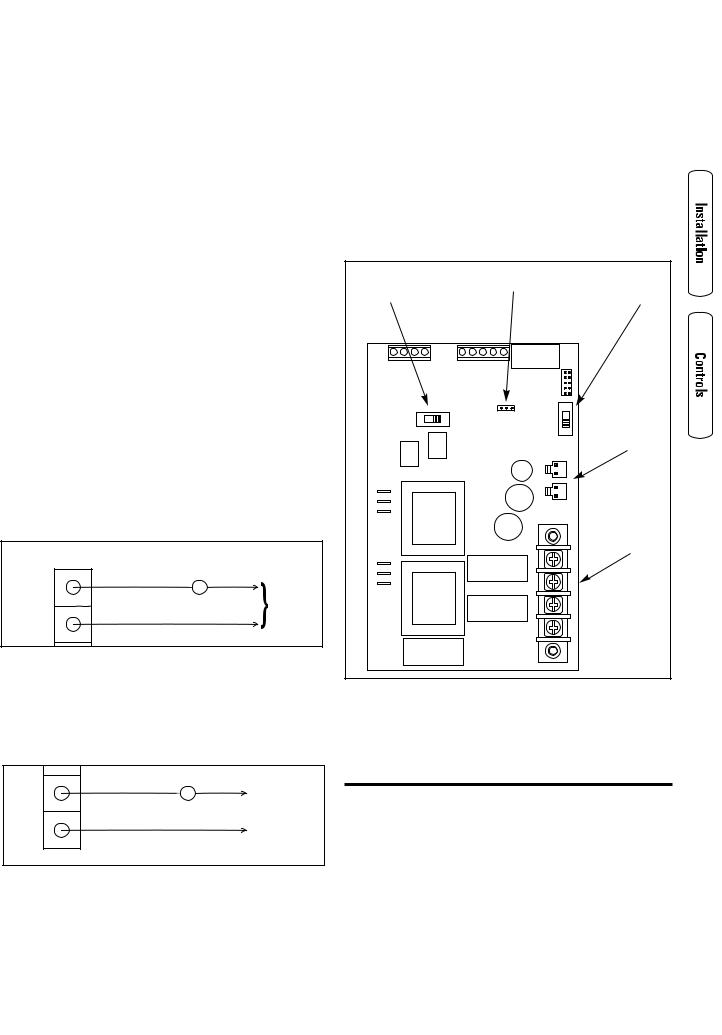

2.Terminals “A-A” on control module are rated for 24 VAC and air conditioner contactor control. Contacts are connected in series with the air conditioner contactor control circuit (Figure 5).

Air Conditioner Contactor

A

24 VAC

A

Figure 5 — Terminals “A-A”

3.Terminals “B-B” on control module are rated for 1 Amp 125 VAC and installer supplied contactor to control a large load. Example: electric hot water heater. Contacts are connected in series with the contactor control circuit (Figure 6).

B |

Contactor |

|

Neutral |

||

B |

||

120 VAC |

||

|

Figure 6 — Terminals “B-B”

4.Tighten all wire connections/fasteners to proper torque. See inside transfer switch enclosure for proper torque values.

System Setup

You must perform the following on the control module before operating the system:

•If generator is installed in an area regularly subjected to temperatures below 40°F (4°C), select a 50 second warm up time by moving jumper installed on JP2 (Figure 7) from ‘20’ position to ‘50’ position.

•Place 2 position switch (Figure 7) in ‘NG’ or ‘LP’ position, whichever is appropriate for your system.

•Place 3 position switch (Figure 7) to match KW rating of installed generator.

3 Position |

JP2 |

2 Position |

Switch |

|

Switch |

|

|

CT1 & CT2 |

|

|

Connectors |

|

|

Supervisory |

|

|

Contacts |

Figure 7 — Control Module

Controls

Other than a Manual Override lever, there are no operator controls because this is an automatic transfer switch. The manual override is to be used only by licensed professionals.

7

Operation

To select automatic transfer operation, do the following:

1A. For models 071018 & 071019, set disconnect switch that sends utility power to transfer switch to “On” position. This switch is probably located in the main breaker panel.

1B. For models 071020 & 071021, set utility breaker in transfer switch “On” position.

2.Set generator main circuit breaker to its “On” position.

3.Install 15 Amp fuse in generator control panel.

4A. If generator is equipped with a system ON/OFF switch, set switch to “On” position.

4B. If generator is equipped with a AUTO/OFF/MANUAL switch, set switch to “AUTO” position.

The system will now be in automatic operation mode.

When the generator is providing power to the transfer switch, the control module is constantly monitoring generator power. If the air conditioner is called to run, and there is sufficient generator power available, the control module will close contacts “A-A” to air conditioner contactor. Contacts “B-B” will open before contacts A-A close. If loads are too great for generator, contacts A-A and/or B-B will open. When air conditioning is not needed, A-A will open. If enough power is available, B-B will close.

Testing the Automatic Transfer Switch

Turn the disconnect switch feeding the transfer switch contactor to the “Off” position. The Automatic Sequence of the system will follow. To go back to utility power, turn the disconnect to the “On” position.

Automatic Sequence

Utility Fail

The Home Standby Generator set senses when utility voltage is below 70 percent of nominal. Engine start sequence is initiated after 6 second time delay.

Engine Warm-Up

Time delay to allow for engine warm-up before transfer fixed at 20 seconds or 50 seconds with removal of jumper on control board (see System Setup).

Transfer

Transfer from utility to generator supply occurs after voltage is above set levels. Minimum engine run time is 5 minutes after transfer.

Utility Pickup

Voltage pickup level is 80 percent of nominal voltage.

Retransfer

Retransfer from generator to utility supply is approximately 10 seconds after utility voltage supply is above utility pickup level and minimum run time is completed.

Engine Cool Down

Engine will run for 60 seconds after retransfer.

When Calling the Factory

Before contacting Briggs and Stratton Power Products regarding service or repair of this transfer switch, obtain the Model Number and Serial Number from the unit data decal located on or inside the enclosure.

To contact Briggs and Stratton Power Products call 1-800-743-4115, between 8:00 AM and 5:00 PM CT.

8 |

BRIGGSandSTRATTON.COM |

Maintenance

The transfer switch is designed to be maintenance free under normal usage. However, inspection and maintenance checks should be made on a regular basis. Maintenance will consist mainly of keeping the transfer switch clean.

Visual inspections should be done at least once a month. Access to transfer switch must not be obstructed. Keep

3 feet (1 m) clearance around transfer switch. Check for an accumulation of dirt, moisture and/or corrosion on and

around the enclosure, loose parts/hardware, cracks and/or discoloration to insulation, and damaged or discolored components.

Exercise the transfer switch at least once every three months as described in section Testing the Automatic Transfer Switch unless a power outage occurs and home generator system has gone through an automatic sequence. Allow generator to run for at least 30 minutes.

Contact a licensed electrical professional to inspect and clean the inside of your transfer switch at least once a year.

Specifications

UL® 1008 Listed Transfer Switch |

|

|

|

Model 071018 |

|

Model 071020 |

|

Maximum Load Current . |

. . . . . . . . . . . . . . . . . . . .100 Amps |

Maximum Load Current . |

. . . . . . . . . . . . . . . . . . . .100 Amps |

Rated AC Voltage . . . . . |

. . . . . . . . . . . . . . . . . . . . .250 Volts |

Rated AC Voltage . . . . . |

. . . . . . . . . . . . . . . . . . . . .250 Volts |

Poles . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . . .2 |

Poles . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . . .2 |

Frequency . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . .50/60 Hz |

Frequency . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . .50/60 Hz |

Fault Current Rating . . . . |

22,000 RMS Symmetrical Amperes |

Fault Current Rating . . . . |

22,000 RMS Symmetrical Amperes |

Supervisory Contacts Rating: |

Supervisory Contacts Rating: |

||

A-A Terminals . . . . . . . |

. . . . . . . . . . . . . . . . . . .24 Volt AC |

A-A Terminals . . . . . . . |

. . . . . . . . . . . . . . . . . . .24 Volt AC |

B-B Terminals . . . . . . . |

. . .1 Amp, 125 Volt AC, Pilot Duty |

B-B Terminals . . . . . . . |

. . .1 Amp, 125 Volt AC, Pilot Duty |

Weight . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . .21 lbs. |

Weight . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . .32 lbs. |

Model 071019 |

|

Model 071021 |

|

Maximum Load Current . |

. . . . . . . . . . . . . . . . . . . .200 Amps |

Maximum Load Current . |

. . . . . . . . . . . . . . . . . . . .200 Amps |

Rated AC Voltage . . . . . |

. . . . . . . . . . . . . . . . . . . . .250 Volts |

Rated AC Voltage . . . . . |

. . . . . . . . . . . . . . . . . . . . .250 Volts |

Poles . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . . .2 |

Poles . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . . .2 |

Frequency . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . .50/60 Hz |

Frequency . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . .50/60 Hz |

Fault Current Rating . . . . |

25,000 RMS Symmetrical Amperes |

Fault Current Rating . . . . |

25,000 RMS Symmetrical Amperes |

Supervisory Contacts Rating: |

Supervisory Contacts Rating: |

||

A-A Terminals . . . . . . . |

. . . . . . . . . . . . . . . . . . .24 Volt AC |

A-A Terminals . . . . . . . |

. . . . . . . . . . . . . . . . . . .24 Volt AC |

B-B Terminals . . . . . . . |

. . .1 Amp, 125 Volt AC, Pilot Duty |

B-B Terminals . . . . . . . |

. . .1 Amp, 125 Volt AC, Pilot Duty |

Weight . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . .34 lbs. |

Weight . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . .44 lbs. |

9

Troubleshooting

Problem |

Cause |

Correction |

|||

Automatic transfer switch does not |

1. |

Generator breaker open. |

1. |

Reset generator circuit breaker. |

|

transfer to generator |

2. |

Generator voltage not acceptable. |

2. |

Refer to generator manual. |

|

|

|

|

|

|

|

|

1. |

Utility disconnect breaker open |

1. |

Reset utility disconnect breaker |

|

Automatic transfer switch does not |

|

(Models 071020 & 071021 only). |

|

(Models 071020 & 071021 only). |

|

2. |

Service disconnect breaker open. |

2. |

Reset service disconnect breaker. |

||

transfer to utility |

|||||

3. |

Utility voltage not acceptable. |

3. |

Wait for utility voltage to return to |

||

|

|||||

|

|

|

|

normal. |

|

|

|

|

|||

Generator is still running after switch |

Engine cool down period. |

Engine should stop after 1 minute. |

|||

transfers to utility power |

|

|

|

|

|

|

|

|

|

|

|

|

1. |

A-A or B-B contacts not operating |

1. |

Check A-A or B-B contacts for |

|

|

|

correctly. |

|

proper operation and/or check |

|

Supervised loads (air conditioner, etc.) |

|

|

|

control wiring to external load. |

|

2. |

Too much load on generator. |

2. |

Decrease load to generator. |

||

are not operating when generator is |

|||||

3. |

Current transformer not connected. |

3. |

Plug CT connectors into control |

||

supplying power |

|||||

|

|

|

board. |

||

|

|

|

|

||

|

4. |

Broken current transformer. |

4. |

Contact local Briggs & Stratton |

|

|

|

|

|

Power Products service center. |

|

|

|

|

|

|

|

|

1. |

Minimum engine run time has not |

1. |

Wait five minutes for transfer |

|

Generator is still running after utility |

|

elapsed. |

|

switch to retransfer to utility power. |

|

power is restored |

2. |

Fuse(s) in transfer switch is |

2. |

Check fuse(s) and replace if |

|

|

|

defective. |

|

necessary. |

|

|

|

|

|

|

|

|

10 |

BRIGGSandSTRATTON.COM |

|

|

|

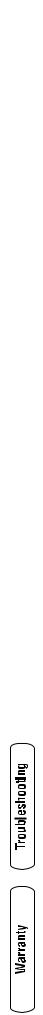

Schematic and Wiring Diagram, Models 071018 and 071019

11

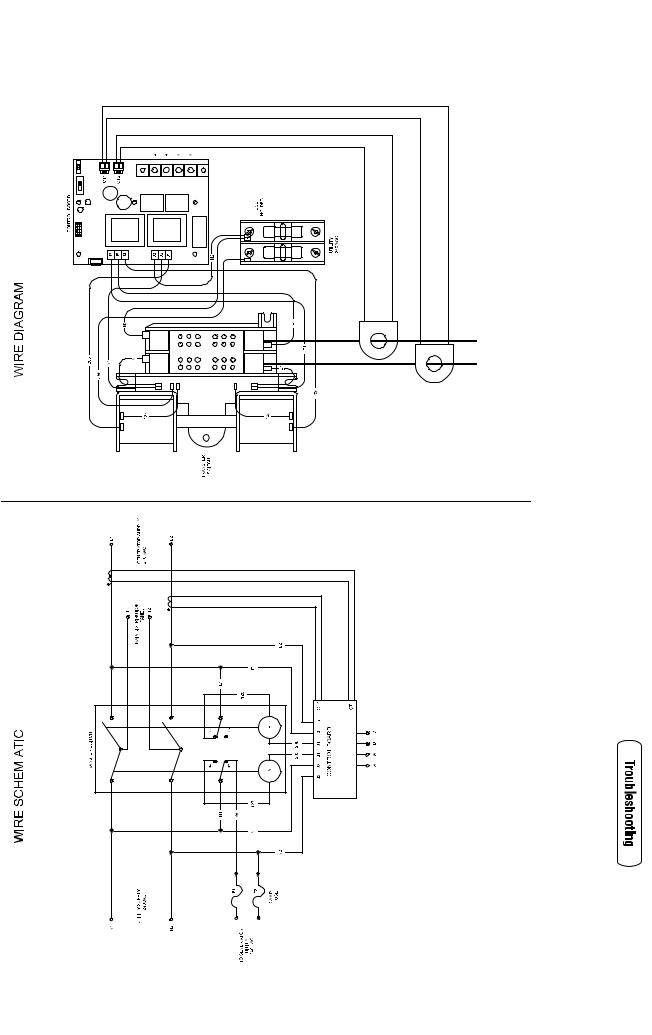

Schematic and Wiring Diagram, Models 071020 and 071021

|

12 |

BRIGGSandSTRATTON.COM |

|

|

|

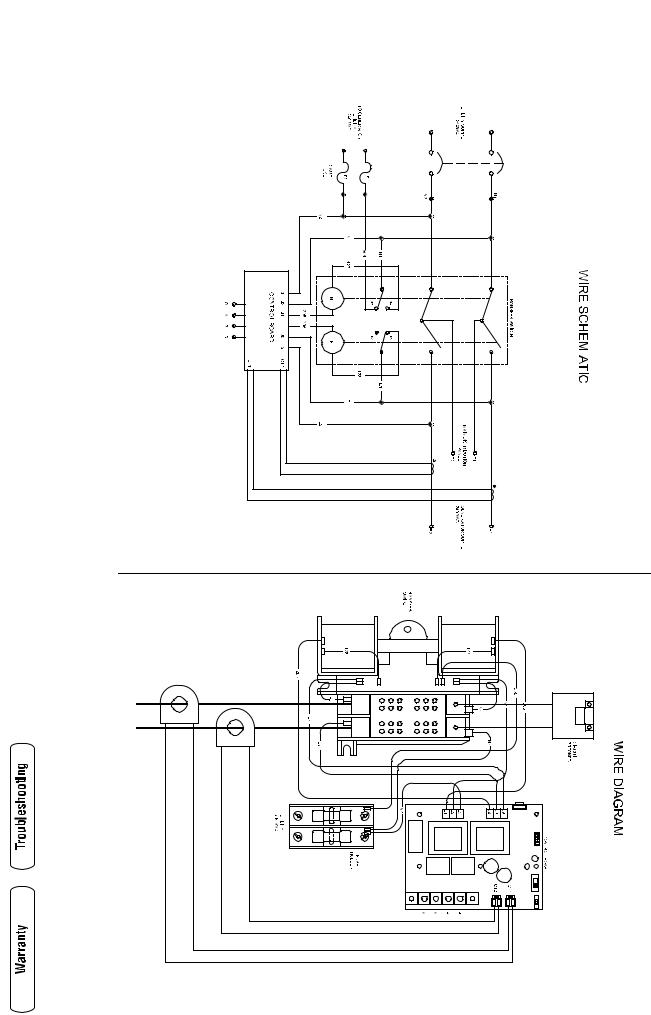

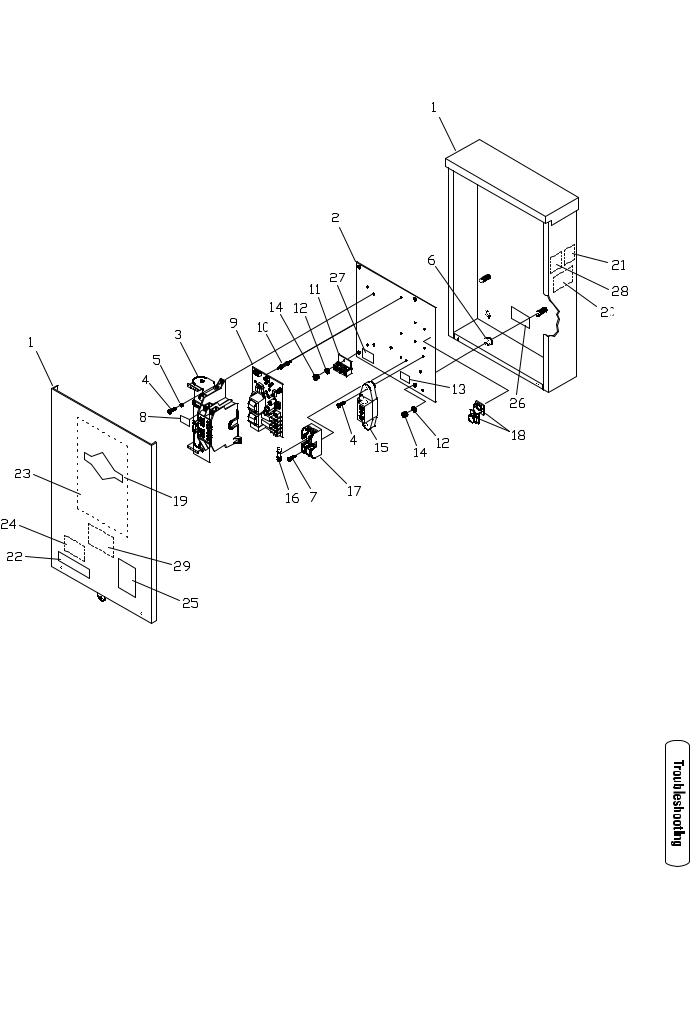

Illustrated Parts List, Model 071018

Item |

Part # |

Description |

Item |

Part # |

Description |

1 |

NSP |

ENCLOSURE, 16" x 12" x 6" |

18 |

197355GS |

CLIP, Latching Wire |

2 |

NSP |

BACK PANEL |

19 |

198136GS |

DECAL, B & S Logo |

3 |

195667GS |

TRANSFER SWITCH, 100A, with |

20 |

196355GS |

DECAL, CT Warning |

|

|

Cover & Handle |

21 |

197294GS |

DECAL, Contacts Rating |

4 |

* |

PPHMS, #10 - 32 x 1/2" |

22 |

198615GS |

DECAL, Intelligen Logo |

5 |

* |

WASHER, Ext. Tooth, #10 |

23 |

196522GS |

DECAL, 100A, ATS |

6 |

192150GS |

SPACER |

24 |

NSP |

DECAL, UL Listed, ATS |

7 |

* |

PPHMS, #6-32 x 3/8" |

25 |

190992GS |

DECAL, Warning Shock |

8 |

193159GS |

DECAL, Reinstall After |

26 |

190984GS |

DECAL, Fuse |

9 |

197279GS |

CONTROL, Board |

27 |

B4986GS |

DECAL, Ground |

10 |

201685GS |

SPACER |

28 |

197198GS |

DECAL, Wire Circuits |

11 |

196094GS |

GROUND LUG |

29 |

192165GS |

DECAL, APPVD CB |

12 |

* |

WASHER, Lock 1/4" |

|

|

|

13 |

192597GS |

DECAL, Utility, 240 VAC |

Items Not Illustrated |

|

|

14 |

* |

NUT, 1/4" - 20 |

|

195728GS |

CURRENT TRANSFORMER |

15 |

192696GS |

TERMINAL, Neutral |

|

|

|

16 |

B4857GS |

FUSE |

* - Items without part numbers are common fasteners and |

||

17 |

192151GS |

FUSE HOLDER |

are available at local hardware stores. |

||

13

Loading...

Loading...