Page 1

BioFrac™ Fraction Collector

User Guide

Version 2.0

Page 2

Page 3

BioFrac™ Fraction Collector

User Guide

Version 2.0

Catalog # 741-0002

Page 4

Bio-Rad Technical Support Department

The Bio-Rad Technical Support department in the U.S. is open Monday through Friday,

5:00 AM to 5:00 PM, Pacific Standard Time. Worldwide technical support is available on

the Web at www.consult.bio-rad.com.

Phone: 1-800-424-6723, option 2

Fax: 1-510-741-5802

Email: LSG.TechServ.US@Bio-Rad.com (U.S.)

LSG.TechServ.Intl@Bio-Rad.com (International)

Web: www.consult.bio-rad.com

Notice

No part of this publication may be reproduced or transmitted in any form or by any

means, electronic or mechanical, including photocopy, recording, or any information

storage or retrieval system, without permission in writing from Bio-Rad.

Bio-Rad reserves the right to modify its products and services at any time. This user guide

is subject to change without notice. Although prepared to ensure accuracy, Bio-Rad

assumes no liability for errors or omissions, or for any damage resulting from the

application or use of this information.

Combicon is a trademark of Phoenix Contact, Inc. Costar is a trademark of Corning, Inc.

Dell is a trademark of Dell Computer Corp. Eppendorf is a trademark of Eppendorf AG.

PEEK is a trademark of Victrex PLC. Scienceware is a trademark of Bel-Art Products.

Tefzel is a trademark of E.I. du Pont de Nemours & Co. Titertube is a trademark of Nortech

Laboratories Inc. Tygon is a trademark of Norton Co. Windows is a trademark of Microsoft

Corporation.

Copyright © 2001–2012 by Bio-Rad Laboratories. All rights reserved.

Page 5

Table of Contents

Chapter 1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Physical Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Chapter 2 Front and Rear Panel Controls and Connectors . . . . . . . 9

Front Panel Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Rear Panel Connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Chapter 3 System Configuration and Plumbing . . . . . . . . . . . . . . . 13

Fraction Collector Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Connecting Instruments and Devices to the BioFrac Fraction Collector . . . . . 16

Connecting to a BioLogic DuoFlow Chromatography System . . . . . . . . . . . 17

Connecting to a BioLogic LP System or to a Model EP-1 Econo Pump . . . 18

Connecting to the Econo Gradient Pump and a Chart Recorder . . . . . . . . . 20

Connecting the Model EP-1 Econo and Econo Gradient Pumps. . . . . . . . . 21

Connecting to Components Not Manufactured by Bio-Rad . . . . . . . . . . . . 21

Setting Up the Fraction Collector Racks . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Chapter 4 The User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Main Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Main Screen (Local Mode) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Main Screen (LP/Econo Mode) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Run Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

The Run Screen in Local Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

User Guide | iii

Page 6

Table of Contents

The Run Screen in LP/Econo Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Rack Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Method Library Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Calibration Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Advanced Collection Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Collection Windows Table Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Results Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Chapter 5 Stand-Alone Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Collect All . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Peak Detection by Threshold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Collect by Windows. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Collect by Windows and Threshold. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Collect Using a Delay Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Example: Collect All with Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Example: Peak Collection by Threshold and Delay. . . . . . . . . . . . . . . . . . . . 71

Example: Collection Using Time Windows and Delay. . . . . . . . . . . . . . . . . . 73

Chapter 6 LP/Econo Mode Operation. . . . . . . . . . . . . . . . . . . . . . . . 75

Chapter 7 Maintenance and Troubleshooting . . . . . . . . . . . . . . . . . 79

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Appendix A Bubble Filter Time . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Appendix B Rear Panel Connector Information. . . . . . . . . . . . . . 85

15-Pin D Connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

8-Pin Mini-DIN Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

3-Pin Combicon Connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

iv | BioFrac Fraction Collector

Page 7

Table of Contents

Appendix C Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Appendix D Warranty and Ordering Information . . . . . . . . . . . . . 93

Warranty Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

User Guide | v

Page 8

Table of Contents

vi | BioFrac Fraction Collector

Page 9

1 Introduction

Overview

The BioFrac™ fraction collector provides automated collection options for analytical

and preparative chromatography applications. It can be used as a stand-alone

collector or as a companion to any chromatography system. The BioFrac fraction

collector is capable of performing basic to complex fraction collection schemes and

can be used at flow rates up to 100 ml/min. The fraction collector accommodates

numerous rack options from microplates to bottles and carboys.

User Guide | 1

Page 10

1 | Introduction

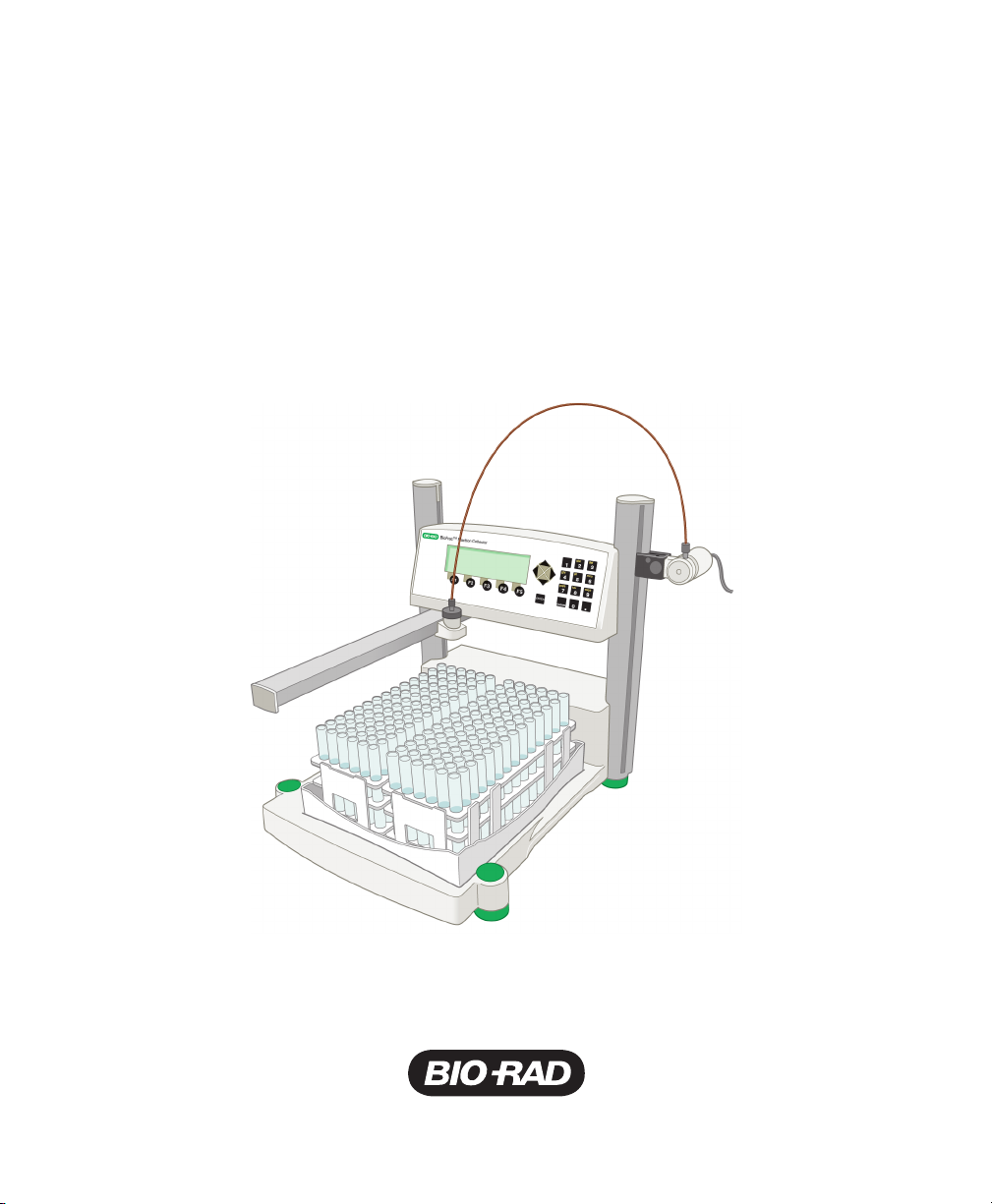

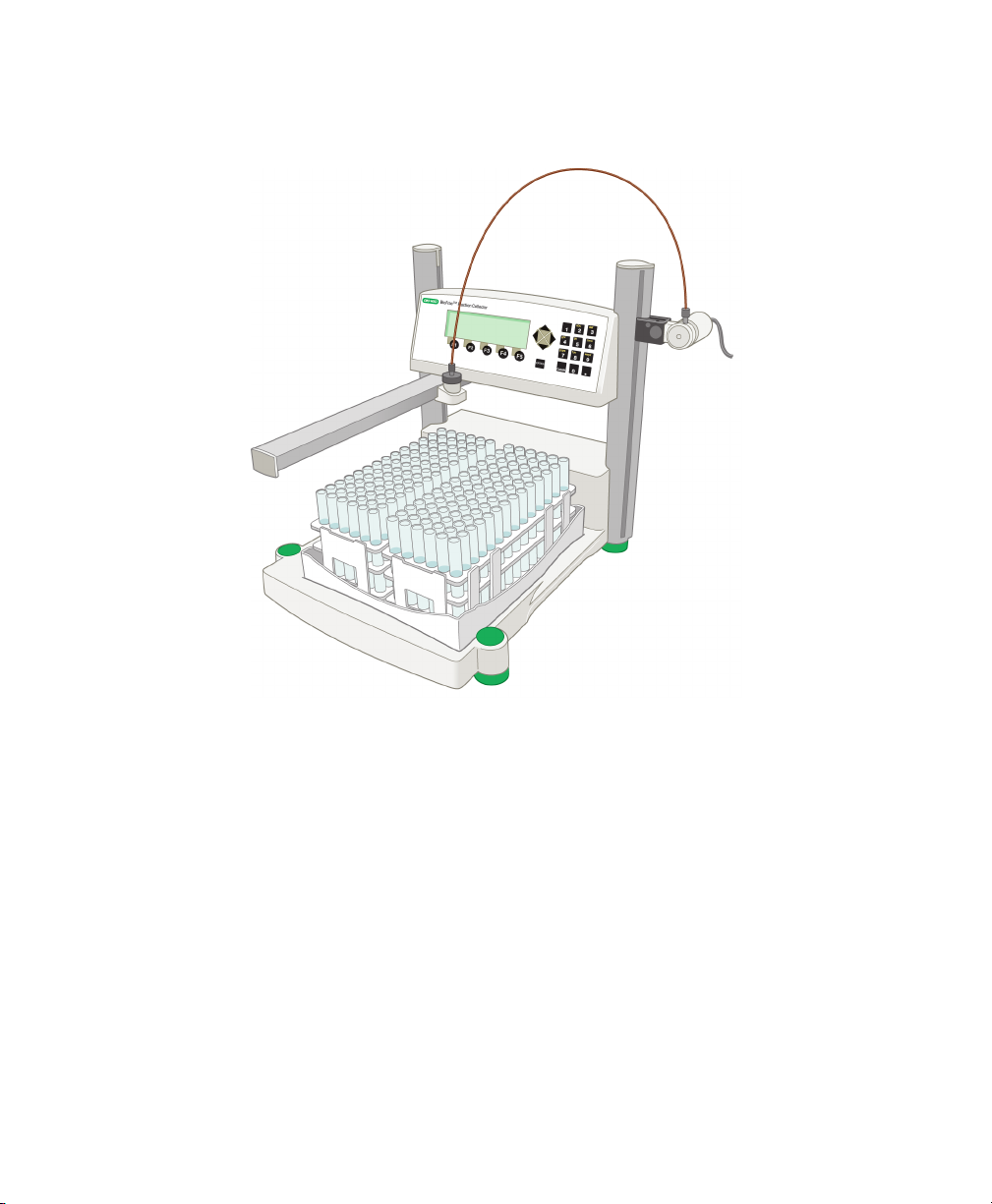

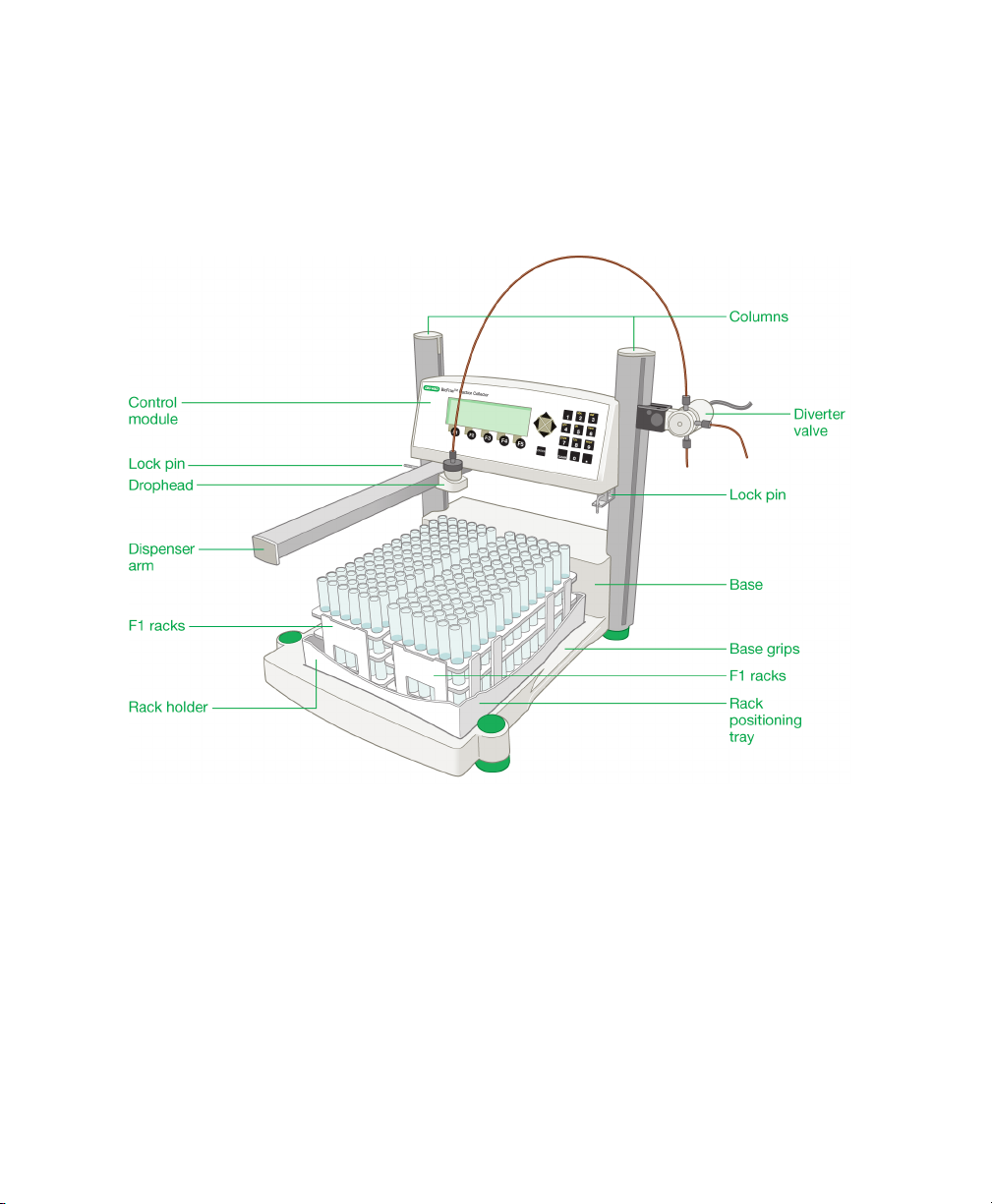

Fig. 1. BioFrac fraction collector with two F1 racks (12–13 mm tubes).

Features

The key features of the BioFrac fraction collector include the following:

Microprocessor control with easy-to-use front panel controls and a

menu-driven software interface for method setup

Method library for saving up to 20 user-defined fraction collection methods

Local and remote starting of the fraction collector

Collection by time, volume, or drops

2 | BioFrac Fraction Collector

Page 11

Overview

Advanced fraction collection functions. Peak detection, Time, or Volume

windows (up to 20) or a combination of Peak Detection with Time or

Volume windows

Manually adjustable control module that accommodates tube heights up to

150 mm

Compatibility with chromatography systems from Bio-Rad as well as other

manufacturers

Modular system that can be stacked directly on top of the NGC™,

BioLogic DuoFlow™, and BioLogic™ LP chromatography systems

Accommodates several inexpensive, off-the-shelf racks for tubes

(12–20 mm and 30 mm diameter), Eppendorf tubes or microcentrifuge

tubes (0.5 ml, 1.5 ml, and 2 ml) and scintillation vials. Racks are

autoclavable

Ability to collect up to 180 fractions in tubes or 384 fractions in 96-well

microplates

Optional Prep-20 adaptor for preparative collection in up to 20 collection

vessels of any size, from milliliter to liter collection volumes

Optional ice bath (with tube grips) that doubles as a holder for microplates.

Tube grips hold tubes firmly in any position while decanting. Rack allows

cooling of 13 mm tubes on ice. As a microplate holder it accommodates

12-, 24-, 48-, and 96-well microplates and Titertube tubes that adhere to

SBS standards for microplates

Diverter valve to divert flow and minimize spillage during tube changes.

Diverts unwanted eluent to waste and eliminates spills during fraction

advances

Multirun capability for overlaying fractions or collection of experiments

sequentially

Serpentine arm movement. Can be changed to a column or row pattern for

microplates and Titertube tubes

User Guide | 3

Page 12

1 | Introduction

Optional drop former optimized for small-volume drop dispensing

Ability to start/stop an external pump and chart recorder

Screen sleep mode for longer display life

Unpacking

When unpacking the fraction collector, carefully inspect the containers for any

damage that may have occurred in shipping. Severe damage to a container may

indicate damage to its contents. If you suspect damage to the contents may have

occurred, file a claim immediately with the carrier in accordance with their

instructions before contacting Bio-Rad Laboratories.

Caution: Do not lift the fraction collector by its dispenser arm.

Grip the base of the fraction collector and lift it slowly out of its packing. Do not lift

the unit by its dispenser arm. Remove the remaining contents from each of the

boxes and check all of the parts against the supplied packing list. The BioFrac

fraction collector is shipped with the following:

Fraction collector unit

(recommended when collecting into microplates)

AC power cord

Fittings kit (Figure 2)

Instruction guide

Tube rack #F1 (2) for 12–13 mm tubes

Diverter valve (including an hex key)

Combicon connector (included with instruction guide)

Note: If any part is missing or damaged, contact Bio-Rad Laboratories

immediately.

4 | BioFrac Fraction Collector

Page 13

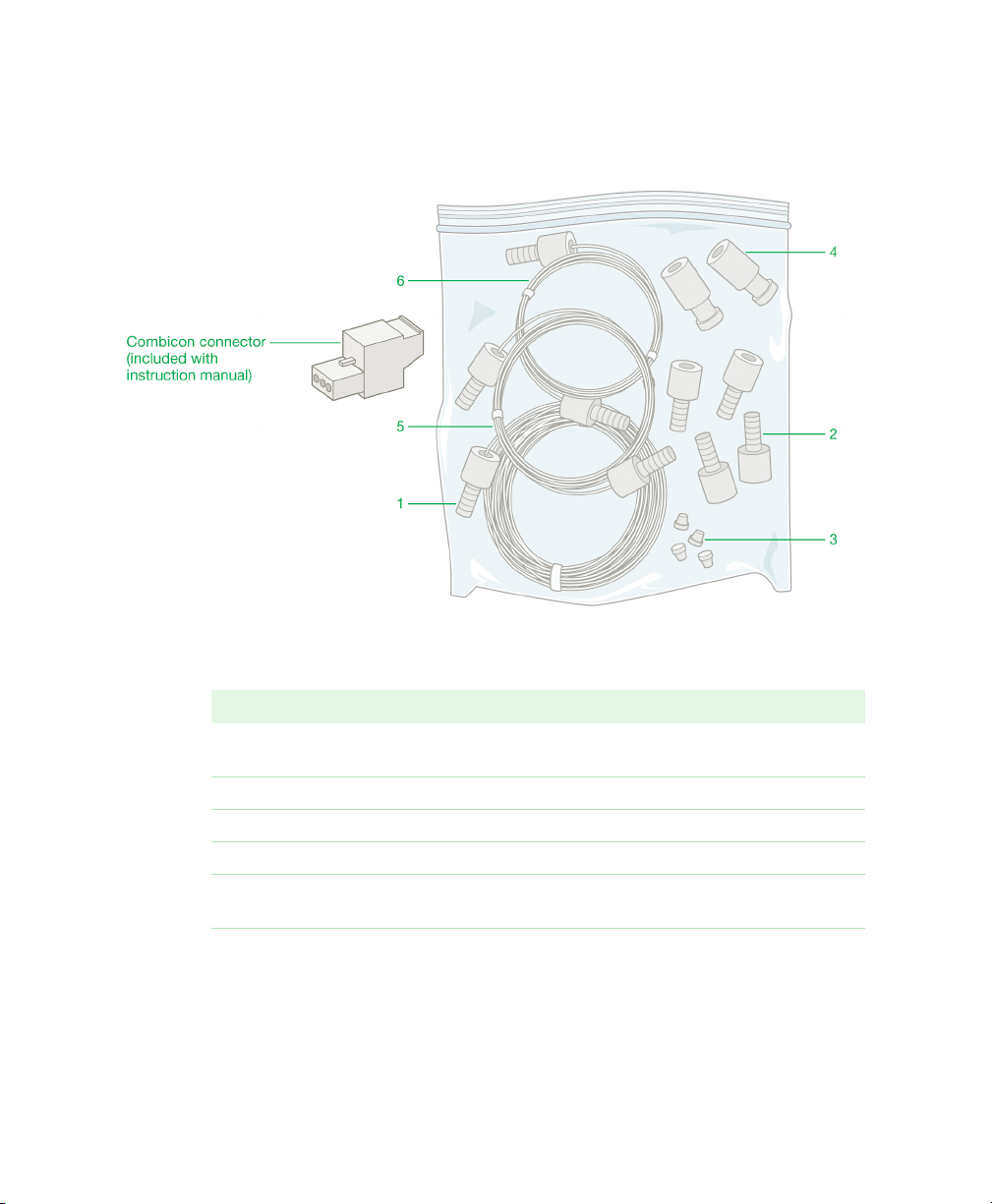

Fig. 2. Fittings kit.

Overview

LEGEND

Item Quantity Contents of Fittings Kit

1 1 1.0 m Tefzel tubing, 1/16" OD, 0.030" ID, with one 1/4-28

fitting

2 4 Fittings, 1/4-28, 1/16" OD

3 4 Ferrules, 1/16" OD

4 2 Unions, luer to 1/4-28

5 1 26” PEEK tubing, 1/16" OD, 0.030" ID, with two 1/4-28

fittings labeled collect HF

6 1 26” PEEK tubing, 1/16" OD, 0.020" ID, with two 1/4-28

fittings labeled collect

User Guide | 5

Page 14

1 | Introduction

Physical Description

Figure 3 identifies the physical features of the BioFrac fraction collector, and the

accompanying table describes the features in greater detail.

Fig. 3. Physical features of the BioFrac fraction collector.

6 | BioFrac Fraction Collector

Page 15

Overview

Feature Description

Control module The fraction collector head contains the

display, function keys, and alphanumeric

keypad (see

Controls and Connectors

height may be adjusted to accommodate tube

heights up to 150 mm.

Base The fraction collector base holds the rack

positioning tray, power switch, and I/O

connectors. It is designed so that it can be

stacked on top of the NGC, BioLogic DuoFlow,

and BioLogic LP chromatography system

workstations if benchspace is limited.

Columns The columns hold the fraction collector head

and serve as a rack for mounting the diverter

valve or other devices, such as a pH probe and

a UV monitor, using Bio-Rad bar clamps

(Cat. #750-0265).

Rack positioning tray Accurate dispensing requires that racks be

positioned using the rack-positioning tray.

Molded indents on the tray allow the rack feet

to be placed securely on the rack-positioning

tray. The tray holds two full racks (F1, F2, or F3)

on one face and can be inverted for positioning

of four half-racks (H1, H2, H3, or H4). See

Chapter 2, Front and Rear Panel

, on page 9). Its

Chapter 3, System Configuration and

Plumbing

options.

Dispenser arm The dispenser arm moves the drophead in a

serpentine motion over each of the collection

tubes. The arm movement can be changed to a

column or row pattern for microplates and

Titertube tubes.

, on page 13 for available rack

User Guide | 7

Page 16

1 | Introduction

Feature Description

Drophead Consists of the drop former, a photodiode cell

Diverter valve The diverter valve minimizes spillage during

Lock pin The height adjustment lock pins, located on

for drop counting, and a clear glass tube that

protects the photodiode cell from splashes. The

inlet tubing is connected to the drop former,

which provides uniform drop size. The drop

former accepts 1/4-28 fittings. An optional drop

former is available that has been optimized for

small-volume drop dispensing (25 µl drops).

drophead movement. The BioFrac diverter

valve is designed to have a minimal internal

volume and is 100% flushed in order to

minimize loss of chromatographic resolution.

either side of the front of the control module,

are used to secure the drophead height.

8 | BioFrac Fraction Collector

Page 17

2 Front and Rear Panel

Controls and Connectors

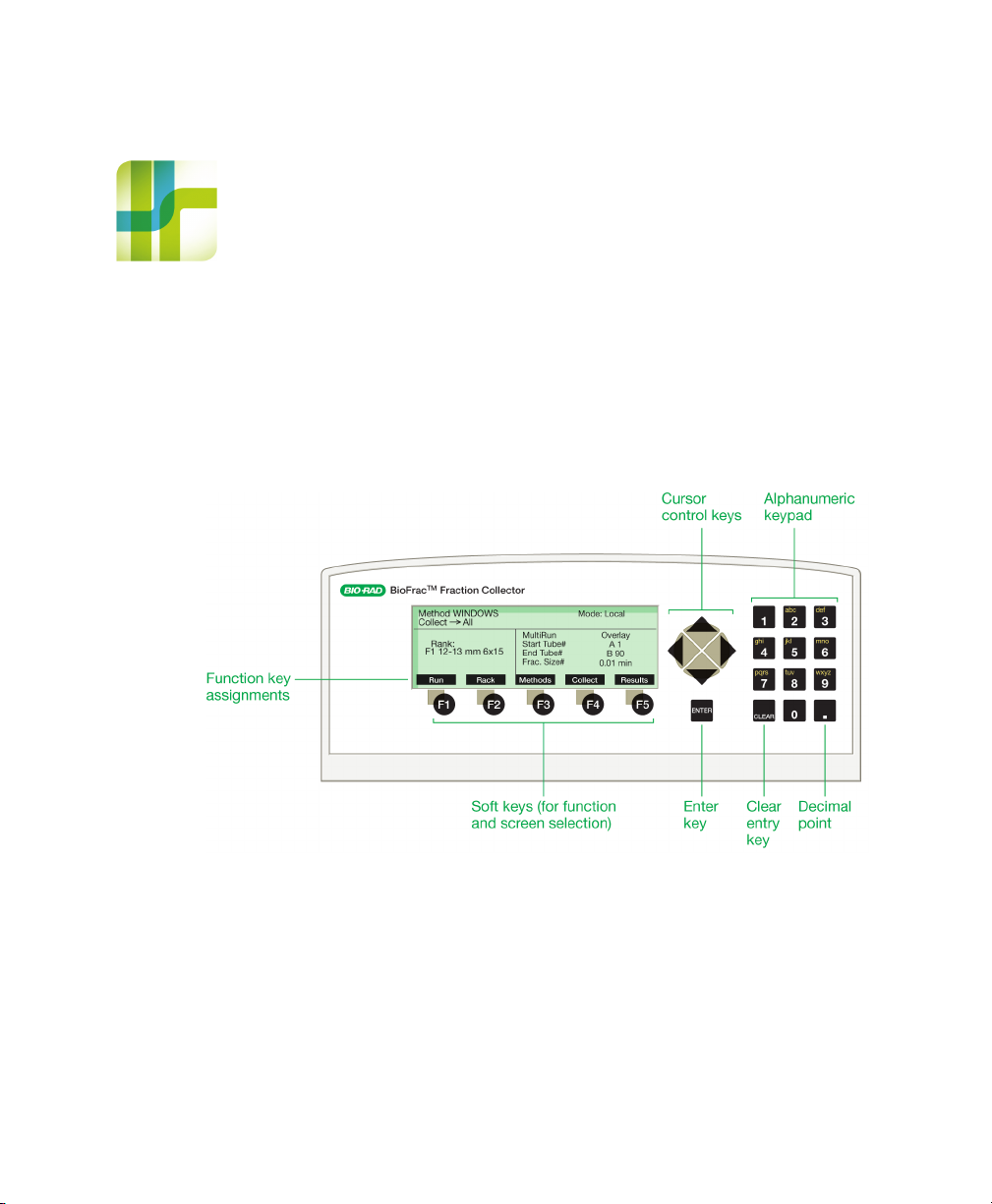

The controls and connectors on the front and rear of the panel are illustrated and

described in this chapter.

Front Panel Controls

Fig. 4. Front panel controls.

User Guide | 9

Page 18

2 | Front and Rear Panel Controls and Connectors

Table 1. Front panel controls

Feature Description

Cursor keys Used to move the cursor on the LCD display up, down,

left, or right.

Function keys These five keys are located directly below the LCD

display. The function each key executes is displayed

above it.

Clear Entry key Clears a cursor field or closes a menu option list.

Decimal point key Used to enter a decimal point.

Enter key Accepts a numeric value that has been entered.

Alphanumeric keypad Used to enter a decimal value in numeric fields and

alphanumeric characters in text fields. In a text field, the

character displayed is incremented with each press of

the keypad (for example, pressing the 2 key in turn

displays 2, A, B, C, 2, and so on.)

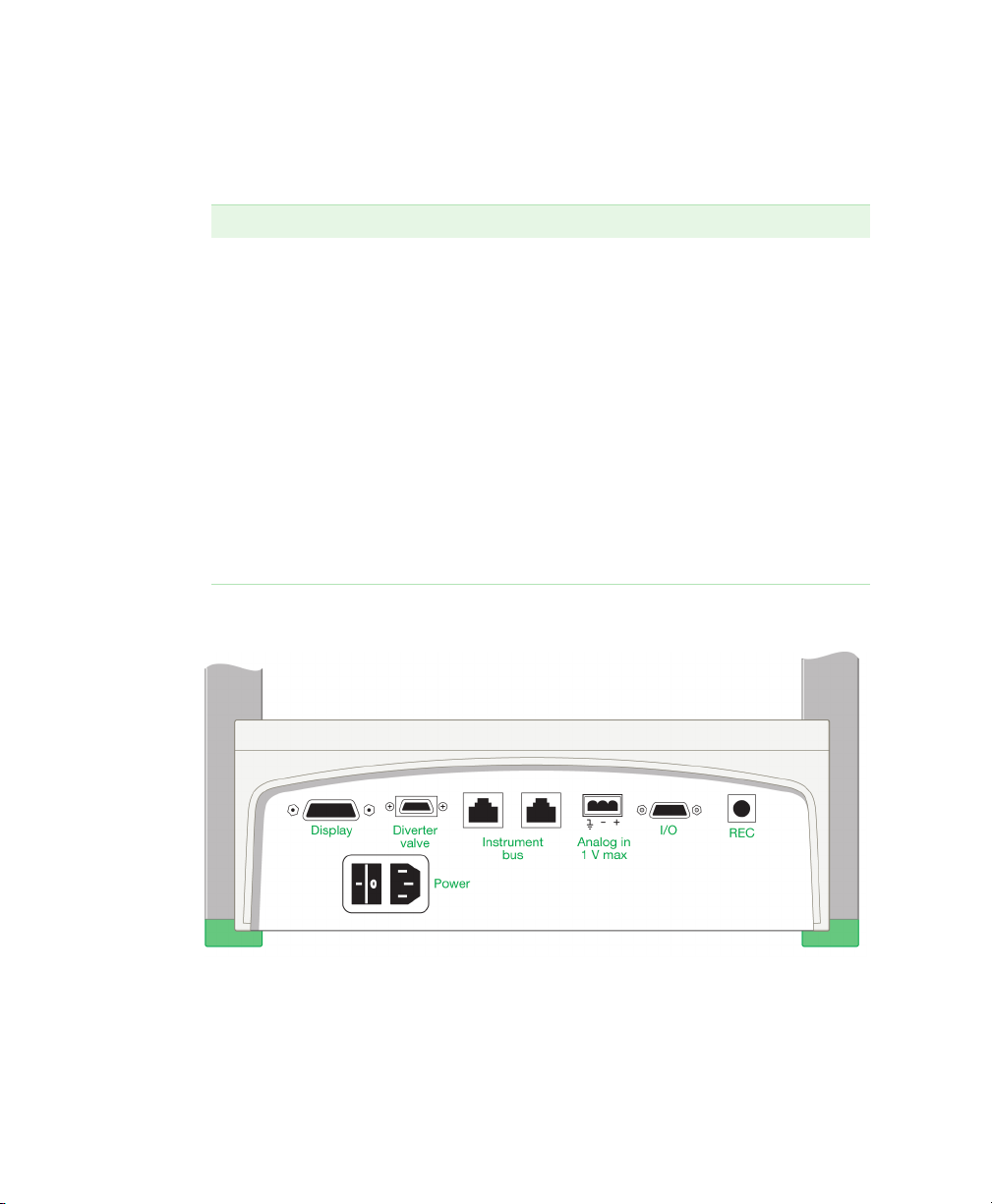

Rear Panel Connectors

Fig. 5. Rear panel connectors.

10 | BioFrac Fraction Collector

Page 19

Table 2. Rear panel connectors

Connector Description

Display cable – connects the fraction collector control

module to the power supply and other ports in the base of

the fraction collector.

Diverter valve connector – used to connect the diverter

valve to the fraction collector.

I/O connector – a 15-pin D connector used for

connecting the following instruments to the BioFrac

fraction collector:

BioLogic™ LP chromatography system,

Model EP-1 Econo

fraction advances.

Econo gradient pump. The fraction collector controls all

fraction collection parameters.

External pump. With a BioFrac accessory cable (15-pin

to bare wires) connected to the I/O port, the fraction

collector can receive start, stop, and fraction advance

signals from an external pump. (The pump must have

compatible control circuitry logic. See

Rear Panel Connector Information

Instrument Bus – for connecting the BioFrac to a

BioLogic DuoFlow™ system using system cables 17, 18,

19, or 21.

Rear Panel Connectors

™

™ pump. This system controls

Appendix B,

, on page 85.)

User Guide | 1 1

Page 20

2 | Front and Rear Panel Controls and Connectors

Table 2. Rear panel connectors, continued.

Connector Description

Rec connector – this 8-pin mini-DIN connector controls

the diverter valve or a chart recorder:

When connected to a BioLogic LP system or

Model EP-1 Econo pump, the connector receives

diverter valve control signals.

When connected to a chart recorder, the fraction

collector controls paper feed, pen up/down, and event

marks. (The chart recorder must have compatible

control circuitry logic. See

Connector Information

Combicon connector – used to connect a UV monitor or

other detector for Peak Detection by Threshold. (See

Chapter 3, System Configuration and Plumbing, on

page 13 for cable information.)

Appendix B, Rear Panel

, on page 85.)

12 | BioFrac Fraction Collector

Page 21

3 System Configuration and

Plumbing

The BioFrac™ fraction collector is shipped assembled and requires minimal

plumbing and cabling to prepare it for use. Once assembled, the BioFrac device can

be operated in the following configurations:

BioLogic DuoFlow system control

LP/Econo™ mode collection with Bio-Rad components

Stand-alone fraction collection (Local mode) with Bio-Rad components

Stand-alone fraction collection with components that are not

manufactured by Bio-Rad

The following sections of this chapter describe how to set up the BioFrac fraction

collector and how to connect instruments and devices to work with it.

User Guide | 1 3

Page 22

3 | System Configuration and Plumbing

Fraction Collector Setup

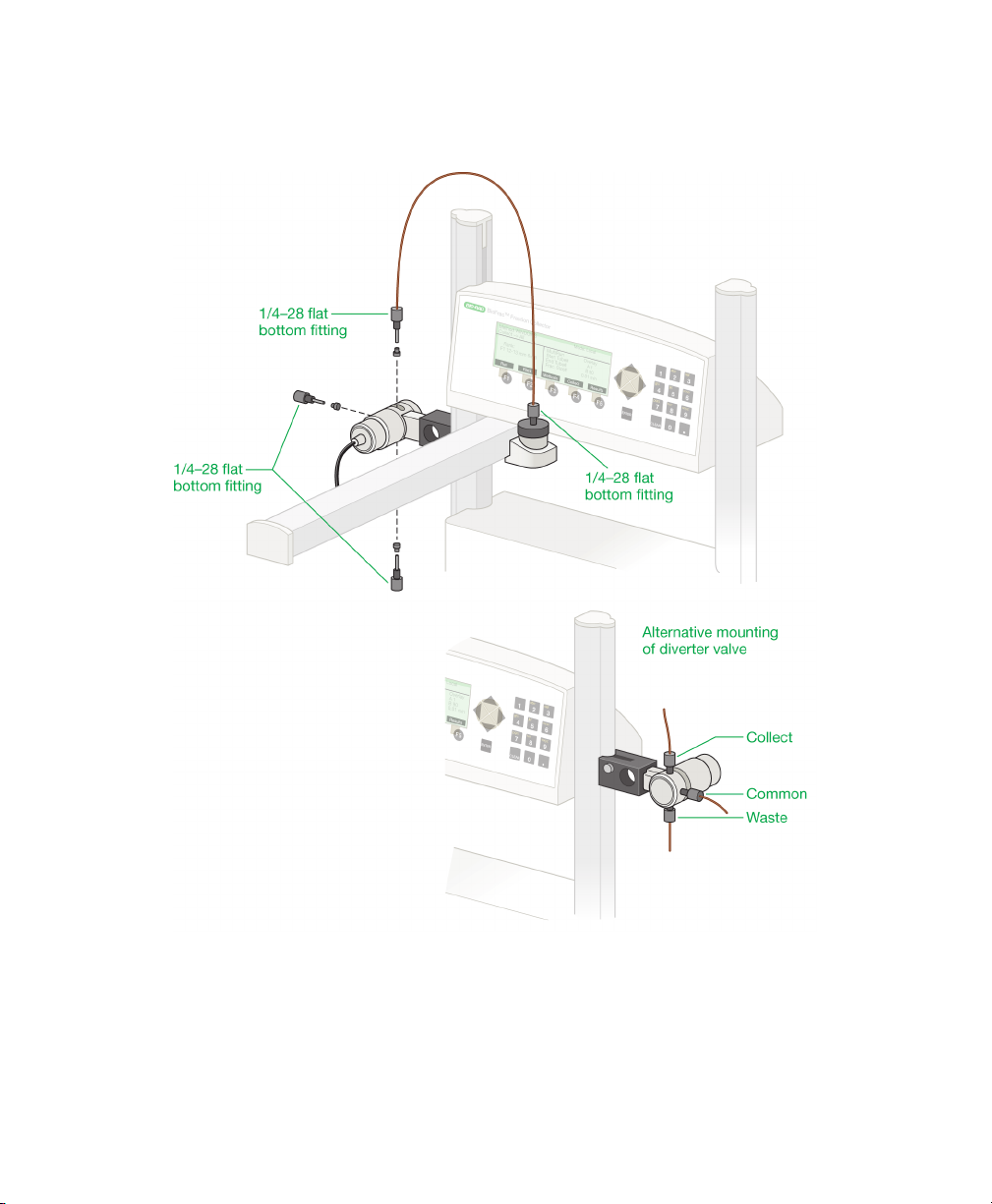

Fig. 6. Plumbing the BioFrac fraction collector.

14 | BioFrac Fraction Collector

Page 23

Fraction Collector Setup

To set up the BioFrac fraction collector

1. Place the fraction collector on a level surface on a laboratory or coldroom

bench or in a cold cabinet. Alternatively, if benchspace is limited, the modular

fraction collector can be stacked on top of the NGC, BioLogic DuoFlow™, or

BioLogic™ LP chromatography system workstations.

2. Connect the fraction collector display cable to the port labeled Display on the

back of the fraction collector. (See Figure 5 on page 10.)

3. Connect the diverter valve cable to the Diverter Valve port on the back of the

fraction collector. (See Figure 5 on page 10.)

4. Attach the diverter valve to either the right or left column. The diverter valve

should be attached so that the Collect port is pointed up and Waste port is

pointing down (see Figure 6 on page 14). Use the included hex key to secure

the diverter valve to the column.

5. Connect all power cords to available grounded, surge-protected outlets.

6. Connect the preassembled 26-inch PEEK 1/16" OD tubing, supplied in the

BioFrac fittings kit, to the Collect port of the diverter valve and to the drophead.

Use the 0.02" ID (orange) tubing for flow rates less than 20 ml/min and the 0.03"

ID (green) tubing for flow rates greater than 20 ml/min.

Note: The diverter valve is rated to a maximum pressure of 30 psi.

If tubing other than that found in the fittings kit is used to plumb the fraction

collector, make sure all tubing lengths are kept to a minimum. This reduces the

delay volume (see Collect Using a Delay Function on page 67) and

backpressure. Tubing choice is dependent on the flow rate and pressure

characteristics of the pumping system. For flow rates above 20 ml/min, use

0.03" ID or 1/8" OD, 0.062" ID tubing (available from most tubing/fitting

suppliers).

7. Attach the 0.03" ID Tefzel tubing, supplied in the fraction collector fittings kit, to

the Waste port of the diverter valve and place the other end into a waste

collection vessel.

Note: If using flow rates greater than 20 ml/min, be sure to use tubing that

has a 0.03" or larger ID.

User Guide | 1 5

Page 24

3 | System Configuration and Plumbing

8. Attach the tubing from your chromatography system to the Common port on

the diverter valve using either a 1/4-28 fitting or luer to 1/4-28 union. The

BioFrac fittings kit includes 1/4-28 fittings (for 1/16" OD tubing) and luer to

1/4-28 unions.

9. Connect the fraction collector to your chromatography system as described in

the next section, Connecting Instruments and Devices to the BioFrac Fraction

Collector.

Connecting Instruments and Devices to the BioFrac Fraction Collector

The BioFrac fraction collector can be operated in any of the following

configurations.

BioLogic DuoFlow system control. The system controls the operation of

the fraction collector through the system bus. See Connecting to a

BioLogic DuoFlow Chromatography System on page 17 for details.

LP/Econo mode collection with Bio-Rad components such as the BioLogic

LP system and Model EP-1 Econo™ Pump. The BioLogic LP system

Econo pump controls all aspects of fraction collection.

Stand-alone fraction collection (Local mode) with Bio-Rad components,

such as the Econo gradient pump, a BioLogic QuadTec™ detector, a

Model EM-1 Econo UV monitor, and/or a Model 1327 chart recorder.

Note: The fraction collector provides complete control of fraction

collection.

Stand-alone fraction collection with components that are not

manufactured by Bio-Rad, such as a pump, UV monitor, and/or chart

recorder. In Local mode, the fraction collector provides complete control of

fraction collection and can start/stop an external device such as a pump or

chart recorder. In LP/Econo mode, the controller provides complete control

16 | BioFrac Fraction Collector

Page 25

Connecting Instruments and Devices to the BioFrac Fraction Collector

of fraction collection. Devices not manufactured by Bio-Rad must be

capable of transistor to transistor logic (TTL) control.

Note: Before proceeding, make sure power to each component to be

connected is turned off. Be sure to use a grounded, surge-protected outlet

when plugging in the power cables.

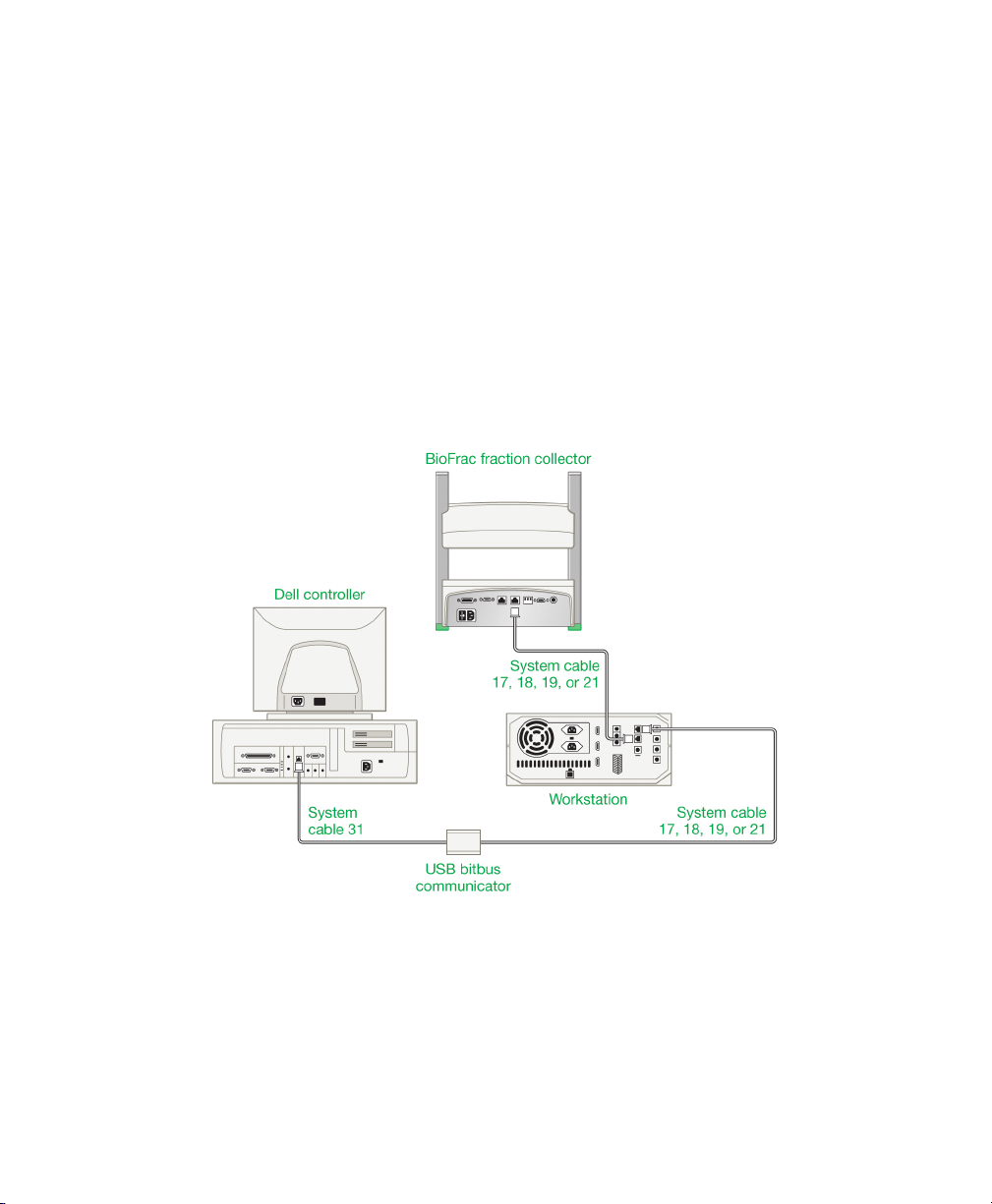

Connecting to a BioLogic DuoFlow Chromatography System

Connect the BioFrac fraction collector to the BioLogic DuoFlow system using

system cables 17, 18, 19, or 21.

Fig. 7. Connecting the fraction collector to a BioLogic DuoFlow chromatography

system.

User Guide | 1 7

Page 26

3 | System Configuration and Plumbing

To connect the fraction collector to a BioLogic DuoFlow system

1. Connect the bus cable to the connector marked INSTRUMENT BUS on the

base of the fraction collector.

2. Connect the other end of the bus cable to either the INSTRUMENT BUS

connector on the back of the BioLogic DuoFlow workstation or to other

Bio-Rad components that are daisy chained to the BioLogic DuoFlow

workstation by the instrument bus.

3. Place the BioFrac fraction collector in Local mode with the Main screen

displayed (see Main Screen on page 36). Start the BioLogic DuoFlow software

and press System in the manual screen fraction collector dialog box.

Note: The BioFrac fraction collector must be in Local mode and on the

Main screen before the BioLogic DuoFlow system can control it.

Connecting to a BioLogic LP System or to a Model EP-1 Econo Pump

To connect the fraction collector to the BioLogic LP system or Model EP-1 Econo

pump requires system cables 3 and 15. System cable 15 relays the fraction advance

signal to the BioFrac device, and system cable 3 allows the BioLogic LP system or

Model EP-1 Econo pump to control the BioFrac fraction collector’s diverter valve.

Fig. 8. Connecting the fraction collector to a BioLogic LP system and

Model EP-1 Econo pump.

18 | BioFrac Fraction Collector

Page 27

Connecting Instruments and Devices to the BioFrac Fraction Collector

To connect the fraction collector to the BioLogic LP system or

Model EP-1 Econo pump

1. Connect system cable 15:

a. Connect the cable’s 15-pin D connector to the port labeled I/O on the

fraction collector.

b. Connect the mini-DIN connector to the port labeled Fraction Collector on

the BioLogic LP system or the port labeled

pump.

2. Connect system cable 3:

a. Connect one of the cable’s mini-DIN connectors to the REC port on the

fraction collector.

b. Connect the other mini-DIN connector to the port labeled Diverter Valve on

the BioLogic LP system or the port labeled

pump.

3. If you are connected to a BioLogic LP system, press Collector on the faceplate

and then press the MODEL softkey followed by the BIOFRAC (or 2128) softkey.

4. When prompted to verify that an external valve cable is connected, enter Yes.

on the Model EP-1 Econo

on the Model EP-1 Econo

5. Follow the procedure, To run the fraction collector in LP/Econo mode on

page 75.

User Guide | 1 9

Page 28

3 | System Configuration and Plumbing

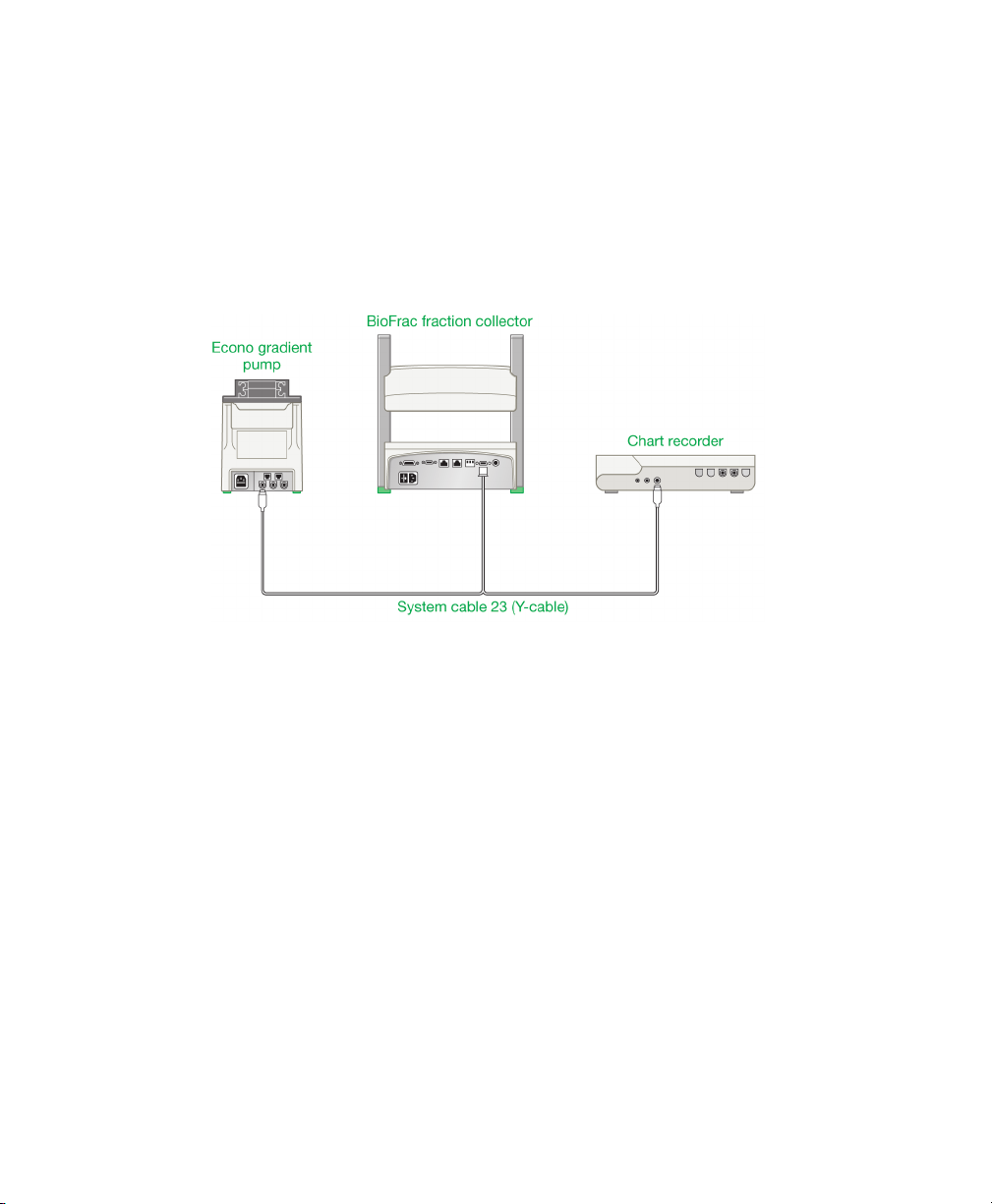

Connecting to the Econo Gradient Pump and a Chart Recorder

The following configuration shows the fraction collector set up with an Econo

gradient pump and a chart recorder. This system allows full use of the fraction

collector’s advanced programming features.

Fig. 9. Connecting the fraction collector, Econo gradient pump, and chart

recorder.

To connect the fraction collector, Econo gradient pump, and chart

recorder

1. Connect the mini-DIN connector to the I/O connector on the Econo gradient

pump.

2. Connect the 15-pin D-connector to the I/O connector on the fraction collector.

3. If a chart recorder is present, connect the cable’s remaining end to the chart

recorder DIN connector. If the chart recorder is not present, place this portion of

the cable aside.

4. If collecting fractions by threshold, connect a detector to the fraction collector

and chart recorder as described in this chapter.

5. Follow the procedures in Chapter 5, Stand-Alone Operation, on page 57.

20 | BioFrac Fraction Collector

Page 29

Connecting Instruments and Devices to the BioFrac Fraction Collector

Connecting the Model EP-1 Econo and Econo Gradient Pumps

The BioFrac fraction collector can start an Econo gradient pump or

Model EP-1 Econo pump remotely. To make the necessary connections you will

need a BioFrac accessory cable (catalog # 731-8290) and system cable 7 (catalog #

731-8267).

1. Connect the BioFrac accessory cable green/black and blue/white wires to the

system cable 7 blue wire.

2. Connect the BioFrac accessory cable’s orange/black wire to the system cable 7

yellow wire if you are connecting to an Econo gradient pump, or red wire if you

are connecting to a Model EP-1 Econo pump.

3. Trim off all unused wires.

4. Connect the end of the BioFrac accessory cable with the 15-pin D connector to

the I/O port on the BioFrac fraction collector.

5. Connect the system cable 7 mini-DIN connector to the I/O port on the Econo

gradient pump or Model EP-1 Econo pump.

6. With the fraction collector in Local mode, press Run to start the fraction

collector and pump.

7. If you are collecting by volume, be sure to enter the pump flow rate into the

BioFrac device’s flow rate entry field.

Note: Pressing Stop on the BioFrac fraction collector will not stop the Econo

gradient pump run. The EGP program must be stopped from the Econo

gradient pump faceplate.

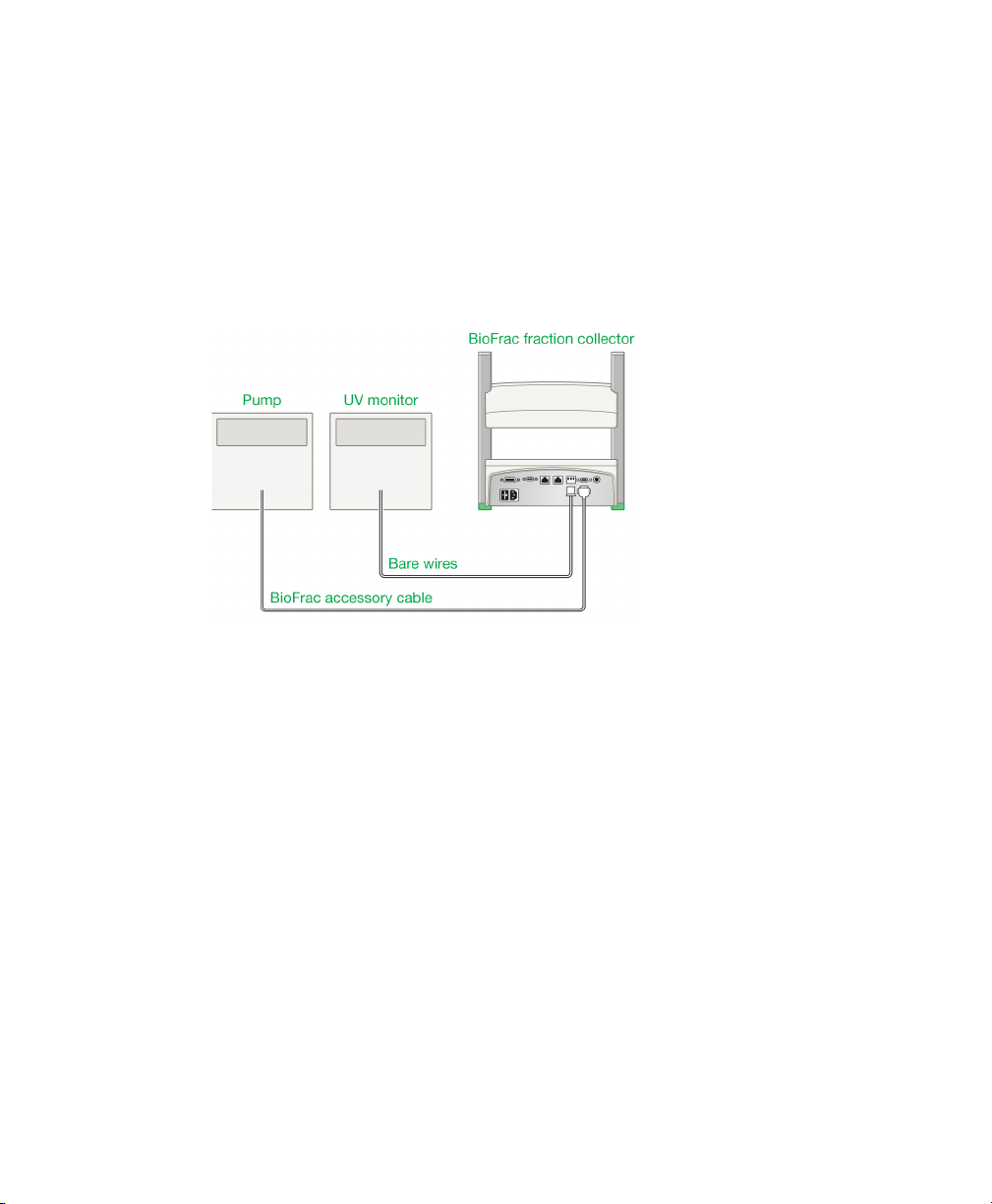

Connecting to Components Not Manufactured by Bio-Rad

The BioFrac fraction collector is designed to work with a variety of components

from other manufacturers. The BioFrac fraction collector can control remote devices

such as pumps, chart recorders, and UV detectors, and it can accept start/stop

signals from other equipment, such as pumps and UV detectors. The following is a

description of the remote fraction collection control options. To connect the fraction

User Guide | 2 1

Page 30

3 | System Configuration and Plumbing

collector to another manufacturer’s pump, UV monitor, and/or chart recorder, you

need a BioFrac accessory cable (15-pin to bare wires), system cable 7 (mini-DIN to

bare wires), and 2-wire shielded cable (26 gauge or larger, available from most

electronics or hardware stores). In addition, the pump and chart recorder circuit

logic must be Start/closed circuit = ON; Stop/open circuit = OFF. The UV monitor’s

analog output must be 100 mV or 1 V. (Refer to Appendix B, Rear Panel Connector

Information (page 85), and Appendix C, Specifications (page 91), for details.)

Fig. 10. Connecting the fraction collector to components other than Bio-Rad’s.

To remotely start or stop an external pump from the BioFrac fraction

collector

1. As described in Chapter 5, Stand-Alone Operation (page 57), set the fraction

collector to Local mode. In Local mode, all fraction collection parameters are

programmed on the BioFrac device’s front panel.

2. Connect the BioFrac accessory cable (15-pin to bare wires; see Appendix B,

Rear Panel Connector Information, on page 85) to the I/O port on the back of

the fraction collector.

22 | BioFrac Fraction Collector

Page 31

Connecting Instruments and Devices to the BioFrac Fraction Collector

3. Connect the BioFrac accessory cable green/black wire (pin #9) to the start pin

on the remote instrument. Refer to your particular pump’s documentation for

further information.

4. Connect the orange/black wire (pin #10) to the remote instrument’s signal

ground. When Run is pressed on the BioFrac instrument, the remote start relay

pins (pins #9 and #10) are connected and the start signal is relayed to the

remote device.

To remotely start or stop the fraction collector

1. Set up the fraction collection parameters as described in

Chapter 5, Stand-Alone Operation, on page 57 with the fraction collector in

Local mode. In Local mode, the fraction collector controls all aspects of fraction

collection.

2. Connect a BioFrac accessory cable (15-pin to bare wires, see Appendix B, Rear

Panel Connector Information, on page 85) to the I/O port on the back of the

fraction collector.

3. Connect pin #5 (orange wire) to the signal ground, pin #15 (blue/white wire).

Making this connection allows the BioFrac to listen for a start/stop signal.

4. Connect pin #6 (blue wire) to one terminal of the start/stop relay on the

controlling device and connect pin #15 (blue/white wire) to the other terminal of

the start/stop relay.

Refer to the documentation for your controller before completing the setup.

Pressing start on the controlling device starts the BioFrac by connecting pin #6 to

ground. Fraction collection is stopped when the last tube is reached, Stop is

pressed on the BioFrac, or the connection between pin #6 and ground is broken by

pressing Stop on the controlling device.

Note: When doing a remote start, we recommend that you test the collection

parameters by pressing Run and then Stop on the BioFrac instrument before

running an experiment. The BioFrac does a series of error checks at the start of

a run and will not start a run if it finds an error in the setup.

User Guide | 2 3

Page 32

3 | System Configuration and Plumbing

To remotely control the drophead and diverter valve

1. Set up the fraction collection parameters as described in Chapter 6, LP/Econo

Mode Operation, on page 75. In LP/Econo mode, the remote instrument

controls all aspects of fraction collection.

2. Connect a BioFrac accessory cable (15-pin to bare wires; see Appendix B, Rear

Panel Connector Information, on page 85) to the I/O port on the back of the

fraction collector.

3. Connect the I/O port pin #1 (black wire) to the pin controlling the fraction

advances on the remote instrument.

4. Connect the I/O port pin #15 (blue/white wire) to the signal ground of the

remote instrument.

5. Connect system cable 7 (mini-DIN to bare wires; see Appendix B, Rear Panel

Connector Information, on page 85), to the REC connector on the back of the

fraction collector.

a. Connect REC pin #2 (orange wire) to the diverter valve control pin on the

remote controller.

Note: If you cannot control the BioFrac diverter valve remotely,

connect REC pin #2 (orange wire) to REC pin #8 (green wire). This

causes the BioFrac diverter valve to open when Engage is pressed on

the fraction collector (see LP/Econo mode in Chapter 4, The User

Interface, on page 35). If you cannot control the BioFrac diverter valve,

you will need to supply a diverter valve with your system. The Collect

port of the second diverter valve should be plumbed to the common

port of the BioFrac diverter valve.

b. Connect REC pin #8 (green wire) to the signal ground on the remote

controller.

6. On the BioFrac LP/Econo Main screen press Engage (F1). The BioFrac will now

wait for the fraction advance and diverter valve signals.

24 | BioFrac Fraction Collector

Page 33

Connecting Instruments and Devices to the BioFrac Fraction Collector

Setting Up the Fraction Collector Racks

The BioFrac fraction collector is designed to accommodate a variety of rack

options, including both custom-molded and off-the-shelf racks. Custom racks

include the ice bath/microplate and Prep-20 racks. The top of the ice bath rack

holds microplate (12-, 24-, 48-, and 96-well) and Titertube tube racks that adhere to

Society of Biomolecular Screening (SBS) standards for microplates. Inexpensive

off-the-shelf racks, which accommodate tubes, scintillation vials, and Eppendorf

tubes, can be purchased from Bio-Rad or most scientific product vendors. The rack

options are shown in the next two figures and listed in

Table 3.

User Guide | 2 5

Page 34

3 | System Configuration and Plumbing

26 | BioFrac Fraction Collector

Page 35

Connecting Instruments and Devices to the BioFrac Fraction Collector

User Guide | 2 7

Page 36

3 | System Configuration and Plumbing

Table 3. BioFrac fraction collector racks

Format

Rack ID

F1 741-0010 Holds 12–13 mm diameter

F2 741-0011 Grip rack, holds 15–16 mm

F3 741-0012 Grip rack, holds 18–20 mm

H1 741-0013 For 1.5–2.0 ml capless

H2 741-0014 For 0.5 ml capless

H3 741-0015 For 16 mm scintillation vials 4 racks 5 x 6 30 (120)

H4 741-0016 For 50 ml conical vials 4 racks 2 x 3 6 (24)

H4-High 741-0020 For 50 ml conical vials 4 racks 2 x 3 6 (24)

Ice bath/

microplate

rack

P1 224-0096 96-well standard plate 4 plates 96-well 96 (384)

P2 48-well microplates 4 plates 48-well 48 (192)

P3 24-well microplates 4 plates 24-well 24 (96)

P4 12-well microplates 4 plates 12-well 12 (48)

TT1 4 racks 96-well 96 (384)

Bio-Rad

Catalog # Rack Description

tubes up to 100 mm in height

diameter tubes up to 150 mm

in height

diameter tubes up to 150 mm

in height

microtubes

microtubes

741-0017 Ice bath for 13 mm diameter

tubes up to 100 mm in

height. This rack also serves

as a holder for 12-, 24-, 48-,

and 96-well microplates and

microtiter tubes that adhere

to the SBS standard format

176-6023 96-deep well, 2 ml 4 plates 96-well 96 (384)

Rack

Capacity

2 racks 6 x 15 90 (180)

2 racks 5 x 12 60 (120)

2 racks 4 x 10 40 (80)

4 racks 6 x 7 42 (168)

4 racks 7 x 9 63 (252)

1 rack 10 x 12 120

Column

x Rows

Tubes

Per Rack

(Total)

28 | BioFrac Fraction Collector

Page 37

Connecting Instruments and Devices to the BioFrac Fraction Collector

Table 3. BioFrac fraction collector racks, continued.

Format

Rack ID

Prep-20 741-0018 Preparative rack 1 2 x 10 20 funnels

Bottle For 250 ml bottles 1 4 bottles

Other racks compatible with the BioFrac fraction collector are available from Scienceware

(www.belart.com). Compatible racks include the no-wire and no-wire grip full racks (248 x 105 x

64 mm and 246 x 104 x 64 mm) and half racks (128 x 105 x 43 mm and 128 x 105 x 43 mm) in

formats listed for racks F1–F3 and H1–H4.

Bio-Rad

Catalog # Rack Description

Rack

Capacity

Column

x Rows

Tubes

Per Rack

(Total)

To prepare the BioFrac fraction collector for fraction collection, set up the unit as

described in the following sections.

Racks F1, F2, and F3

Place the rack positioning tray into the base of the fraction collector, deep side

facing up. Position each rack so that its legs are in the rack guides. Adjust the

fraction collector’s control module appropriately for the height of the tubes being

used. The height adjustment lock pins (see

lock the drophead at the desired height. Tube number 1 is located in the front, left

corner of the each rack.

Figure 11 on page 32) can be used to

Racks H1, H2, H3, H4, and H4-High

Place the rack positioning tray into the base of the fraction collector, deep side

facing down. Position each rack so that its legs are in the rack guides. Adjust the

fraction collector control module head appropriately for the height of the tubes

being used. The height adjustment lock pins (see

to lock the drophead at the desired height. Tube number 1 is located in the front, left

corner of the each rack. For racks H1 and H2, use only capless microtubes.

Figure 11 on page 32) can be used

User Guide | 2 9

Page 38

3 | System Configuration and Plumbing

Ice Bath

Remove the lid of the ice bath/microplate rack and fill the tub approximately ½ full

with crushed ice, replace the lid and insert 13 x 100 mm culture tubes. Remove the

rack positioning tray from the fraction collector and replace it with the ice bath rack.

Adjust the fraction collector control module appropriately for the height of the tubes

being used. The height adjustment lock pins (see

to lock the drophead at the desired height. Tube number 1 is located in the front, left

corner of the rack.

Microplates and Titertube Tubes (Racks P1, P2, P3, P4, and TT1)

Remove the rack positioning tray from the fraction collector and replace it with the

ice bath/microplate rack. Position the ice bath/microplate rack such that rack tube

number 1 is in the left, front corner. Mount the plates on the rack using the plate

positioning tabs located on the top of the rack. Adjust the fraction collector control

module appropriately for the height of the plates being used. The height adjustment

lock pins (see

desired height. Position the plates such that tube A1 is in the left, front corner. In

order to obtain a uniform fraction size when collecting fractions smaller than 0.5 ml,

we strongly suggest that fraction size be specified in drops rather than time or

volume. Alternatively, the microplate Drop Head Kit (catalog # 741-0088) can be

used to obtain finer resolution of fraction sizes since it delivers an approximately

25 l drop.

Figure 11 on page 32) can be used to lock the drophead at the

Figure 11 on page 32) can be used

Preparative (Prep-20) Adaptor

Attach Tygon tubing to each funnel that is long enough to reach the collection

vessels (20 feet of 3/8" OD, 1/4" ID Tygon tubing is provided for this purpose.)

Ensure that no kinks constrict flow in the tubing. Gravity flow from the prep adaptor

requires that the container used for collection be mounted below the Prep-20

adaptor funnels. A drain trough is provided as added security in the event the tubing

becomes plugged or kinked, preventing sample loss. The drain trough tubing should

be inserted into a clean empty collection vessel.

30 | BioFrac Fraction Collector

Page 39

Connecting Instruments and Devices to the BioFrac Fraction Collector

To install the Prep-20 adaptor, remove the two green rubber plugs on the left, front

and right, front of the fraction collector. After attaching the Tygon tubing, insert the

Prep-20 adaptor into the preparative rack holder slots. Notice that the drain trough

slopes slightly towards the drain funnel. The collection port tubing extends down the

front of the fraction collector.

Note: The Prep-20 adaptor is rated for use with flow rates up to 100 ml/min.

(For discussion of the plumbing for high flow rates, see Chapter 3, System

Configuration and Plumbing, on page 13.)

Bottles

Place the rack positioning tray, deep side facing up, and place the bottles in the

circles labeled A, B, C, and D. Adjust the fraction collector head appropriately for the

height of the bottles being used.

Adjusting the Drophead Height

The BioFrac fraction collector accommodates collection vessel heights up to 150

mm. Detents, arranged at predefined heights, are positioned along both columns for

added security. The detent positions accommodate all standard tube and

microplate heights. Lock pins fit snugly within the detents to secure the control

module height and prevent the control module from slipping.

User Guide | 3 1

Page 40

3 | System Configuration and Plumbing

To adjust the drophead height

1. Disengage the lock by pulling both lock pins outward from the fraction collector.

The lock pins can be disabled by turning the handles sideways (Figure 11).

2. Move the control module to the desired height (Figure 12).

3. Move the control module up or down until the lock pins click into position.

Fig. 11. Lock pin adjustment.

32 | BioFrac Fraction Collector

Page 41

Connecting Instruments and Devices to the BioFrac Fraction Collector

Fig. 12. Height adjustment.

User Guide | 3 3

Page 42

3 | System Configuration and Plumbing

34 | BioFrac Fraction Collector

Page 43

4 The User Interface

Control of the fraction collector interface is through the arrow, ENTER, CLEAR, and

alphanumeric keys that are located to the right of the display or through the function

keys located below the display.

Fig. 13. BioFrac™ fraction collector user interface.

Navigation between the fields is accomplished using the arrow keys. Numbers

and/or letters are entered into the alphanumeric fields using the alphanumeric

keypad. Use ENTER to accept the changed parameter. CLEAR deletes the entered

data. The left arrow key can also be used to backspace and delete one character at

a time. Each button on the keypad shows the characters assigned to it. In numeric

fields only numbers are accessible. In text fields sequential pressing of a key toggles

through the available characters (for example pressing the 2 key in turn displays 2,

User Guide | 3 5

Page 44

4 | The User Interface

A, B, C, 2, and so on). The five function keys are used to move between different

screens or perform predefined functions. When the cursor is in a menu selection

field, pressing ENTER causes the menu to be displayed. Once a menu is displayed,

the up/down arrow keys are used to navigate through the menu items. Pressing

ENTER selects the menu item shown at the cursor position.

Main Screen

The Main screen provides information about the operation mode (Local or

LP/Econo), method name, rack, and fraction collection parameters. The parameter

fields displayed depend on whether the fraction collector is in Local mode (see

Figure 14, Table 4, and Table 5) or LP/Econo mode (see Figure 15, Table 6, and

Table 7).

Main Screen (Local Mode)

In Local mode, the Main screen is used to set the multirun mode, start and end tube

numbers, fraction size, fraction size units, and flow rate (see Figure 14, Table 4, and

Table 5). Function keys are used to start a run (see Local Mode) or switch to the

Rack, Method Library, Advanced Collection, and Results screens.

Fig. 14. Main screen (Local mode).

36 | BioFrac Fraction Collector

Page 45

Main Screen

Table 4. Main screen parameters (Local mode)

Parameter Function

Method Displays the current method name (text only).

Collect Displays the currently selected collection mode: All, Threshold,

Windows, Windows/Threshold (text only).

Rack Displays the currently selected rack (text only).

MultiRun Menu for choosing the multiple run function:

Overlay – causes collection to occur in the same tubes for each

subsequent experiment. In this mode the initial end tube should

be equal to or greater than the number of tubes required for

each experiment.

Seq. Tube+1 – increments the start and end tube numbers at

the end of each run so that one tube is skipped between runs.

In this mode the initial end tube should be set to reflect the

number of tubes required for each experiment rather than the

number of tubes in the rack. If the incremented start or end

tube number exceeds the rack’s tube capacity, a message

appears stating that there are not enough tubes for the next

run.

Seq. Rack – increments the start and end tube numbers at the

end of each run so that each run starts at a different rack. In this

mode, the initial end tube should be set to reflect the number of

tubes required for each experiment rather than the total number

of tubes available. If the incremented start or end tube number

exceeds the rack’s tube capacity, a message appears stating

that there are not enough tubes for the next run.

Start Tube #

End Tube #

Frac. Size Defines the current fraction size in time (min), volume (ml), or

Used to set the start tube and end tube. A, B, C, and D

correspond to the specific rack position and the associated

number corresponds to the tube position within each rack. Start

tube and end tube are automatically updated at the end of an

experiment if MultiRun is set to Seq. Tube+1 or Seq. Rack.

drops.

User Guide | 3 7

Page 46

4 | The User Interface

Table 4. Main screen parameters (Local mode), continued.

Parameter Function

min/ml/drop Menu for choosing the fraction size units, time (min),

Flow Rate Used to define the flow rate. Must be set if collecting by

Table 5. Main screen function keys (Local mode)

Function Key Function

Run Starts an experiment and displays the Run screen (see Run

Rack Displays the Rack screen (see

Methods Displays the Method Library screen (see

Collect Displays the Advanced Collection parameter screen (see

Results Displays the Results screen. This screen displays the run

volume (ml), drops.

Note: If collecting by volume, the flow rate must be

entered in the flow rate field.

volume. This field is not displayed if collecting in time or drop

mode.

Screen on page 42

).

Rack Screen on page 46).

Method Library

Screen on page 48

).

Advanced Collection Screen on page 51).

results of the last completed experiment (see

on page 56

).

Results Screen

38 | BioFrac Fraction Collector

Note: The contents of this screen are lost when Run is

pressed or the fraction collector is turned off.

Page 47

Main Screen

Main Screen (LP/Econo Mode)

In LP/Econo mode, the Main screen is used to set the multirun mode and start and

end tube numbers (see Figure 15, Table 6, and Table 7). All other fraction collection

parameters are controlled remotely. Function keys are used to engage the fraction

collector so that it will accept remote divert and fraction advance signals (see

LP/Econo Mode) or to select a rack from the rack screen.

Fig. 15. Main screen (LP/Econo mode).

Table 6. Main screen parameters (LP/Econo mode)

Parameter Function

Method LP/Econo (text only).

Collect LP/Econo (text only).

Rack Displays the currently selected rack (text only).

User Guide | 3 9

Page 48

4 | The User Interface

Table 6. Main screen parameters (LP/Econo mode), continued.

Parameter Function

MultiRun Menu for choosing the multiple run function:

Start Tube #

End Tube #

Overlay – causes collection to occur in the same tubes for

each subsequent experiment. In this mode, the fraction

collector moves back to the start tube when the end tube is

filled. Stop is used to disengage the experiment.

Seq. Tube+1 – increments the start and end tube numbers at

the end of each run so that one tube is skipped between runs.

In this mode, the initial end tube should be set to reflect the

number of tubes required for each experiment rather than the

number of tubes in the rack. If the incremented start or end

tube number exceeds the rack’s tube capacity, a message

appears stating that there are not enough tubes for the next

run. The start tube and end tube are incremented each time

the fraction collector is disengaged by pressing stop or by

filling the end tube.

Seq. Rack – increments the start and end tube numbers at the

end of each run so that each run starts on a different rack. In

this mode, the initial end tube should be set to reflect the

number of tubes required for each experiment rather than the

total number of tubes available. If the incremented start or end

tube number exceeds the rack’s tube capacity, a message

appears stating that there are not enough tubes for the next

run. The start tube and end tube are incremented each time

the fraction collector is disengaged by pressing stop or by

filling the end tube.

Used to set the start and end tube. A, B, C, and D correspond

to the rack position. The associated number corresponds to

the tube position within each rack. Start tube and end tube are

automatically updated at the end of an experiment if MultiRun

is Seq. Tube+1 or Seq. Rack.

40 | BioFrac Fraction Collector

Page 49

Main Screen

Table 7. Main screen function keys (LP/Econo mode)

Function Key Function

Engage Moves the drophead to the start tube and causes the fraction

collector to listen for fraction advance and diverter valve

signals.

Rack Displays the Rack Selection screen.

User Guide | 4 1

Page 50

4 | The User Interface

Run Screen

The Run screen provides information about the progress of the current run. The

information displayed on the screen depends on the type of method being used and

whether the fraction collector is in Local or LP/Econo mode.

The Run Screen in Local Mode

In Local mode, the information displayed includes run status, run time, fraction

filled, fraction size, and drophead position. In addition, UV (%AUFS, that is,

absorbance units full scale) and threshold values are displayed during threshold

collection (see Figure 16, Table 8, and Table 9). Run volume is displayed when

collecting by volume. Four function keys are available during a run to stop or pause

an experiment, do tube advances, and control the diverter valve.

Fig. 16. Run screen (Local mode).

42 | BioFrac Fraction Collector

Page 51

Run Screen

Table 8. Run screen parameters (Local mode)

Parameter Function

Status Displays the current fraction collection status:

Collecting – the diverter valve is in the collect

position and fractions of a user-specified size

are being collected.

Diverting – the diverter valve is in the Waste

position. Run Paused!: The run is currently

paused and the diverter valve is at Waste. A

warning is displayed that the diverter valve is

diverting to Waste.

Collecting Non-Peak – the diverter valve is in

the collect position but is collecting fractions

of non-peak size.

Will Collect at End of Delay – the fraction

collector is waiting for the delay time before

it switches the diverter valve to Collect.

Will Divert at End of Delay – the fraction

collector is waiting for the delay time before

it switches the diverter valve to Waste.

Run Time Displays the current run time (in hours and

minutes). Stops incrementing during a pause. If

collecting by volume, the run volume is also

displayed.

Cur. Rack # Tube # Displays the current rack position and tube

number.

Threshold Displays the current threshold setting as a

percentage of full scale (%AUFS). (Displayed

only if collecting by threshold).

Current UV Displays the current UV signal value as a

percentage of full scale (%AUFS). (Displayed

only if collecting by threshold).

User Guide | 4 3

Page 52

4 | The User Interface

Table 9. Run screen function keys (Local mode)

Function Key Function

Stop Stops the current experiment and displays the

Advance Advances the drophead by one tube.

Divert/Collect Toggles the diverter valve between Collect and

Pause Pauses fraction collection and switches the

Resume Resumes fraction collection after a pause.

Results screen.

Waste.

diverter valve to Waste during the pause.

44 | BioFrac Fraction Collector

Page 53

Run Screen

The Run Screen in LP/Econo Mode

In LP/Econo mode the Run screen shows the current diverter valve status and

drophead position (see Figure 17 and Table 10). This screen has a Stop function key

that causes the fraction collector to stop listening for fraction advance and diverter

valve signals and returns the drophead to the home position.

Fig. 17. Run screen (LP/Econo mode).

Table 10. Run screen parameters (LP/Econo mode)

Parameter Function

Status Displays the current fraction collection status.

Collecting – the diverter valve is in the Collect

position.

Diverting – the diverter valve is in the Divert to

Waste position.

Cur. Rack # Tube # Displays the current rack position and tube

number.

Overlay Cycle The number of times that the fraction collector

has overlaid fractions in the current set of runs.

(Displayed only in Overlay mode).

User Guide | 4 5

Page 54

4 | The User Interface

Rack Screen

The Rack screen is used to select the rack type and collection pattern to be used in

a method (see Figure 18, Table 11, and Table 12). The default collection pattern is

serpentine; however, it may be changed to collection by row or by column when

collecting in microplates or Titertube tubes. The Divert Between Tubes feature can

be used to reduce the amount of liquid spilled during tube advances. When this

option is turned on (default), the diverter valve switches to waste during tube

advances. However, if this option is turned off (recommended when collecting in

drop mode at low flow rates), the diverter valve switches to Waste only when the

drophead is moving between nonadjacent tubes.

Fig. 18. Rack screen.

Table 11. Rack screen parameters

Parameter Function

Current Rack Menu used for rack selection.

Divert Between Tubes Allows the user to turn off the Divert Between

Collection Pattern Displays the current fraction collection pattern.

46 | BioFrac Fraction Collector

Tubes function. The fraction collector still

diverts when the drophead is moving between

nonadjacent tubes.

This pattern can be changed to row or column

for microplates and Titertube tubes.

Page 55

Rack Screen

Table 12. Rack screen function keys

Function Key Function

Done Accepts all changes and returns to the Main

screen.

Cancel Aborts all changes and returns to the Main

screen.

User Guide | 4 7

Page 56

4 | The User Interface

Method Library Screen

The Method Library screen is used to retrieve, save, or delete user-defined

collection methods (see Figure 19 and Table 13). Up to 20 methods may be stored.

Function keys are used to load, save, and delete methods or to get to the

Calibration screen (see Calibration Screen on page 49).

Fig. 19. Method Library screen.

The Method Library displays the Default and user-defined methods.

Table 13. Method Library screen function keys

Function Key Function

Done Returns the display to the Main screen.

Calib Displays the Calibration screen (see

Load Loads the method pointed to by the cursor.

Save Allows the current fraction collection

Delete Deletes the method pointed to by the cursor.

48 | BioFrac Fraction Collector

Calibration Screen on page 49).

parameters to be saved as a method. A method

name can be up to 16 characters long.

Page 57

Calibration Screen

Use the Calibration screen to adjust the drophead calibration, screen contrast, sleep

mode, and to zero the analog-to-digital converter (AtoD). Refer to

information about the use of each function key.

Table 14. Calibration screen function keys

Function Key Function

Done Returns the display to the Method Library

Contrst Allows the user to set the display contrast. The

X–Y axis Places the fraction collector in rack calibration

Calibration Screen

Table 14 for more

screen.

up and down arrow keys are used to increase

and decrease the screen brightness,

respectively.

mode. Allows the user to calibrate the fraction

collector X–Y arm. Calibration should rarely be

required. Calibration is done on an F1 rack that

has 13 x 100 mm glass tubes in positions A1,

A15, and B90 (plastic tubes should not be

used). See

X–Y Arm on page 50

Calibrating the Fraction Collector

.

Caution: Using this function overwrites

the previous calibration.

Zero AD Allows the user to zero any voltage offset in the

analog-to-digital (AtoD) converter. The AtoD is

used to convert the analog UV signal used for

threshold collection to a digital signal. In the

event of an offset in the AtoD voltage, the

Current UV signal (see

the run screen may be in error. This calibration

should rarely be required.

To zero the AtoD, press Zero AD, connect a

shorting plug (Combicon connector with the

analog IN(+) and IN(–) pins connected to the

analog IN (ground)), then press Next.

Figure 16) displayed on

User Guide | 4 9

Page 58

4 | The User Interface

Table 14. Calibration screen function keys, continued.

Function Key Function

Sleep Allows the user to select how many minutes the

Calibrating the Fraction Collector X–Y Arm

To calibrate the Fraction Collector X–Y arm

Caution: Using this function overwrites the previous calibration.

1. Remove the drop former top by twisting it counterclockwise and gently lifting it

out.

2. Press X–Y Axis and then Next.

3. While looking through the drophead, center it over tube A15 using the arrow

keys, and press Next.

4. Center the drophead over tube A1 using the arrow keys, press Next.

5. Center the drophead over tube B90 using the arrow keys, press Save.

display should wait before going into sleep

mode. Pressing any button will wake up the

display.

6. Replace the top of the drop former by inserting it into the drophead and twisting

it clockwise.

50 | BioFrac Fraction Collector

Page 59

Advanced Collection Screen

The Advanced Collection screen is used to turn threshold and windows collection

on or off and to set threshold and delay parameters (see Figure 20, Table 15, and

Table 16). Threshold parameters are displayed only when threshold is turned on.

From this screen, the threshold level and UV detector input voltage (100 mV or 1 V)

can be entered and the user can specify whether non-peak fractions are to be

collected or not. A bubble filter time constant can also be entered. During threshold

collection the bubble filter function suppresses unwanted fraction advances due to

air bubbles passing through the UV detector. See Appendix A, Bubble Filter Time,

on page 83, for more information about the bubble filter function.

When windows collection is turned on, the Table function key, F3, is used to display

the Collection Windows Table screen (see Collection Windows Table Screen on

page 54). The Collection Windows Table screen is used to enter all collection

windows parameters. If you are collecting by threshold and windows, turn on

threshold before entering the Collection Windows Table screen.

Advanced Collection Screen

Fig. 20. Advanced Collection screen.

Table 15. Advanced Collection screen parameters

Parameter Function

Windows Menu for turning Collection by Windows on or off.

Threshold Menu for turning Collection by Threshold on or off.

User Guide | 5 1

Page 60

4 | The User Interface

Table 15. Advanced Collection screen parameters, continued.

Parameter Function

%AUFS Current threshold setting. (Displayed only when Threshold is

Full Scale Menu for defining the UV detector’s output voltage.

NonPeak Frac. Turns collection of non-peak fractions on or off. (Displayed

Size The non-peak fraction size. The non-peak fraction size has

Bubble Filter Time constant entered in seconds, used to filter false peaks

Delay A delay time used to precisely synchronize the UV signal

on).

(Displayed only if Threshold is on.) The detector input

voltage can be set to either 100 mV or 1 V.

only if Threshold is on).

the same units as the fraction size and delay parameters.

(Displayed only when Threshold is on).

above a threshold due to electrical noise or air bubbles.

Typically a bubble filter time of 0 or 1 sec will suffice. For a

discussion of bubble filter time, refer to

Bubble Filter Time

Threshold is on).

with event marks on the chart recorder and tube advances.

Delay must be less than or equal to the fraction size.

Note: Using delay will result in a timing offset between tube

advances and the displayed fraction fill volume shown on

the Run screen. Delay has the same units as the fraction

size parameter. For a discussion of the delay function, see

, on page 83. (Displayed only when

Appendix A,

Collect Using a Delay Function on page 67.

52 | BioFrac Fraction Collector

Page 61

Advanced Collection Screen

Table 16. Advanced Collection screen function keys

Function Key Function

Done Accepts all changes and returns to the Main screen.

Cancel Aborts all changes, including changes made in the

Collection Windows Table screen (see the Table function

key).

Table Changes the screen to the Collection Windows Table screen

(see

Collection Windows Table Screen on page 54).

(Visible only when Windows is on).

User Guide | 5 3

Page 62

4 | The User Interface

Collection Windows Table Screen

The Collection Windows Table screen is used to enter the collection windows

parameters (see Figure 21, Table 17, and Table 18). Up to 20 different collection

windows can be defined, each with a different fraction size and threshold. The

threshold parameter column (Thold) shown in Figure 21 is displayed only when

threshold collection has been turned on in the Advanced Collection screen (see

Advanced Collection Screen on page 51). Windows start and end parameters are

entered in minutes (when collecting by time or drops) or in milliliters (when collecting

by volume). The menu at the top of the fraction size column can be used to change

the fraction size units. The global fraction size and threshold entered on the Main

screen (see Main Screen on page 36) and Advanced Collection screen, respectively,

are the default fraction size and threshold for the first window.

Fig. 21. Collection Windows Table screen.

Table 17. Collection Windows Table screen parameters

Parameter Function

Start

End

54 | BioFrac Fraction Collector

The Collection Windows Table start and end

times are in units of time (min) or volume (ml).

The Collection Windows Table start and end

times are in units of time if collecting fractions

by drop.

Page 63

Collection Windows Table Screen

Table 17. Collection Windows Table screen parameters, continued.

Parameter Function

FrcSz The fraction size for the current window (min,

ml, drops). The header for this column is also a

menu that can be used to change the fraction

size units to min, ml, or drops.

Thold The threshold value for each collection window.

Table 18. Collection Windows Table Screen function keys

Function Key Function

Done Saves any changes, contingent upon pressing

Done on the Advanced Collection screen, and

exits the Collection Windows Table screen.

Cancel Aborts all changes and returns to the Advanced

Collection screen.

Insert Inserts a new window at the position pointed to

by the cursor.

Caution: If 20 windows are defined, pressing

Insert causes window #20 to be deleted.

Delete Deletes a window at the position pointed to by

the cursor.

New Deletes all windows.

User Guide | 5 5

Page 64

4 | The User Interface

Results Screen

The Results screen provides a list of the tubes associated with each peak or

window. When collecting by threshold, a peak is defined as the tubes collected

while the UV signal was above threshold. The Results screen is displayed at the end

of each run, if the run was not started remotely, or can be viewed by pressing F5 on

the Main screen (see Main Screen on page 36). The information on this screen is lost

when a new run is started or the fraction collector is turned off.

Fig. 22. Results screen.

Table 19. Results screen parameters

Parameter Function

Window/Peak If collecting by Windows, the window number is displayed.

Tubes List of the tubes associated with each window or peak.

The Done key returns you to the Main screen.

56 | BioFrac Fraction Collector

If collecting by Threshold or by Windows and Threshold,

the peak number is displayed.

Page 65

5 Stand-Alone Operation

Normal operation of the BioFrac™ fraction collector is in Local mode (stand-alone

mode). As a stand-alone fraction collector, the BioFrac device may be used to

collect fractions based on time (minutes), volume (milliliters), or drops (up to a flow

rate of 5.0 ml/min). In Local mode, the fraction collector controls all aspects of

fraction collection and is not in communication with Bio-Rad’s BioLogic DuoFlow™

chromatography system, BioLogic™ LP system, or Model EP-1 Econo™ pump.

However, it may be connected to separate components, such as a UV monitor, a

chart recorder, and a pump, as described in

the BioFrac Fraction Collector on page 16.

There are four modes of collection, each of which can include a delay function:

Collect All — enables you to collect an entire run without diverting any

fluid to waste.

Peak Detection by Threshold — enables you to collect peaks by defining

a threshold value (percent of full scale) above which fractions will be

collected. This method can be used only when the fraction collector is

connected to a UV monitor. When the UV signal is less than the threshold,

fluid is diverted to waste. Alternatively, it may be collected in tubes with a

non-peak fraction size. A slope function is built into the threshold function

so that double peaks above the set threshold level are detected and

collected separately.

Connecting Instruments and Devices to

Note: False peaks above a threshold (such as electrical noise or air

bubbles) may be filtered using the bubble filter time function. See Appendix

A, Bubble Filter Time, on page 83.

User Guide | 5 7

Page 66

5 | Stand-Alone Operation

Windows Collection — enables you to specify periods of time or volumes

(windows) during which fractions are to be collected. For example, a

window can be defined to start after an initial void volume. The BioFrac

fraction collector lets you define up to 20 different time or volume windows.

The liquid delivered during a collection window is collected into tubes,

whereas the liquid delivered outside of a collection window is diverted to

waste.

Peak Detection by Threshold with Time or Volume Windows — enables

you to combine the Peak Detection by Threshold and the Time or Volume

Windows methods discussed above. This method can be used only when

the fraction collector is connected to a UV monitor. You can program up to

20 different time or volume windows, each with its own threshold level.

This is a useful feature to compensate for baseline drift.

Note: False peaks above a threshold (such as electrical noise or air

bubbles) may be filtered using the bubble filter time function. See Appendix

A, Bubble Filter Time, on page 83.

Delay Function — the purpose of the delay function is to synchronize the

fraction collection event marks and the signal from the UV monitor (output

on a chart recorder) with the actual delivery of liquid into collection tubes.

This features allows easy post-run analysis of a chromatogram. The delay

function is slightly different for each of the collection modes: All, Threshold,

Windows, and Threshold with Windows. As a consequence, the event

marks on the chart recorder will vary depending on the individual

application.

Regardless of the type of collection method programmed, the method will end once

the end tube number is reached. Always ensure that the start and end tube numbers

are set to allow completion of your collection method.

58 | BioFrac Fraction Collector

Page 67

Collect All

Fig. 23. Running a Collect All method.

Collect All

To run a Collect All method

1. On the Main screen, ensure that Collect is set to Collect –> All. If the screen is

not set to Collect –> All, press Collect (F4) and turn Windows and Threshold off.

Alternatively, press Method (F3) and load the method Default.

2. To select a rack, press Rack (F2) and choose a rack from the Rack menu.

Choose whether you want the diverter valve to divert to waste during fraction

advances. If you are collecting in microplates or Titertube tubes, choose a

collection pattern: Serpentine, Row, or Column.

Note: Whenever a new rack is selected, the start tube and end tube

values are updated to reflect the maximum number of tubes available for

the selected rack.

3. Choose the appropriate MultiRun mode for your experiment (see Table 4 on

page 37 for a description of the MultiRun function).

4. Set the start tube and end tube rack position and tube number.

User Guide | 5 9

Page 68

5 | Stand-Alone Operation

The fraction collector stops when the last tube is reached unless a stop

command is received before it reaches the last tube. At the end of a run, the

start tube number and end tube number will be automatically updated

according to the MultiRun mode selected.

5. Set the fraction size units (min, ml, or drops) and enter the fraction size. If

collecting by volume, you must enter a flow rate.

6. (Optional) Press Collect (F4) and set the delay time (see Collect Using a Delay

Function on page 67).

7. (Optional) Press Methods (F3) and save your method.

8. Press Run (F1) to start the experiment.

At any point during the run you can use the Run screen function keys (see

Table 8 on page 43).

60 | BioFrac Fraction Collector

Page 69

Peak Detection by Threshold

Fig. 24. Running a Collect by Threshold method.

Peak Detection by Threshold

To run a Collect by Threshold method

1. To select a rack, press Rack (F2) and then choose a rack from the Rack menu.

Choose whether or not you want the diverter valve to divert to waste during

fraction advances. If you are collecting in microplates or Titertube tubes,

choose a collection pattern: Serpentine, Row, or Column.

Note: Whenever a new rack is selected, the start tube and end tube values

are updated to reflect the maximum number of tubes available for the

selected rack.

2. Choose the appropriate MultiRun mode for your experiment (see Table 4 on

page 37 for a description of the MultiRun function).

3. Set the start tube and end tube rack position and tube number.

User Guide | 6 1

Page 70

5 | Stand-Alone Operation

The fraction collector stops when the last tube is reached unless a stop

command is received before it reaches the last tube. At the end of a run, the

start tube number and end tube number are automatically updated according

to the MultiRun mode selected.

4. Set the fraction size units (min, ml, drops) and set the fraction size. If collecting

by volume, you must enter a flow rate.

5. Press Collect (F4) and turn Threshold on. Set the global %AUFS and set the

detector input voltage to either 100 mV or 1 V full scale depending on your

detector’s output voltage. Press Done. On the Main screen, Collect should now

read Collect –> Threshold.

6. For collection of non-peak fractions, change NonPeak Frac. from Divert to

Collect and enter a size for the non-peak fractions.

7. (Optional) Set the bubble filter time. This function detects and filters false peaks

(such as electrical noise or air bubbles). Typically, a bubble filter time of 0 or 1

sec will suffice. (For a discussion of the bubble filter time function, see

Appendix A, Bubble Filter Time, on page 83.)

8. (Optional) Press Collect (F4) and set the delay time.

9. (Optional) press Method (F3) and save your method.

10. Press Run (F1) to start the experiment.

At any point during the run you may use the Run screen function keys (see

Table 8 on page 43).

62 | BioFrac Fraction Collector

Page 71

Collect by Windows

Fig. 25. Running a Collect by Windows method.

Collect by Windows

To run a Collect by Windows method

1. To select a rack, press Rack (F2) and then choose a rack from the Rack menu.

Choose whether you want the diverter valve to divert to waste during fraction

advances.

2. (Optional) If you are collecting in microplates or Titertube tubes, choose a

collection pattern: Serpentine, Row, or Column.

3. Whenever a new rack is selected, the start tube and end tube values are

updated to reflect the maximum number of tubes available for the selected

rack.

4. Choose the appropriate MultiRun mode for your experiment (see Table 4 on

page 37 for a description of the MultiRun function.

5. Set the start tube and end tube rack position and tube number. The fraction

collector stops when the last tube is reached unless a stop command is