INSTALLATION,USE & CARE MANUAL

(French version page 17)

DIMENSIONS: 35 1/16’’ (890 mm)(W) x 201/2’’ (520 mm)(D)

Models PMMN...D7X (2 or 5)D PM363I0X

IMPORTANT: SAVE FOR LOCAL ELECTRICAL INSPECTOR’S USE.

READ AND SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE.

OBSERVE ALL GOVERNING CODES AND ORDINANCES.

WARNING: If the information in this manual is not followed exactly, a fire or

explosion may result causing property damage, personal injury or death.

Do not store or use gasoline or other flammable vapors and liquid in the vicinity of

this or any other appliance.

WHAT TO DO IF YOU SMELL GAS

- Do not try to light any appliance.

- Do not touch any electrical switch.

- Do not use any phone in your building.

- Immediately call your gas supplier from a neighbor’s phone. Follow

the gas supplier’s instructions.

- If you cannot reach your gas suppliers, call the fire department.

Installation and service must be performed by a qualified installer, service agency

or the gas supplier.

Read this instruction booklet before installing and using the appliance.

The manufacturer will not be responsible for any damage to property or to persons caused by

incorrect installation or improper use of the appliance.

The manufacturer reserves the right to make changes to its products when considered necessary and useful,

without affecting the essential safety and operating characteristics.

This appliance has been designed for non-professional, domestic use only.

2

WARRANTY AND SERVICE

All Bertazzoni products are covered by a 2 years parts and labor warranty.

Service on all Bertazzoni products shall be carried out by factory-trained professionals only.

For warranty service please contact Customer Service at the numbers indicated below.

CUSTOMER SERVICE

English/Spanish hotline (866) 905-0010

French hotline (800) 561-7625

Fax (714) 428-0040

Email BERTAZZONIHELP@SERVICEPOWER.COM

Mailing address

SERVICEPOWER

1503 South Coast drive

Suite 320

Costa Mesa CA 92626

REPLACEMENT PARTS

Only Bertazzoni replacement parts may be used in performing service on the appliance.

Replacement parts are available from factory authorized parts distributors.

INDEX:

Installation Instructions……………………………………..………………………………………… pag.4

Inserting the hotplate……………………………………………..………………………………….. pag.5

Requirements……………………………………..……………………………….…………………. pag.5

Attaching the hotplate……………………………………..…………………………………………. pag.6

Gas connection……………………………………..……………………………………………… …. pag.6

Electrical connection……………………………………..……………………….…………………. pag.7

Wiring diagrams……………………………………..…………………………….…………… ……. pag.7

Room ventilation…………………………………….……………………………………………….. pag.7

Location and venting…………………………………….………………………………………….. pag.7

Replacement of nozzles……………………………………..……………………………………… pag.7

Regulation of burners……………………………………………...……………………………….. pag.7-8

Descriptions…………………………………………………………………………………………… pag.8

Service & maintenance instructions……………………………..…………………………………. pag.8

User instructions……………………………………………..………………………………………. pag.9

Using burners……………………………………………………..………………………………….. pag.10

Using ceramic induction elements…………………………………………………………………. pag.11-14

Cleaning the appliance……………………………………………..………………… …………….. pag.14

Troubleshooting…………………………………………………..…………………………………… pag.15

Figures………………………………………………...…………..………………………………….. pag.33

3

Before Installation

If receiving the unit from a transportation company, it is customer’s obligation to inspect the package and

note any damage on the delivery receipt. After delivery have your induction cooktop carefully unpacked, and

again check for any visible damage. If you find any damage on the unit at this point, immediately inform your

dealer or distributor. Although the responsibility for shipping lies with the carrier, your dealer/dis-tributor will

assist you with your claim.

If the unit is not supposed to be installed for some time, you should keep it in its original packaging, stored in

a dry and safe place.

Read through the sections of this manual which pertains to installation, and make sure that all of the

requirements can be met.

Ensure that your electric power supply is correct.

Installation instructions

This appliance shall only be installed by an authorized person. This appliance shall be installed in

accordance with the manufacturers installation instructions, IMPORTANT: this appliance must be

installed in accordance with the norms in force of the country concerned.

The installation of this appliance must conform to local codes and ordinances. In the absence of

local codes, Installations must conforms to American National Standards, National Fuel Gas Code

ANSI Z223.1 – latest edition** or B149.1.

If local codes permit, a flexible metal appliance connection with the new AGA or CGA certified

design, max. 5 feet (1,5 m) long, ½” I.D. recommended for connecting this cooktop to the gas supply

line. Do not bend or damage the flexible connector when moving the cooktop. The pressure regulator

has ½” female pipe thread. You will need to determine the fitting required, depending on the size of

your gas supply line, the flexible metal connector and the shutoff valve.

The appliance, when installed, must be electrically grounded in accordance with local codes or, in

the absence of local codes, with the National Electrical Code, ANSI/NFPA 70.

The appliance and its individual shutoff valve must be disconnected from the gas supply piping

system any pressure testing of that system at test pressure in excess of ½ psi (3,5 kPa).

The appliance must be isolated from the gas supply piping system by closing its individual manual

shutoff valve during any pressure testing of the gas supply piping system at test pressures equal

to or less than ½ psi (3.5 kPa).

For use with a pressure regulator. The regulator supplied must be used with this appliance.

The gas appliance pressure regulator must be set for the gas with which the appliance is used.

This appliance can be used with Natural Gas and LP Gas. It is shipped from the factory adjusted for

use with Natural Gas: CONVERSION FIXED ORIFICES ARE LOCATEDIN THE LITERATURE PACK

SUPPLIED WITH THE UNIT.

Injectors kit for the change of type of gas are contained inside the package jointly with the hob

installation kit and Instruction booklet.

The maximum inlet gas supply pressure incoming to the gas appliance pressure regulator is 20’’

water column (5 kPa) .

The minimum gas supply pressure for checking the regulator setting shall be at least 1“ w.c. (249 Pa)

above the inlet specified manifold pressure to the appliance (this operating pressure is 4” w.c.

(1.00 kPa) for Natural Gas and 11” w.c. (2.75 kPa) for LP Gas).

ATTENTION: A manual valve shall be installed in an accessible location in the gas line external to the

appliance for the purpose of turning on or shutting off gas to the appliance

WARNING: Do not use aerosol sprays in the vicinity of this appliance while it is in operation

4

Inserting the hotplate

After having removed the various loose parts from the internal and external packing, make sure that the

hotplate in not damaged and is suitable for the specific gas usage. The gas type label is on the underside of

the hotplate base.

In case of doubt, do not use the appliance and contact skilled personnel.

Keep all the packing parts (polystyrene foam, cardboard, staples, etc.) away from children.

Consider the critical dimensions of the appliance, before making an opening in the top surface of the bench

top. (relative measurements as per Fig 1- 2).

If your counter is produced from porous materials which tend to swell if in contact with humidity, and water, to

better protect the cut-out, use proper sea-lants on the edge which would prevent any penetration of humidity

and water.

Chamfer all exposed edges of decorative laminates to prevent further chipping.

Radius corners of the cut-out and file them to ensure smooth edges and prevent corner cracking.

Rough edges and inside corners which are not rounded as well a s forced fits can contribute to cracking of

counter top laminate.

Requirements

1. Overhead clearances (Minimum values)

The minimum overhead clearances shall be in accordance with the minimum values indicated in the table

n.1 and are shown and in the fig. 1- 2

Range hoods and exhaust fans shall be installed in accordance with the manufacturer’s instructions.

However, in no case shall the clearance between the top of the highest burner of the cooking appliance and

the range hood be less than 25 ½”( 650mm).

Any other downward facing combustible surface less than 600mm above the top of the highest burner shall

be protected for the full width and depth of the cooking surface area.

However, in no case shall this clearance to any surface be less than 17

Maximum depth for the overheads cabinet is 13” (330mm)

3/4”(450mm.)

2. Side clearances (Minimum values)

The different side clearances shall be in accordance with the minimum values indicated in the table n.1 and

are shawn and in the fig. 1- 2

The cooking surface area is defined as that part of the appliance where cooking normally takes place and

does not include those parts of the appliance containing control knobs.

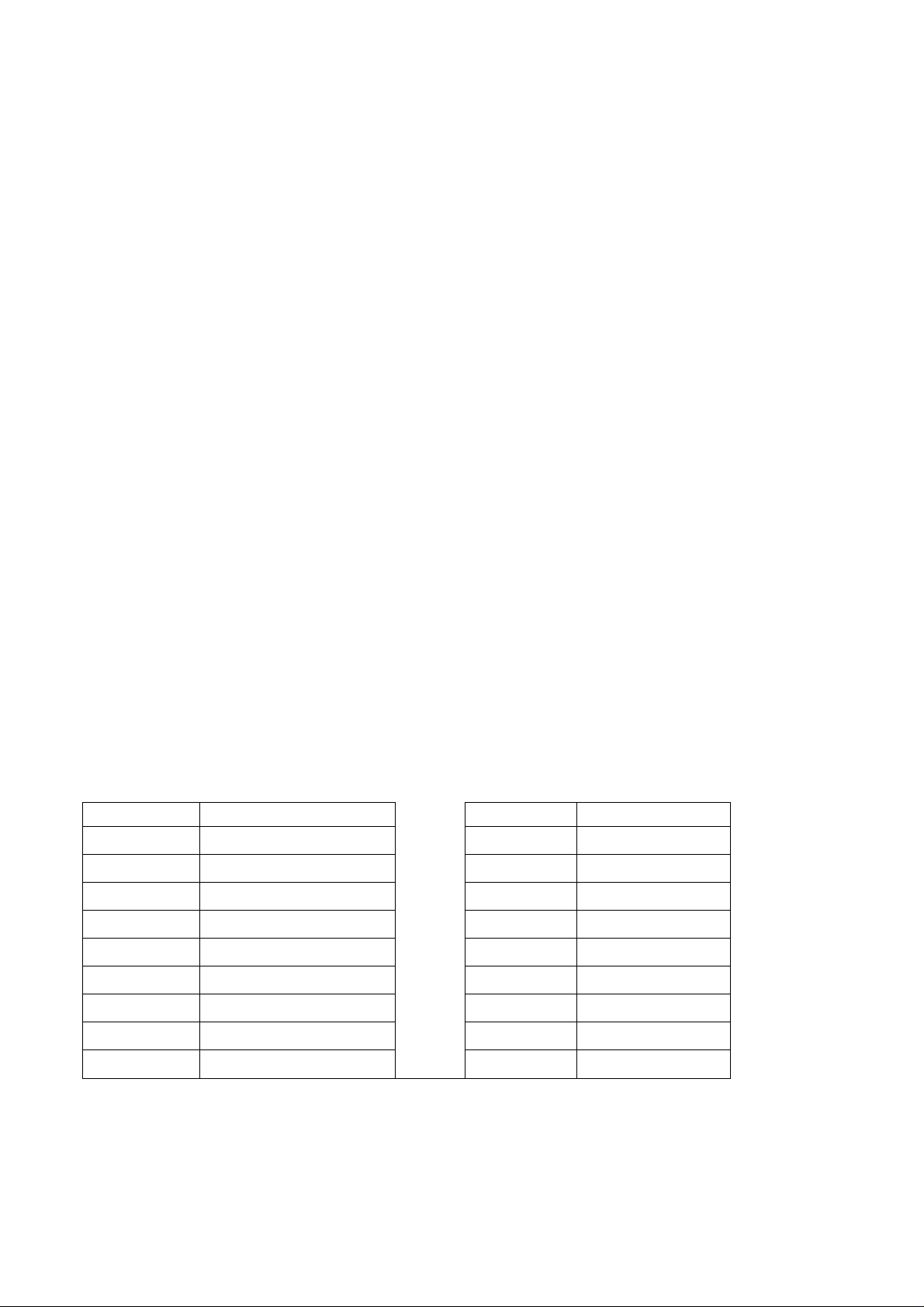

Table n.1

Min. Clearances inches (mm) Min. Clearances inches (mm)

20”

L1

L2

L3

L4

L5

L6

L7

L8

L9

(500)

1

9/16“ (40)

2

3/4” (70)

18” (457)

24” (610)

13” (330)

36

1/2“ (925)

1

9/16“ (40)

6

3/4” (172)

L10

L11

W

D

B1 (*)

B2 (*)

B3 (*)

B4 (*)

34 1/4” (870)

36“ (915)

35 1/16“ (890)

20

1/2“ (520)

2

3/8“ (60)

6“ (152)

2 3/8“ (60)

6“ (152)

(*) Note:

-B1 is the min. clearance between the front edge of the appliance and the front edge of the cabinet.

-B2 and B4 are the min. clearance between the left/right side edge of the appliance and the side wall (if

present).

-B3 is the min. clearance between the back edge of the appliance and the back wall.

5

Attaching the hotplate

To prevent liquids from leaking accidentally into the underlying storage space, the appliance is equipped with

a special gasket. To apply this gasket, carefully follow the instructions in Fig. 3. Lay out the protective sealing

strips along the edges of the opening in the bench top and carefully overlap the strip end. (See Fig. 3). insert

the hotplate into the bench top opening. With a screwdriver assemble the brackets to the hotplate bottom by

means of the screws . (See Fig. 4A-4B). Slide the hooks into position and secure them with the screws.

Trim the part of the sealing strips which extend beyond the hotplate base

Gas connection

Before connecting the appliance to the gas supply, first remove the plastic plug on which is pressfitted into the gas inlet union; to remove, just pull it off.

1. Check the ‘gas type’ sticker attached to the hotplate. Details of the injector sizes used are recorded on the

data plate located on the base of the appliance.

2. This appliance shall be installed in accordance with installation requirements of the local gas authority of

the appropriate installation code.

3. Before installing the hotplate consider the location of the gas supply and routing the gas line.(Refer fig.6)

4. For LPG models the gas supply is connected to the regulator which is supplied loose. The inlet connection

has a 1/2” B.S.P. male thread. IT IS ESSENTIAL THAT

THE ELBOW ON THE APPLIANCE BE HELD FIRMLY WITH A SPANNER WHEN CONNECTING THE

SUPPLY. DO NOT OVER TIGHTEN. The regulated pressure For LPG is 11” w.c. (See Fig. 5).

5. For NG models the gas supply is connected to the regulator which is supplied loose. The inlet connection

has a 1/2” B.S.P. male thread. IT IS ESSENTIAL THAT

THE ELBOW ON THE APPLIANCE BE HELD FIRMLY WITH A SPANNER WHEN CONNECTING THE

SUPPLY. DO NOT OVER TIGHTEN. The regulated pressure For NG is 4” w.c. (See Fig. 5).

6. For gas inlet position of appliance refer Fig 5, 6 and 7. After installing the gas supply and making all

connections check thoroughly for possible leaks. Turn all control knobs on the unit to ‘OFF’ position. Open

the valve on the gas supply. Using a soap and water solution check each gas connection one at the time, by

brushing the solution over the connection. Presence of bubbles will indicate a leak. Tighten the fitting and recheck for leaks. If it is not possible to correct the leak, replace fitting. Under no circumstances use matches

or flame for checking leaks.

It is essential that the gasket and the pressure test point stopper are properly installed to avoid gas leakage

7.To checking inlet pressure at the appliance operate as follow:

a) Disconnect electric power before pressure checking be carried out.

b) Take off one of the gas burner cap and the relative flame spreader in order to get access to the

burner injector.

c) Put in position the pressure detector directly on the burner injector afterward open the relative burner

knob at maximum position keeping it pressed, then measure the outlet pressure from the burner

injector.

d) Once the pressure checking has been carried out, replace the burner cap and flame spreader in the

correct and original position and re-connect electric power to the appliance.

8. Turn on appliance control cock and light each burner. Check for a clear blue flame without yellow tipping.

If burners show any abnormalities check that they are located properly and in line with the injector nipple.

9. Sometimes the burners will not ignite immediately and seem to ‘blow’ slightly when they do ignite. This

usually due to air in the gas lines, which will clear itself within seconds.

10. If after following the instructions given, satisfactory performance cannot be obtained, contact the local

gas authority for advice and assistance.

6

Electrical connection

The appliance is equipped with a 4 ft. (1.2 m.) flexible metal cable with 4 wires ready for connection to a

dedicated 4 wire grounded power supply/junction box: (fig.8)

Voltage 120/208 V a.c., Frequency 60Hz. Max Current: 2800W /13,5 A

Voltage 120/240 V a.c., Frequency 60Hz. Max Current: 3700W /15,5 A

Black wire

Red wire

White wire

Green wire

: connect to L1 (hot)

: connect to L2 (hot)

: connect to N (neutral)

: connect to GND (ground)

A dedicated line and junction box should be used to connect the oven to a 20 A circuit.

Wiring diagrams Fig. 20.

Room ventilation – Location and venting.

ATTENTION: An exhaust fan may be used with the appliance; in each case it shall be installed in

conformity with the national standards in force.

ATTENTION: Exhaust hood operation may affect other vented appliances; in each case it shall be

installed in conformity with the national standards in force.

Conversion to different types of gas

Before carrying out any maintenance work, disconnect the appliance from the gas and electric

supply. For Natural Gas fit regulator assembly described in Fig. 5. For LP Gas fit assembly described

in fig. 5.

- CHANGING THE NOZZLES FOR USE WITH OTHER TYPES OF GAS:

To change the nozzles of the burners use the following procedure:

Lift up the burners and unscrew the nozzles ( Fig. 9) using an adjustable spanner of 7 mm and change the

nozzles with those designed for the new gas supply according to the information given in TABLE A shown

below.

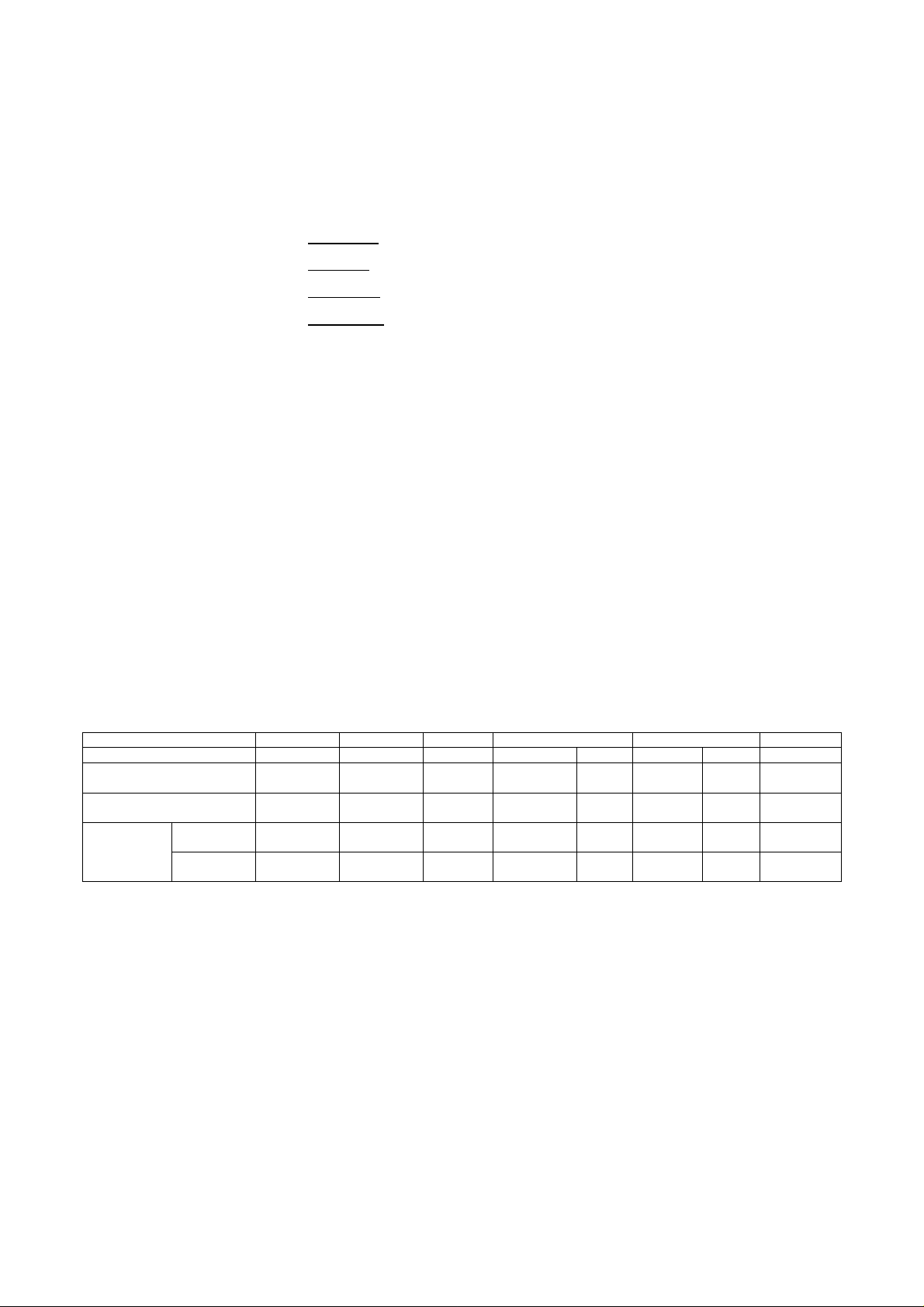

TABLE A: Adapting to different types of gas

Burner Inj. size Gas Pressure Max Rate Min Rate By-pass size

1/100mm Type [i.w.c.] [BTU/h] [W] [BTU/h] [W] [1/100mm]

Semi-Rapid

Rapid

Inner 80 NG 4” 2730 799 900 264 Regulated

Dual 50 LP(Propane) 11” 2900 849 900 264 29

burner Outer N°2 x 130 NG 4” 15000 4394 4500 1318 Regulated

N°2 x 83 LP(Propane) 11” 16400 4804 4500 1318 65

CAUTION: save the orifices removed from the appliance for future use

117 NG 4” 6000 1759 1500 439 Regulated

73 LP(Propane) 11” 6300 1845 1500 439 36

155 NG 4” 10400 3046 2500 732 Regulated

98 LP(Propane) 11” 11400 3339 2500 732 47

Regulation of burners

Regulation of the "MINIMUM" on the burners

To regulate the minimum on the burners carry out the following procedure indicated below:

1) Turn on the burner and put the knob onto position MINIMUM ( small flame ).

2) Remove the knob ( Fig. 11) of the tap which is set for standard pressure. The knob is found on the bar of

the tap itself.

3) Beside the tap bar on the work top, use a small screwdriver that fits the screw (gold) found on the lower

part of the tap and turn the fixing screw to the right or left until the flame of the burner is regulated in the most

suitable way to MINIMUM.

4) Make sure that that the flame does not go out when changing the position quickly from MAXIMUM to the

MINIMUM position.

ATTENTION: The regulation described above can be carried out only with burners using natural gas,

while with burners using propane gas the screw must be fully screwed in, in a clockwise direction.

7

Adaptation of the pressure regulator for use with different type of gas

The pressure regulator supplied with the appliance is a convertible type pressure regulator for use with

Natural Gas at a nominal outlet pressure of 4” w.c. or LP gas at a nominal outlet pressure of 11” w.c. and it is

pre-arranged from the factory to operate with one of these gas/pressure as indicated in the pre-arranging

labels affixed on the appliance, package and Instruction booklet.

To convert the regulator for use with the other gas different from which one it is pre-arranged it is enough

perform the following operations:

1) Unscrew by hand the upper metal stopper of the regulator (Fig. 5).

2) Unscrew by hand the white plastic piece screwed under the above mentioned metal stopper, afterward

screw it again in opposite way under the metal stopper (for gas reference see the written “LP” and “NAT” with

relative indicating arrows on the white piece).

3) Screw again by hand the metal stopper in the original position on the regulator.

Operating in this way the gas regulator is converted for use with the other gas/pressure.

Descriptions

DESCRIPTIVE CAPTION FOR HOB (fig.10)

1. Dual burner

2 Rapid burner

3. Rear Induction element

4. Front induction element

5. Semi-rapid burner

6. Dual out burner control knob

7. Dual in burner control knob

8. Rapid burner control knob

9. Medium burner control knob

10. Front Induction element control knob

11. Rear Induction element control knob

Service & maintenance instructions

Service and maintenance only to be carried out by an authorised person

To replace parts such as burners, valves and electric components, the hotplate must be removed from the

bench top by releasing the attachment hooks, loosening the attachment screws of each burner, unscrewing

the hotplate attachments nuts which are visible at the bottom of the surface, removing the hotplate top and

finally replacing the defective parts.

Note: if the valves must be replaced, first disassemble the ignitions switches wires.

It is recommended to replace the valve gaskets each time the valve is replaced, thus ensuring a perfect seal

between the body and the gas train.

WARNING: Disconnect power before servicing unit.

For the location of the wall receptable for the connection of the three-pin earthed plug of the

appliance, see indications given in Fig. 1- 2

WARNING: After first installation of the appliance or after any service intervention concerning main

gas parts of the appliance, make the leak test using water with soap on the gas connections in order

to verify the correct installation. Do not use fire for gas leak testing.

8

User instructions

IMPORTANT SAFETY INSTRUCTIONS

1 - Proper Installation - Be sure your appliance is properly grounded and installed by a qualified technician.

2 - Never Use your Appliance for Warming or Heating the Room.

3 - Do Not Leave Children Alone - Children should not be left alone or unattended in an area where

appliance is in use. They should never be allowed to sit or stand on any part of the appliance.

4 - Wear Proper Apparel - Loose-fitting or hanging garments should never be worn while using the

appliance.

5 - User Servicing - Do not repair or replace any part of the appliance unless specifically recommended in

the manual. All other servicing should be referred to a qualified technician.

6 - Storage in or on Appliance - Flammable materials should not be stored near surface units.

7 - Do Not Use Water on Grease Fires - Smother fire or flame or use dry chemical or foam-type extinguisher.

8 - Use Only Dry Potholders - Moist or damp potholders on hot surfaces may result in burns from steam. Do

not let potholder touch hot heating elements. Do not use a towel or other bulky cloth.

9 - Use Proper Pan Size - This appliance is equipped with several, differently sized, induction elements.

Select cookware having flat bottoms, large enough to cover the surface unit heating element. Proper size

pots and pans will also improve efficiency.

10 - DO NOT TOUCH SURFACE UNITS OR AREAS NEAR UNITS - Surface units may be hot even though

they are dark in color. Areas near surface units may become hot enough to caus e burns.

11. Do Not Heat Unopened Food Containers - Build-up of pressure may cause container to burst and result

in injury..

12. Never Leave Surface Units Unattended at High Heat Settings - Boil-over causes smoking and greasy

spillovers that may ignite.

13. Do not use aluminum foil, aluminum liners or aluminum containers on the unit.

14. Cookware Handles Should Be Turned inward and Not Extend Over Adjacent Surface Units - To reduce

the risk of burns, and spillage due to unintentional contact with a pot/pan, which is used for cooking, the

handle of the piece should be positioned so that it is turned inward, and does not extend over adjacent

surface units.

15. Do not Cook on Broken Cooktop - If cooktop should break, cleaning solutions and spillovers may

penetrate the broken cooktop and create a risk of electric shock. Contact a qualified technician immediately.

16. Clean Cooktop With Caution - If a wet sponge or cloth is used to wipe spills on a hot cooking area, be

careful to avoid steam burns. Some cleaners can produce noxious fumes if applied to a hot surface.

CAUTION

Do not store items of interest to children in cabinets above or around the cooktop -children cli m bing on the

cooktop to reach items, could be seriously injured.

WARNINGS:

Keeping appliance area clear and free from combustible materials, gasoline and other flammable

vapors and liquid.

Do not store dangerous or flammable material in the cabinet areas above appliance; store them in a

safe place in order to avoid potential hazards.

For safe use of appliance, do not use it for space heating.

Do not use aerosol sprays in the vicinity of this appliance while it is in operation

For description of hotplates refer to installation instructions.

9

Using burners

A diagram is etched on the control panel above each knob which indicates which burner corresponds to that

knob. (fig.12-13-14-15)

Manual ignition:

Manual ignition is always possible even when the power is cut off or in the event of prolonged power failure.

Turn the knob that corresponds to the burner selected counterclockwise to the MAXIMUM position at the

etched star (large flame) and place a lit match up to the burner.

Burners fitted with a safety device (thermocouple):

Turn the knob that corresponds to the burner selected counterclockwise to the MAXIMUM position at the

etched star (large flame) and then press the knob down to activate the spark ignition. Once ignited, keep

pressing the knob for about 10 seconds to allow the flame to heat the thermocouple. If the burner does not

remain alight after releasing the knob repeat the above procedure,

Note: Dual burner is composed by two burner (inside and outside); each one operates under the relative gas valve

indipendently from the other one.

Note: It is recommended not to try to ignite the burner if the relative flame cap is not in the correct position

Tips for using burners correctly:

WARNING: During use of each gas burner(s) adjust the burner flame size properly so it does not

extend beyond the edge of the cooking utensil. This is an instruction based on safety considerations

- Use suitable pots for each burner (see Fig. 18 and Table B)

- When the liquid is boiling, turn down the knob to the MINIMUM position.

- Always use pots with a cover.

Table B

Burner Recommended pan diameters inches (mm)

Medium 51/8”- 103/8”(140 – 260)

Large 77/8”- 103/8” (180 – 260)

Dual 82/3”-103/8” (220 – 260)

Correct usage of pans:

- Dry the bottom of the pan before placing it on the hotplate.

- Use pots with a flat, thick bottom, except for wok cooking.

- When using the burners, ensure that the handles of the pans are correctly positioned. Keep children away

from the appliance.

- When cooking foods with oil and fat, which are very flammable, the user should not leave the appliance

unattended.

WARNING: If the power is cut off, the burners can be lit with matches.

The burners equipped with a safety thermocouple can only be lit when the knob is in the MAXIMUM position

(large flame etching).

Note: The use of a gas cooking appliance produces heat and humidity in the room where it is installed.

Therefore, proper ventilation in the room is needed and natural ventilation openings must remain

unobstructed and activating the mechanical exhaust fan/range hood. Intensive and continuous use of the

appliance may require additional ventilation, for example by opening a window, or increasing the power of

the mechanical exhaust fan/range hood, if installed.

10

Using the ceramic induction elements

Safety Precautions - Read before operating your cooktop

Your induction-cooking unit has been designed for residential use and food preparation, and all of the safety

parameters have been designed accordingly.

The unit incorporates numerous safety devices and controls, a few of which will be mentioned below:

- A number of sensors monitor the temperature of the internal components. If any of these sensors senses

that the component temperature is above the limit, the power output of the unit will automatically be reduced,

allowing the component to cool down. Once this is achieved, the unit will continue to operate normally at the

output level set initially by the operator..

-Each induction element is equipped with a sensor which is continuously monitoring the temperature of the

bottom of the pan to prevent the pan from overheating.

-Each induction element is equipped with a pan sensing device. This device will not allow the element to turn

on unless it senses an induction-compatible pot or pan on the element covering enough surface area. If no

pot/pan is detected, the digital display will flash indicating that there is no power on the element. Once an

induction-compatible piece of cookware is sitting properly on the element, the digital display will become

steady, and the cookware will start heating up. Note that a small object as a fork, a spoon, a piece of jewelry,

etc. will not be mistaken for a cooking utensil, and it will not trigger this sensor. Moreover, this device will

distinguish between pots and pans which are and are not suitable for induction cooking.

If a piece of cookware, which is not suitable for induction cooking, is placed on an element, there will be no

power output on the element.

We reserve the right to make any changes to internal components, as well as, to make any (cosmetic)

modifications on the outside in an effort to improve our products.

Users with pacemakers or defibrilators must consult with their pacemaker manufacturer or their physician

prior to using this cooktop which incorporates an induction heating source.

If a crack appears in the glass surface, disconnect the unit immediately to avoid any risk of electric shock. If

the unit is connected directly to supply inside a junction box, then disconnect its breaker, or remove fuses

manually.

Do not use your cooktop until the glass top has been replaced.

When cooking, never use aluminum foil, never place products wrapped in aluminum foil or products deepfrozen in aluminum packs on the cooktop.

Aluminum foil could melt and damage the vitroceramic glass beyond repair.

The Principle of Induction

When an induction element, also called: ‘a heating zone’ or simply: ‘a coil’ - is switched on, the appropriate

piece of cookware used, and a desired level of heating power selected, the electronic circuit unit (‘induction

generator’ or ‘inverter’) powers up the induction element which creates a magnetic field. This magnetic field

continuously changes in terms of frequency and intensity, and this creates induced ‘eddy’ currents in the

bottom of the pot or pan and ultimately results in heat. The heat is transferred directly to the food being

cooked.

Thus, induction heat makes the cookware a direct source of heat, featuring high level of efficiency with

extremely low energy loss and unparalleled heating level control.

With induction cooking there is very little ‘heating inertia’. Induction cooking elements do not incorporate a

heat generating element, unlike convectional electric rings, halogen or radiant elements etc, therefore, heat

levels can be changed very quickly.

For induction, energy efficiency is within a range of 90-95%, compared with 55-65% for conventional and

radiant element, or 45% - 55% for gas fueled burners. The energy efficiency contributes to substantial

energy savings, both beneficial to the owner as well as the environment.

Induction cooking elements are sensitive to the cookware type being used :

- If there is no cookware placed on the element, or if the cookware is not of induction grade, there will be no

power emitted by the element.

- If the the piece of cookware is placed partially on the element, or if it is smaller than the element, the

internal sensors will reduce power to the element.

- If the pot/pan is fully removed from the element, the power output will be instantaneously reduced to ‘0’.

The controls will turn the element off after a minute, unless the piece is returned onto the element.

11

When compared to other methods of cooking, induction cooking has a very low level of ambient heat, thus

making cooking more pleasurable, with a reduced need for ventilation.

Finally, the vitroceramic glass as a cooking surface barely becomes hot and this makes cleaning much

easier.

When using induction elements, some cookware may produce faint humming sound. This is a normal

occurrence. The noise is a result of vibrations caused by induced currents.

For a proper choice of pots and pans, please see “Cookware for Your Inductio n”

SET THE COOKING TEMPERATURE AS FOLLOWS

Set he heat setting the control knob.

OFF= element off

1= lowest setting

9= highest setting

B= Powerboost function

A= Heating accelerator

Led indicator

H = Residual heat

B = Powerboost Function

= Power ON

These knobs provide control of the induction cooking zones above each knob there is indication of the zone

controlled..

Push and turn the knob to the right to set the zone's operating power; the settings range from a minimum of

1 to a maximum of 9. (fig.16-17)

Heating accelerator

Each cooking zone is equipped with a heating accelerator.

This system allows the zone to be operated at peak power for a time proportional to the heating power

selected.

To start the heating accelerator, turn the knob to the left, select setting "A" and then release.

You now have 3 seconds to select the heating setting between 1 and 9.

While the heating accelerator is in operation, the heating level can be increased at any time. The "full power"

time will be modified accordingly. If the power is reduced by turning the knob anticlockwise, the heating

accelerator is automatically deactivated.

Powerboost Function

The power function allows the user to operate each heating zone continuously at the maximum power for a

time of no more than 10 minutes. This function can be used, for example, to bring a large amount of water to

the boil in a hurry, or to turn up the heat under meat.

Push and turn the knob clockwise and set heating level 9, then use the knob to set the "B" position and

release il. "B" appears on the corresponding zone display.

After 10 minutes, the power is reduced automatically, "B" led is switched off.

However, the power function can be turned ott at any time by reducing the heating level. .

When the power function is selected for one heating zone, the power absorbed by the second zone might

be reduced to supply the maximum available energy to the first zone.

If a pan is removed from the cooking zone while the power function is on, the function is switched off.

Child lock

The child lock function prevents switching on of the control unit, to avoid unwanted operation, for example by

children, While child lock is activated, no cooking zone can be used.

The child-lock mode is activated by overwinding the two knobs in anti-clockwise direction for mode than 1, 5

secs-alternatively: one knob for more 5 secs; AND less than 30 secs to avoid failure detection.

The child-lock is disabled in the same way.

Aktivation/disabling is only possible if both knob input units are in zero position.

12

Type of pans

This type of appliance can only operate with pans of special kinds.

The bottom of the pan must be iron or steel/iron to generate the magnetic field necessary for the heating

process

Vessels made from the following materials are not suitable:

glass;

porcelain;

pottery;

steel, aluminium or copper without magnetic bottom;

To check that a pan is suitable, simply piece a magnet close to its bottom:

if the magnet is attracted, the pan is suitable for induction cooking.

The pans used for cooking must have certain minimum diameters to ensure satisfactory operation.

Pans larger than the cooking zones can also be used, but it is important to ensure that the bottom of the

pan does not touch other cooking zones, and that it is always centred over the perimeter of the cooking

zone.

Use only vessels specially designed for induction cooking, with thick, completely flat bottom; if these are not

available, the pans used must not have crowned (concave or convex) bottom. (fig.19)

Residual heat

Each cooking zone is equipped with a device which warns of residual heat. After any cooking zone is

switched off, a ‘H’ may appear on the display. This warns that the cooking zone concerned is still very hot.

Cooking can be restarted while the ‘H’ is on.

Attention:

Take care not to spill sugar or sweet mixtures onto the hob during cooking, or to place materials or

substances which might melt (plastic or aluminium foil) on it; if this should occur, to avoid damage to the

surface, turn the heating off immediately and clean with the scraper supplied while the cooking zone is still

warm. If the ceramic hob is not cleaned immediately, residues may form which cannot be removed once the

hob has cooled.

Important!

Keep a close eye on children because they are unlikely to see the residual heat warming lights. The cooking

zones are still very hot for some time after use, even if they are switched off. Make sure that children never

touch them.

WARNING: Under no circumstance use aluminium foil or plastic containers to hold the food while cooking on

a glass-ceramic hob.

WARNING: Do not touch the cooking area as long as the light indicating residual heat on the glass-ceramic

hob, is “on”; this indicates that the temperature in the relative area is still high.

WARNING: Never place pan with bottoms which are not perfectly flat and smooth on the hob

WARNING: If you notice a crack in the ceramic hob, disconnect the appliance from the electricity supply and

contact a service centre

WARNING: Your glass-ceramic hob is thermal shock resistant and resistant to both heat and cold.

If you drop a heavy pot on your hob it will not break.

On the contrary, if a hard object, such as the salt shaker or the spice bottle strikes the edge or the corner of

the hob, the hob may break.

WARNING: never use the glass-ceramic hob as support surface.

Matching Pots & Pans with Elements, etc.

All elements,14,5cm (5 3/4”), are best used:

- With small pieces of cookware - but normally not smaller then 10 cm (4”);

-For slow cooking and simmering (sauces, creams, etc.);

-For cooking small quantities of food.

Minimum 10cm (3 15/16”)pots, maximum 25cm (10”) pots.

When cooking large quantities of food, it is always better to use a large diameter pot/pan covering the

element. Thus, better and more efficient heat distribution will be achieved and food will be cooked evenly.

13

To Do or Not To Do

You must:

- Always place your cookware in such a way that its center is aligned with the centre of the element.

- Avoid hitting the vitroceramic glass with cookware or any hard objects. The glass surface is highly resistant

but not unbreakable.

- Pick-up your cookware when moving them around. Do not slide them and avoid excessive rubbing of the

top, as this leave scratches and erase the markings

- Avoid using cookware with rough or deformed bottoms.

- Avoid leaving any metal cooking accessories, knives and forks, or metal objects on the cooktop. They may

get hot if left close to any heating element in use.

- Avoid storing flammable products in the cabinets under your cooktop.

- Never leave an empty pot/pan on an induction heating element, even when the element is turned OFF.

-Only use maximum power for boiling and frying.

-Never try heating up a closed can.

- Avoid preheating your non-stick pans (e.g. with teflon coating) at maximum heat.

- Avoid storing solid and heavy items in the cabinets above your cooktop.They may accidentally be dropped

and damage the glass top.

Your cooktop must never be used as a storage space or a surface for piling up of any material.

Do not connect any appliances to the plugs above or near to the induction cooktop; connection cable

insulation can melt if in contact with heat, and this may result in an injury and a property damage.

Cooking recommendations

FOOD KNOB POSITION

Melting

Chocolate, chocolate coating, butter 1-2

Heating

Frozen vegetables eg.spinach 2-4

Broth 8-9

Thick soup 2-3

Milk (without lid) 1-2

Simmering

Delicate sauce 7-8

Spaghetti sauce 2-3

Pot roast 5-7

Fish (without lid) 6-8

Cooking

Rice 3-4

Potatoes boild in their skins 5-7

Boiled potatoes 5-7

Fresh vegetable 5-7

Frozen vegetable 5-7

Pasta 8-9

Pudding (without lid) 7-8

Cereals 3-4

Frying

Pork chop 8-9

Chicken breast 6-7

Bacon 8-9

Eggs 7-8

Fish 8-9

Pancakes 8-9

14

Cleaning the appliance:

Never use abrasive cleaners

Before cleaning the appliance it should be disconnected from the power supply.

Cleaning the work surface: periodically clean the burner heads, the enamelled steel pan supports and the

burner caps using warm water.

Any spillage must always be removed as soon as possible using a rag.

If it become difficult to open or close a valve, do not force it, but immediately request the assistance

of the technical service personnel.

Cleaning the enamelled parts: Enamelled parts should be cleaned frequently with soapy water. Never use

abrasive powder. Do not leave acidic or alkaline substances on the enamelled parts (such as vinegar, lemon

juice, salt, tomato sauce, etc.) and do not wash the enamelled parts while they are still hot.

Cleaning the stainless steel parts: Clean the parts with soapy water and dry them with a soft cloth. The

shine is maintained by periodically using suitable products which can be found in the supermarket. Never

use abrasive powders.

Cleaning the burner caps: Lift the burner caps from the burner heads and wash them in soapy water and

dry thoroughly. Before replacement on the burner head ensure that the holes are not clogged.

Cleaning the glass ceramic: Warning: Do not use any kind of cleaner on the glass while the surface is hot,

use only the razor blade scraper. The resulting fumes can be hazardous to your health. Heating the cleaner

can chemically attack and damage the surface.

Clean the surface when it is completely cool with the following exception: remove dry sugar, sugar syrup,

tomato products and milk immediately with the razor blade scraper.

Wipe off spatters with a clean, damp sponge or a paper towel. Rinse and dry. Use white vinegar if smudge

remains; rinse.

Apply a small amount of the glass ceramic cooktop cleaner. When dry, buff surface with a clean paper towel

or cloth.

TYPE OF STAIN WHAT TO DO

Minor Soak the area to be cleaned with soapy

water, then wipe it.

Accumulated burnt-on

stains

Rings and traces of lime

scale

Burnt-on stains following

sugar spillage, melted

aluminum or plastic.

Soak the area to be cleaned with warm

soapy water. Use a special scraper for

vitroceramic glass to remove grease and

food particles. Finish off with a cleaning

sponge, then wipe it clean.

Apply warm white vinegar on the stain. Let

it sit, then wipe off with a soft cloth.

OR

Use a commercial cleaner on affected

area. Note that such cleaner may leave

stains on stainless steel frame, thus

protect exposed stainless steel.

- Apply special vitroceramic glass cleaner

on the surface, preferably one which

contains silicone (protective action).let it

sit, then finish off with a cleaning sponge,

then wipe it clean.

ACCESSORIES or AGENTS

EMPLOYED

Cleaning sponges & mild

detergents

Cleaning sponges, mild

detergents and cleaning agents

for vitroceramic glass

Cleaning cloth, white vinegar, or

diluted descaling agent.

Vitroceramic cleaning agents and

sponge.

Allowable: Non-abrasive Paste - Ordinary Sponge or Special Sponge for Delicate Items

Not allowable: Abrasive-backed sponge - Powder

15

Troubleshooting

You have doubts about whether your cooktop is working correctly this does not necessarily mean there is a

breakdown. Nevertheless, check the following points

PROBLEMS POSSIBLE CAUSES WHAT SHOULD YOU DO?

When you switch the unit on the

supply-line breaker trips off or the

supply-line fuse burn

Your cooktop makes a faint

clicking noise when in operation

The unit doesn’t work at all There may be a power supply or

After turning an element ON, and

having a pot /pan placed on the

element, there is no heat and the

digital indicator continues flashing

Cookware makes noise during

cooking

The cooktop gives off a smell

when first used for cooking

Servicing of an induction unit is to be done by an authorized service agent. Contact your dealer for service

location closest to your residence. Never try servicing the unit yourself.

If any crack on the vitroceramic glass can be noticed, or the glass is broken DO NOT USE THE UNIT.

Disconnect the electrical supply to the unit by tripping the breaker off (if the unit is hard-wired to the supply)

or just unplug the unit (if there is a plug on the supply cable).

Your unit may be connected

incorrectly, or there is an internal

problem

This noise occurs when the power

is being shared between two

induction elements

internal problem

The pot/pan you are trying to use

is not suitable with induction

cooking or its diameters is under

10 cm (4”)

Your cookware create noise from

vibrations caused by induced

current

A new unit Use each heating element for an

Have the connection checked

first, if ok contact your service

agent.

This is a normal occurrence

Check your beakers

/fuses/connection cable

If ok contact your service agents

Use another piece of cookware

suitable for induction cooking

Under high power this

phenomenon is normal with some

types of pots and pans. There is

no danger for the cooktop

hour with a pan filled with water

After sale service:

Dealer /Importer: Name, address, phone

SERVICE CENTERS

Name Phone

MANUFACTURER:

BERTAZZONI SPA

VIA PALAZZINA, 8 – 42016 – GUASTALLA (REGGIO E.) ITALY

Tel. 0522/226411 – telefax 0522/226440 – http://www.bertazzoni-italia.com

16

Installation, Service et Instructions pour l’Utilisateur

Tables de cuisson gaz à encastrer

DIMENSIONS: 36 1/2’’ (925 mm)(W) x 211/4’’ (540 mm)(D)

Models PMMK..D7X (2 or 5)D PM3630GX

IMPORTANT: A CONSERVER POUR L’UTILISATION DE L’INSPECTEUR ELECTRIQUE

LOCAL.

LIRE ET CONSERVER CES INSTRUCTIONS POUR LES REFERENCES FUTURES.

OBSERVER TOUS LES CODES ET LES ORDONNANCES PRINCIPAUX.

ATTENTION: Au cas où les informations dans ce manuel ne seraient pas suivies

avec précision, un incendie ou une explosion peuvent se produire en provoquant

des dommages matériels, des blessures ou la mort.

Ne pas stocker ou utiliser d’essence, d’autres vapeurs ou liquides inflammables à

proximité de celui-ci ou de n’importe quel autre appareil.

CE QU’ON DOIT FAIRE EN CAS D’ODEUR DE GAZ

- N’essayez d’allumer aucun appareil.

- Ne touchez aucun interrupteur électrique.

- N’utilisez aucun téléphone dans votre établissement.

- Appelez immédiatement votre fournisseur de gaz par le téléphone d’un voisin.

Suivez les instructions du fournisseur de gaz.

- Si vous ne pouvez pas atteindre vos fournisseurs de gaz, appelez les pompiers.

L’installation et le service doivent être exécutés par un installateur qualifié, une

agence de service ou par le fournisseur du gaz.

Lisez ce livret d’instructions avant d’installer ou em ployer l’appareil.

Le fabricant ne sera responsable d’aucun dommage à la propriété ou aux personnes provoqué par

l’installation incorrecte ou l’utilisation inexacte de l’appareil.

Le fabricant se réserve le droit d’apporter des modifications à ses produits au cas où il le jugerait nécessaire

ou utile, sans influencer les caractéristiques essentielles de sécurité et de fonctionnement.

Cet appareil a été uniquement conçu pour une utilisation non-professionnelle et domestique.

17

GARANTIE ET SERVICE

Tous les produits Bertazzoni sont garantis 2 ans pièces et main-d'œuvre.

Les réparations concernant tous les produits Bertazzoni doivent uniquement être prises en charge par des

professionnels formés par l'entreprise.

Pour le service de garantie, veuillez contacter le Service clientèle aux numéros indiqués ci-dessous.

SERVICE CLIENTÈLE

Numéro d'appel gratuit en anglais/espagnol (866) 905-0010

Numéro d'appel gratuit en français (800) 561-7625

Fax (714) 428-0040

Email BERTAZZONIHELP@SERVICEPOWER.COM

Adresse postale

SERVICEPOWER

1503 South Coast drive

Suite 320

Costa Mesa CA 92626

PIÈCES DE RECHANGE

Seules les pièces de rechange Bertazzoni peuvent être utilisées lors des opérations de maintenance sur

l'électroménager.

Les pièces de rechange sont disponibles auprès des distributeurs de pièces de rechanges agréés.

INDEX:

Instructions d’installation..…………………………………..………………………... page 19

Insertion de la table de cuisson..………………………………..………………….. . page 19

Exigences…..……………………………………..……………………………….….. page 20

Fixation de la table de cuisson….………………………..………………………….. page 20

Branchement du gaz………………………………..………………………………… . page 20-21

Branchement électrique…………………………………..……………………….….. page 21

Schéma de câblage..………………………………..…………………………….…... page 21

Ventilation du local……………………………………………………………… …… page 22

Positionnement et dégazage…………………………….…………………………… page 22

Remplacement des becs….…………………………………..……………………… page 22

Réglage des brûleurs…. …………………………………………...………………… page 22

Descriptions……………………………………………………………………………. page 23

Instructions de service et d’entretien………………………………..…………….... page 23

Instructions pour l’utilisateur……………………………………………..………… . page 23-24

Utilisation des brûleurs…………………………………………..……………… …… page 25

Utilisation du plaque induction…………….……………………..………………… … page 26-30

Nettoyage de l’appareil……………………………………………..………………… page 31

Dépannage ……………………………………………..……………………………… page 32

Figures………………………………………………...…………..…………………… page 33

18

Instructions pour l’installation

Cet appareil devra uniquement être installé par une personne autorisée. Il devra être installé selon

les instructions d’installation des fabricants. IMPORTANT: cet appareil doit être installé selon les

normes en vigueur du pays concerné.

L’installation de cet appareil doit se conformer aux codes et aux ordonnances locaux. En l’absence

de codes locaux, l’installation de cet appareil doit se conformer aux Normes Nationales Américaines,

‘’National Fuel Gas Code’’ ANSI Z223.1 – dernière édition** ou B149.1.

Au cas où les codes locaux le permettraient, utilisez un dispositif de raccordement en métal flexible

avec le nouveau dessin certifié AGA ou CGA, de 1,5 mètres de longueur maximum, ½” I.D.

recommandé pour le branchement de cette table de cuisson au conduit d’amenée des gaz. Ne pliez

pas ou n’endommagez pas le connecteur flexible en déplaçant la table de cuisson. Le régulateur de

pression a un filetage au pas du gaz femelle de ½”. Vous devrez déterminer le raccordement

demandé, selon la dimension du conduit d’amenée des gaz, du connecteur en métal flexible et du

robinet d’arrêt.

L’appareil, lorsqu’il est installé, doit être mis à la terre selon les codes locaux ou, en l’absence de

ceux-ci, avec le ‘’National Electrical Code’’, ANSI/NFPA 70.

L’appareil et son robinet d’arrêt individuel doivent être débranchés du système du conduit d’amenée

des gaz pendant tous les essais sous pression de ce système à une pression d’essai supérieure à ½

psi (3,5 kPa).

L’appareil doit être isolé du système du conduit d’amenée des gaz, en fermant son robinet d’arrêt

individuel pendant tous les essais sous pression de celui-ci à une pression égale ou inférieure à ½

psi (3.5 kPa).

Pour l’utilisation avec un régulateur de pression. Le régulateur fourni doit être employé avec cet

appareil.

Le dispositif de réglage de pression doit être prédisposé pour le gaz avec lequel l’appareil est

employé.

Cet appareil peut être utilisé avec Gaz Naturel ou Gaz LP. Il est livré par l’usine et réglé pour

l’utilisation avec Gaz Naturel: LES INJECTEURS FIXE POUR LA CONVERSION DU GAZ SONT PLACE’

DANS L’EMBALLAGE IN DOTATION AVEC L’APPAREIL.

Le kit d’injecteurs pour le changement du type de gaz est contenu dans l’emballage avec le kit

d’installation de la table et le livret d’instructions.

La pression d’alimentation maximum du gaz en entrée dans le régulateur de pression de l’appareil à

gaz est de 20’’ colonne d’eau (w.c.) (5 kPa)

La pression d’alimentation minimum du gaz pour le contrôle du réglage du régulateur doit être au

moins de 1“ colonne d’eau (w.c.) (249 Pa) au-dessus de la pression du collecteur d’admission à

l’appareil spécifiée (cette pression de fonctionnement est de 4” colonne d’eau (1.00 kPa) pour le Gaz

Naturel et 11” colonne d’eau (2.75 kPa) pour le Gaz LP).

ATTENTION: Une valve manuelle doit être installée dans une position accessible dans la ligne du gaz

externe à l’appareil afin d’ouvrir ou d’arrêter le gaz à l’appareil.

AVERSTISSEMENT: Ne pas utiliser de pulvérisateurs d’aérosol à proximité de cet appareil lorsqu’il

est en fonction.

Insertion de la table de cuisson

Après avoir enlevé les différentes parties libres à l’intérieur et à l’extérieur de l’emballage, assurez-vous que

la table de cuisson ne soit pas endommagée et qu’elle soit appropriée pour l’utilisation du gaz spécifique.

L’étiquette du type de gaz se trouve en dessous de la base de la table de cuisson.

En cas de doute, n’employez pas l’appareil et contactez le personnel préposé.

Gardez toutes les pièces de l’emballage (mousse de polystyrène, carton, agrafes, etc.) loin des enfants.

Considérez les dimensions critiques de l’appareil, avant d’effectuer une ouverture dans la surface supérieure

du banc de travail. (mesures relatives selon la Fig 1- 2).

19

Exigences

1. Distances des meubles suspendus (Valeurs minimum)

Les distances minimum devront être conformes aux valeurs minimum indiquées dans la table n.1 et sont

illustrées dans la fig. 1- 2

Les hottes de cuisine et les ventilateurs aspirant doivent être installés selon les instructions du fabricant.

Cependant, dans aucun cas, la distance entre la partie supérieure du brûleur le plus haut de l’appareil de

cuisson et la hotte d’aspiration devra être inférieure au 25 ½ ” ( 650mm).

N’importe quelle autre surface combustible orientée vers le bas à moins de 600mm vers la partie supérieure

du brûleur le plus haut devra être protégée pour sa largeur complète et profondeur de la zone à cuire.

Cependant, dans aucun cas cette distance à n’importe quelle surface, devra être inférieure à 17

La profondeur maximum des armoires suspendues est de 13” (330mm)

2. Distances latérales (Valeurs minimum)

Les différentes distances latérales devront être conformes aux valeurs minimum indiquées dans la table n.1

et illustrées dans la fig. 1- 2. La zone de la surface à cuire est définie comme la partie de l’appareil où on fait

normalement la cuisson, et n’inclut pas les parties de l’appareil qui contiennent les boutons de contrôle.

Table n.1

Modèles de tables

de cuisson

Distances Min. pouches (mm) Distances Min. pouches (mm)

L1

L2

Type A

Type B

20”

(500)

1

9/16“ (40)

Modèles de tables

de cuisson

L10

L11

Type A

Type B

34 1/4” (870)

36“ (915)

3/4”(450mm.)

L3

L4

L5

L6

L7

L8

L9

3/4“ (70)

18” (457)

24” (610)

13” (330)

36

1/2“ (925)

1

9/16“ (40)

6

3/4” (172)

W

D

B1 (*)

B2 (*)

B3 (*)

B4 (*)

35 1/16“ (890)

20

1/2“ (520)

2

3/8“ (60)

6“ (152)

2 3/8” (60)

6“ (152)

2

(*) Notes:

-B1 est la distance min. entre le bord frontal de l’appareil et le bord frontal de l’armoire.

-B2 et B4 sont les distances minimum entre le bord latéral droit/gauche de l’appareil et le mur latéral (si

présent).

-B3 est la distance minimum entre le bord arrière de l’appareil et le mur arrière.

Fixation de la table de cuisson

Pour empêcher aux liquides de fuir accidentellement dans l’espace de stockage sous-jacent, l’appareil est

équipé d’une garniture spéciale. Pour appliquer cette garniture, suivez attentivement les instructions dans la

Fig. 3. Disposez les bandes d’étanchéité protectrices le long des bords de l’ouverture du banc de travail et

couvrez soigneusement l’extrémité de la bande. (Voir Fig. 3). Insérez la table de cuisson dans l’ouverture du

banc de travail. A l’aide d’un tournevis assemblez les supports en dessous de la table de cuisson au moyen

des vis . (Voir Fig. 4A-4B). Positionnez les crochets dans la position et fixez-les avec les vis.

Recoupez la partie des bandes protectrices qui s’étendent au-delà de la ba se de la table de cuisson.

Branchement du gaz

Avant de brancher l’appareil à l’alimentation gaz, enlevez d’abord le bouchon en plastique qui est

monté en force dans le raccord d’admission du gaz; pour l’enlever, le tirer simplement.

1. Vérifiez l’étiquette du ‘’type de gaz’’ attachée à la table de cuisson. Les détails concernant les dimensions

des injecteurs utilisés sont indiqués sur la plaquette des données située sur la base de l’appareil.

2. Cet appareil devra être installé selon les conditions d’installation de l’autorité locale du gaz du code

d’installation approprié.

20

3. Avant d’installer la table de cuisson considérez la position de l’alimentation gaz et l’itinéraire de la ligne du

gaz.( Se référer à la fig.6)

4. Pour les modèles LPG la ligne de distribution de gaz est connectée au régulateur qui est fourni

séparément. Le branchement d’entrée a un filetage mâle de 1/2” B.S.P ( filetage Whitworth pour tuyaux). IL

EST ESSENTIEL QUE LE COUDE SUR L’APPAREIL SOIT FERMEMENT RETENU AVEC UNE CLE

LORSQU’ON BRANCHE L’ALIMENTATION. NE PAS SERRER. La pression réglée pour LPG est de 11”

colonne d’eau. (Voir Fig. 5).

5. Pour les modèles GN (gaz naturel) la ligne de distribution de gaz est connectée au régulateur qui est

fourni séparément. Le branchement d’entrée a un filetage mâle de 1/2” B.S.P. ( filetage Whitworth pour

tuyaux). IL EST ESSENTIEL QUE LE COUDE SUR L’APPAREIL SOIT FERMEMENT RETENU AVEC UNE

CLE LORSQU’ON BRANCHE L’ALIMENTATION. NE PAS SERRER. La pression réglée pour GN est de 4”

colonne d’eau (Voir Fig. 5).

6. Pour la position d’entrée du gaz de l’appareil, référez-vous à la Fig 5, 6 et 7. Après avoir installé

l’alimentation du gaz et après avoir effectué tous les branchements, contrôlez soigneusement les

éventuelles fuites. Tournez tous les boutons de commande de l’unité sur la position ‘OFF’. Ouvrez la valve

sur l’alimentation du gaz. En utilisant une solution avec du savon et de l’eau contrôlez tous les

branchements du gaz, un après l’autre, en frottant la solution sur le raccord. La présence de bulles indiquera

une fuite. Serrer le raccordement et recontrôlez les fuites. Au cas où il ne serait pas possible de corriger la

fuite, remplacez le raccord. Pour n’importe quelle circonstance utilisez des allumettes ou des flammes pour

vérifier les fuites.

Il est essentiel que la garniture et la fermeture du point d’essai de la pression soient correctement installés

pour éviter la fuite de gaz

7. Pour vérifier l'itroduction de pression dans l'appareil il faut agir comme il suit:

a) Disjoindre la courent électrique avant de vérifier la pression.

b) Enlever un des chapeaux de brûleurs et la relative tete bruleur au fin d'accéder au injector du brûleur.

c) Mettre en position le détecteur de pression directement sur l'injector du brûleur ensuite ouvrir la relative

manette en la gardant poussée à la position maxima, aprés mesurez la sortie de pression par l'injector du

brûleur.

d) Quand on a terminé le contrôle de la pression, remettre le chapeau du brûleur et la tete bruleur dans la

position originale et correcte et rejoindre la courente électrique à l'appareil.

8. Ouvrez le robinet de commande sur l’appareil et allumez chaque brûleur. Vérifiez une flamme bleu-clair

sans formation de pointes jaunes. Si les brûleurs montrent quelques anomalies, vérifier qu’ils soient

positionnés correctement et en ligne avec la tête d’injecteur à filetage mâle.

9. Parfois les brûleurs ne s’enflamment pas immédiatement et semblent ‘souffler’ légèrement quand ils

s’allument. Cela est dû à l’air dans les canalisations de gaz, qui disparaîtra dans peu de secondes.

10. Si après les instructions données, une performance satisfaisante n’a pas été obtenue, contactez

l’autorité locale du gaz pour demander conseil et assistance.

Branchement électrique

L'appareil est équipé d'un câble en métal souple de 1,2 mètre (4 pieds) muni de 4 fils pré-équipés pour le

raccordement à un système dédié de mise à la terre à 4 fils/boîte à bornes : (fig.8)

Tension 120/208 Vca, Fréquence 60Hz. Courant max. : 2800 W /13,5 A

Tension 120/240 Vca, Fréquence 60Hz. Courant max. : 3700 W /15,5 A

Fil noir

: brancher sur L1 (sous tension)

Fil rouge : brancher sur L2 (sous tension)

Fil blanc : brancher sur N (neutre)

Fil vert : brancher sur GND (masse)

Utiliser une ligne dédiée et une boîte à bornes pour raccorder le four à un circuit 20 A.

Schémas de câblage voir la Fig. 20

21

Ventilation du local – Positionnement et dégazage

NOTE : Un ventilateur extracteur qui aide l’evacuation des produits de la combustion peut etre utilisé

dans le local où se trouve l’appareil ; en chaque cas il doit etre eventuellement installé

conformement aux normes nationals en vigueur.

NOTE : Le fonctionnement d’une hotte d’aspiration peut avoir influence sur les autres appareils a gaz

qui functionnent dans le meme local ; en chaque cas elle doit etre eventuellement installée

conformement aux normes nationals en vigueur.

Conversion à différents types de gaz

Avant d’effectuer n’importe quel travail d’entretien, débranchez l’appareil de l’alimentation gaz et

électrique. Pour le Gaz Naturel utilisez le régulateur illustré en Fig. 5. Pour LP Gaz utilisez celui

illustré en Fig. 5.

- REMPLACEMENT DES BECS POUR L’UTILISATION AVEC D’AUTRES TYPES DE GAZ:

Pour changer les becs des brûleurs, suivez le procédé suivant:

Soulevez les brûleurs et dévissez les becs ( Fig. 9) en employant une clé réglable de 7 mm et changez les

becs avec ceux conçus pour la nouvelle alimentation de gaz, selon les informations fournies dans le

TABLEAU A ci-dessous.

TABLEAU A: Adaptation aux différents types de gaz

Brûleur Diam inj. GaZ Pressure Dèbit nom. Dèbit reduit By-pass size

1/100mm Type [i.w.c.] [BTU/h] [W] [BTU/h] [W] [1/100mm]

Semi-Rapide

Rapide

Brûleur 50 LP(Propane) 11” 2900 849 900 264 29

Dual

N°2 x 83 LP(Propane) 11” 16400 4804 4500 1318 65

Intérieur

Extérieure

ATTENTION: gardez les orifices enlevés de l’appareil pour une utilisation future

117 NG 4” 6000 1759 1500 439 réglé

73 LP(Propane) 11” 6300 1845 1500 439 36

155 NG 4” 10400 3046 2500 732 réglé

98 LP(Propane) 11” 11400 3339 2500 732 47

80 NG 4” 2730 799 900 264 réglé

N°2 x 130 NG 4” 15000 4394 4500 1318 réglé

Réglage des brûleurs

Réglage du "MINIMUM" sur les brûleurs

Pour régler le minimum sur les brûleurs suivez le procédé indiqué ci-de ssou s:

1) Allumez le brûleur et mettez le bouton sur la position de MINIMUM ( petite flamme ).

2) Enlevez le bouton ( Fig. 11) du robinet qui est réglé pour la pression standard. Le bouton se trouve sur la

barre du robinet-même.

3) Enfoncez la pointe d'un petit tournevis à côté de la tige du robinet de la table en correspondance de la vis

dorée située sur la partie inférieure du robinet et tournez la vis à droite ou à gauche jusqu'à ce que la flamme

du brûleur soit réglée correctement au MINIMUM.

4) S’assurer que la flamme ne sorte pas en changeant rapidement la position du MAXIMUM en position de

MINIMUM.

ATTENTION: Le réglage décrit ci-dessus peut être seulement effectué avec des brûleurs qui

emploient le gaz naturel, tandis qu’avec les brûleurs qui emploient le gaz propane, la vis doit être

complètement vissée, dans le sens des aiguilles d’une montre.

Adaptation du régulateur de pression pour l’utilisation avec des différents types de

gaz

Le régulateur de pression fourni avec l’appareil est un régulateur de pression du type convertible pour

l’utilisation avec Gaz Naturel à une pression de sortie nominale de 4” w.c. (colonne d’eau) ou LP gaz à une

pression de sortie nominale de 11” w.c. (colonne d’eau) et il est pré disposé par l’usine pour fonctionner avec

un de ces gaz/pression, comme indiqué sur les étiquettes de réglage apposée s su r l’appareil, l’emballage et

le livret d’instructions.

Pour convertir le régulateur pour l’utilisation avec un gaz différent de celui qui a été arrangé il suffit

d’effectuer les opérations suivantes:

22

1) Dévisser à la main le bouchon en plastique supérieur du régulateur (Fig. 5).

2) Dévisser à la main la pièce en plastique blanche vissée sous le bouchon en métal su smentionné, ensuite

le visser encore dans le sens opposé sous le bouchon en métal (pour la référe nce du gaz voir l’écriture “LP”

et “NAT” avec les flèches relatives sur la partie blanche).

3) Visser encore à la main le bouchon en métal dans la position originale sur le régulateur.

En opérant de cette façon, le régulateur est transformé pour l’utilisation avec l’autre gaz/pression.

Descriptions

LEGENDE DESCRIPTIVE POUR LA TABLE DE CUISSON (Fig. 10)

1. Brûleur dual (poêle chinoise)

2. Brûleur rapide

3. Plaque céramique à induction posterieur

4. Plaque céramique à induction anterieur

5. Brûleur moyen

6. Bouton de commande du brûleur extérieur dual

7. Bouton de commande du brûleur intérieur dual

8. Bouton de commande du brûleur rapide

9. Bouton de commande du brûleur moyen

10. Bouton de commande du plaque induction anterieur

11. Bouton de commande du plaque induction posterieur

Instructions de service et d’entretien

Le service et l’entretien doivent seulement être exécutés par une personne autorisée

Pour remplacer les parties telles que les brûleurs, les valves et les composants électriques, la table de

cuisson doit être enlevée du banc de travail en libérant les crochets de fixage, desserrant les vis de fixage

de chaque brûleur, dévissant les écrous de fixage crochets de fixation de la table de cuisson qui sont

visibles au fond de la surface, enlevant la partie supérieure de la table de cuisson et remplaçant ensuite les

pièces défectueuses.

Avertissement: si les valves doivent être remplacées, désassemblez d’abord les câbles des interrupteurs

d’allumage.

Il est recommandé de remplacer les joints de la valve chaque fois que la valve est remplacée, assurant, de

cette façon, l’étanchéité parfaite entre le corps et le train de gaz.

ATTENTION: Débranchez l’alimentation avant l’entretien de l’unité.

Pour le positionnement de la prise au mur pour le branchement de la bonde de mise à terre à trois

pôles de l’appareil, voir les indications illustrées en Fig. 1- 2

ATTENTION: Après la première installation de l’appareil ou après n’importe quelle intervention

d’entretien concernant les parties principales du gaz de l’appareil, effectuez le test de fuite en

utilisant de l’eau avec du savon sur les raccordements de gaz pour vérifier l’installation correcte.

N’utilisez pas de feu pour le test de fuite du gaz.

Instructions pour l’utilisateur

1 – Installation convenable - S'assurer que l'appareil est convenablement installé et mis à la terre par un

technicien qualifié.

2 – Ne jamais utiliser l’appareil pour chauffer la pièce.

3– Ne pas laisser les enfants sans surveillance – Les enfants ne doivent pas rester seuls ou sans

surveillance à l’endroit où l’appareil est utilisé. Ne jamais leur permettre de s’asseoir ou de se tenir

debout sur l’appareil.

4 – Porter des vêtements appropriés – Ne jamais porter de vêtements amples ou pendants durant

l’utilisation de l’appareil.

5 – Faire appel à un centre d’assistance – Ne pas réparer ou remplacer des pièces de l’appareil à moins que

le manuel ne le recommande spécifiquement. Toutes les autres opérations d’entretien doivent être

confiées à un technicien qualifié.

6 – Stockage dans ou sur l’appareil – Ne pas stocker de matériaux inflammables à proximité des unités de

surface.

23

7 – Ne pas utiliser d’eau ou de feux de friture – Couvrir le feu ou la flamme ou éteindre à l’aide d’un

extincteur à poudre ou à mousse.

8 – Utiliser uniquement des poignées sèches - Des poignées de tissu humides posées sur des surfaces

chaudes peuvent provoquer des brûlures dues à la vapeur. Faire en sorte que la poignée ne touche pas

les éléments chauffants. Ne pas utiliser de serviette ou autre linge épais.

9 – Utilisation de récipients de taille adéquate – Cet appareil est équipé de plusieurs foyers à induction de

différentes tailles. Choisir des batteries de cuisine à fond plat, suffisamment larges pour couvrir l’élément

chauffant de l’unité de surface. Le choix de récipients de bonne taille améliorera également l’efficacité de

la cuisson.

10 – NE PAS TOUCHER LES UNITÉS DE SURFACE OU LES SURFACES À PROXIMITÉ DES UNITÉS –

Les unités de surface peuvent être chaudes, même si elles présentent une couleur foncée. Les surfaces

à proximité des appareils de surface peuvent devenir chaudes et provoquer des brûlures.

11 – Ne pas réchauffer de boîtes de conserve fermées – La pression accumulée peut faire exploser la boîte

et provoquer des blessures.

12 – Ne jamais laisser des unités de surface réglées sur des paramètres de puissance élevée sans surveillance –

Les débordements provoquent de la fumée et des salissures graisseu ses qui peuvent s’enflammer.

13- Ne pas utiliser de feuilles d’aluminium, de revêtements en aluminium ou de barquettes en aluminium sur l’unité.

14 - LES POIGNÉES DES BATTERIES DE CUISINE DOIVENT ETRE TOURNÉES VERS L’INTÉRIEUR ET

NE PAS DÉBORDER SUR LES ÉLÉMENTS CHAUFFANTS – Pour réduire le risque de brûlures et le

renversement dû à un contact accidentel avec la batterie de cuisine, la poignée du récipient doit être

tournée vers l’intérieur et ne pas déborder sur les unités de surface adjacentes.

15 - NE PAS CUISINER SUR UNE PLAQUE DE CUISSON CASSÉE – Si la plaque de cuisson se brise, des

produits d’entretien et des salissures risquent de pénétrer à l’intérieur de la plaque de cuisson et de

provoquer un choc électrique. Contacter immédiatement un technicien d’entretien agréé.

16 - NETTOYER LA PLAQUE DE CUISSON AVEC PRUDENCE – en cas d’utilisation d’une éponge ou d’un

chiffon mouillé pour essuyer des salissures sur une zone de cuisson chaude, prendre garde d’éviter les

brûlures provoquées par la vapeur. Certains produits d’entretien appliqués sur une surface chaude

dégagent des fumées toxiques.

ATTENTION

Ne pas ranger d'objets susceptibles d'éveiller la curiosité des enfants dans les meubles placés au-dessus ou

autour de la plaque de cuisson. Les enfants qui grimpent sur la plaque de cuisson pour les atteindre risquent

de se blesser grièvement.

ATTENTION:

Maintenir la zone de l’appareil propre et libre des matériaux combustibles, de l’essence et d’autres

vapeurs et liquides inflammables.

Ne stockez aucun matériel dangereux ou inflammable dans les meubles suspendus sur l’appareil;

stockez-les dans un lieu sûr pour éviter les risques potentiels.

Pour une utilisation sûre de l’appareil, ne l’employez pas pour le chauffage des locaux.

N’utilisez pas de pulvérisateurs d’aérosol à proximité de cet appareil lorsqu’il est en fonction

Pour la description des tables de cuisson, référez-vous aux instructions d’installation.

24

Utilisation des brûleurs

Un diagramme est gravé sur le tableau de commande sur chaque bouton qui indique quel brûleur

correspond à ce bouton. (fig.12-13-14-15)

Allumage manuel:

L’allumage manuel est toujours possible même lorsque l’alimentation est débranchée ou en cas de panne de

courant prolongée.

Tournez le bouton qui correspond au brûleur choisi dans le sens contraire des aiguilles d’une montre dans la

position de MAXIMUM à l’étoile gravée (flamme large) et mettez une allumette allumée sur le brûleur.

Brûleurs équipés d’un dispositif de sécurité (thermocouple):

Tournez le bouton qui correspond au brûleur choisi dans le sens contraire des aiguilles d’une montre à la

position de MAXIMUM à l’étoile gravée (flamme large) et puis appuyez sur le bouton pour activer l’allumage

par étincelle. Une fois qu’il est allumé, continuez à appuyer sur le bouton pendant 10 secondes environ, pour

permettre à la flamme de chauffer le thermocouple. Si le brûleur ne reste pas allumé après avoir relâché le

bouton, répétez le procédé ci-dessus.

Note: Le brûleur dual est composé de deux brû leurs (interne et externe) ; chacun d’eux fonctionne sous la valv e à gaz

indépendamment de l’autre.

Avertissement: Il est recommandé de ne pas essayer d’allumer le brûleur si le chapeau de la flamme

relative, n’est pas en position correcte.

Suggestions pour une utilisation correcte des brûleurs:

ATTENTION: Pendant l’utilisation de chaque brûleur réglez la dimension de la flamme du brûleur

correctement de façon à ce qu’elle ne se prolonge pas au-delà du bord des ustensiles de cuisine.

C’est une instruction basée sur des considérations de sécurité

- Utilisez les casseroles appropriées pour chaque brûleur (voir la Fig. 18 et le Tableau B)

- Quand le liquide bout, tournez le bouton vers le bas à la position de MINIMUM.

- Utilisez toujours des casseroles avec un couvercle.

Tableau B

Brûleur Diamètres recommandés en pouces pour les casseroles (mm)

Moyen 51/8”- 103/8”(140 – 260)

Large 77/8”- 103/8” (180 – 260)

Dual (poêle chinoise) 82/3”-103/8” (220 – 260)

Utilisation correcte des casseroles:

- Essuyez le fond de la casserole avant de la positionner sur la plaque de cuisson.

- Utilisez les pots avec un fond plat et épais, à l’exception de la cuisson avec poêles chinoises.

- Quand vous utilisez les brûleurs, assurez-vous d’avoir positionné correctement les manches des

casseroles. Tenir les enfants loin de l’appareil.

- Quand vous cuisinez des mets avec de l’huile ou de la graisse, qui sont très inflammables, l’utilisateur ne

devra pas laisser l’appareil sans surveillance.

ATTENTION: Si l’alimentation est découpée, les brûleurs peuvent être allumés avec des allumettes.

Les brûleurs équipés d’un thermocouple de sécurité peuvent seule ment être allumés lorsque le bouton est

en position de MAXIMUM (gravure de flamme large).

Avertissement: L’utilisation d’un appareil de cuisson à gaz produit de la chaleur et de l’humidité dans la

chambre où il est installé. Par conséquent, une ventilation appropriée dans la chambre est nécessaire ainsi

que les ouvertures normales de ventilation qui doivent être sans obstructions et doivent activer les

ventilateurs à tirage d’air/hottes d’aspiration. Une utilisation intensive et continue de l’appareil peut exiger

une ventilation additionnelle, par exemple en ouvrant une fenêtre, ou en augmentant la puissance du

ventilateur à tirage d’air/hotte d’aspiration, si installés.

25

Utilisation du plaque induction

Précautions de sécurité - À lire avant de démarre r la plaque de cuisson

La plaque de cuisson à induction a été conçue pour une utilisation domestique et pour la préparation des

aliments ; tous les paramètres de sécurité ont été réglés dans ce but.

L’unité comprend de nombreux dispositifs et commandes de sécurité, dont certains seront évoqués ciaprès :

- Un certain nombre de capteurs contrôlent la température des composants internes. Si l’un des capteurs

détecte une augmentation de température au-delà du seuil admissible, la puissance émise à l’unité est

automatiquement réduite pour que le composant puisse refroidir. Au terme de cette manœuvre, l’unité

continue à fonctionner normalement au niveau de puissance initialement réglé par l’opérateur.

- Chaque foyer à induction est équipé d’un capteur qui contrôle constamment la température sur le fond de

la casserole afin de prévenir sa surchauffe.