Page 1

INSTRUCTION MANUA L

ITEM NUMBER: BE1-87B-S5AA1YN0N0F

CURRENT SENSING: 1A/5A, 50/60Hz

POWER SUPPLY: 125/250V AC/DC

SERIAL NUMBER: H0015870 REV A

BE1-87B

Voltage CurrentVoltage

CT OV

40%

20%

30%

60%

Alarm

10%

50%

70%

80%

Reset

Pickup

250

Pickup

200

50

100

150

350

400

300

1.00

.25

2.50

1.75

Tri p

Test

Power

Relay

Bus

Differential

Tri p

D2853-1

12-19-00

®

minute

Test

one

Press

CT

FOR

BUS DIFFERENTIAL REL AY

BE1-87B

Publication: 9282300990

Revision: P 10/14

Page 2

Page 3

INTRODUCTION

sensing circuit creates a low

This instruction manual provides information about the operation and installation of the BE1-87B Bus

Differential Relay. To accomplish this, the following information is provided:

• General Information and Specifications

• Controls and Indicators

• Functional Description

• Installation

• Testing

WARNING!

To avoid personal injury or equipment damage, only qualified personnel should

perform the procedures in this manual.

The paddle plugs should be removed prior to performing a current circuit

insulation test. The design of the voltageresistance path to gro und when the pad dle p lugs ar e insta lled, w hich res ults i n

incorrect test results.

NOTE

Be sure that the BE1-87B is hard-wire d to earth ground with no smaller t han

12 AWG copper wire attac hed to the ground terminal on the rear of the unit

case. When the BE1-87B is configured in a system with other devices, it is

recommended to use a separate lead to the ground bus from each unit.

9282300990 Rev P BE1-87B Introduction i

Page 4

First Printing: June 1999

WARNING

Basler Electric does not assume any responsibility to compliance or noncompliance with national code,

understood prior to installation, operation, or maintenance.

For terms of service relating to this product and software, see the Commercial Terms of Products and

Services document available at www.basler.com/terms.

This publication contains confidential information of Basler Electric Company, an Illinois corporation. It

procedures, contact Basler Electric for the latest revision of this manual.

The English-language version of this manual serves as the only approved manual version.

Printed in USA

© 2014 Basler Electric, Highland Illinois 62249 USA

All Rights Reserved

October 2014

READ THIS MANUAL. Read this manual before installing, operating, or maintaining the BE1-87B.

Note all warnings, cautions, and notes in this manual as well as on the product. Keep this manual with

the product for reference. Only qualified personnel should install, operate, or service this system.

Failure to follow warning and cautionary labels may result in personal injury or property damage.

Exercise caution at all times.

local code, or any other applicable code. This manual serves as reference material that must be well

is loaned for confidential use, subject to return on request, and with the mutual understanding that it will

not be used in any manner detrimental to the interests of Basler Electric Company and used strictly for

the purpose intended.

It is not the intention of this manual to cover all details and variations in equipment, nor does this

manual provide data for every possible contingency regarding installation or operation. The availability

and design of all features and options are subject to modification without notice. Over time,

improvements and revisions may be made to this publication. Before performing any of the following

BASLER ELECTRIC

12570 STATE ROUTE 143

HIGHLAND IL 62249 USA

http://www.basler.com, info@basler.com

PHONE +1 618.654.2341 FAX +1 618.654.2351

ii BE1-87B Introduction 9282300990 Rev P

Page 5

REVISION HISTORY

Revision and Date

Trip Test

General Information,

paragraphs in Section 2,

and added

The following inform ation provides a h istorical summary of th e changes made to this instruction manual

(9282300990) and hardware of the BE1-87B. Revisions are listed in reverse chronological order.

Manual

P, 10/14

O

N, 02/12

M, 01/09

L, 02/07

K, 11/06

J, 07/05

I

H, 06/05

G, 10/03

F, 01/03

Change

• Corrected output contacts specifications in Section 1.

• Added description of hold timer in Section 2.

• Improved Figures 4-1 and 4-8.

• This revision letter not used.

• Moved Input Impedance table from Section 3 to Section 1.

• Simplified note under Table 2-7.

• Standardized case and cover drawings in Section 4.

• Added information about why it is necessary to press the

Pushbutton for up to one minute in Sections 2 and 3.

• Added chassis ground symbol on the ground terminal in Figure 4-10.

• Corrected terminals 15 & 16 numbering in Figures 4-16 and 4-17.

• Added Storage statement in Section 4.

• Minor text edits throug hou t manu al.

• Updated Intentional Delay Jumper instructions on pages 2-11 and 3-5.

• Added option “R” mounting type to Style Number.

• Updated Output Contact ratings in Section 1.

• Added 19” Horizontal Rack-Mount Front and Side views to Section 4,

Installation.

• Added GOST-R certification to Section 1,

Specifications.

• Improved Figure 2-7.

• This revision letter not used.

• Added Two Different Ratio CTs paragraph to Section 2, Application.

• Added information to Internal Faults

Application.

• Improved Figure 2-7.

• Clarified wording of timing specification in Section 1, General

Information, and remove d Figur e 1-3.

• Reworded first paragraph of Sec tion 2, Application, and last paragraph

of Sample Calculation sub-section.

• Removed the polarity mar ks from terminals 15 and 16 of Figures 4-14

and 4-15.

• Information was added to Section 2, Application.

• Moved CT circuit testing information from Section 3, Human-Machine

Interface to Section 5, Testing.

• Moved illustration of Figure 3-3 to Section 4, Installation

terminal designations

• Added metric equivalen ts and mounting depth dimension to F igure 3-4

and moved illustration to Section 4, Installation.

• Corrected various minor errors throughout the manual.

9282300990 Rev P BE1-87B Introduction iii

Page 6

Manual

Revision and Date

E, 10/01

D, 03/01

C, 04/00

B, 11/99

A, 08/99

—, 06/99

Change

• Corrected the terminal numbering in Figure 2-5.

• Changed the Power Supply Status Contacts label to Relay Trouble

Contacts in Figures 4-13 and 4-14.

• Corrected various minor errors throughout the manual.

• Updated drawings, as required, to reflect changes to the cases and

overlays as a result of “pillow-type” switch implementation for CT Test

pushbutton.

• Updated the style chart with front cover with CT test access option.

• Section 1: Added UL recognition to specifications. Changed voltage

rating specification from “75% of tap setting” to “300 Vac for 1 hour”.

• Section 2: Corrected equation reference under Sample Calculation.

• Section 4: Revised F igures 4-1 and 4-2 to show proper position o f the

Reset button access on the S1 case.

• Changed all power supply status referenc es from “Relay Trouble Alarm”

to “Power Supply Status”.

• Added and updated drawings throughout the manual to accommodate

the three-phase version of the BE1-87B.

• Corrected various errors in the illustrations.

• Initial release

Hardware

Version

T

S

R

Q

P

O

N

M

L

K

J

H

G

F

E

D

C

B

Change

• Improved snubber resistor and SCR protection circuit.

• Updated internal documentation.

• Improved ribbon cable.

• This revision letter not used .

• Improved reset switch on front panel.

• This revision letter not used.

• Improved factory assembly process.

• Improved snubber circuitry to prevent false tripping.

• Internal factory documentation updated.

• Improved power supply board.

• Improved stability of Relay Trouble output contacts during power-

up/power-down.

• Not released to production.

• Corrected labeling for CR1 and CR3 polarity on the SCR circuit board.

• Improved relay stability during cycling of operating power.

• CT Test pushbutton chang ed t o “pi llow -type” switch. Optional cas e cov er

with CT Test pushbutton access introduced.

• Improved immunity to ESD.

• Applied Revision A e nhanc ements to thr ee-phas e re lays with new c ircu it

board design.

• New circuit board design released for single-phase relays.

iv BE1-87B Introduction 9282300990 Rev P

Page 7

Hardware

Version

A

—

• Enhanced temperature stability and SWC immunity in single-phase

• Initial release

Change

relays.

9282300990 Rev P BE1-87B Introduction v

Page 8

vi BE1-87B Introduction 9282300990 Rev P

Page 9

CONTENTS

SECTION 1 • GENERAL INFORMATION ................................................................................................ 1-1

SECTION 2 • APPLICATION .................................................................................................................... 2-1

SECTION 3 • HUMAN-MACHINE INTERFACE ....................................................................................... 3-1

SECTION 4 • INSTALLATION .................................................................................................................. 4-1

SECTION 5 • TESTING ............................................................................................................................ 5-1

9282300990 Rev P BE1-87B Introduction vii

Page 10

viii BE1-87B Introduction 9282300990 Rev P

Page 11

SECTION 1 • GENERAL INFORMATION

TABLE OF CONTENTS

SECTION 1 • GENERAL INFORMATION ................................................................................................ 1-1

General .................................................................................................................................................. 1-1

Features ................................................................................................................................................. 1-1

Standard Features .............................................................................................................................. 1-1

Model and Style Number ....................................................................................................................... 1-1

Style Number Example ....................................................................................................................... 1-2

Specifications ......................................................................................................................................... 1-2

Current and Voltage Settings ............................................................................................................. 1-3

Frequency .......................................................................................................................................... 1-3

Pickup Accuracy ................................................................................................................................. 1-3

Output Contacts ................................................................................................................................. 1-3

Current Rating .................................................................................................................................... 1-3

Voltage Rating .................................................................................................................................... 1-3

Targets ............................................................................................................................................... 1-3

Isolation .............................................................................................................................................. 1-3

Surge Withstand Capability (SWC) .................................................................................................... 1-4

Impulse Test ....................................................................................................................................... 1-4

Radio Frequency Interference ............................................................................................................ 1-4

Electrostatic Discharge (ESD) ............................................................................................................ 1-4

UL Recognition ................................................................................................................................... 1-4

GOST-R Certification ......................................................................................................................... 1-4

Environment ....................................................................................................................................... 1-4

Shock.................................................................................................................................................. 1-4

Vibration ............................................................................................................................................. 1-4

Weight ................................................................................................................................................ 1-4

Case Size ........................................................................................................................................... 1-4

Figures

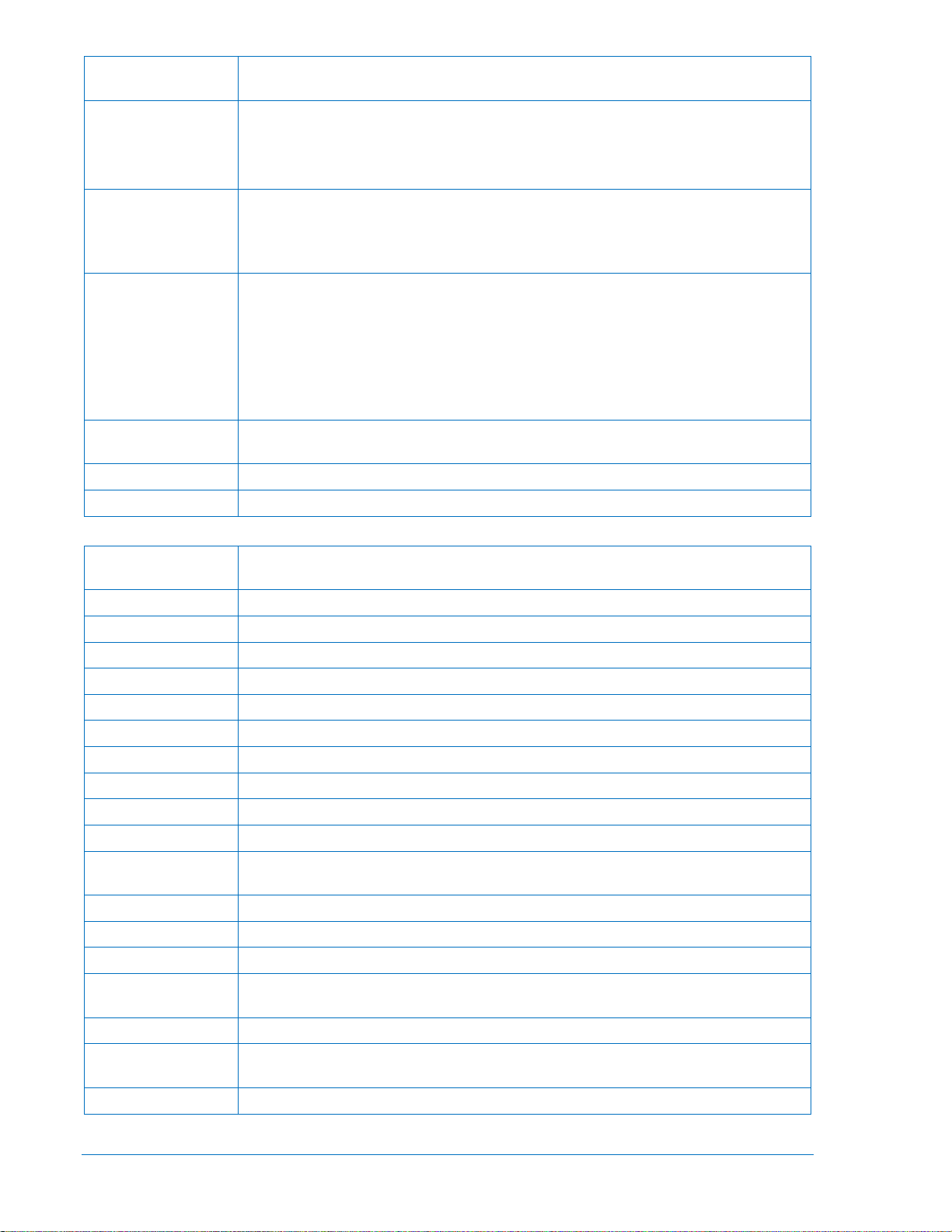

Figure 1-1. BE1-87B Style Chart ............................................................................................................... 1-1

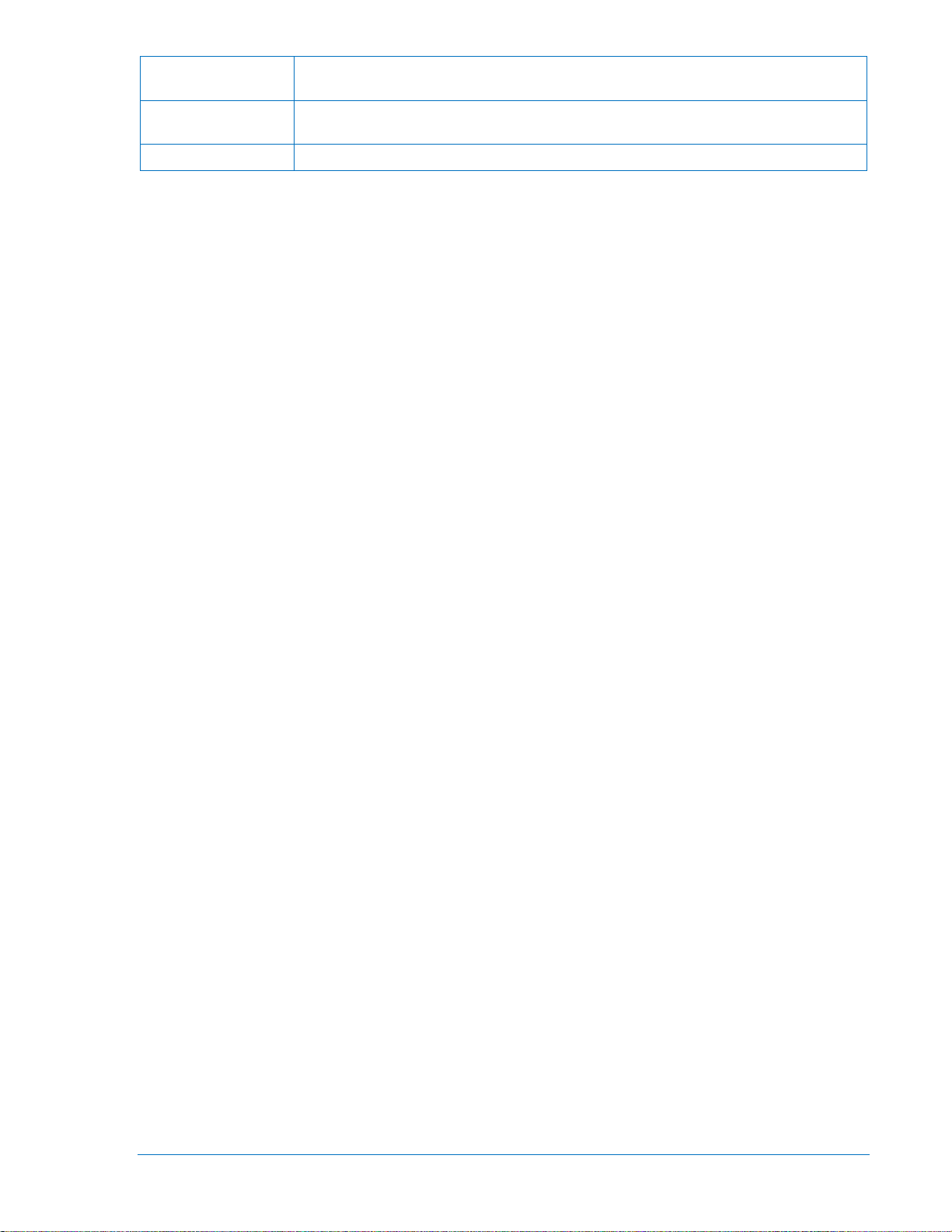

Figure 1-2. Typical Pickup Current Response Time without a Trip Delay................................................. 1-2

Tables

Table 1-1. BE1-87B Power Sup ply Spec i ficat ions .................................................................................... 1-2

Table 1-2. Input Impedance While Triggered and Not Triggered .............................................................. 1-3

9282300990 Rev P BE1-87B Application i

Page 12

ii BE1-87B Application 9282300990 Rev P

Page 13

SECTION 1 • GENERAL INFORMATION

General

The BE1-87B is a high-speed, high-impedance, soli d-state differential re lay. It was designed spec ifically

for bus differentia l pro tec ti o n. B ec ause of the relay’s high imp eda nc e, it c an be used in other applica tio ns ,

such as the protection of shunt reactors. Con tact your local Bas ler Applications Eng ineer for information

about additional applications.

Features

The BE1-87B offers high-speed fault protection, wh ich may be applie d to individual ele ments or zones of

ac power systems. It op erates in less than 7 mil liseconds for fault levels of 1.5 times the curren t pickup

and less than 5.5 milliseconds for fault levels above six times the current pickup. This high-speed

operation minimizes pot ential damage to the protect ed equipment. Response c haracteristics for sensin g

input ranges one and two are shown in Section 5, Testing.

Standard Features

Available in single-phase or three-phase models

• S1 and M1 double ended drawout cases and 19” rack-mount

• Percent of pickup voltage alarm

• Differential logic test

• LED trip output indicators

• Power supply status

• Ten position incremental adjust for the voltage and current pickup settings

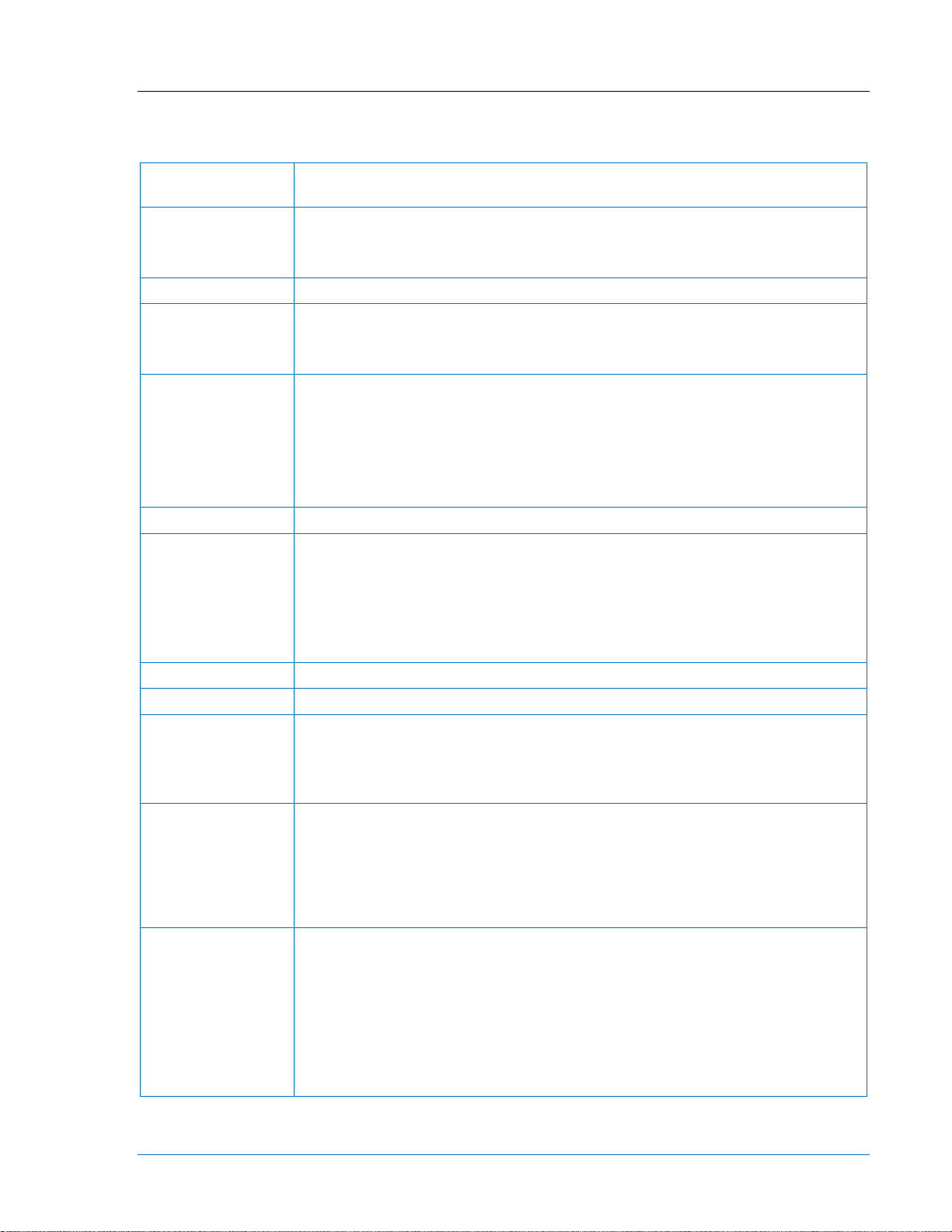

Model and Style Number

The electrical characteristics and operational features included in a specific relay are defined by a

combination of letters and numbers, which constitutes the device’s style number. The style number

together with the model nu mber describ es the feature s and options in a particu lar device and a ppears on

the front panel as the item number. They also appear in the drawout cradle, and inside the case

assembly. The model number BE1-87B designates the relay as a Basler Electric Class 100, highimpedance bus differential relay. The style chart is shown in Figure 1-1.

Figure 1-1. BE1-87B Style Chart

9282300990 Rev P BE1-87B Application 1-1

Page 14

Style Number Example

The style number identif ication ch art defines th e electric al character istics and operation feat ures incl uded

in the BE1-87B relay. For ex ample, if the style num ber were BE1-87B S 5AA1YN0N0F, the dev ice would

have the following:

BE1-87B

S.......... Single-phase current sensing

5 .......... 5 ampere current sensing input range

A ......... Front case cover with CT test button access

A1 ....... Instantaneous timing

Y.......... 48/125 Vac/Vdc power supply

N ......... No Option

N ......... No Option

N ......... No Option

0 .......... No Option

F .......... Semi-flush case mounting

Specifications

Timing

A maximum of seven milliseconds at 1.5 times the pickup setting.

A maximum of 5.5 milliseconds above six times the pickup setting.

Figure 1-2 illustrates typical response times.

Figure 1-2. Typical Pickup Current Response Time without a Trip Delay

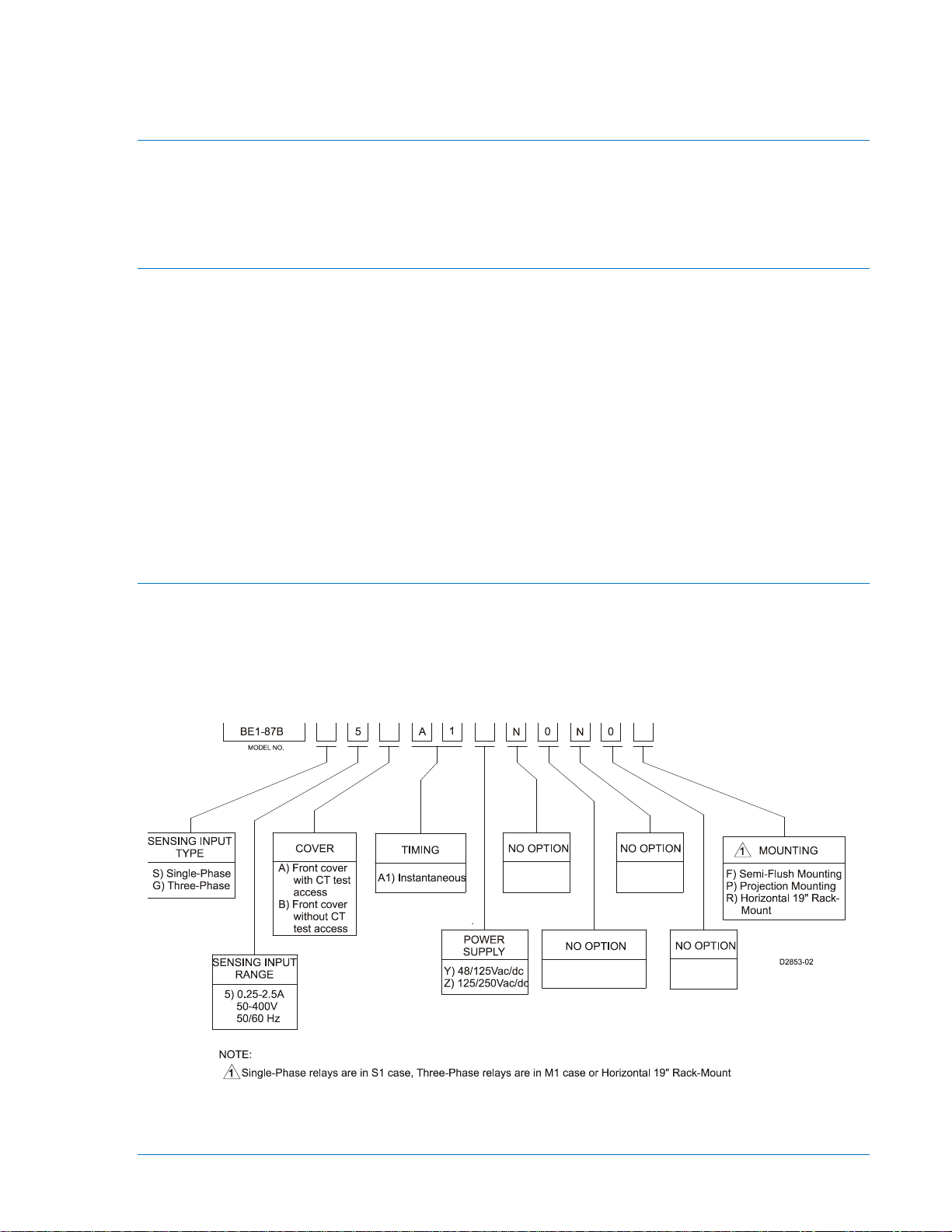

Power Supply

Power for the internal circuitry may be obtained from either an ac or a dc external power source as

indicated in Table 1-1.

Table 1-1. BE1-87B Power Supply Spec i fications

Type

Y 48/125 Vdc

Z 125/250 Vdc

1-2 BE1-87B Application 9282300990 Rev P

Nominal Input

Voltage

110Vac

110/230Vac

Input Voltage

Range

24 to 150 Vdc

90 to 132 Vac

60 to 250 Vdc

90 to 230 Vac

Burden at Nominal

(Maximum)

7.5 W

15.0 VA

7.5 W

20.0 VA

Page 15

Current and Voltage Settings

Voltage Alarm Pickup ............................. 10 to 80% in 10% increments

Voltage Pickup ........................................ 50 to 400 V in 50 V increments

Current Pickup ........................................ 0.25 to 2.5 A in 0.25 A increments

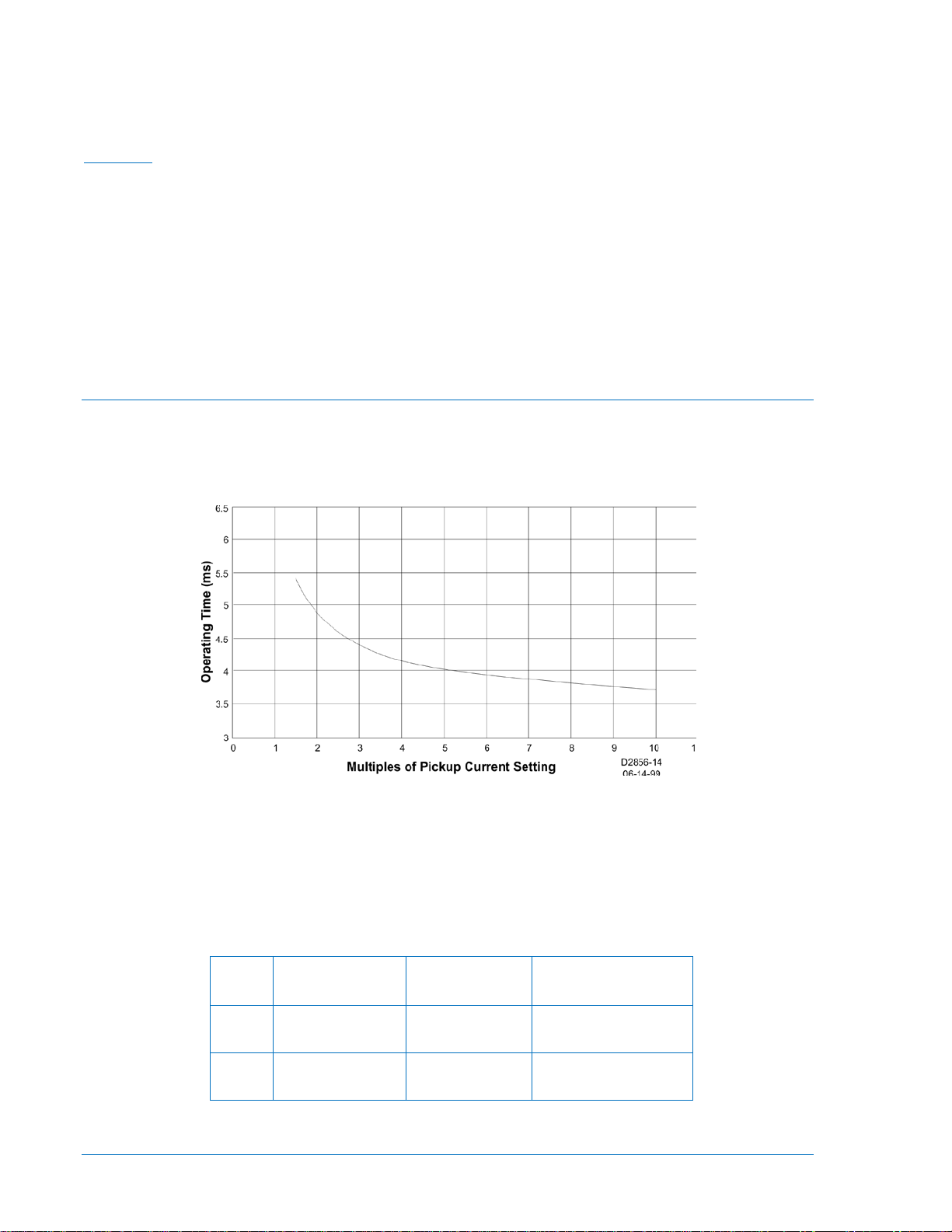

Table 1-2 describes input impedance w hile the SCRs are triggered (low impedance) and while the SCRs

are not triggered (high impedance).

Table 1-2. Input Impedance While Triggered and Not Triggered

Impedance State

Low Impedance (SCRs Triggered, Current Circuit Active) 0.05 0.05

High Impedance (SCRs Not Triggered, Voltage Circuit Active)

Input Impedance in Ohms

60 Hz Nominal 50 Hz Nominal

4000 - j3300

5100 ∠ –40°

4500 - j3100

5500 ∠ –35°

Frequency

Nominal 50 or 60 Hz, ± 5 Hz

Pickup Accuracy

±5% of the setting over the operating ranges for both current and voltage. Pickup accuracy over the ±5 Hz

nominal frequency variation is within ±8% of the nominal frequency value.

Output Contacts

Output contacts are rated as follows.

Resistive

120/240 Vac ............................................ Make and carry 30 Adc for 0.2 s , c arr y 7 Adc c ont in uo us ly, br eak

7 Aac

125/250 Vdc ............................................ Make and carry 30 Adc for 0.2 s, c ar ry 7 Adc continuously, break

0.3 Adc

Inductive

120 Vac, 240 Vac, 125 Vdc, 250 Vdc ..... Break 0.1 A (L/R = 0.04)

Current Rating

Continuous .............................................. 10 A rms

1 second, symmetrical ............................ 160 A rms

5 cycles, symmetrical ............................. 480 A rms

2 cycles, fully offset ................................ 215 A

Voltage Rating

The nature of the BE1-87B relay’s application is that voltage is not applied continuously. For calibration

and test purposes, it may be of value to apply input voltage for a longer duration than the few milliseconds

that would typify an internal or external power system fault. For test and calibration purposes, the BE187B has been designed to withstand 300 Vac for a maximum duration of 60 minutes.

Targets

LED indication (Trip LED) is latched with an internal, mechanical latching relay. Reset is accomplished by

pressing the Reset button on the front panel.

Isolation

In accordance with IEC 255-5 and IEEE C37.90, one-minute dielectric (high potential) tests were

performed as follows.

All circuits to ground ............................... 2000 Vac or 2828 Vdc

Each circuit to all other circuits ............... 2000 Vac or 2828 Vdc.

9282300990 Rev P BE1-87B Application 1-3

Page 16

Surge Withstand Capability (SWC)

Oscillatory and Fast Transient ................ Qualified to IEEE C37.90.1-1989

Impulse Test

Qualified to IEC 255-5.

Radio Frequency Interference

Maintains proper operation when tested for interference in accordance with IEEE C37.90.2 1995.

Electrostatic Discharge (ESD)

In accordance with IEEE C37.90.3, contact discharges of 8 kilovolts and air discharges of 15 kilovolts

were applied with no misoperation occurring.

UL Recognition

Recognized per Standard 508, UL File Number E97033.

Note that output contacts are not UL recognized for voltages greater than 250 V.

GOST-R Certification

GOST-R certified per the relevant standards of Gosstandart of Russia.

Environment

Temperature

Operating Range .................................... −40°C to 70°C (−40°F to 158°F)

Storage Range ........................................ −40°C to 85°C (−40°F to 185°F)

Humidity

Qualified to IEC 68-2-38, First Edition 1974

Shock

Qualified to IEC 255-21-2, Class 1.

Vibration

Qualified to IEC 255-21-1, Class 1.

Weight

1-phase Relay ......................................... 14.3 lb (6.5 kg) maximum

3-phase Relay ......................................... 19.2 lb (8.8 kg) maximum

Case Size

1-phase Relay ......................................... S1

3-phase Relay ......................................... M1 or 19” Rack-Mount

Case dimensions are provided in Section 4, Installation.

1-4 BE1-87B Application 9282300990 Rev P

Page 17

SECTION 2 • APPLICATION

TABLE OF CONTENTS

SECTION 2 • APPLICATION .................................................................................................................... 2-1

Application.............................................................................................................................................. 2-1

Application with Lightning Arr es ters ................................................................................................... 2-1

Application with a Lockout Function ................................................................................................... 2-1

Current Source for High Impedance Differential Relaying ................................................................. 2-1

BE1-87B Flexibility ................................................................................................................................. 2-2

Bus Protection Application ................................................................................................................. 2-2

Shunt Reactor Protection Application ................................................................................................ 2-4

Mixing Two Different Ratio CTs ......................................................................................................... 2-5

General Settings Guidelines .............................................................................................................. 2-5

Operating Principles ............................................................................................................................... 2-5

External Faults ................................................................................................................................... 2-6

Internal Faults ..................................................................................................................................... 2-7

Characteristics ..................................................................................................................................... 2-10

Differential Voltage Pickup ............................................................................................................... 2-10

Differential Pickup Current ............................................................................................................... 2-10

Alarm Voltage Pickup ....................................................................................................................... 2-10

Trip Test Pushbutton ........................................................................................................................ 2-11

CT Test Pushbutton ......................................................................................................................... 2-11

Power LED ....................................................................................................................................... 2-11

Intentional Delay Jumper.................................................................................................................. 2-11

Operating Times ............................................................................................................................... 2-11

Calculation of Settings ......................................................................................................................... 2-12

Calculation of Voltage Differentia l Sett in gs ...................................................................................... 2-12

Bus Protection .................................................................................................................................. 2-13

Shunt Reactor Protection ................................................................................................................. 2-13

Application with Mixed Multi-Ratio CTs ............................................................................................ 2-13

Current Element Setting ................................................................................................................... 2-14

Minimum Fault to Trip (Voltage Element) ......................................................................................... 2-14

Sample Calculation .............................................................................................................................. 2-15

CT Test Circuit Calculations ................................................................................................................ 2-16

General ............................................................................................................................................. 2-16

Definition of Terms ........................................................................................................................... 2-16

Calculation Steps ............................................................................................................................. 2-17

Example Calculation ......................................................................................................................... 2-17

Figures

Figure 2-1. External AC Connections for Bus Protec t io n .......................................................................... 2-3

Figure 2-2. External DC Connections for Bus Prot ection .......................................................................... 2-4

Figure 2-3. External AC Connections for Shunt Reactor Protection, Multi-Phase and Line-to-Ground

Faults ......................................................................................................................................................... 2-4

Figure 2-4. External AC Connections for Shunt Reactor Protection, Ground Faults ................................ 2-5

Figure 2-5. Illustration of Single Line-to-Ground Fault at Location F1 ...................................................... 2-7

Figure 2-6. Typical Secondary Excitation for 1200/5 Bushing Current Transformer ................................. 2-8

Figure 2-7. Simplified Internal Connection Diagram for BE1-87B Relay ................................................... 2-9

Figure 2-8. Voltage Appearing Acros s Ful l Windi ng of CT ...................................................................... 2-10

Figure 2-9. Voltage Appearing Acros s Ful l Windi ng of CT ...................................................................... 2-17

Figure 2-10. Voltage Appearing Acr os s Full Wind ing of CT .................................................................... 2-18

9282300990 Rev P BE1-87B Application i

Page 18

ii BE1-87B Application 9282300990 Rev P

Page 19

SECTION 2 • APPLICATION

CAUTION

CAUTION

Application

The BE1-87B solid-state, high-speed, high-impedance differential relay is available in single or threephase models. The relay was specifically des igned to provide high-s peed differential protection for high

voltage buses, critical medium, and low voltage buses. Because of its design and sensitivity, the relay can

also be used for shunt reactor protection. While bus schemes require three-phase protection, shunt

reactors may be protected with only one single-ph ase relay for ground faults . Regardless of the scheme

employed or the equipment protected, the following applications apply to the BE1-87B relay.

Application with Lightning Arresters

The BE1-87B is a hig h-speed relay des igned to operate in a half-cycle or less . As a result, apply ing the

relay to a bus wit h lightning arresters must b e addressed. The relay pick up current range is adjustab le

between 0.25 to 2.5 amper es rms. If lightning ar resters will b e connected to the bus, use the 2.5 amper e

sensitivity setting so as to prevent the possibility of a differential operation during a normal arrester

operation. If no light ning arres ters ar e use d, start with t he 0. 5 amp ere sens itivi ty setti ng and adjus t as the

application dictates.

If lightning arresters ar e added to an exis ting bus, as might be the case w hen

adding a transformer, be sure to increase the Pickup Current setting of the

BE1-87B to the 2.5 ampere setting.

Application with a Lockout Function

Contacts from the lockout relay (86) should be connected across terminals 5 and 6 (single-phase or

phase A for 3-phase models), 3 an d 4 (phase B), and 1 an d 2 (phase C) of the BE1-87B relay to shor tcircuit the SCRs in the inpu t circuit after a trip ou tput has been initiated. This al lows the relay to con tinue

operation as a conventiona l overcurrent relay and at t he same time protect agains t exceeding the shorttime rating of the internal SCRs. The relay can be used in any application where the total secondary

current is not more tha n the current waveform of a fully-offset f ault with 215 amperes rms symmetric al

available, provided the lockout relay (86) has an operate time of 1 cycle or less (16 milliseconds).

If the BE1-87B relay co ntrol power (power supply voltage) is removed, relay

terminals 5 and 7 (single-phase model) or 5 and 7, 3 and 7, and 1 and 7

(three-phase model) should be short ed by pull ing the connect ion pl ug. If th is is

not done, the BE1-87B relay c ould b e da mag ed d ue t o c ontin uous f aul t c urr ent

flowing through the relay SCRs.

Current Source for High Impedance Differential Relaying

Predictable current trans former (CT) performanc e is critic al to the eff ective oper ation of a high impeda nce

differential scheme. Where prac tical, t he following current tr ansformer guide lines s hould be appl ied when

using the BE1-87B relay.

• All CTs should be of toroidal design and be fully distributed around the core.

• All CTs should have the same full ratio value and be connected to the full ratio taps.

• All CTs should have the same voltage rating, accuracy class, and thermal rating.

• The CTs should be dedicated to the differential application.

• When adding to an existi ng differenti al scheme, a t lea st one set of CTs in the ne w breaker shou ld be

ordered with the same ratio and accuracy class as the differential CTs used in the existing scheme.

• CTs cannot have pr imary or secondary voltage limiti ng devices, as the resulting shor t-circuit could

cause an unwanted operation of the differential.

9282300990 Rev P BE1-87B Application 2-1

Page 20

BE1-87B Flexibility

Because of the flexible wid e range design of the BE1-87B, it is possible to ap ply the relay in situations

where the current sensin g input circuit is less tha n ideal. It should be noted, however, that th e possibility

of less sensitive settings, equipment overvoltage, or false operation could resu lt. Careful review of the

following application notes is recommended:

• It is possible to use a m ixtu re of mult i-ratio CTs , howe ver, it is essent ial th at the tapped value h as the

same turns ratio as the other para llel CTs in the circuit. When ta ps are selec ted other than f ull ratio,

use the highest available ta p s etting th at w ill a llow all CT s in the sc heme to hav e t he s ame turns r atio .

Tap settings other than full ratio re quire a calculation of the peak vo ltage developed across the full

winding resulting fro m autotransfor mer action. Th e resulting v oltage shou ld not ex ceed the insula tion

breakdown values of the connected equipment. The equation for this calculation is derived in the

paragraph on operating pr inciples in this section and repeated in the paragraphs on Calculation of

Settings.

• All CTs used in the differential circuit should have negligible leakage reactance on the connected

taps. Most, if not all, multi-ratio internal, bushing, and column type CTs made in the last 30 years

meet this requirement. All CTs wound on toroidally shaped cores meet this requirement if the

windings (on the tap used) are com pletely dis tributed around th e core (co nsult y our CT manufacturer

if you have questions). It m ay be pos sible to us e CTs t hat do not me et th is requir ement if the leak age

reactance is known. T he leakage reac tance is added algebraically to t he resistanc e of the CT circui t

in question. Less sensitive protection will occur as a result of a higher pickup setting.

• It may be possible, although not recommended, to use the differential circuit CTs jointly for other

functions as long as an accur ate impedance of the other functi on is known. The performance of the

system under these c onditions can be ca lculated by alge braically adding th e other impedanc e to the

CT winding and cab le resistance. Less sens itive protection will occ ur as a result of a hi gher pickup

setting. Also, considerat ion must be given to the haz ards of false operatio n due to extra connections

and errors in test ing the added devices . To ensure pr oper relay setting, all cable and CT sec ondary

winding resistances should be ev aluated before a decision is made to a dd other devices to th e BE187B CT circuits.

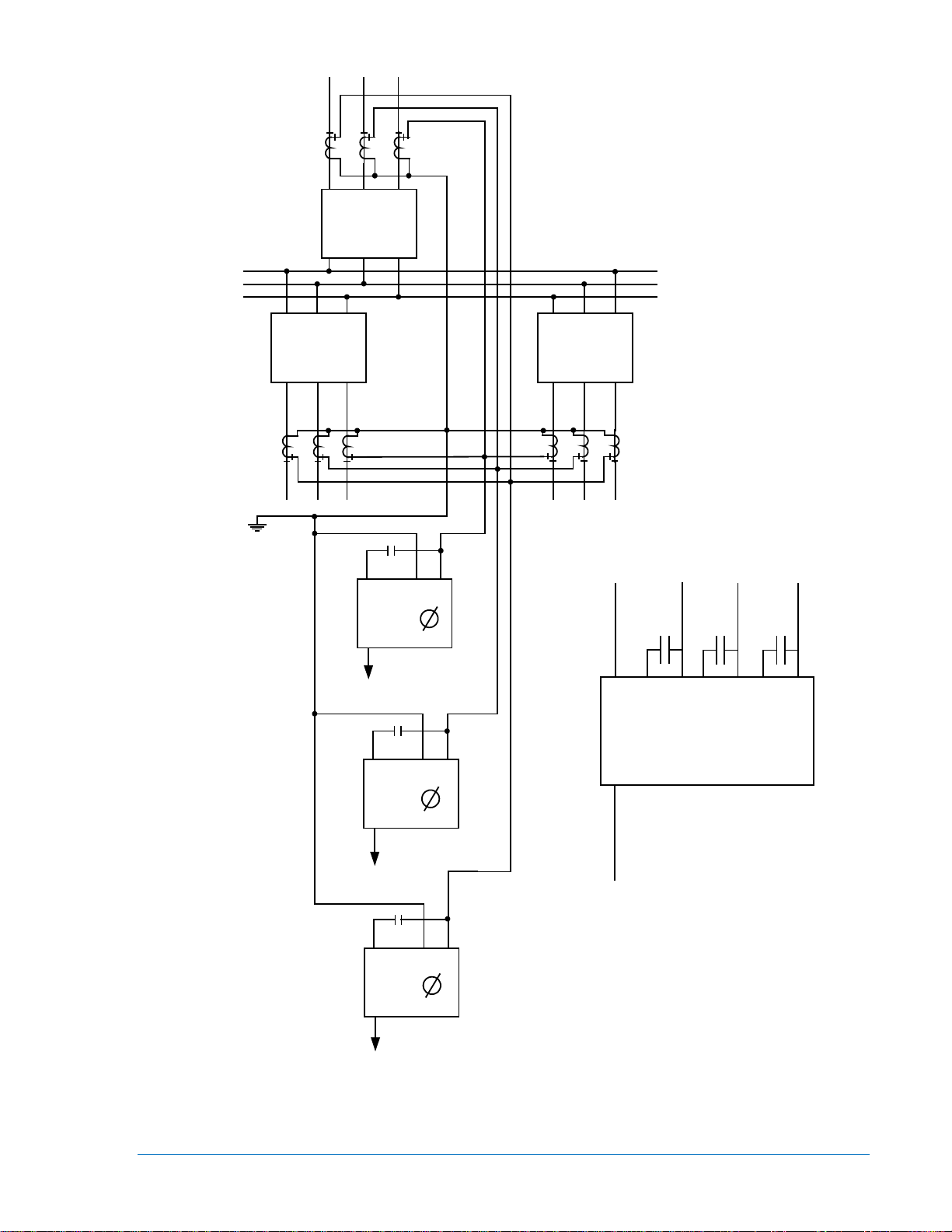

Bus Protection Application

Three single-phase BE1-87 B r elays or one t hree-phase BE1-87B relay and an aux iliar y loc kout relay (86) ,

provide a complete m ulti-p hase and gr ound bus fault protection package. Typical external c onnect ions to

the relays are shown in Figures 2-1 and 2-2. The connections are illustrat ed for a bus w ith three circ uits,

but the protection can easil y be ex tended if more c ircu its are adde d to the bus . For addit ional circ uits, it is

only necessary to connect the CTs associated with the added circuits to the respective junction points and

to connect the contac ts of the lock out relay in the r espective trip c ircuits. The rel ay voltage tap s etting is

based on the maximum voltage that can be developed across the differential junction point during an

external fault. Calc ulation of the max imum voltage is easily made an d methods fo r doing so are giv en in

the paragraph under calculation of settings. A sample calculation for a bus differential scheme is also

provided.

2-2 BE1-87B Application 9282300990 Rev P

Page 21

TO SURGE

GROUND

52-1

52-3

52-2

3 2 1

3

2

1

3

2

1

TO SURGE

GROUND

Single Phase

87B- 1

RELAY HOUSE

GROUND

TO SURGE

GROUND

D2853-3

5-26-99

86

567

86

5

6

7

86

5

6

7

Single Phase

87B- 2

Single Phase

87B- 3

86

86

86

Three Phase

87B Relay

1

23

4

5

6

7

N

1 2 3

Surge

Ground

Figure 2-1. External AC Connections for Bus Pr otection

9282300990 Rev P BE1-87B Application 2-3

Page 22

86 86 86

BLOCK AUTOMATIC

RECLOSING

86

87

86

87

52-1

52-252-1

52-3

52-2

52-3

86 86 86

a

aa

TC

TC

TC

(+)

(-)

D2853-4

5-24-99

87 - BE1-87B BUS DIFFERENTIAL RELAY

86 - LOCKOUT RELAY

15

16

17

18

TRIP 1

OUTPUT

TRIP 2

OUTPUT

19

20

87

13

14

VDIFF

ALARM

11

12

RELAY

TROUBLE

TO 2 AND 3

SINGLE PHASE RELAYS

TO 2 AND 3

SINGLE PHASE RELAYS

BE1 - 87B

86

BE1 - 87B

86

BE1 - 87B

86

1

2

3

01

0203

86 - LOCKOUT RELAY

* TO SURGE GROUND

*

*

*

1

2

3

D2853-5

5-25-99

5

6

7

5

6

7

5

6

7

86

86

86

Three Phase

87B Relay

1

23

4

5

6

7

N

1 2 3

*

Figure 2-2. External DC Connecti ons for Bus Protec t io n

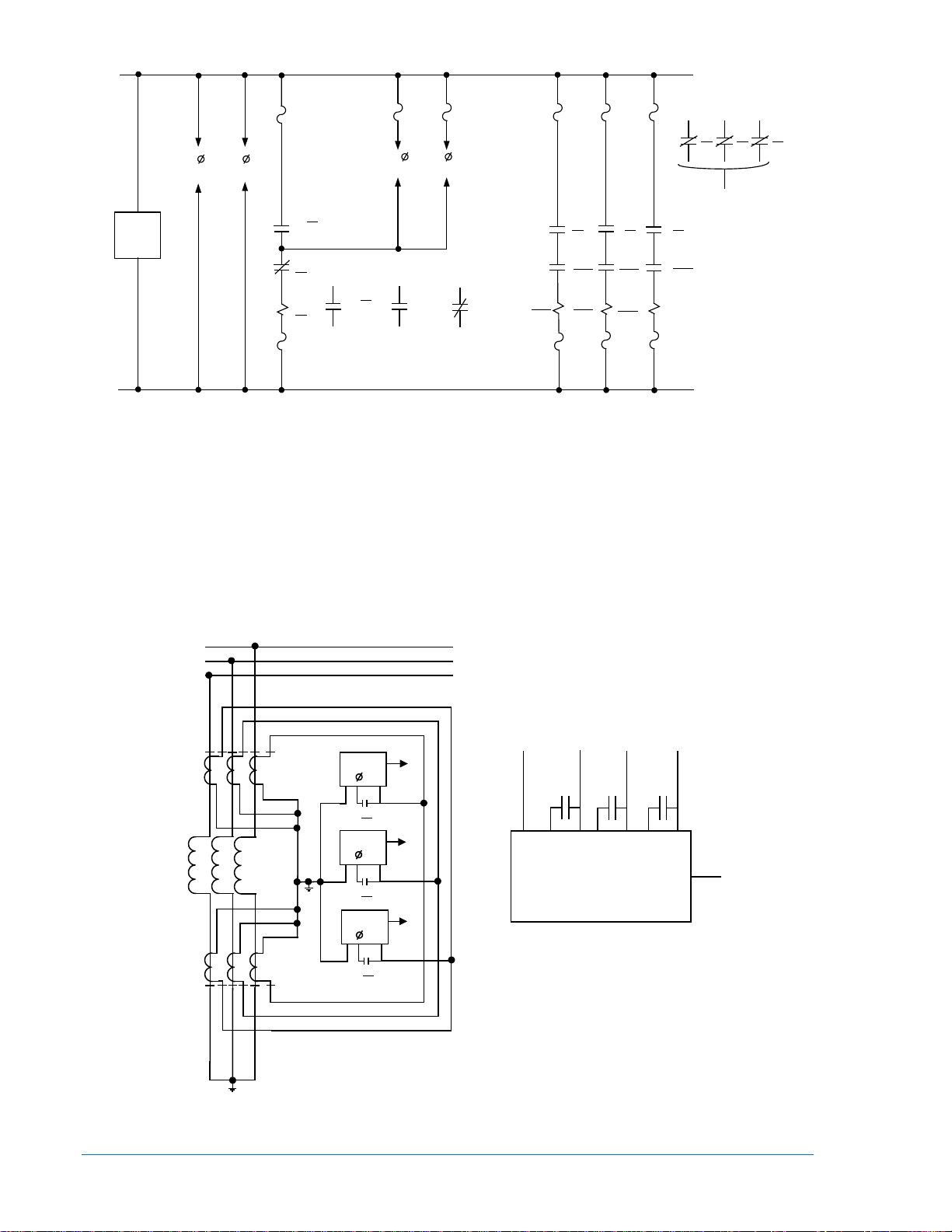

Shunt Reactor Protection Application

Differential protection of s hunt reactors may be pr ovided by using only one sin gle-phase BE1-87B relay ,

three single-phase relays, or one three-phase relay. Typical ac external connec tion diagrams for these

schemes are shown in Figures 2-3 and 2-4. The dc connections will be similar to those show n in Fig ure 2-

2. Only ground fault protection will be provided when one relay is applied. Application of either three-

phase arrangement wi ll provide both multi-phase an d phase-to-gro und fault prote ction. Calcu lation of the

voltage tap setting is basically the same as for the bus app lication. The procedures for calculating the

voltage tap setting for either scheme are provided under Calculation of Settings.

2-4 BE1-87B Application 9282300990 Rev P

Figure 2-3. External AC Connections for Shunt Reactor Protection,

Multi-Phase and Line-to-Ground Faults

Page 23

BE1 - 87B

5

6

7

86

TO SURGE

GROUND

1

2

3

1

2

3

86 - LOCKOUT RELAY

D2853-6

5/25/99

Figure 2-4. External AC Connections for Shunt Reactor Protection, Ground Faults

Mixing Two Different Ratio CTs

While high impedance bus protec tion is bes t conf igure d with all CT s hav ing a co mmon rat io, it is p ossibl e

to utilize two different ratio CTs within one bus protection zone. The process by which this is

accomplished is detailed in the paper “Bus Protective Relaying, Methods and Application” located at

www.basler.com

.

General Settings Guidelines

To obtain the max imum set ting sens itivity, the CT loop res istance shou ld be minimized s o that the low est

possible voltage setting can be selected. For switchyard applications where there is a large distance

between the breaker and the relay panel, it may be desirable to locate the differential junction in the

switchyard since the resistance of the fault CT loop may otherwise be too large. To minimize the

impedance from the current transformers to the junction point, all the secondary windings should be

paralleled in the swi tchyard and as clos e as possible to the c urrent transformer s. Optimally, the junction

point should be equidistant from all current transformers.

The cable resistance fr om the junction point to the re lay is not included as a

part of the fault CT l oop r esistanc e. It is perm issibl e to locate junctio n poi nts at

the panel, providing that the relay setting gives the desired sensitivity.

NOTE

Operating Principles

The BE1-87B high impedance, differential relay operates on the instantaneous value of CT secondary

voltage to which the relay is connected. All the CTs in the differ ential circuit must have the same tur ns

ratio. If all CTs hav e the same turns ratio, the volta ge developed acros s the relay duri ng normal system

conditions is very small. Th e diagram in Figure 2-1 illus trates typical external ac connections to the relay

for use in a bus differential sc heme. As shown in the diagram, a typical differential connec tion is used

consisting of the CT circuits from each bus device connected in wye and paralleled at one location

9282300990 Rev P BE1-87B Application 2-5

Page 24

(summing point) on a per-phase basis. Three single-phase BE1-87B relays or one three-phase relay

)2R(R )(I 22 Vpeak

LSF

+=

)2R(R IV

LSFR

+=

provide complete protection of the bus. The relay will generate a trip output when the instantaneous

voltage applied across 5 and 7, or 3 and 7, or 1 and 7 o f the thr ee-phase model (A, B, and C res pec tive ly ),

exceeds the voltage pickup setting (V

) and the fault current is greater than the current sensitivity

DIFF

setting.

External Faults

If the differential protection scheme is to perform satisfac torily, then it must not trip for faults external to

the zone of protection . For example, Figure 2-5 shows a on e-line diagram for a three input diff erential

scheme. The BE1-87 B must not operat e for a fault at F1. Since the CT s in the faulted f eeder (CT 3) will

see the most current , assume they will saturate completely, thus causing t he magnetizing reactance to

drop to zero. The total current fr om the other CTs (CT 1 and 2) is for ced through the par allel comb ination

of the high impedance relay (5,000 Ω) and the saturated CT secondary. The saturated CT secondary

winding resistance is i n series with any resistance of the CT leads and connection cables (the total of

which presents a much lower resistance than the 5,000 Ω).

Therefore, nearly all the secondary fault current will flow through the saturated CT. A voltage drop V

caused by the flow of the fault curr ent in this parallel path will a ppear across the BE1-87B relay. For this

fault, the highest volta ge th at coul d be dev elop ed at th e relay w ould oc cur when t he assoc iated CT (CT 3)

saturates completely, an d the others ( CT1 and CT2) did not sat urate at all. When a CT with a distributed

toroidal winding (on t he tap used) saturates complet ely, it produces no voltage and the impedance, as

seen at the secondary w inding, is ver y nearly equal to the winding resistance ( very small impedance).

Thus the highest peak voltage that can be developed across the relay during an external fault will be

equal to the voltage produced by the total secondary fault current flowing through the control cable

resistance plus the wi nding res istance of the CT asso ciated wit h the faulte d feed er. Refer to th e exampl e

case in Figure 2-5 while applying Equation (1):

R

(EQUATIO N 1)

I

= rms symmetrical value of fault current in the fault CT in secondary amps.

F

R

= CT secondary winding resistance plus any lead resistance (at highest expected operating

S

temperature)

= Cable resistance from junction point to CT (at highest expected operating temperature)

R

L

Equation (1) above yi elds the p eak volt age develop ed at the r elay for a complet ely offset wav e of curr ent

having an rms symmetrical value of I

secondar y amperes. Because the BE1-87B relay is cal ibrated in

F

symmetrical rms volts, Equation (2) below, whic h yields the r ms voltage v alue, is us ed in the paragra phs

on Calculation of Settings.

(EQUATION 2)

The pickup voltage of the B E1-87B mus t be set abov e this valu e of rms volt age and above t he rms value

of the other voltages o btain ed in a si milar m anner on a ll the cir cuits of the b us. B ec ause the peak vo ltage

is proportional to the fault c urrent, the highest pos sible v alue of expected f ault cur rent in rms sy mmetrical

amperes should be used in making the evaluation.

2-6 BE1-87B Application 9282300990 Rev P

Page 25

Figure 2-5. Illustration of Single Line-to-Ground Fault at Location F1

Internal Faults

During internal faults on the bus, al l of the CTs will be oper ating into the re latively high impe dance of the

BE1-87B. Under thes e c o n dit ions, the maximum funda ment al fr equ ency v olt age t hat c an be pr od uc ed w ill

be limited to values as dictated by the CT secondary fund amental frequency excitation charac teristics.

Examination of a typical CT secondary excitation characteris tic will show that the available fundam ental

frequency voltage flattens off beyond the knee of the curve. However, the peak voltages that can be

produced are not indicated on the stan dar d exc itat ion c urv e.

The concept of how the CT responds during an internal fault is given in greater detail in the p aper “Bus

Protective Relaying, Methods and Applic ation” located at www.basler.com

to say that, for interna l faults , the peak volta ges will alway s be great er tha n indic ated by t he avera ge, and

will continue to incr ease in magnitude as the exc itation is increased. Becaus e the peak voltages durin g

internal faults will be much greater than the peak voltages experienced during external faults, and

because the BE1-87B relay operates as a function of the instantan eous voltage, the relay can be s et to

be selective between internal and external faults. An indication of the peak voltages that a CT can

produce can be determined by a simple modification to the CT secondary excitation characteristic.

The modification is shown by the lines CPB in Figur e 2-6, which now def ine the excitati on characteris tics

as a function of the peak voltages. Stu dies have shown th at the peak voltages produced will be at least

equal to or greater than those established by the modified characteristics. These characteristics are

useful in determining the minimum internal fault for w hich the relay will operate. The m ethod for making

the modifications, and the ir us es in determ ining t he se nsitivity , are prov ided in t he Calculation of Sett ings,

Minimum Fault to Trip sub-section in this chapter.

. Let us summarize the matter

9282300990 Rev P BE1-87B Application 2-7

Page 26

Figure 2-6. Typical Secondary Excitation for 1200/5 Bushing Current Transformer

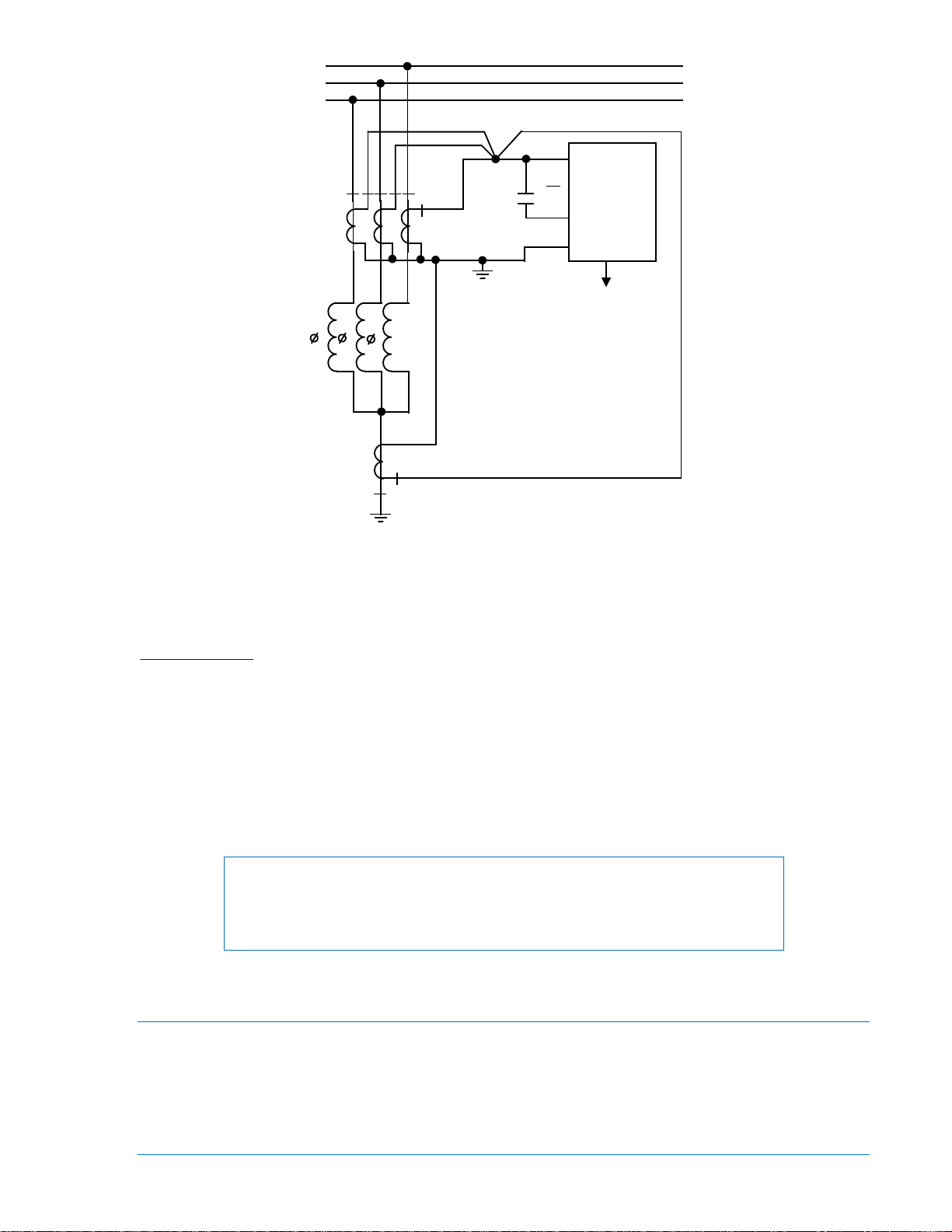

Figure 2-7 illustrat es, in simplified form, the internal connections of the BE1-87B relay. When an inter nal

fault occurs, the peak volta ge developed in the secondary of the feeder CTs will appear ac ross the relay

input network via phase A, phase B, or phase C. Under normal conditions, while operating power is

available to the relay, the SCR firing is accomplished via the voltage sensing circuitry by the pulse

amplifier. When the SCRs fire, the CT circuits will be shorted and the total secondary fault current will flow

through the SCR circ uits and the primary of current t ransformer T1. If the total secondary fault current,

and hence the primary current of T1 is above the pickup level of the relay , a trip output wil l be provided

via the output relay.

When relay-operating power is not available, the BE1-87B can no longer trip the output contacts.

However the SBS (Silicon Bilateral Switch) circuitry provides voltage protection for the SCRs and the

relay internal circuitr y. When the peak v oltage exceeds the swi tching voltage of t he SBS, it will con duct,

causing the correspond ing SCR to be triggere d to the ON condition. During subsequent ha lf cycles, the

SCRs will be trigg ered alternately. Note t hat the SBS, acros s the SCRs, exhibits high impedance in the

OFF state and will turn ON and conduct whe n a switching voltage above the relay maximum s etting is

reached. The SBS ac ts only as a fails afe, triggering the SCRs in the even t control power (p ower supply

voltage) is lost and a fault has occurred.

2-8 BE1-87B Application 9282300990 Rev P

Page 27

Figure 2-7. Simplified Internal Connection Diagram for BE1-87B Relay

)(V (2.83) )(V 22 V

DIFFDIFFR

==

22

2

1DIFF

R

2

1

F

N

)(N )(V (2.83)

)(V

N

N

V ==

22

For convenience, th e BE1-87B relay voltage s ettings are c alibrat ed in terms of r ms sy mmetrica l vo lts and

all calculations for setti ngs are made in terms of rms sy mmetrical quantities. The relay responds to the

instantaneous value of applied voltage, and this maximum instantaneous value can be two times the

square root of two or 2.83 times V

for fully offset waveforms. As soon as the relay operates, the

DIFF

shorting action of the SCR path r educes th is voltage to a ver y low level . Th us the m axim um peak volt age

that can be produced in the differential circuit will be limited to the value calculated in Equation 3 below.

(EQUATION 3)

V

= maximum instantaneous peak voltage that can be developed in the differential circuit

R

V

= BE1-87B voltage set point in rms symmetrical volts

DIFF

) = conversion of rms symmetrical volts to corresponding peak volts of a fully offset voltage wave

(

Where CTs with taps set o n other t han the f ull wi ndin g are inv olved, the v olta ge dev elope d acros s the fu ll

winding of these CTs c an be greater t han the differ enti al circuit volta ge as a resu lt of the aut otransfor mer

action. For example, c onsider the simple circuit of F igure 2-8. The voltage in the differential circuit, an d

consequently across C T1 a nd CT 2, wi ll b e l imite d to V

. But the voltage across the ful l wi ndi ng o f CT 3 w il l

R

be greater by the ratio of the total number of turns of the CT to the actual turns used.

(EQUATION 4)

= voltage across the full winding

V

F

N

= total number of CT secondary turns

1

N

= number of CT secondary turns used, i.e. tap settings

2

2.83 =

The voltage across the full winding (V

(peak value of fully offset wave)

) should not exceed the insulation breakdown of the connected

F

equipment. The val ue of t h e ac tu al pe ak v olt age th at can be produced f or any relay tap sett ing an d mixed

multi-ratio CT combination may be evaluated using Equation (4).

9282300990 Rev P BE1-87B Application 2-9

Page 28

whenever an rms symmetrical

BE1-87B

N2

N1

V

N2

CT1

N2

CT2

CT3

VF=

N1

N2

VR

V = VOLTAGE DEVELOPED ACROSS FULL WINDING

V = MAXIMUM INSTANTANEOUS VOLTAGE

NI = TOTAL NUMBER OF CT TURNS

N2 = NUMBER OF CT TURNS USED (TAP SETTING)

D2853-10

5-25-99

F

R

R

VF

Figure 2-8. Voltage Appearing Acros s Full Windi ng of C T

Characteristics

Operation of the BE1-87B relay is initiated as a function of the instantaneous voltage developed across

terminals 5 and 7 (s ingle-phase mode l) of the relay. Howev er, an output will not be produced unles s the

total secondary fault cur rent that flows through the relay after the SC Rs fire is greater than the pickup

current setting. In t his fashion both voltage and current are required to pr oduce an output. The volt age

selector switch settin g and curr ent selector s witc h setti ng determi ne the v oltag e and c urrent req uire ments

needed to produce an output.

Differential Voltage Pickup

The BE1-87B pickup volta ge selector switch allows for a setting rang e of 50 to 400 volt rms sy mmetrical

in 50-volt increments. This s ets the voltage lev el at which the back to back intern al SCRs will trigger . The

SCRs will trigger whenever the instantaneous value of the applied voltage is equal to twice the peak value

of the rms symmetrical pickup voltage setting. Refer to Equation 3.

NOTE

The voltage VR is equal to the peak voltage of a fully offset voltage wave

having an rms symm etrical value equal to the pic kup voltage selector switch

setting. Because of this the SCRs will fire

voltage greater than twice the voltage selector switch setting is applied, or

whenever the corresponding peak voltage is exceeded on an instantaneous

basis as in the case of an interna l fault. When the SCR s fire, prov ided th e total

secondary fault cur rent t hat flows in the relay is greater than the p ick up c urr en t

setting, the relay will produce an output.

Differential Pickup Current

Pickup current is defined as the rms value of a sy mmetrical sinus oidal current th at must flow into the 8 7B

in order to provide a contact output. T he BE1-87B has a pickup cur rent selector switch that allows for a

range of 0.25 to 2.5 amperes rms in 0.25 ampere increments. However, the relay internally operates off of

the instantaneous pe ak of this sinusoidal curr ent. For example, if the re lay is set at 1 amp, the cur rent

sensing element monitors for instantaneous current riding above 1.414 amps.

Alarm Voltage Pickup

The BE1-87B is equipped with a different ial voltage alar m function. The fu nction is used to det ect steady

state voltage imbalances across the input sens ing circuit of the relay (Terminals 5 and 7, 3 and 7 , and 1

2-10 BE1-87B Application 9282300990 Rev P

Page 29

and 7 for the three-phase model). The setting range for the alarm pickup is 10% to 80% of the rms

CAUTION

differential voltage pic kup setting (V

input terminals exc eeds the voltage pickup s etting times the voltag e alarm percentage sett ing (V

) in increments of 10%. W hen the rms voltage acr oss the sensing

DIFF

DIFF

x %

set), the CT OV LED illuminates and the alarm output contact closes (T erminals 13 and 14). W hen the

input voltage falls below th e alarm voltage threshold, the CT OV LED turns OFF and the alarm outp ut

contacts open. The response time of the alarm contacts and the LED is intentionally slow to prevent

nuisance alarms (ap proximately one seco nd). If th e Shorted CT Test Cir cuit is u sed, set the a larm un it at

minimum (10%).

Example:

A relay with a d ifferential pickup voltage (V

alarm voltage setting of 10%, will alarm at 20 volts rms (200 x 0.1 = 20 volts).

) setting of 200 vo lts rms symmetrical and an imbal ance

DIFF

Trip Test Pushbutton

The Trip Test pushbutton i s recessed behind the front panel and is accessed through a small opening.

Insert a small, nonc onductive tool throug h the front panel to de press the Trip Tes t pushbutton. Trip test

simulates a trip condit ion and verifies the operation of both out put trip contacts and the trip LED. Upo n

releasing the Trip T es t pushbutton, the trip outp ut co ntacts will reset, but the L ED r emai ns l it. T o clear the

Trip LED indication, press the Reset button.

Activation of the Tri p Test button will trip the loc kout device (86) and the bus

breakers unless appropriate steps are taken.

CT Test Pushbutton

The CT Test pushbutton is a “pillow-type” button located on the face of the relay. The button can be

accessed by either removi ng the st andard c over to ac tuate or throu gh th e externa l button ac tuators of the

optional cover. The CT Test pushbutton provides a method for tes ting the “health” of the en tire current

circuit by injecting a calculated value of external test voltage across the current circuit. If the current circuit

is healthy, the voltage acr oss the relay will be high enough to light the Alar m LED and close the alarm

output contacts, termina ls 13 and 14. If there is a short c ircuit in the current circuit, all of the tes t voltage

will be dropped acr oss an external test r esistor and neith er the LED nor the alarm output will o perate. If

this occurs, further c ur ren t circuit tests shoul d be perf o rmed. This function is av a ilabl e o nly w hen power is

applied to the relay and the CT diagnostic test source assembly (9282300014) is connected to terminals 7

and 10 of the relay. The Test Circuit Calculations sub-section provides details on applying this featur e.

Power LED

This LED lights when normal operating power is applied to relay terminals 15 and 16.

Intentional Delay Jumper

A user-settable jum per is lo cated on t he Control c ircuit board to select e ither no i ntentional delay ( jumper

position 1 to 2), or a 20-mill isecond delay∗ (jumper pos ition 2 to 3) added to the trip response t ime. For

applications having a tap within the zone of protection that is protected by a high-speed fuse, the 20

millisecond intentional delay∗ is intended to prevent tripping the bus for a fault on the fused tap. The

current detector circ uit rese t time is appr oximately 1 mil lisecond so t hat the ac and dc c omponents of the

differential current, as reproduced at the CT secondary, must drop below pickup in less than 19

milliseconds. A second ary error may occur due to the fast dropout of the primar y current when the fuse

operates.

∗ Ac tual intentional time delay is a functio n of pickup current. For currents ex ceeding twice the pickup

setting, intentional time delay is 20 milliseconds. For currents less than twice the pickup setting,

intentional time delay is 25 milliseconds.

Operating Times

The BE1-87B operates in less than 7 milliseconds (1/2 cy cle) for faults 1.5 times the cur rent pickup. The

BE1-87B operates in less than 5.5 milliseco nds for fault levels above 6 times the current pickup. High-

9282300990 Rev P BE1-87B Application 2-11

Page 30

speed operation minimizes potential damage to th e protected equipm ent. Refer to Figures 1-2 and 1-3 in

N

I

)PR (R 1.25 V

F

LSDIFF

+=

Section 1, General Infor mat ion for illustrations of response times.

Hold Timer

The BE1-87B has a hold timer (200 milliseco nds, fixed) that prev ents the Trip output relay contacts from

opening prematurely.

Calculation of Settings

The BE1-87B relay is set bas ed on the max imu m poss ible voltag e that can be pr oduced in the differ entia l

circuit as a result of a fault external to the zone of protec tion. Determination of t he maximum voltage for

this condition is subject to simple calculations , and thus, the relay s etting is easily determ ined. The relay

has a setting range 50 to 400 volts rms in 50-volt steps.

It is first necessary to c alculate t he max imum vo ltage t hat can b e pro duced in the different ial cir cuit for an

external fault. Once that value is determin ed, th e appr opr iate vo ltage s etti ng ca n be se lecte d. If a mixtur e

of multi-ratio CTs is used (not recommended) or if the CTs are applied on taps other than full ratio,

calculations must be performed to determine if excessive voltages will be produced across the full winding

of the CT. Last, the mini mum internal fault for which the relay will just operate will be calculated.

Calculation of Voltage Differential Settings

The minimum acceptable differential voltage setting can be determined using the following equation.

(EQUATION 5)

V

= minimum acceptable vo ltage tap setti ng. Since V

DIFF

one of the available settin g s , the next higher s etti ng should be used. The available v oltage set t in gs ar e 50

to 400 volts rms in 50-volt increments.

= dc resistance of fault CT secondary windings and leads to the CT makeup box (at maximum

R

S

expected operating temperature).

= s ingle conductor dc res istance of the curr ent circuit cable for a one-way run fr om the different ial

R

L

junction point to the fault CT makeup box (at maximum expected operating temperature).

P = one (1.0) for three-phase faults and (2.0) for single-phase to ground faults.

I

= maximum external fault current in the fault CT in primary symmetrical rms amperes.

F

N = CT ratio.

1.25 = margin for safety.

The following comments may be made with respect to the evaluation of Equation 5.

• It is only necessary to calculate three-phas e and single-phase-to-grou nd faults. If the results yield a

satisfactory application, the application will also be satisfactory for multi-phase faults.

• For single-phase-to-groun d faults, the differential circuit is such that the CT secondary fault current

will flow through both of the fault CT cables; th us the multiplier P must be set equal to two. On the

other hand, the CT sec ondary currents dur ing a balanced three-p hase fault will r esult in 0 current in

the return cable; thus only the one-way cable resistance is involved, and P is set equal to one.

• If the single-phase-to-gr ound fault current at a given location is greater than or equal to the three-

phase fault current, the calculations need only be made for the single-phase-to-ground faults.

• The resistance of t he CT s and connecting cables w il l inc r ease with increasing te mperature; therefore,

if adequate margin is to be maintained at all t imes, Equation 5 shou ld be evaluated usi ng resistance

values corresponding to the maximum expected operating temperature (see sample calculation in this

section).

The methods to be used in calc ulating the voltage tap setting using Equation 5 will to some extent be

dependent on the typ e of appl ication. T he follow ing paragr aphs discus s different areas in which t he BE187B relay may be applied.

in genera l will not come o ut exactly equal t o

DIFF

2-12 BE1-87B Application 9282300990 Rev P

Page 31

Bus Protection

Two methods will be out lin ed for ev alua ting Equat ion 5 in or der t o deter mine a n appropr iate re lay vo ltage

tap setting.

Method 1. The first m ethod offers a simplified conse rvative approach to the probl em and requires that

equation 5 be evalua ted only once. With this method, it is assumed that a s ingle-phase-toground fault with a current magn itude equa l to th e maximum interru pting r ating of the breaker

occurs on the feeder assoc iated wit h the CT hav ing th e longest c able run fr om the diff erent ial

junction point. Under thes e assumptions, the effect of the fau lt current, I

, is maximized, and

F

so is the effect of cable resis tance, becaus e the highe st value of res istance is used and P is

set equal to 2. Thus, the highest possible value of V

will be obtained.

DIFF

Method 2. The second method offers an exact approach b ut requires that Equation 5 be eval uated a

number of times in order t o obtain th e maximu m V

. With this method, calcul ations must be

DIFF

made for the maximum single-phase-to-ground fault a nd the maximum three-phase fault just

off each of the n fee der s on the bus . Ther e f ore, E quat i on 5 m us t b e evaluated 2n times us in g

the associated value of cable resistance and P = 1 or P = 2, as required.

In general, Method 2 will p roduce a lower voltage tap s etting than Method 1, but Method 1 is s impler to

utilize. The user sho uld begin with Meth od 1. If the volta ge setting resulting from the use of this method

results in adequate sensitivity, a unique advantage is realized in that the setting does not require

recalculation following future changes in the power system that result in higher fault current magnitudes. If

the sensitivity resulting from the use of Method 1 does not prove adequate, then Method 2 should be

used. Each method is outlined below.

Method 1 (Simplified Conservative Approach)

a. Use the maximum int errupting rating of the circ uit breaker as the maximum single-phase-to-ground

symmetrical fault current (I

b. R

is based on the distance from the differential junction point to the most distant CT.

L

c. Calculate V

substituting the values of current and resistance from a. and b. and set P = 2.

DIFF

d. Select the highest available voltage setting that just accommodates the voltage calculated in c.

above.

).

F

Method 2 (Exact Approach)

a. Determine the maximum three-phase and s ing le-phase-to-ground fault c ur rents f or fau lts j us t off eac h

of the n breakers on the bus.

is the one-way dc resistance of the cable from the associated CT to the differential junction point.

b. R

L

c. For each breaker in turn, c alculate V

separately, utilizing the as sociated maximum ex ternal three-

DIFF

phase symmetrical fault c ur rent in t he fault CT, with P = 1 and the maxim um ex t er nal sin gl e-phase-toground symmetrical fault current in the fault CT, with p = 2.

d. Use the highest V

resulting from the calculations and select the next highest available voltage

DIFF

setting that just accommodates this value.

Shunt Reactor Protection

Depending on the type of protection required, shu nt reactors may be prot ected by the BE1-87B rel ay in

one of two ways (see Figures 2-3 and 2-4). Since the shunt reactors cont ribute no current to an exter nal

fault, Equation 5 sho uld be evaluated us ing the highe st magnitude of c urrent that c an flow in the reac tor

under any system condi tion, exclusive of a fault in t he reactor. If the differ ential junction point is locate d

near the reactors, the r esistance of the CT connecting c ables can probably be ignored, an d Equation 5

need only be evaluated using the CT resistance and the maximum expected current. If the cable

resistance cannot be ignored, use the maximum expected reactor current and P = 2. After a value of

VDIFF has been calc ulated, select t he next higher a vailable voltage sett ing that just acc ommodates this

voltage.

Application with Mixed Multi-Ratio CTs

Where CTs are used on other than their full windings, (not recommended) the application should be

evaluated after a voltage setting has been selected to determine that excessive voltages are not

developed across the ful l windings of these CTs as a result of autotransformer action. It is desirabl e to

limit the peak value of the voltage to less than the insulation breakdown of the connected equipment.

9282300990 Rev P BE1-87B Application 2-13

Page 32

Refer to Equation 4 under Operating Principles for information on how to calculate the peak voltage

NI (I)x I

R

n

1x

MIN

+=

∑

=

across the full winding.

See Figure 2-8 for an ill us trat ion o f ter ms fr om E qua tio n 4. If V

is less than the ins ulat io n br e akdown, and

F

if the current rating of the CT is not exceeded, the application is permissible. Equation (4) should be

evaluated for the CT havi ng the highest N1/N2 ratio. If the c ondition of Equation (4) is met for th is CT,

then it will also be met for the remaining CTs.

Current Element Setting

The setting of the current element is based upon four factors.

1. The current setting n eeds to be set so that the relay will oper ate at minimum fault levels. The mai n

application where this wi ll be of concern wi ll be when one w ishes to ensure op eration of the rel ay for

ground faults on impedanc e grounded s ystems . This matter is discus sed in t he Minimum F ault to Tr ip

sub-section.

2. The current setti ng should be set high whe n there are surge arres ters in the zone of protection. T his

factor was discussed in the Application with Lightn ing Arr es ters sub-section.

3. The third factor is hard to quantify. It is possible for noise t o be induced on the bus differential CT

circuit by the magne tic fields generated by out-of-zone f ault currents. This includes magn etic fields

generated by both the pr imary fault currents and by secondary fault currents where CT leads are in

the same conduit at the differ ential relay CT leads. Du e to the high impedanc e of the bus differentia l

circuit, the induced v oltage can be high enough to c aus e the relay v oltage e lement to transient ly pick

up. However, this induc ed voltage cann ot carry any a ppreciable curre nt after the BE1-87B SCRs are

turned on. If the BE1-87 B voltage element operates but current in the CT string remains low (less

than the BE1-87B current element s etting) after the SCRs turn on, th e relay will not trip. Hence, th e

current element is s et at some level that will prevent ind uced pickup of th e relay for this condition. A

typical setting for this purpose is 0.5 amperes.

4. The current should be s et high enough so that if the BE 1-87B CT T est feature is used ( to test for CT

short-circuits), the cur rent t hat is in duc ed in th e rel ay by t he test w ill be les s than the current setting of

the relay by a comfortable margin. This matter is discuss ed in the CT Test Circ uit Calculation s subsection.

Minimum Fault to Trip (Voltage Element)

NOTE

In the following sensitivity analysis, relay impedance i s rounded to 5000 ohms

for simplicity and the algebraic addition of current magnitudes rather than a

more exact phasor additi on of currents is us ed. A comparison of the s implified

calculation approach to the more exact calculation approach results in a

minimum fault sensitivity value that is higher than when the more exact

approach is used. Hence, the simplified approach is a more conservative

method for finding minimum sensitivity.

After the differential voltage setting has been established, a check should be made to determine the

minimum internal fau lt curr ent th at wil l just c ause the voltag e elem ent of th e rel ay t o operate. T his c urrent

level should be compared t o the current element setti ng. The greater of these two qua ntities determines

the relay minimum fau lt-to-trip. The minimum f ault-to-tr ip should be less than the bus mini mum fault du ty.

This will be an issue mainly with imped ance-gro unded sy stems. The followin g expres sion can be used to

determine the minimum internal fault current required for a particular tap setting.

(EQUATION 6)

= minimum rms symmetrical internal fault current required to operate the BE1-87B relay

I

min

n = number of CTs (number of circuits)

I = secondary excitation current of individual CT at a voltage equal to (VDIFF)

I

= current in the relay at pickup setting

R

N = CT ratio on tap used

2-14 BE1-87B Application 9282300990 Rev P

Page 33

The excitation currents , (I)1, (I)2,……(I)n will be a function of the peak vol tages that can be produced i n

22

5000

)(V (2)

I

DIFF

R

=

ρ1

ρ1

ρ1

the secondary of the respe ctive CT s. It is pos sible to deter min e the curr ents wit h the aid of the secon dary

excitation characteris tic for the respec tiv e CT. But it is firs t necess ary to mod ify th e charac teristic s so th at

they are plotted as a function of the peak voltages that can be produc ed. The procedure for doing so is

provided in the following paragraphs.

1. Determine the knee point coordinates of the standard excitatio n curve (E

and Ie). These po ints will

S

be indicated on the giv en characteristic, or they can be found graphically by determinin g the point

where a 45-degree line is tangent to the knee of the excitation curve.

2. Calculate and plot the following point on the same sheet with the excitation curve:

V = (7) (E

)

S

I = (5) (Ie) (EQUATION 7)

3. Draw a line having a s lope of ½ through the p oint (V, I) c alculated and plott ed in step 2. A slop e of ½

corresponds to one log cy cle on the vertical axis (volt age) and two log cycles on the hor izontal axis

(current) (See line A-B in Figure 2-6).

4. Extend the lower part of the excitati on curve in a straight l ine until it intersect s line A-B draw n in step

3 (see line C-D in Figure 2-6).

The curve (CPB) formed b y these two lines now represents the mod ified excitation characteristic s as a

function of the peak voltages that can be produced. After the curve has been drawn, calculate the

following corresponding excitation current I.

=

V

S

= voltage coordinate for determining I

V

S

V

DIFF

(V

) (EQUATION 8)

DIFF

= differential voltage setting of the BE1-87B

NOTE

The first term in Equation 6 reduces the nI if all the CTs have the same

characteristics. The second term in Equation 6 represents the current (I

)

R

drawn by the relay just at the operating point. It can be calculated as follows:

(EQUATION 9)

Sample Calculation

The various steps for determining the setting of the BE1-87B in a typical bus application will be

demonstrated with the aid of a worked example. Assume t he protected zone includes fiv e breakers, all

rated at 69 kV, 1500 M VA, and 1200 amperes, with a max imum interrupting rating of 1 2,500 amperes.

The excitation curve for the 1200/5 bushing CTs in these breakers is shown in Figure 2-6.

A current sensitivity setting of 0.5 amperes will be used. The voltage tap setting will be deter mined by

using Method 1 described i n the preceding p aragraph s. The value of R

+ 2 (0.0347) = 0.525 Ω. It is assumed that this resistance corresponds to the maximum expected

operating temperatur e. It is further assumed that the lon gest CT cable run is 442 feet, and number 10

AWG copper wire is used. The one-way cable resistance at 25 d egrees C is 0.450 Ω. The resistance

value of the wire at 25 deg rees C or at any temperatu re T1 may be corrected to any temperature T2 by

means of the following equation.

RT2 = [1 +

(T2-T1)] RT1

from Figure 2-6 is (0.0019) (240)

S

RT2 = Resistance in ohms at T2, degrees C

RT1 = Resistance in ohms at T1, degrees C

= Temperature coefficient of resistance at T1

For standard anneale d copper,

= 0.00385 at T1 = 25 degrees C . If the max imum expected op erating

temperature is assumed to be 50 degrees C, then the following applies.

9282300990 Rev P BE1-87B Application 2-15

Page 34

RT2 = [1 + 0.00385 (50-25)] 0.450

5000

)(V (2)

I

DIFF

R

=

amperes 0.04

5000

(100) (2)

I

R

==

= (1.096) (0.450) = 0.493 Ω

Substituting the various quantities in Equation 5 yields:

V

= 1.25 [.524 + 2 (0.493)] 12500/240

DIFF

= 98.31 volts

Since 98.31 volts is not an exact equal to one of t he V

setting, sel ect the next higher available settin g,

DIFF

which is 100 volts.

= 100 volts

V

DIFF

Since the CTs are all used on the full winding (suggested practice), there is no need to check that

excessive voltages will be produced in the CT circuits. Now that V

setting has been selected, the

DIFF