Bosch OptiFlow Professional GWH12 1 CTD E23 F3 OL Installation Manual

Installation Manual

Gas continuous flow water heaters

OptiFlow Professional

6720808877-00.1V

GWH12 1 CTD E23/31 F3 OL

6 720 810 559 (2016/06) AU

Read installation manual prior to installation of this appliance!

Read user manual before putting this unit in operation!

Observe the warnings in the manuals!

The installation location must meet the requirements for sufficient ventilation!

Installation by an authorised person only!

6 720 810 559 (2016/06) OptiFlow Professional

2 | Index

Index

1 Key to symbols and safety instructions . . . . . . . . . . 3

1.1 Key to symbols . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 General safety instructions . . . . . . . . . . . . . . 3

2 Product details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1 Declaration of Conformity . . . . . . . . . . . . . . 5

2.2 Type overview . . . . . . . . . . . . . . . . . . . . . . . . 5

2.3 Included items . . . . . . . . . . . . . . . . . . . . . . . . 5

2.4 Rating plate . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.5 Description of appliance . . . . . . . . . . . . . . . . 5

2.6 Accessory . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

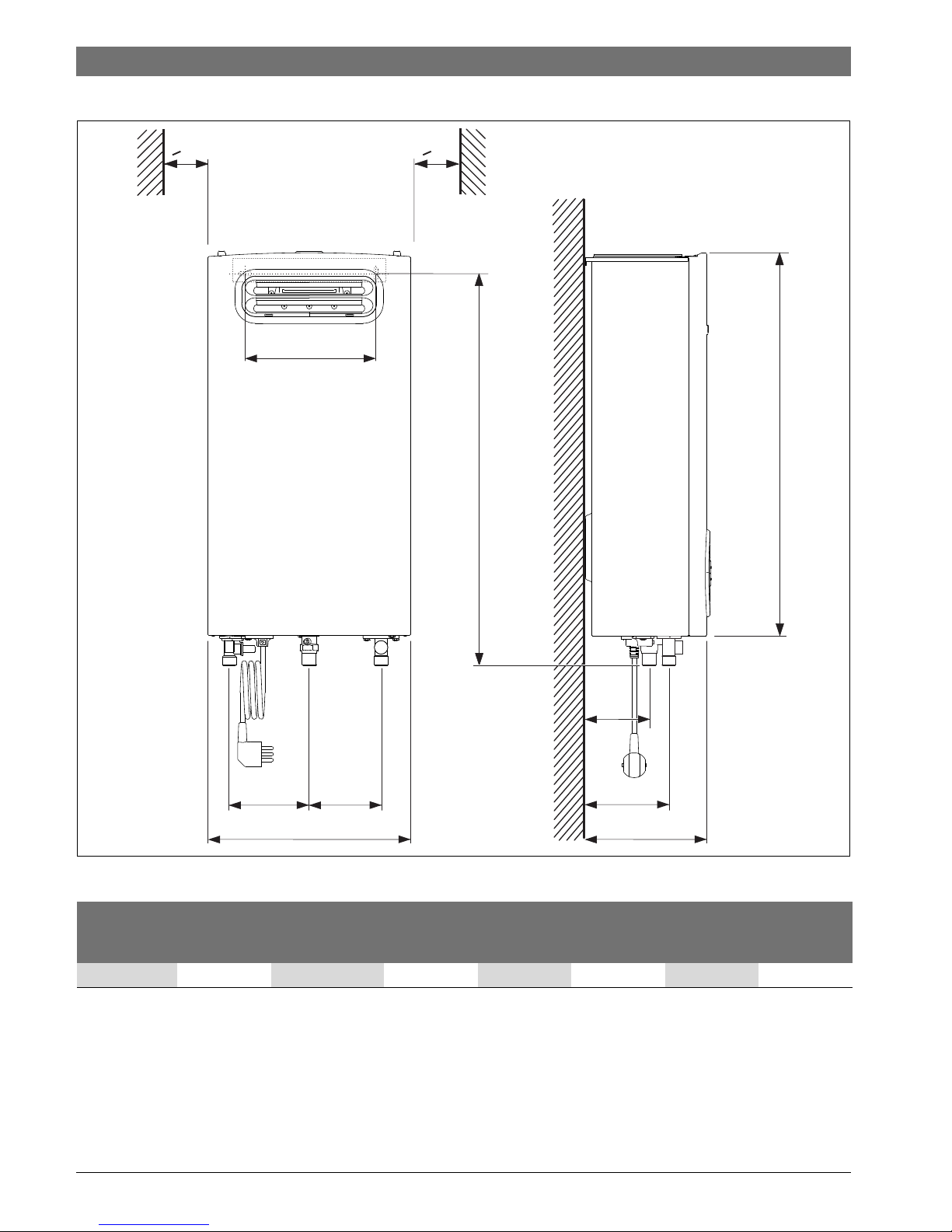

2.7 Dimensions and minimum clearances . . . . . 6

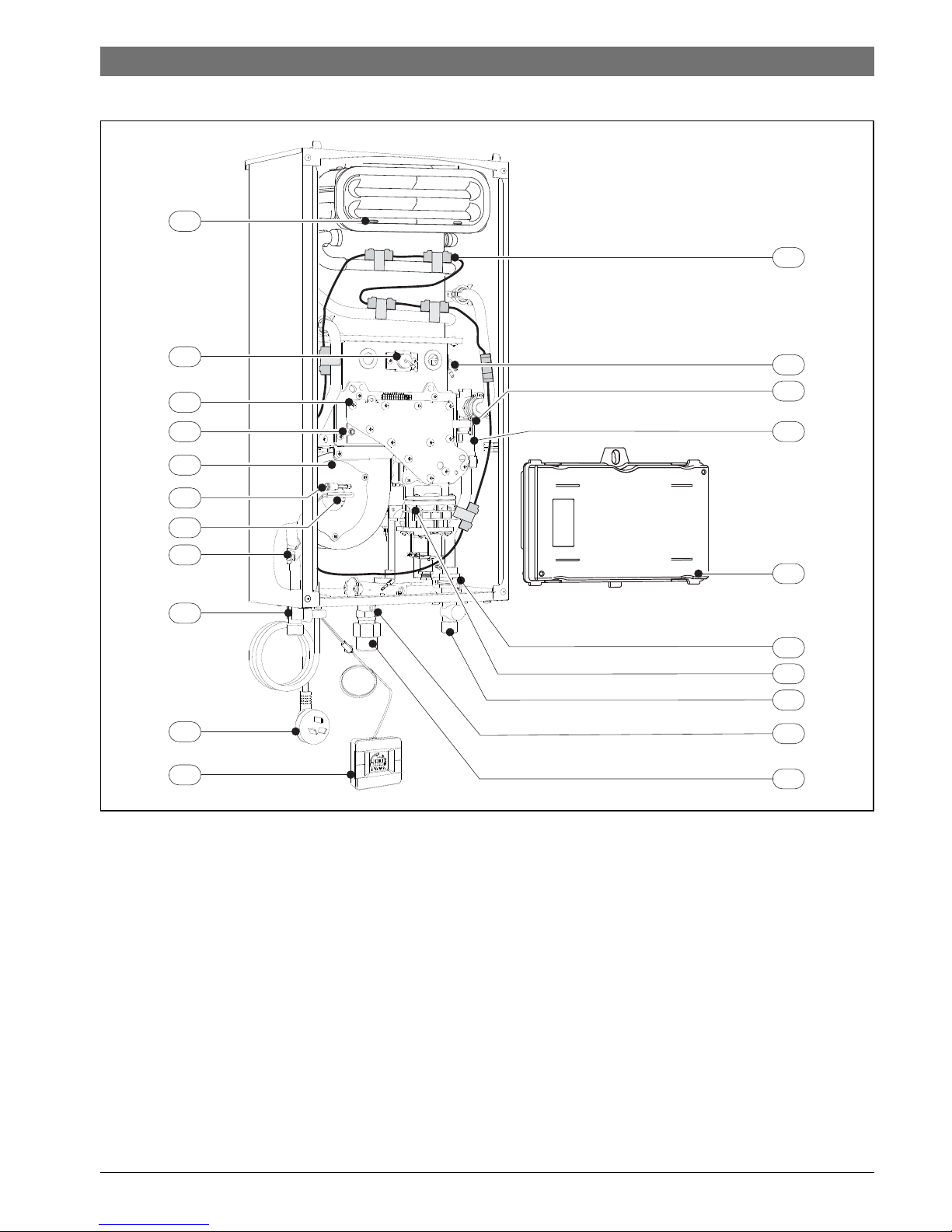

2.8 Appliance layout . . . . . . . . . . . . . . . . . . . . . . 7

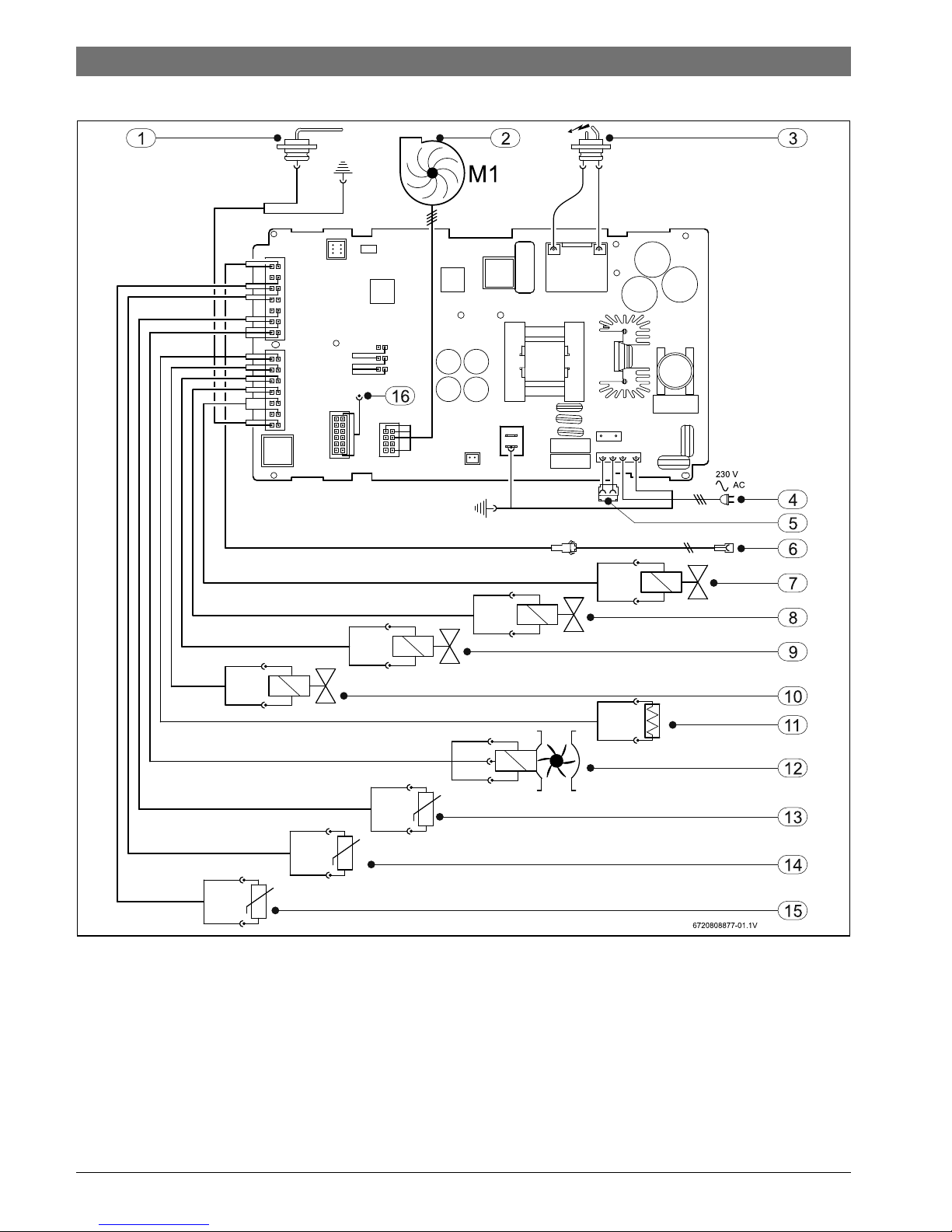

2.9 Electrical wiring diagram . . . . . . . . . . . . . . . 8

2.10 Specification . . . . . . . . . . . . . . . . . . . . . . . . . 9

3 Regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4 Installation (only by authorised technicians) . . . . 10

4.1 Choice of installation site . . . . . . . . . . . . . . 11

4.1.1 Regulations concerning the

installation site . . . . . . . . . . . . . . . . . . . . . . 11

4.2 Minimum clearances . . . . . . . . . . . . . . . . . . 11

4.3 Installing the appliance . . . . . . . . . . . . . . . . 12

4.4 Water connection . . . . . . . . . . . . . . . . . . . . 12

4.4.1 Temperature mixing device

(not supplied with the appliance) . . . . . . . 12

4.5 Gas connection . . . . . . . . . . . . . . . . . . . . . . 12

4.6 Altitude of installation site region . . . . . . . . 12

4.7 Remote control connection (optional) . . . . 13

5 Electrical connection

(only by authorised technicians) . . . . . . . . . . . . . . 13

5.1 Connecting the power cable . . . . . . . . . . . . 13

5.2 Commissioning of the appliance . . . . . . . . 14

6 Regulating the gas

(only for authorised technicians) . . . . . . . . . . . . . . 14

6.1 Factory regulation . . . . . . . . . . . . . . . . . . . . 14

6.2 Service function . . . . . . . . . . . . . . . . . . . . . 14

6.3 Adjusting the appliance . . . . . . . . . . . . . . . 15

6.3.1 Access to the pressure heads . . . . . . . . . . . 15

6.3.2 Adjusting the maximum flow

(Parameter P1) . . . . . . . . . . . . . . . . . . . . . . 15

6.3.3 Adjusting the minimum flow

(Parameter P2) . . . . . . . . . . . . . . . . . . . . . .15

6.3.4 Adjusting pressure in the burner

(Parameter P0) . . . . . . . . . . . . . . . . . . . . . .16

6.4 Factory default settings . . . . . . . . . . . . . . . 16

7Maintenance

(only by authorised technicians) . . . . . . . . . . . . . . .17

7.1 Periodic maintenance works . . . . . . . . . . . 17

7.2 Replacement of the fuse

(electronic control unit) . . . . . . . . . . . . . . . .17

7.3 Start-up after completion of maintenance 17

8 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

9 Environment / disposal . . . . . . . . . . . . . . . . . . . . . . . 20

10 Water quality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

11 Warranty details . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6 720 810 559 (2016/06)OptiFlow Professional

Key to symbols and safety instructions | 3

1 Key to symbols and safety instructions

1.1 Key to symbols

Warnings

The following keywords are defined and can be used in this

document:

• NOTICE indicates a situation that could result in damage to

property or equipment.

• CAUTION indicates a situation that could result in minor to

medium injury.

• WARNING indicates a situation that could result in severe

injury or death.

• DANGER indicates a situation that will result in severe

injury or death.

Important information

Additional symbols

1.2 General safety instructions

If you notice dark combustion gases or sooting:

▶ Isolate the Gas supply to the heater.

▶ Notify an authorised technician.

Installation, assembly, and modifications

Installation, assembly, and modifications to the heater must

only be performed by an authorised technician.

Maintenance

▶ The water heater is required to have a service and safety

inspection every two years.

▶ The installer is responsible for the safety and

environmental compatibility of the installation, according

to local regulations.

▶ The Owner/User is responsible for keeping the area around

the water heater free from debris.

▶ Safe access to inspect and service the water heater is the

responsibility of the property owner.

▶ Use only genuine Bosch spare parts.

Explosive and highly flammable material

▶ Do not store or use flammable material (paper, spray cans,

solvents, paints, etc) near the heater.

Combustion air and surrounding air

▶ The combustion air and surrounding air must be free from

corrosive substances.

▶ Do not spray aerosols or use chemicals around the heater

unless heater is disconnected from the power supply.

Risk of damage due to operator error

User error can result in injury and damage to property.

▶ Ensure that children never play with or operate this

appliance.

▶ Ensure that only personnel who can operate this appliance

correctly have access to it.

▶ Refer to the operating and user instructions before

adjusting the water heater.

To be installed and serviced only by an authorised person

The “authorised installing person” is responsible for:

• Correct installation and commissioning of this appliance.

• Ensuring the appliance performs to the specifications

stated on the rating label.

• Demonstrating the operation of the appliance to the

customer before leaving.

• Handing these instructions to customer.

THIS APPLIANCE IS NOT SUITABLE FOR POOL OR SPA POOL

APPLICATIONS.

NOT SUITABLE FOR COMMERCIAL BOOSTING OF A WARM

WATER RECIRCULATION SYSTEM"

Regulations

All local by-laws and regulations pertaining to installation and

use of gas appliances must be observed.

This appliance must be installed in accordance with the

manufacturers installation instructions, AS/NZS5601, AS/

NZS3500, and all Local Building & Gas fitting regulations.

Warnings in this document are identified by a

warning triangle printed against a grey

background.

Keywords at the start of a warning indicate

the type and seriousness of the ensuing risk

if measures to prevent the risk are not taken.

This symbol indicates important information

where there is no risk to people or property.

Symbol Explanation

▶ Step in an action sequence

Cross-reference to another part of the document

•List entry

– List entry (second level)

Table 1

6 720 810 559 (2016/06) OptiFlow Professional

4 | Key to symbols and safety instructions

This appliance must not be installed indoors or in an enclosed

space. This appliance is approved for outdoor installation only.

Do not install this appliance with any modification or alteration.

Failure to install this appliance in accordance with these

installation instructions will void the warranty and may create

an unsafe situation.

Installation

Important information

▶ Determine most suitable location for the appliance. Install

only on an external wall as close as possible to the most

frequently used hot water outlet.

▶ Ensure the mounting structure is capable of supporting the

weight of the appliance once installed. Secure the heater to

the wall using fixings suitable for the weight of the

appliance and the wall material.

▶ Install gas and water isolation valves as close as possible to

the heater. Only use gate valve or full flow ball valve (fixed

mechanism type) for cold water.

▶ Check the cold water supply pressure to ensure it meets

the required supply pressure for the appliance. (see

table 5).

▶ If inlet water pressure exceeds 800 kPa a pressure limiting

valve (500 kPa) MUST be fitted. The prefer able location for

the pressure limiting valve is at the water meter.

▶ Where the pressure l imiting valve is less than 3 metres from

the hot water unit, it must be fitted in conjunction with a

cold water expansion valve (700 kPa), between the water

heater and the pressure limiting valve.

▶ Failure to comply with this requirement may void the

warranty.

▶ Refer to AS/NZS5601 for the relevant gas pipe sizing.

▶ After finishing the gas piping system, the pipes must be

thoroughly purged and leak tested. This test must be

performed with the gas isolation valve of the appliance

closed.

▶ Ensure the gas pressure and flow through the regulator are

appropriate for the consumption of the heater (see table

5). Refer to As/NZS5601 and AS3500.1 for the relevant

pipe size.

Note: Incorrect pipe sizing or gas supply pressure may cause

the appliance to under perform. Service calls for incorrect pipe

sizing and/or gas pressure, will NOT be covered under

warranty.

Safety of electrical appliances for domestic use and similar

purposes

The following requirements apply in accordance with EN

60335-1 in order to prevent hazards from occurring when

using electrical appliances:

DANGER:

This appliance must not be installed indoors

or in an enclosed space in accordance with

AS/NZS5601.

DANGER: Explosion Risk!

▶ Always turn off the gas valve before

carrying out any work on components

which carry gas.

DANGER: Appliance malfunction!

This appliance must be installed with no

obstructions to air entry openings.

▶ Periodic checking of openings to ensure

no blockage or obstruction of the air

openings from plants, debris or insects

must be carried out.

The installation of gas, water, and electrical

supply, and the initial startup are to be

performed by an authorised person.

Not suitable for pool or spa pool applications.

Not suitable for commercial boosting of

warm water recirculation systems.

Installation in marine environments can lead

to premature corrosion. Premature corrosion

due to the installation environment would not

be covered by warranty.

All gas appliances require adequate air intake

to ensure correct combustion. Insects and

dirt ingress may affect combustion causing

sooting. If you notice sooting from the flue

outlet the unit would require servicing. Pest

and dirt ingress is not covered by the

manufacturers warranty.

6 720 810 559 (2016/06)OptiFlow Professional

Product details | 5

“This appliance can be used by children of 8 years and older, as

well as by people with reduced physical, sensory or mental

capabilities or lacking in experience and knowledge, if they are

supervised and have been given instruction in the safe use of

the appliance and understand the resulting dangers. Children

must not play with the appliance. Cleaning and user

maintenance must not be performed by children without

supervision.”

“If the power cable is damaged, it must be replaced by the

manufacturer, its customer service department or a similarly

qualified person, so that risks are avoided.”

2 Product details

2.1 Declaration of Conformity

The appliance has been AS 4552 tested.

2.2 Type overview

[GWH]Gas continuous flow water heater

[12] Capacity (l/min)

[1] Generation

[CT] Thermostatic

[D] Digital user interface

[E] Electric ignition

[23] Appliance set for natural gas

[31] Appliance set for Universal LP gas

[F3] Open flue with fan

[O] Outdoor installation

[L] Locked water temperature adjustment

2.3 Included items

• Gas continuous flow water heater

• Fixing brackets

• Appliance documentation

2.4 Rating plate

The rating plate is located on the outside of the appliance, on

the bottom.

The particular room has the indications on the performance of

the appliance, approval data and the serial number.

2.5 Description of appliance

• Wall-mounted appliance

• Remote control with multifunctional display panel

(optional)

• Appliance for operating with natural gas or Universal LPG

• Electronic ignition

•Water flow sensor

•Water valve

• Temperature sensors for monitoring the temperature of the

incoming and outgoing water of the appliance.

•Safety devices:

–Flame sensor rod

–Thermal fuse

– Outgoing water temperature sensor

– Electronic control unit

–Air temperature sensor

– Frost-protection

• Electrical connection: 230 V, 50 Hz

2.6 Accessory

• Remote control

Model GWH12 1 CTD E23/31 F3 OL...

Table 2

GWH 12 1CTDE23 F3 OL

GWH 12 1CTDE31 F3 OL

Table 3

6 720 810 559 (2016/06) OptiFlow Professional

6 | Product details

2.7 Dimensions and minimum clearances

Fig. 1 Dimensions (in mm)

B

C

240

A

583

6720808877-02.1V

>10 >10

107120

80

51

Connections

Water Gas

A B C Cold Hot Nat. LPG

GWH12 300 570 170 ½“ ½“ ½“ ½“

Table 4 Dimensions (in mm)

6 720 810 559 (2016/06)OptiFlow Professional

Product details | 7

2.8 Appliance layout

Fig. 2

[1] Flue terminal

[2] Flame sensor rod

[3] Burner

[4] Air pressure test point

[5] Fan

[6] Air temperature sensor of the box

[7] Thermal fuse

[8] Hot water temperature sensor

[9] Hot water outlet

[10] Connecting lead with plug

[11] Remote control (optional)

[12] Ignition electrode

[13] Gas pressure test point

[14] Water flow sensor and Water valve

[15] Electronic control box

[16] Cold water temperature sensor

[17] Gas valve

[18] Cold water valve

[19] Incoming gas pressure test point

[20] Gas inlet

[21] Frost protection

6720808877-03.1V

10

2

3

4

5

8

9

6

7

11

15

13

14

20

18

19

17

16

21

12

1

6 720 810 559 (2016/06) OptiFlow Professional

8 | Product details

2.9 Electrical wiring diagram

Fig. 3 Electrical diagram

[1] Flame sensor rod

[2] Fan

[3] Ignition electrode

[4] Power supply

[5] Connection for frost-protection device

[6] Connection for remote control (optional)

[7] Modulation electrovalve (gas)

[8] Segmentation electrovalve 1 (gas

[9] Segmentation electrovalve 2 (gas)

[10] Safety electrovalve (gas)

[11] Thermal fuse

[12] Water flow sensor

[13] Air temperature sensor

[14] Hot water temperature sensor

[15] Cold water temperature sensor

[16] Water valve

Loading...

Loading...