Briggs & Stratton Liquid-Cooled Home Generator System User Manual

Operator’s Manual

Liquid-Cooled

Home Generator System

Manual No. 205051GS Rev. A (01/18/2008)

Thank you for purchasing this quality-built Briggs & Stratton home generator. We’re pleased that you’ve placed your confidence in the Briggs & Stratton brand. When operated and maintained according to the instructions in this manual, your Briggs & Stratton home generator will provide many years of dependable service.

This manual contains safety information to make you aware of the hazards and risks associated with home generator systems and how to avoid them. This home generator system is designed and intended only for use as an optional home standby system that provides an alternate source of electric power and to serve loads such as heating, refrigeration systems, and communication systems that, when stopped during any power outage, could cause discomfort or inconvenience. This product is not intended for any other purpose and does not qualify for emergency standby as defined by NFPA 70 (NEC).

This home generator requires professional installation before use. Refer to the separate Installation Manual for full information. Follow the instructions completely. Save these instructions for future reference.

Where to Find Us

You never have to look far to find Briggs & Stratton support and service for your generator. Consult your Yellow Pages. There are thousands of Briggs & Stratton authorized service dealers worldwide who provide quality service. You can also contact Briggs & Stratton Customer Service by phone at (800) 743-4115, or use the Service Center Locator at BRIGGSandSTRATTON.COM, which provides a list of Briggs & Stratton Authorized Dealers.

See Installation Manual for system purchase date and component identification numbers

Briggs & Stratton Power Products Group, LLC

900 North Parkway

Jefferson, WI 53549

Copyright © 2008 Briggs & Stratton Power Products Group, LLC. All rights reserved. No part of this material may be reproduced or transmitted in any form by any means without the express written permission of Briggs & Stratton Power Products Group, LLC.

Table of Contents

Safety Rules . . . . . . . . . . . . . . . . . . 4

Installation . . . |

. . . . . . . . . . . . . . . |

|

7 |

For the Home Owner . . . . . . . . . . . . . . . . . . . . |

. |

7 |

|

For the Installing Dealer/Contractor . . . . . . . . . . . . . . |

. |

7 |

|

Owner Orientation . |

. . . . . . . . . . . . . . . . . . . . |

. |

7 |

Fuel Factors . . . |

. . . . . . . . . . . . . . . . . . . . . |

|

. 7 |

Generator Location |

. . . . . . . . . . . . . . . . . . . . . |

|

. 8 |

Essential Circuits . |

. . . . . . . . . . . . . . . . . . . . . |

|

. 8 |

Delivery Inspection |

. . . . . . . . . . . . . . . . . . . . . |

|

. 9 |

Features and Controls . . . . . . . . . . . . . . 10

Operation . . . . . . . . . . . . . . . . . . 13

Automatic Operation . . . . . . . . . . . . . . . . . . . . . 13 Setting Exercise Timer . . . . . . . . . . . . . . . . . . . . 14

Maintenance . . . . . . . . . . . . . . . . . 14

Fault Detection System . . . . . . . . . . . . . . . . . . . . 14 Generator Maintenance . . . . . . . . . . . . . . . . . . . . 16 Engine Oil . . . . . . . . . . . . . . . . . . . . . . . . . 16 Engine Coolant System . . . . . . . . . . . . . . . . . . . . 17 Battery . . . . . . . . . . . . . . . . . . . . . . . . . . 17 Storage . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Troubleshooting . . . . . . . . . . . . . . . . 19 Warranty . . . . . . . . . . . . . . . . . . 20 Product Specifications . . . . . . . . . . . . . . 22

Español |

Français |

Save These Instructions

Safety Rules

The safety alert symbol ( ) is used with a signal word (DANGER, CAUTION, WARNING), a pictorial and/or a safety message to alert you to hazards. DANGER indicates a hazard which, if not avoided, will result in death or serious injury. WARNING indicates a hazard which, if not avoided, could result in death or serious injury. CAUTION indicates a hazard which, if not avoided, might result in minor or moderate injury. NOTICE indicates a situation that could result in equipment damage. Follow safety messages to avoid or reduce the risk of injury or death.

) is used with a signal word (DANGER, CAUTION, WARNING), a pictorial and/or a safety message to alert you to hazards. DANGER indicates a hazard which, if not avoided, will result in death or serious injury. WARNING indicates a hazard which, if not avoided, could result in death or serious injury. CAUTION indicates a hazard which, if not avoided, might result in minor or moderate injury. NOTICE indicates a situation that could result in equipment damage. Follow safety messages to avoid or reduce the risk of injury or death.

The manufacturer cannot possibly anticipate every possible circumstance that might involve a hazard. The warnings in this manual, and the tags and decals affixed to the unit are, therefore, not all-inclusive. If you use a procedure, work method or operating technique that the manufacturer does not specifically recommend, you must satisfy yourself that it is safe for you and others. You must also make sure that the procedure, work method or operating technique that you choose does not render the generator system unsafe.

Hazard Symbols and Meanings

Explosion |

Fire |

Electrical Shock |

Toxic Fumes |

Rotating Parts |

Hot Surface |

Auto Start |

Explosive Pressure |

Chemical Burn |

warning

warning

Storage batteries give off explosive hydrogen gas during recharging.

Slightest spark will ignite hydrogen and cause explosion.

Battery electrolyte fluid contains acid and is extremely caustic.

Contact with battery contents will cause severe chemical burns.

A battery presents a risk of electrical shock and high short circuit current.

•DO NOT dispose of battery in a fire.

•DO NOT allow any open flame, spark, heat, or lit cigarette during and for several minutes after charging a battery.

•DO NOT open or mutilate the battery.

•Wear protective goggles, rubber apron, and rubber gloves.

•Remove watches, rings, or other metal objects.

•Use tools with insulated handles.

warning

warning

Running engine gives off carbon monoxide, an odorless, colorless, poison gas.

Breathing carbon monoxide can cause headache, fatigue, dizziness, vomiting, confusion, seizures, nausea, fainting or death.

•Operate generator ONLY outdoors.

•Install a battery operated carbon monoxide alarm near the bedrooms.

•Keep exhaust gas from entering a confined area through windows, doors, ventilation intakes, or other openings.

warning

warning

The engine exhaust from this product contains chemicals known to the State of California to cause cancer, birth defects, or other reproductive harm.

BRIGGSandSTRATTON.COM

warning

warning

Generator produces hazardous voltage.

Failure to properly ground generator can result in electrocution.

Failure to isolate generator from power utility can result in death or injury to electric utility workers due to backfeed of electrical energy.

•When using generator for backup power, notify utility company.

•DO NOT touch bare wires or receptacles.

•DO NOT handle generator or electrical cords while standing in water, while barefoot, or while hands or feet are wet.

•If you must work around a unit while it is operating, stand on an insulated dry surface to reduce shock hazard.

•DO NOT allow unqualified persons or children to operate or service generator.

•In case of an accident caused by electrical shock, immediately shut down the source of electrical power and contact the local authorities. Avoid direct contact with the victim.

•Despite the safe design of the home generator, operating this equipment imprudently, neglecting its maintenance or being careless can cause possible injury or death.

•Remain alert at all times while working on this equipment. Never work on the equipment when you are physically or mentally fatigued.

•Before performing any maintenance on the generator, disconnect the battery cable indicated by a NEGATIVE, NEG or (-) first. When finished, reconnect that cable last.

•After your home generator is installed, the generator may crank and start without warning any time there is a power failure. To prevent possible injury, always set the generator’s system switch to OFF AND remove the 15 Amp fuse BEFORE working on the equipment.

warning

warning

Propane and Natural Gas are extremely flammable and explosive.

Fire or explosion can cause severe burns or death.

•Install the fuel supply system according to N.F.P.A 37 and other applicable fuel-gas codes.

•Before placing the home generator into service, the fuel system lines must be properly purged and leak tested.

•After the generator is installed, you should inspect the fuel system periodically.

•NO leakage is permitted.

•DO NOT operate engine if smell of fuel is present or other explosive conditions exist.

•DO NOT smoke around the generator. Wipe up any oil spills immediately. Ensure that no combustible materials are left in the generator compartment. Keep the area near the generator clean and free of debris.

warning

warning

Contact with muffler area can result in serious burns.

Exhaust heat/gases can ignite combustibles or structures causing a fire.

•DO NOT touch hot parts and AVOID hot exhaust gases.

•Allow equipment to cool before touching.

•DO NOT install the generator closer than 5 feet (1.5m) from any combustibles or structures with combustible walls having a fire resistance rating of less than 1 hour.

warning

warning

Starter and other rotating parts can entangle hands, hair, clothing, or accessories.

•NEVER operate generator without protective housing or covers.

•DO NOT wear loose clothing, jewelry or anything that may be caught in the starter or other rotating parts.

•Tie up long hair and remove jewelry.

caution

caution

Installing the control panel’s 15A fuse could cause the engine to start.

•DO NOT install this fuse until all plumbing and wiring has been completed and inspected.

caution

caution

Excessively high operating speeds increase risk of injury and damage to generator.

Excessive load will cause engine shutdown..

•DO NOT tamper with governed speed. Generator supplies correct rated frequency and voltage when running at governed speed.

•DO NOT modify generator in any way.

CAUTION

CAUTION

Avoid prolonged or repeated skin contact with used motor oil.

•Used motor oil has been shown to cause skin cancer in certain laboratory animals.

•Thoroughly wash exposed areas with soap and water.

notice

Exceeding generators wattage/amperage capacity can damage generator and/or electrical devices connected to it.

•See Essential Circuits.

•Start generator and let engine stabilize before connecting electrical loads.

notice

Improper treatment of generator can damage it and shorten its life.

•Use generator only for intended uses.

•If you have questions about intended use, ask dealer or contact Briggs and Stratton.

•Operate generator only on level surfaces.

•Adequate, unobstructed flow of cooling and ventilating air is critical to correct generator operation.

•The Coolant Fill, Battery and Control Panel doors must be installed whenever the unit is running.

•DO NOT expose generator to excessive moisture, dust, dirt, or corrosive vapors.

•Despite the safe design of the home generator, operating this equipment imprudently, neglecting its maintenance or being careless can cause possible injury or death.

•DO NOT start engine with air cleaner base removed.

•DO NOT insert any objects through cooling slots.

•DO NOT use the generator or any of its parts as a step. Stepping on the unit can cause stress and break parts. This may result in dangerous operating conditions from leaking exhaust gases, fuel leakage, oil leakage, etc.

•If connected devices overheat, turn them off and disconnect them from generator.

•Shut off generator if:

-electrical output is lost;

-equipment sparks, smokes, or emits flames; -unit vibrates excessively.

BRIGGSandSTRATTON.COM

Installation

We sincerely appreciate your patronage. For this reason, Briggs & Stratton has made every effort to provide for a safe, streamlined and cost-effective installation. Because each installation is unique, it is impossible to know of and advise the trade of all conceivable procedures and methods by which installation might be achieved. Neither could we know of possible hazards and/or the results of each method or procedure. For these reasons,

Only current licensed electrical and plumbing contractors should attempt home generator system installations. Installations must strictly comply with all applicable codes, industry standards and regulations.

Your Briggs & Stratton home generator is supplied with this “Operator’s Manual” and a separate “Installation Manual”. These are important documents and should be retained by the owner after the installation has been completed.

For the Home Owner

To help you make informed choices and communicate effectively with your installation contractor(s),

Read and understand Owner Orientation in this manual before contracting or starting your home generator installation.

To arrange for proper installation, contact the store at which you purchased your Briggs & Stratton home generator, your dealer, a licensed electrician or your utility power provider.

The home generator warranty is VOID unless the system is installed by licensed electrical and plumbing professionals.

The Emission Control System for this generator is warranted for standards set by the U.S. Environmental Protection Agency and by the California Air Resources Board (CARB).

For the Installing Dealer/Contractor

For most applications, the Installation manual contains all the information required to properly install and start the home generator. This Operator’s Manual describes essential circuit selection, routine operation and owner maintenance procedures.

If you need more information, call (800) 743-4115, between 8:00 AM and 5:00 PM CT.

Owner Orientation

This section provides home generator owners with the information necessary to achieve the most satisfactory and cost effective installation possible.

The illustrations are for typical circumstances and are meant to familiarize you with the installation options available with your home generator. A thorough understanding of these options will provide fundamental control over the cost of your installation, as well as ensure your final satisfaction and security.

Federal and local codes, appearance, noise levels, fuel types, and distances are the factors that must be considered when negotiating with an installation professional. Remember that as the distance from the existing electrical service and gaseous fuel supply increases, and the number of 90 degree bends in the fuel supply increases; equal compensations

in piping and wiring materials must be allowed for. This is necessary to comply with local codes and overcome electrical voltage drops and gaseous fuel pressure drops.

The factors mentioned above will have a direct affect on the overall price of your home generator installation.

NOTE: In some areas you may need to acquire electrical permits for installing the home generator, building permits for installing gas lines, and permits for noise allowances. Your installer should check your local codes AND obtain the permits before installing the system.

Fuel Factors

This home generator system was factory tested and adjusted using natural gas. It can also operate on liquid propane (LP vapor). For proper engine function, factors that are inherent to each of these fuels, your location and the duration of possible utility interruptions are important considerations in the following fuel guidelines:

•Use clean, dry fuel, free of moisture or any particulate material. Using fuels outside the following recommended values may cause performance problems.

•For engines set up to run on propane vapor (LP), commercial grade HD5 propane with a minimum fuel energy of 2500 BTUs/ft3 with maximum propylene content of 5% and butane and heavier gas content of 2.5% and minimum propane content of 90%.

warning

warning

Propane and Natural Gas are extremely flammable and explosive.

Fire or explosion can cause severe burns or death.

•The home generator is equipped with an automatic safety gas “fuel shut-off” valve.

•DO NOT operate the equipment if the “fuel shut-off” valve is missing or inoperative.

Power Decrease at High Altitude or High Temperature

Air density is less at high altitudes, resulting in less available engine power. Specifically, engine power will decrease 3.5% for each 1,000 feet (300 meters) above sea level and 1% for each 10° F (5.6°C) above 77°F (25°C). Make sure you and your installer consider these factors when determining total generator load.

Generator Location

The actual physical location of your home generator has a direct affect on:

1.The amount of plumbing required to fuel your generator.

2.The amount of wiring required to control and connect your generator.

NOTE: Specific location guidelines are discussed in the Installation Manual. Acquaint yourself with that information and confer with your installer. Be sure to ask how your site might affect installation costs and compliance with local codes and standards.

Generator Clearances

The generator must be installed outdoors. DO NOT install generator where exhaust gas could accumulate and enter inside or be drawn into a potentially occupied building.

Ensure exhaust gas is kept away from any windows, doors, ventilation intakes or other openings that can allow exhaust gas to collect in a confined area. Prevailing winds and air currents should be taken into consideration when positioning generator. See the Installation Manual for full details on safe generator location.

warning

warning

Exhaust heat/gases can ignite combustibles or structures causing a fire.

•DO NOT install the generator closer than 5 feet (1.5m) from any combustibles or structures with combustible walls having a fire resistance rating of less than 1 hour.

Essential Circuits

As a home generator owner, it is important that you clearly identify the circuits in your building that are “essential” to you.

It is also important that your installer understand which circuits you want to include as “Essential Circuits”. Depending on the power consumed by these circuits, most or all of them can be switched to the home generator for the duration of normal power interruption.

The wattage reference table that follows will assist you with your decision-making process. It provides the wattage used by many ordinary household devices. Use it as a guide when selecting your essential circuits. Review this information with your installer and ask about any technical considerations that might affect your installation. This chart serves as a guide only. For exact wattage use an appropriate wattage meter.

|

Device |

Running Watts |

|

|

|

q |

Air Conditioner (12,000 Btu)* |

1700 |

|

|

|

q |

Air Conditioner (24,000 Btu)* |

3800 |

q |

Air Conditioner (40,000 Btu)* |

6000 |

|

|

|

q |

Battery Charger (20 Amp) |

500 |

|

|

|

q |

Circular Saw (6-1/2”) |

800 to 1000 |

q |

Clothes Dryer (Electric)* |

5750 |

|

|

|

q |

Clothes Dryer (Gas)* |

700 |

|

|

|

q |

Clothes Washer* |

1150 |

q |

Coffee Maker |

1750 |

|

|

|

q |

Compressor (1 HP)* |

2000 |

|

|

|

q |

Compressor (1/2 HP)* |

1400 |

q |

Compressor (3/4 HP)* |

1800 |

|

|

|

q |

Curling Iron |

700 |

|

|

|

q |

Dehumidifier* |

650 |

q |

Electric Blanket |

400 |

|

|

|

q |

Electric Range (per element) |

1500 |

|

|

|

q |

Electric Skillet |

1250 |

q |

Freezer* |

700 |

|

|

|

q |

Furnace Fan (1/2 HP)* |

800 |

|

|

|

q |

Garage Door Opener* |

500 to 750 |

q |

Hair Dryer |

1200 |

|

|

|

q |

Hand Drill |

250 to 1100 |

|

|

|

q |

Iron |

1200 |

q |

Jet Pump* |

800 |

|

|

|

q |

Light Bulb |

100 |

|

|

|

q |

Microwave Oven |

700 to 1000 |

q |

Milk Cooler* |

1100 |

|

|

|

q |

Oil Burner on Furnace |

300 |

|

|

|

q |

Oil Fired Space Heater (140,000 Btu) |

400 |

q |

Oil Fired Space Heater (30,000 Btu) |

150 |

|

|

|

q |

Oil Fired Space Heater (85,000 Btu) |

225 |

|

|

|

q |

Radio |

50 to 200 |

q |

Refrigerator |

700 |

|

|

|

q |

Slow Cooker |

200 |

|

|

|

q |

Submersible Pump (1 HP)* |

2000 |

q |

Submersible Pump (1/2 HP)* |

1500 |

|

|

|

q |

Submersible Pump (1-1/2 HP)* |

2800 |

|

|

|

q |

Sump Pump* |

800 to 1050 |

q |

Table Saw (10”)* |

1750 to 2000 |

|

|

|

q |

Television |

200 to 500 |

|

|

|

q |

Toaster |

1000 to 1650 |

*Allow three (3) times listed watts for starting device

BRIGGSandSTRATTON.COM

Essential Circuit Selection

When selecting the essential circuits that will be switched to “Standby Power,” it is important that the sum of the combined circuit loads does not exceed the wattage/ amperage capacity of the generator. To help you with your selection of essential circuits, please consider the following:

•Add up the total wattage of all electrical devices to be connected at one time. This total should NOT be greater than the generator’s wattage capacity.

The rated wattage of lights can be taken from light bulbs. The rated wattage of tools, appliances and motors can usually be found on a data plate or decal affixed to the device.

•If the appliance, tool or motor nameplate does not list wattage, multiply volts times the ampere rating to determine watts (Volts x Amps = Watts).

Some electric motors (induction types) require about three times more watts of power for starting than for running. This surge lasts for only a few seconds. Be sure you allow for this high starting wattage when selecting electrical devices that will be energized by the home generator:

•Figure the watts required to start the largest motor.

•Add that to the total running watts of all other connected loads.

This Briggs & Stratton home generator complies with the following “stationary standby power rating”:

The standby power rating is applicable for supplying power for the duration of normal power interruption. No sustained overload capability is available for this rating.

This rating is applicable to installations served by a reliable normal utility source. This rating is only

applicable to variable loads with an average load factor of 80% of the standby rating. The standby rating is only applicable for optional standby power where the generator set serves as the backup to the normal utility source.

Use the wattage reference table provided and mark those circuits you consider “critical” or “essential”. Make sure you and your installer consider the system’s altitude above sea level and the ambient temperature range when determining total generator load.

In a utility outage, you need to ‘manage’ power distribution by turning off non-essential loads. Some examples of non essential loads are as follows:

•Pool pump

•Hot tub

•Electric hot tub and/or pool heaters

•Central air conditioners

•Electric hot water heaters

•Electric range and/or oven

•Arc welder

•Non essential electric heaters

Delivery Inspection

Carefully inspect the home generator for any damage that may have occurred during shipment.

IMPORTANT: If loss or damage is noted at time of delivery, have the person(s) making delivery note all damage on the freight bill and affix his signature under the consignor’s memo of loss or damage. If loss or damage is noted after delivery, separate the damaged materials and contact the carrier and your installer for claim procedures. Missing or damaged parts are not warranted.

The home generator system is supplied with:

•Home generator

•Fully-serviced coolant system

•Fully-serviced oil/lubricating system

•UL569/CSA8.3-listed flexible fuel hook-up

•Installation and start-up manual

•Operator’s manual

•Engine operator’s manual

•Installation checklist

•Two access door keys

•One spare 15A fuse

•10 Pole control panel connector

•Remote LED indicator kit (red LED/plate/screws)

To be supplied by Installer:

•650 CCA 55 amp-hour starting battery

•Connecting wire and conduit

•Fuel supply valves/plumbing

•Various specialty tools/equipment

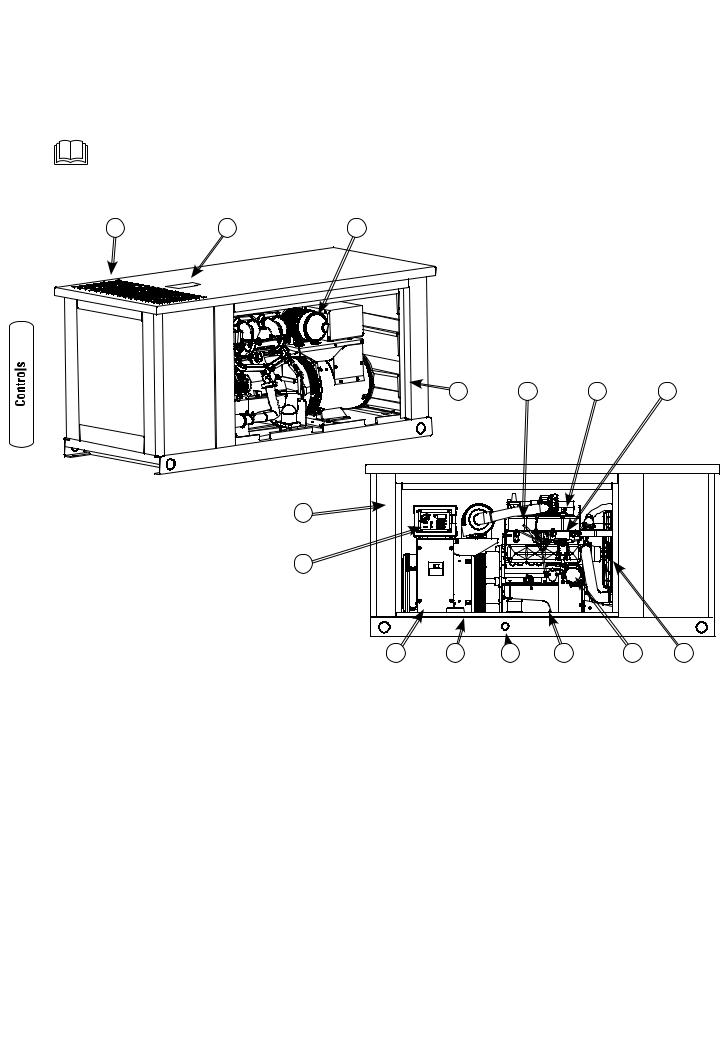

Features and Controls

Home Generator

Read this Operator’s Manual and Safety Rules before operating your generator.

Compare the illustrations with your generator to familiarize yourself with the locations of various controls and adjustments. Save this manual for future reference.

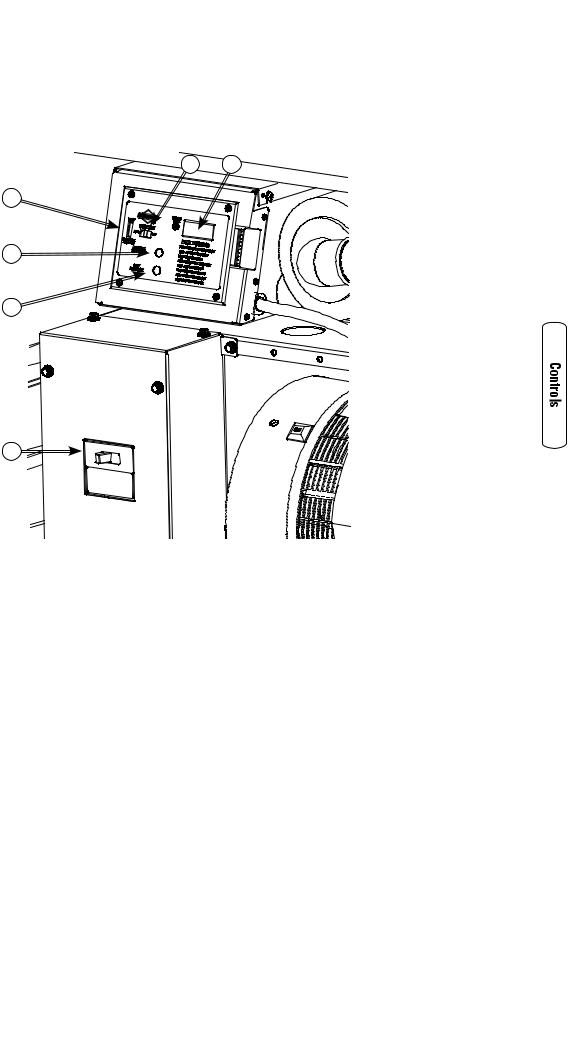

A B C

D E F G

R |

|

|

|

|

|

P |

|

|

|

|

|

N |

M |

L |

K |

J |

H |

Generator is pictured with access doors removed for clarity

A - Exhaust Port — High-performance muffler lowers engine noise to comply with most residential codes.

B - Coolant Fill Door — Provides access for servicing engine with oil and coolant.

C - Air Cleaner — Protects engine by filtering dust and debris out of intake air.

D - Battery Door opening — Provides access to starting battery and air cleaner.

E - Oil Dip Stick — Used to check the engine oil level.

F - Oil Fill Cap — Remove to service the engine with recommended oil.

G - Engine Label — Identifies engine model and type.

H - Coolant Recovery Bottle — Provides visual indicator of engine coolant level.

J - Oil Filter — Filters engine oil to prolong system life. K - Oil Drain Plug — Provided to facilitate oil changing. L - Fuel Inlet — Fuel supply is connected here.

M - Unit Data Decal (located on base) — Identifies unit by serial number.

N - Circuit Breaker Enclosure - Equipped with removable bottom to assist with conduit connection.

P - Control Panel — Used for various test, operation and maintenance functions. See System Control Panel on the next page.

R - Control Panel Door opening — Provides access to control panel.

NOTE: Circuit Breaker enclosure equipped with removable bottom panel to assist with conduit connection.

10 |

BRIGGSandSTRATTON.COM |

System Control Panel

Compare this Control Panel illustration with your generator to familiarize yourself with the location of these important controls:

E F

D |

C |

B |

A |

A - Circuit Breaker — Protects the system from shorts and other over-current conditions. Must be ON to supply power to the Automatic Transfer Switch.

B - Set Exercise Button — Used to set the exercise cycle start time and day-of-the-week. Exercise cycle only occurs in AUTO mode.

C - Manual Over-Ride Button — With system switch in AUTO position, push the manual over-ride switch to start the generator. To turn off the generator, push and hold the manual over-ride switch again until engine stops.

D - 15 Amp Fuse — Protects the home generator DC control circuits. If the fuse has ‘blown’ (melted open) or was removed, the engine cannot crank or start. Replace the fuse using only an identical ATO 15A fuse.

E - System Switch — This two-position switch is the most important control on the system and is used as follows:

•“AUTO” position is the normal operating position. If a utility power outage is sensed, the system will start the generator. When utility power is restored, AUTO lets the engine stabilize internal temperatures, shuts off the generator, and waits for the next utility power outage.

•“OFF” position turns off running generator, prevents unit from starting and resets any detected faults.

F - Digital Display — Displays the total number of hours the generator has been running and fault codes. Used to schedule maintenance tasks and for troubleshooting operational problems with the home generator. All fault conditions are described in Fault Detection System.

11

D

C

B

A

A

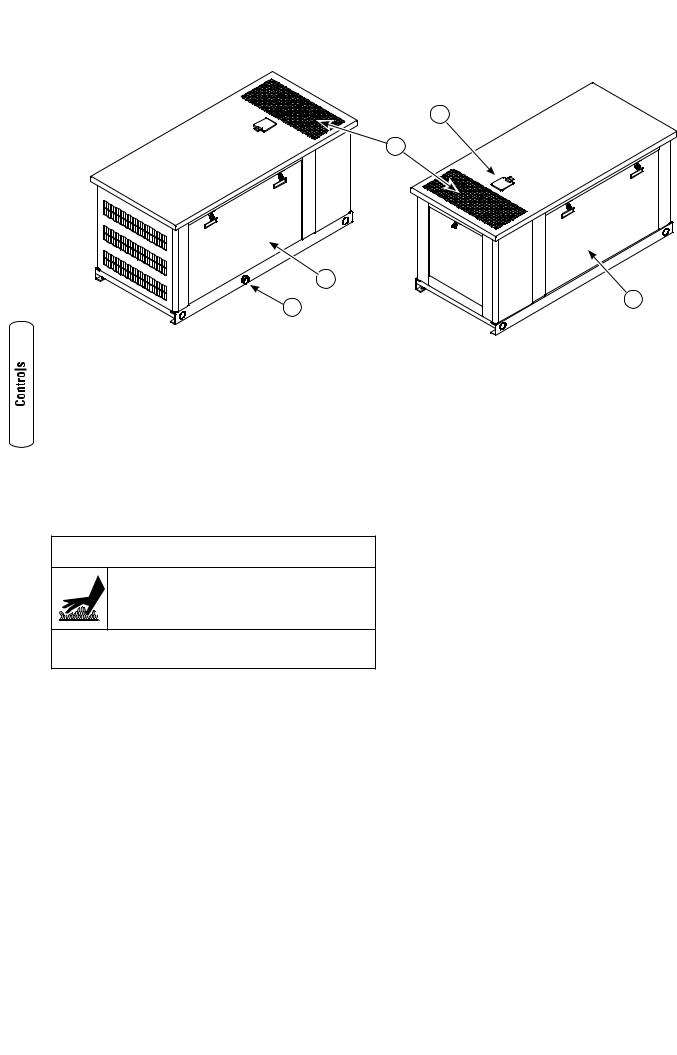

Access Doors

The home generator is equipped with an enclosure that has three access doors, as shown above. The doors are named for a significant component located behind them, as follows:

AFuel Inlet port (shown for reference)

BControl Panel door

CExhaust opening (shown for reference)

DCoolant Fill door

EBattery door

WARNING

WARNING

Contact with muffler area can result in serious burns.

•DO NOT touch hot parts and AVOID hot exhaust gases.

•Allow equipment to cool before touching.

The enclosure also includes muffler and radiator access panels, used for cleaning those components. Those panels should remain closed at all other times.

E

Each home generator is equipped with two identical keys. These keys fit the locks that secure the access doors.

To Open an Access Door:

1.Insert key into lock of access door handle you wish to open and turn one quarter turn counterclockwise. Remove key. Handle will remain unlocked until you relock it.

2.Grasp door’s handle and turn one quarter turn counterclockwise to open.

3.Coolant Fill door is unlocked in the same manner. It can be used for adding coolant or engine oil.

To Close an Access Door:

1.Close door and turn handle one quarter turn clockwise.

2.Insert key into lock in handle and turn one quarter turn clockwise. Remove key.

NOTE: The Coolant Fill, Battery and Control Panel doors must be installed whenever the unit is running.

12 |

BRIGGSandSTRATTON.COM |

Operation

Important Owner’s Considerations

Engine Oil

notice

Any attempt to crank or start the engine before it has been properly serviced with the recommended coolant or oil will result in equipment failure.

•Refer to Maintenance in the Operator’s Manual and engine manual for coolant and oil fill information.

•Damage to equipment resulting from failure to follow this instruction will void engine and generator warranty.

This engine is shipped from the factory pre-run and filled with non-synthetic oil (API SL 10W-30W). This allows for system operation in a wide range of temperature and climate conditions. Before starting the engine, check oil level and ensure that engine is serviced as described in the engine operator’s manual.

NOTE: The use of multi-grade oil does not alter the required oil change intervals described in the engine operator’s manual.

Coolant System

This engine is shipped from the factory filled with a 50-50 mix of automotive (Dex-Cool™ orange) anti-freeze

and water. This will provide optimum year round protection against freezing, boiling and corrosion. The coolant system incorporates a water heater that operates when ambient temperature is below 80ºF AND utility power is present at the transfer switch. Before starting the engine, check coolant level as described in the engine operator’s manual.

Battery

The installer must supply a sealed, rechargeable 12 Volt DC, 650 Cold Cranking Amps (CCA) 55 amp hour starting battery. The battery may not be at full charge when installed. If battery voltage is below 12 Volts, charge the battery. See Battery in the Maintenance section for details.

15 Amp Fuse

The generator’s 15 Amp fuse is critical to correct system operation. Your installer will ensure the fuse is properly installed upon completion of the installation.

Automatic Operation

To select automatic operation, do the following:

1.Confirm 15 Amp fuse is installed in control panel.

2.Set the main distribution panel circuit breaker that sends utility voltage to the transfer switch to ON.

3.Set the generator’s main circuit breaker to its ON position.

4.Set the control panel System switch to AUTO.

caution

caution

With the system switch set to AUTO, the engine may crank and start at any time without warning. Such automatic starting normally occurs when utility source voltage drops below a preset level or during the normal exercise cycle.

•To prevent possible injury that may be caused by such sudden starts, always set the system switch to OFF if performing maintenance on the system.

•Remove the 15 Amp fuse before working on or around the generator or transfer switch.

Checking Automatic Operation

To check the system for proper automatic operation, proceed as follows:

1.Turn OFF main distribution panel circuit breaker sending power to automatic transfer switch.

The engine will crank and start when utility voltage is lost and the sensor has timed out. Let the system go through its entire automatic operation sequence.

2.With generator output supplying its loads, turn ON main distribution panel circuit breaker that supplies utility power to Automatic Transfer Switch.

3.The automatic transfer switch will transfer loads back to utility power after 5 minute minimum run time and utility is restored.

4.The generator will run for an additional one minute for engine cool down, then shut down.

NOTE: If utility is restored and generator does not shut down after 10 minutes, set system switch to OFF and contact your installer or local service center.

This completes the test procedures for automatic operation. The home generator will now start automatically and will supply power to the transfer switch when utility power is lost.

13

Setting Exercise Timer

The home generator is equipped with an exercise timer that will start and exercise the system once every seven days. During this exercise period, the unit runs for approximately 20 minutes and then shuts down. Electrical load transfer DOES NOT occur during the exercise cycle (unless an utility power outage occurs).

A button on the control panel is labeled “Set Exercise” (see System Control Panel). The specific day and the specific time of day this button is pressed is programmed into the control board memory. This date and time is then used to automatically initiate the system exercise cycle. The “SET EXERCISE” legend on the control panel will flash until the set exercise cycle is set.

To perform the Set Exercise procedure:

1.Choose the day and time you want your home generator to exercise.

2.On that day and time, press and hold down the “Set Exercise” button for three seconds.

NOTE: “SET EXERCISE” will flash until the button is pressed for three seconds, then “SET EXERCISE” will illuminate for 5 seconds, and finally turn off.

3.The unit will then start and run it’s 20 minute exercise cycle.

For example, if you press the “Set Exercise” button on Sunday morning at 10:00 AM, the unit will run an immediate exercise cycle and an exercise cycle every following Sunday at 10:00 AM (+/- 1/2 hour).

NOTE: “Set Exercise” will only work if the unit is in the Automatic mode and this exact procedure is followed. The exerciser will need to be re-set if the 15 Amp fuse is removed or changed, or if the 12 Volt DC battery is disconnected.

If you want to change the day and time the unit exercises, simply perform the “Set Exercise” procedure at the exact weekday and time you want it to take place.

Maintenance

Servicing the System

To service the home generator system:

1. Remove 15 Amp fuse from control panel. 2, Set control panel System switch to OFF.

3.Set the generator’s main circuit breaker to its OFF position.

4.Utility voltage is present. Disconnect power before servicing by removing the two 10 Amp fuses from the transfer switch.

Fault Detection System

The generator may have to run for long periods of time with no operator present. For that reason, the system is equipped with sensors that automatically shut down the generator

in the event of potentially damaging conditions, such as low oil pressure, high temperature, over speed, and other conditions.

The generator’s control panel has a digital display that shows fault codes, like “FC_1”. The table below lists the detected fault, the fault code as displayed on the control panel, and the number of blinks seen on the remote LED indicator.

Fault Description |

Fault Codes |

LED Flashes |

Low battery voltage |

FC_1 |

1 |

Low oil pressure |

FC_2 |

2 |

Low voltage |

FC_3 |

3 |

Engine fails to start |

FC_4 |

4 |

Low frequency |

FC_5 |

5 |

Engine overspeed |

FC_6 |

6 |

|

|

|

High temperature |

FC_7 |

7 |

Transfer switch fault |

FC_8 |

8 |

The remote LED indicator is installed at a convenient inside location. The LED will remain lit when the generator is in AUTO. Should a system fault be detected, the LED will turn on and off in a series of blinks that identify the problem. The blink pattern is repeated with a brief pause between each series of blinks.

Reset Fault Detection System

The operator must reset the fault detection system each time it activates. To do so, place the control panel System switch in the OFF position for 5 seconds or more. Remedy the fault condition, then return the home generator to service by placing the system switch in the AUTO position.

14 |

BRIGGSandSTRATTON.COM |

A description of each fault and suggested remedies are as follows:

No LED - Discharged Battery

If there is a detected fault condition but the LED is not blinking, this is because the battery is completely discharged. To remedy the problem, remove the 15 Amp fuse and disconnect the battery from the generator. Take the battery to a local battery store for analysis. Replace the battery after it has been fully recharged, connecting the NEGATIVE cable last. Then install the 15 Amp fuse in the control panel.

NOTE: With the battery installed, all wiring to transfer switch and home generator completed, utility power supplied to the Automatic Transfer Switch, and the unit in AUTO mode, the battery receives a trickle charge while the engine is not running. The trickle charge is not able to recharge a battery that is completely discharged. See Battery in Maintenance.

Low Battery Voltage (FC_1)

This fault is indicated by fault code FC_1 and one blink on the LED indicator. This condition occurs if the generator cannot start because the starting battery output power is below that needed to crank the engine. Causes for this problem may be a faulty battery or battery charge circuit.

To remedy the problem, contact your local service center to check the battery charge output. Remove the 15 Amp fuse and disconnect the battery from the generator. Take the battery to a local battery store for analysis.

Replace the battery after it has been fully recharged, connecting the NEGATIVE cable last. Then install the 15 Amp fuse.

Low Oil Pressure (FC_2)

This fault is indicated by fault code FC_2 and two blinks on the remote LED indicator. The unit is equipped with an oil pressure switch which uses normally closed contacts held open by engine oil pressure during operation. Should oil pressure drop below the 8 psi range, switch contacts close and the engine is shut down.

To remedy the low oil pressure condition, add the recommended oil to the FULL mark on the dipstick.

If the low oil pressure condition still exists, the engine will start, then shut down again. The fault code will appear and the LED will flash. In this case, contact a Briggs & Stratton Authorized Dealer.

Low Voltage (Generator, FC_3)

This fault is indicated by fault code FC_3 and three blinks on the LED indicator. This condition is caused by a restriction in the fuel flow, a broken or disconnected signal lead, a failed alternator winding, the control panel circuit breaker is open, or the generator is overloaded.

To remedy the problem, contact your installer or a Briggs & Stratton Authorized Dealer.

Engine Fail To Start (FC_4)

This fault is indicated by fault code FC_4 and four blinks on the LED indicator. This feature prevents the generator from damaging itself if it continually attempts to start in spite

of another problem, such as no fuel supply. Each time the system is directed to start, the unit will crank for 10 seconds, pause for 10 seconds, and repeat. If the system does not begin producing electricity after approximately 2 minutes, the unit will stop cranking and the LED will blink.

Check to make sure the generator’s main circuit breaker is in the ON position in order for the sensing leads to verify that the unit is running.

The most likely cause of this problem is no fuel supply. Check the internal and external fuel shut off valves to ensure they are fully open. Other causes could be failed spark plug(s), failed engine ignition, or the engine air filter is clogged. You may need to contact your installer for assistance if you can’t remedy these problems.

Low Frequency (FC_5)

This fault is indicated by fault code FC_5 and five blinks on the LED indicator. This feature protects devices connected to the transfer switch by shutting the generator down if the engine runs slower than 55 Hz for three seconds. This condition is caused by a failed engine component or by excessive loads on the generator. To remedy the problem, contact your installer or a Briggs & Stratton Authorized Dealer.

Engine Overspeed (FC_6)

This fault is indicated by fault code FC_6 and six blinks on the LED indicator. This feature protects devices connected to the transfer switch by shutting the generator down if the engine happens to run faster than the preset limit. The overspeed fault is detected as follows:

•If the generator output frequency is 65-70 Hz, after three seconds, the generator will shut down.

•If the generator output frequency is greater than 70 Hz, the generator will shut down immediately.

This condition is caused by a failed engine component. To remedy the problem, contact your installer or a Briggs & Stratton Authorized Dealer.

15

High Temperature (FC_7)

This fault is indicated by fault code FC_7 and seven blinks on the LED indicator. The contacts of the coolant temperature switch are normally open. If the engine coolant temperature exceeds approximately 115.5°C (240°F), the fault is detected and the engine shuts down.

Common causes for this condition include running the unit with all access doors removed, obstructed air inlet or

exhaust port, low oil or coolant level, or debris in the engine compartment or radiator.

To resolve the problem, let the engine cool down and remove any accumulated debris and obstructions. Ensure that the access doors are installed whenever the unit is running.

Transfer Switch Fault (FC_8)

This fault is indicated by fault code FC_8 and eight blinks on the LED indicator (if transfer switch is equipped with fault detection). The most likely cause of this fault is a blown fuse in the transfer switch.

To remedy the problem, contact your installer or a Briggs & Stratton Authorized Dealer.

Generator Maintenance

The generator warranty does not cover items that have been subjected to operator abuse or neglect. To receive full value from the warranty, the operator must maintain the system as instructed in the engine operator’s manual.

All adjustments should be made at least once each season. Follow the requirements in the engine operator’s manual.

Generator maintenance consists of keeping the unit clean. Operate the unit in an environment where it will not be exposed to excessive dust, dirt, moisture or any corrosive vapors. Cooling air louvers on the enclosure must not become clogged with snow, leaves, or any other foreign material.

Check the cleanliness of the unit frequently and clean when dust, dirt, oil, moisture or other foreign substances are visible on its exterior/interior surface.

NOTE: DO NOT use direct spray from a garden hose to clean generator. Water can enter the engine and generator and cause problems.

Engine Maintenance

An engine manual was packaged with this system. Please refer there for all engine-related maintenance topics. However, proper engine cooling and lubrication are so important we give them special mention here.

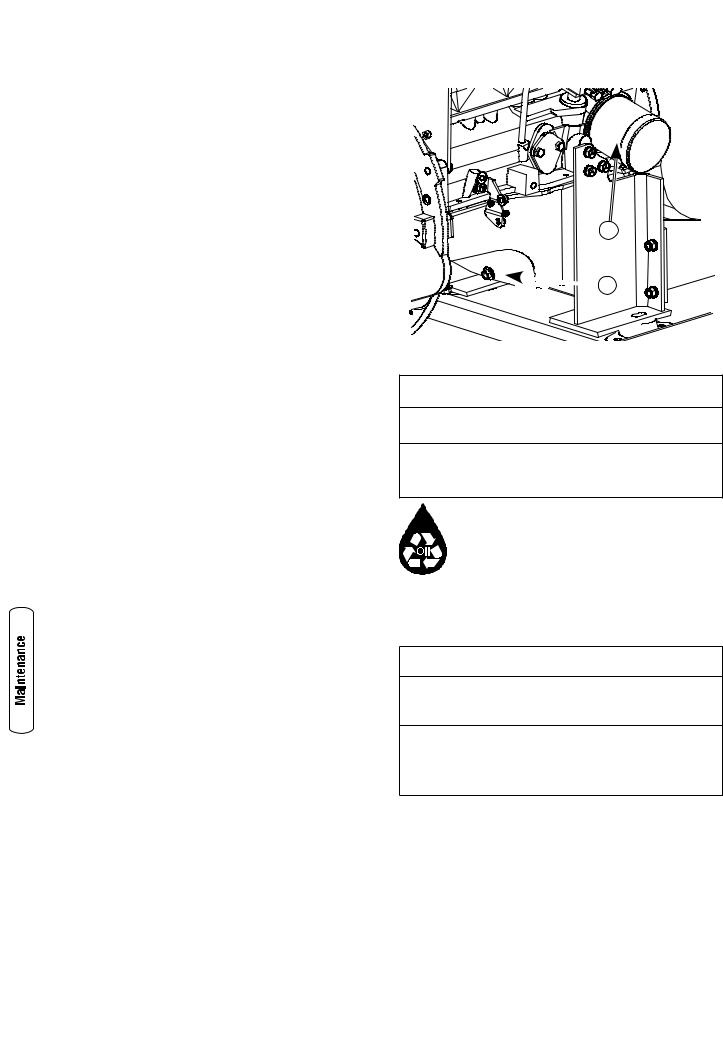

Engine Oil

The system is filled with the recommended non-synthetic oil (API SL 10W-30W). This allows for system operation in a wide range of temperature and climate conditions.

NOTE: Refer to the engine operator’s manual for recommended oil change intervals.

Shown here is the oil drain location (B) and the oil filter (A).

A

B

B

Changing Engine Oil

CAUTION

CAUTION

Avoid prolonged or repeated skin contact with used motor oil.

•Used motor oil has been shown to cause skin cancer in certain laboratory animals.

•Thoroughly wash exposed areas with soap and water.

KEEP OUT OF REACH OF CHILDREN. DON’T POLLUTE. CONSERVE RESOURCES. RETURN USED OIL TO COLLECTION CENTERS.

1.Disconnect the negative battery terminal from battery.

2.Change oil while the engine is still warm from running, as described in the engine operator’s manual.

notice

Any attempt to crank or start the engine before it has been properly serviced with the recommended oil will result in equipment failure.

•Refer to Maintenance and engine manual for oil fill information.

•Damage to equipment resulting from failure to follow this instruction will void engine and generator warranty.

To fill your engine with oil:

Follow the oil grade recommendation and oil fill instructions given in the engine operator’s manual.

To make the task of adding oil more convenient, we recommend use of a funnel attached to a length of tubing long enough to reach from the Coolant Fill door to the oil fill opening on the engine valve cover.

16 |

BRIGGSandSTRATTON.COM |

Engine Coolant System

With the engine cold, check the coolant level in the coolant reservoir, seen inside the Control Panel door. Maintenance instructions for engine coolant are found in the engine operator’s manual.

Battery

Charging the Battery

If it is necessary to charge the battery, proceed as follows:

1.Set generator’s system switch to OFF.

2.Remove 15 Amp fuse from control panel.

3.Disconnect negative battery cable to negative battery terminal (indicated by NEGATIVE, NEG, or (-).

notice

Failure to disconnect negative battery cable will result in equipment failure.

•DO NOT attempt to jump start the battery.

•Damage to equipment resulting from failure to follow this instruction will void warranty.

4.Charge battery with battery charger at 2 Amps until battery holds 12 Volts.

warning

warning

Storage batteries give off explosive hydrogen gas during recharging.

Slightest spark will ignite hydrogen and cause explosion.

Battery electrolyte fluid contains acid and is extremely caustic.

Contact with battery contents will cause severe chemical burns.

A battery presents a risk of electrical shock and high short circuit current.

•DO NOT dispose of battery in a fire.

•DO NOT allow any open flame, spark, heat, or lit cigarette during and for several minutes after charging a battery.

•DO NOT open or mutilate the battery.

•Wear protective goggles, rubber apron, and rubber gloves.

•Remove watches, rings, or other metal objects.

•Use tools with insulated handles.

NOTE: With the battery installed and utility power available to the transfer switch, the battery receives a trickle charge whenever the engine is not running. It may take up to

72 hours to fully charge a discharged battery with the trickle charge. The trickle charge is not able to recharge a battery that is completely discharged.

5.Connect negative battery cable to negative battery terminal (indicated by NEGATIVE, NEG, or (-)).

6.Ensure hardware on both positive and negative battery terminals is secure.

7.Reinstall 15 Amp fuse in control panel.

caution

caution

Installing the control panel’s 15A fuse could cause the engine to start.

•DO NOT install this fuse until all plumbing and wiring has been completed and inspected.

8.Set generator’s system switch to AUTO.

9.Reset exercise timer. See Setting Exercise Timer.

Servicing the Battery

If it is necessary to service the battery, proceed as follows:

1.Set control board System switch to OFF.

2.Remove 15 Amp fuse from control panel.

3.Service or replace battery as required.

4.Connect red battery cable to battery positive terminal (indicated by POSITIVE, POS, or (+)).

5.Connect negative battery cable to negative battery terminal (indicated by NEGATIVE, NEG, or (-).

6.Ensure hardware on both positive and negative battery terminals is secure.

7.Reinstall 15 Amp fuse in control panel.

8.Set generator’s system switch to AUTO.

9.Reset exercise timer. See Setting Exercise Timer.

To Clean the Generator

notice

Improper treatment of generator can damage it and shorten its life.

•DO NOT expose generator to excessive moisture, dust, dirt, or corrosive vapors.

•DO NOT insert any objects through cooling slots.

•Use a damp cloth to wipe exterior surfaces clean.

•Use a soft, bristle brush to loosen caked on dirt, oil, etc.

•Use a vacuum cleaner to pick up loose dirt and debris.

•Use low pressure air (not to exceed 25 psi) to blow away dirt. Inspect cooling air slots and openings on the generator. These openings must be kept clean and unobstructed.

17

When Calling the Factory

You must have the following information at hand if it is necessary to contact a local service center regarding service or repair of this unit:

1.Obtain the unit Model Number and Serial Number from the unit data label. See Controls for location of the label or refer to the information recorded on the inside front cover of the Installation Manual.

2.Obtain the engine identification numbers from the engine label. See the engine operator’s manual for location of this information. Please note that several different home generator systems are described in this manual, so your unit’s appearance may vary from that presented herein.

Storage

The Briggs & Stratton home generator is designed for long term service as a backup generator. As such, there is no need to take any storage precautions. However, if it

becomes necessary to take the system out of service for an extended period, call Briggs and Stratton Technical Services at (800) 743-4115, between 8:00 AM and 5:00 PM CT for specific recommendations. Refer to the engine operator’s manual for additional information

|

18 |

BRIGGSandSTRATTON.COM |

|

|

|

Troubleshooting

Problem |

|

Cause |

|

Correction |

|

|

|

|

|

|

|

Engine is running, but no AC output is |

1. |

Circuit breaker open or defective. |

1. |

Reset or replace circuit breaker. |

|

2. |

Fault in generator control panel. |

2. |

Contact local service facility. |

||

available. |

3. |

Poor wiring connections or |

3. |

Check and repair. |

|

|

|

defective transfer switch. |

|

|

|

|

|

|

|

|

|

|

1. |

Short circuit in a connected load. |

1. |

Disconnect shorted electrical load. |

|

Engine runs good at no-load but “bogs |

2. |

Generator is overloaded. |

2. |

See Essential Circuits. |

|

3. |

Shorted generator circuit. |

3. |

Contact local service facility. |

||

down” when loads are connected. |

4. |

Fuel pressure or mixture is |

4. |

See Gaseous Fuel System in the |

|

|

|

incorrect. |

|

Installation Manual. |

|

|

5. |

Kinked fuel line. |

5. |

Remove kink. Replace if necessary. |

|

|

|

|

|

|

|

|

1. |

15 Amp fuse missing or blown. |

1. |

Install (new) 15 Amp fuse. See |

|

|

|

|

|

System Control Panel. |

|

Engine will not start; or starts and runs |

2. |

Fuel supply turned off or depleted. |

2. |

Open fuel valve(s); check propane |

|

rough. |

|

|

|

tank. |

|

3. |

Failed battery. |

3. |

Replace battery. |

||

|

|||||

|

4. |

Fuel pressure is incorrect |

4. |

See Gaseous Fuel System in the |

|

|

|

|

|

Installation Manual. |

|

Engine shuts down during operation. |

1. |

Fuel supply turned off or depleted. |

1. |

Check fuel valves, fill propane tank. |

|

2. |

Fault indicator blinking. |

2. |

Count blinks and refer to Fault |

||

|

|

|

|

Detection System. |

|

|

|

|

|

|

|

Loss of power on essential circuits. |

1. |

Generator circuit breaker is open. |

1. |

Reset circuit breaker. |

|

2. |

Transfer switch problems. |

2. |

See the transfer switch manual. |

||

|

|||||

|

|

|

|

|

19

BRIGGS & STRATTON HOME POWER PRODUCTS GROUP, LLC

STANDBY GENERATOR OWNER WARRANTY POLICY

Effective January 1, 2008 replaces all undated Warranties and all Warranties dated before January 1, 2008

LIMITED WARRANTY

Briggs & Stratton Power Products Group, LLC will repair or replace, free of charge, any part(s) of the equipment that is defective in material or workmanship or both. Travel expenses will be reimbursed as specified under the Briggs and Stratton Warranty Guidelines document to authorized Briggs & Stratton dealers for performing warranty repair work. This warranty is effective for the time periods and subject to the conditions stated below. For all warranty service, find the nearest Authorized Service Dealer in our dealer locator map at BRIGGSandSTRATTON.COM.

THERE IS NO OTHER EXPRESS WARRANTY. IMPLIED WARRANTIES, INCLUDING THOSE OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED TO ONE YEAR FROM PURCHASE, OR TO THE EXTENT PERMITTED BY LAW. ANY AND ALL IMPLIED WARRANTIES ARE EXCLUDED. LIABILITY FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES ARE EXCLUDED TO THE EXTENT EXCLUSION IS PERMITTED BY LAW. Some states or countries do not allow limitations on how long an implied warranty lasts, and some states or countries do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation and exclusion may not apply to you. This warranty gives you specific legal rights and you may also have other rights which vary from state to state or country to country.

WARRANTY PERIOD

WARRANTY PERIOD

Consumer Use |

4 years or 2000 hours, whichever comes first |

Commercial Use |

2 years or 1000 hours, whichever comes first. First year 100% full |

|

coverage; second year alternator and engine only |

Rental Use |

None |

|

|

The warranty period begins on the date of purchase by the first retail consumer or commercial end user, and continues for the period of time stated above. “Consumer use” means personal residential household use by a retail consumer. “Commercial use” means all other uses, including use for commercial

or other income producing purposes. “Rental use” means any use of this product in a temporary or semi-permanently installed rental application. Once equipment has experienced commercial or rental use, it shall thereafter be considered as commercial or rental use for purposes of this warranty.

NO WARRANTY REGISTRATION IS NECESSARY TO OBTAIN WARRANTY ON BRIGGS & STRATTON PRODUCTS. SAVE YOUR PROOF OF PURCHASE RECEIPT. IF YOU DO NOT PROVIDE PROOF OF THE INITIAL PURCHASE DATE AT THE TIME WARRANTY SERVICE IS REQUESTED, THE MANUFACTURING DATE OF THE PRODUCT WILL BE USED TO DETERMINE THE WARRANTY PERIOD.

ABOUT YOUR WARRANTY

We welcome warranty repair and apologize to you for being inconvenienced. Any Authorized Service Dealer may perform warranty repairs. Most warranty repairs are handled routinely, but sometimes requests for warranty service may not be appropriate. For example, warranty service would not apply if equipment damage occurred because of misuse, lack of routine maintenance, and shipping, handling, warehousing or improper installation. Similarly, the warranty is void if the manufacturing date or serial number(s) on the equipment has been removed or the equipment has been altered or modified. During the warranty period, the Authorized Service Dealer, at its option, will repair or replace any part that, upon examination, is found to be defective under normal use and service. This warranty will not cover the following repairs and equipment:

•Normal Wear: Outdoor Power Equipment and engines, like all mechanical devices, needs periodic parts and service to perform well. This warranty does not cover repair when normal use has exhausted the life of a part or the equipment.

•Installation and Maintenance: This warranty does not apply to equipment or parts that have been subjected to improper or unauthorized installation or alteration and modification, misuse, negligence, accident, overloading, overspeeding, improper maintenance, repair or storage so as, in our judgment, to adversely affect its performance and reliability.

• Exclusions: For further clarification of engine warranty policies and procedures, contact Power Solutions Incorporated at 1-630-350-9400 or visit www. PSIengines.com. IMPCO Technologies is the holder of the Manufacturer of Record of all Environmental Protection Agency (EPA) compliance issues related to the use and performance of the engine.

This warranty excludes wear items such as engine oil, oil gauges, o-rings, filters, fuses, spark plugs, or anti-freeze, starting batteries, etc., or damage or malfunctions resulting from accidents, abuse, modifications, alterations, or improper servicing or freezing or chemical deterioration. Accessory parts are excluded from the product warranty. This warranty excludes failures due to acts of God and other force majeure events beyond the manufacturers control. Also excluded is used, reconditioned, and demonstration equipment; equipment used for prime power in place of utility power and equipment used in life support applications.

Warranty terms continue on next page.

20 |

BRIGGSandSTRATTON.COM |

Other Exclusions:

1.Any costs for adjustments, loose or leaking connections or clamps, installation or start-up operations fuel system cleaning and obstruction (due to chemical, dirt, carbon, lime, and so forth) and any failures caused by contaminated fuels, anti-freeze or oil, etc.

2.Units sold for primary power applications as defined by the U.S. & Canadian National Electric Codes whether utility power exists or where utility power does not normally exist

3.Any rental unit applications

4.Any loss of revenue that is a direct or indirect result of the failure of this unit

5.Failures caused by any external forces or Act of God such as, but not limited to freezing, theft, fire, collision, wars or riots, vandalism, lightning, earth quake wind storm, hail, volcanic eruption, water or flood damage, tornados, hurricanes, terrorist acts or nuclear holocaust

6.Any incidental, consequential or indirect damages caused by defects in materials or workmanship or any delay in repair of replacement of the defective part(s)

7.Failure due to misapplication or misrepresentation

8.Telephone, satellite, facsimile, cell phone, internet or any other communication expenses

9.Overtime, holiday or emergency labor expenses

10.Any mode of transportation deemed as abnormal in our judgment such as planes, ferries, railroad, buses, helicopters, snowmobiles, snow-cats, offroad vehicles, etc.

11.Any and all expenses incurred investigating performance complaints unless defective BSHPP materials and/or workmanship were the direct cause of the problem

12.Overnight freight costs for replacement parts

13.Other rental equipment used while warranty repairs are being performed (i.e., generators, material handling equipment, etc.)

14.Bodily injuries including death which results from the product’s failure 204949E, Rev. B, 1/17/2008

BRIGGS & STRATTON POWER PRODUCTS GROUP, LLC

JEFFERSON, WI, USA

21

Loading...

Loading...