Page 1

Instruction Manual

EN Monitor Mounts

TC9217MM-W, TC9220MM-W, TC9227MM-W

1 of 11

ISSUED: 06-25-99 SHEET #: 039-9003-8 02-08-05

Page 2

TC9217MM-W, TC9220MM-W, TC9227MM-W | Instruction Manual |

EN

|

2

Bosch Security Systems | February 3, 2005

MONITOR MOUNT COMPATIBILITY CHART

For Bosch LTC Series Monitors

Bosch Monitor Ceiling Wall

Model No. Mount Mount

Monochrome

LTC 2009/51, /61 MM3000 TC9209MM-W

LTC 2012/51, /61 MM3000 TC9209MM-W

LTC 2017/50, /60 TC9217MM-C TC9217MM-W

LTC 2020/90 TC9220MM-C TC9220MM-W

Color

LTC 2810/90, /91 TC9217MM-C TC9217MM-W

LTC 2813/90 TC9217MM-C TC9217MM-W

LTC 2814/90 TC9217MM-C TC9217MM-W

LTC 2821/90, /91 TC9220MM-C TC9220MM-W

LTC 2910/90 MM3000 TC9209MM-W

LTC 2915/91 TC9217MM-C TC9217MM-W

LTC 2917/91 TC9217MM-C TC9217MM-W

LTC 2919/90 TC9220MM-C TC9220MM-W

27ST220L TC9227MM-C TC9227MM-W

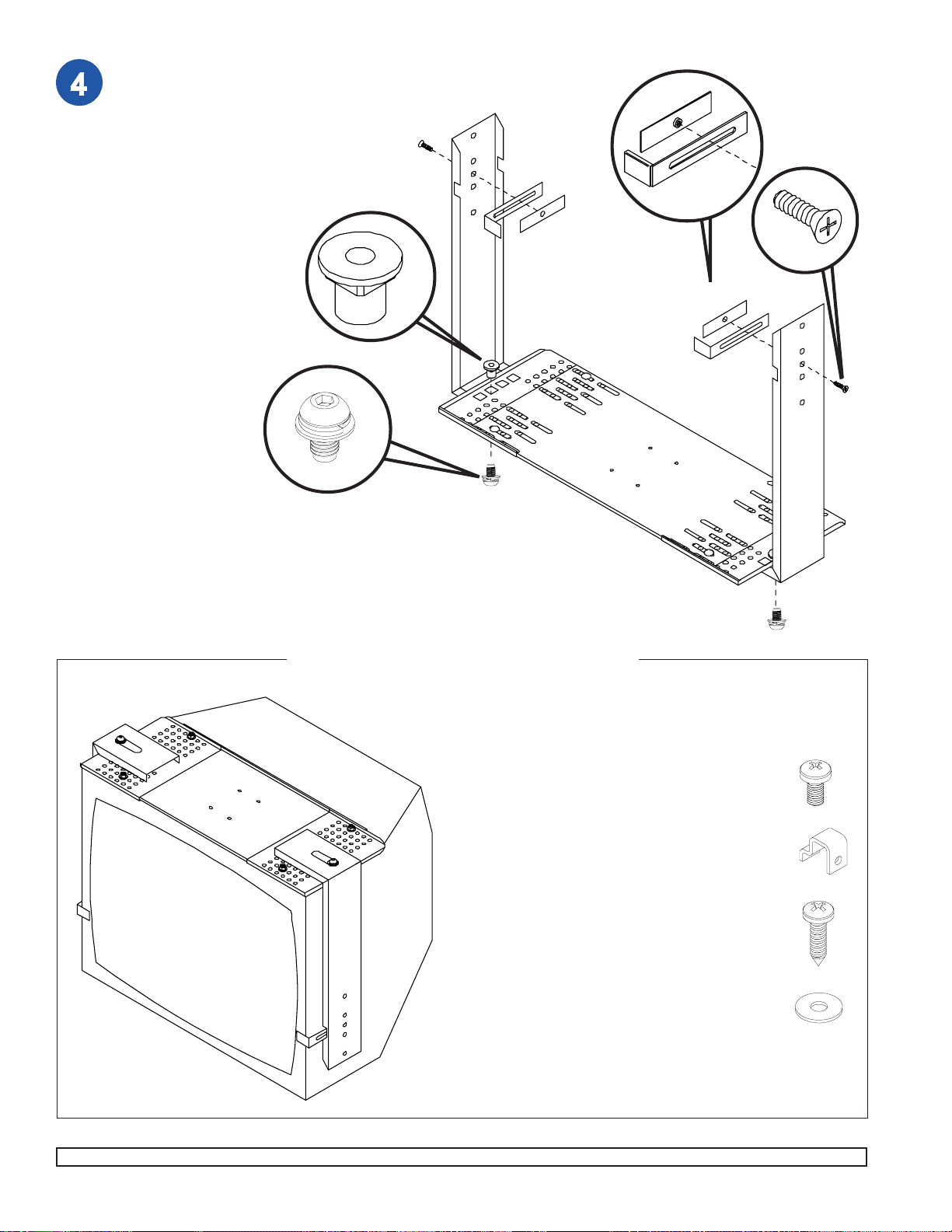

Installation Hint for TC9217MM, TC9220MM, and TC9227MM Series Monitor Mounts, RE: Step 4.

For proper center of gravity alignment of Bosch monitors on the bottom support tray, a recommended starting point is to

use the third (3rd) square hole from the front edge of the tray to mount the vertical support arm using pin E.

SERVICE

If the unit needs servicing, contact the nearest Bosch Security Systems Service Center for authorization to return

and shipping instructions.

Service Centers

USA

Phone: 800-366-2283 or 717-735-6638

Fax: 800-366-1329 or 717-735-6639

CCTV Spare Parts

Phone: 800-894-5215 or 408-956-3853 or 3854

Fax: 408-957-3198

E-mail: BoschCCTVparts@ca.slr.com

Canada

Phone: 514-738-2434

Europe, Middle East & Asia Pacific Region

Phone: 32-1-440-0711

For additional information, see www

.boschsecurity.com.

2 of 11

ISSUED: 06-25-99 SHEET #: 039-9003-8 02-08-05

Page 3

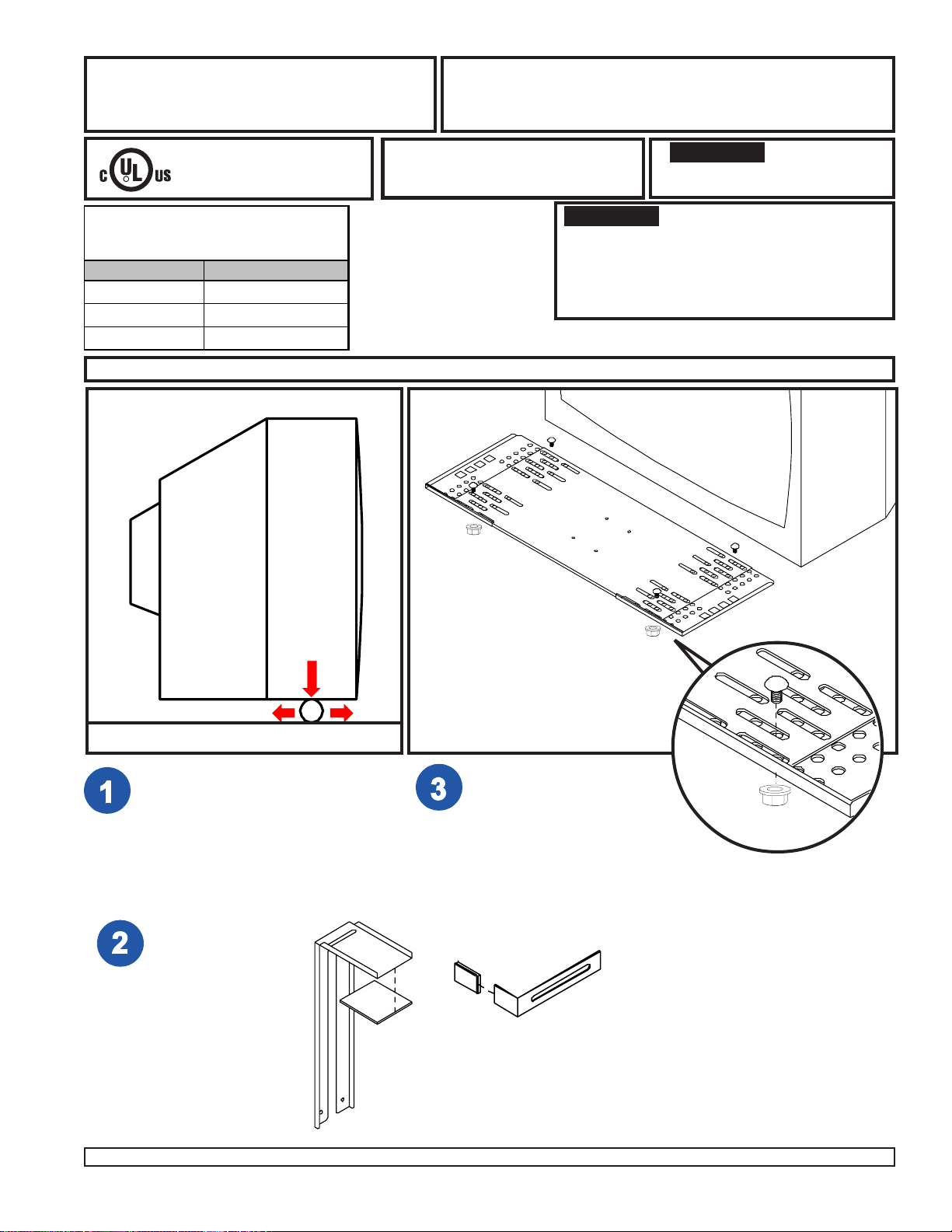

Installation and Assembly

BOSCH Monitor Wall Mounts

BOSCH

Models: TC9217MM-W , TC9220MM-W,

TC9227MM-W

This product is intended for use with UL

R

Product is UL rated up to ___ TV

sizes, per attached chart

Model #:

TC 9 217 MM-W

TC 9 220 MM-W

TC 9 227 MM-W

Listed products and must be installed by a

qualified professional installer.

TV size

17"

21"

27"

Each monitor mount is for use with a single TV or monitor of a specified size only.

SIDE VIEW

TV

Before you start make sure all parts

shown (see parts list, page 9) are

included with your bracket.

IMPORTANT! If attaching a VCR Mount

carefully study both product instruction sheets

before assembly. The interface bracket

(included with the VCR Mount) must be

attached during monitor mount assembly to

avoid disassembly later.

A

IMPORTANT! Read entire

instruction sheet before you

start installation and assembly .

TV

CENTER OF

GRAVITY

FLOOR

Place TV onto a piece of pipe as

shown. (Pipe should be a few inches

wider than the TV.) Roll TV back and

forth to find the balance point. This is

the center of gravity. Mark the center

of gravity on the side of the TV.

Attach adhesive

pads (X) to top

clamps (Q).

Insert plastic

covers (CC) onto

ends of anti-rollout

hooks (R).

Q

X

Adjust support tray (A, three

pieces) to match width of TV.

Lock support tray using four

carriage bolts (B), washer/

nut combo (C). Tighten

securely.

CC

R

B

C

3 of 12

ISSUED: 06-25-99 SHEET #: 039-9003-8 02-08-05

Page 4

Attach support tray (A)

to vertical support arms

(P) as shown.

Note: Choose the square

hole which aligns closest

with the center of gravity

mark on the TV (as

determined in step 1).

Attach anti-rollout hooks

(R) as shown using M6

screws (Z) and retainer

bars (Y). Note: Extruded

side of retainer bar (Y)

goes towards anti-rollout

hook (R).

Hand tighten only.

E

P

R

Y

Y

R

Z

Y

R

A

TV

(UPSIDE DOWN)

J

O P T I O N A L

TV BOTTOM

Although top clamps (Q) and anti-rollout

hooks (R) [see step 7] will provide more than

adequate support for the TV, some installers

may wish to also attach the support tray to

the TV bottom.

Using uni-clips (G) and M5 screws (F) (see

instruction card in fastener pack), or #10 x

3/4" particle board screws (H) and washers

(I) (for attachment to mounting bosses if

present), or a combination of both, attach

support tray (A) to TV bottom. [To do this

place TV upside down on a flat stable

surface and position support tray upside

down on TV bottom.] Attach at four places

as close to the four corners of the TV bottom

as possible.

A

P

F

G

H

I

4 of 12

ISSUED: 06-25-99 SHEET #: 039-9003-8 02-08-05

Page 5

For Wood Stud Walls drill three 5/32" (4 mm) dia. holes to a minimum depth of 2.5" (64 mm) into stud center.

Attach wall arm (W) using three #14 x 2.5" (6 mm x 65 mm) wood screws (V).

WARNING

• Tighten wood screws so wall arm is firmly attached, but do not tighten with excessive force! Overtightening can

cause stress damage to wood screws, greatly reducing their holding power. Tighten to 80 in • lb (9 N.M.) maxi-

mum torque.

WOOD

STUD

WALL

W

V

5 of 12

ISSUED: 06-25-99 SHEET #: 039-9003-8 02-08-05

Page 6

WARNING

• When installing BOSCH wall mounts on cinder block, verify that you have a minimum of 1-3/8" of actual concrete

surface in the hole to be used for the concrete anchors. Do not drill into mortar joints! Be sure to mount in a solid

part of the block, generally 1" minimum from the side of the block. Cinder block must meet ASTM C-90 specifications. It is suggested that a standard electric drill on slow setting is used to drill the hole instead of a hammer drill

to avoid breaking out the back of the hole when entering a void or cavity .

• Concrete must be 2000 psi density minimum. Lighter density concrete may not hold concrete anchor .

• Make sure that the wall will safely support four times the combined load of the equipment and all attached hardware and components.

For Concrete Walls use wall arm (W), making sure

that it is level, as a template to mark holes. Drill 1/

4" (6 mm) dia. holes to a minimum depth of 2.5" (64

mm). Insert concrete anchors in holes flush with

wall as shown (right). Place wall arm (W) over

anchors and secure with #14 x 2.5" (6 mm x 65

mm) wood screws (V). Tighten all fasteners.

1

concrete

wall

ACC 204

WARNING

• Tighten wood screws so that wall plate is firmly

attached, but do not overtighten. Overtightening can

damage the screws, greatly reducing their holding

power.

• Never tighten in excess of 80 in • lb (9 N.M.).

• Make sure that mounting screws are anchored into the

center of the studs. The use of an "edge to edge" stud

finder is highly recommended.

WARNING

• Concrete anchors are not intended for attachment to

concrete wall covered with a layer of plaster, drywall,

or other finishing material. If mounting to concrete wall

covered with plaster/drywall is unavoidable, plaster/

drywall (up to 5/8" thick) must be counterbored as

shown below. If plaster/drywall is thicker than 5/8",

custom fasteners must be supplied by installer .

Drill hole(s) and insert anchor(s)

2

Place arm over anchor(s) and secure with screw(s)

wall arm

ACC 204

3

Tighten all fasteners

wall

arm

INCORRECT

plaster/

dry wall

CUT AW A Y VIEW

concrete

wall

arm

CORRECT

plaster/

dry wall

concrete

6 of 12

ACC 204

CONCRETE

WALL

W

V

ISSUED: 06-25-99 SHEET #: 039-9003-8 02-08-05

Page 7

Note: Slots in corners of top clamps (Q) and corners of vertical support arms (P) allow for the installation of safety belt

(model ACC 666, sold separately). If using this belt, install it now.

Q

Q

DETAIL 1

Q

DETAIL 2

R

Z

R

R

P

A

R

P

Position TV onto support tray (A). Position anti-rollout hooks (R) against front edge of TV.

Q

P

K

WARNING

• Each anti-rollout hook (R) should have at least 1/4” of surface contact with the front of the TV. If this is not the

case the support tray (A) must be adjusted smaller [see step 2], or the vertical support arms (P) adjusted inward

[see step 4].

Insert top clamps (Q). Note: Top clamps (Q) fit between rollout protectors (R) and vertical support arms (P)

[DETAIL 1]. Press down on each top clamp (Q) while securely tightening each M6 screw (Z).

By hand, thread one serrated flange head screw (K) into each vertical support arm (P) into one of three threaded

holes [1, 2, or 3; DETAIL 2]. Choose the threaded hole that will allow just enough tilt clearance [see step 9].

Leave about 1/4" of exposed thread.

FIRST: From the top fully thread flush mount tube

(T) into threaded fitting in wall arm or ceiling plate.

Install the wall arm or ceiling plate according to

instructions included with it.

NEXT: Attach right and left tilt brackets (AA & BB)

to horizontal support (S) using four screws &

washer combo (J). Before tightening screws make

sure tilt brackets are adjusted horizontally to align

precisely with screws in the side of vertical support

arms (P). Attach horizontal support (S) to wallarm

or ceiling plate using fiber washers (M & N), spacer

(U, only included with smaller models) and retaining

collar (O). IMPORTANT: Retaining collar (O)

requires a safety screw [refer to DETAIL 3, page 8].

FINALLY: Be sure that hooks in right and left tilt

brackets (AA & BB) are open end forward. Hang the

TV / bracket assembly.

M

O

WMJ 025H

**

U

N

BB

T

CMJ 470,

CMJ 480,

CMJ 490

S

AA

WMJ 018,

WMJ 022

T

*

J

WARNING

P

Wall arms & ceiling plates

*

include their own

instructions. Fixed length

and adjustable extension

columns are also available.

Included with models

**

TC9217MM and

TC9220MM only.

7 of 12

• Do not lift more weight than you can handle!

Use additional manpower or mechanical lifting

equipment to safely lift and hang the TV /

Bracket assembly!

Insert one screw & washer combo (J) through slot

in each tilt bracket (AA & BB). Hand tighten.

ISSUED: 06-25-99 SHEET #: 039-9003-8 02-08-05

Page 8

T

S

F

DETAIL 3

(BOTTOM VIEW)

TIL T CLEARANCE

O

S

When attaching the horizontal support (S) to wall arm or

ceiling plate, carefully thread retaining collar (O) onto end of

flush mount (T) tube (or extension column). Tighten at least

four complete turns ending with one of the small threaded

holes aligned with slot in the end of flush mount tube (T) (or

extension column). Insert and tighten one M5 screw (F).

WARNING

• Set screw (F) is self tapping and may be hard to get

started but is essential to this installation. Failure to

install this screw can cause the mount to fall.

Adjust TV to desired tilt then tighten screws. Maximum tilt

is 30°. If tilt clearance is a problem revisit step 7, DETAIL 2.

WARNING

• Tighten all screws securely .

8 of 12

ISSUED: 06-25-99 SHEET #: 039-9003-8 02-08-05

Page 9

Parts Li st

De scri p ti o n Qty. Par t # Par t # Par t #

left end support t ray 1 128-1023 128-1026 128-1026

A1

right end s upport tray 1 128-1024 128-1027 128-1027

A2

cent er s upport t ray 1 128-1128 128-1134 128-1135

A3

5/16 - 18 x 1/2" carriage bolt 4 520-9207 520-9207 520-9207

B

5/16-18 washer/nut combo 4 530-1016 530-1016 530-1016

C

M10-1.5 x .7 flange nut 2 520-9261 520-9261 520-9261

E

M5 x . 8 x 10 m m s crew 6 520-9250 520-9250 520-9250

F

uni-clip 4 2245-081 2245-081 2245-081

G

#10 x 3/ 4" parti cle board screw 4 500-9006 500-9006 500-9006

H

#10 flat washer 4 540-9400 540-9400 540-9400

I

M10 s oc ket head l oc k/flat was her c om bo s crew 8 520-1041 520-1041 520-1041

J

M10 s errated flange head sc rew 2 520-1105 520-1105 520-1105

K

fiber washer - large inside dia. 1 540-9432 540-9432 540-9432

M

fiber washer - small i ns i de dia. 1 540-9431 540-9431 540-9431

N

reta i ni ng col l ar 1 1800-375 1800-375 1800-375

O

vertic al support arm 2 128-1107 128-1109 128-1111

P

top c l amp 2 128-1138 128-1138 128-1138

Q

anti-rollout hook 2 128-1116 128-1116 128-1116

R

horizont al s upport 1 128-1016 128-1017 128-1018

S

flush mount t ube 1 1446-014 1446-014 1446-014

T

spacer 1 128-0067 128-0067 -

U

#14 x 2 . 5" (6 m m x 65 m m) s crew 4 5S1 -015 -C03 5S1-0 15-C0 3 5S1-01 5-C03

V

si ngle wall arm 1 128-1059 128-1059 128-1069

W

adhesive pads (not s hown) 2 570-0024 570-0024 570-0024

X

retainer bar 2 128-1117 128-1117 128-1117

Y

M6 x 18mm flat phi ll ips s c rew 2 520-1166 520-1166 520-1166

Z

til t brack et right 1 128-1342 128-1337 128-1337

AA

til t brack et left 1 128-1341 128-1336 128-1336

BB

plastic cover for anti -rollout hook 2 590-1055 590-1055 590-1055

CC

TC9217MM-W TC9220MM-W TC9227MM-W

Note: Parts may appear slightly different than illustrated.

R

T

Y

U

P

Y

BB

A1

R

A3

P

X

Q

A2

N

S

M

O

X

B

W

C

AA

Q

V

E

J

Z

F

G

I

H

K

CC

9 of 12

ISSUED: 06-25-99 SHEET #: 039-9003-8 02-08-05

Page 10

Mount

Model

Number

TC9217MM-W

TC9220MM-W

TC9227MM-W

GENERAL WALL MOUNT KIT SPECIFICATIONS

TV/Monitor

Support

Product BOSCH rated

when attached to...

Tray

Depth (D)

10"

(254 mm)

10"

(254 mm)

14"

(356 mm)

10"

(254 mm)

14"

(356 mm)

14"

14"

18" (457 mm) for models TC9217MM-W, TC9220MM-W.

14"

22.5" (572 mm) for models TC9227MM-W.

14"

Screen Size

(330 mm) (432 mm)

(482 mm) (533 mm)

(482 mm) (533 mm)

(635 mm) (686 mm)

(635 mm) (686 mm)

(635 mm) (686 mm)

Reach (R)

(635 mm) (686 mm)

(762 mm) (889 mm)

(686 mm) (889 mm)

13" - 17"

19" - 21"

19" - 21"

25" - 27"

25" - 28"

25" - 27"

14"

(940 mm) (1067 mm)

14"

WARNING

(889 mm) (1067 mm)

• Weight of TV or monitor not to exceed Max. Load

Capacity (BOSCH rating)!

wood

stud

125 lb

(57 kg)

125 lb

(57 kg)

125 lb

(57 kg)

125 lb

(57 kg)

125 lb

(57 kg)

125 lb

300 lb

300 lb

300 lb

300 lb

300 lb

concrete,

cinder block

or brick

150 lb

(65 kg)

150 lb

(65 kg)

150 lb

(65 kg)

150 lb

(65 kg)

150 lb

(65 kg)

150 lb

300 lb

300 lb

300 lb

300 lb

300 lb

0

30

range

R

tilt

wall

TV

support tray

D

10 of 12

ISSUED: 06-25-99 SHEET #: 039-9003-8 02-08-05

Page 11

11 of 12 ISSUED: 06-25-99 SHEET #: 039-9003-8 02-08-05

Page 12

© 2005 Bosch Security Systems GmbH

3935 890 28113 05-05 | February 3, 2005 | Data subject to change without notice.

Americas

Bosch Security Systems

130 Perinton Parkway

Fairport, New York, 14450, USA

Phone: +1 (585) 223 4060

Fax: +1 (585) 223 9180

E-mail: security.sales@us.bosch.com

www.boschsecurity.us

Europe, Middle East, Africa

Bosch Security Systems B.V.

P.O. Box 80002

5600 JB Eindhoven, The Netherlands

E-mail:

ema.securitysystems@bosch.com

http://www.boschsecurity.com

Asia-Pacific

Bosch Security Systems Pte Ltd

38C Jalan Pemimpin

Singapore 577180, Singapore

Phone: +65 319 3488

Fax: +65 319 3499

E-mail:

sg.securitysystems@bosch.com

http://www.boschsecurity.com

11 of 11

ISSUED: 06-25-99 SHEET #: 039-9003-8 02-08-05

Loading...

Loading...