Page 1

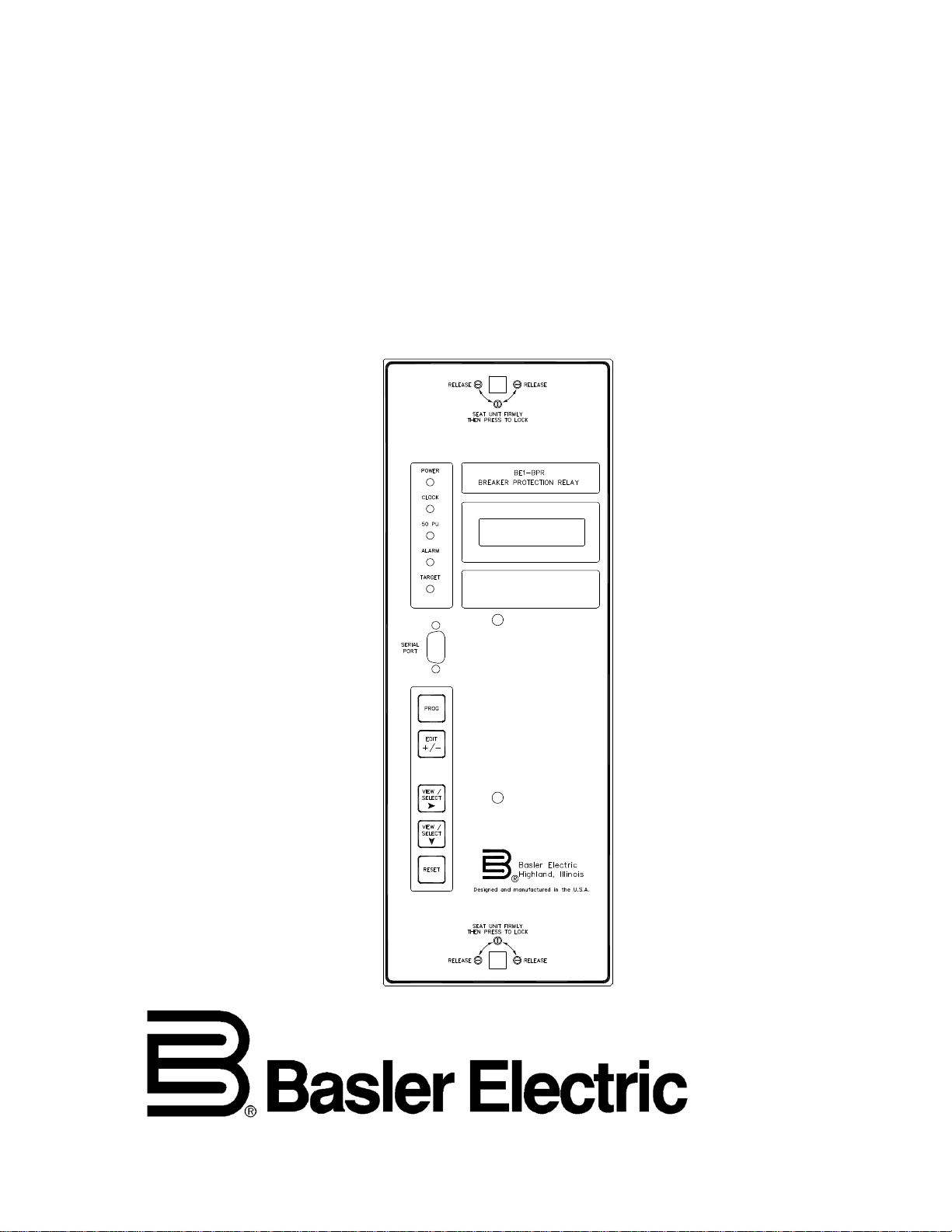

INSTRUCTION MANUAL

FOR

BREAKER PROTECTION RELAY

BE1-BPR

P0052-90

Publication: 9272000990

Revision: J 04/12

Page 2

Page 3

INTRODUCTION

This instruction manual provides information about the operation and installation of the BE1-BPR Breaker

Protection Relay. To accomplish this, the following information is provided:

General Information and Specifications

Application

Human-Machine Interface

Functional Description

Installation and Maintenance

Calibration and Testing

WARNING!

To avoid personal injury or equipment damage, only qualified personnel should

perform the procedures in this manual.

NOTE

Be sure that the BE1-BPR is hard-wired to earth ground with no smaller than 12

AWG copper wire attached to the ground terminal on the rear of the unit case.

When the BE1-BPR is configured in a system with other devices, it is

recommended to use a separate lead to the ground bus from each unit.

9272000990 Rev J BE1-BPR Introduction i

Page 4

First Printing: December 1994

Printed in USA

© 2012 Basler Electric, Highland Illinois 62249 USA

All Rights Reserved

April 2012

CONFIDENTIAL INFORMATION

of Basler Electric, Highland Illinois, USA. It is loaned for confidential use, subject

to return on request, and with the mutual understanding that it will not be used in

any manner detrimental to the interest of Basler Electric.

It is not the intention of this manual to cover all details and variations in equipment, nor does this manual

provide data for every possible contingency regarding installation or operation. The availability and design

of all features and options are subject to modification without notice. Should further information be

required, contact Basler Electric.

BASLER ELECTRIC

12570 STATE ROUTE 143

HIGHLAND IL 62249 USA

http://www.basler.com, info@basler.com

PHONE +1 618.654.2341 FAX +1 618.654.2351

ii BE1-BPR Introduction 9272000990 Rev J

Page 5

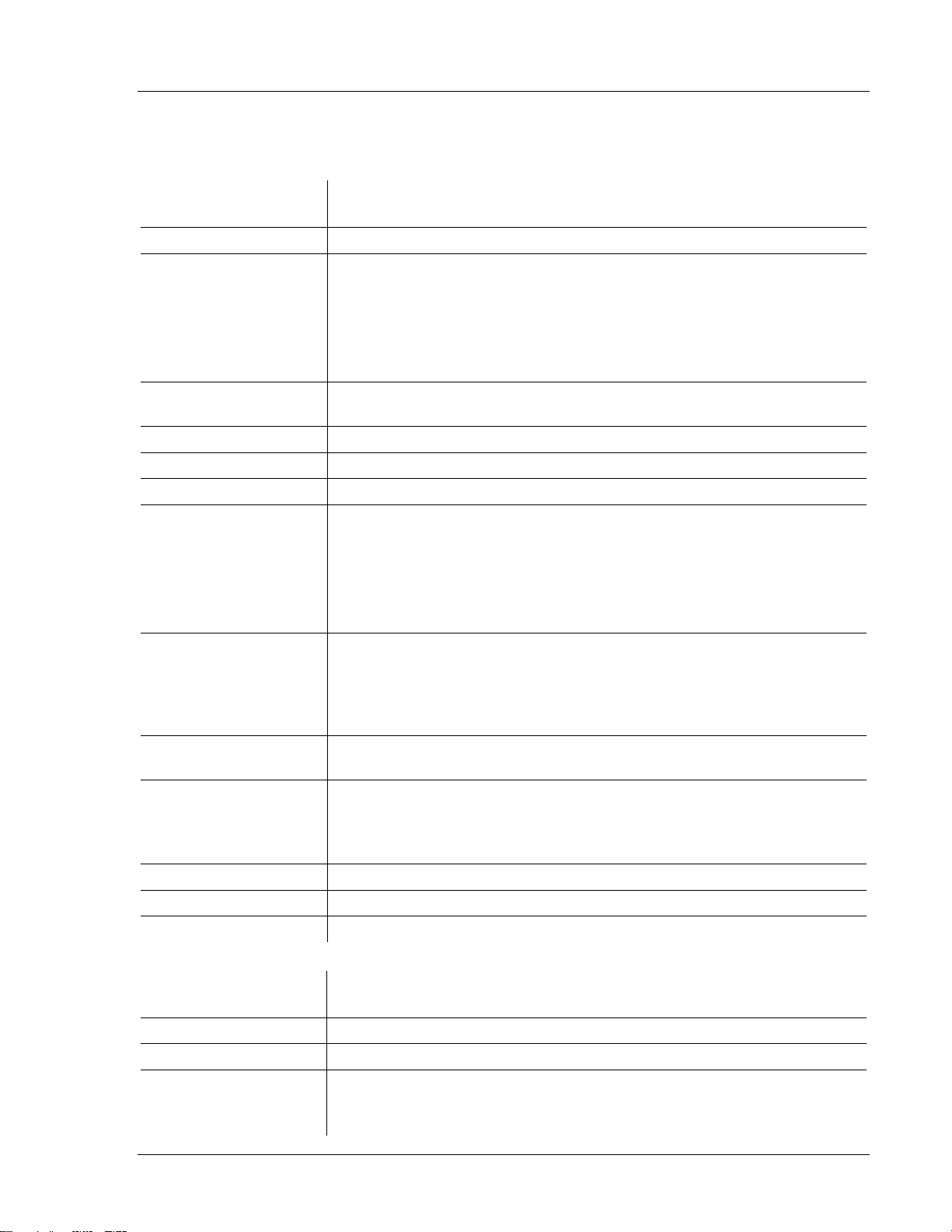

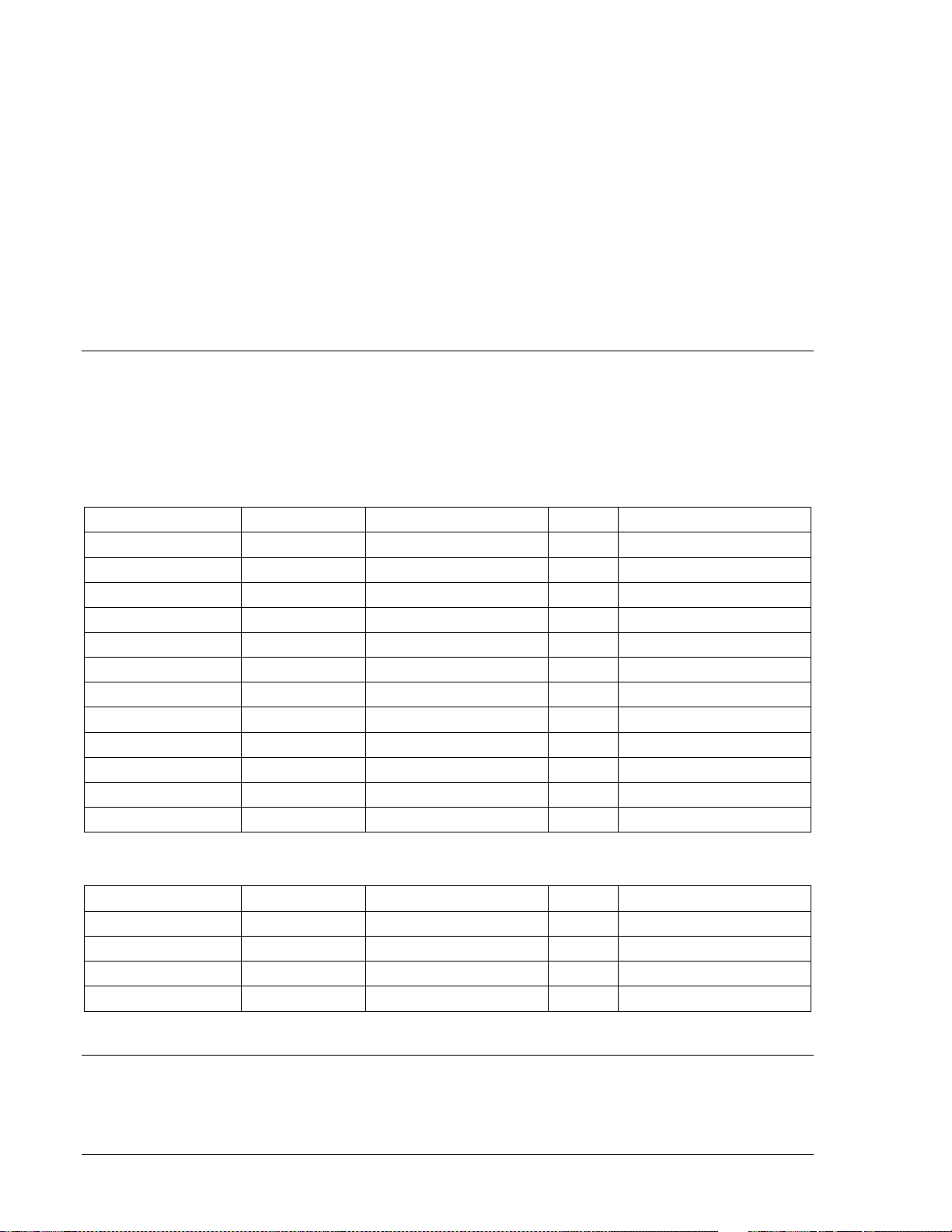

REVISION HISTORY

The following information provides a historical summary of the changes made to the BE1-BPR hardware

and firmware. The corresponding revisions made to this instruction manual (9272000990) are also

summarized. Revisions are listed in reverse chronological order.

Firmware

Version and Date

3.33, 07/11

3.32, 02/04

3.31, 02/02

3.30, 10/99

3.29, 06/99

3.27, 01/99

3.26, 11/98

3.23, 08/97

3.22, 02/97

3.21, 11/96

3.03, 06/96

3.02, 06/96

3.00, 12/94

Improved production testing at the factory.

Corrected PW command operation when used with B, F, or R

command suffix.

Eliminated fault log data errors.

Corrected HMI LCD flickering and the skipping of DIAG records when

certain diagnostic alarms are present.

Corrected fault log data errors.

Corrected over-range display error for primary current above 10 Aac

and a CT ratio less than 99.

Added POSC command.

Corrected operation of Ti parameter in BKRCON setting.

Implemented new device serial number format.

Added fourth password level for OUT command.

Modified ACCESS command so that password access can be

obtained in multiple access areas simultaneously.

Added ID screen to front panel HMI.

Removed extraneous text from settings reported by the SHOWSET

command.

Changed time delay setting (TD command) range and recloser time

delay setting (TD79 command) range from 0 to 60 seconds to 10

milliseconds to 60 seconds. A setting of 0 disables the timer.

Changed the minimum input contact recognition and debounce timer

(LI command) from 1 millisecond to 4 milliseconds.

Corrected PHOLD command operation in regard to the recloser (79)

Close output.

Improved pickup and dropout performance at very low pickup

settings.

Added Model/Program screen to the list of Maintenance screens

available at the front panel HMI.

Eliminated sporadic LO command errors.

Resolved communication errors during RS-485 multidrop operation.

Initial release

Change

Manual

Revision and Date

J, 04/12

I

H, 05/08

9272000990 Rev J BE1-BPR Introduction iii

Minor text edits.

This revision letter not used.

Added information for model numbers 9272000328, 9272000329,

9272000330, and 9272000331.

Updated Table 1-4, Contact Sensing Burden.

Change

Page 6

Manual

Revision and Date

G, 01/08

F, 08/04

E, 12/98

D, 07/98

C, 01/96

B, 07/95

Change

Added GOST-R to Section 1, General Information, Specifications.

Added manual part number and revision to footers.

Updated front panel drawings.

Text was added to describe the contact sensing circuitry with jumper-

selectable turn-on and turn-off points. A procedure and diagram for

configuring the contact sensing jumpers was added to Section 7.

Power supply holdup time specification was increased.

Where applicable, drawings were modified to reflect new front panel

design for horizontal- and vertical- units.

Figure 7-2 was changed to show revised mounting depth for the

horizontal-mount unit.

Call-outs were added to Figure 7-5 to identify mounting hole locations

for vertical-mount units used in retrofit installations. M2 panel

openings were added.

More data about the IRIG input was added to Section 1, General

Information, and Section 7, Installation.

POSC command and description was added to Section 4, Functional

Description.

BKRCON command information was altered because of an expanded

Tc and Ti setting range.

CTI parameter was removed from CT command text and all settings

lists.

A note box discussing the need to modify older settings files for use

with newer versions of the BE1-BPR was added to Section 6,

Communications.

Diagrams and text were added to Section 5, BESTlogic

Programmable Logic, Contact Input Logic to better explain the

recognition and debounce settings of the LI command.

A detailed table of contents was placed at the beginning of

appropriate sections. The table of contents at the beginning of the

manual was simplified by listing only section numbers and titles.

Manual style was updated.

Output relay pickup time for OUT1 was changed to 4 ms typical, 5 ms

maximum.

Manual was revised to provide a more complete functional

description.

Communication command information was summarized in table form

and missing command information was added.

Panel drilling diagram of Figure 7-5 was updated and connection

diagram of Figure 7-13 was added.

Appendix A, Terminal Emulation was added.

Testing procedures of Section 8, Calibration and Testing were

updated and clarified.

The manual style was updated.

Revised manual to include added IRIG-B functions.

Made revisions throughout manual to reflect the vertical mounting

option. Added Figures 3-4, 7-3, 7-4, and 7-5.

Minor corrections were made in Reclosing Mode and FLOG

Command.

Corrected Figure 4-2.

iv BE1-BPR Introduction 9272000990 Rev J

Page 7

Manual

Revision and Date

A, 04/95

—, 12/94

Added a description of the reclosing functions.

Initial release

Change

9272000990 Rev J BE1-BPR Introduction v

Page 8

This page intentionally left blank.

vi BE1-BPR Introduction 9272000990 Rev J

Page 9

CONTENTS

SECTION 1 • GENERAL INFORMATION ................................................................................................ 1-1

SECTION 2 • APPLICATION .................................................................................................................... 2-1

SECTION 3 • HUMAN-MACHINE INTERFACE ....................................................................................... 3-1

SECTION 4 • FUNCTIONAL DESCRIPTION ........................................................................................... 4-1

SECTION 5 • BESTlogic PROGRAMMABLE LOGIC ............................................................................... 5-1

SECTION 6 • COMMUNICATIONS .......................................................................................................... 6-1

SECTION 7 • INSTALLATION .................................................................................................................. 7-1

SECTION 8 • CALIBRATION AND TESTING .......................................................................................... 8-1

SECTION 9 • MAINTENANCE .................................................................................................................. 9-1

APPENDIX A • TERMINAL COMMUNICATION ....................................................................................... A-1

APPENDIX B • COMMAND SUMMARY ................................................................................................... B-1

APPENDIX C • RELAY SETTINGS RECORD ......................................................................................... C-1

9272000990 Rev J BE1-BPR Introduction vii

Page 10

This page intentionally left blank.

viii BE1-BPR Introduction 9272000990 Rev J

Page 11

SECTION 1 • GENERAL INFORMATION

TABLE OF CONTENTS

SECTION 1 • GENERAL INFORMATION ................................................................................................ 1-1

DESCRIPTION....................................................................................................................................... 1-1

APPLICATION - STANDARD MODELS ................................................................................................ 1-1

Breaker Failure ................................................................................................................................... 1-1

Breaker Reclosing .............................................................................................................................. 1-1

Timing Diagnostics ............................................................................................................................. 1-2

Breaker Arc Detector .......................................................................................................................... 1-3

IRIG Standard Time Format ............................................................................................................... 1-3

APPLICATION - ENHANCED MODELS ............................................................................................... 1-3

Breaker Contact Maintenance and Resistor Protection ..................................................................... 1-3

Fault Recording .................................................................................................................................. 1-4

MODEL NUMBERS ............................................................................................................................... 1-4

SPECIFICATIONS ................................................................................................................................. 1-4

Current Sensing ................................................................................................................................. 1-5

Current Detector Pickup Time ............................................................................................................ 1-5

Current Detector Dropout Time .......................................................................................................... 1-5

Current Pickup Range ........................................................................................................................ 1-5

Current Pickup Accuracy .................................................................................................................... 1-5

Sample Rate ....................................................................................................................................... 1-5

Oscillograph Recording Range .......................................................................................................... 1-5

Oscillograph Data Accuracy ............................................................................................................... 1-5

Oscillograph Recording Format.......................................................................................................... 1-6

Contact Sensing Input Recognition Time ........................................................................................... 1-6

Contact Sensing Input Range ............................................................................................................ 1-6

Contact Sensing Input Burden ........................................................................................................... 1-6

IRIG Input ........................................................................................................................................... 1-6

Timers ................................................................................................................................................. 1-6

Timer Accuracy .................................................................................................................................. 1-7

Real Time Clock Set Ability ................................................................................................................ 1-7

Real Time Clock Resolution ............................................................................................................... 1-7

Real Time Clock Stability ................................................................................................................... 1-7

Real Time Clock Accuracy ................................................................................................................. 1-7

BESTlogic Operate Time .................................................................................................................... 1-7

Output Relays ..................................................................................................................................... 1-7

Display ................................................................................................................................................ 1-7

Targets/Indicators ............................................................................................................................... 1-8

Keypad ............................................................................................................................................... 1-8

Communications ................................................................................................................................. 1-8

Power Supply ..................................................................................................................................... 1-8

Isolation .............................................................................................................................................. 1-8

Surge Withstand Capability ................................................................................................................ 1-8

Radio Frequency Interference (RFI) .................................................................................................. 1-9

Temperature ....................................................................................................................................... 1-9

Shock .................................................................................................................................................. 1-9

Vibration ............................................................................................................................................. 1-9

Gost-R Certification ............................................................................................................................ 1-9

Weight ................................................................................................................................................ 1-9

Figures

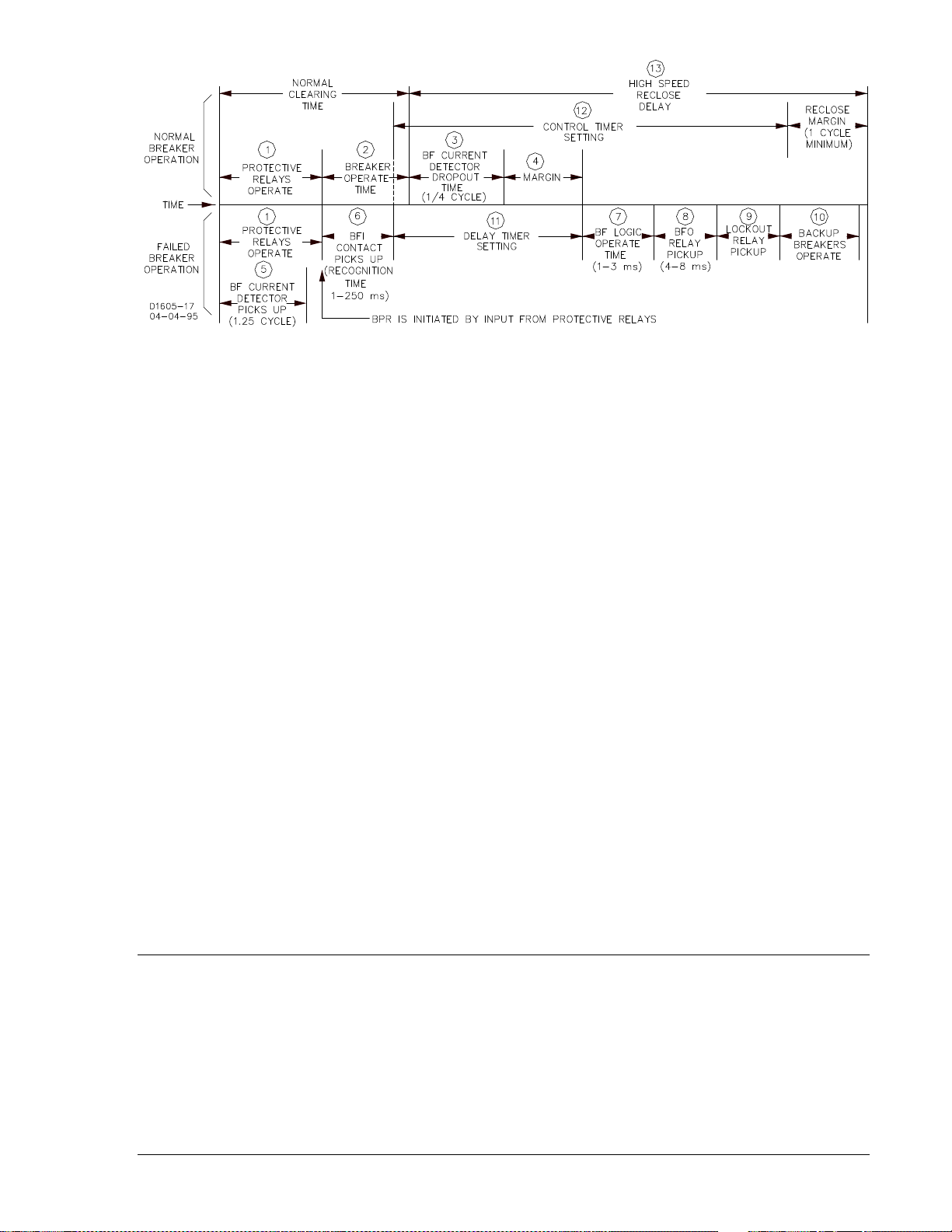

Figure 1-1. Breaker Failure Timing Diagram ............................................................................................. 1-3

9272000990 Rev J BE1-BPR General Information i

Page 12

Tables

Table 1-1. BE1-BPR Relays, 5 Aac CT Secondary

Table 1-2. BE1-BPR Relays, 1 Aac CT Secondary

Table 1-3. Contact Sensing Turn-On Voltage

Table 1-4. Contact Sensing Burden

Table 1-5. Power Supply Specifications

................................................................................... 1-4

................................................................................... 1-4

........................................................................................... 1-6

.......................................................................................................... 1-6

.................................................................................................... 1-8

ii BE1-BPR General Information 9272000990 Rev J

Page 13

SECTION 1 • GENERAL INFORMATION

DESCRIPTION

BE1-BPR Breaker Protection Relays are three-phase and neutral, microprocessor based relays designed

to provide power systems with protection and security against monitored breaker failure or to initiate

multiple shot breaker reclosings.

These relays incorporate a powerful means of programming internal relay logic to satisfy a wide range of

user requirements without making any relay hardware changes. Microprocessor based design provides

the basic features of a programmable logic controller (PLC) combined with an instantaneous overcurrent

module. Cased in a 19 inch rack-mount or a vertical panel mount, the relay offers installation versatility. A

wide temperature, 2 lines by 16 character display provides diagnostic and setup information. Two RS-232

serial ports (one each front and rear) and one RS-485 serial port (rear) provide remote communication

and relay control.

Built-in diagnostics and monitoring features provide information for both the health of the relay and the

health of the breaker being monitored. Relay diagnostics include continuous background monitoring of the

power supplies, analog-to-digital (A/D) converter, random-access memory (RAM), read-only memory

(ROM), and electrically-erasable programmable ROM (EEPROM). A dedicated alarm (ALM) relay output

provides power supply, microprocessor, and software alarm status. Breaker diagnostics include a timing

diagnostic log, breaker contact duty monitoring, breaker resistor protection, and breaker arc detection.

Other monitoring features include oscillographic fault records and fault summary logs. BE1-BPR relays

use the Inter-Range Instrumentation Group (IRIG), Format B for high timing accuracy and resolution.

APPLICATION - STANDARD MODELS

Breaker Failure

BE1-BPR relays are intended to provide a preprogrammed solution for most breaker failure relaying

applications. Breaker failure relaying is the use of a current monitoring relay to determine whether or not

current continues to flow into a faulted circuit after a breaker has been instructed to interrupt the circuit. If

current continues to flow into the faulted circuit after a defined period of time has elapsed (sufficient for

the breaker to have interrupted the current), the circuit breaker is considered to have failed. Steps must

then be taken to trip the next set of breakers in the power system to prevent system damage. Breaker

failure schemes must be designed to isolate both the faulted circuit and the failed breaker.

Several reasons why a breaker fails to clear a fault are:

• Trip circuit is open (broken wire, blown fuse, open trip coil).

• Interrupting mechanism stuck, leaving a single phase of a three-phase circuit connected.

• Interrupter flash-over due to the loss of dielectric strength through contamination or damage.

• Operating mechanism failed to operate.

Breaker failure relays detect these conditions and initiate backup procedures.

Breaker failure relays are applied on a per breaker basis. That is, one breaker failure relay for each

breaker in the substation. BE1-BPR relay outputs must be arranged to initiate the tripping of all the circuit

breakers necessary to isolate the fault if the protected circuit breaker fails to operate. The relay may also

need to initiate transfer tripping of remote breakers to accomplish this task. Transfer tripping of the remote

line end for a breaker failure should also block reclosing of the remote circuit breakers. External lockout

relays are typically used to trip and block reclosing of the backup breakers because they normally require

a positive operator action to reset them.

Typically, breaker failure protection is applied to transmission and sub-transmission systems. However,

breaker failure protection may be applied to any portion of the power system where failure of a circuit

breaker to operate properly could result in severe system damage or instability. Breaker failure protection

can also be used to selectively clear a failed breaker in a station with multiple buses without clearing the

entire station.

Breaker Reclosing

BE1-BPR relays can be configured as multiple shot reclosing relays that operate in parallel and

independently from the breaker failure function.

9272000990 Rev J BE1-BPR General Information 1-1

Page 14

Three major factors should be considered when establishing a reclosing philosophy.

• Desired number or reclosure attempts.

• Time delay between breaker opening and reclosure.

• Supervisory control.

The first major factor is the desired number of reclosure attempts. Where most faults are attributable to

heavy tree exposure, as in distribution networks, multiple reclosure attempts are common. This is

possible because of low voltage levels and is desirable considering customer inconvenience during

outages. BE1-BPR relays are programmable for up to three reclosure attempts per sequence. This allows

tailoring of the reclosing sequence to the specific needs of the circuit.

The second major factor is the time delay between breaker opening and reclosure. On sub-transmission

and distribution networks, it is necessary to ensure that motors are no longer running and that local

generation is off-line prior to attempting reclosure. At the same time, a rapid reclosure minimizes damage,

ionization, and system shock in transmission networks. After the first reclosure attempt, additional

attempts are generally delayed to allow for de-ionization of the interrupter. BE1-BPR relays have three

reclosing shots and each shot has a programmable time delay. Three outputs are available. They are

CLOSE, RECLOSE FAIL, and LOCKOUT.

A third major factor to be considered in reclosing is supervisory control. Supervisory control allows the

operator to maintain control of the system at all times. BE1-BPR relays have two supervisory inputs

(WAIT and LOCKOUT). WAIT stops the reclose sequence at any point and allows the sequence to

continue when the WAIT input is removed. LOCKOUT drives the reclose function immediately to lockout

status and takes precedence over all other inputs.

Timing Diagnostics

To perform the typical breaker failure operation previously described, the breaker failure relay must be

informed by a breaker failure initiate (BFI) contact that the breaker is being opened. One or more timers,

in conjunction with the overcurrent element, determine if the breaker failure output (BFO) picks up.

Typically one or more delay timers are used to delay the BFO until the primary protection scheme has

had enough time to operate. A control timer may be also be used to turn off the BFO after the backup

protection has had enough time to operate.

Calculation of the correct timer values is an important part of setting up the relay. You must know how

long it takes for the internal and external devices to operate. Typical timing sequences are listed in the

following paragraphs and shown in Figure 1-1. Parentheses in the listed timing information indicate

related times in Figure 1-1. Specific timing data for BE1-BPR relays is provided in the latter part of this

section.

Normal Breaker Operation Required Timing Information

(1) Time for protective relays to operate — (this includes sending a trip signal to the breaker and

sending a BFI signal to the BE1-BPR).

(2) Time required for the breaker to open.

(3) Time required for the BE1-BPR overcurrent detector to drop out.

(4) Margin to allow for variations in normal sequence timing plus a safety factor.

(12) Control timer setting = the length of time to maintain the breaker failure operating window. Control

timer setting must coordinate with the high speed reclose delay (13).

(13) Time to allow for arc de-ionization.

Failed Breaker Operation Required Timing Information

(5) Time for the BFI overcurrent detector to pickup.

(6) Time required for the BFI contact to be recognized by the BE1-BPR.

(7) Time for the BF logic to operate.

(8) Time for the BFO relay to operate.

(9) Time for the external lockout relay to pickup.

(10) Time for the backup breakers to operate.

(11) Delay timer setting = the sum of (breaker operate time (2) + BF current detector dropout time (3) +

margin (4)) minus BFI contact pickup time (6).

1-2 BE1-BPR General Information 9272000990 Rev J

Page 15

Figure 1-1. Breaker Failure Timing Diagram

Because timing is such an important part of breaker failure protection, the BE1-BPR relay provides timing

diagnostics to assist in determining if the timer settings are optimal and to allow other aspects of the

protection system to be checked. This timing diagnostic is a Timer Log or TLOG. An example of its use is

to create a log of the margin remaining between when a fault is cleared and when a breaker failure would

occur. After a normal breaker operation clears a fault, the time remaining from when the BE1-BPR

overcurrent fault detector drops out and the breaker failure delay timer would have timed out is the

MARGIN. This time can be recorded by saving the time left on the delay timer when the fault detector

drops out by using the program timer log alarm (PTLOG) command. The time logged will correspond to

the MARGIN value in Figure 1-1. If there is a discrepancy between the calculated and actual margin value

stored in the TLOG, corrective action can be taken to correct the protection timing before a serious

problem occurs. If the MARGIN is too small or too large, the delay timer setting can be adjusted for

optimal operation. The PTLOG command also allows an alarm time to be programmed so that if the

MARGIN drops below a pre-determined value, the Alarm output (ALM) can be automatically closed to

signal the operator that immediate attention is required. Timing diagnostics can be programmed for each

of the six timers available.

Breaker Arc Detector

An important breaker diagnostic feature is the detection of low level arcing across an open breaker

(flashover). Flashover might occur because lightning struck and a surge suppressor failed or air pressure

in an air blast circuit breaker is lost. If left undetected, severe damage to the breaker contacts could

result. BE1-BPR relays can detect this type of fault using an extra low level phase overcurrent pickup and

a long moving average filter. These features have been provided as standard features in the BE1-BPR

relays. Used with the programmable logic, a breaker arc detector can be programmed to provide a

breaker close output to close the breaker and extinguish the arc. Additional interlocks may be added to

the logic to inhibit the breaker close signal if the breaker is isolating a faulted line.

IRIG Standard Time Format

The IRIG function allows the BE1-BPR relay to synchronize the on-board real time clock with a standard

IRIG demodulated time signal. Synchronization is automatic and the BE1-BPR initiates synchronization at

regular intervals (approximately 20 seconds) in order to maintain the one millisecond overall accuracy.

APPLICATION - ENHANCED MODELS

Enhanced BE1-BPR models have all of the features of standard models plus the additional features

described in the following paragraphs.

Breaker Contact Maintenance and Resistor Protection

Enhanced model BE1-BPR relays can perform two protection diagnostic functions other than the breaker

failure function. One, they can estimate breaker contact duty (wear) and signal when preventative

maintenance is needed. Two, they can estimate breaker opening resistor heating and provide a block

reclose signal to protect the breaker resistor when the resistor heating could exceed the maximum

resistor rating.

9272000990 Rev J BE1-BPR General Information 1-3

Page 16

Fault Recording

Enhanced model BE1-BPR relays can also be configured to record and save digital fault data for all three

phases plus neutral (0 to 200 amperes) and the digital state of each input and output contact. Analog

waveforms are digitized by sampling the waveforms at a periodic rate and converting the measured

signals to digital values. When a fault occurs, the digital data is stored as a fault record. Multiple fault

records can be stored and recalled through the serial port by an operator. To display the fault waveform

for analysis, recalled data can be imported into a data base file and converted into a graph. Standard

programs that read and display ASCII data (in accordance with IEEE Standard Common Format for

Transient Data Exchange (COMTRADE) for Power Systems) can also be used. BESTView application

software provides a simple terminal interface to communicate with the relay, retrieve and display

COMTRADE oscillographic fault data, and provide a remote front panel interface. This software is not

required to communicate with the relay. However, it combines the functions of a number of separate

packages into one program that is optimized for the BE1-BPR relay. To order this software free of charge,

contact the Customer Service Department of the Power Systems Group, Basler Electric, and request the

BESTView Software Package.

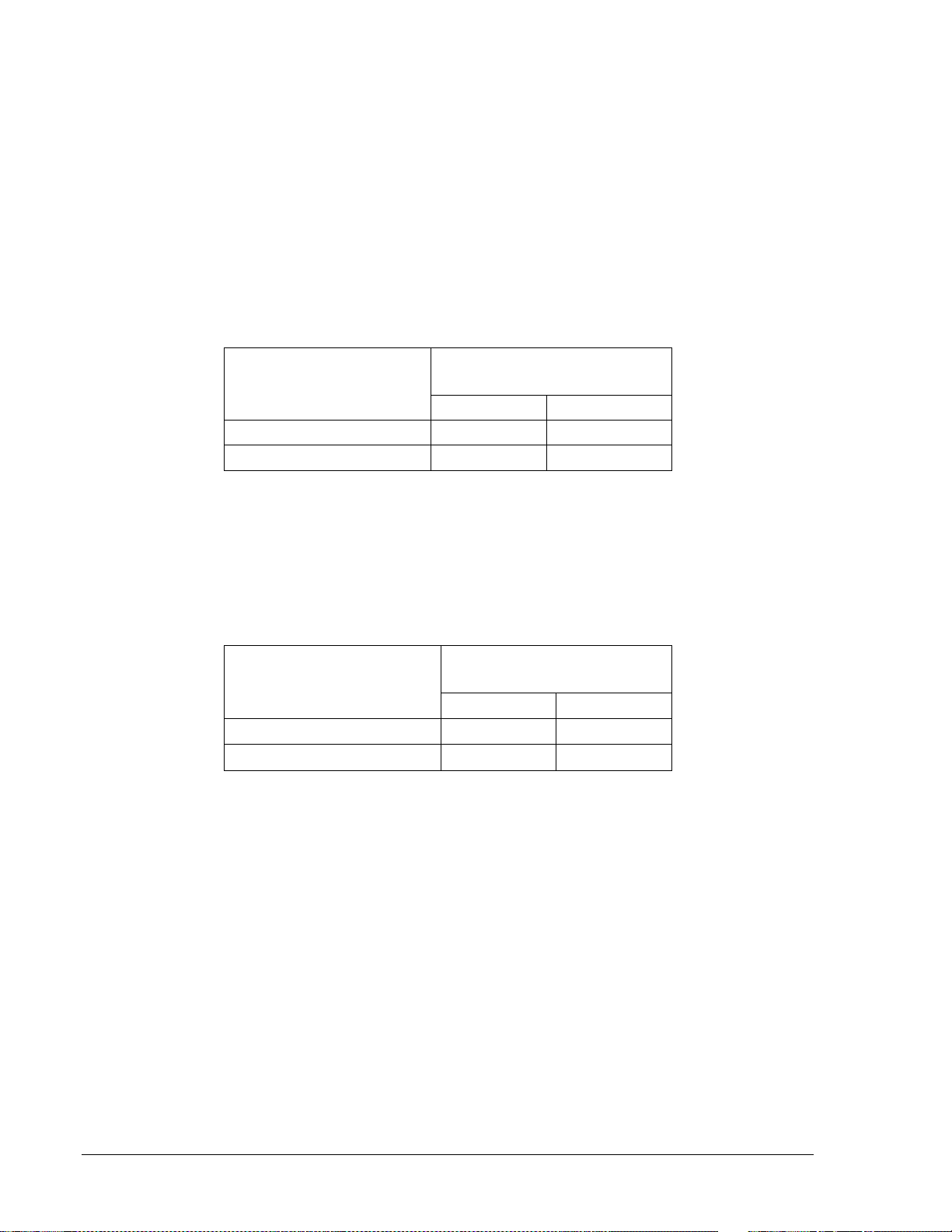

MODEL NUMBERS

Tables 1-1 and 1-2 provide information for the nominal current input to the current transformers, part

number, options, mounting style, and operating power supply voltage. Standard BE1-BPR relays do not

have oscillography, fault records, contact duty logs, or two calibration levels (current metering is limited to

10 amperes).

Table 1-1. BE1-BPR Relays, 5 Aac CT Secondary

Part Number Options Mounting Style IRIG Power Supply

9272000300 Standard 19” Rack Mount Yes 48/125 Vac/Vdc

9272000301 Standard 19” Rack Mount Yes 125/250 Vac/Vdc

9272000302 Enhanced 19” Rack Mount Yes 48/125 Vac/Vdc

9272000303 Enhanced 19” Rack Mount Yes 125/250 Vac/Vdc

9272000309 Standard Vertical Mount Yes 48/125 Vac/Vdc

9272000310 Standard Vertical Mount Yes 125/250 Vac/Vdc

9272000311 Enhanced Vertical Mount Yes 48/125 Vac/Vdc

9272000312 Enhanced Vertical Mount Yes 125/250 Vac/Vdc

9272000328 Enhanced Vertical Mount Yes 48/125 Vac/Vdc

9272000329 Enhanced 19” Rack Mount Yes 48/125 Vac/Vdc

9272000330 Enhanced Vertical Mount Yes 125/250 Vac/Vdc

9272000331 Enhanced 19” Rack Mount Yes 125/250 Vac/Vdc

Table 1-2. BE1-BPR Relays, 1 Aac CT Secondary

Part Number Options Mounting Style IRIG Power Supply

9272000304 Standard 19” Rack Mount Yes 48/125 Vac/Vdc

9272000305 Standard 19” Rack Mount Yes 125/250 Vac/Vdc

9272000306 Enhanced 19” Rack Mount Yes 48/125 Vac/Vdc

9272000307 Enhanced 19” Rack Mount Yes 125/250 Vac/Vdc

SPECIFICATIONS

BE1-BPR Breaker Protection Relays have the following features and capabilities.

1-4 BE1-BPR General Information 9272000990 Rev J

Page 17

Current Sensing

Four isolated inputs with a maximum burden of less than 0.1 ohm.

5 Ampere CT: Maximum continuous current: 20 Aac

Maximum one second current: 500 Aac

1 Ampere CT: Maximum continuous current: 4 Aac

Maximum one second current: 80 Aac

Current Detector Pickup Time

Instantaneous Fault Detector (50/60 Hz RMS Filter Type 1 and 3)

1 ¼ cycle maximum for current 125% greater than pickup.

Moving Average Window Fault Detector (50/60 Hz RMS Filter Type 2)

Maximum pickup time is (Window_size/C_PM + 1 ¼ (cy)), where Window_size = Filter window size in

cycles (Range 1 - 100) and C_PM = Current Pickup Multiple

Current Detector Dropout Time

Instantaneous Fault Detector (50/60 Hz RMS Filter Type 1 and 3)

Dropout/pickup ratio: 90%, typical. One-quarter cycle (4.2 milliseconds @ 60 hertz) from the time the

current falls below and stays below 25% of the RMS level or 1 ¼ cycle from the time the RMS current

signal decreases to less than 75% of pickup.

Moving Average Window Fault Detector (50/60 Hz RMS Filter Type 2)

Maximum dropout time is (Window_size-(Window_size/C_PM) + 1 ¼ (cy)), where Window_size = Filter

window size in cycles (Range 1 - 100) and C_PM = Current Pickup Multiple level before dropout.

Current Pickup Range

Three independent settings, selectable as three-phase or neutral.

Instantaneous Fault Detector (50/60 Hz RMS Filter Type 1 and 3)

5 ampere CT: 0.25 to 9.99 amperes selectable in 0.01 increments

1 ampere CT: 0.05 to 2.00 amperes selectable in 0.01 increments

Moving Average Window Fault Detector (50/60 Hz RMS Filter Type 2)

5 ampere CT: 0.05 to 1.00 amperes selectable in 0.01 increments

1 ampere CT: 0.01 to 0.20 amperes selectable in 0.01 increments

Current Pickup Accuracy

Instantaneous Fault Detector (50/60 Hz RMS Filter Type 1 and 3)

5 ampere CT: ±2% of pickup setting or ±0.05 Aac (whichever is greater)

1 ampere CT: ±2% of pickup setting or ±0.01 Aac (whichever is greater)

Moving Average Window Fault Detector (50/60 Hz RMS Filter Type 2):

5 ampere CT: ±25% with window of 10 cycles or larger

1 ampere CT: ±25% with window of 10 cycles or larger

Sample Rate

12 samples per cycle (720 samples per second at 60 hertz, 600 samples per second at 50 hertz).

Oscillograph Recording Range

5 ampere CT: 0 - 200 amperes, rms

1 ampere CT: 0 - 40 amperes, rms

Oscillograph Data Accuracy

±0.2% of full scale or 5% of reading, whichever is greater

9272000990 Rev J BE1-BPR General Information 1-5

Page 18

Oscillograph Recording Format

IEEE C37.111-1991, IEEE Standard Common Format for Transient Data Exchange (COMTRADE) for

Power Systems.

Contact Sensing Input Recognition Time

User programmable 4 - 255 milliseconds ±0.01% of setting to closest sample time (one-twelfth cycle = 1.4

milliseconds at 60 hertz or 1.7 milliseconds at 50 hertz).

Contact Sensing Input Range

Energizing levels for contact sensing inputs are jumper selectable. Table 1-3 lists the turn-on range for

each control voltage range and jumper position. Refer to Section 7, Installation, Contact Sensing Inputs,

for jumper location.

Table 1-3. Contact Sensing Turn-On Voltage

Turn-On Range

Nominal Control Voltage

48/125 Vac/Vdc 26 V to 38 V 69 V to 100 V

125/250 Vac/Vdc 69 V to 100 V 138 V to 200 V

(JP200 through JP206)

Pin 1 - Pin 2 Pin 2 - Pin 3

Contact Sensing Input Burden

Burden per contact for sensing depends on the power supply model and the input voltage. The input

sensing range is the same as the dc power supply range. Table 1-4 provides appropriate burden

specifications.

Table 1-4. Contact Sensing Burden

Turn-On Range

Nominal Control Voltage

48/125 Vac/Vdc

125/250 Vac/Vdc

IRIG Input

Signal: The IRIG input accepts a demodulated (dc level-shifted) signal.

Maximum input signal level is 25 volts.

Burden: Burden is nonlinear and rated at 4 kΩ at 5 Vdc.

Timers

Standard (TD[n]): Six microprocessor controlled timers. Programmable in milliseconds,

seconds, or cycles. Ranges and increments are: 10 to 999 milliseconds

in 1 millisecond increments; 1 to 60 seconds in 0.1 second increments;

or 1 to 3,600 cycles in 1 cycle increments. A setting of 0 will disable the

timer. If programmed in cycles, the BE1-BPR relay will display the

equivalent time in milliseconds.

Reclosing (TD79[n]): Six microprocessor controlled timers. Programmable in milliseconds,

seconds, or cycles. Ranges and increments are: 10 to 999 milliseconds

in 1 millisecond increments; 1 to 99 seconds in 0.1 second increments;

100 to 600 seconds in 1 second increments; or 1 to 9,999 in 1 cycle

increments.

(JP200 through JP206)

Pin 1 - Pin 2 Pin 2 - Pin 3

16 kΩ 28 kΩ

56 kΩ 92 kΩ

1-6 BE1-BPR General Information 9272000990 Rev J

Page 19

Timer Accuracy

Standard (TD[n]): +4 and -1 milliseconds ±0.01% of setting

Reclosing (TD79[n]): +20 and -1 milliseconds ±0.01% of setting

Real Time Clock Set Ability

±1 second

Real Time Clock Resolution

±1 second

Real Time Clock Stability

±30 ppm typical

Real Time Clock Accuracy

Relays with IRIG, ±1 millisecond. If IRIG signal is lost, accuracy defaults to the real time clock stability.

BESTlogic Operate Time

Operate time is 1.4 milliseconds typical, 2.8 milliseconds maximum at 60 hertz.

Output Relays

Any output contact closed by the relay logic will be held closed for 200 to 250 milliseconds even if the

initial cause of the closing goes away. After 200 to 250 milliseconds, the relay close time is determined by

the state of the relay logic. This minimum hold time may be disabled by using the PHOLD command.

Factory Presets

ALARM Output: Output contacts close when ALARM logic (LOA) is true or power is lost.

Outputs 1 - 5: Output contacts close when the corresponding logic equation (LO1 -

LO5) is true.

Pickup Time (All models except 9272000328, 9272000329, 9272000330, and 9272000331)

ALARM: 8 milliseconds typical, 10 milliseconds maximum

OUTPUT 1: 4 milliseconds typical, 5 milliseconds maximum

OUTPUT 2, 3, 4, 5: 8 milliseconds typical, 10 milliseconds maximum

Pickup Time (Models 9272000328, 9272000329, 9272000330, and 9272000331 only)

ALARM: 8 milliseconds typical, 10 milliseconds maximum

OUTPUT 1, 2: 4 milliseconds typical, 5 milliseconds maximum

OUTPUT 3, 4, 5: 8 milliseconds typical, 10 milliseconds maximum

Resistive Ratings

120 Vac: Make, break, and carry 7 Aac continuously

250 Vdc: Make and carry 30 Adc for 0.2 s, carry 7 Adc continuously,

break 0.3 Adc

500 Vdc: Make and carry 15 Adc for 0.2 s, carry 7 Adc continuously,

break 0.3 Adc

Inductive Ratings

120 Vac, 125/250 Vdc: Break 0.3 A (L/R = 0.04)

Display

Two-line, 16 character alphanumeric LCD (liquid crystal display) with LED (light emitting diode) backlight.

Operating Temperature: -40°C to +70°C (-40°F to +158°F)

Display contrast may be impaired at temperatures below -20°C (-4°F).

9272000990 Rev J BE1-BPR General Information 1-7

Page 20

Targets/Indicators

Five diagnostic LED indicators are provided.

POWER: Green LED (normally ON) to indicate power supply is operating.

CLOCK: Green LED (normally OFF) turns ON to indicate that the clock needs to

be set.

50PU: Red LED (normally OFF) turns ON to indicate one or more of the inputs

has exceeded the pickup level(s).

ALARM: Red LED (normally OFF) turns ON to indicate problems. Output A

(ALARM) de-energizes (closes) when ALARM LED is ON.

TARGET: Red LED (normally OFF) turns ON if one or more of the relay outputs

has been energized. (If programmed by the PTARGET command.)

Keypad

Five keys are used to access information on the display and enter settings.

Communications

Only one communication port can be active at any time.

Front panel connector: RS-232, 9-pin, female, D-sub DCE

Rear panel connectors: RS-232, 9-pin, female, D-sub DCE

RS-485, 3-position terminal block

Baud Rate: 300, 600, 1200, 2400, 4800, 9600, and 19200

Buffer Size: 40 characters

Protocol: ASCII and binary data transmissions

Power Supply

Power for the internal circuitry may be derived from ac or dc external power sources. Power supply data

is provided in Table 1-5.

Table 1-5. Power Supply Specifications

Power Supply

Range

48/125 V 48 Vdc

125/250 V 125 Vdc

Isolation

All output and power supply terminals have MOV suppressors. Maximum applied voltage must be no

greater than 300 volts where MOV suppressors are used. Surge suppression capacitors are installed

between terminal pairs and between terminals and chassis ground. When testing with 1,500 Vac, leakage

current (approximately 8 milliamperes per terminal) is expected. 1.500 Vac (RMS) at 45 to 65 hertz for

one minute or 2,121 Vdc may be applied between circuit groups, and between circuit group and chassis

ground in accordance with IEC 255-5 and ANSI/IEEE C37.90-1989 (Dielectric Tests).

Nominal Input

Voltage

125 Vdc

120 Vac

120 Vac

250 Vdc

240 Vac

Input Voltage

Range

40 to 60 Vdc

90 to 150 Vdc

100 to 130 Vac

90 to 150 Vdc

100 to 130 Vac

180 to 300 Vdc

200 to 260 Vac

Burden at Nominal

(Maximum)

8 W (10 W)

8 W (10 W)

8 W (10 W)

8 W (10 W)

8 W (10 W)

8 W (10 W)

8 W (10 W)

Surge Withstand Capability

Qualified to ANSI/IEEE C37.90.1-1989, Standard Surge Withstand Capability (SWC) Tests for Protective

Relays and Relay Systems. Note: This qualification does not include the front RS-232 communication

port.

1-8 BE1-BPR General Information 9272000990 Rev J

Page 21

Radio Frequency Interference (RFI)

Field tested using a 5 W, hand-held transceiver operating at random frequencies centered around 144

MHz and 440 MHz, with the antenna located six inches from the relay in both horizontal and vertical

planes.

Temperature

Operating: -40°C to +70°C (-40°F to +158°F)

Storage: -40°C to +70°C (-40°F to +158°F)

Shock

Type tested to withstand 15 G in each of three mutually perpendicular planes, swept over the range of 10

to 500 Hz for a total of 6 sweeps; 15 minutes each sweep, without structural damage or degradation of

performance.

Vibration

Type tested to withstand 2 G in each of three mutually perpendicular planes, swept over the range of 10

to 500 Hz for a total of 6 sweeps; 15 minutes each sweep, without structural damage or degradation of

performance.

Gost-R Certification

Gost-R certified, No. POCC US.ME05.B03391; complies with the relevant standards of Gosstandart of

Russia. Issued by accredited certification body POCC RU.0001.11ME05.

Weight

12 lb (5.44 kg) maximum

9272000990 Rev J BE1-BPR General Information 1-9

Page 22

This page intentionally left blank.

1-10 BE1-BPR General Information 9272000990 Rev J

Page 23

SECTION 2 • APPLICATION

TABLE OF CONTENTS

SECTION 2 • APPLICATION .................................................................................................................... 2-1

GENERAL .............................................................................................................................................. 2-1

APPLICATION DATA ............................................................................................................................. 2-1

Contact Sensing Inputs ...................................................................................................................... 2-1

Fault Detectors ................................................................................................................................... 2-1

General Purpose Timers .................................................................................................................... 2-5

Reclosing Timers ................................................................................................................................ 2-6

Output Contacts ................................................................................................................................. 2-7

Trip Circuit Monitor Logic ................................................................................................................... 2-7

Breaker Arc Detector .......................................................................................................................... 2-9

Breaker Resistor Protection ............................................................................................................. 2-10

Breaker Failure Protection with Pre-Insertion Resistors .................................................................. 2-11

Breaker Contact Duty Log ................................................................................................................ 2-11

Reclosing Functions ......................................................................................................................... 2-12

PREPROGRAMMED LOGIC DESCRIPTION ..................................................................................... 2-12

Breaker Failure Logic 1 for Standard Relays (BFL1) ....................................................................... 2-12

Breaker Failure Logic 2 for Standard Relays (BFL2) ....................................................................... 2-13

Breaker Failure Logic 3 for Standard Relays (BFL3) ....................................................................... 2-14

Breaker Failure Logic 1 for Enhanced Relays (BFL1E) ................................................................... 2-15

Breaker Failure Logic 2 for Enhanced Relays (BFL2E) ................................................................... 2-17

Breaker Failure Logic 3 for Enhanced Relays (BFL3E) ................................................................... 2-18

Figures

Figure 2-1. Maximum Instantaneous Pickup Timing ................................................................................. 2-2

Figure 2-2. Maximum Instantaneous Dropout Timing ............................................................................... 2-3

Figure 2-3. Maximum Pickup Timing with 10 Cycle MAF FD .................................................................... 2-3

Figure 2-4. Maximum Dropout Timing with 10 Cycle MAF Fault Detector

Figure 2-5. Multiple Breaker Arrangement ................................................................................................ 2-5

Figure 2-6. Delay Timer Operation ............................................................................................................ 2-5

Figure 2-7. Control Timer Operation .......................................................................................................... 2-6

Figure 2-8. Trip Circuit Monitor Schematic Diagram ................................................................................. 2-8

Figure 2-9. Trip Circuit Monitor Logic Diagram ......................................................................................... 2-8

Figure 2-10. Trip Circuit Monitor Timing Diagram ..................................................................................... 2-8

Figure 2-11. Trip Circuit Monitor with BFI Sensing .................................................................................... 2-9

Figure 2-12. Breaker Arc Detector Circuits ............................................................................................. 2-10

Figure 2-13. Breaker Resistor Protection Circuits ................................................................................... 2-10

Figure 2-14. Breaker Contact Duty Log Circuits ...................................................................................... 2-11

Figure 2-15. Reclosing Logic Circuit ........................................................................................................ 2-12

................................................ 2-4

9272000990 Rev J BE1-BPR Application i

Page 24

This page intentionally left blank.

ii BE1-BPR Application 9272000990 Rev J

Page 25

SECTION 2 • APPLICATION

GENERAL

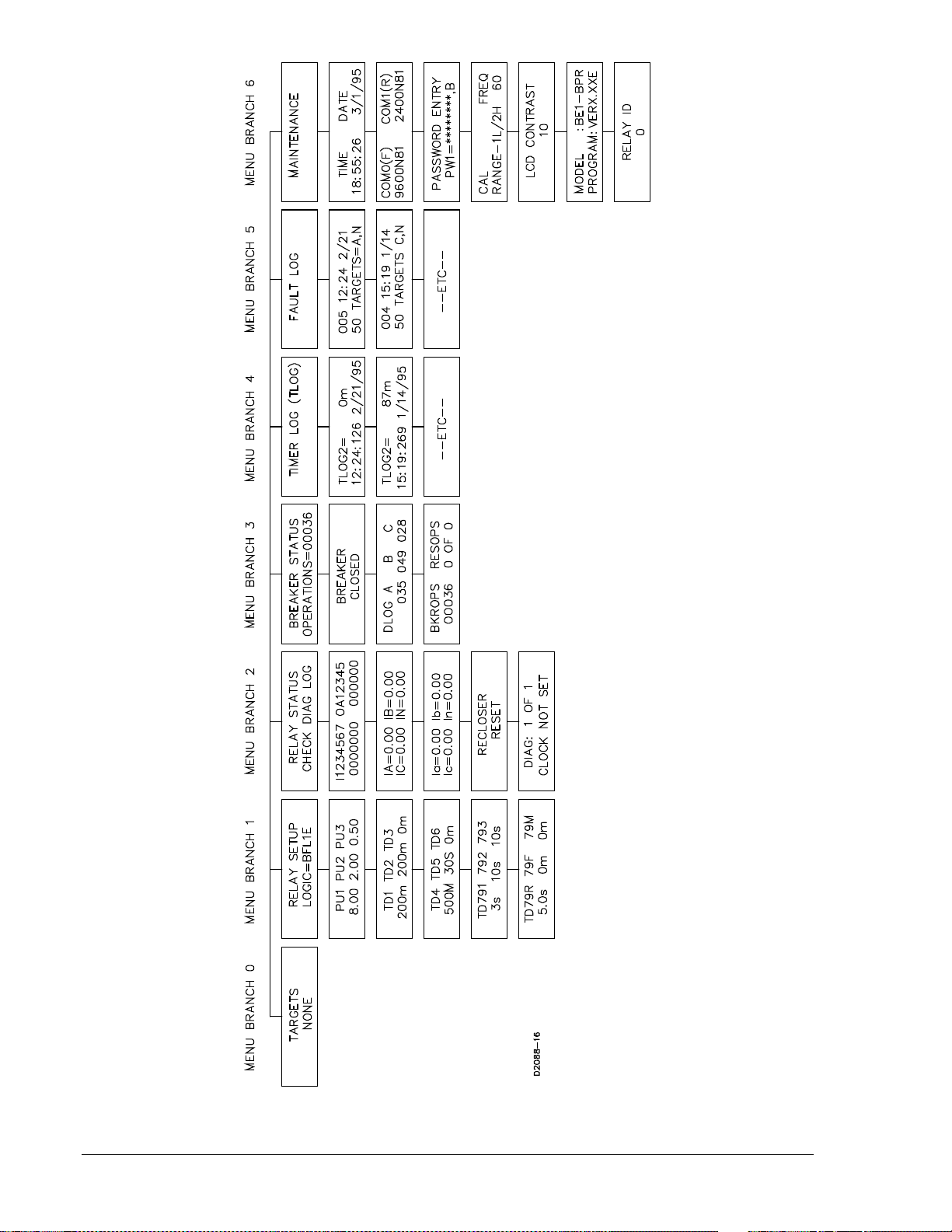

BE1-BPR relays have seven inputs and five outputs plus an alarm output. There are three general

purpose overcurrent fault detectors, six multipurpose timers, a three-shot recloser, and special outputs

that are internally generated by the microprocessor. Using simple Boolean expressions, the user can

logically connect the various functional blocks to create a custom, application specific, logic scheme to

handle special protection requirements.

Standard model relays have the following special features:

• Three shot recloser.

• Pre-insertion breaker resistor operations counter with programmable reset and block reclose signal.

• Six configurable timing diagnostic logs each with an optional alarm setting. This feature can be used

to monitor the various protection system parameters such as the margin between normal breaker

operation and breaker fail.

Enhanced model relays have the standard model features plus these special features:

• Twelve entry fault log detailing the system and relay status at the time the fault trigger occurred

• Twelve entry COMTRADE fault record consisting of configuration (CFG) and data (DAT) files. The

COMTRADE data contains 4 cycles of pre-fault and 16 cycles of post-fault data sampled at 12

samples per cycle. Each sample consists of the analog-to-digital converter values for each current

channel as well as 32 digital channels (a digital channel is for the digital status of an input, output, or

alarm).

2

• Integrated I

t breaker contact duty monitor with alarm.

A minimum of three basic breaker failure schemes are pre-programmed into nonvolatile memory. These

schemes take full advantage of the special features available in this relay without requiring the user to do

any programming. The user only selects the scheme desired and enters the pickup and timer settings.

APPLICATION DATA

Contact Sensing Inputs

Each BE1-BPR relay provides seven opto-isolated contact sensing inputs. Three inputs (IN1-3) are each

completely isolated. Inputs 4 and 5 (IN4, IN5) share one common terminal and inputs 6 and 7 (IN6, IN7)

share another common terminal. Each input has programmable recognition and debounce (time allowed

for the external contacts to stabilize) times. Typically the default setting of four milliseconds recognition

and twelve millisecond debounce should be used unless extremely slow or irregular contacts are applied.

The default setting assures that the signal be present on at least two consecutive scans of the input

status before recognition can occur.

It is recommended that for protective functions, a positive TRUE logic be used to enable protective

outputs. This prevents a broken wire or loose connection from causing a protective trip. For example, a

52b input would be preferred for protection logic that is enabled when the breaker opens (i.e. block

reclose or breaker arcing/flash over) and a 52a input would be preferred for protection logic that should

be enabled when the breaker closes. On the other hand, for a diagnostic alarm, a negative TRUE logic

may be preferred since it will give an alarm if the checked diagnostic occurs and also give an alarm

(depending on the logic) for a bad or broken connection.

Fault Detectors

BPR relays provide three independent fault detectors. Each fault detector can be programmed for phase

or neutral input sensing. Also, each fault detector can be setup to operate as an instantaneous (50) or

moving average filter (MAF) fault detector.

Instantaneous (50) Fault Detector Type 1

An instantaneous fault detector provides a typical one cycle pickup and one-quarter cycle dropout for high

speed operation. A three cycle software delay is imposed on any Type 1 fault detector when the current

9272000990 Rev J BE1-BPR Application 2-1

Page 26

level is less than 40 milliamperes above the pickup setting. This prevents noise induced trips from

4

6

8

10

12

14

16

18

20

22

1.05 1.25 2 5 20 40

MULTIPLES OF PICKUP

MAX. PICKUP TIME (ms)

PU=5.00A

PU=0.25A

PU=9.99A

D2838-21

occurring. The Type 1 is used in BF logic schemes and is programmed by setting the fault detector logic

(LF) type to PI (phase overcurrent) or NI (neutral overcurrent) and the digital filter selection to 1.

For the fault detector to pickup, the RMS value of the last cycle of current must be above the pickup

setting. Due to the analog input circuitry design, the RMS value is clamped (limited) at approximately 13

amperes. As the multiple of pickup level increases, the pickup time decreases. Because of the limiting

above 13 amperes, the pickup time does not appreciably decrease at high multiples of pickup. Also, the

pickup may be delayed up to one-quarter cycle because the RMS current is calculated every quarter

cycle. However, in no case will the pickup be slower than one and one-quarter cycles.

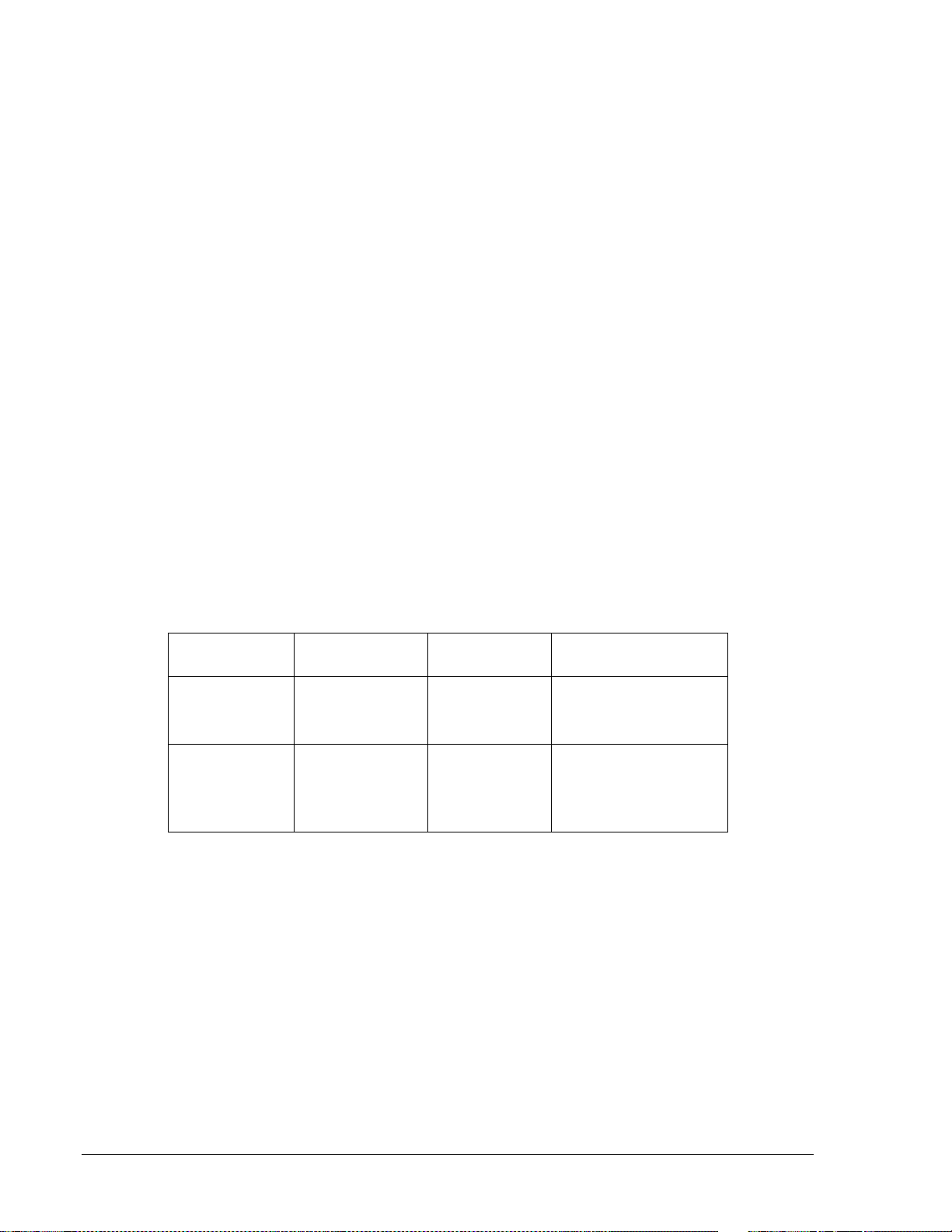

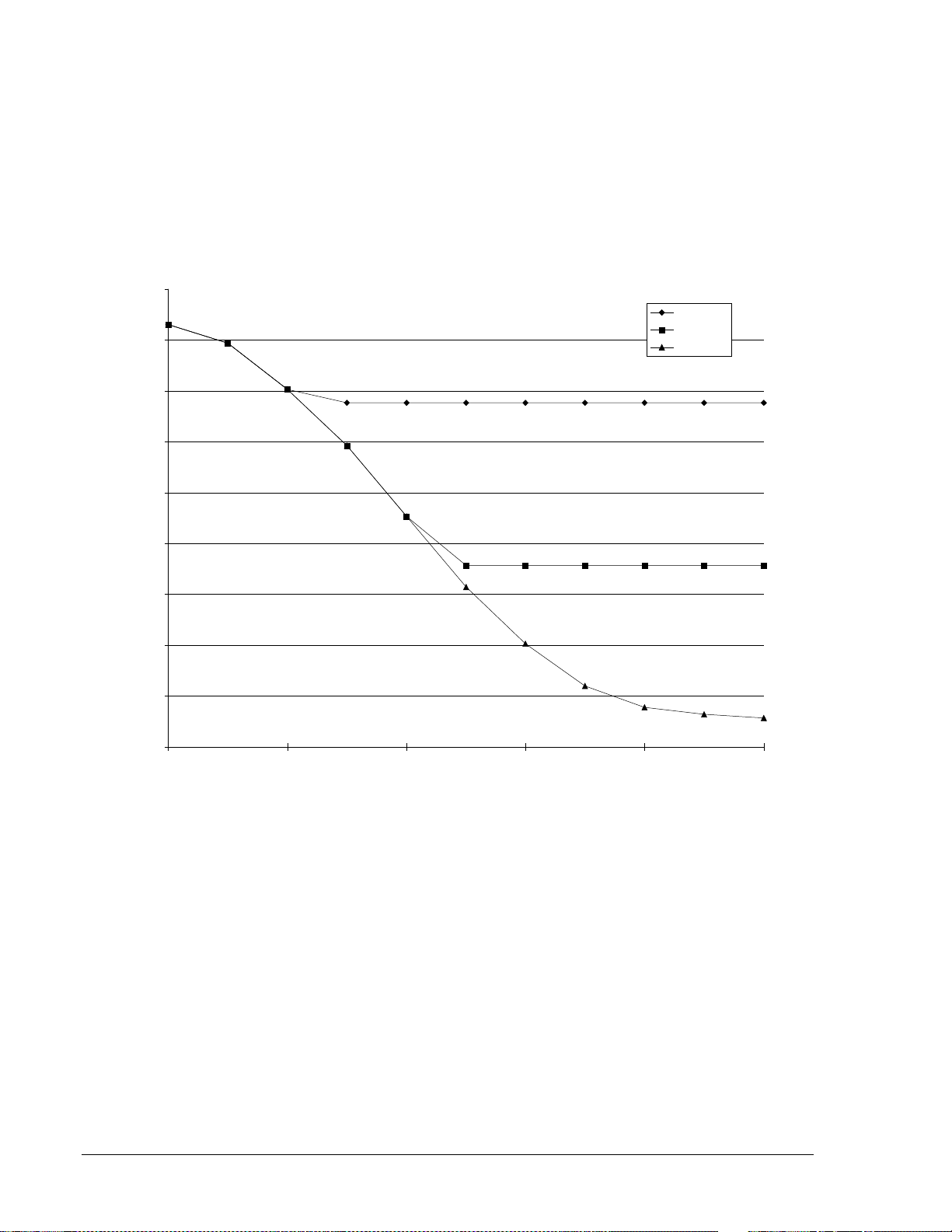

Figure 2-1 shows maximum pickup timing versus current input levels.

Figure 2-1. Maximum Instantaneous Pickup Timing

For the Type 1 fault detector to dropout, one of two conditions must occur. One, three sequential analogto-digital (A/D) samples must be less than one-fourth of the RMS current level for the last quarter-cycle

calculation. Two, the RMS current signal level must decrease to less than 75% of pickup. Samples are

made twelve times per line cycle and RMS current is calculated four times per line cycle. Three samples

are used to compensate for zero crossings and noise. A short dropout delay is advantageous for BF logic

in order to allow for the minimum timing margin in critical applications.

Figure 2-2 shows maximum dropout timing versus current input levels.

2-2 BE1-BPR Application 9272000990 Rev J

Page 27

0

2

4

6

8

10

12

14

16

1.05 1.25 2 5 20 40

MULTIPLES OF PICKUP BEFORE DROP OUT

MAX. DROPOUT TIME (ms)

PU=9.99A

PU=5.00A

PU=0.25A

PU=9.99A

PU=5.00A

PU=0.25A

D2838-22

20

40

60

80

100

120

140

160

180

1.05 1.25 2 5 20 40

MULTIPLES OF

PICKUP

MAX. PICKUP TIME (ms)

PU=1.00A, 10 CYC

PU=0.50A, 10 CYC

PU=0.05A, 10 CYC

PU=1.00A, 10 CYC

PU=0.50A, 10 CYC

PU=0.05A, 10 CYC

D2838-23

Figure 2-2. Maximum Instantaneous Dropout Timing

Moving Average Filter Fault Detector Type 2

A moving average filter (MAF) fault detector provides for a slower but more consistent pickup at low

current levels. A MAF fault detector should be used in applications where the current to be detected is

less than 0.25 ampere. Typically, the response time for pickup and dropout depends on the number of

cycles averaged and how high the input current is above pickup.

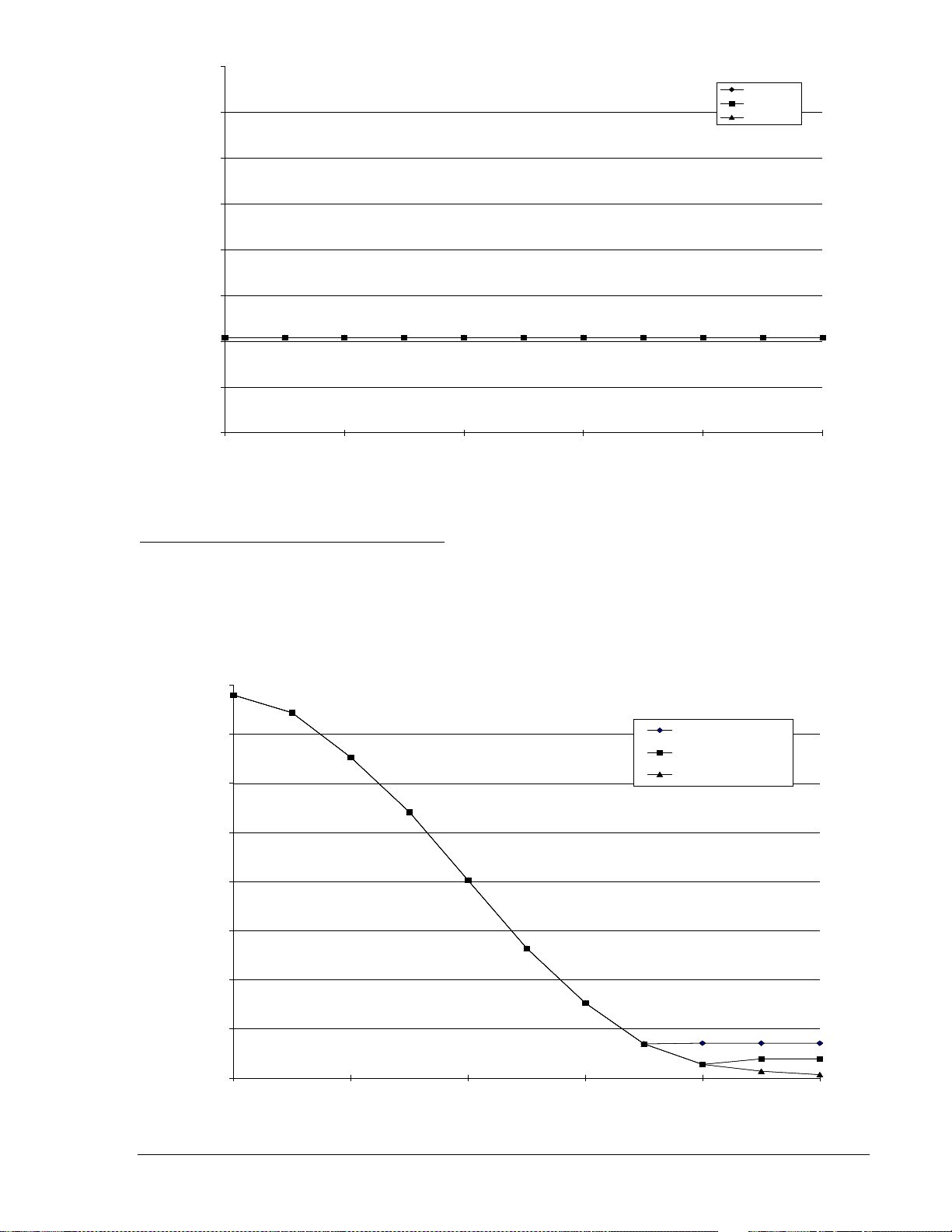

Figure 2-3 shows maximum pickup timing versus current input levels for a 10 cycle MAF fault detector.

Figure 2-3. Maximum Pickup Timing with 10 Cycle MAF FD

9272000990 Rev J BE1-BPR Application 2-3

Page 28

This MAF fault detector is programmed by setting the fault detector digital filter selection to 2 (DFLTR2).

20

40

60

80

100

120

140

160

180

200

1.05 1.25 2 5 20 40

MULTIPLES OF PICKUP BEFORE DR OPOUT

MAX. DROPOUT TIME (ms)

PU=1.00A, 10 CYC

PU=0.50A, 10 CYC

PU=0.05A, 10 CYC

PU=1.00A, 10 CYC

PU=0.50A, 10 CYC

PU=0.05A, 10 CYC

D2838-24

For the MAF fault detector to pickup (or dropout), the rms value of the average of the last 'n' cycles of

current must be above (or below) the pickup setting. Typically, this filter is slow to pickup and slow to

dropout but it is intended for use in low current applications where speed is not critical.

Figure 2-4 shows maximum dropout timing versus current input levels for a 10 cycle MAF fault detector.

Figure 2-4. Maximum Dropout Timing with 10 Cycle MAF Fault Detector

Three-Phase Fault Instantaneous (50) Fault Detector Type 3

This fault detector has the same characteristics as the Type 1 instantaneous fault detector with the

exception that all three phases must be picked up before the fault detector will pickup. This fault detector

can be used in BF logic schemes and is programmed by setting the fault detector logic (LF) type to PI

(phase overcurrent) and the digital filter selection to 3.

A 3-phase fault is the worst case fault for system stability and requires fast clearing times with small

margins. A 3-phase fault detector and a separate timer could be used in addition to the 3-phase fault

detector and timer to allow BF protection for both worst case faults and normal faults.

Application of Fault Detectors

Phase and Ground Instantaneous Fault Detectors. Normally, it is adequate to monitor the three phase

currents as they represent the current in the poles of the protected breaker. However, if the sensitivity of

the ground relays is significantly higher than the sensitivity of the phase relays, it may be desirable to

apply a ground fault detector so that you can be assured that the breaker failure protection will pickup for

any fault that is sensed by the initiating relays. Each fault detector can be independently set to monitor

either the three phase current inputs or the neutral current input. Fault detector F1 is programmed as a

phase instantaneous fault detector and fault detector F2 is programmed as a neutral instantaneous fault

detector in all of the preprogrammed logic schemes.

Three-Phase Instantaneous Fault Detectors. For system stability, a three-phase fault is the worst case.

The dynamic stability of the system is not affected as much by the other fault combinations. Since threephase faults are generally rarer than the other fault combinations, it may be desirable to enhance security

by treating three-phase faults differently. One of the fault detectors can be set up as a PI, 3 (phase

current, Type 3) fault detector to supervise a timer set at the three phase fault, dynamic stability limit. The

normal timer supervised by the other fault detectors would then be set with a longer time delay (with more

margin) set at the two phase and ground fault (the next worst case), dynamic stability limit.

2-4 BE1-BPR Application 9272000990 Rev J

Page 29

Low Level Current Detector. If the breaker fails while being opened for normal load switching or due to re-

INITIATE

OUTPUT

RESET

TD[n]

D2635-11

strike after the line has been isolated, the currents flowing across the failed interrupter may be too low to

reliably detect by conventional means. The Type 2 fault detector’s moving average filter allows the BE1BPR to discern the low level line charging current from random noise. The application of this fault detector

is described in detail in the Breaker Arc Detector sub-section. Fault detector F3 is programmed as a

phase MAF fault detector in all pre-programmed logic schemes.

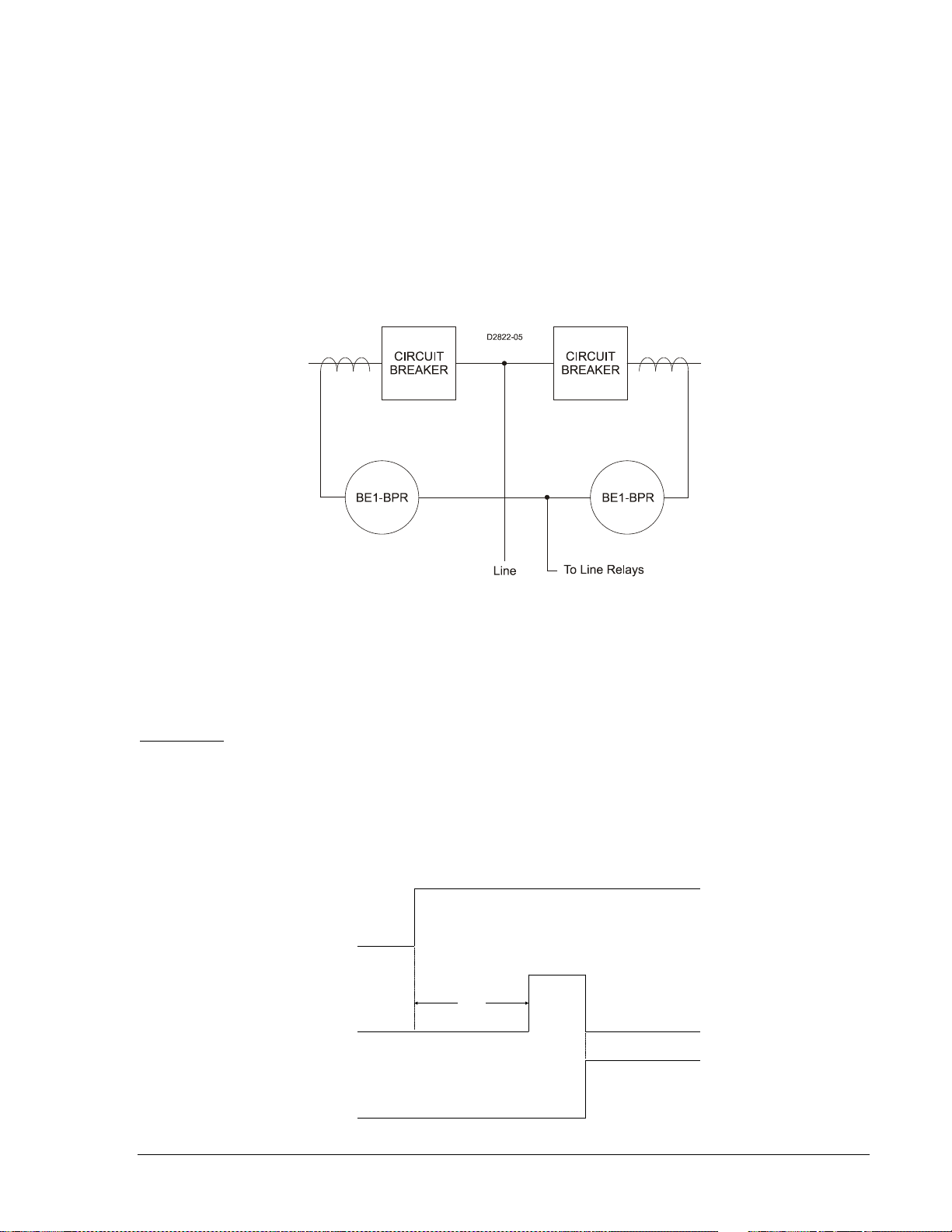

Multiple Breaker Arrangements. In ring bus and breaker and half bus applications, CTs from two breakers

are often connected in parallel. If the BE1-BPR is connected to these CTs as shown in Figure 2-5, low

fault detector pickup settings should be used with caution. In this arrangement, the CT feeding the BE1BPR can be energized on the secondary side from the CT on the adjacent circuit breaker. This results in

current flowing in the BE1-BPR even when the protected circuit breaker has successfully interrupted the

fault. This secondary excitation current is generally negligible except when flux remnants or high

current/burden causes the CT to saturate.

Figure 2-5. Multiple Breaker Arrangement

General Purpose Timers

Each BPR relay provides six independent timers for breaker failure timing and diagnostics. Each timer

can be programmed as a delay or a control timer and can have independent START and RESET

conditions. Each timer can also provide a diagnostic log and/or alarm. These features are explained in the

following paragraphs.

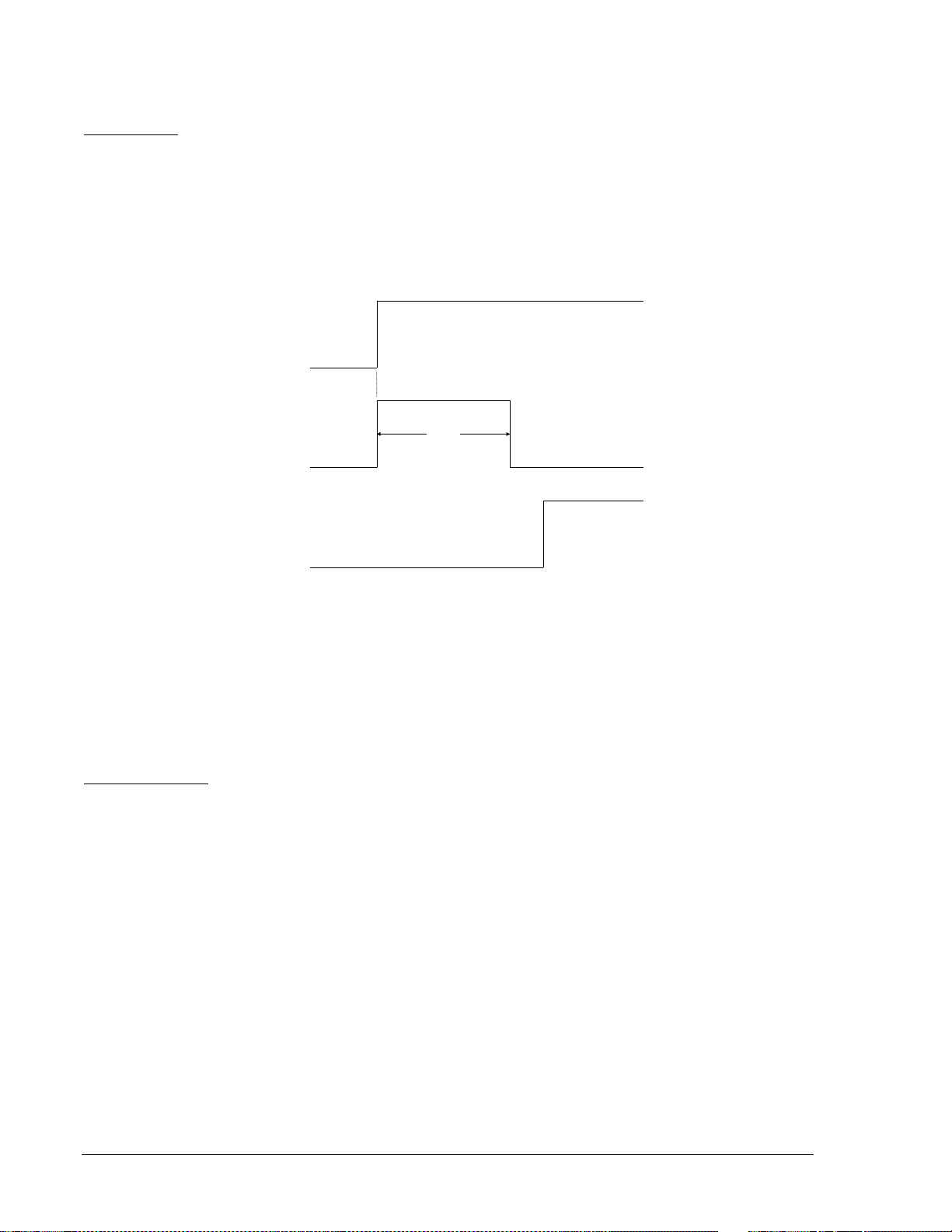

Delay Timer

A Delay timer has two inputs START and RESET, and one output T[n]. The timer will not start until the

start condition becomes TRUE and the RESET input is FALSE. Once the timer is started, a preprogrammed time delay, TD[n], is loaded and the timer starts timing out. Toggling of the START input has

no effect once the timer is started. The timer times out TD[n] time after the timer is started unless the

timer is RESET before the time expires. If the timer times out, then the T[n] output becomes TRUE. After

timeout, T[n] remains TRUE until the timer is RESET. Delay timer operation is illustrated in

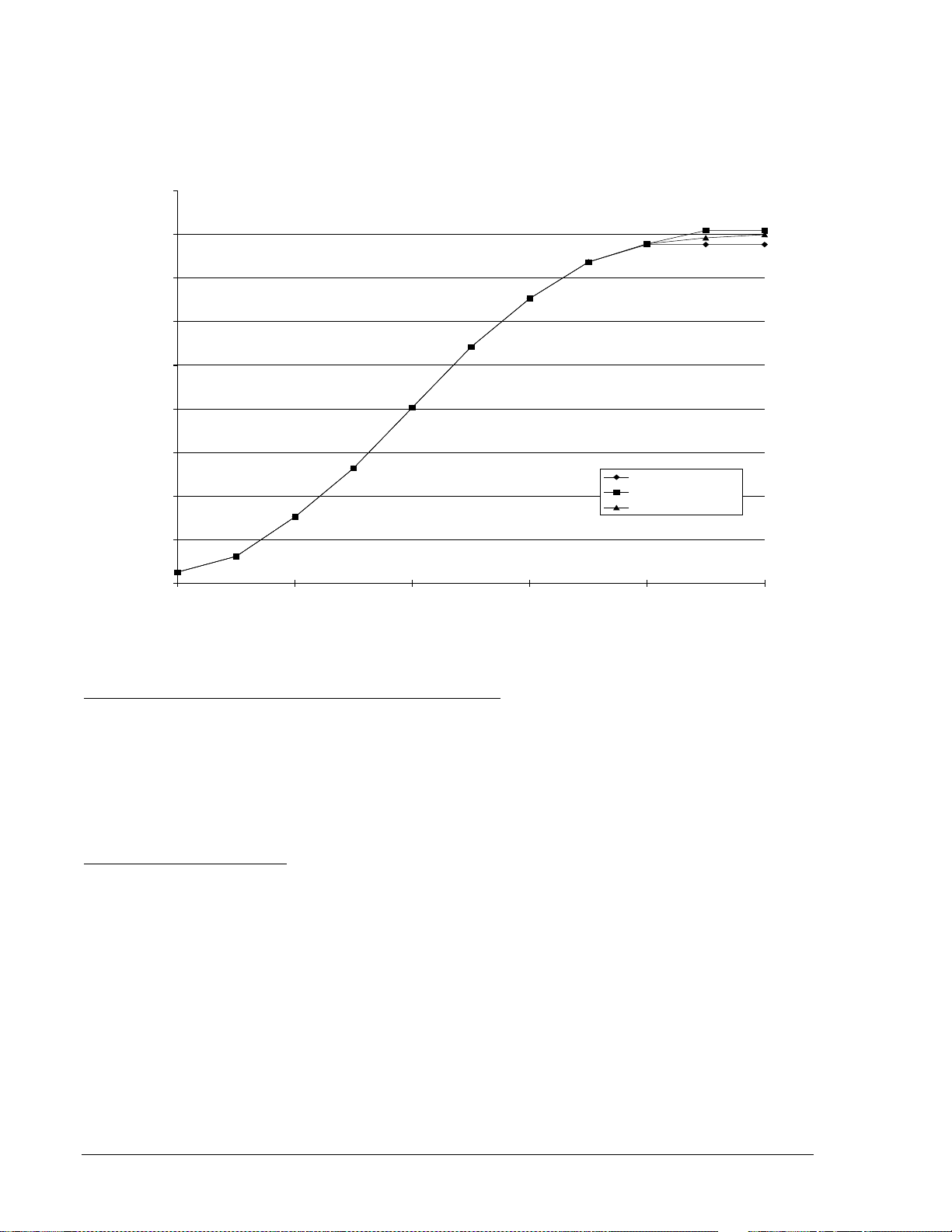

Figure 2-6.

Figure 2-6. Delay Timer Operation

9272000990 Rev J BE1-BPR Application 2-5

Page 30

This type of timer is used to delay an operation in order to allow time for other processes to occur. For

INITIATE

OUTPUT TD[n]

RESET

D2635-12

example, in breaker failure applications, a delay timer is user to delay the breaker failure output until the

primary protection scheme has sufficient time to operate the breaker and open the circuit.

Control Timer

A Control timer has two inputs START and RESET, and one output T[n]. The timer will not start until the

start condition becomes TRUE and the RESET input is FALSE. Once the timer is started, a preprogrammed time delay, TD[n], is loaded and the timer starts timing out. The timer times out TD[n] time

after the timer is started unless the timer is RESET before the time expires. During the entire period the

timer is ON (i.e. not timed out and not reset), the output T[n] is TRUE. If the timer times out, then the T[n]

output becomes FALSE. After timeout, the T[n] remains FALSE until the timer is RESET and a new

START input is received. Control timer operation is illustrated in

Figure 2-7.

Figure 2-7. Control Timer Operation

This type of timer is used to provide a limited window of time for an operation to occur or to provide a

feedback signal to latch-in an input for a predetermined time. For example, in breaker failure applications,

a control timer can be used to latch-in a BFI input to ensure that once a BFI occurs a premature opening

of the BFI for whatever reason does not disable the BF logic.

Another application is to prevent a BF operation due to stuck contacts on the BFI input. BFI input stuck

contacts would cause a false trip any time the fault detector picks up. This problem can be minimized by

using a control timer to limit the window of opportunity for which the input can cause a trip output.

Timer Diagnostics

In many applications it is desirable to have a record of the timing relationship between different events. In

order to acquire this record, data must be available and accumulated over a period of time. A method to

obtain and collect this data has been incorporated into the BE1-BPR relays. This method allows relative

or absolute timing between any input, output or internal operation (i.e. timers, fault detectors) to be logged

into a circular 40 event record. The data can be retrieved for analysis using the TLOG[n] command. In

addition, because some timing requirements are critical to proper system operation, an optional alarm

output can be automatically triggered if the time logged is outside a predetermined level. The logic used

to save a timer value to the log and the optional alarm time is programmable using the PTLOG[n]

command.

Refer to Section 1, General Information, Timing Diagnostics, for detailed information on BF timing and an

example of using the timing diagnostics to create a MARGIN log.

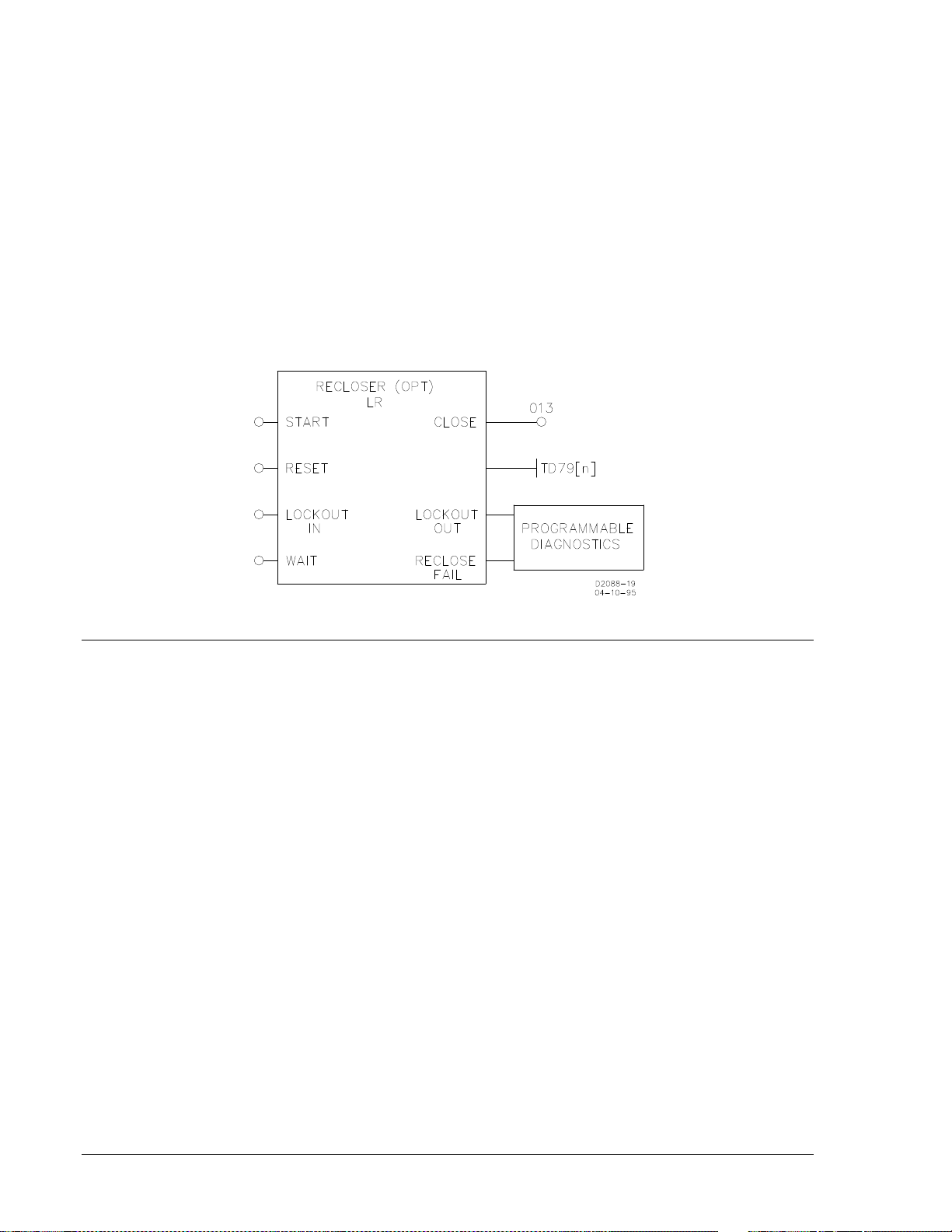

Reclosing Timers

Each BE1-BPR relay provides six independent reclosing timers. Three reclosing timers (TD791, TD792,

and TD793) provide time delays for the multiple shots (one, two, and three). TD79R is the reset time

delay, TD79F is the reclose fail time delay, and TD79M is the maximum cycle timer.

Reclosing timer delay settings are programmable from the front panel or the serial port using the TD79

command. The three reclosing time delays can be set at zero or from 10 to 999 milliseconds in 1

millisecond increments, 1 to 99 seconds in 0.1 second increments, or 100 to 600 seconds in 1 second

2-6 BE1-BPR Application 9272000990 Rev J

Page 31

increments. Each of the reclosing timers may be disabled by a setting of zero. When a reclosing timer set

at zero is reached in the reclosing sequence, the reclosing sequence is interrupted and the relay will enter

lockout.

Reset timer (TD79R) begins timing out when the RESET logic becomes TRUE (breaker closes). The

reset timer is reset when the breaker trips. If the reset timer times out while the breaker is closed, the

recloser goes to RESET.

If enabled, the reclose fail timer (TD79F) starts whenever a reclose output is given and stops when the

RESET logic indicates the breaker has closed. If the reclose fail timer times out before the RESET logic

becomes TRUE, the recloser sets the reclose fail diagnostic flag. The reclose fail diagnostic flag can be

inhibited by setting the time delay to zero. The reclose fail function can be inhibited by setting the

reclosing mode (TYPE) in the LR command to zero (0).

If the total reclosing time between reset states exceeds the maximum reclose cycle timer (TD79M) setting

(excluding time while in the WAIT state), the recloser goes to the lockout state. The maximum reclose

cycle timer can be inhibited by setting the time delay to zero.

Output Contacts

Each BE1-BPR relay has five isolated normally open (NO) output contacts (OUT1-OUT5) plus one

isolated normally closed (NC) alarm output (ALM). Output contact OUT1 is a high speed contact with a

maximum operating time of ¼ cycle. By using the PTARGET command, output relays can be

programmed to latch target data into memory.

Output contacts OUT1 through OUT5 are controlled by the status of the internal logic of signals O1

through O5. If O[n] becomes TRUE, then the corresponding output relay is energized and closes the

normally open contacts. If the PHOLD feature is enabled, the output contacts are held in an energized

state for 200 to 250 milliseconds when O[n] becomes TRUE. Each output contact then resumes following

the internal logic. The PHOLD function ensures that the TRIP output doesn’t interrupt the trip coil current

but allows the trip coil current to be interrupted by the 52A contact. Section 4, Functional Description,

provides more information about the PHOLD command.

All output contacts are factory set to NO. However, OUT1 - OUT4 may be changed to NC by changing a

soldered jumper next to the output relays on the printed circuit board. NO contacts are typically used in

trip circuits and using this type of contact allows the relay electronics to be drawn out without activating

the trip logic. If a NC contact is desired, such as for a block reclose signal, then external shorting switches

or a low cost auxiliary relay with NC contacts should be used to allow the electronics to be drawn out.

The ALARM output is a NC contact that is energized to provide a NO signal during normal operation. If

the relay fails or an internal diagnostic signals that an alarm condition exists, the ALARM output deenergizes and closes the output contacts to signal an alarm condition. If the electronics are drawn out of

the case, the ALARM output also opens.

Trip Circuit Monitor Logic

Logic for monitoring the trip circuit and alarming for loss of voltage (open fuse) or loss of continuity (open

trip coil) is provided in the preprogrammed breaker fail schemes. Figure 2-8 shows input 2 (I2) being used

as a trip circuit monitor (TCM) sensing element. It is placed in parallel with the retrip output of the relay.

Figure 2-9 shows a diagram of the logic. If the breaker has multiple trip circuits, an additional input can be

used for TCM sensing with trip circuit 2. For example, if the trip circuit 2 TCM input were input 3 (I3), the

expression for virtual output 6 (O6) would be changed to /I1∗/I2+/I1∗/I3.

9272000990 Rev J BE1-BPR Application 2-7

Page 32

Figure 2-8. Trip Circuit Monitor Schematic Diagram

86

Breaker

Retrip

O5

IOIT

21

IN2 (TCM)

Trip Ckt 1 Sense

P

T

52a

52TC1

N

D2822-06

T4

AN

D

ICS

ICS LI1

LI2

I1

I2

O6

IN1

IN2

52b

Trip Circuit

Monitor

DELAY TIMER

START

RESET

OUT

T4

LT4

D2822-07

08-07-98

A

LEGEND

Fault occurs, TCM shorted by Line relay 21 Protective Relays

Breaker opens, trip circuit opened TCM Trip Circuit Monitor

Relay drops out, trip bus floating O6 TCM Timer Start

Breaker closed T4 TCM Ti mer

Delay Time

21

52a

52b

TCM

O6

T4

D2822-08

08-07-98

A B C D

B

C

D

Figure 2-9. Trip Circuit Monitor Logic Diagram

When the breaker is closed, the trip bus T, is at negative potential through the low impedance path of the

trip coil and the TCM senses logic 1. Figure 2-10 illustrates the timing of this logic. When a trip occurs, the

trip bus is at positive potential, the voltage across the TCM is shorted, and it senses logic 0. When the

breaker opens, the 52a contact is series with the trip coil opens, the protective relay drops out, the trip

bus is at positive potential through the high impedance of the sensing element or the indicating light (if

used), and the TCM continues to sense a logic 0. The breaker status input (IN1) in the logic diagram is

used to block the function while the breaker, and therefore, the trip circuit are open. The timer is used to

prevent an alarm output during the transition between the closed and open states.

2-8 BE1-BPR Application 9272000990 Rev J

Figure 2-10. Trip Circuit Monitor Timing Diagram

Page 33

Figure 2-11 illustrates a problem that can occur when using the trip circuit monitor feature. If the breaker

52a

N

P

T

BFI

or

62X

TCM

+

V

-

+

V

-

86

Breaker

Retrip

O5

IOIT21

IN2 (TCM)

Trip Ckt 1

Sense

P

T

52a

52TC1

N

62X

a. Schematic Diagram

b. Equivalent Voltage

Divider Circuit

D2822-09

08-07-98

failure initiate (BFI) sensing is connected directly to the breaker trip bus as shown in Figure 2-11a, the

equivalent circuit shown in Figure 2-11b occurs. If the diode of the circuit is not included, a voltage divider

circuit will be created between the BFI sensing and the TCM sensing when the 52a contact or the trip coil

is open.

Figure 2-11. Trip Circuit Monitor with BFI Sensing

In Figure 2-11a, a 62x BFI auxiliary relay is shown. In this case, the impedance of the 62x coil will be

small compared to the impedance of the TCM circuit so the TCM will always be at logic 1. This will

prevent the TCM logic from working, even if the trip coil is open. In the case that the high impedance BFI

sensing input of the BE1-BPR is connected directly to the trip bus, the TCM and the BFI impedances will

be of similar magnitude causing the voltage to be divided nearly equally. This can result in spurious BFI

signals to the breaker failure protection scheme when the breaker is open. Normally, when redundant

systems are used, each relay system will be on its own circuit and the BFI sensing for each relay system

will be isolated from the tripping circuit so this is not a problem.

Breaker Arc Detector

Once a breaker is open, an arc or flashover from a lightning strike may occur if the surge suppressors fail

or air pressure is lost in an air blast circuit breaker. If this arc is not extinguished, the breaker can be

damaged or destroyed. If the breaker was opened due to a fault on the line, then protective relays on the

line will operate. If the line is not cleared, the relay logic will trip the backup breakers to clear the line and

save the breaker.

If both ends of the line are open with no fault, then the breaker may just be carrying low level, line

charging current. This current will not operate the protective relays because it is well below the normal

loading levels. However, it is enough to destroy the breaker if not cleared. To provide protection for this

situation, a very sensitive fault detector is needed that operates at line charging current levels and is only

enabled when the breaker is open. When the fault is detected, the arc can be cleared by reclosing the

breaker or operating backup protection for breaker failures. Reclosing will not affect safety of personnel if

normal working practices are followed to disconnect any sections of the line being worked on (the line

would be energized by the arc in any case). If the breaker reclosed into a faulted line, the normal

protection devices would immediately re-open the line.

The BE1-BPR relay has a sensitive low level pickup for this application (MAF fault detector). Figure 2-12

shows the breaker arc detector circuits with the three-phase MAF fault detector (F3). It is easy to inhibit

the relay based on the breaker status by programming the relay logic. As discussed previously in the fault

detector application paragraphs, the MAF fault detector filter is slow to pickup and dropout. Therefore, the

fault detector response must be delayed to allow time for normal load or fault current to clear the filter

section. For example, if a 60 cycle MAF fault detector is used and set at 0.1 ampere (below line charging

current levels), then the MAF fault detector remains picked-up for 1 second after the breaker opens

because it takes that long for the filter buffer to clear. Therefore, the MAF fault detector output must be

delayed for a time longer than the filter length to ensure that only a sustained current signal causes an

output. This delay time could be 20 to 30 seconds longer.

9272000990 Rev J BE1-BPR Application 2-9

Page 34

Figure 2-12. Breaker Arc Detector Circuits

The breaker arc detector logic employed in the preprogrammed schemes logically ANDs the MAF fault

detector (F3) and the 52b input (I1) to start a delay timer (T5). Timer delay can be as long as 60 seconds.

The timer delay should be set to 1.5 to 2.0 times the MAF window time. Both the fault detector and

breaker status must stay unchanged for the entire length of the time delay or the timer is reset. If the timer

does time out, the breaker arc output (O4) closes. This output could be used to reclose the breaker,

extinguish the arc, prevent secondary circuit switcher failure, externally parallel the BFO, or to give an

alarm.

Breaker Resistor Protection

Breaker resistor protection is a BE1-BPR relay feature that monitors the number of times a breaker

opening resistor has been used and the amount of elapsed time between operations. If additional

openings (operations) would exceed the resistor maximum power rating, the breaker resistor protection

feature operates output 13 (O13), which can be used as a block reclose output. Breaker resistors are

typically rated to handle X operations (i.e. - 5 operations) in T time (i.e. - 15 minutes cooling time for each

operation). The resistor protection is a self contained module (Figure 2-13) that counts and time tags each