Page 1

INSTRUCTION MANUAL

FOR

TRANSFORMER DIFFERENTIAL RELAY

BE1-87T

BE1-87T

TRANSFORMER DIFFERENTIAL

Style No. D2E A1J D1S0F

R

Serial No. XXXXXXXXXXXX

PUSH TO

ENERGIZE

OUTPUT

R

U

P0052-22

Publication: 9171300990

Revision: V 03/12

Page 2

Page 3

INTRODUCTION

This instruction manual provides information about the operation and installation of the BE1-87T

Transformer Differential relay. To accomplish this, the following information is provided:

General Information and Specifications

Controls and Indicators

Functional Description

Installation

Test Procedures

WARNING!

To avoid personal injury or equipment damage, only qualified personnel should

perform the procedures in this manual.

NOTE

Be sure that the BE1-87T is hard-wired to earth ground with no smaller than 12

AWG copper wire attached to the ground terminal on the rear of the unit case.

When the BE1-87T is configured in a system with other devices, it is

recommended to use a separate lead to the ground bus from each unit.

9171300990 Rev V BE1-87T Introduction i

Page 4

First Printing: June 1990

Printed in USA

Copyright © 1990-2012 Basler Electric, Highland Illinois 62249 USA

All Rights Reserved

March 2012

CONFIDENTIAL INFORMATION

of Basler Electric, Highland Illinois, USA. It is loaned for confidential use,

subject to return on request, and with the mutual understanding that it will not

be used in any manner detrimental to the interest of Basler Electric.

It is not the intention of this manual to cover all details and variations in equipment, nor does this manual

provide data for every possible contingency regarding installation or operation. The availability and design

of all features and options are subject to modification without notice. Should further information be

required, contact Basler Electric.

For terms of service relating to this product and software, see the Commercial Terms of Products and

Services document available at www.basler.com/terms

.

BASLER ELECTRIC

12570 STATE ROUTE 143

HIGHLAND IL 62249-1074 USA

http://www.basler.com, info@basler.com

PHONE +1 618.654.2341 FAX +1 618.654.2351

ii BE1-87T Introduction 9171300990 Rev V

Page 5

REVISION HISTORY

The following information provides a historical summary of the changes made to the BE1-87T instruction

manual (9171300990). Revisions are listed in reverse chronological order.

Manual

Revision and Date

V, 03/12

U, 08/11

T, 03/11

S, 09/10

R, 09/07

Q, 10/05

P, 05/03

N, 09/00

Change

Updated format of Table 1-3, Power Supply Ratings, to be consistent

with other manuals.

Standardized case and cover drawings in Section 4.

nd

Updated 2

harmonic restraint specs for 5 A & 1 A CTs in Section 5.

Updated formatting to current style used.

nd

Updated 2

& 5th harmonic restraint specs in Section 1.

Updated “K” type power supply burden in Table 1-3.

Updated GOST-R statement in Section 1.

Updated rear case drawings in Section 4.

Removed references to extender card in Sections 4 and 5.

Updated Storage statement in Section 4.

Replaced magnetic type targets with electronic type targets.

Updated power supply burden data and output contact ratings.

Updated front panel illustrations to show laser graphics.

Moved content of Section 6, Maintenance to Section 4, Installation.

Added GOST-R certification to Section 1, General Information.

In Section 1, General Information, Specifications, corrected values for

Maximum Current per Input for 1 Ampere CT Units.

In Section 5, Test Procedures, corrected values inside CAUTION box

for 1 AMP CT on page 5-14.

Added a thumbscrew to the figure on the manual front cover.

Added “not all styles” to the Power Supply Output heading on page 3-

4 as well as added “NOTE” and a text box around the second last

paragraph on page 3-4.

Added the new thumbscrew to Figure 4-1 and changed the height

dimensions in Figure 4-2.

Clarified the terminal numbers on Figure 4-6b.

Added a shorting bar between terminals 6 & 7 in Figure 4-11.

Added a shorting bar and normally open contact and normally closed

contact effecting terminals 1, 2, & 5 in Figure 4-12.

Step 13 was corrected on pages 4-31 and 4-39 to include R

in the

w

formulas.

Values were changed to Table 5-4 under Option 1-0 for Unrestrained

Trip.

Corrected Table 1-3 to show power supply ranges.

Changed instruction manual front cover, Figures 4-1, 4-3, and 4-5 to

show new unit case covers.

Changed Figure 4-32 per markup.

9171300990 Rev V BE1-87T Introduction iii

Page 6

Manual

Revision and Date

M, 04/99

L, 05/97

K, 03/97

J, 01/96

Change

Table 3-1 changed mid range nominal volt 125 Vac to 120 Vac.

Corrected Figures 4-24, 4-31a, and A-3

Corrected page 4-38, Step 10; added note to page 4-39, Step 13, and

corrected Steps 14 and 16.

Page A-2, changed 3-Phase fault ratio current to 3-phase fault

current.

Page A-3, corrected formulas for Figure A-3.

Under Section 4, Procedure One, Verify CT Performance, changed

the procedure to the ANSI accuracy class method. This forced

changes in the following steps: 12, 13, 14, 16, 18, 20, and 21.

Under Section 4, Procedure Two, Verify CT Performance, changed

the procedure to the ANSI accuracy class method. This forced

changes in the following steps: 12, 13, 14, and 16.

Added ECO revision information to Table 8-1.

Added Setting Note 7 (ANSI Accuracy Class Method) to Appendix A.

To delete the part number from the front cover of the manual.

Deleted all references to Service Manual 9171300620.

Changed the Title of Section 2 from “Controls and Indicators” to

“Human-Machine Interface”.

Replaced the Power Supply Options paragraphs with a new Power

Supply paragraph explaining the new power supply design.

Deleted Figure 3-2 and added Table 3-1, Wide Range Power Supply

Voltage Ranges.

Changed Power Supply Status Output for Type G power supply on

the formerly page 3-6 (now page 3-4) from terminals 9 and 20 to

terminals 9 and 19.

Added information to Section 4 to help the user understand the

procedures better.

Deleted all NOTES FOR USERS OF SENSING INPUT TYPE F

RELAYS and added Section 7, Difference Data.

Changed previous Section 7, Manual Change Information, to Section

8.

Added an Appendix A to clarify the setting procedures.

Added an index to help the user find information easier.

Changed the format of the manual.

Deleted “Difference Data” (formerly Section 7) and included notes for

users of Type F relays.

Moved all information regarding relay settings and checking relay

setting from Section 5, Testing and Setting, to Section 4, Installation.

Section 5 now contains information on test procedures.

Combined 50 and 60 Hz Verification Tests.

Various editorial changes.

Reformatted instruction manual as Windows Help file for electronic

documentation.

iv BE1-87T Introduction 9171300990 Rev V

Page 7

Manual

Revision and Date

I, 01/95

Added outline (box) to Figure 5-8 to highlight the figure.

Change

Page 5-42, Step 5, changed, “should be less than 4.45” to, “must be

less than 4.45”.

Added note to page 5-43, Step 10 and corrected the formula in Step

10.

Page 5-45, Step 18, corrected formula and high side results; and

Step 19, changed last sentence from H (13 x tap) to S (21 x tap).

Page 5-46, Steps 20 and 21, corrected figure references.

H, 12/94

Page 1-6, changed Specification for Restrained Output, Pickup

Accuracy.

Changed Section 5, Testing and Setting, Verification Tests (all

models): Steps 1, 4, 5, and 8; and Table 5-4.

Page 5-50, Jumper Positions Wye-Delta 1, Step 3: Corrected Input 2

terminal identifications.

Page 5-51, Jumper Positions Delta2-Delta2, Step 2: Corrected

verification statement.

G, 09/94

Changed all sections to reflect new Option 1-1.

Added to Section 5 four examples for testing relays to clarify test

procedures.

Added to Section 5 one procedure for setting relays.

Corrected typographical and illustration errors.

F, 03/93

Changed formula pages 5-4, 5-10, 5-16, and 5-22 from I = the square

root of K over t, to I = K over the square root of t.

E, 01/93

Manual was revised to incorporate a revision in the relay that made

sensing input type F obsolete and included the 1 A, 60 hertz and 5 A,

50 hertz model relays.

Section 5, Test Setup, diagrams were changed to clarify relay

connections.

Added three relay Internal Connection diagrams.

Changed unrestrained maximum time to trip, reference old Tables 5-4

and 5-8 (new Tables 5-4, 5-8, 5-12, and 5-16).

Renamed Section 7, Manual Change Information to Section 8,

Manual Change Information and added new Section 7, Difference

Data to support BE1-87T relays with Sensing Input Type F.

D, 06/92

Manual was revised to include the 1 A, 50 Hz model relay and

reformatted to a new Instruction Manual style.

Additional connection diagrams were included in Section 4 and test

plug information was added to Section 6.

Minor typographical errors were also corrected.

C, 03/91

Table 5-1 was expanded and Figure 5-4 Test Setup illustration was

added.

Miscellaneous editing.

B, 03/91

Manual (with the exception of Section 2) was rewritten for ease of

use.

A, 06/90

Figure 3-1 (Functional Block Diagram) corrected.

Formula in caution note (formerly on p. 4-17, now on p. 5-2)

corrected.

Miscellaneous editing.

9171300990 Rev V BE1-87T Introduction v

Page 8

vi BE1-87T Introduction 9171300990 Rev V

Page 9

CONTENTS

SECTION 1 • GENERAL INFORMATION ................................................................................................ 1-1

SECTION 2 • CONTROLS AND INDICATORS ........................................................................................ 2-1

SECTION 3 • FUNCTIONAL DESCRIPTION ........................................................................................... 3-1

SECTION 4 • INSTALLATION .................................................................................................................. 4-1

SECTION 5 • TEST PROCEDURES ........................................................................................................ 5-1

SECTION 6 • DIFFERENCE DATA .......................................................................................................... 6-1

APPENDIX A • SETTING NOTES ............................................................................................................ A-1

9171300990 Rev V BE1-87T Introduction vii

Page 10

viii BE1-87T Introduction 9171300990 Rev V

Page 11

SECTION 1 • GENERAL INFORMATION

TABLE OF CONTENTS

SECTION 1 • GENERAL INFORMATION ................................................................................................ 1-1

Introduction ............................................................................................................................................ 1-1

Description ............................................................................................................................................. 1-1

Application.............................................................................................................................................. 1-2

Single-Phase ...................................................................................................................................... 1-2

Three-Phase ....................................................................................................................................... 1-2

Percentage Restraint .......................................................................................................................... 1-2

Second-Harmonic Restraint ............................................................................................................... 1-2

Fifth-Harmonic Restraint .................................................................................................................... 1-3

Unrestrained Trip ................................................................................................................................ 1-3

Options ................................................................................................................................................... 1-3

Push-To-Energize Output Pushbuttons ............................................................................................. 1-3

Auxiliary Output Contacts ................................................................................................................... 1-3

Power Supply ..................................................................................................................................... 1-3

Model and Style Number ....................................................................................................................... 1-4

Style Number Example ....................................................................................................................... 1-4

Specifications ......................................................................................................................................... 1-5

Figures

Figure 1-1. Style Number Identification Chart ........................................................................................... 1-4

Figure 1-2. Percentage Restraint Characteristic ....................................................................................... 1-6

Figure 1-3. Unrestrained Response Times and Restrained Response Times .......................................... 1-8

Tables

Table 1-1. Multiples of Tap ........................................................................................................................ 1-6

Table 1-2. Harmonic Attenuation

Table 1-3. Power Supply Specifications

............................................................................................................... 1-7

.................................................................................................... 1-9

9171300990 Rev V BE1-87T General Information i

Page 12

ii BE1-87T General Information 9171300990 Rev V

Page 13

SECTION 1 • GENERAL INFORMATION

Introduction

These instructions provide information concerning the operation and installation of BE1-87T Transformer

Differential Relays. To accomplish this, the following is provided:

• Specifications

• Functional characteristics

• Mounting information

• Setting procedures and examples

WARNING!

To avoid personal injury or equipment damage, only qualified personnel should

perform the procedures presented in these instructions.

These instructions may be used in place of all earlier editions. For change information, see Section 8.

Description

BE1-87T Transformer Differential Relays provide primary protection for power transformers and are

available in either Single-Phase or Three-Phase configurations. The solid-state BE1-87T compares the

currents entering and leaving the protected transformer. If a fault is detected, the relay initiates a trip

signal to isolate the power transformer. This limits damage to the transformer and minimizes the impact on

the power system.

BE1-87T relays use three types of restraint:

NOTE FOR USERS OF SENSING INPUT TYPE F RELAYS

Users of BE1-87T relays with Sensing Input Type F (three-phases three inputs

per phase) will find Difference Data in Section 6 of this manual that describes

features specific to these relays. The three-phase, three inputs per phase

design, previously available as Sensing Input Type F, has been modified and

is now available as Sensing Input Type G. Due to differences in components

and output terminal connections, Type G relays are not compatible with earlier

versions of the BE1-87T with Sensing Input Type F. There are also differences

in the output connections as described in Section 6, Difference Data.

• Percentage of through-current

• Second harmonic

• Fifth harmonic

Selectivity in differential relaying is based on the ability to distinguish between internal and external faults.

This is achieved by comparing the currents into and out of a power transformer. Comparing these currents

often requires more than two inputs. For example:

• Power transformers may have a significant portion (greater than 10%) of the current flowing in a

third or tertiary winding.

• Power transformers can have multiple breakers for a given winding (e.g., ring bus or breaker-and-

a-half bus).

BE1-87T relays are available with up to five restraint inputs for the single-phase unit and up to three

restraint inputs per phase for the three-phase unit.

9171300990 Rev V BE1-87T General Information 1-1

Page 14

Application

In general, power transformers have different values of current flowing through their primary, secondary,

and tertiary windings. These currents have specific phase relationships depending upon the connections

of the individual windings (e.g., wye/delta). As inputs to a differential relay, these currents must be

compensated or scaled so that the relay can compare the inputs and determine when an unbalance

exists. Under ideal operating conditions, the scaled vector sum of these currents is zero.

Because it is practically impossible to match the magnitudes of these detected currents from the various

power windings using standard CT ratios, the currents are matched within the relay by scaling each of the

applied currents by an appropriate factor called a Tap Setting. This is set by means of the front panel

INPUT dials. By selecting suitable tap ratios, the applied currents are scaled within the relay to achieve

the desired balance for normal operating conditions. BE1-87T relays offer a range of available tap settings

for inputs between 0.4 A to 1.78 A (Sensing Input Range Options 2 and 4 for a 1 A CT) or 2.0 to 8.9 A

(Sensing Input Range Options 1 and 3 for a 5 A CT). These settings are independently adjustable in

increments of 0.02 A for Sensing Input Range Options 2 and 4, or 0.1 A for Sensing Input Range Options

1 and 3. These small increments allow more precise scaling of the applied currents and usually eliminate

the need for installing auxiliary ratio-matching CTs.

Single-Phase

BE1-87T Single-Phase relays require phase angle compensation to be accomplished externally by proper

connection of the system CT secondaries. A wye/delta transformer requires that the CT secondaries be

connected in delta for the wye winding and in wye for the delta winding. This type of connection also

eliminates the zero-sequence component of current which could cause a false trip (operation) during

external ground fault conditions on the wye system.

Three-Phase

BE1-87T Three-Phase relays can provide zero-sequence filtering and compensation for phase shifts

introduced by the connections of the power transformer. This 30° Phase Shift compensation (either ±30°

or no compensation) is field selectable. Additionally, this feature allows sharing the transformer differential

relay CTs with other relays or instrumentation.

BE1-87T relays use the highest input current (in per unit values) to operate on maximum restraint. The

relay does not have a conventional operate winding in the internal magnetics. Operating current is

developed within the electronics of the relay.

Percentage Restraint

A primary concern in differential relay applications is security against high current levels caused by faults

outside the protected zone. Inevitable differences in the saturation characteristics between current

transformers require a compensating decrease in relay sensitivity. It is also necessary to be able to adjust

the sensitivity to compensate for transformer voltage taps or CT mismatches. This is accomplished by

providing a restraint factor proportional to the current flowing through the protected zone (throughcurrent).

BE1-87T relays maintain sensitivity at a specified ratio of trip current to through current. This ratio,

generally referred to as slope, is front-panel adjustable in 5% increments from 15 to 60%.

Second-Harmonic Restraint

Magnetizing inrush current presents another problem unique to transformer differential relays. Relays

must be capable of detecting the small differences in current caused by the shor ting of a limited number

of turns, yet remain secure against the occurrence of magnetizing currents many times the transformer

rating (as seen at one set of terminals).

Although magnetizing inrush is usually associated with the energizing of the transformer, any abrupt

change in the energizing voltage may produce this phenomenon. Common causes are the transients

generated during the onset, evolution, and removal of external faults. Desensitizing the relay only during

energization is therefore insufficient.

Magnetizing inrush produces an offset sine wave rich in all harmonics. BE1-87T relays use the second

harmonic to restrain operation because it predominates and because it does not occur in significant

magnitude or duration at other times.

1-2 BE1-87T General Information 9171300990 Rev V

Page 15

Three-phase BE1-87T relays use second-harmonic sharing. The second-harmonic content of all three

phases is summed together to derive the restraint for each phase. As a result, the second-harmonic

inhibit range and the associated factory setting, is higher than on single-phase relays.

Fifth-Harmonic Restraint

Power transformer overexcitation causes additional exciting current to flow into one set of terminals. This

presents an apparent differential (or operating) current not attributable to an internal fault. Although

potentially damaging, overexcitation is not an internal fault and, therefore, is not an appropriate condition

for transformer differential relay operation. One of the principal components in the complex waveform

produced during overexcitation is the fifth harmonic. BE1-87T relays use fifth-harmonic restraint to inhibit

the differential relay operation.

Unrestrained Trip

Severe internal transformer faults may cause CT saturation. Under such circumstances, harmonicrestraint transformer differential relays may fail to trip because of the extremely high harmonic content in

the waveform. Lack of operation can result in severe transformer damage.

BE1-87T relays provide an independent unrestrained tripping function. When set above the possible

inrush current magnitude, this function provides high-speed protection for the most severe internal faults.

Options

Push-To-Energize Output Pushbuttons

Two PUSH-TO-ENERGIZE OUTPUT switches are available as a means to verify external output wiring

without the inconvenience of having to test the entire relay. Option 2-S provides a small pushbutton switch

for each isolated output function (Restrained and Unrestrained) and may be actuated by inserting a thin,

non-conducting rod through access holes in the front panel. Refer to Figures 2-1 through 2-4 for location.

Appropriate power must be applied to Power Supply terminals 3 and 4 (shown in Figures 4-7 through 4-

10) for these pushbuttons to operate the output relays. However, it is not necessary to apply currents to

the sensing inputs of the relay for these switches to function.

Auxiliary Output Contacts

Three types of auxiliary output contacts are available: Normally open, normally closed and SPDT. The

contacts can be made to respond to a restrained trip, an unrestrained trip, or both. Refer to the Functional

Description: Auxiliary Relay Option for further information.

Power Supply

Various power supply options are available to allow the BE1-87T to be used with standard supply

voltages. See the Style Number Identification Chart, Figure 1-1, for details.

9171300990 Rev V BE1-87T General Information 1-3

Page 16

Model and Style Number

The electrical characteristics and operational features of the BE1-87T Transformer Differential Relay are

defined by a combination of letters and numbers that make up its Style Number. The Model Number

together with the Style Number, describe the options included in a specific device and appear on the front

panel, drawout cradle and inside the case assembly.

Upon receipt of a relay, be sure to check the Style Number against the requisition and the packing list to

ensure that they agree.

Style Number Example

The Style Number Identification Chart (Figure 1-1) defines the electrical characteristics and operational

features included in BE1-87T relays. For example, if the Style Number were G1E-A1Y-D1S0F, the device

would have the following:

BE1-87T

G

1

E

A1

Y

D

1

S

0

F

Model Number (designates the relay as a Basler Electric, Class 100, Transformer Differential

Relay)

Three-phase sensing with three inputs per phase

2.0 to 8.9 A Sensing Range at 60 Hz

One unrestrained output contact and one restrained output contact

No intentional delay in the outputs

48/125 Vdc switchable

Current operated targets

Percent I

Push-to-Energize outputs

No auxiliary output

Semi-flush mounting

display and high-speed trip

OP

Figure 1-1. Style Number Identification Chart

1-4 BE1-87T General Information 9171300990 Rev V

Page 17

Specifications

I

K

t

=

Maximum

I

Minimum Pi

ckup

Percent of

Slope

Restraint

=

Minimum Pi

ckup

Percent of

Slope

=

=

0.35

20

1.75

%

The BE1-87T relay is available in either single-phase or three-phase configurations and with the following

features and capabilities.

Current Sensing Inputs

Maximum Current Per Input

1 Ampere CT Units 4 A continuous; 50 A or 50 X tap (whichever is less) for 1 second.

5 Ampere CT Units 20 A continuous; 250 A or 50 X tap (whichever is less) for 1

For ratings other than one second, the rating may be calculated as:

Where:

Current Sensing Burden

Tap Setting Control (Scaling)

1 Ampere CT Units 0.4 to 1.78 in 0.02 A increments.

5 Ampere CT Units 2.0 to 8.9 A, in 0.1 A increments.

The unit is designed to operate from the secondary of current

transformers rated at either 1 A or 5 A. Frequency range is ±5 Hz of

nominal.

second.

t is the time (in seconds) that the current flows

K = 50 A or 50 X tap, whichever is less (1 Amp CT Units), or

K = 250 A or 50 X tap, whichever is less (5 Amp CT Models)

Less than 0.02 ohm per phase.

Front panel rotary switches, labeled INPUT, permit scaling the

sensed input current (or tap setting) over the range of:

Restrained Output

Pickup Range Front panel thumbwheel switches adjust pickup of the restrained

Pickup Accuracy

Minimum Pickup

For example:

output as a percentage of the through current. The range is 15 to

60% of the operating current in 5% increments.

±6% of pickup ±100 mA (5 Ampere Units) or ±20 mA (1 Ampere

units).

0.35 ±6% of tap setting. Refer to Tabl e 1-1 and Figure 1-2. Table 1-1

provides calculated intersection points of the slope characteristic

and the minimum pickup (in multiples of tap) as shown in Figure

1-2. The calculation was derived from the formula:

The relay operates when the per unit difference current (operating

current) is above the 0.35 pu or the slope line in Figure 1-2.

Calculation examples are found in Section 5.

9171300990 Rev V BE1-87T General Information 1-5

Page 18

Table 1-1. Multiples of Tap

Front Panel Setting % 15 20 25 30 35 40 45 50 55 60

Maximum Restraint

Current At Minimum

Pickup In Multiples of

Tap

2.33 1.75 1.40 1.17 1.00 0.875 0.778 0.700 0.636 0.583

Figure 1-2. Percentage Restraint Characteristic

Second-Harmonic Restraint Inhibit of the restrained output occurs when the second-

harmonic component exceeds a pickup setting which is 12%

of the operating current for single-phase units or 18% for

three-phase units.

Fifth-Harmonic Restraint Inhibit of the restrained output occurs when the fifth-harmonic

component exceeds a pickup setting which is 35% of the

operating current.

Unrestrained Output

Pickup Range Front panel thumbwheel switches adjust the pickup point of

Pickup Accuracy

the unrestrained output over a range of 6 to 21 times the tap

setting in increments of 1 x Tap.

±3% of the front panel setting.

1-6 BE1-87T General Information 9171300990 Rev V

Page 19

Outputs

Resistive

120/240 Vac Make 30 A for 0.2 seconds, carry 7 A continuously and break

250 Vdc Make and carry 30 A for 0.2 seconds, carry 7 A continuously

500 Vdc Make and carry 15 A for 0.2 seconds, carry 7 A continuously

Inductive

120/240 Vac, 125/250 Vdc Make and carry 30 A for 0.2 seconds, carry 7 A continuously

Output contacts are rated as follows.

7 A.

and break 0.3 A.

and break 0.1 A.

and break 0.3 A, (L/R = 0.04).

Target Indicators

Single-Phase Units Either an internally-operated or a current-operated target is

Three-Phase Units Either internally operated or current operated targets (as

Harmonic Attenuation

Parameter

(50 Or 60 Hz Models)

Through Current 0 0 0 0 12 dB

Operating Current 0 0 0 0 12 dB

2nd Harmonic Restraint 12 dB 0 12 dB 12 dB 12 dB

5th Harmonic Restraint 12 dB 12 dB 12 dB 0 12 dB

Target indicators may be either internally-operated or currentoperated (operated by a minimum of 0.2 A through the output

trip circuit). When the target is current-operated, the

associated output circuit must be limited to 30 A for 0.2

seconds, 7 A for 2 minutes and 3 A continuously.

supplied (as selected by the Style Number) for each trip

output (i.e., the restrained and the unrestrained functions).

selected) indicate the function (restrained or unrestrained)

that caused the trip, and the tripped phase (A, B, C).

Refer to Tabl e 1-2.

Table 1-2. Harmonic Attenuation

Minimum Attenuation at Indicated Fundamental

50/60 Hz 100/120 Hz 150/180 Hz 250/300 Hz 500 Hz

9171300990 Rev V BE1-87T General Information 1-7

Page 20

Timing

(For 60 Hz units only)

Refer to Figure 1-3 for Unrestrained Response Times and

Restrained Response Times.

Figure 1-3. Unrestrained Response Times and Restrained Response Times

1-8 BE1-87T General Information 9171300990 Rev V

Page 21

Isolation

In accordance with IEC 255-5 and ANSI/IEEE C37.90-1989,

one minute dielectric (high potential) tests, as follows:

All circuits to ground: 2,121 Vdc

Input to output circuits: 1,500 Vac or 2,121 Vdc

Power Supply

Type

K (midrange) 48 Vdc 24 to 150 Vdc 9.0 W

J (midrange)

L (low range) 24 Vdc 12 to 32 Vdc * 9.0 W

Y (midrange)

Z (high range)

* Type L power supply initially requires 14 Vdc to begin operating. Once operating, the input voltage may

be reduced to 12 Vdc and operation will continue.

Surge Withstand Capability

Refer to Tabl e 1-3.

Table 1-3. Power Supply Ratings

Nominal

Input Voltage

125 Vdc 24 to 150 Vdc 9.0 W

120 Vac 90 to 132 Vac 21.0 VA

48 Vdc 24 to 150 Vdc 8.5 W

125 Vdc 24 to 150 Vdc 9.0 W

250 Vdc 68 to 280 Vdc 9.5 W

240 Vac 90 to 270 Vac 28.0 VA

Qualified to ANSI/IEEE C37.90.1-1989, Standard Surge

Withstand Capability (SWC) Tests for Protective Relays and

Relay Systems, and IEC 255-5 Impulse Test and Dielectric

Tes t.

Input Voltage Range

Burden at

Nominal

Radio Frequency Interference

(RFI)

UL Recognition

GOST-R Certification

Patent

Shock

Vibration

Operating Temperature

Storage Temperature

Maintains proper operation when tested in accordance with

IEEE C37.90.2-1987, Trial-Use Standard Withstand

Capability of Relay Systems to Radiated Electromagnetic

Interference from Transceivers.

UL Recognized per Standard 508, UL File No. E97033. Note:

Output contacts are not UL Recognized for voltages greater

than 250 V.

GOST-R certified per the relevant standards of Gosstandart

of Russia.

Patented in U.S., 1991, U.S. Patent No. 5014153.

Patented in Canada, 1993.

In standard tests, the relay has withstood 15 g in each of

three mutually perpendicular axes without structural damage

or degradation of performance.

In standard tests, the relay has withstood 2 g in each of three

mutually perpendicular axes swept over the range of 10 to

500 Hz for a total of six sweeps, 15 minutes each sweep,

without structural damage or degradation of performance.

–40°C (–40°F) to 70°C (158°F)

–65°C (–85°F) to 100°C (212°F)

9171300990 Rev V BE1-87T General Information 1-9

Page 22

Weight

22.3 lbs (10.1 kg) maximum (three-phase unit)

Case Size

19.5 lbs (8.85 kg) maximum (single-phase unit)

All units are supplied in an M1 case size. See Section 4,

Installation for case dimensions.

1-10 BE1-87T General Information 9171300990 Rev V

Page 23

SECTION 2 • CONTROLS AND INDICATORS

TABLE OF CONTENTS

SECTION 2 • CONTROLS AND INDICATORS ........................................................................................ 2-1

Location of Controls and Indicators ....................................................................................................... 2-1

Figures

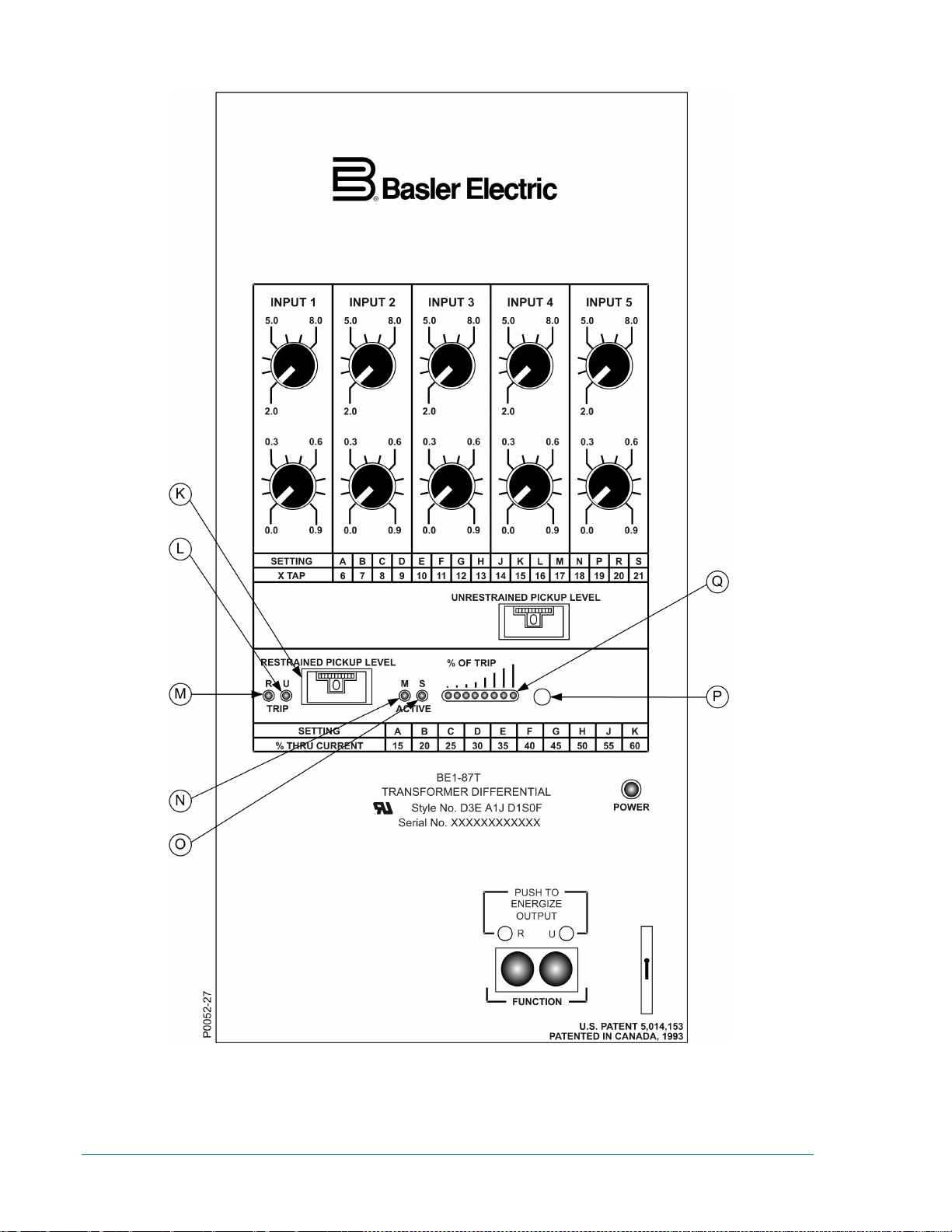

Figure 2-1. Sensing Input Range 1 or 3 Three-Phase, Three Inputs ........................................................ 2-4

Figure 2-2. Sensing Input Range 1 or 3, Single-Phase, Five Inputs ......................................................... 2-5

Figure 2-3. Sensing Input Range 2 or 4, Three-Phase, Two Inputs .......................................................... 2-6

Figure 2-4. Controls Mounted Inside the Relay ......................................................................................... 2-7

Figure 2-5. Sensing Input Range 2 or 4, Option 1-1, Single-Phase, Five Inputs, % OF TRIP Option ...... 2-8

Tables

Table 2-1. Controls and Indicators ............................................................................................................ 2-1

9171300990 Rev V BE1-87T Controls and Indicators i

Page 24

ii BE1-87T Controls and Indicators 9171300990 Rev V

Page 25

SECTION 2 • CONTROLS AND INDICATORS

Location of Controls and Indicators

Table 2-1 lists and briefly describes the operator controls and indicators of the BE1-87T Transformer

Differential Relay. Reference the call-out letters A through M to Figures 2-1 to 2-3; N through Q to Figure

2-5. Exploded views of controls that are mounted inside the relay (call-out letters B, D and I) are shown in

Figure 2-4.

Table 2-1. Controls and Indicators

Letter Control or Indicator Function

A INPUT (or TAP) Switches Front panel INPUT switches are used to scale the

transformer currents. There are two of these rotary

switches for each input.

1 Ampere CT Units

5 Ampere CT Units

B 30° Phase Shift Jumpers

(three-phase units ONLY)

C

D CALIBRATE Switch

E POWER Indicator

UNRESTRAINED PICKUP

LEVEL Switches

(three-phase units ONLY)

Each of the upper switches is calibrated to represent

the tenths and units digits (0.4 through 1.6) of tap

value. Each of the lower switches is calibrated to

represent two-hundredths of tap value for each

increment. Always add the setting of the lower switch to

that of the upper switch. For example, if a setting of

1.02 is desired, the upper switch must be at 1.0 and the

lower switch must be at 0.02. The total setting range for

each input is 0.4 to 1.78.

Each of the upper switches is calibrated to represent

the units digit (2 through 8) of tap value. Each of the

lower switches is calibrated to represent tenths of tap

value. Always add the setting of the lower switch to that

of the upper switch. For example, if a setting of 5.0 is

desired, the upper switch is set to 5.0, the lower switch

must be at 0.0. The total setting range for each input is

2.0 to 8.9.

These jumpers control the internal phase shift of the

relay, either +30°, -30°, or 0°, depending upon the

position of the jumpers provided for each input on the

Analog #2 Board, shown in Figure 2-4. Additional

information is in Section 4.

This thumbwheel switch establishes the desired pickup

setting for all phases of the unrestrained output. The

adjustment range is from 6 to 21 times the phase tap

setting, in increments of 1.

A two-position switch is located on each Analog #1

Board and is easily accessible on the right side of the

relay when it is withdrawn from the case. In the

CALIBRATE position, these switches inhibit the

harmonic share feature when calibrating the 2nd

Harmonic Restraint. In the NORMAL position, the relay

will operate normally.

This LED will illuminate when operating power is

supplied to the internal circuitry of the relay.

9171300990 Rev V BE1-87T Controls and Indicators 2-1

Page 26

Letter Control or Indicator Function

F

G FUNCTION Targets Option

H Target Reset Switch

I Auxiliary Relay Control

J ELEMENT Targets Option

K

L UNREST. TRIP Indicator

M REST. TRIP Indicator

N M Indicator Red LED lights when the % OF TRIP pushbutton P is

O S Indicator Red LED lights when the % OF TRIP pushbutton P is

P Percent of Trip Pushbutton Pushbutton that is used to activate the % of TRIP

PUSH-TO-ENERGIZE

OUTPUT Switches Option

Switches Option

(three-phase units ONLY)

RESTRAINED PICKUP

LEVEL Switches

Two momentary pushbutton switches are accessible by

inserting a 1/8 inch diameter non-conducting rod

through access holes in the front panel. Switch R,

when actuated, closes the Restrained Output Relay

contacts. Switch U, when actuated, closes the

Unrestrained Output Relay contact(s).

NOTE

The optional Auxiliary Relay contacts (Option 3-1, 3-2

or 3-5) will also be operated by the PUSH-TO-

ENERGIZE switches if enabled by the two internal

Auxiliary Relay Control Switches. (Refer to LETTER I.)

Electronically-latched LED targets that indicate an

unrestrained or restrained output has occurred.

Resets the electronically-latched targets.

Two internal slide switches, S1 and S2, enable the

optional Auxiliary Output Relay to close only when a

restrained output occurs (S1 ON), only when an

unrestrained output occurs (S2 ON), or to close when

either output occurs (S1 and S2 ON).

When shipped from the factory, the Auxiliary Relay will

be configured with S1 and S2 ON.

NOTE

The switches are located on the mother board and are

only accessible by withdrawing the relay case.

Electronically-latching LED targets indicate the phase

that caused a trip operation.

Thumb-wheel switches (one per phase element) are

used to adjust the desired percent of allowable

through-current restraint from 15 to 60 % in 5 %

increments. (Through-current is the greatest relative

individual input current.)

The through-current restraint characteristic is

individually adjustable for phases A, B, and C.

In a three-phase unit, all three switches are typically

kept at identical settings.

Red LED lights when there is an unrestrained pickup.

Red LED lights when there is a restrained pickup.

pressed and the restraint current is below the slope

characteristic kneepoint as defined in Table 1-1. That

is, the relay will operate at minimum pickup (0.35 times

tap).

pressed and the restraint current is above the slope

characteristic kneepoint as defined in Table 1-1. That

is, the relay will operate based on the restraint

characteristic.

LEDs.

2-2 BE1-87T Controls and Indicators 9171300990 Rev V

Page 27

Letter Control or Indicator Function

Q % OF TRIP Indicators Option When the % OF TRIP pushbutton P is pushed, eight

LEDs, shown in Figure 2-5, are used to indicate the

approximate percentage of operating current to:

Minimum pickup (LED M also lights); or

Slope characteristic pickup (LED S also lights).

The eight LEDs represent the following approximate

percentages.

1 LED: 3% (Yellow LED)

2 LEDs: 7% (Yellow LED)

3 LEDs: 11% (Yellow LED)

4 LEDs: 20% (Red LED)

5 LEDs: 40% (Red LED)

6 LEDs: 60% (Red LED)

7 LEDs: 80% (Red LED)

8 LEDs: 100% (Red LED)

A bar chart above the LEDs shows the relative

percentage of trip.

9171300990 Rev V BE1-87T Controls and Indicators 2-3

Page 28

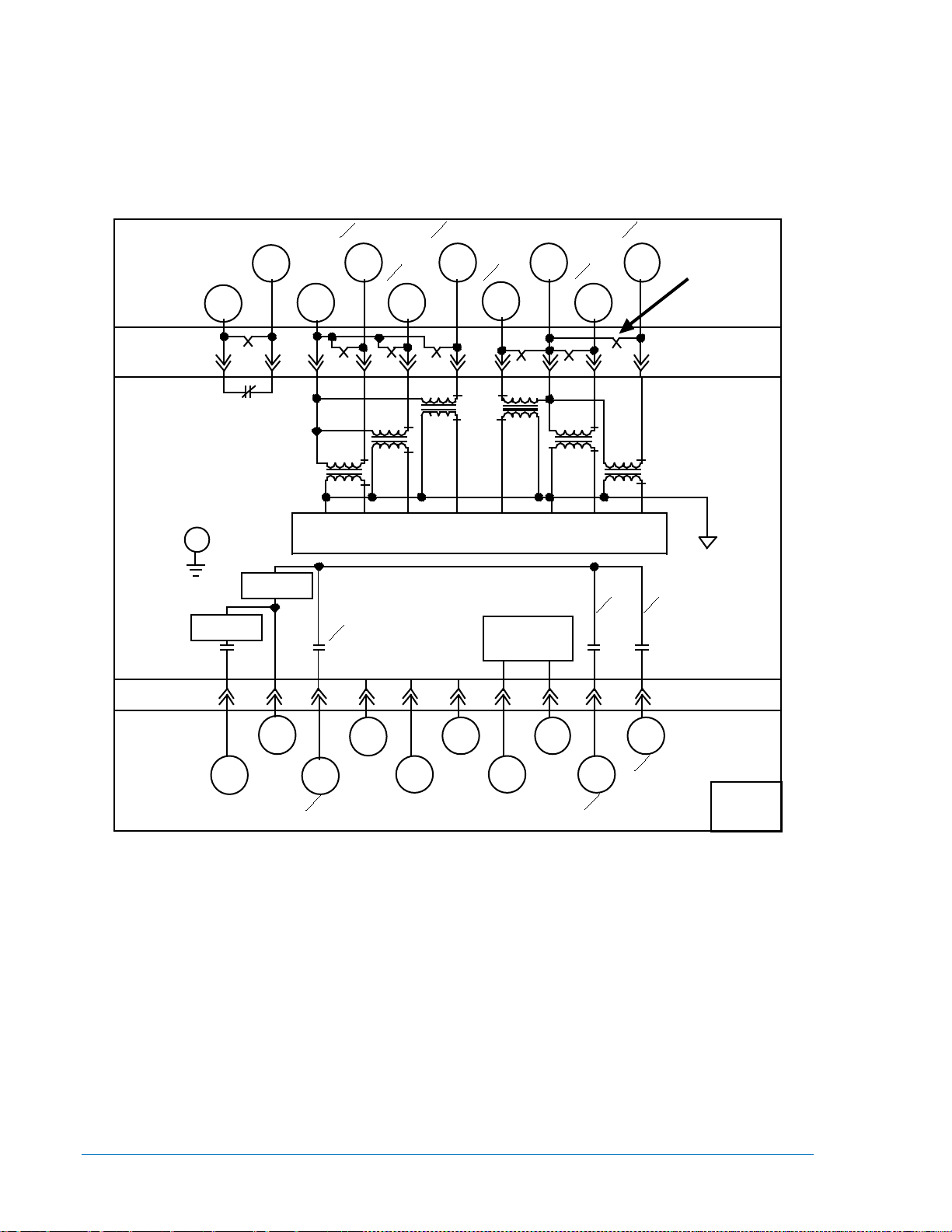

Figure 2-1. Sensing Input Range 1 or 3 Three-Phase, Three Inputs

2-4 BE1-87T Controls and Indicators 9171300990 Rev V

Page 29

Figure 2-2. Sensing Input Range 1 or 3, Single-Phase, Five Inputs

9171300990 Rev V BE1-87T Controls and Indicators 2-5

Page 30

Figure 2-3. Sensing Input Range 2 or 4, Three-Phase, Two Inputs

2-6 BE1-87T Controls and Indicators 9171300990 Rev V

Page 31

SECTION OF THE (VERTICAL)

MOTHER BOARD AT LEFT

REAR OF RELAY

I

S2

2

AUX

UNRES

P6

J2

D

B

AUX RES

ON

S1

CR19

CR7

42

LH EDGE OF ANALOG #2

BOARD (THE 4TH BOARD

DOWN, COUNTING THE

MAGNETIC BOARD.)

AR

J11

J2

VR2

TP+12V

C1

J1

0A

0B

0C

J9

J10

IN

1

IN

2

IN

3

∆

1

∆

2

WYE

∆

1

∆

2

WYE

∆

1

∆

2

WYE

P0052-26

BE1-87T

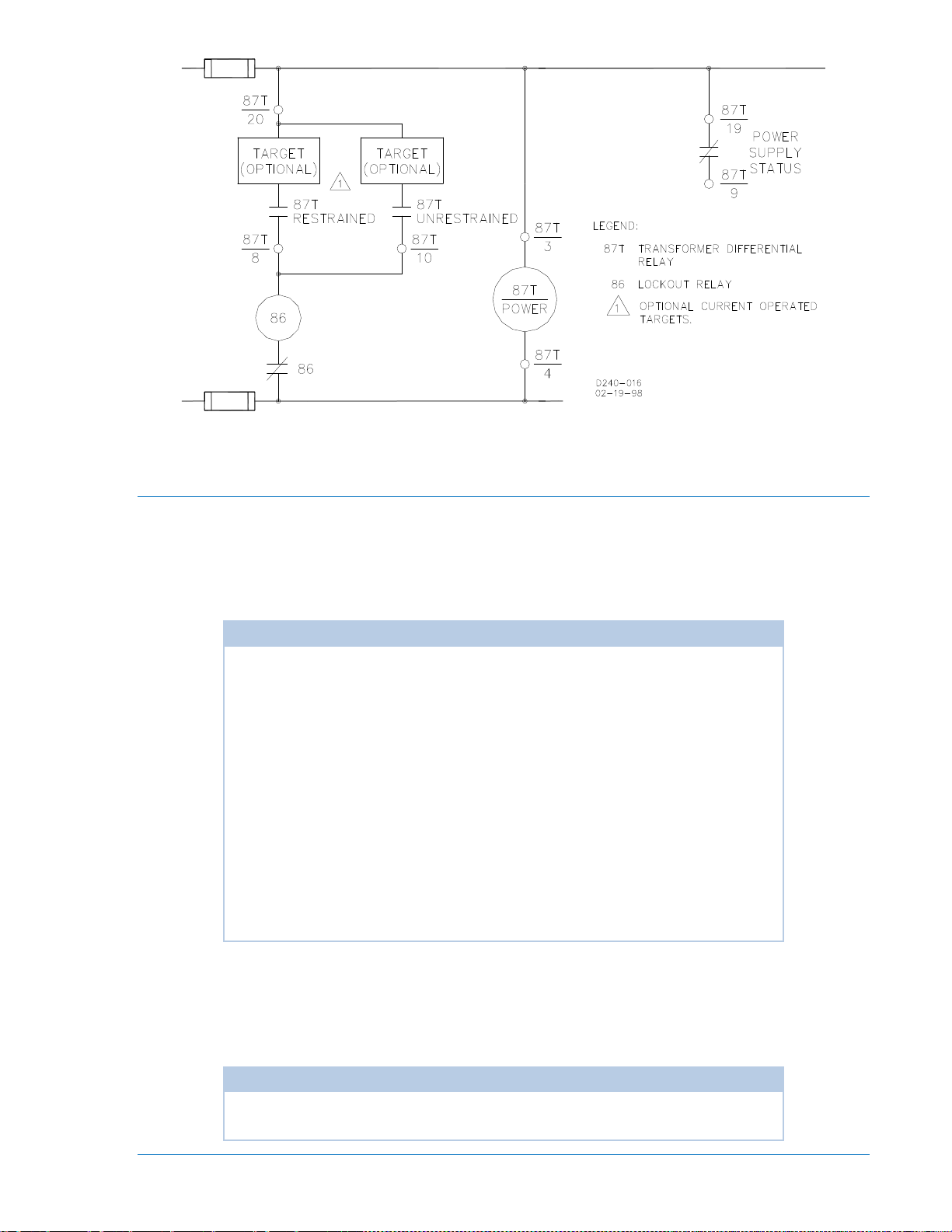

Figure 2-4. Controls Mounted Inside the Relay

9171300990 Rev V BE1-87T Controls and Indicators 2-7

Page 32

Figure 2-5. Sensing Input Range 2 or 4, Option 1-1, Single-Phase, Five Inputs, % OF TRIP Option

2-8 BE1-87T Controls and Indicators 9171300990 Rev V

Page 33

SECTION 3 • FUNCTIONAL DESCRIPTION

TABLE OF CONTENTS

SECTION 3 • FUNCTIONAL DESCRIPTION ........................................................................................... 3-1

General .................................................................................................................................................. 3-1

Description ............................................................................................................................................. 3-1

Current Transformers ......................................................................................................................... 3-1

Scaling ................................................................................................................................................ 3-1

Summing ............................................................................................................................................ 3-1

30° Internal Phase Shift (Three-Phase Relays ONLY) ...................................................................... 3-1

Restrained Trip Output ....................................................................................................................... 3-3

Unrestrained Trip Output .................................................................................................................... 3-3

Auxiliary Relay Option ........................................................................................................................ 3-4

Power Supply ..................................................................................................................................... 3-4

Power Supply Status Output (Optional) ............................................................................................. 3-4

Target Indicators (Optional)................................................................................................................ 3-4

% of Trip ............................................................................................................................................. 3-5

Figures

Figure 3-1. Functional Block Diagram ....................................................................................................... 3-2

Figure 3-2. Functional Block Diagram, Phase B and Phase C ................................................................. 3-2

9171300990 Rev V BE1-87T Functional Description i

Page 34

ii BE1-87T Functional Description 9171300990 Rev V

Page 35

SECTION 3 • FUNCTIONAL DESCRIPTION

3

General

BE1-87T relays are solid-state devices that protect transformers by providing output contact closure when

the scaled current into the protected transformer does not equal the scaled current out, within defined

limits. These relays are harmonically restrained to prevent tripping during initial energization and external

fault conditions. A through-current restraint also provides security against tripping for external faults. An

unrestrained tripping element is included to provide a high-speed trip in the event of a particularly severe

fault within the transformer.

Description

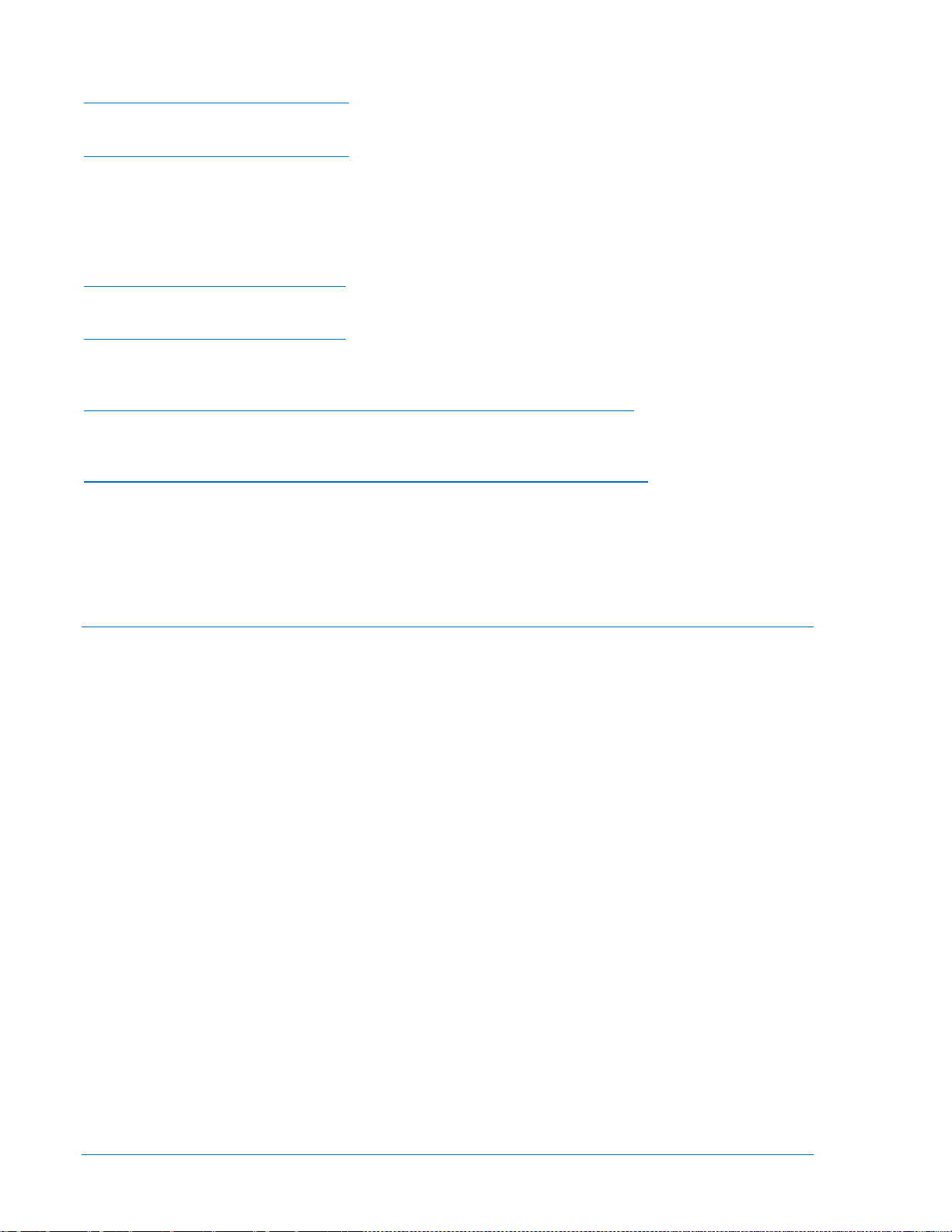

The functional block diagrams of Figures 3-1 and 3-2 illustrate the overall operation of the BE1-87T

Transformer Differential Relay. (Figure 3-1 shows Phase A or single-phase functions; Figure 3-2 shows

the additional functions for phases B and C.) Since the three phases are functionally similar, only phase A

is shown in detail in Figure 3-1. Note that in a three-phase unit, there may be one restrained output for

each phase (Output Type Option E in the third position of the Style Number), or one restrained output that

serves for all three phases (Option F in the third position). When Target Option C or D is specified for a

three-phase Unit (in the seventh position), an individual target is supplied for each phase.

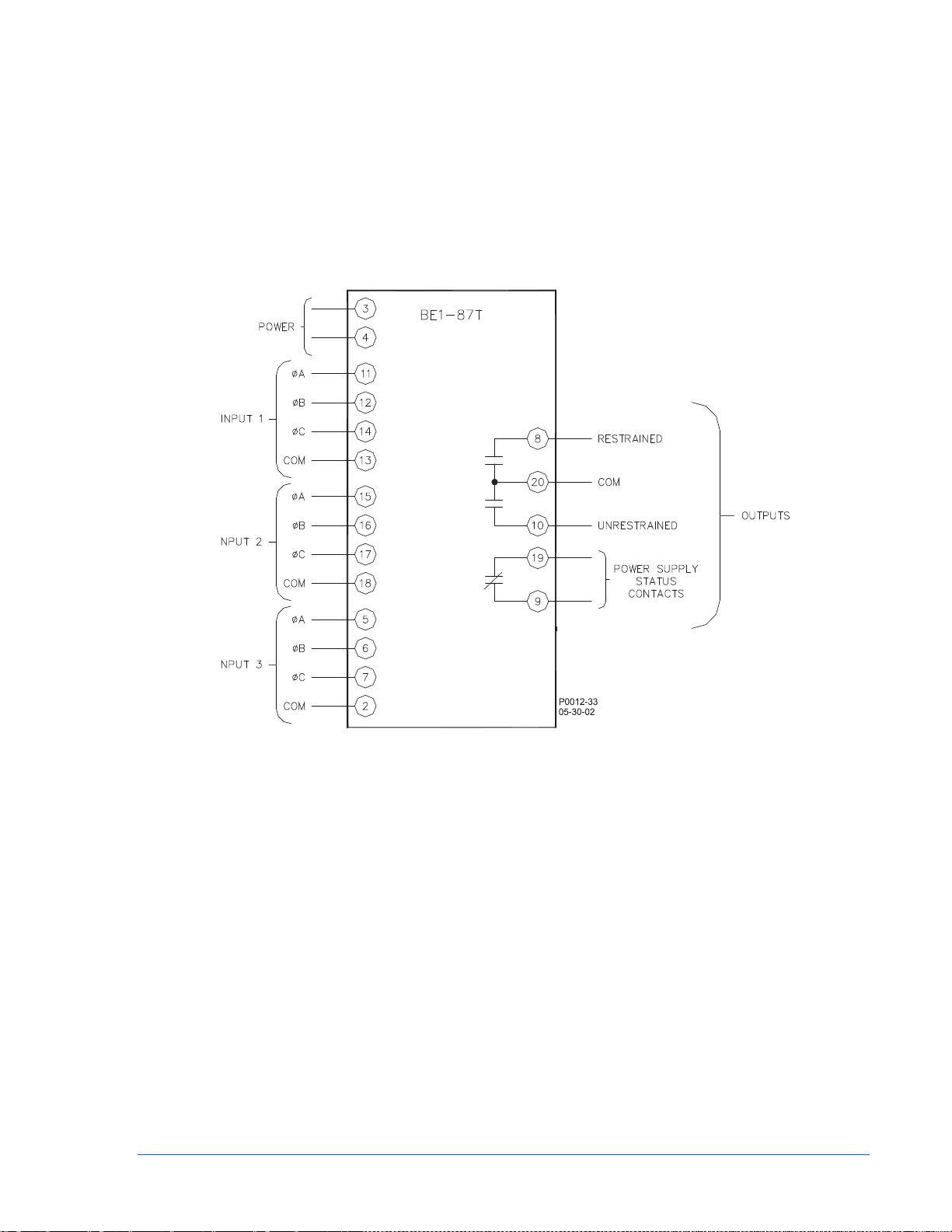

Current Transformers

In the protected zone of the power system, CTs with a 1 ampere or 5 ampere secondary winding supply

not

the sensing current for each input. This is

connected ahead of the BE1-87T. Sensing currents are, in turn, applied to relay internal input

transformers. These transformers provide system isolation.

shown in Figure 3-1 or Figure 3-2. Other relays may be

Scaling

Input currents are scaled by the front panel INPUT rotary switches that introduce resistances to the

internal CT secondaries. The switches are calibrated in 0.02 ampere increments from 0.4 to 1.78 ampere

for 1 ampere CT units (Options 2 or 4 in the second position of the Style Number), and in 0.1 ampere

increments from 2.0 to 8.9 amperes for 5 ampere CT models (Options 1 or 3 in the second). The many

graduations of adjustment are provided to allow each input to approach an ideal representation of the

actual operating per unit value.

Summing

Analog signals representing each input contribution are vector summed (shown as Summing in Figure 3-

1). This summing process produces the operating current (I

currents.

Ideally, and with perfectly matched CTs, a transformer without an internal fault should cause I

exactly zero on a continuous basis. When not zero, a fault would be indicated. However, saturation effects

caused by heavy through-current or magnetic inrush can cause a temporary imbalance even though no

internal fault has occurred. To prevent a false trip under such conditions, various types of restraint are

used. Each restraint is specific to a potential cause of misoperation. These are individually discussed in

the topic Restrained Trip Output.

) that is the phasor sum of the input

OP

to be

OP

30° Internal Phase Shift (Three-Phase Relays ONLY)

For three-phase units, the inputs to the Summing function are first routed through the 30° Phase Shift

circuit. There the signals may be advanced or retarded by 30° or passed through unchanged.

Compensating phase shift direction (shown as the Phase Shift Setting circuit in Figure 3-1) is determined

by the position of three jumpers on the internal Analog #2 Board. (The location of these jumpers is shown

in Figure 2-4.) The internal phase shift will accomplish the corresponding zero sequence blocking. The

current magnitude will be increased by

later in detail in Section 4).

and must be taken into account in the tap setting (explained

9171300990 Rev V BE1-87T Functional Description 3-1

Page 36

Figure 3-1. Functional Block Diagram

B

C

4

RESTRAINED

UNRESTRAINED

RESTRAINED

UNRESTRAINED

TARGET

TARGET

B SAME AS A

0

0

OR

OR

B

0

C0C SAME AS A

0

0

0

0

OPTIONAL

RESTRAINED

CONTACTS

FOR EACH OF

3 PHASES

(SEE NOTE

5

BE1-87T

D741-001b

7-11-94

COM.

IN. 1

IN. 2

IN. 3

COM.

IN. 1

IN. 2

IN. 3

0

B

0

C

S2

S1

IN. 3, B SCALE

IN. 3, C SCALE

0

0

IN. 1, B SCALE

IN. 1, C SCALE

0

0

OPERATING

POWER

POWER

SUPPLY

POWER

SUPPLY

STATUS

5

REST.

TRIP

AUX.

OPTION

UNREST

TRIP

TARGET

UNRESTRAINED

B

RESTRAINED

6

POWER

TO INTERNAL

CIRCUITRY

Iop1

SHIFT SETTING:

+30

°

, -30

°

, 0

°

8

LEDs

CALCULATE

MAXIMUM

INDIVIDUAL

CURRENT

THEN TRIP

op

I

IF

>

%

max

I

% OF

TRIP

UNREST. SETTING

COM.

IN. 1

IN. 2

IN. 3

IN. 4

IN. 5

TO OTHER PHASES

(THREE-PHASE ONLY)

UNREST

TRIP

(6 TO 21

TIMES TAP)

2

0

30

°

SHIFT

(ONLY ON

3 UNITS)

0

0

SCALING

( TAP)

SCALING

( TAP)

SCALING

( TAP)

IN. 2, B SCALE

IN. 2, C SCALE

0

0

SCALING

( TAP)

0

C05TH >

SETTING

=INHIBIT

3

2ND >

SETTING

=INHIBIT

3

OR

B

C00

4

TARGET

TARGET

SCALING

( TAP)

POWER

SUPPLY

SENSOR

FIFTH

HARMONIC

RESTRAINT

FILTERS

SECOND

HARMONIC

RESTRAINT

FILTERS

SUMMING:

ALGEBRAIC

SUM OF

INPUTS =

OPERATING

CURRENT

( )

I

op

OR

30

°

SHIFT

(ONLY ON

3 UNITS)

0

0

30

°

SHIFT

(ONLY ON

3 UNITS)

0

0

2

max

I

% I

max

REST.

T

PICKUP

CONTROL

% I

max

op

I

UNREST.

SETTING

THEN TRIP

IF I >

op

A

OR

1

0

0

BE1-87T

D741-001a

7-11-94

NOTES

1 Present in three-phase units ONLY.

2 Inputs 4 and 5 are available in single-phase units ONLY.

3 The settings are calibrated to a specified percentage of the harmonic to the fundamental. See Harmonic

Restraints for factory settings.

4 Phase Targets are supplied on three-phase units ONLY.

5 Restrained Trip Contact:

• One contact for single-phase units.

• One contact or one contact per phase available on three-phase units.

6 Three-phase units use the sum of the second harmonic from each phase to restrain each phase.

7 Phase Targets are supplied on three-phase units ONLY.

8 Restrained Trip Contact:

• One contact for single-phase units.

• One contact or one contact per phase available on three-phase units.

3-2 BE1-87T Functional Description 9171300990 Rev V

Figure 3-2. Functional Block Diagram, Phase B and Phase C

Page 37

Restrained Trip Output

Restrained trip output contacts are subject to three types of restraint (i.e., inhibit) signals:

• Percentage restraint

• Second-harmonic restraint

• Fifth-harmonic restraint

These signals are developed within the relay in response to external conditions and block the restrained

output contacts from closing.

Percentage Restraint

Percentage restraint developed from the maximum through current and the slope setting determines the

minimum operating current I

produce a Restraint Trip output. The I

(Figure 3-1) in a comparator where I

OP

desired trip level is adjustable on the front panel RESTRAINED

OP

PICKUP LEVEL switches shown in Figures 2-1 through 2-3.

Comparators in the Calculate Max. Individual Current circuit determine which input (of a particular phase)

is receiving the greatest current. That input is chosen and then called the I

then scaled by the front panel RESTRAINED PICKUP LEVEL switches (shown as the Restrained Pickup

Control in Figure 3-1). The resulting signal (%I

extended to the Then Trip comparator and the I

The Then Trip circuitry compares the operating current (I

than %I

(and there is no 5th or 2nd harmonic restraint to cause an inhibit as described below), a

MAX

), that represents the percentage of through-current is

MAX

Divided By %I

OP

OP

MAX

) to %I

function.

Restrained Trip output is produced.

Divided By %I

I

OP

. If IOP is greater than the preset percent of %I

%I

MAX

contains eight comparators and compares IOP to the preset percentage levels of

MAX

for a specific comparator, the LED associated with

MAX

that comparator lights. The eight LEDs represent the following approximate percentages:

First LED: 3%

Second LED: 7%

Third LED: 11%

Fourth LED: 20%

Fifth LED: 40%

Sixth LED: 60%

Seventh LED: 80%

Eighth LED: 100%

must be greater than %I

OP

signal. The I

MAX

. If the operating current is greater

MAX

output is

MAX

MAX

to

NOTE

As each successive LED lights, all previous or lesser percentage value LEDs

will also light.

Harmonic Restraints

Development of a restrained trip output may be inhibited by either of two harmonic restraints. These are

generated by bandpass filters tuned to the second and fifth harmonics of the operating current.

Comparators monitor these signals. When the fifth-harmonic content exceeds 35% of the operate current

(indicating overexcitation of the transformer) or when the second-harmonic content exceeds 12% (singlephase) or 18% (three-phase) of the operate current (indicating a magnetic inrush condition), an inhibit

signal is developed that blocks operation of the Restrained Trip output contact. (Stated percentages

represent the factory setting.)

Unrestrained Trip Output

IOP is also compared against a reference established by the front panel UNRESTRAINED PICKUP

LEVEL switch is shown in Figures 2-1 through 2-5. When this reference is exceeded, the Unrestrained

Tr i p output relay is energized. An unrestrained trip is not affected by through-current or harmonic inhibits.

9171300990 Rev V BE1-87T Functional Description 3-3

Page 38

Auxiliary Relay Option

Auxiliary relays (Option 3-1, 3-2 or 3-5 in the tenth position of the Style Number) are accompanied by two

switches, S1 and S2, which allow the relays to respond to a restrained trip (S1 ON) or to an unrestrained

trip (S2 ON), or both (S1 and S2 ON). These switches (letter I of Figure 2-4 and described in Table 2-1)

are located on the mother board and are shipped in the ON position. Auxiliary relays may be disabled by

opening both switches (S1 and S2 OFF).

Power Supply

Relay operating power is developed by a wide-range, isolated, low-burden, switching power supply that

delivers ±12 Vdc to the relay’s internal circuitry. The power supply is not sensitive to the input power

polarity. A front panel LED power indicator lights to indicate that the power supply is functioning properly.

Style number designations and input voltage ranges for the available power supply models are provided

in Section 1, General Information.

Power Supply Status Output (Optional)

The Power Supply Status output relay has normally closed (NC) contacts. The relay is energized by the

presence of nominal voltage at the output of the power supply. Normal operating voltage then keeps the

relay continuously energized and its contacts open. However, if the power supply voltage falls below

requirements, the Power Supply Status output relay will de-energize and close the contacts.

The Power Supply Status output is not associated with any magnetically latched target. The POWER LED

on the front panel provides a visual indication of the normal operating status of the power supply.

NOTE

Sensing Input Types A through E (first position of the Style Number) have

paddle-operated shorting bars included in the relay case (terminals 19 and 20)

so that the Power Supply Status output terminals can provide a remote

indication that the BE1-87T has been withdrawn from its case or that it has

been taken out of service by removing the connection plugs. Sensing Input

Type G relays do NOT have shorting bars on the Power Supply Status output.

Sensing Input Type G units use terminal 9 (lower terminal block) and terminal

19 (upper terminal block) for the Power Supply Status output.

Target Indicators (Optional)

When the Target option is specified as either C or D, shown in the seventh position of the Style Number,

electronically latched indicators, labeled FUNCTION, are incorporated in the front panel. The

electronically latched and reset targets consist of red LED indicators. The appropriate target is tripped

when either a restrained (R) or unrestrained (U) output occurs. Latched targets are reset by operating the

target reset switch on the front panel. If relay operating power is lost, any illuminated (latched) targets are

extinguished. When relay operating power is restored, the previously latched targets are restored to their

latched state.

When targets are specified for three-phase relays, three additional ELEMENT targets are incorporated to

indicate the phase involved. Only the FUNCTION targets, restrained (R) or unrestrained (U) are available

for single-phase units.

Relays can be equipped with either internally operated targets (Type C) or current operated targets (Type

D). Both target types are reset by operating the target reset switch.

• Type C target (referred to as internally operated) is actuated by an integral driver circuit that

responds directly to the relay internal logic. This type of target is tripped regardless of the amount

of current flowing through the associated output contact.

• Type D target (referred to as current operated) is actuated when a minimum of 0.2 A flows

through the associated output contacts. To accomplish this, a special reed relay is placed in

series with the contact to signal the target indicator. (The series impedance of the reed relay is

less than 0.1 ohm.) Current in the output circuit must be limited to 30 amperes for 0.2 seconds, 7

amperes for 2 minutes and 3 amperes continuously.

3-4 BE1-87T Functional Description 9171300990 Rev V

Page 39

NOTE

87T target indicators consisted of

Prior to September 2007, the BE1magnetically latched, disc indicators. These mechanically latched target

indicators have been replaced by the electronically latched LED targets in use

today.

% of Trip

When the % of trip pushbutton Q is pushed, eight LEDs, shown in Figure 2-5, are used to indicate the

percentage of operating current to: Minimum pickup (LED M also lights); or Slope characteristic pickup

(LED S also lights). The eight LEDs represent the following percentages:

1 LED: 3% (Yellow LED)

2 LEDs: 7% (Yellow LED)

3 LEDs: 11% (Yellow LED)

4 LEDs: 20% (Red LED)

5 LEDs: 40% (Red LED)

6 LEDs: 60% (Red LED)

7 LEDs: 80% (Red LED)

8 LEDs: 100% (Red LED)

A bar chart above the LEDs shows the relative percentage of trip.

9171300990 Rev V BE1-87T Functional Description 3-5

Page 40

3-6 BE1-87T Functional Description 9171300990 Rev V

Page 41

SECTION 4 • INSTALLATION

TABLE OF CONTENTS

SECTION 4 • INSTALLATION .................................................................................................................. 4-1

General .................................................................................................................................................. 4-1

Relay Operating Precautions ................................................................................................................. 4-1

Mounting ................................................................................................................................................ 4-2

Dielectric Test ........................................................................................................................................ 4-9

Connections ........................................................................................................................................... 4-9

Relay Disassembly .............................................................................................................................. 4-17

Precautions ...................................................................................................................................... 4-17

Circuit Board Removal Procedure .................................................................................................... 4-17

Disabling Unused Inputs ...................................................................................................................... 4-18

Single-Phase Units ........................................................................................................................... 4-20

Three-Phase Units ........................................................................................................................... 4-20

Sensing Connection Diagrams ............................................................................................................ 4-20

Single-Phase Input Sensing Connections ........................................................................................ 4-20

Three-Phase Input Sensing Connections ........................................................................................ 4-24

Setting the BE1-87T ............................................................................................................................. 4-33

Method.............................................................................................................................................. 4-33

Procedure One ................................................................................................................................. 4-33

Procedure Two ................................................................................................................................. 4-42

Checking the Relay Settings and System Inputs ................................................................................. 4-49

Maintenance......................................................................................................................................... 4-50

Storage ................................................................................................................................................. 4-50

Test Plug .............................................................................................................................................. 4-51

Figures

Figure 4-1. Panel Cutting/Drilling, Semi-Flush, M1 Case .......................................................................... 4-2

Figure 4-2. M1 Case Dimensions, Rear View, Double Ended, Semi-Flush Mount ................................... 4-3

Figure 4-3. M1 Case Dimensions, Side View, Double Ended, Semi-Flush Mount

Figure 4-4. Panel Cutting/Drilling, Double Ended, Projection Mount, M1 Case

Figure 4-5. M1 Case Dimensions, Rear View, Double Ended, Projection Mount

Figure 4-6. M1 Case Dimensions, Side View, Double Ended, Projection Mount

Figure 4-7. M1 Case Cover Dimensions, Front View

Figure 4-8. Case Terminals: Single-Phase

Figure 4-9. Case Terminals: Three-Phase, Two Input (Sensing Input Type E), Output Option E

Figure 4-10. Case Terminals: Three-Phase, Two Input (Sensing Input Type E), Output Option F

Figure 4-11. Case Terminals: Three-Phase, Three Input (Sensing Input Type G), Output Option E

Figure 4-12. Internal Connections: Single-Phase, Five Input (Sensing Input Type D), Output Option E

Figure 4-13. Internal Connections: Three-Phase, Two Input (Sensing Input Type E), Output Option E

Figure 4-14. Internal Connections: Three-Phase, Two Input (Sensing Input Type E), Output Option F

Figure 4-15. Internal Connections: Three-Phase, Three Input (Sensing Input Type G), Output Option E

15

Figure 4-16. Control Circuits: Single-Phase, Output Option E

Figure 4-17. Control Circuits: Three-Phase, Two Input (Sensing Input E), Output Option E

Figure 4-18. Control Circuits: Three-Phase, Two Input (Sensing Input E), Output Option F

Figure 4-19. Control Circuits: Three-Phase, Three Input (Sensing Input G), Output E

Figure 4-20. Side View of Cradle Assembly

Figure 4-21. Unused Input-Disabling Jumpers, Analog #1 Board: Option 1-0

Figure 4-22. Unused Input-Disabling Jumpers, Analog #1 Board: Option 1-1

Figure 4-23. Typical Single-Phase Sensing Connections

Figure 4-24. Single-Phase Connections, Delta-Wye Configuration ........................................................ 4-21

Figure 4-25. Single-Phase Connections, Wye-Wye Configuration

Figure 4-26. Single-Phase Connections, Delta-Delta-Wye Configuration

Figure 4-27. Single-Phase Connections, Delta-Wye Configuration With Two Load Busses

Figure 4-28. 30° Phase Shift Compensation Jumpers

. 4-

................................... 4-4

........................................ 4-5

..................................... 4-6

...................................... 4-7

................................................................................ 4-8

............................................................................................... 4-9

.......... 4-10

........ 4-10

..... 4-11

4-12

4-13

4-14

................................................................ 4-15

.................. 4-16

.................. 4-16

.......................... 4-17

............................................................................................ 4-18

........................................ 4-19

........................................ 4-19

....................................................................... 4-21

......................................................... 4-22

............................................... 4-23

.................. 4-24

............................................................................ 4-26

9171300990 Rev V BE1-87T Installation i

Page 42

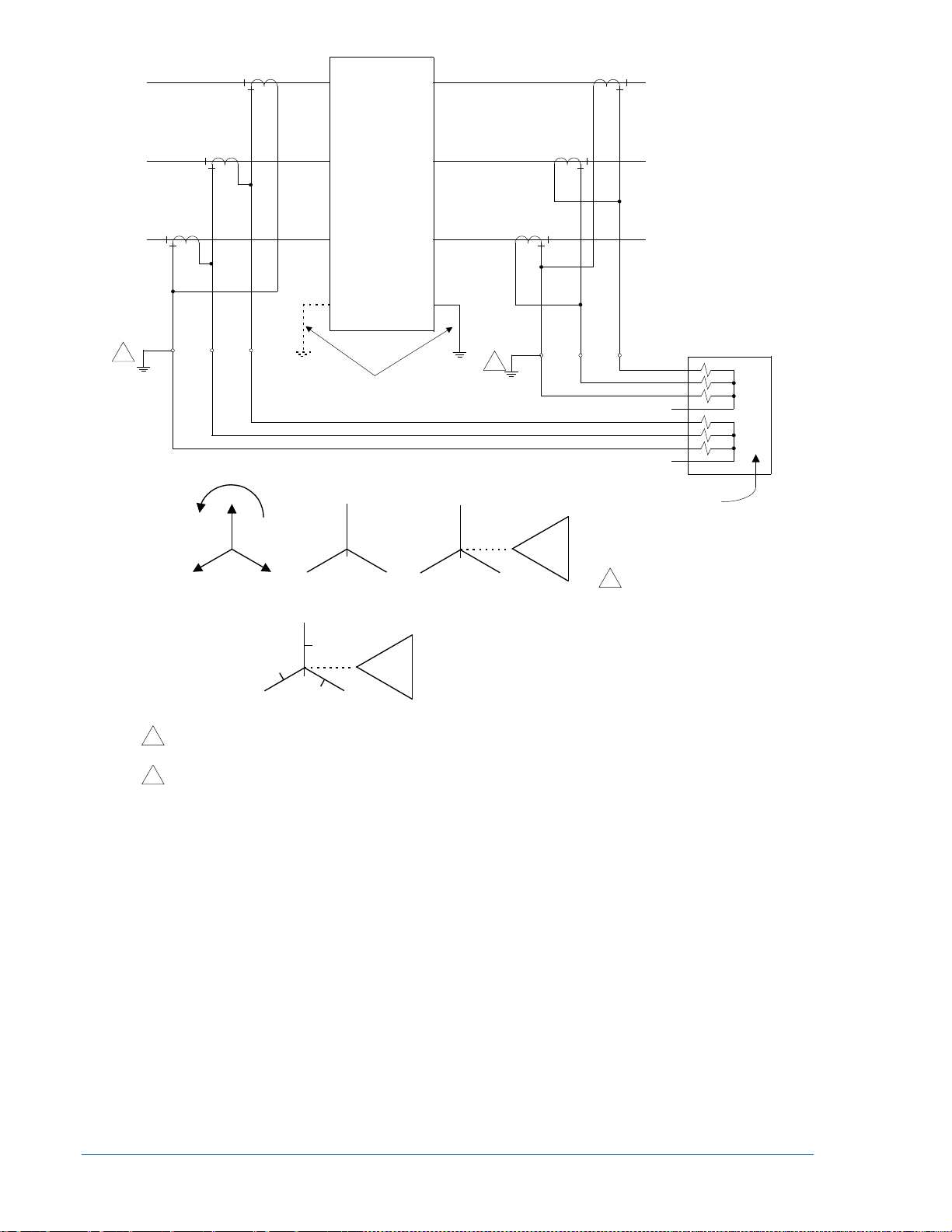

Figure 4-29. Three-Phase Connections, Delta-Wye Configuration, CT Compensation .......................... 4-27

Figure 4-30. Three-Phase Connections, Delta-Wye Configuration, Internal Phase Compensation

Figure 4-31. Three-Phase Connections, Wye-Delta Configuration, Internal Phase Compensation

Figure 4-32. Three-Phase Connections, Delta-Delta Configuration

Figure 4-33. Three-Phase Connections, Wye-Wye or Autotransformer Configuration, CT Compensation

30

Figure 4-34. Three-Phase Connections, Wye-Wye or Autotransformer Configuration, Internal Phase

Compensation

Figure 4-35. Three-Phase Connections, Autotransformer With Loaded Delta Tertiary

Figure 4-36. Application Example: Autotransformer With Tertiary Winding

Figure 4-37. Slope Needed to Accommodate Total Mismatch with Adequate Margin

Figure 4-38. Two Winding Transformer Relay Setting Calculation Example

4-

Tables

Table 4-1. List of Variables ...................................................................................................................... 4-34

Table 4-2. Examples of Suitable Slope Settings

Table 4-3. Single-Phase Input Terminals

Table 4-4. Input Conditions For Non-Trip Three-Phase Sensing

....... 4-27

....... 4-28

........................................................ 4-29

.......................................................................................................................................... 4-31

.......................... 4-32

............................................ 4-35

............................ 4-40

.......................................... 4-42

..................................................................................... 4-41

................................................................................................ 4-49

............................................................ 4-50

ii BE1-87T Installation 9171300990 Rev V

Page 43

SECTION 4 • INSTALLATION

General

When not shipped as part of a control or a switchgear panel, the relay is shipped in a sturdy carton to

prevent damage during transit. Immediately upon receipt of a relay, check the model and Style Number

against the requisition and packing list to see that they agree. Visually inspect the relay for damage that

may have occurred during shipment. If there is evidence of damage, immediately file a claim with the

carrier and notify the Regional Sales Office, or contact a sales representative at Basler Electric, Highland,

Illinois.

In the event the relay is not to be installed immediately, store the relay in its original shipping carton in a

moisture- and dust-free environment. For more information, see Storage in Section 4. When the relay is to

be placed in service, it is recommended that the Verification Tests, shown in Section 5, be performed

prior to installation.

Relay Operating Precautions

Before installation or operation of the relay, note the following precautions.

1. A minimum of 0.2 A in the output circuit is required to ensure operation of current-operated

targets.

2. The relay is a solid-state device and has been type tested in accordance with the requirements

defined under Dielectric Test. If a wiring insulation test is required on the panel assembly in

which the relay is to be installed, it is suggested that the connection plugs (or paddles) of the

relay be removed and the cradle withdrawn from the case so as not to produce false readings

during the wiring insulation test.

3. When the connection plugs are removed, the relay is disconnected from the operating circuit

and will not provide system protection. Always be sure that external operating (monitored)

conditions are stable before removing a relay for inspection, testing, or servicing. Be sure that

connection plugs are in place before replacing the front cover.

CAUTION

To prevent possible false tripping, the upper connection plug should be in

place prior to removing or installing the lower connection plug.

4. Thumbwheel switches should not be changed while the relay is in service. Momentary

undesired indications and outputs may occur.

WARNING!

The TEST PROCEDURES require familiarity with solid-state relay circuits. To

avoid personal injury or equipment damage, do not proceed unless qualified in

this area.

NOTE

Several procedures in this manual require the removal of printed circuit

boards. Refer to the topic Relay Disassembly before installing the BE1-87T.

9171300990 Rev V BE1-87T Installation 4-1

Page 44

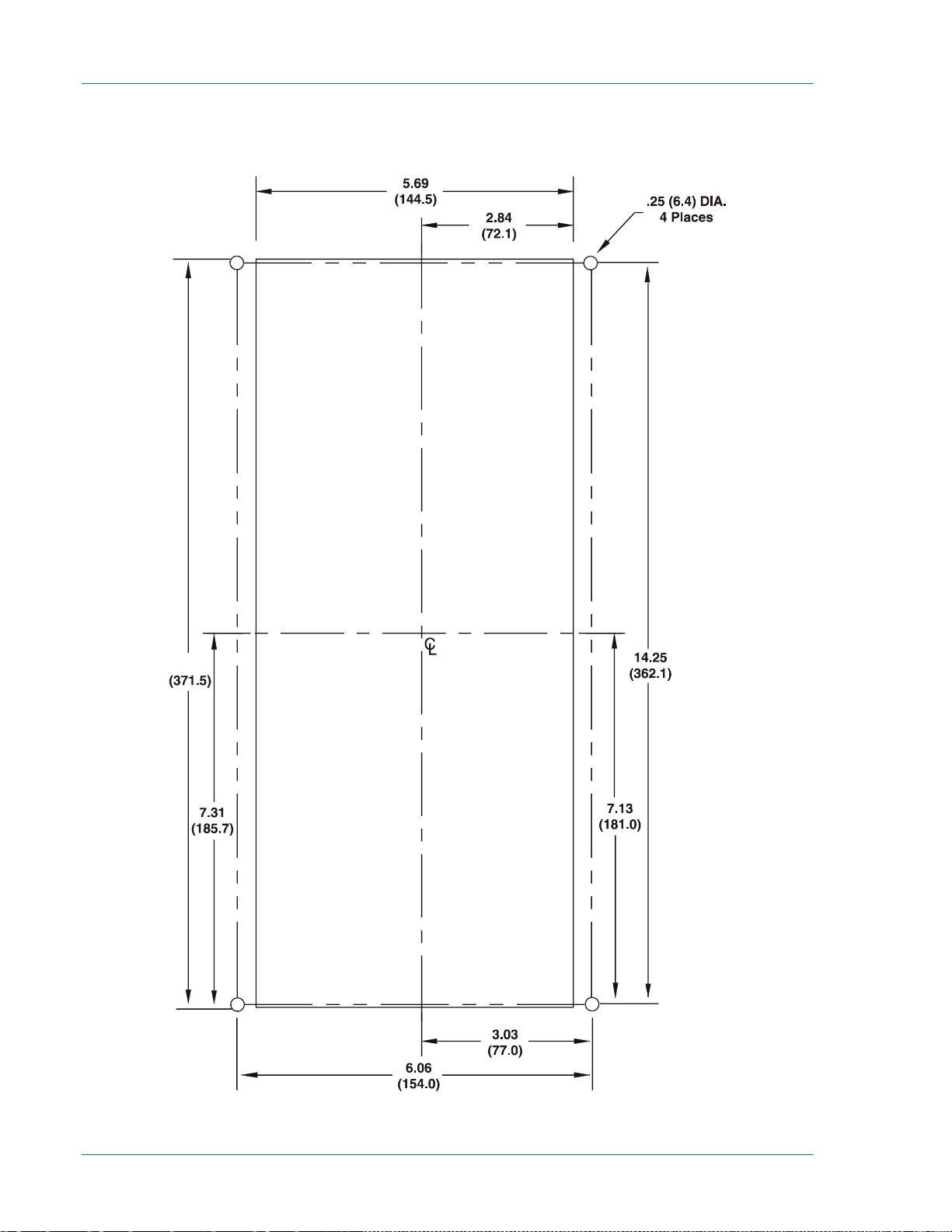

Mounting

14.63

P0066-74

Because the BE1-87T, Transformer Differential Relay, is of solid-state design. It does not have to be

mounted vertically. Any convenient mounting angle may be chosen. The BE1-87T relay is supplied in a

standard M1 size drawout case and can be either semi-flush or projection mounted (Option 4). Refer to

Figures 4-1 through 4-7 for outline dimensions and panel drilling diagrams.

Figure 4-1. Panel Cutting/Drilling, Semi-Flush, M1 Case

4-2 BE1-87T Installation 9171300990 Rev V

Page 45

Figure 4-2. M1 Case Dimensions, Rear View, Double Ended, Semi-Flush Mount

9171300990 Rev V BE1-87T Installation 4-3

Page 46

P0066-76

10-32 SCREWS

10-32 SCREWS

MOUNTING PANEL

2.195

(55.75)

.31

(7.9)

.31

(7.9)

.75

(19.1)

6.19

(157.2)

1.95

(49.53)

7.03

(178.56)

7.03

(178.56)

Figure 4-3. M1 Case Dimensions, Side View, Double Ended, Semi-Flush Mount

4-4 BE1-87T Installation 9171300990 Rev V

Page 47

Figure 4-4. Panel Cutting/Drilling, Double Ended, Projection Mount, M1 Case

9171300990 Rev V BE1-87T Installation 4-5

Page 48

Figure 4-5. M1 Case Dimensions, Rear View, Double Ended, Projection Mount

4-6 BE1-87T Installation 9171300990 Rev V

Page 49

P0066-78

10-32 SCREWS

10-32 SCREWS

2.195

(55.75)

.31

(7.9)

.31

(7.9)

.75

(19.1)

6.19

(157.2)

1.95

(49.53)

7.03

(178.56)

7.03

(178.56)

TERMINAL EXTENTION (TYP.)

FOR DETAILED INSTRUCTIONS,

SEE THE TERMINAL PROJECTION

MOUNTING KIT SUPPLIED.

.25

(6.4)

5/16-18 STUD

2 PLACES

MOUNTING PANEL

Figure 4-6. M1 Case Dimensions, Side View, Double Ended, Projection Mount

9171300990 Rev V BE1-87T Installation 4-7

Page 50

P0066-79

Figure 4-7. M1 Case Cover Dimensions, Front View

4-8 BE1-87T Installation 9171300990 Rev V

Page 51

Dielectric Test

In accordance with IEC 255-5 and ANSI/IEEE C37.90-1989, one minute dielectric (high potential) tests

may be performed as follows.

• All circuits to ground: 2,121 Vdc

• Input to output circuits 1,500 Vac or 2,121 Vdc

Note that this device employs decoupling capacitors to ground at all the output terminals, and at the

power supply terminals (3, 4). Accordingly, a leakage current of approximately 15 milliamperes per 1000

Vac is to be expected.

Connections

Incorrect wiring may result in damage to the relay. Be sure to check the model and Style Number against

the options listed in the Style Number Identification Chart (Figure 1-1) before connecting and energizing a

particular relay.

NOTE

Be sure the relay case is hard-wired to earth ground with no smaller than 12

AWG copper wire attached to the ground terminal on the rear of the relay