Page 1

LIGHTBUS

Bus Terminal Controller

BC2000

Technical Documentation

Version 1.1

2006-11-06

Page 2

Please note the following

Target group

This description is only intended for the use of trained specialists in control

and automation engineering who are familiar with the applicable national

standards.

Safety requirements

The responsible staff must ensure that the application or use of the

products described satisfy all the requirements for safety, including all the

relevant laws, regulations, guidelines and standards.

The documentation has been prepared with care. The products described

are, however, constantly under development. For that reason the

documentation is not in every case checked for consistency with

performance data, standards or other characteristics, and does not

represent an assurance of characteristics in the sense of § 459, Para. 2 of

the German Civil Code. In the event that it contains technical or editorial

errors, we retain the right to make alterations at any time and without

warning. No claims for the modification of products that have already been

supplied may be made on the basis of the data, diagrams and descriptions

in this documentation.

©

This manual is copyrighted. Any reproduction or third party use of this

protected publication, whether in whole or in part, without the written

permission of Elektro Beckhoff GmbH, is forbidden.

Page 3

Table of Contents

Table of Contents

1. Foreword 3

Notes on the documentation 3

Liability Conditions 3

Delivery conditions 3

Copyright 3

Safety Instructions 4

State at Delivery 4

Description of safety symbols 4

2. Basic Principles 5

Description of the BC2000 5

The Beckhoff Bus Terminal System 5

The interfaces 7

Electrical power supply 7

Power contacts feeding points 7

Power contacts 8

Fieldbus connection 8

Configuration and Programming Interface 8

Terminal Bus Contacts 8

Galvanic isolation 8

Operating Modes of the Bus Terminal Controller 9

Mechanical structure 10

Preparing for Operation and Diagnostics 12

3. The Beckhoff BC2000 Lightbus Coupler 15

Introduction to the Beckhoff Lightbus System 15

4. Settings in the TwinCAT System Manager 17

Basic Settings 17

PLC Cycle Time 18

PLC Variables 18

Remanent Variables 19

Terminal Bus Update 19

Program Download via the Fibre Optic Ring 19

Program Download via the RS232 Interface 20

ADS Functions 20

PLC Runtime System 21

Registers of the Bus Terminal Controller 22

Diagnostics in the BC2000 22

5. Settings in TwinCAT PLC 23

Terminal Bus Reset 23

Coupler Reset 23

Manufacturer’s Configuration 23

Cycle Time Measurement 23

Boot Project 23

Coupler Options 24

6. Appendix 25

Absolute Addressing in the BC2000 25

7. Index 26

8. Support and Service 27

Beckhoff's branch offices and representatives 27

Beckhoff Headquarters 27

BC2000 2

Page 4

Foreword

Foreword

Notes on the documentation

This description is only intended for the use of trained specialists in control and automation engineering

who are familiar with the applicable national standards. It is essential that the following notes and

explanations are followed when installing and commissioning these components.

Liability Conditions

The responsible staff must ensure that the application or use of the products described satisfy all the

requirements for safety, including all the relevant laws, regulations, guidelines and standards.

The documentation has been prepared with care. The products described are, however, constantly under

development. For that reason the documentation is not in every case checked for consistency with

performance data, standards or other characteristics. None of the statements of this manual represents a

guarantee (Garantie) in the meaning of § 443 BGB of the German Civil Code or a statement about the

contractually expected fitness for a particular purpose in the meaning of § 434 par. 1 sentence 1 BGB. In

the event that it contains technical or editorial errors, we retain the right to make alterations at any time

and without warning. No claims for the modification of products that have already been supplied may be

made on the basis of the data, diagrams and descriptions in this documentation.

Delivery conditions

In addition, the general delivery conditions of the company Beckhoff Automation GmbH apply.

Copyright

©

This documentation is copyrighted. Any reproduction or third party use of this publication, whether in

whole or in part, without the written permission of Beckhoff Automation GmbH, is forbidden.

3 BC2000

Page 5

Foreword

i

Safety Instructions

State at Delivery

All the components are supplied in particular hardware and software configurations appropriate for the

application. Modifications to hardware or software configurations other than those described in the

documentation are not permitted, and nullify the liability of Beckhoff Automation GmbH.

Description of safety symbols

The following safety symbols are used in this documentation. They are intended to alert the reader to the

associated safety instructions..

This symbol is intended to highlight risks for the life or health of personnel.

Danger

This symbol is intended to highlight risks for equipment, materials or the

Attention

environment.

This symbol indicates information that contributes to better understanding.

Note

BC2000 4

Page 6

Basic Principles

Up to 64 bus terminals

each having 2 I/O channels

for each signal form

De-centralised wiring of

each I/O level

IPC as controller

Standard C - rail assembly

Modularity

Description of the BC2000

The BC2000 is a slave with PLC functionality. It has a fieldbus interface,

the Lightbus. The bus terminal controller is programmable, and is

programmed using the TwinCAT software in the IEC61131-3 programming

languages. Applied in combination with the C1220 or FC200x Lightbus PC

card and the TwinCAT PLC software, the BC2000 permits decentralisation

of the control tasks. This is a way of removing parts of the application out

of the central control system to relieve the CPU and the field bus.

Distributed counters, controllers and switches are typical applications for

the bus terminal controller. The reaction times are dependent upon the bus

communication and the overall control system, and maintenance of

function is possible even when the bus or control system fails (e.g. an

orderly transfer of the processes into a secure condition).

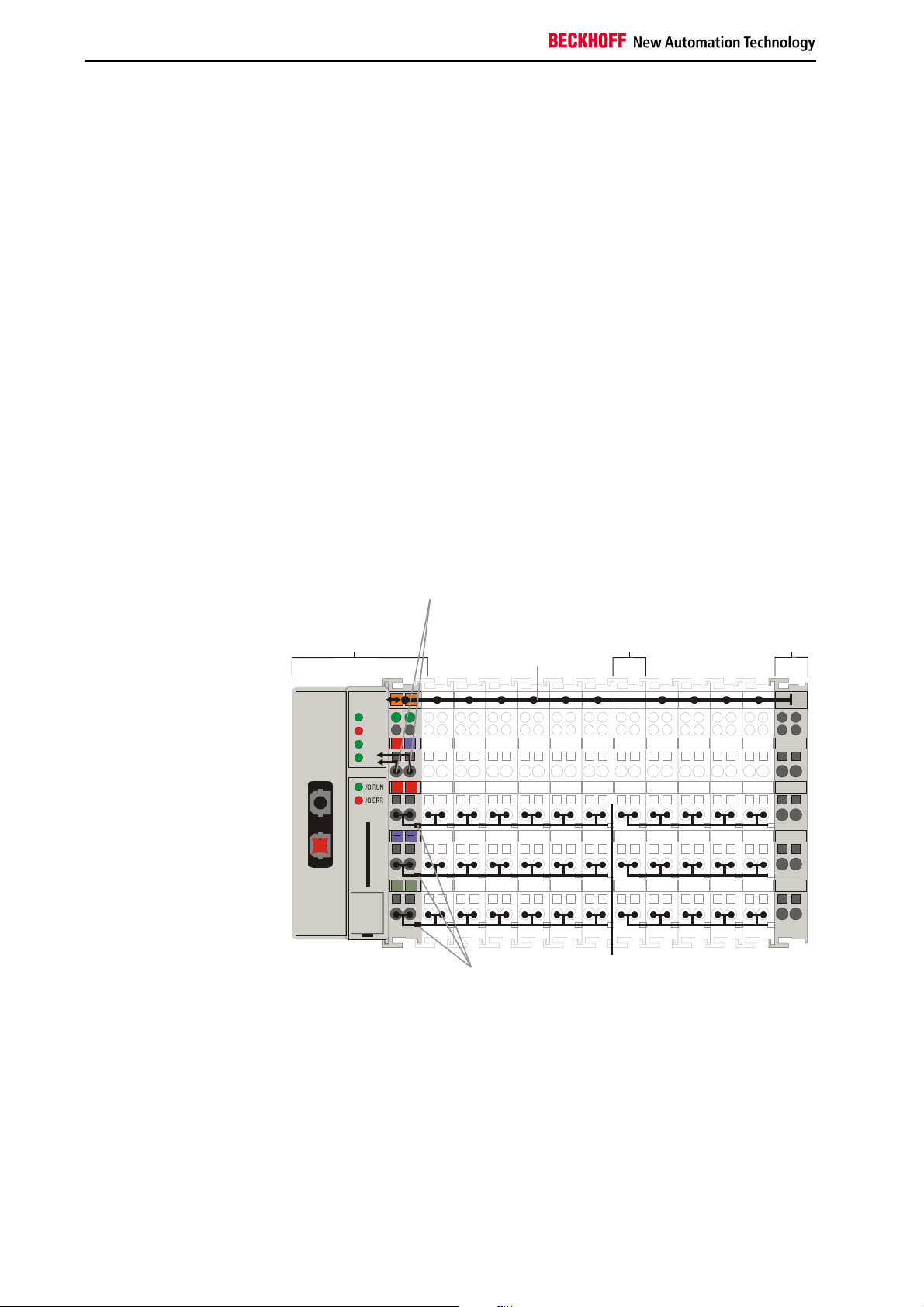

The Beckhoff Bus Terminal System

The bus terminal system is the universal interface between a fieldbus

system and the sensor / actuator level. A unit consists of a bus terminal

controller as the head station, and up to 64 electronic series terminals, the

last one being an end terminal. For each technical signal form, terminals

are available each having two I/O channels, and these can be mixed in any

order. All the terminal types have the same mechanical construction, so

that difficulties of planning and design are minimised. The height and depth

match the dimensions of compact terminal boxes.

Fieldbus technology allows more compact forms of controller to be used.

The I/O level does not have to be brought to the controller. The sensors

and actuators can be wired de-centrally, using minimum cable lengths. The

controller can be installed at any location within the plant. The use of an

industry PC as the controller means that the operating and observing

element can be implemented in the controller’s hardware. The controller

can therefore be located at an operating panel, in a control room, or at

some similar place. The bus terminals form the de-centralised input/output

level of the controller in the switching cabinet and the subsidiary terminal

boxes. The power sector of the plant is also controlled over the bus system

in addition to the sensor/actuator level. The bus terminal replaces the

conventional series terminal as the wiring level in the switching cabinet.

The switching cabinet can have smaller dimensions.

The Beckhoff bus terminal system unites the advantages of a bus system

with the possibilities of the compact series terminal. Bus terminals can be

driven within all the usual bus systems, thus reducing the controller parts

count. The bus terminals then behave like conventional connections for

that bus system. All the performance features of the particular bus system

are supported.

The easy, space-saving assembly on a standard C-rail, and the direct

wiring of actuators and sensors without cross-connections between the

terminals standardises the installation. The consistent labelling scheme

also contributes.

The small physical size and the great flexibility of the bus terminal system

allows it to be used wherever a series terminal is also used. Every type of

connection, such as analogue, digital, serial or the direct connection of

sensors can be implemented.

The modular assembly of the terminal strip with bus terminals of various

Basic Principles

5 BC2000

Page 7

Basic Principles

End terminal

isolation

Potential

contacts

Supply voltage

II/O-Lightbus

Beckhoff Lightbus

Display of the channel state

K bus

End terminal

Potential feed terminals for

galvanically isolated groups

The principle of the

bus terminal

functions limits the number of unused channels to a maximum of one per

function. The presence of two channels in one terminal is the optimum

compromise of unused channels and the cost of each channel. The

possibility of galvanic isolation through potential feed terminals also helps

to keep the number of unused channels low.

The integrated LEDs show the state of the channel at a location close to

the sensors and actuators.

The terminal bus (known as the K bus) is the data path within a terminal

strip. The terminal bus is led through from the bus terminal controller

through all the terminals via six contacts on the terminals‘ side walls. The

end terminal terminates the terminal bus. The user does not have to learn

anything about the function of the terminal bus or about the internal

workings of the terminals and the bus terminal controller. Many software

tools that can be supplied make project planning, configuration and

operation easy.

The operating voltage is passed on to following terminals via three power

contacts. You can divide the terminal strip into arbitrary galvanically

isolated groups by means of potential feed terminals. The feed terminals

play no part in the control of the terminals, and can be inserted at any

points within the terminal strip.

Up to 64 terminals can be used within one terminal strip;

Potential feed terminals and end terminals are included in this count.

bus coupler

BC2000

for the

bus coupler

feed

terminal

Terminal bus

Additional characteristics of

the bus terminal controllers

0201

CYC

ERR

24V

0V

WD

PLC

+ +

BECKHOFF

BC2000

PE PE

Power

Galvanic

The bus terminal controller (BC) differs from the bus coupler (BK) in that in

addition to operating the terminal bus, a PLC task runs in the BC2000.

Unlike bus couplers, the signals from the terminals are processed by the

PLC task, while the fieldbus carries the in- and outputs of the PLC task.

It is also possible to partition the terminals in such a way that some of the

terminals are processed by the PLC task while others are passed over the

fieldbus to a master.

BC2000 6

Page 8

02

01

+

+

PE

PE

B

C

K

H

O

24V

0V

00

X0

CYC

ERR

WD

II/O-Lightbus

Power LEDs

Bus coupler / power contacts

Terminal bus (K bus)

II/O-Lightbus

IN

OUT

Configuration

and programming

interface

Bus coupler power supply

24 V DC / GND

Power contacts

feeding points

Power contacts

WD

PLC

Bus terminal controllers for

various fieldbus systems

The Beckhoff BC2000

Lightbus coupler

Various bus terminal controllers can be used to couple the electronic

terminal strip quickly and easily to different fieldbus systems. It is also

possible to convert to another fieldbus system at a later time. The bus

terminal controller performs all the monitoring and control tasks that are

necessary for operation of the connected bus terminals. The operation and

configuration of the bus terminals is carried out exclusively by the bus

terminal controller. Nevertheless, the parameters that have been set are

stored in each bus terminal, and are retained in the event of voltage dropout. Fieldbus, terminal bus and I/O level are galvanically isolated.

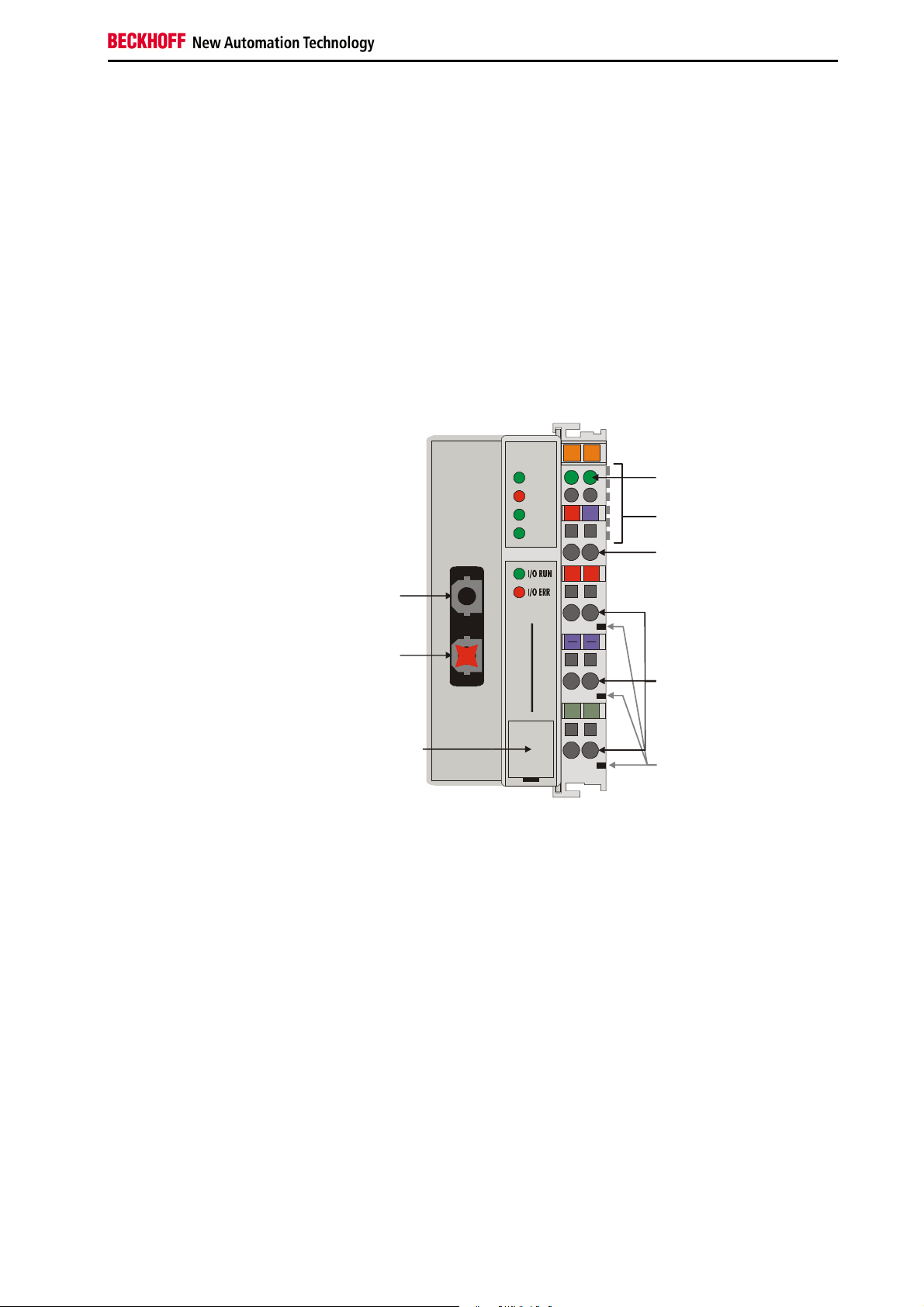

The interfaces

A bus terminal controller has six different methods of connection. These

interfaces are designed as plug connectors and as spring-loaded terminals.

Basic Principles

24 V DC to the topmost

terminals “24 V” and “0 V”

Bottom 3 terminal pairs for

feed

Maximum 24 V

Maximum 10 A

Electrical power supply

The bus terminal controllers require a 24 V DC supply for their operation.

The connection is made by means of the upper spring-loaded terminals

labelled “24 V” and “0 V”. The supply voltage feeds the bus terminal

controller electronics and, over the terminal bus, the bus terminals. The

power supply for the bus terminal controller electronics and that of the

terminal bus are electrically separated from the potential of the field level.

Power contacts feeding points

The bottom six connections with spring-loaded terminals can be used to

feed the supply for the peripherals. The spring-loaded terminals are joined

in pairs to a power contact. The feed for the power contacts has no

connection to the voltage supply for the bus terminal controller. The design

of the feed permits voltages of up to 24 V. The assignment in pairs and the

electrical connection between feed terminal contacts allows the connection

wires to be looped through to various terminal points. The current drawn

from the power contacts must not exceed 10 A for long periods. The

current rating between two spring-loaded terminals is identical to that of the

connecting wires.

7 BC2000

Page 9

Basic Principles

Spring contacts on the side

Beckhoff Lightbus

Fibre optic ring

Beckhoff Z1000 connector

Serial interface under the

front cover

6 contacts on the side

3 potential groups:

Field bus

Terminal bus (K bus)

Peripheral level

Power contacts

On the right hand face of the bus terminal controller there are three spring

contacts for the power contact connections. The spring contacts are hidden

in slots so that they can not be accidentally touched. By attaching a bus

terminal the blade contacts on the left hand side of the bus terminal are

connected to the spring contacts. The tongue and groove guides on the top

and bottom of the bus terminal controllers and of the bus terminals

guarantees that the power contacts mate securely.

Fieldbus connection

There is a recessed front face on the left hand side. The typical Beckhoff

Lightbus connector can be inserted here. The Beckhoff Lightbus consists

of an optical fibre ring into which the bus terminal controller is inserted.

Here the plug out of which red light shines when the Beckhoff Lightbus is

switched on is inserted into the upper socket. On the figure this is labelled

with „IN“. Optical fibre connectors of type Beckhoff Z1000 are required for

the connection.

Configuration and Programming Interface

The bus terminal controllers have an RS232 interface at the bottom of the

front face. The miniature connector can be joined to a PC with the aid of a

connecting cable and the KS2000 configuration software. The interface

permits the bus terminals to be configured, for example adjusting the

amplification factors of the analogue channels. The interface can also be

used to change the assignments of the bus terminal data to the process

image in the bus terminal controller. The functionality of the configuration

interface can also be reached via the fieldbus using string communication

facility.

This interface is also used for programming the BC2000. The cable for the

interface is supplied along with TwinCAT BC.

Terminal Bus Contacts

In order to connect the bus terminal controller to the bus terminals, the bus

terminal controller has gold contacts on the right hand side. When the bus

terminals are pushed together the gold contacts automatically make the

connection between the bus terminals. The voltage supply to the terminal

bus electronics in the bus terminals and the data exchange between the

bus terminal controller and the bus terminals is carried out by the terminal

bus. A part of the data exchange takes place via a ring structure within the

terminal bus. Opening the terminal bus, e.g. by pulling out one of the bus

terminals, opens the ring. Data exchange is no longer possible. Special

mechanisms nevertheless allow the bus terminal controller to identify the

location of the interruption and to report it.

Galvanic isolation

The bus terminal controllers operate by means of three independent

potential groups. The supply voltage feeds the terminal bus electronics in

the bus terminal controller and the terminal bus itself, which is electrically

separate. The supply voltage is also used to generate the operating

voltage for the fieldbus.

Remark: All the bus terminals are galvanically isolated from the terminal

bus. The terminal bus is thus galvanically isolated from everything else.

BC2000 8

Page 10

24VDC

Bus coupler

Bus terminals

Operating Modes of the Bus Terminal

Power On self test

Bus terminal test

Structure list

OK

Structure of the potential

levels in the bus terminal

system

Field bus

Controller

Start-up behaviour of the

bus terminal controller

Immediately after being switched on, the bus terminal controller checks, in

the course of a “self test”, all the functions of its components and the

communication of the terminal bus. The red I/O LED blinks while this is

happening. After completion of the self-test, the bus terminal controller

starts to test the attached bus terminals (in a „bus terminal test“), and reads

in the configuration. The bus terminal configuration is used to generate an

internal structure list, which is not accessible from outside. In case of an

error, the bus terminal controller enters the „STOP“ state. Once the start-up

has completed without error, the bus terminal controller enters the "fieldbus

start" state.

PLC Start /

Communication start

Basic Principles

Terminal bus (K bus)

Peripheral level

Stop

9 BC2000

Page 11

Basic Principles

1

0

0

49

12

02

01

+

+

PE

PE

00

X0

00

.1

PE

PE

PLC

The bus terminal controller can be made to enter the normal operating

state by switching it on again once the fault has been rectified.

Mechanical structure

The system of the Beckhoff bus terminals is characterised by low physical

volume and high modularity. When planning a project it must be assumed

that at least one bus terminal controller and a number of bus terminals will

be used. The mechanical dimensions of the bus terminal controllers are

independent of the fieldbus system. If optical fibre cable with Z1000 plugs

is used, the clearances of the bus terminal controller are not exceeded.

Bus terminal controller

dimensions

II/O-Lightbus

CYC

ERR

WD

24V

E0

0V

.0

Assembly and connection

+ +

94

BECKHOFF

BC2000

The total width of the unit is composed of the width of the bus terminal

controller with the KL9010 bus end terminal plus the width of the bus

terminals being used. Depending on function, the bus terminals are 12 or

24 mm wide. The front wiring increases the total height of 68 mm by about

5 to 10 mm, depending on the wire thickness.

The bus terminal controller and all the bus terminals can be clipped by light

pressure onto a 35 mm C-mounting rail. A locking mechanism prevents the

individual housings from being pulled off again. For removal from the

mounting rail the orange coloured tension strap releases the latching

mechanism, allowing the housing to be pulled off the rail without any force.

Up to 64 bus terminals can be attached to the bus terminal controller on

the right hand side. When plugging the components together, be sure to

assemble the housings with groove and tongue against each other. A

properly working connection can not be made by pushing the housings

together on the mounting rail. When correctly assembled, no significant

gap can be seen between the attached housings.

The right hand part of the bus terminal controller can be compared to a bus

terminal. Eight connections on the top permit connection with solid or fine

wires. The connection is implemented with the aid of a spring device. The

spring-loaded terminal is opened with a screwdriver or rod, by exerting

gentle pressure in the opening above the terminal. The wire can be

BC2000 10

Page 12

Basic Principles

Insulation testing

PE power contacts

inserted into the terminal without any force. The terminal closes

automatically when the pressure is released, holding the wire securely and

permanently.

The connection between the bus terminal controller and the bus terminals

is automatically realised by pushing the components together. The transfer

of the data and the supply voltage for the intelligent electronics in the bus

terminals is performed by the terminal bus. The supply of the field

electronics is performed through the power contacts. Plugging together the

power contacts creates a supply rail. Since some bus terminals (e.g.

analogue bus terminals or 4-channel digital bus terminals) are not looped

through these power contacts (or not completely) the bus terminal contact

assignments must be considered. The potential feed terminals interrupt the

power contacts, and represent the start of a new supply rail. The bus

terminal controller can also be made use of to feed the power contacts.

The power contact labelled “PE” can be used as a protective earth. For

safety reasons this contact mates first when plugging together, and can

ground short-circuit currents of up to 125 A. It should be noted that, for

reasons of electromagnetic compatibility, the PE contacts are

capacitatively coupled to the mounting rail. This can both lead to

misleading results and to damaging the terminal during insulation testing

(e.g. breakdown of the insulation from a 230 V power consuming device to

the PE conductor). The PE conductor to the bus terminal controller must be

disconnected for the insulation testing. In order to uncouple further feed

locations for the purposes of testing, the feed terminals can be pulled at

least 10 mm out from the connected group of other terminals. In that case,

the PE conductors do not have to be disconnected.

The “PE” power contact must not be used for other potentials.

Technical data BC 2000

Number of bus terminals

Digital peripheral signals

Analogue peripheral signals

Peripheral bytes

Fieldbus medium

Plug connector

Baud rate

Electrical power supply

Input current

Power-on surge

Terminal bus output current

Voltage of the power

contact

Power contacts current

drawn

Voltage stability

Typical weight

Operating temperature

Storage temperature

Relative humidity

Vibration/shock stability

EMC immunity, burst / ESD

Installation location

Protection class

64

256 inputs and outputs

128 inputs and outputs

512 inputs and 512 outputs

Z1100 optical fibre

Z1000 for Z1100

2.5 Mbaud

24 V (- 15% / +20%) EN 61131

70 mA + (total terminal bus current)/4

500 mA max.

2.5 x steady operating current

1750 mA max.

24 V DC / AC

10 A

500 Veff (power contact / supply voltage)

170 g

0°C ... +55°C

-25°C ... +85°C

95% without dew formation

according to IEC 68-2-6 / IEC 68-2-27

according to EN 61000-4-4 / EN 61000-4-2, limit values in accordance with

EN 50082-2

arbitrary

IP20

11 BC2000

Page 13

Basic Principles

PLC data

Programmability

Program memory

Data memory

Remanent flags

Runtime system

PLC cycle time

Programming languages

BC 2000

via the programming interface (TwinCAT BC/TwinCAT)

or via optical fibre ring (TwinCAT)

32 kbytes / 96 kbytes

32 kbytes / 64 kbytes

512 bytes

1 PLC task

approx. 3 ms for 1000 instructions (including terminal bus I/O cycle)

IL, LD, FBD, SFC, ST

The diagnostic LEDs

Local errors

Blink code

Preparing for Operation and Diagnostics

After switching on, the bus terminal controller immediately checks the

connected configuration. Error-free start-up is signalled by extinction of the

red LED “I/O ERR“. If the “I/O ERR” LED blinks, an error in the area of the

terminals is indicated. The error code can be determined from the

frequency and number of blinks. This permits rapid rectification of the error.

There is a detailed description in the chapter on „The Diagnostic LEDs“.

The bus terminal controller has two groups of LEDs for the display of

status. The upper group with four LEDs indicates the status of the

respective field bus. The significance of the “field bus status LEDs“ is

explained in the next sections of this manual - it conforms to conventional

field bus displays.

On the upper right hand side of the bus terminal controllers are two more

green LEDs that indicate the supply voltage. The left hand LED indicates

the 24 V supply of the bus terminal controller. The right hand LED signals

the supply to the power contacts.

Two LEDs, the “I/O” LEDs, in the area below the field bus status LEDs

referred to above, serve to indicate the operating status of the bus

terminals and the connections to these terminals. The green LED lights up

in order to indicate fault-free operation. „Fault-free“ means that the

communication with the fieldbus system is also running. The red LED

flashes to indicate an error. The red LED blinks with two different

frequencies. The error is encoded in the blinks as follows:

Fast blinking

First slow sequence

Second slow sequence

Start of the error code

Error type

Error location

Start of the error code Error type Error location

BC2000 12

Page 14

Error code Error

argument

Persistent,

continuous

blinking

1 pulse

2 pulses

3 pulses

4 pulses

5 pulses

9 pulses

14 pulses

15 pulses

16 pulses

EMC problems - Check power supply for overvoltage or

0

1

2

0

n (n > 0)

0 Terminal bus command error - No terminal connected; attach terminals.

0

n

n Terminal bus error with register

0

n

n Terminal n has the wrong format - Start the coupler again, and if the error

n Number of terminals is no longer

n Length of the terminal bus data is no

Description Remedy

EEPROM checksum error

Inline code buffer overflow

Unknown data type

Programmed configuration

Incorrect table entry / bus coupler

Incorrect table comparison

(terminal n)

Terminal bus data error

Break behind terminal n

communication with terminal n

Checksum error in program flash

memory

Terminal n is not consistent with the

configuration that existed at boot

image entry

correct

longer correct

Error location

The number of pulses indicates the position of the last bus terminal before

the fault. Passive bus terminals, such as a power feed terminal, are not

included in the count.

When the error is rectified, the bus terminal controller does not stop

flashing. Operating state of the bus terminal controller: „Stop“. The bus

terminal controller can only be re-started by switching off the supply

voltage.

Fieldbus errors

The fieldbus status LEDs indicate the operational state of the fieldbus. The

functions of the Beckhoff Lightbus are indicated by the „CYC“, „ERR“ and

„WD“ LEDs.

The meaning of the first three LEDs is:

CYC the LED lights up for the duration of each telegram

ERR is switched on by a faulty telegram, and switched off again by

three correct telegrams

WD watchdog, lights for 100 ms after the bus terminal controller has

been addressed

Basic Principles

undervoltage peaks

- Implement EMC measures

- If a terminal bus error is present, it can be

localised by a restart of the coupler (by

switching it off and then on again)

- Set manufacturer’s setting with the KS2000

- Connect fewer terminals; too many entries in

the table for the programmed configuration

- Software update required for the coupler

- Check programmed configuration for

correctness

- Incorrect table entry / bus coupler

- One of the terminals is defective; halve the

number of terminals attached and check

whether the error is still present with the

remaining terminals. Repeat until the

defective terminal is located.

- Check whether the n+1 terminal is correctly

connected; replace if necessary.

– Check whether the end terminal 9010 is

connected.

Replace terminal n.

- Set manufacturer’s setting with the KS2000

- Set manufacturer's setting with the KS2000,

which will delete the boot project

occurs again then exchange the terminal

- Start the coupler again, and if the error

occurs again after this, use the KS2000

software to set manufacturer’s settings

- Start the coupler again, and if the error

occurs again after this, use the KS2000

software to set manufacturer’s settings

13 BC2000

Page 15

Basic Principles

PLC

PLC LED

If the PLC LED lights, the program has started on the BC2000. The LED

flashes while a boot project is being created.

Diagnostic LEDs on the

BC2000

CYC

ERR

WD

CYC ERR WD Meaning Remedy

lit

lit

lit

blinking

off

off

off

off lit Telegrams are passing cyclically along

off lit I/O-RUN flashes The PLC cycle time that has been

off off The ring is functioning, but the bus

off off The controller only occasionally

lit off (Physical) bus fault, faulty telegrams are

blinking off Occasional CRC error (green I/O LED

off off No operating voltage, serious fault, no

The bus terminal controller interrogates the configuration of the bus

terminals after it has been switched on, then performs exchange of data

with the terminals. This means that the red I/O LED goes out after a faultfree start-up, and the green I/O LED lights. The green I/O-LED lights with

the PLC timing on the bus terminal controller. If no program is running on

the BC2000, the pre-set cycle time for triggering the terminal bus is used.

Everything is satisfactory

the ring

Inputs are read and outputs are set.

set is too long > 100 ms

Re-examine the control software

terminal controller is not being

addressed

accesses the bus. The outputs drop

away.

circulating in the ring, e.g. optical fibre

damaged, previous module faulty, plug

not properly inserted

lights)

Inputs are read; outputs are not

updated;

function

or the assignment list

Re-examine the control software

Check:

- whether the optical fibre cable is

inserted

- whether the optical fibre cable is

broken

- whether previous module is

ready for operation

Optical fibre connection damaged

- Electrical power supply

BC2000 14

Page 16

The Beckhoff BC2000 Lightbus Coupler

The Beckhoff BC2000 Lightbus Coupler

System configurations and

device types

Introduction to the Beckhoff Lightbus

System

The Beckhoff Lightbus has achieved wide acceptance in the world of

automation engineering through its speed and its compatibility across

manufacturers. The Beckhoff Lightbus was developed within a control

concept for the implementation of NC axes on the industry PC. The goal of

the project was to develop a fast, secure I/O level for the PC suitable for

industrial application. Nowadays a large number of various products are

available from independent manufacturers. The operation of different

Beckhoff Lightbus devices in one bus system is ensured by the

implementation support and the protocol ASICs from BECKHOFF.

The Beckhoff Lightbus is designed for fast data exchange on the sensor /

actuator level. Central control devices (such as, for example,

programmable logic controllers) communicate here over a fast serial

connection with distributed input and output devices. Data is exchanged

with these distributed devices cyclically, and, if necessary, with different

priorities. The central controller (master) reads the input information from

the slaves, and sends the output information to the slaves. The bus cycle

time must here be shorter than the central controller’s program cycle time,

which in many applications is less than 1 ms.

A high data throughput is not in itself sufficient for successful use of a bus

system. Ease of handling, good diagnostic facilities and secure

transmission technology are also of the utmost importance if the user’s

demands are to be satisfied. These properties are ideally combined in the

Beckhoff Lightbus.

For the transmission of 512 bits of input data and 512 bits of output data

distributed over 32 bus devices, the Beckhoff Lightbus needs approx.

0.8 ms at a transmission rate of 2.5 Mbit/s. The demand for a short system

reaction time is thus ideally satisfied.

A single master system can be implemented with the Beckhoff Lightbus. A

maximum of 254 slaves can be connected to one bus. In the BC2000 bus

terminal controller, a station address between 1 and 254 is automatically

selected during the start-up phase. The specifications for the system

configuration contain the number of stations, the assignment of the station

addresses to the I/O addresses, data consistency of the I/O data and the

format of the diagnostics messages. Every Beckhoff Lightbus system

consists of different device types

A Beckhoff Lightbus slave is a peripheral device (sensor/actuator) that

reads input information and passes output information on to the

peripherals. It is also possible to have devices that only handle either input

or output information. Typical Beckhoff Lightbus slaves are devices with

binary inputs/outputs for 24 V or 230 V, analogue inputs, analogue outputs,

counters, incremental encoders etc.. The quantity of input and output

information is device-dependent, and is limited to 32 bits of input data and

32 bits of output data for each protocol ASIC. For slaves that handle more

than 32 bits of data, such as, for instance, the BC2000, an extended

procedure is utilised. Using an addressed access procedure, reading and

writing up to 256 x 16 bits is possible. This means that a system can

handle up to 254 stations x 508 bytes (not all of the 512 bytes are available

for user data) with only one Beckhoff Lightbus system. For reasons of

expense, and for technical reasons associated with implementation, the

masters that are available nowadays work with a max. user data length of

3 kbyte (24000 inputs and outputs).

15 BC2000

Page 17

The Beckhoff BC2000 Lightbus Coupler

Master interfaces supporting the bus terminal controller are the PC cards

C1220 as from Version 4.01, and the FC200x. These cards are supported

by TwinCAT software as from version 2.6 (build 315).

Fundamental properties of

optical fibre transmission

technology

The Medium

Network topology

Medium

Number of

stations

Transmission rate

Max. bus length

Min. bending

radius

Plug connector

Ring system, active devices between the cable sections

Z1100 plastic optical fibre

Z1101 plastic optical fibre with PU cladding

Z1110 HCS – optical fibre

Z1111 HCS – optical fibre

254 stations in the ring

2.5 Mbit/s

with plastic optical fibre with HCS optical fibre

0.3 m to 45 m up to 300 m

3 cm 4 cm

Z1000 standard plug for

plastic optical fibres

Z1010 standard plug for HCS

optical fibres

BC2000 16

Page 18

Settings in the TwinCAT System Manager

Settings in the TwinCAT System Manager

Basic Settings

The basic properties of the bus terminal controller are handled in the

system manager.

The terminals of the bus terminal controller can be assigned directly to the

Lightbus master or to the BC2000. Terminals that are assigned directly to

the BC2000 are displayed in the system manger with „PLC“, and are not

visible to the master. A further distinction between „Complex“ and

„Compact“ is also made in the analogue terminals.

Complex: complete representation of the analogue terminals with

control/status, 4 bytes input/output per channel

Compact: user data only, 2 bytes per channel

The terminals that are assigned to the master are invisible to the bus

terminal controller. If it is desired to make a terminal visible to both systems,

the terminal must first be assigned to the BC2000, and then the data from

the terminal are transmitted to the master via the PLC variables.

17 BC2000

The settings for the PLC in the bus terminal controller are found under the

„PLC“ tab. All the basic settings that control the properties of the PLC in the

BC2000 are handled there.

Page 19

Settings in the TwinCAT System Manager

Back

-

PLC Cycle Time

Example of cycle time

optimisation

Mean cycle time

PLC Cycle Time

The PLC cycle time determines the program’s repetition frequency. This

time is not deterministic. This means that when the program in the bus

terminal controller needs more time, the PLC cycle time rises. If the

program needs less than the cycle time, it is repeated at intervals of the set

cycle time.

The processing of the Lightbus and the serial interfaces is executed in the

background time. This should be set to approx. 20 % of the PLC cycle time.

The „mean cycle time“ is measured in order to optimise the system. You will

find this item in PLC Control under Online\Coupler. About 20% – 30% is

added to this, and the result entered as the PLC cycle time. The

background time is then set to 20% of the PLC cycle time.

PLC cycle time

Mean cycle time

10 ms

ground

time

PLC cycle time = mean cycle time + 20% = 10 ms + 20% = 12 ms

Background time = PLC cycle time * 0,2 = 12 ms * 0,2 = 2,4 ms ≈ 2 ms

The measured cycle time also includes that required for the terminal bus

update. This results in a connection between the number of terminals that

are inserted and the cycle time. Before initiating the program, the bus

terminal controller executes a terminal bus update, in order to interrogate

the inputs. After the program has been executed, the BC2000 carries out

another terminal bus update, in order to write the current outputs. The

background time follows this. The cycle time can also be shortened, if the

terminal bus update is carried out simultaneously for inputs and outputs

(see Terminal Bus Update).

PLC Variables

PLC variables are variables that are situated in the BC2000 from addresses

%IB128 and %QB128. This offset can be shifted. These addresses are not

assigned to any terminal, so that signals or data can be transmitted to or

received from the master via the PLC variables.

BC2000 18

Page 20

Remanent Variables

Retained or remanent variables are data that retain their value when

voltage is not present. In PLC Control this data is placed in the allocated

flags area. Following the default setting, this means that all the variables

from %MB0 - %MB63 are RETAIN data. The maximum setting is 512 bytes.

Terminal Bus Update

Double Cycle Terminal bus inputs before the PLC cycle

Before PLC Terminal bus inputs and outputs before the PLC cycle

After PLC Terminal bus inputs and outputs after the PLC cycle

Program Download via the Fibre Optic Ring

TwinCAT offers a facility for transferring the program to the BC2000 over

the optical fibre ring. To do this, string communication and the Ams/Ads

must be activated in the system manager under the ADS/AMS tab. The

TwinCAT system is started after the configuration has been saved. Now the

BC2000 target system can be selected in PLC Control.

Settings in the TwinCAT System Manager

Terminal bus outputs after the PLC cycle

Selection of the target

platform

(Only for TwinCAT)

Selection of the target

system

When TwinCAT PLC Control is restarted, the program asks for the target

platform, i.e. the device on which the user will want his program to run.

TwinCAT offers two target platforms, the PC as a controller and the BC2000

coupler. For the program transfer with the bus terminal controller there are

again two possibilities. „AMS“ is for communication over the fieldbus, while

the „serial“ communication takes place via the PC’s serial interface and the

BC2000 programming interface.

Once the program has been written, the target system is selected under the

„Online“ symbol bar. In this example, the C1220 with the Box1 and the RunTime1 of the bus terminal controller.

19 BC2000

Page 21

Settings in the TwinCAT System Manager

Communication parameters

Program Download via the RS232 Interface

Every bus terminal controller offers the possibility of being programmed via

the PC’s RS232 interface. This can be implemented with the aid of a special

cable (included when TwinCAT BC is supplied).

For this purpose, the serial interface is selected in PLC Control.

The settings for the serial interface, port number, baud rate etc. are found

under Online/Communication parameters in PLC Control.

The bus terminal controller requires the following setting:

Baud rate 19200

Stop bits: 1

Parity: even

General

BC2000 20

ADS Functions

The ADS functions provide a method for accessing the bus terminal

controller information directly. ADS function blocks can be used in TwinCAT

PLC Control for this. The function blocks are contained in the

„PLCSystem.lib“ library. It is also equally possible to call the ADS functions

from AdsOCX. The properties of the PLC runtime system can be retrieved

through port number 800, while port number 100 give access to the

Page 22

registers of the bus terminal controller and the terminals.

Port 800

Index Group / Index Offset

Example

PLC Runtime System

The port number in the BC2000 for the PLC is fixed at 800.

Index Group Meaning

16#4020

16#4021

16#4080

16#F020

16#F021

16#F030

16#F031

The variable in the flags area %MB10 is read directly by the PLC

programme in TwinCAT. The NetId of the target system is given for this

purpose. This number is found in the system manager, and is entered as a

string. The variable „Var1“ is declared as a 2 byte variable (INT or WORD).

As soon as Go_ADSREAD is switched to TRUE, the function block is

active, and the value contained in the BC2000 at %MB10 and %MB11 is

returned in „Var1“.

Settings in the TwinCAT System Manager

Index Offset

Allocated flags area

%MB

Allocated bit flags area

%MX

Cycle time and basic settings 0: minimum cycle time in 1/125

Input

%IB

Input bit

%IX

Output

%QB

Output bit

%QX

0 .. 511

0 .. 4095

ms WORD

1: maximum cycle time in 1/125

ms WORD

2: current cycle time in 1/125 ms

WORD

3: mean cycle time in 1/125 ms

WORD

4: Number of PLC cycles after the

start DWORD

5: Nominal cycle time in ms

WORD

6: Background time in ms WORD

7: Length of the remanent flags

from %MB0 WORD

8: Start(1)/Stop(0) of the cycle

time measurement WORD

9: Time of the terminal bus cycle

WORD

0: Double Cycle

1: Before Cycle

2: After Cycle

0 .. 511

0 .. 4095

0 .. 511

0 .. 4095

21 BC2000

Page 23

Settings in the TwinCAT System Manager

i

Port 100

Index Group / Index Offset

Note

Registers of the Bus Terminal Controller

The port number in the BC2000 for register communication is fixed at 100.

Index Group

0

1-64

Index Offset

High WORD Low WORD

0-127 0-255 Controller registers

0-3 1-64 Terminal registers

Meaning

High WORD table number of the

controller

Low WORD register number of

the table

High WORD channel number

Low WORD register number of

the terminal

When reading registers it should be noted that the time out for the ADS

block is set to a time longer than 1 sec.

Diagnostics in the BC2000

It is possible to read the diagnostic data in the bus terminal controller. This

information is located in the flags area.

Flag byte

%MW508

%MW510

Meaning

Bit 0: Fieldbus error

Bits 1-15: reserved

Bit 0: Terminal bus error

Bit 1: Configuration error

Bits 2-15: reserved

BC2000 22

Page 24

Settings in TwinCAT PLC

Some of the settings for the BC2000 are only possible in PLC Control.

These are primarily a matter of properties that have a direct effect on the

program.

The points that follow here are found in PLC Control under „ONLINE“

„Coupler“.

Settings in TwinCAT PLC

Terminal Bus Reset

The terminal bus reset has its effect on the coupler’s internal bus. If there is

an error, which can be seen by the flashing of the „I/O ERR“ LED, the

terminal bus can be re-started. At the same time the number of connected

terminals is shown to the user in a message box.

Coupler Reset

The coupler will go through the same initialisation sequence as occurs

when the coupler is switched on.

Manufacturer’s Configuration

The coupler’s default values are written into the tables, and any boot project

that may be present is de-activated. The manufacturer’s configuration is

only activated after the coupler is reset.

Cycle Time Measurement

This measurement is related to the running time needed for the program to

execute and the terminal bus update. (See the chapter on „PLC Cycle

Time“)

Boot Project

In order to save the program, „Create a boot project“ is found under the

„Online“ menu item. This permits the program to be started automatically

after switching on. If the boot project is saved in the bus terminal controller

the „PLC“ LED on the BC2000 flashes.

23 BC2000

Page 25

Settings in TwinCAT PLC

Coupler Options

The maximum size of the program memory and of the data memory can be

set in PLC Control under „Projects“, „Options“, „Coupler“. In the „small

memory model“, a variable size for the data and program memories is

possible. The maximum memory size is 64 kbyte. In the „large memory

model“ a maximum of 96 kbyte program memory and 64 kbyte data

memory are the upper limits.

It should be noted that in the „large memory model“ the EEPROM is also

used.

BC2000 24

Page 26

Appendix

Appendix

Absolute Addressing in the BC2000

Input Output

KL3002 %IB0 Status KL3002 %QB0 Control

KL3002 %IB1 Empty KL3002 %QB1 Empty

KL3002 %IB2 D0 KL3002 %QB2 D0

KL3002 %IB3 D1 KL3002 %QB3 D1

KL3002 %IB4 Status KL3002 %QB4 Control

KL3002 %IB5 Empty KL3002 %QB5 Empty

KL3002 %IB6 D0 KL3002 %QB6 D0

KL3002 %IB7 D1 KL3002 %QB7 D1

2 x KL1002 %IX8.0..

%IX8.3

KL4002 %QB9 D1

KL4002 %QB10 D0

KL4002 %QB11 D1

2 x KL2012 %QX12.0..

... ... ... ...

PLC variable

INT Offset0_1

Inputs

PLC variable

INT Offset0_2

Inputs

%IB128..129 PLC variable

%IB130..131 PLC variable

KL4002 %QB8 D0

%QX12.3

%QB128..129

INT Offset0_1

Outputs

%QB130..131

INT Offset0_2

Outputs

Terminals 2, 3, 6, 7 and 10 are directly assigned to the Lightbus master,

and are therefore neither visible to the BC2000, nor do they appear in the

PLC’s input and output process image.

25 BC2000

Page 27

Index

Index

A

ADS Functions 18

Assembly 8

B

Background time 16

BC2000 dimensions 8

Blink code 10

Boot project 21

C

Configuration Interface 6

Connection 8

Coupler options 22

Coupler reset 21

Cycle time 16

Cycle time measurement 21

D

Data memory 22

Device description 3

Diagnostic LEDs 10

Diagnostics 10, 20

E

Electrical power supply 5

End terminal 4

F

Fieldbus connection 6

Fieldbus errors 11

K

K bus 4

L

Lightbus 13

Lightbus connector 6

M

Manufacturer’s configuration 21

Master interface 13

Mechanical structure 8

N

Number of terminals 3

O

Optical fibre 14

P

PLC Cycle Time 16

PLC data 10

PLC Variables 16

Port 100 20

Port 800 19

Power contacts 5

Program download 17

Program memory 22

R

Remanent Variables 17

G

Galvanic isolation 6

S

Setting up for operation 10

System Manager 15

I

Insulation testing 8

Interfaces 5

T

Terminal bus reset 21

Terminal Bus Update 17

BC2000 26

Page 28

Support and Service

Support and Service

Beckhoff and their partners around the world offer comprehensive support and service, making available

fast and competent assistance with all questions related to Beckhoff products and system solutions.

Beckhoff's branch offices and representatives

Please contact your Beckhoff branch office or representative for local support and service on Beckhoff

products!

The addresses of Beckhoff's branch offices and representatives round the world can be found on her

internet pages: http://www.beckhoff.com

You will also find further documentation for Beckhoff components there.

Beckhoff Headquarters

Beckhoff Automation GmbH

Eiserstr. 5

33415 Verl

Germany

phone: + 49 (0) 5246/963-0

fax: + 49 (0) 5246/963-198

e-mail: info@beckhoff.com

web: www.beckhoff.com

Beckhoff Support

Support offers you comprehensive technical assistance, helping you no only with the application of

individual Beckhoff products, but also with other, wide-ranging services:

• support

• design, programming and commissioning of complex automation systems

• and extensive training program for Beckhoff system components

hotline: + 49 (0) 5246/963-157

fax: + 49 (0) 5246/963-9157

e-mail: support@beckhoff.com

Beckhoff Service

The Beckhoff Service Center supports you in all matters of after-sales service:

• on-site service

• repair service

•

spare parts servive

• hotline service

hotline: + 49 (0) 5246/963-460

fax: + 49 (0) 5246/963-479

e-mail: service@beckhoff.com

27 BC2000

Loading...

Loading...