Page 1

Dear «aurora» Customer

032907.52.04_0910_a430/a440/a450_EN

BERNINA has added another great sewing and embroidery

computer to the very successful aurora product line. The new

aurora 450 has a new hook system which enables you dear

BERNINA customer to make wider stitches.

Now BERNINA offers three different aurora models – the

BERNINA customer can choose their perfect sewing and

embroidery computer according to her needs and wishes. All

aurora models have the capability to add the world famous

BERNINA Stitch Regulator. The aurora 440 QE has this great

presser foot included in the standard accessories.

The aurora 430 / 440 QE / 450 are designed to give you the

best sewing features possible. If you choose to expand your

creative possibilities by exploring the world of embroidery, you

can connect your sewing computer to your home PC and

purchase an embroidery module from your BERNINA Dealer,

and you can become an embroidery virtuoso.

I wish you great satisfaction and a wonderful experience with

your new aurora sewing and embroidery computer.

H.P. Ueltschi

President

BERNINA International AG

CH - 8266 Steckborn

www.bernina.com

Page 2

Safety instructions

032907.52.04_0910_a430/a440/a450_EN

2

IMPORTANT SAFETY INSTRUCTIONS !

When using an electrical appliance, basic safety precautions should always be followed, including

the following:

Read all instructions before using this sewing computer. When the sewing computer is not in use,

it should be disconnected from the electricity supply by removing the plug from the outlet.

DANGER

To reduce the risk of electrical shock:

1. An appliance should never be left

unattended when plugged in.

2. Always unplug this sewing computer

from the electrical outlet immediately

after using and before cleaning.

WARNING

To reduce the risk of burns, fire, electrical

shock or injury to persons:

1. Do not allow to be used as a toy. Close

attention is necessary when this sewing

computer is used by or near children

and infirm persons. This sewing

computer is not intended for use by

persons (including children) with

reduched physical, sensory or mental

capabilities, or lack of experience and

knowledge, unless they have been

given supervision or instruction concerning use of the sewing computer by a

person responsible for their safety.

Children should be supervised to

ensure that they do not play with the

sewing computer.

2. Use this sewing computer only for its

inten ded use as described in this

manual. Use only attachments recommended by the manu facturer as

contained in this manual.

3. Never operate this sewing computer if:

• it has a damaged cord or plug,

• it is not working properly

• it has been dropped or damaged,

• it has fallen into water

Return the sewing computer to the nea-

rest authorized BERNINA dealer or

service center for examination, repair,

electrical or mechanical adjustment.

4. Never operate the sewing computer

with any air vents blocked. Keep

ventilation openings of the sewing

computer and foot controller free from

accumulation of lint, dust and fabric

remnants and the like.

5. Keep fingers away from all moving

parts. Special care is required around

the sewing needle.

6. Always use the BERNINA original

stitch plate. The wrong plate can cause

needle breakage.

7. Do not use bent needles.

8. Do not pull or push fabric while

stitching, this may deflect the needle,

causing it to break.

9. Turn power switch to «0» (off) when

making any adjust ments in the needle

area, such as threading or changing

the needle, threading the bobbin or

changing the presser foot etc.

10. Always unplug the sewing computer

from the electrical outlet when removing covers, lubricating or when making

any other user servicing adjustments

mentioned in this instruction manual.

11. Never drop or insert any object into any

openings on the sewing computer.

12. Do not use the sewing computer

outdoors.

13. Do not operate where aerosol (spray)

products are being used or where

oxygen is being administered.

14. To disconnect, turn all controls to the

off («0») position then remove the plug

from the outlet.

15. Do not unplug by pulling on the cord,

instead, grasp the plug before pulling.

16. No responsibility will be taken on behalf

of BERNINA for any possible damage

as the result of misuse of the sewing

computer.

17. Under no circumstances should the

sewing computer be left unattended

when using the embroidery module.

18. This sewing computer is provided with

double insulation (except USA / Canada). Use only identical replacement

parts. See instructions for servicing of

double-insulated machines.

SERVICING DOUBLE-

INSULATED

PRODUCTS

In a double-insulated product, two systems

of insulation are provided instead of

grounding. No grounding means is provided on a double-insulated product nor

should a means for grounding be added to

the product. Servicing a double-insulated

product requires extreme care and knowledge of the system and should only be

done by qualified service personnel.

Replacement parts for a double-insulated

product must be identical to those parts in

the product. A double insulated product is

marked with the words «DOUBLE INSULATION» or «DOUBLE INSULATED».

The symbol may also be marked on

the product.

This sewing and embroidery computer

is intended for household use only.

SAVE THESE

INSTRUCTIONS!

Page 3

Contents

032907.52.04_0910_a430/a440/a450_EN

Your sewing computer 4 - 22

Accessories 4-7

Details aurora 430 / 440 QE / 450 8-9

Setting up the sewing computer 10-17

Thread tension 17

Important facts on threads and needles 18-19

Stitch plate, Feed dog and Fabric feed 20-21

Presser foot pressure, Balance 22

Cleaning / Trouble shooting 57-58

Display 23 - 29

Display 23

Function buttons 24-25

Memory 26-29

3

Applications 30 - 56

Stitch selection 430 / 440 QE / 450 30-32

Temporary altered stitch memory 33

Application of practical stitches, Quilt stitches, Decorative stitches 34-47

Buttonholes - Important information 48

Application of buttonholes / Eyelets / Button sew - on 49-56

All about embroidery 59 - 80

Details 59

Accessories 60-62

Setting up the embroidery computer 63-67

Important embroidery information 67-69

Embroidery operating requirements 70

Bernina embroidery software 70-71

Software - EC on PC 72-77

Starting to embroider 78

Mega-Hoop 79-80

Stitch summary 81-83

Index 84 - 85

Page 4

4

Key to signs

032907.52.04_0910_a430/a440/a450_EN

4

Key to signs

C

!

Supplementary information!

Helpful tips!

Please refer to the safety

instructions! Risk of injury!

Very important!

Risk of damage!

All rights reserved.

In order to improve the product, and for our customers' benefit, all of the

sewing and embroidery computer's features, parts, and accessories are

subject to unannounced changes and alterations at any time.

27

28

Additional information on the corresponding subject you

will find on the

relevant page.

Text

Herbert Stolz

Drawings

Müller-Melzer ID, Kreuzlingen

Design concept

Susanne Ribi

Copyright

2008 BERNINA International AG, Steckborn

Page 5

5

Accessories

032907.52.04_0910_a430/a440/a450_EN

Accessories

9

7

10

1

Presser feet*

Standard accessories:

5

3

4

8

1 5 bobbins (one in bobbin case)

2 Needle selection 130/705H

3 Seam ripper

4 Brush

5 Seam guide

6

6 Height compensating tool

7 3 spool discs

8 Small screwdriver

Accessories

• foot control

• instruction manual

• power cable

• warranty card

• Free Hand System presser foot lifter

• slide-on table

• seam guide for slide-on table

• Instructional presentation CD-ROM

9 Angular torx key

10 Foam pad

11 Oiler filled

aurora 430 / 440 QE

2

11

aurora 450

1

, 1C

430/440

450

Reverse pattern

foot

Straight stitch

Practical and

decorative stitch

Quilt stitch

•

Eyelets

•

Securing

20

, 20C

440

450

Open embroidery

foot

Embroidery,

Appliqué, Satin

stitch seams,

Monograms

2

, 2A

430

450

Overlock foot

Overlock seam,

Overlock hem,

Narrow satin stitch

•

For knits and

wovens

•

Edge finishing

37

440

Patchwork foot

1/4” / 6mm

Patchwork with 1/4”

or 1/8” (6mm/3mm)

seam allowance

3A

Automatic buttonhole foot with

slide

4

Zipper foot

Sewing in zippers,

Straight stitch

Buttonholes on

smooth fabrics,

Darning

42

440

BSR foot

Straight stitch, Freehand

quilting

5

Blindstitch foot

Blind hem,

Edge stitching,

Straight stitch

Blindstitch

for hems and

•

blindstitch

applique

50

440

Walking foot

For fabrics which stick or tend

to slip; Quilting,

Straight stitch, Quilt stitch

Decorative stitch

• sewing difficult fabrics, e.g.

velvets, matching plaids,

squares, etc.

9

Darning foot

Darning, Monograms or freehand

embroidery

Straight stitch,

Basting stitch

Darning

•

•

sewing on

buttons

Compensation

plate for sewing

buttonholes**

Improves the fabric

feed when sewing

buttonholes in

difficult fabrics

* can vary from country to country

** Optional accessories

Page 6

6

Accessories

032907.52.04_0910_a430/a440/a450_EN

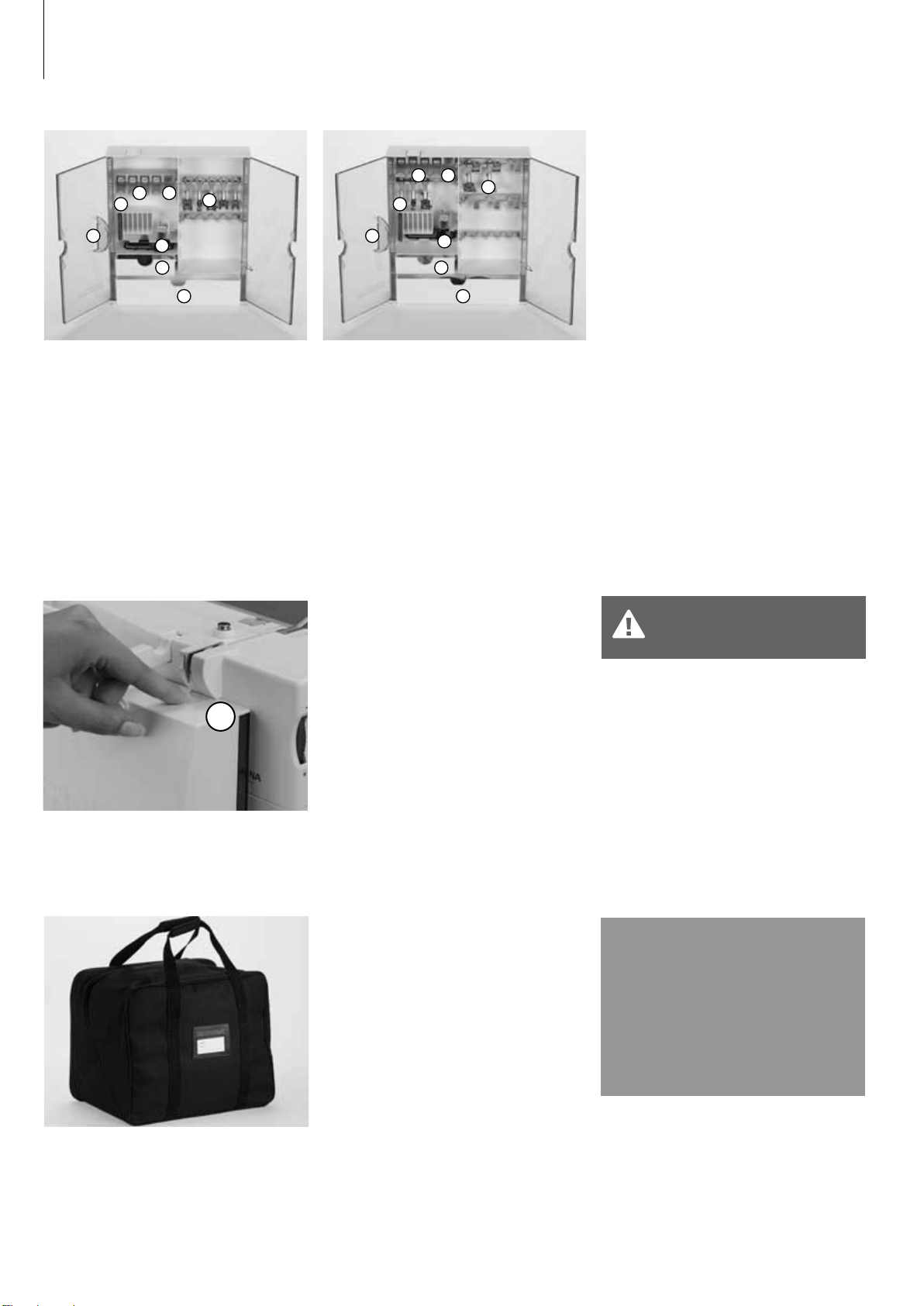

Accessory box 430 / 440 QE Accessory box 450

D

F

D

F

H H

E

E

J J

Free standing accessory box

• On the back of the box, pull both feet out

until they click into place

• stand box in desired position

G

B B

C C

A

G

Storing accessories

Standard accessories are supplied in a

plastic bag. The box is equipped with one

small and one large drawer (B and C) as

well as compartments for bobbin holders

D and presser feet E. (Additional compart-

ments and drawers are available as

optional extras).

Attaching the accessory box to the

sewing computer

• close the doors

• push feet back into position

• attach the box to the sewing computer

(catch A must engage); inserting the

presser foot lifter into the opening J

Removing the accessory box

• press catch A on the top of the box

• remove box to the rear

• push the bobbins into the compartments

provided

• to remove a bobbin, press the compart-

ment holder F lightly

• insert presser foot into holder E

• Buttonhole foot with slide no. 3A can be

stored in compartment G

• the needle selection box can be stored in

compartment H

First lower the presser foot

lifter!

Reinforced soft cover

• protects from dust and dirt

• protects sewing computer when

transporting

• compartments for accessories

C

The cover and accessory box

come with the sewing

computer. The cover should

be used to protect the sewing

computer when it is not in use.

The foot control, power cable,

sewing table and instruction

manual can be stored in the

cover.

Page 7

Optional accessories

032907.52.04_0910_a430/a440/a450_EN

BERNINA Specialty Presser Feet

The standard selection of presser feet covers most normal sewing requirements, but we recommend the use of

BERNINA specialty presser feet for specific sewing tasks such as quilting, heirloom sewing, home decorating,

tailoring, etc. They are available from your BERNINA dealer.

Optional accessories

7

3

Buttonhole foot

Buttonholes

32

Pintuck foot

Straight stitch

•

Sewing pintucks

in fine fabrics

8

Jeans foot

Straight stitching in

thick, firm fabrics

35

Invisible zipper

foot

Sewing in zippers,

Straight stitch

10C/10

Edge stitch foot

Straight stitch

Stitching edges

•

39

Embroidery foot

Zig-zag stitch,

Decorative stitches

•

Buttonhole

seams

•

sewing decorative stitches

14

Zipper foot with

guide

Sewing in zippers,

Straight stitch

43

Freemotion

couching foot

Straight stitch

•

Attaching cords

in a curved effect

18

Button sew-on

foot

Sewing on buttons,

hooks and eyes

57

Patchwork foot

with guide 1/4” /

6mm

Patchwork with 1/4”

or 1/8” (6mm/3mm)

seam allowance

21

Braiding foot

Zig-zag stitch

Couching with

•

wool to 3mm or

light cord

Punching-Kit

only 430/440 QE

Straight stitch

•

felting

We recommend to use the BERNINA lens

set for more sewing comfort (better view of

needle area).

Straight Stitch Plate 450 Straight Stitch Plate 430 / 440 QELens set

Page 8

Details

032907.52.04_0910_a430/a440/a450_EN

8

Details

11

12

13

17

10

9

26

7

29

30

31

25

27

28

23

22

21

1824

19

20

16

14

15

Front view

8

5

2

1

6

3 4

32

38

33

35

34

Back view

36

37

Page 9

Front view

032907.52.04_0910_a430/a440/a450_EN

1 Bobbin cover

2 Stitch plate

3 Attachment base for special accessories

4 Darning hoop connection

5 Presser foot

6 Needle clamp

7 Thread guide

8 Needle threader

9 Thread take-up cover

10 Thread path

11 Thread take-up

12 Holder for stitch card

13 Bobbin winder with on/off switch and thread

cutter

14 Stitch selection buttons

15 «clr» (clear) button

16 #-button (hash)

17 Stitch width buttons

18 Stitch length buttons

19 «mem» (Memory / Operating buttons)

20 Alphabet / Motif scroll buttons

21 Balance / BSR button

22 Securing function button

23 Pattern begin button

24 Display

25 Needle position buttons

26 Needle stop up/down button

27 Mirror image button

28 Slide speed control

29 Start / Stop - button

30 Pattern end button

31 Quick reverse button

32 FHS (Free Hand System) connection

41

Side view (Head frame)

40

42

38

39

43

Details

9

Back view

33 Horizontal spool pin

34 Carrying handle

35 Rear thread guideng

36 CFL sewing light

37 Slide-on table socket

38 Bobbin pre-tension

Side view (Head frame)

39 Tension adjustment wheel

40 Presser foot pressure

41 Presser foot lifter

42 Thread cutter on head frame

43 Magnifying glass holder

Side view (handwheel)

44 Handwheel

45 Spool pin (vertical, collapsible)

46 Power switch on/off («0»)

47 Power plug socket

48 PC connection

49 Embroidery module connection

(optional accessory)

50 Foot control socket

51 Drop feed dog

51

49

50

48

44

45

46

47

Side view (handwheel)

Page 10

10

032907.52.04_0910_a430/a440/a450_EN

Setting up the sewing computer

Power switch / Power cable

C

The power cable

• plug A into sewing computer

• plug B into wall socket

Foot control cable

• plug C into sewing computer

Foot control

D

Refer to the

safety instructions

!

A

B

The power switch (D)

The switch is on the handwheel side

I the sewing computer is switched on («I»)

0 the sewing computer is switched off («0»)

The sewing light is switched on and off with

the power switch.

Important! (USA/Canada

only)

This sewing computer has a

po la rized plug (one blade

wider than the other). To

re duce the risk of electrical

shock, this plug is intended

to fit in a polarized outlet

only one way. If the plug

does not fit fully in the outlet,

reverse the plug. If it still

does not fit, contact a

qualified electrician to install

the proper outlet. Do not

modify the plug in any way!

i

Sewing speed

• control the sewing speed by depressing

the foot control

• raise or lower the needle by tapping on

the foot control with your heel

B

A

C

Cable tidy

• wind the cable around the spool

• insert the plug into A

When sewing

• unwind the cable to the desired length

and slip into B or C

Important!

(USA/Canada only)

Use only foot controller

type LV1 with sewing

computer model aurora 430 /

440 QE / 450.

Page 11

Setting up the sewing computer

032907.52.04_0910_a430/a440/a450_EN

11

CFL Sewing Light

Contrary to an ordinary bulb, the CFL

sewing light has a better illumination and a

longer life.

Please note that a defec tive

CFL sewing light must ONLY

be replaced by an authorized

technician. The sewing

computer must be brought to

an authorized BERNINA

dealer!

Free Hand System (FHS) presser foot lifter

Your dealer can adjust the

FHS if necessary.

C

Raising and lowering the presser foot

• knee-operated presser foot lever to raise

and lower the presser foot - your hands

remain free to guide the fabric

• with your knee push lever to the right

• the feed dog is lowered simultaneously

• the feed dog is raised as soon as the

first stitch is sewn

Attaching the presser foot lifter

• insert the lever into respective opening

- you should be able to operate the FHS

with your knee in your normal sitting

position

Slide-on table

Larger sewing surface

• the slide-on table increases the sewing

surface

To attach

• raise needle and presser foot

• slide over free-arm to the right until it

engages

Always raise needle and

presser foot when attaching

or removing the slide-on

table!

To remove

• raise needle and presser foot

• use slight pressure - with your thumb

against the housing and the index against

the table - to slide it off to the left

Seam guide

• slide into extension table guides from left

or right

• can be moved over full table length

Scale

• «0» corresponds to the center needle

position

Page 12

12

Setting up the sewing computer

032907.52.04_0910_a430/a440/a450_EN

Threading the upper thread

A

• attach the appropriate spool disc;

diameter of spool determines disc size.

There must be no clearance between the

disc and the spool

• take thread through rear guide A

• then into slit of upper thread tension

• pull thread down to the right of the

take-up cover to B

• take thread up to the left of the

cover to C in the direction of the arrow,

placing it in the take-up lever

• take thread down and through guides D

and E

Attaching the thread spool

• raise the needle and presser foot

• turn the power switch to «0» (off)

• attach the foam pad

• place thread spool on spool holder in

such way that the thread unwinds

clockwise

C

B

D

E

Refer to the

safety instructions!

!

Page 13

13

Threading the Double Needle

032907.52.04_0910_a430/a440/a450_EN

A

Setting up the sewing computer

Threading the First Thread

• place thread spool on horizontal spool

pin and thread

• guide the thread to the front in the slit

and past the tension disc A on the right

side

• thread sewing computer as usual and

thread the right needle

Threading the Second Thread

• when using the supplementary spool pin

(vertical) always attach the foam pad

(prevents the thread from getting caught

on the spool pin)

• place thread spool on the additional

spool pin and thread

• guide the thread to the front in the slit

and past the tension disc A on the left

side

• thread the left needle

• threads must not be twisted together

By using the Supplementary

thread guide (special accesso-

C

A

ries), thread winds off the

spool much easier.

Threading the Triple Needle

• two thread spools and one full bobbin

are needed

• place one thread spool on horizontal

spool pin

• place second thread spool and the

bobbin, separated by a spool disc, on

additional spool pin (both spools have to

turn in the same direction)

• thread as usual by guiding two threads

on the left side of the tension disc A and

one thread on the right side of the disc

Page 14

14

Setting up the sewing computer

032907.52.04_0910_a430/a440/a450_EN

Needle threader

A

B

Press lever down

• Raise needle

• Lower presser foot

• Hold thread to the left and back

• Press down lever A, guiding the thread

around hook B to the right, to the needle

Thread cutter

Guide thread in front of the needle

• Pull thread from the front into the thread

guide until it catches (wire hook) and pull

from the back forwards over the thread

cutter on the right side of the CFL sewing

light

• The thread is cut and at the same time

held in place

Thread cutter on head frame

• pull both threads from front to back over

the cutter

• the threads release automatically as

soon as the first stitch is sewn

A

Release lever

• Release lever A

• Put the thread under the foot and pull

the thread backwards or

• Put the thread under the foot, then pull it

from front to back over the thread cutter

on left side of the head frame

Double and triple needles

must be threaded by hand.

C

Supplementary spool pin

Collapsible vertical spool pin

• essential aid for sewing with more than

one thread, i.e. double needle work

• turn pin up to stop when sewing

A

• we recommend to use foam pad A for

better stabilizing of the spool and even

unwinding of the thread

Page 15

15

Winding the bobbin

032907.52.04_0910_a430/a440/a450_EN

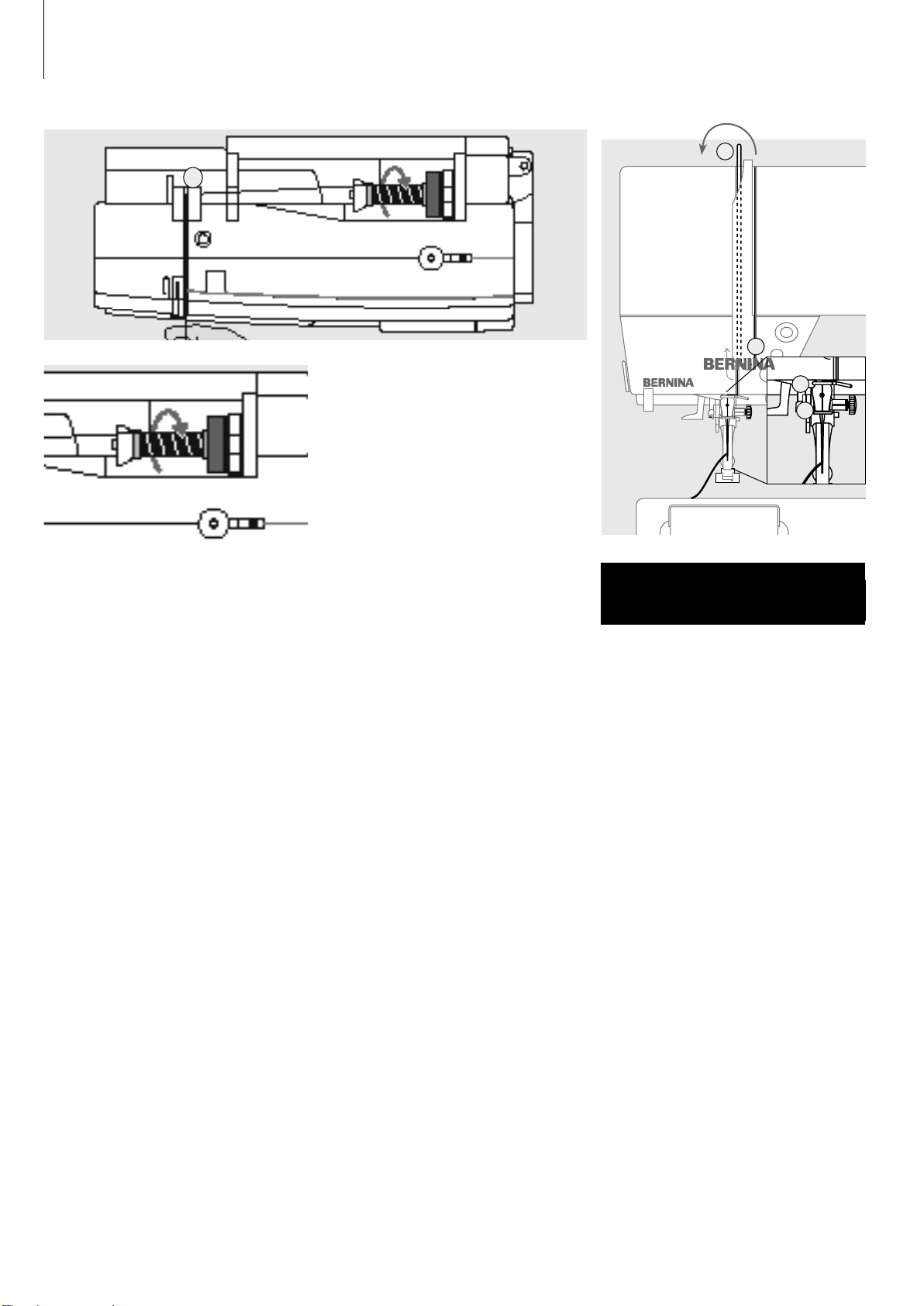

Winding the bobbin

• turn power switch to «I» (on)

• place empty bobbin on spindle

Threading the bobbin

• place thread on spool pin

• attach appropriate spool disc - diameter

of thread spool determines disc size

• following the direction of the arrow, take

thread through the rear guide and

around the pre-tension stud

Setting up the sewing computer

• wind the thread two to three times

around the empty bobbin and cut off any

excess thread on the thread cutter

• push engaging lever against bobbin, the

winder works automatically

• the motor will stop automatically when

the bobbin is full

Thread cutter

• pull thread over thread cutter when

removing the bobbin • then proceed as mentioned above

Winding the bobbin while sewing or

embroidering

• place thread spool on vertical spool

then, following the direction of the arrow,

take thread through the thread guide

and around the pre-tension stud

Inserting the bobbin

Inserting the bobbin

Insert the bobbin so that the thread winds

clockwise.

Pulling the thread under the spring

Pull the thread into the slit, then to the left

under the spring.

Clockwise turning of the bobbin

The bobbin must turn clockwise.

C

The bobbins are inserted and

threaded in the same way in

the aurora models 430, 440 QE

and 450.

Page 16

Setting up the sewing computer

032907.52.04_0910_a430/a440/a450_EN

16

Bobbin case*

A

To remove the bobbin case

• raise the needle

• turn power switch to «0» (off)

• open the bobbin cover

• grasp the latch of the bobbin case

• remove case

* pictures = aurora 450

Changing the needle

To insert the bobbin case

• hold the bobbin case latch

• aurora 430 / 440 QE: the finger on the

case should point upwards

• aurora 450: bobbin case opening points

up

• insert so that it clicks into place

• close the bobbin cover

Bobbin thread cutter

• insert the bobbin case

• take the thread over cutter A and cut it

• the bobbin thread does not have to be

brought up as the loose end is just the

right length to start sewing

Refer to the

safety instructions!

!

Removing the needle

• raise the needle

• turn power switch to «0» (off)

• lower the presser foot

• loosen the needle clamp screw

• pull the needle down to remove

Inserting the needle

• flat side of needle to the back

• insert the needle as far as it will go

• tighten the needle clamp screw

Refer to the

safety instructions!

!

Page 17

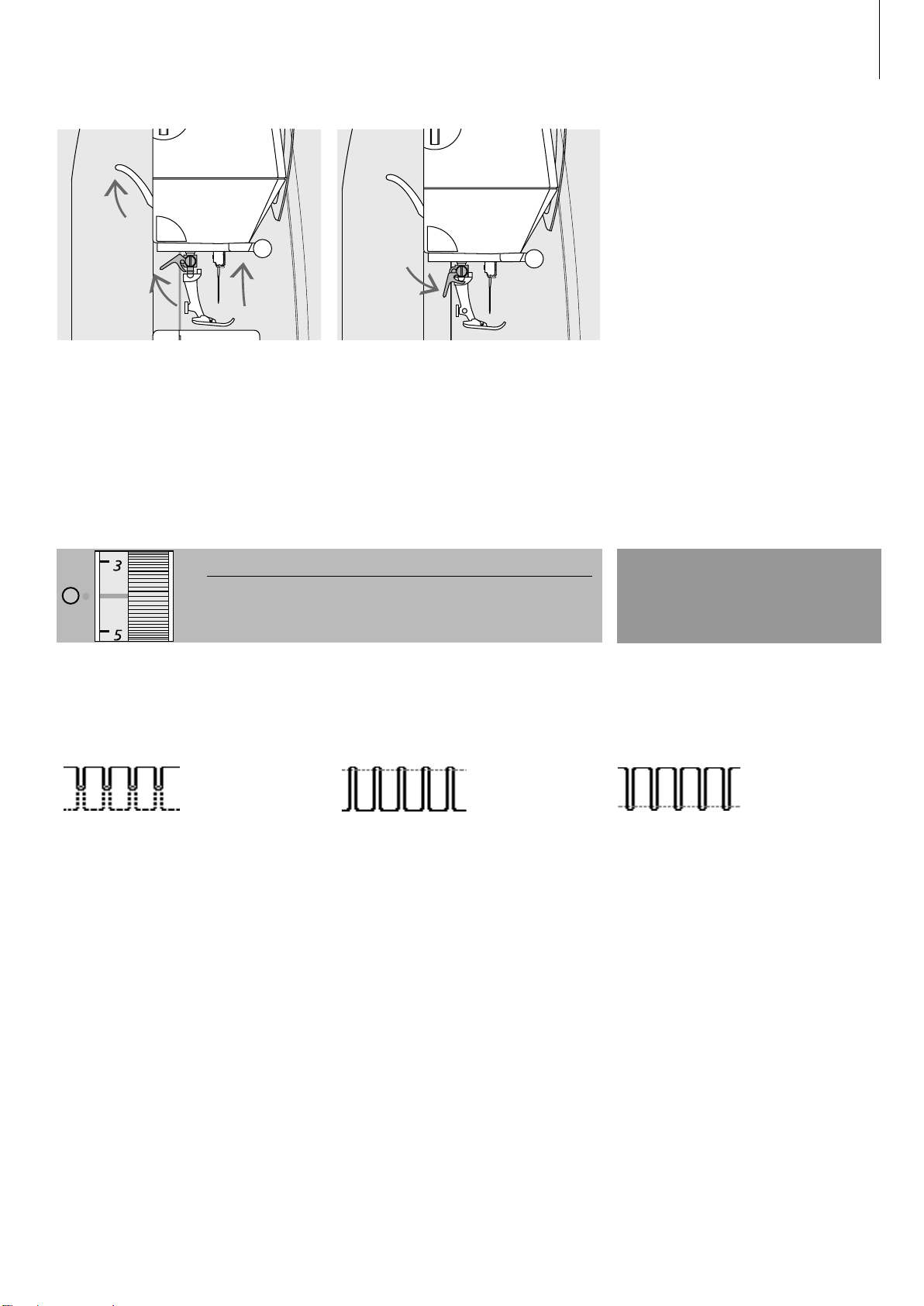

Changing the presser foot

032907.52.04_0910_a430/a440/a450_EN

Setting up the sewing computer

17

Changing the presser foot

• raise the needle and presser foot

• turn power switch to «0» (off)

• raise the clamping lever

• remove the presser foot

Thread tension

For example:

A

The basic setting

• is indicated when the red line on the

tension adjustment wheel is in line with

the marking A

Tension Needle

Metallic thread ca. 3 90

Monofilament ca. 2–4 80

Attaching the presser foot

• guide the foot upwards over the cone

• press the clamping lever down

• the tension does not need adjusting for

normal sewing work

C

For special sewing work,

the thread tension can be

adjusted to suit the selected

fabric and stitch pattern.

Thread tension settings

Perfect stitch formation

• the stitch formation is in the fabric

Upper thread tension too tight

• the lower thread is pulled more to the

right side of the fabric

• to reduce the upper thread tension turn

tension adjustment wheel to 3 - 1

Upper thread tension too loose

• the upper thread is pulled more to the

wrong side of the fabric

• to increase the upper thread tension turn

tension adjustment wheel to 5 - 10

Page 18

Important facts about thread and needles

032907.52.04_0910_a430/a440/a450_EN

18

Important facts about thread and needle

With the right combination of thread and needle optimum sewing results are achieved.

The following are the guidelines: replace needle when starting a new sewing project.

Thread

The thread is chosen according to use. For a perfect sewing

result, thread and material quality play an important role. It is

recommended to use quality brand threads.

Cotton thread

• cotton threads are particularly suitable for cotton fabrics

• mercerized cotton threads have a slight sheen

Polyester thread

• polyester thread is suitable for practically all sewing needs

• it has a high tensile strength and is particularly colorfast

• polyester thread is more flexible and is recommended where a

strong and elastic seam is required

Guidelines Needle No.

fine fabrics:

fine thread (darning thread,

embroidery thread) 70–75

mediumweight fabrics:

normal thread 80–90

heavyweight fabrics:

heavier thread 100, 110, 120

Needle, thread and fabric

The correct needle size depends on the selected thread and

fabric. Fabric type and structure determine which thread weight,

needle size and needle tip should be used.

Needle summary

BERNINA requires needle system 130/705 H. This system

number refers to shank shape as well as to length and form of the

needle point.

Checking the needle condition

The needle condition should be checked and the needle replaced

regularly. A defective needle not only damages the fabric but also

the sewing computer.

130 / 705 H S 70

Shank diameter

= 0.7 mm (needle size)

Needle point

e.g. medium ball point

Needle scarf

Flat shank

Shank length

Needle/thread combination

In order to check the needle/thread compatibility, the correct size thread must correspond with the correct size needle.

Correct needle/thread

combination

When sewing, the thread should travel

smoothly down the long groove on the

front of the needle.

Too thin thread or too thick needle

The sewing thread has too much play in

the groove. This could lead to skipped

stitches and damage to the thread.

Too thick thread or too fine needle

The thread rubs on the edges of the

groove and can get jammed. This can

break the thread.

Page 19

Needle summary

032907.52.04_0910_a430/a440/a450_EN

Many materials are easier to sew if the appropriate needle is used.

Important facts about thread and needles

19

Type of needle

Universal

130/705 H

Jersey/Stretch

130/705 H-S

130/705 H-SES

130/705 H-SUK

Leather

130/705 H-LL

130/705 H-LR

Jeans

130/705 H-J

Microtex

130/705 H-M

Quilting

130/705 H-Q

Model

Normal point, slightly rounded

Ball point

Cutting point

Very fine point

Especially fine point

Fine point

Suitable for

For nearly all natural and

synthetic fabrics (woven and

knitted)

Jersey, stretch fabrics

Natural and synthetic leather and

plastic

Heavyweight fabrics such as

denim, canvas, overalls

Micro fiber fabrics and silk

Straight and topstitching

Needle size

60 –100

70–90

90–100

80–110

60–90

75–90

Embroidery

130/705 H-E

Metafil

130/705 H-MET

Cordonnet/

Topstitching

130/705 H-N

Wing needle

130/705 HO

Double wing

needle

130/705 H-ZWI-HO

Double needle

130/705 H-ZWI

Large eye, slight ball point

Large eye

Small ball point, long eye

Wide needle (wing)

Needle distances for 430 / 440 QE /

450: 1,0 / 1,6 / 2,0 / 2,5 / 3,0 / 4,0;

plus 6,0 / 8,0 for 450

Embroidery on all natural and

synthetic fabrics

Sewing with metallic threads

Topstitching with thick thread

Hemstitching

Special effects with hemstitch

embroidery

Visible hems in stretch fabrics,

pintucks, decorative sewing

75–90

75-90

80–100

100–120

100

70–100

Triple needle

130/705 H-DRI

Special needles are available at your BERNINA dealer.

Needle distance 3.0

Decorative sewing

80

Page 20

Stitch plate, feed-dog and fabric feed

032907.52.04_0910_a430/a440/a450_EN

20

Stitch plate

A A

9mm (inch- or mm-measurements) just

aurora 450

Stitch plate markings

• the stitch plates are marked with vertical

lines in millimeters or inches

• mm measurements are at the front

• inch measurements are at the back

• the measurements correspond to the

distance from the needle to the line

Feed dog

5,5mm (inch- or mm-measurements)

• needle insertion point is position 0

(center needle position)

• the mm/inch measurements are marked

to the right and left

• the lines help to guide the fabric for

sewing seams and for topstitching

• the horizontal markings are helpful for

sewing corners and buttonholes, etc.

Button flush with housing =

Sewing position

Removing the stitch plate

• turn power switch off («0»)

• raise the presser foot and needle

• lower the feed dog

• press the stitch plate down at the

back right corner until it flips up

• remove the stitch plate

Replacing the stitch plate

• place the stitch plate over the opening A

and press down until it clicks into place

Button depressed = Darning position

• for freehand sewing, e.g. darning,

freehand embroidery, freehand quilting

• for embroidery with the embroidery

module

Button on handwheel side

Feed dog and fabric feed

Let the fabric feed evenly.

Feed dog and stitch length

With each stitch the feed dog moves

forward by one step. The length of this

step is determined by the stitch length

selected.

Pulling, pushing or holding back the fabric will result in uneven stitches.

With an extremely short stitch length, the

steps are also very short. The fabric moves

under the foot quite slow ly, even at full

sewing speed.

Buttonholes, satin stitch and de co rative

stitches are all sewn with a very short stitch

length.

Page 21

21

Stitch plate, feed-dog and fabric feed

1

1

032907.52.04_0910_a430/a440/a450_EN

Feed dog and fabric feed with height compensating tool

The feed dog works accurately when the

foot is level.

Uneven layers

To solve this problem, place one, two or

three compensating plates as required

behind the needle under the presser foot

to level it.

If the foot is at an angle, e.g. when sewing

over thick to thin or vice-versa, the feed

dog cannot grip and feed the fabric and the

fabric might jam.

To correct the height in front of the foot,

place one or more plates to the right of the

foot close to the needle. Sew until the foot

is level again and remove the plates.

Feed dog and sewing corners

The space between the two rows of the

feed dog is relatively large due to the

width of the stitch plate hole.

Place one or more plates as close as

possible to the edge of the fabric on the

right side of the presser foot. This allows

for better feeding of the fabric when

sewing corners.

Page 22

Presser foot pressure and Balance

032907.52.04_0910_a430/a440/a450_EN

22

Presser foot pressure

Dial on head frame

• the pressure is adjusted at the left side of the head frame

Standard pressure

• for normal sewing work

• default = 47

• the default setting is always visible, it

blinks

Increased pressure

• for firm fabrics

• improves fabric feed

Balance

Different fabrics, threads, stabilizers and interfacings can affect programmed stitches so,

that sometimes they might not join or might overlap, i.e. the stitches that make up the

pattern are too close together or too far apart.

These effects can be corrected with the Balance so that the stitch formation can be

adjusted where necessary to suit the fabric.

Balance for practical and decorative stitches

When sewing soft fabrics such as jersey or tricot, the fabric tends to stretch under the

presser foot which also stretches the stitch being sewn. For example, the Honeycomb

stitch opens up and is too long. Thicker fabrics might cause the stitch to overlap, making

it too short. Correcting with the Balance is very easy. Test-sew first!

Reduced pressure

• for jerseys and loose knits

• to prevent fabric from stretching

• adjust pressure so that the fabric still

feeds correctly

Do not forget to reset the

balance by pressing the

C

balance or clr button after

sewing with adjusted balance

values.

Stitch formation too long Stitch formation too close Desired stitch formation

• press the Balance button

• press the left Needle position button =

shorter stitch length (maximum 9 steps)

• press the Balance button

• press the right Needle position button =

longer stitch length (maximum 9 steps)

Page 23

Display

032907.52.04_0910_a430/a440/a450_EN

aurora 430 / 440 QE aurora 450

Screen display

23

3

2

1

5

10

8

7

9

15

19

16 17 18

20

11 12 13

22

21

1 Satin stitch: dense, short zig-zag stitch

2 Stitch length: basic setting blinks

constantly

3 Stitch length: actual value

4 Stitch width: basic setting blinks

constantly

5 Stitch width: actual value

6 Needle position: 11 positions

7 Presser foot pressure: basic setting

blinks

8 Arrow and presser foot symbol: blink

when presser foot is raised and the

sewing computer is started

9 Feed dog symbol: blinks when feed

dog is not lowered in the BSR mode

and embroidery mode

3

4

6

14

23

2

1

10 Triple digital display

a. Presser foot indicator: displays

matching foot for selected stitch

b. Presser foot pressure: displays

presserfoot pressure during

adjusting

c. Balance: displays the balance

steps during balancing

11 Balance: visible when the

Balance button is pressed

12 Buttonhole: visible when

buttonhole is selected

13 «mem»: visible when Memory

is open

14 Stitch: graphic or numeric

15 Needle stop up / down: default stop

up/ in BSR mode down

5

10

8

7

9

15

19

16 17 18

20

11 12 13

21

4

6

14

22

23

16 Mirror image: left / right

17 Pattern begin/Pattern end

18 Continuous reverse sewing

19 Securing function

20 BSR: Bernina Stitch Regulator

21 Cleaning notification: visible when the

sewing computer must be cleaned/oiled

22 Service notification: visible when the

sewing computer must be taken for a

service to the BERNINA dealer

23 Alphabet

Page 24

24

032907.52.04_0910_a430/a440/a450_EN

Functions

Function buttons

Stitch width

• left button = narrows the stitch width

• right button = widens the stitch width

• keep button pressed = quick steps

• the basic setting of the selected stitch

blinks constantly

Pattern begin

• press the button

• the needle moves to the beginning of a

stitch or stitch program

Securing function (with 4 stitches)

• press the button before starting to sew =

individual stitches or stitch combination

will be secured at the beginning

• press the button during an individual

stitch = the stitch will be secured at the

end

• the sewing computer stops

• press the button during stitching a stitch

combination = the stitch combination will

be secured at the end

• the sewing computer stops

Stitch length

• left button = shortens the length

• right button = elongates the length

• keep button pressed = quick steps

• the basic setting of the selected stitch

blinks constantly

Mirror image (left/right)

• press the button

• mirror image of selected stitch will be

sewn

Needle up/down

In the basic setting the arrow points up.

• press the button briefly:

• the needle will go up or down (same as

tapping on the foot control)

• press the button longer:

• the needle will go down

• the arrow on the display points down

• the sewing computer stops with the

needle down

• press the button longer again:

• the needle will go up

• the arrow on the display points up

• the sewing computer stops with the

needle up

Needle position

• left button = needle to the left

• right button = needle to the right

• keep button pressed = quick steps

• total of 11 needle positions: 5 left,

5 right and 1 center

«clr» (clear)

• press the button

• stitch length, stitch width, needle

positions are returned to basic settings

• active functions are deleted

Exception:

needle stop down

Balance / BSR

Balance

• press the button

• the balance symbol on the display is

active

• press the left arrow of the needle

position = subtracts space between

stitches

• press the right arrow of the needle

position = adds space between stitches

• press the button again = the balance is

turned off, the altered stitch returns to the

basic settings

• altered needle position settings remain

during the balance process

Slide speed control

• the motor speed can be freely adjusted

from minimum to maximum with the slide

control

• when winding the bobbin thread the

speed of the winder can be regulated,

when the sewing computer is not sewing

BSR

• with the attached BSR foot the BSR

function is switched on and off by

pressing the button

mem (Memory)

• press the -button

• «mem» will appear on the display

• the empty memory spaces (90) or (60)

and the cursor blink

• use the left arrow and the -button

to scroll and program stitches, letters and

numbers

Page 25

25

Functions

032907.52.04_0910_a430/a440/a450_EN

Reverse sewing

quick reverse:

• press the button

• sews in reverse until the button is

released

• programs buttonholes

• programs darning length

• seam end in securing program no. 5

• manual securing at beginning and end of

seam

continuous reverse:

• press button until a beep is heard before

sewing and the symbol is visible on the

display

• the sewing computer sews the chosen

stitch in reverse

• to cancel: press button until a beep is

heard before sewing and the symbol

goes off

Pattern end / Pattern repeat

press the button while sewing

• the sewing computer stops at the end of

the active single stitch or the active stitch

in a stitch combination (in Memory)

press and release button before sewing

• the Pattern end symbol appears on the

display

• a single stitch or the first stitch of a stitch

combination in the Memory will be sewn

1x, the sewing computer will stop

• when continuing to sew the Pattern end

function is turned off again and the

Pattern end symbol disappears

press button until a beep is heard before

sewing

• the Pattern end symbol appears on the

display

• a stitch or stitch combination in the

Memory will be sewn 1x

• the Pattern end function is active as long

as the button is pressed again until a

beep is heard before sewing

• the Pattern end symbol on the display

disappears

Start-Stop button

• starts and stops the sewing computer

when operating it without foot control

• starts and stops the sewing / embroidery

computer in the embroidery mode with

attached embroidery module

• starts and stops the BSR function when

BSR foot is attached and plugged in;

without foot control

Stitches

• in single mode, press the arrow buttons

to scroll through all stitch patterns

Alphabets, numbers

• press the center-button

• one of the existing fonts will appear on

the display

• press the Alphabet button to select the

font

• press the right button to scroll letters,

numbers and special characters forwards (A B C...)

• press the left button to scroll special

characters backwards ( ] [ ) ...)

Letters/numbers/special characters

A B C D E F G H I J K L M N

O P Q R S T U V W X Y Z Ä Ö Ü

Å Æ Œ Ø Ñ È É Ê À Â

1 2 3 4 5 6 7 8 9 0

_ - . ' ! + = & ÷ ? % ç @ ( ) [ ]

#-button

Standard = graphic display

• press button and enter desired stitch

number

• the stitch will be displayed graphically

(image)

Alternative = numeric display

• press button until a short beep is heard

• the display of the active stitch will change

from graphic (image) to numeric (num-

ber)

• further stitches will now be displayed

numerically (number)

switch again to standard display in the

same manner

Entering 3 digit stitch numbers:

• press button until the number «1»

appears

• now enter the other two numbers

Page 26

26

Functions - Memory

032907.52.04_0910_a430/a440/a450_EN

Memory

Memory buttons

• use the left button to scroll the contents

backwards

• use the center button to open and close

the Memory

• use the

forward scroll

-button to save and

Programming practical and decorative stitches

Any combination of 90 (aurora 440 QE) or

60 (aurora 430 / 450) stitches, letters or

numbers can be saved in Memory, which

is long term-memory. They remain saved

until deleted by the user. Power failures or

disconnection from the electricity supply do

not affect the Memory. Alterations to the

stitch length, width or needle position can

be made at any time. Individual stitches,

letters or numbers can be deleted or

overwritten.

Open Memory

• press the

• the cursor on the left and the available

number of empty memory spaces (e.g.

60) start to blink, and «mem» appears

These stitch patterns and programs can not be programmed:

Buttonholes / securing stitch No. 5, No. 61 (450)

C

Eyelets No. 20, 21 (450), No. 18, 19 (440), No. 17 (430)

Button sew-on program No. 19 (450), No. 17 (440), No. 16 (430)

Darning program No. 22 (450), No. 20 (440), No. 18 (430)

Large fly stitch No. 23 (450)

Basting stitch No. 24 (450), No. 21 (440), No. 19 (430)

-button

• select desired stitch

• stitch image appears on the display

• press the -button

• the stitch is programmed

• the number of available Memory spaces

appears

• select the next stitch

• press the -button to save,

continue in the same manner

Sew begin

When the foot control or the

Start - Stop - button is pressed,

the sewing computer automatically starts sewing the stitch

combination from the beginning.

Page 27

27

aurora 430 / 440 QE aurora 450

032907.52.04_0910_a430/a440/a450_EN

Functions - Memory

A B

Example A:

Sewing a stitch combination continuously

• press the -button

• select stitch, e.g. No. 155 (440) or 126

(430)

• press the -button, select new

stitch, e.g. stitch No. 92 (440) or 69

(430), press the

-button, etc.

• sew the stitch combination

• press the

-button = the stitch

combination will be saved

• during the process of saving an

hourglass is visible on the display

Example B:

Combining stitch and function (Mirror

image) and sewing continuously

• program desired stitch, e.g. No. 159

(440) or 130 (430)

• activate Mirror image, program mirrored

stitch No. 159 (440) or 130 (430)

Example A:

Sewing a stitch combination continuously

• press the -button

• select stitch, e.g. No. 143

• press the -button, select new

stitch, e.g. stitch No. 95, press the

-button, etc.

• sew the stitch combination

• press the -button = the stitch

combination will be saved

• during the process of saving an

hourglass is visible on the display

Example B:

Combining stitch and function (Mirror

image) and sewing continuously

• program desired stitch, e.g. No. 152

• activate Mirror image, program mirrored

stitch No. 152

• sew stitch combination, the stitches

alternate (original and mirror image)

Decorative stitch combinations with embroidery thread

• gives stitches a fuller appearance

Stitch combinations on double fabric

• bottom layer does not pucker

Stitch combinations on single fabric

• always use an appropriate stabilizer as a backing

• remove after sewing

• thread the lower thread in the finger of the bobbin case for best results

(430 / 440 QE)

• sew stitch combination, the stitches

alternate (original and mirror image)

Page 28

28

Functions - Memory

032907.52.04_0910_a430/a440/a450_EN

Programming alphabets and numbers

Open Memory

• press the -button

• the cursor on the left and the available

number of empty memory spaces (e.g.

60) start to blink, and «mem» appears

Example: Programming letters and numbers

• open Memory, select font

• enter letters and/or numbers

• the entered letter or number appears on the display

• activate the Securing function

• the sewing computer secures at the beginning of the entered combination

• to save the combination press the -button

• during the process of saving an hourglass is visible on the display

• trim connecting threads

Select alphabet

• press the Alphabet button to select the

alphabet of your choice

• the letter A in the alphabet of your choice

appears on the display

Programming letters/numbers

• select letter/number

• press (save) button = letter/

number is programmed

• the number of empty Memory spaces is

indicated

• select the next letter/number

• program, using etc.

• programming several words

• to insert a space, select ( _ )

• program, using

• program the next word

• if adjustments are made to the stitch

length or width, all programmed letters

and/or numbers will be affected

• if only single letters or numbers are to be

altered, each letter must be altered

individually

Block capitals

Double block capitals

Script (Italics)

Kyrillic capitals (450)

A

A

Page 29

29

Corrections in Memory

032907.52.04_0910_a430/a440/a450_EN

Functions - Memory

Balance in Memory

• the contents of the Memory as a whole

can be balanced as follows:

• close Memory

• touch the Balance button

• open Memory, now balance

the entire contents of the Memory with

both needle position buttons

The contents of the Memory remain saved

even when the sewing computer is

disconnected from the electrical supply.

They can be recalled at any time.

Overwriting individual stitches, letters

or numbers

• press the

to the stitch you wish to overwrite

or left button and scroll

The contents of the Memory will be lost if

the sewing computer is switched off

without pressing the -button before

closing the Memory, as they were not

saved.

• select new stitch number / letter /

number, new stitch length/width or

needle position

• press

• the original stitch is corrected (over-

written)

-button (to save)

Deleting individual stitches, letters or

numbers

• press the -button or left button and

scroll until the stitch you wish to delete

appears on the display

• press the «clr»-button

• the desired stitch/letter/number is

deleted

Delete complete Memory contents

• press the «clr»-button, keep depressed

and press the

• release both buttons

• leave Memory by pressing again

Stitch selection

• stitches1–10:

press the appropriate button; stitch

graphic and basic width and length

settings appear on the display

• stitches11–99:

press the #-button and the appropriate

number

• stitches from 100

press the #-button longer until a «1»

appears in display, then enter the last

two digits of the stitch

Leaving Memory

• press the -button

• during the process of saving an

hourglass is visible on the display

• all entries are saved

• Memory closes

• the word «mem» disappears from the

display

Select button 0 and stitch

No. 10 will be selected

C

(Standard buttonhole)

Page 30

Application of practical stitches

11

23

21

25

20

22

26

27

28

24

032907.52.04_0910_a430/a440/a450_EN

30

Stitch selection

Straight stitch

All non-stretch fabrics. All

straight stitch work

Zig-zag

Most fabric types. All simple

zig-zag such as clean finishing

fine fabrics. Sewing on elastic

and lace

Vari-overlock

Primarily for fine jerseys,

stretch overlock seams and

hems

Running stitch

Most types of fabric. Mending,

patching, reinforcing seams,

etc.

Securing stitch

All types of fabric. Secures the

beginning and end of seams

sewn with straight stitch

Triple straight and triple

zig-zag

Reinforced seams in tough,

heavy fabrics, topstitching

Blindstitch

Most types of fabric. Blind

hems, scallop edging effect on

soft jerseys and fine fabrics,

decorative seams

Double overlock

All types of knit. Overlock =

sew and neaten in one

operation, decorative seams

Super stretch

Open seam for all super-stretch

fabrics

Standard buttonhole

Fine to mediumweight fabrics.

Blouses, shirts, trousers,

bedlinens, etc.

Narrow buttonhole

Light- to mediumweight fabrics.

Blouses, dresses, trousers,

children’s and baby clothes,

crafts

Stretch buttonhole

All stretch fabrics made from

cotton, wool, silk and synthetic

fibers

aurora 430

Keyhole buttonhole

Heavyweight, non-stretch

fabrics. Jackets, coats, trousers, leisure wear

Straight stitch buttonhole

For reinforcing buttonholes,

pocket edges, especially for

stitching buttonholes in leather

or imitation leather

Hand-look buttonhole

Light- to mediumweight woven

fabrics. Blouses, dresses,

leisure wear, bedding

Darning program

Automatic darning for fine and

mediumweight fabrics

Basting stitch

Basting seams, hems, quilts,

etc.

Reinforced overlock

Medium-to heavyweight knits

and toweling, overlock seams,

flat joining seams

Gathering stitch

Most types of fabric. Gathering

with shirring elastic. Butted

seams = butting two pressed

edges and sewing together

Universal stitch

Firm fabrics such as felt and

leather. Flat joining seams,

visible seams, sewing on

elastic, decorative seams

Sewn-out zig-zag

Clean finishing woven fabrics,

reinforcing edges, attaching

elastic, decorative seaming

Lycra stitch

All two-way stretch fabrics, flat

joining seams and hems,

reinforced seaming on underwear

Stretch stitch

All stretch fabrics, open seam

in sportswear

Button sew-on program

For buttons with 2 and 4 holes

Straight stitch eyelet

Opening for cords and narrow

ribbons, decorative work

Jersey stitch

Natural, blended or synthetic

fabrics and delicate knits.

Visible seams and hems.

Mending jersey/interlock

Honeycomb stitch

Most types of interlock and

woven fabrics. Visible seams

and hems, etc.

Knit overlock

All knits, machine or handmade, overlock seam. Sews and

finishes edges in one operation

Page 31

31

aurora 440 QE

23

24

31

16

17

25

29

28

21

22

13

14

15

20

27

26

30

032907.52.04_0910_a430/a440/a450_EN

Application of practical stitches

Round buttonhole

For medium- to heavyweight

fabrics of all types. Clothing,

jackets, coats, rainwear

Keyhole buttonhole

Heavyweight, non-stretch

fabrics. Jackets, coats, trousers, leisure wear

Straight stitch buttonhole

For reinforcing buttonholes,

pocket edges, especially for

stitching buttonholes in leather

or imitation leather

Straight stitch eyelet

Opening for cords and narrow

ribbons, decorative work

Darning program

Automatic darning for fine and

mediumweight fabrics

Basting stitch

Basting seams, hems, quilts,

etc.

Gathering stitch

Most types of fabric. Gathering

with shirring elastic. Butted

seams = butting two pressed

edges and sewing together

Universal stitch

Firm fabrics such as felt and

leather. Flat joining seams,

visible seams, sewing on

elastic, decorative seams

Sewn-out zig-zag

Clean finishing woven fabrics,

reinforcing edges, attaching

elastic, decorative seaming

Lycra stitch

All two-way stretch fabrics, flat

joining seams and hems,

reinforced seaming on underwear

Stretch stitch

All stretch fabrics, open seam

in sportswear

Hand-look buttonhole

Light- to mediumweight woven

fabrics. Blouses, dresses,

leisure wear, bedding

Button sew-on program

For buttons with 2 and 4 holes

Narrow zig-zag eyelet

Opening for cords and narrow

ribbons, decorative work

Stretch overlock

Mediumweight knits, toweling

and firm wovens. Overlock

seams, flat joining seams

Jersey stitch

Natural, blended or synthetic

fabrics and delicate knits.

Visible seams and hems.

Mending jersey/interlock

Honeycomb stitch

Most types of interlock and

woven fabrics. Visible seams

and hems, etc.

Reinforced overlock

Medium-to heavyweight knits

and toweling, overlock seams,

flat joining seams

Knit overlock

All knits, machine or handmade, overlock seam. Sews and

finishes edges in one operation

Page 32

Application of practical stitches

13

032907.52.04_0910_a430/a440/a450_EN

32

aurora 450

Round buttonhole

For medium- to heavyweight

fabrics of all types. Clothing,

jackets, coats, rainwear

Round buttonhole with a

square end

For medium- to heavy-weight

fabrics: clothing, jackets, coats,

rain clothing

Keyhole buttonhole

Heavyweight, non-stretch

fabrics. Jackets, coats,

trousers, leisure wear

Keyhole buttonhole with a

tapered end

For firm, non-stretchable

fabrics: jackets, coats, leisurewear

Narrow zig-zag eyelet

Opening for cords and narrow

ribbons, decorative work

Straight stitch eyelet

Opening for cords and narrow

ribbons, decorative work

Darning program

Automatic darning for fine and

mediumweight fabrics

Large fly stitch

For medium- to heavy-weight

fabrics. To reinforce pocket

openings, zippers and plackets

Jersey stitch

Natural, blended or synthetic

fabrics and delicate knits.

Visible seams and hems.

Mending jersey/interlock

Honeycomb stitch

Most types of interlock and

woven fabrics. Visible seams

and hems, etc.

Universal stitch

Firm fabrics such as felt and

leather. Flat joining seams,

visible seams, sewing on

elastic, decorative seams

Sewn-out zig-zag

Clean finishing woven fabrics,

reinforcing edges, attaching

elastic, decorative seaming

Hand-look buttonhole

Light- to mediumweight woven

fabrics. Blouses, dresses,

leisure wear, bedding

Straight stitch buttonhole

For reinforcing buttonholes,

pocket edges, especially for

stitching buttonholes in leather

or imitation leather

Button sew-on program

For buttons with 2 and 4 holes

Basting stitch

Basting seams, hems, quilts,

etc

Gathering stitch

Most types of fabric. Gathering

with shirring elastic. Butted

seams = butting two pressed

edges and sewing together

Stretch overlock

Mediumweight knits, toweling

and firm wovens. Overlock

seams, flat joining seams

Lycra stitch

All two-way stretch fabrics, flat

joining seams and hems,

reinforced seaming on underwear

Stretch stitch

All stretch fabrics, open seam

in sportswear

Reinforced overlock

Medium-to heavyweight knits

and toweling, overlock seams,

flat joining seams

Page 33

33

Temporary altered stitch Memory

032907.52.04_0910_a430/a440/a450_EN

Temporary altered stitch Memory

Temporary altered stitch Memory

• for all types of stitches and materials

• altered stitch length, stitch width and

needle position will be saved automatically

• sewing of an altered stitch (e.g. zig-zag)

• selecting and sewing another stitch (e.g.

straight stitch)

• when returning to the individually altered

zig-zag the alterations will remain

• the Altered stitch Memory can contain

as many stitches as needed

Reset to basic settings

• individual stitches can be reverted to

basic settings manually

• press the «clr» button

• when turning the sewing computer off all

altered stitch settings in the Altered stitch

Memory will be deleted

Application:

• especially valuable when using two

alternating applications such as finishing

edges, zig-zag, adjusting vari-overlock to

suit the material

• straight stitch seam: use altered stitch

length

• blindstitch: altering stitch width and stitch

length to suit material

C

The temporary altered stitch

memory can hold as many

stitch alterations as needed

(these are stitch length, stitch

width, needle position, mirror

image and balance).

Page 34

Practical stitches - Application

032907.52.04_0910_a430/a440/a450_EN

34

Straight Stitch

Stitch:

Needle:

Thread:

Feed dog:

Presser foot:

Straight stitch No. 1

size and type suitable for the fabric selected

cotton or polyester

up

430 / 440 QE: Reverse pattern foot No. 1

450: Reverse pattern foot No. 1C

Straight Stitch

• after turning the sewing computer on,

the Practical Stitch appears

Application

• suitable presser foot to be selected

according to the technique, e.g. manual

darning

• suitable for all fabrics

Adjust the stitch length to suit

the fabric

For example use a longer stitch

length (approximately 3 - 4mm)

with denim, a shorter length

(2 - 2.5mm) with batiste.

Adjust the stitch length to suit

the thread

For example use a longer stitch

length (approximately 3 - 5mm)

when sewing with cordonnet

thread for topstitching.

Activate needle stop down

Prevents the fabric from slipping

when you stop to adjust stitch or

pivot.

Triple Straight Stitch Seam

Stitch:

Needle:

Thread:

Feed dog:

Presser foot:

Triple straight stitch No. 6

Jeans or 80-90 universal

cotton or polyester

up

430 / 440 QE: Reverse pattern foot No. 1

450: Reverse pattern foot No. 1C,

Jeans foot No. 8 (optional accessory)

Open Seam

• durable seam for firm and densely

woven fabrics such as denim and

corduroy

• reinforced seam subject to hard wear

For heavy layers or very

densely woven fabrics:

A Jeans needle or Jeans foot

No. 8 will help when sewing very

heavy fabrics, such as denim or

canvas.

Decorative top stitch

Lengthen out stitch and use as a

decorative top stitch with denim.

Page 35

Edge stitching

032907.52.04_0910_a430/a440/a450_EN

Practical stitches - Application

35

Stitch:

Needle:

Thread:

Feed dog:

Presser foot:

Narrow edgestitching

Outer edges

• place edge of fold against the guide on

the Blindstitch foot

• select needle position at desired

distance from the folded edge

Straight stitch No. 1

size and type suitable for the fabric selected

cotton, polyester or cordonnet (topstitching)

up

Blindstitch foot No. 5

430 / 440 QE: Reverse pattern foot No. 1

450: Reverse pattern foot No. 1C

Edge stitch foot No. 10 (optional accessory)

C

Hem edges

• place edge of fold against the guide on

the Blindstitch foot (inside upper edge of

hem)

• select needle position right to sew along

the upper edge

Needle position

• left for outer edge

• right for inner edge (hem edges)

Presser foot

• Blindstitch foot No. 5

Foot No. 5:

use any left or far right needle

position

Foot No. 10:

all needle position

Wide edgestitching

Guiding the fabric

Presser foot as a guide:

• guide the folded edge along the edge of

the presser foot

Stitch plate as a guide:

• guide the folded edge along the marks

on the stitch plate (for stitching 3/8” to

1 1/8” (1 to 2.5cm) from the edge)

Seam guide as a guiding aid:

• insert the seam guide into the hole on

the back of the presser foot shaft

• adjust as desired

• tighten the screw

• guide the folded edge along the seam

guide

• to sew parallel lines, guide the seam

guide along a previously sewn line of

stitches

Edgestitching with seam guide

• a big help when sewing parallel

lines, grids, etc.

Needle position

• adjust the needle position to select

desired distance between rows of

topstitching or from fabric edge

Presser foot

• 430 / 440 QE: Reverse pattern foot No. 1

• 450: Reverse pattern foot

No. 1C

Page 36

36

Practical stitches - Application

032907.52.04_0910_a430/a440/a450_EN

Securing stitch (straight stitch)

Feed dog:

Presser foot:

Darning program

Stitch:

Needle:

Thread:

Securing stitch No. 5

size and type suitable for the fabric selected

cotton or polyester

up

430 / 440 QE: Reverse pattern foot No. 1

450: Reverse pattern foot No. 1C

Securing stitch

• for all fabrics

• secures beginning and end of seam

Sewing long seams

• quicker securing at beginning and end of

seam

• exact, regular and safe securing in all

fabrics

Seam begin

• the sewing computer secures seam

automatically (5 stitches forward,

5 stitches reverse)

• continue with straight stitch forward

Seam end

• press the Quick reverse

button on head frame; the

sewing computer secures

automatically (5 stitches

reverse, 5 stitches forward)

• the sewing computer stops automatically when securing is complete

Stitch:

Needle:

Thread:

Feed dog:

Presser foot:

430: Darning program No. 18

440 QE: Darning program No. 20

450: Darning program No. 22

size and type suitable for the fabric selected

darning thread

up

Automatic buttonhole foot No. 3A

430 / 440 QE: Reverse pattern foot No. 1

450: Reverse pattern foot No. 1C

Quick darning of holes or worn areas

Replaces threads with the grain in all

fabrics.

Preparation

• stretch fabric into darning hoop; prevents

puckering

Move project accordingly for a wider and/or

longer darning area.

Darning with Reverse pattern foot

No. 1C, No. 1 (automatic stitch count)

• insert the needle in the top left of the

worn area

• sew the first vertical row and stop the

sewing computer

• press the quick reverse button on head

frame (length is programmed)

• complete the Darning program, the

sewing computer stops automatically

• clear the program by pressing the «clr»

button

Reinforcement

• use fine fabric or interlining as

a backing

Darning with the Automatic buttonhole

foot with slide No. 3A

• only for small tears and worn areas for a

darn of maximum 1 1/2” (3cm) in length

• same procedure as with foot No. 1C,

No.1

Corrections of the automatic darning

area

• if the darning becomes distorted, correct

with the Balance (see page 22 for more

information on the Balance function)

Page 37

37

Manual darning

032907.52.04_0910_a430/a440/a450_EN

Practical stitches - Application

Stitch:

Needle:

Thread:

Feed dog:

Presser foot:

Straight stitch No. 1

size and type suitable for the fabric selected

darning thread

down

Darning foot No. 9

Darning holes or worn areas

Replaces both lengthways and crossways

threads in all fabrics.

Preparation

• stretch fabric into darning hoop

(optional accessory) to prevent

distortion

• use the slide-on table

Sewing

• move the darning hoop smoothly by

hand

• work from left to right without using

pressure

• when changing direction on top and on

bottom, move in curves (avoid points as

this prevents holes and thread

breakage)

• work in different lengths so that the

thread is «lost» in the fabric

Poor stitch formation

• if the thread is lying on the right

side of the fabric, the hoop is

being moved too quickly

• if there are knots on the wrong

side of the fabric, the hoop is

being moved too slowly

Thread breaks

• if thread breakage is a problem, it could be that the hoop

is not being moved smoothly

1. Stitch over the hole

• sew the first rows to cover the hole (not

too close, sewing beyond the worn area)

• work the rows in irregular lengths

• turn work by a quarter turn - 90°

2. Cover the first rows

• sew over the first rows - not too close for

a soft finish

• turn work by a half turn - 180°

3. Complete darning

• sew loosely and in same direction as 2nd

rows

Page 38

38

Practical stitches - Application

032907.52.04_0910_a430/a440/a450_EN

Zig-zag Stitch

Stitch:

Needle:

Thread:

Feed dog:

Presser foot:

Zig-zag stitch No. 2

size and type suitable for the fabric selected

cotton or polyester

up

430 / 440 QE: Reverse pattern foot No. 1

450: Reverse pattern foot No. 1C

Zig-zag Stitch

• suitable for all fabrics

• overcasting

• elastic seams

• decorative sewing

Oversewing Edges

• guide edge of fabric into the center of

the presser foot

• do not select too wide a width or too

long a stitch – the edge should lie flat

and not roll

• needle goes into fabric on one side and

over the edge into the air on the other

side

• use a fine darning thread for lightweight

fabric

Oversewing edges

If edges roll, use the Vari-overlock stitch and foot No. 2A (450) /

No. 2 (430 / 440 QE).

Embroidery with satin stitch

Experiment with adjusting the

stitch width for new decorative

effects.

Satin Stitch

• dense stitch used for appliqué,

embroidery, etc.

• shorten stitch length, satin stitch

setting will be indicated by

parallel lines on stitch length bar

Sewing on Elastic, Shirring Elastic/Cord

Stitch:

Stitch width:

Needle:

Thread:

Feed dog:

Presser foot:

430: Universal stitch No. 24

440 QE: Universal stitch No. 26

450: Universal stitch No. 29

depends on width of elastic

type and size to suit the fabric selected

cotton or polyester

up

430 / 440 QE: Reverse pattern foot No. 1

450: Reverse pattern foot No. 1C

Embroidery foot No. 6 (optional accessory)

Sewing on Elastic

• for gathering long lengths of fabric

• for ruffles and flounces in fine fabrics,

outer garments, sportswear, children’s

and doll clothing, crafts, etc.

• works well for gathered sleeve edges

and neck openings

Preparation

• cut elastic to length required

Sewing

• oversew the elastic, adjusting the stitch

width to be slightly wider than the

elastic

• needle must not pierce the elastic

• after sewing, adjust the gathers evenly

Secure the beginning and end

of elastic

Sew a few straight stitches

backwards and forwards to

secure the elastic.

Quick hem finish

• for children’s or doll clothing

• sew sleeve edges with elastic

before sewing seams

Page 39

39

Stretch Overlock Seam

032907.52.04_0910_a430/a440/a450_EN

Practical stitches - Application

Stitch:

Needle:

Thread:

Feed dog:

Presser foot:

Vari-overlock seam

440 QE: Stretch overlock No. 23

450: Stretch overlock No. 26

universal, ballpoint or stretch

cotton or polyester

up

430 / 440 QE: Overlock foot No. 2, Reverse pattern foot No. 1

450: Overlock foot No. 2A, Reverse pattern foot No. 1C

Closed Seam

• overlock seam in coarse or loose knits

Sewing

• sew stretch overlock along the fabric

edge

• the stitch should sew over the edge of

the fabric on the right swing of the

needle

Stitch:

Needle:

Thread:

Feed dog:

Presser foot:

Vari-overlock No. 3

size and type suitable for the fabric selected

cotton or polyester

up

430 / 440 QE: Overlock foot No. 2, Reverse pattern foot No. 1

450: Overlock foot No. 2A, Reverse pattern foot No. 1C

Overlock foot No. 2A, No. 2 is specially

designed for overlock stitches. The pin on

the foot allows for more thread in each

stitch so that the elasticity of the seam is

maintained.

Closed seam

Stretchy seam in fine, soft knits such as

silk jersey and interlock.

Sewing

• guide the raw edge along the pin on the

overlock foot

• the stitch will form over the pin and over

the edge of the fabric

Page 40

40

Practical stitches - Application

032907.52.04_0910_a430/a440/a450_EN

Double overlock seam

Stitch:

Needle:

Thread:

Feed dog:

Presser foot:

Double overlock No. 8