Bradford White URG2PDV40S6N, URG2PDV50S6N, URG2PDV50H6N Installation Manual

POWER DIRECT VENT GAS WATER HEATER

A Spanish language version of these instructions is available by contacting the company listed on the rating plate.

La version espanola de estas instrucciones se puede obtener al escribirle a la fabrica cuyo nombre aparece en la placa de especificaciones.

INSTALLATION AND OPERATING INSTRUCTION MANUAL

WARNING: If the information in these instructions is not followed exactly, a fire or explosion may result causing property damage, personal injury or death.

FOR YOUR SAFETY

Do not store or use gasoline or other flammable, combustible, or corrosive vapors and liquids in the vicinity of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS

•Do not try to light any appliance.

•Do not touch any electrical switch; do not use any phone in your building.

•Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s instructions.

•If you cannot reach your gas supplier, call the fire department. Installation and service must be preformed by a qualified technician.

For your family’s comfort, safety and convenience we recommend this water heater be installed and serviced by a plumbing professional.

238-51006-00D REV 5/18

CONGRATULATIONS!

You have just purchased one of the finest water heaters on the market today!

This installation, operation and instruction manual will explain in detail the installation and maintenance of your new Power Direct Vent Gas Water Heater. We strongly recommend that you contact a plumbing professional for the installation of this water heater.

We require that you carefully read this manual, as well as the enclosed warranty, and refer to it when questions arise. If you have any specific questions concerning your warranty, please consult the plumbing professional from whom your water heater was purchased. For your records we recommend that you write the model, serial number and installation date of your water heater in the maintenance section in the back of this manual.

This manual should be kept with the water heater.

Special Flammable Vapor Ignition Resistant System:

This water heater is equipped with a Flammable Vapor Ignition Resistant System. In the event of improper usage or storage of gasoline or other flammable materials in the location where the water heater is installed, the technology will resist ignition of the flammable vapors outside the confines of the water heater.

The Flammable Vapor Ignition Resistant System features:

•Flammable Vapor Sensor.

•Automatic Ignition Device.

•Sight Window to observe operation of pilot and burner.

FOR YOUR SAFETY: Activation of the Flammable Vapor Ignition Resistant System occurs when flammable vapors are present in the room where the water heater is installed. If flammable vapors are detected and/or sensed:

•Do not try to light any appliance.

•Do not touch any electrical switch; Do not use any phone in your building.

•Leave the premises and immediately call the fire department from a neighbor’s phone. Follow the fire department’s instructions.

Once the flammable vapor has been evacuated, contact your plumbing professional or the manufacturer for further instructions. Replacement of a Flammable Vapor Ignition Resistant System equipped water heater due to a flammable vapor shutdown is not covered under the terms of the limited warranty.

2

TABLE OF CONTENTS |

|

|

page |

GENERAL INFORMATION ................................................................. |

4 |

INSTALLATION. .................................................................................. |

5 |

Locating The Water Heater ......................................................... |

5 |

Minimum Clearances ................................................................... |

8 |

Venting .......................................................................................... |

8 |

Specifications for |

|

48 Gal. (181.6 L)...................................................................... |

12 |

Specifications for |

|

40 Gal. (151.4 L) |

|

50 Gal. (189.2 L)...................................................................... |

24 |

Vent pipe preparation and joining.................................................... |

35 |

Water Connections ...................................................................... |

36 |

Gas Connections.......................................................................... |

39 |

Electrical Connections ................................................................ |

40 |

Wiring Diagram ...................................................................... |

41 |

GENERAL OPERATION ..................................................................... |

42 |

Lighting and Shutdown Instructions......................................... |

43 |

Thermostat Adjustment............................................................... |

44 |

Burner Flame Check .................................................................... |

45 |

MAINTENANCE................................................................................... |

46 |

TROUBLESHOOTING......................................................................... |

50 |

PARTS LIST AND PARTS LIST DRAWING....................................... |

53 |

INSTALLATION INSTRUCTIONS FOR POTABLE WATER AND |

|

SPACE HEATING ................................................................................ |

54 |

NOTES ................................................................................................. |

55 |

3

GENERAL INFORMATION

This gas-fired water heater’s design is certified by CSA International under the

American National Standard Z21.10.1 and CSA 4.1-M, most current editions at the time of manufacture. This is a category III water heater.

This water heater must be installed in accordance with local codes or, in the absence of local codes, the National Fuel Gas Code, ANSI Z223.1-Latest Edition) and/or in Canada CAN/CGA B149 Installation Codes (Latest Editions). The warranty for this water heater is in effect only when the water heater is installed, adjusted, and operated in accordance with these Installation and Operating Instructions. The manufacturer will not be held liable for any damage resulting from alteration and/or failure to comply with these instructions.

This water heater is not design certified for installation in a mobile home. Such an installation may create a hazardous condition and will nullify the warranty.

CAUTION

CAUTION

Incorrect operation of this appliance may create a hazard to life and property and will nullify the warranty.

WARNING

WARNING

Prior to connecting the gas supply line to a gas fired water heater, ensure that the gas supply line does not have moisture/water or dirt/scale inside the gas line. Commonly this check is done at the lowest point in the gas distribution system prior to gas burning appliances.

Do not use this appliance if any external part to the tank has been submerged in water. You should contact a qualified service technician to inspect the appliance and to replace any part of the control system including the combination gas control which has been submerged in water. See the Gas Connections section of this manual before servicing or replacing a water heater that has had any external part to the tank submerged in water.

DANGER

DANGER

Do not store or use gasoline or other flammable, combustible, or corrosive vapors and liquids in the vicinity of this or any other appliance.

IMPORTANT

Before proceeding, please inspect the water heater and its components for possible damage. DO NOT install any water heater with damaged components. If damage is evident then please contact the supplier where the water heater was purchased or the manufacturer listed on the rating plate for replacement parts.

4

General Information continued-

Make sure that you check the rating plate and combination gas control on the water heater to be certain that the type of gas being supplied corresponds with the marking on the rating plate and combination gas control.

A sacrificial anode(s) is used to extend tank life. Removal of any anode, except for inspection and/or replacement, will nullify the warranty. In areas where water is unusually active, an odor may occur at the hot water faucet due to a reaction between the sacrificial anode and impurities in the water. If this should happen, an alternative anode(s) may be purchased from the supplier that installed this water heater. This will minimize the odor while protecting the tank. Additionally, the water heater should be flushed with appropriate dissolvers to eliminate any bacteria.

INSTALLATION

Locating The Water Heater

WARNING

WARNING

Water heaters are heat producing appliances. To avoid damage or injury, do not store materials against the water heater or vent-air intake system. Use proper care to avoid unnecessary contact (especially by children) with the water heater and vent-air intake components. UNDER

NO CIRCUMSTANCES MUST FLAMMABLE MATERIALS, SUCH AS GASOLINE OR PAINT THINNER BE USED OR STORED IN THE VICINITY OF THIS WATER HEATER, VENT-AIR INTAKE SYSTEM OR IN ANY LOCATION FROM WHICH FUMES COULD REACH THE WATER HEATER OR VENT-AIR INTAKE SYSTEM.

DO NOT install the water heater in any location where gasoline or flammable vapors are likely to be present.

Water heaters in residential garages must be installed and located, or protected, to avoid physical damage. For other installations refer to local codes. In the absence of local codes, the water heater must be installed in compliance with the National Fuel Gas Code, (ANSI Z223.1- Latest Edition), or in Canada CAN/CGA B149.1 Natural Gas Installation Code (Latest Edition) or CAN/CGA B149.2 Propane Installation Code (Latest Edition).

The location of this water heater is of the utmost importance. Before installing this water heater, read the installation section of these instructions. After reading these installation and operating instructions, select a location for the water heater where the floor is level and is easily accessible to gas and water supply lines. DO NOT locate the water heater where water lines could be subjected to freezing temperatures. Make sure the cold water pipes are not located directly above the gas control so that condensate during humid weather does not drip on the controls.

5

Installation (Locating The Water Heater) continued-

Water heater corrosion and component failure can be caused by the heating and breakdown of airborne chemical vapors. Examples of some typical compounds that are potentially corrosive are: spray can propellants, cleaning solvents, refrigerator and air conditioning refrigerants, swimming pool chemicals, calcium and sodium chloride, waxes and process chemicals. These materials are corrosive at very low concentration levels with little or no odor to reveal their presence. NOTE: DAMAGE TO THE WATER HEATER CAUSED

BY EXPOSURE TO CORROSIVE VAPORS IS NOT COVERED BY THE WARRANTY. DO NOT OPERATE THE WATER HEATER IF EXPOSURE HAS OR WILL OCCUR. DO NOT STORE ANY POTENTIALLY CORROSIVE COMPOUNDS IN THE VICINITY OF THE WATER HEATER.

To comply with NSF requirements this water heater is to be:

a)Sealed to the floor with sealant, in a smooth and easily cleanable way, or

b)Installed with an optional leg kit that includes legs and/or extensions that provide a minimum clearance of 6” beneath the water heater.

WARNING

WARNING

Liquefied petroleum gases/propane gas are heavier than air and will remain at floor level if there is a leak. Basements, crawl spaces, closets, and areas below ground level will serve as pockets for accumulation of leaking gas. Before lighting, smell all around the appliance area for gas. Be sure to smell next to the floor.

IF YOU SMELL GAS:

•Do not try to light any appliance.

•Do not touch any electric switch; do not use any telephone in your building.

•Immediately call your gas supplier from a neighbor’s telephone. Follow the gas supplier’s instructions.

•If you cannot reach your gas supplier, call the fire department.

DO NOT OPERATE APPLIANCE UNTIL THE LEAKAGE IS CORRECTED!

6

Installation (Locating The Water Heater) continued-

WARNING

WARNING

DO NOT ATTEMPT TO LIGHT ANY GAS APPLIANCE IF YOU ARE

NOT CERTAIN OF THE FOLLOWING:

•Liquefied petroleum gases/propane gas and natural gas have an odorant added by the gas supplier that aids in the detection of the gas.

•Most people recognize this odor as a “sulfur” or “rotten egg” smell.

•Other conditions, such as “odorant fade” can cause the odorant to diminish in intensity, or “fade”, and not be as readily detectable.

•If you have a diminished sense of smell, or are in any way

unsure of the presence of gas, immediately contact your gas supplier from a neighbor’s telephone.

Gas detectors are available. Contact your gas supplier, or plumbing professional, for more information.

The water heater must be located close enough to the outside wall to keep the venting distance within the maximum distance described in the installation instructions. Locate the water heater as close as possible to the vent opening. Read the venting section in this installation instruction manual before locating the water heater.

This water heater must be located in an area where leakage of the tank or water line connections and the combination temperature and pressure relief valve will not result in damage to the area adjacent to the water heater or to lower floors of the structure. When such locations cannot be avoided, a suitable drain pan adequately piped for proper drainage must be installed under the water heater. The drain pan, as described above, can be purchased from your plumbing professional. The drain pan must be piped to an adequate drain. The piping must be at least 3/4 inch (1.9 cm) in diameter and pitched for proper drainage.

It is recommended that a minimum clearance of four (4) inches (10.2 cm) be provided on the side of the water heater for servicing and maintenance of the combination temperature and pressure relief valve.

This water heater MUST be installed indoors out of the wind and weather.

Note: For California installation this water heater must be braced, anchored, or strapped to avoid falling or moving during an earthquake. See instructions for correct installation procedures. Instructions may be obtained from DSA Headquarters Office, 1102 Q Street, Suite 5100, Sacramento, CA 95811.

7

Minimum Clearances

WARNING

WARNING

Failure to adhere to these installation and operating instructions may create a hazard to life and property and will nullify the warranty.

This installation must allow access to the front of the water heater and adequate clearance must be provided for servicing and operating this water heater. The water heater may be installed on either a combustible or non-combustible floor. If the water heater is to be installed directly on carpeting, it must be installed on top of a metal or wood panel extending beyond the full width and depth of the appliance by at least three (3) inches (7.6 cm) in any direction or, if the appliance is to be installed in an alcove or closet, the entire floor must be covered by the panel. The minimum clearances to combustibles for this water heater are: zero (0) inch (0 cm) from the sides and rear, five (5) inches (12.7 cm) from the front of the jacket, zero (0) inch (0 cm) from the vent connector and fifteen (15) inches (38.1 cm) from the jacket top. Increase distances to provide clearance for servicing.

Venting

Figure 1 – Direct Vent Terminal Clearances

8

Venting continued-

|

|

Canadian |

US |

|

|

|

Installations1 |

Installations2 |

|

A= |

Clearance above grade, veranda, porch, deck or balcony |

12 inches |

12 inches |

|

(30 cm) |

(30 cm) |

|||

|

|

|||

B= |

Clearance to window or door that may be opened |

12 inches |

12 inches |

|

(30 cm) |

(30 cm) |

|||

|

|

|||

C= |

Clearance to permanently closed window |

*b |

*b |

|

|

|

|

|

|

D= |

Vertical clearance to ventilated soffit located above the terminal within a |

*b |

*b |

|

horizontal distance of 2 feet (61 cm) from the center line of the terminal |

||||

|

|

|

||

E= |

Clearance to unventilated soffit |

*b |

*b |

|

|

|

|

|

|

F= |

Clearance to outside corner |

*b |

*b |

|

|

|

|

|

|

G= |

Clearance to inside corner |

*b |

*b |

|

|

|

|

|

|

|

|

3 feet (91 cm) |

|

|

|

Clearance to each side of center line extended above meter/regulator |

within a height 15 |

|

|

H= |

feet (4.6 m) above |

*b |

||

assembly |

the |

|||

|

|

|||

|

|

meter/regulator |

|

|

|

|

assembly |

|

|

I= |

Clearance to service regulator vent outlet or oil tank vent |

36 inches |

*b |

|

(91 cm) |

||||

|

|

|

||

J= |

Clearance to non-mechanical air supply inlet to building or the |

12 inches |

12 inches |

|

combustion air inlet to any other appliance |

(30 cm) |

(30 cm) |

||

|

||||

|

|

|

3 feet |

|

|

|

6 feet |

(91 cm) |

|

K= |

Clearance to a mechanical air supply inlet |

above if |

||

(1.83 m) |

within 10 |

|||

|

|

|||

|

|

|

feet |

|

|

|

|

horizontally |

|

L= |

Clearance above paved sidewalk or paved driveway located on public |

7 feet |

7 feet |

|

property |

(2.13 m)† |

(2.13 m)† |

||

|

||||

M= |

Clearance under a veranda, porch, deck, or balcony |

12 inches |

12 inches |

|

(30 cm) ‡ |

(30 cm) ‡ |

|||

|

|

1In accordance with the current CAN/CGA-B149 Installation Codes.

2In accordance with the current ANSI Z223.1-(Latest edition)/NFPA 54 National Fuel Gas Code.

† A vent shall not terminate directly above a sidewalk or paved driveway that is located between two singlefamily dwellings and serves both dwellings.

‡ Permitted only if a veranda, porch, deck or balcony is fully open on a minimum of two sides beneath the floor.

*a) A minimum clearance value determined by testing in accordance with section 5.21.1 of ANSI Z21.10.1, latest edition.

*b) “Clearance in accordance with local installation codes and the requirements of the gas supplier”.

The vent system must terminate so that proper clearances are maintained as cited in local codes or the latest edition of the National Fuel Gas Code, ANSI Z223.1.73.4e and 7.8a, b as follows:

1.Do not terminate near soffit vents or crawl space or other area where condensate or vapor could create a nuisance or hazard or cause property damage.

2.Do not terminate the exhaust vent terminal where condensate or vapor could cause damage or could be detrimental to the operation of regulators, relief valves, or other equipment.

3.Do not terminate the exhaust vent terminal over public area or walkways where condensate or vapor can cause nuisance or hazard.

4.The vent shall terminate a minimum of 12” (25.4 cm) above expected snowfall level to prevent blockage of vent termination.

9

Venting continued-

NOTICE

In locations where sustained outside air temperatures are below freezing, it is possible for the vent terminations to accumulate ice build-up due to adverse local climate conditions (prevailing wind direction, wind speed, termination orientation, etc.). The optional concentric vent terminal is more resistant to this ice build-up. In more severe temperature conditions, an optional manufacturer approved air intake relief device is available and may be installed, per the instructions, to prevent nuisance shut down of the water heater. The air intake relief device may be installed with the concentric vent termination or the standard separate vent terminations. Consult the concentric vent and/or the air intake relief device instructions for installation requirements.

Vent pipes serving power vented appliances are classified by building codes as “vent connectors”. Required clearances from combustible materials must be provided in accordance with information in this manual under LOCATION OF WATER HEATER and CLEARANCES, and with National Fuel Gas Code and local codes.

Clearance to combustibles for all venting pipes and terminals

|

For installations in Canada |

For installations in the US |

Refer to vent pipe and terminal |

0” minimum |

manufacturer’s installation instructions |

|

for clearances to combustibles |

DO NOT place of insulation or other materials in the required clearance spaces between the venting to combustible material unless otherwise specified.

WARNING

WARNING

Risk of carbon monoxide poisoning or fire due to joint separation or pipe breakage.

This water heater must be properly vented and connected to an approved vent system in good condition. DO NOT operate water heater with the absence of an approved vent system. A clean and unobstructed vent system is necessary to allow noxious fumes that could cause injury or loss of life to vent safely and will contribute toward maintaining the water heater’s efficiency. The acceptance of the venting system is dependent upon full compliance with these installation instructions.

Venting system must not pass through rated fire separations.

The venting system must be free to expand and contract. This venting system must be supported in accordance with these instructions.

10

Venting continued-

NOTICE

For installations in Canada, field supplied vent piping must comply with CAN/CGA B149.1 (latest edition) and be certified to the Standard For Type BH, Class II, 65°C, Gas Venting Systems, ULC S636. Components of this listed system shall not be interchanged with other vent systems or unlisted pipe/fittings. All components and specified primers and cements of the certified vent system must be from a single system manufacturer and not intermixed with other system manufacturer’s vent system parts. The supplied vent connector and vent termination are certified under ULC S636 and are also certified as part of the water heater. Refer to the following tables for approved venting materials, primers, and cements. All approved primers and cements are to be used within their marked time limitations.

Approved Venting Materials

|

For installations in the US only |

For installations in CANADA |

||

|

• |

PVC DWV (ASTM D-2665) |

• ULC S636 approved PVC for |

|

|

• PVC Sch. 40, 80, 120 (ASTM- |

flue gas venting rated Class II, |

||

|

|

D1785) |

65°C |

|

|

• CPVC Sch. 40, 80 (ASTM- |

• ULC S636 approved CPVC for |

||

|

|

F441) |

flue gas venting rated Class II, |

|

|

• |

CPVC (ASTM D2846) |

65°C |

|

|

• |

ABS Sch. 40 DWV (ASTM |

|

|

|

|

D2661) |

|

|

|

|

Approved Primers and Cements |

|

|

|

|

|

|

|

|

For installations in the US only |

For installations in CANADA |

||

|

• |

PVC and CPVC Primer |

• ULC S636 approved Primer and |

|

|

|

(ASTM-F656) |

Cement for flue gas venting |

|

|

• |

PVC Cement (ASTM D-2564) |

rated Class II, 65°C |

|

•CPVC Cement (ASTM F493)

•ABS Primer and Cement (ASTM D-2235)

NOTICE

Use of cellular core PVC (ASTM F891), cellular core CPVC, or Radel®

11

(polyphenosulfone) in non-metallic venting systems is prohibited, and covering non-metallic venting with thermal insulation is prohibited.

Venting System Condensation

Condensate formation does not occur in all installations of power direct vented water heaters, but should be protected against on installations where condensation can form in the venting system.

Formation of condensation in the venting system of Power Vented water heaters is dependent upon installation conditions including, but not limited to:

ambient temperature and humidity of installation location; ambient temperature and humidity of venting space; vent distance and slope;

and product usage.

In order to effectively control condensate from adversely affecting the mechanical components of the water heater several methods may be employed:

1.For horizontal installations the vent pipe can be installed with a downward slope (not less than 1/8" (3 mm)) and away from the blower.

2.In order to prevent condensate from draining back into the blower (vertical or horizontal runs), an optional condensate kit is available as a service part (Condensate kit, p/n 239-45875-00). A factory supplied exhaust adapter with drain outlet mounts directly to the blower outlet and is secured with two hose clamps, one to the blower and the other to the vent pipe. Tubing is provided to drain any accumulated condensate away from the water heater and to a suitable drain. The kit comes complete with instructions for proper installation.

PART I - Venting Specifications for: 48 Gallon (181.6L)

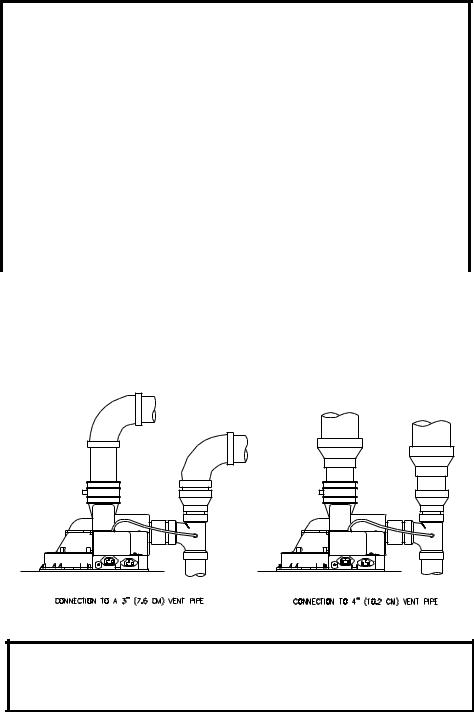

This water heater is a power vented appliance and is designed to intake and exhaust the products of combustion through 3” (7.6 cm) or 4” (10.2 cm) diameter vent pipe to the outdoors. This water heater may be either vented horizontally through the wall or vertically through the roof. Use a 3” (7.6 cm) to 4” (10.2 cm) reducer to connect to the intake and outlet when using 4” (10.2 cm) vent pipe. Apply the proper cement at the joint locations. Table 1 lists the maximum vent lengths for this water heater using 3” (7.6 cm) intake and exhaust pipe. If possible, locate the water heater so that the venting length and number of elbows are kept to the minimum distance necessary to reach the outside. If the installation requires venting lengths that exceed the lengths listed for 3” (7.6 cm) vent pipe in Table 1, then use 4” (10.2 cm) vent pipe for the vent connector.

12

Venting continued-

Table 2 lists the venting distances allowed with 4” (10.2 cm) diameter vent pipe.

When venting with 4” (10.2 cm) vent pipe, use a 4” (10.2 cm) to 3” (7.6 cm) reducer to exit through the building wall with 3” (7.6 cm) vent pipe. Use the 3” (7.6 cm) vent terminal supplied with the water heater to terminate on the outside of the building. If the length of 3” (7.6 cm) vent pipe needed to go through the wall is greater than 14” (35.5 cm), use 4” (10.2 cm) to go through the wall and reduce to 3” (7.6 cm) vent pipe immediately after exiting the outside wall. Refer to the venting illustrations on the following pages. Make sure the vent pipe terminal elbow fitting is at least 1” (2.5 cm) away from the edge of the wall.

IMPORTANT

The minimum equivalent length for the exhaust portion of the vent is 7 feet. The maximum equivalent vent length for the exhaust is 60 feet for 3” diameter pipe and 100 feet for 4” diameter pipe. The intake portion of the vent must be equal to or less than the vent length of the exhaust.

The tables below are provided for your quick reference, some installations may require a greater number of elbows. When calculating equivalent vent length, one 90º elbow is equivalent to 5 feet.

TABLE 1 - VENT CONNECTOR LENGTHS

FOR 3” (7.6 cm) DIAMETER VENT PIPE

|

# of Elbows |

Maximum straight |

Minimum |

|||

|

Length ft (m) |

straight |

||||

Terminating |

(excl. vent |

|||||

48 gal. |

|

|

Length |

|||

|

term.) |

|

|

|||

|

|

|

|

|

ft (m) |

|

Through the Wall |

1 |

55 (16.8) |

|

2 |

(.6) |

|

Through the Wall |

2 |

50 (15.2) |

|

2 |

(.6) |

|

Through the Wall |

3 |

45 (13.7) |

|

2 |

(.6) |

|

Through the Wall |

4 |

40 (12.2) |

|

2 |

(.6) |

|

Through the Roof |

0 |

60 (18.3) |

|

7 |

(2.1) |

|

Through the Roof |

1 |

55 (16.8) |

|

7 |

(2.1) |

|

Through the Roof |

2 |

50 (15.2) |

|

7 |

(2.1) |

|

Through the Roof |

3 |

45 (13.7) |

|

7 |

(2.1) |

|

13

Venting continued-

TABLE 2 -VENT CONNECTOR LENGTHS

FOR 4” (10.2 cm) DIAMETER VENT PIPE

|

# of 90° |

Maximum straight |

Min |

||

|

Length ft (m) |

straight |

|||

Terminating |

Elbows (excl. |

||||

48 gal. |

|

Length |

|||

|

vent term.) |

|

|||

|

|

|

|

ft (m) |

|

Through the Wall |

1 |

95 (29.0) |

|

10 (3.1) |

|

Through the Wall |

2 |

90 (27.4) |

|

10 (3.1) |

|

Through the Wall |

3 |

85 (25.9) |

|

10 (3.1) |

|

Through the Wall |

4 |

80 (24.4) |

|

10 (3.1) |

|

Through the Wall |

5 |

75 (22.9) |

|

10 (3.1) |

|

Through the Roof |

0 |

100 (30.5) |

|

15 (4.6) |

|

Through the Roof |

1 |

95 (29.0) |

|

15 (4.6) |

|

Through the Roof |

2 |

90 (27.4) |

|

15 (4.6) |

|

Through the Roof |

3 |

85 (25.9) |

|

15 (4.6) |

|

Through the Roof |

4 |

80 (24.4) |

|

15 (4.6) |

|

NOTE: When using 4” (10.2 cm) vent pipe, use two 4” (10.1 cm) to 3” (7.6 cm) reducers for each portion of the vent. One reducer is installed just after the blower and the other reducer is used just prior to exiting the building. Exit the building wall with 3” (7.6 cm) vent pipe using the 3” (7.6 cm) 90° vent terminal supplied. Two 45° elbows are equivalent to one 90° elbow.

Figure 2

IMPORTANT

All of the Venting connections must be leak checked with a soap and water solution upon initial start up of the water heater. Any leaks must be repaired before continuing operation of the water heater.

14

Venting continued-

THROUGH THE WALL VENTING: (HORIZONTAL VENTING WITH STANDARD VENT TERMINALS).

Cut two 3 1/2 in. (8.9 cm) diameter holes in the wall at the point where the vent connector is going to pass through the wall. Use the proper cement to secure the 90° vent terminal provided with the water heater to the vent connector. The distance between the edge of the 90° vent terminal and the exterior wall (see Figure 3) must be 1 in. (2.5 cm). The exhaust and intake must not be less than 16 in. (40.6 cm) apart (see figure 4a) and the exhaust terminal must be a minimum of 3 in. (7.6cm) higher than the intake terminal. Use the proper cement and assembly procedures to secure the vent connector joints between the terminal and the blower outlet. Provide support brackets for every 5 feet (1.5m) of horizontal vent.

3” VENT INSTALLATION

4” VENT INSTALLATION

Figure 3

15

Venting continued-

Vent terminal configurations for through the wall venting.

When venting through the wall, the exhaust terminal must exit the structure at a minimum distance of 16” (40.6 cm) from the intake terminal. The exhaust terminal must exit the structure at a minimum of 3 in. (7.6 mm) higher than the intake terminal. The exhaust terminal must not be located below the intake terminal for any reason (see figure 4a below for examples of acceptable vent terminal configurations).

Figure 4a

CAUTION

CAUTION

NEVER INSTALL AIR INTAKE ABOVE EXHAUST

When local conditions present a risk of ice accumulation on the vent terminals, the configurations in 4b and 4c or the concentric termination are preferred.

The air intake screen can be removed for cold installations but this may make the air intake susceptible to debris buildup from birds or other animals. If the air intake screen is removed to prevent freezing, it is recommended that the air inlet screen be installed during the spring.

Figure 4b

16

Venting continued-

Figure 4c

IMPORTANT

When using the vent terminal configuration shown in 4c the extra elbows must be accounted for in the total vent length see Table 3 or Table 4.

17

Loading...

Loading...