Page 1

BC3150 - Bus Terminal

Controller for PROFIBUS

Version: 1.1.0

Date: 2006-02-10

Page 2

Page 3

Contents

Contents

BC3150 - Bus Terminal Controller for PROFIBUS

1. Foreword 4

Notes on the Documentation 4

Safety Instructions 5

Documentation Issue Status 6

2. Product Overview 7

BCxx50 - Overview 7

The Principle of the Bus Terminal 8

The Beckhoff Bus Terminal System 9

Technical Data 11

Technical Data - BCxx50 11

Technical Data - PROFIBUS DP 13

Technical Data - PLC 14

3. Mounting and Wiring 15

Mounting 15

Dimensions 15

Installation 16

Wiring 17

Potential Groups, Insulation Testing and PE 17

Power supply 19

Programming cable 20

PROFIBUS Connection 21

PROFIBUS Cabling 23

Fieldbus Components 1

Page 4

Contents

4. Parameterization and Commissioning 25

Start-up Behavior of the Bus Terminal Controller 25

Setting the slave address 26

Configuration 27

Overview 27

Creating a BX File 29

Downloading a BX Configuration 30

Uploading a BX Configuration 32

Bus Terminal Controller resources 34

ADS via Serial 36

ADS Connection via Serial Interface 36

PROFIBUS 37

PROFIBUS Settings 37

Master Configuration 38

Basic Device File (GSD) 38

Creating a TwinCAT PC File 39

Variable Mapping - PROFIBUS DP 41

BC3150 at 3rd party controller 42

SIEMENS S7 42

Configuration - Siemens S7 Controller 42

Configuration: Siemens S7 Controller with BX3100 43

K-Bus 46

K-Bus 46

PLC 48

Inserting a PLC project 48

Measuring the PLC Cycle Time 49

KS2000 50

KS2000 50

5. Programming 51

BCxx50 PLC features 51

TwinCAT PLC 52

TwinCAT PLC Error Codes 53

Remanent data 55

Allocated Flags 56

Local process image in delivery state 57

Mapping of the Bus Terminals 59

Local process image in the TwinCAT configuration 60

Creating a boot project 61

Communication between TwinCAT and BX/BCxx50 62

Up- and downloading of programs 63

2 Fieldbus Components

Page 5

Contents

Libraries 67

Übersicht 67

TcBaseBX 69

System Task Info 69

System Task Info Type 70

System Info 71

System Info Type 72

ADS 73

Local ADS Port Numbers 73

ADS Services 74

BX Debug Function 75

Overview 75

Program Transmission 76

Transmission via Serial Interface 76

Transmission via PROFIBUS 78

Process Image 80

PROFIBUS Process Image 80

6. PROFIBUS 81

System Introduction 81

Fieldbus Overview 81

PROFIBUS DP 85

PROFIBUS DPV1 87

Cables, Plugs and Switches 88

Topology 91

7. Error handling and diagnosis 92

Diagnostics 92

Diagnostic LEDs 94

8. Appendix 97

First steps with the BC3150 97

Moving from BC to BX 99

Firmware Update 102

General Operating Conditions 105

Standards for Device Testing 107

Bibliography 108

List of Abbreviations 109

Support and Service 110

Fieldbus Components 3

Page 6

Notes on the Documentation

1. Foreword

Notes on the Documentation

This description is only intended for the use of trained specialists in control and automation engineering who are

familiar with the applicable national standards. It is essential that the following notes and explanations are followed

when installing and commissioning these components.

Liability Conditions

The responsible staff must ensure that the application or use of the products described satisfy all the requirements for

safety, including all the relevant laws, regulations, guidelines and standards.

The documentation has been prepared with care. The products described are, however, constantly under

development. For that reason the documentation is not in every case checked for consistency with performance data,

standards or other characteristics. None of the statements of this manual represents a guarantee (Garantie) in the

meaning of § 443 BGB of the German Civil Code or a statement about the contractually expected fitness for a

particular purpose in the meaning of § 434 par. 1 sentence 1 BGB. In the event that it contains technical or editorial

errors, we retain the right to make alterations at any time and without warning. No claims for the modification of

products that have already been supplied may be made on the basis of the data, diagrams and descriptions in this

documentation.

© This documentation is copyrighted. Any reproduction or third party use of this publication, whether in whole or in

part, without the written permission of Beckhoff Automation GmbH, is forbidden.

4 Fieldbus Components

Page 7

Safety Instructions

Safety Instructions

Safety Rules

The responsible staff must ensure that the application or use of the products described satisfy all the requirements for

safety, including all the relevant laws, regulations, guidelines and standards.

State at Delivery

All the components are supplied in particular hardware and software configurations appropriate for the application.

Modifications to hardware or software configurations other than those described in the documentation are not

permitted, and nullify the liability of Beckhoff Automation GmbH.

Personnel Qualification

This description is only intended for the use of trained specialists in control and automation engineering who are

familiar with the applicable national standards.

Description of safety symbols

The following safety symbols are used in this operating manual. They are intended to alert the reader to the

associated safety instructions.

This symbol is intended to highlight risks for the life or health of personnel.

Danger

This symbol is intended to highlight risks for equipment, materials or the environment.

Warning

This symbol indicates information that contributes to better understanding.

Note

Fieldbus Components 5

Page 8

Safety Instructions

Documentation Issue Status

Version Comment

1.1.0 Notes to meet the UL requirements added.

•

1.0.1

1.0.0 First release (only German version available)

Chapter Creating a boot project corrected

•

minor routine corrections (typing errors, orthography etc.)

•

English version available

Firmware BC3150

To make a firmware update, you need a serial cable and the KS2000 Configuration Software or the firmware update

program.

Firmware Comment

0xB0 Firmware Version 0xB0

The firmware and hardware version (delivery status) can be found on the label at the bottom of the Bus Terminal

Controller.

6 Fieldbus Components

Page 9

Safety Instructions

2. Product Overview

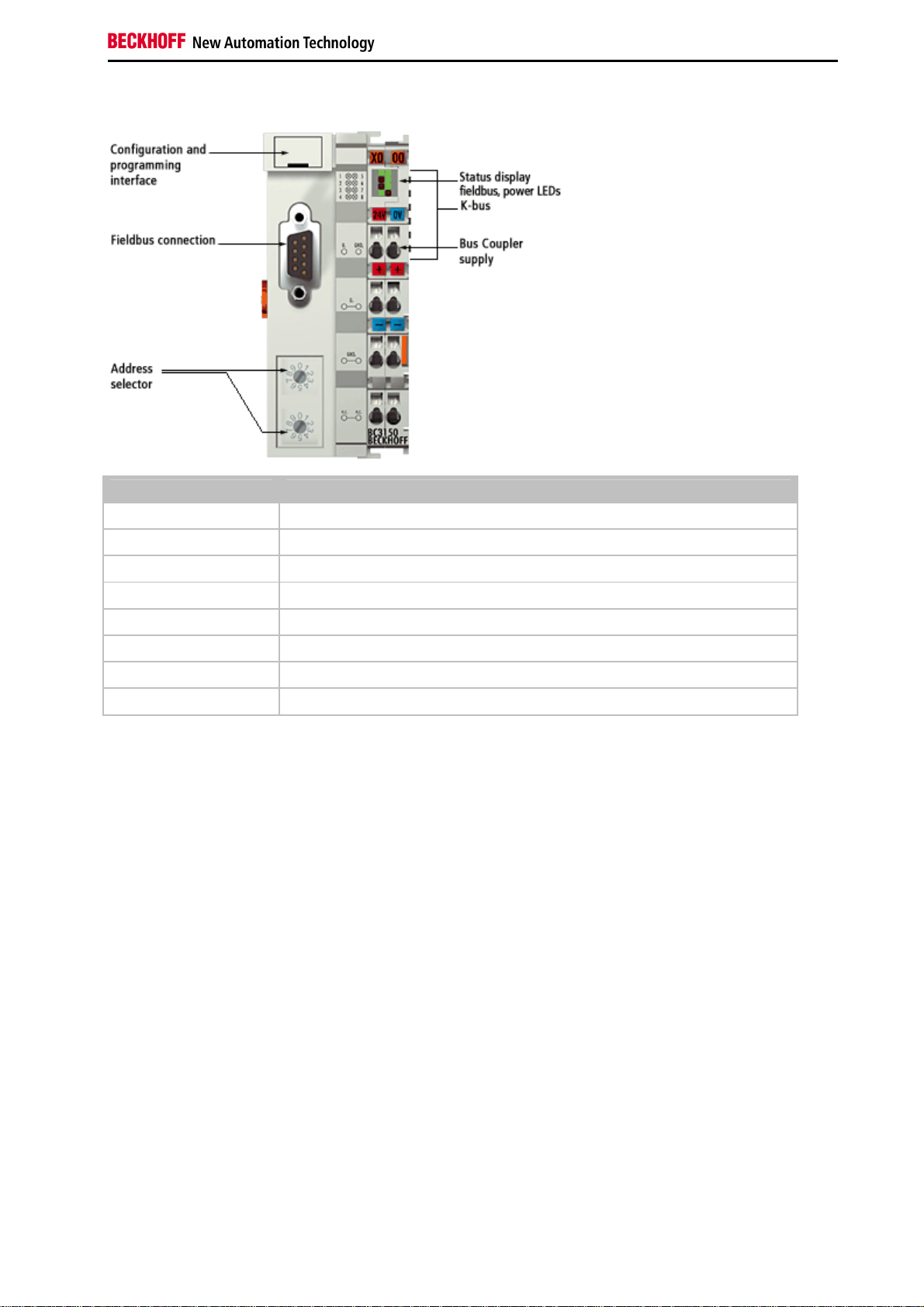

BCxx50 - Overview

Bus Terminal Controllers are Bus Couplers with integrated PLC functionality. The BCxx50 Bus Terminal Controllers

have a fieldbus interface, are intelligent slaves and can be used as remote intelligence within the system. They are

located in a cost-optimized and compact housing. In contrast to the BCxx00 range, the BCxx50 range supports up to

255 Bus Terminals via the K-Bus extension.

The Bus Terminal Controller is programmed using the TwinCAT programming system according to IEC 61131-3. The

BCxx50 configuration/programming interface is used for loading the PLC program. If the TwinCAT software PLC is in

use, the PLC program can also be loaded via the fieldbus.

The inputs and outputs of the connected Bus Terminals are assigned in the default setting of the mini-PLC. Each

individual Bus Terminal can be configured in such a way that it exchanges data directly through the fieldbus with the

higher-level automation device. Similarly, pre-processed data can be exchanged between the Bus Terminal

Controller and the higher-level controller via the fieldbus.

Fieldbus interface

The variants of the BCxx50 series Bus Terminal Controllers differ in terms of their fieldbus interfaces. Five different

versions cover the main fieldbus systems:

•

BC3150: PROFIBUS DP

•

BC5150: CANopen

•

BC5250: DeviceNet

•

BC8150: RS232 or RS485 (without fieldbus interface)

Programming

The BCxx50 devices are programmed according to the powerful IEC 61131-3 standard. Like for all other BECKHOFF

controllers, the TwinCAT automation software is the basis for parameterization and programming. Users therefore

have the familiar TwinCAT tools available, e.g. PLC programming interface, System Manager and TwinCAT Scope.

Data is exchanged optionally via the serial port (COM1) or via the fieldbus through BECKHOFF PC FCxxxx fieldbus

cards.

Configuration

The configuration is also carried out using TwinCAT. The fieldbus interface can be configured and parameterized via

the System Manager. The System Manager can read all connected devices and Bus Terminals. After the

parameterization, the configuration is saved on the BCxx50 via the serial interface. The configuration thus created

can be accessed again later.

Fieldbus Components 7

Page 10

Safety Instructions

The Principle of the Bus Terminal

8 Fieldbus Components

Page 11

Safety Instructions

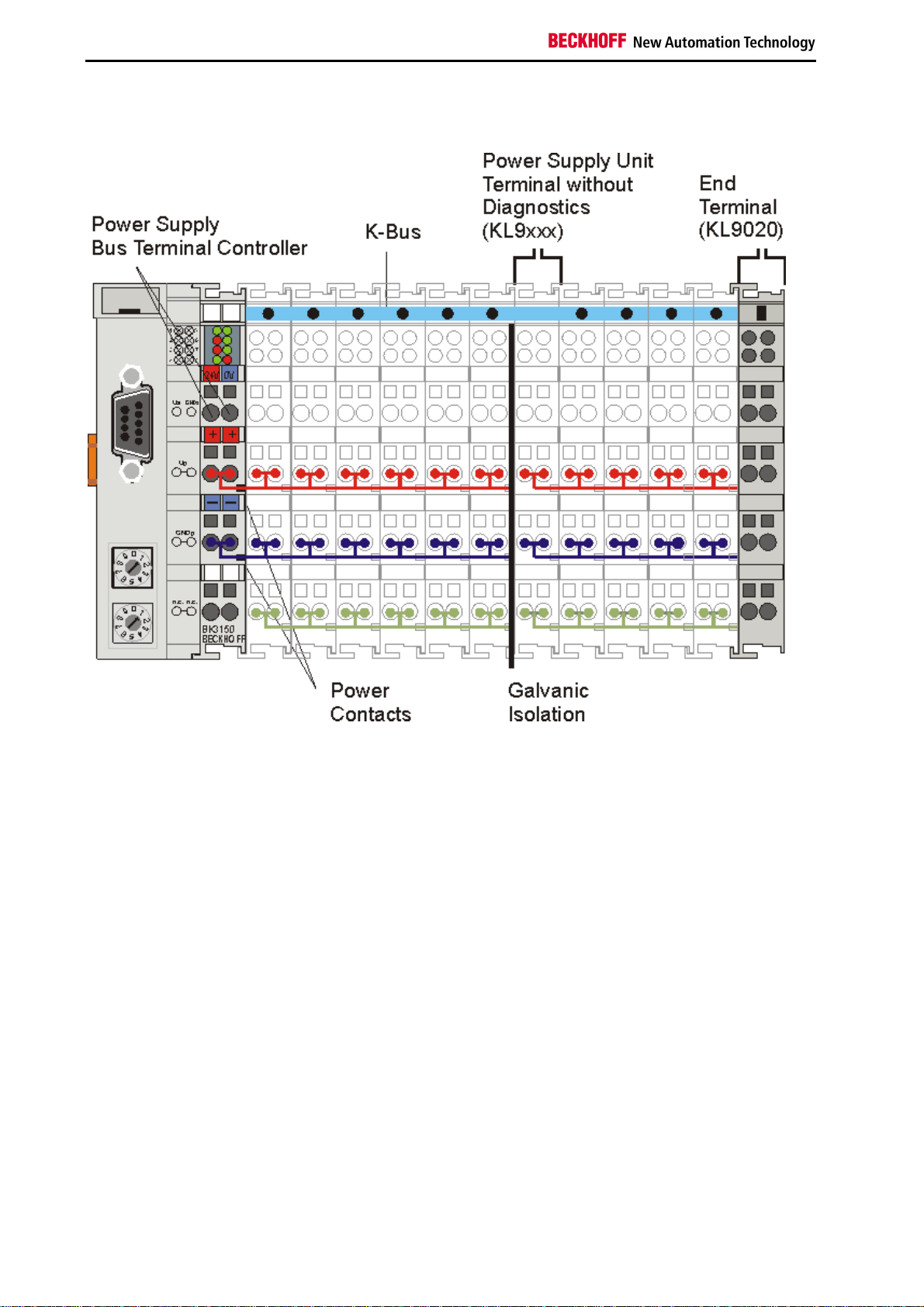

The Beckhoff Bus Terminal System

Up to 64 Bus Terminals each having 2 I/O channels for each signal form

The Bus Terminal system is the universal interface between a fieldbus system and the sensor / actuator level. A unit

consists of a Bus Coupler as the head station, and up to 64 electronic series terminals, the last one being an end

terminal. For each technical signal form, terminals are available each having two I/O channels, and these can be

mixed in any order. All the terminal types have the same mechanical construction, so that difficulties of planning and

design are minimized. The height and depth match the dimensions of compact terminal boxes.

Decentralized wiring of each I/O level

Fieldbus technology allows more compact forms of controller to be used. The I/O level does not have to be brought to

the controller. The sensors and actuators can be wired decentrally, using minimum cable lengths. The controller can

be installed at any location within the plant.

Industrial PCs as controllers

The use of an Industrial PC as the controller means that the operating and observing element can be implemented in

the controller’s hardware. The controller can therefore be located at an operating panel, in a control room, or at some

similar place. The Bus Terminals form the decentralized input/output level of the controller in the control cabinet and

the subsidiary terminal boxes. The power sector of the plant is also controlled over the bus system in addition to the

sensor/actuator level. The Bus Terminal replaces the conventional series terminal as the wiring level in the control

cabinet. The control cabinet can have smaller dimensions.

Bus Couplers for all usual bus systems

The Beckhoff Bus Terminal system unites the advantages of a bus system with the possibilities of the compact series

terminal. Bus Terminals can be driven within all the usual bus systems, thus reducing the controller parts count. The

Bus Terminals then behave like conventional connections for that bus system. All the performance features of the

particular bus system are supported.

Assembly on standardized C mounting rails

The easy, space-saving, assembly on a standardized C-rail, and the direct wiring of actuators and sensors, without

cross-connections between the terminals, standardizes the installation. The consistent labelling scheme also

contributes.

The small physical size and the great flexibility of the Bus Terminal system allows it to be used wherever a series

terminal is also used. Every type of connection, such as analog, digital, serial or the direct connection of sensors can

be implemented.

Modularity

The modular assembly of the terminal strip with Bus Terminals of various functions limits the number of unused

channels to a maximum of one per function. The presence of two channels in one terminal is the optimum

compromise of unused channels and the cost of each channel. The possibility of electrical isolation through potential

feed terminals also helps to keep the number of unused channels low.

Display of the channel state

The integrated LEDs show the state of the channel at a location close to the sensors and actuators.

K-Bus

The K-Bus is the data path within a terminal strip. The K-Bus is led through from the Bus Coupler through all the

terminals via six contacts on the terminals’ side walls. The end terminal terminates the K-Bus. The user does not

have to learn anything about the function of the K-Bus or about the internal workings of the terminals and the Bus

Coupler. Many software tools that can be supplied make project planning, configuration and operation easy.

Fieldbus Components 9

Page 12

Safety Instructions

Potential feed terminals for isolated groups

The operating voltage is passed on to following terminals via three power contacts. You can divide the terminal strip

into arbitrary isolated groups by means of potential feed terminals. The potential feed terminals play no part in the

control of the terminals, and can be inserted at any locations within the terminal strip.

Up to 64 terminals can be used within one terminal strip. This count does include potential feed terminals, but not the

end terminal.

Bus Couplers for various fieldbus systems

Various Bus Couplers can be used to couple the electronic terminal strip quickly and easily to different fieldbus

systems. It is also possible to convert to another fieldbus system at a later time. The bus coupler performs all the

monitoring and control tasks that are necessary for operation of the connected Bus Terminals. The operation and

configuration of the Bus Terminals is carried out exclusively by the Bus Coupler. Nevertheless, the parameters that

have been set are stored in each Bus Terminal, and are retained in the event of voltage drop-out. Fieldbus, K-Bus

and I/O level are electrically isolated.

If the exchange of data over the fieldbus is prone to errors or fails for a period of time, register contents (such as

counter states) are retained, digital outputs are cleared, and analog outputs take a value that can be configured for

each output when commissioning. The default setting for analog outputs is 0 V or 0 mA. Digital outputs return in the

inactive state. The timeout periods for the Bus Couplers correspond to the usual settings for the fieldbus system.

When converting to a different bus system it is necessary to bear in mind the need to change the timeout periods if

the bus cycle time is longer.

The interfaces

A Bus Coupler has six different methods of connection. These interfaces are designed as plug connectors and as

spring-loaded terminals.

10 Fieldbus Components

Page 13

Safety Instructions

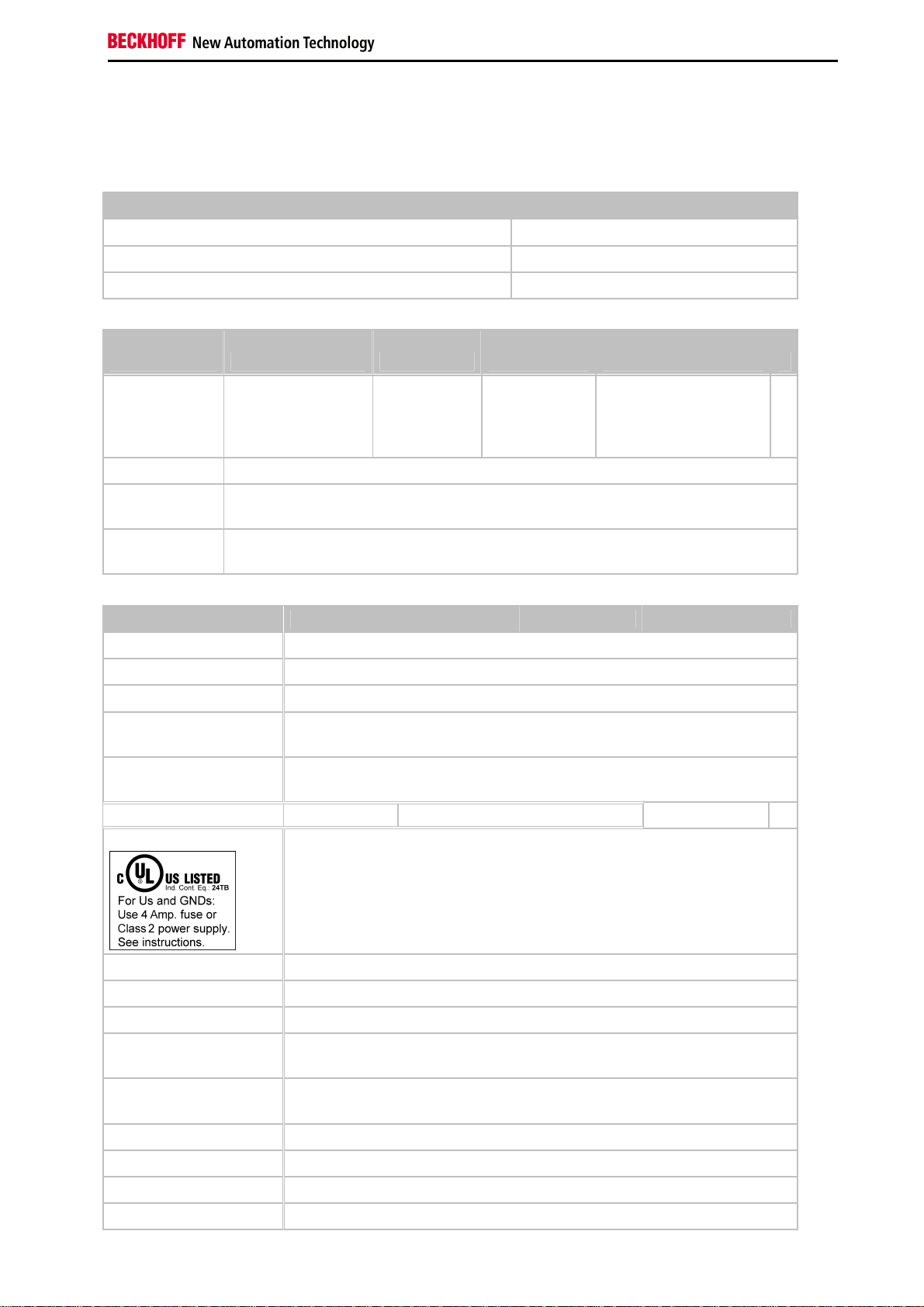

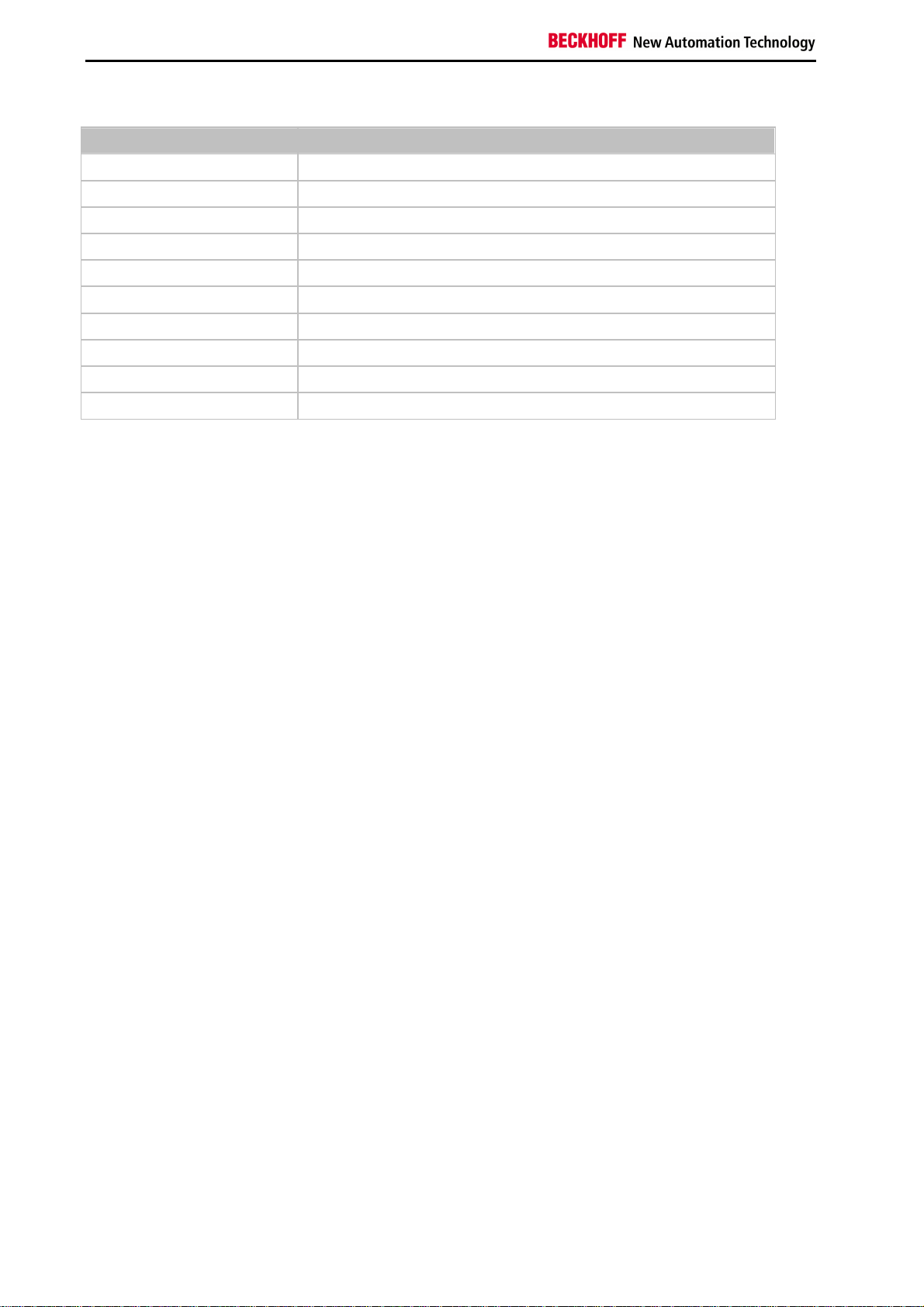

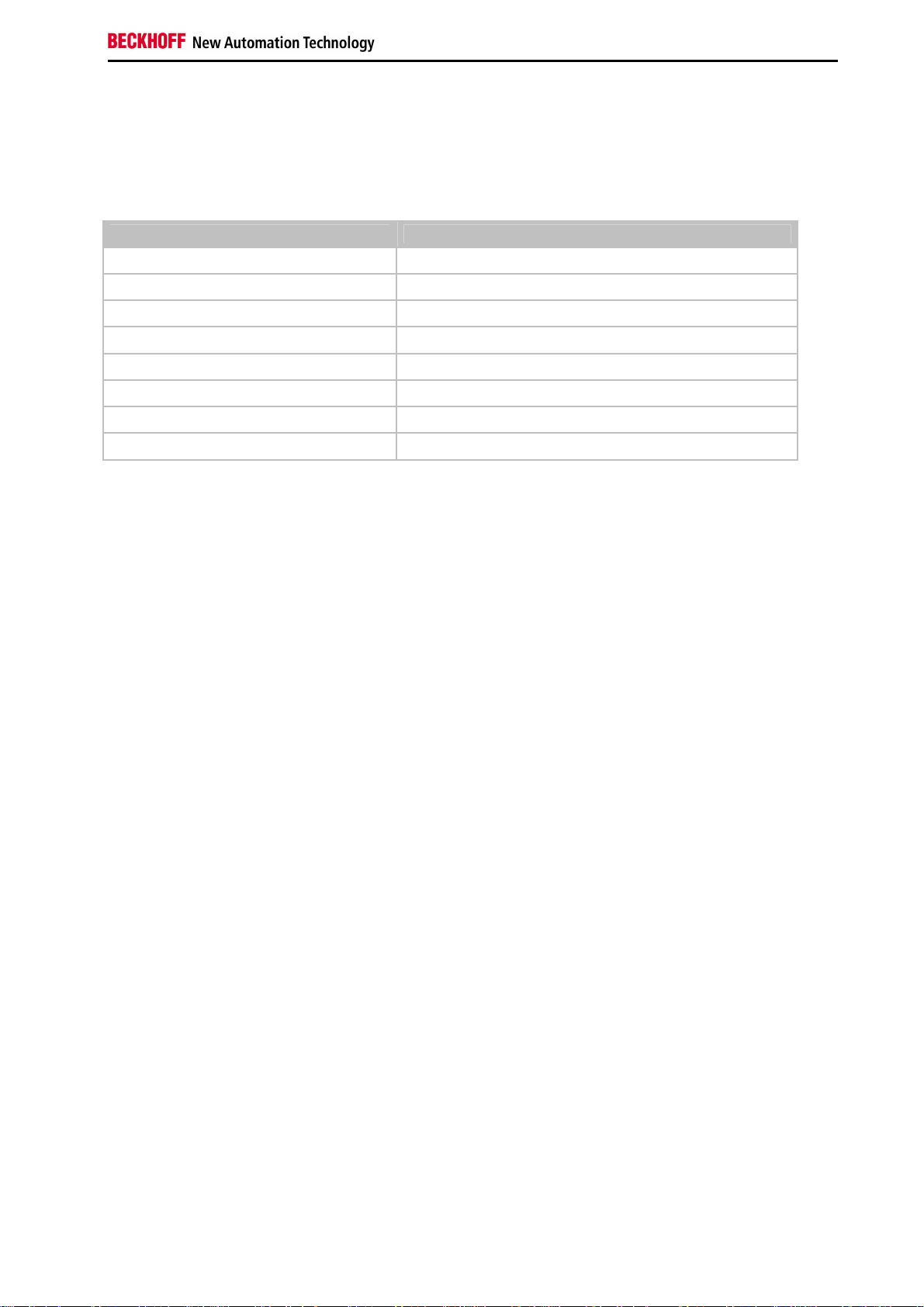

Technical Data

Technical Data - BCxx50

Technical data BCxx5x

Processor 16 bit micro-controller

Diagnostic LEDs 2 x power supply, 2 x K-Bus

Configuration and programming software TwinCAT PLC

Fieldbus

interface BC3150 BC5150 BC5250 BC8150 -

Fieldbus PROFIBUS DP CANopen DeviceNet - Serial ADS

- KS8000 Protocol

- ModbusRTU

- ModbusASCII

Interfaces

Serial interface COM1 (RS232 for configuration and programming, automatic baud rate detection

9600/19200/38400/57600 baud)

Terminal Bus (KBus)

Technical data BC3150 BC5150 BC5250 BC8150 -

Digital peripheral signals 2040 inputs/outputs

Analog peripheral signals 1024 inputs/outputs

Configuration possibility via TwinCAT or the controller

Maximum fieldbus byte

number

Maximum number of bytes

- PLC

Bus connection D-sub, 9-pin Open Style Connector, 5 pin D-sub, 9-pin -

64 (255 with K-Bus extension)

depending on fieldbus

2048 bytes of input data, 2048 bytes of output data

-

Power supply (Us)

Input current (Us) 60 mA + (total K-Bus current)/4

Starting current approx. 2.5 x continuous current

K-Bus current (5 V) maximum 1000 mA

Power contact voltage

(Up)

Power contact current load

(Up)

Recommended fuse (Up) ≤ 10 A

Dielectric strength 500 V

Weight approx. 100 g

Dimensions (W x H x D) approx. 44 mm x 100 mm x 68 mm

24 VDC (-15%/+20%) To meet the UL requirements use a 4 A fuse or a power

supply that has to satisfy NEC class 2!

maximum 24 VDC

maximum 10 A

(power contact / supply voltage / fieldbus)

rms

Fieldbus Components 11

Page 14

Safety Instructions

Technical data BC3150 BC5150 BC5250 BC8150 -

Operating temperature 0°C... +55°C

Storage temperature -25°C... +85°C

Relative humidity 95 % no condensation

Vibration / shock resistance conforms to EN 60068-2-6 / EN 60068-2-27, EN 60068-2-29

EMC resistance burst / ESD conforms to EN 61000-6-2 / EN 61000-6-4

Installation pos. Variable

Protection class IP20

12 Fieldbus Components

Page 15

Safety Instructions

Technical Data - PROFIBUS DP

System data PROFIBUS (BC3150)

Number of I/O modules 126 (BC3150 max. 99 devices)

Number of I/O points depending on controller

Data transfer medium shielded copper cable 2 x 0.25 mm², cable type A according to EN 50170

Segment length up to 1200 m

Number of segments 3

Data transfer rate up to 12 MBaud

Topology RS485 line, optical fiber ring

Transmission time approx. 0.5 ms with 10 stations for 32 bits input/output at 12 MBaud

Fieldbus Components 13

Page 16

Safety Instructions

Technical Data - PLC

PLC data BCxx5x

Programmability via serial programming interface or via the fieldbus

Program memory 48 kbyte

Source code memory 128 kbyte

Data memory 32 kbyte

Remanent flags 2 kbyte

PLC cycle time Approx. 3,0 ms for 1000 IL commands (without I/O cycle)

Programming languages IEC 6-1131-3 (IL, LD, FBD, ST, SFC)

Run time 1 PLC task

Online Change Yes

Up/Down Load Code Yes/Yes

14 Fieldbus Components

Page 17

Safety Instructions

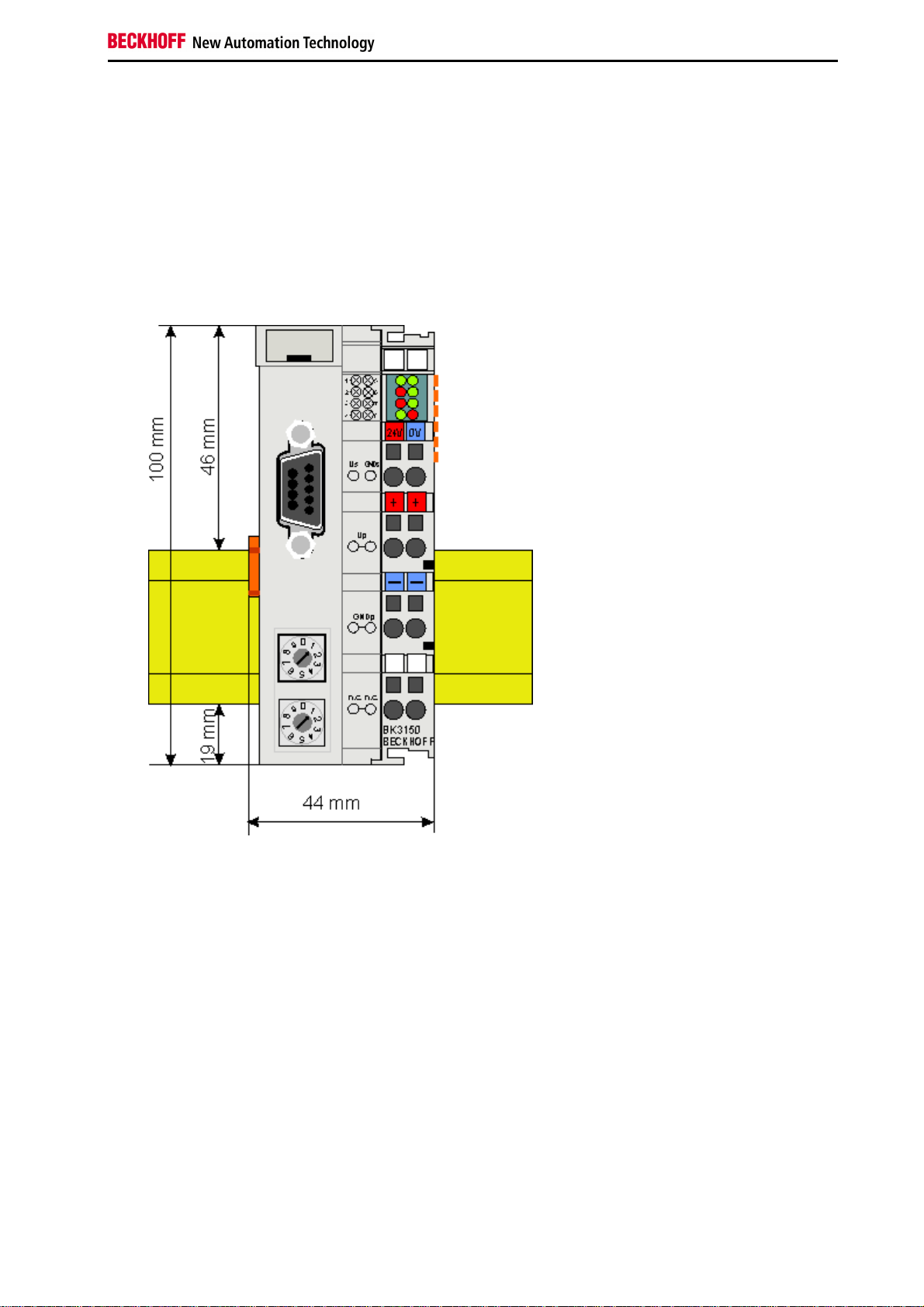

3. Mounting and Wiring

Mounting

Dimensions

The Beckhoff Bus Terminal system is characterized by low physical volume and high modularity. When planning a

project it must be assumed that at least one Bus Coupler and a number of Bus Terminals will be used. The

mechanical dimensions of the Bus Couplers are independent of the fieldbus system.

Fig. 1.0 BCxx50

The total width of the fieldbus station is the width of the Bus Coupler/Bus Terminal Controller plus the width of the

Bus Terminals being used (incl. KL9010 bus end terminal). Depending on design, the Bus Terminals are 12 or 24 mm

wide. The height is 100 mm.

The BCxx50 series Bus Terminal Controllers are 68 mm deep.

Fieldbus Components 15

Page 18

Safety Instructions

Installation

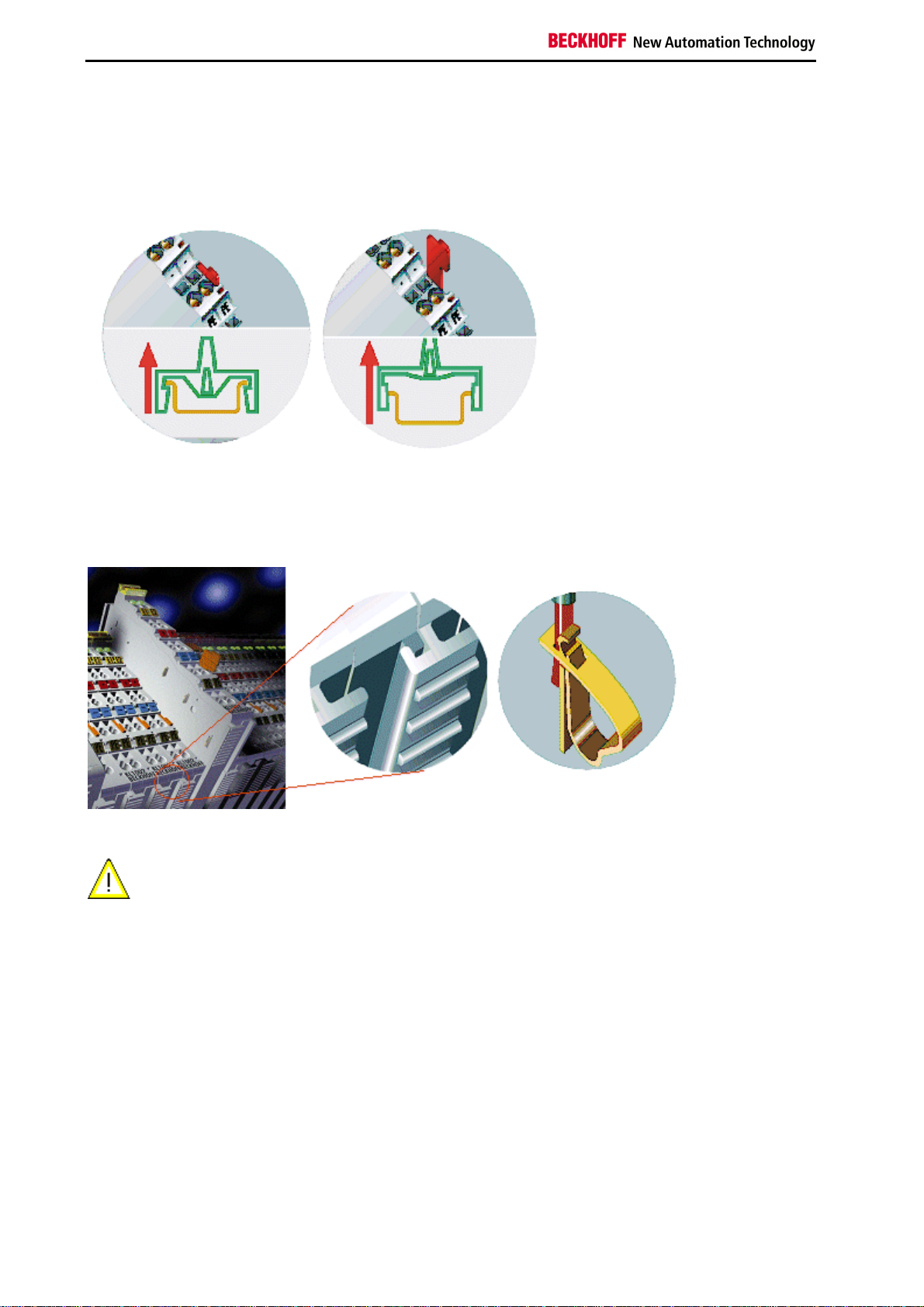

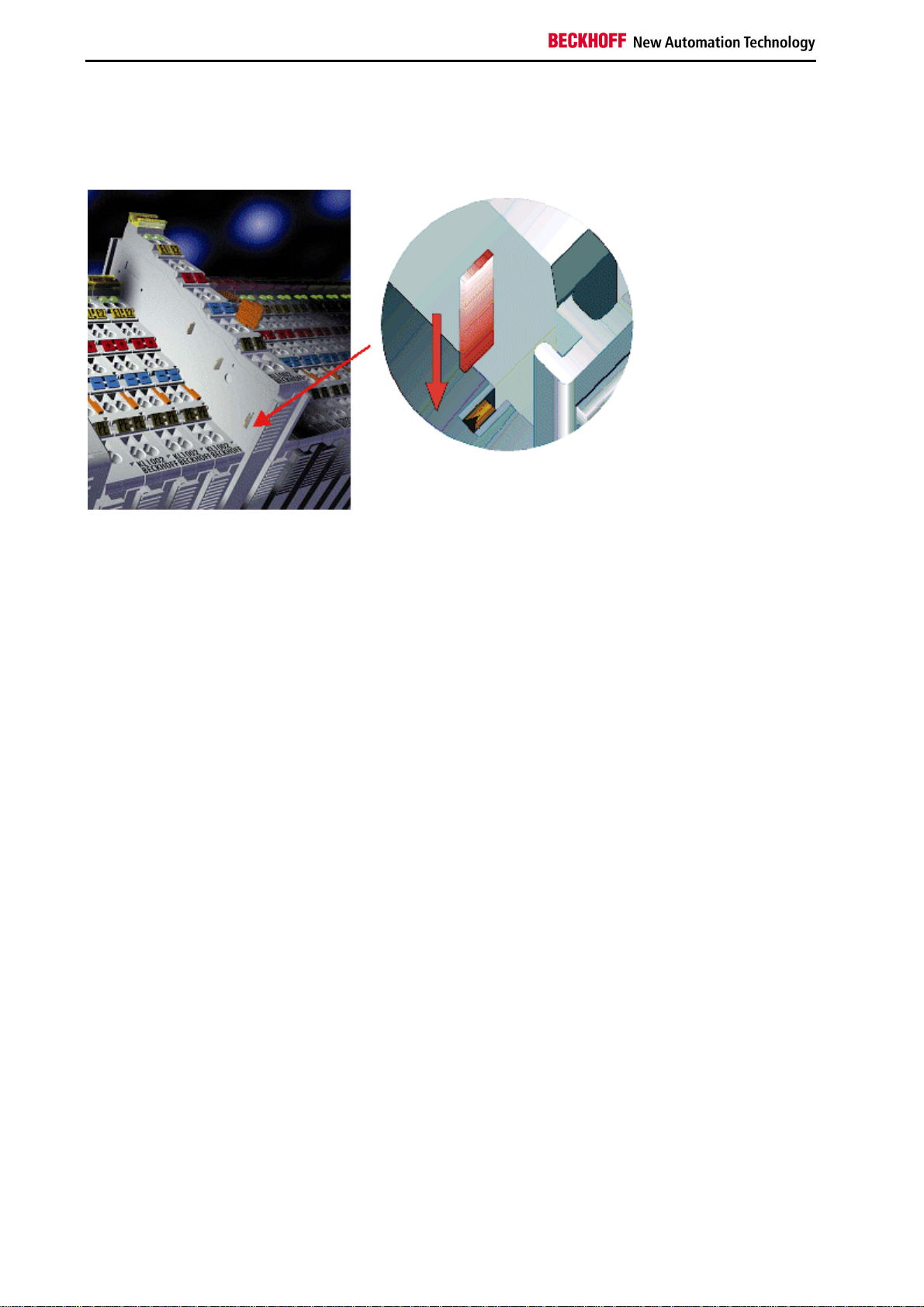

The Bus Coupler and all the Bus Terminals can be clipped, with a light press, onto a 35 mm mounting rail. A locking

mechanism prevents the individual housings from being pulled off again. For removal from the mounting rail the

orange colored tension strap releases the latching mechanism, allowing the housing to be pulled off the rail without

any force.

Up to 64 Bus Terminals can be attached to the Bus Coupler on the right hand side. When plugging the components

together, be sure to assemble the housings with groove and tongue against each other. A properly working

connection can not be made by pushing the housings together on the mounting rail. When correctly assembled, no

significant gap can be seen between the attached housings.

Insertion and removal of Bus Terminals is only permitted when switched off. The

Warning

electronics in the Bus Terminals and in the Bus Coupler are protected to a large measure

against damage, but incorrect function and damage cannot be ruled out if they are plugged

in under power.

The right hand part of the Bus Coupler can be compared to a Bus Terminal. Eight connections at the top enable the

connection with solid or fine wires from 0.08 mm² to 2.5 mm². The connection is implemented with the aid of a spring

device. The spring-loaded terminal is opened with a screwdriver or rod, by exerting gentle pressure in the opening

above the terminal. The wire can be inserted into the terminal without any force. The terminal closes automatically

when the pressure is released, holding the wire securely and permanently.

16 Fieldbus Components

Page 19

Safety Instructions

Wiring

Potential Groups, Insulation Testing and PE

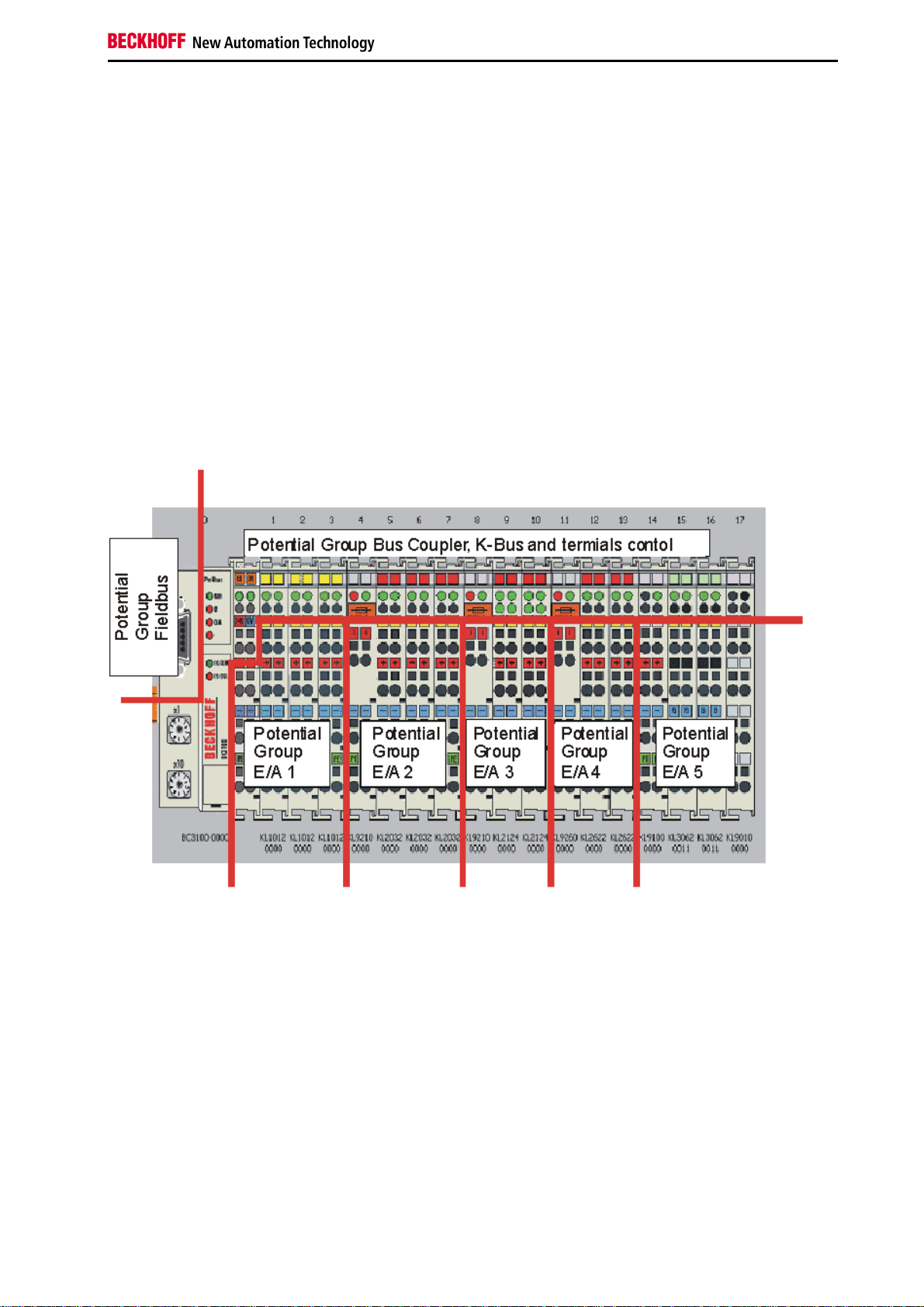

Potential groups

The Beckhoff Bus Terminals stations usually have three different potential groups:

•

The fieldbus interface is electrically isolated (except for individual Low Cost couplers) and forms the first potential group

•

Bus Coupler / Bus Terminal Controller logic, K-Bus and terminal logic form a second galvanically separated

potential group

•

The inputs and outputs are supplied via the power contacts and form further potential groups.

Groups of I/O terminals can be consolidated to further potential groups via potential supply terminals or separation

terminals.

Insulation testing

The connection between the Bus Coupler / Bus Terminal Controller and the Bus Terminals is automatically realized

by pushing the components together. The transfer of the data and the supply voltage for the intelligent electronics in

the Bus Terminals is performed by the K-Bus. The supply of the field electronics is performed through the power

contacts. Plugging together the power contacts creates a supply rail. Since some Bus Terminals (e.g. analog Bus

Terminals or 4-channel digital Bus Terminals) are not looped through these power contacts (or not completely) the

Bus Terminal contact assignments must be considered.

The potential feed terminals interrupt the power contacts, and represent the start of a new supply rail. The Bus

Coupler / Bus Terminal Controller can also be made use of to feed the power contacts.

Fieldbus Components 17

Page 20

Safety Instructions

PE power contacts

The power contact labelled PE can be used as a protective earth. For safety reasons this contact mates first when

plugging together, and can ground short-circuit currents of up to 125 A.

It should be noted that, for reasons of electromagnetic compatibility, the PE contacts are capacitively coupled to the

mounting rail. This can both lead to misleading results and to damaging the terminal during insulation testing (e.g.

breakdown of the insulation from a 230 V power consuming device to the PE conductor). The PE conductor to the

Bus Coupler / Bus Terminal Controller must be disconnected for the insulation testing. In order to uncouple further

feed locations for the purposes of testing, the feed terminals can be pulled at least 10 mm out from the connected

group of other terminals. In that case, the PE conductors do not have to be disconnected.

The PE power contact must not be used for other potentials.

18 Fieldbus Components

Page 21

Safety Instructions

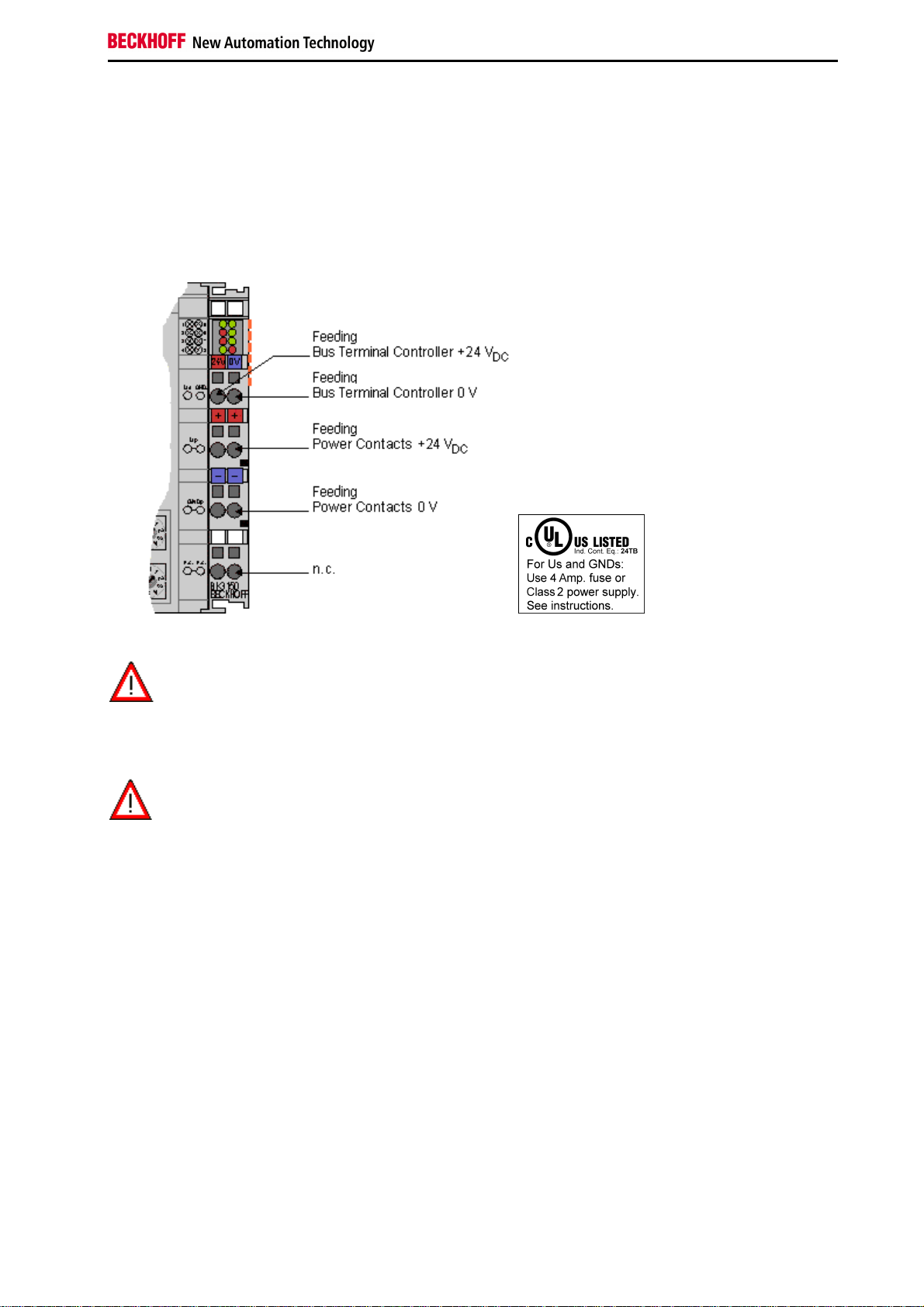

Power supply

Bus Terminal Controller and Bus Terminal supply (Us)

The Bus Terminal Controller requires a supply voltage of 24 VDC for its operation.

The connection is made by means of the upper spring-loaded terminals labelled 24 V and 0 V. This supply voltage

feeds the Bus Coupler / Bus Terminal Controller electronics and, over the K-Bus, the electronics of the Bus

Terminals. It is electrically separated from the potential of the field level.

UL requirements

For the compliance of the UL requirements Us should only be supplied

•

Danger

To meet the UL requirements, Us must not be connected to unlimited power sources!

Danger

by a 24 VDC supply voltage, supplied by an isolating source and protected by

means of a fuse (in accordance with UL248), rated maximum 4 Amp.

•

by a 24 VDC power source, that has to satisfy NEC class 2.

A NEC class 2 power supply shall not be connected in series or parallel with another (class 2) power source!

Power contacts supply (Up)

The bottom six connections with spring-loaded terminals can be used to feed the supply for the peripherals. The

spring-loaded terminals are joined in pairs to a power contact. The feed for the power contacts has no connection to

the voltage supply for the BC electronics.

The spring-loaded terminals are designed for wires with cross-sections between 0.08 mm2 and 2.5 mm2.

The assignment in pairs and the electrical connection between feed terminal contacts allows the connection wires to

be looped through to various terminal points. The current load from the power contact must not exceed 10 A for long

periods. The current carrying capacity between two spring-loaded terminals is identical to that of the connecting

wires.

Power contacts

On the right hand face of the Bus Terminal Controller there are three spring contacts for the power contact

connections. The spring contacts are hidden in slots so that they can not be accidentally touched. By attaching a Bus

Terminal the blade contacts on the left hand side of the Bus Terminal are connected to the spring contacts. The

tongue and groove guides on the top and bottom of the Bus Terminal Controllers and of the Bus Terminals

guarantees that the power contacts mate securely.

Fieldbus Components 19

Page 22

Safety Instructions

Programming cable

Use the KS2000-Z2 programming cable for serial programming of the Bus Terminal Controller. This cable is included

in the scope of supply of the KS2000 software, or it can be ordered separately (order number KS2000-Z2).

KS2000-Z2

The programming cable offers the option of programming the BCxx50 via the serial interface.

When the programming cable (between BCxx50 and PC) is connected, the ground

Warning

connection of the Bus Terminal controller must not be interrupted or disconnected, since

this may destroy the programming cable.

20 Fieldbus Components

Page 23

Safety Instructions

PROFIBUS Connection

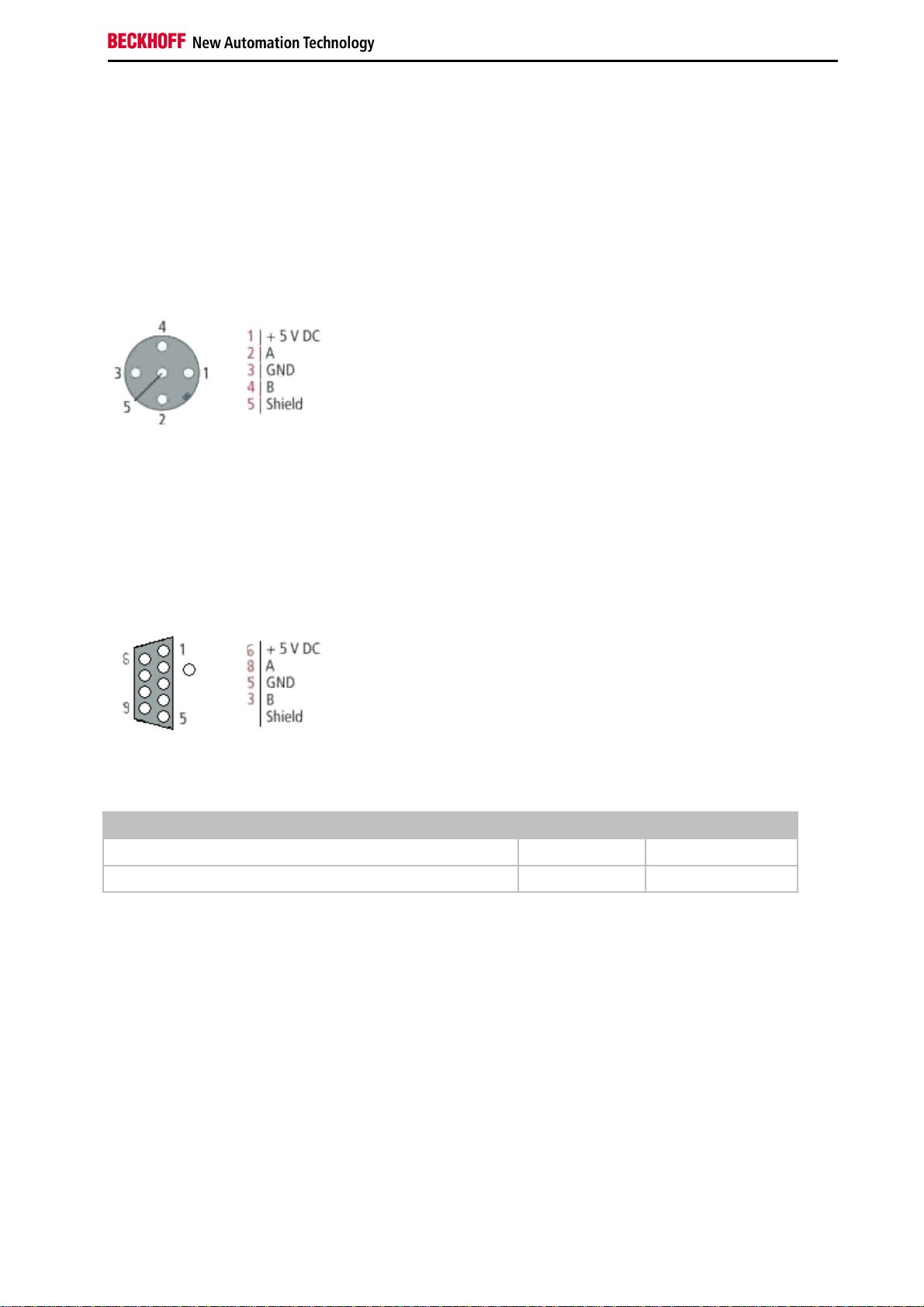

M12 circular connector

The M12 socket is inverse coded, and has five pins. Pin 1 is 5 VDC and 3 is GND for the active termination resistor.

These must never be misused for other functions, as this can lead to destruction of the device. Pin 2 and pin 4 are

the Profibus signals. These must never be swapped over, as this will prevent communication. Pin 5 is the shield, and

this is capacitatively coupled to the Fieldbus Box chassis.

M12 socket pin assignment

Nine pole D-Sub

Pin 6 is 5 VDC und Pin 5 is GND for the active termination resistor. These must never be misused for other functions,

as this can lead to destruction of the device. Pin 3 and pin 8 are the Profibus signals. These must never be swapped

over, as this will prevent communication. Shield is connected to the D-Sub housing that is coupled with lowresistance to the mounting rail.

D-Sub socket pin assignment

Profibus conductor colors

Profibus conductors M12 D-Sub

B red Pin 4 Pin 3

A green Pin 2 Pin 8

Fieldbus Components 21

Page 24

Safety Instructions

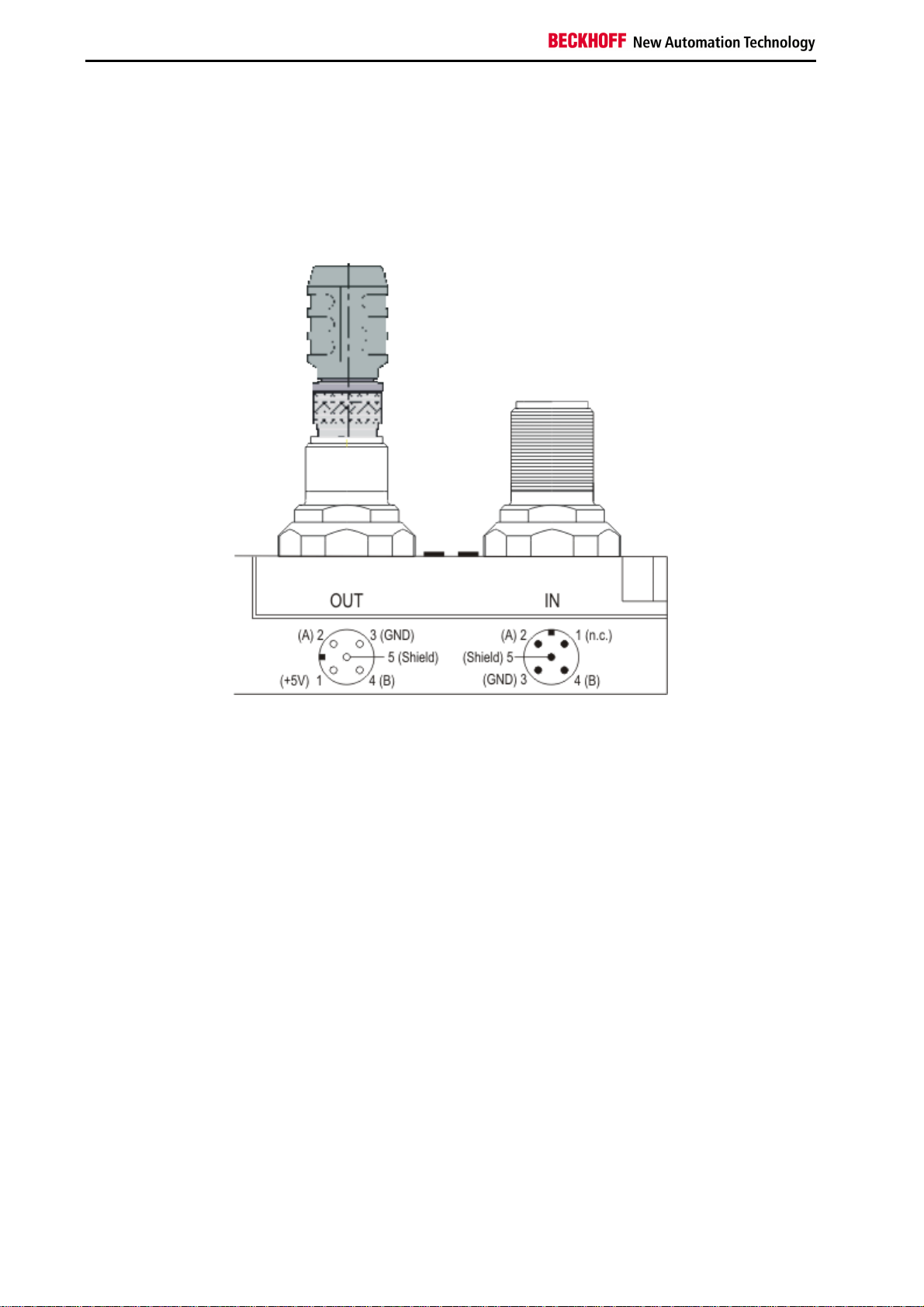

Connection of FieldbusBox modules

The connection of the Fieldbus Box modules is done direct or via a T-piece (or Y-piece).

The B318 series does have a male and female connector, that means no external T-piece is required. The supply

voltage (+5VDC) for the termination resistor is only supplied via the female M12 connector. The termination resistor

ZS1000-1610 is only available with male connector, therefore the incoming PROFIBUS line should end in a female

connector.

Two T-pieces are available:

•

ZS1031-2600 with +5VDC on male and female connector for the termination resistor

•

ZS1031-2610 with +5VDC only on the female connector

22 Fieldbus Components

Page 25

Safety Instructions

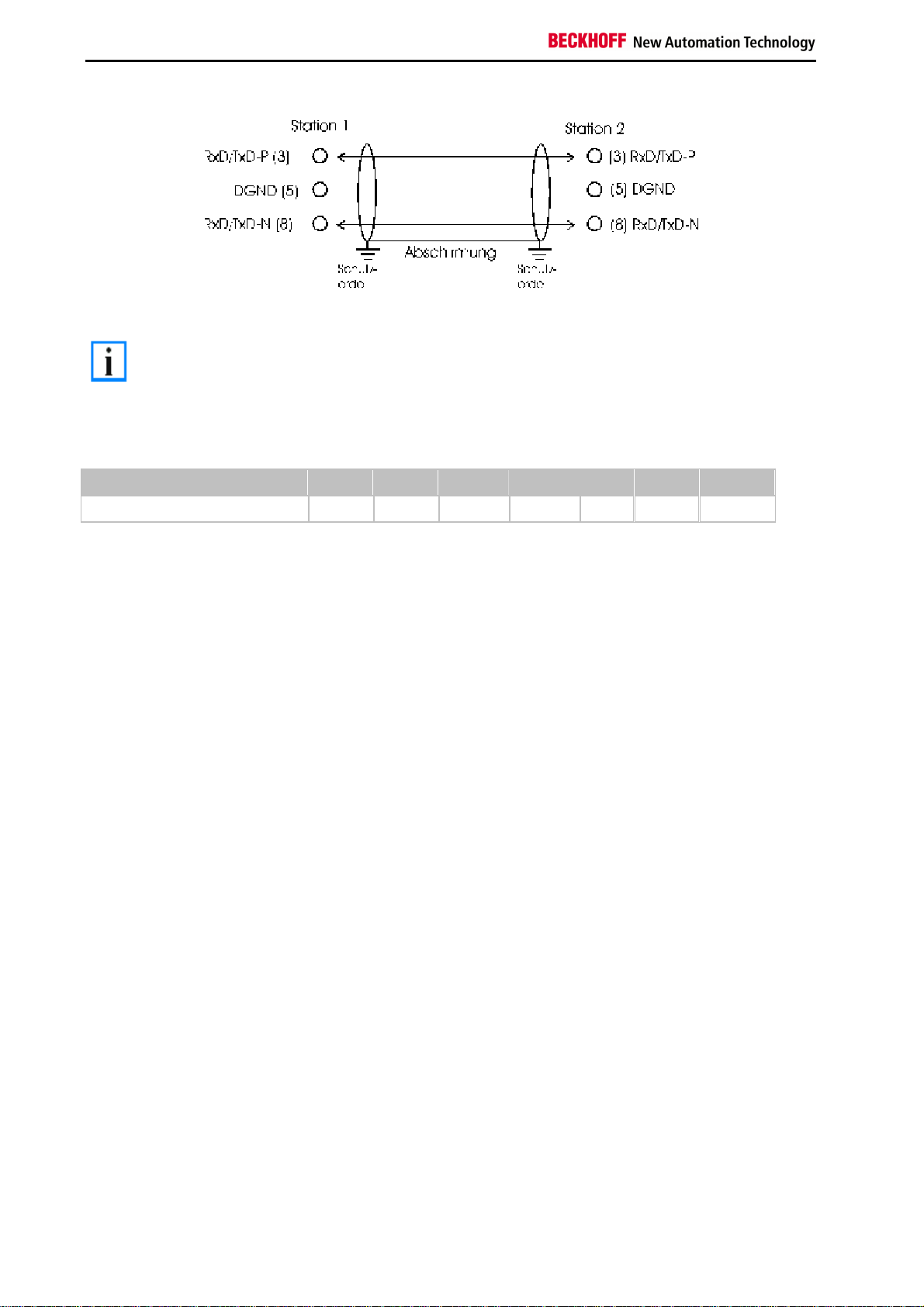

PROFIBUS Cabling

Physical aspects of the data transmission are defined in the Profibus standard (see Profibus layer 1: Physical Layer).

The types of area where a fieldbus system can be used is largely determined by the choice of the transmission

medium and the physical bus interface. In addition to the requirements for transmission security, the expense and

work involved in acquiring and installing the bus cable is of crucial significance. The Profibus standard therefore

allows for a variety of implementations of the transmission technology while retaining a uniform bus protocol.

Cable-based transmission

This version, which accords with the American EIA RS-485 standard, was specified as a basic version for

applications in production engineering, building management and drive technology. A twisted copper cable with one

pair of conductors is used. Depending on the intended application area (EMC aspects should be considered) the

screening may be omitted.

Two types of conductor are available, with differing maximum conductor lengths (see the RS-485 table).

RS485 - Fundamental properties

RS-485 transmission according to the Profibus standard

Network topology Linear bus, active bus terminator at both ends, stubs are possible.

Medium Screened twisted cable, screening may be omitted, depending upon the

environmental conditions (EMC).

Number of stations 32 stations in each segment with no repeater. Can be extended to 127 stations

with repeater

Max. bus length without

repeater

Max. bus length with

repeater

Transmission speed

(adjustable in steps)

Plug connector 9-pin D-Sub connector for IP20

100 m at 12 MBit/s

200 m at 1500 KBit/s, up to 1.2 km at 93.75 KBit/s

Line amplifiers, or repeaters, can increase the bus length up to 10 km. The

number of repeaters possible is at least 3, and, depending on the manufacturer,

may be up to 10.

9.6 kBit/s; 19.2 kBit/s; 93.75 kBit/s; 187.5 kBit/s; 500 kBit/s; 1500 kBit/s; 12 MBit/s

M12 round connector for IP65/67

Cabling for Profibus DP and Profibus FMS

Note the special requirements on the data cable for baud rates greater than 1.5 MBaud. The correct cable is a basic

requirement for correct operation of the bus system. If a simple 1.5 Mbaud cable is used, reflections and excessive

attenuation can lead to some surprising phenomena. It is possible, for instance, for a connected Profibus station not

to achieve a connection, but for it to be included again when the neighboring station is disconnected. Or there may be

transmission errors when a specific bit pattern is transmitted. The result of this can be that when the equipment is not

operating, Profibus works without faults, but that there are apparently random bus errors after start-up. Reducing the

baud rate (< 93,75 kBaud) corrects this faulty behavior.

If reducing the baud rate does not correct the error, then in many cases this can indicate a wiring fault. The two data

lines maybe crossed over at one or more connectors, or the termination resistors may not be active, or they may be

active at the wrong locations.

Installation is made a great deal more straightforward if pre-assembled cables from

Note

BECKHOFF are used! Wiring errors are avoided, and commissioning is more rapidly

completed. The BECKHOFF range includes fieldbus cables, power supply cables, sensor

cables and accessories such as terminating resistors and T-pieces. Connectors and cables

for field assembly are nevertheless also available.

Fieldbus Components 23

Page 26

Safety Instructions

In systems with more than two stations all devices are wired in parallel. It is essential that

Note

the bus cables are terminated with resistors at the conductor ends in order to avoid

reflections and associated transmission problems.

Distances

The bus cable is specified in EN 50170. This yields the following lengths for a bus segment.

Baud rate in kbits/sec 9.6 19.2 93.75 187.5 500 1500 12000

Cable length in m 1200 1200 1200 1000 400 200 100

Stubs up to 1500 kbaud <6.6 m; at 12 Mbaud stub segments should not be used.

Bus segments

A bus segment consists of at most 32 devices. 126 devices are permitted in a Profibus network. Repeaters are

required to refresh the signal in order to achieve this number. Each repeater is counted as one device.

IP-Link is the subsidiary bus system for Fieldbus Boxes, whose topology is a ring structure. There is an IP master in

the coupler modules (IP230x-Bxxx or IP230x-Cxxx) to which up to 120 extension modules (IExxxx) may be

connected. The distance between two modules may not exceed 5 m. When planning and installing the modules,

remember that because of the ring structure the IP-Link master must be connected again to the last module.

Installation guidelines

When assembling the modules and laying the cables, observe the technical guidelines provided by the Profibus User

Organization (Profibus Nutzerorganisation e.V.) for Profibus DP/FMS (see www.profibus.com).

Checking the Profibus wiring

A Profibus cable (or a cable segment when using repeaters) can be checked with a few simple resistance

measurements. The cable should meanwhile be removed from all stations:

1. Resistance between A and B at the start of the lead: approx. 110 Ohm

2. Resistance between A and B at the end of the lead: approx. 110 Ohm

3. Resistance between A at the start and A at the end of the lead: approx. 0 Ohm

4. Resistance between B at the start and B at the end of the lead: approx. 0 Ohm

5. Resistance between screen at the start and screen at the end of the lead: approx. 0 Ohm

If these measurements are successful, the cable is okay. If, in spite of this, bus malfunctions still occur, this is usually

a result of EMC interference. Observe the installation notes from the Profibus User Organization (www.profibus.com).

24 Fieldbus Components

Page 27

Safety Instructions

4. Parameterization and Commissioning

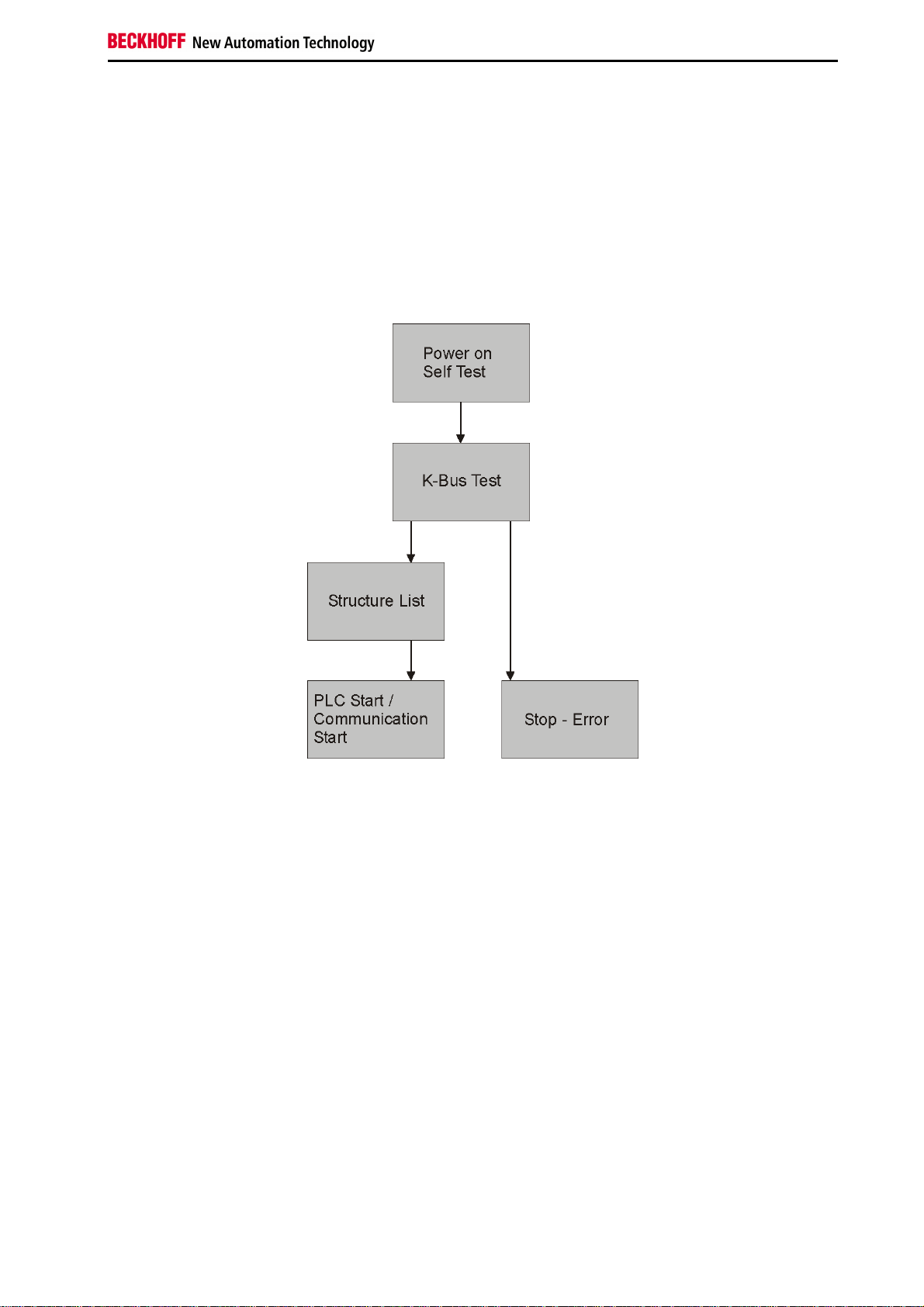

Start-up Behavior of the Bus Terminal Controller

After being switched on, the Bus Terminal Controller checks its state, configures the K-Bus, creates a structure list on

the basis of the inserted bus terminals and starts it's local PLC.

The I/O LEDs illuminate and flash as the Bus Coupler starts up. If there are no errors, the I/O LEDs should stop

flashing within about 2-3 seconds. In the case of an error, the flash code of the according LED depends on the error

type (see Diagnostic LEDs).

Fieldbus Components 25

Page 28

Safety Instructions

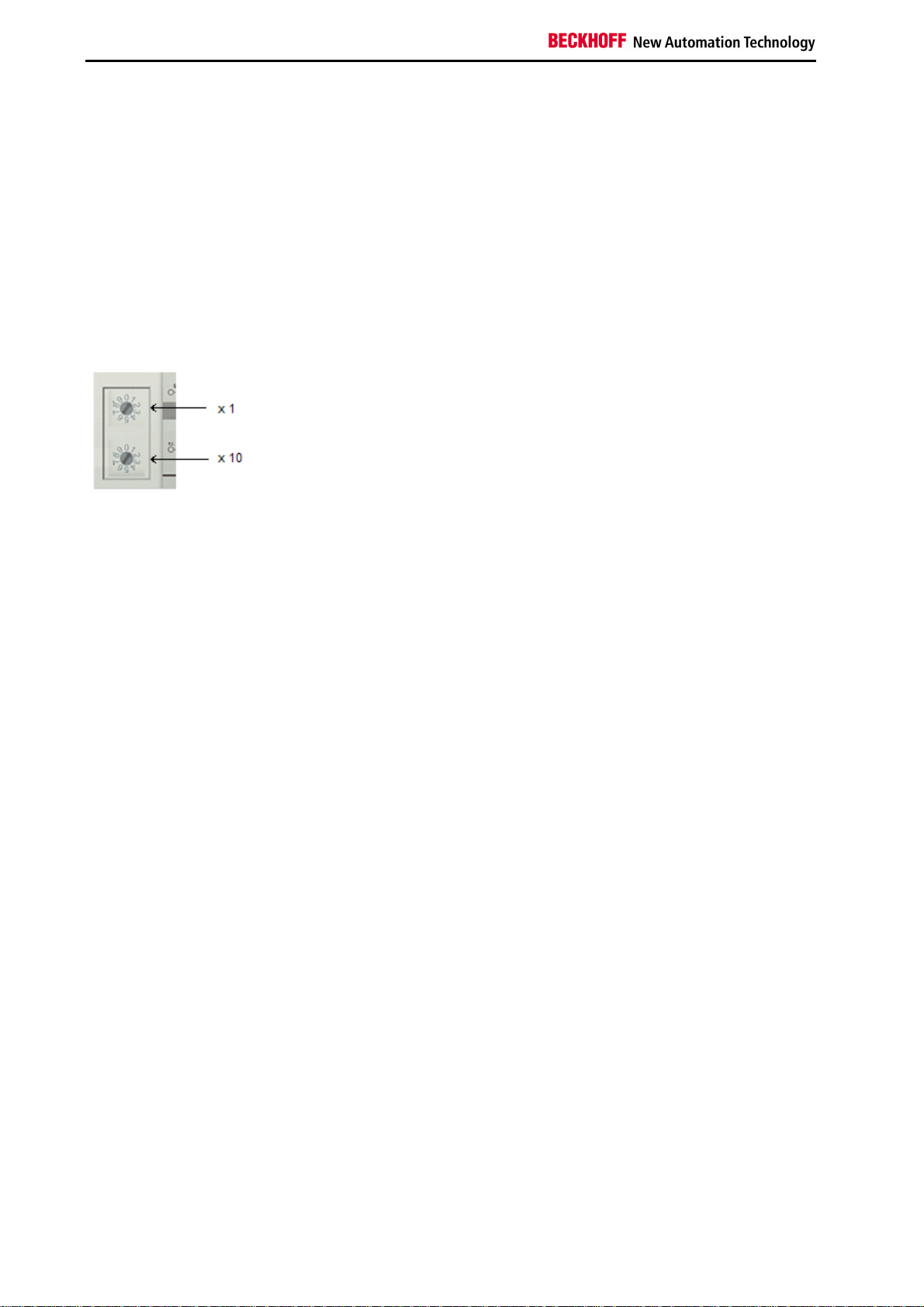

Setting the slave address

The address must be set via the two rotary selection switches. The default setting is 11. All addresses are permitted,

although each address may only occur once within the network. For changing an address the Bus Coupler must be

switched off. The switches can be set to the required position using a screwdriver. Ensure that the switches engage

correctly. The lower switch is the 10-multiplier, the upper switch is the 1-multiplier. The change in address is active as

soon as the module is switched on.

Example

You want to set address 34:

•

lower rotary selection switch Sx11: 3

•

upper rotary selection switch Sx10: 4

26 Fieldbus Components

Page 29

Safety Instructions

Configuration

Overview

Configuration types

DEFAULT-CONFIG

Bus Terminals are mapped in the order they are inserted, i.e. first the complex Bus Terminals followed by the digital

Bus Terminals.

The complex Bus Terminals are mapped as follows:

•

Word Alignment

•

complex representation

The fieldbus slave interface are the PLC variables. The PLC variables have addresses from %QB1000 and %IB1000.

TWINCAT-CONFIG

Bus Terminals and PLC variables can be linked freely in TWINCAT-CONFIG (TC-file required). The configuration is

transferred to the coupler via the System Manager and ADS.

The following is required for TwinCAT Config:

•

Via the fieldbus (PROFIBUS, CANopen, Ethernet)

PROFIBUS: (BC3150, BX3100)

- PC with FC310x from version 2.0 and TwinCAT 2.9 build 1000

- BX3100 with firmware from 0.28 with CIF60 or CP5412

- TwinCAT 2.9 build 946

(WARNING: only one ADS communication is permitted with the Hilscher cards, i.e. either System Manager

or PLC Control)

CANopen: (BC5150, BX5100)

PC with FC510x from version 1.76 or higher and TwinCAT 2.9 build 1030

DeviceNet: (BC5250, BX5200)

on request

Ethernet: (BX9000):

- TwinCAT 2.10 Build xxxx

•

Via serial ADS TwinCAT 2.9 build 1010 for NT4.0, 2000 or XP

- BX3100 version 1.00

- BX5100 version 1.00

- BX5200 version 1.10

- BX8000 version 1.00

- BC3150, BC5150, BC5250 Frimware B0

- BC8150 TwinCAT 2.10 Build 1244

The BX can be parameterised via the System Manager of the TwinCAT program.

•

Variable I/O mapping

•

Type-specific PROFIBUS data (only BC3150 or BX3100)

•

RTC (Real Time Clock) (only BX-controller)

•

SSB bus (Smart System Bus) (only BX-controller)

•

PLC settings

•

K-Bus settings

The configuration can be transferred to the BXxxxx or BCxx50 via fieldbus ADS protocol or with the serial ADS

protocol.

Fieldbus Components 27

Page 30

Safety Instructions

The TwinCAT configuration can be used to link variables, I/Os and data. The following is possible:

•

PLC - K-BUS

•

PLC - fieldbus (e.g. PROFIBUS slave interface)

•

K-Bus - fieldbus (only the BX-Controller)

In addition, the TwinCAT configuration can be used to parameterise special behaviour, for example whether data are

preserved or set to "0" in the event of a fieldbus error.

The real-time clock can be set via a tab in the system manager.

Individual steps

1. Setting the fieldbus address

2. Opening the system manager and creating a TC-file

3. Configuring fieldbus data in the TC-file

4. Saving the TC-file

5. Opening a new system manager, creating a PC file and reading in saved TC-file

6. Creating a link to a PLC task

7. Saving the configuration

8. Starting the TwinCAT system

9. Opening the system manager for the TC-file, completing the configuration and transferring it to the BXxxxx

or BCxx50

10. Transferring the program to the BXxxxx or BCxx50

11. Creating a boot project

28 Fieldbus Components

Page 31

Safety Instructions

Creating a BX File

For configuring the BX, a BX file has to be created in the System Manager. To simplify matters, files for the basic

units have already been prepared. Open the respective BX Controller via New from Template.

Select the associated BX Controller.

All BX Controller components are now available.

•

Fieldbus interface

•

K-Bus Interface

•

PLC Program

•

SSB (only BX-Controller)

Please refer to the relevant section for device configuration.

Fieldbus Components 29

Page 32

Safety Instructions

Downloading a BX Configuration

The configuration is transferred to the Bus Terminal Controller via ADS.

ADS serial (all BX and BCxx50-Controller)

Enter the serial ADS connection, as described in section Serial ADS.

ADS fieldbus (only BX3100, BX5100, BX9000, BC3150, BC5150)

A prerequisite is that TwinCAT operates as the master and data exchange is active, i.e. physical and PROFIBUS,

CANopen configuration must be completed, and data must be exchanged from the master (FC310x, FC510x) to the

Bus Terminal Controller.

Selecting the target system

Select the BXxx00 to which you wish to upload the configuration. F8 opens the dialog for downloading the associated

device.

Select the associated Bus Terminal Controller.

The device state (BX) is displayed at the bottom right of the System Manager.

In Config Mode / FreeRun the configuration can now be transferred to the BX. If the BX is in Stop Mode, ADS

communication has not yet been activated. In this case, the configuration cannot be downloaded.

30 Fieldbus Components

Page 33

Safety Instructions

For activating the configuration select Ctrl+Shift+F4 or Activate Configuration.

The current configuration is uploaded to the BX. The display will show Store Config, and the BUS and I/O LED will

flash. After the configuration has been transferred successfully to the BX, the BX display should show TwinCAT

Config. The required program can now be transferred to the BX (program download via the fieldbus).

Fieldbus Components 31

Page 34

Safety Instructions

Uploading a BX Configuration

The configuration is transferred to the Bus Terminal Controller via ADS.

ADS serial (all BX and BCxx50-Controller)

Enter the serial ADS connection, as described in section Serial ADS.

ADS fieldbus (only BX3100, BX5100, BX9000, BC3150, BC5150)

A prerequisite is that TwinCAT operates as the master and data exchange is active, i.e. physical and PROFIBUS,

CANopen configuration must be completed, and data must be exchanged from the master (FC310x, FC510x) to the

Bus Terminal Controller.

Selecting the target system

Select the BXxx00/BCxx50 to which you wish to upload the configuration. F8 opens the dialog for downloading the

associated device.

Select the associated Bus Terminal Controller.

The device state (Bus Terminal Controller) is displayed at the bottom right of the System Manager.

32 Fieldbus Components

Page 35

Safety Instructions

Click on the red folder. The TwinCAT configuration will now be uploaded.

Fieldbus Components 33

Page 36

Safety Instructions

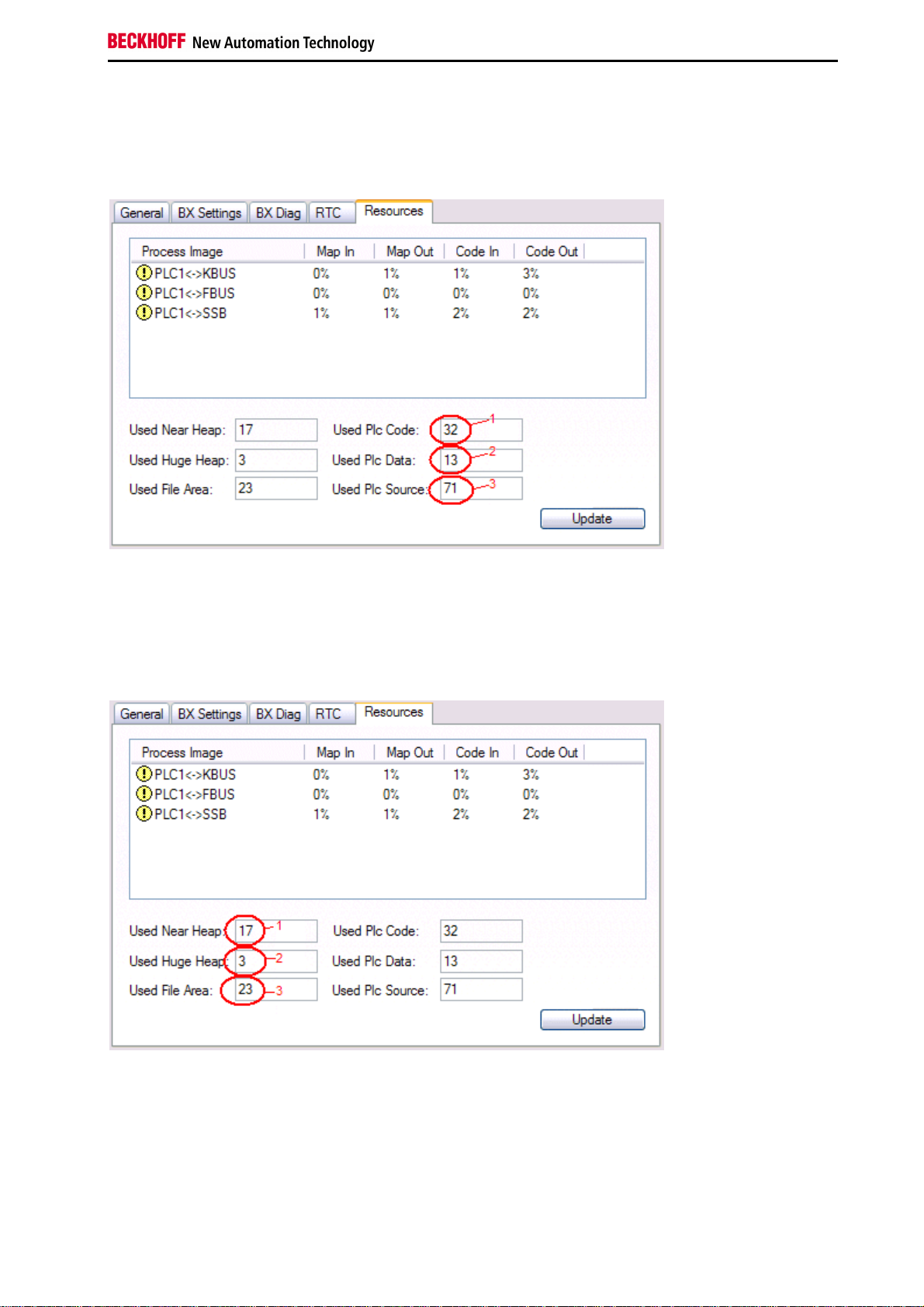

Bus Terminal Controller resources

The system manager indicates the memory resources used by the Bus Terminal Controller in the Resources tab of

the Bus Terminal Controller.

Mapping code

The mapping code is required for calculating the TwinCAT configuration (see Fig. 1). The percentages are added up.

In the example from Fig 1., 8% of the memory is used for the mapping calculation.

Fig. 1: Memory for code mapping

Data memory mapping

Data memory for mapping. The values are to be considered individually, i.e. each value can be up to 100%.

Fig. 2 Data memory mapping

34 Fieldbus Components

Page 37

Safety Instructions

Used code and data memory

Fig. 3 (1): "Used PLC code" in %.

Fig. 3 (2): "Used PLC data" in % of memory.

Fig. 3 (3): "Used PLC Source" in %.

Fig. 3: Code and data memory

Other memory

Fig.4 (1): "Used Near Heap" is required for the COM interface and SSB. % values.

Fig.4 (2): "Used Huge Heap" is required for ADS communication. % values. This value should be less than 30 %.

Fig.4 (3): "Used file Area" is required for TwinCAT configuration, the TSM file and 16kB flash access. % values.

Fig.4: Other memory

Fieldbus Components 35

Page 38

Safety Instructions

ADS via Serial

ADS Connection via Serial Interface

(from firmware version 1.xx or 0.99x - Bus Terminal Controller of BX series and at all BCxx50)

for TwinCAT 2.9 build 1010 (TwinCAT level PLC, NC or NCI)

To ensure correct function of the serial ADS connection, only one connection is permitted.

Note

After successful configuration via the System Manager, close the System Manager before

starting programming.

Initializing the ADS connection

Enter the Bus Terminal Controller in the remote connection under TwinCAT. Click on the TwinCAT icon and open

the feature menu. The following settings can be made under the >AMS Remote< tab.

Remote Name: Any

AMS Net Id: 1.1.1.1.1.1 (Default)

Address: Com Port: baud rate, parity, data bits, stop bits

Transport: "COM port" is to be chosen here

No strings can be entered under address when the dialog is first called (see above). Enter

Note

Communication starts as soon as TwinCAT is in Config or RUN mode. The COM port is not closed until TwinCAT

stops, after which it is available for other programs.

name, AMS Net ID, and transport type and close the dialog. When the dialog is called

again you can enter your COM port.

Reading AMS Net ID

The AMS Net ID can be read from the menu via the display of the Bus Terminal Controller of the BX series.

AMS

1.1.1.1.1.1

Note

If the Bus Terminal Controller has been addressed via a fieldbus ADS connection before

the serial ADS connection was used, the System Manager will automatically have changed

the AMS Net ID. Read the current ADS number.

AMS Net ID

36 Fieldbus Components

Page 39

Safety Instructions

PROFIBUS

PROFIBUS Settings

The PROFIBUS-relevant settings are made in the DP slaves tab.

Reaction to PROFIBUS Error

In the event of a PROFIBUS error (e.g. PROFIBUS cable is pulled), the output data of the PROFIBUS master are

retained unchanged or set to 0 (depending on the parameterization). From the BX3100 perspective these are input

data that are transferred from the PROFIBUS master to the BX3100.

DP data format

The PROFIBUS data can be transferred in Intel or Motorola format.

Checking the DP configuration data

The configuration data can

•

not be checked at all;

•

checked for correct length; or

•

checked for length and content

Fieldbus Components 37

Page 40

Safety Instructions

Master Configuration

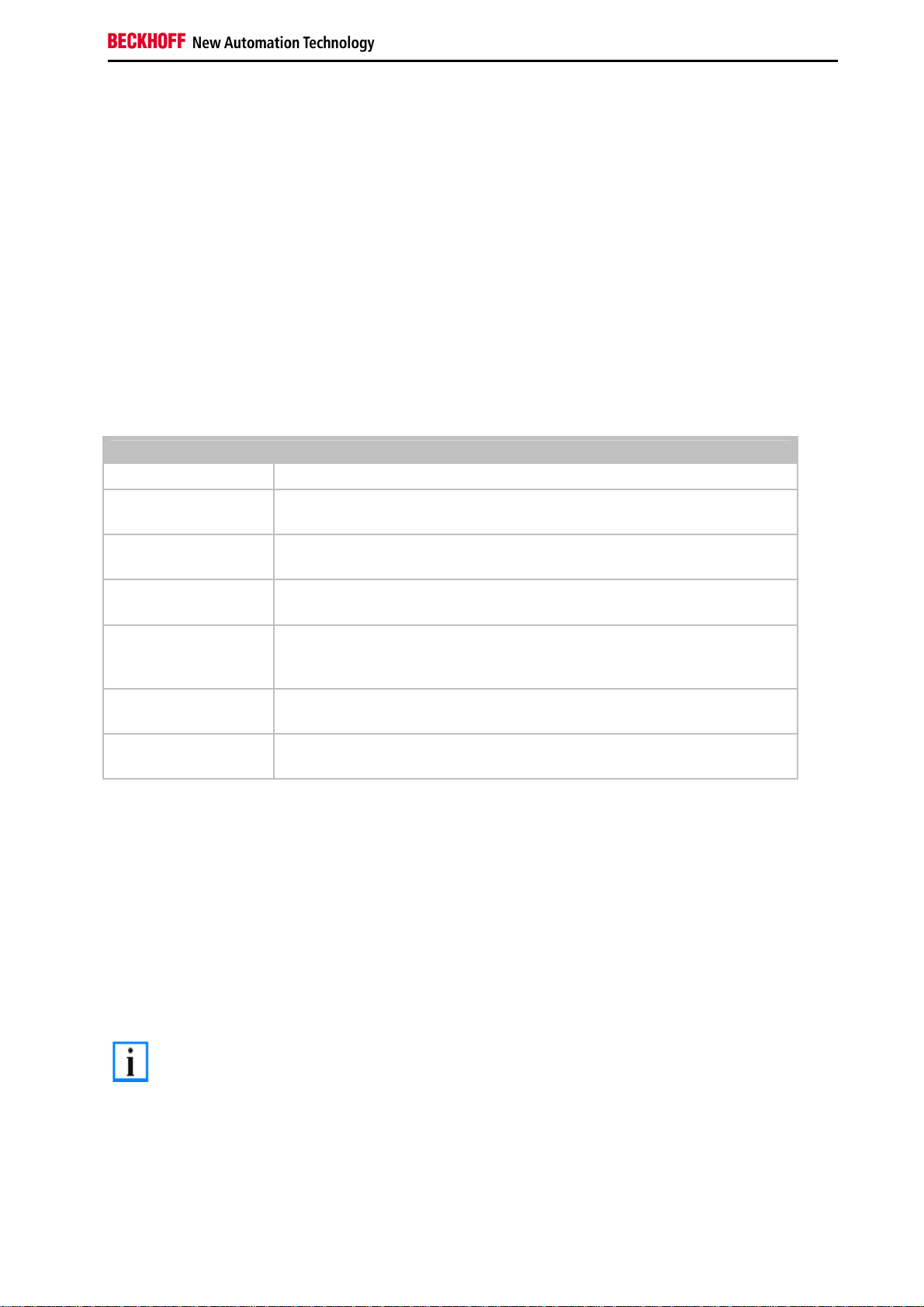

Basic Device File (GSD)

All field devices with PROFIBUS slave interface are described via the GSD file. The BC3150 is a PROFIBUS DP

slave. For data exchange, the GSD file has to be inserted in the master configuration tool. The maximum length of

input and output data 128 bytes in each direction.

Download GSD file (German):

Download GSD file (English):

The GSD file can describe the following data types:

Variable Length

Integer 8 1 byte

UnInteger 8 1 byte

Integer 16 2 bytes

UnInteger 16 2 bytes

Integer 32 4 bytes

UnInteger 32 4 bytes

Float 32 4 bytes

Data types that are not listed, e.g. BOOL variables, can be described via the length. For this purpose, the GSD file

includes configuration data starting with a byte and ending with 64 words.

38 Fieldbus Components

Page 41

Safety Instructions

Creating a TwinCAT PC File

DEFAULT CONFIG

DEFAULT-CONFIG contains the PROFIBUS data from the address %IB1000 input and %QB1000. The data length

depends on the number of configured PROFIBUS data. A maximum of 244 bytes of input date and 244 bytes of

output data can be parameterised. No further settings are required for this configuration type.

Fig.1: Inserting BX3100.

Inserting the BX3100 in a PROFIBUS master via the System Manager

Select your PROFIBUS master PC card in the System Manager and right-click on your PROFIBUS master card. The

PROFIBUS devices will then be offered for selection, among them a BX3100. Select this and confirm with OK.

Opening an existing BX file

If you wish to work with the DEFAULT-CONFIG, interrupt the process at this point (see Creating PROFIBUS data in

DEFAULT-CONFIG). Otherwise select your configured BX file. If no such file exists, you have to create one (Creating

a BX file). Once you have selected your BX file, all required PROFIBUS data are copied automatically into your

project from this file. You now have to create a link to your task and set the PROFIBUS address. The configuration

can then be saved and the TwinCAT system started.

Fieldbus Components 39

Page 42

Safety Instructions

Creating PROFIBUS data in DEFAULT-CONFIG

The PROFIBUS data can now be created. Various variables are available:

- Integer 8 bit

- Integer 16 bit

- Integer 32 bit

- UnInteger 8 bit

- UnInteger 16 bit

- UnInteger 32 bit

- FLOAT 32 bit

They have to match the variable types currently projected in the BX.

Data sizes from 1 byte to 64 words are available.

Fig.2: Creating PROFIBUS data

ADS Communication has to be selected for preparing the configuration. If the configuration data are to be transferred

via the fieldbus, data communication has to be active, i.e. the BX must exchange data with the controller.

40 Fieldbus Components

Page 43

Safety Instructions

Variable Mapping - PROFIBUS DP

Creating the PROFIBUS data.

Fig. 1: Creating PROFIBUS data

For linking with the PLC project, the PLC program must be read in. Add your PLC program under PLC Configuration.

The PLC variables can now be linked with the fieldbus variables.

Ensure that the maximum permissible number of PROFIBUS data is not exceeded

Note

(BX3100: max. 244 bytes inputs and 244 bytes outputs)!

(BC3150: max. 128 bytes inputs and 128 bytes outputs)!

Fieldbus Components 41

Page 44

Safety Instructions

BC3150 at 3rd party controller

SIEMENS S7

Configuration - Siemens S7 Controller

Inserting the images

In order to assign an image to the devices in the Siemens software, the following graphics must be copied into the

Step7\S7Data\ncbmp directory.

BC3150d.DIB

BC3150n.DIB

BC3150s.DIB

Inserting the GSD files

•

Go to Extras\Install new GSD in the hardware catalog for your Step7.

•

Select the directory in which the BECKHOFF GSD is located, and import the files.

•

You will then find them in the hardware catalog under Profibus DP\Other field devices\I/O.

42 Fieldbus Components

Page 45

Safety Instructions

Configuration: Siemens S7 Controller with BX3100

BX3100 parameter data

Fig. 1: Settings

Fieldbus Components 43

Page 46

Safety Instructions

BX3100 module configuration

Example 1

1 x BX3100

Fig. 2: Example for entering individual bytes. Note: Each individual byte requires one byte of ConfigData.

44 Fieldbus Components

Page 47

Safety Instructions

Fig. 3: Example for entering associated bytes.

Fieldbus Components 45

Page 48

Safety Instructions

K-Bus

K-Bus

BX Settings tab

Check Terminals during Start-up

When a boot project is created, the current Bus Terminal configuration is stored. The connected Bus Terminals are

checked when the BX is restarted. If this option is selected, the Bus Terminal Controller will not commence data

exchange. The PLC project will not be started.

Auto K-Bus Reset

After correction of a K-Bus fault, the Bus Terminal Controller will automatically re-commence data exchange.

Ensure that the outputs are reactivated immediately and that analog outputs retain their

Warning

Clear Outputs on Breakpoint

If break points are set in PLC Control, the K-Bus is no longer processed, i.e. the outputs are set to a safe state (zero).

K-Bus Sync Mode

Writing and reading of the Bus Terminals can occur synchronous with Task1, Task2 or the fieldbus.

K-Bus Re-Trigger

If the processor is busy dealing with the PLC project or the SSB, the K-Bus cannot be processed for a certain amount

of time. This leads to triggering of the Bus Terminal watchdog and dropping of the outputs. The Bus Terminal

Controller is set to re-trigger the K-Bus watchdog 3 times after 85 ms respectively. The K-Bus watchdog would then

be activated.

K-Bus Re-Trigger 0: 100 ms

K-Bus Re-Trigger 1: 2 x 85 ms = 70 ms

K-Bus Re-Trigger 2: 3 x 85 ms = 255 ms

K-Bus Re-Trigger 3: 4 x 85 ms = 340 ms

programmed value, if this is not dealt with in your PLC project.

Reaction on K-Bus Error

In the event of a K-Bus error, the K-Bus inputs are set to "0" or retain their last state.

Response on PLC-Stop

The user can set the behavior of the fieldbus output data in the event of the PLC project being stopped. The master

will use these data as input data. In the event of a PLC stop, the data can be set to "0" or remain unchanged.

46 Fieldbus Components

Page 49

Safety Instructions

BX Diag tab

Display of cycle time for task 1, task 2, K-Bus, fieldbus processing and SSB overhead.

Factory Settings - the Bus Terminal Controller is set back to its delivery state. These settings are reactivated via

Restart System or by switching the system off and on again (display shows DEFAULT-CONFIG).

K-Bus variables

PLCInterface: Not supported (only included for moving CX or BX projects)

KBus-State: see Diagnostics

Fieldbus Components 47

Page 50

Safety Instructions

PLC

Inserting a PLC project

For variable mapping, configuration has to be specified in the system manager. This is where the link between PLC

and hardware is specified. The variables can process and link bit, byte, word or data structures. Automatic

addressing via the System Manager is possible, but should be checked for offset.

A valid project has to be compiled and saved in PLC Control. These data are saved as a *.tpy file. For inserting a

PLC project, right-click on PLC - Configuration. Select your current PLC project.

Link the PLC variable with the hardware (e.g. digital Bus Terminal).

Once all links have been created, activate the configuration Actions/Activate Configuration (Ctrl+Shift+F4) and start

TwinCAT Set/Reset TwinCAT to Run Mode. Ensure that the correct target system is selected (bottom right in the

System Manager window).

48 Fieldbus Components

Page 51

Safety Instructions

Measuring the PLC Cycle Time

The task time is set in PLC Control. The default setting is 20 ms.

In the default setting, the PLC program is called every 20 ms, as long as the general cycle time is less than 20 ms.

The cycle time can be measured in the System Manager in order to determine your system load. To ensure troublefree operation, the set task time should be 20 to 30 % higher than the measured cycle time. A precise cycle time

breakdown can be found under K-Bus tab description.

Fieldbus Components 49

Page 52

Safety Instructions

KS2000

KS2000

The KS2000 software can provide assistance for the configuration or diagnosis of the connected Bus Terminals. The

KS2000 software cannot be used for parameterization or configuration of Bus Terminal Controller of BX series and

BCxx50. The TwinCAT System Manager has to be used for the settings.

The COM 1 interface features automatic baud rate detection between 9.6 and 56.4 kBaud*.

Note

The BXxxxx Controller is supported from version 4.3.14.

Note

50 Fieldbus Components

Page 53

Safety Instructions

5. Programming

BCxx50 PLC features

Description Value

Data memory 32 kbyte

Program memory 48 kbyte minus task-configuration minus POUs during online change

Source code memory 128 kbyte

RETAIN 2 kbyte

INPUT 2 kbyte

OUTPUT 2 kbyte

FLAG 4 kbyte

Max. variable size 16 kbyte

Max. POUs Limited by memory

Fieldbus Components 51

Page 54

Safety Instructions

TwinCAT PLC

The Beckhoff TwinCAT Software System turns any compatible PC into a real-time controller with a multi-PLC system,

NC axis control, programming environment and operating station. The TwinCAT programming environment is also

used for programming the BC/BX. If you have TwinCAT PLC (Windows NT4/2000/XP) installed, you can use the

fieldbus connection or the serial port for downloading and debugging software. If you are programming with TwinCAT

BC (also compatible with Windows 95/98/ME), the connection to the BC is made exclusively via the serial port.

TwinCAT I/O or TwinCAT PLC can also be used as the Ethernet Master (host), in order to exchange process data

with the Bus Terminal Controller. TwinCAT provides you with the System Manager as a configuration tool, as well as

the drivers and the ADS protocol.

Bus Terminal Controller of BX series and BCxx50

These 2nd-generation Bus Terminal Controllers are configured with the TwinCAT System Manager and programmed

with TwinCAT PLC Control. TwinCAT PLC has to be installed (Windows NT4, Windows 2000, Windows XP) for these

couplers.

Minimum requirement: TwinCAT from Version 2.9 build 940

Programming and program transfer

•

via the serial interface

•

via the fieldbus interface (only at Bus Terminal Controllers for PROFIBUS, CANopen and Ethernet)

Online Change

The Bus Terminal Controller of BX series and BCxx50 supports online change. This means that the PLC program is

replaced with a new program without interrupting the program. The switch-over to the new program occurs after the

task is completed. This means that two versions of the PLC program have to be stored. 512 kB are available, which

therefore have to be divided by 2, leaving 256 kB for the actual program. In addition, several kB are required for task

configuration etc. During an online change, dynamic data are stored in memory. Should a program approach the

memory limit (program size greater than 240 kB), the online change may no longer work, even though the program

may still be written to the BX after "Rebuild all".

When is online change not available?

Online change is not available under certain conditions

•

Inserting of a new library

•

Change in task setting

•

"Rebuild all"

•

Controller memory limit is almost reached (PLC program greater than 90%)

52 Fieldbus Components

Page 55

Safety Instructions

TwinCAT PLC error codes

Error type Description

PLC compiler error Maximum number of POUs (...) exceeded

PLC compiler error Out of global data memory ...

Error POUs

For each block one POU (process object unit) is created. 256 blocks are available by default.

If libraries are integrated this value may be insufficient. In this case, the number of POUs should be increased.

To this end, open

the controller settings in the PLC Control under Projects/Options.

Changing these settings will deactivate online changes.

Fieldbus Components 53

Page 56

Safety Instructions

Global memory error

2 x 16 kB of data are available by default. If large data quantities are to be used, this range should be increased. A

maximum of 14 data segments are possible for the BX.

54 Fieldbus Components

Page 57

Safety Instructions

Remanent data

2 kB of remanent data are available for the BX controller. These data are declared as VAR RETAIN in PLC Control:

Example:

VAR RETAIN

Test :BOOL;

Count :INT;

END_VAR

Retain data are located between VAR RETAIN and END_VAR. These data are stored in a NOVRAM and are

consistent across the whole 2 kB range. The RETAIN data are stored in the NOVRAM after each cycle. For 2 kB

approx. 2 ms are required (for 1 kB approx. 1 ms). The variables can be configured locally or globally. Variables are

located (%I...,%Q.., %M...) are not use as a Retain data.

VAR_RETAIN should not be used in function blocks. All FB data are copied into the retain

Note

Note

memory. This leads to an unnecessary increase in cycle time, and the retain memory is

filled with unnecessary data.

Variables, they have an address (%I...,%Q.., %M...), are not allowed to declare as a retain

variables.

Example for remanent data in the function block

Because all the data in a function block will be saved if even only one remanent bit is included, this should be

avoided if at all possible. A programming example can be found below.

Function block Test (no program code required - in ST a semicolon is sufficient)

FUNCTION_BLOCK Test

VAR_INPUT

END_VAR

VAR_OUTPUT

END_VAR

VAR

END_VAR

VAR_IN_OUT

Counter :INT;

END_VAR

MAIN program

PROGRAM MAIN

VAR

fb_Test:Test;

END_VAR

VAR RETAIN

iCounter1:INT;

END_VAR

fb_Test(Counter:=iCounter1);

Fieldbus Components 55

Page 58

Safety Instructions

Allocated Flags

4 kB of allocated flags are available. They can be used to assign different variable types to the same address, e.g. for

converting strings to bytes. Data can also be placed here that can be read or written via ADS by the controller.

The BX Controllers do not save the allocated variables as remanent data.

Note

Reading/writing of allocated flags via ADS

The flags may also be read via the controller and ADS. In PROFIBUS, the DPV-1 services are used for this purpose,

in CANopen SDO communication is used.

The AmsNetId can be taken from the System Manager, or it can be displayed in the BX menu.

The PLC port number is 800.

Index group Meaning Index offset (value range)

0x4020 Flag (only BXxxx0) 0..4096

Example

BX program

VAR

Flag_01 AT %MB0: WORD;

END_VAR

TwinCAT PC/CX Master Programm

VAR

fbADRSREAD: ADSREAD;

Flag_M: WORD;

END_VAR

fbADRSREAD(

NETID:='172.16.3.0.2.3' , (* AMSNetId BX *)

PORT:=800 , (* 800 - PLC *)

IDXGRP:=16#4020 , (* 0x4020hex flags *)

IDXOFFS:=0 , (* byte offset *)

LEN:=2 , (* Lenght byte *)

DESTADDR:=ADR(Merker) ,

READ:=TRUE ,

TMOUT:=t#1s );

IF NOT fbADRSREAD.BUSY THEN

fbADRSREAD(READ:=FALSE);

END_IF

56 Fieldbus Components

Page 59

Safety Instructions

Local process image in delivery state

The process image of the BX controller consists of an input, output and flag area. In addition, there are unallocated

data without fixed address. They are created without specifying an address. For this type of variable, 256 kbyte (48

kbyte BCxx50) of memory are available on the BX Controller. The maximum size of a variable or structure (array) is

16 kbyte. For the allocated data 2048 bytes of input data and 2048 bytes of output data are available. The BX has 4

kbyte of memory for the allocated flag area. In the delivery state (default configuration) of the BX, fixed addresses are

allocated for all connected Bus Terminals. The data for PROFIBUS communication start from address offset 1000

The length of the PROFIBUS data depends on the number of configured data. The maximum length is 244 bytes

(BX3100) / 128 bytes (BC3150).

Inputs Outputs

Bus Terminal %IB0 ... Bus Terminal %QB0 ...

PROFIBUS data (PLC variable) %IB1000 ... PROFIBUS data (PLC variables) %QB1000 ...

... %IB2047 Maximal ... %QB2047 Maximal

dec

Addressing of the connected Bus Terminals

The default setting is for all the connected Bus Terminals to be assigned to the local process image. Mapping within

the Bus Terminal Controller is carried out according to the following rule:

First come all the complex Bus Terminals, in whatever sequence they are physically inserted, followed by the digital

Bus Terminals which are padded to a whole byte. The default mapping of the complex Bus Terminals is:

.

•

complete evaluation

•

Intel format

•

Word alignment

Example structure

Bus Terminal Controller: 1 x BXxxxx/BCxx50

Position 1: 1 x KL1012

Position 2: 1 x KL1104

Position 3: 1 x KL2012

Position 4: 1 x KL2034

Position 5: 1 x KL1501

Position 6: 1 x KL3002

Position 7: 1 x KL4002

Position 8: 1 x KL6001

Position 9: 1 x KL9010

Process image

Bus Terminal Position Input image Output image

KL1501 5 %IB0...%IB5 %QB0...%QB5

KL3002 6 %IB6...%IB13 %QB6...%QB13

KL4002 7 %IB14...%IB21 %QB14...%QB21

KL6001 8 %IB22...%IB29 %QB22...%QB29

KL1012 1 %IX30.0..30.1 KL1104 2 %IX30.1..30.5 KL2012 3 - %QX30.0..30.1

KL2034 4 - %QX30.2..30.5

KL9010 9 - -

Fieldbus Components 57

Page 60

Safety Instructions

If you do not know the address of the Bus Terminals that you have assigned to the local

Note

PLC (BC/BXxx00):

Perform your hardware configuration in the System Manager. After you have entered all the

Bus Terminals and PLC variables, click with the right mouse button on the BC/BXxx00 in

the hardware tree, and select the menu item Export variables information.... A file is saved,

and this file can be inserted in the System Manager under Project - Import. Now you will

have the entry TwinCAT import under the global variables, and you will find here all the

variables that you have assigned to the local PLC (BC/BXxx00).

58 Fieldbus Components

Page 61

Safety Instructions

Mapping of the Bus Terminals

The precise assignment of the byte-oriented Bus Terminals may be found in the configuration guide for the particular

bus terminal. This documentation is available on the Beckhoff CD Products & Solutions or on the Internet under

http://www.beckhoff.com.

Byte oriented Bus Terminals Bit oriented Bus Terminals

KL1501 KL10xx, KL11xx, KL12xx, KL17xx

KL25xx KL20xx, KL21xx, KL22xx, KL26xx, KL27xx

KL3xxx

KL4xxx

KL5xxx

KL6xxx

KL8xxx

KL9110, KL9160, KL9210, KL9260

Fieldbus Components 59

Page 62

Safety Instructions

Local process image in the TwinCAT configuration

The TwinCAT configuration (TwinCAT CONFIG) enables free mapping between PROFIBUS / K-Bus / PLC variables.

Variables can be linked independent of their address via the System Manager.

In the TwinCAT configuration, all Bus Terminals have fixed addresses. If a Bus Terminal is inserted, the whole

address range may be shifted. Many data are unnecessary and take up valuable address memory space. The

TwinCAT configuration rectifies this disadvantage. Allocated variables can be linked freely with a Bus Terminal.

Parameterization is carried out in the System Manager, and the configuration is then transferred to the BX (see

TwinCAT configuration).

60 Fieldbus Components

Page 63

Safety Instructions

Creating a boot project

Approximately 250 kB of flash are available.

For creating a boot project

•

on the Bus Terminal Controller of BX-Series app. 250 kByte of flash are available

•

on the Bus Terminal Controller of BCxx50-Series app. 48 kByte of flash are available

PLC Control

After logging in, a boot project can be created in TwinCAT PLC Control.

•

Opening a PLC project

•

Selecting the target system (or selection the serial interface)

•

BX/BCxx50 login

•

Creating the boot project (Online\Create boot project)

Once a valid boot project is present on the BX/BCxx50 controller, the green PLC LED is on.

At the Bus Terminal Controller of BX-Series the PLC LED will flash orange during the creation of the boot project. If

no boot project is available on the BX the PLC LED shines orange.

Deleting a boot project

A boot project can be deleted from the BX/BCxx50. The following steps must be followed:

•

Opening the project

•

BX/BCxx50 login

•

Deleting the boot project (Online\Delete boot project)

Once the boot project was deleted, the PLC LED will be orange.

After an online change, the boot project is still the old project. To use the current project

Note

(after the online change) as the boot project, the boot project has to be recreated.

Bypassing the start of the boot project*

At the Bus Terminal Controller of BX-Series the start up of an existing boot project can be avoided by pressing the

Navi switch during booting. This will not delete the boot project. The project can still be used when the controller is

switched on again.

* from version 0.85

Fieldbus Components 61

Page 64

Safety Instructions

Communication between TwinCAT and BX/BCxx50

It makes sense to define a data structure for transferring data between TwinCAT and Bus Terminal Controller. Please

note the following to account for the differences in data management on the two systems.

•

If two different data types are sent in sequence (e.g. byte and INT), the following variable is set to the next

even address offset

•

Boolean variables should never be allocated individually within a structure, since they would invariably occupy 1 byte. Boolean expressions should always be masked in a byte or word.

Example 1: Structure on the BX and on the PC

Variable BX memory PC memory (TwinCAT)

Byte %..B0 %..B0

INT (1) %..B2 %..B1

INT (2) %..B4 %..B3

Because the first byte is followed by a different variable type (INT), it was set to the next free even address in the

BX/BCxx50. In order to achieve the same data structure on both systems, a dummy byte has to be inserted in the PC

project (see example 2).

Example 2: Structure on the BX and on the PC with identical memory allocation

PC memory

Variable BX memory

Byte %..B0 %..B0

Byte

(Dummy)

INT (1) %..B2 %..B2

INT (2) %..B4 %..B4

Data structure

Type PB_Data

STRUCT

wVar_1:WORD;

iValue_1:INT;

iValue_2:INT;

iValue_3:INT;

END_STRUCT

END_TYPE

Creating a variable structure

VAR_Global

strData_Out AT %QB1000:PB_Data; (*PLC Variables *)

bInput_01 AT %IX0.0:BOOL; (* Input from a terminal *)

END_VAR

%..B1 (not necessarily required, since the system deals with this itself if the

variable does not exist)

(TwinCAT)

%..B1

Small programming example

strData_Out.wVar_1.0:=bInput_01;

A mixed data structure should not contain any Real values. If it does, the High and Low

Note

Note

word must be swapped in the BX/BCxx50or in the TwinCAT master project. It is better to

use an array of Real values or to transfer the Real values individually.

It is also possible to transfer larger fieldbus data blocks, in order to leave a reserve for your

structure. Disadvantage: These reserves are then transferred with each fieldbus telegram,

causing additional load for the fieldbus communication.

62 Fieldbus Components

Page 65

Safety Instructions

Up- and downloading of programs

The Bus Terminal Controller has 256 kB of memory for the source code. It can be used for storing the program, the

task configuration, and the libraries. Should the memory be insufficient, the source code may be stored without task

configuration and libraries. This takes up significant less memory space!

General Settings

The timing of the source code download to the target system can be specified via Edit/Options.

Fieldbus Components 63

Page 66

Safety Instructions

Downloading a program

The source code can be transferred to the target system on request. This requires the user to be logged in with his

program. Under Online/Sourcecode download the program code can now be transferred to the Bus Terminal

Controller.

After a short delay, a window will open that indicates the download progress.

64 Fieldbus Components

Page 67

Safety Instructions

Uploading a program

For uploading the program code again, open a new file in PLC Control. Then click on the PLC button.

Select the data transfer route. For the Bus Terminal Controller

- BCxx50 or BX via AMS, if they are connected via the fieldbus with the BX, or

- BCxx50 or BX via serial, if they are connected via the serial interface.

Then select the device and confirm with OK.

The source code will now be uploaded.

Fieldbus Components 65

Page 68

Safety Instructions

Password

You can protect your project with a password (in PLC Control Project/Options/Passwords).

66 Fieldbus Components

Page 69

Safety Instructions

Libraries

Libraries overview

The TwinCAT Automation Software offers various libraries for the BCxx50 series Bus Terminal Controllers (Bus

Coupler with PLC functionality) (see BECKHOFF information system).

Download

The libraries are also included in this documentation. For extracting the libraries, click on the disk icon with the left

mouse button and copy the libraries into the directory TwinCAT\PLC\LIB.

•

Standard

•

TcSystemBCxx50 TcSystemBCxx50 requires the TcBaseBCxx50 library.

•

TcBaseBCxx50

•

ChrAscBX.lbx

Always use the latest libraries in conjunction with the latest BC firmware. If you update the

Note

firmware of your Bus Terminal Controller, please also update the libraries. Copy the new

libraries into the LIB folder, remove them from your project and re-insert them.

TcSystemBCxx50

Firmware

ADS Version

ADSREAD B0 B0 B1 B0 ADSWRITE B0 B0 B1 B0 ADSRDWRT B0 B0 B1 B0 ADSWRTCTL B0 B0 B1 B0 ADSRDSTATE B0 B0 B1 B0 ADSRDDEVINFO B0 B0 B1 B0 -

Bit Functions Version

CLEARBIT32 B0 B0 B1 B0 CSETBIT32 B0 B0 B1 B0 GETBIT32 B0 B0 B1 B0 -

BC3150 BC5150 BC5250 BC8150 -

Firmware

BC3150 BC5150 BC5250 BC8150 -

SETBIT32 B0 B0 B1 B0 -

Firmware

Controller Version

FB_BasicPID - B0 B0 B1 B0 -

- - - - - - -

File Access Version

FB_ReadFromFile - - - - FB_WriteToFile - - - - FB_ReadWriteFile - - - - -

BC3150 BC5150 BC5250 BC8150 -

Firmware

BC3150 BC5150 BC5250 BC8150 -

Fieldbus Components 67

Page 70

Safety Instructions

Firmware

Memory Functions Version

BC3150 BC5150 BC5250 BC8150 -

MEMCMP B0 B0 B1 B0 MEMCYP B0 B0 B1 B0 MEMMOVE B0 B0 B1 B0 MEMSET B0 B0 B1 B0 -

Firmware

NOVRAM Functions Version

BX3100 BX5100 BX5200 BX8000 -

- - - - - - -

Firmware

SFC Version

BC3150 BC5150 BC5250 BC8150 -

AnalyzeExpression - - - - AppendErrorString - - - - SFCActionControl - - - - -

Firmware

System / Time / TBus Version

BC3150 BC5150 BC5250 BC8150 -

DRAND B0 B0 B1 B0 SYSTEMTIME_TO_DT B0 B0 B1 B0 DT_TO_SYSTEMTIME B0 B0 B1 B0 GetSysTick B0 B0 B1 B0 PresetSysTick B0 B0 B1 B0 Reboot B0 B0 B1 B0 -

Firmware

Debug Version

BC3150 BC5150 BC5250 BC8150 -

F_ReadDebugTimer F_StartDebugTimer -

68 Fieldbus Components

Page 71

Safety Instructions

TcBaseBX

System Task Info

VAR_GLOBAL

SystemTaskInfo : SYSTEMTASKINFOTYPE;

END_VAR

System flags are implicitly declared variables. Using the Input Assistant, a variable SystemTaskInfoArr can be found

under system variables. This variable is a field with four structures of type SYTEMTASKINFOTYPE. The structure

definition can be found in the system library. The index in this field is the task ID.

Development environment Target system type PLC libraries to be linked

TwinCAT v2.9.0 BCxx50 Controller TcBaseBCxx50.lbx

Fieldbus Components 69

Page 72

Safety Instructions

System task info type

TYPE SYSTEMTASKINFOTYPE

STRUCT

active : BOOL;

taskName : STRING(16);

firstCycle : BOOL;

cycleTimeExceeded : BOOL;

cycleTime : UDINT;

lastExecTime : UDINT;

priority : BYTE;

cycleCount : UDINT;

END_STRUCT

END_TYPE

Key

active: This variable indicates whether the task is active.

taskName: the task name.

firstCycle: during the first PLC task cycle, this variable has the value TRUE.

cycleTimeExceeded: this variable indicates whether the set task cycle time was exceeded.

cycleTime : set task cycle time in multiples of 100 ns.

lastExecTime: cycle time required for the last cycle in multiples of 100 ns.

priority: set task priority.

cycleCount: cycle counter.

Development environment Target system type PLC libraries to be linked

TwinCAT v2.9.0 BCxx50 Controller TcBaseBCxx50.lbx

70 Fieldbus Components

Page 73

Safety Instructions

System Info