Page 1

8

027908 422187

QUADRO COMANDO

CONTROL PANEL

CENTRALE DE COMMANDE

SELBSTÜBERWACHENDE STEUERUNG

CUADRO DE MANDOS

QUADRO DE COMANDO

D811944_03 07-08-12

88

MONTAGEANLEITUNG

ISTRUZIONI DI INSTALLAZIONE

INSTALLATION MANUAL

INSTRUCTIONS D’INSTALLATION

INSTRUCCIONES DE INSTALACION

INSTRUÇÕES DE USO E DE INSTALAÇÃO

PERSEO CBD 230.P SD

PERSEO CBD 230.P SD

Attenzione! Leggere attentamente le “Avvertenze” all’interno! Caution! Read “Warnings” inside carefully! Attention! Veuillez lire attentivement les Avertissements qui se trouvent à l’intérieur! Achtung! Bitte lesen Sie

aufmerksam die „Hinweise“ im Inneren! ¡Atención¡ Leer atentamente las “Advertencias”en el interior! Let op! Lees de “Waarschuwingen”tigre aan de binnenkant zorgvuldig!

Page 2

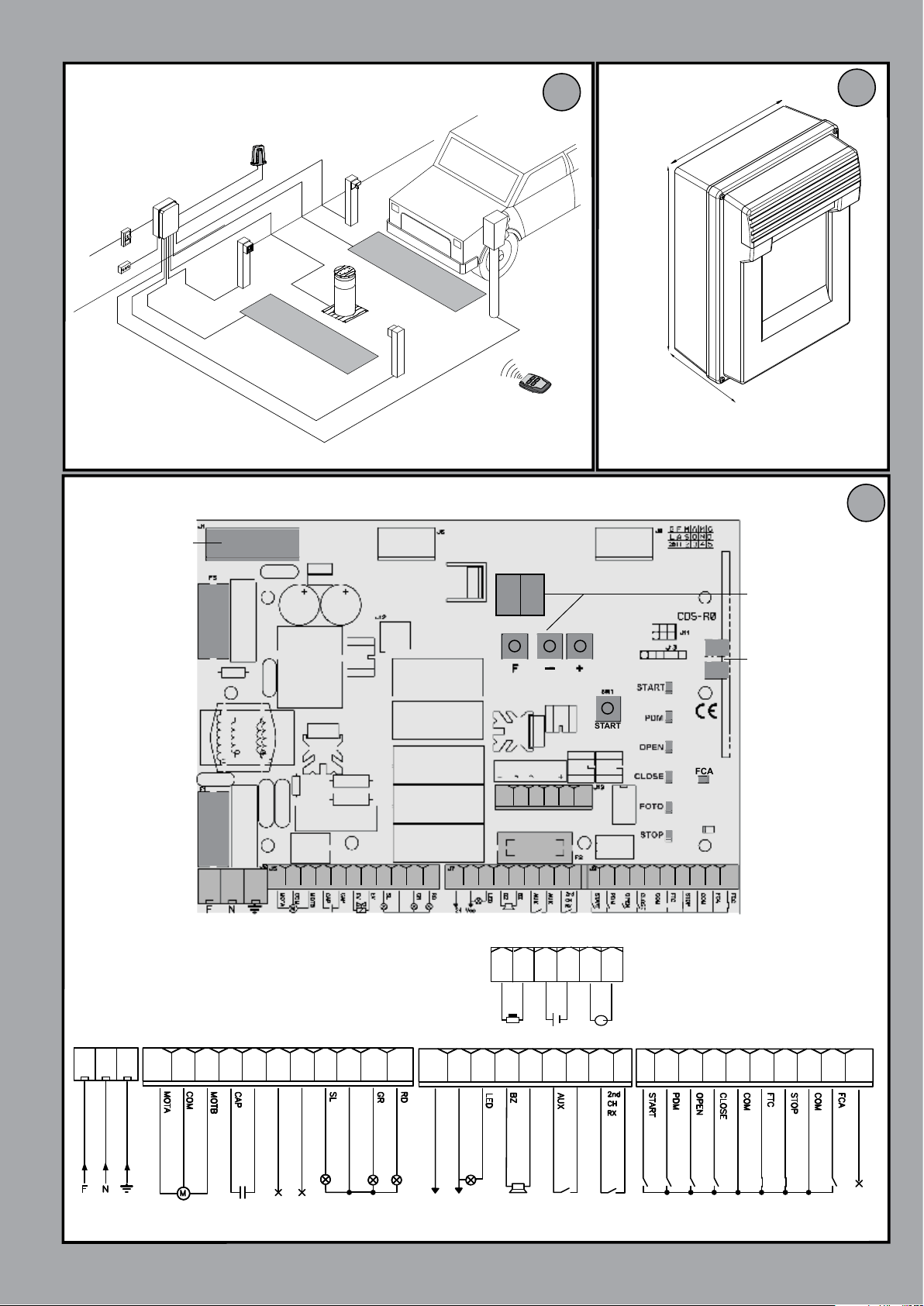

INSTALLAZIONE VELOCE-QUICK INSTALLATION-INSTALLATION RAPIDE

SCHNELLINSTALLATION-INSTALACIÓN RÁPIDA -

PREDISPOSIZIONE TUBI, TUBE ARRANGEMENT,

PRÉDISPOSITION DES TUYAUX, VORBEREITUNG DER LEITUNGEN,

DISPOSICIÓN DE TUBOS, DISPOSIÇÃO DOS TUBOS

2

3x1mm

2

RG58

2x1,5mm

2

3x1mm

2

2

2x1mm

2

16x1mm

3x1,5mm

2

4x1mm

3x1mm

A

2

INSTALAÇÃO RÁPIDA

200,05 mm

275,5 mm

126,08 mm

126,08

B

Connettore Trasformatore/

Transformer Connector/

Connecteur Transformateur/

Steckverbindung Transformator/

Conector Transformador/

Conector Transformador

F3 250mA T

F3 250mA T

F1 6.3F 230V

8. 8.

F2 1A T

START

J10

FCA

C

Display + Tasti programmazione/

Display + programming keys

Acheur + touches programmation/

Display + Programmierungstaten/

Pantalla + botones

Display mais teclas de programação

Ricevente radio integrata/

Built-in radio-receiver/

Récepteur radio intégré/

Integrierter Funkempfänger/

Receptor radio incorporado /

Receptor rádio integrado

programación/

J2 J5 J7 J9

220-230V ~

50-60Hz

2 - PERSEO CBD 230.P SD

ANT

SHIELD

BAT

EF

+

MOT

230V 40W

230V 40W

230V 40W

24 Vac 1A Max

24 Vac 0,1A Max

24 Vac 0,1A Max

Max 24V 0,5A

Max 24V 0,5A

NO NO NO NO NONC NC

Page 3

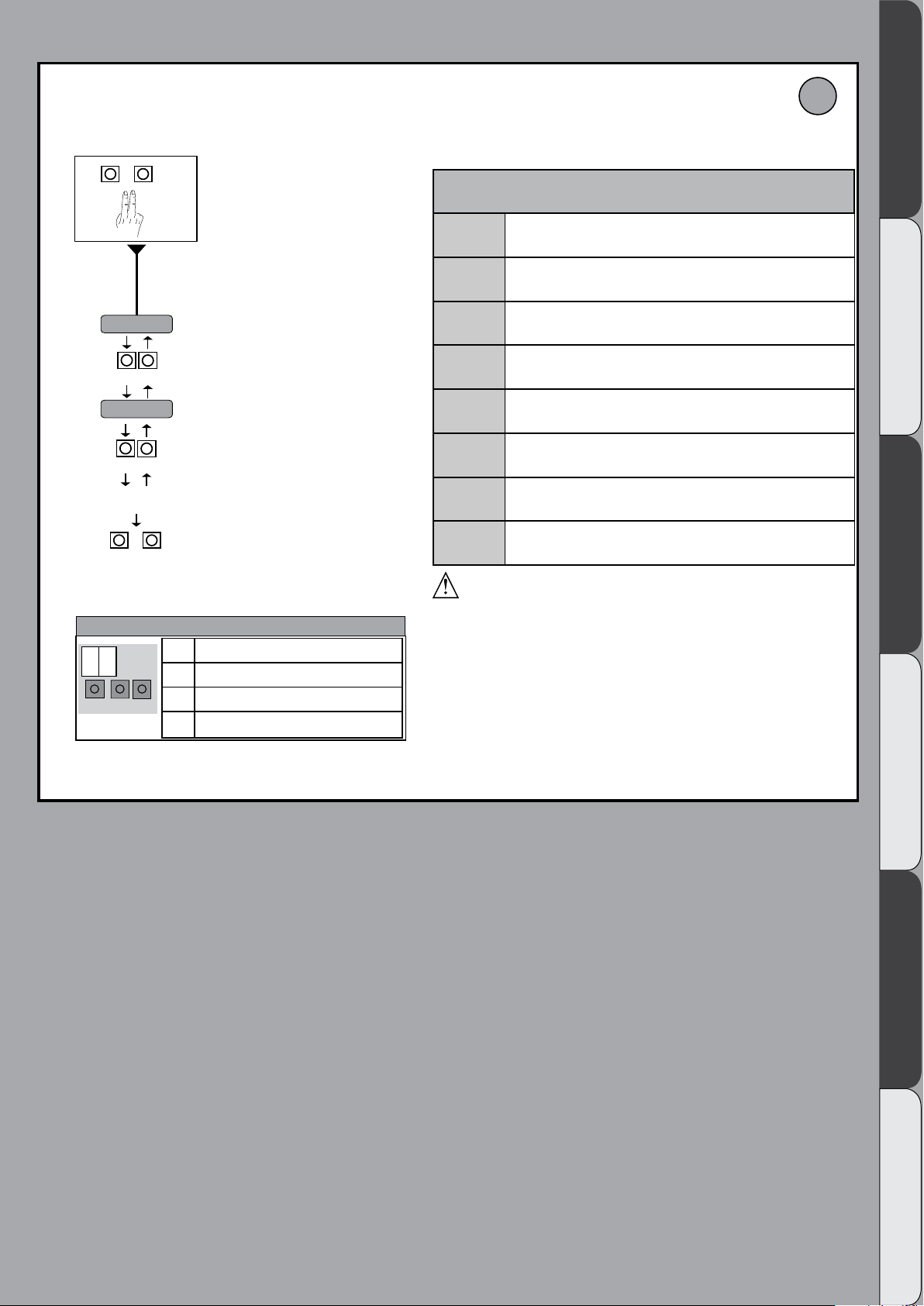

ITALIANO ENGLISH

SELEZIONE DISSUASORE - SELECT BOLLARD -

SÉLECTION BORNE ESCAMOTABLE

AUSWAHL POLLER - SELECCIÓN DISUASOR - SELEÇÃO DISSUASOR

+

F +

x 2s

G6

-

+

G8

-

+

.....H6, H8, D5.....

Salvataggio e Uscita / Save and Exit / Sauvegarde et Sortie /

Speichern und Verlassen/ Guardado y Salida /

+

+

Guardar e Sair

Scorri avanti / Scroll forward / Déler vers l’avant / Bildlauf vor /

+

Desplazar hacia delante / Navegar para frente

Scorri indietro / Scroll back /Déler vers l’arrière/ Bildlauf zurück

-

/ Desplazar hacia atrás / Navegar para trás

Accesso al menu / Call up menu / Accès au menu / Zugang zum

x2s

F + +

Menü / Acceso al menú / Acesso ao menu

Salvataggio e uscita / Save and exit / Sauvegarde et sortie /

F + +

Speichern und Verlassen / Guardado y salida / Guardar e sair

F +

LEGENDA - KEY - LÉGENDE - LEGENDE - LEYENDA - LEGENDA

8. 8.

-

F

LEGENDA - KEY - LÉGENDE - LEGENDE - LEYENDA - LEGENDA

g6

G8

H8

d5

D7

E5

E7

F7

Wählen Sie die Netzfrequenz mit dem Parameter Ht.

Seleccionar frecuencia de red mediante parámetro Ht.

Selecionar a frequência de rede mediante o parâmetro Ht.

Non disponibile, Not available, Pas disponible, Nicht verfügbar, No disponible,

Não disponível

Non disponibile, Not available, Pas disponible, Nicht verfügbar, No disponible,

Não disponível

Non disponibile, Not available, Pas disponible, Nicht verfügbar, No disponible,

Não disponível

STOPPY MBB 219-500 C.

STOPPY MBB 219-700 C.

Non disponibile, Not available, Pas disponible, Nicht verfügbar, No disponible,

Não disponível

Non disponibile, Not available, Pas disponible, Nicht verfügbar, No disponible,

Não disponível

Non disponibile, Not available, Pas disponible, Nicht verfügbar, No disponible,

Não disponível

Selezionare frequenza di rete tramite parametro Ht.

Select mains frequency using Ht parameter.

Sélectionner la fréquence du secteur avec le paramètre Ht.

D

FRANÇAIS

DEUTSCH

PERSEO CBD 230.P SD - 3

ESPAÑOL

PORTUGUÊS

Page 4

J10

ANT

SHIELD

BAT

E

+

D811944_03

EF

2nd CH

RX

Max 24V 0,5A

Max 24V 0,5A

24 Vac 0,1A Max

EF1 EF2 EF3 EF4

FCA1

NO

NO NO NO NO NC NC

FCA2

NO

FCA3

NO

FCA4

NO

BZ1 BZ2 BZ3 BZ4

24 Vac 0,1A Max

24 Vac 1A Max

230V 40W

230V 40W

230V 40W

J2 J5 J7 J9

LED1

Cap 1 Cap 2 Cap 3 Cap 4

LED2 LED3 LED4

M1 M2 M3 M4

220-230V ~

50-60Hz

4 - PERSEO CBD 230.P SD

4 - PERSEO CBD.P

STOPPY

1

STOPPY

2

STOPPY

3

STOPPY

4

Page 5

CALLING UP MENUS Fig.1

D811944_03

F

F

F

LEVEL 1º PROGRAMMING

x 2s

F

00-

/

01-

+ -

02-

00-

/

01-

+ - F +

02-

00-

/

01-

+ -

02-

p1.1

F

p1.2

F

p1.xx

F

00-

/

01-

+ -

02-

F

ENGLISH

+

p2.1

00-

/

01-

+ -

02-

F

00-

/

01-

+ -

02-

F

LEVEL 2º PROGRAMMING

F

p2.2

F

p2.xx

F

00-

/

01-

+ -

02-

F

00-

/

01-

+ -

02-

F

00-

/

01-

LEVEL 3 PROGRAMMING

F

02-

+ -

+

F +

P3.1

F

P3.2

F

P3.XX

F

+

F +

8. 8.

F

-

+

F Confirm

+ Scroll forward

- Scroll back

x2s

F

Access to programming

F + + Next programming level

ST

F

EXIT

Diagnostics

code

01

02

03

04

05

06

07

08

09

10

14

15

Description Notes

Idle

Opening

Stop opening limit switch

Stop opening

Closing

Stop closing limit switch

Stop closing

Stop due to photocell triggering

Opening due to photocell triggering

Photocell triggering pause

Maximum working time in opening reached

Maximum working time in closing reached

PERSEO CBD 230.P SD - 13

Page 6

INSTALLER WARNINGS

WARNING! Important safety instructions. Carefully read and comply with

all the warnings and instructions that come with the product as incorrect

installation can cause injury to people and animals and damage to property.

The warnings and instructions give important information regarding safety,

installation, use and maintenance. Keep hold of instructions so that you can

attach them to the technical le and keep them handy for future reference.

GENERAL SAFETY

This product has been designed and built solely for the purpose indicated herein.

Uses other than those indicated herein might cause damage to the product and

create a hazard.

- The units making up the machine and its installation must meet the requirements

of the following European Directives, where applicable: 2004/108/EC, 2006/95/

EC, 2006/42/EC, 89/106/EC, 99/05/EC and later amendments. For all countries

outside the EEC, it is advisable to comply with the standards mentioned, in addition to any national standards in force, to achieve a good level of safety.

- The Manufacturer of this product (hereinafter referred to as the “Firm”) disclaims

all responsibility resulting from improper use or any use other than that for

which the product has been designed, as indicated herein, as well as for failure

to apply Good Practice in the construction of entry systems (doors, gates, etc.)

and for deformation that could occur during use.

- Before installing the product, make all structural changes required to produce

safety gaps and to provide protection from or isolate all crushing, shearing and

dragging hazard areas and danger zones in general in accordance with the

provisions of standards EN 12604 and 12453 or any local installation standards.

Check that the existing structure meets the necessary strength and stability

requirements.

- Before commencing installation, check the product for damage.

- The Firm is not responsible for failure to apply Good Practice in the construction

and maintenance of the doors, gates, etc. to be motorized, or for deformation

that might occur during use.

- Make sure the stated temperature range is compatible with the site in which the

automated system is due to be installed.

- Do not install this product in an explosive atmosphere: the presence of ammable

fumes or gas constitutes a serious safety hazard.

- Disconnect the electricity supply before performing any work on the system.

Also disconnect buer batteries, if any are connected.

- Before connecting the power supply, make sure the product ’s ratings match the

mains ratings and that a suitable residual current circuit breaker and overcurrent

protection device have been installed upline from the electrical system. Have

the automated system’s mains power supply tted with a switch or omnipolar

thermal-magnetic circuit breaker with a contact separation that meets code

requirements.

- Make sure that upline from the mains power supply there is a residual current

circuit breaker that trips at no more than 0.03A as well as any other equipment

required by code.

- Make sure the earth system has been installed correctly: earth all the metal parts

belonging to the entry system (doors, gates, etc.) and all parts of the system

featuring an earth terminal.

- Installation must be carried out using safety devices and controls that meet

standards EN 12978 and EN 12453.

- Impact forces can be reduced by using deformable edges.

- In the event impact forces exceed the values laid down by the relevant standards,

apply electro-sensitive or pressure-sensitive devices.

- Apply all safety devices (photocells, safety edges, etc.) required to keep the

area free of impact, crushing, dragging and shearing hazards. Bear in mind the

standards and directives in force, Good Practice criteria, intended use, the installation environment, the operating logic of the system and forces generated by

the automated system.

- Apply all signs required by current code to identify hazardous areas (residual

risks). All installations must be visibly identied in compliance with the provisions

of standard EN 13241-1.

- Once installation is complete, apply a nameplate featuring the door/gate’s data.

- This product cannot be installed on leaves incorporating doors (unless the motor

can be activated only when the door is closed).

- If the automated system is installed at a height of less than 2.5 m or is accessible,

the electrical and mechanical parts must be suitably protected.

- Install any xed controls in a position where they will not cause a hazard, away

from moving parts. More specically, hold-to-run controls must be positioned

within direct sight of the part being controlled and, unless they are key operated,

must be installed at a height of at least 1.5 m and in a place where they cannot

be reached by the public.

- Apply at least one warning light (ashing light) in a visible position, and also

attach a Warning sign to the structure.

- Attach a label near the operating device, in a permanent fashion, with information on how to operate the automated system’s manual release.

- Make sure that, during operation, mechanical risks are avoided or relevant

protective measures taken and, more specically, that nothing can be banged,

crushed, caught or cut between the part being operated and surrounding parts.

- Once installation is complete, make sure the motor automation settings are

correct and that the safety and release systems are working properly.

- Only use original spare parts for any maintenance or repair work. The Firm disclaims all responsibility for the correct operation and safety of the automated

system if parts from other manufacturers are used.

- Do not make any modications to the automated system’s components unless

explicitly authorized by the Firm.

- Instruct the system’s user on what residual risks may be encountered, on the

control systems that have been applied and on how to open the system manually in an emergency. give the user guide to the end user.

- Dispose of packaging materials (plastic, cardboard, polystyrene, etc.) in accordance with the provisions of the laws in force. Keep nylon bags and polystyrene

out of reach of children.

WIRING

WARNING! For connection to the mains power supply, use: a multicore cable with

a cross-sectional area of at least 5x1.5mm

phase power supplies or 3x1.5mm

type H05 VV-F cable can be used with a cross-sectional area of 4x1.5mm2). To connect auxiliary equipment, use wires with a cross-sectional area of at least 0.5 mm

- Only use pushbuttons with a capacity of 10A-250V or more.

- Wires must be secured with additional fastening near the terminals (for example,

using cable clamps) in order to keep live parts well separated from safety extra

low voltage parts.

- During installation, the power cable must be stripped to allow the earth wire

to be connected to the relevant terminal, while leaving the live wires as short

as possible. The earth wire must be the last to be pulled taut in the event the

cable’s fastening device comes loose.

WARNING! safety extra low voltage wires must be kept physically separate from

low voltage wires.

Only qualied personnel (professional installer) should be allowed to access

live parts.

CHECKING THE AUTOMATED SYSTEM AND MAINTENANCE

Before the automated system is nally put into operation, and during maintenance

work, perform the following checks meticulously:

- Make sure all components are fastened securely.

- Check starting and stopping operations in the case of manual control.

- Check the logic for normal or personalized operation.

- For sliding gates only: check that the rack and pinion mesh correctly with 2 mm

of play along the full length of the rack; keep the track the gate slides on clean

and free of debris at all times.

- For sliding gates and doors only: make sure the gate’s running track is straight

and horizontal and that the wheels are strong enough to take the weight of the

gate.

- For cantilever sliding gates only: make sure there is no dipping or swinging

during operation.

- For swing gates only: make sure the leaves’ axis of rotation is perfectly vertical.

- Check that all safety devices (photocells, safety edges, etc.) are working properly

and that the anti-crush safety device is set correctly, making sure that the force

of impact measured at the points provided for by standard EN 12445 is lower

than the value laid down by standard EN 12453.

- Impact forces can be reduced by using deformable edges.

- Make sure that the emergency operation works, where this feature is provided.

- Check opening and closing operations with the control devices applied.

- Check that electrical connections and cabling are intact, making extra sure that

insulating sheaths and cable glands are undamaged.

- While performing maintenance, clean the photocells’ optics.

- When the automated system is out of service for any length of time, activate the

emergency release (see “EMERGENCY OPERATION” section) so that the operated

part is made idle, thus allowing the gate to be opened and closed manually.

-

If the power cord is damaged, it must be replaced by the manufacturer or their

technical assistance department or other such qualied person to avoid any risk .

- If “D” type devices are installed (as dened by EN12453), connect in unveried

mode, foresee mandatory maintenance at least every six months

WARNING!

Remember that the drive is designed to make the gate/door easier to use and

will not solve problems as a result of defective or poorly performed installation

or lack of maintenance

SCRAPPING

Materials must be disposed of in accordance with the regulations in force. There

are no particular hazards or risks involved in scrapping the automated system. For

the purpose of recycling, it is best to separate dismantled parts into like materials

(electrical parts - copper - aluminium - plastic - etc.).

DISMANTLING

If the automated system is being dismantled in order to be reassembled at another

site, you are required to:

- Cut o the power and disconnect the whole electrical system.

- Remove the actuator from the base it is mounted on.

- Remove all the installation’s components.

- See to the replacement of any components that cannot be removed or happen

to be damaged.

2

or 4x1.5mm2 when dealing with three-

2

for single-phase supplies (by way of example,

Anything that is not explicitly provided for in the installation manual is not allowed. The operator’s proper operation can only be

guaranteed if the information given is complied with. The Firm shall

not be answerable for damage caused by failure to comply with the

instructions featured herein.

While we will not alter the product’s essential features, the Firm reserves the right, at any time, to make those changes deemed opportune to improve the product from a technical, design or commercial

point of view, and will not be required to update this publication

accordingly.

D811944_03

2

.

14 - PERSEO CBD 230.P SD

AVVERTENZE PER L’INSTALLATORE D811766_06

Page 7

INSTALLATION MANUAL

1) GENERAL INFORMATION

D811944_03

The PERSEO CBD 230.P SD control board comes with standard factory settings.

Any change must be made using the programmer with built-in display.

Its main features are:

Control of up to 4 bollards: STOPPY MBB -500 C. - STOPPY MBB 219-700 C.

Note: Bollards of the same type must be used.

- Separate inputs for safety devices

- Built-in radio receiver rolling code with transmitter cloning.

The board has a terminal strip of the removable kind to make maintenance or

replacement easier. It comes with a series of prewired jumpers to make the installer ’s

job on site easier. If the terminals are being used, remove the relevant jumpers.

2) TECHNICAL SPECIFICATIONS

Power supply* 220-230V 50-60Hz (*)

Motor outpu 220-230V~; 3A max

Flashing light/trac light 220-230V~; 40W

Accessory output: 24V~; 1A max

LED Output 24V~ 0,1A max

Buzzer Output 24V~ 0,1A max

Aux Contact Max 24V 0,5A

2nd Ch rx Contact Max 24V 0,5A

Low voltage/mains insulation >2Mohm 500Vdc

Operating temperature range -20° C+ 60° C

Thermal overload protection built into motor

Dielectric rigidity mains/LV 2500Vac for 1 second

Dimensions See Fig.B

Fuses See Fig.C

3) RECEIVER TECHNICAL SPECIFICATIONS

Max. n° of radio transmitters that

can be memorized

Frequency 433.92 MHz

2048

Code by means of Rolling-code algorithm

N° of combinations 4 billion

RADIO CHANNEL FUNCTIONALITY

PR1

PR 2

Select the command from parameter

R1

Closes the relay contact on the terminal

block J4 “2nd CH RX”

(* other voltages to order)

Usable transmitter versions:

All ROLLING CODE transmitters compatible with

3) TUBE ARRANGEMENT Fig. A

4) CONTROL PANEL DIMENSIONS Fig.B

5) TERMINAL BOARD WIRING Fig. C

WARNINGS - When performing wiring and installation, refer to the standards in

force and, whatever the case, apply good practice principles.

Wires carrying dierent voltages must be kept physically separate from each other,

or they must be suitably insulated with at least 1mm of additional insulation.

Wires must be secured with additional fastening near the terminals, using devices

such as cable clamps.

All connecting cables must be kept far enough away from the dissipater.

WARNING! For connection to the mains power supply, use a multicore

cable with a cross-sectional area of at least 3x1.5mm2 of the kind provided

for by the regulations in force.

To connect the motors, use a cable with a cross-sectional area of at least 1.5mm2

of the kind provided for by the regulations in force. By way of example, if the

cable is run outside (unprotected), it must be at least type H07RN-F, while if it is

run inside (in a raceway), it must be at least type H05 VV-F.

ENGLISH

POWER TERMINAL BLOCK J2

Terminal Description

L N E

MO TA

M

COM

MOTB

CAP

CAP

EV

EV

SL

SL-COM GR-RD-COM

GR

RD

Single-phase power supply 220-230V 50/60Hz, with earth cable

L Live

N Neutral

E Earth

Motor connection

MOTA Motor opening

COM Motor Common

MOTB Motor closing

Motor capacitor

Not used

SL Flashing Light - max. 40W

SL-COM/ GR-RD-COM 230V

GR Green Light - max. 40W

RD Red Light - max. 40W

PERSEO CBD 230.P SD - 15

Page 8

POWER TERMINAL BLOCK J5

Terminal Description

24 Vac

INSTALLATION MANUAL

D811944_03

OUT24

Output 24V~, 1A MAX

24 Vac

BZ

AUX

2nd

CH

RX

INPUTS TERMINAL BLOCK J9

Terminal Description

START

PDM

OPEN

LED

BZ

AUX

COM

COM

COM

LED (Cover lights)

Self-powered output. 24V~, 100mA max

BZ (Cover buzzer)

Self-powered output. 24V, 100mA max

AUX

Free contact relay output; 500mA max, 24V / Vdc

2nd CH RX

Built-in radio receiver 2nd channel N.O. output, max. 500mA, 24 Vac/Vdc

START

N.O. input that operates the bollard’s opening and closing. The command is ignored while opening.

PDM

Programmable input. Use parameters FP, PD and AU for the setting procedure.

OPEN

N.O. input - opening only Connect clocks, daily timers or weekly timers here if wanted.

By keeping this input controlled, the automation performs the opening manoeuvre and will close automatically only

when the input is freed.

COM

CLOSE

FTC

COM

STOP

COM

FCA

COM

FCC

COM

INPUTS TERMINAL BLOCK J10.

Terminal Description

EF

+

BAT

SHIELD

ANT

CLOSE

N.O. input for closing. It allows the automation to be closed only if the safety devices have not triggered.

FTC

NC safety input (photocell). Enter the programme wanted by programming the FT parameter. It triggers only in the

closing phase; it never triggers in opening.

STOP

N.C. safety input. When it is activated, the automation is immediately stopped. During the pause time, a stop control

eliminates the automatic closing, leaving the bollard open waiting for a command.

FCA

Opening limit switch N.O. input. . When activated the opening travel nishes.

Not used

EF Electric brake output

Connection for two white power supply cables for the motor’s parking electric brake.

Activation is possible only when the bollard is completely lifted.

BAT Input for anti blackout electric brake feeder.

Permits the continuous power supply of the electric brake even without electrical energy, preventing the bollard

from lowering spontaneously in case of a blackout. Do not connect the batteries directly to this input but request

the original accessory STOPPY BAT.

ANTENNA

Antenna connection for the integrated receiver.

16 - PERSEO CBD 230.P SD

Page 9

INSTALLATION MANUAL

PR2 for CH2 output chanel

PR1

for CH1output chanel

2 blinks followed by a

pause of about 1 second.

1

1

6 blinks followed by a pause

of about 1 second.

NUMBER OF LED DL1 BLINKING SIGNALS

1

When pressing the key PR1 (for channel 1) or PR2 (for channel 2) for the first time, the receiver sets to the programming

mode. Every time the key PR1 is pressed after that, the receiver switches to the configuration for the subsequent function, that

is indicated by the number of flashings (see table).

For example, if PR2 is pressed for 4 consecutive times, the receiver stores the second channel as timer output

(4 flashings/pause/4 flashings/pause/...).

At this stage, after selecting the channel (PR1 or PR2) and the desired function, the key T (T1-T2-T3 or T4) of the transmitter

will be stored in the memory of the receiver as indicated in the table for programming.

Programming

and

Impulse output

Press the hidden key (Fig.4) on the transmitter until the

LED remains lit, then press the T key (1-2-3 or 4) on

the transmitter until it starts flashing again, wait for the

LED to go off or switch off the power. The transmitter's

T key is now memorized.

LEGEND

Constant blinking.

Automatic memory

storage only

with

impulse output

The key T1 of the transmitter is automatically stored on the output

CH1 while the key T2 on CH2. Do not store the TRC1 with this

function (key T2 is not available).

Press the hidden key (Fig.4) on the transmitter until the

LED remains lit, then press key T1 on the transmitter (if

other keys are pressed, they are ignored) until it starts

flashing again, wait for the LED to go off (10 sec) or

transmit a key to exit. T1 and T2 are now automatically

memorized on CH1 and CH2.

Standard Programming

Advanced Programming

Cancellation of

the entire

receiver memory

WARNING! This operation deletes all of the radiocontrols stored

on channel 1 and channel 2 from the memory of the receiver.

While the LED is flashing, keep buttons PR1 and PR2

on the receiver held down together for longer than 10

sec. The LED flashes very quickly.

By the time the LED goes off, all the transmitters are

deleted and you exit programming mode.

FUNCTION

FUNCTION DESCRIPTION

PROGRAMMING PROCEDURE

The associated output relay stays attracted for 1 second.

You will exit programming mode if no memorizing is performed

for 10 seconds.

X4

WIRELESS PROGRAMMING

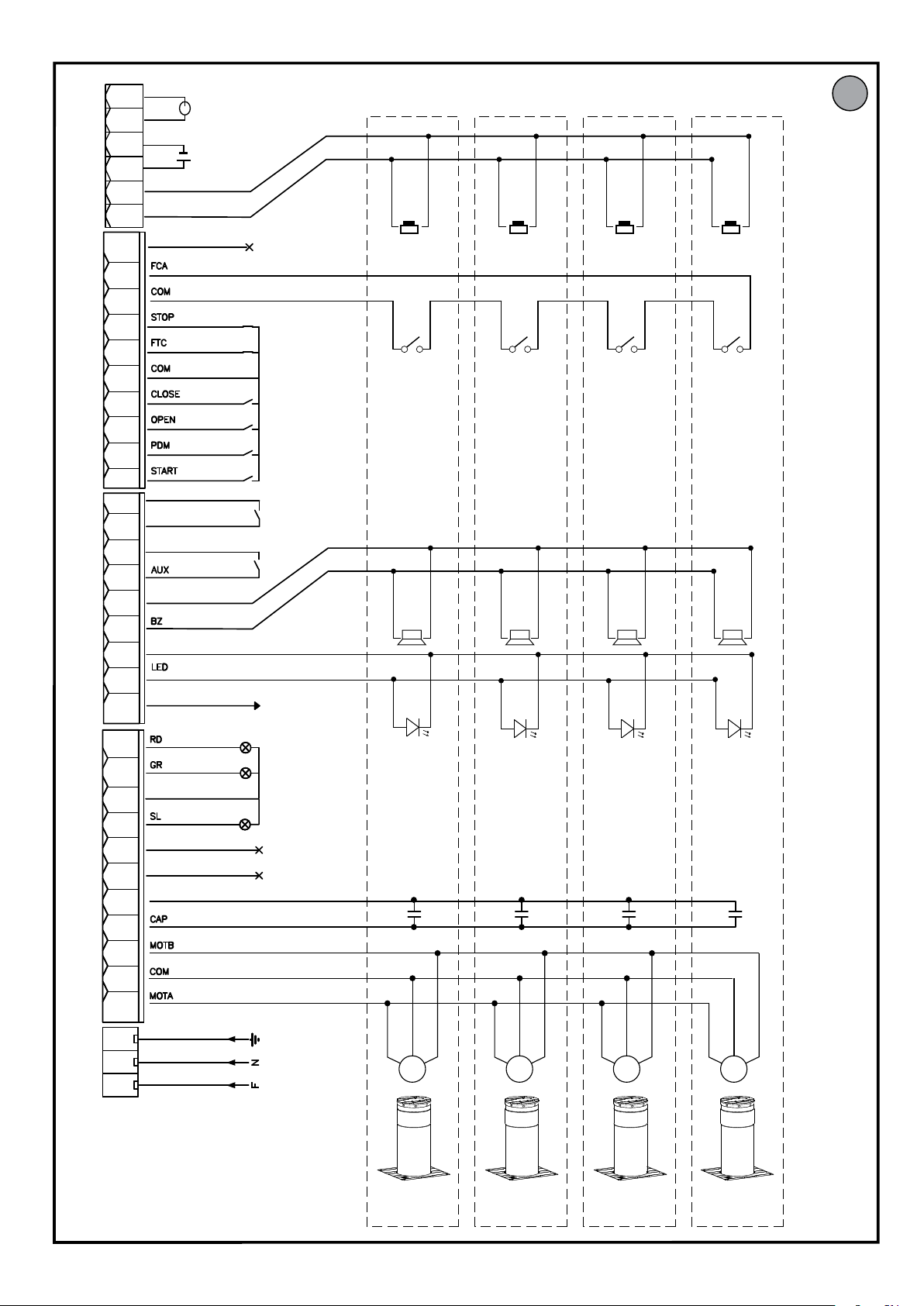

6) SELECT BOLLARD FIG.D

D811944_03

Set the type of motor connected to the board

7) CONNECTIONS FOR SIMULTANEOUS OPERATION FIG.E

The PERSEO CBD 230.P SD control unit can be used to operate up to four

bollards connected in parallel, thus achieving simultaneous operation with a

single control panel.

Use a junction box with a suitable protection rating to wire the bollards together

so as to avoid bulky connections near the control panel.

MOTOR CABLES: Connect in parallel, observing the motors’ polarity by joining

together the black cables, brown cables and blue cables.

CAPACITOR CABLES: Connect in parallel in the terminals provided

ELECTRONIC BRAKE CABLES: Connect in parallel in the terminals provided

LIGHT CABLES: Connect in parallel in the terminals provided

OPENING LIMIT SWITCH CABLES: Connect in series in the terminals provided

BUZZER CABLES: Connect in parallel in the terminals provided

8)CALLING UP MENUS : FIG.1

8.1) LEVEL 1 PROGRAMMING MENU (TABLE “A”)

8.2) LEVEL 2 PROGRAMMING MENU (TABLE “B”)

8.3) LEVEL 3 PROGRAMMING MENU (TABLE “C”)

9) TROUBLESHOOTING

If you encounter a malfunction of any kind, make sure that you have selected

the correct bollard (FIG.D).

- Lights on top cap double ashing. Indicates scheduled maintenance is due.

Check Sr, Nt and NL parameters

- Lights on top cap triple ashing and status 14 or 15 on display at end of

operation. Check the opening limit switch

10) WIRELESS PROGRAMMING

10.1) MANUAL PROGRAMMING

In the case of standard installations where no advanced functions are required,

it is possible to proceed to manual storage of the transmitters, making referen-

ce to programming table A and to the example for basic programming.

1) If you wish the transmitter to activate output 1, press pushbutton PR1, otherwise if you wish the transmitter to activate output 2, press pushbutton PR2.

2) When LED DL1 starts blinking, press hidden key on the transmitter, LED DL1

will remain continuously lit.

3) Press the key of the transmitter to be memorized, LED DL1 will ash quickly

to indicate that it has been memorized successfully. Flashing as normal will then

be resumed.

4) To memorize another transmitter, repeat steps 2) and 3).

5) To exit memorizing mode, wait for the LED to go o completely or press the

key of a remote control that has just been memorized.

IMPORTANT NOTE: ATTACH THE ADHESIVE KEY LABEL TO THE FIRST MEMORISED TRANSMITTER (MASTER).

In the case of manual programming, the rst transmitter assigns the key code

to the receiver; this code is necessary in order to carry out subsequent cloning

of the radio transmitters.

10.2) SELF-LEARNING MODE PROGRAMMING

This mode is used to copy the keys of a transmitter already stored in the receiver

memory, without accessing the receiver.

The rst transmitter is to be memorised in manual mode (see paragraph 8.4).

a) Press hidden key on the transmitter already memorised.

b) Press key T on the transmitter already memorised, which is also to be attributed

to the new transmitter.

c) Within 10 s., press hidden key on the new transmitter to be memorised.

d) Press key T to be attributed to the new transmitter.

e) To memorise another transmitter, repeat the procedure from step (c) within a

maximum time of 10 seconds, otherwise the receiver exits the programming mode.

f ) To copy another key, repeat from step (a), having waited for the receiver to exit the

programming mode (or after disconnecting the receiver from the power supply).

ENGLISH

PERSEO CBD 230.P SD - 17

Page 10

INSTALLATION MANUAL

TABLE “A” - LEVEL 1° PROGRAMMING

Parameter Denition Default

Selects the

Lo

CL

Ft

OB

PF

LD

Bu

functioning

logic.

Close input

conguration

Photocells 02

Not available

Warning ash 00

Bollard lights 00

Buzzer 01

01

00

03

Cross Out

Setting Used

00

01

02

00

01

02

00

01

02

00

01

02

03

0-30

00

01

02

03

00

01

Optional Extras Description

Hold-to-run

Semi automatic

Automatic

Standard close input The command causes the device to close

Close-when-released input

The close command acts as a release closing and safety

function.

During closure, it reopens and waits for the photoelectric

cell free commands.

When closing it reopens; reclosing after 1’’ when the photocell is disengaged

When closing it reopens; reclosing after 5’’ when the photocell is disengaged

Not available

Cover lights ashing during movement, cover lights xed

when the bollard is opened and closed

Cover lights ashing during movement and with bollard

closed, cover lights xed when the bollard is open

Cover lights always ashing

Cover lights ashing during movement and with bollard

open, cover lights xed when the bollard is closed

Buzzer o

Buzzer on during movement

The automation works when the commands are held

down. The start command opens once and closes once.

The automation works with jog commands, without

automatic reclosing. Hence, when fully open, to control

closing you need to act on the start or close command

respectively.

The automation works in jogs.When the opening

manoeuvre is completed in the standard cycle, automatic reclosing is activated after the pause time set

(parameter tP).

Close-when-released input

This mode has been developed so the bollard closes

automatically only when the vehicle has completely

passed by the photocell or magnetic detector (the

most suitable accessories for this purpose). Connect

the NO contact of the detector or photocell to the

Close contact terminals.

If the vehicle is on the detector or in front of the photocell it does not cause immediate closing but rather you

have to wait for the signal to be released.

The close command acts as a release closing and safety

function.

When closing, the close command engaging stops the

automation. When disengaged the bollard resumes

closing.

Before each start, the ashing light is activated, for the

set time, along with the AUX output, if set (AU parameter). A 0 pre-ashing is disabled.

D811944_03

Resetting

dF

tP

default parameters.

Pause time

(expressed in

seconds)

18 - PERSEO CBD 230.P SD

00

01

02

00

03

04

05

10

1-99

No resetting

Resetting the default parameters.

To reset the default parameters, set parameter dF on 1

and exit the menu’.

Not available

Waiting time before automatic closing in Automatic

mode (Lo parameter).

Page 11

TABLE “B” - LEVEL 2° PROGRAMMING

D811944_03

INSTALLATION MANUAL

Parameter Denition Default

Sr

Nt

NL

AV

Te

Cr

Request for

maintenance

Programming

maintenance

cycles in

thousands

Programming

maintenance

cycles in

millions

AUX

TERMON 00

Slow-down

speed

00

00

0.0

00

20

Cross Out

Setting Used

00

01

02

00-99

0.0-9.9

00

01

02

03

04

05

06

07

08

09

10

11

00-30

10-45

Optional Extras Description

disabled the request for maintenance is not active.

active on the congured outputs

active on the congured outputs and the bollard lights ash

twice

scheduled maintenance required

photocell triggering

$ non disponibile

PDM contact actuated The AUX output is activated if the PDM input is closed.

bollard closed The AUX output is activated when the bollard is closed.

bollard open The AUX output is activated when the bollard is open.

stop contact actuated The AUX output is activated if the Stop input is open.

warning ash

start contact The AUX output is activated if the Start input is closed.

open contact The AUX output is activated if the Open input is closed.

blackout

assistance required

at the end of the countdown, by means of counters nt

and nL, one of the programmed outputs is activated

(see parameter Av)

at the end of the countdown, by means of counters nt

and nL, one of the programmed outputs is activated

(see parameter Av) and the bollard lights ash twice.

Thanks to the combination of the two parameters

the countdown can be set after which a request for

maintenance is signalled.

Thousands can be set with the nt parameter, millions

with the nL parameter. Example: to set 275,000 maintenance manoeuvres set nL on 0.2 and nt on 75. The

value displayed in the parameters updates along with

the manoeuvres.

If the maintenance request is enabled (Sr parameter),

the AUX output is activated once the value set for

parameter nt and nl is reached.

The AUX output is activated if the photocell input is

open, photocell triggered.

The AUX output is activated as described in the Pf

pre-ashing parameter.

The AUX output is activated when the device is

switched on

If congured, the contact indicates that the electronic

control unit has detected an error in the automated device and, more specically, has detected that the limit

switches are broken. Whatever the case, the lights on

the top cap triple ash to report the error.

Sets the temperature dierence between the bollard’s

motor and the ambient temperature in centigrade

degrees.

If the parameter is not zero, the control unit will heat

the motor in order to obtain the set temperature

dierence.

Example: TE=15. The control unit will ensure that the

motor maintains a temperature that is 15° above the

ambient temperature.

By setting the parameter FP=3, it is possible to enable

or disable the Termon system, operating directly on the

PDM input.

Sets the deceleration speed at the end of the closing

manoeuvre.

The value of the deceleration speed at the end of

opening is preset by the company.

ENGLISH

PERSEO CBD 230.P SD - 19

Page 12

TABLE “C” - LEVEL 3° PROGRAMMING

Parameter Denition Default

Cross Out

Setting Used

D811944_03

Optional Extras Description

PD

Pa

CP

FP

R1

HT

PDM dynamic

input polarity

Output AUX

polarity

Commands

during pause

Special PDM

functions

Radio channel 1

command

selection

Select mains

frequency

00

00

01

00

00

01

00

01

01

00

01

00

02

03

00

01

01

02

30

20-80

Input congured as NO

Input congured as NC

Output congured as NO

Output congured as NC

OFF

ON

None Not congured.

Opening consent

Opening consent and pause time reset

TERMON enabling

Channel 1 deactivated

Channel 1 set as START

Channel 1 set as OPEN

The outputs can be congured as NO or NC, but in

the event of a power outage, the contacts will open

anyway

Depending on how the parameter is set, the automated device accepts or rejects commands during pause

time..

PDM is used to enable opening. Until it is pressed, no

opening command is accepted through the OPEN

input. If PDM is held down, no closing command is

accepted through the CLOSE input, meaning the

bollard stays open.

The PDM functions as described in point 1, but in case

of automatic logic, the pause time is reloaded.

The PDM function enables the TERMON system. Based

on the setting of the PD parameter, the closing or

opening of the contact activates or deactivates the

TERMON system. This makes it possible to interface a

schedule with a potential free contact to optimise the

heating system.

20 - PERSEO CBD 230.P SD

Loading...

Loading...