Page 1

Version : 4.5

Date: 2015

Language: English

Article no.: TDmlAX

BECKHOFF

Startup

Servo Drive AX5000

(1.5 A – 40 A)

Please read this document carefully before installing and commissioning the servo drive.

-04-01

-5000-0000-0200

Page 2

1 Foreword BECKHOFF Drive Technology

Notes:

2 Version : 4.5 AX5000

Page 3

BECKHOFF Drive Technology 1 Foreword

Chapter Page

Table of Contents - AX5000 Startup

1 Foreword ............................................................................................................... 5

1.1 Notes on the documentation ............................................................................... 5

1.2 Disclaimer ........................................................................................................... 5

1.3 Trademarks ........................................................................................................ 5

1.4 Patent Pending ................................................................................................... 5

1.5 Copyright ............................................................................................................ 6

1.6 Documentation issue status ............................................................................... 6

1.7 Appropriate use .................................................................................................. 7

1.7.1 Dual Use (EU 1384/2014) .................................................................................. 7

1.8 Documented servo drives ................................................................................... 8

2 Safety .................................................................................................................... 9

2.1 General safety instructions ................................................................................. 9

2.1.1 Safety rules ........................................................................................................ 9

2.1.2 Disclaimer ........................................................................................................... 9

2.1.3 Description of safety symbols ............................................................................. 9

2.1.4 Personnel qualification ..................................................................................... 10

2.2 Special safety instructions for AX5000 ............................................................. 10

3 Guidelines and Standards ................................................................................. 12

3.1 CE conformity ................................................................................................... 12

3.2 Electromagnetic compatibility ........................................................................... 12

3.3 UL-Listing in USA and Canada ......................................................................... 13

3.3.1 UL-specific chapter changes ............................................................................ 13

3.3.2 UL-specific chapter ........................................................................................... 13

3.3.3 UL-specific notes .............................................................................................. 14

3.4 Electrical isolation according to EN 50178 / VDE 160 ...................................... 14

4 Product description ........................................................................................... 15

4.1 Type code ......................................................................................................... 15

4.2 Scope of supply ................................................................................................ 15

4.2.1 Standard scope of supply ................................................................................. 15

4.2.2 Accessories ...................................................................................................... 16

4.3 Name plate ....................................................................................................... 16

4.4 Technical data .................................................................................................. 17

4.4.1 Permissible ambient and operating conditions ................................................. 17

4.4.2 Electrical data - single-channel servo drive (AX51xx)....................................... 17

4.4.2.1 Single-phase connection .................................................................................. 17

4.4.2.2 Three-phase connection ................................................................................... 18

4.4.3 Electrical data - two-channel servo drive (AX52xx) .......................................... 19

4.4.3.1 Single-phase connection .................................................................................. 19

4.4.3.2 Three-phase connection ................................................................................... 19

4.4.4 Mechanical data (single-channel servo drive) .................................................. 20

4.4.5 Mechanical data (two-channel servo drive) ...................................................... 20

4.5 General overview (AX5101 – AX5112 and AX520x) ........................................ 21

4.6 General overview (AX5118, AX5125 und AX5140) .......................................... 22

4.7 Overview of connectors/terminal points ............................................................ 23

AX5000 Version : 4.5 3

Page 4

1 Foreword BECKHOFF Drive Technology

4.7.1 X01 - wide voltage input ................................................................................... 23

4.7.2 X02 - DC link (AX5101 - AX5125 und AX520x) ................................................ 23

4.7.3 X02 - DC link (Only AX5140) ............................................................................ 23

4.7.4 X03 - 24 VDC supply ......................................................................................... 23

4.7.5 X04, X05 - EtherCAT connection ..................................................................... 24

4.7.6 X06 – Digital I/Os ............................................................................................. 24

4.7.7 X11 (channel A) , X21 (channel B) - feedback, high-resolution ........................ 25

4.7.8 X12 (channel A) , X22 (channel B) - resolver/hall ............................................ 25

4.7.9 X13 (channel A) , X23 (channel B) - motor connection (power) ....................... 26

4.7.10 X13 - motor connection (power - only AX5140) ................................................ 26

4.7.11 X14 (channel A), X24 (channel B)-motor brake, thermal contact, OCT ............ 26

4.7.12 X07 – internal and external brake resistor ........................................................ 27

4.8 Dimensions ...................................................................................................... 28

5 Installation .......................................................................................................... 30

5.1 Mechanical installation ..................................................................................... 30

5.1.1 Installation in the control cabinet ...................................................................... 30

5.1.1.1 Installation example - AX5101-AX5112 and AX5201-AX5206 ......................... 31

5.1.1.2 Installation example - AX5118, AX5125 and AX5140 ...................................... 31

5.2 Electrical installation ......................................................................................... 32

5.2.1 Mains supply connection (X01) ........................................................................ 33

5.2.1.1 External protection for individual devices, CE-compliant .................................. 33

5.2.1.2 Internal protection, CE-compliant ..................................................................... 33

5.2.1.3 External protection, UL-compliant .................................................................... 34

5.2.1.4 Internal protection, UL-compliant ..................................................................... 34

5.2.1.5 External drive system protection ...................................................................... 35

5.2.2 24 VDC - supply network connection (X03) ....................................................... 36

5.2.3 Connection of several servo drives to form a drive system .............................. 36

5.2.3.1 Connection example - module AX5901 and AX5911 (AX Bridge) .................... 37

5.2.3.2 Connection example - wiring in series without AX Bridge ................................ 38

5.2.4 Configuration example, general ....................................................................... 39

5.2.5 Connection diagram AX5101 – AX5112 and AX520x ...................................... 40

5.2.6 Connection diagram AX5118, AX5125 and AX5140 ........................................ 41

5.3 Motors and cables ............................................................................................ 42

6 Important information for commissioning ....................................................... 43

7 Project planning – important information ........................................................ 44

7.1 Drive train design ............................................................................................. 44

7.1.1 Control quality, mass inertia ratio and load connection .................................... 44

7.2 Energy management ........................................................................................ 44

7.3 EMC, earthing, screen connection and potential .............................................. 45

7.4 Control cabinet ................................................................................................. 45

8 Appendix ............................................................................................................ 46

8.1 Support and Service ......................................................................................... 46

8.1.1 Beckhoff's branch offices and representatives ................................................. 46

8.1.2 Beckhoff Headquarters..................................................................................... 46

8.1.3 Beckhoff Support .............................................................................................. 46

8.1.4 Beckhoff Service .............................................................................................. 46

4 Version : 4.5 AX5000

Page 5

BECKHOFF Drive Technology 1 Foreword

Hazard to individuals!

1 Foreword

1.1 Notes on the documentation

This description is only intended for trained specialists in control, automation and drive

engineering who are familiar with the applicable national standards. It is essential that the

following notes and explanations are followed when installing and commissioning these

components. The responsible staff must ensure that the application or use of the products

described satisfy all the requirements for safety, including all the relevant laws, regulations,

guidelines and standards. The "General safety instructions" and "Special safety instructions

for AX5000" sections are also essential.

Further and more detailed information regarding the individual sections and

CAUTION

An overview is provided on the inside of the rear cover, which can be folded out.

1.2 Disclaimer

The documentation has been prepared with care. The products described are, however,

constantly under development. For this reason, the documentation may not always be have

been fully checked for consistency with the performance data, standards or other

characteristics described. In the event that it contains technical or editorial errors, we retain

the right to make alterations at any time and without warning. No claims for the modification

of products that have already been supplied may be made on the basis of the data,

diagrams and descriptions in this documentation.

safety can be found in the “AX5000 User manual” on the enclosed CD or

can be downloaded from our website at www.beckhoff.com. If you do not

have access to the “AX5000 User manual” please refrain from working on

the AX5000 and notify our support division.

1.3 Trademarks

Beckhoff®, TwinCAT®, EtherCAT®, Safety over EtherCAT®, TwinSAFE® and XFC® are

registered trademarks of and licensed by Beckhoff Automation GmbH.

Other designations used in this publication may be trademarks whose use by third parties

for their own purposes could violate the rights of the owners.

1.4 Patent Pending

The EtherCAT Technology is covered, including but not limited to the following patent

applications and patents:

EP1590927, EP1789857, DE102004044764, DE102007017835

with corresponding applications or registrations in various other countries.

The TwinCAT Technology is covered, including but not limited to the following patent

applications and patents:

EP0851348, US6167425 with corresponding applications or registrations in various other

countries.

AX5000 Version : 4.5 5

Page 6

1 Foreword BECKHOFF Drive Technology

Version

Comment

4.5

New chapter:

4.7.11; 5.2.1.1

4.4

Chapter-Update:

4.4.2; 4.4.3

4.3

New chapter:

1.5; 2.1.2; 4.3; 5.3; 8.1.2

4.2

Deleted chapter:

5.3

4.1

General revision

4.0

General revision on account of the cULus-Listing of the AX5000.

3.9

Chapter-Update:

4.7.4

3.8

Chapter-Update:

4.3; 4.4.1; 4.7.11; 7.5

3.7

Chapter-Update:

1.1; 4.4.4; 5.1.1.2

3.6

Chapter-Update:

2.2; 4.4.2.2; 4.6; 4.7.11

3.5

Chapter-Update:

6

3.4

Chapter-Update:

4.7.11

3.3

New chapter:

4.7.3

3.2

Chapter-Update:

4.7.2

3.1

Chapter-Update:

1.5 Copyright

© Beckhoff Automation GmbH & Co. KG

The reproduction, distribution and utilization of this document as well as the communication

of its contents to others without express authorization are prohibited.

Offenders will be held liable for the payment of damages. All rights reserved in the event of

the grant of a patent, utility model or design.

1.6 Documentation issue status

5.2.5; 5.2.6

Chapter-Update:

1.7.1

Chapter-Update:

7.5

New chapter:

4.7.11; 5.2.1.1; 7.5

6 Version : 4.5 AX5000

Page 7

BECKHOFF Drive Technology 1 Foreword

3.0

Chapter-Update:

1.8; 4.6; 4.7.9; 4.7.11; 7

2.5

Chapter-Update:

4.6.7; 6

2.4

Chapter-Update:

1.3; 1.4

2.3

Chapter-Update:

6

2.2

Chapter-Update:

2.2; 3.1; 4.6.6; 4.6.8; 5.1.1; 5.2.1.5

2.1

Chapter-Update:

4.1; 4.6.6; 5.2.3

2.0

General revision on account of the UL-Listing of the AX5000.

1.3

Chapter-Update:

1.1; 4.4.2.1; 4.4.2.2; 4.4.3.1; 4.4.3.2; 5.2.1; 5.2.1.1

1.2

General routine corrections

1.1

First edition

1.0

only german

Caution – Risk of injury!

brought into a safe state in the event of a fault in the drive system.

4.2.1; 4.4.2.2; 4.4.4; 4.8; 5.1.1.2; 5.2.1.1

New chapter:

1.1; 1.2; 1.5; 4.5; 5.2

New chapter:

2.2; 5.2.3.1

New chapter:

1.7 Appropriate use

The servo drives of the AX5000 series are exclusively designed for torque, speed and

position control of suitable asynchronous and synchronous three-phase current motors. The

maximum permissible effective motor voltage must be at least equal the effective mains

voltage fed into the servo drive.

The servo drives from the AX5000 series are designed for installation as components in

electrical systems or machines and may be operated only as integrated system or machine

components.

Electronic equipment is not fail-safe. The machine manufacturer is

WARNING

The servo drives may only be operated in enclosed control cabinets and in accordance with

the conditions described in the "Technical data" section.

responsible for ensuring that the connected motors and the machine are

1.7.1 Dual Use (EU 1384/2014)

As published on December 30, 2014 by EU Commission Delegated Regulation

1382/2014, standard frequency inverters – and with that also Beckhoff products AX5000

– become newly classified Dual-Use items: the item list Annex I of the Dual-Use

AX5000 Version : 4.5 7

Page 8

1 Foreword BECKHOFF Drive Technology

Council Regulation 428/2009 has been changed accordingly, Frequency inverters

(listed in item position 3A225) with „operating frequency of 600 Hz or more“ are now

export controlled items. As a consequence some modifications have to be noticed.

Firmware versions without extension (Dual Use) can be used in consideration of Hardware

Versions with following drives:

• HW Version 1.0 (AX5xxx-0000-x0xx): Serial Number < 68.000

• HW Version 2.0 (AX5xxx-0000-x2xx): Serial Number < 140.000

• HW Version 2.0 (AX5xxx-0000-x21x)

Firmware versions with extension (Dual Use) can be used in consideration of Hardware

Versions with all drives

1.8 Documented servo drives

This documentation describes the following servo drives in the AX5000 range:

AX5101

AX5103

AX5106

AX5112

AX5118

AX5125

AX5140

AX5201

AX5203

AX5206

8 Version : 4.5 AX5000

Page 9

BECKHOFF Drive Technology 2 Safety

DANGER

Acute risk of injury!

WARNING

Risk of injury!

CAUTION

Hazard to individuals!

Attention

Hazard to devices and environment

Note

Note or pointer

UL pointer

This symbol indicates important information about the UL-compliant.

2 Safety

2.1 General safety instructions

2.1.1 Safety rules

Consider the following safety instructions and descriptions!

Product specific safety instructions are to be found on the following pages or in the areas

mounting, wiring, commissioning etc..

2.1.2 Disclaimer

All the components are supplied in particular hardware and software configurations

appropriate for the application. Modifications to hardware or software configurations other

than those described in the documentation are not permitted, and nullify the liability of

Beckhoff Automation GmbH & Co. KG.

2.1.3 Description of safety symbols

The following safety symbols with a adjoining safety advise are used in this manual. You

have to read the adjoining safety advice carefully and adhere it strictly.

If you do not adhere the safety advise adjoining this symbol, there is

immediate danger to life and health of individuals!

If you do not adhere the safety advise adjoining this symbol, there is

danger to life and health of individuals!

If you do not adhere the safety advise adjoining this symbol, there is

obvious hazard to individuals!

If you do not adhere the notice adjoining this symbol, there is obvious

hazard to materials and environment.

This symbol indicates information that contributes to better understanding.

AX5000 Version : 4.5 9

Page 10

2 Safety BECKHOFF Drive Technology

Serious risk of injury through high electrical voltage!

safe once the voltage has fallen below 50 V.

Serious risk of injury through hot surfaces!

sufficiently.

WARNING

Danger of injury due to uncontrolled movements!

2.1.4 Personnel qualification

This description is only intended for trained specialists in control, automation and drive

engineering who are familiar with the applicable national standards.

2.2 Special safety instructions for AX5000

The safety instructions are designed to avert danger and must be followed during

installation, commissioning, production, troubleshooting, maintenance and trial or test

assemblies.

The servo drives of the AX5000 series are not designed for stand-alone operation and must

always be installed in a machine or system. After installation the additional documentation

and safety instructions provided by the machine manufacturer must be read and followed.

• Never open the servo drive when it is live. Wait until the DC link

WARNING

capacitors are discharged. The voltage measured between the DC+ and

DC- terminals (X02) must have fallen below 50 V. Opening the device

(with the exception of expansion card slots) invalidates all warranty and

liability claims against Beckhoff Automation GmbH.

• Negligent, improper handling of the servo drive and bypassing of the

safety devices can lead to personal injury or death through electric

shock.

• Ensure that the protective conductor is connected properly.

• Disconnect the servo drive from the mains supply and secure it against

reconnection before connecting or disconnecting the pluggable terminals.

• Disconnect the servo drive from the mains supply and secure it against

reconnection before working on electrical parts with a voltage > 50 V.

• Due to the DC link capacitors dangerous voltage may persist at the DC

link contacts "X02" after the servo drive has been disconnected from the

mains supply. After disconnecting the servo drive wait 5 minutes and

measure the voltage at the DC link contacts DC+ and DC-. The device is

WARNING

10 Version : 4.5 AX5000

• The surface temperature may exceed 50 °C, resulting in a risk of burns.

• Avoid touching the case during or shortly after operation.

• Leave the servo drive to cool down for at least 15 minutes after it is

switched off.

• Use a thermometer to check whether the surface has cooled down

Read and take note of chapter 6 ‘Important information for commissioning’

each time before commissioning the AX5000

Page 11

BECKHOFF Drive Technology 2 Safety

Hazard to individuals!

Directive in national legislation.

Hazard to devices and environment

- Do not touch the motor plug during operation of the AX5000.

• Carefully read this manual before using the servo drive thoroughly,

CAUTION

Attention

paying particular attention to the safety instructions. In the event of any

uncertainties please notify your sales office immediately and refrain from

working on the servo drive.

• Only well trained, qualified electricians with sound knowledge of drive

equipment may work on the device.

• During the electrical installation it is essential to ensure that the correct

fuses/protective circuit breakers are used between the mains supply and

the servo drive. Further information can be found in the "Electrical

installation" section.

• If a servo drive is installed in a machine it must not be commissioned

until proof of compliance of the machine with the latest version of the EC

Machinery Directive has been provided. This includes all relevant

harmonised standards and regulations required for implementation of this

• During installation it is essential to ensure that the specified ventilation

clearances and climatic conditions are adhered to. Further information

can be found in the "Technical data" and "Mechanical installation"

sections.

• If the servo drive is operated in contaminated ambient air, the cooling

openings must be checked regularly for blockage. These checks should

be carried out several times per day.

• The servo drives contain components at risk from electrostatic discharge

caused by improper handling:

- Please ensure you are electrostatically discharged before touching

the servo drive directly.

- Avoid contact with highly insulating materials

(synthetic fibres, plastic film etc.).

- Place the servo drive on a conductive surface.

AX5000 Version : 4.5 11

Page 12

3 Guidelines and Standards BECKHOFF Drive Technology

Hazard to individuals!

conformity of the complete machine or system.

3 Guidelines and Standards

3.1 CE conformity

The servo drives of the AX5000 series comply with the

• EC Low-Voltage Directive, 2006/95/EC

Applied harmonised standards:

61800-5-1

Servo drives are not covered by the EC Machinery Directive. Operation

CAUTION

3.2 Electromagnetic compatibility

The servo drives of the AX5000 series comply with the

• 2004/108/EC EMC Directive

Applied harmonised standards:

IEC / EN 61000-4-2

IEC / EN 61000-4-3

IEC / EN 61000-4-4

IEC / EN 61000-4-5

IEC / EN 61000-4-6

IEC / EN 61000-6-1

IEC / EN 61000-6-2

IEC / EN 61000-6-3

IEC / EN 61000-6-4

IEC / EN 61800-3

of the servo drives in machines or systems is only permitted once the

machine or system manufacturers has provided evidence of CE

12 Version : 4.5 AX5000

Page 13

BECKHOFF Drive Technology 3 Guidelines and Standards

AX5000 with UL-Listing

AX5203 und AX5206

Drive system with UL-Listing!

Please consult our Application Department with respect to the requirements

for a drive system with UL-Listing.

Fusing

AX5101

AX5103

AX5106

AX5201

AX5203

AX5206

AC supply (max.) *)

6 A

12 A

20 A

12 A

20 A

20 A

24 V supply (max.)

3 A

Brake resistor

electronic

Fusing

AX

5101

5103

5106

5112

5118

5125

5140

5201

5203

5206

AC suppl (max.)*)

6 A

12 A

20 A

20 A

35 A

45 A

80 A

12 A

20 A

20 A

24 V supply (max.)

3 AT

Brake resistor

elektronisch

3.3 UL-Listing in USA and Canada

The following servo drives from the AX5000 series have a UL-Listing and must bear the

CUS symbol

AX5101, AX5103, AX5106, AX5112, AX5118, AX5125, AX5140, AX5201,

on the name plate. If you wish to operate an AX5000 in USA or Canada , please check that

there is a CUS symbol on the name plate.

Below is a list of the relevant chapters that are amended with respect to the UL-Listing.

Furthermore, UL-specific remarks are listed. It is essential to observe these specifications.

3.3.1 UL-specific chapter changes

“5.2.1 Mains supply connection (X01)”

AX5000 shall be connected only to a grounded wye-source where the

maximum voltage does not exceed 277 V to ground.

“5.2.3 Connection of several servo drives to form a drive system”

3.3.2 UL-specific chapter

“5.2.1.3 External protection, UL-compliant”

Integral solid state short circuit protection does not provide branch circuit protection. Branch

circuit protection must be provided in accordance with the Manufacture Instructions, National

Electrical Code and any additional local codes.

Suitable for use on a circuit capable of delivering not more than 18000 rms symmetrical

amperes, 480 V maximum, when protected by RK5 class fuses.

Single-phase

*) Mains fuses according to type “RK5” must be used.

Three-phase

*) Mains fuses according to type “RK5” must be used.

AX5000 Version : 4.5 13

Page 14

3 Guidelines and Standards BECKHOFF Drive Technology

When protected by RK5 class fuses:

Rated 80 A, min. 480 V

Canada!

by Beckhoff Automation.

AX5112

Rated 20 A, min. 480 V

AX5118

Rated 35 A, min. 480 V

AX5125

Rated 45 A, min. 480 V

AX5140

3.3.3 UL-specific notes

Use in a Pollution Degree 2 environment

Use 75 °C Copper Conductors min.

Control Board rating = 24 V

Drive intended for use over a range of motor sizes. Internal motor overload protection

level is adjustable:

The internal motor protection is parameterised via the IDN P-0-0062 “Thermal motor model”,

based on the value of the IDN S-0-0111 “Motor continuous stall current”. The IDN P-0-0062

“Time constant” is specified by the motor manufacturer and must be entered here. The IDN

P-0-0062 “Warning limit” (Default) is responsible for deciding when a warning is to be

generated. The IDN P-0-0062 “Error limit” (Default) is responsible for deciding when the

motor is to be switched off. The default values take into account the specific characteristics

of the servomotors.

In Canada use only in combination with unit AX2090-TS50, manufactured

3.4 Electrical isolation according to EN 50178 / VDE 160

The power section (motor connection, DC link connection and mains connection) and the

control unit are doubly insulated against each other, so that safe protection against

accidental contact is ensured at all terminals of the control unit without additional measures.

The air and creepage distances also meet the requirements of the above standard.

14 Version : 4.5 AX5000

Page 15

BECKHOFF Drive Technology 4 Product description

X 5 Z Y b a d c X A -

Product line:

Servo Drives

Series:

5000

Number of channels:

channel

channel

Rated current per channel

channel units:

01, 03, 06, 12, 18, 25,

40, 60, 72, 90

channel units:

01, 03, 06

Version:

0 = Standard

1 = Customer

Hardware features:

00 = Standard

01 = Cold Plate

02 = Auxiliary fan

---

4 Product description

The servo drives of the AX5000 series are available as single- or multi-channel versions and

are optimised in terms of function and cost-effectiveness. In conjunction with EtherCAT, the

real-time Ethernet system, the integrated control technology offers minimum cycle times and

supports fast, highly dynamic positioning tasks.

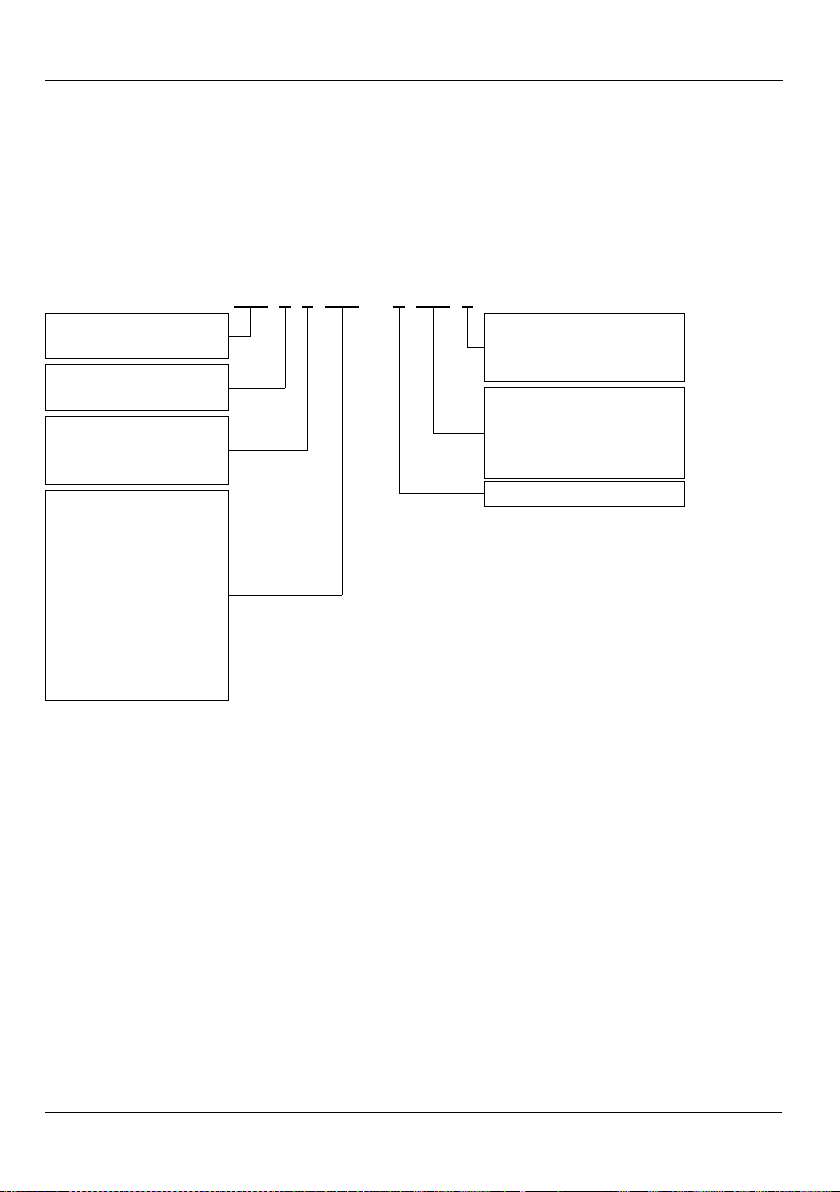

4.1 Type code

1 = single-

2 = two-

Single-

or:

91 = 110 A

92 = 143 A

93 = 170 A

Two-

4.2 Scope of supply

-specific

The scope of delivery may vary depending on the ordered configuration. Before installing the

device please ensure that all ordered components were delivered and that they are

undamaged. In the event of any damage please contact the carrier immediately and

document the damage.

4.2.1 Standard scope of supply

− AX5000 in the performance class according to the order

− Connectors for:

X01: Mains input

X02: DC link

X03: DC power supply 24 V

X06: Digital inputs and outputs

X07: External brake resistor (only AX5140)

− Startup (this manual)

− Complete documentation on CD

AX5000 Version : 4.5 15

Page 16

4 Product description BECKHOFF Drive Technology

Accessories with UL-Listing!

that the accessories also have a UL-Listing.

1

Catalog number

6

Output rated voltage

11

Customer-specific

2

Max. ambient temperature

7

Output rated current

12

wye-source only

3

Input rated voltage

8

Output frequency range

13

CE - Conform

4

Input rated current

9

Protection class

14

cULus – Listed

5

Input frequency

10

Serial number

Large

Small

4.2.2 Accessories

A comprehensive list of accessories can be found in the complete Beckhoff catalogue or on

our website at www.beckhoff.com.

If you wish to operate an AX5000 in USA or Canada , please make sure

4.3 Name plate

The servo drive features two name plates. A comprehensive name plate can be found on the

right-hand side. An extract showing the main data can be found at the top of the servo drive.

name

plate

name

plate

16 Version : 4.5 AX5000

Page 17

BECKHOFF Drive Technology 4 Product description

UL-Listing!

USA or Canada.

Ambient / operating conditions

Permissible values

Ambient temperature during operation

0 °C to +50 °C

Ambient temperature during transport /

storage

-25 °C to +70 °C

Air humidity

5 % to 95 %, non-condensing

Pollution degree

2 according to EN 60204/EN 50178

Corrosion protection

Normally not required.

measures must be agreed with the manufacturer.

Operating altitude

up to 1000 m above sea level

Installation position

vertical

Ventilation

Total device current ≤ 3 A: free convection

controlled fan

Protection class

IP 20

Vibration test (EN 60068-2-6)

Frequency range: 10-500 Hz

59-500 Hz = 1 g

Shock test (EN 60068-2-27)

Half sine wave amplitude: 5 g

(total 18)

Repetitive shock test (EN 60068-2-27)

Half sine wave amplitude: 5 g

(total 6000)

EMC

Category C3 - standard

Category C2, C1 - auxiliary filter required

Electrical data

AX5101

AX5103

AX5106

Rated output current

1.5 A

3 A

4.5 A

Minimum channel current at full current

resolution

Max. output current

(1)

4.5 A

7.5 A

13 A

Rated supply voltage

1x 100

-10%

– 240

+10% VAC

Max. DC link voltage

890 VDC

Rated apparent power

4.4 Technical data

It is essential to observe chapter 3.3 if you wish to operate an AX5000 in

4.4.1 Permissible ambient and operating conditions

Under extreme operating conditions separate

Total device current > 3 A: built-in temperature-

Amplitude: 10-58 Hz = 0,075 mm pk-pk

Duration: 30 ms

Number of shocks: 3 per axis and direction

Duration: 30 ms

Number of shocks: 1000 per axis and direction

4.4.2 Electrical data - single-channel servo drive (AX51xx)

4.4.2.1 Single-phase connection

0.35 A 1 A 1 A

AX5000 Version : 4.5 17

Page 18

4 Product description BECKHOFF Drive Technology

Electrical data

AX5101

AX5103

AX5106

S1 mode (selection)

230 V

0.6 kVA

1.2 kVA

2.4 kVA

Power dissipation

(2)

35 W

50 W

85 W

Max. continuous braking power

(with internal brake resistor)

Max. braking power

(with internal brake resistor)

Min. brake resistor

(external brake resistor)

Max. braking power

(with external brake resistor)

Electrical data

AX

5101

5103

5106

5112

5118

5125

5140

Rated output current [A]

1,5 3 6

12

18

25

(1)

40

Minimum channel current [A]

at full current resolution

Max. output current

(3)

[A]

4,5

7,5

13

26

36

50

80

(4)

Rated supply voltage [VAC]

3x 100

-10%

– 480

+10%

(2)

Max. DC link voltage [VDC]

890

Rated apparent power [kVA]

480 V

1,2

2,5

5,0

10,0

15,0

20,8

33,3

Power dissipation

(5)

[W]

35

50

85

160

255

340

510

Max. continuous braking power [W]

(with internal brake resistor)

Max. braking power [kW]

(with internal brake resistor)

Min. brake resistor [Ω]

(external brake resistor)

Max. braking power [kW]

(external brake resistor)

120 V

0.3 kVA

50 W 50 W 150 W

(1)

I

for max. 7 s

eff

(2)

S1 mode, including power supply unit, without brake chopper

4.4.2.2 Three-phase connection

0,35 1 1 6 8 12 18

S1-mode (selection)

120 V

230 V

400 V

0,3

0,6

1,0

0,6

1,2

2,1

1,2

2,4

4,2

0.6 kVA

14 kW

47 Ω

15 kW

2,5

4,8

8,3

3,4

7,2

12,5

1.2 kVA

4,8

10,0

17,3

8,3

16,0

27,7

50 50 150 90 200 200 150

14 26 26 26

47 47 47 30 22 22 22

15 15 15 23,5 32 32 32

(1)

cULus = 24 A

(2)

cULus = AX5118 und AX5125 = 3 x 480 VAC

(3)

I

for max. 7 s

eff

(4)

I

for max. 7 s, if rotating field frequency >3 Hz at max. 40°C

eff

(5)

S1 mode, including power supply unit, without brake chopper

(4)

Brake resistor < 22 Ω –> Please consult our Application Department

18 Version : 4.5 AX5000

± 10%

(4)

Page 19

BECKHOFF Drive Technology 4 Product description

Electrical data

AX5201

AX5203

AX5206

Rated output current / channel

1.5 A

3 A

6 A

Minimum channel current at full current

resolution

Maximum rated channel current

3 A

4.5 A

9 A

Total rated output current

3 A

4.5 A

9 A

Max. output current

(1)

/channel

5 A

10 A

13 A

Max. output current

(1)

total device

current

Rated supply voltage

1x 100

-10%

– 240

+10% VAC

Max. DC link voltage

890 VDC

Rated apparent power

230 V

1.2 kVA

2.4 kVA

4.8 kVA

Power dissipation

(2)

55 W

85 W

160 W

Max. continuous braking power

(with internal brake resistor)

Max. braking power

(with internal brake resistor)

Min. brake resistor

(external brake resistor)

Max. braking power

(with external brake resistor)

Electrical data

AX5201

AX5203

AX5206

Rated output current per channel

1.5 A

3 A

6 A

Minimum channel current at full current

resolution

Maximum rated channel current

3 A

6 A

9 A

Total rated output current

3 A

6 A

12 A

Max. output current

(1)

/channel

5 A

10 A

13 A

Peak output current

(1)

total device

current

Rated supply voltage

3x 100

-10%

– 480

+10% VAC

Max. DC link voltage

890 VDC

Rated apparent power

120 V

0.6 kVA

1.2 kVA

2.5 kVA

4.4.3 Electrical data - two-channel servo drive (AX52xx)

4.4.3.1 Single-phase connection

0.35 A 1 A 1 A

10 A 20 A 26 A

S1 mode (selection)

120 V

0.6 kVA

50 W 150 W 90 W

(1)

I

for max. 7 s

eff

(2)

S1 mode, including power supply unit, without brake chopper

4.4.3.2 Three-phase connection

0.35 A 1 A 1 A

10 A 20 A 26 A

1.2 kVA

14 kW

47 Ω

15 kW

2.5 kVA

S1 mode (selection)

AX5000 Version : 4.5 19

Page 20

4 Product description BECKHOFF Drive Technology

Electrical data

AX5201

AX5203

AX5206

230 V

480 V

1.2 kVA

2.5 kVA

2.4 kVA

5.0 kVA

4.8 kVA

10.0 kVA

Power dissipation

(2)

55 W

85 W

160 W

Max. continuous braking power

(with internal brake resistor)

Max. braking power

(with internal brake resistor)

Min. brake resistor

(external brake resistor)

Max. braking power

(with external brake resistor)

Mechanical data

AX

5101

5103

5106

5112

5118

5125

5140

Weight [kg]

ca. 4

ca. 4

ca. 5

ca. 5

ca. 11

ca. 11

ca. 13

Width [mm]

92

185

Height without plugs [mm]

274

Depth without connectors/ [mm]

accessories

232

Mechanical data

AX5201

AX5203

AX5206

Weight

approx. 5 kg

approx. 6 kg

approx. 6 kg

Width

92 mm

Height without plugs

274 mm

Depth without connectors / accessories

232 mm

400 V

2.1 kVA

4.2 kVA

50 W 150 W 90 W

(1)

I

for max. 7 s

eff

(2)

S1 mode, including power supply unit, without brake chopper

4.4.4 Mechanical data (single-channel servo drive)

4.4.5 Mechanical data (two-channel servo drive)

8.3 kVA

14 kW

47 Ω

15 kW

20 Version : 4.5 AX5000

Page 21

BECKHOFF Drive Technology 4 Product description

Item description:

No

Designation

1

X11 – feedback connection, encoder

2

X12 – feedback connection, resolver

3

X21 – feedback connection, encoder

channel B (only for two-channel unit)

4

X22 – feedback connection, resolver

channel B (only for two-channel unit)

5

X3x – optional slot for safety card

X4x – optional slot for expansion cards

6

Navigation rocker

7

Status LED for EtherCAT output

8

Labeling field

9

X05 – socket for EtherCAT output

10

X03 – power supply 24 V DC input

11

X14 – sensor for motor temperature and brake

12

X24 – sensor for motor temperature and brake

channel B (only for two-channel unit)

13

X23 – motor connection (U, V, W, PE)

channel B (only for two-channel unit)

14

X13 – motor connection (U, V, W, PE)

15

X01 – mains supply 100 – 480 V

16

X02 – DC link output

Connection for the external brake resistor

17

890 V DC voltage at the DC link

below 50 V.

18

X04 – socket for EtherCAT input

19

Labeling field

20

Status LED for EtherCAT input

21

Display

22

X06 – connection for digital inputs and outputs

4.5 General overview (AX5101 – AX5112 and AX520x)

The servo drive shown below is a two-channel device. Components that are only available

for the second channel are identified in the item description.

(890 V DC voltage)

terminals. Dangerous voltage may

WARNING

AX5000 Version : 4.5 21

be present for 5 minutes after the

device is switched off. The device

is safe once the voltage has fallen

Page 22

4 Product description BECKHOFF Drive Technology

No

Designation

No

Designation

1

X11 – feedback connection, encoder

11

X07 – external brake resistor

(only AX5140)

2

X12 – feedback connection, resolver

12

X13 – motor connection (U, V, W, PE)

3

X3x – optional slot for safety card

X4x – optional slot for expansion cards

13

X01 – mains supply 100 – 480 V

4

Navigation rocker

14

X02 – DC link output

(only AX5118 u. AX5125)

5

Status LED for EtherCAT output

15

X04 – socket for EtherCAT input

6

Labeling field

16

Labeling field

7

X05 – socket for EtherCAT output

17

Status LED for EtherCAT input

8

X03 – power supply 24 V DC input

18

Display

9

Max. 890 V DC voltage at the

DC link terminals. Dangerous

fallen below 50 V.

19

X06 – connection for digital inputs and outputs

10

X14 – sensor for motor temperature and brake

4.6 General overview (AX5118, AX5125 und AX5140)

The servo drive illustrated below is an AX5140; the devices with 18 A or 25 A are structurally

similar apart from pos. 11 "X07" (external brake resistor).

Item description:

(890 V DC voltage)

Connection for the external brake resistor

WARNING

voltage may be present for 5

minutes after the device is

switched off. The device is

safe once the voltage has

22 Version : 4.5 AX5000

Page 23

BECKHOFF Drive Technology 4 Product description

Connection

Tightening

torque

3-phase

1-phase

L1

Phase L1

Phase L1

L2

Phase L2

not used

L3/ N

Phase L3

Neutral conductor

PE

Protective conductor

Terminal point

Connection

Tightening

torque

DC+

DC link +

external brake resistor

and drive system

DC –

DC link –

Terminal point

Connection

Tightening

torque

DC+

DC link +

DC –

DC link –

Serious risk of injury through high electrical voltage!

Remove the white hexagon plugs only if you wire the terminal points again.

Terminal

point

Connection

Current

consumption

Tightening

torque

Up +

24 V

- periphery

voltage)

Depending on the

(see X06 and X14,X24)

Us +

24 V

- system

rated current)

-12 A = 0.4 A – 0.8 A

40 A = 1,6 A

GND

GND

4.7 Overview of connectors/terminal points

4.7.1 X01 - wide voltage input

Terminal point

0,5 -0,6 Nm

4.7.2 X02 - DC link (AX5101 - AX5125 und AX520x)

0,5 -0,6 Nm

4.7.3 X02 - DC link (Only AX5140)

only for drive system 1,2 -1,5 Nm

890 V DC voltage at the DC link terminals. Dangerous voltage may be

WARNING

present for 5 minutes after the device is switched off.

Remove the connector only if you want to build a drive system with a AXBridge.

4.7.4 X03 - 24 VDC supply

DC -0/+25%

(e.g. separate braking

DC ±25%

supply (depending on

AX5000 Version : 4.5 23

connected consumers

0,5 – 0,6 Nm

18 A - 25A = 1,1 A

Page 24

4 Product description BECKHOFF Drive Technology

Terminal point

Connection

X04 (IN)

incoming EtherCAT line

X05 (OUT)

outgoing EtherCAT line

CAUTION

Destruction of the AX5000!

Note

Output current

Terminal point

Connection

Output current

24

Output voltage (Up 24 VDC +)

1 A max.

0

Input 0

1 Input 1

2

Input 2

3

Input 3

4 Input 4

5 Input 5

6 Input 6

7

Input 7 or output (configurable) (Up 24 VDC +)

0.5 A max.

0 V

Output voltage GND (-)

4.7.5 X04, X05 - EtherCAT connection

4.7.6 X06 – Digital I/Os

This connector is not designed for external power supply. It is supplied via

the 24 V supply (Up) of connector X03.

The specified output currents are maximum values. The actual values

depend on your current configuration.

24 Version : 4.5 AX5000

Page 25

BECKHOFF Drive Technology 4 Product description

Pin

EnDAT / BiSS

Hiperface

Sin / Cos 1Vpp

TTL

1

SIN +

SIN +

SIN +

n.c.

2

GND_5 V

GND_9 V

GND_5 V

GND_5 V

3

COS +

COS +

COS +

n.c.

4

US_5 V *)

n.c.

US_5 V *)

US_5 V *)

5

DX + (Data)

DX + (Data)

n.c.

B +

6

n.c.

US_9 V *)

n.c.

n.c.

7

n.c.

n.c.

REF Z

REF Z

8

CLK + (Clock)

n.c.

n.c.

A +

9

REFSIN

REFSIN

REFSIN

n.c.

10

GND_Sense

n.c.

GND_Sense

GND_Sense

11

REF COS

REF COS

REF COS

n.c.

12

US_5 V Sense

n.c.

US_5 V Sense

US_5 V Sense

13

DX - (Data)

DX - (Data)

n.c.

B -

14

n.c.

n.c.

Z +

Z +

15

CLK - (Clock)

n.c.

n.c.

A -

Feedback system

Resolver

Analog Hall sensor

1

Temperature

1300 Ω ± 3%

n.c.

2

AGND

n.c. 3 COS - (S3)

n.c. 4 SIN - (S4)

n.c. 5 REF - (R2)

n.c.

6

n.c.

SIN 1Vpp

7

n.c.

-120° oder -90° 1Vpp *

8

n.c.

Us_9 V (supply)

9

Temp._GND

n.c.

10

COS + (S1)

n.c.

11

SIN + (S2)

n.c.

12

REF + (R1)

n.c.

13

n.c.

REFSIN 1 Vpp

14

n.c.

REF -120° oder -90° 1Vpp *

15

n.c.

GND (supply)

4.7.7 X11 (channel A) , X21 (channel B) - feedback, high-resolution

*) The max. output current per channel is 0,25 A

4.7.8 X12 (channel A) , X22 (channel B) - resolver/hall

Pin

(only PTC, Klixon or

bimetal!)

Switchpoint:

*) The angle must be configured

AX5000 Version : 4.5 25

Page 26

4 Product description BECKHOFF Drive Technology

Terminal point

Connection

U

Motor connection U

V+

Motor connection V

W

Motor connection W

PE

Protective conductor

Shroud

Screen

Terminal point

Connection

U

Motor connection U

V+

Motor connection V

W

Motor connection W

PE

Protective conductor

Shroud

Screen

Grounding shield!

due to a poor shield connection of the motor.

Terminal point

Connection

Output current

T-

Temp. - *

T+

Temp. + *

PE

Signal pair screen

B-

Brake GND

B+

Brake (Up) +

1.5 A max.

4.7.9 X13 (channel A) , X23 (channel B) - motor connection (power)

(AX5101 - AX5125 und AX520x)

4.7.10 X13 - motor connection (power - only AX5140)

The grounding shield of the motor is connected via the shield plate in the

Attention

motor connector. Please tighten the knurled screws of the motor connector

with a screwdriver. It is possible that some feedback problems may caused

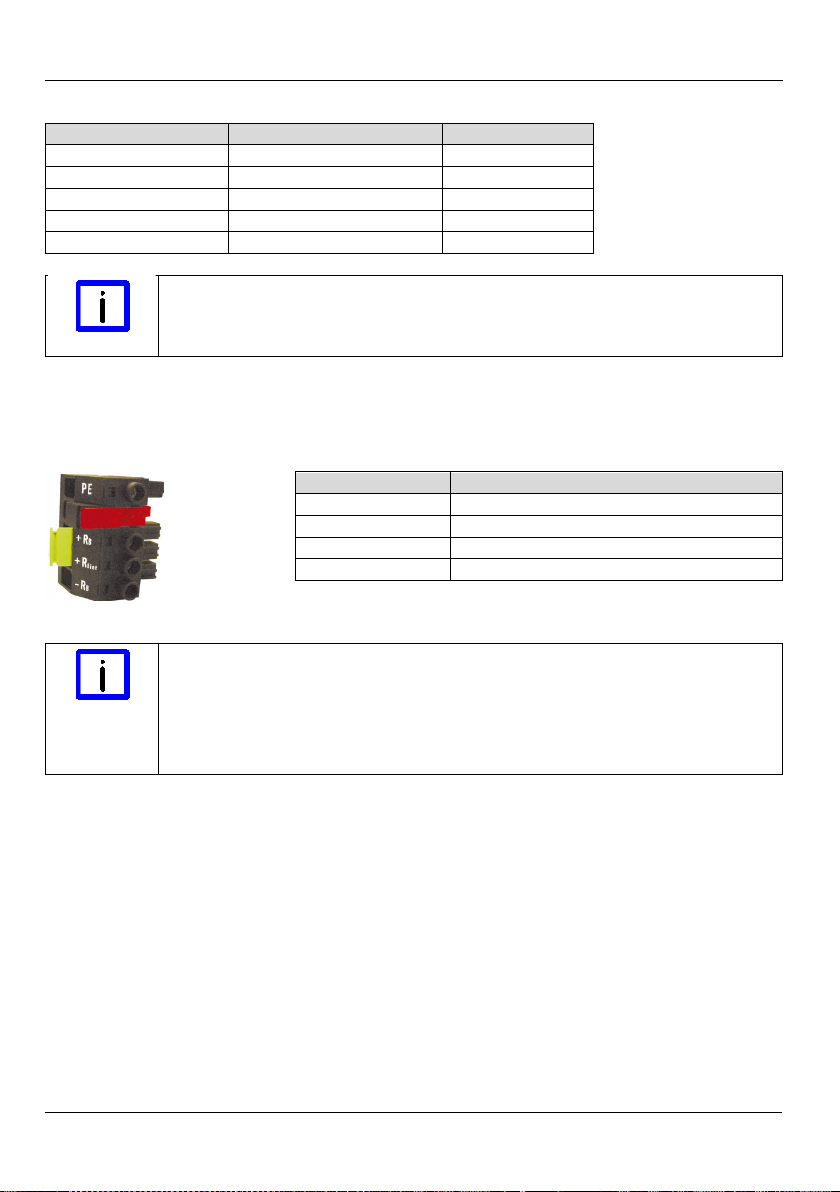

4.7.11 X14 (channel A), X24 (channel B)-motor brake, thermal contact, OCT

AX5000-xxxx-0000 (Hardware 1)

*) Switch, KTY 83-1xx or KTY 84-1xx

26 Version : 4.5 AX5000

Page 27

BECKHOFF Drive Technology 4 Product description

Terminal point

Connection

Output current

T-

OCT – and temperature

T+

OCT + and temperature

PE

Signal pair screen

B-

Brake GND

B+

Brake (Up) +

2.2 A max.

Note

Output current

Terminal point

Connection

PE

Protective conductor

+ RB

External brake resistor +

+ R

Bint

Internal brake resistor +

– RB

Brake resistor GND

Operation of AX5140

"FD4B – undervoltage"

AX5000-xxxx-0200 (Hardware 2)

The specified output current is the maximum value. The actual value

depends on your current configuration.

4.7.12 X07 – internal and external brake resistor

(Only AX5140)

Commissioning the AX5140 can only be carried out when the terminal

Note

points "+R

resistor is connected (terminal points "+R

" and "+RB" are bypassed (delivery state) or an external brake

Bint

" and "-RB"). If these measures

B

are not taken then the AX5140 will be stopped with the error message

AX5000 Version : 4.5 27

Page 28

4 Product description BECKHOFF Drive Technology

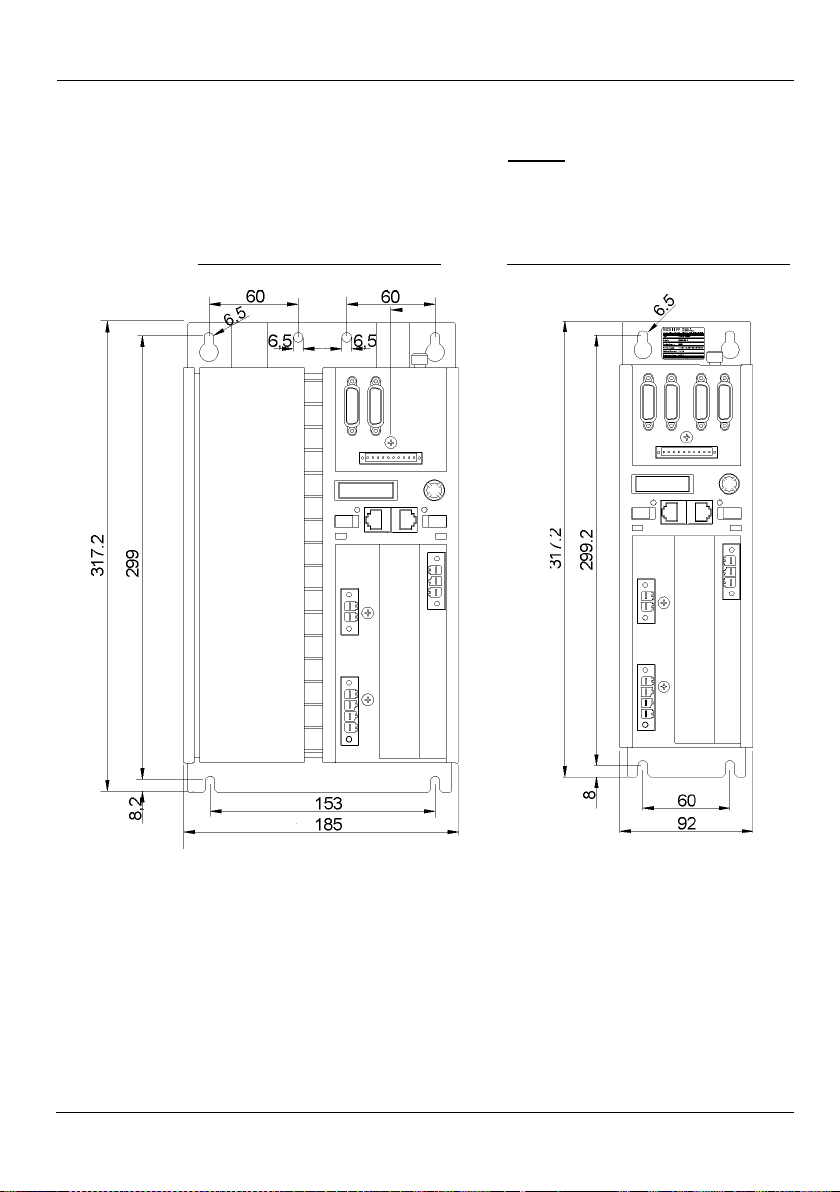

4.8 Dimensions

The specified measurements relate to the actual device, without connectors and cables. The

fitting dimensions for control cabinet installation can be found in section "Mechanical

installation Installation examples".

AX5118, AX5125 and AX5140 AX5101-AX5112 / AX5201-AX5206

All dimensions are in mm

28 Version : 4.5 AX5000

Page 29

BECKHOFF Drive Technology 4 Product description

AX5000

without AX bridge

AX5000

with AX bridge

All dimensions are in mm

AX5000 Version : 4.5 29

Page 30

5 Installation BECKHOFF Drive Technology

Caution – Risk of injury!

• Safety boots must be worn.

WARNING

Caution - Risk of injury through electric shock!

Destruction of the servo drive!

• It is essential to adhere to the required distances (see diagrams below).

WARNING

Caution - Risk of injury through electric shock!

Attention

Grounding!

5 Installation

• The servo drives may only be installed by trained, qualified personnel.

WARNING

5.1 Mechanical installation

Attention

5.1.1 Installation in the control

The qualified personnel must know and comply with the national accident

prevention regulations.

De-energise all electrical components (servo drive, control cabinet, etc.)

before commencing the installation or deinstallation.

• Always install the servo drive vertically.

• Provide adequate ventilation for the servo drive. The permissible ambient

conditions are specified in the "Technical data" section.

cabinet

The mounting plate must be earthed according to the statutory regulations.

If the ground connection of the AX5000 is not done as specified it is

possible to get trouble with some EMC issues.

30 Version : 4.5 AX5000

Page 31

BECKHOFF Drive Technology 5 Installation

5.1.1.1 Installation example - AX5101-AX5112 and AX5201-AX5206

5.1.1.2 Installation example - AX5118, AX5125 and AX5140

AX5000 Version : 4.5 31

Page 32

5 Installation BECKHOFF Drive Technology

UL-Listing!

USA or Canada.

Serious risk of injury through electric shock!

voltage has fallen below 50 V.

Caution – Risk of injury through electric shock!

the motor is prevented from rotating by the internal brake.

Destruction of the equipment!

“IDN-Description”).

5.2 Electrical installation

It is essential to observe chapter 3.3 if you wish to operate an AX5000 in

Due to the DC link capacitors dangerous voltage may persist at the DC link

DANGER

WARNING

contacts "X02" after the servo drive has been disconnected from the mains

supply. After disconnecting the servo drive wait 5 minutes and measure the

voltage at the DC link contacts DC+ and DC-. The device is safe once the

• Before installation, wiring and commissioning it is essential to read the

section on "Safety".

• Before installing, uninstalling or connecting the servo drive and the

motors please note the following:

- Remove all relevant mains fuses.

- Switch off the main system switch and secure it with a lock.

- Put up a warning sign.

• The control and power connections for the motors may be live, even if

• Check the rated voltage and current of the servo drive and the connected

Attention

32 Version : 4.5 AX5000

motors.

• When the AX5000 is disconnected from the mains supply (emergency

stop, mains contactor etc.), wait at least 3 minutes before starting again

or query the status of the IDN "P-0-0205" (see documentation of the

Page 33

BECKHOFF Drive Technology 5 Installation

Connection to the standard mains supply (TT/TN) with earthed centre is

www.beckhoff.com.

Fire hazard through short circuit!

drives feature integrated self-protection.

Fusing

AX5101

AX5103

AX5106

AX5201

AX5203

AX5206

AC supply *)

10 A

10 A

16 A

10 A

16 A

20 A

24 V supply *)

5 A

Brake resistor

electronic

Fusing

AX

5101

5103

5106

5112

5118

5125

5140

5201

5203

5206

AC supply *)

6 AT

6 A

10 A

20 A

35 A

35 A

50 A

10 A

10 A

20 A

24 V supply

*)

5 A

Brake resistor

elektronisch

Circuit

Fuse

24 V - system voltage

3.4 AF

24 V - peripheral voltage

electronic

Brake resistor

electronic

5.2.1 Mains supply connection (X01)

The servo drives of the AX5000 series are equipped with a wide voltage input "X01" and can

be connected to voltage systems between single-phase 100 V

three-phase 100 V

AC -10%

- 480 V

AC +10%

.

described below. Details for connections to other supply systems (e.g. ITmains supply, isolating transformer etc.) can be found in the “AX5000 User

Note

single-phase 100

manual” on the enclosed CD or can be downloaded from our website at

-10%

- 240

+10% VAC

three-phase 100

5.2.1.1 External protection for individual devices, CE-compliant

• The following data refer to individual devices. Please note the total

CAUTION

current of all connected devices in a multi-axis system.

• The recommended fuses are designed for line protection. The servo

Single-phase

AC -10%

- 240 V

-10%

AC +10%

- 480

and

+10% VAC

*) Application class "gG" mains fuses according to IEC 60269 with characteristic “T” or

"C" type automatic circuit breakers must be used.

Three-phase

*) Application class "gG" mains fuses according to IEC 60269 with characteristic “T” or

"C" type automatic circuit breakers must be used.

5.2.1.2 Internal protection, CE-compliant

AX5000 Version : 4.5 33

Page 34

5 Installation BECKHOFF Drive Technology

Fusing

AX5101

AX5103

AX5106

AX5201

AX5203

AX5206

AC supply (max.) *)

6 A

12 A

20 A

12 A

20 A

20 A

24 V supply (max.)

3 A

Brake resistor

electronic

Fusing

AX

5101

5103

5106

5112

5118

5125

5140

5201

5203

5206

AC suppl (max.)*)

6 A

12 A

20 A

20 A

35 A

45 A

80 A

12 A

20 A

20 A

24 V supply (max.)

3 A

Brake resistor

elektronisch

When protected by RK5 class fuses:

Rated 80 A, min. 480 V

Circuit

Fuse

24 V - system voltage

3.4 AF

24 V - peripheral voltage

electronic

Brake resistor

electronic

5.2.1.3 External protection, UL-compliant

Integral solid state short circuit protection does not provide branch circuit protection. Branch

circuit protection must be provided in accordance with the Manufacture Instructions, National

Electrical Code and any additional local codes.

Suitable for use on a circuit capable of delivering not more than 18000 rms symmetrical

amperes, 480 V maximum, when protected by RK5 class fuses.

Single-phase

*) Mains fuses according to type “RK5” must be used.

Three-phase

*) Mains fuses according to type “RK5” must be used.

AX5112

Rated 20 A, min. 480 V

AX5118

Rated 35 A, min. 480 V

AX5125

Rated 45 A, min. 480 V

AX5140

5.2.1.4 Internal protection, UL-compliant

34 Version : 4.5 AX5000

Page 35

BECKHOFF Drive Technology 5 Installation

Special requirements for a drive system

requirements for a drive system with UL-Listing.

5.2.1.5 External drive system protection

Rule of thumb: Determine the total device rated current, multiply by correction factor and

round it up to the next higher standard level.

Example: 1 x AX5103 + 2 x AX5201 + 2 x AX5203

3 A + 6 A

Please consult our Application Department with respect to the special

+ 12 A = 21 x 1,1 = 23,1 A selected 25 A

AX5000 Version : 4.5 35

Page 36

5 Installation BECKHOFF Drive Technology

Note

If one transformer is used for the 24 VDC power supply, the connections US

Drive system with UL-Listing!

Please consult our Application Department with respect to the requirements

for a drive system with UL-Listing.

Hazard to the equipment

≠

contactor etc.).

Danger for persons and equipment

AX Bridge is limited to 85 A.

Attention

Destruction of the external brake resistor

5.2.2 24 VDC - supply network connection (X03)

The 24 VDC connection "X03" is used for supplying control electronics and periphery with

DC voltage. The control electronics and the periphery can be supplied separately with two

different voltage sources.

and UP must be bridged, in order to ensure that both the control electronics

and the periphery are supplied.

Supply through via one transformer Supply via two transformers

5.2.3 Connection of several servo drives to form a drive system

• The connection sequence of the devices is not arbitrary. The total rated

Attention

current of the device must decrease from the power supply.

AX5112-AX5203-AX5106-AX5201 = OK; AX5201-AX5112-AX5203

• All devices in a drive system are always to be disconnected from and

reconnected to the mains supply together (emergency stop, mains

Note the total rated current of the connected devices.

CAUTION

According to CE the current carrying capacity of power busbars of the

An external brake resistor may not be connected to the X02 terminal point

(DC link) in a drive system. Use an external brake module AX5021 for this.

36 Version : 4.5 AX5000

OK

Page 37

BECKHOFF Drive Technology 5 Installation

CAUTION

Hazard to inviduals through electric shock

Hazard to inviduals and equipment

current and must comply with EN60204-1.

Terminal points

Conductor design

max. Conductor

cross-section

Tightening torque

L1-L3, PE

single wire

10 mm2

2,2 Nm

L1-L3, PE

flnely stranded with

wire end sleeves

16 mm2

2,2 Nm

L1-L3, PE

flnely stranded /

stranded

25 mm2

2,2 Nm

5.2.3.1 Connection example - module AX5901 and AX5911 (AX Bridge)

This connection option enables a safe system to be set up very quickly. The modules are

attached to plug contacts X01, X02 and X03, the relevant slides are pushed to the left and

screwed tight. According to CE the current carrying capacity of power busbars of the

AX Bridge is limited to 85 A.

Move all busbar sliders to the left limit stop in order to ensure full current

carrying capacity. Then tighten all screws with a torque of 2.2 Nm.

Please ensure that the connection line for the AX5901 supply module is

CAUTION

The supply connection is established as described in sections 5.2.1 and 5.2.2.

Information of the terminal points

adequately dimensioned. The dimensioning depends on the total rated

AX5000 Version : 4.5 37

Page 38

5 Installation BECKHOFF Drive Technology

Hazard to inviduals and equipment

• Avoid phase reversal between the devices!

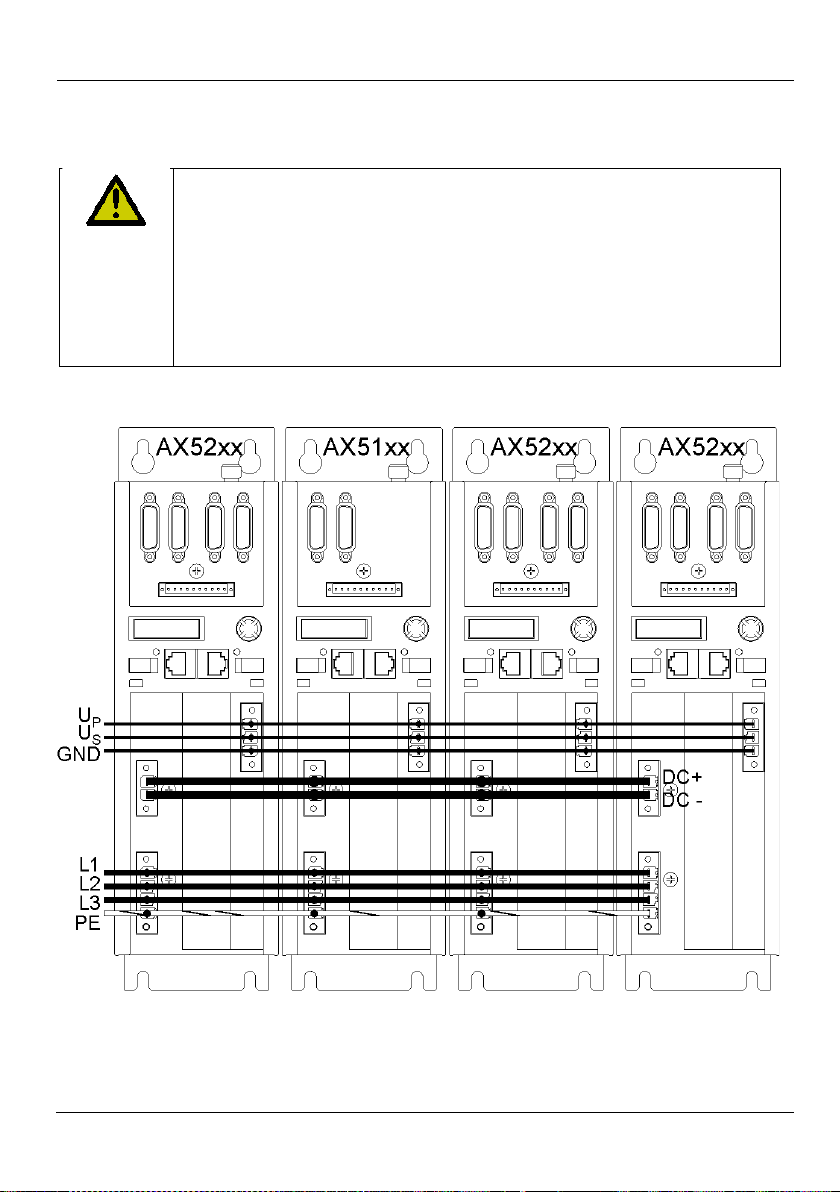

5.2.3.2 Connection example - wiring in series without AX Bridge

Wire the relevant connections using individual cables.

• Please ensure that the final supply network connection cable is

CAUTION

adequately dimensioned. The dimensioning depends on the total rated

current and must comply with EN60204-1.

• To establish a DC link system wire the X02 connections with a suitable

cable. Voltages up to 890 V may be present.

• The connectors are designed for a maximum current of 41 A and a

maximum conductor cross-section of 6 mm².

The supply connection is established as described in sections 5.2.1 and 5.2.2.

38 Version : 4.5 AX5000

Page 39

BECKHOFF Drive Technology 5 Installation

5.2.4 Configuration example, general

AX5000 Version : 4.5 39

Page 40

5 Installation BECKHOFF Drive Technology

5.2.5 Connection diagram AX5101 – AX5112 and AX520x

40 Version : 4.5 AX5000

Page 41

BECKHOFF Drive Technology 5 Installation

5.2.6 Connection diagram AX5118, AX5125 and AX5140

AX5000 Version : 4.5 41

Page 42

5 Installation BECKHOFF Drive Technology

Motor choke

AX5101 - AX5112 a.AX52xx

AX5118 a. AX5125

AX5140

C21)

C3

C22)

C3

C2

C3

Without

< 25 m

< 25 m

< 25 m

< 25 m

-

< 35 m

AX2090MD50-0012

< 100 m

< 100 m

- - - - AX2090-

MD50-0025

-

-

< 50 m

< 50 m

-

-

Motor choke

AX5101 - AX5112 a.AX52xx

AX5118 a. AX5125

AX5140

C21)

C3

C22)

C3

C2

C3

Without

< 20 m

< 20 m

< 20 m

< 20 m

-

< 35 m

AX2090MD50-0012

< 100 m

< 100 m

- - - - AX2090-

MD50-0025

-

-

< 50 m

< 50 m

-

-

Note

We recommend that feedback wires and motor wires used have the same

5.3 Motors and cables

With longer motor cables the resulting commutation currents can affect the control quality

and lead to EMC faults. Use the tables below to check whether motor chokes or mains filters

have to be used in your application. When selecting the control cabinet ensure that there is

adequate space for motor chokes, mains filters, etc.

Lay the power and signal cables in separate metal cable ducts or, if both types of cable use

the same metal cable duct, make sure there is an earthed metal dividing wall between the

cables.

Maximum cable length (including extensions) for a rated motor voltage up to 400 V

1)

For compliance with EN 61800-3 only with mains filter AX2090-NF50-0014.

2)

For compliance with EN 61800-3 only with mains filter AX2090-NF50-0032.

In exceptional cases (sensitive sensors, etc.) it can be necessary to use a motor choke even

for motor cable lengths < 25 m.

Maximum cable length (including extensions) for a rated motor voltage up to 480 V

1)

For compliance with EN 61800-3 only with mains filter AX2090-NF50-0014.

2)

For compliance with EN 61800-3 only with mains filter AX2090-NF50-0032.

In exceptional cases (sensitive sensors, etc.) it can be necessary to use a motor choke even

for motor cable lengths < 20 m.

length.

42 Version : 4.5 AX5000

Page 43

BECKHOFF Drive Technology 6 Important information for commissioning

Caution – Risk of injury!

brought into a safe state in the event of a fault in the drive system.

Increased attention in the case of vertical axes!

mean the sudden falling down of a load in this case.

6 Important information for commissioning

Electronic equipment is not fail-safe. The machine manufacturer is

WARNING

Please be aware each time before commissioning the AX5000 that connected motors can

make uncontrolled movements, which cannot always be prevented even by the AX5000’s

integrated diagnostic system, or may permit uncontrolled movements until the diagnostic

system responds. Analyse your system and take suitable precautions to prevent damage

being caused by these uncontrolled movements.

Potential causes of uncontrolled movements:

The diagnostic system of the AX5000 is equipped with complex plausibility checks, which

constantly monitor installation, operation, parameterisation and operation and, if necessary,

interrupt them with a diagnostic message. The points listed below are naturally also

monitored as standard, but it is not possible to include all eventualities; therefore, with

respect to the following points, you must always consider whether the driven axes can only

perform permissible movements.

• Incorrect commutation results (e.g. during wake & shake), It is essential to observe

chapter “AX5000 User manualcommissioningcommutation methodscommutation

error “F2A0”” on our Homepage.

• Specific caution with motors of third parties: always execute the command „P-0-0166“

without load when changing the motor or feedback or when changing the SysMan-file

(.TSM) and evaluate the result. Correct the commutation offset if applicable., as described

in chapter “AX5000 User manual Commissioning Commutation methods”.

• Input of invalid parameters

• Measuring transducer and/or signal transducer defective or incorrectly adjusted

• Cables defective or not adequately screened

• Incorrectly attached sensors

responsible for ensuring that the connected motors and the machine are

When commissioning vertical axes, the risk consideration described above

CAUTION

AX5000 Version : 4.5 43

is to be carried out with particular care. An uncontrolled movement can

Page 44

7 Project planning – important information BECKHOFF Drive Technology

Control quality / Dynamics

Mass inertia ratio

Good

up to 3:1

Average

up to 5:1

Bad

up to 10:1

7 Project planning – important information

The more thoroughly a machine or plant project is thought through in advance, the less risk

there is of having to carry out expensive modifications during or after commissioning. This

applies to both the mechanical and electrical design. This section can only give a rough

overview of electrical design. Further information can be found in the publication "Project

planning aid” under Downloads on our website at www.beckhoff.com

7.1 Drive train design

Application, servo drive, motors and gear mechanism must be adapted to each other so that

there is an adequate safety margin for all components as a degree of sluggishness appears

over time due to high temperatures or wear. Make sure that the components in the working

area of the system have adequate reserves so that the working life is not impaired and the

necessary control quality can be maintained.

7.1.1 Control quality, mass inertia ratio and load connection

Control quality is dependent on the parameters "mass inertia ratio" and "load connection":

The "Control quality / dynamics" is primarily affected by the mass moment of inertia: a poor

"Control quality / dynamic" due to an unfavourable mass moment of inertia cannot be

improved even with a very good load connection. Likewise, however, a good "Control quality

/ dynamic" due to a favourable mass moment of inertia can be reduced through a poor load

connection.

7.2 Energy management

If the quality of the mains supply is impaired due to wide fluctuations in voltage, then both

the servo drive specification and the speed range of the motor will need to be considered.

With a positive tolerance for voltage fluctuation the upper limit value of the wide voltage

input of the AX5000 needs to be taken into account. With a negative tolerance of the voltage

fluctuation it must be checked whether the decrease in speed caused by the low voltage is

permissible. With these motors what is known as field weakening operation (check

availability) of the servo drive may provide a solution. If the mains supply does not meet the

specifications for operation of the AX5000, then isolating transformers, mains chokes, mains

filters or other measures may be required. An energy efficient drive system operates in a

drive system with a shared DC link and shared internal and possibly also external brake

resistors or brake modules. If you are already using similar drive systems, the AX5000 offers

a convenient diagnostic system for determining the load on the brake resistors and for

transferring the values. Previous experience with drive systems shows that in such a system

much smaller or even no external brake resistors / brake modules need to be used.

44 Version : 4.5 AX5000

Page 45

BECKHOFF Drive Technology 7 Project planning – important information

7.3 EMC, earthing, screen connection and potential

The AX5000 corresponds to EMC category "C3" (industrial sector) in terms of conducted

interference emissions. If you wish to use components which comply with a higher category

you can limit the AX5000 conducted interference emissions with the aid of additional filters

to such a degree that this complies with the EMC category "C2" (residential and industrial

environment) or "C1" (residential environments).

Ensure that there is adequate earthing (large-area low-impedance connection) of all relevant

components (incl. control cabinet). The AX5000 incl. periphery, control cabinet, machine bed

and motors must be at the same potential, as the AX5000 control quality will suffer under

differing potentials and operational malfunction may result. Using the screen connection for

potential equalisation is not permitted. If you are unable to provide a uniform reference

potential you need to lay potential equalisation cables of adequate dimensions.

Smooth operation is only guaranteed by faultless screen connections of the cables. The

screens must be applied generously at both ends and must on no account be disconnected.

Use pre-assembled Beckhoff motor and feedback cables as these are optimally adapted to

the drive system and reduce interference to a minimum. Ensure that the connectors are

properly connected: this applies to the motor connector in particular.

7.4 Control cabinet

The dimensions of the control cabinet must be sufficient to accommodate all components

with the specified distances. Remember that high temperatures may necessitate forced

cooling. Position the control cabinet as close as possible to the machine so that the motor

cables can be as short as possible.

In addition, the control cabinet should have an earthed metal rear panel to which the

AX5000 incl. periphery are attached so that safe earthing can be guaranteed. If you are

unable to guarantee these conditions you need to earth the AX5000 and the relevant

components using an approved cable of adequate size.

AX5000 Version : 4.5 45

Page 46

8 Appendix BECKHOFF Drive Technology

8 Appendix

8.1 Support and Service

Beckhoff and their partners around the world offer comprehensive support and service,

making available fast and competent assistance with all questions related to Beckhoff

products and system solutions.

8.1.1 Beckhoff's branch offices and representatives

Please contact your Beckhoff branch office or representative for local support and service on

Beckhoff products!

The addresses of Beckhoff's branch offices and representatives round the world can be

found on her internet pages: http://www.beckhoff.com

You will also find further documentation for Beckhoff components there.

8.1.2 Beckhoff Headquarters

Beckhoff Automation GmbH & Co. KG

Hülshorstweg 20

33415 Verl

Germany

Phone: +49(0)5246/963-0

Fax: +49(0)5246/963-198

E-Mail: info@beckhoff.com

8.1.3 Beckhoff Support

Support offers you comprehensive technical assistance, helping you no only with the

application of individual Beckhoff products, but also with other, wide-ranging services:

• Support

• Design, programming and commissioning of complex automation systems

• Extensive training program for Beckhoff system components

Hotline : +49(0)5246/963-157

Fax : +49(0)5246/963-9157

E-Mail : support@beckhoff.com

8.1.4 Beckhoff Service

The Beckhoff Service Center supports you in all matters of after-sales service:

• On-site service

• Repair service

• Spare parts service

Hotline : +49(0)5246/963-460

Fax : +49(0)5246/963-479

E-Mail : service@beckhoff.com

46 Version : 4.5 AX5000

Loading...

Loading...