Page 1

GRADIENT PUMP MAINTENANCE KIT

FOR THE BIOLOGIC SYSTEM

CATALOG NUMBER 750-0164

The BioLogic System Gradient Pump require minimal maintenance to stay in good working condition.

This maintenance kit includes the piston seals, check valves, and piston wipers for routine maintenance of the pump heads.

1. Replacing a piston seal. (Refer to Figure 1.)

a. Disconnect all tubing from the pump head.

b. Using the supplied Allen wrench, remove the four Pump Head Module Assembly screws on

the

face

of the Pump Head Module in the order shown. Gently pull the pump head away

from the Workstation.

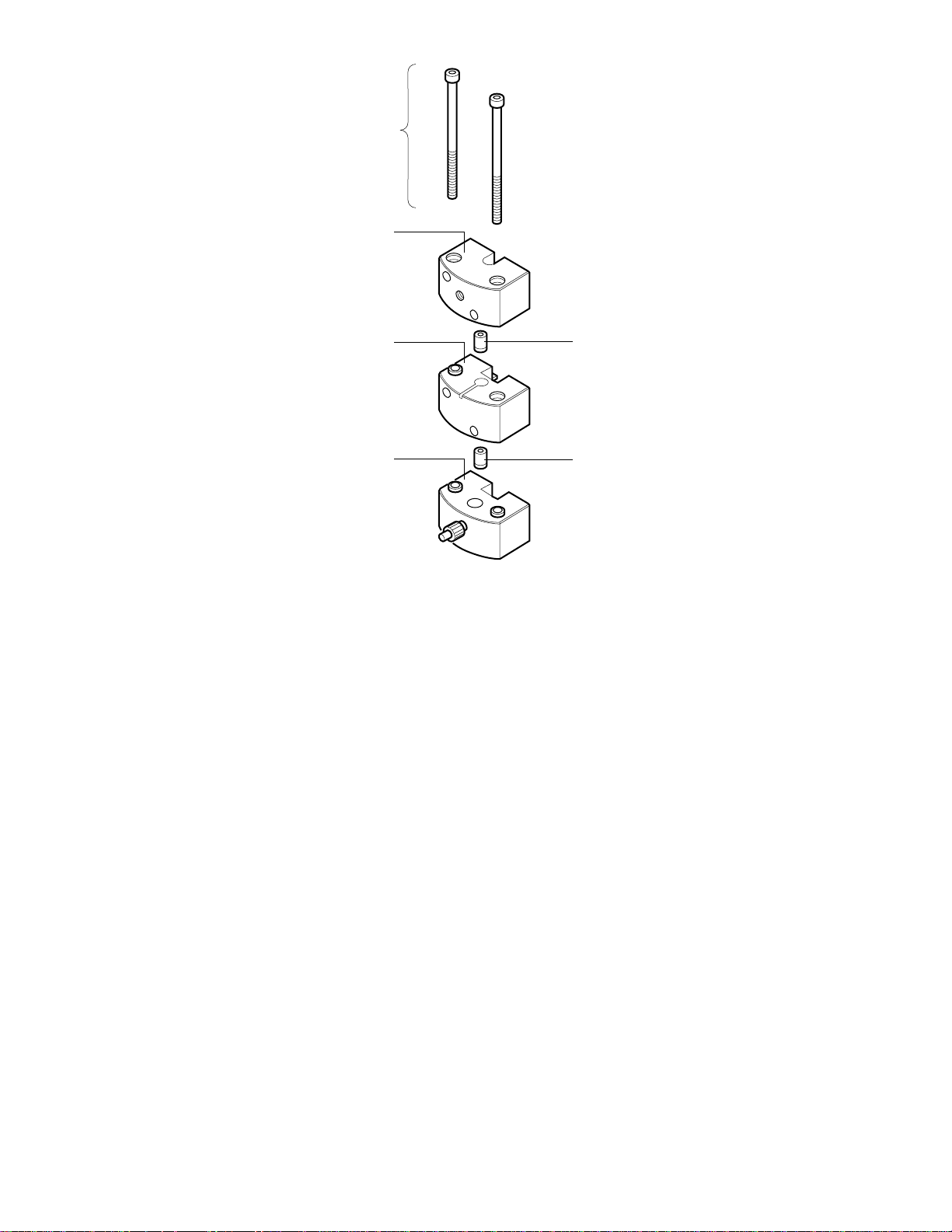

Figure 1. BioLogic Workstation Gradient Pump Mechanism Parts

c. Remove the washout block from the back of the pump head module by gently pulling it away.

d. Note that there are two piston seals per pumphead. Always replace both seals at the same

time. Once a piston seal is removed from its gland, it cannot be reused. It is recommended to

pre-condition the new seals by soaking or sonicating them in water for several minutes.

Always shake off or blot excess moisture from the seals before installation.

e. Using the Piston Seal Removal Tool, pry the seal from the gland. To do this, you insert the tip

of the Seal Removal Tool into the seal and gently pry the seal away. (See Figure 2.)

f. To install a new seal, line it up with the gland and use the Washout Block to seat the seal.

g. When both seals have been replaced, reassemble the pump head by reversing the

sequence shown in Figure 1. Firstly, wipe the pistons with a dampened cloth to ensure that

no crystallized salt residues are present which could damage the new seals. Then, position

Bio-Rad Laboratories, 2000 Alfred Nobel, Hercules CA 94547 • Phone (510) 741-1000

WASHOUT

BLOCK

SPRING RETAINER

PISTON WIPER

PUMP HEAD

MODULE

ASSEMBLY

SCREWS

PUMP HEAD

MODULE

1

4

3

2

Page 2

the Washout Block onto the pistons and set the pump head module back onto the Washout

Block on the BioLogic Workstation. (The Washout Block guides the pump head module in the

reattachment process and protects the pistons.)

h. Replace the four screws until the pump head module is secure on the Workstation but do not

overtighten.

Figure 2. Removing the Piston Seals (view showing the back of the Pump Head Module)

2. Cleaning and replacing a check valve.

a. Remove the Pump Head Module from the Workstation. Refer to Figure 1 and the previous

procedure.

b. Remove the two Pump Head Module Assembly screws at the

top

of the module. See Figure

3.

NOTE: Never remove the top screws without first removing the Pump Head Module from the

Workstation.

The pump head can now be separated into three parts and the two check valves will be

accessible.

c. To clean the check valves, remove them from the assembly and clean by sonication in a bath

of warm water with detergent or in a bath of methanol. After sonication, rinse thoroughly.

Using a syringe, inject filtered, deionised water through the check valve.

d. Reassemble the pump head with either a cleaned check valve or a new check valve.

Because the orientation of the check valve is critical, they are designed to fit into the pump

head module in one direction only.

e. Reassemble the pump head as shown in Figure 3. Replace the two pump head module

assembly screws and tighten firmly.

f. Position the Washout Block over the pistons and set the pump head module back onto the

Washout Block on the BioLogic Workstation. See Figure 1. (The Washout Block guides the

pump head module in the reattachment process and protects the pistons.)

g. Replace the four screws until the pump head module is secure on the Workstation but do not

overtighten.

GLAND

BACK OF PUMP

HEAD MODULE

PISTON SEALS

PISTON SEAL

REMOVAL TOOL

Page 3

PUMP HEAD

MODULE

ASSEMBLY

SCREWS

OUTLET HEAD

PUMPING HEAD

PRIMING HEAD

Figure 3. Pump Head Module Assembly

CHECK VALVE

CHECK VALVE

3. Replacing the Piston Wiper

Piston wipers are available in the event that they are lost during any of the pump maintenance

procedures. If the piston wiper has fallen out of the spring retainer, simply place a new piston

wiper onto the piston which then rests on the spring retainer. See Figure 1.

4. Plumbing the Gradient Pump

a. For inlets to the Gradient Pump, it is essential to use the wide-bore tubing supplied with your

system, which is 1/8” OD (0.062” ID) 37)(.

Note: Using smaller bore tubing will not provide sufficient flow of liquid to the Gradient Pump.

This will lead to entrapment of air bubbles in the pump heads which in turn causes an erratic

delivery of liquid and may stall the pump.

b. The remainder of the Gradient Pump system is plumbed with 1/16” OD (0.020” ID) Tefzel

tubing.

Daily Maintenance

Washing behind the piston seal extends seal life. Insert a 10 ml syringe filled with deionised water

in the Washout Port luer fitting. Each pumphead should get a 10 ml washout once per day,

preferably at the end of the day's operation. Run off water exits the pump through the Washout

Drain between the two pump heads. It can be collected in a small beaker.

Page 4

Storage of the Workstation

If the BioLogic System will be stored for a long period, be sure to remove all traces of buffer salts from

the Workstation pump heads, valves and monitors by flushing extensively with deionized water followed by a 20 % solution of ethanol to prevent microbial growth.

Technical Assistance

For additional help, contact your local Bio-Rad representative. In the United States, call Technical

Service at 1-800-4BIORAD.

Ordering Information

750-0160 Inlet line "dipper" filters (6)

750-0161 Piston Seals (4)

750-0162 Check Valves (1)

750-0164 Gradient Pump Maintenance kit

750-0165 Piston Wipers (4)

4106054 Rev C

Loading...

Loading...