Page 1

SECTION 2 • QUICK START

TABLE OF CONTENTS

SECTION 2 • QUICK START .................................................................................................................... 2-1

General .................................................................................................................................................. 2-1

About This Manual ............................................................................................................................. 2-1

Section................................................................................................................................................ 2-1

BESTlogic .............................................................................................................................................. 2-1

Characteristics of Protection and Control Elements .......................................................................... 2-2

Element Logic Settings ....................................................................................................................... 2-3

Output Logic Settings ......................................................................................................................... 2-3

User Interfaces ....................................................................................................................................... 2-3

Front Panel HMI ................................................................................................................................. 2-3

ASCII Command Communications .................................................................................................... 2-4

BESTCOMS™ for BE1-CDS240, Graphical User Interface ............................................................... 2-5

Getting Started ....................................................................................................................................... 2-6

Connections ....................................................................................................................................... 2-6

Entering Test Settings ........................................................................................................................ 2-6

Checking the State of Inputs .............................................................................................................. 2-7

Testing ................................................................................................................................................ 2-7

FAQ/Troubleshooting ............................................................................................................................. 2-7

Frequently Asked Questions (FAQs) ................................................................................................. 2-7

Figures

Figure 2-1. 87 Phase Differential Element ................................................................................................ 2-2

Figure 2-2. 51 HMI Screen ........................................................................................................................ 2-4

Tables

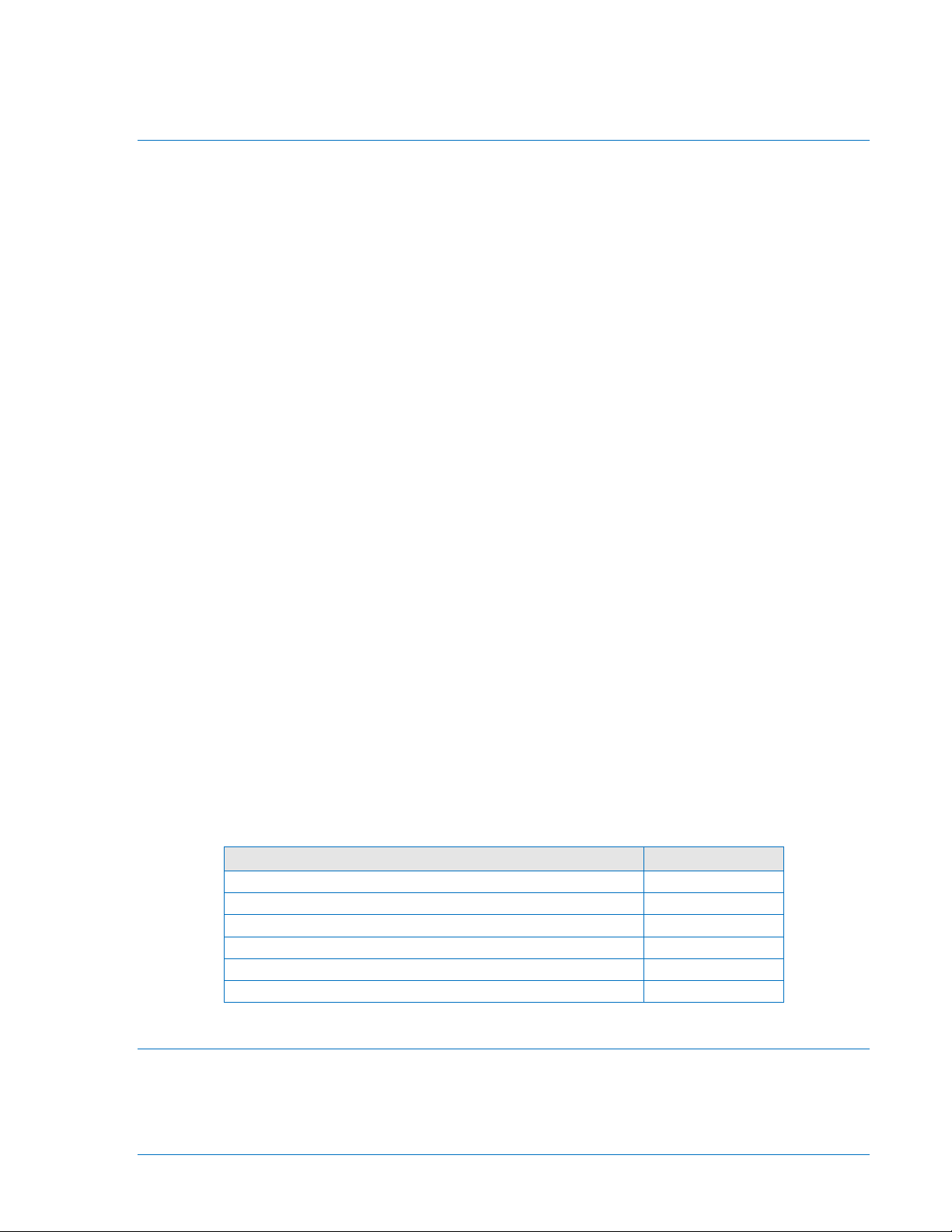

Table 2-1. Function Categories and Manual Sections Cross-Reference .................................................. 2-1

Table 2-2. Trip LED Truth Table ................................................................................................................ 2-9

9365200990 Rev M BE1-CDS240 Quick Start i

Page 2

ii BE1-CDS240 Quick Start 9365200990 Rev M

Page 3

SECTION 2 • QUICK START

Section

Input and Output Functions

3

Protection and Control

4

Metering

5

Reporting and Alarm Functions

6

BESTlogic Programmable Logic

7

Application

8

General

This section provides an overview of the BE1-CDS240 Current Differential System. You should be familiar

with the concepts behind the user interfaces and BESTlogic before you begin reading about the detailed

BE1-CDS240 functions. Sections 3 through 6 in this manual describe in detail each function of the BE1CDS240.

The following information is intended to provide the reader with a basic understanding of the three user

interfaces (front panel human-machine interface (HMI), ASCII serial communications link, and the

BESTCOMS™ for BE1-CDS240 software) and the security features provided in the BE1-CDS240 relay.

Detailed information on the operation of the HMI (human-machine interface) is in Section 10, and the

information on ASCII command communications is in Section 11. BESTCOMS is a Windows® based

software application (graphical user interface) that enhances communication between the PC user and

the BE1-CDS240 relay. BESTCOMS for the BE1-CDS240 is provided free of charge with the BE1CDS240 and details are provided in Section 14.

Also covered in this section is an overview of BESTlogic. BESTlogic is a highly flexible programmable

logic system that allows the user to apply the available functions with complete flexibility and customize

the system to meet the requirements of the protected power system. Detailed information on using

BESTlogic to design complete protection and control schemes for the protected circuit can be found in

Section 7, BESTlogic Programmable Logic, and Section 8, Application.

Sections 3 through 6 describe each function provided in the BE1-CDS240 relay and include references to

the following items. Note that not all items are appropriate for each function.

• Human-machine interface (HMI) screens for setting the operational parameters.

• BESTCOMS for setting the operational parameters.

• BESTCOMS for setting up the BESTlogic required for functions in your protection and control

scheme.

• Outputs from the function such as alarm and BESTlogic variables or data reports.

• HMI screens for operation or interrogation of the outputs and reports provided by each function.

• ASCII commands for operation or interrogation of the outputs and reports provided by each function.

About This Manual

The various application functions provided by this multifunction relay are divided into four functional

categories: input/output functions, protection and control functions, metering functions, and reporting and

alarm functions. Detailed descriptions of each individual function, setup, and use are covered in the

Sections as shown in Table 2-1. Detailed information on using programmable logic to create your

protection and control scheme is described in Section 7, BESTlogic Programmable Logic.

Table 2-1. Function Categories and Manual Sections Cross-Reference

Section Title

BESTlogic

Each of the protection and control elements in the BE1-CDS240 is implemented as an independent

function that is equivalent to a single function, discrete device counterpart. Each independent element

has all of the inputs and outputs that the discrete component counterpart might have. Programming

BESTlogic is equivalent to choosing the devices required by your protection and control scheme and

drawing schematic diagrams to connect the inputs and outputs to obtain the desired operational logic.

9365200990 Rev M BE1-CDS240 Quick Start 2-1

Page 4

The concept is the same but the method is different in that you choose each element by enabling it and

use Boolean logic expressions to connect the inputs and outputs. The result is that you have even greater

flexibility in designing your system than you had using discrete devices. An added benefit is that you are

not constrained by the limitations in flexibility inherent in many multifunction relays.

One user programmable, custom logic scheme created by the user may be programmed and saved in

memory. Or, the user may choose from one preprogrammed logic scheme embedded in the relay

firmware or several preprogrammed logic schemes in the BESTCOMS logic library that can be copied to

the relay. Preprogrammed schemes can reduce or eliminate the need for programming by the user.

Preprogrammed logic settings can also be modified after being saved in the relay. This provides a good

starting point for a custom logic scheme. To modify the preprogrammed scheme, it is necessary to enter a

unique name for the new logic before modifying the settings. Naming the new logic distinguishes it from

the preprogrammed logic scheme. In the 16 character preprogrammed logic name, the last 4 characters

refer to revision A, dash (-), and BE (Basler Electric). When customizing a programmed logic scheme, it is

recommended that the user include the revision level of their scheme and change the BE to a 2-digit code

representative of the user's company name. For example, if VA Power were modifying the CDS240BATX-A-BE the preprogrammed logic scheme might be CDS240-BATX-B-VP, the B standing for revision

level B, and VP for VA Power.

There are two types of BESTlogic settings: element (function block) logic settings and output logic

settings. These will be described briefly in the following paragraphs. Detailed information on using

BESTlogic to design complete protection and control schemes for the protected circuit can be found in

Section 7, BESTlogic Programmable Logic and Section 8, Application.

Characteristics of Protection and Control Elements

As stated before, each element (function block) is equivalent to a discrete device counterpart. For

example, the transformer differential element in the BE1-CDS240 relay has all of the characteristics of a

version of the BE1-87T transformer differential relay with similar functionality. Figure 2-1 shows the 87

phase differential element inputs and outputs.

Figure 2-1. 87 Phase Differential Element

Two inputs:

• Mode (enable/disable 87 operation)

• BLK (block 87 operation)

Five outputs:

• 87RPU (87 Restrained Pickup)

• 87RT (87 Restrained Trip)

• 87UT (87 Unrestrained Trip)

nd

• 2NDHAR (2

• 5THHAR (5

Harmonic Inhibit Status)

th

Harmonic Inhibit Status)

Five operational settings:

• Minimum pickup

• Slope

nd

Harmonic Inhibit

• 2

th

Harmonic Inhibit

• 5

• Unrestrained Pickup

Of the above characteristics, the five operational settings are not included in the logic settings. They are

included in the protection settings. This is an important distinction. Since changing logic settings is similar

to rewiring a panel, the logic settings are separate and distinct from the operational settings such as

pickups and time delays.

2-2 BE1-CDS240 Quick Start 9365200990 Rev M

Page 5

Element Logic Settings

To use a protection or control element, two items need to be set. These are the mode and the input logic.

The mode is equivalent to deciding which devices you want to install in your protection and control

scheme. You then must set the logic variables that will be connected to the inputs.

For example, the 51N element has two modes (disabled and enabled), and one input, block (torque

control). To use this element, the logic setting command might be SL-51N=1,/IN2 for Set Logic-51N to be

Mode 1 (enabled) with the element blocked when contact sensing Input 2 is not (/) energized. Contact

Sensing Input 2 would be wired to a ground relay enable switch.

As noted before, the protection settings for this element, pickup, time dial, and curve, must be set

separately in the setting group settings. The setting might be S0-51N=6.5,2.1,S1R for Set in Setting

Group 0 - the 51N function = to pickup at 6.5 amps with a time dial of 2.1 using curve S1 with an

integrating reset characteristic.

The 51N element has two logic output variables, 51NT (Trip) and 51NPU (Picked Up). The combination of

the logic settings and the operational settings for the element govern how these variables respond to logic

and current inputs.

Output Logic Settings

BESTlogic, as implemented in the BE1-CDS240, supports up to 16 output expressions. The output

expressions are called virtual outputs to distinguish them from the physical output relays. In the BE1CDS240, any virtual output (VO1 through VO16) can drive any physical output relay (OUT1 through

OUT14). VOA is different in that it will always drives physical output relay, Out A which is the fail safe

alarm output. Other virtual outputs may be assigned to or removed from OUTA, but VOA will always drive

OUTA. In addition, any of the virtual outputs can be used for intermediate logic expressions.

For example, OUT1 is wired to the trip bus of a circuit breaker. To set up the logic to trip the breaker, the

BESTlogic setting command might be SL-VO1=VO11+101T+BFPU for Set Logic - Virtual Output 1 = to

Virtual Output 11 (which is the intermediate logic expression for all of the element tripping outputs) or (+)

101T (the trip output of the virtual breaker control switch) or (+) BFPU (the pickup output of the breaker

failure element that indicates that breaker failure has been initiated). To assign this to OUT1, the

BESTlogic command would be SL-OUT1=VO1.

User Interfaces

Three user interfaces are provided for interacting with the BE1-CDS240 relay: the front panel HMI, ASCII

communications, and the BESTCOMS for BE1-CDS240 software. The front panel HMI provides access to

a subset of the total functionality of the device. ASCII communications provides access to all settings,

controls, reports, and metering functionality of the system. The BESTCOMS for BE1-CDS240 software

provides a Windows based, user-friendly environment for editing settings files and uploading and

downloading them from the relay (see Section 14 for details).

Front Panel HMI

The front panel HMI consists of a two line by a 16 character LCD (liquid crystal display) with four scrolling

pushbuttons, an edit pushbutton, and a reset pushbutton. The EDIT pushbutton includes an LED to

indicate when edit mode is active. There are five other LEDs for indicating power supply status, relay

trouble alarm status, programmable major and minor alarm status, and a multipurpose Trip LED that

flashes to indicate that a protective element is picked up. The Trip LED lights continuously when the trip

output is energized and seals in when a protective trip has occurred to indicate that target information is

being displayed on the LCD. A complete description of the HMI is included in Section 10, Human-Machine

Interface.

The BE1-CDS240 HMI is menu driven and organized into a menu tree structure with six branches. A

complete menu tree description with displays is also provided in Section 10, Human-Machine Interface. A

list of the menu branches and a brief description for scrolling through the menu is in the following

paragraphs.

1. REPORT STATUS. Display and resetting of general status information such as targets, alarms,

recloser status, etc.

2. CONTROL. Operation of manual controls such as virtual switches, selection of active setting

group, etc.

3. METERING. Display of real time metering values.

9365200990 Rev M BE1-CDS240 Quick Start 2-3

Page 6

4. REPORTS. Display and resetting of report information such as time and date, demand registers,

breaker duty statistics, etc.

5. PROTECTION. Display and setting of protective function setting parameters such as logic

scheme, pickups, time delays, etc.

6. GENERAL SETTINGS. Display and setting of non-protective function setting parameters such as

communications, LCD contrast, and CT ratio.

Each screen in the menu tree displays the path in the upper left hand corner of the screen. Additionally,

each screen is assigned a number in the HMI section. The path indicates the branch and level in the

menu tree structure. This path should help you to keep track of where you are when you leave the menu

tree top level. You scroll through each level of the menu tree by using the right and left scrolling

pushbuttons. To go to a level of detail, you use the down scrolling pushbutton. Each time you go to a

lower level in the menu tree, another string is added to the path and separated by a backslash.

For example, to check or change the 51N pickup setting in Setting Group 3, you would press the right or

left scrolling pushbuttons to get to Screen \PROT - PROTECTION. You would then press the down

scrolling pushbutton to get to the next level of detail and the right or left scrolling pushbutton to get to

Screen \PROT\SG3 - SETTING GROUP 3. To continue, you would press the down and then the right or

left scrolling pushbuttons to get to Screen \PROT\SG3\51 INVERSE TIME OVERCURRENT and then

Screen \PROT\SG3\51\51 - 51 Settings. On the screen shown in Figure 2-2, the pickup, time dial and

curve settings for the 51P/N/Q functions can be read and/or edited. To return to the top level from this

location, you would press the Up scrolling pushbutton three times.

Figure 2-2. 51 HMI Screen

ASCII Command Communications

The BE1-CDS240 relay has three independent communications ports for serial communications. Basler

Terminal in BESTCOMS can be connected to any of the three ports so that the user may send commands

to the relay. Alternatively, a computer terminal or PC running a terminal emulation program such as

Windows Terminal can be used in the same manner. Communication with the relay uses a simple ASCII

command language. When a command is entered via a serial port, the relay responds with the

appropriate action. The ASCII command communications is designed for use in both human-to-machine

interactions and in batch download type operations. The following paragraphs briefly describe the

command structure and then discuss human-to-machine interactions and batch command text file

operations for interacting with the relay. The operation of the ASCII commands is described in detail in

Section 11, ASCII Command Interface.

Command Structure

An ASCII command consists of a command string made up of one or two letters followed by a hyphen

and an object name. The first letter specifies the general command function and the second a subgrouping. The object name is the specific function for which the command is intended. If the command

string is entered by itself, it is a read command. If the command string is entered followed by an equal

sign and one or more parameters, it is a write command. The general command groupings are organized

into six major groups plus several miscellaneous commands. These commands are as follows:

C CONTROL. Commands to perform select before operate control actions such as tripping and closing

the circuit breaker, changing the active setting group, etc. Sub-groupings include S for Select and O

for Operate.

G GLOBAL. Perform global operations that do not fall into the other general groupings such as

password security. Sub-groupings include S for security settings.

2-4 BE1-CDS240 Quick Start 9365200990 Rev M

Page 7

M METERING. Read all real time metering values. This general command grouping has no sub-

groupings.

P PROGRAM. Subgroup command to read or program a setting.

R REPORTS. Read and reset reporting functions such as time and date, demand registers, breaker

duty statistics, etc. Sub-groupings include: A for Alarm functions, B for Breaker monitoring functions,

D for Demand recording functions, F for Fault summary reporting functions, G for General

information and S for Sequence of Events recorder functions.

S SETTINGS. Set all setting parameters that govern the functioning of the relay. Sub-groupings

include: 0,1,2,3 for settings in setting groups, A for alarm settings, B for breaker monitoring settings,

G for general settings, L for logic settings.

MISCELLANEOUS. These include Access, Exit, and Help.

Examples of object names would be 51N for the neutral inverse time overcurrent element or PIA for the A

phase, peak current demand register.

For example, to check the 51N pickup setting in Setting Group 3, you would enter S3-51N for Settings,

Group 3-51N. The relay would respond with the current pickup, time dial, and curve settings for the 51N

element. To edit these settings, the same command would be used with an = followed by the new settings

and the enter pushbutton. The user should note that it is necessary to use the Access and Exit

commands when using the write version of these commands.

Human-to-Machine ASCII Command Operations

The ASCII command scheme allows the user to read and/or write settings and operational items on a

function-by-function basis. However, this also requires a great many commands. The mnemonic format of

the commands is designed to facilitate interactive communications with the relay. It is not necessary to

remember all of the object names. Most commands support a multiple read version where it is not

necessary to specify a complete object name. You can enter the first two letters of a command and the

relay will respond with all applicable objects.

For example, you want the relay to report the breaker operations counter reading. You can enter RB for

Report Breaker and the relay will respond with all of the breaker report objects including the operations

counter. If you had remembered that the object name is OPCNTR, you could have entered RB-OPCNTR

and received only the operations counter report. Partial object names are also supported. For example,

you wish to read the entire peak-since-reset demand registers. You can enter RD-PI for Report Demand Peak Current (I) and the relay will respond with the values and time stamps for A, B, C, N and Q. To reset

all five of the peak since reset demand registers, enter the command RD-PI=0. To read only the value for

the neutral demand, the full object name would have been entered (RD-PIN).

Batch Command Text File Operations

With a few exceptions, each function of the relay uses one command to set it and each setting command

operates on all of the parameters required by that element. See the example mentioned above in the

paragraph titled Command Structure. This format results in a great many commands to fully set the relay.

Also, the process of setting the relay does not use a prompting mode where the relay prompts you for

each parameter in turn until you exit the setting process. For these reasons, a method for setting the relay

using batch text files is recommended.

In batch upload type operations, the user creates an ASCII text file of commands and sends it to the

relay. To facilitate this process, the response from a multiple read command is output from the BE1CDS240 in command format. Therefore, the user need only enter S for Set (with no subgroup) and the

relay responds with all of the setting commands and their associated parameters. If the user enters S2 for

Set Group 2, the relay responds with all of the setting commands for Setting Group 2. The user may

capture this response to a file, edit it using any ASCII text editor, and then send the file back to the relay.

See Section 11, ASCII Command Interface, for a more detailed discussion of how to use ASCII text files

for setting the relay.

BESTCOMS™ for BE1-CDS240, Graphical User Interface

Basler Electric's graphical user interface (GUI) software, BESTCOMS, is an alternative method for quickly

developing setting files in a friendly, Windows based environment. Using the GUI, you may prepare

setting files off-line (without being connected to the relay) and then upload the settings to the relay at your

convenience. These settings include protection and control, operational and logic, breaker and

transformer monitoring, metering and fault recording. Engineering personnel can develop, test, and

replicate the settings before exporting it to a file and transmitting the file to technical personnel in the field.

9365200990 Rev M BE1-CDS240 Quick Start 2-5

Page 8

On the field end, the technician simply imports the file into the BESTCOMS database and uploads the file

to the relay where it is stored in nonvolatile memory.

The GUI also has the same preprogrammed logic scheme that is stored in the relay in addition to a library

of additional logic schemes. This gives the engineer the option (off-line) of developing his setting file using

a preprogrammed logic scheme, customizing a preprogrammed logic scheme, or building a scheme from

scratch. Files may be exported from the GUI to a text editor where they can be reviewed or modified. The

modified text file may then be uploaded to the relay. After it is uploaded to the relay, it can be brought into

the GUI, but it cannot be brought directly into the GUI from the text file. The GUI logic builder uses basic

AND/OR gate logic combined with point and click variables to build the logic expressions. This reduces

the design time and increases dependability.

The GUI also allows for downloading industry standard COMTRADE files for analysis of stored

oscillography data. Detailed analysis of the oscillography files may be accomplished using BESTWAVE

software. For more information on Basler Electric's Windows based BESTCOMS (GUI) software, refer to

Section 14, BESTCOMS™ Software.

Getting Started

Connections

Figure 12-25, in Section 12, Installation, shows typical external dc control connections. If your relay has

Power Supply Option 1 or 2, it can be supplied by normal 120 V ac house power. These two power supply

options (1 and 2) are the midrange and high range AC/DC power supplies. The contact sensing inputs are

half-wave rectified opto-isolators. The default contact recognition and debounce settings enable their use

on ac signals as well as dc signals.

Section 12 also shows typical external ac sensing connections. The relay measures the A phase, B

phase, and C phase current magnitudes directly from the three current sensing inputs on Circuit #1 (this

is dependent on style configuration). Circuit #2 measures the A phase, B phase, and C phase current

magnitudes directly from the three current sensing inputs. The neutral and negative-sequence

magnitudes are calculated from the fundamental component of each of the three-phase currents. When

evaluating the negative-sequence functions, the relay can be tested using a two-phase current source. To

fully evaluate the operation of the relay in the power system, it is desirable to use a three-phase current

source.

Connect a computer to the front RS-232 port (refer to Section 12, Installation, for connection diagrams).

Apply power and set the clock using the RG-TIME= and RG-DATE= commands (refer to Appendix C,

Terminal Communication, and Section 11, ASCII Command Interface, for additional information).

Entering Test Settings

Use BESTOMS to enter test settings (see Section 14, BESTCOMS Software, for details) or enter SG (Set

General) to get a listing of the general setting commands with default parameters and put them in a text

file as described previously in Batch Command Text File Operations. Then enter S0 (Setting Group Zero)

to get a listing of the Setting Group 0 protection setting commands with default parameters and put them

in a text file. With these two subgroups of settings, you will not see the global security settings, user

programmable BESTlogic settings, settings for protection Setting Groups 1, 2, and 3, settings for alarm

functions, and the settings for breaker monitoring functions.

Open the SG file in a text editor, change settings as required, and save the changes. For example:

• The ratios for the phase and neutral current transformers (CT2, CTG).

• The demand interval and CT circuit to monitor for the phase, neutral and negative-sequence

currents (DIP, DIN, DIQ).

• The nominal system frequency (FREQ).

• The normal phase-sequence (ABC or ACB) for the system (PHROT).

Open the S0 file in a text editor, change settings, as required, and save the changes. For example:

• The differential taps setting by putting the 87 function in manual and selecting tap values (87).

• The pickup, time dial, and curve for the 51 functions (51P, 51N, 51Q).

While editing this file, it is necessary to set a logic scheme to be active using the SL-N= (Set Protection

LOGIC) command. The default setting is BASIC-87, which means that several protection elements are

2-6 BE1-CDS240 Quick Start 9365200990 Rev M

Page 9

enabled and interconnected but are disabled with settings of zero. See Section 8, Application, for

diagrams that describe the BASIC-87 logic scheme.

Enter A= to gain setting access and then send each of these text files to the relay as described above

under Batch Command Text File Operations. Do not forget to add E;Y (Exit; Save Settings? Yes) to the

end of both files.

As you gain knowledge of the relay, you can experiment with the rest of the settings. To set up a file with

all user settings, enter S and the relay will respond with all settings in command format. The acceptance

test procedure in Section 13, Testing and Maintenance, provides a basic procedure for creating a file with

all user settings.

Checking the State of Inputs

Section 8, Application, shows the Basic Differential (CDS240-BA87-A-BD) logic diagram. Review this

logic to help understand the following discussion. In this scheme, IN1 and IN2 are being used to show the

position of the breakers in the sequence of events record (SER). Input 3 is showing the status of the 86

lockout relay. Inputs 6 to 8 can be used for alarm annunciation. You can quickly review the state of the

inputs in three different ways: one, through the front panel HMI, two, using the ASCII command interface,

or three using BESTCOMS, Metering screen.

The front panel HMI displays the input status on Screen 1.4.1, \STAT\OPER\INPUT. A diagram showing

all of the menu tree branches is located in Section 10, Human-Machine Interface. To get to this screen,

press the Up scrolling pushbutton until you reach the top screen in the current branch. You know when

you have reached the top screen because the screen stops changing when you press the Up scrolling

pushbutton. From this position, press the Right scrolling pushbutton until you have reached the screen

titled, \STATUS BE1-CDS240 REPORT STATUS. From this position, press the Down scrolling

pushbutton one time (\STAT\TARGETS) and press the Right scrolling pushbutton three times. At this

time, you should see the OPERATIONAL STATUS Screen, \STAT\OPER_STAT. If you press the Down

scrolling pushbutton from this screen, you should see the INPUTS Screen, \STAT\OPER\INPUT.

Another method would be to use the ASCII command interface. One command that you can use to see

the status of the inputs is RG-STAT. Another command is RG-INPUT. This command will only read the

status of the inputs and nothing else.

Testing

To determine if the relay is responding correctly to each test, the following commands are useful.

• RG-TARG, (report general targets): reports the targets from the last fault.

• RF, (report faults): reports a directory listing of the twelve fault summary reports. The fault

summary reports are numbered from 1 to 255, then wrap around, and start over. RF-### reports

the ### report.

• RS-##, (report sequence of events record), ## events: reports the most recent ## changes of

state in the protection and control logic.

FAQ/Troubleshooting

Frequently Asked Questions (FAQs)

1.) Will the Trip LED reset after pressing the Reset key on the front panel?

The Reset key is context sensitive. To reset the Trip LED or the targets, the Targets screen

must be displayed. To reset the alarms, the Alarms screen must be displayed.

2.) Is the power supply polarity sensitive?

No, the power supply will accept either an ac or dc voltage input. However, the contact sensing

for the programmable inputs is polarity sensitive. See Section 12, Installation, for a typical interconnection diagram.

9365200990 Rev M BE1-CDS240 Quick Start 2-7

Page 10

3.) What voltage level is used to develop current flow through the contact sensing inputs?

Voltage level is dependent on the power supply option (BE1-CDS240 style) and the position of

the contact-sensing jumper. See Section 12, Installation, for additional information.

4.) How can the BE1-CDS240 be configured into a simple transformer differential relay?

Two preprogrammed schemes perform this function. One is CDS240-BA87-A-BE from the

BESTCOMS logic library (Basic Differential) and the other is the embedded logic scheme

CDS240-BATX-A-BE (Basic Transformer). See Section 8, Application, for additional

information.

5.) How can the BE1-CDS240 be configured into a generator differential relay?

The BE1-CDS240 can be configured into a generator differential relay by loading the

preprogrammed logic scheme CDS240-BA87-A-BE from the BESTCOMS library. You may

disable the 2nd and 5th harmonic functions by setting these thresholds to zero. See Section 8,

Application, for additional information.

6.) Do I have to connect my current transformers in a special way to compensate for the

phase shift between the high side and low side of a transformer?

No, the BE1-CDS240 can compensate for phase shift. See Section 3, Input and Output

Functions, for additional information.

7.) Should I be concerned about zero-sequence blocking in my CT connections?

No, the BE1-CDS240 can compensate for zero-sequence blocking. See Section 3, Input and

Output Functions, for additional information.

8.) Does the BE1-CDS240 trip output contact latch after a fault?

The answer to the question is Yes and No. In general, once the fault goes away the output

contacts open. The BE1-CDS240 does offer an option to ensure that the contact will stay

closed for at least 200 milliseconds. See Section 3, Input and Output Functions, for additional

information on that function. However, BESTlogic can latch the relay outputs. See Section 8,

Application, Application Tips, for additional information.

9.) A function will not work when I put in settings such as the pickup and time delays.

Make sure that the logic function is enabled.

10.) How many overcurrent elements does the BE1-CDS240 have available?

The BE1-CDS240 has seventeen instantaneous overcurrent and thirteen time overcurrent

elements. Just like any element, each of these elements can be assigned to any output for

building logic equations.

11.) Can I make logic settings at the front panel?

No, the front panel cannot program logic settings. Logic settings must be programmed using

the ASCII command interface or BESTCOMS communication software.

12.) Since the BE1-CDS240 is a programmable device, what are the factory defaults?

The factory default logic is BASIC-87 logic. Default settings are shown with each function in the

instruction manual. For input or output default settings see Section 3, Input and Output

Functions. For protection and control functions, see Section 4, Protection and Control.

2-8 BE1-CDS240 Quick Start 9365200990 Rev M

Page 11

13.) Does the BE1-CDS240 have a battery installed as the back-up power source for the

Trip

PU

Targets

LED

0 0 0

Off

0 0 1

On

0 1 0

Flash

internal clock on loss of power?

Yes, as an option. The relay also uses a capacitor as a back-up power source for the internal

clock on loss of power. This design maintains the clock for at least eight hours. See Section 1,

General Information, Specifications, for additional information.

14.) Since the BE1-CDS240 has overcurrent elements in addition to the differential protection

functions, are the timing curves the same as Basler Electric's other numeric overcurrent

relays?

Yes, the timing curves are the same as other Basler Electric numerical overcurrent relays such

as the BE1-851, BE1-951, and BE1-IPS100.

15.) Why do I keep getting access conflict errors when I am communicating with the relay?

If you have tried to gain access to more than one port at a time, an access conflict results. The

unit has three different communication ports. The front HMI and front RS-232 are considered

the same port and are the first port (COM 0). The rear RS-232 (COM 1) is the second and the

rear RS-485 (COM 2) is the third port. If you have gained access at the front panel HMI and the

5-minute timeout has not ended, you cannot gain access at another port. The front RS-232 can

still be accessed because the HMI and front RS-232 are considered the same port. Access

needs to be gained only when a write to the BE1-CDS240 is required (control or setting change

or report reset). Data can be read and reports can be obtained without gaining access. After

gaining access though one of the ports, the session can be ended with the Exit command. If

access is gained, but the session is not ended, a 5-minute timeout will end the session and any

changes that were not saved will be lost. If you are using the BESTCOMS program, the access

and exit commands are executed for you.

16.) Why doesn't the trip LED behave as expected when the relay picks up and trips? A

closely related question would be why don't the targets work?

If the logic is setup to the point were the protective element is tripping at the desired current

level, but the targets, trip LED, and fault records are not behaving as expected, then there are

two commands (SG-TRIGGER and SG-TARGET) that need to be checked for proper

operation. The SG-TRIGGER command needs to have the PU trigger and TRIP trigger logic

correctly programmed. This should initiate the fault record. The SG-TARGET command needs

the protective element (function) enabled to log targets. See Section 6, Reporting and Alarms,

Fault Reporting, to get more details on how to correctly program these commands. The trip

LED has two different functions in the relay. When the SG-TRIGGER PU expression is true and

the TRIP expression is false, the trip LED flashes. When both the SG-TRIGGER PU and TRIP

expression are true, the trip LED lights solidly. When neither expression is true, the trip LED

lights solidly if there are latched targets. A flashing LED means one of the protection elements

is in a picked-up state and timing towards trip. Once the trip occurs, the LED turns on solidly.

The LED will not change state until the target has been reset. If the fault has not cleared, the

LED turns on again. Table 2-2 is a truth table for the Trip LED and it should help to interpret the

LED indications.

Table 2-2. Trip LED Truth Table

0 1 1 Flash

1 0 0 On

1 0 1 On

1 1 0 On

1 1 1 On

9365200990 Rev M BE1-CDS240 Quick Start 2-9

Page 12

17.) Is the IRIG signal modulated or demodulated?

The IRIG signal is demodulated (dc level-shifted digital signal). See Section 1, General

Information; Section 6, Reporting and Alarms; and Section 12, Installation, for additional

information.

18.) Can the IRIG signal be daisy-chained to multiple BE1-CDS240 units?

Yes, multiple BE1-CDS240 units can use the same IRIG input signal by daisy-chaining the

BE1-CDS240 inputs. The burden data is non-linear, approximately 4 kilo-ohms at 3.5 Vdc and 3

kilo-ohms at 20 Vdc. See Section 1, General Information; Section 6, Reporting and Alarms; and

Section 12, Installation, for additional information.

19.) How can I find out the version number of my BE1-CDS240?

The application version can be found in three different ways.

1) Use the HMI, Screen 4.6.

2) Use the ASCII command interface with the RG-VER command.

3) Use BE1-CDS240 BESTCOMS (the version is provided on the General Operation

Screen, Identification Tab).

20.) How are reports and other information obtained from the relay saved in files for future

use?

Through BESTCOMS, select print from the dropdown menu and then select RTF export, which

allows the user to save the file to any location. In addition, text transferred from the relay to your

terminal emulation software can be selected and copied to the clipboard. The clipboard

contents are pasted into any word processor such as Microsoft® Notepad and saved with an

appropriate file name.

2-10 BE1-CDS240 Quick Start 9365200990 Rev M

Loading...

Loading...