BRADY B-427 Technical Data Sheet

Page 1 of 3

Technical Data Sheet

BRADY B-427 THERMAL TRANSFER PRINTABLE TRANSLUCENT VINYL TAPE

TDS No. B-427

Effective Date: 08-Jul-2008

Description: GENERAL

Print Technology: Thermal Transfer

Material Type: Translucent vinyl

Finish: Provided in a self-laminated format with a white printable zone and a translucent overlaminating area.

Adhesive: Permanent acrylic

APPLICATIONS

B-427 is an excellent material for wire and cable identification. This material has good clarity, conformability and is self-extinguishing. B-427 has outstanding water and oil resistance.

RECOMMENDED RIBBONS

Brady Series R4300 black and R4500 colored (red, blue, green) for thermal transfer printing.

REGULATORY/AGENCY APPROVALS

B-427 is UL Recognized to UL969 Labeling and Marking Standard when printed with the Brady

Series R4300 and R6200 ribbons. See UL files MH17154 for specific details.

B-427 is RoHS compliant to 2005/618/EC MCV amendment to RoHS Directive 2002/95/EC.

NoteDue to past non-compliant B-427 materials in the market, only B-427 products with RoHS compliance statement on product packaging are RoHS compliant.

Details: |

|

|

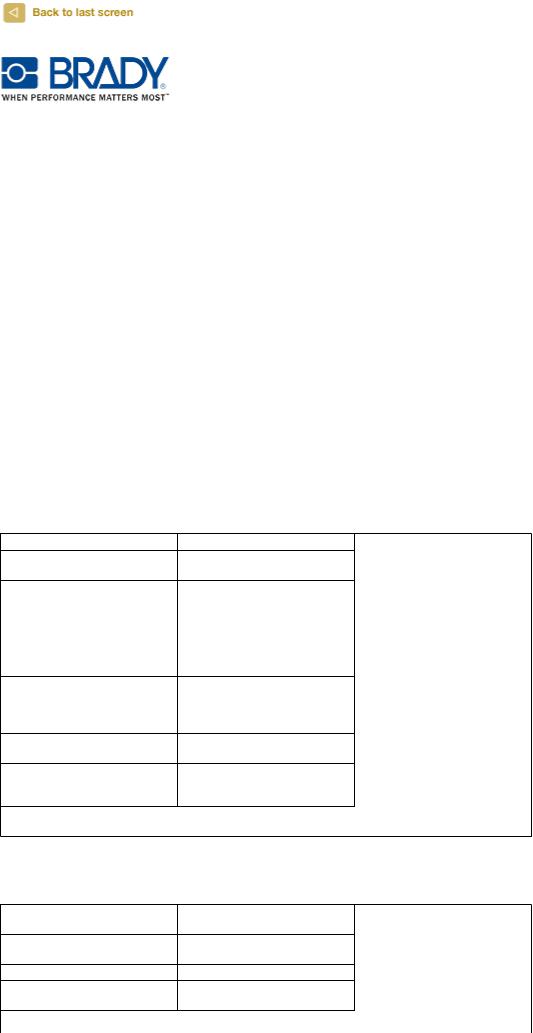

PHYSICAL PROPERTIES |

TEST METHODS |

AVERAGE RESULTS |

Thickness |

ASTM D 1000 |

|

|

-Total Thickness |

0.0040 inch (0.102 mm) |

Adhesion to: |

ASTM D 1000 |

|

-Stainless Steel |

20 minute dwell |

38 oz/in (42 N/100 mm) |

|

24 hour dwell |

49 oz/in (54 N/100 mm) |

-Polypropylene |

20 minute dwell |

25 oz/in (28 N/100 mm) |

|

24 hour dwell |

33 oz/in (36 N/100 mm) |

Tack |

ASTM D 2979 |

|

|

Polyken™ Probe Tack |

13.3 oz (378 g) |

|

(1 second dwell, 1 cm/sec |

|

|

separation) |

|

Drop Shear |

PSTC-7 (except use 1/2" x 1" |

3.3 hours |

|

sample) |

|

Tensile Strength and Elongation ASTM D 1000 |

|

|

|

-Machine |

12 lbs/in (210 N/100 mm), 152% |

|

-Cross |

11 lbs/in (193 N/100 mm), 195% |

Flammability |

ASTM D 1000 |

ABT less than 10 seconds |

|

Average Burn Time |

|

Performance properties tested with white printable zone of B-427 printed with Brady Series R4300 black thermal transfer ribbon. Samples wrapped around 0.080” OD TFE wire in a self-laminating format.

PERFORMANCE |

TEST METHODS |

TYPICAL RESULTS |

PROPERTIES |

|

|

High Service Temperature |

30 days at 158°F (70°C) |

Slight discoloration. No visible |

|

|

effect at 140°F (60°C) |

Low Service Temperature |

30 days at -40°F (-40°C) |

No visible effect |

Humidity Resistance |

30 days at 100°F (37°C), 95% |

No visible effect |

|

R.H. |

|

Weatherability |

ASTM G 155, Cycle 1 |

No visible effect |

|

|

|

http://www.bradyid.com/bradyid/domino/contentView.do?display=printerFriendly&url=http:/... 22/10/2009

Loading...

Loading...