Bio-Rad BioLogic DuoFlow Pathfinder 80 System DuoFlow Chromatography System Starter Kit User Manual

Page 1

BioLogic DuoFlow

F3 F4 F5

1 2 3

4 5 6

7 8 9

0

F1 F2

A B

VALVE A VALVE B

BioFrac Franction Collector

™

Chromatography System

Starter Kit

Instruction Manual

Catalog # 760-0135

Page 2

Table of Contents

Introduction .......................................................................................1

1. Starter Kit Components ..............................................................1

2. Materials You Will Need...............................................................1

I. BioLogic DuoFlow System ....................................................3

Section 1. DuoFlow System Preparation .........................................3

1.1 Prime the Workstation Pumps.....................................................5

1.2 Move the AVR7-3 Inject Valve to the Purge Position....................5

1.3 Purge the Workstation Pumps ....................................................5

1.4 Manual Control of the Workstation Pumps ..................................6

1.5 Flush the System Through to the Fraction Collector ....................6

BioFrac Fraction Collector

1.6 Turn on the UV Lamp ..................................................................6

DuoFlow UV Detector

QuadTec UV/Vis Detector

1.7 Manual Screen Chromatogram Window......................................7

1.8 Status Bar...................................................................................7

Section 2. Anion Exchange Separation of Protein Standards........8

2.1 Overview of the Procedure..........................................................8

2.2 Prepare Buffers...........................................................................9

2.3 Prepare Sample..........................................................................9

2.4 Install UNO Q1 Column ............................................................10

2.5 Prime the Pumps and Equilibrate the UNO Q1 Column ............10

2.6 Create a New Method...............................................................10

Page 3

II. DuoFlow Maximizer and Pathfinder Systems.....................18

Section 3. System Preparation.......................................................18

3.1 Prime the Workstation Pumps ..................................................20

3.2 Move the AVR7-3 Inject Valve to the Purge Position..................20

3.3 Purge the Workstation Pumps ..................................................21

3.4 Manual Control of the Pumps ...................................................21

3.5 Flush the System Through to the Fraction Collector ..................21

BioFrac Fraction Collection

3.6 Turn on the UV Lamp................................................................22

DuoFlow UV Detector

QuadTec UV/Vis Detector

3.7 pH Electrode Calibration ...........................................................23

3.8 Manual Screen Chromatogram Window ...................................23

3.9 Status Bar ................................................................................24

Section 4. Anion Exchange Separation of Protein Standards ......24

4.1 Overview of the Procedure........................................................24

4.2 Prepare Solutions .....................................................................25

4.3 Prepare Sample........................................................................26

4.4 Install the UNO Q1 Column.......................................................26

4.5 Prime the Pumps and Equilibrate the UNO Q1 Column.............27

4.6 Create a New Method...............................................................29

Section 5. Ordering Information.....................................................36

Page 4

Introduction

This instruction manual and starter kit contents may be used for the BioLogic

DuoFlow system and the BioLogic DuoFlow Maximizer

chromatography systems. The use of the starter kit with these systems is

described in Sections 1 and 3, respectively.

1. Starter Kit Components

This starter kit contains the following items for running a separation:

• 50 ml of buffer A, 250 mM Tris-HCI buffer, pH 8.1 (10x concentrate)

• 50 ml of buffer B, 250 mM Tris-HCI buffer, pH 8.1, plus 5.0 M NaCl (10x concentrate)

• 50 ml of Maximizer solution A1, 500 mM Tris-HCl (10x concentrate)

• 50 ml of Maximizer solution A2, 500 mM Tris base (10x concentrate)

• 50 ml of Maximizer solution B2, 5.0 M NaCl (2.5 x concentrate)

• One vial of anion exchange protein standard (catalog #125-0561)

• One 1 ml disposable sample injection syringe

• One 50 µl sample loop

The chromatographic separation for this kit requires approximately 6 minutes.

2. Materials You Will Need

In order to prepare the starter kit buffer solutions you will need the following

materials:

• Filtered high-quality water (i.e., HPLC grade water)

™

and Pathfinder

™

• One 500 ml graduated cylinder

• One 1 L side-arm flask

• Stirbar and stirplate

• Vacuum source for degassing

• Two 500 ml bottles

• Fraction collection tubes, 13 x 100 mm (at least 14 tubes)

• 100 ml beaker

1

Page 5

If you are using the DuoFlow Maximizer or Pathfinder systems you will also need

the following materials:

• pH 7.00 and pH 10.00 standard buffer

• One 200 ml graduated cylinder (optional)

• Two additional 500 ml bottles

• Fraction collection 1.5 or 2 ml micro tubes

2

Page 6

I. BioLogic DuoFlow System

Section 1. DuoFlow System Preparation

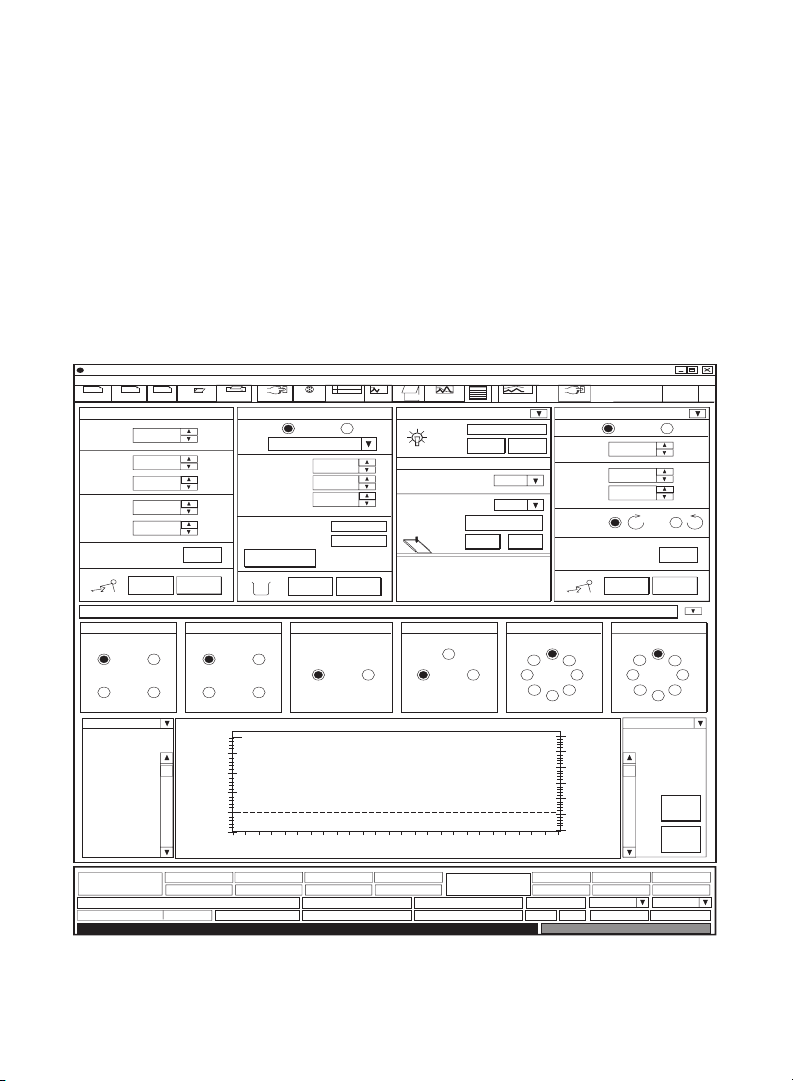

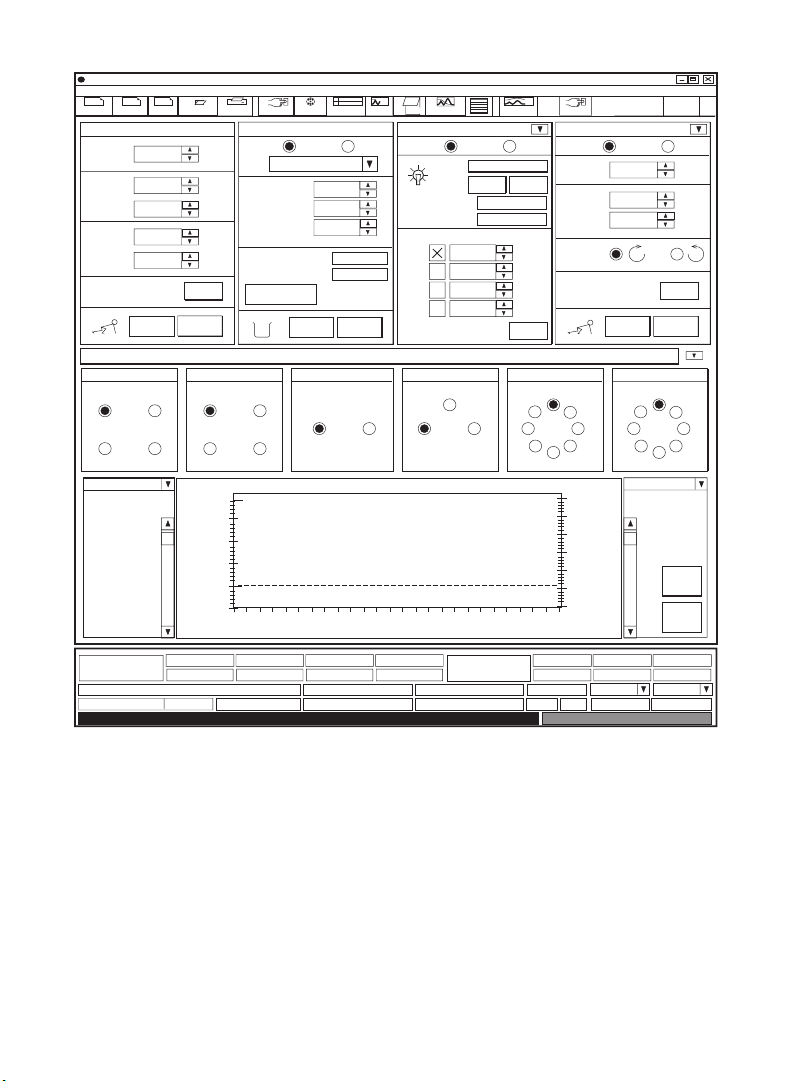

When the DuoFlow system is turned on, the Manual screen is displayed (see

Figures 1 and 2). This screen displays instrument control panels that provide

direct control of the pumps, valves, fraction collector, UV detector, QuadTec

UV/Vis detector, and Econo™Gradient Pump. The arrow button in the upper

right corner of the detector control panel toggles between the UV and QuadTec

detector control panels. Only those instruments connected to the system will be

displayed.

BioLogic Duo-Flow - - - no method -

File View Utilities Options Window Help

New

Method

Flowrate

Inlet A

Inlet B

High

limit

Low

limit

SVT5-4 at port 1 SVT3-2 at port 3SV5-4 at port 2

1

4

UV Conductivity

Zero baseline for the UV detector

New

Edit

Method

Run Browser Manual Setup Setup

Gradient Pump: F10

1.00

50

50

700

0

START

QuadTec

Gradient Pump: F10 UV Conductivity

0.00 ml/min

2

3

50 %B

Report

Fraction Collector: BioFrac

Mode: System

ml/min

%

%

psi.

psi.

Set

STOP

1

4

1.50

1.00

0.50

0.00

AU

F1 (12-13 mm tubes)

Rack:

Start Tube:

End Tube:

Fraction size:

Tube number:

Volume left:

Advance

2

3

100% Buffer B

50

02 46 8

1 psi 0.2583 AU 0.000 mS/cm

Fig. 1. Manual Control Screen with UV detector

wash

1

2

load

Protocol

1

20

1.00

1

START STOP

Workstation Valves

Run

Local

Notes

Conductivity range

(mS/cm):

ml

UV range (AU):

L21

Fractions

Minutes

PostRun

UV Detector

Chart Recorder

AVR7-3 at port 4

I

Econo Gradient

Log

Settings

Zero Baseline

ON OFF

5

1.0

Event Mark

P

Pump

Econo Gradient Pump 1

Mode: System

Flowrate

EGP %B

% Split

Flow

Direction

OFFON

AVR9-8 at port 5

I

82

37

6

4

5

400.0

300.0

200.0

100.0

0.0

10

mS/cm

Flow Rate EGP %B

1.000

0

0.00

START STOP

AVR9-8 at port 6

I

82

6

5

0 %B0.00 ml/min 0%

SIM1/pHSIM1/SIG

™

Bio-Rad

Web

ml/min

%

%

Set

Resize

Clear

Traces

% Split

Local

37

4

3

Page 7

4

BioLogic Duo-Flow - - - no method -

Fig. 2. Manual Control Screen with QuadTec detector

File View Utilities Options Window Help

New

Method

Flowrate

Inlet A

Inlet B

High

limit

Low

limit

New

Edit

Method

Run Browser Manual Setup Setup

Gradient Pump: F10

1.00

50

50

700

0

START

ml/min

%

%

psi.

psi.

Set

STOP

Report

Fraction Collector: BioFrac

Mode: System

F1 (12-13 mm tubes)

Rack:

Start Tube:

End Tube:

Fraction size:

Tube number:

Volume left:

Advance

wash

1

2

load

Protocol

1

20

1.00

1

START STOP

Notes

Run

Local Mode: System Local

Mode: System Local

Lamp Type

Range

ml

Log

PostRun

Settings

QuadTec Detector

Zero Baseline

ON OFF

Deuterium

190 - 370 nm

Wavelength Selection

280

260

214

405

nm

nm

nm

nm

Set

Econo Gradient Pump 1

Flowrate

1.000

0

EGP %B

% Split

0.00

Flow

Direction

START STOP

Workstation Valves

SVT5-4 at port 1 SVT3-2 at port 3SV5-4 at port 2

1

4

1

2

3

4

UV Conductivity

1.50

1.00

0.50

0.00

AU

QuadTec

0.00 ml/min

Sets fraction collector to system mode

WL1 - 280 nm

0.2232 AU

Gradient Pump: F10

50 %B

2

3

100% Buffer B

50

02 46 8

WL2 - 260nm WL3 - 214nm WL4 - 405nm

0.15 AU 1.15 AU

2 psi 0.2583 AU 0.000 mS/cm

UV

AVR7-3 at port 4

L21

Fractions

Minutes

0.30 AU

I

P

Econo Gradient

Pump

Conductivity

AVR9-8 at port 5

I

82

37

6

4

5

400.0

300.0

200.0

100.0

0.0

10

mS/cm

Flow Rate EGP %B

0 %B0.00 ml/min 0%

AVR9-8 at port 6

82

6

I

5

SIM1/pHSIM1/SIG

Bio-Rad

Web

ml/min

%

%

Set

Resize

Clear

Traces

% Split

37

4

Page 8

1.1 Prime the Workstation Pumps

a. Immerse the workstation pump A and B inlet lines in a container of HPLC

grade (filtered, degassed) or other high quality water.

b. Connect the syringe (supplied with the fittings kit) to the priming port of

pump A.

c. Turn the priming port counter-clockwise one full turn to open the seal. Gently

withdraw the syringe plunger to draw water into the pump head.

d. Repeat this operation several times until no air bubbles are visible in the inlet

tubing.

e. Tighten the priming port by turning it clockwise.

f. Repeat this priming procedure for pump B.

1.2 Move the AVR7-3 Inject Valve to the Purge Position

Prior to purging the pumps at 10 ml/min it is essential to place the AVR7-3 valve

in the purge position. This directs the flow to waste and not to the column and

detector.

To change the position of the AVR7-3 inject valve, select P from the Manual

screen valve control panel for the AVR7-3 valve. If you plugged the AVR7-3 inject

valve into port 4 on the workstation rear panel, you will see a valve box

designated AVR7-3 at port 4. The three buttons of this box correspond to valve

positions as follows: L = Load position, I = Inject position, P = Purge position. To

move the AVR7-3 valve to Purge position, click button P.

The default position at power up and at the end of a programmed method for the

AVR7-3 is L. For all other automated valves the default is position 1.

1.3 Purge the Workstation Pumps

a. Make sure that the AVR7-3 inject valve is in the Purge position.

b. Press the Purge buttons A then B on the front of the workstation. The

workstation pumps will run at a default flow rate of 10 ml/min and the

indicator light will flash green.

c. Run each pump for 2 minutes. Press the purge buttons again to stop the pump.

5

Page 9

6

1.4 Manual Control of the Workstation Pumps

The workstation pump parameters are set from the Manual screen either by

clicking in the appropriate field and entering a value from the keyboard or by

using the arrows. You can set the flow rate between 0.01 to 10 ml/min and the

gradient composition between 0 and 100% B.

To start the pump, click the Start button. Note that the running man icon will start

running. To change the pump parameters while the pump is running, enter the

new value and then click on the Set button.

Pressure limits can be adjusted to match the pressure limits of a column. If the

pressure limit is exceeded, the pump will stop and an alarm will sound. If you are

using an UNO

™

Q1 column, set the high limit to 700 psi and the low limit to 20 psi.

1.5 Flush the System Through to the Fraction Collector

With the gradient pumps stopped, move the AVR7-3 valve back to position L

(Load) by clicking L (AVR7-3) on the Manual screen.

From the gradient pump control panel on the Manual screen, set the pump flow

rate to 1.0 ml/min and start the pump. Water will flow through the UV or QuadTec

and conductivity flow cells to the fraction collector, as described below.

BioFrac

™

Fraction Collector

The BioFrac fraction collector has two operating modes:

• System—Controlled by the DuoFlow system

• Local—Controlled from its own faceplate in stand-alone mode

Ensure that the System button is selected.

When in System mode, the fraction collector control panel will show fields for

Rack type, Start tube, End tube, Fraction size, Tube number, Volume left, a

toggle button for Start and Stop, and a button for Advance (see Figures 1 and 2).

1.6 Turn on the UV lamp

DuoFlow UV detector

a. The UV lamp automatically turns on when you turn on power to the

workstation. The UV lamp can be turned on and off by clicking the On and

Off buttons from the UV detector control panel on the Manual screen

(see Figure 1). Check that the lamp is on; the mercury lamp requires

approximately 30 minutes to warm up.

Page 10

b. Click the Zero Baseline button to zero the UV signal. The Status bar along

the bottom of the screen provides AU output for the detector. Ensure that it

goes to zero when you select the zero baseline option.

QuadTec UV/Vis detector

a. The QuadTec detector should be powered On before starting the BioLogic

software. If the QuadTec detector is not powered up, exit the software,

power up the QuadTec detector and restart the software. When connection

is completed, “SLAVE” appears in the corner of QuadTec faceplate. The

QuadTec appears in its own control panel as shown in Figure 2.

b. From the QuadTec detector control panel on the Manual screen (Figure 2),

set the four wavelengths of the QuadTec detector to 280, 260, 214, and 405 nm.

Select Set. The active wavelengths will appear in the lower screen status bar.

c. Click the Zero Baseline button to zero the four UV/Vis signals. The Status bar

along the bottom of the screen provides AU output for the detector. Ensure

that it goes to zero when you select the zero baseline option.

1.7 Manual Screen Chromatogram Window

A feature of the Manual screen is its ability to display up to eight traces of a

chromatogram; including UV/Vis, pH, conductivity, %Buffer B, and pressure

traces, over a 10-minute interval. This is useful during column equilibration. The

chromatogram window is displayed at the bottom of the screen, under the valve

control panel (See Figures 1 and 2). Features of the chromatogram window

include:

• The time axis is reset automatically at the end of 10 minutes or reset manually by

clicking the Clear Traces button

• The chromatogram window can be enlarged by pressing the Resize button.

• A chromatogram trace may be selected for scaling by using the drop-down

menus on the upper right and left of the display

• The Y-axis scale can be changed using the scroll bars on the right or left of the

display

• The maximum and minimum axis settings can be changed by pressing Settings

on the manual screen toolbar.

1.8 Status Bar

At the bottom of the Manual screen is a status bar that is continually updated

with system parameters.

7

Page 11

Section 2. Anion Exchange Separation of Protein Standards

The starter kit enables you to learn to use the DuoFlow system by programming

and running a separation of a premixed anion exchange standard containing

equine myoglobin, conalbumin, chicken ovalbumin and soybean trypsin inhibitor

using a 1.3 ml UNO Q1 column (catalog #720-0001). Equine myoglobin is not

retained on the UNO Q1 column and elutes in the void volume. Conalbumin,

chicken ovalbumin, and soybean trypsin inhibitor bind to the column and require

increased salt concentrations for elution. Separation requires approximately

6 minutes.

2.1 Overview of the Procedure

Run Conditions

• Buffer A 25 mM Tris-HCl, pH 8.1

• Buffer B 25 mM Tris-HCl, pH 8.1, 0.5 M NaCl

• Flow rate 4.00 ml/min

• Sample volume 50 µl

• UV detection 0.1 AUFS

• QuadTec detection 0.1 AUFS (λ = 280 nm), 0.1 AUFS (λ = 260 nm),

1.0 AUFS (λ = 214 nm), and 0.4 AUFS (λ = 304 nm)

• Conductivity 100 mS/cm

General Procedure

Step 1 Prepare buffer

Step 2 Prepare sample

Step 3 Install the UNO Q1 column

Step 4 Prime the workstation pumps and equilibrate the column

Step 5 Write a method

a. Program the instrument Setup

b. Program the method Protocol

c. Load sample into 50 µl loop

d. Select Run

e. Select Start

8

Page 12

2.2 Prepare Buffers

During solution preparation, wear appropriate laboratory protective clothing

including, eye protection, and gloves. Avoid skin and eye contact with starter kit

solutions. In case solutions come in contact with eyes, rinse immediately with

plenty of water and get medical advice.

Buffer A

a. Empty the contents of the bottle labeled buffer A into a 500 ml graduated

cylinder and add filtered, high-quality water to a 500 ml volume.

b. Place the contents of the graduated cylinder into a 1 L side-arm flask and

drop in a stirbar. Cap the side arm flask, place it on a stirplate and connect it

to a vacuum source. Degas the buffer for approximately 15 minutes with

gentle stirring.

c. When degassing is complete, pour the buffer into a bottle and label it “Buffer A,

25 mM Tris-HCI, pH 8.1”.

Buffer B

Prepare buffer B by following the same procedure for preparation of buffer A.

Label the buffer as “Buffer B = 25 mM Tris-HCl, pH 8.1, 0.5 M NaCl”.

Conversion of Maximizer Solutions to Buffers A and B

The starter kit contains solutions for use with the DuoFlow Maximizer or

Pathfinder systems. These can be converted to buffer A, 25 mM Tris-HCI, pH 8.1,

and buffer B = 25 mM Tris-HCl, pH 8.1, 0.5 M NaCl as follows:

a. Dilute Maximizer solutions A1 and A2 to 500 ml each with filtered water.

b. Combine 150 ml of diluted A1, 100 ml of diluted A2 and the entire contents

of solution B2. Dilute the mixture to 500 ml. Check the pH and adjust to pH 8.1,

if necessary. Degas the solution and label it as “Buffer B, 25 mM Tris-HCI,

pH 8.1, 0.5 M NaCl“.

c. Combine the remaining diluted solutions A1 and A2 with water in a 1:1:2

ratio (i.e., 250 ml each of diluted A1 and A2 with 500 ml water). Check the

pH and adjust it to pH 8.1, if necessary. Degas the solution and label it as

“Buffer A, 25 mM Tris-HCI, pH 8.1”.

2.3 Prepare Sample

a. Remove the aluminum cap from the anion exchange standard vial. Slowly

remove the rubber plug from the vial (the contents may be under vacuum).

9

Page 13

b. Add 1.0 ml of prepared buffer A to the vial.

c. Replace the rubber stopper and gently invert the vial to solubilize the protein

standards.

2.4 Install the UNO Q1 column

Remove the end caps from the UNO Q1 column. Keeping tubing lengths to a

minimum, connect 1/16" tubing from port 4 of the AVR7-3 inject valve to the

column inlet. Connect the column outlet to the bottom of the UV flow cell or to

the QuadTec flow cell. Secure the column in a vertical position.

2.5 Prime the Pumps and Equilibrate the UNO Q1 Column

Ensure the pumps are stopped and the inject valve is in the purge position.

Re-prime and purge pumps A and B as described in Section 1.1 of this manual.

Set the inject valve to position L (Load). Set the flow rate to 2.0 ml/min. Set the

UV range to 0.1 AUFS and the conductivity range to 100 mS/cm.

a. Wash the column with 6.5 ml (5 column volumes) of buffer B at 2 ml/min.

b. Equilibrate the column with 13 ml (10 column volumes) of 100% buffer A.

The conductivity monitor on the status bar should now read ≤ 3 mS/cm.

2.6 Create a New Method

In the Manual screen, select the Browser icon from the tool bar. In the Browser

screen you will enter a user name for your method (refer to page 6-1 of the

DuoFlow instruction manual for more information on the Browser screen)

according to the following steps:

• Select the Browser icon from the tool bar menu

• Select the New icon from the upper left side of the Browser screen

• Select New from the drop-down menu and enter your user name in the dialog

box.

• Click on the Project icon for your user name

• Select New and New Method. Enter your method name (or use default

Method 1)

• Click OK to proceed to the instrument/devices Setup screen

10

Page 14

BioLogic Duo-Flow - <user name> - <project name> - <method name> - <run name>

Edit

File View Utilities Options Window Help

New

Method

New

Edit

Method

Run Browser Manual Setup Delete

Report

Available Devices

Aux Load

Pump

Collector

Fraction

wash

1

load

2

Protocol

Run

Notes

PostRun

Log

Settings

Devices in setup

BioFrac Fraction Collector, Rack: F1 (12-13 mm tubes)

UV Detector

Signal Import Module 2 pH Range: 0.00 to 14.00 pH

Buffer Blender

Detectors

Conductivity Monitor

SV5-4 Valve - Inlet A

SVT3-2

Valve

AVR7-3

Valve

SV3

P

U

M

P

INJECT

SV5-4

Valve

AVR9-8

Valve

SV5-4 Valve - Inlet B

AVR7-3 Valve - Sample Inject Port 4

Gradient Pump: F10

Inlet A:

25 mM Tris-HCl, pH 8.1

Inlet A is assigned to SV5-4 Valve - at Port 1

25 mM Tris-HCl, pH 8.1 plus 0.5M NaCl

Inlet B:

Inlet B is assigned to SV5-4 Valve - at Port 2

Port 1

Port 2

Bio-Rad

Web

QuadTec

WL1 - 280nm

Gradient Pump: F10 UV Conductivity

1.00ml/min

0 %B2

0.40

WL2 - 260nm

AU

0.15

AU

WL3 - 214nm

1.15

AU

438 psi 1.003 AU 1.23 mS/cm

WL4 - 405nm

0.30

AU

Econo Gradient

Pump

Flow Rate EGP %B

0 %B0.00 ml/min 0%

0.548 Volt

% Split

SIM1/pHSIM1/SIG

7.00 pH

Fig. 3. Setup editor

Program the Instrument Setup

In the Setup screen select the instruments and devices to be used for the Starter

Kit method. The icons grouped on the left side of the screen (refer to Figure 3,

Available Devices) show all the instruments and devices that can be connected

to the BioLogic DuoFlow systems.

The list of devices in the right box (Devices in Setup) identifies those devices

selected for use with a specific method. The initial default Devices in Setup are a

UV detector, conductivity monitor, and an AVR7-3 inject valve. These come

11

Page 15

standard with the BioLogic DuoFlow system. The DuoFlow QuadTec system

includes a QuadTec UV/Vis detector in place of a UV detector.

a. Click on the Fraction Collector button in the Available Devices box. A dialog

box will appear asking you to choose the type of collector; i.e., a generic

collector, a Model 2110, or a BioFrac. Click on BioFrac and click the OK

button. You will now see BioFrac fraction collector in the Devices in Setup

box. The F1 Rack (12–13 mm tubes) is automatically selected.

b. If you are using a QuadTec UV/Vis detector, click on the Detectors button in

the Available Devices box. A dialog box will appear asking you to choose a

detector. Select QuadTec and check each of the four wavelength boxes.

Enter the wavelengths: (1) 280 nm, (2) 260 nm, (3) 214 nm, and (4) 405 nm.

Press OK.

c. In the Gradient Pump section of the setup screen enter your buffer names. In the

buffer A field, type in 25 mM Tris-HCI, pH 8.1. In the buffer B field type in 25 mM

Tris-HCI + 0.5 M NaCl, pH 8.1.

d. The Setup is now complete. To save the device setup, choose Save Setup

under the File menu and enter a name for your Setup.

e. You are now ready to program the separation steps for your method. To

program your method, press the Protocol icon on the tool bar.

Program the Method Protocol

a. From the Options pull-down menu, ensure that Use Volume (ml) is selected,

so that the programming base is Volume.

b. Program the separation method listed below and in Figure 4.

• From the left side of the screen, press the fraction collection icon. In

the pop-up window that appears, choose Collect All with a fraction

size of 2.00 ml and a delay of 0.0. Make sure the correct rack type is

displayed.

• Program the remaining steps using the Add Step icons from the left

side of the screen.

12

Page 16

BioLogic DuoFlow - <user name> - <project name> - <method name> - <run name>

File View Utilities Options

Edit

New

Method

Add Step

Isocratic

Flow

Load/Inject

Sample

Linear

Gradient

Change

Valve

Column

Switching

Repeat

Steps

New

Edit

Method

Run Browser Manual Setup

V

Report

0.00

1

0.00

2

1.00

3

1.00

4

5

1.50

2.30

6

7

15.30

18.10

8

26.10

Hold

Pause

Alarm

Zero

Baseline

Lamp

EGP

Fraction

Collection

Window Help

Collection Fractions of size 2.00 ml during entire run

Isocratic Flow

Zero Baseline

Load/Inject Sample

Isocratic Flow

Linear Gradient

Isocratic Flow

Isocratic Flow

wash

1

2

load

Protocol

Notes

Run

A: 25.0 mM Tris pH 8.1

B: 25.0 mM Tris plus 0.5 M NaCI

UV Detector

Sample

Static Loop

A: 25.0 mM Tris pH 8.1

B: 25.0 mM Tris plus 0.5 M NaCI

A: 25.0 mM Tris pH 8.1

B: 25.0 mM Tris plus 0.5 M NaCI

A: 25.0 mM Tris pH 8.1

B: 25.0 mM Tris plus 0.5 M NaCI

A: 25.0 mM Tris pH 8.1

B: 25.0 mM Tris plus 0.5 M NaCI

PostRun

Log

End of Protocol

Settings

100%

0%

Auto Inject Valve

100%

0%

100% --> 50%

0% --> 50%

0%

100%

100%

0%

Cut Copy Paste DeleteEdit

Volume: 1.00 ml

Flow: 4.00 ml/min

Volume: 0.50 ml

Flow: 4.00 ml/min

Volume: 0.80 ml

Flow: 4.00 ml/min

Volume: 13.00 ml

Flow: 4.00 ml/min

Volume: 2.80 ml

Flow: 4.00 ml/min

Volume: 8.00 ml

Flow: 4.00 ml/min

Bio-Rad

Web

QuadTec

WL1 - 280nm

0.40

AU

WL2 - 260nm

0.15

AU

WL3 - 214nm

1.15

AU

WL4 - 405nm

0.30

AU

Maximizer + Gradient Pump: F10 UV Conductivity

1.00ml/min

0 %B2

438 psi 1.003 AU 1.23 mS/cm

Fig. 4. Protocol screen

13

Econo Gradient

Pump

Flow Rate EGP %B

0 %B0.00 ml/min 0%

0.548 Volt

% Split

SIM1/pHSIM1/SIG

7.00 pH

Page 17

Step Number Start (ml) Step

1. 0.0 Collect fractions of size 2.00 ml during entire run

2. 0.0 Isocratic flow with 100% 25 mM Tris-HCI, pH 8.1,

0% 25 mM Tris-HCI, 0.5 M NaCl, pH 8.1

at 4.00 ml/min for 1.0 ml

3. 1.0 Zero Baseline to set UV baseline to 0.0. Select

either UV detector or QuadTec detector.

4. 1.0 Load inject sample, static loop: Inject 0.5 ml

sample at 4.00 ml/min. You will be injecting the

loop size of 50 µl.

5. 1.5 Isocratic flow with 100% 25 mM Tris-HCI, pH 8.1,

0% 25 mM Tris-HCI, 0.5 M NaCl, pH 8.1

at 4.00 ml/min for 0.8 ml

6. 2.3 Linear gradient with 0% to 50% 25 mM Tris,

0.5 M NaCl, pH 8.1 at 4.00 ml/min for 13.0 ml

7. 15.3 Isocratic flow with 0% 25 mM Tris, pH 8.1,

100% 25 mM Tris, 0.5 M NaCl, pH 8.1

at 4.00 ml/min for 2.8 ml

8. 18.1 Isocratic flow with 100% 25 mM Tris, pH 8.1,

0% 25 mM Tris, 0.5 M NaCl, pH 8.1

at 4.00 ml/min for 8.0 ml

9. 26.1 End of protocol

c. When you have finished programming the method, press the toolbar button

RUN. A dialog box will ask you to name the run. Accept the default Run 1

and click the OK button. You will now see the Run screen (see Figure 5).

The Run Screen

a. The toolbar buttons on the left side of the screen enable you to check that

the screen display ranges for UV (see page 8), QuadTec UV/Vis and

conductivity are correctly set and that the gradient pump pressure limits are

appropriate (700 psi high and 20 psi low limit), for the UNO Q1 column.

b. If you have been equilibrating the column while writing the method, you will

notice that the Status Bar is displaying the flow rate and values for UV,

QuadTec UV/Vis, and conductivity detectors. If necessary, you may wish to

14

Page 18

zero the UV or QuadTec UV/Vis trace by clicking on the Zero baseline button

in the appropriate box. This button may be selected at any time.

c. To scale the on-screen chromatogram trace display axes, use the scroll bars

located on the left and right axes of the chromatogram window.

d. To enlarge the view select the Resize button to the right of the

chromatogram display.

Start the Run

a. Ensure that sufficient tubes are in the fraction collector rack (approximately 14).

The drophead will automatically move to tube 1 when the run is started.

b. Ensure that the AVR7-3 valve is in the LOAD position (position L). If it is not,

return to the Manual Screen by clicking the toolbar Manual button and click

on valve position L.

c. Ensure that the 50 µl sample loop is connected to ports 3 and 6 of the inject

valve. Completely fill the loop with protein standard via port 2 using the

syringe and needle provided. Do not remove the syringe from the injection

port after filling the loop or the sample will siphon to waste.

d. To launch the Run, click on the green Start toolbar button. The sample will

be loaded automatically.

e. When the run is finished, the pumps automatically stop and a “Run Finished”

message appears in the bottom right of the status bar.

f. Figures 5 and 6 show typical run screens and chromatograms for this

separation using the UV or QuadTec UV/Vis detectors.

15

Page 19

BioLogic Duo-Flow - Demo Chromatography - Standard UV Detector - Sample Run

File View Utilities Options

Edit

New

Method

New

Edit

Method

Run Browser Manual Setup

Report

Window Help

wash

1

2

load

Protocol

Run

Notes

PostRun

Log

Frac. Collector

Advance

Divert Valve

1324567891011121314

0.100

100.0% Buffer B

Fractions

Collect

Waste

Grad. Pump

High psi

700

Low psi

0

0.075

0.050

-50.0

Set

Chart Recorder

UV Range

1.0

0.025

Settings

Full View

ConductivityUV

50.0

40.0

30.0

20.0

10.0

Bio-Rad

Web

Event

mark

UV Detector

Zero

Baseline

-0.000

00:00:00 00:02:00 00:04:00 00:06:00

AU

Hr:Min:Sec

Protocol: > 1 0.00 Collection Fractions of size 2.00 ml during entire run

QuadTec

Zero

Baseline

Run Time

0:00.0

QuadTec

Run Volume

0.0 ml

WL1 - 280nm

0.2222 AU

Step Time Left Fraction Vol. Left

Econo Gradient

Pump

Flow Rate EGP %B

Maximizer + Gradient Pump: F10 UV Conductivity

0.00ml/min

50 %B

0 psi 0.2583 AU 3.63 mS/cm

Fig. 5. Run Screen (UV detector and conductivity traces)

Valve Info

0.000 Volt

0.0

-10.0

mS/cm

% Split

0 %B0.00 ml/min 0%

SIM1/pHSIM1/SIG

8.05 pH

16

Page 20

BioLogic Duo-Flow - Demo Chromatography - Standard UV Detector - Sample Run

File View Utilities Options

Edit

New

Method

New

Edit

Method

Run Browser Manual Setup

Report

Window Help

wash

1

2

load

Protocol

Run

Notes

PostRun

Log

Frac. Collector

Advance

Divert Valve

1324567891011121314

0.100

100.0% Buffer B

Fractions

Collect

Waste

Grad. Pump

High psi

700

Low psi

0

0.075

0.050

-50.0

Set

Chart Recorder

UV Range

1.0

0.025

Settings

Full View

ConductivityQuadTec (280 nm)

50.0

40.0

30.0

20.0

10.0

Bio-Rad

Web

Event

mark

UV Detector

Zero

Baseline

-0.000

00:00:00 00:02:00 00:04:00 00:06:00

AU

Protocol: > 1 0.00 Collection Fractions of size 2.00 ml during entire run

QuadTec

Zero

Baseline

Run Time

0:00.0

QuadTec

Run Volume

0.0 ml

WL1 - 280nm

0.2223 AU

Maximizer + Gradient Pump: F10

0.00ml/min

50 %B

Fig. 6. Run screen QuadTec UV/Vis traces

0.0

Hr:Min:Sec

Step Time Left Fraction Vol. Left

WL2 - 260nm WL3 - 214nm WL4 - 405nm

0.15 AU 1.15 AU

0.30 AU

Econo Gradient

Pump

Conductivity

0 psi 0.2580 AU 3.63 mS/cm

0.0

-10.0

Valve Info

Flow Rate EGP %B

0 %B0.00 ml/min 0%

0.000 Volt

mS/cm

% Split

SIM1/pHSIM1/SIG

8.05 pH

17

Page 21

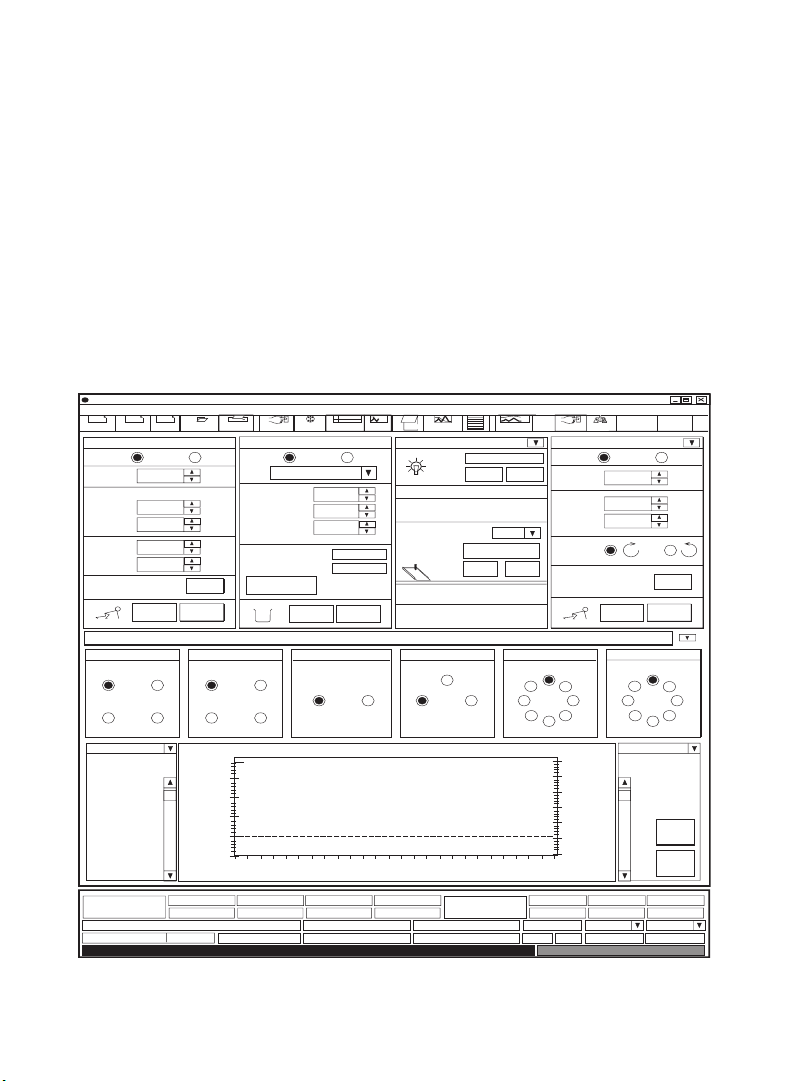

II. DuoFlow Maximizer and

Pathfinder Systems

Section 3. System Preparation

When the DuoFlow Maximizer or Pathfinder system is turned on, the Manual

screen is displayed in either Buffer Blending (Figure 7) or Non-Buffer Blending

mode (Figure 8). This screen displays instrument control panels that provide

direct control of the pumps, valves, fraction collector, UV detector, QuadTec

UV/Vis detector, and Econo gradient pump. The arrow in the upper right corner

of the detector control panel toggles between the UV and QuadTec detector

control panels. The button in the upper right hand corner of the valve control

panel toggles between the workstation and Maximizer valve control panels.

BioLogic Duo-Flow - - - no method -

File View Utilities Options Window Help

New

Method

Maximizer+Gradient Pump: F10

Flowrate

pH

Inlet B

High

limit

Low

limit

SVT5-4 at port 1 SVT3-2 at port 3SV5-4 at port 2

1

4

UV Conductivity

Switch to the QuadTec faceplate

New

Edit

Method

Run Browser Manual Setup Setup

1.00

Tris (25 mM)

8.10

0

700

0

START

QuadTec

Gradient Pump: F10 UV Conductivity

0.00 ml/min

Set

STOP

2

1

4

3

AU

WL1 - 280 nm

0.2225 AU

0 %B2

Report

Fraction Collector: BioFrac

Mode: System

F1 (12-13 mm tubes)

Rack:

ml/min

Start Tube:

End Tube:

%

Fraction size:

psi.

psi.

Tube number:

Volume left:

Advance

2

3

100% Buffer B

1.50

1.00

50

0.50

-0

0.00

02 46 8

1 psi 0.2577 AU 3.63 mS/cm

wash

1

load

2

Protocol

1

20

1.00

1

START STOP

Workstation Valves

Notes

Run

LocalMode: System Local Mode: System Local

ml

UV range (AU):

L21

Fractions

Minutes

PostRun

UV Detector

Chart Recorder

Signal Import Module

SIM 1 is connected

AVR7-3 at port 4

I

Econo Gradient

Log

Settings

Zero Baseline

ON OFF

1.0

Event Mark

P

Pump

OFFON

AVR9-8 at port 5

82

6

Setup

Econo Gradient Pump 1

Flowrate

1.000

0

EGP %B

% Split

0.00

Flow

Direction

START STOP

I

37

4

5

400.0

300.0

200.0

100.0

0.0

10

mS/cm

Flow Rate EGP %B

0 %B0.00 ml/min 0%

0.000 Volt 6.53 pH

AVR9-8 at port 6

I

82

6

5

SIM1/pHSIM1/SIG

Bio-Rad

Web

Set

Resize

Clear

Traces

% Split

ml/min

%

%

37

4

Fig. 7. Manual screen (Buffer Blending mode)

18

Page 22

BioLogic Duo-Flow - - - no method -

File View Utilities Options Window Help

New

Method

Maximizer+Gradient Pump: F10

Mode: System

Flowrate

Composition Inlet Valves

Inl A

Inl B

High

limit

Low

limit

New

Edit

Method

Run Browser Manual Setup Setup

1.00

%

50

%

50

700

0

START

Report

Fraction Collector: BioFrac

Mode: System

Local

ml/min

A1

B1

psi.

psi.

Set

A2

B2

F1 (12-13 mm tubes)

Rack:

Start Tube:

End Tube:

Fraction size:

Tube number:

Volume left:

Advance

STOP

wash

1

load

2

Protocol

1

20

1.00

1

START STOP

Notes

Run

Local Mode: System Local

Mode: System Local

Log

PostRun

QuadTec Detector

Settings

Zero Baseline

Lamp Type

Range

ml

ON OFF

Deuterium

190 - 370 nm

Wavelength Selection

280

260

214

405

nm

nm

nm

nm

Set

Setup

Econo Gradient Pump 1

Flowrate

1.000

0

EGP %B

% Split

0.00

Flow

Direction

START STOP

Workstation Valves

SVT5-4 at port 1 SVT3-2 at port 3SV5-4 at port 2

1

4

1

2

3

4

UV Conductivity

1.50

1.00

0.50

0.00

AU

QuadTec

0.00 ml/min

Switch to the UV faceplate

WL1 - 280 nm

0.2226 AU

Gradient Pump: F10

50 %B

2

3

100% Buffer B

50

-0

02 46 8

WL2 - 260nm WL3 - 214nm WL4 - 405nm

0.15 AU 0.55 AU 0.30 AU

1 psi 0.2580 AU 3.61 mS/cm

UV Conductivity

Fractions

Minutes

AVR7-3 at port 4

I

L21

Econo Gradient

AVR9-8 at port 5

P

Pump

I

82

37

4

6

5

400.0

300.0

200.0

100.0

0.0

10

mS/cm

Flow Rate EGP %B

0.000 Volt 6.54 pH

AVR9-8 at port 6

82

6

0 %B0.00 ml/min 0%

Fig. 8. Manual Screen (Non-Buffer Blending mode)

I

5

Bio-Rad

Resize

Traces

% Split

SIM1/pHSIM1/SIG

Web

ml/min

%

%

Set

37

4

Clear

19

Page 23

3.1 Prime the Workstation Pumps

a. Immerse Maximizer inlet lines A1, A2, B1, and B2 in a container of HPLC

grade (filtered, degassed) or other high-quality water.

b. From the Manual screen place the Maximizer in Local mode and use the

Valve Port Select button, under the A1/A2 Maximizer valve inlet, to select

inlet port A1.

c. Connect the syringe (supplied with the fittings kit) to the priming port of

pump A.

d. Turn the priming port counter-clockwise one full turn to open the seal. Gently

withdraw the syringe plunger to draw water into the pump head.

e. Repeat this operation several times until no air bubbles are visible in the inlet

tubing.

f. Use the Valve Port Select button on the Maximizer to select solution A2.

Gently withdraw the syringe plunger to draw water into the pump head.

g. Repeat this operation several times until no air bubbles are visible in the inlet

tubing.

h. Tighten the priming port by turning it clockwise.

i. Repeat this priming procedure for pump B and inlets B1 and B2.

3.2 Move the AVR7-3 Inject Valve to the Purge Position

Prior to purging the pumps at 10 ml/min it is essential to place the AVR7-3 valve

in the purge position. This directs the flow to waste and not to the columns and

detector.

To change the position of the AVR7-3 inject valve, select P from the Manual

screen valve control panel for the AVR7-3 valve. Select the workstation or

Maximizer valve control panel that displays the AVR7-3 inject valve. For example, if

you have connected the AVR7-3 inject valve into port 10, you will see a valve box

designated AVR7-3 at port 10 of the Maximizer valve control panel. The three

buttons of this box correspond to valve positions as follows: L = Load position,

I = Inject position, P = Purge position. To move the AVR7-3 valve to Purge

position, click button P.

The default position at power up and at the end of a programmed method for the

AVR7-3 is L. For all other automated valves the default is position 1.

20

Page 24

3.3 Purge the Workstation Pumps

a. Make sure that the inject valve is in the Purge position.

b. Select solutions A2 and B2 from the Valve Port Select buttons on the

Maximizer faceplate.

c. Press the Purge buttons A then B on the front of the workstation. The

workstation pumps will run at 10 ml/min and the indicator light will flash green.

d. Run each pump for 2 minutes and then press the Valve Port Select buttons

on the Maximizer faceplate to select solutions A1 and B1. Run each pump

for 2 minutes more and then press the Purge buttons to stop the pumps.

3.4 Manual Control of the Pumps

The workstation pump parameters can be set from the Manual screen

Maximizer+Gradient Pump control panel either by clicking in the appropriate field

and entering a value from the keyboard or by using the arrows. The appearance

of the these control panels depends on whether the instrument is in Buffer

Blending or Non-Buffer Blending mode. Figures 7 and 8 show examples of the

respective Buffer Blending and Non-Buffer Blending control panels. From these

control panels you can set the flow rate, pressure limits, and buffer composition.

You can switch between these two panels by pressing in the toolbar and

checking or unchecking the “Use Buffer Blending” box on the Maximizer Buffer

Blending Setup screen.

To start the pump, click the Start button. Note that the running man icon will start

running. To change the pump parameters while the pump is running, enter the

new value and then click on the Set button. Pressure limits can be adjusted to

match the pressure limits of a column. If the pressure limit is exceeded, the pump

will stop and an alarm will sound. If you are using an UNO Q1 column, set the

high limit to 700 psi and the low limit to 20 psi.

3.5 Flush the System Through to the Fraction Collector

With the gradient pumps stopped, move the AVR7-3 inject valve back to position

L (Load) by clicking L (AVR7-3) on the Manual screen.

From the gradient pump control panel on the Manual screen, set the pump flow

rate at 1.0 ml/min and start the pump. Water will flow through the UV or QuadTec

and conductivity flow cells to the fraction collector, as described below.

21

Page 25

BioFrac Fraction Collector

The BioFrac fraction collector has two operating modes:

• System—Controlled by the BioLogic DuoFlow system

• Local—Controlled from its own faceplate in stand-alone mode

Ensure that the System button is selected.

When in System mode, the fraction collector control panel on the Manual screen

will show fields for Rack type, Start tube, End tube, Fraction size, Tube number,

Volume left, a toggle button for Start and Stop, and a button for Advance (see

Figures 7 and 8).

3.6 Turn on the UV Lamp

DuoFlow UV Detector

a. The UV lamp automatically turns on when you turn on power to the

workstation. The UV lamp can be turned on and off by clicking the On and

Off buttons from the UV detector control panel on the Manual screen (see

Figure 7). Check that the lamp is on; the mercury lamp requires

approximately 30 minutes to warm up.

b. Select the Zero Baseline button to zero the UV signal. The Status bar along

the bottom of the screen provides AU output for the detector. Ensure that it

goes to zero when you select the zero baseline option.

QuadTec UV/Vis Detector

a. The QuadTec detector should be powered On before starting the BioLogic

software. If the QuadTec detector is not powered up, exit the software, power

up the QuadTec detector, and restart the software. When connection is

completed, “SLAVE” appears in the upper left corner of the QuadTec faceplate.

b. From the QuadTec detector control panel on the Manual screen (Figure 7),

set the four wavelengths of the QuadTec detector to 280, 260, 214, and

405 nm. Select Set. The active wavelength will appear in the lower screen

status bar.

c Click the Zero Baseline button to zero the four UV/Vis signals. The Status bar

along the bottom of the screen provides AU output for the detector. Ensure

that it goes to zero when you select the zero baseline option.

22

Page 26

3.7 pH Electrode Calibration

Prior to starting a run the pH electrode should be calibrated as follows:

a. Remove the electrode from the flow cell and rinse it with deionized water.

b. Place the electrode in pH 7 standard buffer.

c. From the Utilities drop-down menu, select “pH probe calibration”.

d. Enter the temperature and reference pH (at the current temperature) for the

first buffer. Press Set. The temperature can be read from the Display Screen

on the Maximizer.

e. When the pH reading has stabilized, press OK.

f. Rinse the electrode with deionized water.

g. Place the electrode in the pH 10 standard buffer.

h. Enter the reference pH for the second buffer at the current temperature.

Press Set.

i. When the pH reading has stabilized, press OK.

3.8 Manual Screen Chromatogram Window

A feature of the Manual screen is its ability to display up to eight traces of a

chromatogram, including UV/Vis, pH, conductivity, % Buffer B, and pressure

traces over a 10-minute interval. This is useful during column equilibration. The

chromatogram window is displayed at the bottom of the screen, under the valve

control panel (See Figures 7 and 8). Features of the chromatogram window

include:

• The time axis is reset automatically at the end of 10 minutes or may be reset

manually by clicking the Clear Traces button

• The chromatogram window can be enlarged by pressing the Resize button

• A chromatogram trace may be selected for scaling by using the drop-down

menus on the upper right and left of the display

• The Y-axis scale can be changed using the scroll bars on the right or left of the

display

• The maximum and minimum axis settings can be changed by pressing Settings

on the manual screen toolbar

23

Page 27

3.9 Status Bar

At the bottom of the Manual screen is a status bar that is continually updated

with system parameters.

Section 4. Anion Exchange Separation of Protein Standards

The starter kit enables you to learn to use the DuoFlow Maximizer or Pathfinder

systems by programming and running separation of a premixed anion exchange

standard containing equine myoglobin, conalbumin, chicken ovalbumin, and

soybean trypsin inhibitor, using a 1.3 ml UNO Q1 column (catalog #720-0001).

Equine myoglobin is not retained on the UNO Q1 column and elutes in the void

volume. Conalbumin, chicken ovalbumin, and soybean trypsin inhibitor bind to

the column and require increased salt concentrations for elution. Separation

requires approximately 6 minutes.

4.1 Overview of the Procedure

Run Conditions

• Buffer A1 50 mM Tris-HCl

• Buffer A2 50 mM Tris base

• Solution B1 deionized water

• Solution B2 2.0 M NaCI

• Flow rate 4.00 ml/min

• Sample volume 50 µl

• UV detection 0.1 AUFS

• QuadTec detection 0.1 AUFS (λ = 280 nm), 0.1 AUFS (λ = 260 nm),

1.0 AUFS (λ = 214nm), and 0.4 AUFS (λ = 304 nm)

• Conductivity 100 mS/cm

• pH pH 7.1 to pH 9.1

General Procedure

Step 1 Prepare solutions A

, A2, B1, and B

1

Step 2 Prepare sample

Step 3 Install the UNO Q1 column

24

2

Page 28

Step 4 Prime the workstation pumps and inlet valves, and equilibrate the

column

Step 5 Write a method

a. Program in the instrument Setup

b. Program the method Protocol

c. Load sample into 50 µl loop

d. Select Run

e. Select Start

4.2 Prepare Solutions

During solution preparation, wear appropriate laboratory protective clothing,

including eye protection and gloves. Avoid skin and eye contact with starter kit

solutions. In case solutions come in contact with eyes, rinse immediately with

plenty of water and get medical advice.

Note: Solutions A, and A

are diluted to 500 ml, solution B2is diluted to 125 ml.

2

Solution A1

a. Empty the contents of the bottle labeled Solution A1 into a 500 ml graduated

cylinder and add filtered, high-quality water to a 500 ml volume.

b. Place the contents of the graduated cylinder into a 1 L side-arm flask and

drop in a stirbar. Cap the side arm flask, place it on a stirplate and connect it

to a vacuum source. Degas the solution for approximately 15 minutes with

gentle stirring.

c. When degassing is complete, pour the buffer into a bottle and label as

"Solution A1 50 mM Tris-HCl".

Solution A2

a. Empty the contents of the bottle labeled Solution A2 into a 500 ml graduated

cylinder and add filtered, high-quality water to 500 ml. Caution: pH of

Solution A2 is approximately 10.5.

b. Place the contents of the graduated cylinder into a 1 L side-arm flask and

drop in a stirbar. Cap the side arm flask, place it on a stirplate and connect it

to a vacuum source. Degas the solution for approximately 15 minutes with

gentle stirring.

25

Page 29

c. When degassing is complete, pour the buffer into a bottle and label “Solution

A2, 50 mM Tris base”.

Solution B1

Place 1 L of water into a 1 L side-arm flask and drop in a stirbar. Cap the side

arm flask, place it on a stirplate and connect it to a vacuum source. Degas the

solution for approximately 15 minutes with gentle stirring. Label solution as

“Solution B1, water”.

Solution B2

a. Empty the contents of the bottle labeled Solution B2 into a 200 ml graduated

cylinder and add filtered, high-quality water to 125 ml. If you mistakenly

dilute solution B

to 500 ml, add 43.8 g NaCI, stir, and degas until dissolved.

2

b. Place the contents of the graduated cylinder into a 1 L side-arm flask and

drop in a stirbar. Cap the side-arm flask, place it on a stirplate, and connect it

to a vacuum source. Degas the solution for approximately 15 minutes with

gentle stirring.

c. When degassing is complete, pour the buffer into a bottle and label it as

“Solution B2, 2 M NaCl”.

4.3 Prepare Sample

a. Using the fraction collector, collect 1 ml of pH 8.1 Tris, 0% B into a tube.

Alternatively, mix 0.25 ml of Solution A1, 0.25 ml of Solution A2, and 0.5 ml

of water in an Eppendorf tube.

b. Remove the aluminum cap from the anion exchange standard vial. Slowly

remove the rubber plug from the vial (the contents may be under vacuum).

c. Add 1.0 ml of the buffer from step (a) to the vial.

d. Replace the rubber stopper and gently invert the vial to solubilize the protein

standards.

4.4 Install the UNO Q1 Column

Remove end caps from the UNO Q1 column. Keeping tubing lengths to a

minimum, connect 1/16" tubing from port 4 of the AVR7-3 inject valve to the

column inlet. Connect the column outlet to the bottom of the UV flow cell or

QuadTec flow cell. Secure the column in a vertical position.

26

Page 30

4.5 Prime the Pumps and Equilibrate the UNO Q1 Column

Ensure the gradient pumps are stopped and the inject valve is in the purge

position. Place the tubing from inlets A1, A2, B1 and B2 into solutions A1 (TrisHCl), A2 (Tris base), B1 (water), and B2 (NaCl), respectively. Re-prime and purge

the pumps and inlets A1, A2, B1, and B2 as described in Section 3.1 of this

manual.

Set the inject valve to position L (Load). Set the flow rate to 2.0 ml/min. Set the

UV (280 nm) range to 0.1 AUFS and the conductivity range to 100 mS/cm.

Set the buffer recipe by pressing on the toolbar and choosing Tris (25 mM)

as your buffer. Press OK. On the manual screen set the pH to 8.10 and the Salt

Molarity %B to 0.0.

Change the pH scale by pressing the Settings button on the toolbar. Set the

minimum pH to 7.1 and the maximum pH to 9.1 in SIM1/pH.

Applying a 1 or 2-point pH correction (optional).

The Maximizer has been designed to prepare buffers accurately and reproducibly

at a user-defined pH and salt composition. The pH accuracy, however, depends

on how close the selected pH is to the buffer systems pKa. In situations where

high pH accuracy is required, you should apply a 1 or 2-point pH correction as

described below.

Single Point Correction (best for isocratic applications)

a. In the manual screen set the pH to 8.1, the salt composition to 0 %B (or to

the desired %B) and the flow rate to 2.0 ml/min.

b. Take the column out of line if it has been connected and start the pump.

c. When the pH has stabilized, read the pH from the status bar or, alternatively,

collect the effluent and measure the pH using a high quality Tris compatible

pH probe.

d. From the buffer blending setup screen, place a check in the Use pH

Correction box (leave the Use Two Point Correction box unchecked).

e. Set the desired pH to 8.1 and the Observed at 0 % pH, to the pH measured

in step (c).

f. Press OK.

27

Page 31

Two-Point Correction (best for gradient applications)

a. In the manual screen, set the pH to 8.1, the salt composition to 0 %B and

the flow rate to 2.0 ml/min.

b. Take the column out of line, if it has been connected, and start the pump.

c. When the pH has stabilized, read the pH from the status bar or, alternatively,

collect the effluent and measure the pH using a high quality Tris compatible

pH probe.

d. Change %B to 100 % (or to the maximum %B that will be used for the

experiment).

e. When the pH reading has stabilized, read the pH from the status bar or,

alternatively, collect the effluent and measure the pH using a high quality Tris

compatible pH probe.

f. Set the %B back to 0% and re-equilibrate the system with the low salt buffer.

g. From the buffer blending setup screen, place a check in the Use pH

Correction box.

h. Set the desired pH to 8.1 and the Observed at 0 %B pH to the pH measured

in step (c).

i. Place a check in the Use Two Point Correction box and set %B to the value

used in step (d)).

j. Set the Observed at %B pH to the pH measured in step (e).

k. Press OK.

Column Equilibration.

a. Connect the UNO Q1 column.

b. Wash the column with 6.5 ml (5 column volumes) of pH 8.10 Tris (100% B) at

2 ml/min.

28

Page 32

BioLogic Duo-Flow - <user name> - <project name> - <method name> - <run name>

Edit

File View Utilities Options Window Help

New

Method

New

Edit

Method

Run Browser Manual Setup Delete

Aux Load

Pump

Buffer Blender

SVT3-2

Valve

AVR7-3

Valve

Maximizer + Gradient Pump: F10

A1: 50 mM Tris-HCl; A2: 50 mM Tris

Inlet A1:

Is assigned to buffer blender

Inlet A2:

Is assigned to buffer blender

B1: Water; B2: 2.0M NaCl

Inlet B1:

Is assigned to buffer blender

Inlet B2:

Is assigned to buffer blender

QuadTec

Gradient Pump: F10 UV Conductivity

1.00ml/min

Available Devices

SV3

P

U

M

P

INJECT

WL1 - 280nm

0.40 AU

0 %B2

Report

Fraction

Collector

Detectors

WL2 - 260nm

0.15 AU

438 psi 1.003 AU 1.23 mS/cm

SV5-4

Valve

AVR9-8

Valve

wash

1

load

2

Protocol

WL3 - 214nm

1.15 AU

Notes

Run

BioFrac Fraction Collector, Rack: F1 (12-13 mm tubes)

Buffer blender: Tris (25mM)

UV Detector

Signal Import Module 1 pH Range: 0.00 to 14.00 pH

Conductivity Monitor

SV5-4 Valve - Inlet A

SV5-4 Valve - Inlet B

AVR7-3 Valve - Sample Inject Port 10

WL4 - 405nm

0.30 AU

PostRun

Log

Econo Gradient

Pump

Settings

Devices in setup

Flow Rate EGP %B

0 %B0.00 ml/min 0%

0.548 Volt

Port 1

Port 2

SIM1/pHSIM1/SIG

7.00 pH

% Split

Fig. 9. Setup editor

c. Equilibrate the column with 13 ml (10 column volumes) of pH 8.10 Tris (0% B).

When finished, the conductivity monitor on the status bar should read

≤ 3 mS/cm.

4.6 Create a New Method

Bio-Rad

Web

In the Manual screen select the Browser icon from the tool bar. In the Browser

screen you will enter a user name and name for your method (refer to page 6-1

of the DuoFlow instruction manual for more information on the Browser screen)

according to the following steps:

• Select the Browser icon from the tool bar menu

• Select the New icon from the upper left side of the Browser screen

• Select New from the drop-down menu and enter your user name in the dialog

box

• Click on the Project icon for your user name

• Select New and New Method. Enter your method name (or use default

Method 1)

• Click OK to proceed to the instrument/devices Setup screen

29

Page 33

Program the Instrument Setup

In the Setup screen, select the instruments and devices to be used for the Starter

Kit method. The icons grouped on the left hand side of the screen (refer to Figure 3,

Available Devices), show all the instruments and devices that can be connected

to the BioLogic DuoFlow systems.

The list of devices in the right box (Devices in Setup) identifies those devices

selected for use with a specific method. The initial default Devices in Setup are a

UV detector, a conductivity monitor, and an AVR7-3 inject valve, as these come

as standard with the BioLogic DuoFlow system. The DuoFlow QuadTec systems

includes a QuadTec UV/Vis detector in place of a UV detector.

a. Click on the Buffer Blending button in the Available Devices box. A dialog box

will appear. Choose Tris (25) mM from the buffer list and select OK. If desired,

enter the 1 or 2-point pH correction measured in Section 4.5.

30

Page 34

BioLogic DuoFlow - <user name> - <project name> - <method name> - <run name>

File View Utilities Options

Edit

New

Method

Add Step

Isocratic

Flow

Load/Inject

Sample

Linear

Gradient

Change

Valve

Column

Switching

Repeat

Steps

Hold

Pause

Alarm

Zero

Baseline

Lamp

New

Edit

Method

Run Browser Manual Setup

Volume Description Parameters

V

1

0.00

2

0.00

3

1.00

4

1.00

5

1.50

2.30

6

7

15.30

18.10

8

26.10

EGP

Fraction

Collection

Report

Window Help

Collection Fractions of size 2.00 ml during entire run

Isocratic Flow

Zero Baseline

Load/Inject Sample

Isocratic Flow

Linear Gradient

Isocratic Flow

Isocratic Flow

End of Protocol

wash

1

2

load

Protocol

Run

pH 8.10

UV Detector

Sample

Static Loop

pH 8.10

pH 8.10

pH 8.10

pH 8.10

Notes

PostRun

0%B

0%B

0%B -> 25%B5

50%B

0%B

Log

Settings

Volume: 1.00 ml

Flow: 4.00 ml/min

Auto Inject Valve

Volume: 0.80 ml

Flow: 4.00 ml/min

Volume: 13.00 ml

Flow: 4.00 ml/min

Volume: 2.80 ml

Flow: 4.00 ml/min

Volume: 8.00 ml

Flow: 4.00 ml/min

Cut Copy Paste DeleteEdit

Volume: 0.50 ml

Flow: 4.00 ml/min

Bio-Rad

Web

QuadTec

WL1 - 280nm

Maximizer + Gradient Pump: F10 UV Conductivity

1.00ml/min

0 %B2

WL2 - 260nm

0.40 AU

0.15 AU

WL3 - 214nm

1.13 AU

438 psi 1.003 AU 1.23 mS/cm

WL4 - 405nm

0.30 AU

Econo Gradient

Pump

Flow Rate EGP %B

0 %B0.00 ml/min 0%

0.548 Volt

% Split

SIM1/pHSIM1/SIG

7.00 pH

Fig. 10. Protocol editor

b. Click on the Fraction Collector button in the Available Devices box. A dialog

box will appear asking you to choose the type of collector; i.e., a generic

collector, a Model 2110, or BioFrac. Click on BioFrac and click the OK

button. You will now see the BioFrac fraction collector in the Devices in

Setup box. The F1 Rack (12–13 mm tubes) is automatically selected.

c. If you are using a QuadTec UV/Vis detector, click on the Detectors button in

the Available Devices box. A dialog box will appear asking you to choose a

detector. Select QuadTec and check each of the four wavelengths boxes.

Enter the wavelengths: (1) 280 nm, (2) 260 nm, (3) 214 nm, and (4) 405 nm.

Press OK.

d. The Setup is now complete. To save the device setup, choose Save Setup

under the File menu and enter a name for your Setup.

e. You are now ready to program the separation steps for your method. To

program your method, press the Protocol icon on the tool bar.

31

Page 35

Program the Method Protocol

a. From the Options pull-down menu, ensure that Use Volume (ml) is selected,

so that the programming base is Volume.

b. Program the separation method listed below and in Figure 10.

• From the left side of the screen, press the fraction collection icon. In the

pop-up window that appears, choose Collect All with a fraction size of

2.00 ml and a delay of 0.0. Make sure the correct rack type is displayed.

• Program the remaining steps using the add step icons from the left side of

the screen.

Step Number Start (ml) Step

1. 0.0 Collect fractions of size 2.00 ml during entire run

2. 0.0 Isocratic flow with 25 mM Tris-HCI, pH 8.1,

0% 1.0 M NaCl, at 4.00 ml/min for 1.0 ml

3. 1.0 Zero Baseline to set UV baseline to 0.0. Select

either UV detector or QuadTec

4. 1.0 Load Inject Sample Static loop: Inject 0.5 ml

sample using 25 mM Tris, pH 8.1,

0% 1.0 M NaCl at 4.00 ml/min

5. 1.5 Isocratic flow with 25 mM Tris, pH 8.1,

0% 1.0 M NaCl at 4.00 ml/min for 0.8 ml

6. 2.3 Linear gradient with 0% to 25% 1.0 M NaCl

at 4.00 ml/min for 13.0 ml

7. 15.3 Isocratic flow at 25 mM Tris, pH 8.1 and

50% 1.0 M NaCl at 4.00 ml/min for 2.8 ml

8. 18.1 Isocratic flow with 25 mM Tris, pH 8.1,

0% 1.0 M NaCl at 4.00 ml/min for 8.0 ml

9. 26.1 End of protocol

c. When you have finished programming the method protocol, press the toolbar

button RUN. A dialog box will ask you to name the run. Accept the default

Run 1 and click the OK button. You will now see the Run screen (see Figures

11 and 12).

32

Page 36

The Run Screen

a. The toolbar buttons on the left side of the screen enable you to check that

the screen display ranges for UV, QuadTec UV/Vis, pH, and conductivity are

correctly set (see page 24) and that the workstation pump pressure limits are

appropriate (700 psi high and 20 psi low limit) for the

UNO Q1 column.

b. If you have been equilibrating the column while writing the method, you will

notice that the Status Bar is displaying the flow rate and values for UV,

QuadTec UV/Vis, and conductivity. If necessary, you may zero the UV or

QuadTec UV/Vis trace by clicking on the Zero baseline button on the

appropriate box. This button may be selected at any time.

c. To scale the on-screen chromatogram trace display axes, use the scroll bars

located on the left and right axes of the chromatogram window.

d. To enlarge the view select the Resize button to the right of the

chromatogram display.

Start the Run

a. Ensure that sufficient tubes are in the fraction collector rack (approximately

14). The drophead will automatically move to tube 1 when the Run is started.

b. Ensure that the AVR7-3 valve is in the LOAD position (position L). If it is not,

return to the Manual screen by clicking the toolbar Manual button and click

on valve position L.

c. Ensure that the 50 µl sample loop is connected to ports 3 and 6 of the inject

valve. Completely fill the loop with protein standard via port 5 and a syringe

and needle. Do not remove the syringe from the injection port after filling the

loop or the sample will siphon to waste.

d. To launch the Run, click on the green Start toolbar button. The sample will

be loaded automatically.

e. When the run is finished, the pumps automatically stop and a “Run Finished”

message appears in the bottom right of the status bar.

f. Figures 12 and 13 show typical run screens and chromatograms for this

separation using the UV detector or QuadTec UV/Vis detector.

33

Page 37

BioLogic Duo-Flow - Demo Chromatography with Buffe... - Standard UV Detector with Buffer Blending - Sample Run

File View Utilities Options

Edit

New

Method

New

Edit

Method

Run Browser Manual Setup

Report

Frac. Collector

Advance

Divert Valve

0.100

Window Help

wash

1

2

load

Notes

Run

Protocol

1324567891011121314

100.0% Buffer B

Fractions

PostRun

Log

Settings

Full View

100.0

ConductivityUV

Collect

Waste

Grad. Pump

High psi

700

Low psi

0

0.075

0.050

-50.0

75.0

50.0

Set

Chart Recorder

UV Range

1.0

0.025

25.0

Bio-Rad

Web

Event

mark

UV Detector

Zero

Baseline

-0.000

-0.0

00:00:00 00:02:00 00:04:00 00:06:00

AU

Hr:Min:Sec

Protocol: > 1 0.00 Collection Fractions of size 2.00 ml during entire run

QuadTec

Zero

Baseline

Run Time

0:00.0

Run Volume

0.0 ml

WL1 - 280nm

0.2223 AU

Step Time Left Fraction Vol. Left

Econo Gradient

Pump

Valve Info

Flow Rate EGP %B

Maximizer + Gradient Pump: F10 UV Conductivity

0.00ml/min

0 %B2

1 psi 0.2577 AU

3.63 mS/cm

Fig. 11. Run screen (UV detector and conductivity traces)

0.0

mS/cm

0 %B0.00 ml/min 0%

0.000 Volt

% Split

SIM1/pHSIM1/SIG

8.05 pH

34

Page 38

BioLogic Duo-Flow - Demo Chromatography with Buffe... - Standard UV Detector with Buffer Blending - Sample Run

File View Utilities Options

Edit

New

Method

New

Edit

Method

Run Browser Manual Setup

Report

Frac. Collector

Advance

Divert Valve

0.100

Window Help

wash

1

2

load

Notes

Run

Protocol

1324567891011121314

100.0% Buffer B

Fractions

PostRun

Log

Settings

Full View

100.0

ConductivityUV

Collect

Waste

Grad. Pump

High psi

700

Low psi

0

0.075

0.050

-50.0

75.0

50.0

Set

Chart Recorder

UV Range

1.0

0.025

25.0

Bio-Rad

Web

-0.0

Event

mark

UV Detector

Zero

Baseline

-0.000

00:00:00 00:02:00 00:04:00 00:06:00

AU

Hr:Min:Sec

Protocol: > 1 0.00 Collection Fractions of size 2.00 ml during entire run

QuadTec

Zero

Baseline

Run Time

0:00.0

QuadTec

Maximizer + Gradient Pump: F10 UV

0.00ml/min

Run Volume

0.0 ml

WL1 - 280nm

0.2219 AU

0 %B2

Step Time Left Fraction Vol. Left

WL2 - 260nm WL3 - 214nm WL4 - 405nm

0.15 AU 1.15 AU

0.30 AU

Econo Gradient

Pump

Conductivity

1 psi 0.2578 AU 3.62 mS/cm

Fig. 12. Run screen (QuadTec UV/Vis detector traces)

0.0

Valve Info

Flow Rate EGP %B

0 %B0.00 ml/min 0%

0.000 Volt

mS/cm

% Split

SIM1/pHSIM1/SIG

6.53 pH

35

Page 39

Section 5. Ordering Information

Catalog # Description

760-0135 Starter Kit

760-0047 BioLogic DuoFlow Standard System, 100/120 V, includes Dell

controller and monitor, USB Bitbus communicator, F10

workstation, MX-1 mixer, 3-tray rack, AVR7-3 sample inject valve,

fittings kit, UV detector with 5 mm flow cell and 254/280 nm filters,

conductivity monitor, BioFrac fraction collector with diverter valve

and two F1 racks, starter kit, UNO Q1 column and instructions

760-2200 BioLogic Maximizer Kit, 110/120 V, includes Maximizer base unit,

pH electrode and flow cell, Maximizer mixer, starter kit, tubing kit,

system cable 30, US power cord

760-1300 BioLogic QuadTec Detector Kit, includes QuadTec detector with

3 mm PEEK flow cell, Instrument control module (ICM, System

cable 25, 26, and 17 (QuadTec RS-232, ICM power, and bus

communication), US power cord, instructions

741-0002 BioFrac Fraction Collector, includes a 110 V power cord, rack

F1(2), Econo system cable #15, and fittings kit

Collection Tubes*

223-9500 1.5 ml Capless Micro Test Tubes, polypropylene, natural, 500/box

223-9750 13 x 100 mm Clear Polystyrene Test Tubes, 1,000/box

223-9750 13 x 100 mm Natural Polypropylene Test Tubes, 1,000/box

* Additional tubes sizes are available from Bio-Rad. Contact your

local Bio-Rad representative for a liquid handling catalog.

36

Page 40

Bio-Rad Laboratories, Inc.

2000 Alfred Nobel Dr., Hercules, CA 94547 USA

510-741-1000

1-800-424-6723

4006208 Rev. B

For technical service, call your local Bio-Rad office, or in the U.S., call

1-800-4BIORAD (1-800-424-6723)

Loading...

Loading...