Bertazzoni HER100 6 MFE D CR T, HER100 6 MFE D NET, HER100 6 MFE D VI T, HER100 6 MFE T CR T, HER100 6 MFE T NET User Manual

...

INSTALLATION, MAINTENANCE AND USE

INSTRUCTIONS FOR

FREE-STANDING COOKERS

MAS

HER

PRO

READ THE INSTRUCTION BOOKLET BEFORE INSTALLING AND USING THE

APPLIANCE.

The manufacturer will not be responsible for any damage to property or to persons caused by

incorrect installation or improper use of the appliance.

The manufacturer is not responsible for any inaccuracies, due to printing or transcription errors, contained in

this booklet. In addition, the appearance of the figures reported is also purely indicative.

The manufacturer reserves the right to make changes to its products when considered necessary and useful,

without affecting the essential safety and operating characteristics.

3100137

1

CONTENTS:

INSTALLER TECHNICAL MANUAL…………………………………………………………………….. pg.2

APPLIANCE MAINTENANCE ....................................................................................................... pg.4

INSTALLING

RANGE COOKER .........................................

BURNER ADJUSTMENT ONLY MODEL 60X60 .....................................

........................................................... pg.5

..................................... pg.8

GAS HOB……………………………………………………………………………………………………pg.11

THE CHEF TOP ........................................................................................................................... pg.12

INDUCTION …………………………………………………………………………………………........ pg.14

SEPARATE GRILL COMPARTMENT (triple oven cavity models only)…………………………….. pg.17

OVEN… ………………………………………………………………………………………………….... pg.18

USING THE AUTOMATIC PROGRAMMER…………………………………………………………… pg. 25

OVEN TEMPERATURE GUIDE…………………………………………………………………………. pg.30

USING THE THERMOMETER…………………………………………………………………………... pg.31

CLEANING YOUR COOKER ……………………………………………………………………………. pg.32

ACCESSORIE………………………………………………………………………………………………pg.37

TROUBLESHOOTING................................................................................................................... pg.38

USEFUL TIPS................................................................................................................................ pg.40

THIS APPLIANCE HAS BEEN DESIGNED FOR NON-PROFESSIONAL DOMESTIC USE.

This appliance is marked according to the European directive 2002/95/EC

This appliance is marked according to the European directive 2002/96/EC on Waste

Electrical and Electronic Equipment (WEEE).

This guideline is the frame of a European-wide validity of return and recycling on Waste

Electrical and Electronic Equipment.

The symbol on the product indicates that this product may not be treated as household

waste. Instead it shall be handed over to the applicable collection point for the recycling of

electrical and electronic equipment.

Disposal must be carried out in accordance with local environmental regulations for waste disposal.

For more detailed information about treatment, recovery and recycling of this product, please contact your

local city council office.

Warning: If the surface is cracked, switch off the appliance to avoid the possibility of electric shock

The appliance and its accessible parts become very hot during use. Care must be careful not to touch the

heating elements. Children under 16 years old must be kept away if not constantly supervised.

The appliance and its accessible parts become very hot during use. Care must be taken not to touch the

heating elements. All children must be kept away if not constantly supervised.

This appliance can be used by persons with reduced physical, sensory or mental capabilities, provided that

they are supervised by someone who understand the use instructions and the risks involved.

Do not use steam cleaners for cleaning

Caution: make sure the appliance is switched off before replacing the bulb to prevent possibility of electric

shock

Use only the recommended thermal probe for this oven.

For cookers with electric ovens

ATTENTION: The accessible parts can become hot during use. Keep children away from the appliance.

For glass doors: Do not use abrasive cleaning products or metal spatulas with sharp edges to clean the

glass of the oven door since this could scratch the surface and the glass could break.

If the power supply cord is damaged, it must be replaced by the manufacturer, its service agent or similar

qualified person in order to avoid a hazard.

INSTALLER TECHNICAL MANUAL

2

Installer information

The installation, all adjustments, transformations and maintenance listed in this

part of the manual must be carried out only by skilled personnel.

Improper installation may cause damage to persons, animals or property, for

which the manufacture will not be held responsible.

The appliance safety or automatic adjustment devices may be changed during

the service life of the system only by the manufacturer or by the duly authorised

supplier.

Installing the cooker After having removed the various loose parts from the internal and external

packing, make sure that the cooker is not damaged. In case of doubt, do not use

the appliance and contact skilled personnel.

Keep all the dangerous packing parts (polystyrene foam, bags, cardboard,

staples, etc.) away from children.

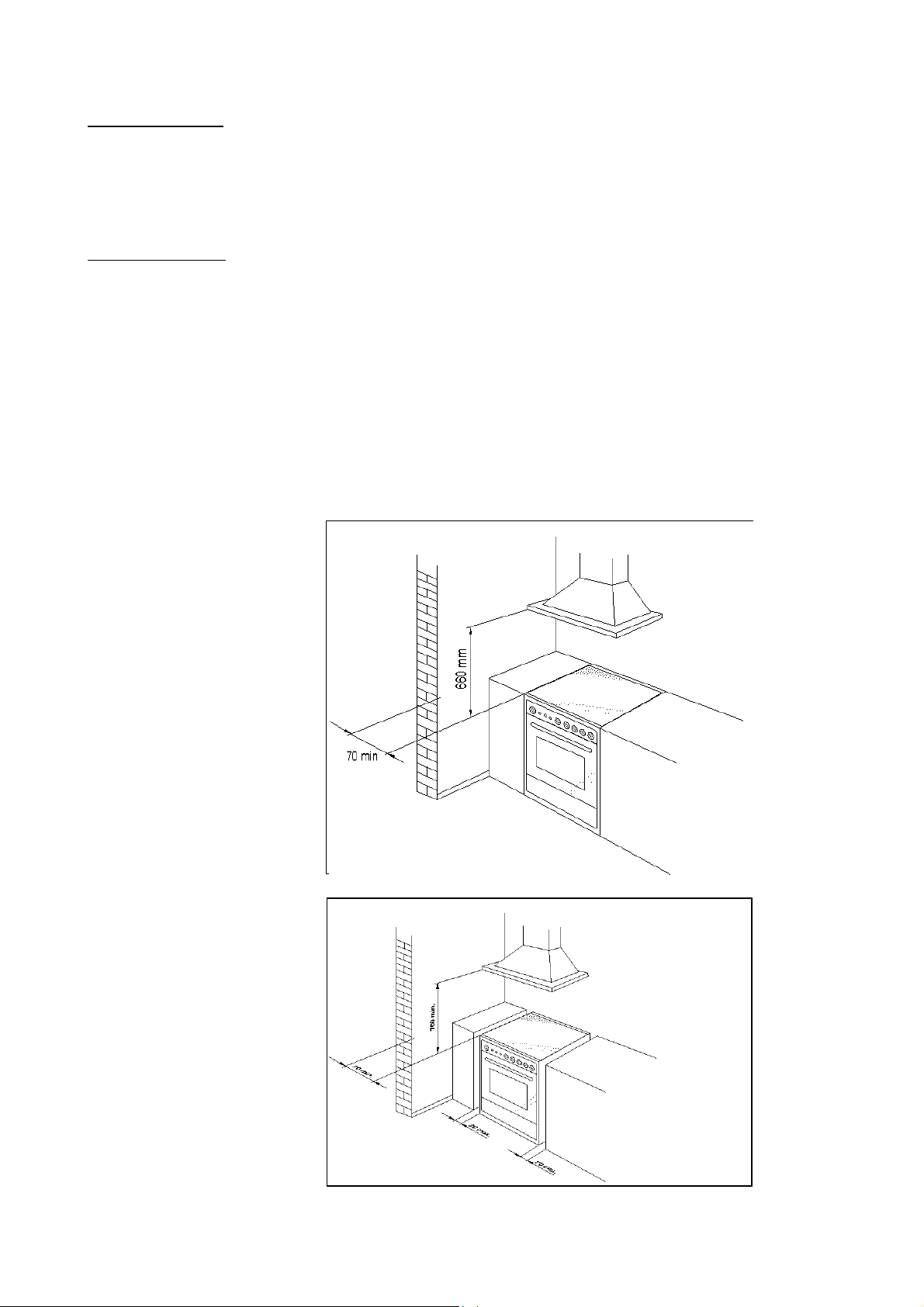

The appliance can be installed as a freestanding unit, next to a wall at a distance of

less than 20mm (Fig.1B, Class 1Installation) or inserted between two walls (see

Fig.1A, Class 2 Subclass 1 Installation). A single sidewall that exceeds the height

of the work surface is possible. This must be at a minimum distance of 70 mm from

the edge of the cooker (see Fig.1B, Class 1 Installation).

Any walls of the adjacent furniture pieces and the wall behind the cooker must be

made with heat-resistant material that can withstand a minimum over temperature

of 65 K.

WARNING: the connection to the gas network must only use metal flexible

pipes that conform with the national standards in force.

Fig.1A

Fig.1B

3

APPLIANCE MAINTENANCE

ATTENTION: IMPORTANT WARNINGS

For cookers resting on a base

ATTENTION: If the cooker rests on a base, take the measures necessary to prevent the cooker from sliding

along the support base.

For cookers with electric ovens

The unit becomes hot during use. Do not touch the heating elements inside the oven.

For cookers with electric ovens

ATTENTION: The accessible parts can become hot during use. Keep children away from the appliance.

For the food warmer compartment (or drop leaf in our case)

ATTENTION: The internal parts of the food warmer can become hot during use.

For glass doors

Do not use abrasive cleaning products or metal spatulas with sharp edges to clean the oven door’s glass

since this could scratch the surface and the glass could brea k.

Do not use steam cleaners to clean the appliance.

Replacing parts Before performing any maintenance operation, disconnect the appliance from the

gas supply and electricity network.

To replace parts such as knobs and burners, just remove them from the seats

without disassembling any part of the cooker.

To replace the oven bulb, just unscrew the protection cap that projects out ins ide the

oven.

Fig.2

WARNING: Before replacing the bulb, disconnect the appliance from the electric

power supply.

WARNING: The power cord supplied with the appliance is connected to that

appliance with an X type connection (in compliance with standards EN 60335-1, EN

60335-2-6 and subsequent amendments) for which it can be installed without the

use of special tools, with the same type of cord as the one installed.

If the power cord becomes worn or damaged, replace it based on the information

reported in types of power cords paragraph .

WARNING: If the power cord is replaced, the installer shall ensure that the ground

cable is longer than the phase cables and also shall comply with the warnings

regarding the electric connection.

To replace the power cable, lift the terminal board’s cover and replace the cable. To

access the terminal board in cookers with a 3x2.5mm² cable, the back panel on the

rear of the appliance must be removed. The power cord should be replaced only by

qualified personnel.

Before disposing of the packaging, please ensure you have removed all the

components.

The up-stand is packed separate and is taped to the back of the cooker. Other

components can be found inside the ovens. All packaging and covering films must

be removed before the installation can commence.

All electric cookers should be installed by a qualified electrician in accordance with

IEE regulations and local electricity provider rules. Building regulations must be

4

considered when undertaking any installation. Failure to install the appliance

correctly will render the warranty null and void.

Range cookers are heavy and should be handled by two people. Never lift or drag a

range by the oven handles as damage may occur.

Note: Pictures and graphics in this manual cover different models and may vary in

minor details from your cooker.

INSTALLING RANGE COOKER

Rating of Services The rating plate is visible in the storage area of the cooker and a copy is also

attached to page two of the user manual.

Before connecting the cooker, check that the requirements on the rating plate

correspond with those of the electrical system and gas supply (where applicable).

Ensure that the electrical system and isolating switches have a suitable capacity to

carry the maximum power as indicated on the rating plate.This chart can be used as

a guide to the electrical supply ratings.

Table N°1

MCB size for dedicated

Cooker model Type

60 cm single oven Gas hob top 13 AMP MCB

*60 cm single oven Induction hob top 32 AMP MCB

60 cm single gas oven Gas hob top 13 AMP MCB

90 cm single hybrid oven Gas hob top 16 AMP MCB

90 cm single gas oven Gas hob top 13 AMP MCB

90 cm single oven Gas hob top 16 AMP MCB

*90 cm single oven Induction hob top 32 AMP MCB

90 cm twin oven Gas hob top 20 AMP MCB

*90 cm twin oven Induction hob top 32 AMP MCB

100 cm twin oven Gas hob top 20 AMP MCB

*100 cm twin oven Induction hob top 32 AMP MCB

100 cm XG (3 oven compartments) Gas hob top 32 AMP MCB

*100 cm XG (3 oven compartments) Induction hob top 40 AMP MCB

120cm twin oven Gas hob top + griddle 32 AMP MCB

* With diversity factor applied

cooker circuit

The cable of

alimentation

H05RR-F or H05VV-F

3X1,5

mm²

H07RN-F 3X4

H05RR-F or H05VV-F

3X1,5

mm²

H05RR-F or H05VV-F

mm²

3X1,5

H05RR-F or H05VV-F

3X1,5

mm²

H05RR-F or H05VV-F

mm²

3X1,5

H07RN-F 3X4

H05BB-F or H05SS-F

3X2,5

mm²

H07RN-F 3X4

H05BB-F or H05SS-F

3X2,5

mm²

H07RN-F 3X4

H07RN-F 3X4

H07RN-F 3X6

H07RN-F 3X4

mm²

mm²

mm²

mm²

mm²

mm²

mm²

Positioning The cooker may be installed in a kitchen or open-plan kitchen diner but not in a

room containing a bath or shower. The cooker should be positioned in an area with

good light and free from draughts.

Any shelf or unit of combustible material should be at least 660mm above the

hotplate. In addition an area of 75mm wide on either side and behind the hotplate

must be clear of any combustible materials to a height of 400mm. Units must not

overhang over the hob.

Kitchen cabinets may be fitted flush to the sides of the cooker, but to allow for

cleaning and servicing

It is recommended that a 2.5mm gap be allowed on each side so that the cooker

may be moved if necessary.

The worktop or kitchen cabinets must not protrude beyond the height of the cooker

hotplate frame.

Ventilation Your appliance is not connected to a combustion products evacuation device. Th

e room in which it is to be installed must have an air supply in accordance with

national standards. The room must have an opening window or equivalent, and

some rooms may require a permanent vent in addition to the opening window.

General guidelines: The cooker must not be installed in a bedsit room of 20m³ or

5

less. If the cooker is installed in a room with a volume of less than 5m³, then a vent

with an effective area of 100cm³ is required. If it is installed in a room with a volume

of between 5m³ and 10m³, then an air vent with an effective area 50cm³ is

necessary. If there are other fuel burning appliances in the room, please consult

national standards for guidance.

Gas connection Before connecting the appliance to the gas network, make sure that the data on the

label attached to the food warmer drawer or on the back of the cooker are

compatible with what is indicated for the gas distribution network.

A label attached to the last page of this handbook and in the food warmer drawer (or

on the back) of the appliance indicates the appliance adjustment conditions: type of

gas and operating pressure.

IMPORTANT: This appliance must be installed in compliance with current national

standards in force and used only in a well-ventilated room.

WARNING: It should be recalled that the appliance utilises a threaded 1/2" gas

cylindrical male fitting according to UNI-ISO 228-1.

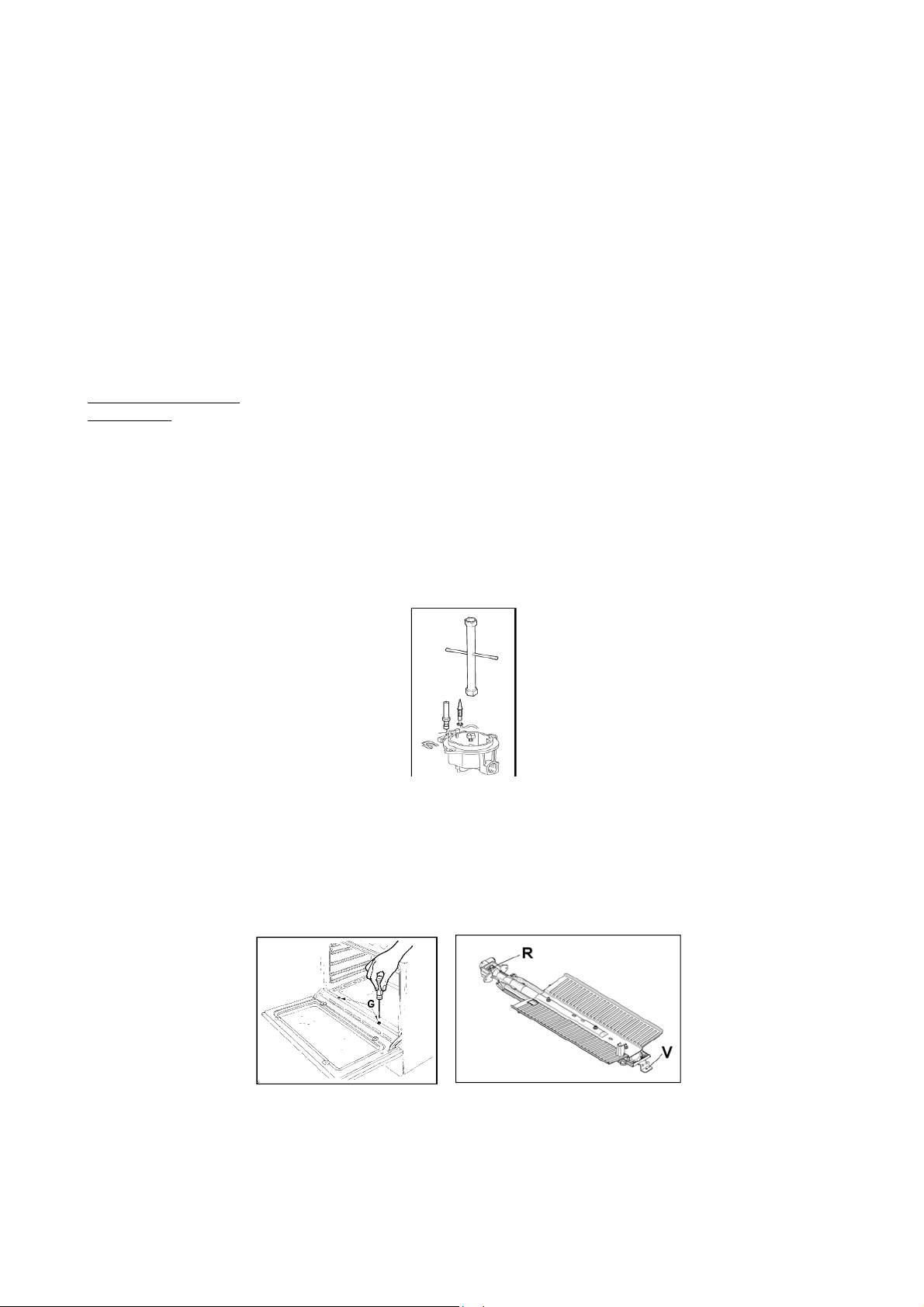

To connect the appliance to the gas network with a flexible rubber hose, a

supplemental hose nipple fitting is needed (Fig.3) which is supplied with the

appliance.

Fig.3

Electrical connection The electric connection must comply with the current leg al stand ards and

regulations.

Before making the connection, check that:

- The system electrical rating and the current outlets are adequate for the maximum

power output of the appliance (see the label applied to back of the cooker).

- The outlet or the system is equipped with an efficient ground connection in

accordance with the current legal standards and regulations. The company will not

be responsible for the non-compliance with these instructions.

letter L (phase) = brown wire;

letter N (neutral) = blue wire;

ground symbol

= green-yellow wire;

- The power cord must be positioned so that an over temperature of 75 K will not be

reached at any point.

- Do not use reductions, adapters or splitters since they might cause false contacts

and lead to dangerous overheating.

When the connection is made directly to the electric network:

- Use a device that ensures disconnection from the mains in which the contacts are

opened to a distance that permits complete disconnection according to the

conditions for over-voltage category III.

- Remember that the ground wire must not be interrupted by the circuit-breaker.

- As an alternative, the electric connection can also be protected by a high-sensitivity

residual current circuit-breaker.

- It is highly recommended to attach the special green-yellow ground wire to an

efficient ground system.

WARNING: If the power cord is replaced, the ground wire (yellow-green) connected

to the terminal, should be longer than the other wires by about 2 cm.

Types of power cords The appliance is equipped with a terminal for the electric connection placed behind,

WARNING: The power cord should be replaced only by qualified personnel.

which is accessible removing the posterior casing.

The cable of alimentation can be.

The power supply cable is suitable for appliance operating on 220-240 V~

6

ATTENTION: The appliance conforms with the regulations of directives

90/396EEC (Gas Directive) regarding gas appliances for domestic use and the

like, 73/23 (Low Voltage Directive) regarding electrical safety and 2004/108/CE,

(EMC Directive) regarding electromagnetic compatibility.

Ensure that the electricity supply is switched off before making the connection. This

appliance must be earthed.

Connection to the electricity supply must be made through the flex cable that is

already attached to the rear of the cooker. The end of the cable is tucked into the

cooker storage area.

Connection to the supply m ust be made thr ough fi xed wiring. It cannot b e co nnec ted

to a normal domestic power socket. A d ouble pole switched cooker box should be

used with contact separation of at least 3mm.

Turn on each hob zone t o check that all elem ents are f unctioning correctly. Re move

all packaging and combustible items from the oven. Turn on the oven selector switch

and thermostat knob to check that the oven is functional on all modes.

Adaptation to different Before performing any maintenance operation, disconnect the appliance from

types of gas

the gas supply and electricity network.

Replacing the gas nozzles to operate with another type of gas:

Follow the instructions below to change the burner nozzles on the work

surface:

- Isolate the appliance from the electric outlet to avoid any type of electric contact.

- Remove the grids from the work surface.

- Remove the burners.

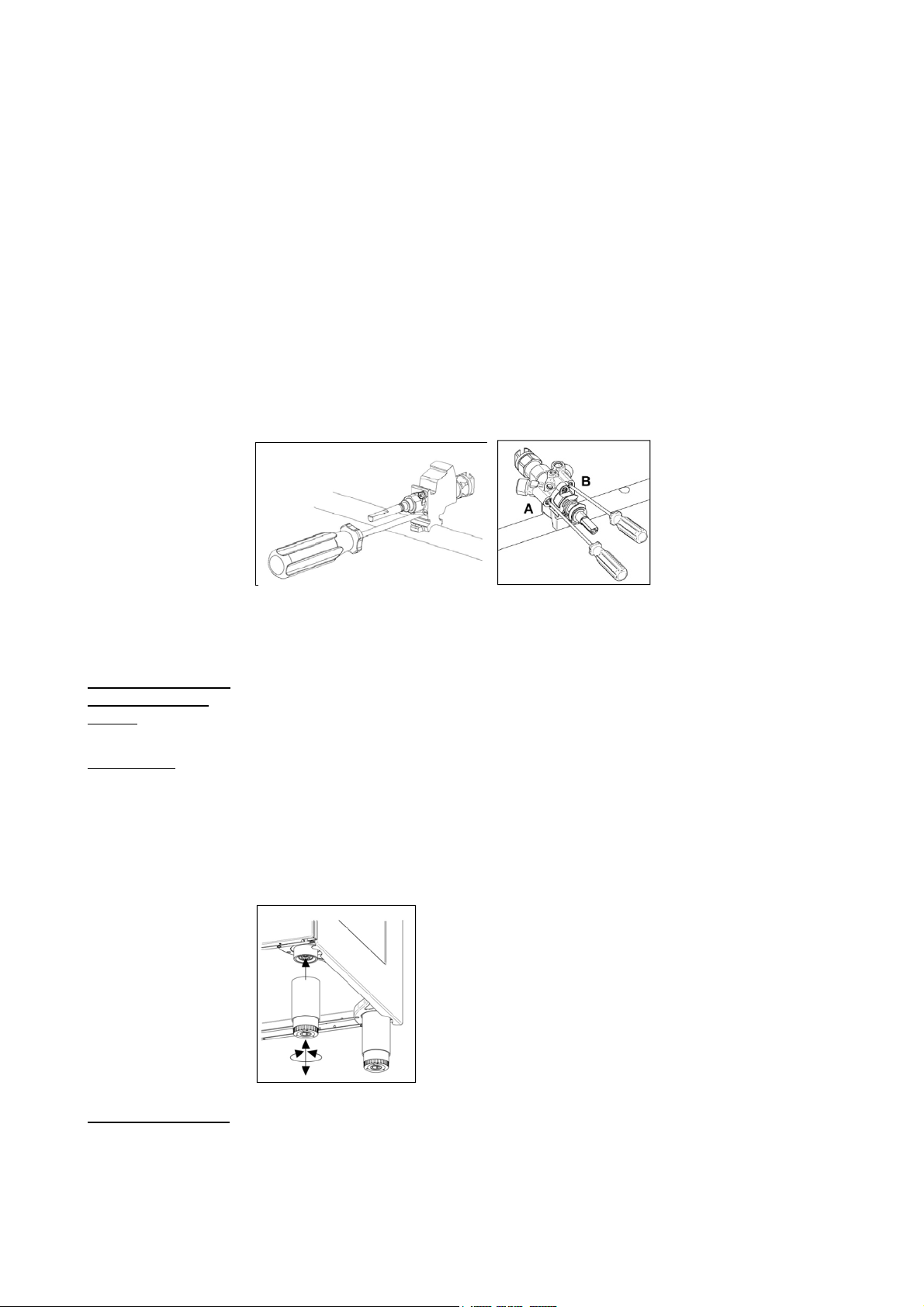

- Unscrew the nozzles using a 7 mm spanner, and replace them (Fig.4) with those

needed for the new type of gas according.

Fig 4

Follow the instructions below to change the oven burner nozzle (model 90x60

single oven):

- Remove the oven level (Fig.5).

- Loosen the screw V and pull out the burner from the support being careful not to

damage the ignition plug and the thermocouple (Fig. 6).

- Unscrew the nozzle R using a 10 mm spanner and replace it with the nozzle

needed for the new type of gas according.

Fig 5 Fig 6

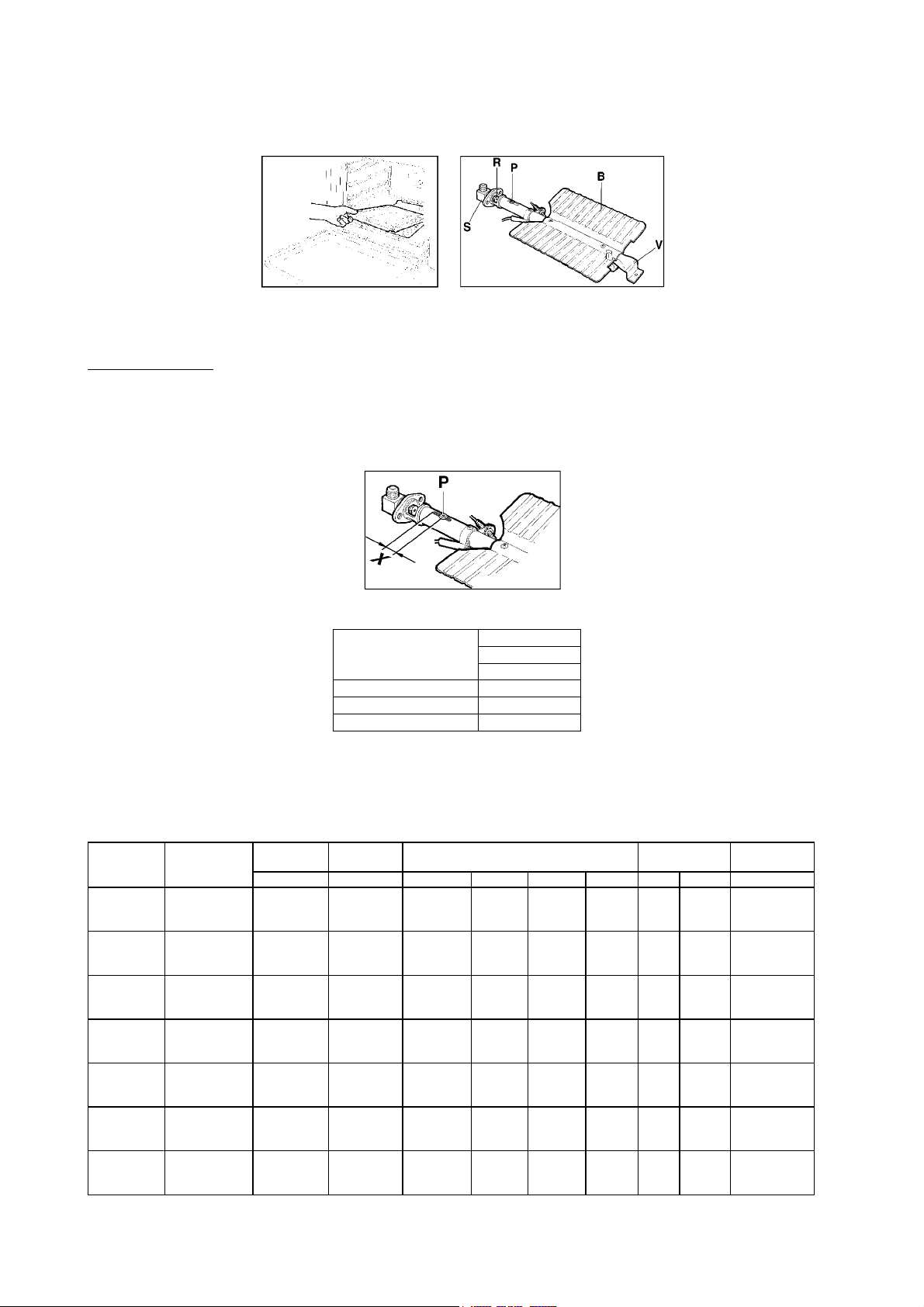

Follow the instructions below to change the oven burner nozzle (model 60x60

single oven):

Remove the oven level (Fig.7).

- Loosen the screw V and pull out the burner from the support being careful not to

damage the ignition plug and the thermocouple (Fig.7).

7

- Unscrew the nozzle R (Fig.8) using a 10 mm span ner and replace it with th e

nozzle needed for the new type of gas according.

Fig 7 Fig 8

OVEN BURNER ADJUSTMENT ONLY MODEL 60X60

Only model 60x60 1)Primary air adjustment:

Oven burner adjustment: follow the instructions below to adjust the primary air for

the over burner:

1) Remove the oven bottom.

2) Loosen the screw P and adjust the position X of the Ve nturi cone (Fig.9)

according to the measurements.

Fig 9

Burner primary air regulation (indicative)

BURNER

Type of gas Oven (mm)

M6

Natural G20 fully open

Butane G30 fully open

Propane G31 fully open

WARNING: After completing the above-mentioned replacements, adjust the

burners, as described in the pa ragraph below. Seal any adjustment and preadjustment devices. Replace the existing label with a new one corresponding to the

new gas adjustment. This label is contained in the spare nozzle bag.

Adaption to various types of gas APPLIANCE CATEGORY:

Burner Types of Gas Pressure Nozzle

Diameter

mbar 1/100 mm. g/h l/h kw kcal/h kw kcal/h 1/100 mm.

Natural G20 20 77 - 95 1 860 0,48 413 34 reg.

Auxiliary Butane G30 30 50 73 - 1 860 0,48 413 34

Propane G31 37 50 71 - 1 860 0,48 413 34

Natural G20 20 117 - 167 1,75 1505 0,6 516 36 reg.

Semi-Rapid Butane G30 30 66 127 - 1,75 1505 0,6 516 36

Propane G31 37 66 125 - 1,75 1505 0,6 516 36

Natural G20 20 129 - 286 3 2580 1,05 903 52 reg.

Rapid Butane G30 30 87 218 - 3 2580 1,05 903 52

Propane G31 37 87 214 - 3 2580 1,05 903 52

Dual Natural G20 20 70 - 76 0,8 688 0,48 413 34 reg.

Inner Butane G30 30 46 58 - 0,8 688 0,48 413 34

Propane G31 37 46 57 - 0,8 388 0,48 413 34

Dual Natural G20 20 110 - 419 4,4 3784 1,8 1548 65 reg.

Outer Butane G30 30 69 298 - 4,1 3526 1,8 1548 65

Propane G31 37 69 293 - 4,1 3526 1,8 1548 65

Natural G20 20 150 - 429 4,5 3870 2 1720 70 reg.

Oven Butane G30 30 95 327 - 4,5 3870 2 1720 70

90X60 Propane G31 37 95 321 - 4,5 3870 2 1720 70

Natural G20 20 125 - 286 3 2580 1 860 48

Oven Butane G30 30 85 218 - 3 2580 1 860 48

60X60 Propane G31 37 85 214 - 3 2580 1 860 48

Rater Capacity Reduced

II

2H3+

Capacity

by-pass

Diameter

8

Check correct operation of the ignition system and operation of burners individually

and in combination. Burner flames should be clear blue, with no yellow tipping. If the

burners show any abnormality check that burner heads are correctly located.

Note: These burners have no aeration adjustment.

Burner "MINIMUM" adjustment:

Work surface burner adjustment: follow the instructions below to adjust the work

surface burner minimum:

- Light the burner and set the knob to the MINIMUM position (small flame).

- Remove the knob of the valve that is press-fit on the rod of that valve.

- Insert a small slotted screwdriver into the hole on the valve body (Fig.10A) and

turn the choke screw to the right or left until the burner flame is adjusted to

minimum.

- For the gas valve of dual burner the choke valve is located on the valve body

(fig. 10B) , the A screw adjust the outer ring, the B screw adjust the inner ring.

- Make sure that the flame does not go out when switching quickly from the

MAXIMUM to the MINIMUM position.

Fig 10A Fig 10B

WARNING: The above-mentioned adjustment should be made only with natural gas

burners, while those operating with liquid gas the screw must be locked at the end

in a clockwise direction.

Test the operation of It should be noted that Bertazzoni SpA cannot accept any liability for direct or

the cooker before

leaving

being repaired, the appliance must always be disconnected from the mains supply; if

indirect damage caused by incorrect connection or improper installation. When

required, notify our customer service.

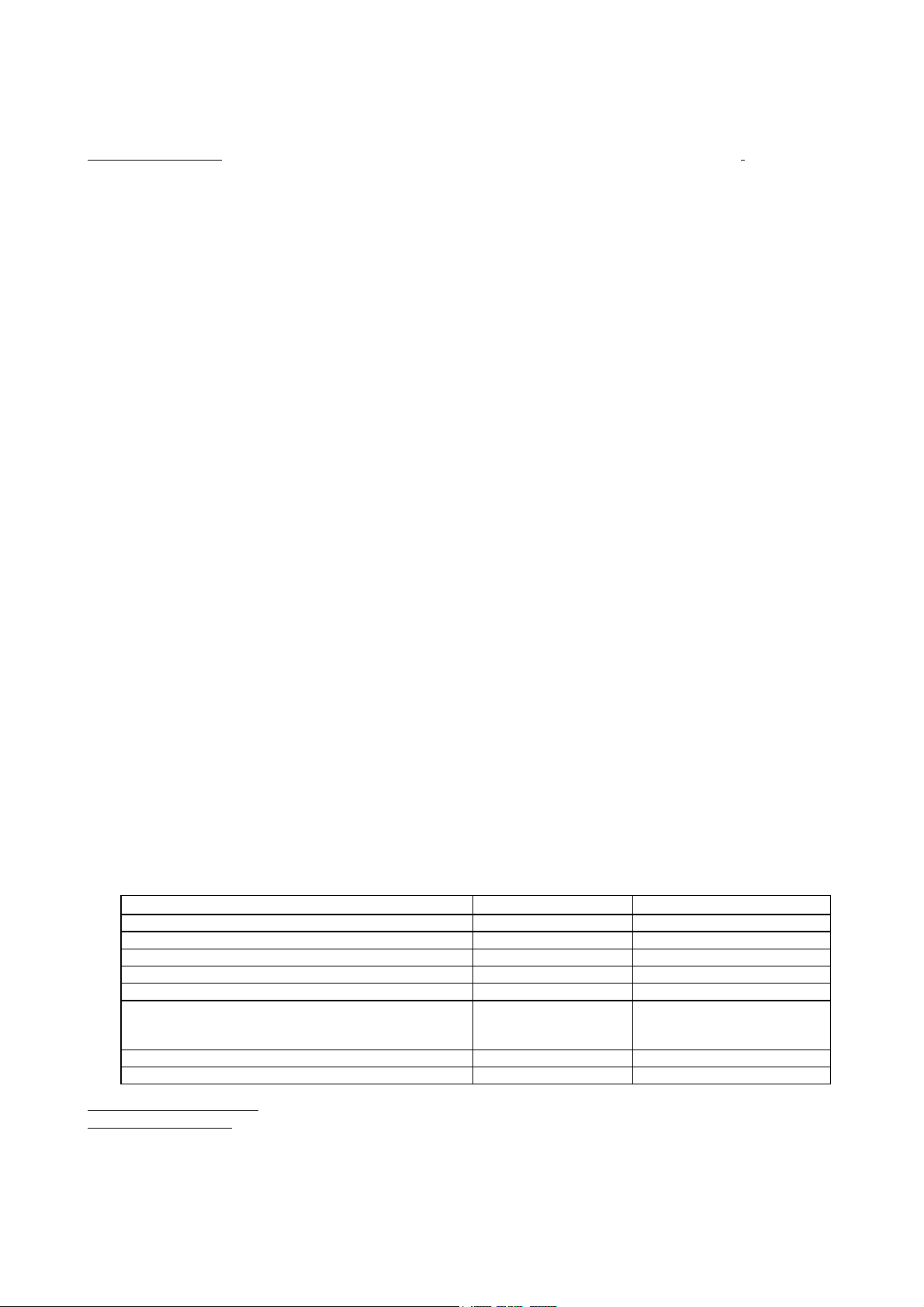

Support legs 4 support legs are supplied separately and are fitted on location to the four corners

of the lower support frame (Fig.11)

After unpacking the cooker, lift it approx 250mm to fit the legs then gently lower the

cooker to keep undue strain from the legs. It is recommended to use a lifting device

instead of tilting the unit.

Transit supports are left in situ. Ea ch leg is fi rmly pushed over one of the t ransit

supports. If the leg s are not used and the coo ker is mounted onto a pli nth, leave

transit legs in position to allow for clearance.

Fig 11

Up-stand Installation The up-stand is packaged at the bottom rear of the cooker. The up-stand is fixed

along the rear of the cooker hob. Screw fixing points for locating the up-stand are at

either end.

1. Place the up-stand on the rear of the hob, line up locating holes and secure with

the screws supplied.

9

Fig 12

Anti-tilt restraint Once legs are adjusted to the correct height, fit the anti-tilt restraint brackets. The

anti-tilt brackets must be fixed to the rear wall as shown below.

1. To calculate the position of brackets up from the floor, measure to the bottom of

the anti-tilt bracket location slots on the back of the cooker and add 32mm.

2. Secure the brackets in position on the rear wall with suitable fixings. (Note that

brackets are fixed 60mm in from the side edges of the cooker).

3. Lift the cooker into place until it sits 130mm away from the wall then gently

manoeuvre the cooker further back until the brackets are fully inserted into the rear

side of the cooker. Care should be taken to not cause damage to the flooring or to

put unnecessary strain on the legs flooring or to put unnecessary strain on the legs .

Fig 13

10

Using the gas hob As the following points:

- To light a burner, press in the control knob (Fig.14A-14B) and turn it anticlockwise, to the large flame position.

- Continue to hold the knob In until the burner lights. Adjust the flame as required,

continue to hold the knob in far 5 to 10 seconds before releasing

- The Chef Top (optional) is powered by the gas burners.

- See page 7 for usage instructions.

GAS HOB

Fig 14A Fig 14B

The dual wok burner The central burner of the dual wok burner can be used independently of the outer

burner to give further flexibility.

- To light the central burner, press in the control knob (Fig.15A-15B) and turn it

anti-clockwise to the bold single ring position

-

Continue to hold the knob in until the burner lights. Adjust the flame as required

The minimum setting is the lighter single ring position.

- To light the outer burner as well as the central burner. turn the knob to the bold

double ring. Adjust the flame as required

The minimum setting far the central and outer burner is the lighter double ring

position.

Fig 15A Fig 15B

Lighting the burners The symbol above each knob indicates which burner that knob controls.

- A flame failure (thermocouple) device on each burner acts as a safety gas cutoff in case the flame is accidentally blown out.

- A thermocouple detects the absence of a flame and stops the supply of gas.

- The thermocouple must be heated for a few seconds when the burner is ignited

before the knob is released.

To light a burner:

1 Push and turn the control knob anti-clockwise to the large flame

position. The ignition candle will spark and ignite the gas.

2 Keep the control knob pressed In for 5-10 seconds to activate the flame failure

device,

then release the knob. Adjust the flame between the large and small

flame symbols as required.

In the event of a power failure the burners can be lit with a match or gas lighter The

flame failure devices will continue to function normally.

GAS BURNER DIMENSION

Burner Diam (mm) Power Utilization

Auxiliary Ø 50 mm 1 kW Use with smaller pans for boiling and simmering and the preparation of

sauces.

Semi-rapid (and

Chef Top)

Rapid Ø 95 mm 3 Kw Use with large and medium pans of water for frying and rapid boiling.

Dual inner/outer Ø 43/140 mm 0.48-5 kW Use with woks,griddles and frying pans or for large pans and rapid

Ø 70 mm 1.75 kW Use for normal frying and boiling in medium and small pans.

boiling.

11

THE CHEF TOP

Using the Chef Top The Chef Top is manufactured from 5mm thick stainless steel designed for a high

heat retention across the plate. The very high cooking temperature makes the Chef

Top ideal for searing meats and vegetables and for oriental style recipes. Some

suggested uses include: steaks, burgers, chicken, fish and other meats, vegetables

fries,

such as peppers, mushrooms and aubergines, stir

kebabs, toasted

sandwiches, naan and pitta breads, fried and scrambled eggs, griddle cakes,

crumpets, English muffins and drop scones.

To assemble the Chef Top:

1 Remove the pan supports that cover the 2 central burners.

2 Screw the feet to the underside of the Chef Top. The two longest feet go to the

rear and the two shortest go to the front (towards the drip tray).

3 Carefully position the Chef Top onto the hob, ensuring that it is seated correctly

and resting on the stainless hob.

Care must be taken when handling the Chef Top. It’s heavy!

Please do not use over dual wok burner

To use the Chef Top:

For instructions on how to season the Chef Top, see next section. The Chef Top can

smoke during use so always turn your extractor hood on before you start cooking.

1 To light the burner. push in and turn the control knob to the large flame position.

Hold the control knob in far 5-10 seconds after the flame has lit to activate the flame

failure device, before releasing.

If the flame extinguishes wait one minute before

attempting to re-ignite.

2 Pre-heat on full power for 5 minutes.

3 Add a small amount of oil and then the food.

4 Adjust the front and back flames as required.

The Chef Top is hottest in the central front and back areas and cooler at the outer

edges. You can control the cooking temperature by moving the food to the outer

edges after the initial searing, similar to the way you would use a barbecue. To avoid

excess spitting use the minimum amount of oil when cooking on the Chef Top.

Use a spatula far turning and serving food. You can also remove any food residues

at the end of

cooking using a spatula. The high temperature of the Chef Top makes

plastic tools unsuitable for use with it. Do not be tempted to move or turn the food

too quickly or often. Wait until the food sears and is released from the cooking

surface before turning.

The following table gives a guide to cooking temperatures and times:

-

These times are purely advisory and will depend on the size and cut of the

food

- Always ensure that food (poultry and fish in particular) is cooked through before

serving.

Food Flame Cooking

Fried egg Low 3 minutes

Aubergine, onions and courgettes (sliced 5mm thick) Medium 10 minutes

Whole prawns (shell on) Medium 5 minutes

Chicken breast Low 17 minutes

Fish (200g) Low 15 minutes

Steak (2,5cm thick) High

High

High

Sauté potatoes Medium 5-7 minutes

Burgers, beef, lamb and vegetables Medium 10 minutes

Rare 2 minutes per side

Medium 4 minutes per side

Well done 6 minutes per side

Using the electric griddle Seasoning the griddle (and Chef Top)

(120cm models only)

Before using the griddle for the first time. It must be seasoned.

If the griddle has not been used for a period of time, it should be re-seasoned.

1 Clean the griddle thoroughly with hot. soapy water to remove any protective

coating.

2 Rinse with a mixture 01 1 litre water and 1 cup white vinegar .Dry thoroughly.

12

3 Pour 1 tsp vegetable oil into the centre 01 the griddle. Rub the oil aver the entire

surface of the griddle using a heavy cloth.

4 Turn the control knob to a maximum setting. Turn the heat off when the oil begins

to smoke. Allow the griddle to cool.

5 Repeat step 3. Be sure to cover the entire surface with the oil.

6 Repeat step 4. Allow the griddle to cool. Wipe the entire surface of the griddle

using a heavy cloth. Apply a very thin layer of vegetable oil. The griddle is now

ready to use.

Using the electric griddle

- Press and turn the knob (Fig.16) anti-clockwise to the selected position.

- Pre-heat at the maximum temperature for 15 minutes, then place the food on

the griddle and cook to the desired temperature.

- The activation of the griddle is shown by the indicator light which is also found

on the front panel of the appliance.

Fig 16

Griddle cooking recommendations

Food knob position Setting

Eggs 5 – 6 150°C to 160°C

Bacon; Breakfast Sausage 6 177°C to 190°C

Toasted Sandwiches 5 – 6 160°C to 177°C

Boneless Chicken Breasts 6 177°C to 190°C

Boneless Pork Chops (15mm thick) 6 177°C to 190°C

Ham Slices (15mm thick) 6 177°C to 190°C

Pancakes; French Toast 6 177°C to 190°C

Potatoes; Hash Browns 7 190°C to 205°C

Cast iron griddle A griddle is available as an optional accessory.

1 Place the griddle on top of the pan support.

To use a griddle:

2 Pre-heat the griddle on lull power tor 4-5 minutes before adding the food. Most

foods (eggs in particular) will require a small amount of oil to help prevent sticking.

Turn the food half-way through the cooking time to sear both sides. The more the

griddle is used, the better the cast iron will absorb oils, giving it a natural non-stick

finish.

13

INDUCTION

60x60 model 90x60 or 100x60 model

Fig 17A Fig 17B

Functions

: Keep Warm 42°C

: Keep Warm 70°C

1…9 : Power Level

P : Booster

A : Heating Accelerator

Hob control knob These knobs provide control of the ceramic hob's cooking zones.

The zone it controls is shown above each knob. Turn the knob to the right to set the

zone's operating power; the settings range from a minimum of 1 to a maximum of 9.

The working power is shown by a display on the hob.

Heating accelerator Each cooking zone is equipped with a heating accelerator.

This system allows the zone to be operated at peak power for a time proportional to

the heating power selected.

To start the heating accelerator, turn the knob to the left, select setting "A" and then

release. The letter "A" will appear on the display on the hob.

You now have 3 seconds to select the heating setting of your choice. Once a setting

between 1 and 9 has been selected, "A" and the chosen setting will flash in

alternation on the display. '

While the heating accelerator is in operation, the heating level can be increased at

any time. The "full power" time will be modified accordingly. If the power is reduced

by turning the knob anticlockwise, option "A" is automatically deactivated.

Power Function The power function allows the user to operate each heating zone continuously at the

maximum power for a time of no more than 10 minutes. This function can be used,

for example, to bring a large amount of water to the boil in a hurry, or to turn up the

heat under meat.

Turn the knob clockwise and set heating level 9, then use the knob to set the "P"

position and release il. "P" appears on the corresponding zone display.

After 10 minutes, the power is reduced automatically, the knob returns to the 9

setting and the "P" disappears.

However, the power function can be turned ott at any time by reducing the heating

level. .

When the power function is selected for one heating zone (e.g. the left front zone),

the power absorbed by the second zone (Ieft rear zone) might be reduced to supply

the maximum available energy to the first zone.

Consequently, the power function takes priority over the heating accelerator.

If a pan is removed from the cooking zone while the power function is on, the

function is switched off.

Holding Function The holding function keeps the temperature of the bottoms of pans at about 42°C or

(60x60 model only)

70°C . This allows foods to be kept hot with optimal energy consumption and to be

heated gently. The holding function can be kept in operation for up to 2 hours.

Bridge Function

The holding function is and is indicated by the relevant symbols on the cooking

zones.

This function allows to use the 2 cooking zones at the right at same time with the

14

(60X60model only)

same features as a single cooking zone. Booster function isn’t allowed.

1 – rotate both knobs, rear right and front right, at the same time in the P position

and keep the knobs in that position.

2 – we see that the ∏ symbol blinks in the display, then after a few seconds the ∏

symbol appears on the rear right display and the front right display shows the power

level.

3 – to control the bridge power level use the knob 4 (front right zone). If you turn the

knob 3 (rear right zone) the display shows a horizontal segment and the bridge

function ends.

HOB

ATTENTION:

Metal items such as cutlery or lids must never be placed on the surface of the hob since they may become

hot.

Cooking zones The appliance is equipped with 4/5 cooking zones having different diameters and

powers. Their positions are clearly marked by rings, while the heating power is only

released in the area shown on the ceramic hob. The 4/5 cooking zones are of HIGH LlGHT type and start to heat up a few seconds after they are switched on. The heat

level of each zone can be regulated from the minimum to the maximum setting using

the knobs on the front panel.

Underneath each cooking zone there is a coil called an inductor, supplied with power

by an electronic system, which generates a variable magnetic field. When a pan is

placed inside this magnetic field, the highfrequency currents concentrate directly on

the bottom of the pan and produce the heat needed to cook the foods.

The 4/5 lights between the cooking zones come on when the temperature of one or

more cooking zones exceeds 60° C.. The lights go out when the temperature drops

to below about 60° C.

60x60 model 90x60 or 100x60 model

Power rating (4 zones model)

Zone number: Power absorption Diameter

1 2300 W 3700 W 210 mm

2 1850 W 3000 W 180 mm

3 1850 W 3000 W 180 mm

4 1850 W 3000 W 180 mm

Normal operation: With power function:

Power rating (5 zones model)

Zone number: Power absorption Diameter

1 1100 W 1400 W 160 mm

2 1100 W 1400 W 160 mm

3 1400 W 2000 W 200 mm

4 2300 W 3000 W 250 mm

5 2300 W 3000 W 200 mm

Normal operation: With power function:

When the hob is used for the first time, it should be heated to its maximum

temperature for long enough to bum off any oily residues left by the manufacturing

process, which might contaminate foods with unpleasant smells.

Types of pans This type of appliance can only operate with pans of special kinds.

The bottom of the pan must be iron or steel/iron to generate the magnetic field

15

necessary for the heating process.

Vessels made from the following materials are not suitable:

glass;

porcelain;

pottery;

steel, aluminium or copper without magnetic bottom;

To check that a pan is suitable, simply place a magnet close to its bottom:

if the magnet is attracted, the pan is suitable for induction cooking. If no magnet is to

hand, put a little water in the pan, place it on a cooking zone and switch it on. If the

symbol appears on the display instead of the power, the pan is not suitable.

The pans used for cooking must have certain minimum diameters to ensure

satisfactory operation.

Pans larger than the cooking zones can also be used, but it is important to ensure

that the bottom of the pan does not touch other cooking zones, and that it is always

centred over the perimeter of the cooking zone (Fig.18A-18B).

Fig 18A Fig 18B

Use only vessels specially designed for induction cooking, with thick, completely flat

bottom; if these are not available, the pans used must not have crowned (concave or

convex) bottom (Fig.19).

Fig 19

Pan present device Each cooking zone is equipped with a "pan present" device, which ensures that

cooking cannot start unless a suitable pan is present on the cooking zone and

properly positioned.

If the user attempts to switch on the cooking zone with the pan not positioned

properly or with a pan which is not of suitable material, a few seconds after the zone

is switched on the symbol will appear to warn the user that an error has been

made.

Residual heat Each cooking zone is equipped with a device which warns of residual heat. After any

cooking zone is switched off, a flashing ‘H’ may appear on the display. This warns

that the cooking zone concerned is stili very hot.

Locking-out the hob When not in use, the hob can be "locked out" to prevent children from accidentally

switching it on.

With the cooking zones off, turn the knobs of zones 1 and 2 to the left

simultaneously until ‘’L’’ appear on the power

display and then release the knobs.

To deactivate it, repeat the same procedure: the cooking zone displays will stop

displaying the ‘’L’’, indicating that the cooking zone lock-out function has been

deactivated.

16

Attention:

Take care not to spill sugar or sweet mixtures onto the hob during cooking, or to

piace materials or substances which might melt (plastic or aluminium foil) on it; if this

should occur, to avoid damage to the surface, tum the heating off immediately and

clean with the scraper supplied while the cooking zone is stili warm. If the ceramic

hob is not cleaned immediately, residues may form which cannot be removed once

the hob has cooled.

Important!

Keep a close eye on children because they are unlikely to see the residual heat

warming lights. The cooking zones are stili very hot for some time after use, even if

they are switched off. Make sure that children never touch them.

WARNING: Under no circumstance use aluminium foil or plastic containers to hold

the food while cooking on a glass-ceramic hob.

WARNING: Do not touch the cooking area as long as the light indicating residual

heat on the glass-ceramic hob, is “on”; this indicates that the temperature in the

relative area is still high.

WARNING: Never place pan with bottoms which are not perfectly flat and smooth on

the hob

WARNING: If you notice a crack in the ceramic hob, disconnect the appliance from

the elettricity supply and contact a service centre

WARNING: Your glass-ceramic hob is thermal shock resistant and resistant to both

heat and cold.

If you drop a heavy pot on your hob it will not break.

On the contrary, if a hard object, such as the salt shaker or the spice bottle strikes

the edge or the corner of the hob, the hob may break.

WARNING: never use the glass-ceramic hob as support surface.

SEPARATE GRILL COMPARTMENT (triple oven cavity models only)

The powerful 2.4kW grill can be used for short periods of time (e.g. toast/muffins) with the door open,

however for better efficiency it is recommended that the door is closed. A cooling fan situated behind the

control panel switches on to keep the control knobs at a comfortable temperature when the grill is in use.

The grill pan assembly The grill compartment is fitted with telescopic runners to make it easier to access

your food. To fix the grill pan onto the runners, simply extend both runners, then

lower the grill pan into place, ensuring the back corners of the grill pan rest against

the vertical pins. The wire trivet that fits into the grill pan is reversible to provide two

grilling heights.

To use the grill:

1 Use the reversible trivet to select the correct height for the food you wish to grill.

Using the trivet at the lowest height will help to slow down the cooking process.

2 Turn the grill control knob (Fig.20A-20B) clockwise to the maximum setting 7. The

adjacent red thermostat light will illuminate. For best results you should preheat the

grill for 3-5 minutes.

3 Once preheated, adjust the grill control knob clockwise to the desired setting 1 to

7.

4 To turn off the grill, turn the control knob anti-clockwise to the "O" position.

At the end of cooking remove the grill pan for cleaning. If high fat content foods have

been prepared with the door closed, leave the grill turned on at maximum

temperature for 5 minutes. This will burn off any fatty residue on the elements.

Always use oven gloves when handling the grill pan and turning food. Do not line the

grill pan with aluminium foil, this can cause damage to the enamel coating and the

grill elements.

It is recommended to use fan assisted grilling at 200°C with the door closed in the

main oven for foods that need grilling for longer than 10 minutes (e.g. meat, fish).

See page 24 for more info.

17

Fig 20A Fig 20B

Most foods such as bread products and bacon are grilled on the higher settings For

thicker cuts of meat, chicken pieces etc. you should use fan assisted grilling in the

main oven. See page 24.

Suggested cooking times

(turn the food halfway through the cooking time):

Food Grill setting Cooking time

Bacon High 7 4 – 6 minutes

Toasted bread or muffins High 7 4 – 6 minutes

Crème brulèe High 7 3 – 5 minutes

Crumpets High 7 4 – 6 minutes

OVENS

Using the gas oven Gas oven:

All the gas oven cookers are equipped with a thermostat and safety device to adjust

the cooking temperature. The oven temperature is set by turning the knob

counterclockwise to match the indicator with the temperature selected. The gas

oven can be combined with a gas grill or an electric grill. See the specific pages for

use information.

Fan gas oven:

Operating the fan of the oven by means of the appropriate switch situated on the

control panel, the circulation of warm air guarantees a uniform heat distribution. The

preheating of the oven can be avoided. However for delicate baking, it is preferable

to warm the oven before introducing the baking-pan. The baking system with the fan

convection changes in part the various traditional baking notions. When roasting

meat it is not necessary to turn the meat anymore and for a roast on the spit, it is not

indispensable to use the spit-roaster, but is sufficient to put the meat directly on the

grate.

With the use of the fan gas oven, the baking temperatures are slightly lower of about

10-15°C compared to those in use with the traditional gas oven. The fan operation of

the oven prevents the operation of the electric grill, which therefore cannot be used

with the fan in action.

The oven can also be used in a traditional way, (by not activating the fan) for foods

requiring heat from the bottom, e.g. pizza.

WARNING: If the burner flames are extinguished accidentally, turn off the control

knob and do not try to relight the oven until after at least 1 minute.

The oven burner can be ignited in different ways:

- Manual lighting (it is always possible even when the power is cut off):

To light the oven, open the oven door and turn the knob so the 260°C on the scale

matches the indicator (Fig.21A-21B for HYB oven and Fig.22A-22B for GEV model).

At the same time put a lit match next to the ignition tube that is visible on the oven

level. Then press the thermostat knob (this makes the gas start to flow) and keep it

pressed, after the burner has been completely lit, for 10 seconds. Release the knob

and make sure that the burner remains on, otherwise repeat the operation.

- Electric ignition (only for the models equipped with this device):

In this case, first open the oven door, then turn the knob to the maximum

temperature setting (260°C). Then press the thermostat knob (models with ignition

trough knob). Wait about 10 seconds after the burner has been completely lit and

then release the knob. Make sure that the burner remains on, otherwise repeat the

18

operation. As for cookers without ignition trough knob, press the thermostat knob

and the key with the spark symbol, wait about 10 seconds after the burner has been

completely lit and then release the knob. Make sure that the burner remains on,

otherwise repeat the operation.

The ignition device should not be used for more than 15 seconds. If after that period

the burner still has not been lit, do not use the device and open the door of the room

or wait at least 60 seconds before trying to light the oven again.

WARNING: when trying to light the oven, the door must always be open. When

using the oven, leave the cooker cover open to prevent it from overheating.

NOTICE: when using the oven for the first time it should be operated for 15-30

minutes at a temperature of about 250° without cooking anything inside in order to

eliminate any moisture and odours from the internal insulation.

During normal oven use, after lighting the burner and setting the desired

temperature, wait about 15 minutes before putting in any food to preheat the oven.

The oven is equipped with 4 guides at different heights level which can be used to

insert shelves or the tray. To keep the oven as clean as possible it is recommended

to cook meat on the tray or on the shelf that has been inserted inside the tray. The

table below lists the general cooking times and the position of the tray for different

types of foods. Personal experience will help to determine any variations in the

values reported in the table. In any case, it is recommended to follow the instructions

of the specific recipe being used.

Temperatures between brackets are referred to the use of oven with fan assisted

gas.

Fig 21A Fig 21B

Fig 22A Fig 22B Fig 23

GAS OVEN COOKING TABLE

MEAT

PORK ROAST 220 (210) 3 60-70

BEEF ROAST (YOUNG STEER) 250 (240) 3 50-60

BEEF ROAST 240 (230) 3 60-70

VEAL ROAST 220 (210) 3 60-70

LAMB ROAST 220 (210) 3 45-55

ROAST BEEF 230 (230) 3 55-65

ROAST HARE 235 (225) 3 40-50

ROAST RABBIT 220 (210) 3 50-60

ROAST TURKEY 235 (225) 3 50-60

ROAST GOOSE 225 (215) 3 60-70

ROAST DUCK 235 (225) 3 45-60

ROAST CHICKEN 235 (225) 3 40-45

FISH 200-225 (190-215) 2 15-25

TEMP °C HEIGHT MINUTES

19

PASTRY

FRUIT PIE 220 (210) 2 35-40

TEA CAKE 190 (180) 2 50-55

BRIOCHES 175 (165) 2 25-30

SPONGE CAKE 235 (225) 2 20

RING CAKE 190 (180) 2 30-40

SWEET PUFF PASTRIES 220 (210) 2 20

RAISIN LOAF 220 (210) 2 15-20

STRUDEL 180 (170) 2 15-20

SAVOIA COOKIES 190 (180) 2 15

APPLE FRITTERS 220 (210) 2 20

SAZOIARDI SANDWICH 220 (210) 2 20-30

TOAST SANDWICH 250 (240) 3 5

BREAD 220 (210) 2 30

PIZZA 220 (210) 2 20

Using the 2 + 0 switch – the symbol indicates that the electric fan, and the oven light have

(only cooker with gas

oven and electric grill)

been turned on (Fig.24A-24B).

– the symbol indicates that only the oven light is turned on (Fig.16A-

16B).

Fig 24A Fig 24B

Using the electric The thermostat supplied with the relative models maintains a constant temperature

thermostat

inside the oven at a specific temperature setting ranging from 50°C to 250°C (Fig.

25A-25B and Fig.25C for pro t version only ).

Turn the knob clockwise and align the selected temperature indicated on the ring

with the index etched on the control panel. Thermostat operation is indicated by an

orange light which will turn off when the temperature inside the oven is 10°C greater

than the temperature setting, and will turn on when the oven is 10°C less than the

temperature setting. The thermostat can control the oven elements only if the

relative switch is in one of the possible oven element operating modes: if the switch

is in position 0, the thermostat has not effect on the oven elements, which remain

off.

Fig 25A Fig 25B Fig 25C

Using the 5 + 0 switch The 5 + 0 switch installed in the hybrid oven models is used, along with the electric

( only cooker with

Hybrid oven (HYB))

or gas thermostat.

To control the electric fan and the oven elements since they can be turned on by

turning the 5 + 0 switch knob and the thermostat knob. Turning just one of the two

knobs will not have any effect on the oven except to turn on the oven light or the

electric fan.

In combination with the electric thermostat, it is used for controlling in parallel with

the thermostat the convection fan and the related oven heating resistance since for

being able to put in operation the convection fan and the resistance both the 5+0

switch knob and the thermostat knob have to be turned on; by turning only one of

20

the two knobs, no effect will result on oven operation except only for lamp or fan

when switched on. Electric oven is heated by two resistances: one upper resistance

and one circular resistance; by turning the switch knob (Fig.26A-26B) the resistance

referred to the symbol printed on the knob ring will be switched on but in order to put

it in operation the thermostat knob has to be turned until the orange light on will

confirm that resistance is in operation. By turning the switch knob on one of the 5

operation mode the lamp will be switched on simultaneously with the related

resistance. Once the temperature and the type of resistance are selected, the

operation of the resistance will be controlled by the thermostat. It is therefore

accepted that during operation the orange light will switch on and off.

To turn off the electric oven set the switch knob to position 0 to prevent the

thermostat from controlling the elements. Setting the thermostat knob to position 0

turns off the elements but it is still possible, using the switch, to turn on the electric

fan and the oven light.

The switch has 5 different fixed positions corresponding to 5 different types of oven

operation:

- the symbol indicates that only the oven light is turned on;

- the symbol indicates that the circular element (3000W) and the electric

fan have been turned on;

- the symbol indicates that the grill element (2500W) and the electric fan

have been turned on;

- the symbol indicates that only the grill element (2500W) has been turned

on

- the symbol indicates that only the electric fan has been turned on.

When the knob is set to one of these five positions, the oven light is always on, thus

indicating that the oven is being energised.

When 5+0 switch is combined with gas thermostat, resistances are switched off;

only lamps and cooling fan operates. It is possible to use the oven convection fan by

selecting on switch knob one of the following modes:

For operating the oven on Dual Energy ranges, see paragraph for use of gas ov en.

Once the gas oven use is finished, switch off all the oven functions by turning the

gas thermostat knob and 5+0 switch knob to position 0 (zero).

Fig 26A Fig 26B

Using the electric oven Before using the ovens for the first time:

- Remove all packaging and accessories from inside the ovens.

- Heat the ovens to 200°C for

½ hour to burn off

manufacturing residues.

- The automatic programmer must be set to Manual mode for ordinary cooking.

- The oven will not function when set in Automatic mode. See page 26.

To use the ovens:

1 Turn the function selector knob (Fig.27A-27B and Fig.28A-28B) clockwise to the

desired function.

The orange light will illuminate, indicating that the element is on.

2 Turn the temperature selector knob (Fig.29A-29B and Fig.30 for PRO T version

only)

clockwise to the desired temperature. The orange light will go out once the

oven has reached temperature and is ready for use. It is normal for this light to go

21

on and off during cooking as the elements maintain the temperature (The operation

of the oven is indicated by the display of the programmer for PRO T version only).

3 To turn the oven off, turn the function selector and temperature knobs anti-

clockwise back to •.

Steam may be generated when cooking. As a precaution, always open the door in

two stages. First, partially open the door by 100mm for a few seconds to allow the

steam to escape, then open the door fully. Keep your face and head away from the

door when opening.

Never line the oven interior with foil as this can cause overheating and damage the

enamel. Never cook on the oven base. Always place dishes and trays onto an oven

shelf. Do not leave the grill pan or other dishes on the oven base as damage to

the oven may occur.

Fig 27A Fig 28A Fig 29A

Fig 27B Fig 28B Fig 29B

Fig 30

Preheating the oven:

'Quickstart' provides the most efficient and fastest way to preheat the main oven (left

hand oven). It will also ensure your oven cooks evenly. Use 'Quickstart' as follows

( ):

1

Select 'Quickstart' (using the oven function selector) and the required cooking

temperature (using the temperature selector). Allow the orange thermostat light to

come on and off several times. This allows the temperature to stabilize before

introducing food (The operation of the oven is indicated by the display of the

programmer for PRO T version only).

2 Select the recurred cooking function and place the food in the oven.

3 When preparing heat sensitive foods such as cakes or meringues using the 'True

Fan' function, allow the orange light to come on and off

the top element to cool slightly.

again several times to allow

'Quickstart' is unsuitable for use as a cooking function It is a quick pre -heat system.

Oven functions When using any of the functions in the multifunction oven (except grilling and

defrosting) it is always recommended that you pre-heat the oven using the

Quick start function, before switching over to your desired cooking function.

22

When using the Fan Assisted or True Fan oven function, it is advisable to reduce the

oven temperature by 20°C if following a recipe written for a conventional oven.

Check the food often through the latter stages of cooking until you are used to the

cooking times and temperatures.

The ovens have a range of cooking functions providing different heat zones. The

'True Fan' function for instance, is most suitable for cakes

'

baking. The

roasting meats and vegetables or frozen potato products.

Fan Assisted

'

function gives more browning so is more suitable for

Example: To cook a turkey:

When cooking a turkey, the grill pan can be used as a roasting

a double layer of extra wide foil, allowing enough foil to wrap the turkey loosely. It

important to allow enough space around the sides and top of the oven for the hot air

to circulate. Make sure that the foil is not touching the sides or top of the oven. In a

9

60cm oven a turkey of

kg can be cooked.

The oven light operates on selection of any oven function

Symbol Function Ovens found in Elements

Quickstar

Defrost

60cm and 90cm

60cm and 90cm

Top plus fan

None

Conventional

oven

All ovens Top and

bottom

Lower

element

All ovens Bottom

Upper

element

All ovens Top Use for browning and reheating dishes such as lasagne,

to 11 kg can be cooked. In a 40cm oven a turkey of 6 – 9

used

It is recommended that the oven is always pre-heated before

use, whatever the cooking temperature. Quick start is not

suitable for cooking - once the oven has reached temperature,

switch to one of the oven functions below.

Place small frozen items on an oven tray at the lowest shelf

position, and set the temperature selector knob to O°C. Never

use heat to defrost as this can pose a health risk. Larger items

such as joints, or a whole chicken or turkey, should be

defrosted in the refrigerator.

Ideal for roasting and for baking items such as bread or rich fruit

cakes on a single shelf.

Use at low temperatures for slow-cooking casseroles, custard

or for warming plates. Use at high temperatures for cooking

sweet and savoury pastry tarts.

moussaka and cauliflower cheese.

Conventional

grill

Rotisserie

All ovens

30cm and 40cm

(version T only)

Grill

Grill

Ideal for crumpets, muffins and Welsh rarebit. Use when grilling

for less than 15mins. For foods needing a longer time use fan

assisted grilling.

The rotisserie motor rotates food under the grill for succulent

results. Suitable for poultry, game birds and rolled and tied

joints of pork or lamb.

Fan assisted

grill

Fan assisted

oven

True fan oven 60cm and 90cm Circular fan

Pizza 60cm and 90cm Bottom plus

60cm and 90cm Grill plus

fan

60cm and 90cm Top and

bottom plus

fan

element

only

others

The fan circulates hot air around the food helping to cook it all

the way through. Ideal for cooking meat such as sausages and

chicken portions. Cooking high water content foods such as

bacon and chops with this function helps to reduce

condensation. (Recommended: Door closed 200°C, 2nd from

top shelf, turn the food over halfway through.

The fan circulates the hot air around the oven for uniform

cooking of larger quantities of food. Use for roasting vegetables,

meat and poultry, or baked fish. This function is the best one for

cooking frozen potato products and breaded/battered chicken or

fish.

This function is suitable for most recipes and is an efficient way

to cook. The temperature is kept uniform throughout the oven

and is particularly suitable for baking on several shelves or for

batch cooking.

Use for cooking pizza, pastry or flat breads to get a

perfectly cooked base.

23

What to use it for

,

desserts and batch

tin

Line the pan with

is

Using the grill

The grill pan consists of a wire trivet and enamel tray. Place food on the wire trivet.

A lower shelf position can be used to slow cooking down, or the temperature can be

reduced. A detachable grill pan handle is supplied for removing the hot tray.

Both the Fan Assisted Grill and Conventional Grill functions are designed to be used

with the oven door closed. This ensures efficient preheating and even cooking.

When grilling, always pre-heat the grill element for 5 minutes before introducing food

(200°C is recommended for preheating). It is recommended that the grill pan is

always removed from the oven when not in use, as air flow around the oven can be

impaired. The grill should be used with the oven door closed. Use the Fan Assisted

Grill function for thicker pieces of meat and when cooking high water

content foods to reduce condensation.

Always use oven gloves when handling the grill pan and turning food. Do not line the

grill pan with aluminium foil, this can cause damage to the enamel coating and the

grill elements.

At the end of

cooking remove the grill pan for cleaning. If high fat content foods have

been prepared, leave the grill turned on at a maximum temperature for 5 minutes to

clean the grill element.

Grill Pan The grill pan should be removed from the oven when not required. If left in the oven

it will block the flow of hot air. This can cause hot spots and could damage the grill

pan and the oven interior. When using in 60cm and 90cm ovens the grill pan can

be used in the top two shelf positions for grilling, or in the bottom two shelf positions

for roasting. When using the grill pan for roasting, the 'True Fan' function should be

used.

When using in 30cm or 40cm ovens the grill pan should only be used in conjunction

with the grill (in the top two shelf positions) or far the rotisserie (in the bottom shelf

position).

Fan assisted grilling

Food Grill setting Cooking time

Chicken places 200°C 30 minutes

Burgers 200°C 18 minutes

Fish fillets 200°C 10-15 minutes

Lamb chops 200°C 15 minutes

Gammon steaks 200°C 15 minutes

Chicken breasta 200°C 30 minutes

Pork chops 200°C 25 minutes

These times are purely advisory and will depend on the size and cut of the food.

Please ensure foods are cooked through before serving (pork, fish and chicken in

particular).

Using the grill or fan Far even grilling it is important to preheat the grill before introducing the food. This

grill functions

will

ensure good sealing and even browning of the food. It is recommended that the

door remain closed for safety and efficiency when using this function. The separate

grill compartment can be used with the door open if preferred, for short grilling

periods (e.g. up to 15 minutes).

Aluminium foil should not be used to line the oven cavity or grill pan. This

can cause overheating, buckling and cracking of the enamel surfaces.

Using the rotisserie Warning: The maximum weight for the rotisserie is 3.5 kg.

(secondary oven

TOP model

back of the oven.

1 Place the grill pan in the bottom shelf position to catch any drips.

) 2 Place the wire support shelf into the oven so that it sits level with the hole at the

0

3 Pre-heat the oven. A temperature of 220

C is recommended.

4 Place one of the forks onto the spit and tighten the thumbscrew.

5 Skewer the meat with the spit, ensuring that the fork firmly pierces and holds the

meat. When cooking poultry, aim for the bone area under the breast.

6 Fit the second fork, again ensuring that the meat is firmly pierced. For poultry, the

24

fork should enter just below the thighs. Tighten the thumbscrew into place. Ensure

that the food is well balanced to avoid stress on the motor drive. The maximum

weight bearing of the spit is 3.5kg.

7 Turn off the oven. Fit the handle to the spit assembly, then place the spit over the

wire support shelf and place the spit end into the hole In the rear oven wall. Locate

the spit support onto the wire shelf. Remove the handle (the handle is used solely

for moving the spit) and close the oven door.

8 Turn the oven back on to the rotisserie/grill function ( ).

As a guide, most meats will require about 15 minutes per 450g at 220°C. Always

check that food is thoroughly cooked and that the juices of poultry run clear when

pierced.

Operating the oven Turn the function selector control knob to switch the light on. The light will remain on

light in the 60cm and

90cm ovens

the light icon. The light will also operate once a function has been selected for

cooking.

while the oven is in use. In the 30cm and 40cm ovens, turn the function control to

Cooling fan The range cooker is fitted with a thermostatically controlled cooling fan designed to

prevent the control panel and knobs from overheating. The fan will operate when a

certain temperature is reached. It will turn off when the temperature decreases.

USING THE AUTOMATIC PROGRAMMER (PRO T model only)

The programmer with touch controls allows to program the cooking cycle with the following cooking tools:

- Delay;

- Cooking time;

- Probe

- Clock or Time

Icons legend

Scroll left/right and up/down (keep press the button to increase

the speed)

Remove selection or leave menu

Confirm selection

Settings menu

System Settings

Timer

Delay

Cooking time

Food probe

Level indicator of temperature

25

Home screen

- To active timer/set up menu touch control zones.

- In this screen the temperature knob is not active.

- To switch directly to the functions cooking selection

knob and the icon of the selected function will appear on the display.

screen turn the function

Timer/set up menù To advance to the system settings select the set-up icon.

In this screen it is possible to set the time (12 or 24h), the type of degrees (metric °C

or imperial °F) and the intensity of the buzzer.

Set up

Select field with and conf irm

Set the desired values and confirm

Leave menù .

Timer

This function is simply a minute minder: the timer can be used independently from

cooking and it will not turn off the oven at the end of the set time. To shut off

automatically the oven, select COOKING TIME (see below).

Set the desired values and confirm

Leave menù .

Functions cooking The display will show the desired function icon turning the function knob

selection

In this setting the touch controls are not active.

N.B. the function knob has the priority and the display will always show the choice of

the function.

26

Choose the desired temperature turning thermostat knob to move to the cooking

tools menu. Wait to 3/4 seconds confirm the selected value and the display will

show the status screen

.

Status screen

Cooking tools menu If not selected any cooking instrument after inactivity of 3/5 seconds the screen

returns to the initial state or to status screen in case the oven is in operation.

Time

Press the touch zone next to (settings menu) to enter the cooking tools menu

screen and select time touching the corresponding touch control zone.

Set the desired values and confirm

Leave menù .

Delay

Press the touch zone next to (settings menu) to enter the cooking tools menu

27

screen and select delay touching the corresponding touch control zone.

Set desired time before oven will turn on and confirm

The oven will turn on at the set time and it will be confirmed with a repeating tone.

Touch any touch control area to stop tone.

Leave menù .

After 3/5 seconds of inactivity the screen returns to the status screen.

Cooking time

Press the touch zone next to (settings menu) to enter the cooking tools menu

screen and select cooking time touching the corresponding touch control zone.

Set the desired duration and confirm

The display will show the countdown.

The oven will turn off at the end of the countdown and it will be confirmed with a

repeating tone. Touch any touch control area to stop tone.

Leave menù .

After 3/5 seconds of inactivity the screen returns to the status screen.

Probe (PRO T model only)

Press the touch zone next to (settings menu) to enter the cooking tools menu

screen and select probe touching the corresponding touch control zone.

28

Set the desired food temperature with and confirm .

The display will show the set temperature and the actual temperature measured by

the probe. The oven will turn off when the desired food temperature is reached. End

of cooking will be confirmed with a tone. To stop tone touch any touch control area.

Leave menù .

After 3/5 seconds of inactivity the screen returns to the status screen.

The probe works by measuring the temperature inside a joint of meat. There are no

set cooking times as the cooking time depends on how long it takes far the internal

temperature of the meat to reach the set care temperature. This can vary depending

on the weight and type of meat. For this reason it is not recommended that the

probe is used with the automatic timer.

The meat is ready when the temperature set on the right hand side of the clock

fascia is reached and the oven then switches off.

Foods suitable for use with the probe are large joints of boneless meat or joints that

have been deboned & stuffed eg. topside of beef, pork fillet. deboned leg of

lamb/pork.

It is important that:

- Meat should be as close to room temperature as possible.

is

- The probe

inserted into the centre of the joint of meat to give accurate results.

Once in the centre of the meat it is cooked to the temperature selected on the clock

fascia panel.

If the probe is not fully inserted to the centre of the meat, the desired cooking

temperature may not be reached.

To use:

1

Remove the probe part cover on the left hand side of the oven and insert the

short metal end of the probe.

2 Then place the meat in the roasting tin on the 2nd shelf from the base of the oven

and insert the long end of the probe into the thickest part of the meat towards the

centre. Make sure the rubber probe cable is not trapped in the door, or touching the

oven shelf as this could affect the results. Any slack in the cable should rest in the

roasting tin.

3 When both temperatures on the display reach the temperature set, the oven will

switch off.

Below there is a chart to be used as a guideline. Meat cooked this way must not

exceed 2.5kg in weight and should be left at room temperature for a couple of hours

before cooking.

The probe is best used for red meats and pork, as suggested by the guideline

29

temperatures below. It is not recommended to cook poultry using the probe.

Cut of meat Preferred result Suggested core temp

Topside of beef Medium rare 63°C

Topside of beef Medium 70°C

Deboned leg of lamb Medium pink 69°C

Deboned leg of pork Cooked through not pink 85°C minimum temp

- The meat does not need to rest before carving as it is cooked at a lower

temperature than roasting.

Important

DO NOT LEAVE THE PROBE IN THE OVEN CAVITY WHEN NOT IN USE.

Reset

To reset the cooking tools (delay / cooking time and probe) bring both knobs on the

zero position “0”.

OVEN TEMPERATURE GUIDE

Selecting the correct cooking temperature

The centre of each number should be In line with the central dot icon on the fascia. When using the 'True

Fan' or the 'Pizza' function, select a temperature 20°C lower than your recipe states. Most recipes are written

for the conventional, but, more recently, magazines, food packaging and cook books have started to add the

required Fan temperature, usually in brackets. There are 4 shelf positions – 1 is the lowest and 4 is the

highest near to the grill.

If cooking one dish use shelf position 2, if cooking more than one tray depending on the height of the tray or

food it is suggested to cook on shelf positions 1 & 3.

NATURAL CONVENTIONAL ELECTRIC OVEN COOKING TABLE

MEAT

PORK ROAST 225 3/4 60-80

BEEF ROAST (YOUNG STEER) 225 3/4 60-80

BEEF ROAST 250 3/4 50-60

VEAL ROAST 225 3/4 60-80

LAMB ROAST 225 3 40-50

ROAST BEEF 230 3/4 50-60

ROAST HARE 250 3/4 40-50

ROAST RABBIT 250 3 60-80

ROAST TURKEY 250 3 50-60

ROAST GOOSE 225 3 60-70

ROAST DUCK 250 3/4 45-60

ROAST CHICKEN 250 3/4 40-45

FISH 200-225 2 15-25

PASTRY

FRUIT PIE 225 2 35-40

TEA CAKE 175-200 2 50-55

BRIOCHES 175-200 2 25-30

SPONGE CAKE 220-250 2 20-30

RING CAKE 180-200 2 30-40

SWEET PUFF PASTRIES 200-220 2 15-20

RAISIN LOAF 250 2 25-35

STRUDEL 180 2 20-30

SAVOIA COOKIES 180-200 2 40-50

APPLE FRITTERS 200-220 2 15-20

SAZOIARDI SANDWICH 200-220 2 20-30

TOAST SANDWICH 250 3 5

BREAD 220 3 30

PIZZA 220 2 20

TEMP °C HEIGHT MINUTES

30

VENTILATED ELECTRIC OVEN COOKING TABLE

MEAT

PORK ROAST 160-170 2 70-100

BEEF ROAST (YOUNG STEER) 170-180 2 65-90

BEEF ROAST 170-190 2 40-60

VEAL ROAST 160-180 2 65-90

LAMB ROAST 140-160 2 100-130

ROAST BEEF 180-190 2 40-45

ROAST HARE 170-180 2 30-50

ROAST RABBIT 160-170 3 80-100

ROAST TURKEY 160-170 3 160-240

ROAST GOOSE 160-180 3 120-160

ROAST DUCK 170-180 2 100-160

ROAST CHICKEN 180 2 70-90

FISH 160-180 2-3

PASTRY

FRUIT PIE 180-200 2 40-50

TEA CAKE 200-220 2 40-45

BRIOCHES 170-180 2 40-60

SPONGE CAKE 200-230 2 25-35

RING CAKE 160-180 2 35-45

SWEET PUFF PASTRIES 180-200 2 20-30

RAISIN LOAF 230-250 2 30-40

STRUDEL 160 2 25-35

SAVOIA COOKIES 150-180 2 50-60

APPLE FRITTERS 180-200 2 18-25

SAZOIARDI SANDWICH 170-180 2 30-40

TOAST SANDWICH 230-250 3 7

BREAD 200-220 3 40

PIZZA 200-220 2 20

TEMP °C HEIGHT MINUTES

When cooking a Dundee cake or rich fruit cake, always wrap 2 layers of brown pape r around the sides and

check after each hour.

A piece of brown paper may need to be put over the top. Always ensure foods are cooked through before

serving, pork, poultry and fish in particular .* See page 22 for more information on cooking a turkey.

USING THE THERMOMETER (Fig.31)

The cooker is fitted with a device to measure the temperature in the middle of the oven.

This lets you check the temperature inside the oven and adjust food cooking temperatures more ac curately.

Electric oven When you turn on the oven, the orange light comes on to indicate that the heating

elements are working: The thermometer dial will start to move towards the set

temperature.

The orange light will keeping coming on and off, indicating that the heating elements

are working to maintain the temperature inside the oven.

The light may go off for a few minutes before the thermometer has reached the

temperature required. This is normal, because operation of the heating elements is