Page 1

MODBUS

Bus Terminal Controller

BC7300

Version: 1.5

Last change: 2006-11-06

Page 2

Please note the following

Target group

Safety requirements

The documentation has been prepared with care. The products described

©

This description is only intended for the use of trained specialists in control

and automation engineering who are familiar with the applicable national

standards.

The responsible staff must ensure that the application or use of the

products described satisfy all the requirements for safety, including all the

relevant laws, regulations, guidelines and standards.

are, however, constantly under development. For that reason the

documentation is not in every case checked for consistency with

performance data, standards or other characteristics, and does not

represent an assurance of characteristics in the sense of § 459, Para. 2 of

the German Civil Code. In the event that it contains technical or editorial

errors, we retain the right to make alterations at any time and without

warning. No claims for the modification of products that have already been

supplied may be made on the basis of the data, diagrams and descriptions

in this documentation.

This manual is copyrighted. Any reproduction or third party use of this

protected publication, whether in whole or in part, without the written

permission of Elektro Beckhoff GmbH, is forbidden.

BC7300

Page 3

Table of contents

1. Foreword 5

Notes on the documentation 5

Liability Conditions 5

Delivery conditions 5

Copyright 5

Safety Instructions 6

State at Delivery 6

Description of safety symbols 6

Table of contents

2. Basic Principles 7

Device Description of the BC7300 7

The Beckhoff Bus Terminal System 7

The interfaces 9

Electrical power supply 9

Power contacts feeding points 9

Power contacts 9

Fieldbus connection 9

Configuration and programming interface 10

KS2000 Software 10

TwinCAT BC 10

K-Bus Contacts 10

Electrical isolation 10

Operating Modes of the Bus Terminal Controller 11

Mechanical structure 11

Technical data 14

Peripheral Data in the Process Image 15

Start-up procedure and Diagnostics 16

Fieldbus errors 18

3. MODBUS 19

Basic Principles 19

Bus Topology 19

Process Data and Memory Map 20

MODBUS Process Image 22

BC7300 Process Image 22

Assignment of the Bus Terminals 23

Setting and Parameterisation of the MODBUS 24

Parameterisation Table 25

The MODBUS Protocol 26

ASCII 26

RTU 26

Functions 27

Read Digital Outputs (Function 1) 27

Read Digital Inputs (Function 2) 28

Read Analog In/Outputs (Function 3) 28

Read Analog Inputs (Function 4) 29

Writing a Digital Output (Function 5) 30

Writing an Analog Output (Function 6) 30

Writing a Number of Digital Outputs (Function 15) 31

Writing a Number of Analog Outputs (Function 16) 32

Writing and Reading Analog Outputs and Inputs 33

(Function 23) 33

Echoes a query (Sub-Function 0) 35

Bus Coupler Reset (Sub-Function 1) 35

Delete All Counter Contents (Sub-Function 10) 35

Bus Communication Error Counter (Sub-Function 11) 35

Error Answer Counter (Sub-Function 13) 35

Slave Answers (Sub-Function 14) 36

BC7300 3

Page 4

Table of contents

Unsent Slave Answers (Sub-Function 15) 36

Number of Error Answers (Sub-Function 16) 36

BC7300 Error Answers 37

4. Bus Terminal Controller 38

PLC Cycle Time 38

PLC Variables 38

Remanent Variables 38

Persistent Data 39

Allocated flags area 40

5. Appendix 41

MODBUS Interface 41

Mapping the Bus Terminals 42

List of references 42

Firmware 42

Table 42

Example Program 43

Explanation of the Program 43

The Program in the Bus Terminal Controller 43

Creating the BOOT Program 44

MODBUS Communication 44

6. Questions and Answers 46

General 46

No communication with the BC7300 46

Mapping of the digital and the byte-oriented Bus Terminals onto a fixed

address 46

Drop of the digital outputs 46

7. Index 47

8. Support and Service 48

Support and Service 48

Beckhoff Headquarters 48

Beckhoff's branch offices and representatives 48

4 BC7300

Page 5

Foreword

Foreword

Notes on the documentation

This description is only intended for the use of trained specialists in control and automation engineering

who are familiar with the applicable national standards. It is essential that the following notes and

explanations are followed when installing and commissioning these components.

Liability Conditions

The responsible staff must ensure that the application or use of the products described satisfy all the

requirements for safety, including all the relevant laws, regulations, guidelines and standards.

The documentation has been prepared with care. The products described are, however, constantly under

development. For that reason the documentation is not in every case checked for consistency with

performance data, standards or other characteristics. None of the statements of this manual represents a

guarantee (Garantie) in the meaning of § 443 BGB of the German Civil Code or a statement about the

contractually expected fitness for a particular purpose in the meaning of § 434 par. 1 sentence 1 BGB. In

the event that it contains technical or editorial errors, we retain the right to make alterations at any time

and without warning. No claims for the modification of products that have already been supplied may be

made on the basis of the data, diagrams and descriptions in this documentation.

Delivery conditions

In addition, the general delivery conditions of the company Beckhoff Automation GmbH apply.

Copyright

©

This documentation is copyrighted. Any reproduction or third party use of this publication, whether in

whole or in part, without the written permission of Beckhoff Automation GmbH, is forbidden.

BC7300 5

Page 6

Foreword

i

Safety Instructions

State at Delivery

All the components are supplied in particular hardware and software configurations appropriate for the

application. Modifications to hardware or software configurations other than those described in the

documentation are not permitted, and nullify the liability of Beckhoff Automation GmbH.

Description of safety symbols

The following safety symbols are used in this documentation. They are intended to alert the reader to the

associated safety instructions..

This symbol is intended to highlight risks for the life or health of personnel.

Danger

This symbol is intended to highlight risks for equipment, materials or the

Attention

environment.

This symbol indicates information that contributes to better understanding.

Note

BC7300 6

Page 7

Basic Principles

Up to 64 Bus Terminals

Each having 2 I/O channels

for each signal form

De-centralised wiring of

each I/O level

IPC as controller

Bus Couplers for all usual

bus systems

Standard C - rail assembly

Modularity

Device Description of the BC7300

The BC7300 Bus Terminal Controller is a Bus Coupler with integrated PLC

functionality and a MODBUS slave interface.

The controller is programmed in IEC 1131-3. Up to 64 terminals belonging

to the Beckhoff Bus Terminal System can be connected to the BC7300.

These include analog signal types for current and voltage, as well as

PT100 and thermocouples, in addition to digital input and output terminals.

The Bus Terminal Controller's MODBUS interface allows a MODBUS

master to be connected.

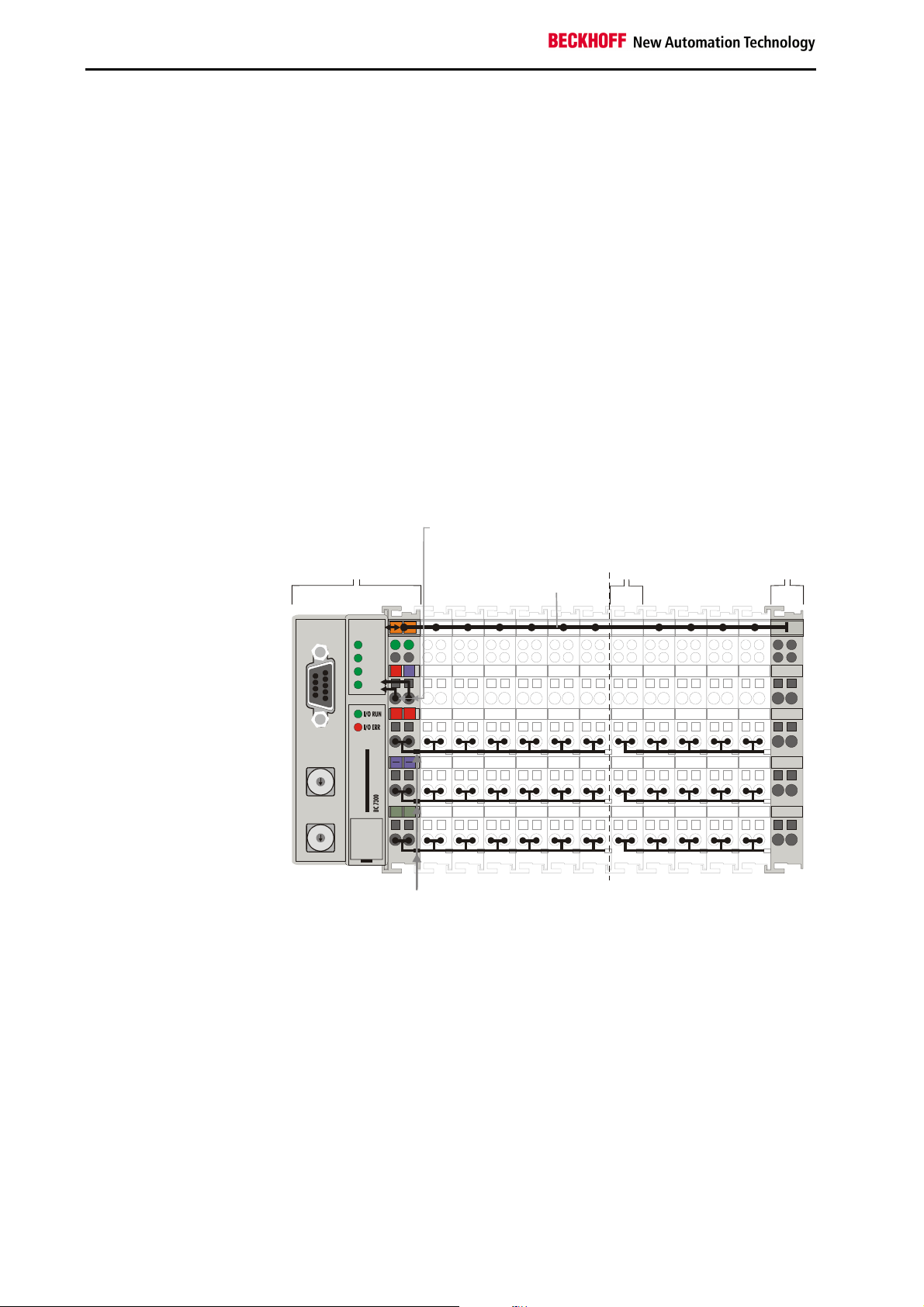

The Beckhoff Bus Terminal System

The Bus Terminal system is the universal interface between a fieldbus

system and the sensor / actuator level. A unit consists of a Bus Coupler as

the head station, and up to 64 electronic series terminals, the last one

being an end terminal. For each technical signal form, terminals are

available each having two I/O channels, and these can be mixed in any

order. All the terminal types have the same mechanical construction, so

that difficulties of planning and design are minimised. The height and depth

match the dimensions of compact terminal boxes.

Fieldbus technology allows more compact forms of controller to be used.

The I/O level does not have to be brought to the controller. The sensors

and actuators can be wired de-centrally, using minimum cable lengths. You

can locate the controller installation anywhere within the plant. The use of

an Industrial PC as the controller means that the operating and observing

element can be implemented in the controller’s hardware. The controller

can therefore be located at an operating panel, in a control room, or at

some similar place. The Bus Terminals form the de-centralised input/output

level of the controller in the control cabinet and the subsidiary terminal

boxes. The power sector of the plant is also controlled over the bus system

in addition to the sensor/actuator level. The Bus Terminal replaces the

conventional series terminal as the wiring level in the control cabinet. The

control cabinet can have smaller dimensions.

The Beckhoff Bus Terminal system unites the advantages of a bus system

with the possibilities of the compact series terminal. Bus Terminals can be

driven within all the usual bus systems, thus reducing the controller parts

count. The Bus Terminals then behave like conventional connections for

that bus system. All the performance features of the particular bus system

are supported.

The easy, space-saving assembly on a standard C-rail, and the direct

wiring of actuators and sensors without cross-connections between the

terminals standardises the installation. The consistent labelling scheme

also contributes.

The small physical size and the great flexibility of the Bus Terminal system

allows it to be used wherever a series terminal is also used. Every type of

connection, such as analog, digital, serial or the direct connection of

sensors can be implemented.

The modular assembly of the terminal strip with Bus Terminals of various

functions limits the number of unused channels to a maximum of one per

function. The presence of two channels in one terminal is the optimum

compromise of unused channels and the cost of each channel. The

possibility of galvanic isolation through potential feed terminals also helps

Basic Principles

BC7300 7

Page 8

Basic Principles

6

6

End Terminal

Potential

contacts

Bus Coupler

Display of the channel state

K-Bus

End terminal

Potential feed terminals for

galvanically isolated groups

The principle of the

Bus Terminal

to keep the number of unused channels low.

The integrated LEDs show the state of each channel at a location close to

the sensors and actuators.

The K-Bus is the data path within a terminal strip. The K-Bus is led

through from the Bus Coupler through all the terminals via six contacts on

the terminals‘ side walls. The end terminal terminates the K-Bus. The user

does not have to learn anything about the function of the K-Bus or about

the internal workings of the terminals and the Bus Coupler. Many software

tools that can be supplied make project planning, configuration and

operation easy.

The operating voltage is passed on to following terminals via three power

contacts. You can divide the terminal strip into arbitrary galvanically

isolated groups by means of potential feed terminals. The feed terminals

play no part in the control of the terminals, and can be inserted at any

points within the terminal strip.

Up to 64 terminals may be located in a terminal strip, including the potential

feed terminals and end terminal.

Bus Coupler

BC7300

power

supply

input

terminal

K-Bus

MODBUS

0

1

9

2

8

3

7

4

5

0

1

9

2

8

3

7

4

5

0201

WD

RX

24V

0V

TX

PLC

+ +

BECKHOFF

PE PE

Power

Potential

isolation

Additional characteristics of

the Bus Terminal

Controllers

Bus Terminal Controllers (BC) differ from Bus Couplers (BK) in that, in

addition to K-Bus processing, a real-time PLC task is also running. Unlike

Bus Couplers, the signals from the terminals are processed by the PLC

task, while the fieldbus carries the in- and outputs of the PLC task. It is

possible, however, to subdivide the Bus Terminals to that some Bus

Terminals are pre-processed by the PLC task, while others are sent

directly over the fieldbus to a supervising system.

Bus Terminal Controllers

for various fieldbus systems

Various Bus Terminal Controllers can be used to couple the electronic

terminal strip with integrated PLC task quickly and easily to different

fieldbus systems. It is also possible to convert to another fieldbus system at

a later time. The Bus Terminal Controller performs all the monitoring and

control tasks that are necessary for operation of the connected Bus

Terminals. The operation and configuration of the Bus Terminals is carried

out exclusively by the Bus Terminal Controller. Fieldbus, K-Bus and I/O

level are galvanically isolated.

BC7300 8

Page 9

02

01

+

+

4

3

2

1

3

2

Power LEDs

Bus Coupler / power contacts

PLC

Basic Principles

If data exchange over the fieldbus fails, the PLC task continues to run as

an autonomous system.

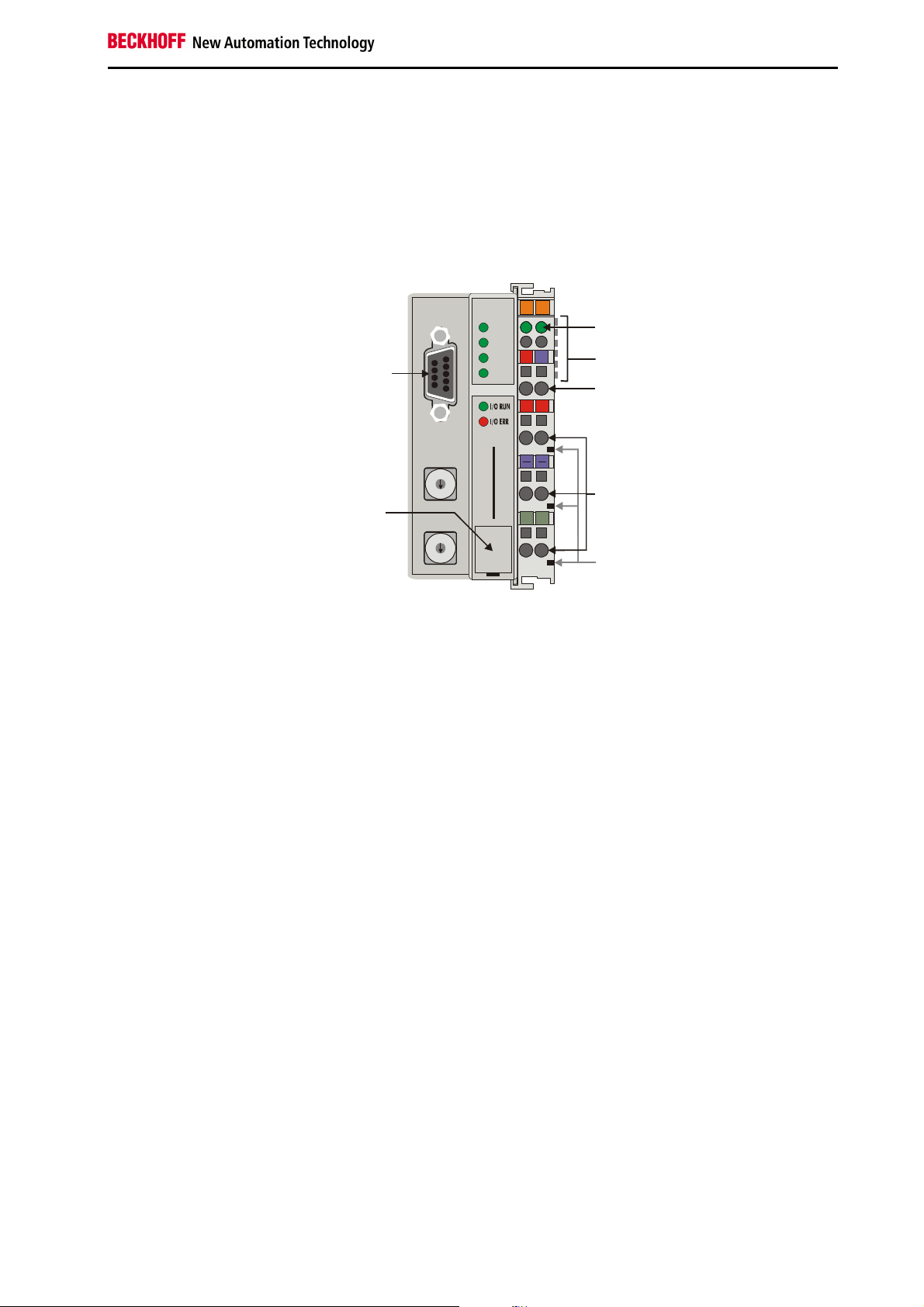

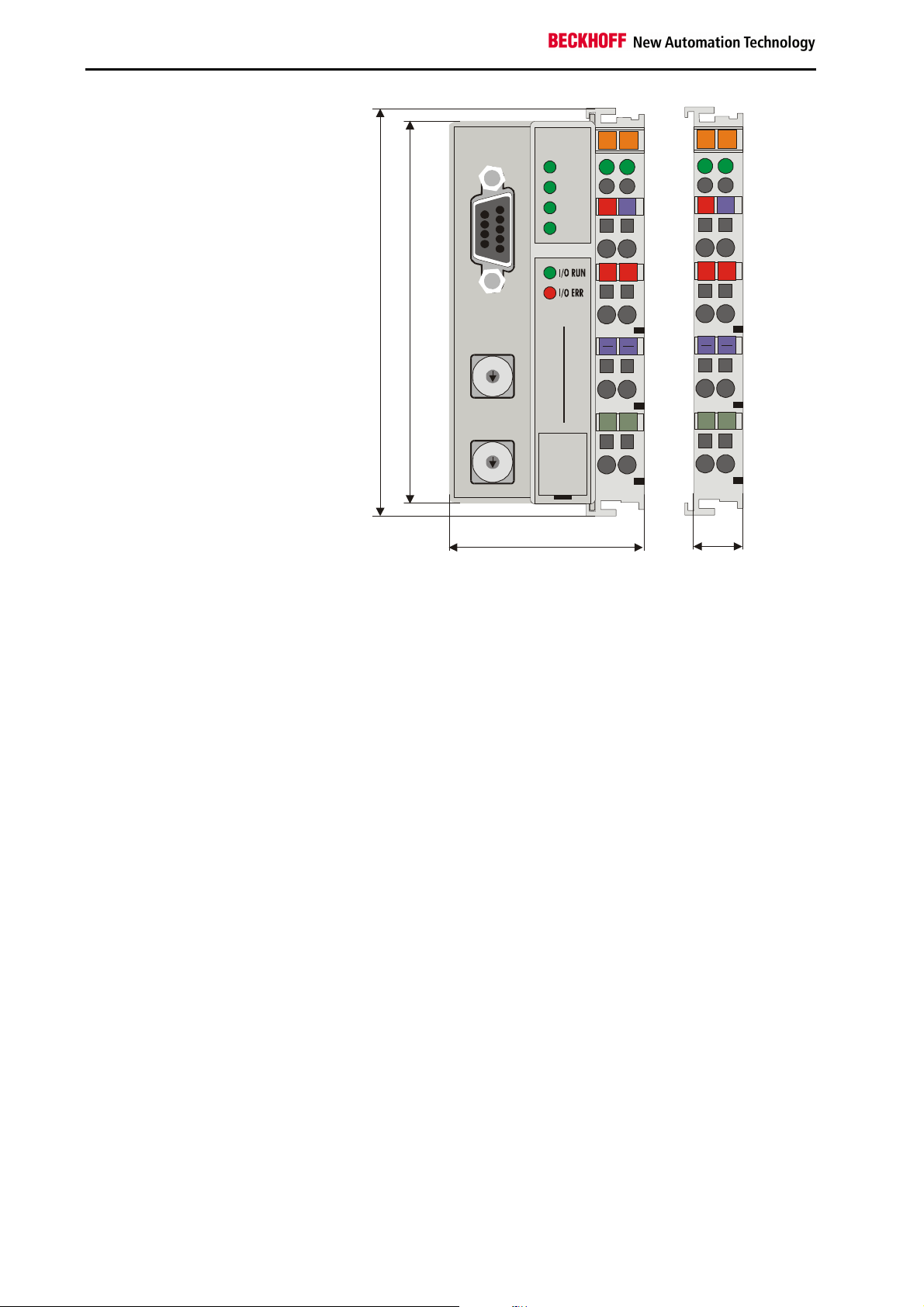

The interfaces

A Bus Terminal Controller has six different methods of connection. These

interfaces are designed as plug connectors and as spring-loaded terminals.

The MODBUS – Bus

Terminal Controller

BC7300

MODBUS

MODBUS

WD

RX

TX

24V

0V

K-Bus

Bus Coupler power supply

24 V DC / GND

0

1

9

Configuration and

programming

interface

8

7

4

6

5

BECKHOFF

BC 7300

PE PE

0

9

8

7

6

5

Power contacts

feeding points

Power contacts

24 V DC to the topmost

terminals “24 V” and “0 V”

Electrical power supply

The Bus Terminal Controllers require a 24 V DC supply for their operation.

The connection is made by means of the upper spring-loaded terminals

labelled “24 V” and “0 V”. This supply voltage feeds not only the Bus

Coupler electronics via the K-Bus, but also the Bus Terminals. The power

supply for the Bus Coupler electronics and that of the K-Bus are electrically

separated from the potential of the field level.

Lower 3 terminal pairs for

power feed

Maximum 24 V

Maximum 10 A

Power contacts feeding points

The bottom six connections with spring-loaded terminals can be used to

feed the supply for the peripherals. The spring-loaded terminals are joined

in pairs to a power contact. The feed for the power contacts has no

connection to the voltage supply for the Bus Coupler. The design of the

feed permits voltages of up to 24 V. The assignment in pairs and the

electrical connection between feed terminal contacts allows the connection

wires to be looped through to various terminal points. The current drawn

from the power contact must not exceed 10 A for long periods. The current

rating between two spring-loaded terminals is identical to that of the

connecting wires.

Spring contacts on the side

Power contacts

On the right hand face of the Bus Terminal Controller there are three spring

contacts for the power contact connections. The spring contacts are hidden

in slots so that they can not be accidentally touched. By attaching a Bus

Terminal the blade contacts on the left hand side of the Bus Terminal are

connected to the spring contacts. The tongue and groove guides on the top

and bottom of the Bus Terminal Controllers and of the Bus Terminals

guarantees that the power contacts mate securely.

9 pin sub-D socket strip

Fieldbus connection

There is a recessed front face on the left hand side. The MODBUS

connection plug can be inserted here. A full description of the fieldbus

interfaces is found elsewhere in this manual. (In the section on The

Medium: Plugs and Cables)

BC7300 9

Page 10

Basic Principles

Serial interface under the

front cover

6 contacts on the side

3 potential groups:

Fieldbus

K-Bus

Peripheral level

Configuration and programming interface

The standard Bus Terminal Controllers have an RS232 interface at the

bottom of the front face. The miniature connector can be joined to a PC

with the aid of a connecting cable and either the KS2000 configuration

software or TwinCAT BC. The interface allows the analog channels to be

configured with the KS2000 software. The BC7300 is programmed via the

same interface.

KS2000 Software

In order to link the MODBUS BK7300 Bus Terminal Controller and the

KS2000 configuration software, the coupler's address selection switch

must be set to "00", and it must be restarted (i.e. the coupler must be

switched off and then on again). The MODBUS must not be connected.

TwinCAT BC

In order to link the MODBUS BK7300 Bus Terminal Controller and the

TwinCAT BC programming software, the coupler's address selection switch

must be set to "00", and it must be restarted (i.e. the coupler must be

switched off and then on again). The MODBUS must not be connected.

K-Bus Contacts

In order to connect the Bus Coupler and Bus Terminals the Bus Coupler

has gold contacts on the right hand side. When the Bus Terminals are

pushed together the gold contacts automatically make the connection

between the Bus Terminals. The voltage supply to the K-Bus electronics in

the Bus Terminals and the data exchange between the Bus Coupler and

the Bus Terminals is carried out by the K-Bus. A part of the data exchange

takes place via a ring structure within the K-Bus. Opening the K-Bus, e.g.

by pulling out one of the Bus Terminals, opens the ring. Data exchange is

no longer possible. Special mechanisms nevertheless allow the Bus

Coupler to identify the location of the interruption and to report it.

Electrical isolation

The Bus Terminal Controllers operate by means of three independent

potential groups. The supply voltage feeds the K-Bus electronics in the Bus

Terminal Controller and the K-Bus itself, which is electrically separate. The

supply voltage is also used to generate the operating voltage for the

fieldbus.

Remark: All the Bus Terminals are galvanically isolated from the K-Bus.

The K-Bus is thus galvanically isolated from everything else.

BC7300 10

Page 11

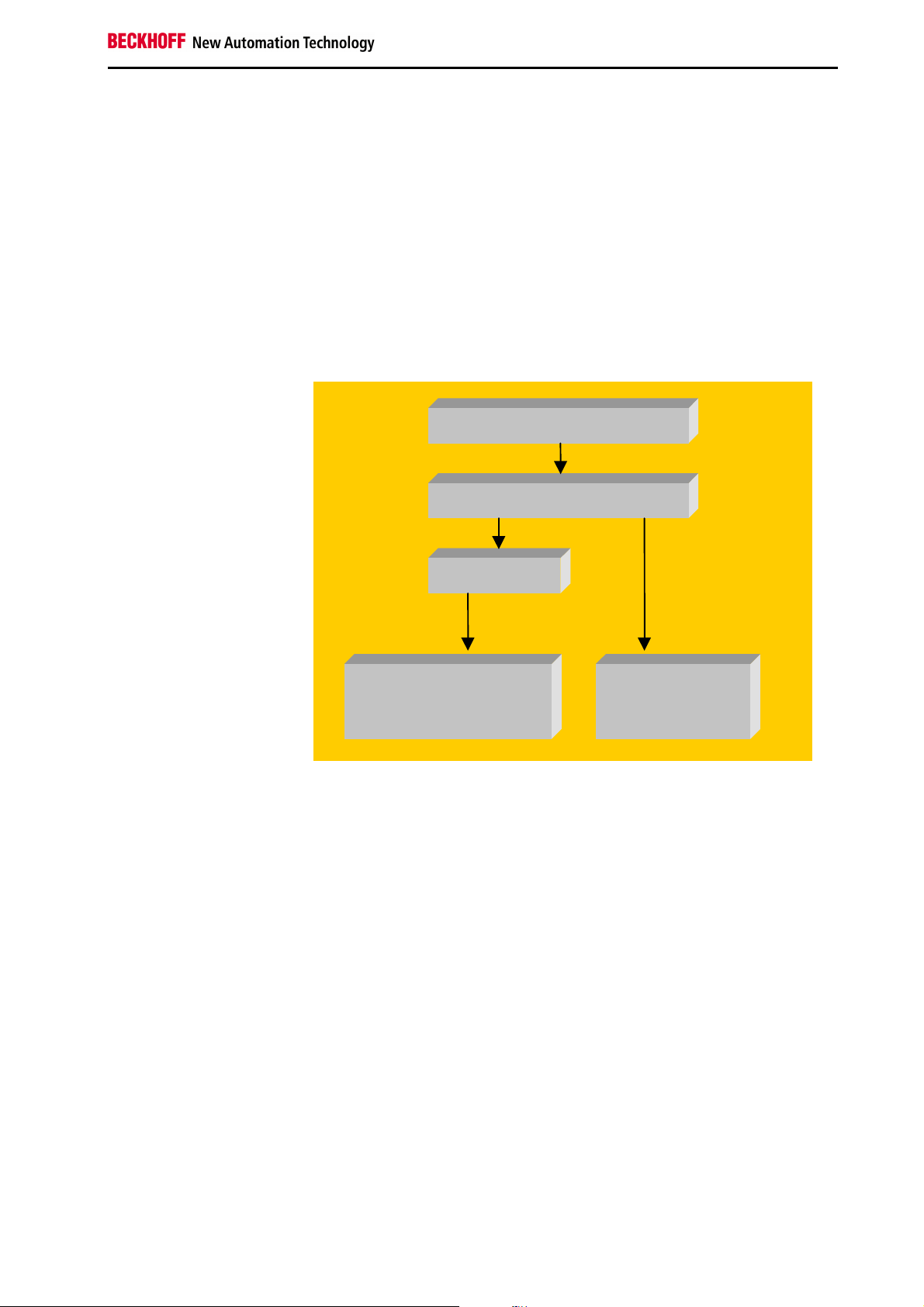

Operating Modes of the Bus Terminal

Controller

Start-up behaviour of the

Bus Terminal Controller

Immediately after being switched on, the Bus Terminal Controller checks,

in the course of a “self test”, all the functions of its components and the

communication of the K-Bus. The red I/O LED blinks while this is

happening. After completion of the self-test, the Bus Terminal Controller

starts to test the attached Bus Terminals (in a "Bus Terminal test"), and

reads in the configuration. An internal structure list is created from the Bus

Terminal configuration. In case of an error, the Bus Terminal Controller

enters the „STOP“ state. Once the start-up has completed without error,

the Bus Terminal Controller enters the "fieldbus start" state.

Basic Principles

Power On self test

Bus Terminal test

Structure list

OK

Error

PLC start /

Communication start

Mechanical structure

The system of the Beckhoff Bus Terminals is characterised by low physical

volume and high modularity. When planning a project it must be assumed

that at least one Bus Coupler and a number of Bus Terminals will be used.

The mechanical dimensions of the Bus Couplers are independent of the

fieldbus system. If large plugs are used, such as, for example, certain bus

plugs for the Profibus, the maximum height of the housing can be

exceeded.

Stop

BC7300 11

Page 12

Basic Principles

020201

01

+++

+

PEPEPE

PE

RUN

MODBUS

24V

24V

4

3

2

1

0

0

47

12

Dimensions of a Bus

Coupler in mm

4

9

RX

TX

PLC

F

F

0

1

9

2

8

3

7

4

6

5

O

H

K

C

E

B

0

1

9

8

7

6

5

0V

0

0

3

7

C

B

0V

The total width in practical cases is composed of the width of the Bus

Coupler with the bus end terminal and the width of the Bus Terminals in

use. Depending on function, the Bus Terminals are 12 or 24 mm wide. The

front wiring increases the total height of 68 mm by about 5 to 10 mm,

depending on the wire thickness.

Assembly and connection

The Bus Coupler and all the Bus Terminals can be clipped by light

pressure onto a 35 mm C-mounting rail. A locking mechanism prevents

the individual housings from being pulled off again. For removal from the

mounting rail the orange coloured tension strap releases the latching

mechanism, allowing the housing to be pulled off the rail without any force.

Work should only be carried out on the Bus Terminals and the Bus Coupler

when switched off. Pulling out and inserting under power can cause

undefined states to be temporarily caused. (A reset of the Bus Coupler, for

example).

Maximum number of

terminals

Up to 64 Bus Terminals can be attached to the Bus Coupler on the right

hand side. When plugging the components together, be sure to assemble

the housings with groove and tongue against each other. A properly

working connection can not be made by pushing the housings together on

the mounting rail. When correctly assembled, no significant gap can be

seen between the attached housings.

The right hand part of the Bus Coupler can be compared to a Bus

Terminal. Eight connections on the top permit connection with solid or fine

wires. The connection is implemented with the aid of a spring device. The

spring-loaded terminal is opened with a screwdriver or rod, by exerting

gentle pressure in the opening above the terminal. The wire can be

inserted into the terminal without any force. The terminal closes

automatically when the pressure is released, holding the wire securely and

permanently.

The connection between the bus coupler and the bus terminals is

automatically realised by pushing the components together. The transfer of

the data and the supply voltage for the intelligent electronics in the Bus

Terminals is performed by the K-Bus. The supply of the field electronics is

performed for the digital Bus Terminals through the power contacts.

BC7300 12

Page 13

Plugging together the power contacts creates a supply rail. Note the circuit

diagrams for the Bus Terminals, since some Bus Terminals do not loop

these power contacts through, or only do so partially (e.g. analog Bus

Terminals or 4 channel digital Bus Terminals). The potential feed terminals

interrupt the power contacts, and represent the start of a new supply rail.

The Bus Coupler can also be made use of to feed the power contacts.

Insulation testing

PE power contacts

The power contact labelled “PE” can be used as a protective earth. For

safety reasons this contact mates first when plugging together, and can

ground short-circuit currents of up to 125 A. Note that, for reasons of

electromagnetic compatibility, the PE contacts are capacitatively coupled to

the mounting rail. This can both lead to misleading results and to damaging

the terminal during insulation testing. (e.g.: breakdown of the insulation

from a 230 V power user to the PE conductor.) The PE conductor to the

Bus Coupler must be disconnected for the insulation testing. In order to

uncouple further feed locations for the purposes of testing, the feed

terminals can be pulled at least 10 mm out from the connected group of

other terminals. In that case, the PE conductors do not have to be

disconnected.

The “PE” power contact must not be used for other potentials.

Basic Principles

BC7300 13

Page 14

Basic Principles

Technical data

The MODBUS – the fieldbus-specific electrical data is listed in this section.

The following table gives an overview of all the data:

Technical data BC7300

Supply voltage

Input current

Power-on surge

K Bus supply current up to

Configuration facility

Number of Bus Terminals

Digital peripheral signals

Analog peripheral signals

Baud rate

Protocol

Bus connection

Voltage of the

power contact

Power contacts current

drawn

Electric strength

Typical weight

Operating temperature

Storage temperature

Relative humidity

Vibrations/Shock resistance

EMC resistance burst / ESD

Installation position

Type of protection

PLC data

Programmability

Program size

Program memory

Data memory

Remanent flags

Runtime system

PLC cycle time

Programming languages

Station addresses

Baud rate in programming

mode

24 V DC

70mA +

(total K-Bus current)/4

500 mA max.

2.5 x steady operating current

1750 mA max.

via KS2000 or the controller

64

256 inputs/outputs

128 inputs/outputs

From 150 baud to 38400 baud

RTU and ASCII

D-Sub RS 485

9-pin

24 V DC / AC max.

10 A max.

500 Veff (power contact / supply voltage / fieldbus)

none

170 g

0°C ... +55°C

-20°C ... +85°C

95% without dew formation

conforms to IEC 68-2-6 / IEC 68-2-27

conforms to EN 50082 (ESD, Burst) / EN 50081

any

IP20

via programming interface (TwinCAT BC/TwinCAT)

approx. 3000 PLC statements

32 kbytes / 96 kbytes

32 kbytes / 64 kbytes

512 bytes

1 PLC task

approx. 3 ms for 1000 instructions (including K-Bus I/O cycle)

IL, LD, FBD, SFC, ST

selectable to 99 via DIP switch

0 Programming mode and configuration mode

1 – 99 Slave address

19,200 baud, 8 data bits, even parity, one stop bit

Current consumption on

the K-Bus

The Bus Terminals require energy for the operation of the K-Bus

electronics, and this is supplied by the Bus Coupler. Find the current

consumption of the K-Bus from the catalogue, or from the appropriate data

sheets for the Bus Terminals. Consider the maximum output current of the

Bus Coupler that is available for supply of the Bus Terminals. A special

power supply terminal (KL9400) can be inserted at any location to insert

more power into the K-Bus. Refer to Beckhoff’s technical support

department regarding the use of a power supply terminal.

BC7300 14

Page 15

Basic Principles

Digital signals

(bit-oriented)

Analog signals

(byte-oriented)

Special signals and

interface

Default assignment of

inputs/outputs to the

process image

Peripheral Data in the Process Image

After being switched on, the Bus Coupler determines the configuration of

the inserted input/output terminals. The assignment of the physical slots for

the input/output channels and the addresses in the process image is

carried out automatically by the Bus Coupler.

The Bus Coupler creates an internal assignment list, in which the

input/output channels have a specific position in the process image. A

distinction is made here according to inputs and outputs, and according to

bit-oriented (digital) and byte-oriented (analog or complex) signal

processing.

Two groups are created, one for inputs and the other for outputs. Each

group has the byte-oriented channels in ascending sequence starting from

the lowest address. The bit-oriented channels are placed after this block.

The digital signals are bit-oriented. This means that one bit in the process

image is assigned to each channel. The Bus Coupler creates a memory

area containing the current input bits, and ensures that the bits in a second

memory area dedicated to the output channels are written out immediately.

The details of the assignment of the input and output channels to the

controller's process image is explained fully with the aid of an example in

the appendix.

The processing of all analog signals is always byte-oriented. Analog input

and output values are represented in memory by two bytes each. Values

are represented in SIGNED INTEGER or two‘s complement format. The

number "0" stands for the input/output value "0 V", "0 mA" or "4 mA". The

maximum value of an output or input value is represented, according to the

standard settings, by "7FFF" (hex). Negative input or output values, e.g. 10 V, are represented from "8000" (hex). The intermediate values are

correspondingly proportional. A range with a resolution of 15 bits is not

achieved for all inputs and outputs. If the actual resolution is 12 bits, the

last three bits have no effect in outputs, while as inputs they are read as

"0". Each channel also has a control and status byte. The control and

status byte is the lowest value byte. The master configuration software

must specify whether the control/status byte is also mapped into the

controller. An analog channel is represented in the process image by 2

bytes of user data.

A Bus Coupler supports Bus Terminals with other interfaces such as

RS232, RS485, incremental encoder and others. These signals can be

considered similarly to the analog signals named above. For some special

signals the bit width of 16 is not sufficient. The Bus Coupler can support

any byte width.

Once it has been switched on, the Bus Coupler finds out how many Bus

Terminals are inserted, and creates an assignment list. The analog and

digital channels, divided into inputs and outputs, are assembled into

separate parts of this list. The assignment starts on the left next to the Bus

Coupler. The software in the Bus Coupler collects the individual entries for

each of the channels in order to create the assignment list counting from

left to right.

BC7300 15

Page 16

Basic Principles

Four groups are distinguished in the assignment:

Functional type of the channel Assignment level

1.

2.

3.

4

Analog outputs assignment by bytes

Digital outputs assignment by bits

Analog inputs assignment by bytes

Digital inputs assignment by bits

Analog inputs and outputs here also represent other Bus Terminals with

complex multi-byte signals (RS232, SSI sensor interface, ...)

Data consistency

Items of data are said to be consistent if their content all belongs together,

and if they are transmitted as a single block. Examples of data items that

belong together are: 1. the high and low bytes of an analog value (word

consistency), and 2. a control/status byte and the associated parameter

word for access to the registers. Data consistency in the interaction of

peripheral devices and their controllers is, in a basic sense, only assured

for a single byte. In other words, the bits of a byte are output or read in

together. Byte consistency is sufficient for handling digital signals.

Whenever values have a length of more than 8 bits, analog values for

instance, the consistency must be extended. The different bus systems

guarantee consistency up to the required length. Correct transfer of the

consistent data from the bus system master to the controller is important.

The corresponding manual for the bus system will provide a detailed

description of the correct procedure, in particular the description of the

used master interfaces. Those chapters of this manual that deal with the

fieldbus refer to the most widespread interfaces.

Complex signal processing

All the byte-oriented signal channels such as RS232, RS485 or

incremental encoders operate to some extent with byte lengths of more

than two. Apart from the difference in length, they are always handled

similarly to the analog signals.

Start-up procedure and Diagnostics

After switching on, the Bus Coupler immediately checks the connected

configuration. Error-free start-up is signalled by extinction of the red LED

“I/O ERR“. If the “I/O ERR” LED blinks, an error in the area of the terminals

is indicated. The error code can be determined from the frequency and

number of blinks. This permits rapid rectification of the error.

The diagnostic LEDs

The Bus Coupler has two groups of LEDs for the display of status. The

upper group with four LEDs indicates the status of the respective fieldbus.

The significance of the “fieldbus status“ LED is explained in the relevant

sections of this manual - it conforms to conventional fieldbus displays.

On the upper right hand side of the Bus Couplers are two more green

LEDs that indicate the supply voltage. The left hand LED indicates the 24 V

supply of the Bus Coupler. The right hand LED signals the supply to the

power contacts.

Local errors

Two LEDs, the “I/O LEDs”, in the area below the field bus status LEDs

referred to above, serve to indicate the operating status of the Bus

Terminals and the connections to these terminals. The green LED lights up

in order to indicate fault-free operation. The red LED blinks with two

different frequencies in order to indicate an error.

BC7300 16

Page 17

The error is encoded in the blinks as follows:

Blink code

Fast blinking

First slow sequence

Second slow sequence

Basic Principles

Start of the error code

Error code

Error code argument

Error code Error

argument

Persistent,

continuous

blinking

1 pulse

2 pulses

3 pulses

4 pulses

5 pulses

9 pulses

14 pulses

15 pulses

16 pulses

EMC problems - Check power supply for overvoltage or

0

1

2

0

n (n > 0)

0 K-Bus command error - No Bus Terminal connected; attach Bus

0

n

n K-Bus error with register

0

n (n>0)

n Bus Terminal n has the wrong format - Start the coupler again, and if the error

n Number of Bus Terminals is no longer

n Length of the K-Bus data is no longer

Start of the error code Error type Error location

Description Remedy

undervoltage peaks

- Implement EMC measures

- If a K-Bus error is present, it can be

localised by a restart of the coupler (by

switching it off and then on again)

EEPROM checksum error

Inline code buffer overflow

Unknown data type

Programmed configuration

Incorrect table entry / Bus Coupler

Incorrect table comparison (Bus

Terminal n)

K-Bus data error

Break behind Bus Terminal n (0:

coupler)

communication with Bus Terminal n

Checksum error in program flash

memory

Bus Terminal n is not consistent with

the configuration that existed at boot

image entry

correct

correct

- Set manufacturer’s setting with the KS2000

- Connect fewer Bus Terminals; too many

entries in the table for the programmed

configuration

- Software update required for the coupler

- Check programmed configuration for

correctness

- Incorrect table entry / Bus Coupler

Terminals.

- One of the Bus Terminals is defective; halve

the number of Bus Terminals attached and

check whether the error is still present with

the remaining Bus Terminals. Repeat until the

defective Bus Terminal is located.

- Check whether the n+1 Bus Terminal is

correctly connected; replace if necessary.

– Check whether the Bus End Terminal 9010

is connected.

Exchange Bus Terminals

Transmit program to the BC7300 again

Check the nth Bus Terminal. If a new Bus

Terminal is to be inserted, delete the boot

project (manufacturer's setting)

occurs again then exchange the Bus Terminal

- Start the coupler again, and if the error

occurs again after this, use the KS2000

software to set manufacturer’s settings

- Start the coupler again, and if the error

occurs again after this, use the KS2000

software to set manufacturer’s settings

The number of pulses (n) indicates the position of the last Bus Terminal

before the fault. Passive Bus Terminals, such as a power feed terminal, are

not included in the count.

In the case of some errors, rectification does not cause the Bus Coupler to

leave the blink sequence. The Bus Coupler stays in the "Stop" state. The

Bus Coupler can only be re-started either by switching the power supply off

and on again, or by a software reset.

Insertion and removal of Bus Terminals is only permitted when switched

BC7300 17

Page 18

Basic Principles

WD

RX

TX

PLC

MODBUS

off. The electronics in the Bus Terminals and in the Bus Coupler are

protected to a large measure against damage, but incorrect function and

damage cannot be ruled out if they are plugged in under power.

The occurrence of a fault in the course of operation does not immediately

trigger the display of error codes by the LEDs. The Bus Coupler must be

requested to diagnose the Bus Terminals. The diagnostic request is

generated after switching on.

MODBUS LEDs

LED: on off

WD Watchdog is active Watchdog is not yet running

or the watchdog time has elapsed

RX Receive Data

Data is being received

TX Transmit Data

Data is being transmitted

PLC Program running

LED flashes while a boot project is being created

WD

If a K-Bus error occurs during operation, the procedures for reaction to a KBus error are executed in accordance with the parameterisation. If the KBus error occurs during booting, the slave is not included in the data

exchange.

Fieldbus errors

A fieldbus error only occurs when the watchdog (WD) period has elapsed.

The watchdog is preset to 1000 ms. The WD is activated as soon as a

"write" access has been made to the coupler's process data (WD LED

goes on). After this, another "write" command must be sent to the process

data within the set WD time, in order to start the WD from zero again.

Once a WD error has occurred, data communication can only be restarted

by resetting the coupler (see "Coupler Reset", under Diagnostics).

The maximum watchdog time is 65000 ms, and it can be set by rotary

switch or via the KS2000 software.

BC7300 18

Page 19

020201

01

+++

+

PEPEPE

PE

RUN

24V

0

9

8

7

6

3

2

1

0

9

8

7

6

3

2

1

B

K

7

3

0

0

02

01

+

+

PE

PE

02

01

+

+

PE

PE

02

01

+

+

PE

PE

020201

01

PE

4

3

2

1

3

2

02

01

02

01

PE

PE

02

01

PE

PE

020201

01

+++

+

PEPEPE

PE

RUN

MODBUS

24V

0

9

4

3

2

1

0

9

4

3

2

1

020102

01

+

+

PE

PE

02

01

+

+

PE

PE

02

01

+

+

PE

PE

MODBUS

Basic Principles

The MODBUS is a master-slave bus system in which only one device (the

master) actively starts a transaction (queries). The passive device (the

slave) then sends an answer (response) if the telegram was directly

addressed to it and provided that it has no errors.

Bus Topology

The BK7300 uses the RS485 physical data transmission. This means that

a two-wire cable is needed for the data transmission. The communication

structure corresponds to the linear topology. At the beginning and end of

the lines the bus requires termination resistors. The structure of the

Modbus network is similar to that of PROFIBUS.

0201

MODBUS

RX

0V

TX

4

5

BECKHOFF

4

5

MODBUS

0

1

9

8

7

4

6

5

0

9

8

7

6

5

0201

RUN

RX

24V

0V

TX

+ +

+++

BECKHOFF

BK 7300

PE PE

PEPEPE

+

+ +

+ +

RX

0V

TX

8

7

6

5

BECKHOFF

BK 7300

8

7

6

5

Broadcast function

Beckhoff Bus Terminal Controllers support the broadcast function. For this

purpose the slave address in the telegram must be set to "00". Slaves do

not answer a broadcast. Not all functions are supported.

Functions that support a broadcast:

• 5 Force single coil

• 6 Preset single register

• 15 Force multiple coils

• 16 Preset multiple register

PIN assignment

The BC7300 uses RS485 for the data transmission. A screened two-wire

cable is sufficient. The connection to the coupler is a 9-pin sub-D socket.

The data line is connected to PIN 3 and PIN 8.

BC7300 19

Page 20

MODBUS

1

5: GND

3: RxD/TxD

RxD/TxD (3)

TxD/RxD (8)

5 V (6)

Cable

Sub-D socket

Bus termination

BC7300

TxD/RxD (3)

RxD/TxD (8)

Abschirmung

BC7300

RxD/TxD (3)

TxD/RxD (8)

8: RxD/TxD

6: 5 V

The MODBUS requires termination resistors at the beginning and end of

the bus lines.

GND (5)

Process Data and Memory Map

The following example illustrates how the process image is constructed in

the Bus Terminal Controller, and the functions of the MODBUS telegram

with which digital and analog values can be read.

The Bus Terminal Controller has two process images. One is the fieldbus

interface and the other is the process image on the Bus Terminal

Controller. Bus Terminals can be assigned to one or the other process

image. The PLC variables offer an interface between these two process

images.

MODBUS

The input process image of the BC7300 starts from address 0x0000. All

the byte-oriented Bus Terminals (see Appendix) are entered here into the

process image first. The bit-oriented Bus Terminals them follow, and each

word (16 bit) is filled before starting a new one. The PLC variables are

entered into the process image last.

The output process image starts at address 0x0800. The entry begins

again here with the byte-oriented Bus Terminals, continues with the bitoriented Bus Terminals and finally the PLC variables.

All the digital signals can be directly addressed with functions 1, 2, 5 and

15.

20 BC7300

Page 21

PE

6

6

+

PE

PE

PEPEPEPEPE

PE

Bus Terminal Controller

The process image in the Bus Terminal Controller ignores all the Bus

Terminals that have been assigned to the MODBUS process image. The

controller first enters all the byte-oriented Bus Terminals, following the

sequence with which they are plugged in. The digital Bus Terminals come

next. The PLC variables are positioned from addresses %I128 and

%Q128.

Example

MODBUS

RUN

RX

TX

PLC

0

1

9

2

8

3

7

4

5

0

1

9

2

8

3

7

4

5

02

24V

0V

+ +

PE P E

+ +

PE P E

+ +

BECKHOFF

BC 7300

PEPEPE

+ +

PE P E

+

PE P E

POS 1 KL1012 MODBUS terminal

POS 2 KL1012 BC7300 terminal

POS 3 KL2012 MODBUS terminal

POS 4 KL2012 BC7300 terminal

POS 5 KL3002 MODBUS terminal

POS 6 KL3002 BC7300 complex terminal

POS 7 KL3002 BC7300 compact terminal

POS 8 KL4032 MODBUS terminal

POS 9 KL4032 BC7300 complex terminal

POS 10 KL4002 BC7300 compact terminal

KL9010

PLC Variables

POS 11 16 bytes INPUT

POS 12 16 bytes OUTPUT

BC7300 21

Page 22

MODBUS

MODBUS example

MODBUS Process Image

Terminals

POS 1. Terminal 2 digital inputs

POS 3. Terminal 2 digital outputs

POS 5. Terminal 2 analog inputs

POS 8. Terminal 2 analog outputs

PLC variables 16 byte inputs

PLC variables 16 byte outputs

BC7300 Process Image

Example for the BC7300

Byte address Terminal Inputs Terminal Outputs

128..143

Functions Offset Length

4, 23 0x0802 16 bit

2 0x0000

3, 6, 16, 23 0x0002 16 bit

1, 5, 15 0x0000

4, 23 0x0800

3, 6, 16, 23 0x0000

4, 23 0x0803

3, 6, 16, 23 0x0003

0

KL3002 (POS 6)

1

2

3

4

5

6

7

8

KL3002 (POS 7)

9

10

11

12

KL4032 (POS 9)

13

14

15

16

17

18

19

20

KL1012 (POS 2)

21

PLC Variables PLC

Status Control

- Data 0 Data 0

Data 1 Data 1

Status Control

- Data 0 Data 0

Data 1

Data 0 Control

Data 1 Data 0 Data 0

Data 1 Data 1

Status Control

- Data 0 Data 0

Data 1

Status Data 0

- Data 1

Data 0 Data 0

Data 1

Bit 0/1 Bit 0/1

-

0x0001

0x0001

0x0801

0x0001

0x0804

0x0805

0x0806

0x0807

0x0808

0x0809

0x080A

0x0004

0x0005

0x0006

0x0007

0x0008

0x0009

0x000A

KL3002

(POS 6)

KL4032

(POS 9)

KL4032

(POS 10)

KL2112

(POS 4)

Variables

1 bit

1 bit

1 bit

1 bit

16 bit

16 bit

16 bit

16 bit

16 bit

16 bit

16 bit

16 bit

16 bit

16 bit

16 bit

16 bit

16 bit

16 bit

16 bit

16 bit

16 bit

16 bit

16 bit

16 bit

Data 1

Data 1

Data 1

-

22 BC7300

Page 23

Assignment of the Bus Terminals

In the default setting, all the Bus Terminals are assigned to the Bus

Terminal Controller. This can be changed with the KS2000 software. The

assignment of the terminals is specified in Table 1 of the BC7300.

Compact

Hex Bin Description

0 00 The Bus Terminal is assigned to the MODBUS, and byte-

1 01 No function

2 10 The Bus Terminal is assigned to the BC, and byte-oriented

3 11 The Bus Terminal is assigned to the BC, and byte-oriented

Compact evaluation of a byte-oriented Bus Terminal means that only the

user data is transmitted.

Example: a KL3xx2 has 2 input words, and a KL4xx2 has 2 output words.

Complex

Complex evaluation of a byte-oriented Bus Terminal means that the user

data and the control and status byte are transmitted.

Example: a KL3xx2 has 4 input words and 4 output words; the same

applies to a KL4xx2.

You will find further information in the documentation for the Bus

Terminals.

Table 1 Default Description

Offset 4

Offset 5

Offset 6

Offset 7

Offset 8

Offset 9

Offset 10

Offset 11

0xFFFF 1.-8. terminal

0xFFFF 9.-16. terminal

0xFFFF 17.-24. terminal

0xFFFF 25.-32. terminal

0xFFFF 33.-40. terminal

0xFFFF 41.-48. terminal

0xFFFF 49.-56. terminal

0xFFFF 57.-64. terminal

KS2000 example

As from Version 2.3.2, the KS2000 software permits the adaptation of the

Bus Terminals to be set via a dialogue. You can update your KS2000

software at www.Beckhoff.de.

oriented Bus Terminals are given compact mapping (user

data only)

Bus Terminals are given compact mapping (user data only)

Bus Terminals are given complex mapping (with control

and status)

BC7300 23

Page 24

MODBUS

Setting and Parameterisation of the

MODBUS

Example

Now you want to set a new rate of 1200 baud

Incorrect Entry

KS2000

The MODBUS is parameterised by means of the rotary switch on the

BC7300. Only the Bus Terminal Controller's end terminal may be inserted

for this.

Only plug the KL9010 into the BC7300. Use the rotary switch to select the

parameters. The x10 address switch is used to select the parameter, while

the x1 address switch is used for the associated setting. The settings can

be found in the table. Connect the Bus Coupler's 24 V supply, and the

Modbus coupler will now start up in parameterisation mode. The LEDs WD,

RX, TX and ERROR are now toggled, and the LEDs I/O RUN and I/O ERR

give the function value.

You want to check whether the correct baud rate has been set.

1. Switch off the Bus Coupler's 24 V supply

2. Remove all the terminals except the KL9010 end terminal

3. Set the x10 address selection switch to 0 and the x1 switch to 3

4. Switch on the Bus Coupler's 24 V supply again

The coupler indicates the set baud rate via the LEDs.

3 x flashes of the I/O RUN and I/O ERR LEDs means 9600 baud

WD,RX,TX,ERROR LEDs

1 2 3 1 2 3 1 2 3 1 2 3

I/O Run, I/O ERR

5. Switch off the Bus Coupler's 24 V supply

6. Set the x10 address selection switch to 3 and the x1 switch to 6

7. Switch on the Bus Coupler's 24 V supply again

The Bus Coupler indicates the new set baud rate via the LEDs.

6 x flashes of the I/O RUN and I/O ERR LEDs means 1200 baud

If a parameter is set that the MODBUS Bus Terminal Controller does not

recognise, this is indicated by a constant even flashing of the I/O RUN and

I/O ERR LEDs, while all the other LEDs remain off.

The parameter settings can also be carried out with the KS2000 software.

24 BC7300

Page 25

Parameterisation Table

Parameter x 10 x 1 Default Parameter value

0 1..9 - Indicates the parameter of the x 10 function

Modbus

Frame

Baud rate

End of Frame Time

Watchdog 100 ms

Watchdog 1000 ms

Factory setting

1

2

3

4 0..9 0 In ms for RTU mode (0 dependent on the baud

5 0..9 0 Watchdog x 100 ms

6 0..9 1 Watchdog x 1000 ms

9 9

1 RTU mode

2

1 8 data bits, no parity one stop bit

2 8 data bits even Parity one stop bit

3 8 data bits odd Parity one stop bit

4 7 data bits even Parity one stop bit

5 7 data bits odd Parity one stop bit

6 one stop bit

7 2 stop bits

8 8 data bits, no parity two stop bits

9 8 data bits even Parity two stop bits

10 8 data bits odd Parity two stop bits

11 7 data bits even Parity two stop bits

12

1 38400 baud

2 19200 baud

3 9600 baud

4 4800 baud

5 2400 baud

6 1200 baud

7 600 baud

8 300 baud

9

1

ASCII mode

1

7 data bits odd Parity two stop bits

3

150 baud

rate)

In seconds for ASCII mode (0 EOF time switched

off)

BC7300 25

Page 26

MODBUS

ASCII frame

RTU frame

The MODBUS Protocol

ASCII

In ASCII mode the telegram starts with a colon ( : ) character (0x3A), and

ends with a carriage return and a line feed (CRLF) (0x0D, 0x0A). The

characters transferred are represented in the ASCII code.

Start Address Function Data LRC END

1

charact

RTU

In RTU mode the protocol starts with a pause of 3.5 characters, and

finishes in the same way (illustrated in the diagram with T1-T2-T3-T4). The

characters permitted for transmission in all fields are hexadecimal 0... 9,

A..., F.

Start Address Function Data CRC

T1-T2-

T3-T4 1 charact

er

:

2

charact

ers

er

2

charact

ers

1

charact

er

n

charact

ers

n

charact

ers

2

charact

ers

Check

2

charact

ers

2

charact

ers

CRLF

END

T1-T2-

T3-T4

26 BC7300

Page 27

Functions

In the MODBUS protocol, the functions determine whether data are to be

read or written, and what kind of data is involved. In the ASCII protocol the

fourth and fifth bytes are function bytes, while in the RTU protocol it is the

second byte.

The Beckhoff MODBUS Bus Terminal Controller supports the following

functions:

Function Code Description

Read coil status

Read input status

Read holding registers

Read input registers

Force single coil

Preset single register

Diagnostics

Force multiple coils

Preset multiple registers

Read / Write Registers

1 Read digital outputs

2 Read digital inputs

3 Read analog outputs / GPR

4 Read analog inputs / GPR

5 Write one digital output

6 Write one analog output /

GPR

8 Read the MODBUS diagnostic register

15 Write a number of digital outputs

16 Write a number of analog

outputs / GPR

23 Write and read a number of process data outputs / GPRs

GPR – General Preset Register (see Modbus Interface)

The functions are briefly described in the next section and clarified with the

aid of an example.

READ COIL STATUS

Read Digital Outputs (Function 1)

Function 1 can be used to read the settings of the digital outputs.

In this example the first 10 digital outputs of slave number 11 are read. The

start address is zero. If an offset is to be entered, this is done in the "Start

address" field.

Query

Start address high

Byte Name Example RTU ASCII

Start frame

Slave address

Function code

Start address low

Count high

Count low

Error Check

LRC / CRC

End of frame

„:“ 0x3A

11 0x0B „0B“ 0x30, 0x42

1 0x01 „01“ 0x30, 0x31

0 0x00 „00“ 0x30, 0x30

0 0x00 „00“ 0x30, 0x30

0 0x00 „00“ 0x30, 0x30

10 0x0A „10“ 0x31, 0x30

0xBC

0xA7

t1-t2-t3 CRLF 0xD, 0xA

„E4“ 0x45, 0x34

Response

The Bus Terminal Controller answers with byte count 2, i.e. 2 bytes of data

are returned. The query was for 10 bits, and these are now distributed over

2 bytes. The third bit in the output process image of the BC7300 is set, and

the Bus Coupler returns a "4" in the first data byte.

BC7300 27

Page 28

MODBUS

READ INPUT STATUS

Read Digital Inputs (Function 2)

Function 2 can be used to read the digital input data.

In this example the first 10 digital inputs of slave number 11 are read. The

Byte Name Example RTU ASCII

Start frame

Slave address

Function code

Byte Count

Data bits 0..7

Data bits 8..15

Error Check

LRC / CRC

End of frame

start address is zero. If an offset is to be entered, this is done in the "Start

address" field.

Query

„:“ 0x3A

11 0x0B „0B“ 0x30, 0x42

1 0x01 „01“ 0x30, 0x31

2 0x02 „02“ 0x30, 0x32

4 0x04 „04“ 0x30, 0x34

0 0x00 „00“ 0x30, 0x30

0x23

0x3D

t1-t2-t3 CRLF 0xD, 0xA

„EE“ 0x45, 0x45

READ HOLDING

REGISTERS

Byte Name Example RTU ASCII

Start frame

Slave address

Function code

Start address high

Start address low

Count high

Count low

Error Check

LRC / CRC

End of frame

„:“ 0x3A

11 0x0B „0B“ 0x30, 0x42

2 0x02 „02“ 0x30, 0x32

0 0x00 „00“ 0x30, 0x30

0 0x00 „00“ 0x30, 0x30

0 0x00 „00“ 0x30, 0x30

10 0x0A „10“ 0x31, 0x30

0xF8

0xA7

t1-t2-t3 CRLF 0xD, 0xA

„E3“ 0x45, 0x33

Response

The Bus Terminal Controller answers with byte count 2, i.e. 2 bytes of data

are returned. The query was for 10 bits, and these are now distributed over

2 bytes. The first bit in the input process image of the BC7300 is set, and

the Bus Coupler returns a "1" in the first data byte.

Byte Name Example RTU ASCII

Start frame

Slave address

Function code

Byte Count

Data 0..7

Data 8..15

Error Check

LRC / CRC

End of frame

„:“ 0x3A

11 0x0B „0B“ 0x30, 0x42

2 0x02 „02“ 0x30, 0x32

2 0x02 „02“ 0x30, 0x32

1 0x01 „01“ 0x30, 0x31

0 0x00 „00“ 0x30, 0x30

0x20

0x29

t1-t2-t3 CRLF 0xD, 0xA

„F0“ 0x46, 0x30

Read Analog In/Outputs (Function 3) 1

Function 3 can be used to read the input and output words and the

registers.

In this example the first two analog outputs of slave number 11 are read.

The analog outputs begin at offset 0x800 (hex). The length indicates the

number of channels to be read.

1

From Firmware B4 reading with function 3 is allowed.

28 BC7300

Page 29

Query

READ INPUT REGISTER

Byte Name Example RTU ASCII

Start frame

Slave address

Function code

Start address high

Start address low

Count high

Count low

Error Check

LRC / CRC

End of frame

„:“ 0x3A

11 0x0B „0B“ 0x30, 0x42

3 0x03 „03“ 0x30, 0x33

8 0x08 „08“ 0x30, 0x38

0 0x00 „00“ 0x30, 0x30

0 0x00 „00“ 0x30, 0x30

2 0x02 „02“ 0x30, 0x32

0xC6

0xC1

t1-t2-t3 CRLF 0xD, 0xA

„E8“ 0x45, 0x38

Response

The Bus Terminal Controller answers with byte count 4, i.e. 4 bytes of data

are returned. The query was for 2 analog channels, and these are now

distributed over 2 words. In the analog output process image, the first

channel has the value 0x3FFF, while the second channel has the value

0x0.

Byte Name Example RTU ASCII

Start frame

Slave address

Function code

Count byte

Data 1 high byte

Data 1 low byte

Data 2 high byte

Data 2 low byte

Error Check

LRC / CRC

End of frame

„:“ 0x3A

11 0x0B „0B“ 0x30, 0x42

3 0x03 „03“ 0x30, 0x31

4 0x04 „04“ 0x30, 0x30

63 0x3F „3F“ 0x33, 0x46

255 0xFF „FF“ 0x46, 0x46

0 0x00 „00“ 0x30, 0x30

0 0x00 „00“ 0x30, 0x30

0xC6

0xC1

t1-t2-t3 CRLF 0xD, 0xA

„B0“ 0x42, 0x30

Read Analog Inputs (Function 4)

Function 4 is used to read the analog inputs.

In this example the first two analog inputs of slave number 11 are read.

The analog outputs begin at offset 0x0000 (hex). The length indicates the

number of words to be read. A KL3002 has 2 words of input data, which is

why the value to be entered in "Count low" is two.

Query

Start address high

Byte Name Example RTU ASCII

Start frame

Slave address

Function code

Start address low

Count high

Count low

Error Check

LRC / CRC

End of frame

„:“ 0x3A

11 0x0B „0B“ 0x30, 0x42

4 0x04 „04“ 0x30, 0x34

0 0x00 „00“ 0x30, 0x30

0 0x00 „00“ 0x30, 0x30

0 0x00 „00“ 0x30, 0x30

2 0x02 „02“ 0x30, 0x32

0x71

0x61

t1-t2-t3 CRLF 0xD, 0xA

„EF“ 0x45, 0x46

Response

The Bus Terminal Controller answers with byte count 4, i.e. 4 bytes of data

are returned. The query was for 2 analog channels, and these will now be

BC7300 29

Page 30

MODBUS

distributed over 2 words. In the analog input process image, the first

channel has the value 0x0038, while the second channel has the value

0x3F1B.

FORCE SINGLE COIL

Writing a Digital Output (Function 5)

Function 5 can be used to write a digital output. In this example the third

digital output of slave number 11 is written. The digital outputs begin at

Byte Name Example RTU ASCII

Start frame

Slave address

Function code

Count byte

Data 1 high byte

Data 1 low byte

Data 2 high byte

Data 2 low byte

Error Check

LRC / CRC

End of frame

offset 0x0000 (hex). The digital value is located in the high byte of the data.

To switch the output on, "Data high" must contain 0xFF (hex), while 0x00

(hex) is used to switch the output off again. "Data low" must contain 0x00

(hex).

Query

„:“ 0x3A

11 0x0B „0B“ 0x30, 0x42

4 0x04 „04“ 0x30, 0x34

4 0x04 „04“ 0x30, 0x30

0 0x00 „00“ 0x30, 0x30

56 0x38 „38“ 0x33, 0x38

63 0x3F „3F“ 0x33, 0x46

11 0x0B „0B“ 0x30, 0x42

0x80

0x7E

t1-t2-t3 CRLF 0xD, 0xA

„6A“ 0x36, 0x41

PRESET SINGLE

REGISTER

Byte Name Example RTU ASCII

Start frame

Slave address

Function code

Start address high

Start address low

Data high

Data low

Error Check

LRC / CRC

End of frame

„:“ 0x3A

11 0x0B „0B“ 0x30, 0x42

5 0x05 „05“ 0x30, 0x35

0 0x00 „00“ 0x30, 0x30

2 0x02 „02“ 0x30, 0x32

255 0xFF „FF“ 0x46, 0x46

0 0x00 „00“ 0x30, 0x32

0x2D

0x50

t1-t2-t3 CRLF 0xD, 0xA

„EF“ 0x45, 0x46

Response

The Bus Terminal Controller answers with the same telegram.

Byte Name Example RTU ASCII

Start frame

Slave address

Function code

Start address high

Start address low

Data high

Data low

Error Check

LRC / CRC

End of frame

„:“ 0x3A

11 0x0B „0B“ 0x30, 0x42

5 0x05 „05“ 0x30, 0x35

0 0x00 „00“ 0x30, 0x30

2 0x02 „02“ 0x30, 0x32

255 0xFF „FF“ 0x46, 0x46

0 0x00 „00“ 0x30, 0x32

0x2D

0x50

t1-t2-t3 CRLF 0xD, 0xA

„EF“ 0x45, 0x46

Writing an Analog Output (Function 6)

Function 6 can be used to access the output process image and the

interface.

The first analog output of slave number 11 is written with function 6. The

analog outputs begin at offset 0x0800 (hex). Here again the offset always

describes a word. This means offset 0x0803 refers to the fourth word in the

output process image.

30 BC7300

Page 31

FORCE MULTIPLE COILS

Query

Byte Name Example RTU ASCII

Start frame

Slave address

Function code

Start address high

Start address low

Data high

Data low

Error Check

LRC / CRC

End of frame

„:“ 0x3A

11 0x0B „0B“ 0x30, 0x42

6 0x06 „06“ 0x30, 0x36

8 0x08 „08“ 0x30, 0x38

0 0x00 „00“ 0x30, 0x30

63 0x3F „3F“ 0x33, 0x46

255 0xFF „FF“ 0x46, 0x46

0xDA

0xB0

t1-t2-t3 CRLF 0xD, 0xA

„A9“ 0x41, 0x39

Response

The Bus Terminal Controller answers with the same telegram.

Byte Name Example RTU ASCII

Start frame

Slave address

Function code

Start address high

Start address low

Data high

Data low

Error Check

LRC / CRC

End of frame

„:“ 0x3A

11 0x0B „0B“ 0x30, 0x42

6 0x06 „06“ 0x30, 0x36

8 0x08 „08“ 0x30, 0x38

0 0x00 „00“ 0x30, 0x30

63 0x3F „3F“ 0x33, 0x46

255 0xFF „FF“ 0x46, 0x46

0xDA

0xB0

t1-t2-t3 CRLF 0xD, 0xA

„A9“ 0x41, 0x39

Writing a Number of Digital Outputs (Function 15)

Function 15 can be used to set or reset a number of digital outputs at the

same time.

In this example the first 20 digital outputs of slave number 11 are written.

The digital outputs begin at offset 0x0000 (hex). Here the offset always

describes a bit. Offset 0x0003 writes to the fourth bit in the output process

image. The length indicates the number of bits, and the "Byte count" is

composed from the combination all the bytes that are to be written.

Example: 20 bits – corresponds to 24 bits – count is 3 bytes (round up to

the nearest byte)

The data bytes contain the values for the individual bits.

In this example, the first 16 bits are set to "TRUE", while bits 17 to 20 are

"FALSE".

BC7300 31

Page 32

MODBUS

Query

PRESET MULTIPLE

REGISTERS

Byte Name Example RTU ASCII

Start frame

Slave address

Function code

Start address high

Start address low

Length high

Length low

Byte Count

Data 1 bit 0..7

Data 2 bit 8..15

Data 3 bit 16..19

Error Check

LRC / CRC

End of frame

„:“ 0x3A

11 0x0B „0B“ 0x30, 0x42

15 0x0F „0F“ 0x30, 0x46

0 0x00 „00“ 0x30, 0x30

0 0x00 „00“ 0x30, 0x30

0 0x00 „00“ 0x30, 0x30

20 0x14 „14“ 0x31, 0x34

3 0x03 „03“ 0x30, 0x33

255 0xFF „FF“ 0x46, 0x46

255 0xFF „FF“ 0x46, 0x46

0 0x00 „00“ 0x30, 0x30

0x01

0x95

t1-t2-t3 CRLF 0xD, 0xA

„D1“ 0x44, 0x31

Response

The Bus Terminal Controller answers with the same telegram.

Byte Name Example RTU ASCII

Start frame

Slave address

Function code

Start address high

Start address low

Data high

Data low

Error Check

LRC / CRC

End of frame

„:“ 0x3A

11 0x0B „0B“ 0x30, 0x42

15 0x0F „0F“ 0x30, 0x46

0 0x00 „00“ 0x30, 0x30

0 0x00 „00“ 0x30, 0x30

0 0x00 „00“ 0x30, 0x30

20 0x14 „14“ 0x30, 0x34

0xDA

0xB0

t1-t2-t3 CRLF 0xD, 0xA

„D2“ 0x44, 0x32

Writing a Number of Analog Outputs (Function 16)

Function 16 can be used to write a number of analog outputs. In this

example the first 2 analog output words of slave number 11 are written.

The analog outputs begin at offset 0x0800 (hex). Here the offset always

describes a word. Offset 0x0003 writes to the fourth word in the output

process image. The length indicates the number of words, and the "Byte

count" is composed from the combination all the bytes that are to be

written.

Example: 4 words – correspond to a byte count of 8

The data bytes contain the values for the analog outputs. In this example,

two words are to be written. The first word is to receive the value 0x7FFF

(hex), and the second word is to receive the value 0x3FFF.

32 BC7300

Page 33

Query

READ / WRITE

REGISTERS

Byte Name Example RTU ASCII

Start frame

Slave address

Function code

Start address high

Start address low

Length high

Length low

Byte Count

Data 1 byte 1

Data 1 byte 2

Data 2 byte 1

Data 2 byte 2

Error Check

LRC / CRC

End of frame

„:“ 0x3A

11 0x0B „0B“ 0x30, 0x42

16 0x10 „10“ 0x31, 0x30

8 0x08 „08“ 0x30, 0x38

0 0x00 „00“ 0x30, 0x30

0 0x00 „00“ 0x30, 0x30

2 0x02 „02“ 0x30, 0x32

4 0x04 „04“ 0x30, 0x34

127 0x7F „7F“ 0x37, 0x46

255 0xFF „FF“ 0x46, 0x46

63 0x3F „3F“ 0x33, 0x46

255 0xFF „FF“ 0x46, 0x46

0xCD

0xE3

t1-t2-t3 CRLF 0xD, 0xA

„1B“ 0x31, 0x42

Response

The Bus Terminal Controller replies with the start address and the length of

the transmitted words.

Byte Name Example RTU ASCII

Start frame

Slave address

Function code

Start address high

Start address low

Length high

Length low

Error Check

LRC / CRC

End of frame

„:“ 0x3A

11 0x0B „0B“ 0x30, 0x42

16 0x10 „10“ 0x31, 0x30

8 0x08 „08“ 0x30, 0x38

0 0x00 „00“ 0x30, 0x30

0 0x00 „00“ 0x30, 0x30

2 0x02 „02“ 0x30, 0x32

0x43

0x02

t1-t2-t3 CRLF 0xD, 0xA

„DB“ 0x44, 0x42

Writing and Reading Analog Outputs and Inputs

(Function 23)

A number of analog outputs can be written and a number of analog inputs

read with one telegram using function 23. In this example the first 2 analog

output words of slave number 11 are written, and the first two analog inputs

are read. The analog outputs start at offset 0x0800 (hex), while the inputs

start at offset 0x0000 (hex). Here the offset always describes a word.

Offset 0x0003 writes to the fourth word in the output process image. The

length indicates the number of words, and the "Byte count" is composed

from the combination all the bytes that are to be written.

Example: 4 words – correspond to a byte count of 8

The data bytes contain the values for the analog outputs. In this example,

two words are to be written. The first word is to receive the value 0x3FFF

(hex), and the second word is to receive the value 0x7FFF.

BC7300 33

Page 34

MODBUS

Query

Read start address

Read start address

Write start address

Write start address

Byte Name Example RTU ASCII

Start frame

Slave address

Function code

Read length high

Read length low

Write length high

Write length low

Byte Count

Data 1 high

Data1 low

Data 2 high

Data 2 low

Error Check

LRC / CRC

End of frame

„:“ 0x3A

11 0x0B „0B“ 0x30, 0x42

23 0x17 „17“ 0x31, 0x37

0 0x00 „00“ 0x30, 0x30

high

0 0x00 „00“ 0x30, 0x30

low

0 0x00 „00“ 0x30, 0x30

2 0x02 „02“ 0x30, 0x32

8 0x08 „08“ 0x30, 0x38

high

0 0x00 „00“ 0x30, 0x30

low

0 0x00 „00“ 0x30, 0x30

2 0x02 „02“ 0x30, 0x32

4 0x04 „04“ 0x30, 0x34

63 0x3F „3F“ 0x33, 0x46

255 0xFF „FF“ 0x46, 0x46

127 0x7F „7F“ 0x37, 0x46

255 0xFF „FF“ 0x46, 0x46

0x76

0xD3

T1-t2-t3 CRLF 0xD, 0xA

„12“ 0x31, 0x32

Response

The Bus Terminal Controller replies with the start address and the length of

the bytes to be transferred in "Byte count". The data information follows. In

this example the first word contains 0x0038 (hex) while the second word

contains 0x3F0B.

Byte Name Example RTU ASCII

Start frame

Slave address

Function code

Byte Count

Data 1 high

Data 1 low

Data 2 high

Data 2 low

Error Check

LRC / CRC

End of frame

„:“ 0x3A

11 0x0B „0B“ 0x30, 0x42

23 0x17 „17“ 0x31, 0x37

4 0x04 „04“ 0x30, 0x34

0 0x00 „00“ 0x30, 0x30

56 0x38 „38“ 0x33, 0x38

63 0x3F „3F“ 0x33, 0x46

11 0x0B „0B“ 0x30, 0x42

0x82

0xDD

t1-t2-t3 CRLF 0xD, 0xA

„58“ 0x35, 0x38

Diagnostics

In the MODBUS, function 08 provides a series of tests for examination of

the communication system between the master and the slave and for

inspection of a variety of internal error states within the slave. A broadcast

telegram is not supported.

The function uses a two-byte sub-function code field in the query to define

the test that is to be carried out. The slave outputs the function code and

the sub-function code as an answer.

The diagnostic queries use a two-byte data field to send diagnostics data

or control information to the slave.

34 BC7300

Page 35

EXAMPLE

Query

Byte Name Example RTU ASCII

Start frame

Slave address

Function code

Subfunction high

Subfunction low

Data high

Data low

Error Check

LRC / CRC

End of frame

„:“ 0x3A

11 0x0B „0B“ 0x30, 0x42

8 0x08 „08“ 0x30, 0x38

0 0x00 „00“ 0x30, 0x30

0 0x00 „00“ 0x30, 0x30

2 0x02 „02“ 0x30, 0x32

3 0x03 „03“ 0x30, 0x33

0xA1

0xC0

t1-t2-t3 CRLF 0xD, 0xA

„E8“ 0x45, 0x38

Response

Byte Name Example RTU ASCII

Start frame

Slave address

Function code

Subfunction high

Subfunction low

Data high

Data low

Error Check

LRC / CRC

End of frame

„:“ 0x3A

11 0x0B „0B“ 0x30, 0x42

8 0x08 „08“ 0x30, 0x38

0 0x00 „00“ 0x30, 0x30

0 0x00 „00“ 0x30, 0x30

2 0x02 „02“ 0x30, 0x32

3 0x03 „03“ 0x30, 0x33

0xA1

0xC0

t1-t2-t3 CRLF 0xD, 0xA

„E8“ 0x45, 0x38

Echoes a query (Sub-Function 0)

Sub-function 0 causes the data that is sent to the slave by the master to be

returned.

Bus Coupler Reset (Sub-Function 1)

Sub-function 1 re-initialises the BC7300. Error counters are reset, and the

coupler executes a self-test. No telegrams are either received or sent while

the coupler is being reset.

Sub-function Data field (query) Data field (response)

00 01 00 00 00 00

Delete All Counter Contents (Sub-Function 10)

Calling this sub-function deletes the contents of all error counters in the

coupler.

Sub-function Data field (query) Data field (response)

00 0B 00 00 Echo Query Data

Bus Communication Error Counter (Sub-Function 11)

Returns the number of faulty communications.

Sub-function Data field (query) Data field (response)

00 0C 00 00 CRC error counter

Error Answer Counter (Sub-Function 13)

This counter contains the number of error answer telegrams that the

coupler has sent.

Sub-function Data field (query) Data field (response)

00 0D 00 00 Error Answer Counter

BC7300 35

Page 36

MODBUS

Slave Answers (Sub-Function 14)

Contains the number of answers that the slave has sent.

Sub-function Data field (query) Data field (response)

00 0E 00 00 Slave Message Count

Unsent Slave Answers (Sub-Function 15)

Contains the number of answers that the slave has not sent. For example,

the slave does not send an answer to a broadcast message.

Sub-function Data field (query) Data field (response)

00 0F 00 00 Slave No Response

Number of Error Answers (Sub-Function 16)

Contains the number of error answers that the slave has sent.

Sub-function Data field (query) Data field (response)

00 10 00 00 Number of error

Count

answers

36 BC7300

Page 37

EXCEPTION RESPONSE

Example

BC7300 Error Answers

When the user sends the slave either a request or information that the Bus

Coupler does not understand, the BC7300 responds with an error report.

This answer contains the function and the error code. 0x80 is added to the

value returned by the function.

Code Name Meaning

1 ILLEGAL FUNCTION Function not implemented

2 ILLEGAL DATA

ADDRESS

3 ILLEGAL DATA VALUE Invalid parameter

4 SLAVE DEVICE ERROR Watchdog or K-Bus error

The following example contains an invalid "Start address".

Query

BYTE Contents Example

1 Slave address 0B

2 Function 01

3 Start address high 0D

4 Start address low FF

5 Data high FF

6 Data low 01

7 LRC

The slave's answer contains the function plus 0x80, together with error