Brady 300MVP, 200MVP User Manual

MVP SERIES

200MVP & 300MVP

THERMAL PRINTERS

Product Guide

May 2003

I. |

INTRODUCTION |

|

|

Product Introduction and Positioning Summary .................................................... |

1 |

II. |

PRINTER OVERVIEW |

|

|

General Features/Unique Characteristics ............................................................. |

2 |

|

Operating Requirements ....................................................................................... |

3 |

|

Label Dispensing/Print Requirements ................................................................... |

4 |

|

User Interface Controls ......................................................................................... |

5 |

|

Sensors................................................................................................................. |

7 |

|

Communication Parameters.................................................................................. |

9 |

|

Maintenance........................................................................................................ |

11 |

|

Printer Tour ......................................................................................................... |

12 |

|

Warranty Information........................................................................................... |

13 |

III. FEATURE / FUNCTION / BENEFITS / SPECIFICATIONS |

|

|

|

Feature/Function/Benefits ................................................................................... |

14 |

|

Printer Specifications |

|

|

200MVP. ........................................................................................................ |

17 |

|

300MVP. ........................................................................................................ |

17 |

IV. COMPETITIVE ANALYSIS |

|

|

|

Brady 200MVP, Brady 300MVP versus Zebra105SL.......................................... |

20 |

|

Brady 300MVP versus Zebra 90XiIII ................................................................... |

21 |

|

Brady 200MVP versus Zebra Z4000 ................................................................... |

22 |

|

Brady MVP Series versus CAB Apollo 3 ............................................................. |

23 |

|

Brady MVP Series versus Argox 3000 ................................................................ |

24 |

|

Brady MVP Series versus Datamax I-4208......................................................... |

25 |

|

Brady MVP Series versus Intermec E4 ............................................................... |

26 |

|

Brady MVP Series versus Printronix T4204 ........................................................ |

27 |

|

Brady MVP Series versus Sato CL-408e ............................................................ |

28 |

|

Brady MVP Series versus TEC B-472................................................................. |

29 |

I.INTRODUCTION

Brady Corporation, the market leader in labelling solutions, is proud to introduce the newest members of the M Series family - the rugged, cost-effective, new 200MVP and 300MVP thermal transfer printers. The MVP series printers provide the best value in an industrial thermal transfer printer. Available in either 203 or 300 dpi, the MVP printers are easy to operate and loaded with features, including colour-coded operator cues and an LCD display. The durable, die cast aluminum frame provides a rugged platform for printing in operations that require label production 12 hours per day, 5 days per week.

MVP Series Product Guide |

Page 1 |

Introduction |

II.PRINTER OVERVIEW

The following sections are designed to quickly familliarise the user with the General Features, Operating Requirements, and Warranty Coverage of the Brady MVP series thermal printers. For more detailed product information, consult the MVP Series User’s Guide.

A.GENERAL FEATURES / UNIQUE CHARACTERISTICS

The 200MVP/300MVP thermal printers are engineered and designed for light to medium volume industrial text labelling and bar-code applications requiring an affordable, performance printer (under €1800 and €2200 respectively).

Some of the unique characteristics specific to the MVP series include:

1.Quality Engineered Main Logic Board and Firmware

The internal make-up and components of the 200MVP/300MVP printers

are engineered for quality and optimised for thermal print capability The MVP series printers are designed to meet the requirements of the value-

conscious consumer with an industrial, labelling application. Depending

on the user’s application preference and system requirements, the 200MVP/300MVP can provide a rugged, reliable print solution to satisfy

a variety of printing requirements.

2.Durable, State-of-the-Art Performance

The 200MVP/300MVP is constructed of a highly durable, die-cast metal frame that enables the printer to provide consistent print quality in many tough industrial environments. Its 10 ips print speed ensures maximum

productivity and output. Add to that, the revolutionary connectivity and control solution of BradyConnect™ (WebView, Alert and ZBI) and you can see just how you get more value per euro with this performance-packed winner!

MVP Series Product Guide |

Page 2 |

Features &Benefits |

3.Foolproof Design / Simple Operation

Regardless of a user’s level of experience or training, the 200MVP/300MVP printers are highly intuitive to operate. Standard features like an LCD display, colour-coded operator cues, auto-calibration and an auto-sensing power supply make system configuration and printer set-up easy.

4.Easy Access to Label and Ribbon Path / Ease of Loading & Maintenance

The MVP series’ embossed loading diagram, enlarged media window and cantilever printhead simplify the printer loading process. The printer’s cantilever printhead with head open-lock feature “locks” in place to enable full uninhibited access to the printhead for cleaning and the media compartment for media loading. In addition, user’s can utilise the media loading diagram that is embossed in the printer’s steel frame or the enlarged media window to monitor media supply status.

5.More Standard Features for the Money

The 200MVP/300MVP printer offers more standard features for the money than ever before. Rugged metal construction, 10 ips print speed, BradyConnect remote monitoring and configuration capability and a standard LCD display are just a few of the ways this printer this printer offers more value per euro than ever before.

B.OPERATING REQUIREMENTS

1.FONT SELECTION

Brady MVP series printers each offer an extensive range of font options for the user to choose from, including:

Character Fonts

The 200MVP/300MVP contains 9 Standard Bitmapped Zebra Fonts including:

(A, B, C, D, E (OCR-B), F, G, H (OCR-A), GS); and 1 Smooth scalable Font

(CG Triumvirate Bold Condensed) scalable up to 10 x 10 point sizes.

Character Sets

The MVP series printers contain full ASCII character sets including IBM Code Page 850 (International Characters and Graphics Symbols).

MVP Series Product Guide |

Page 3 |

Features &Benefits |

Custom Graphics/Logos

The 200MVP/300MVP printer supports user-defined fonts and graphics, including custom logos.

A non-Roman font license option is also available which enables various international fonts, including Serif, Sans Serif, Kanji, Hangul and Chinese, to be downloaded to the printer for specialised global applications. NOTE: Asian font license option REQUIRES either 1MB (minimum) Flash memory or PCMCIA memory card)

For a detailed breakdown of font selections for the MVP series, refer to the Product Specifications section contained in this document.

2.LABEL DISPENSING

The 200MVP or 300MVP printer has the capability of dispensing printed labels in tear-off or peel-off modes. In the tear-off mode, the label remains attached to its stock backing and is presented outside the unit to be torn off against a "tear-off" bar by the user. In the peel-off mode, the label is separated from its stock backing by a peel bar and is presented to the user for easy removal and application. The peel mode works in conjunction with an internal rewind feature that neatly coils the label backing around a spindle for clean operation and tidy removal of label backing material.

MVP Series Product Guide |

Page 4 |

Features &Benefits |

3.PRINT SPECIFICATIONS / REGISTRATION REQUIREMENTS

Media Width: |

1.0" (25mm) min. to 4.5" (114mm) |

|

max. on 200MVP or 300MVP |

Inter-Label Gap |

0.08" (2mm) to 0.16" (4mm) |

(Distance between labels): |

(0.10" -.125” 2.5mm- 3.2mm |

|

Recommended) |

First Dot Location: |

0.10" (2.5mm, not to exceed |

|

–0.5/+1.0mm) from inside edge of |

|

the media ±0.04mm |

Vertical Registration Drift: |

Not to exceed ± 0.0393" (1.0mm) |

Horizontal Registration |

Not to exceed ±0.0591" (1.5mm) |

Drift: |

|

Longitudinal Drift |

± 0.0393" (1.0mm) (with respect |

|

to media type) (between any two |

|

labels printed from the same label |

|

roll): |

Variation |

(from leading label edge to |

|

marking): 0.0393" (1mm) |

Media Thickness |

0.0023" (0.058mm) to 0.010" |

|

(0.25mm); die-cut labels, tickets |

|

and tags. 2.3 mils to 12 mils |

Label Roll Size: |

8.0" (203mm) O.D. max. / 3.0" |

|

(76mm) I.D. min. |

Tear-Off Bar: |

Standard |

Ribbon Orientation: |

Ink Side Out |

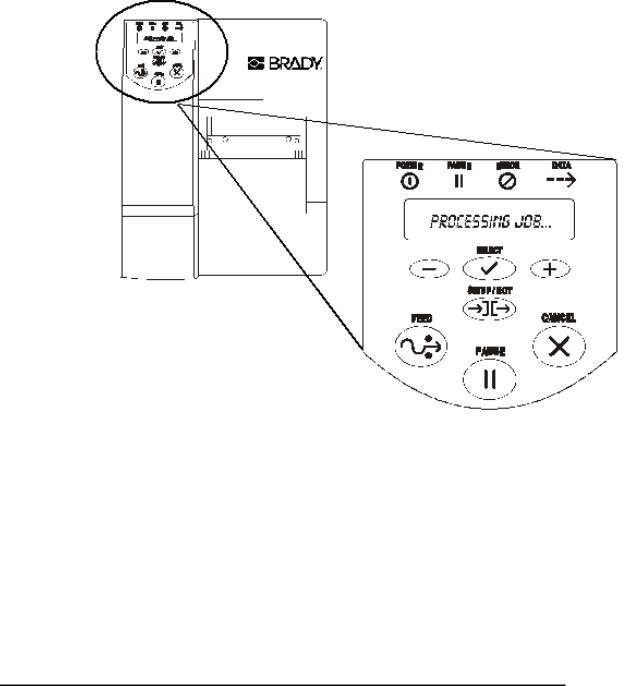

4. USER INTERFACE CONTROLS AND INDICATOR LIGHTS

A MVP series printer is equipped with a standard LCD control panel for easy user interface and operation. A 2-line, 16 character backlit display and tactile feel buttons on the printer’s front panel enable users to finetune and control their print settings, whenever needed, in dim or bright light from any angle. The user can quickly make adjustments and configure the printer to meet the specific needs of the application. Such adjustments can also be accomplished without having to access a computer or software. The drawing of the MVP series front panel (below) depicts the positioning of the indicator lights on the 200MVP/300MVP.

MVP Series Product Guide |

Page 5 |

Features &Benefits |

The LCD display is used in configuring the printer; selecting reports to be printed by the Brady printer which identify available fonts, bar code symbologies, images or formats stored in the printer; or a complete record of the printer’s configuration settings; and diagnostic tests or security passwords. The LCD display is also helpful in specifying error conditions and communicating to the operator when the condition has been corrected.

Figure 1

MVP Series Control Panel

MVP Series Product Guide |

Page 6 |

Features &Benefits |

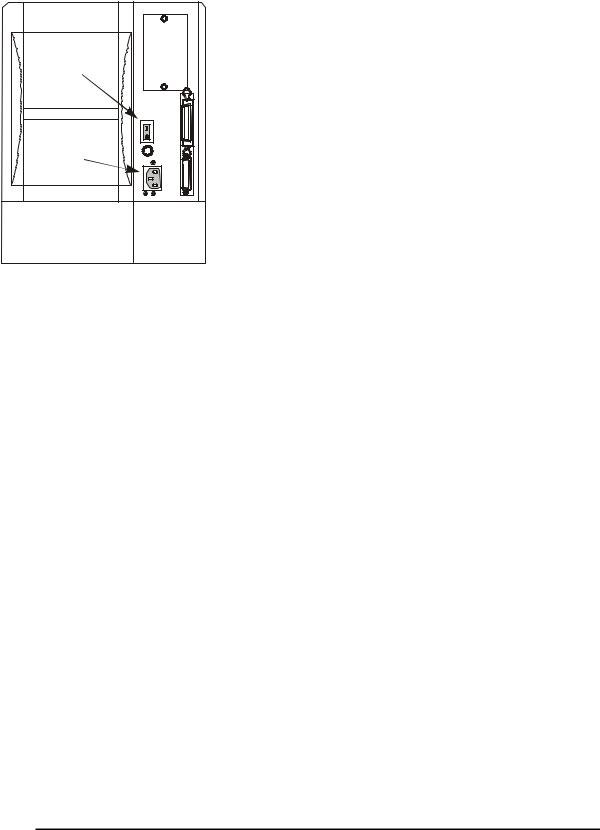

AC |

power |

switch |

Connector |

A/C POWER SWITCH /INDICATOR LIGHT

The power switch is located at the back of the printer

directly above the power cord as indicated by the diagram Figure 2. The power supply in the 200MVP/300MVP

printer works over a broad voltage range ( 90 to 265 VAC ). The power indicator light on the display panel designates when the printer is powered on.

PAUSE BUTTON

Activating the PAUSE key while the printer is printing will cause the printer to stop or pause once the current label is complete. No labels are lost during pause, whereby the PAUSE indicator light will illuminate to easily identify printer status to the user. Users can utilise this key to pause a print job immediately, for any reason, as required. Pressing the PAUSE button again will cause print to resume exactly where it stopped.

DATA INDICATOR

No data light indicates normal operation. A slow flashing data indicator signifies that the printer is unable to accept more data from the host PC. A fast flashing data light

indicates that the printer is receiving data. A constant on data light indicates that a partial format has been received with no subsequent data activity.

ERROR INDICATOR

No error light indicates normal operation. A slow flashing error indicator light signifies a “RIBBON IN” or “PRINTHEAD TEMP” issue. A fast flashing error light indicates a “PRINTHEAD OPEN” error. A constant on error light indicates a “PAPER OUT”, “RIBBON OUT” or “CUTTER JAM” condition. For each error condition, the LCD display will identify the type of error and indicate that the error is cleared once corrective action has occurred.

FEED BUTTON

The FEED key will cause the printer to immediately feed a single blank label. Users can activate the FEED key to test label alignment and positioning and proper printer operation before attempting to print a label.

CANCEL BUTTON

The CANCEL key will cancel a print job when the printer is in PAUSE mode. If print jobs are currently printing in a queue from the host computer, pressing the CANCEL key once will cancel the current print job. To delete all print jobs in the printer’s memory, press and hold the CANCEL key for a minimum of 3 seconds until you see the DATA transmission light go off. This indicates that all print jobs in the queue have been successfully canceled. Users can quickly and easily cancel print jobs, by activating the CANCEL key on the printer’s front panel, saving time and reducing label waste in the advent of a print error.

MVP Series Product Guide |

Page 7 |

Features &Benefits |

SETUP/EXIT

The SETUP/EXIT key, as its name suggests, enters and exits the configuration mode. This also allows a configuration change to be saved temporarily, permanently or a default setting may be used.

SELECT

The SELECT key toggles the INCREMENT (+) and DECREMENT (-) keys between the “scroll mode” and the “change mode”. Press once to use the (+) or (-) keys to change the value of a selection. Press again to use the (+) and (-) keys to scroll through the menu items.

For detailed instructions on how to adjust these settings or for related troubleshooting tips, refer to the 200MVP/300MVP User’s Guide.

5.SENSORS

The following sensor types are contained within the MVP series thermal printers:

Printhead

Sensor:

Transmissive /

Reflective

Media Sensors:

Checks the open/closed status of the printhead. If the printhead is open, the printhead light indicator will immediately flash, warning users of a non-print condition whereby the printhead must be closed before attempting to print.

Transmissive sensors recognise the seethrough "gaps", “notches” or joints between labels as light is permitted to filter through these joints indicating the label’s overall length. Similarly, the reflective sensor option gauges label length via the black marks found on the media backing which reflect light back to the sensor from the label’s joint. Both sensor types enable users to print on diverse label stocks including continuous, notch, black mark, tag stock or perforated and promote the printer’s auto-calibration feature. During auto-calibration, the printer relies on such sensor readings to automatically adjust to varying label lengths promoting worry-free print capability on varying media (label) types.

MVP Series Product Guide |

Page 8 |

Features &Benefits |

Loading...

Loading...