Page 1

NETWORK

ACP PILOT

INSTALLATION &

COMMISSIONING

MANUAL

BROOKES & GATEHOUSE LTD

Premier Way

Abbey Park

Romsey

Hampshire SO51 9DH

England

Tel: (+44) 01 794 518448

Fax: (+44) 01 794 518077

Page 2

SECTION 1 SYSTEM UNITS

SECTION 1 SYSTEM UNITS................................................................1

SITING THE ACP UNIT..................................................................4

MOUNTING PROCEDURE............................................................4

ACP REMOTE COMPASS UNIT..........................................................5

DESCRIPTION...................................................................................5

SITING THE COMPASS UNIT.......................................................6

MOUNTING PROCEDURE............................................................6

NETWORK PILOT DISPLAY................................................................7

SITING THE PILOT DISPLAY HEAD.............................................8

MOUNTING PROCEDURE............................................................8

NMEA INTERFACING .......................................................................9

NMEA INPUT .................................................................................9

NMEA OUTPUT ...........................................................................10

HAND-HELD CONTROLLER .............................................................11

DESCRIPTION.................................................................................11

SITING THE HAND-HELD UNIT..................................................11

MOUNTING PROCEDURE..........................................................11

MAN OVERBOARD BUTTON (MOB) ................................................12

DESCRIPTION.................................................................................12

SITING THE MAN OVERBOARD ALARM BUTTON...................12

MOUNTING PROCEDURE..........................................................12

ACP JOYSTICK ..................................................................................13

DESCRIPTION.................................................................................13

SITING THE JOYSTICK UNIT .....................................................13

MOUNTING PROCEDURE..........................................................14

RUDDER REFERENCE UNIT (RRU)..................................................15

DESCRIPTION.................................................................................15

Key Points When Installing The RRU...........................................16

LINEAR FEED BACK UNIT................................................................20

1 - 1

Page 3

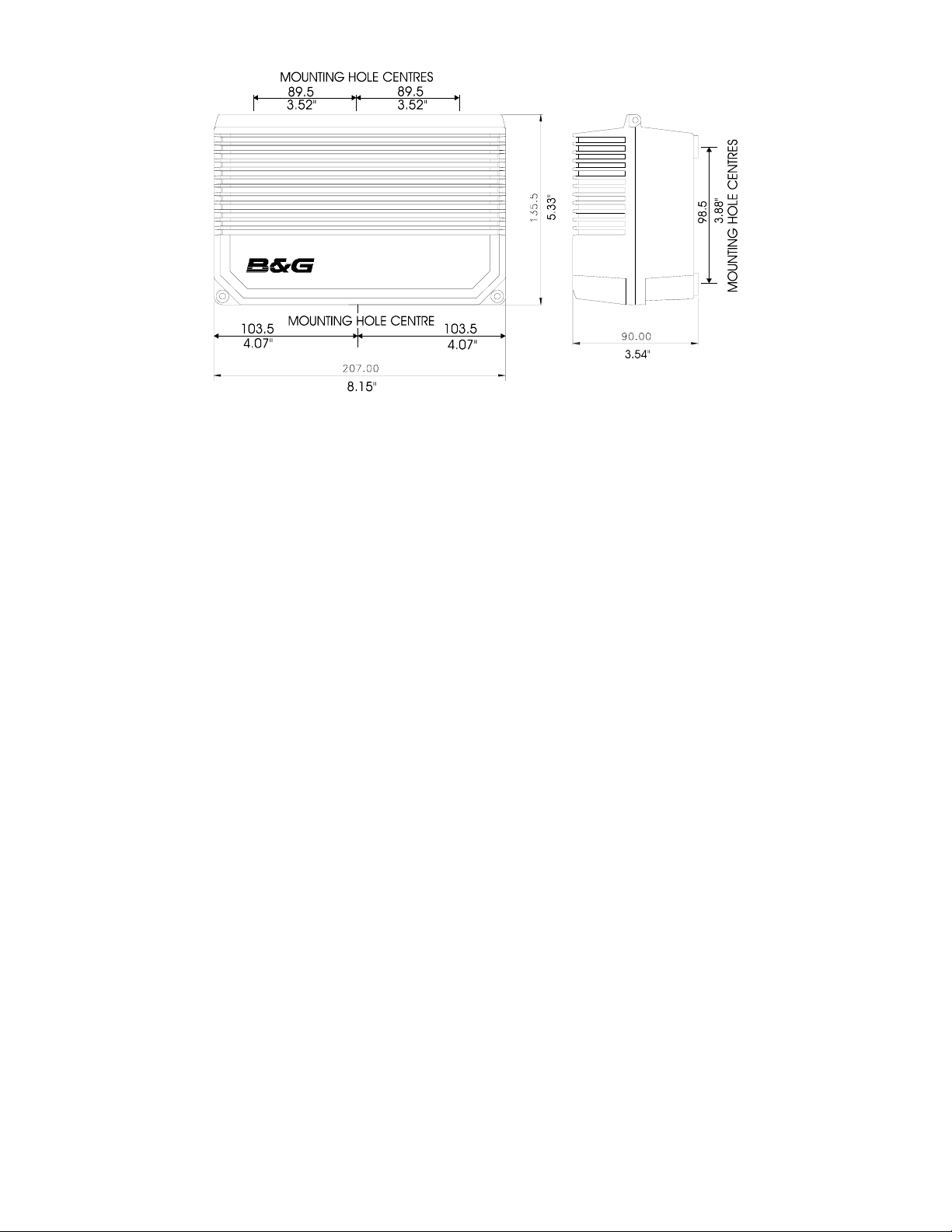

ADVANCED CONTROL PROCESSOR UNIT

DESCRIPTION

The Advanced Control Processor (ACP) Unit contains all the electronics

for the autopilot operation and control of the rudder drive options. It is

designed to be mounted on a vertical, flat , smooth surface. The unit

has a hinged lid to provide easy access to the electrical connections

within. The unit requires the ACP Compass Unit (see next section).

The ACP Unit is available in two configurations:

ACP 1 12V only 12 amps max. output current

ACP 2 12/24V 25 amps max. output current

1 - 2

Page 4

The 12V ACP 1 Unit will control the following rudder drive options:

Size 1/12V Hydraulic Ram Drive RAM-T1-12V blue

•

Size 1/12V Hydraulic Pump PMP-T1-12V blue

•

12V Rotary Drive Unit RDU-T1-12V

•

Stern Drive Unit SDU-T1-12V

•

The 24V ACP 2 unit will control the following rudder drive options:

•

Size 1/12V Hydraulic Ram Drive RAM-T1-12V blue

•

Size 2/12V Hydraulic Ram Drive RAM-T2-12V blue

•

Size 3/24V Hydraulic Ram Drive RAM-T3-24V blue

•

Size 1/12V Hydraulic Pump PMP-T1-12V blue

•

Size 2/12V Hydraulic Pump PMP-T2-12V blue

•

Size 3/24V Hydraulic Pump PMP-T3-24V blue

•

12V Rotary Drive Unit RDU-T1-12V

•

24V Rotary Drive Unit RDU-T3-24V

•

Stern Drive Unit SDU-T1-12V

•

1 - 3

Page 5

SITING THE ACP UNIT

It is recommended that the ACP unit is mounted with the cable entry

•

points downwards. It must not be mounted with the cable entries

uppermost as water may run down the cables and into the unit.

Ensure that there is sufficient space to allow the unit to be hinged

•

open to make connections to terminals inside, and that the hinges of

the two halves of the case may be slid apart.

Select a position sheltered from the direct effects of the environment

•

and from physical damage.

Do not mount the unit within 1m/3ft of engines, starter motors and

•

cables, and other cables carrying heavy current, etc., or 3m/10ft of

Radar or SSB installation cables.

MOUNTING PROCEDURE

Undo the two screws at the corner of the unit, and open fully.

•

The hinges are designed to come apart. This enables the electronics

•

to be split from the base of the unit i.e. the connection and terminal

blocks.

Disconnect the cables between the two halves of the casing.

•

Firmly push the two halves of the computer unit apart.

•

Using the base of the unit as a template, mark the positions of the

•

three mounting screw holes.

Using the self-tapping screws provided secure the base of the unit in

•

position.

Push the two halves of the unit together again and reconnect the

•

cables.

1 - 4

Page 6

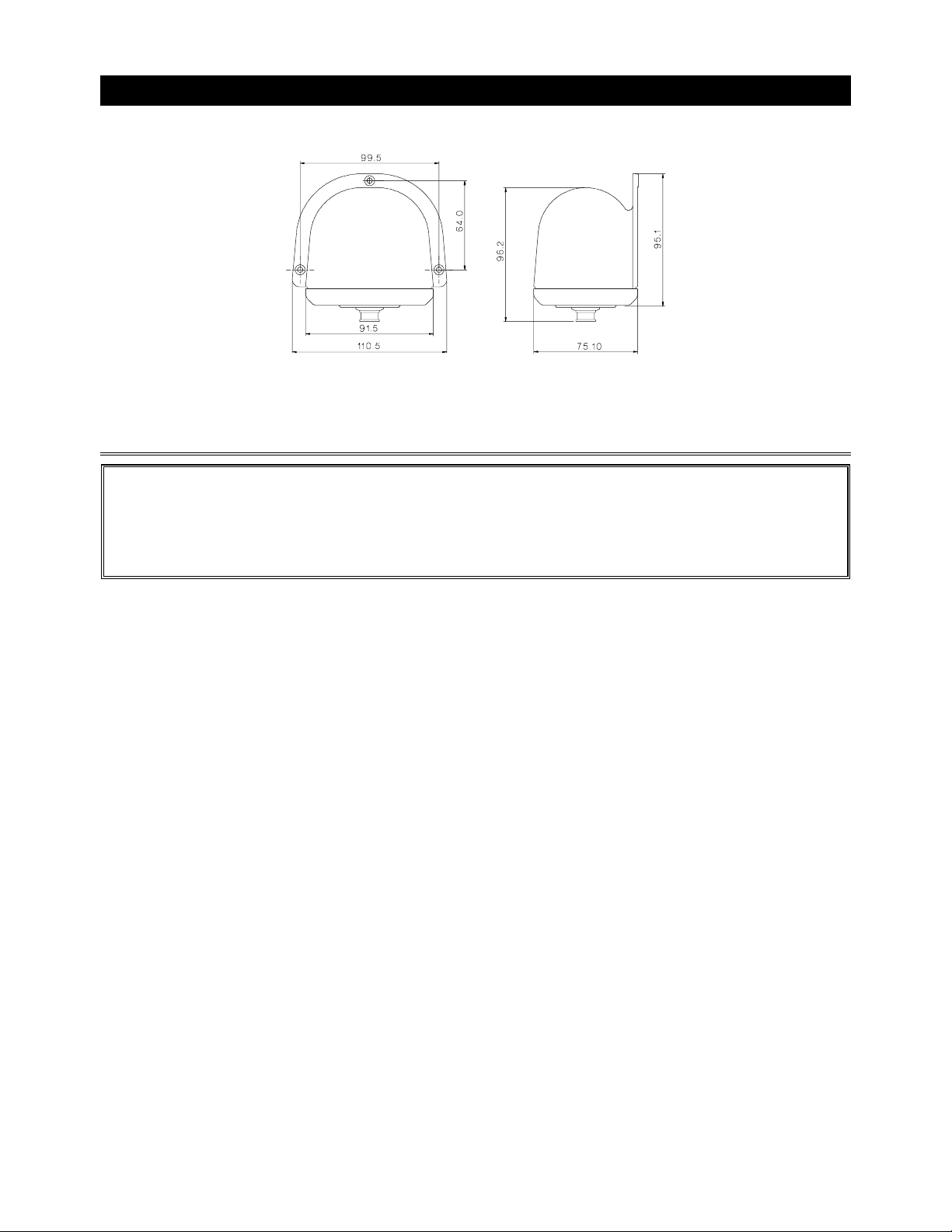

ACP REMOTE COMPASS UNIT

DESCRIPTION

IMPORTANT NOTE:

This external fluxgate compass unit can

ONLY

be used with ACP Pilot Systems or Network Compass displays.

Remove the transit screw after mounting on bulkhead and before

inserting cable connector.

The ACP Remote Compass Unit is a gimbal mounted electronic

fluxgate for use with ACP Pilot Systems. The unit is housed in a sealed

casing constructed of high impact plastic. It is therefore suitable for on

or below deck mounting.

If installed in a vessel with a steel or reinforced concrete hull it may be

necessary to install the external compass unit outside the magnetic

screening affect of the hull and super-structure.

It is supplied with a 12m/36ft, 6-core screened cable, one end with a

sealed connector for the compass unit and the other connecting directly

into the ACP Unit.

1 - 5

Page 7

SITING THE COMPASS UNIT

Mount the unit upright on a flat, vertical bulkhead.

•

A safe distance from external magnetic interference:

•

1m/3ft from VHF, RDF, loudspeakers, depth sounders, engines,

•

power cables carrying heavy current, etc.,

3m/10ft from Radar and SSB Equipment.

•

Reasonably well protected from direct physical damage.

•

With the connector downwards as shown in the above diagram.

•

MOUNTING PROCEDURE

Secure the unit in the selected site using the non-magnetic self-

•

tapping screws provided.

Route the cable to the computer unit avoiding other cables

•

carrying heavy currents, e.g. engine starter, trim tab, etc.

Secure in place with cable clips or tie-wraps.

•

Avoid bending the cable through a tight radius especially near the

•

connector as this may damage the wires inside the cable.

1 - 6

Page 8

NETWORK PILOT DISPLAY

DESCRIPTION

The Network Pilot Display is designed to be mounted above or below

deck. The display head allows control of the autopilot and by installing

multiple display heads, gives control at any station. It can be connected

to all other Network Instruments via the network cable tails to provide an

integrated autopilot and navigational system. It is essential that the

autopilot is initialised before operation, details are given in the

commissioning section of this manual.

In an integrated system boat speed is supplied from Network SPEED or

QUAD units and wind speed and wind angle from Network WIND via

the system network for Steer to Compass and Steer to Vane modes.

Boat speed can also be set using the display head when required.

Plus

When a GPS

the Pilot via the network cable connection. Without a GPS

is included in the system all required data is carried to

Plus

on the

system, NMEA 0183 (v1.5) data can be input to the Pilot via the 3 pin

socket located on the rear of the display unit.

The display heads are supplied with a clip-in mounting bracket which

allows for easy installation, access from behind is not necessary to

secure the unit in place. However to prevent theft or if removal of the

unit is not required then locking studs and thumb-nuts are supplied to

allow for permanent fixing.

1 - 7

Page 9

SITING THE PILOT DISPLAY HEAD

All Network Instruments are designed for mounting on or below deck.

Select a display site that is:

At a convenient position within easy reach of the helmsman

•

On a smooth and flat surface

•

At a compass safe distance 100mm (4")

•

Reasonably well protected from physical damage

•

Accessible from behind for fitting locking studs if required

•

The rear boss of the unit has a breather hole to prevent

•

condensation, protect the rear cover from direct splashes of water.

MOUNTING PROCEDURE

• Use the cutting template supplied to mark the centres of the holes

for the self-tapping screw, the fixing stud holes and the mounting

bracket.

• The template allows 4mm (5/32") between adjacent units or

118mm/ 4 11/16” between centres for the suncover. Increase this

distance if required to maximum of 60mm (2 3/8") between units or

180mm (7 1/8") between centres.

• For greater distances between units extension cables are available.

• Use a 70mm (2 3/4") diameter hole-cutter for the mounting bracket

hole.

• Use a 2.9mm(1/8”) drill for the self-tapping screws.

• Use a 5mm (3/32") drill for the locking stud holes.

• Secure the mounting bracket to the bulkhead with the self-tapping

screws supplied.

• Fit the rubber sealing gasket around the mounting bracket.

• Screw the locking studs into the back of the display head.

• Carefully pass the cable tails through the mounting bracket hole,

connect the power, interconnecting and NMEA input cables to the

display head (if fitted).

1 - 8

Page 10

• Clip the display head into the mounting bracket.

• Secure the display head with the thumb nuts supplied (if required).

NMEA INTERFACING

The Network PILOT can be interfaced to any NMEA 0183 (v1.5)

compatible position fixer. If more than one source of NMEA data is to be

used then it will be necessary to use two Network PILOT display units.

NMEA INPUT

The Network PILOT display head has an NMEA input connector at the

rear, use a special 3m NMEA input cable 612-OA-053 (Red sig+, Blue

sig-).

The Network PILOT uses the follow data from NMEA:

Cross Track Error (XTE), Speed Over Ground (SOG), Bearing: current

position to destination waypoint, Bearing: origin waypoint to destination

waypoint, Distance: current position to waypoint

Waypoint number

The following NMEA sentences are decoded, Note $ID is any NMEA

talker:

$IDAPA XTE, bearing origin to destination waypoint

$IDAPB XTE, bearing origin to destination waypoint,

bearing to waypoint

$IDRMB XTE, bearing and distance to waypoint

$IDXTE XTE

$IDVTG Speed over Ground

$IDBWR Bearing and Distance to waypoint rhumb,

waypoint number

$IDBWC Bearing and Distance to waypoint great circle,

waypoint number

1 - 9

Page 11

NMEA OUTPUT

NMEA output is via the network cable connection tail, use a special 3m

NMEA output cable 610-OA-030 (Red sig+, Blue sig-).

Dependent on system devices, the following sentences are transmitted:

$IIHDM Heading

$IIVHW Speed and heading

$IIDBT Depth below transducer

$IIVWR Apparent wind angle and speed

$IIMTW Water temperature

1 - 10

Page 12

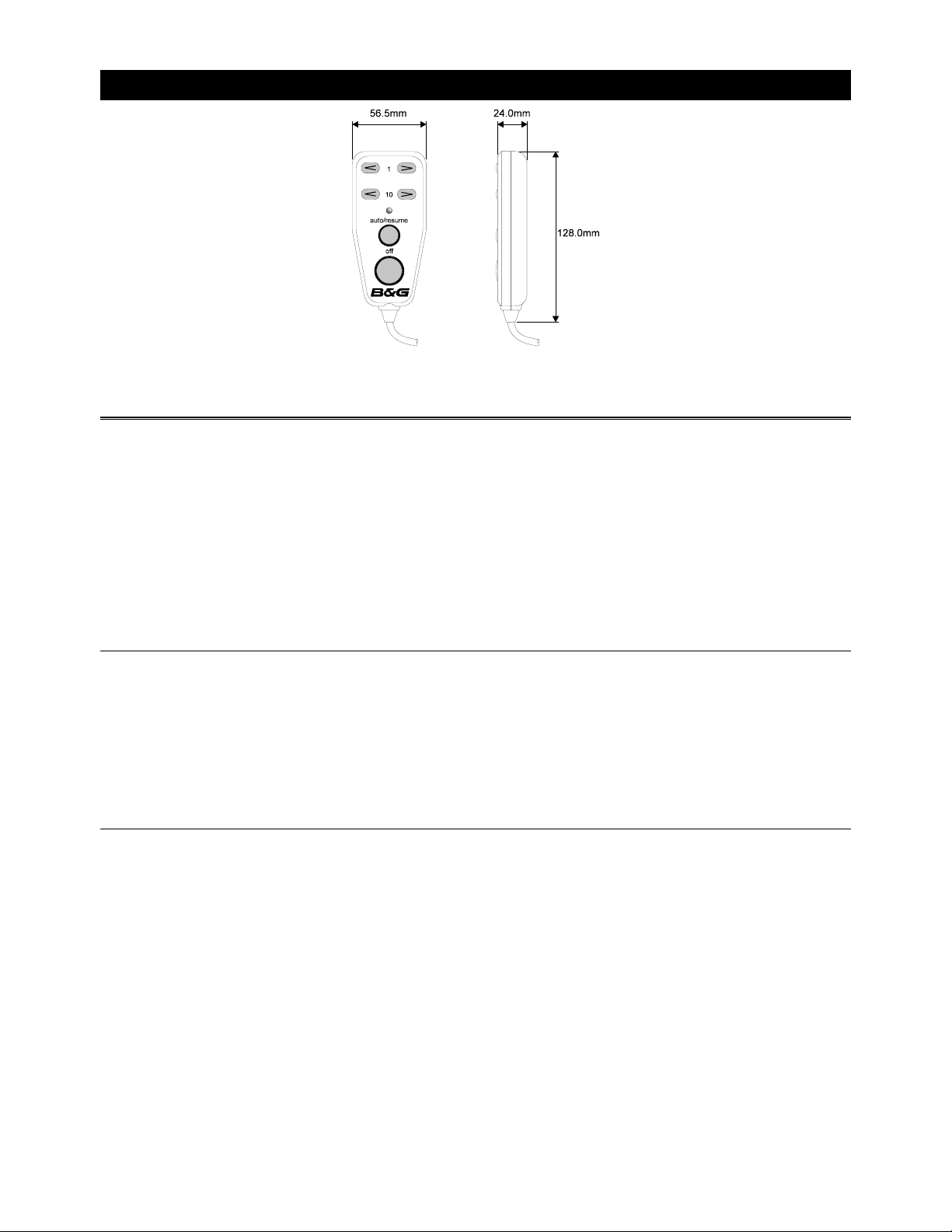

HAND-HELD CONTROLLER

DESCRIPTION

The hand-held remote controller is a waterproof unit that has six

function buttons and a status LED to indicate the operating mode of the

autopilot. The unit provides palm-of-the-hand control of the PILOT. The

cable has a 10 metres /30ft straight section, plus a coiled length that

extends from 1 metre to 3 metres.

SITING THE HAND-HELD UNIT

At a convenient position within easy reach of the helmsman.

•

Ensure at all times the hand-held remote controller's cable does not

•

become snagged on any moving parts e.g. throttle controls.

MOUNTING PROCEDURE

Heavy duty self-adhesive Velcro strip is supplied with the unit.

•

Clean and de-grease the site, stick the Velcro firmly in place.

•

1 - 11

Page 13

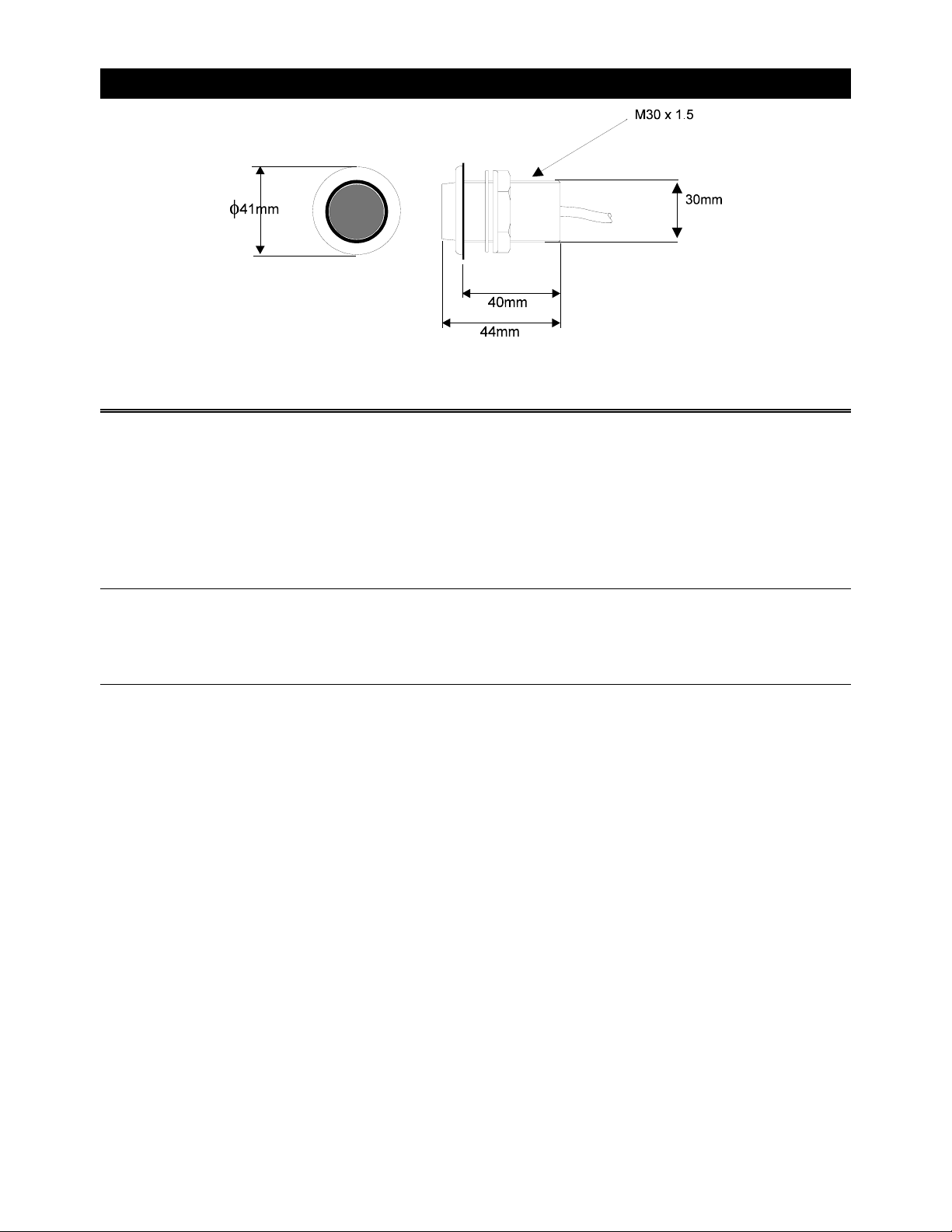

MAN OVERBOARD BUTTON (MOB)

DESCRIPTION

The man overboard alarm button (MOB) is a large red waterproof switch

with 15 metres/45ft of two-core screened cable. This button starts the

MOB sequence of operations when pressed and the audible alarm

sounds (if fitted).

SITING THE MAN OVERBOARD ALARM BUTTON

Select a suitable bulkhead, easily accessible in an emergency.

•

MOUNTING PROCEDURE

With a 32mm (1 1/4") hole-cutter cut a clearance hole for the button

•

body.

Remove the nut and washer, then ensuring the sealing gasket is in

•

place to prevent leakage, carefully feed the cable through the hole.

From behind the bulkhead, fit the washer and nut and tighten.

•

1 - 12

Page 14

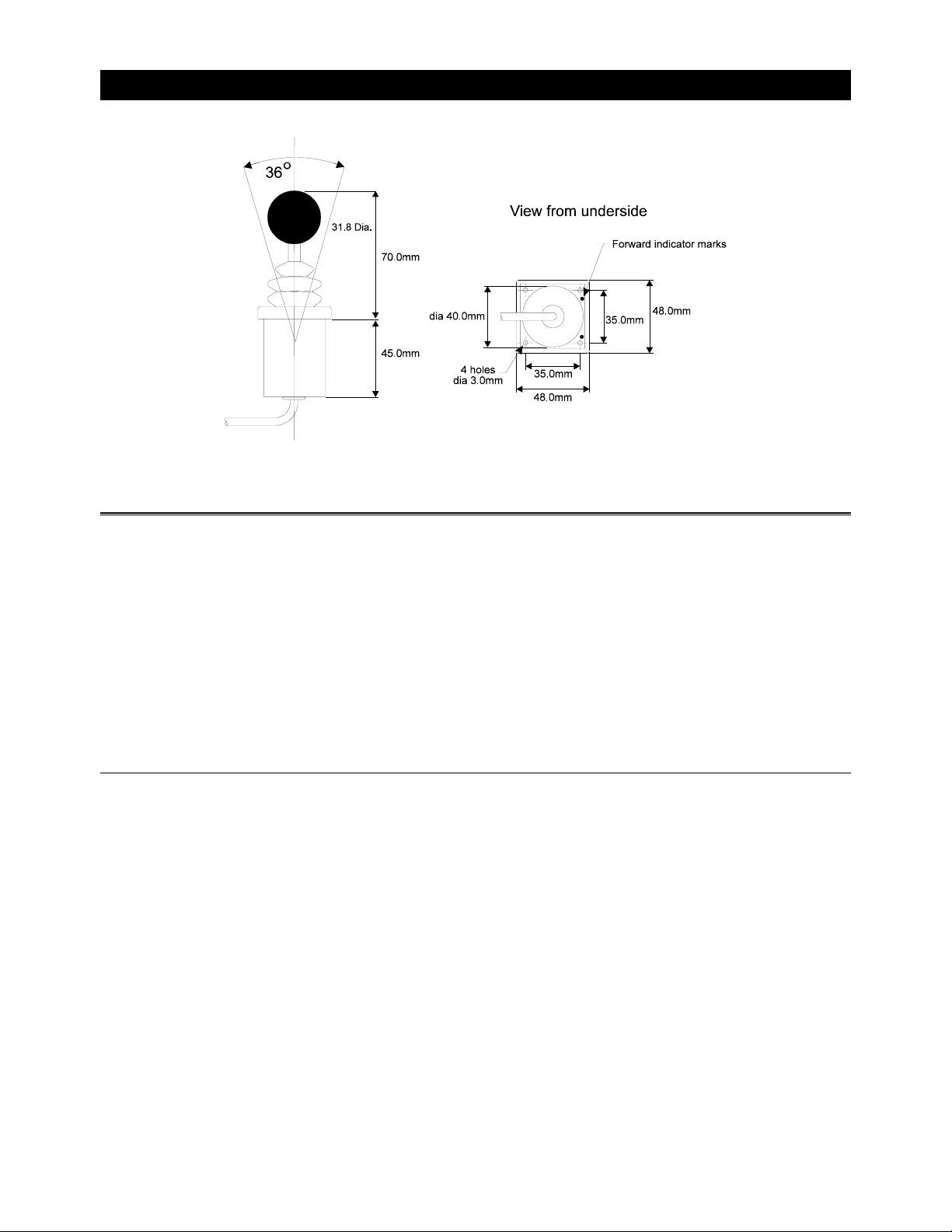

ACP JOYSTICK

DESCRIPTION

The joystick allows direct control of the vessel's rudder via the autopilot

control electronics. The unit is deck-mountable, allowing it to be used

inside or outside the steering positions. A 10m/30ft 6-core screened

cable connects the unit directly into the ACP Units terminals.

Joystick steering is engaged and disengaged with the separate red

button. The lever can only be moved to port or to starboard.

SITING THE JOYSTICK UNIT

At a convenient position within easy reach of the helmsman.

•

1 - 13

Page 15

MOUNTING PROCEDURE

To ensure correct steering sense the unit is marked with two indents,

•

the unit must be installed with these forward.

The unit requires at least 65mm/2.5" clearance behind the selected

•

mounting position.

Use a 40mm (1 9/16th") hole cutter for the joystick body.

•

Ensure the gasket is fitted under the joystick body flange.

•

Secure in place with self-tapping screws.

•

R oute the cable to ACP unit. Connect as per instruction in Section 4

•

of this handbook.

For details on how to install the controller button refer to the MOB

section.

1 - 14

Page 16

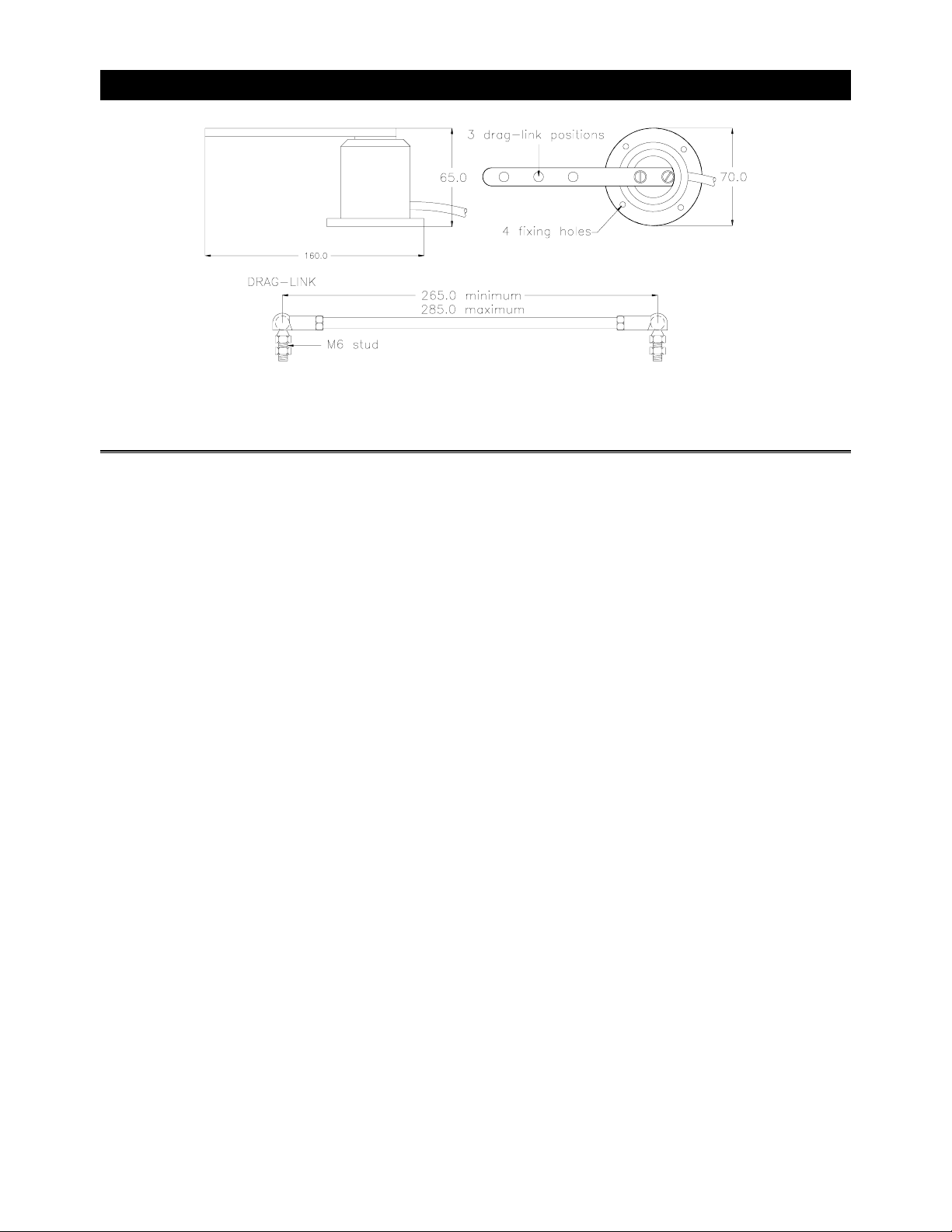

RUDDER REFERENCE UNIT (RRU)

DESCRIPTION

The Rudder Reference Unit (RRU) is a sealed high specification

potentiometer in a robust casing, providing rudder position information

to the Computer Unit. The operating arm is constructed in aluminium

with three positions pre-drilled for the adjustable drag-link. The

drag-link, has ball-joints at each end that connect the unit operating arm

to the tiller arm or steering quadrant. The unit base has four holes to

allow for mounting. The unit is supplied with 10 m/30ft of 3-core

screened cable.

1 - 15

Page 17

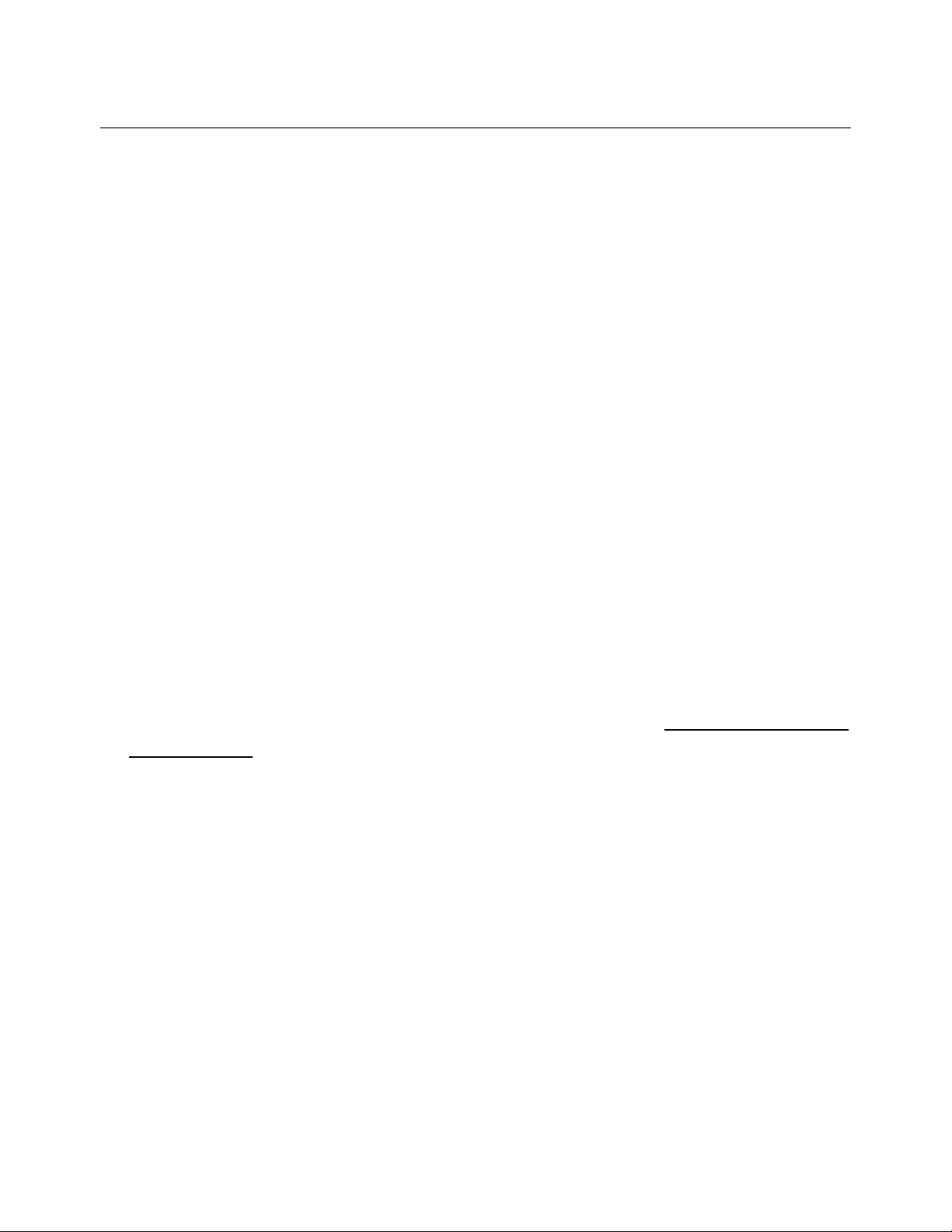

KEY POINTS WHEN INSTALLING THE RRU

General consideration must be given to the steering system and its

•

geometry before starting the RRU installation. Many factors must be

contemplated for a practical solution, the information given here is for

guidance only, although where a maximum or a minimum value is

given these must be adhered to.

Mount the RRU on a flat surface next to the tiller arm or steering

•

quadrant, construct a small platform if necessary.

Do not lengthen the drag-link arm as this can transmit excessive

•

vibration loads to RRU and will invalidate the warranty.

The unit operating arm can be rotated through 360º, the mid-point of

•

the RRU travel is when the operating arm is opposite the cable entry

point.

When the rudder is moved from hard-over port to hard-over starboard

•

the RRU arm should swing through a minimum of 90º, this will ensure

that there is sufficient voltage output to the autopilot. Measure the

voltage difference between the green and blue wires of the RRU,

there should be a minimum of 1 volt change from hard over to hard

over. N.B. If there is less than 1 Volt change the Pilot will not

commission.

After installation check full movement of the steering system ensuring

•

that there is no fouling between the steering gear, RRU parts and

ram drive unit if fitted.

Ensure that there is no backlas h in the linkage between the RRU and

•

the steering gear, otherwise incorrect operation of the autopilot will

occur.

1 - 16

Page 18

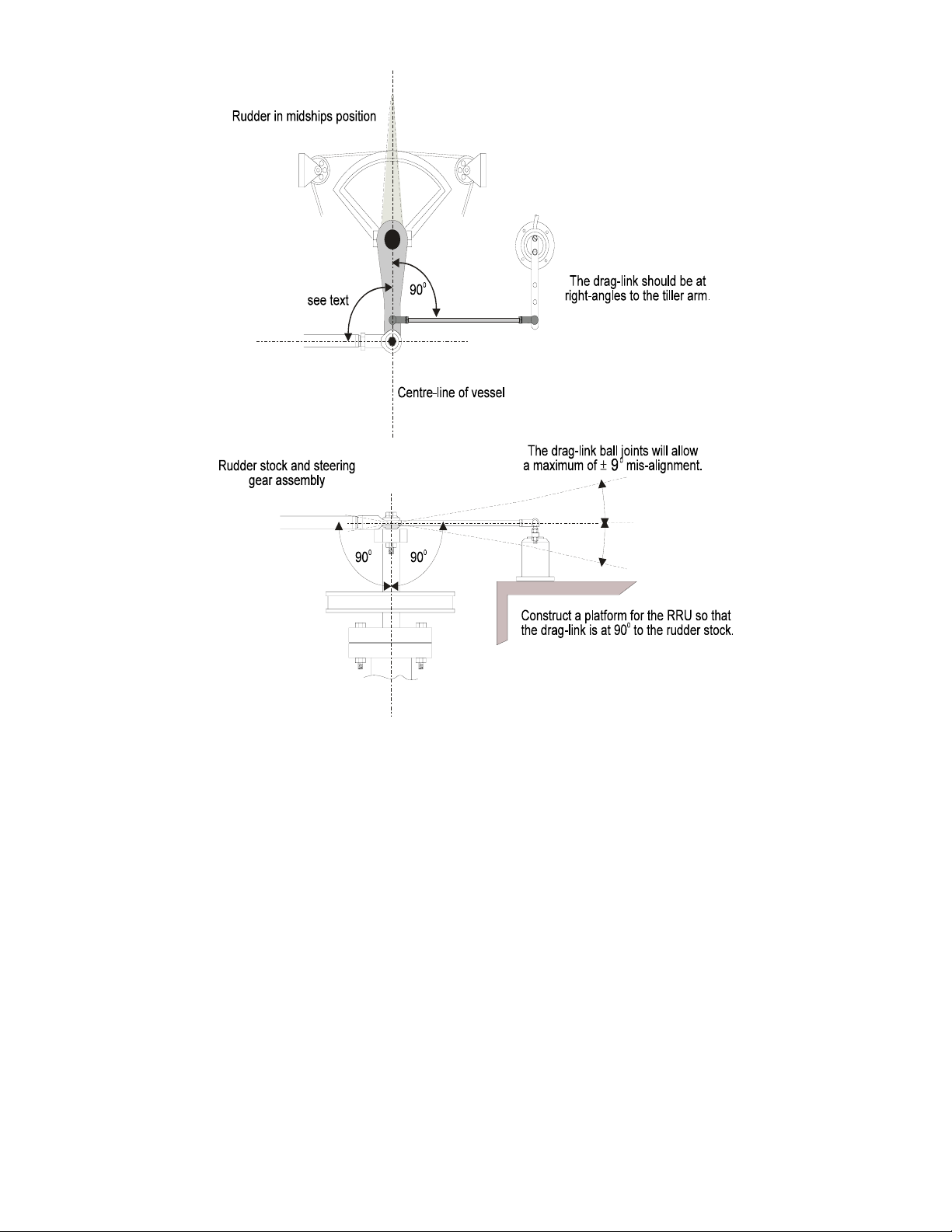

The example shown is a plan view of a typical system with a tiller arm

and quadrant. When viewed in elevation, the ram drive arm and rudder

reference unit drag-link must not be more than ±9º from horizontal.

Ideally everything should be horizontally aligned, this prevents

excessive stress during operation.

1 - 17

Page 19

1 - 18

Page 20

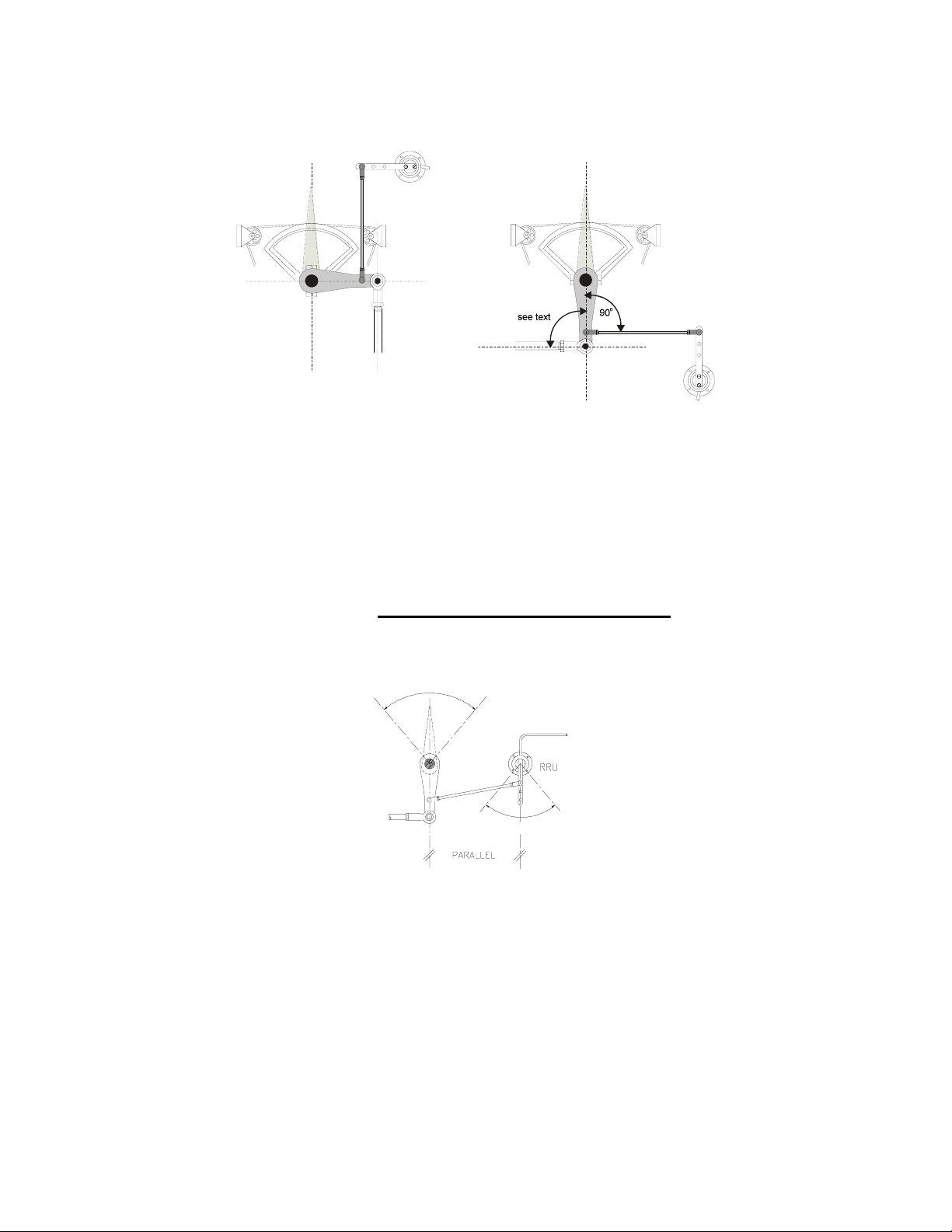

ARIA

The RRU can be mounted in many different positions and orientations

depending on the layout of the steering system.

If the maximum rudder angle is less than 90º then the position of the

RRU or the drag-link must be adjusted so that the operating arm of the

RRU swings through a minimum of 90º and the output voltage

difference is greater than 1 volt from port to starboard lock. Measure the

output of the RRU between the green and blue wires. N.B. If there is

less than 1 Volt difference the Pilot will not commission

.

1V MINIMUM

V

TION

90° MINIMUM RRU AN G LE

1 - 19

Page 21

The rudder hard over angle should only be limited by the rudder stops

and not the RRU linkage. Check that when hard over the RRU arm and

drag-link, do not form a straight line. If this occurs the steering system

could become damaged or jammed endangering the boat and crew.

Rectify this immediately by adjusting the position of the RRU.

LINEAR FEED BACK UNIT

Where installation of the conventional Rudder Reference unit is difficult

or physically impossible a Linear Feedback unit can be used. The

Linear Feedback unit comprises of a tube approximately 23mm/ 7/8” in

diameter and 324mm/ 12 3/4” long. This assembly is clamped to the

side of the Linear actuator using a special bracket kit. The Linear Feed

Back shaft is attached to the tiller bracket using the pin supplied with all

Blue rams.

This unit requires careful installation and alignment which should be

carried out by your dealer / supplier. For electrical connection see

section 4.

1 - 20

Page 22

SECTION 2 RUDDER DRIVE OPTIONS

RAM DRIVE UNIT __________________________________2

DESCRIPTION _____________________________________2

BLUE RAMS(DRIVE DATA) __________________________2

SIZE 1 & 2 HYDRAULIC DRIVE PUMP DIMENSIONS _____6

RAM DRIVE UNIT INSTALLATION _____________________7

Key Points On Installation ___________________________8

A Typical Ram Drive Unit Layout (REFER TABLE 2-5) _____9

Ram Mounted Parallel To Vessels Centre-Line __________10

KEY POINTS ON INSTALLATION. ___________________11

MOUNTING A BLUE RAM ON A VERTICAL BULKHEAD__11

SPLITTING THE RAM DRIVE UNIT____________________13

BLUE HYDRAULIC DRIVE PUMPS ___________________14

DESCRIPTION ____________________________________14

Pump Data ______________________________________14

Key Points On Installation __________________________15

HYDRAULIC DRIVE PUMP DIMENSIONS ______________ 16

HYDRAULIC DRIVE PUMP INSTALLATION EXAMPLES__19

2 - 1

Page 23

RAM DRIVE UNIT

DESCRIPTION

A compact DC driven reversible hydraulic pump and hydraulic cylinder

assembly for boats without hydraulic steering systems. Three sizes of

ram drive are available giving a wide thrust range to suit all sizes and

types of vessel.

BLUE RAMS(DRIVE DATA)

Type 1 and type 2 rams combine motor, pump and hydraulic cylinder as

one unit referred to as an actuator. Type 3 rams are supplied split into a

separate motor/pump unit, reservoir and hydraulic cylinder, connected

by 1 metre/ 3ft hoses. Longer hoses are available, contact your dealer.

The units can also be mounted on a vertical bulkhead see page 2-12.

2 - 2

Page 24

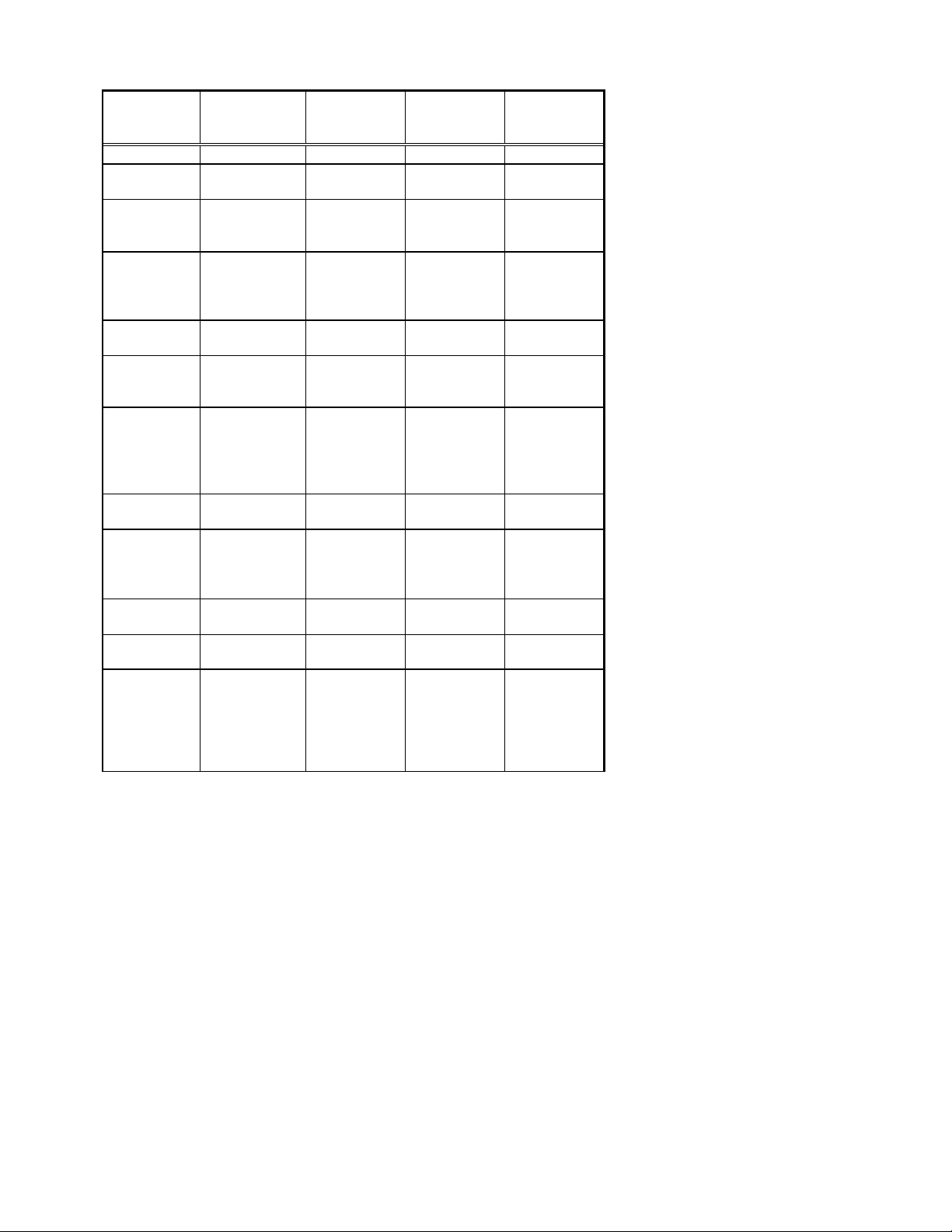

RAM

DRIVE

TYPE

ACP UNIT

MOTOR

SUPPLY

SOLENOID

VALVE

SUPPLY

PEAK

THRUST

PEAK

CURRENT

MAXIMUM

STROKE

FULL

BORE

AREA

ANNULUS

AREA

ROD

DIAMETER

TILLER

ARM

for 700

rudder

MAXIMUM

TORQUE

WEIGHT

HELM TO

HELM TIME

extend

retract

RAM SIZE1

BLUE

ACP1 ACP2 ACP2 only ACP2 only

12V DC 12V DC 12V DC 24V DC

12V DC

1.25A (max)

425 kg force

935 lbs-force

14A @

12V

254mm

10"

1208 mmsq,

1.872 "sq

1005

mmsq,

1.558 "sq

16 mm,

0.623 "

214 mm

8.4 "

892 Nm

7867 lb.ins

7 kg,

15 lbs 6oz

15.7 sec

13.4 sec

(8Kg force)

RAM SIZE 1

BLUE

12V DC

1.25A (max)

680 kg

force

1496 lbs-

force

20A @

12V

254mm

10"

1208 mmsq,

1.872 "sq

1005

mmsq,

1.558 "sq

16 mm,

0.623 "

214 mm

8.4 "

1427 Nm

12574 lb.ins

7 kg,

15 lbs 6oz

15.7 sec

13.4 sec

(8Kg force)

RAM SIZE 2

BLUE

12V DC

1.25A (max)

680 kg

force

1496 lbs-

force

25A @

12V

254mm

10"

1208 mmsq,

1.872 "sq

1005

mmsq,

1.558 "sq

16 mm,

0.623 "

214 mm

8.4 "

1427 Nm

12566 lb.ins

7 kg,

15 lbs 6oz

11.9 sec

10.2 sec

(200Kg

force)

RAM SIZE 3

BLUE

24V DC

0.8A (max)

1062 kg

force

2342 lbs-

force

17A @

24V

305mm

12 "

1885 mmsq,

2.921 "sq

1570

mmsq,

2.434 "sq

20 mm,

0.623 "

257

mm

10.16 "

2688 Nm

23780 lb.ins

10.3 kg,

22lbs 11oz

14.6 sec

12.6 sec

(200Kg

force)

The following table may be used to determine the steering system

geometry for different maximum rudder angles and ram type. The last

three columns show the peak torque available (in Kgm), amidships

position and at the maximum rudder angle, with the latter two with the

motor running at 50% duty cycle.

Refer to the diagrams on page 2-6, 2-10, 2-11, 2-13.

2 - 3

Page 25

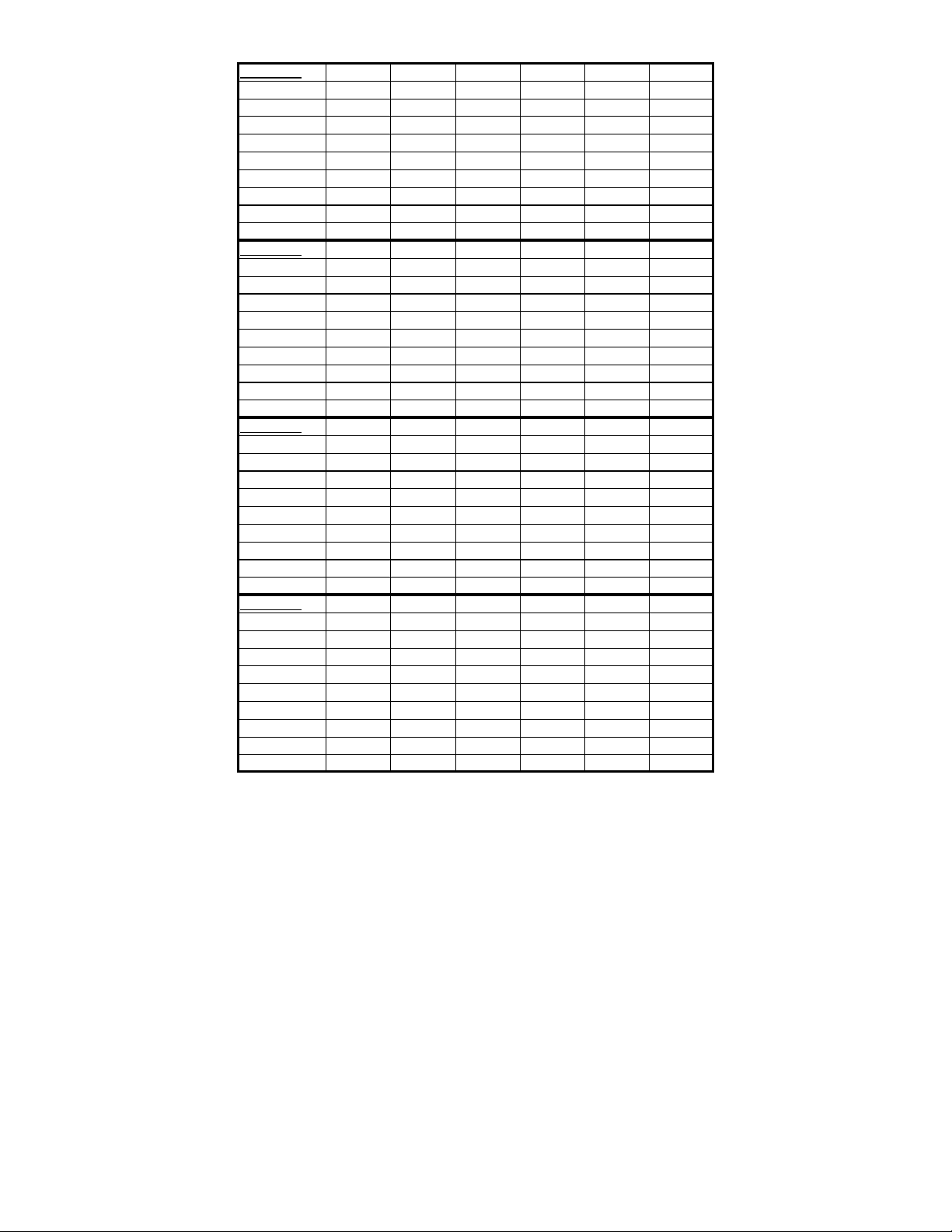

RA M-T1-12V

568

5

2

1/2 m a x Tiller arm Offs e t Thrus t To rq u e at T o rq u e at Torq u e

rudder angle m m mm (peak m idships midships (at max

a b c Kgf) (peak Kgm) (50% Kgm) 50% Kgm)

25 290 272 425 123 123 118

30 245 227 425 104 104 90

35 214 196 425 91 91 74

40 190 172 425 81 81 62

45 173 155 425 74 74 52

50

RA M-T1-12V

1/2 m a x Tiller arm Offs e t Thrus t To rq u e at T o rq u e at Torq u e

rudder angle m m mm (peak m idships midships (at max

a b c Kgf) (peak Kgm) (50% Kgm) 50% Kgm)

25 290 272 680 197 197 179

30 245 227 680 167 167 144

35 214 196 680 145 145 119

40 190 172 680 129 129 99

45 173 155 680 118 118 83

50 160 142 680 109 109 70

RA M-T2-12V

1/2 m a x Tiller arm Offs e t Thrus t To rq u e at T o rq u e at Torq u e

rudder angle m m mm (peak m idships midships (at max

a b c Kgf) (peak Kgm) (50% Kgm) 50% Kgm)

25

30

35 214 196 680 145 95 77

40 190 172 680 129 84 64

45 173 155 680 118 77 53

50 160 142 680 109 71 4

RA M-T3-24V midstroke = 690mm ACP2 only d= 51mm

1/2 m a x Tiller arm Offs e t Thrus t To rq u e at T o rq u e at Torq u e

rudder angle m m mm (peak m idships midships (at max

a b c Kgf) (peak Kgm) (50% Kgm) 50% Kgm)

25 350 326 1062 372 372 337

30 295 271 1062 313 313 271

35 257 233 1062 273 273 223

40 230 206 1062 244 244 187

45 210 186 1062 223 223 157

50 193 169 106

midstroke = 505mm ACP1 only d= 73.3

160 142 42

midstroke = 505mm ACP2 only d= 73.3mm

midstroke = 505mm ACP2 only d= 73.3mm

290 272 680 197 128 116

245 227 680 167 108 94

205 205 131

68 44

°

°

°

°

2 - 4

Page 26

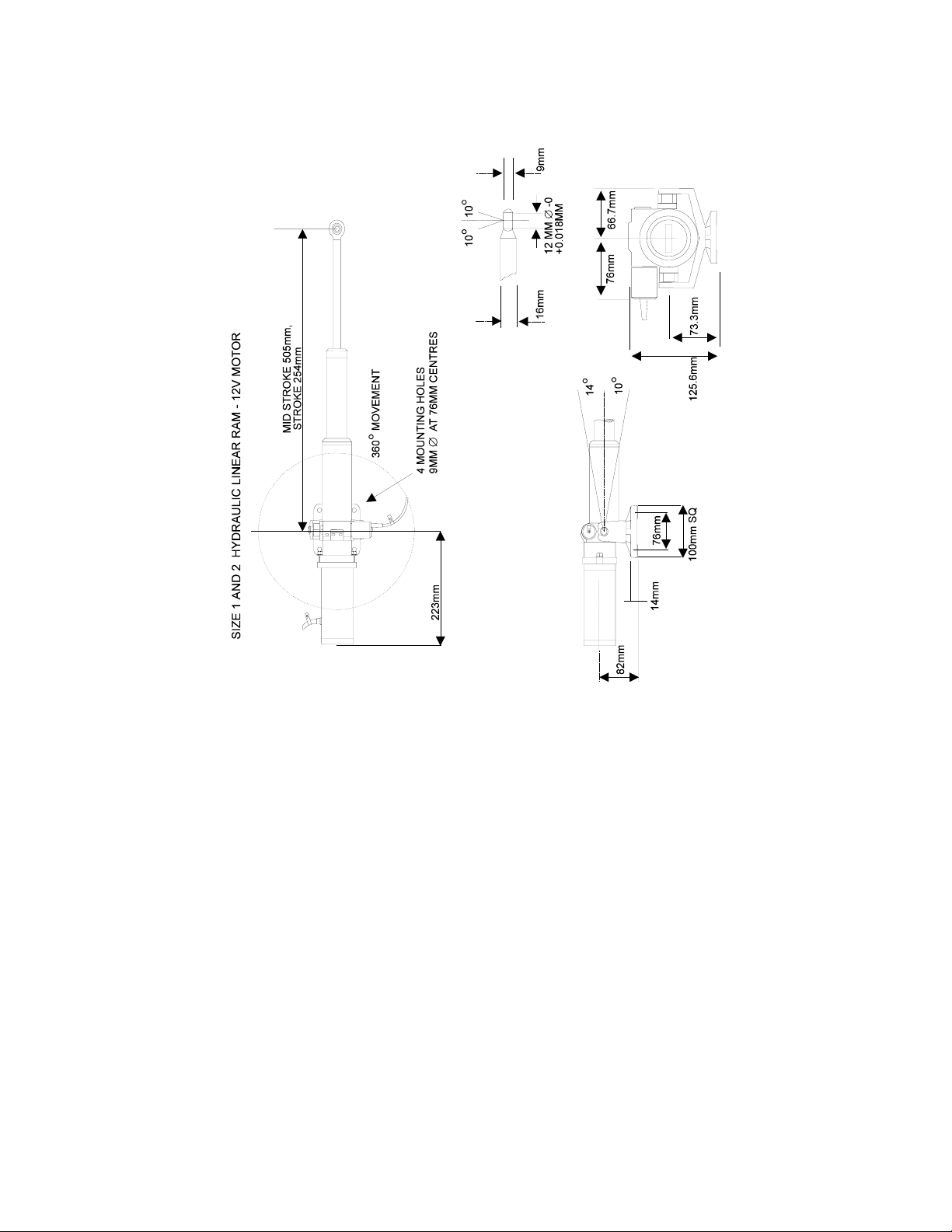

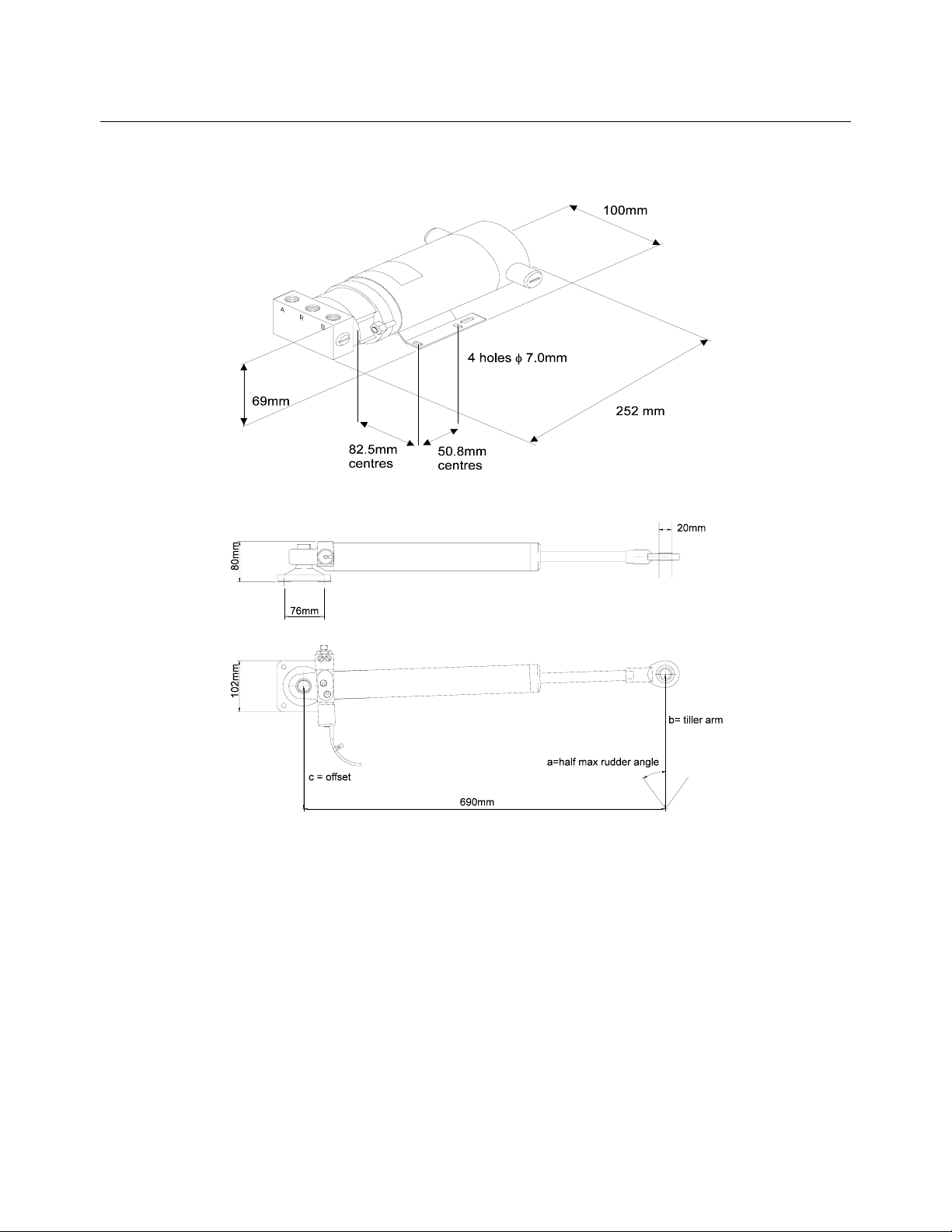

RAM DRIVE UNIT DIMENSIONS - BLUE SIZE 1 AND 2 ACTUATORS

AND BLUE RAMS.

2 - 5

Page 27

SIZE 1 & 2 HYDRAULIC DRIVE PUMP DIMENSIONS

PUMP AND RAM DRIVE UNIT DIMENSIONS - BLUE SIZE 3

(REFERTO TABLE 2-5)

2 - 6

Page 28

RAM DRIVE UNIT INSTALLATION

General consideration must be given to the steering system and its

geometry before starting the installation. Many factors must be

contemplated for a practical solution, the information given here is for

guidance only, although where a maximum or minimum value is given

this must be adhered to. It is essential that the unit is only installed in a

fully functional steering system, with no backlash or stiffness when

operating. Rectify any steering problems before installation of the ram

drive unit or the autopilot will not function correctly.

2 - 7

Page 29

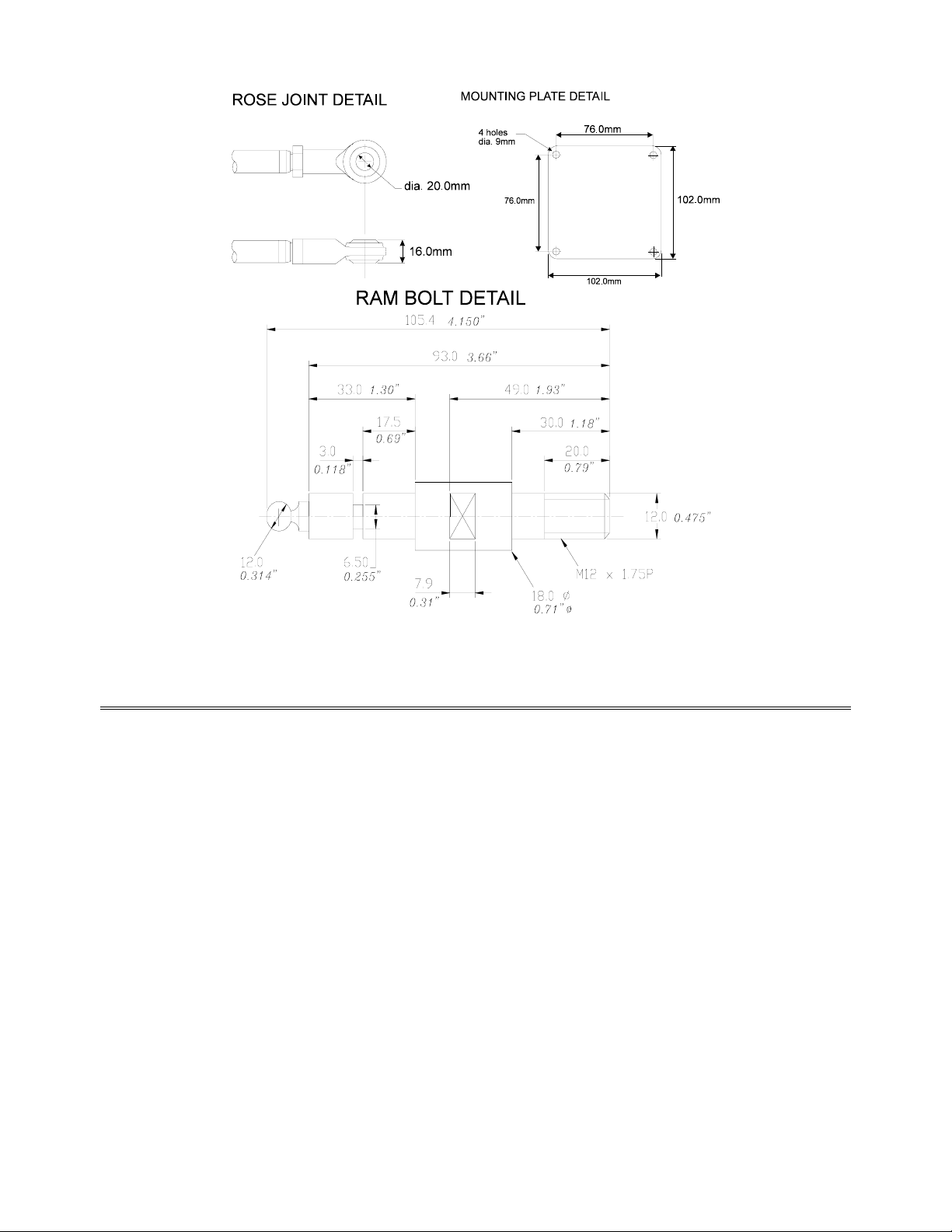

KEY POINTS ON INSTALLATION

Check that the steering gear is in good condition. Rectify any steering

•

defects prior to installation of the ram.

The ram drive unit must be secured onto a flat, rigid base, it maybe

•

necessary to construct a platform section for the mounting plate. For

angled rudder stocks an angled platform section will have to be

constructed.

All setting up and aligning of the ram drive unit with the steering

•

system should be carried out with the rudder in the amidships

position and the ram arm at the centre point of its travel.

The angle between the ram arm and the tiller arm should be as

•

shown in the next two diagrams.

The ram arm should ideally be at right-angles to the rudder stock.

•

The ball-joint on the end of the ram arm will allow a

MAXIMUM

of ±9º

of misalignment.

FOR TYPE 3 RESERVOIR INSTALLATION

Do not turn the black reservoir tap on or attempt to move the

piston rod until all of the following are completed:

The base foot of the ram and pump have been bolted into position.

•

The reservoir has been fixed to a bulkhead above the ram and pump.

•

The sealed reservoir transit cap has been replaced by the breather

•

cap supplied.

The reservoir has been filled with the oil supplied.

•

The reservoir tap has been switched to the

•

position allowing the

‘ON’

oil to flow between the reservoir and the pipe.

(TAP ‘ON’ POSITION IS IN LINE WITH THE PIPE)

2 - 8

Page 30

A TYPICAL RAM DRIVE UNIT LAYOUT (REFER TABLE 2-5)

b = tiller arm

length

a=half max rudder angle

d

2 - 9

Page 31

RAM MOUNTED PARALLEL TO VESSELS CENTRE-LINE

(REFER TO TABLE 2-5)

2 - 10

Page 32

KEY POINTS ON INSTALLATION.

•

Make sure that the rudder angle is limited by the rudder stops

and not the limit of travel of the ram arm. Failure to do this will

damage the unit and invalidate the warranty.

Make sure that there is sufficient space at each end for the ram arm

•

to extend fully, the ram stroke length is shown in the table below.

Check for full movement and security of the steering gear before

•

applying any power to the autopilot system, refer to the installation

check list in the commissioning section of this handbook.

MOUNTING A BLUE RAM ON A VERTICAL BULKHEAD

Due to the restricted movement of the ram of +14

°, 10°

for the size 1

and 2 and +/- 5° for the size 3, it is important that the maximum rudder

angle is carefully measured and the positioning of the RAM, tiller arm

length and offset are carefully followed from the diagrams on the next

page.

FAILURE TO COMPLY WITH THESE DIMENSIONS MAY CAUSE

PREMATURE FAILURE OF THE RAM, AND PLACE GREAT

STRESS ON THE STRUCTURE OF THE VESSEL.

The Size 1 and 2

Blue

Ram may be mounted in any orientation, without

the need to fit an external reservoir. The Size 3 Ram requires an

external reservoir which must be mounted above the unit. Care must be

taken to ensure that the connecting pipes are not in anyway kinked or

turned through any tight bends.

2 - 11

Page 33

VERTICAL BULKHEAD INSTALLATION.(REFER TABLE 2-5)

b= tiller arm

5

5

=d

a=half max rudder angle

2 - 12

Page 34

SPLITTING THE RAM DRIVE UNIT

IMPORTANT NOTE:

care must be taken to ensure that a high degree of cleanliness is

observed and no dirt, moisture or foreign objects are allowed to enter

the system. When filling or topping up the external reservoir only use

a good quality ISO 10 hydraulic oil e.g., Q8 DYNOBEAR 10 (10cSt at

40°C)

It is not possible to split linear actuators.

Type 1 and type 2

and hydraulic cylinders connected by hoses, are available from your

dealer. These are supplied with 1 metre hoses. Units with longer hoses

are also available. These can be supplied with quick connect couplings

and pre-filled hoses. Such units do not need to be bled.

Type 3

Units with longer hoses are available from your dealer. These can be

units are supplied as split units, connected by 1 metre hoses.

When dealing with any hydraulic system great

units comprising separate ram/pumps, reservoirs

supplied with quick connect couplings and pre-filled hoses. Such units

do not need to be bled.

2 - 13

Page 35

BLUE HYDRAULIC DRIVE PUMPS

DESCRIPTION

The Reversible Hydraulic Drive Pump has a small high speed pump

driven by a 12 or 24V DC permanent magnet motor. The pump has pilot

check valves to prevent back driving and a pilot operated reservoir

valve to enable the unit to drive balanced or unbalanced cylinders. The

unit has Port and Starboard 1/4" BSP service ports and a 1/4" BSP

reservoir port.

PUMP DATA

HYDRAULIC PUMP

TYPE

PUMP TYPE Reversible

SUPPLY VOLTAGE 12V DC 12V DC 24V DC

TYPICAL OPERATING

CURRENT RANGE

MAXIMUM PRESSURE 1000 psi 1000 psi 1000 psi

MAXIMUM FLOW RATE

at continuous duty motor

loading

CYLINDER CAPACITY 100-300cc,

WEIGHT 3 kg

PMP-T1-12V PMP-T2-12V PMP-T3-24V

Reversible

DC motor

5 to 17.5 Amps 5 to 22.5 Amps 6 to 17.5 Amps

750 cc/min,

46 ins3/min

6.1 to 18.3 in3

6.6 lbs

DC motor

1420 cc/min,

87in3/min

275 to 550cc,

16.8 to 33.6in3

3 kg

6.6 lbs

Reversible

DC motor

1980 cc/min,

121 in3/min

525 to 750cc,

32 to 46in3

4 kg

8.8 lbs

2 - 14

Page 36

KEY POINTS ON INSTALLATION

A position should be chosen convenient for the steering system

hydraulic delivery lines.

The site should be rigid and flat to prevent excess vibration.

•

Shielded from the direct effects of the elements.

•

Minimise the lengths of the hydraulic lines from the pump to the

•

cylinder and where possible the pump motor supply cables.

2 - 15

Page 37

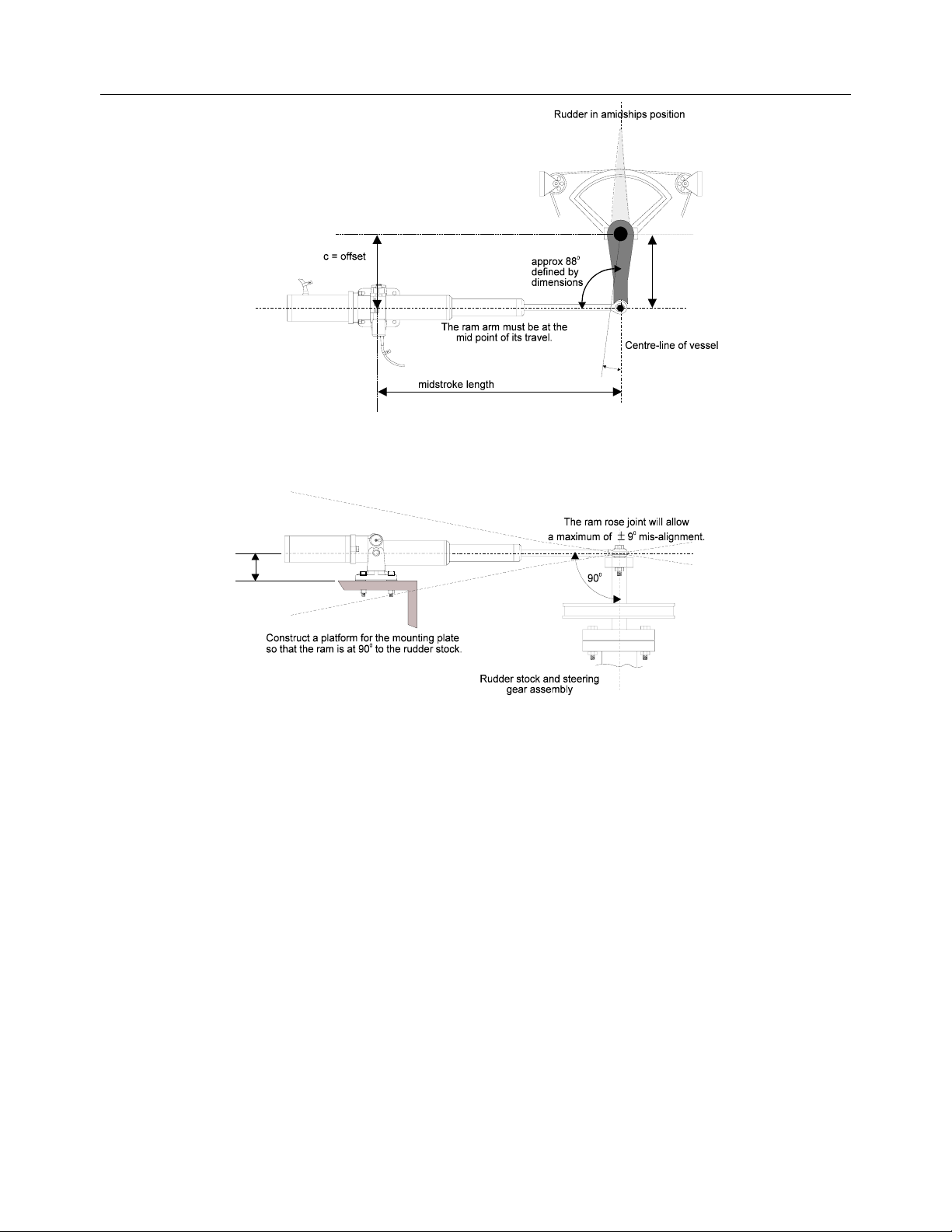

HYDRAULIC DRIVE PUMP DIMENSIONS

Type 1 and 2

Type 3

105mm

(4.13)

4 holes φ 7.0mm

80mm

(3.15)

88.9mm

(3.5)

centres

(0.28)

50.8mm

(2.00)

centres

240 mm

(9.45)

2 - 16

Page 38

HYDAULIC DRIVE PUMP INSTALLATION

IMPORTANT NOTE:

care must be taken to ensure that a high degree of cleanliness is

observed and no dirt, moisture or foreign objects are allowed to enter

the system. When bleeding your hydraulic steering system only use a

good quality ISO10 hydraulic oil e.g. Q8 DYNOBEAR or equivalent

(10cSt at 40° C).

Drain the steering system from the lowest point, usually at a cylinder

1.

coupling.

Fit T-pieces into the port and starboard delivery lines, couple the

2.

lines to the appropriate service ports of the pump using flexible

hydraulic hose.

Couple the reservoir port to the reservoir/balance line from the helm

3.

units. A low pressure, transparent plastic tube can be used. Ensure

that this line rises gradually with no down turns.

When dealing with any hydraulic system great

Refill the steering system as recommended by the manufacturer,

4.

using clean hydraulic fluid.

Fill the cylinder by temporally removing the cylinder couplings and

5.

hoses at each end, refit the hoses securely.

Starting at the highest helm unit, fill the helm reservoir.

6.

Slowly turn the steering wheel two turns to port and then to

7.

starboard, checking the level of fluid in the helm unit reservoir at all

times.

Next turn the wheel fully in one direction until a slight pressure is felt,

8.

continuously monitor the reservoir level.

Repeat in the opposite direction and continue in this manner until

9.

topping up is no longer necessary.

2 - 17

Page 39

10.

When satisfied that the steering is fully bled manually, apply power

to the pump unit.

11.

Turning the wheel fully from lock to lock will cause the pump to self

purge.

12.

Check the fluid level in the helm unit reservoir.

13.

When the system appears to be fully functional, with the pump

running and the helm hard over check for leaks.

14.

Secure all hoses and cables to prevent damage.

2 - 18

Page 40

HYDRAULIC DRIVE PUMP INSTALLATION EXAMPLES

Single Station System Example

Dual Station System Example

2 - 19

Page 41

Dual Station System With Bypass Example

Dual Station Pressurised System Example

2 - 20

Page 42

SECTION 3

ADDITIONAL RUDDER DRIVE OPTIONS

OUTDRIVE DRIVE UNIT____________________________________2

DESCRIPTION ___________________________________________2

OUTDRIVE DRIVE UNIT DATA _____________________________2

MOUNTING BRACKET KITS _______________________________2

OUTDRIVE DRIVE UNIT - DIMENSIONS _____________________3

ROTARY DRIVE UNIT _____________________________________4

DESCRIPTION ___________________________________________4

ROTARY DRIVE DATA____________________________________4

ROTARY DRIVE UNIT DIMENSIONS ________________________5

ROTARY DRIVE SPROCKET WHEEL SELECTION_____________6

3 - 1

Page 43

OUTDRIVE DRIVE UNIT

DESCRIPTION

A compact reversible 12V DC hydraulic pump/reservoir unit with

actuating cylinder for autopilot control of outdrive power-assisted

hydraulic steering systems. Mounting brackets for attaching the cylinder

to the power steer unit depends upon engine type and are listed below.

Other brackets available on request. Mechanical installation instructions

are supplied with the brackets.

OUTDRIVE DRIVE UNIT DATA

PUMP

TYPE

SUPPLY

WEIGHT

MOUNTING BRACKET KITS

VOLVO

STANDARD

VOLVO AQ. D40 345-30-281

MERCRUISER 345-30-282

OMC 345-30-283

YAMAHA 345-30-284

Reversible DC

motor

12V DC

2.7kg

345-30-280

3 - 2

Page 44

OUTDRIVE DRIVE UNIT - DIMENSIONS

3 - 3

Page 45

ROTARY DRIVE UNIT

DESCRIPTION

A compact reversible 12V or 24V DC motor and gearbox, with an

electrically operated clutch acting on the output shaft for autopilot

control of mechanical steering systems. Connection to the steering

system is most commonly via sprocket gears and chain. These to be

supplied by the installer. As a guide the following should be considered

for the drive sprocket:

UK/Euro 13 tooth 3/8" pitch (steel)

USA 10-20 tooth (steel) for Type 40 or 41 chain.

The recommended target hardover to hardover time should be 10 to 12

seconds.

ROTARY DRIVE DATA

SUPPLY VOLTAGE

PEAK OUTPUT TORQUE Type 1

MAXIMUM SHAFT SPEED

TYPICAL POWER CONSUMPTION

CLUTCH SUPPLY

MOUNTING FOOT

WEIGHT

Type 2

The Rotary Drive Unit has a mounting foot that can be

rotated in 45° steps to allow for most installation

requirements.

12V or 24V Options

15 Nm / 132lb ins

45 Nm / 398lb ins

20 rpm

3 to 7 amps

12V or 24V , 1 amp max.

variable in 45° steps

8Kg / 17.64lbs

3 - 4

Page 46

ROTARY DRIVE UNIT DIMENSIONS

3 - 5

Page 47

ROTARY DRIVE SPROCKET WHEEL SELECTION

The number of teeth on the drive sprocket wheel must be chosen to

match each installation. The following guide may be used to select an

appropriate sprocket. The aim is to achieve a hardover to hardover time

of 10 to 12 seconds.

Note:

The Rotary drive has a speed of 20 RPM or 1 revolution per 3

seconds or 3.7 revolutions in 11 seconds

Turn the wheel from hardover port to hardover starboard and count

•

the number of turns of the driven sprocket

number of turns =N

e.g. N = 3.1

Divide 3.7 by N to give the required reduction ratio.

•

ratio = 3.7 / N

e.g.

ratio

= 1.19

Count the number of teeth on the Driven sprocket and divide by the

•

ratio to give the required number of teeth on the Driver sprocket.

driver teeth = driven teeth / ratio

e.g. if driven teeth = 25

driver teeth = 25 / 1.19 = 20.9

Select a sprocket with the number of teeth closest to calculated value

•

e.g. select driver sprocket with

20 teeth

3 - 6

Page 48

Check hardover time using formula:

•

Hardover time = Number of turns of Driven sprocket

x 3 x (Driven teeth/Driver teeth)

e.g. hardover time = 3.1 x 3 x (25/20)= 11.6

The calculated value for the hardover time using a driven sprocket with

25 teeth and a driver sprocket with 20 teeth would be suitable for this

boats steering system.

NOTE:

For larger boats a longer hardover time of up to 15 seconds

may be more appropriate, in this case choose a driver sprocket with

fewer teeth.

3 - 7

Page 49

Section 4 ACP UNIT INSTALLATION

CABLE AND CONNECTION INFORMATION..................................................... 2

EMC COMPLIANCE......................................................................................... 2

G

ENERAL WIRING NOTES

P

ILOT DRIVE UNIT CABLES

All rudder drives - heavy duty power cables................................................. 4

Rams and rotary drives - clutch/valve cables............................................... 4

ACP UNIT TERMINAL DETAILS......................................................................... 5

Wire colour coding and abbreviations..........................................................5

CLUTCH VOLTAGE SELECTION....................................................................... 6

......................................................................................2

....................................................................................4

ACP2 D

NETWORK AND ALARM CONNECTIONS......................................................... 8

REMOTE COMPASS CONNECTIONS................................................................ 9

HANDHELD, MOB AND JOYSTICK.................................................................. 10

HYDRAULIC RAM DRIVE CONNECTIONS...................................................... 11

BLUE RAM SOLENOID WIRING DETAILS ...................................................... 12

HYDRAULIC PUMP CONNECTIONS........................................................ ........ 13

STERNDRIVE DRIVE UNIT CONNECTIONS.................................................... 14

12V/24V ROTARY DRIVE CONNECTIONS ...................................................... 15

CONTINUOUS DRIVE UNIT CONNECTIONS................................................... 16

PROPORTIONAL SOLENOID CONNECTION..................................................17

DIRECT PADDLE INPUT CONNECTION..................................... ..................... 18

IP SWITCH LOCATION

...............................................................................7

LINEAR FEEDBACK CONNECTION ................................................................ 19

-B&G PADDLE CONNECTION.......................................................................... 19

NON-B&G PADDLEWHEEL CONNECTION......................... ............................ 20

4 - 1

Page 50

CABLE AND CONNECTION INFORMATION

EMC COMPLIANCE

B&G equipment is designed to be operated in leisure craft. Every care

has been taken in its design and testing to ensure compliance with the

European EMC Directive, provided it is installed and operated in

accordance with the instructions as supplied, and the units and cables

are used unmodified. Specific attention is drawn to the requirements to

maintain cable separation, where stated.

Transmissions from poorly installed or maintained Single Sideband

equipment may adversely affect the functioning of this equipment. On

vessels fitted with SSB, it is essential that such equipment is installed

following good installation practice and as recommended by the

manufacturer.

GENERAL WIRING NOTES

IMPORTANT NOTE: DO NOT APPLY POWER TO THE PILOT

SYSTEM UNTIL ALL UNITS ARE CONNECTED AND THE WIRING

HAS BEEN CHECKED.

Where spade connectors are supplied always use the correct

•

crimping tool to attach them to the cable. This is extremely important

where high currents are to be passed i.e. rudder drive unit supply

cables.

Keep supply cables as s hort as possible to reduce the possibility of a

•

voltage drop in the cables.

Always fit a fuse or circuit breaker in supply cables. A 25Amp MCB is

•

recommended for the heavy duty power cables.

Clearly identify each cable to prevent incorrect connection.

•

Cables that have a screening braid must have the screen connected

•

as shown on the connection diagrams. The method for connecting

screened cables may vary according to model and are shown in

detail on the accompanying

installation sheet: IS-0777

.

4 - 2

Page 51

All cables should be routed at least 1m / 3ft from cables or

•

components that carry or generate high currents, e.g. alternators,

starter motors and cabling, trim-tab cables, etc.

To minimise interference avoid routing Network cables alongside

•

high power radio or Radar cables, allow 3m/10ft spacing, or within

1m/3ft of engine starter motors and cables and other cables carrying

heavy current.

To prevent damage to cabling always secure in position using cable

•

clips or tie-wraps. Where cables pass through bulkheads always

protect the cable from chafing by fitting grommets.

Do not allow cables to rest in bilges where prolonged immersion in

•

water, fuel, etc. could occur.

Always fit splash covers and lids on processors, computer units and

•

junctions boxes, where supplied.

4 - 3

Page 52

PILOT DRIVE UNIT CABLES

ALL RUDDER DRIVES - HEAVY DUTY POWER CABLES

TOTAL

CABLE

LENGTH

UPTO

8m/26ft

UPTO

12m/40ft

UPTO

20m/65ft

RAMS AND ROTARY DRIVES - CLUTCH/VALVE CABLES

UPTO

9m/30ft

UPTO

15m/50ft

B&G CABLE

PART No.

135-0A-128 4.0mm² 12 AWG

Not available 6.0mm² 10 AWG

Not available 10.0mm² 7 AWG

135-0C-096 0.5mm² 22 AWG

135-0B-096 0.5mm² 22 AWG

COPPER

AREA

CABLE

GAUGE

4 - 4

Page 53

ACP UNIT TERMINAL DETAILS

NOT

USED

WIRE COLOUR CODING AND ABBREVIATIONS

R

BLK

BL

BR

G

WIRE COLOUR TABLE

Red

Black

Blue

Brown

Green

V

Y

O

W

BLANK

Violet

Yellow

Orange

White

Silver

(Not

Used)

4 - 5

Page 54

CLUTCH VOLTAGE SELECTION

NOTE:

The ACP1 Computer Unit does not have dip switches for clutch

voltage selection. The clutch output voltage is fixed at 12V and is

therefore only suitable for Size 1/12V Rams and pumps and 12V rotary

drives.

The ACP2 Computer Unit can output different clutch/solenoid voltages

depending upon the size of rudder drive unit fitted, the clutch/solenoid

valve is only required for rams or rotary drive units. This is achieved by

setting dip switches on the Computer Drive PCB. Access to the

switches is obtained by removing the 4 screws holding the Computer

PCB in the lid of the Computer Unit, carefully lift the PCB clear.

Set the switches as per the table below. The default setting is 9V,

switch 4 ON, suitable for Size 1/12V Rams and Size 2/12V Rams.

ACP 2:

DIP

CLUTCH

DRIVE

SWITCH

1 24V 24V ROTARY

2 18V SIZE 3/24V

3 12V 12V ROTARY

4 9V SIZE 1/2 12V

VOLTAGE

SIZE/TYPE

RAM

RAMS

(to save power)

4 - 6

Page 55

ACP2 DIP SWITCH LOCATION

NOTE

in the top left-hand corner of the PCB mates together properly.

: When reassembling the computer unit ensure that the connector

4 - 7

Page 56

NETWORK AND ALARM CONNECTIONS

NOT

USED

Cable 612-0A-064 (6 metres)

Cable 135-0A-096

(cut off green wire)

4 - 8

Page 57

REMOTE COMPASS CONNECTIONS

NOT

USED

4 - 9

Page 58

HANDHELD, MOB AND JOYSTICK

NOT

USED

4 - 10

Page 59

HYDRAULIC RAM DRIVE CONNECTIONS

4 - 11

Page 60

BLUE RAM SOLENOID WIRING DETAILS

The following information applies to the Size 1, Size 2 and Size 3 Blue

Rams only.

1. Remove the solenoid wiring connector by unscrewing the centre

screw.

2. Remove the screw from the connector housing.

3. Remove the rubber gasket.

4. Use a small screwdriver through the screw hole to carefully push

against the connector block. This will push the front of the connector

block out ready for wiring.

5. Run the cable through the cable entry in the cover and then connect

as follows: Pin 1 Blue Wire

Pin 2 Brown Wire

6. The cable screen must be cut back and sleeved.

Connect the two halves of the connector back together, tighten the

plastic cable clamp nut, replace the rubber seal and refit the connector

onto the solenoid using the centre screw to fully secure it.

4 - 12

Page 61

HYDRAULIC PUMP CONNECTIONS

12V

Hydraulic Pump

4 - 13

Page 62

STERNDRIVE DRIVE UNIT CONNECTIONS

4 - 14

Page 63

12V/24V ROTARY DRIVE CONNECTIONS

TS1

Heavy Duty

Power Supply

(12V OR 24V)

Black

DRIVE

SUPPLY

DRIVE

SUPPLY

IN

OUT

++

CLU

Bl

Br

ALM

Bl

Br

RBlkBlk R

TS2 TS3

Blk

Blk

Bl

HAND HELD

Y

G

V

Br

W

R

Scr

NET

G

Bl

R

Blk

Y

G

V

Br

W

R

G

W

R

Blk

BOAT

SPEED

Bl

R

MOB

G

R

Bl

RRU

TS4

O/G

O/G

Y

G

W

COMPASS

Bl

R

Bl

R

JOYSTICK

G

Red

25A CIRCUITBREAKER

*NOTE: 12VUNIT, 12V SUPPLY

24V UNIT, 24V SUPPLY

Red

Black

Rudder Reference Unit

Rotary DriveUnit

(12V OR 24V)

4 - 15

Page 64

CONTINUOUS DRIVE UNIT CONNECTIONS

These are general wiring instructions only, showing the installation of

the Computer Unit outputs to drive the continuous drive pump solenoid

valves. The continuous drive pump motor will also require a heavy duty

supply, this is not supplied however suitable units can be obtained from

your dealer. Clutch output is used to control the motor supply.

NOTE: The ram solenoid must be designed to operate at the same

voltage as the pump.

NOT

USED

Black

Brown

Blue

Relay

Continuous

Running Pump

RAM

SOLENOID

Note:

Heavy Duty Relay

Not Supplied

4 - 16

Page 65

PROPORTIONAL SOLENOID CONNECTION

These are general wiring instructions only, showing the installation of

the ACP 2 Computer Unit outputs to drive proportional solenoid valves.

The continuous drive pump motor will also require a heavy duty supply,

this is not shown on this diagram. The clutch output could be used to

control the motor supply, the clutch output is only active while the

rudder is being moved. (See Setting The Rudder Drive Type in Section

5).

TS1

DRIVE

SUPPLY

DRIVE

SUPPLY

IN

OUT

++

RBlk

CLU

Bl

Br

ALM

Bl

Br

RBlk

TS2 TS3

Blk

Blk

Bl

Bl

HAND HELD

Y

Y

G

G

V

V

Br

Br

W

W

R

R

G

NET

W

R

Blk

TS4

G

R

Blk

Bl

R

G

R

Bl

BOAT

MOB

RRU

SPEED

O/G

O/G

Y

G

W

COMPASS

Bl

R

Bl

R

JOYSTICK

G

Heavy Duty

Power Supply

Black

Circuit Breaker

Red

Black

Brown

Clutch output

if required

Red

Blue

Valve

Interface

Solenoid Valves

Port

Starboard

Rudder Reference Unit

4 - 17

Page 66

DIRECT PADDLE INPUT CONNECTION

TS1

CLU

Bl

Br

ALM

Bl

Br

HAND HELD

NET

TS2 TS3

Blk

Bl

Y

G

V

Br

W

R

G

W

R

Blk

G

R

Blk

Bl

R

G

R

Bl

BOAT

MOB

RRU

TS4

O/G

O/G

SPEED

Y

G

W

COMPASS

Bl

R

Bl

R

JOYSTICK

G

Cut back the un-used

coloured wires:

Please consult your dealer

for the specific speed sensor

and housing suitable for your vessel

4 - 18

Page 67

LINEAR FEEDBACK CONNECTION

For Linear Feedback installations, connect the wires from the sensor to

the processor using the reference table below.

Linear Feedback

Unit

Network ACP Rudder

Reference

Red Red

Black Blue

White Green

-B&G PADDLE

CONNECTION

Linear Feedback Unit

4 - 19

Page 68

NON-B&G PADDLEWHEEL CONNECTION

Using a non-B&G speed sensor (SEE PAGE 4-21).

The speed sensor must have a speed signal output from a hall-effect

device giving positive pulses of 12v maximum.

1. Locate the cable from the speed sensor to the instrument input.

2. Cut cable (if necessary) and insert a junction box (B&G part no. 28800-001). Connect like colour to like colour.

3. Use a length of 2-core screened cable (B&G part no. 135-0B-098

9m/29.5ft) to connect the speed signal and ground of the paddle

sensor to the speed input of the ACP computer unit.

4. Calibrate the speed input in accordance with the instructions given

in the COMMISSIONING (5-30) section of this manual.

4 - 20

Page 69

Non B&G Display

Non B&G

Paddle Unit

ACP UNIT PADDLE

TERMINALS (TS3)

GREEN SPEED

FUNCTION CABLE

135-0B-098

RED WIRE

SIGNAL INPUT

RED NOT USED NOT USED

BLACK GROUND BLUE WIRE

SILVER SCREEN SCREEN

4 - 21

Page 70

SECTION 5 COMMISSIONING

NETWORK PILOT COMMISSIONING______________________________3

PILOT INSTALLATION CHECK LIST ______________________________3

DRIVE UNIT & STEERING SYSTEM_______________________________3

HYDRAULIC RAMS: __________________________________________3

BLUE SIZE 3 RAM INSTALLATION CHECK LIST ___________________4

HYDRAULIC PUMPS:_________________________________________4

ROTARY DRIVES: ___________________________________________4

RUDDER REFERENCE INSTALLATION____________________________4

LINEAR FEEDBACK UNIT INSTALLATION__________________________5

COMPASS INSTALLATION______________________________________5

ELECTRONICS INSTALLATION __________________________________5

TO ENTER COMMISSIONING MODE ____________________________6

READY TO BEGIN COMMISSIONING____________________________6

TO EXIT COMMISSIONING MODE ______________________________6

RE-ENTERING COMMISSIONING MODE_________________________7

COMMISSIONING PARAMETERS ________________________________7

COMMISSIONING ALONGSIDE __________________________________8

COMMISSIONING DURING A SEA TRIAL __________________________8

COMMISSIONING ALONGSIDE __________________________________9

SELECTING THE BOAT TYPE __________________________________10

SETTING THE RUDDER END STOPS ____ ___ _____________________11

SETTING THE PORT END STOP ________________________________11

SETTING THE STARBOARD END STOP __________________________11

SETTING THE MIDSHIPS POSITION _____________________________12

SELECTING THE RUDDER DRIVE TYPE _________________________13

RUDDER HARD-OVER TIME ___________________________________14

BOAT LENGTH ______________________________________________16

SETTING IN METRES _________________________________________16

SETTING IN FEET ____________________________________________16

MAGNETIC DIP ANGLE _______________________________________17

MAGNETIC DIP ANGLE COMPENSATION CHART__________________17

SETTING THE MAGNETIC DIP VALUE ___________________________18

COMPASS ALIGNMENT_______________________________________19

VERIFY OPERATION OF RUDDER DRIVE ________________________20

COMMISSIONING SEA TRIAL __________________________________22

ENGAGING THE AUTOPILOT __________________________________23

5 - 1

Page 71

RESETTING THE RUDDER MIDSHIPS POSITION __________________23

CALIBRATION OF THE PILOT COMPASS ________________________24

CHECKING THE COMPASS OFFSET____________________________ _25

AUTOMATIC RUDDER GAIN ___________________________________25

CHECKING THE AUTOMATIC RUDDER GAIN LEARNING __________26

MANUAL RUDDER GAIN ______________________________________26

SETTING THE RUDDER GAIN MANUALLY ________________________27

RUDDER GAIN VALUE TABLE ________________________________28

BOAT LAG__________________________________________________28

SETTING THE BOAT LAG VALUE ____________________ ___________29

BOAT LAG VALUE TABLE ____________________________________29

CALIBRATION OF DIRECT SPEED INPUT ________________________30

POWER STEER MODE ________________________________________30

USE OF POWER STEER MODE _______________________________30

SELECTING POWER STEER MODE _____________________________31

5 - 2

Page 72

NETWORK PILOT COMMISSIONING

Before the Network Pilot can be used, it is necessary to set and

calibrate various parameters. This procedure is called Commissioning.

This manual covers both ACP 1 and ACP 2 Pilot systems.

PILOT INSTALLATION CHECK LIST

The check list below should be used prior to the commissioning of the

autopilot to ensure that the entire system is correct before applying

power.

DRIVE UNIT & STEERING SYSTEM

1. Drive unit securely fixed to a rigid part of the boat structure ❒

2. Gauge of power cable is appropriate.............❒

HYDRAULIC RAMS:

1. Boat end stops must limit the rudder movement, not the stroke of

the Hydraulic ram.........................................❒

2. Split pin that holds the pivot pin in the mounting foot must be secure

.....................................................................❒

3. Absence of oil leaks .....................................❒

4. Correct diameter bolt in universal ball joint, correct size hole in tiller

.....................................................................❒

5. Ram free to move side to side & up and down ❒

6. Additional reservoir fitted if black ram mounted on its side ❒

7. Reservoir at highest point if ram split...........❒

5 - 3

Page 73

BLUE SIZE 3 RAM INSTALLATION CHECK LIST

1. The base foot of the ram and pump have been firmly bolted into

position

2. The Reservoir has been fixed to a bulkhead ABOVE the Ram and

Pump.

3. The sealed reservoir transit cap has been replaced by the Breather

cap supplied.

4. The Reservoir has been switched to the ON position allowing oil to

flow between the reservoir and the pipe.

5. TAP ON POSITION IS IN LINE WITH THE PIPE. The piston rod can

now be extended or retracted and the pump run.

HYDRAULIC PUMPS:

1. Absence of oil leaks ........................................❒

2. Absence of air in the hydraulic steering ..........❒

ROTARY DRIVES:

1. No backlash or excessive slackness in chain.❒

RUDDER REFERENCE INSTALLATION

1. Base securely fixed to boat structure............❒

2. Arm securely fixed to boss............................❒

3. Ball joint securely fixed to arm......................❒

4. Linkage has not been over extended............❒

5. No slack or backlash in the linkage ..............❒

6. Linkage does not foul when rudder moved hardover to hardover

......................................................................❒

7. Arm moves through at least 90° when rudder moved hardover to

hardover (there must be at least 1 volt difference between the end

stops)............................................................❒

8. Ball joint securely fixed to quadrant/tiller.......❒

5 - 4

Page 74

LINEAR FEEDBACK UNIT INSTALLATION

1. Ensure that the Linear Feed back unit is firmly clamped to the

side of the Linear actuator using the bracket kit supplied.

2. Check to see the shaft of the Linear Drive Unit has sufficient

lubrication, use only high quality grease.

3. Ensure that the Ram stroke does not exceed the stroke of the

Linear Feedback Unit.

COMPASS INSTALLATION

1. Clear of sources of magnetic interference, including power cables to

other equipment, if in doubt check 1 metre around with small hand

compass. Look on the other side of the bulkhead! ....❒

2. Fitted as near to centre of motion of boat as other factors allow, aft

of centre preferred because usually less motion than fore of centre

.....................................................................❒

ELECTRONICS INSTALLATION

1. Cables secure..............................................❒

2. Cables undamaged......................................❒

3. No loose bits of wire.....................................❒

4. Screens connected in accordance with wiring instructions and

sleeved where appropriate...........................❒

5 - 5

Page 75

TO ENTER COMMISSIONING MODE

With the autopilot in Standby,

press

same time. The display will

change to the following display.

AUTO

and

key at the

OFF

READY TO BEGIN COMMISSIONING

TO EXIT COMMISSIONING MODE

Press the RED

OFF

key.

5 - 6

Page 76

RE-ENTERING COMMISSIONING MODE

When the autopilot has been

commissioned it is possible to

change the values that have been

set by pressing the

OFF

will now show

the

parameter to be changed.

keys together. The display

COMMISN

SETUP

key to select the

AUTO

and

. Use

COMMISSIONING PARAMETERS

The following is a list of the parameters that have to be set, they are

selected by pressing the

BT TYPE -Select boat type: Sail, Power P, Power D

SET RDP -Rudder end stop Port

SET RDS -Rudder end stop Starboard

SET RDM -Rudder Mid position

DRIVE A -Rudder drive type selection

ST RDT -Rudder Hard-over time

BLN10.0M -Boat waterline length in Metres

SETUP

key while in Commissioning mode.

BLN 32F -Boat waterline length in Feet

BLG 0.3 -Boat lag value

DIP 0 -Magnetic Dip Angle compensation

SWING -Compass Deviation Correction

CMP 000º -Compass alignment correction

RGN 0.50 -Rudder gain value

SC 6.25 -Speed sensor calibration

POWER -Power steer mode

The procedures for commissioning can be divided into two sections.

The first to be carried out alongside and the second to be carried out or

checked during the course of a sea trial. The order in which the

commissioning procedures are carried out is not necessarily the order in

which they appear when the

the key until the one that is required is displayed.

SETUP

key is pressed, continue pressing

5 - 7

Page 77

COMMISSIONING ALONGSIDE

Set the following parameters prior to a sea trial.

BT TYPE Select type of boat

SET RDP Rudder end stop Port

SET RDS Rudder end stop Starboard

SET RDM Rudder Mid position

DRIVE A Select the rudder drive type

ST RDT Rudder Hard-over time

BLN10.0M Boat waterline length in Metres (or Feet)

BLN 32F Boat waterline length in Feet

DIP 0 Magnetic Dip Angle correction

CMP 000º Compass alignment correction

POWER Power steer mode to verify that the autopilot can drive the

rudder

COMMISSIONING DURING A SEA TRIAL

The following parameters should be set and checked during the initial

sea trial.

SET RDM Rudder Mid position (reset)

SWING Internal Compass Deviation Correction

BLG 0.3 Boat Lag value

RGN 0.50 Rudder Gain value

SC 6.25 Speed sensor calibration Hz/Knot (availability is software

version dependant)

POWER Power steer mode

5 - 8

Page 78

COMMISSIONING ALONGSIDE

The following commissioning parameters will be set in this section of

commissioning:

1. BT TYPE

2. SET RDP Rudder end stop Port

3. SET RDS Rudder end stop Starboard

4. SET RDM Rudder mid position

5. DRIVE A

6. ST RDT Rudder Hard-over time

7. BLN10.0M Boat waterline length in Metres

8. BLN 32F Boat waterline length in Feet

9. DIP 0 Magnetic Dip Angle correction

10. CMP 000º Compass alignment correction

11. POWER Power steer mode to verify that the autopilot can

drive the rudder

Select type of boat

Select the rudder drive type

5 - 9

Page 79

SELECTING THE BOAT TYPE

There are three selections available:

SAIL

For all sail boats.

POWER D

POWER P

For power boats with planing hulls.

Press

SETUP

key, select

BT TYPE

.

For power boats with displacement.

Press

ENTER

key.

Display

flashes.

Use

to select

▼

the boat

type.

▲

or

Press the

ENTER

key to

memorise

the setting.

5 - 10

Page 80

SETTING THE RUDDER END STOPS

Before the Network PILOT can be used it must know the position of the

rudder end stops.

SETTING THE PORT END STOP

Press

SETUP

key, select

RDP

SET

Move the

rudder to hard

over port

position.

Press

to set

ENTER

PORT

end stop, the

display

confirms

setting is

successful.

SETTING THE STARBOARD END STOP

Press

SETUP

key, select

RDS

.

SET

Move the

rudder to hardover starboard

position.

Press

to set

ENTER

STBD

end stop, the

display

confirms

setting is

successful.

5 - 11

Page 81

SETTING THE MIDSHIPS POSITION

Press

key, select

RDM

SETUP

.

SET

Move the

rudder to the

amidships

position.

Press

to set the

position, the

display

ENTER

MID

confirms

setting is

successful.

5 - 12

Page 82

SELECTING THE RUDDER DRIVE TYPE

Depending upon the type of rudder drive unit fitted the PILOT controls

the rudder drive motor in different ways, this optimises the autopilot

steering response.

There are three selections available:

1. DRIVE A

voltages.

2. DRIVE B

manufactures.

3. DRIVE C

Press

SETUP

key, select

DRIVE A

.

Ram drives, Hydraulic pumps, Rotary drives, all sizes and

Pedestal drive motors fitted by some steering gear

Outdrive drive units and Continuous drive units.

Press

ENTER

key. The

display

flashes.

Use ▲ or

to select

▼

the drive

type.

Press

ENTER

key to

memorise

the setting.

5 - 13

Page 83

RUDDER HARD-OVER TIME

To finish the rudder end stop commissioning procedure the autopilot

must calculate the rudder hard-over port to hard-over starboard time.

The following points must observed before carrying out the procedure:

1. If the boat is equipped with hydraulic power assisted steering the

engines must be running during setting the rudder end stops.

2. The rudder hard-over to hard-over time can only be calculated

with the boat stationary.

If during timing the display shows the error message

ERR 18

,

check:

The boat speed is less than 3 knots.

•

The rudder reference unit must move through an angle of at least 90°

•

when the wheel is turned from hardover to hardover.

The output variation from the rudder reference unit is greater than 1

•

volt from hard-over port to hard-over starboard. Refer to Section 1

Rudder Reference Unit for installation details and check the

installation.

The separate power supply to the ACP control unit is switched on.

•

5 - 14

Page 84

Press the

SETUP

display

RDT

.

key to

ST

Press

ENTER

key, the

autopilot will

drive the rudder

to the port end

stop position.

Then it will

measure the

time taken from

port to

starboard and

back, coming to

rest in the

midships

position.

During the

timing

calculation,

the autopilot

display will

show

WAIT

.

The Rudder

Angle Bar

Display now

indicates

rudder angle,

check that it

indicates

correctly.

5 - 15

Page 85

BOAT LENGTH

Boat waterline length must be entered into the autopilot for it to steer

accurately. This value can be entered in Metres or Feet.

SETTING IN METRES

Press

Press

Adjust the

Press

SETUP

key to

select

BLN10.0M

ENTER

key.

Display

flashes.

.

SETTING IN FEET

Press

SETUP

key to

select

.

32F

BLN

Press

ENTER

key.

Display

flashes.

value,

= value

▲

up

= value

▼

down

Adjust the

value,

= value

▲

up

= value

▼

down

ENTER

key, the

new value

is

memorised

.

Press

ENTER

key, the

new value

is

memorised

.

5 - 16

Page 86

MAGNETIC DIP ANGLE

BOATS FASTER THAN 20 KNOTS ONLY

All magnetic compasses are effected by ‘Northerly turning errors’ in the

Northern Hemisphere or ‘Southerly turning errors’ in the Southern

Hemisphere, which increase with boat speed and magnetic dip angle in

higher latitudes. These can cause heading instability at boat speeds

greater than 20 knots when steering with an autopilot. By entering the

dip value indicated on the compensation chart, the autopilot will be able

to correct for these errors and improve the heading stability. Use the

minimum value necessary to stabilise the heading.

MAGNETIC DIP ANGLE COMPENSATION CHART

5 - 17

Page 87

SETTING THE MAGNETIC DIP VALUE

Press

SETUP

key, select

DIP 0

.

Press

ENTER

key,

Display

flashes.

Adjust the

value,

= value

▲

up

= value

▼

down

Press

ENTER

key,

the value

is

memorised

.

5 - 18

Page 88

COMPASS ALIGNMENT

The Compass Alignment electronically compensates for the

misalignment between the autopilot's fluxgate compass and the Earth's

magnetic field. Use the following procedure:

The boats actual heading must be known, use a compensated bowl

1.

compass or hand-held compass for reference.

Enter the actual heading to correct the misalignment.

2.

For Example:

The boats actual heading is Due North, 000.

•

The autopilot display is indicating West, 270.

•

Enter the Compass Alignment value of 000.

•

Compass Offset should be checked during a sea trial to ensure that it

has been entered accurately.

Press

SETUP

key, select

CMP

.

Press

ENTER

key,

Display

flashes.

Adjust the

value,

= value

▲

up

= value

▼

down

Press

ENTER

key, the

value is

memorised

.

5 - 19

Page 89

VERIFY OPERATION OF RUDDER DRIVE

Power Steer mode can be used to verify that the Rudder Drive is

•

operating correctly.

Turn the wheel so the rudder is in the midships position (if possible).

•

NOTE:

When the

AUTO

position it was in when

key is pressed the rudder will return to the

POWER

set at the midships position then

Press

SETUP

key, select

POWER

With the

rudder

amidships.

.

Press

AUTO

to engage

power

steer.

key

Use the

or

<10

keys to

move the

rudder

to port or

starboard

for each

press.

steer was engaged. If the rudder was

AUTO

key will return it to that position.

Use the <1

10>

or 1> keys

to move

the rudder

3

º

0.6

º

to port

or

starboard

for each

press.

5 - 20

Page 90

It is now necessary to carry out a Sea Trial to finish the autopilot

Commissioning.

IMPORTANT NOTE:

Until all parameters have been set or checked

the autopilot should not be used to steer the boat.

5 - 21

Page 91

COMMISSIONING SEA TRIAL

The commissioning sea trial should be carried out in open water on a

calm day. The procedures for the remainder of the commissioning

involve continual course and speed changes. It is very important to

maintain a constant lookout at all times. Use proper seamanship when

clearing turns to ensure the commissioning is carried out safely.

The autopilot will be initially operating from the factory default values for

Boat Lag (

B LAG

) and Rudder Gain (

R GAN

), these are different for

sail or power boats. During the sea trial the Pilot learning algorithm will

automatically set and adjust the value for Rudder Gain. The values for

boat lag and rudder gain will be checked and adjusted to finely tune the

autopilot steering performance when necessary. The default values are

automatically set depending upon the type of vessel by the setting

BTYPE

.

IMPORTANT NOTE

On the initial sea trial

•

Always maintain a proper lookout.

•

If in doubt, disengage the autopilot with the red OFF key on any Pilot

•

DO NOT EXCEED 15 KNOTS

.

Display or Hand-held Controller, and return to manual steering.

The following parameters should be set and checked during the initial

sea trial.

SET RDM Rudder mid position (reset)

SWING Internal Compass Deviation Correction

BLG 0.3 Boat Lag value

RGN 0.50 Rudder Gain value

SC 6.25 Speed sensor calibration

POWER Power steer mode

5 - 22

Page 92

ENGAGING THE AUTOPILOT

Steer the boat onto a suitable heading, allow time for the boat to

1.

settle on this course.

Select autopilot mode

2.

Press

3.

Controller.

The autopilot will now be steering the boat on the selected heading.

4.

Alter course in multiple increments using the 10º and 1º course

5.

change buttons on any Network Pilot Display or Hand-held

Controller.

Press the red

6.

manual steering.

AUTO

key on any Network Pilot Display or Hand-held

OFF

COMP

key to disengage the autopilot and return to

(compass) with the

MODE

key.

RESETTING THE RUDDER MIDSHIPS POSITION

Due to hull design and steering characteristics the best rudder midships

position can only be set when underway at normal cruising speed.

Adjust the midships position as follows.

Steer the boat into the wind.

•

Boats with twin engines must have the engine revs balanced.

•

Boats with trim tabs must have them in the normal cruising position.

•

Enter commissioning mode by pressing

•

AUTO

and

OFF

keys.

5 - 23

Page 93

Press

SETUP

key, select

RDM

.

SET

Move the

wheel to the

midships

position. Check

that the boat

settles onto a

steady, straight

course.

Press

ENTER

to reset the

midships

position, the

display

confirms the

setting is

successful.

CALIBRATION OF THE PILOT COMPASS

This procedure will automatically correct the autopilot's compass for any

deviation errors. It should be carried out in open water, preferably on a

calm day, with minimal wind and waves.

Press

1.