Page 1

2006

-

11

-

06

PROFIBUS

Bus Terminal Controller

BC3100

Technical Hardware Documentation

Version 2.1

Page 2

Foreword

Contents

Foreword 3

Notes on the documentation 3

Safety Instructions 4

Basic information 5

The Beckhoff bus terminal system 5

The interfaces 7

The operating modes of the bus coupler 9

Mechanical construction 10

Electrical data 12

The peripheral data in the process image 13

Commissioning and diagnostics 15

Run and reaction times 17

Memory requirement 18

PROFIBUS-DP basics 19

Introducing the system 19

PROFIBUS DP 19

The transfer medium: plugs and cables 24

Configuration of the masters 26

PROFIBUS bus terminal controller BC3100 29

Parameterization 29

Configuration 32

Auto-configuration 32

Diagnostics 35

Data exchange 37

Other DP services 39

Acyclic DPV1 services 39

Annex 42

Example: a process image in the bus terminal controller 42

Representation of analog signals in the process image 46

Assignment of terminals in the integrated PLC 47

Support and Service 51

Beckhoff Headquarters 51

2 BC3100

Page 3

Foreword

Foreword

Notes on the documentation

This description is only intended for the use of trained specialists in control and automation engineering

who are familiar with the applicable national standards. It is essential that the following notes and

explanations are followed when installing and commissioning these components.

Liability Conditions

The responsible staff must ensure that the application or use of the products described satisfy all the

requirements for safety, including all the relevant laws, regulations, guidelines and standards.

The documentation has been prepared with care. The products described are, however, constantly under

development. For that reason the documentation is not in every case checked for consistency with

performance data, standards or other characteristics. None of the statements of this manual represents a

guarantee (Garantie) in the meaning of § 443 BGB of the German Civil Code or a statement about the

contractually expected fitness for a particular purpose in the meaning of § 434 par. 1 sentence 1 BGB. In

the event that it contains technical or editorial errors, we retain the right to make alterations at any time

and without warning. No claims for the modification of products that have already been supplied may be

made on the basis of the data, diagrams and descriptions in this documentation.

Delivery conditions

In addition, the general delivery conditions of the company Beckhoff Automation GmbH apply.

Copyright

©

This documentation is copyrighted. Any reproduction or third party use of this publication, whether in

whole or in part, without the written permission of Beckhoff Automation GmbH, is forbidden.

BC3100

3

Page 4

Foreword

i

Safety Instructions

State at Delivery

All the components are supplied in particular hardware and software configurations appropriate for the

application. Modifications to hardware or software configurations other than those described in the

documentation are not permitted, and nullify the liability of Beckhoff Automation GmbH.

Description of safety symbols

The following safety symbols are used in this documentation. They are intended to alert the reader to the

associated safety instructions..

This symbol is intended to highlight risks for the life or health of personnel.

Danger

This symbol is intended to highlight risks for equipment, materials or the

Attention

environment.

Note

This symbol indicates information that contributes to better understanding.

4

BC3100

Page 5

Basic information

Basic information

Up to 64 bus terminals

each with 2 I/O channels

for any form of signal

Decentralized wiring of the

I/O level

IPC as control unit

Bus terminal controllers for

all current bus systems

Standard C rail assembly

Modularity

Display of channel status

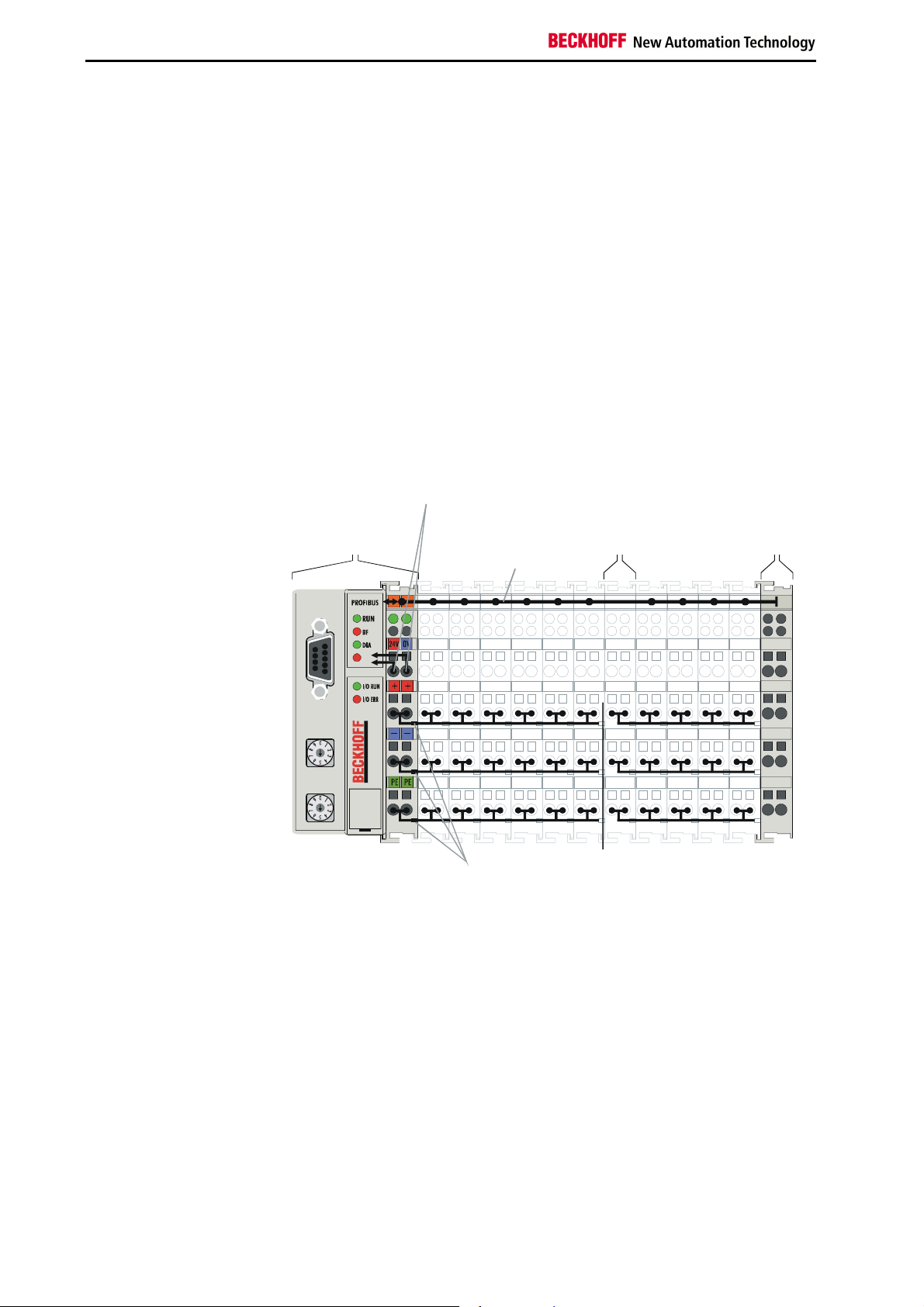

The Beckhoff bus terminal system

The bus terminal system is the universal connecting link between a

fieldbus system and the sensor/actor level. A unit consists of a bus terminal

controller or a bus coupler, which is the interface to the fieldbus, and up to

64 electronic terminals, of which the last is an end terminal. Terminals,

each with two I/O channels, are available for any form of technical signal

and can be combined as desired. The various types of terminal are all

constructed in the same way, so that the planning costs are kept extremely

low. The height and depth of the construction are calculated for compact

terminal cabinets.

Fieldbus technology makes it possible to use compact control

architectures. The I/O level does not need to be taken right up to the

control unit. Sensors and actors can be connected decentrally with minimal

lengths of cable. You can position the control unit at any convenient

location in the installation. Using an industrial PC as control unit makes it

possible to implement the operating and monitoring element as part of the

control hardware, so the control unit can be located on an operating desk,

control point or similar. The bus terminals constitute the decentralized

input/output level of the control unit in the switch cabinet and its

subordinate terminal cabinets. As well as the sensor/actor level, the power

unit of the equipment is also controlled via the bus system. The bus

terminal replaces a conventional terminal as the cabling level in the switch

cabinet; the switch cabinet can be made smaller.

The Beckhoff bus terminal system combines the advantages of a bus

system with the functionality of compact terminals. Bus terminals can be

used on all current bus systems and serve to reduce the diversity of parts

in the control unit, while behaving like the conventional standard units for

the relevant bus system and supporting the entire range of functionality of

the bus system.

The simple and compact assembly on a standard C rail, and the direct

cabling of actors and sensors without cross connections between the

terminals, serve to standardize the installation, as does the uniformly

designed labeling.

The small size and great flexibility of the bus terminal system mean that

you can use it anywhere that you could use a terminal and use any type of

connection – analog, digital, serial or direct sensors.

The modular construction of the terminal row, using bus terminals with

various functions, limits the number of unused channels to at most one per

function. Two channels to a terminal is the optimum solution for the number

of unused channels and the cost per channel. The possibility of using

power input terminals to provide separate power supplies also helps to

minimize the number of unused channels.

The integrated light-emitting diodes close to the sensor/actor indicate the

status of each channel.

BC3100

5

Page 6

Basic information

Bus end

isolation

contacts

Profibus

The K-bus

End terminal

Power input terminals

for

separately powered groups

The principle of the bus

terminal

The K-bus is the path taken by data within the terminal row. The bus

terminal controller carries the K bus through all the terminals by means of

six contacts on the side walls of the terminals, and the end terminal

terminates the K bus. The user does not need to know anything about the

function of the K bus or the internal operation of terminals and bus terminal

controllers. There are numerous software tools available which provide for

convenient planning, configuration and operation.

Three power contacts pass the operating power to the following terminals.

You can use power input terminals to subdivide the terminal row as desired

into groups, each with a separate power supply. These power input

terminals are not taken into account for addressing the terminals, you can

insert them at any position along the terminal row.

You can install up to 64 terminals on a terminal row, including power input

terminals and the end terminal.

Bus terminal

controller

BC3100

Powersupply Potential

for the input

BC3100 terminal

terminal

K- bus

x1

x10

BC3100

PotentialPower

Additional characteristics of

the bus terminal controllers

Bus terminal controllers for

various field bus systems

6

The bus terminal controllers (BC) differ from the bus couplers (BK) by

virtue of the fact that a real time PLC task runs in addition to processing of

the K-bus. Contrary to the bus couplers, by default the signals of the

terminals are processed by the PLC task while inputs and outputs of the

PLC task are then transmitted through the field bus. It is possible, however,

to split up terminals so that some terminals are preprocessed by the PLC

task, while others are forwarded directly via the field bus to the higher-level

system.

Various bus terminal controllers can be used to link the electronic terminal

strip with an integrated PLC task swiftly and easily to diverse field bus

systems. Later conversion to a different field bus system is also possible.

The bus terminal controller assumes all checking and control tasks that are

needed for operation of the connected bus terminals. The bus terminals

are operated and configured exclusively via the bus terminal controller. The

field bus, the K-bus and the I/O level are electrically isolated.

BC3100

Page 7

Basic information

02

01

+

4

3

2

1

Power LEDs

Bus coupler / power contacts

The PLC task continues running as an autonomous system if the exchange

of data via the field bus should temporarily fail.

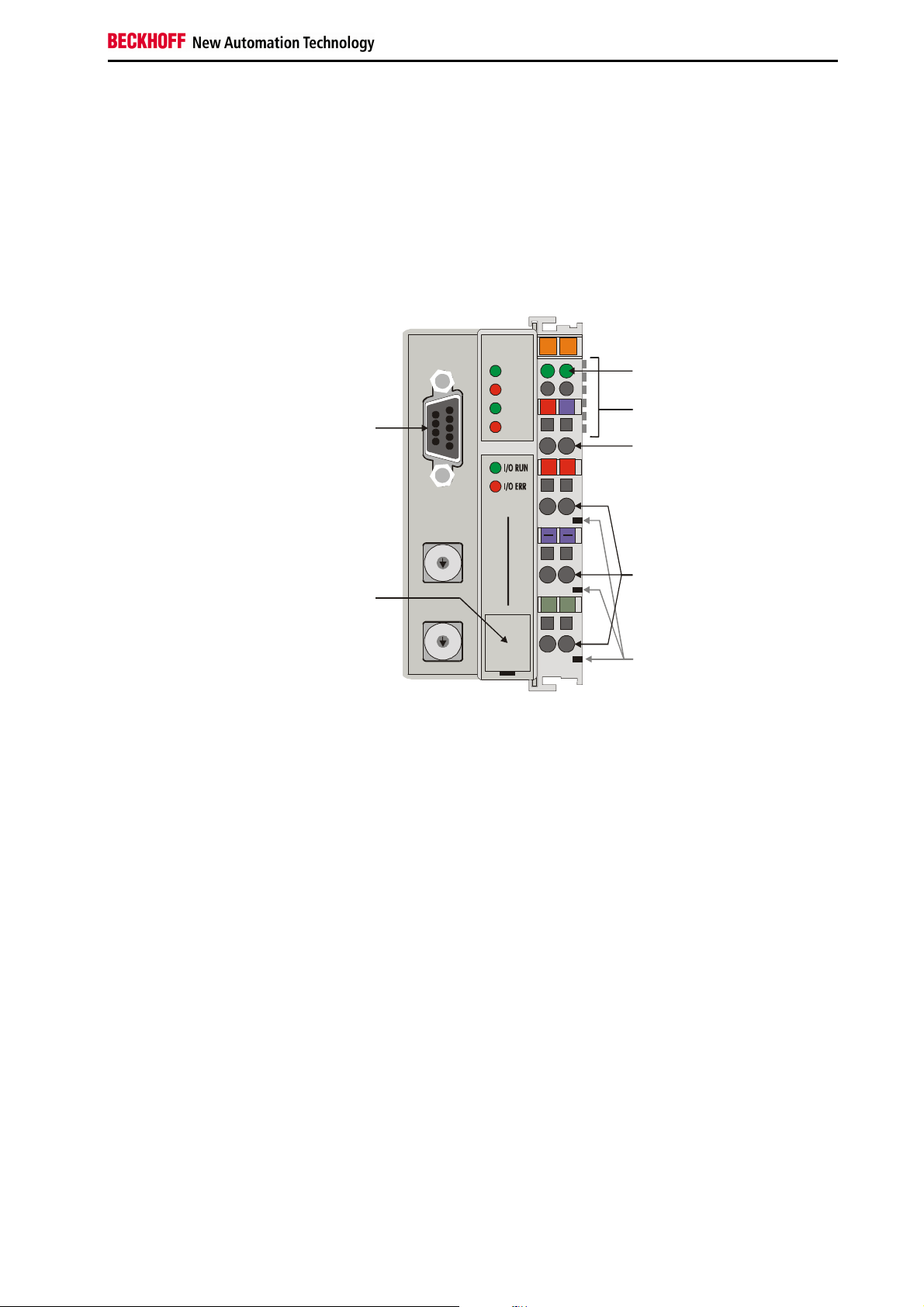

The interfaces

There are six ways of making a connection to a bus terminal controller.

These interfaces are designed as plug connections and spring terminals.

The Profibus controller

BC3100

PROFIBUS

RUN

BF

DIA

24V

00X0

0V

K-bus

Profibus

Power supply bus coupler

+

24 V DC / GND

x1

0

1

9

2

8

3

7

4

6

x10

0

9

8

7

6

5

BECKHOFF

BC3100

PE PE

5

Configuration

port

24 V DC on the topmost

terminals

Power supply

The bus terminal controllers need an operating power of 24 V DC which is

connected via the topmost spring terminals, labeled "24 V“ and "0 V“. This

power supply serves not only the electronic components of the bus

terminal controller but (via the K bus) also the bus terminals. The power

supply of the bus terminal controller circuitry and that of the K-bus

(Terminal bus) are electrically isolated from the voltage of the field level.

Lower 3 terminal pairs for

power input

maximum 24 V

maximum 10 A

Power supply to the power contacts

The six lower connections with spring terminals can be used to supply

power to the peripherals. The spring terminals are connected in pairs to the

power contacts. The power supply to the power contacts has no

connection to the power supply of the bus couplers. The power input is

designed to permit voltages up to 24 V. The pair-wise arrangement and the

electrical connection between the feed terminal contacts makes it possible

to loop through the wires connecting to different terminal points. The load

on the power contact may not continuously exceed 10 A. The current

capacity between two spring terminals is the same as the capacity of the

connecting wires.

Spring contacts at the side

Power contacts

On the right-hand side face of the BC3100 are three spring contacts which

are the power connections. The spring contacts are recessed in slots to

prevent them from being touched. When a bus terminal is connected, the

blade contacts on the left-hand side of the bus terminal are connected to

BC3100

the spring contacts. The slot and key guides at the top and bottom of the

Input

power contacts

power contacts

7

Page 8

Basic information

bus terminal controller and bus terminals ensure reliable location of the

power contacts.

9-pin Sub-D female

connector

Serial interface under the

front flap

6 contacts at the side

3 supply groups:

fieldbus

K-bus

peripheral level

Fieldbus connection

On the left-hand side there is a flat recessed area where you can plug in

the typical Profibus male connectors. You will find a detailed description of

the fieldbus interfaces in another part of this manual (In the chapter "The

transfer medium: plugs and cables“).

Configuration interface

On the bottom side of the front area, the bus terminal controllers are

equipped with an RS 232 interface. The miniature connector can be

connected to a PC with a connecting cable and the KS2000 configuration

software. The interface permits configuration of the analog channels.

Depending on the scope of performance of the field bus, this functionality

can also be realized with field bus-specific functions.

The miniature connector also serves to connect to the TwinCAT PLC

programming environment on a PC. It is used to load, start and stop the

program, breakpoints are set and the program is run in the STEP mode

etc.

Depending on the scope of performance of the field bus and the availability

of a corresponding TwinCAT field bus interface, this functionality can also

be realized via the field bus, with the result that several bus terminal

controllers that are physically connected to the same field bus can be

operated without replugging an RS 232 connection. This feature is

currently not yet supported by TwinCAT.

K-bus contacts

The connections between the BC3100 and the bus terminals are effected

by gold contacts at the right-hand side of the bus terminal controller. When

the bus terminals are plugged together, these gold contacts automatically

complete the connection to the bus terminals. The K-bus is responsible for

the power supply to the electronic components of the K-bus in the bus

terminals, and for the exchange of data between the BC3100 and the bus

terminals. Part of the data exchange takes place via a ring structure within

the K-bus. Disengaging the K bus, for example by pulling on one the bus

terminals, will break this circuit so that data can no longer be exchanged.

However, there are mechanisms in place which enable the bus terminal

controller to locate the interruption and report it.

Supply isolation

The BC3100 operate with three independent supplies. The input power

supplies the electrically isolated K-bus circuitry in the bus terminal

controller and the K-bus itself. The power supply is also used to generate

the operating power for the fieldbus.

Note: All the bus terminals are electrically isolated from the K bus, so that

the K-bus is completely electrically isolated.

8

BC3100

Page 9

Basic information

Periphery level

Bus terminals

Bus coupler

24 V DC

Bus terminal test Structure list

Setting up the power levels

in the bus terminal system

K-bus

Field bus

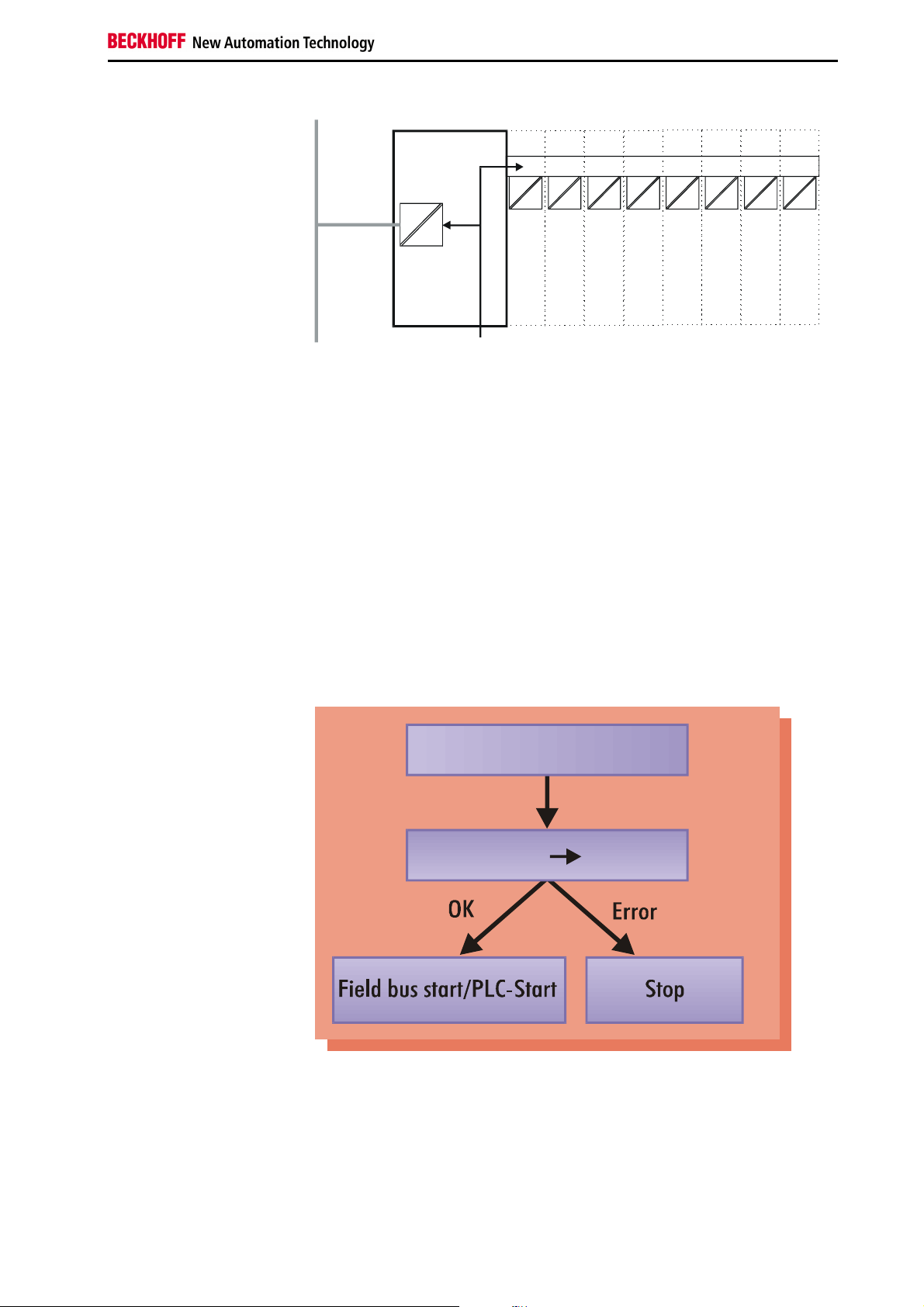

Start-up behavior of the bus

terminal controller

The operating modes of the bus coupler

After power on, in a "self-test" the bus terminal controller checks all

functions of its components and communication by the K-bus. The red I/O

LED flashes during this phase. After successful completion of the self-test,

the bus terminal controller begins to test the plugged in bus terminals (bus

terminal test) and reads the configuration. An internal structure list is

created on the basis of the bus terminals' configuration. The bus terminal

controller assumes the "STOP" operating state in the event of an error.

After error-free start up, the bus terminal controller assumes the "field bus

start/PLC start" state. If a PLC program is stored in the flash memory, it is

loaded and started regardless of whether the field bus is running. The

inputs of the PLC task have been set to zero during start up.

Power on selftest

BC3100

Depending on the field bus functionality, the bus terminal controller reports

a possible error via the field bus. The BC3100 generally has to be restarted

after the error has been remedied.

9

Page 10

Basic information

020201

01

+++

+

PEPEPE

PE

RUN

DIA

24V

4

3

2

1

0

0

47

12

X1

Mechanical construction

The Beckhoff bus terminal system is remarkable for its compact

construction and high degree of modularity. When you design the

installation you will need to plan for one bus terminal controller and some

number of bus terminals. The dimensions of the bus terminal controller do

not depend on the fieldbus system. If you use large plugs, for example like

some of the bus plugs used for the Profibus, they may protrude above the

overall height of the cabinet.

Dimensions of a bus

terminal controller

PROFIBUS

BF

24V

0V 0V

94

0

1

9

2

8

3

7

4

6

5

BECKHOFF

X10

0

1

9

8

7

6

5

The overall width of the construction is the width of the BC3100, including

the bus end terminal, plus the width of the installed bus terminals. The bus

terminals are 12 mm or 24 mm wide, depending on their function.

Depending on the gauge of cables used the overall height of 68 mm may

be overstepped by about 5 mm to 10 mm by the cables at the front.

Assembly and connections

It takes only a slight pressure to latch the bus terminal controller and the

various bus terminals onto a supporting 35mm C rail and a locking

mechanism then prevents the individual housings from being removed.

You can remove them without effort if you first release the latching

mechanism by pulling the orange tab. You should carry out work on the

bus terminals and the bus terminal controller only while they are switched

off: if you plug or unplug components while the power is on you may briefly

provoke some undefined state (and, for instance, reset the bus coupler).

You can attach up to 64 bus terminals in series on the right-hand side of

the BC3100. When you assemble the components, make sure that you

mount the housings so that each slot comes together with the

corresponding key. You cannot make any functional connections merely by

pushing the housings together along the supporting track. When they are

correctly mounted there should be no appreciable gap between the

adjacent housings.

The right-hand side of a BC3100 is mechanically similar to a bus terminal.

There are eight connections on the top which can be used to connect to

thick-wire or thin-wire lines. The connection terminals are spring loaded.

BC3100

10

BC3100

Page 11

Basic information

Insulation test

PE power contacts

You open a spring terminal by applying a slight pressure with a screwdriver

or other pointed tool in the opening above the terminal and you can then

insert the wire into the terminal without any obstruction. When you release

the pressure the terminal will automatically close and hold the wire

securely and permanently.

The connection between bus terminal controller and bus terminals is

automatically effected by latching the components together. The K bus is

responsible for passing data and power to the electronic components of the

bus terminals. In the case of digital bus terminals, the field logic receives

power via the power contacts. Latching the components together has the

effect that the series of power contacts constitutes a continuous power

track. Please refer to the circuit diagrams of the bus terminals: some bus

terminals do not loop these power contacts through, or not completely (e.g.

analog bus terminals or 4-channel digital bus terminals). Each power input

terminal interrupts the series of power contacts and constitutes the

beginning of a new track. The bus terminal controller can also be used to

supply power to the power contacts.

The power contact labeled "PE“ can be used as protective earth or ground.

This contact stands proud for safety reasons and can carry short-circuit

currents of up to 125A. Note that in the interests of electromagnetic

compatibility the PE contacts are capacitively connected to the supporting

track. This may lead to spurious results and even damage to the terminal

when you test the insulation (e.g. insulation test for breakdown using a

230V mains supply to the PE line). You should therefore disconnect the PE

line on the bus coupler while you carry out insulation tests. You can

disconnect other power supply points for the duration of the test by drawing

the power supply terminals out from the remaining row of terminals by at

least 10mm. If you do this, there will be no need to disconnect the PE

connections.

The protective earth power contact ("PE“) may not be used for any other

connections.

BC3100

11

Page 12

Basic information

Electrical data

The electrical data specific to the field bus is listed in this chapter. The

following table shows the data in an overview:

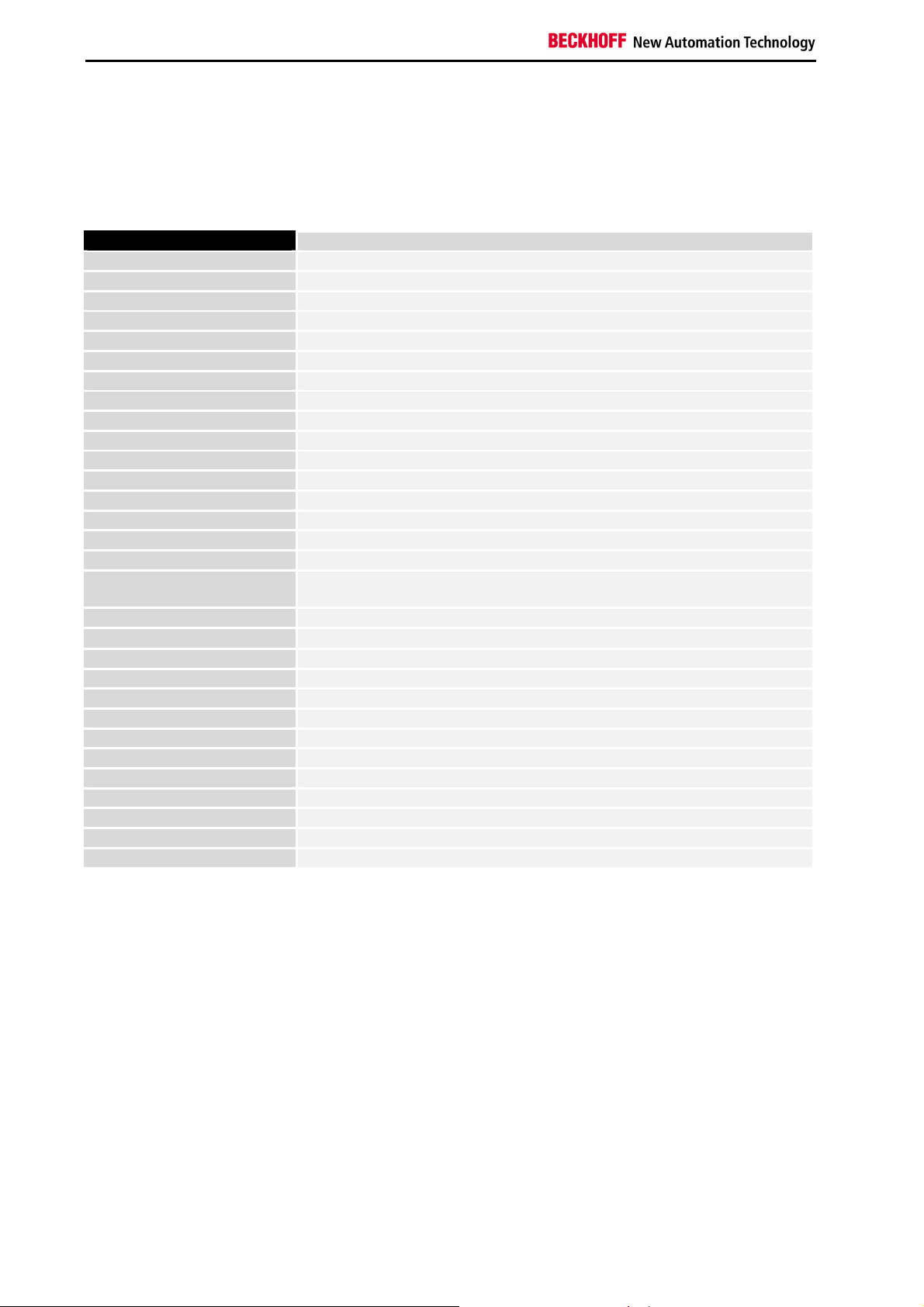

Technical data’s BC3100

Number of bus terminals

Digital peripheral signals

Analog peripheral signals

Maximum number of bytes

Programming possibility

Program size

Program memory

Data memory

Permament flags

Run time system

PLC cycle time

Programming languages

Field bus interface

Baud rates

Bus connection

Power supply

Input current

Power-on current

Recommended fuse

K-bus power supply up to

Power contact voltage

Power contact current load

Diaelectric strength

Operating temperature

Storage temperature

Relative humidity

Vibration/shock resistance

EMC/emssion

Installed position

Degree of protection

64

256 inputs/outputs

128 inputs/outputs

512 bytes I and 512 bytes O

via programming interface (TwinCAT BC) or Profibus-DP (TwinCAT)

approximately 3000 plc statements

32 kbytes

32 kbytes

512 bytes

1 PLC task

approximately 3 ms for 1000 commands (including K-bus I/O cycle)

IL, LAD, CSF, SFC, ST

Profibus-DP

automatic baud rate detection up to 12 MBaud

1 x D-sub connector, 9-pole, with screen

24 V DC, (20...29 V DC)

70 mA + (total K-bus current/4

500 mA max.

2.5 x continuous current

≤ 10 A,

1750 mA

24 V DC max.

10 A max.

500 Vrms (Power contact/supply voltage/field bus)

0°C ... +55°C

-25°C ... +85°C

95%, no condensation

in accordance withIEC 68-2-6 / IEC 68-2-27

in accordance with EN 50082 (ESD, Burst) / EN 50081

any

IP20

Current consumption on the

K-Bus

For operation of the K-bus electronics, the bus terminals require energy

from the K-bus that is supplied by the bus terminal controller. Refer to the

catalog or the corresponding data sheets of the bus terminals for details of

the K-bus current consumption. In doing so, pay attention to the maximum

output current of the bus terminal controller that is available for powering

the bus terminals. Using a special power supply terminal (KL9400), power

can be fed back into the K-bus at any chosen point. If you wish to use a

power supply terminal, please contact Beckhoff’s technical support.

12

BC3100

Page 13

Basic information

The peripheral data in the process image

After power on, the BC3100 determines the configuration of the plugged-in

input/output terminals. The affiliations between the physical slots of the

input/output channels and the addresses of the process image are defined

automatically or by programming by the bus terminal controller depending

on the settings via the configuration interface. If these affiliations are

programmed, digital and analog signals can be distributed channel by

channel in any order to the process image of the PLC task (global variables

%I* (inputs) and %Q* (outputs)) or of the field bus (process data that is

transferred through the field bus). The setting is defined manually with the

configuration interface or, depending on the field bus functionality of the

bus terminal controller, with the TwinCat System Manager at the variable

level.

By default, automatic allocation is set for the bus terminal controllers. This

is described below:

The BC3100 creates an internal allocation list in which the input/output

channels have a specific position in the process image. Here, a distinction

is made according to inputs and outputs and according to bit-oriented

(digital) and byte-oriented (analog or complex) signal processing.

Two groups with only inputs and only outputs each are formed. The byteoriented channels are located in ascending order at the lowest address in

one group. The bit-oriented channels are located after this block.

Digital signals

(bit-oriented)

Digital signals are bit-oriented. This means that one bit of the process

image is assigned to each digital channel. The bus terminal controller sets

up a block of memory containing the current input bits and arranges to

immediately write out the bits from a second block of memory which

belongs to the output channels.

The precise assignment of the input and output channels to the process

image of the control unit is explained in detail in the Appendix by means of

an example.

Analog signals

(byte-oriented)

The processing of analog signals is always byte-oriented and analog input

and output values are stored in memory in a two-byte representation. The

values are held as "SIGNED INTEGER“ or "twos-complement“. The digit

"0“ represents the input/output value "0V“, "0mA“ or "4mA“. When you use

the default settings, the maximum value of the input/output value is given

by "7FFF“ hex. Negative input/output values, such as -10V, are

represented as "8000“ hex and intermediate values are correspondingly

proportional to one another. The full range of 15-bit resolution is not

realized at every input/output level. If you have an actual resolution of 12

bits, the remaining three bits have no effect on output and are read as "0“

on input. Each channel also possesses a control and status byte in the

lowest value byte. If the control/status byte is mapped in the control unit

has to be configured in the master configuration software. An analog

channel is represented by 2 bytes user data in the process image.

Special signals and

interface

A bus terminal controller supports bus terminals with additional interfaces,

such as RS232, RS485, incremental encoder, etc.. These signals can be

regarded in the same way as the analog signals described above. A 16-bit

data width may not be sufficient for all such special signals; the bus coupler

can support any data width.

Word Alignment

The analog or special signals are mapped with word alignment when the

peripheral signals are allocated into the process image of the PLC task

BC3100

13

Page 14

Basic information

and, depending on the field bus, into the process image.

Process image allocation

By default, all terminals are allocated to the process image of the PLC task

(beginning with the address %Q*0 or %I*0) but, via the configuration

interface, the peripheral signals can also be allocated terminal by terminal

to the field bus process image, with the result that they would be

transmitted directly via the field bus without pre-processing by the PLC

task.

Default assignment of

inputs and outputs to the

process image

When the BC3100 is first switched on it determines the number of attached

bus terminals and sets up a list of assignments. This list distinguishes

between analog channels and digital channels and between input and

output; which are grouped separately. The assignments begin immediately

to the left of the BC3100. The software in the bus coupler creates the

assignment list by collecting the entries for the individual channels one at a

time, counting from left to right. These assignments distinguish four groups:

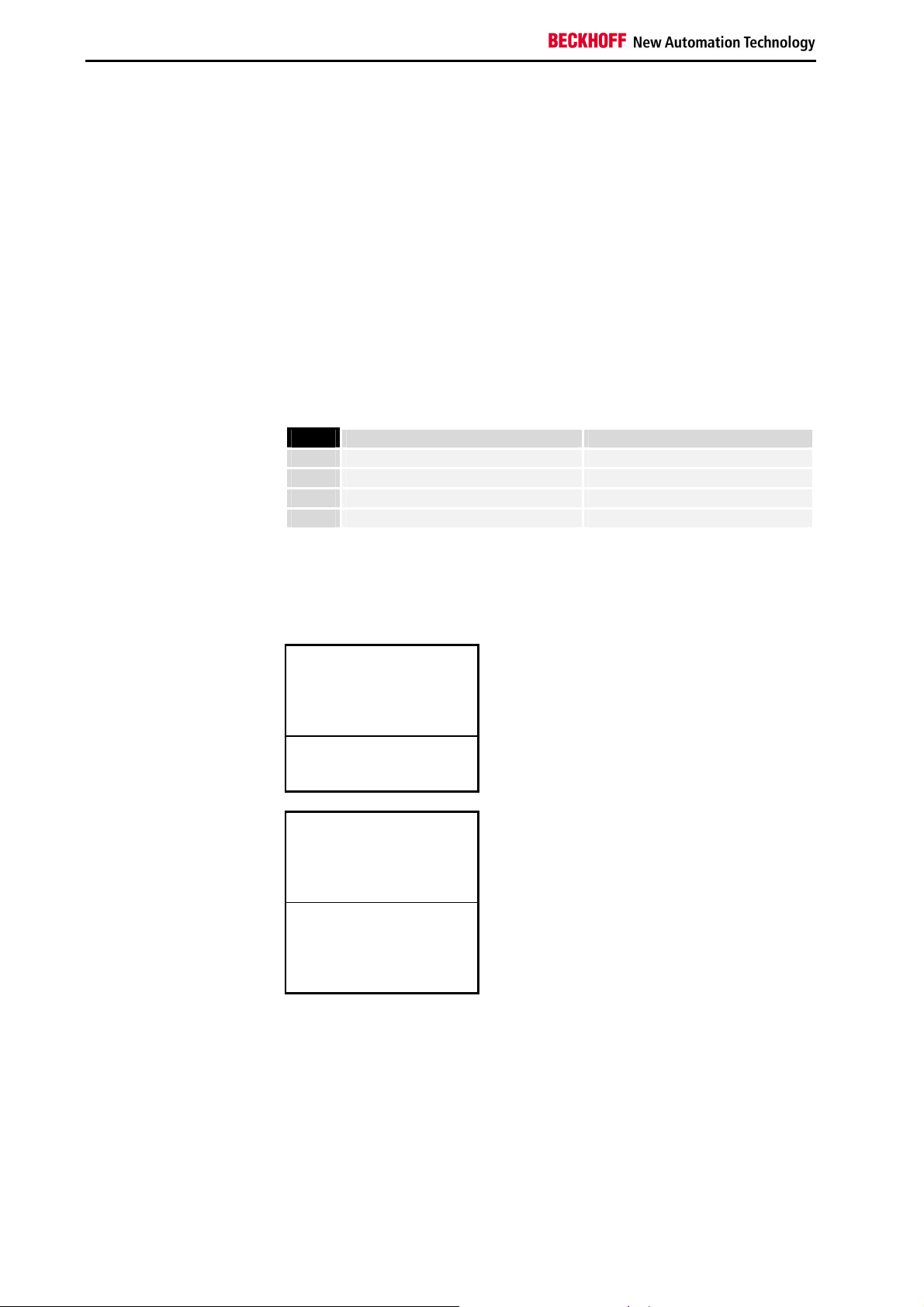

Function type of the channel Assignment level

1.

Analog outputs byte-wise assignment

2.

Digital outputs bit-wise assignment

3.

Analog inputs byte-wise assignment

4

Digital inputs bit-wise assignment

Analog inputs/outputs are representative of other complex multi-byte signal

bus terminals (RS232, SSI sensor interface, ...)

Output data in the BC3100

Overview of the subdivision of the process image in the BC3100

O0

...

byte-oriented data

...

Ox

Ox+1

bit-oriented data

Ox+y

Input data in the BC3100

I0

...

byte-oriented data

...

Ix

Ix+1

...

bit-oriented data

...

Ix+y

Assignment of the process

image of the PLC task to

the field bus process image

Depending on the setting, the affiliations between the inputs and the

outputs of the PLC task and the field bus process image are defined

automatically by the BC3100 via the configuration interface or by

programming. When assignments are programmed, inputs and outputs can

be distributed bit by bit in any order to the field bus process image. This is

set manually with the configuration interface or, depending on the field bus

functionality of the bus terminal controller, with the TwinCAT System

Manager at the variable level.

By default, automatic assignment is set for the bus terminal controllers. In

this case, one coherent area each of the inputs or outputs of the PLC task

can be mapped into the field bus process image. The initial offset and

14

BC3100

Page 15

Basic information

length of the area to be mapped can be set by way of the configuration

interface. As the terminal signals are placed into the process image of the

PLC task as from address zero, the first meaningful offset as from when

inputs and outputs of the PLC task are mapped into the field bus process

image is the first free address where there are no longer any terminal

signals.

Data consistency

Processing complex signals

Data which contains no contradictions is said to be consistent. The

following consistency is required here: 1. The high byte and low byte of an

analog value (word consistency), 2. The control/status byte and the

corresponding parameter word for accessing the register. The interaction

of the peripherals with the control unit means that data can initially be

guaranteed consistent only within an individual byte: the bits which make

up a byte are read in together, or written out together. Byte-wise

consistency is quite adequate for processing digital signals but is not

sufficient for transferring values longer than eight bits, such as analog

values. The various bus systems guarantee consistency to the required

length. It is important to use the appropriate procedure for importing this

consistent data from the master bus system to the control unit. You will find

a detailed description of the correct procedure in the User Guide of the

appropriate bus system, in particular in the description of the standard

master units that are installed. The chapters of this manual which deal with

the fieldbus refer to the most common of these standard units.

All byte-oriented signal channels such as RS232, RS485 and incremental

encoder, can use byte lengths greater than two. Apart from the actual

difference in length, the procedure is always comparable with that for

analog signals.

Commissioning and diagnostics

The diagnostic LEDs

After power on, the bus terminal controller immediately checks the

connected configuration. Error-free start up is signalled by virtue of the fact

that the red "I/O ERR" LED goes off. When it flashes, the "I/O ERR" LED

indicates an error in the area of the terminals. The error code can be

determined by the frequency and number of flashes. This enables swift

troubleshooting.

The bus terminal controller has two groups of LEDs to provide a status

display. The top group consisting of four LEDs indicates the status of the

respective field bus. The meanings of the "field bus" status LEDs are

explained in the corresponding chapters of this manual. They correspond

to the usual field bus displays.

There are two further green LEDs on the top right hand side of the bus

terminal controller to indicate the supply voltage. The left hand LED

indicates the 24 V power supply of the bus terminal controller. The right

hand LED signals the power supply of the Power contacts.

BC3100

15

Page 16

Basic information

Local errors

Two LEDs, the "I/O Leds" in the area under the above-mentioned field bus

status LEDs, serve to indicate the operating states of the bus terminals and

of the connection to these bus terminals. The green LED lights up

whenever the signals to the terminals are being exchanged via the K-bus.

After an error-free start up of the bus terminal controller, the K-bus

exchange always takes place, even if the PLC program or the field bus is

not running. The reaction (inputs or outputs change to zero or remain

unchanged) to errors (field bus not running correctly or PLC task has

assumed the STOP state) can be set via the configuration interface. To

indicate errors, the red LED flashes at two different frequencies. Errors are

encoded as follows in the flashing code:

Fast flashing

First slow sequence

Second slow sequence

Error code Error argument Description

1 pulse

2 pulses

3 pulses

4 pulses

5 pulses

6 pulses

8 pulses

9 pulses

0

1

2

0

n (n > 0)

0 Terminal bus command error

0

n

n Terminal bus error during register

0

p(p>0)

0

p(p>0)

0

The number of pulses (n) indicates the position of the last bus terminal

before the error. Passive bus terminals, for example an infeed terminal, are

not counted.

In the case of some errors, the bus terminal controller does not end the

flashing sequence when the error has been remedied. The bus terminal

controller's operating state is still "Stop". The bus terminal controller can

only be restarted by switching the supply voltage off and on or by means of

a software reset.

It is only permitted to unplug bus terminals from the network and to plug

them in again after switching off. The electronic circuitries of the bus

terminals and of the bus terminal controller are largely protected against

destruction, but malfunctions and damage cannot be ruled out if terminals

are plugged together under a live voltage.

The occurrence of an error during ongoing operation does not immediately

trigger output of the error code via the LEDs. The bus terminal controller

must be prompted to diagnose the bus terminals. The diagnostic request is

generated after power on.

Start of the error code

Error code

Error argument

EEPROM checksum error

Inline code buffer overflow

Unknown data type

Programmed configuration

Invalid table entry/

Bus terminal controller

Invalid table comparison (terminal n)

Terminal bus data error

Breakage after terminal n (0: BC3100)

communication with terminal n

Not enough DP-Cfg_Data received

Invalid DP-Cfg_Data byte

Not enough DP-User_Prm_Data received

Invalid DP-User_Prm_Data byte

Invalid checksum in the

PLC program

16

BC3100

Page 17

Basic information

Field bus error

PLC-RUN

PLC program in flash

memories

Cycle time of the PLC task

K-bus reaction time

The red BF LED on the bus terminal controller lights up whenever the

BC3100 is not participating in the Profibus-DP exchange of data.

The Green RUN LED on the bus terminal controller lights up whenever the

PLC task is in the RUN state.

When the PLC program is downloaded with the TwinCAT PLC

programming environment, the program is initially stored only in the RAM.

The program is transferred from the RAM to the flash memory by means of

the Online -> Create a boot project command. The red DIA LED on the bus

terminal controller goes on during this storage operation.

Run and reaction times

The PLC task is called up cyclically and time-controlled, whereby the cycle

time can be set via the configuration interface (default time: 5 ms). The

minimum cycle time is 1 ms. 20% of the timing resources should be

reserved for execution of the background processes. The PLC task's run

time is composed of the data exchange via the K-bus, the operating

system of the PLC task and the actual PLC program.

The PLC task's run time can be measured with the KS2000 configuration

software. The nominal cycle time and the time for background execution

can then be set on the basis of this measurement.

The reaction time on the K-bus is determined by shifting and saving of the

data. The following table contains measured values for typical setups. It is

possible to extrapolate to larger numbers.

Terminals inserted on the bus terminal

Digital

OUT

4 0 0 150

8 0 0 170

12 0 0 170

16 0 0 200

20 0 0 200

24 0 0 220

28 0 0 220

32 0 0 245

0 4 0 150

0 8 0 180

0 12 0 180

0 16 0 200

0 20 0 200

0 24 0 230

0 28 0 230

0 32 0 250

4 4 0 170

8 8 0 195

12 12 0 220

16 16 0 250

20 20 0 275

24 24 0 300

28 28 0 325

32 32 0 350

4 4 1 (KL3202) 630

4 4 2 (KL3202) 700

controller

Digital

IN

Analog

IN/OUT

Run time on the K-bus

T_cycle

(us)

BC3100

17

Page 18

Basic information

Memory requirement

Memory requirement for

various PLC commands

The PLC task currently has 32 kbytes each for program and data memory.

The memory requirement for a number of PLC commands is given below:

Command / Library Code Data Comment

32k available 32k RAM available

Overhead

BITFUN.LIB

CONVERT.LIB

COUNTER.LIB

MATH.LIB

STDFB.LIB

STRING.LIB

TIMER.LIB

TRIGONOM.LIB

LD/ST Byte variable

LD /ST Word variable

LD /ST Dword variable

ADD Byte variable

ADD Word variable

ADD Dword variable

SHL / ROL Byte variable

SHL / ROL Word variable

SHL / ROL Dword

variable

1k 6,5k

0 0 Created INLINE

0 0 Created INLINE

1.5k 0

-- -- Not yet available

1k 0

2.5k 0

1.5k 0

-- -- Not yet available

4

4

8

6

6

16

6

6

-- Not yet available

18

BC3100

Page 19

PROFIBUS-DP basics

System configurations and

device types

PROFIBUS-DP basics

Introducing the system

The PROFIBUS enjoys a very wide acceptance in automation technology

due to its openness and its wide manufacturer-independent distribution.

The PROFIBUS was developed in the course of a group project on the

fieldbus concept which aimed at agreeing on a standard. Numerous

different products are now available from independent manufacturers

which all conform to the standard DIN 19245 parts 1 and 2. Standardsconform PROFIBUS devices can be operated on any bus system.

PROFIBUS specifies the technical and functional characteristics of a serial

fieldbus system which can be used to network distributed digital and

analog field automation devices with low range (sensor/actuator level) to

midrange performance (cell level). PROFIBUS makes a distinction

between master and slave devices; master devices are those which govern

the data traffic on the bus.

A master may send messages without an external request, provided it has

the authority to access the bus. The PROFIBUS protocol also describes

masters as "active stations“.

Slave devices are peripheral devices. Typical slave devices are sensors,

actuators, transducers and Beckhoff bus couplers or bus terminal

controllers. They are not assigned any bus access privileges, i.e. they may

only acknowledge received messages or send messages to a master at its

request. Slaves are also referred to as passive stations.

PROFIBUS DP

PROFIBUS DP is designed for rapid data exchange at sensor/actor level,

where centralized control devices (such as stored program control units)

communicate with decentralized input and output devices by means of a

fast serial connection. The exchange of data with these decentralized

devices is carried out predominantly cyclically. The centralized control unit

(master) reads the input data from the slaves and writes the output data to

the slaves, whereby the cycle time of the bus needs to be shorter than the

program cycle time of the central control unit, which will be under 10 ms in

many applications.

Rapid data throughput alone is not sufficient for the successful

implementation of bus system. Ease of handling, good diagnostic facilities

and fault-proof data transfer technology must all be provided in order to

fulfill the users’ requirements. The characteristics have been optimally

combined in PROFIBUS DP.

At a data transfer rate of 12 Mbits/s, Profibus-DP needs less than 2 ms to

transfer 512 bits of input data and 512 bits of output data distributed to 32

stations. This meets the requirement for a short system reaction time.

You can use PROFIBUS DP to implement mono-master or multi-master

systems, which gives you a high degree of flexibility as regards the system

configuration. Up to 126 miscellaneous devices (master or slaves) can be

BC3100

19

Page 20

PROFIBUS-DP basics

attached to one bus. The bus couplers BK3xx0 permit you to select a

station address between 0 and 99. The quantities specified in the system

configuration include the number of stations, the assignments of station

addresses to I/O addresses, the consistency of the I/O data, the format to

be used for diagnostic messages and bus parameters that are to be used.

Each PROFIBUS DP system is made up of a number of different types of

device. We distinguish three types, depending on the tasks involved:

DP master class 1 (DPM1), such as an IM308-C or TwinCAT

This is a central control unit which exchanges information with the

decentralized stations (DP slaves) in a fixed message cycle. Typical

devices include stored program control units (PLC), numeric control units

(CNC) or robot control units (RC).

DP master class 2 (DPM2)

Devices of this type are programming, planning or diagnostic devices. They

are used to configure the DP system when the equipment is set up and

taken into service.

DP slave, e.g. the bus couplers or bus terminal controllers.

A DP slave is a peripheral device (sensor/actor), which reads in input

information and passes output information to the peripherals. Devices

which only input information, or only output information, are also possible.

Typical DP slaves are devices with binary I/O ports for 24V or 230V,

analog inputs, analog outputs, counters etc.. The volume of input and

output information depends on the individual device, up to a maximum of

244 bytes for input data and 244 bytes for output data. Due to cost factors,

and for technical and implementational reasons, many of the currently

available devices operate with a maximum data length of 32 bytes. The

Profibus coupler BK3000 can use the full length of 244 bytes, although the

master unit IM308-C restricts this to 52 bytes for input data. The IM308-B

enables you to use up to 122 bytes of input data.

In a mono-master system, only one master is active on the bus during the

operating phase of the bus system. The SPS control unit is die central

control element. The DP slaves are coupled to the SPS control unit

decentrally by means of the transfer medium. This system configuration

achieves the shortest bus cycle time.

In multi-master operation there are a number of masters on a single bus.

These either constitute independent subsystems, each consisting of one

DPM1 and the corresponding DP slaves or additional planning and

diagnostic devices. All the DP masters can read the input and output

mappings of the DP slaves. Although the output can be written by only one

DP master (namely the DPM1 which was appointed when the system was

specified). Multi-master systems achieve an average bus cycle time. If

timing is critical to your application you should connect up a diagnostic tool

to monitor increases in the bus cycle time.

Device master file (GSD)

The manufacturers of PROFIBUS DP provide users with documentation

covering the performance characteristics of the devices, in the form of a

device data sheet and a device master data file. The layout, content and

coding of this device master data (the GSD) are standardized. It facilitates

convenient project planning with any desired DP slaves using planning

20

BC3100

Page 21

PROFIBUS-DP basics

devices from a variety of manufacturers. The PNO archives this information

for all manufacturers and will supply information on request about

manufacturers’ device master files.

A PROFIBUS master configuration program reads the DMF data and

transfers the appropriate settings to the master. You will find a description

of this in the relevant software manual supplied by the manufacturer of

your master.

Type file (200)

The widespread and user-friendly master interfaces for a PLC include the

IM308-C from Siemens. A COMProfibus software under Windows is

available for configuration of the master. During configuration of this master

interface for the Profibus, the features of the slave devices are documented

by the manufacturers in the form of a type file and are made available to

users as a file. The contents and coding of this type file are Siemensspecific and are supported by Beckhoff, as well as by other manufacturers.

It enables convenient configuration of any chosen DP slaves with a PC

under the user interface of Windows 3.1 and subsequent Windows

versions. GSD files, type files and bitmaps are available for the Beckhoff

bus couplers or bus terminal controllers.

The GSD or type file can be downloaded from the mailbox 0 52 46 / 96 3 45 5, AREA 15, or via the Internet (www.beckhoff.com or ftp.beckhoff.com)

or can be ordered on a diskette.

Diagnostic functions

The extensive diagnostic functions of PROFIBUS DP make it possible to

localize errors rapidly. The diagnostic messages are transferred via the bus

and collated by the master. They are subdivided into three levels:

Diagnostic type

Station-

related

Module-

related

Channel-

related

Messages dealing with the general operating condition of

a subscriber, such as overheating or low voltage

These messages indicate a diagnostic message is

pending for a subscriber within a particular I/O sub-area

(e.g. 8-bit output module)

This locates the cause of the error in an individual input/

output bit (channel), such as: short circuit on output 2

The bus couplers and bus terminal controller support the diagnostic

functions of the PROFIBUS DP. The manner in which the control unit

evaluates the diagnostic data depends on what support is given by the

master. Please refer to the device manual of your master units to see how

to handle the diagnostics. (Note for ET200U experts: the diagnostics is

device-specific, as for the ET200U; a module in the bus terminal enables

you to evaluate the diagnostics for a specific station and track it right down

to an individual channel in the bus terminal.)

Sync and Freeze Mode

In addition to the subscriber-related user data traffic, which DPM1 deals

with automatically, the DP master can also send control commands to an

individual DP slave, to a group, or to all of the slaves simultaneously; these

control commands are transferred as multicast functions. You can use

such control commands to impose the operating modes Sync and Freeze

to synchronize the DP slaves. This facility provides for an event-driven

synchronization of the slaves. They enter Sync mode when they receive a

Sync control command from their appointed DP master. In this operating

mode, the outputs from all the DP slaves are frozen in their current state. If

user data is subsequently transferred, the output data is stored at the DP

slaves, although the output status values remain unchanged. When the

next Sync control command is received from the master, the stored output

BC3100

21

Page 22

PROFIBUS-DP basics

data is switched through to the outputs. The user can terminate Sync

operation by issuing an Unsync control command.

Similarly, a Freeze control command sends the addressed DP slaves into

Freeze mode. In this operating mode, the inputs of all the DP slaves are

frozen in their current state. The input data is not updated again until the

DP master sends the next Freeze control command to the relevant

devices. You terminate Freeze operation by issuing an Unfreeze control

command.

System behavior

To ensure that the devices are largely exchangeable, the system behavior

for the PROFIBUS DP has also been standardized. It depends principally

on the operating mode of the DPM1, which can be governed either locally

or from the planning device via the bus. The following principal modes are

distinguished:

Modes

Stop

Clear

Operate

No data communication is taking place between the DPM1 and

the DP slaves.

The DPM1 reads the input information of the DP slaves and keeps

the outputs of the DP slaves in a safe state.

The DPM1 is in the data transfer phase. In a cyclic

communication, the inputs of the DP slaves are read and the

output information is transferred to the DP slaves.

The DPM1 uses a multicast command to broadcast its local status

cyclically at regular intervals to all its subordinate DP slaves (the interval

can be configured). The system’s response to an error (such as the failure

of a DP slave) which occurs during the data transfer phase of the DPM1 is

determined by the operating parameter "Auto Clear“. If this parameter has

been set to "True“, then, as soon as any one DP slave ceases to be ready

to transfer user data, the DPM1 will switch the outputs of all its subordinate

DP slaves to a stable state and then enter Clear mode. If the parameter is

set to "False“, then the DPM1 will remain in Operate mode even in an error

situation and the user can govern the system response himself.

Data traffic between DPM1

and the DP slaves

The DPM1 automatically deals with data traffic between itself and its

subordinate DP slaves in a fixed and continually repeating order. During

the planning phase of the bus system, the user specifies which DP slaves

belong to which DPM1, which DP slaves should be included in the cyclic

transfer of user data, and which should be excluded from it.

The data traffic between the DPM1 and the DP slaves can be subdivided

into three phases: parametrization, configuration and data transfer. Before

it admits a DP slave to the data transfer phase, the DPM1 checks – in the

phases parametrization and configuration – whether the intended

configuration from the original plan agrees with the actual device

configuration. This check covers the device type, the format and length

information and the number of inputs and outputs, all of which must agree.

This gives the user reliable protection against parameter errors. In addition

to transferring user data, which the DPM1 carries out automatically, it is

also possible, at the user’s request, to transmit new parameters to the DP

slaves.

Protective mechanisms

In the field of decentralized peripherals, security considerations make it

imperative that systems should be equipped with highly effective protective

functions to prevent incorrect parametrization or a failure of the

communications equipment. On both the DP master and the DP slaves,

PROFIBUS DP uses monitoring mechanisms which are implemented as

22

BC3100

Page 23

PROFIBUS-DP basics

timeout monitors. The monitoring interval is specified when the DP system

is planned.

On the DP master

The DPM1 uses the Data_Control_Timer to monitor the transfer of user

data to and from the DP slaves. A separate monitoring timer is used for

each of the subordinate DP slaves. If a monitoring interval elapses without

any data being transferred, the monitor will report a timeout. The user will

be informed if this occurs. If automatic error response has been specified

(Auto_Clear = True), the DPM1 will leave Operate mode, switch the

outputs of its DP slaves to a secure state and go into Clear mode.

On the DP slave

Each DP slave maintains a response monitor to enable it to recognize

errors in the DP master or the transfer route. If a response monitoring

interval elapses without any data being exchanged with the superordinate

DP master, the DP slave will independently switch its outputs to the secure

state. In the case of a multi-master system additional security is necessary

to restrict access to the inputs and outputs of the DP slaves and to ensure

that direct accesses are made only by the authorized master. The DP

slaves therefore provide the other DP masters with a mapping of their

inputs and outputs which can be read by any DP master, even without

authority.

Identity number

Each DP slave and each DPM1 must have an individual identity number so

that a DP master can recognize the types of the attached devices without

entailing a significant protocol overhead. The master compares the identity

numbers of the attached DP devices with the identity numbers in the

planning data specified by the DPM2. No user data will be transferred

unless the correct device types have been attached to the bus with the

correct station addresses. This ensures that the system is protected from

planning errors.

Beckhoff PROFIBUS couplers, like all DP slaves and DPM1s, possess an

identity number allocated by the PNO. The PNO administers these identity

numbers together with the device master data and identity numbers are

also given in the type files.

BC3100

23

Page 24

PROFIBUS-DP basics

The transfer medium: plugs and cables

Physics of the transmission

Channel-related

disturbances

24

The physical data transfer is defined in the PROFIBUS standard. See

PROFIBUS layer 1 (physical layer).

The sphere of operation of a fieldbus system is substantially determined by

the selected transfer medium and the physical bus interface. Besides the

requirements of data transfer security, the necessary expenditure for

procuring and installing the bus cable is of crucial significance. The

PROFIBUS standard therefore provides for various forms of

communications technology while maintaining its standard bus protocol.

Cable transfer: this version, which confirms to the US standard EIA

RS-485, has been specified as the basic version for applications in the field

of production technology, building management technology and drive

technology. It uses a single twisted-pair copper cable. Shielding may be

unnecessary, depending on the planned application (take electromagnetic

compatibility aspects into consideration).

Two cable types with different maximum cable lengths are available. See

table entitled "RS485". The pin assignments on the connector and the

wiring are shown in the figure. Please pay attention to the special

requirements for the data cable at board rates in excess of 1.5 MBaud. The

right cable is a basic requirement for disturbance-free operation of the bus

system. When using the "normal" 1.5 Mbaud cable, astonishing

phenomena may occur as the result of reflections and excessive

attenuation. This may consist of the following: any one station is without a

connection and it resumes the connection when the neighbouring station is

extracted. Or, data transfer errors may occur when a certain bit pattern is

transferred. This means that the Profibus operates without disturbance but

without functioning of the system and randomly reports bus errors after

start up. The error behaviour described is eliminated by reducing the baud

rate ( < 93.75 kBaud).

If reducing the baud rate does not remedy the problem, this is frequently

due to a wiring error. Either the two data lines have been swapped on one

or several connectors or the terminators are not on or are activated in the

wrong place.

Fiber-optic conductor: the specification for a data transfer technology

based on fiber-optic conductors was elaborated in PNO for applications in

environments that are subject to extreme interference and to increase the

range at high data transfer rates. The specification is currently available as

a draft PNO guideline. The PROFIBUS COUPLER requires an external

module for conversion from RS485 to fiber-optic. The setup is clearly more

complex because of the need for an optical converter to convert from

RS485 to the "fiber-optic sub ring".

BC3100

Page 25

PROFIBUS-DP basics

1

5: GND

3: RxD/TxD- P

Pin assignments of the

D-Sub socket

RS-485

Data transfer technology

to the Profibus standard

Network

topology

Medium

Number of stations

Max. bus length

without repeaters

with repeaters

Transfer rates

Plug

RS485 fundamental characteristics:

Linear bus, active bus terminator at both ends,

branch lines are possible

Shielded twisted cable, shielding may be

dispensed with in suitable environments

(electromagnetic compatibility)

32 stations in each segment without repeaters,

extendible to 127 with repeaters

9.6, 19.2, 93.75 kBaud = 1200 m

187.5 kBaud = 1000 m

500 kBaud = 400 m

1500 kBaud = 200 m

3, 6 12 Mbaud = 100 m

Using repeaters (line amplifiers) increases the

max. bus length to the order of 10 km. The

number of possible repeaters is at least 3 and

may be up to 10, depending on the

manufacturer

9.6, 19.2, 93.75, 187.5, 500, 1500 Kbit/s, up to

12 Mbit/s in discrete steps

9-Pin D-Sub plug

Cables for

PROFIBUS DP and

PROFIBUS FMS

8: RxD/TxD- N

6

In systems which contain more than two stations, all the subscribers are

connected in parallel. The bus cable must always be terminated at the

ends of the lines, to prevent reflections and the transmission problems they

cause.

In order to loop the cable through without any gaps it is necessary to affix

two cables within one plug. Siemens’ SINEC L2 bus connections are very

suitable for this. These SINEC plugs are constructed to accommodate two

bus cables with the corresponding wire terminals and shielding. At the end

of the line you can use a small switch in the plug to activate the terminating

resistor. Please observe the manufacturer’s assembly instructions.

You should also note that the terminating resistor requires a 5 V power

supply for optimal operation. This means that if the plug is removed from

the bus coupler, or the power supply of the bus coupler fails, the level at

BC3100

25

Page 26

PROFIBUS-DP basics

the terminating resistor will vary, which may affect the data transfer.

Configuration of the masters

Example for the master

IM308-C

Interfacing for PLC Simatic

S5

The Profibus bus terminal controller operates with two different process

images: the PLC process image to which all bus terminals or only some of

the bus terminals configured on the one specific BC3100 are assigned, as

well as the Profibus DP process image to which a part of the bus terminals

can be assigned. For details of parameterization and configuration, please

refer to the chapter entitled Profibus bus terminal controller BC3100.

The Profibus master exchanges a coherent input and output data block

with each Profibus coupler/controller. The master assigns the bytes from

this data block from the addresses of the process image. The

COMProfibus software supports configuration when using the PLC master

of the IM308-C. Use the manufacturers' corresponding tools for other

masters (see also chapter entitled Master device file and type file).

Support files for master configuration:

Master / Software Remarks File

IM308-B

COMET200

IM308-C

COMProfibus

English

Language-

independent

General

General

General

In an example, we will show what settings have to be made in

COMProfibus to configure the Profibus master IM308-C.

Diverse bus terminals are connected to a BC3100:

In this example, the bus terminal controller's PLC program requires 5 bytes

of input signals (DP outputs of the master) and returns 6 bytes of output

signals (DP inputs of the master).

The corresponding entries for the identifiers can be selected conveniently

by way of the order number. The following window shows the selected

identifier:

BK3000TD.200

Bitmaps BUSKLEMN.BMP

BUSKLEMS.BMP

BK3000AD.200

BK3000AE.200

BK3000AX.200

(for BK30XX) BK30BECF.GSD

BK3010.GSD

(for BK31XX) BK31BECE.GSD

BK3110.GSD

(for BC3100) BC3100.GSD

26

BC3100

Page 27

PROFIBUS-DP basics

When a box in the "Order no." column is double clicked, a menu appears

for selection of the required identifier for the correspondingly plugged in

terminals or data lengths of the PLC process image.

Various possibilities of assigning process data are available in the case of

the BC3100. The various assignment possibilities are explained in detail in

the next chapter (Profibus bus terminal controller BC3100). In the

appendix, you will also find an example in relation to the possible settings.

BC3100

27

Page 28

PROFIBUS-DP basics

Ensuring data consistency

Consistency of a station's data is ensured by the Profibus data transfer

protocol. Consistency throughout the entire process image must be

achieved by activating the "SYNC" and "FREEZE" operating modes in the

masters.

FREEZE and SYNC capability is preselected for the slave parameters (see

figure) and cannot be deactivated. The control software checks FREEZE

and SYNC.

Activation of response monitoring ensures that an error message is created

in the event of failure of the corresponding station belonging to the master

and that the control software is enable to initiate exception handling.

Response monitoring can be selected individually for each station.

Response monitoring on is the default. The COMProfibus software issues

a warning whenever monitoring is to be deactivated.

Inconsistencies may occur as the result of asynchronous access by the

controller CPU (mostly PLC) to the data area of the Profibus master. Data

consistency is ensured automatically with the configuration of a "multi-byte

signal" and module consistency in the COMProfibus configuration software

for IM308-C. With regard to further master interfaces, please consult the

corresponding manufacturers' manuals for an explanation.

The IM 308-C as Profibus DP master is a common PLC interface.

A Windows program, COMProfibus, and extensive descriptions are

available for the Profibus DP master interface IM308-C. In connection with

the Siemens S5, it is recommended to use the IM308-C because of its

better handling and the possibility of freely assigning peripheral addresses

byte by byte. Versions 2.1 or higher can be considered to be particularly

convenient. An extended type file can be read in with these versions. The

entries in the type file automatically assume the settings for guaranteeing

data consistency. (The figures on the previous pages originate from the

COMProfibus software.)

28

BC3100

Page 29

PROFIBUS bus terminal controller BC3100

PROFIBUS bus terminal controller BC3100

Parameterization

Besides the parameterization in the DP standard, manufacturer-specific

operating parameters (User_Prm_Data) can also be transferred with the

Set_Prm service. These are distinguished by the fact that they are

transferred once from the master to the slave during establishment of the

connection. User_Prm_Data overwrites the settings that have been made

by way of the configuration interface. If these settings are not to be

overwritten, User_Prm_Data must not be sent. The User-Prm_Data of the

bus terminal controller BC3100 is based on the following structure:

Byte No. Description

Byte 0

Byte 1

Byte 2

Byte 3

Byte 4

Byte 5

Byte 6

Byte 7

Byte 8

Byte 9

Byte 10

Byte 11

Bit 0: Start-Bit monitoring on (0) / off (1)

Bit 1: Stop-Bit monitoring on (0) / off (1)

Bit 2: Watchdog time base 10ms (0) / 1ms (1)

Bit 3-5: 0 (reserved for expansions)

Bit 6: Fail_Safe off (0) / on (1)

Bit 7: DPV1-MSAC_C1 connection disabled (0) / enabled (1)

0 (reserved for expansions)

0 (reserved for expansions)

0 (reserved for expansions)

0 (reserved for expansions)

Bit 1: diagnostics via 2-byte diagnostics interface (1)

Diagnostics via DP diagnostics (Slave_Diag) (0)

Bit 0, 2-7: 0 (reserved for expansions)

0 ( reserved for expansions)

Bit 0: auto reset on the terminal bus in the event of an error on

(1)/off(0)

Bit 1: automatic terminal diagnostics on(1)/off(0)

Bit 4: diagnostics of digital terminals is mapped to the process

image (0)/ is not mapped to the process image (1)

Bit 2,3, 5-7: 0 (reserved for expansions)

0 (reserved for expansions)

Bit 0: 1

Bit 1: 1

Bit 2: 0

Bit 3: data format for auto configuration: INTEL (0)/MOTOROLA(1)

Bit 4: 0

Bit 5: 1

Bit 6: 1

Bit 7: 0

Bit 0,1: reaction to field bus error/termination of DP data

exchange/Clear_Data

1: affiliated terminal bus outputs change to 0

2: affiliated terminal bus outputs remain unchanged

Bit 2,3: Reaction to terminal bus error

1: affiliated DP inputs change to 0

2: affiliated DP inputs remain unchanged

Bit 4-7: 0 (reserved for expansions)

Max. DP diagnostic data length (value range 16, 24, 32, 40, 48, 56,

64)

BC3100

29

Page 30

PROFIBUS bus terminal controller BC3100

Byte No. Description

Byte 12

Byte 13

Reserved for expansions

Bit 0: flags are stored in the NOVRAM (1)/are not stored (0)

Bit 1: PLC run time measurement on (1)/off (0)

Bit 2,3: terminal bus/PLC cycle sequence

0: terminal bus inputs before PLC cycle, terminal bus outputs

after PLC cycle

1: terminal bus inputs and outputs before PLC cycle

2: terminal bus inputs and outputs after PLC cycle

Bit 4: Nominal cycle time and background execution time are

set via TWinCAT BC / TWinCAT PLC (1) / are set via

UserPrmData (0) (Byte 43: Nominal cycle time, Byte 44:

Background execution time)

Bit 5: BC state is copied into flag (1) (PROFIBUS state into flag

byte 508,509, terminal bus state into flag byte 510,511) / is not

copied into flag

Byte 14

Bit 0: 1

Bit 3: in the event of a PLC STOP, the affiliated terminal bus

outputs remain unchanged (1)/the affiliated terminal bus

outputs are set to 0 (0)

Bit 4: in the event of a terminal bus error, the affiliated PLC

inputs remain unchanged (1) / the affiliated PLC intputs are set

to 0 (0)

Bit 5: in the event of a field bus error, the affiliated PLC inputs

remain unchanged (1)/ the affiliated PLC inputs are set to 0 (0)

Bit 6: in the event of a PLC STOP, the affiliated DP outputs

remain unchanged (1)/the affiliated DP outputs are set to 0 (0)

Byte 15

Bit 0,1:

0: 1. Terminal is assigned to the DP process image

2: 1. Terminal is assigned to the PLC process image and is

mapped compactly (only with useful data)

3: 1. Terminal is assigned to the PLC process image and

mapped completely

Bit 2,3:

0: 2. Terminal is assigned to the DP process image

2: 2. Terminal is assigned to the PLC process image and

mapped compactly (only with useful data)

3: 2. Terminal is assigned to the PLC process image and

mapped completely

Bit 4,5:

0: 3. Terminal is assigned to the DP process image

2: 3. Terminal is assigned to the PLC process image and

mapped compactly (only with useful data)

3: 3. Terminal is assigned to the PLC process image and

mapped completely

Bit 6,7:

0: 4. Terminal is assigned to the DP process image

2: 4. Terminal is assigned to the PLC process image and

mapped compactly (only with useful data)

3: 4 Terminal is assigned to the PLC process image and

mapped completely

...

...

30

BC3100

Page 31

PROFIBUS bus terminal controller BC3100

Byte No. Description

Byte 30

Bytes 31-36

Byte 37

Byte 38

Byte 39

Byte 40

Byte 41

Byte 42

Byte 43

Byte 44

Bytes 45,46

Bit 0,1:

0: 61. Terminal is assigned to the DP process image

2: 61. Terminal is assigned to the PLC process image and

mapped compactly (only with useful data)

3: 61. Terminal is assigned to the PLC process image and

mapped completely

Bit 2,3:

0: 62. Terminal is assigned to the DP process image

2: 62. Terminal is assigned to the PLC process image and

mapped compactly (only with useful data)

3: 62. Terminal is assigned to the PLC process image and

mapped completely

Bit 4,5:

0: 63. Terminal is assigned to the DP process image

2: 63. Terminal is assigned to the PLC process image and

mapped compactly (only with useful data)

3: 63. Terminal is assigned to the PLC process image and

mapped completely

Bit 6,7:

0: 64. Terminal is assigned to the DP process image

2: 64. Terminal is assigned to the PLC process image and

mapped compactly (only with useful data)

3: 64. Terminal is assigned to the PLC process image and

mapped completely

Reserved for expansions

Initial address in the PLC input process image as from which

plc inputs are to be transferred as DP outputs (high byte)

Initial address in the PLC process image as from which PLC

inputs are to be transferred as DP outputs (low bytes)

Length of the PLC inputs that are to be transferred as DP

outputs

Initial address in the PLC output process image as from which

PLC outputs are to be transferred as DP Inputs (high bytes)

Initial address in the PLC output process image as from which

PLC outputs are to be transferred as DP inputs (low byte)

Length of the PLC outputs that are to be transferred as DP

inputs

Nominal PLC cycle time (in ms, value range: 1 - 255)

Background execution time (in ms, value range: 1 -255)

Length of the remanant flags (as from MB0, which are stored in

the NOVRAM, value range: 1 - 512)

If no bus terminal controllers assume the last programmed value. Remark:

the default setting of the User_Prm_Data can be taken from the GSD file.

BC3100

31

Page 32

PROFIBUS bus terminal controller BC3100

Configuration

2-byte diagnostic interface

Assignment of terminals

Digital terminals

Analog terminals

The configuration data to be transferred with the Chk_Cfg service defines

which process data is exchanged with the Data_Exchange service.

Identifier Description

0xB1

2-byte PLC interface

When the 2-byte diagnostic interface is activated, the next identifier in the

configuration data must be assigned as follows, as otherwise this identifier

is dropped:

Identifier Description

0xB1

2-byte diagnostic interface

Auto-configuration

When using auto configuration, only those terminals may be considered

that have been assigned to the DP process image.

The data of all digital input or output terminals is combined in one byte

array each in the sequence of the slots. The following identifiers can be

used for digital data:

Identifier Description

0x1n

0x2n

0x3n

These identifiers can be assigned as required so that the total of the input

or output bytes each corresponds to the existing data length of digital

inputs and outputs (rounded up to 1 byte).

As the digital data is transferred after all analog data, the digital identifiers

must be defined after all analog identifiers.

For each channel, the analog terminals have 8 bits of control or status data

and user data. These terminals belong to the intelligent terminals and

support register communication (8 bits of control or status data, 16 bits of

I/O data per channel). Specific coding in the control or status data defines

whether the first 16 bits of the user data are to be interpreted as register

communication I/O data.

One code must be defined for each analog terminal or each analog

channel. Their sequence depends on the slots.

There are up to 5 different codes per channel for mapping them in the DP

(n+1)-byte digital inputs

(n+1)-byte digital outputs

(n+1)-byte digital inputs and outputs

32

BC3100

Page 33

PROFIBUS bus terminal controller BC3100

process data:

Identifier Description

A:

Only the value is sent (no register communication possible)

B:

The complete channel is sent (register communication possible)

C:

The value plus control plus status is sent (no register

communication possible)

D:

The value plus status is sent (no register communication

possible)

E:

The value plus control is sent (no register communication

possible)