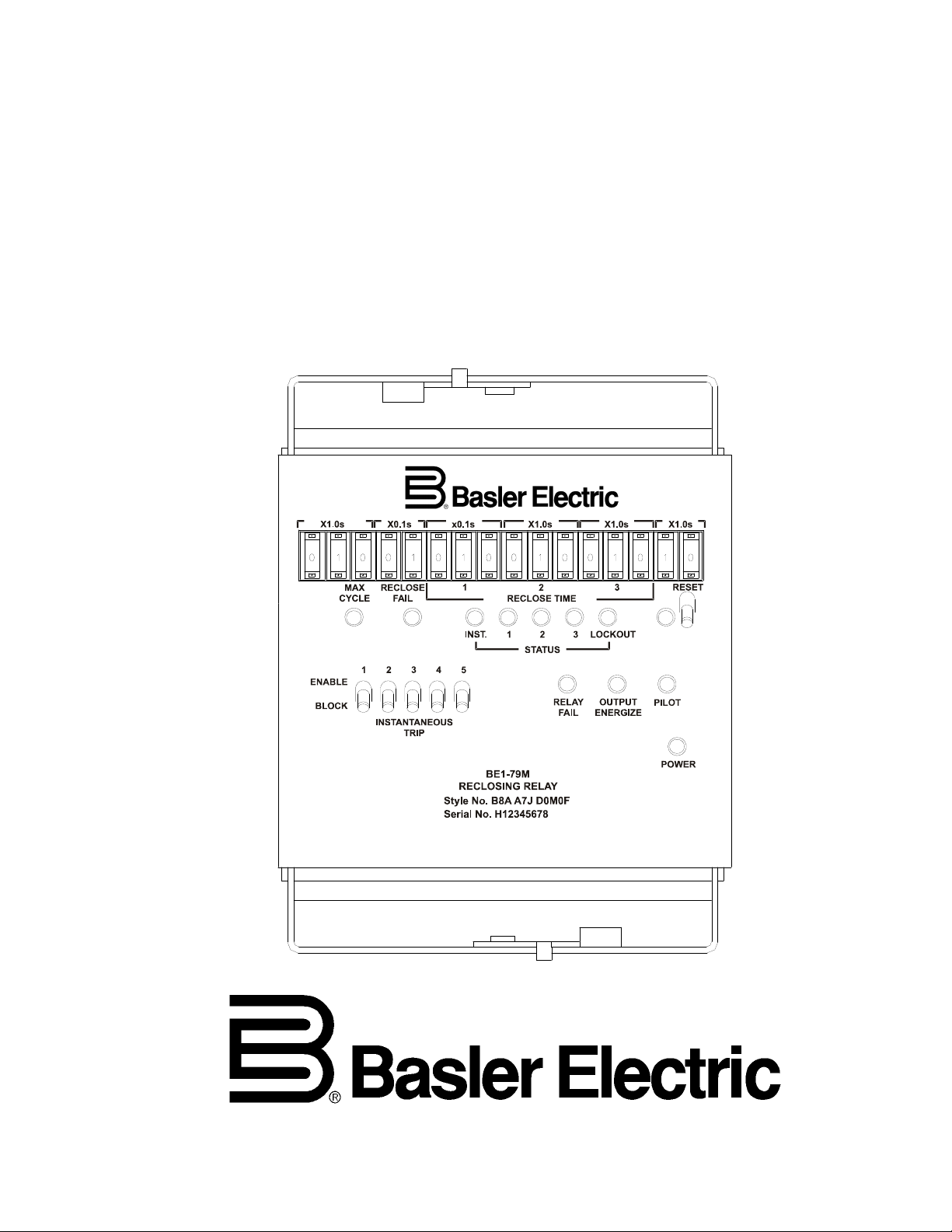

Page 1

INSTRUCTION MANUAL

FOR

MULTIPLE SHOT RECLOSING RELAY

BE1-79M

P0046-01

Publication: 9170100990

Revision: N 04/12

Page 2

Page 3

INTRODUCTION

This instruction manual provides information about the operation and installation of the BE1-79M Multiple

Shot Reclosing Relay. To accomplish this, the following information is provided:

General Information and Specifications

Controls and Indicators

Functional Description

Installation

Testing

Maintenance

WARNING!

To avoid personal injury or equipment damage, only qualified personnel should

perform the procedures in this manual.

NOTE

Be sure that the BE1-79M is hard-wired to earth ground with no smaller than

12 AWG copper wire attached to the ground terminal on the rear of the unit

case. When the BE1-79M is configured in a system with other devices, it is

recommended to use a separate lead to the ground bus from each unit.

9170100990 Rev N BE1-79M Introduction i

Page 4

First Printing: January 1986

Printed in USA

© 2009-2012 Basler Electric, Highland Illinois 62249 USA

All Rights Reserved

April 2012

CONFIDENTIAL INFORMATION

of Basler Electric, Highland Illinois, USA. It is loaned for confidential use,

subject to return on request, and with the mutual understanding that it will not

be used in any manner detrimental to the interest of Basler Electric.

It is not the intention of this manual to cover all details and variations in equipment, nor does this manual

provide data for every possible contingency regarding installation or operation. The availability and design

of all features and options are subject to modification without notice. Should further information be

required, contact Basler Electric.

For terms of service relating to this product and software, see the Commercial Terms of Products and

Services document available at www.basler.com/terms

.

Basler Electric

12570 State Route 143

Highland IL 62249-1074 USA

www.basler.com, info@basler.com

PHONE +1 618.654.2341 FAX +1 618.654.2351

ii BE1-79M Introduction 9170100990 Rev N

Page 5

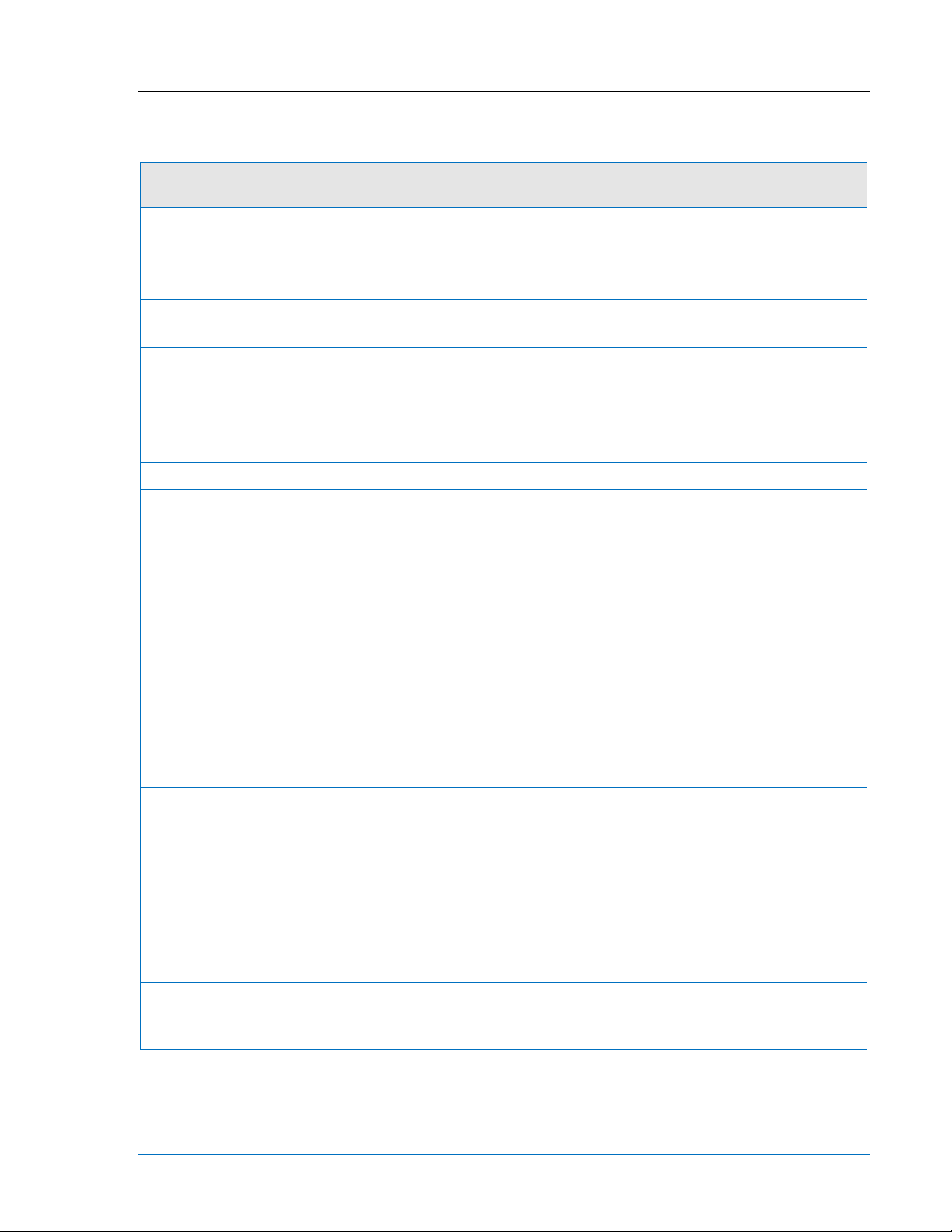

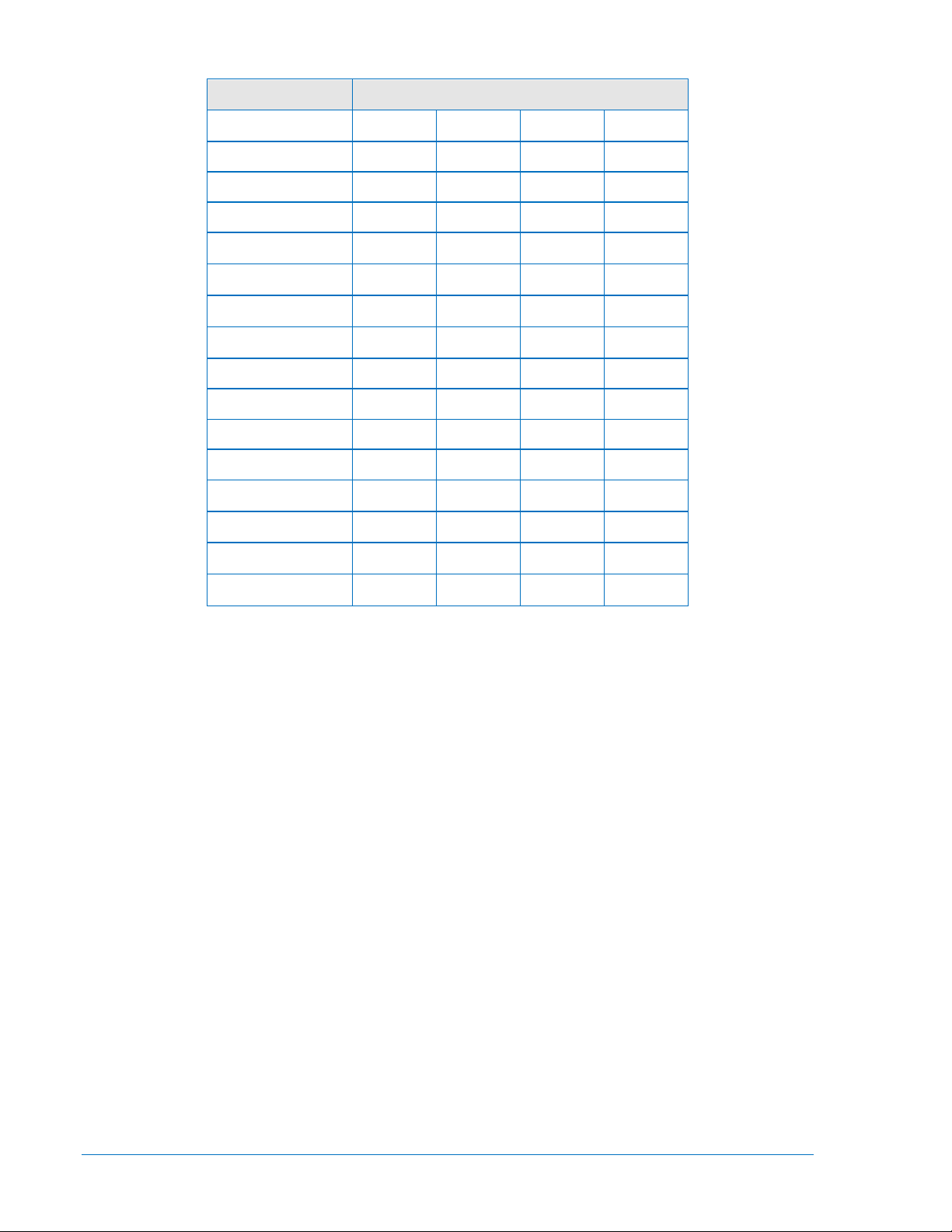

REVISION HISTORY

The following information provides a historical summary of the changes made to this instruction manual

(9170100990) of the BE1-79M.

Manual

Revision and Date

N, 04/12

M, 01/11

L, 06/09

K, 11/06

J, 06/98

I, 01/97

H

Change

Improved accuracy of Pilot timings.

Improved Figures 3-6 and 4-11.

Removed reference to test set from Figure 5-1.

Standardized case and cover drawings in Section 4.

Updated Note 2 for Style Chart in Section 1.

Updated Figure 2-1 to match latest board layout.

Updated Storage statement in Section 6.

Removed In-House Repair from Section 6.

Removed BE1-79M Test Set from Section 6.

Updated power supply options descriptions in Style Chart.

Added manual part number and revision letter to page footers.

Added Notes 1 and 4 to style chart in Section 1.

Deleted reference to Service Manuals.

Replaced Power Supply paragraph on page 3-6 starting with “Basler

Electric enhanced the power supply…”

Deleted Figure 3-4 and added Table 3-3.

Corrected the Figure numbering following Figure 3-4.

Changed the burden data for new power supply in Table 1-2.

Separated Section 4 into two sections. Now Section 5 is TESTS and

ADJUSTMENTS.

Revised all numbers referring to figures, tables, and sections involved

in this change.

Added new dimension figures to include all options available (S1

Double-Ended and both mounting positions).

Added case ground to Figure 4-9.

Changed the format of the manual.

Corrected Figure 1-1 by adding 7, 8 to note #2.

Changed Specifications to reflect the updates in the Outputs, RFI,

and Surge Withstand Capability.

Clarified first paragraph on page 3-3.

Changed “INST” to “2

Added disconnects to 20 and 11 in Figure 4-3.

Revised Section 5, paragraph 1 to include both Service Manual

numbers.

Corrected an error on page 5-2.

Changed Introduction to include Service Manual, Publication

9170100623.

Added new Figures 4-3 and 4-9.

ND

TIME DELAY” in Figure 3-7.

9170100990 Rev N BE1-79M Introduction iii

Page 6

Manual

Revision and Date

G

F

E

D

C

B

A

—, 01/86

Change

Changed Style Number Identification Chart first character from A to B

in response to ECA 12237.

Changed operational Test Procedure, Section 4 to improve

procedures and correct typographical error.

Added old Style Number Identification Chart to Section 7.

Manual revised to support the following relay changes:

o Six additional control output options.

o Two additional reclose time delay options.

o Y-type power supply option.

o Reset timer 1-100 second time delay option.

o Four additional special contact assignments options.

o A four function field selectable logic switch.

o Moved sensing input power module from outside the case to

inside the case.

Added Section 7, Difference Data, to support BE1-79M Relay revision

D and previous.

Operational test procedure revised.

Pages 5-5 and 5-6 added.

Section 6 added.

Page 3-9: Subsection entitled Reclosing Event Memory

rewritten for

clarification.

Pages 4-2 through 4-5: Operational test procedure revised.

Pages 5-2 through 5-4: Subsection entitled Test Plug Adapter

added.

Added Qualifications to specifications listing, revised isolation test

and dielectric test.

Page 3-2: Added footnote to Table 3-1.

Added two paragraphs beginning with “Each reclose attempt…”

Page 3-7 Figure 3-2 corrected.

Page 3-3: Subsection entitled Instantaneous Trip Enable clarified.

Manual revised to reflect software changes, which introduced an

additional category (Unsuccessful Reclosers) to the Reclose Event

Memory.

Initial release

iv BE1-79M Introduction 9170100990 Rev N

Page 7

CONTENTS

SECTION 1 • GENERAL INFORMATION ................................................................................................ 1-1

SECTION 2 • HUMAN-MACHINE INTERFACE ....................................................................................... 2-1

SECTION 3 • FUNCTIONAL DESCRIPTION ........................................................................................... 3-1

SECTION 4 • INSTALLATION .................................................................................................................. 4-1

SECTION 5 • TESTS AND ADJUSTMENTS ............................................................................................ 5-1

SECTION 6 • MAINTENANCE .................................................................................................................. 6-1

SECTION 7 • DIFFERENCE DATA .......................................................................................................... 7-1

9170100990 Rev N BE1-79M Introduction v

Page 8

vi BE1-79M Introduction 9170100990 Rev N

Page 9

SECTION 1 • GENERAL INFORMATION

TABLE OF CONTENTS

SECTION 1 • GENERAL INFORMATION ................................................................................................ 1-1

Purpose .................................................................................................................................................. 1-1

Application.............................................................................................................................................. 1-1

Model and Style Number ....................................................................................................................... 1-2

Style Number Example ....................................................................................................................... 1-2

Style Number Change ........................................................................................................................ 1-2

Compatibility ....................................................................................................................................... 1-2

Specifications ......................................................................................................................................... 1-4

Temperature ....................................................................................................................................... 1-4

Figures

Figure 1-1. Style Number Identification Chart ........................................................................................... 1-3

Tables

Table 1-1. Burden (Nominal) Per Non-isolated Sensing Contact .............................................................. 1-6

Table 1-2. Power Supplies ........................................................................................................................ 1-6

9170100990 Rev N BE1-79M General Information i

Page 10

ii BE1-79M General Information 9170100990 Rev N

Page 11

SECTION 1 • GENERAL INFORMATION

Purpose

The BE1-79M Multiple Shot Reclosing Relay automatically recloses circuit breakers, which have been

tripped by protective relays or other devices in power transmission and distribution systems.

• Over 90% of faults occurring on overhead lines may be cleared by momentarily de-energizing the

line. Once the circuit breaker has been opened to de-energize the line, the BE1-79M provides a

reliable automatic reclosure. The advantages are:

• Improved Service Continuity - returns the line to service quickly, preserving line integrity and

minimizing outage effects on critical loads.

• System Stability - prevents disjointing of the system grid.

• Higher Line Loading - decreases likelihood of loss of line.

Application

Four major factors should be considered when establishing a reclosing philosophy.

• Desired number of reclosure attempts.

• Time delay between breaker opening and reclosure.

• Supervisory control.

• System coordination.

The first major factor is the desired number of reclosure attempts. Where most faults are attributable to

heavy tree exposure, as in distribution networks, multiple reclosure attempts are common. This is

possible because of low voltage levels and is desirable considering customer inconvenience during

outages. The BE1-79M is programmable for up to four reclosure attempts per sequence. This allows

tailoring of the reclosing sequence to the specific needs of the circuit.

The second major factor is the time delay between breaker opening and reclosure. On subtransmission

and distribution networks, it is necessary to ensure that motors are no longer running and that local

generation is off-line prior to attempting reclosure. At the same time, a rapid reclosure minimizes damage,

ionization, and system shock in transmission networks. After the first reclosure attempt, additional

attempts are generally delayed to allow for de-ionization of the interrupter. The BE1-79M incorporates one

instantaneous reclosing attempt with bypass capability, and up to three individually adjustable, timedelayed, reclosing attempts.

A third major factor to be considered in reclosing is supervisory control. Supervisory control allows the

operator to maintain control of the system at all times. The BE1-79M has inputs available to bypass the

instantaneous reclose attempt and to drive the relay to LOCKOUT inhibiting relay operation at any time.

In addition, a separate input is available which may be used to initiate a pilot reclosing sequence.

The fourth major factor is system coordination. The BE1-79M has outputs available which may be used to

block or enable instantaneous tripping of the circuit breaker and block a transformer's automatic load tap

changer operation during a reclosing sequence.

9170100990 Rev N BE1-79M General Information 1-1

Page 12

Model and Style Number

The electrical characteristics and operational features included in a specific relay are defined by a

combination of letters and numbers, which constitutes the device's style number. The style number

together with the model number describe the features and options in a particular device and appear on

the front panel, drawout cradle and inside the case assembly. The model number BE1-79M designates

the relay as a Basler Electric, Class 100, Multiple Shot Reclosing Relay. The BE1-79M style chart is

shown in Figure 1-1.

Style Number Example

The following style number identification chart illustrates the features and options for BE1-79M relays. For

example, if the style number were BE1-79M B6A A6J C0L0F, the device would have the following

features:

BE1-79M Model Number

B Multiple shot

6 Lockout and reset with reclose fail and maximum cycle

A Instantaneous trip enable

A6 Reclose time delay adjustable from 0.1 to 99.9 seconds

J Operating power derived from 125 Vdc or 120 Vac source

C Reset time delay adjustable from 10 to 1000 seconds

0 Standard contact assignment

L Non-isolated contact sensing

0 No option 3 available

F Semi-flush mounting

Style Number Change

Effective November 18, 1991 (serial number 2812 and subsequent), the BE1-79M Multiple Shot

Reclosing Relay, style number identification for multiple shot is changed from A to B. This style number

change was made to differentiate relays with sensing input power module on the outside of the case

(style number A) and relays with the sensing input power module inside the case (style number B).

Section 7 of this manual provides difference data for style number A relays.

Compatibility

Relays with style number B are backwards compatible. That is, they may be used in place of relays with

style number A. The only exception is for a relay with a type Z power supply (250 Vdc/230 Vac) and

isolated sensing. For details, see section 7 of this manual.

Relays with style number A are NOT forward compatible. They may NOT be used in place of relays with

style number B.

1-2 BE1-79M General Information 9170100990 Rev N

Page 13

Figure 1-1. Style Number Identification Chart

9170100990 Rev N BE1-79M General Information 1-3

Page 14

Specifications

isolated sensing,

Accurate within 1% of

increments or

Accurate within 1% of setting or 0.5 seconds,

The BE1-79M Relay is available with the following features and capabilities.

Contact Sensing

Reclose Initiate

Breaker (52b)

Pilot Initiate

Instantaneous Reclose

Bypass

Drive to Lockout

Power Supply

Outputs

Timing

The contact sensing circuits require user-supplied contacts with a

minimum rating of 0.025 A at 250 Vdc. Sensing current is supplied by

the relay in styles with isolated sensing. Styles with non-isolated

sensing require an applied sensing voltage equal to the relay dc power

supply input rating. Burden per contact for nondependent on power supply type, is listed in Table 1-1.

Refer to Table 1-2.

Output contacts are rated as follows:

Resistive

120 Vac Make, break, and carry 7 Aac continuously.

250 Vdc Make and carry 30 Adc for 0.2 seconds, carry 7 Adc

continuously, break 0.3 Adc.

500 Vdc Make and carry 15 Adc for 0.2 seconds, carry 7 Adc

continuously, break 0.3 Adc.

Inductive

120 Vac, 125 Vdc, 250 Vdc Break 0.3 A (L/R = 0.04)

Reclose

Pilot (Optional)

Reset

Reclose Fail (Optional) Adjustable from 0.1 to 9.9 seconds in 0.1 second increments. Accurate

Maximum Cycle (Optional) Adjustable from 1 to 1000 seconds in 1 second increments. Accurate

Temperature

Operating

Storage

1-4 BE1-79M General Information 9170100990 Rev N

Adjustable from 00.1 to 99.9 seconds in 0.1 second increments.

Accurate within 1% of setting or 0.05 seconds, whichever is greater.

Optionally adjustable from 1 to 999 seconds in one second increments

for the second and third reclose time delays.

setting or 0.5 seconds, whichever is greater.

Optionally adjustable from 0.03 to 0.99 seconds in 0.01 increments.

Accurate to within ±0.01 seconds of setting. If reclose time delay option

A8 is not specified, pilot reclose time is ≤ 0.035 seconds.

Adjustable from 10 to 1,000 seconds in 10-second

optionally adjustable from 1 to 100 seconds in 1 second increments. A

setting of 00 indicates a 1000 second reset time or optionally a 100

second reset time.

whichever is greater.

within 1% of setting or 0.05 seconds, whichever is greater.

within 1% of setting or 0.5 seconds, whichever is greater.

–40°C (–40°F) to 70°C (158°F)

–65°C (–85°F) to 100°C (212°F)

Page 15

Radio Frequency

Relay Systems to Radiated Electromagnetic Interference from

nd held

perpendicular planes without structural damage or degradation of

sweeps, 15 minutes each sweep, without structural damage or

ugh 4 and 11 through 20, the maximum voltage

applied must be no greater than 300 V because of the MOV

1989 Standard Surge Withstand

1989 Standard Surge Withstand

Interference (RFI)

Maintains proper operation when tested for interference in accordance

with IECC C37.90.2-1989, Trial-Use Standard Withstand Capability of

Transceivers, and 99-1188, field tested using a 5 watt, ha

transceiver operating at random frequencies centered around 144 MHz

and 440 MHz, with the antenna located 6 inches from the relay in both

horizontal and vertical planes.

Shock

Vibration

Isolation

Surge Withstand Capability

Oscillatory

Fast Transient

In standard tests, the relay has withstood 15g in each of three mutually

performance.

In standard tests the relay has withstood 2g in each of three mutually

perpendicular planes swept over the range of 10 to 500 Hz for six

degradation of performance.

At terminals 1 thro

suppressors employed at these locations. At the remaining terminals,

2,500 Vac at 60 Hz for one minute may be applied in accordance with

IEC 255-5 and ANSI/IEEE C37.90-1989 (Dielectric Test).

Qualified to ANSI/IEEE C37.90.1Capability (SWC) Tests for Protective Relays and Relay Systems.

Qualified to ANSI/IEEE C37.90.1Capability (SWC) Tests for Protective Relays and Relay Systems.

Impulse Test

GOST-R Certification

Weight

Case Size

Qualified to IEC 255-5.

GOST-R certified per the relevant standards of Gosstandart of Russia.

13 lbs (5.9 kg)

S1; Refer to Section 4, Installation.

9170100990 Rev N BE1-79M General Information 1-5

Page 16

Table 1-1. Burden (Nominal) Per Non-Isolated Sensing Contact

Power Supply Type K J L Z

Nominal Burden Per Input 0.75 W 1.60 W 0.70W 2.20 W

NOTE: For type Y Power supply, use burden for type K or type J power supply depending on nominal

operating voltage.

Table 1-2. Power Supplies

Type

K (midrange) 48 Vdc 24 to 150 Vdc 5.4 W

J (midrange)

L (low range) 24 Vdc 12 to 32 Vdc * 5.3 W

Y (midrange)

Z (high range)

∗ Type L power supply may initially require 14 Vdc to begin operating. Once operating, the voltage may

be reduced to 12 Vdc and operation will continue.

Nominal

Input Voltage

125 Vdc 24 to 150 Vdc 5.3 W

120 Vac 90 to 132 Vac 13.2 VA

48 Vdc 24 to 150 Vdc 5.4 W

125 Vdc 24 to 150 Vdc 5.3 W

250 Vdc 68 to 280 Vdc 5.4 W

240 Vac 90 to 270 Vac 14.1 VA

Input Voltage Range

Burden at

Nominal

1-6 BE1-79M General Information 9170100990 Rev N

Page 17

SECTION 2 • HUMAN-MACHINE INTERFACE

TABLE OF CONTENTS

SECTION 2 • HUMAN-MACHINE INTERFACE ....................................................................................... 2-1

Controls and Indicators .......................................................................................................................... 2-1

Figures

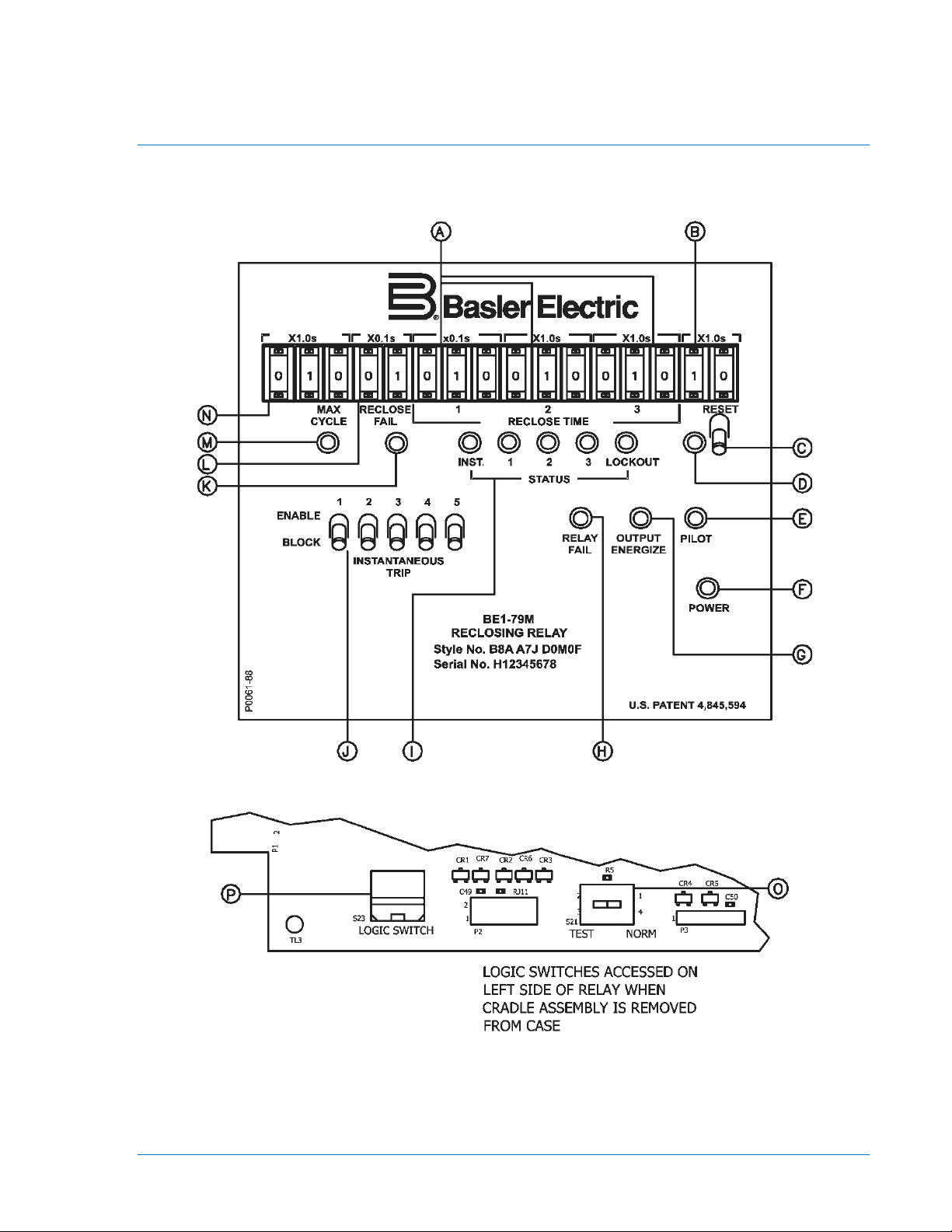

Figure 2-1. Location of Controls and Indicators ........................................................................................ 2-1

Tables

Table 2-1. BE1-79M Controls and Indicators (Refer to Figure 2-1) .......................................................... 2-2

Table 2-2. Logic Switch (S23) Positions and Functions Enabled

.............................................................. 2-4

9170100990 Rev N BE1-79M Human-Machine Interface i

Page 18

ii BE1-79M Human-Machine Interface 9170100990 Rev N

Page 19

SECTION 2 • HUMAN-MACHINE INTERFACE

Controls and Indicators

Figure 2-1 illustrates the location of controls and indicators on the front panel. Table 2-1 explains the callouts shown in Figure 2-1. Table 2-2 lists the functions enabled per logic switch (S23) position.

Figure 2-1. Location of Controls and Indicators

9170100990 Rev N BE1-79M Human-Machine Interface 2-1

Page 20

Table 2-1. BE1-79M Controls and Indicators (Refer to Figure 2-1)

delayed reclosure attempts. Individually thumbwheel

al. Thumbwheel

adjustable from 10 to 1000 seconds in 10 second

adjustable from 0.1 to 9.9 seconds in 0.1 second

Locator Control or Indicator Function

A RECLOSE TIME

Controls (1, 2, 3)

B RESET Control

C RESET Switch

D RESET LED

E PILOT or RESET INHIBIT

LED (Optional)

Establish reclose time delays for corresponding time-

adjustable from 00.1 to 99.9 seconds in 00.1 second

increments or if reclose time delay option is A7, second and

third RECLOSE TIME thumbwheels are adjustable from

001 to 999 seconds in one second increments. A setting of

000 on a RECLOSE TIME thumbwheel indicates the

reclosing attempt is not desired and sends the relay to

lockout at this point in the reclosing sequence.

Establishes automatic reset interv

increments. Optionally adjustable from 1 to 100 seconds in

1 second increments. A setting of 00 indicates a reset time

of 1000 seconds or optionally, 100 seconds.

Momentary toggle switch, which extinguishes STATUS

LEDs (except LOCKOUT). Accessible by linkage, which

extends through bottom of front cover.

ON when relay is in RESET.

With PILOT option, LED is ON when pilot output relay coil

is energized. Remains ON until activation of manual

RESET lever, power loss, or when relay reaches RESET if

STATUS LED reset is optionally selected by logic switch

S23. With RESET INHIBIT option, LED is ON when reset

inhibit input is closed.

F POWER LED

G OUTPUT ENERGIZE LED

H RELAY FAIL LED

I STATUS LEDs

(INST., 1, 2, 3)

(LOCKOUT)

J INSTANTANEOUS TRIP

(Optional)

K RECLOSE FAIL LED

(Optional)

L RECLOSE FAIL Control

(Optional)

ON when the power supply is delivering a nominal ±12 Vdc

to internal circuitry.

ON when reclose output relay coil is energized.

ON when relay is not operable. Also ON during power-up

sequence.

Latched ON to indicate progression of reclosing sequence.

Extinguished by RESET lever, power loss, or when relay

reaches RESET if STATUS LED reset is optionally

selected by logic switch S23.

ON when relay is in LOCKOUT. (Non-latching.)

Five toggle switches, which enable or block instantaneous

tripping of circuit breaker. Numbers correspond to the relay

state or a specific trip depending on the type of reclosing

sequence in progress.

ON when circuit breaker 52b contact does not open within

selected time after reclose output has been energized.

Limits duration of reclose command signal. Thumbwheel

increments. For a setting of 00, the reclose command

signal is continuous until the breaker closes.

M MAX. CYCLE LED

(Optional)

2-2 BE1-79M Human-Machine Interface 9170100990 Rev N

ON when maximum cycle limit, as established by the MAX.

CYCLE control, has been exceeded.

Page 21

Locator Control or Indicator Function

With MAX. CYCLE, establishes maximum cycle limit

sequence until RESET or LOCKOUT). Thumbwheel

Field selectable, 16 position switch (S23) enables

N MAX. CYCLE or PILOT TIME

Control (Optional)

(maximum allowable interval from initiation of reclosing

adjustable from 1 to 1000 seconds in 1 second increments.

A setting of 000 allows a 1000-second maximum cycle.

With reclose time delay option A8 (PILOT TIME), the two

least significant digits are used for the pilot time delay for a

pilot reclose attempt. Thumbwheel adjustable from 0.03 to

0.99 seconds. A setting of .00, .01, and .02 is equivalent to

.03 setting.

O NORMAL/TEST Switch

P

Logic Switch

With Power-up to Reclose enabled, relay will close the breaker during powerup if relay was in RESET when powered down and Pilot Initiate or Reclose

Initiate is present during power-up.

Provides selection of relay operating mode.

combinations of the following functions.

• Memory save

• Power-up to reclose

• Recognition dropout

• Status LED reset

Refer to Table 2-2 for switch positions and functions

enabled. To be enabled, function changes require relay

power removal and power-up after setting switch position.

CAUTION

9170100990 Rev N BE1-79M Human-Machine Interface 2-3

Page 22

Table 2-2. Logic Switch (S23) Positions and Functions Enabled

Position Functions Enabled

0∗∗

1 RD

2 SL

3 SL RD

4

5

6

7

8 MS

9 MS RD

A MS SL

B MS SL RD

C MS

D MS

E MS

PR∗

PR∗

PR∗

PR∗

PR∗

PR∗

PR∗

RD

SL

SL RD

RD

SL

F MS

NOTES:

∗∗ Default position from factory

RD = Recognition Dropout

SL = Status LED Reset

PR∗ = Power-up to Reclose (Refer to Caution preceding Table 2-2)

MS = Memory Save

PR∗

SL RD

2-4 BE1-79M Human-Machine Interface 9170100990 Rev N

Page 23

SECTION 3 • FUNCTIONAL DESCRIPTION

TABLE OF CONTENTS

SECTION 3 • FUNCTIONAL DESCRIPTION ........................................................................................... 3-1

General .................................................................................................................................................. 3-1

Functional Description ........................................................................................................................... 3-1

Contact Sensing ................................................................................................................................. 3-1

Contact Interface ................................................................................................................................ 3-3

Logic Switch ....................................................................................................................................... 3-3

Thumbwheels ..................................................................................................................................... 3-4

Instantaneous Trip Enable (Optional) ................................................................................................ 3-4

Microprocessor ................................................................................................................................... 3-4

Program Monitor ................................................................................................................................. 3-4

Power Loss Detector .......................................................................................................................... 3-4

Outputs ............................................................................................................................................... 3-5

Power Supply ..................................................................................................................................... 3-5

Operational Characteristics .................................................................................................................... 3-6

Power-Up............................................................................................................................................ 3-6

Reset ...................................................................................................................................................... 3-7

Lockout ................................................................................................................................................... 3-7

Reclosing Sequences ......................................................................................................................... 3-8

Reclose Fail ........................................................................................................................................ 3-8

Maximum Cycle .................................................................................................................................. 3-8

Block Load Tap Changer.................................................................................................................... 3-8

Control Outputs and Special Contact Assignments ......................................................................... 3-11

Reclosing Event Memory ..................................................................................................................... 3-11

Purpose ............................................................................................................................................ 3-11

Data Retrieval ................................................................................................................................... 3-12

Data Retention ................................................................................................................................. 3-12

Clearing Stored Data ........................................................................................................................ 3-13

Figures

Figure 3-1. Functional Block Diagram ....................................................................................................... 3-2

Figure 3-2. Contact Sensing Board Link Position

Figure 3-3. Recognition Dropout Timing

Figure 3-4. Power-up Flow Chart

Figure 3-5. Reclosing Sequences

Figure 3-6. Reclosing Flow Chart

Tables

Table 3-1. Function of Sensing Contacts .................................................................................................. 3-1

Table 3-2. Output Contacts

Table 3-3. Wide Range Power Supply Voltage Ranges

Table 3-4. REM Data Retrieval Modes

...................................................................................... 3-3

................................................................................................... 3-4

.............................................................................................................. 3-7

............................................................................................................. 3-9

............................................................................................................ 3-10

....................................................................................................................... 3-5

........................................................................... 3-6

.................................................................................................... 3-12

9170100990 Rev N BE1-79M Functional Description i

Page 24

ii BE1-79M Functional Description 9170100990 Rev N

Page 25

SECTION 3 • FUNCTIONAL DESCRIPTION

sequence. This contact is also required during the

General

The BE1-79M Multiple Shot Reclosing Relay is a microprocessor-based device, which responds to the

state of external contacts. In responding, the Relay provides automatic reclosure once the circuit breaker

has opened to de-energize the line. Refer to Section 1 for major factors to consider when establishing a

reclosing philosophy.

Functional Description

The following paragraphs describe the Relay circuit functions illustrated in Figure 3-1.

Contact Sensing

Depending on style, contact-sensing current is obtained either directly from the Multiple Shot Reclosing

Relay or from any power source with a voltage rating the same as the Relay power supply dc input voltage. When the Relay provides the contact sensing current, isolated contact sensing is employed. When

another power source provides the contact sensing current, non-isolated contact sensing is employed.

Relays with a Y type wide range power supply have a field selectable link (J2) on the contact sensing

board to match the nominal power supply input voltage of 48 Vdc or 125 Vdc. Selection must be done at

the time of installation and prior to application of power. This option is factory set for 125 Vdc. Figure 3-2

shows the link set to the 125 Vdc position.

Table 3-1. Function of Sensing Contacts

Contacts Designation Function

Pilot Initiate

(Optional)

(Note ∆1)

Breaker 52b

Reclose Initiate

(Note ∆2)

Instantaneous

Reclose Bypass

Drive to Lockout DTL

NOTES:

∗ If the appropriate initiate contact (RI or PI) is not received within the corresponding period, the relay

is forced to the lockout state.

∆1. Input is Reset Inhibit (RES INH) if option 1 is 1.

∆2. Input is Reclose Wait (REC WAIT) if option 1 is 2. Input is Reclose Permissive (RP) if option 1 is 4.

PI

RI

IRB

Form A contact which, when closed, initiates a pilot reclosing

(Optional)

sequence to initiate each reclose attempt. ∗

Form B auxiliary contact of the controlled breaker utilized to

determine the state of the breaker.

Form A contact which, when closed, initiates a normal reclosing

sequence. This contact is also required during the sequence to

initiate the individual time delays and subsequent reclose output

closures. ∗

Form A contact which, when closed, cause the instantaneous

reclosure attempt to be bypassed.

Form A contact which, when closed, instantaneously drives the

Multiple Shot Reclosing Relay into lockout.

9170100990 Rev N BE1-79M Functional Description 3-1

Page 26

RECLOSE

RECLOSE

FAIL

PILOT/

TRIP

INSTANTANEOUS

ENABLE

TAP

LOAD

BLOCK

CHANGER

LOCKOUT

FAIL

RELAY

BUFFER

DRIVER

RELAY

FAIL

INST.

1

2

3

LOCKOUT

MAX

RECLOSE

OUTPUT

PILOT/

RESET

CYCLE

FAIL

ENERGIZE

LED INDICATORS

PROGRAM

MONITOR

REGULATOR

VOLTAGEPOWER

SUPPLY

POWER

POWER

LOSS

DETECTOR

RECOGNITION DROPOUT

STATUS LED RESET

MEMORY

SEQUENCE

RECLOSE

MICROPROCESSOR

ENABLE

TRIP

INST.

MEMORY SAVE

POWER UP TO RECLOSE

RESET

MAX

THUMBWHEELS

CYCLE/

FAIL

RECLOSE

RECLOSE

1 2 3

B

U

F

F

E

R

CONTACTINTERFAC

E

RECLOSE

INITIATE

(RI)

BREAKER

(52B)

PILOT

INITIATE

(PI)

INST

RECLOSE

BYPASS

(IRB)

DRIVE

TO

LOCKOUT

(DTL)

10-21-91

D714-006

BE1-79M

LOGIC SWITCH

RESET

INHIBIT

PILOT

TIME

INPUT IS RESET INHIBIT (RES INH) IF OPTION 1 IS 1.

INPUT IS RECLOSE WAIT (REC WAIT) IF OPTION 1 IS 2.

INPUT IS RECLOSE PERMISSIVE (RP) IF OPTION 1 IS 4.

321

1

2

3

PRE-LOCKOUT

Figure 3-1. Functional Block Diagram

3-2 BE1-79M Functional Description 9170100990 Rev N

Page 27

Figure 3-2. Contact Sensing Board Link Position

Recognition and response to closure of the sensing contacts is time dependent. All contact sensing inputs

must be present for a minimum of 6 milliseconds before recognition. For a reclosing sequence to begin,

the 52b contact closure must occur within 17.5 milliseconds after either RI or PI has dropped out. For a

longer output recognition (200 milliseconds), logic switch S23 provides a field selectable option (recognition dropout). If RI and PI are initiated simultaneously, PI takes priority. If a Pilot reclosing sequence is

initiated, IRB has no effect. DTL overrides all other inputs. The function of each set of sensing contacts is

described in Table 3-1.

Contact Interface

Contact interface circuits provide current limiting, filtering, and optoisolation. This interfacing translates the

state of the individual sensing contacts to logic levels. These logic levels are entered onto the data bus,

via buffers, for use by the microprocessor.

Logic Switch

Logic switch S23, is a field selectable, 16-position switch (0 through F), that enables any combination of

four functions. Refer to Table 2-2 for logic switch positions and functions enabled. The four functions are

Memory Save, Power-up to Reclose, Recognition Dropout, and Status LED Reset.

Memory Save

•

at which the reclosing sequence was interrupted. Within 100 milliseconds of when power is reapplied, the relay will resume the reclosing sequence. Memory save function will occur ONLY if the

relay was in a reclosing sequence. It will not occur if the relay was in RESET, RELAY FAIL, or

LOCKOUT.

•

Power-up to Reclose

programmed reclose after power is restored if the breaker is open (52b) and normal initiate (RI or

PI) is present.

•

Recognition Dropout

seconds. The relay initiates a reclosing sequence if a 52b occurs within 200 milliseconds of an RI

Figure 3-3

or PI. illustrates the recognition dropout timing relationship.

Status LED Reset - After a reclosing sequence, the relay initiates STATUS LED reset (INST., 1, 2,

•

3, and PILOT) when the relay reaches RESET.

- When power is lost, the relay initiates the memory circuit to store the exact point

- When power is lost during a RESET condition, the relay initiates a first

- This function replaces the standard recognition dropout time of 17.5 milli-

9170100990 Rev N BE1-79M Functional Description 3-3

Page 28

RI, PI

52b

RECOGNITION

DROPOUT TIME

6-17-91

D806-008

Switch S23, on the edge of the contact sensing board, is accessible by removing the drawout cradle from

the case. When S23 is changed to select different functions, the relay must be powered down and power

reapplied to enable selected functions.

Figure 3-3. Recognition Dropout Timing

Thumbwheels

Front panel thumbwheel switches allow the user to program various time settings and limit reclosure

attempts. The switches select individual diodes, producing binary coded decimal words, which are read

by the microprocessor.

Instantaneous Trip Enable (Optional)

Five front panel toggle switches allow the user to select ENABLE or BLOCK instantaneous tripping of the

circuit breaker. Instantaneous tripping may be enabled or disabled for any single trip or combination of

trips. The microprocessor interrogates the individual switches at appropriate times to determine the

desired state of the instantaneous trip enable output contacts. When LOCKOUT or RESET occurs and

normally open ITE, the instantaneous trip enable output contacts are closed while the breaker is closed if

instantaneous trip enable switch 1 is in the enable position.

Microprocessor

The BE1-79M uses an 8-bit, low power, CMOS microprocessor which performs all timing and decisionmaking functions.

Program Monitor

Operation of the microprocessor is monitored by the program monitor. In normal operation, the microprocessor outputs pulses at regular intervals. If these pulses are disrupted, the program monitor stops

microprocessor operation and forces the output buffers to high impedance. This causes all output contacts to assume their normal states and lights the RELAY FAIL LED. If this situation is the result of

something other than hardware failure, it may be remedied by momentarily interrupting operating power.

Power Loss Detector

The power loss detector circuit compares the output of the power supply to a reference voltage. If the

power supply output falls below the reference voltage, the power loss detector circuit sends an interrupt

signal to the microprocessor. Upon receipt of this signal, the microprocessor stores status data in the nonvolatile reclose sequence memory. This data indicates the progression of a reclosing sequence or state of

the Multiple Shot Reclosing Relay at the time power was lost. At this point, the relay fail contacts close

and all further functions of the relay cease until input power is removed and restored. When power is

restored, the microprocessor uses this data, if logic switch S23 memory save function is enabled and the

power loss occurred during a reclosing sequence, to resume operation from the point of power loss. The

relay compensates for any change of state of the breaker which may have occurred during power off.

However, the remaining least significant digits of the maximum cycle time, reclose delay time, and the

remaining reclose fail time are not stored. If the two most significant digits of the remaining maximum

3-4 BE1-79M Functional Description 9170100990 Rev N

Page 29

cycle time at power loss are 00, the least significant digit is seen as 9 on power restoration. If the relay is

in RESET when power is lost and logic switch S23 power-up to reclose function is enabled, the relay will

close the breaker during power-up if RI or PI is present.

Outputs

Output commands from the microprocessor light LED indicators and are amplified by driver circuits to

energize the coils of the output relays. Individual output contacts and their functions are listed in Table

3-2.

Table 3-2. Output Contacts

Output Contacts Function

Reclose

Lockout Normally open contacts are closed to indicate lockout.

Relay Fail

Reclose Fail

(Optional)

Pilot (Optional)

Pre-lockout (Optional)

Instantaneous Trip

Enable (Optional)

Block Load Tap

Changer (Optional)

Normally open contacts are closed to energize the closing coil of the controlled

circuit breaker.

Normally closed contacts will be closed to indicate a malfunction of the

microprocessor or power supply. (These contacts open on the completion of the

power-up sequence.)

Normally open contacts are closed to indicate that the breaker has not

responded to the reclose command output in the allotted time.

Normally open contacts are closed to energize the closing coil of the controlled

circuit breaker on the first reclosure attempt of a pilot initiated reclosing

sequence.

Normally open contact that is closed to signify that the last programmed reclose

attempt is taking place.

Normally open or normally closed contacts change state to enable an

instantaneous tripping scheme during the reclosing sequence. These contacts

are controlled by the front panel switches and the selected reclosing sequence.

A normally open ITE will close to enable instantaneous tripping, and a normally

closed ITE will open to enable instantaneous tripping.

Normally closed or normally open contacts change state to disable automatic

load tap changer operation during a reclosing sequence.

Power Supply

Basler Electric enhanced the power supply design for unit case relays. This new design created three,

wide range power supplies that replace the four previous power supplies. Style number identifiers for

these power supplies have not been changed so that customers may order the same style numbers that

they ordered previously. The first newly designed power supplies were installed in unit case relays with

EIA date codes 9638 (third week of September 1996). A benefit of this new design increases the power

supply operating ranges such that the 48/125 volt selector is no longer necessary. Specific voltage ranges

for the three new power supplies and a cross reference to the style number identifiers are shown in Table

3-3.

Relays with a Y type power supply also have a field selectable link (J2) on the contact sensing board to

match the power supply nominal input voltage of 48 Vdc or 125 Vdc. The contact sensing functional

description at the beginning of this section described the field selectable link J2.

9170100990 Rev N BE1-79M Functional Description 3-5

Page 30

Table 3-3. Wide Range Power Supply Voltage Ranges

Power Supply Style Chart Identifier Nominal Voltage Voltage Range

Low Range L 24 Vdc

Mid Range J, K, Y

High Range Z

∗ 14 Vdc required to start the power supply.

Relay operating power is developed by the wide range, isolated, low burden, flyback switching, solid-state

power supply. Nominal +12/–12 Vdc is delivered to the relay internal circuitry. Input (source voltage) for

the power supply is not polarity sensitive. A red LED turns ON to indicate that the power supply is functioning properly.

48, 125 Vdc,

120 Vac

125, 250 Vdc,

120, 240 Vac

12 to 32 Vdc ∗

24 to 150 Vdc,

90 to 132 Vac

62 to 280 Vdc,

90 to 270 Vac

Operational Characteristics

Due to the microprocessor-based design of the BE1-79M Multiple Shot Reclosing Relay, many of its

operational characteristics are not apparent in the block diagram. The remaining information in this section is focused on the software-controlled features of the relay.

Power-Up

The application of operating power results in one of four states as illustrated in Figure 3-4. Depending on

conditions and the RESET delay setting, the interval from power application to the resultant state may be

from 10 to 1000 seconds or optionally from 1 to 100 seconds. When the resultant state is reached, the

relay fail output contacts open and the RELAY FAIL LED is extinguished.

3-6 BE1-79M Functional Description 9170100990 Rev N

Page 31

POWER IS

APPLIED

D0757-12

IS

MEMORY SAVE

ENABLED

?

N

IS

CIRCUIT

BREAKER

OPEN

?

N

START

RESET

TIMER

BREAKER

OPEN BEFORE

RESET

?

N

Y Y

Y

Y

POWER

LOST DURING

REC. SEQ.

?

N

IS

POWER UP

TO RECLOSE

ENABLED

?

N

RESTORE OUTPUT

STATES

(OPEN RELAY FAIL)

< 0.1 SEC.

Y

POWER

LOST WHILE IN

RESET

?

Y

N

RESET

N

TIMED

OUT

?

Y

RESET

LOCKOUT PROGRAMMED

RECLOSE WITH FIRST

RECLOSE

CONTINUE

RECLOSING

SEQUENCE

Figure 3-4. Power-up Flow Chart

Reset

A reclosing sequence may only be initiated when the relay is in RESET. RESET is indicated by a front

panel LED. For the relay to reach RESET, the controlled breaker must remain closed for the duration of

the reset time delay setting. If the breaker reopens prior to this time, the relay will proceed to the next

reclosing attempt. If the number of programmed reclosing attempts has been exhausted, the relay will

drive to LOCKOUT.

Lockout

LOCKOUT, a state inhibiting relay operation, is produced by any of the following conditions:

• Number of breaker openings exceeds the number of programmed reclosure attempts

• Closure of the drive-to-lockout input contacts

• Reclose failure

• Duration of a reclosing sequence exceeds the maximum cycle setting

9170100990 Rev N BE1-79M Functional Description 3-7

Page 32

The lockout output contacts close and the LOCKOUT LED lights to indicate lockout. LOCKOUT is terminated when the controlled breaker is closed (manually or by other means) and remains closed for the

duration of the reset time delay setting.

Reclosing Sequences

The BE1-79M Multiple Shot Reclosing Relay can generate three types of reclosing sequences. Each type

is described in the following paragraphs and illustrated in Figure 3-5 and Figure 3-6.

Reclose Initiated Sequence

•

stantaneous reclosing attempt followed by up to three time-delayed reclosing attempts. All

reclose command outputs occur through the reclose output contacts in this sequence.

•

Reclose Initiated Sequence with Instantaneous Reclose Bypass

IRB signals, this sequence produces up to three time-delayed reclosing attempts. All reclose

command outputs occur through the reclose output contacts in this sequence.

•

Pilot Initiated Sequence

taneous reclosing attempt through the pilot output contacts, and up to two time-delayed reclosing

attempts through the reclose output contacts. The time-delayed reclosing attempts are controlled

by RECLOSE TIME delay settings 2 and 3. RECLOSE TIME delay setting 1 is bypassed in this

sequence (unless set to 000, in which case the relay drives to LOCKOUT). The IRB signal has no

influence on this sequence.

Each reclose attempt requires the presence of either the RI or PI contact input before the respective

reclose sequence can be performed. The RI input must also be present prior to each individual time

delay.

When a Pilot Initiated reclose sequence has been started by the presence of the PI input, the associated

closure of the reclose output relay also requires the presence of the PI input. If the breaker re-opens after

the instantaneous closure of the reclose output relay, then the RI or PI input must be present in order for

the second reclose time delay to occur. The RI or PI input must also be present for the third time delay.

The flow chart of Figure 3-6 is a simplified representation of reclosing sequence initiation and progression. In actual operation all reclosing attempts are continuous (as indicated by the dashed lines) unless

limited by the reclose fail or maximum cycle options. The number of reclosing attempts may be limited by

adjusting any one of the reclose time delay settings to 000. This produces LOCKOUT when a breaker trip

occurs at this point in a reclosing sequence.

- Initiated by the 52b and RI signals, this sequence produces one in-

- Initiated by the 52b, RI, and

- Initiated by the 52b and PI signals, this sequence produces one instan-

Reclose Fail

The reclose fail option allows the user to limit the duration of reclose command outputs. If the breaker fails

to respond to the reclose command in the allotted time, the reclose fail and lockout contacts close and

their associated LEDs light. The first reclosure attempt in a pilot initiated reclosing sequence is continuous

regardless of the reclose fail setting. All reclose command outputs are continuous if the reclose fail option

is not present or if the RECLOSE FAIL setting is 00.

Maximum Cycle

The maximum cycle option limits the duration of a reclosing sequence as determined from sequence

initiation (presence of 52b and RI or PI) to automatic relay RESET or LOCKOUT. If RESET or LOCKOUT

is not reached in the allotted time, the MAX. CYCLE LED lights and the relay drives to LOCKOUT.

Block Load Tap Changer

The optional block load tap changer output contacts are opened to disable automatic transformer load tap

changer operations while a reclosing sequence is in progress.

3-8 BE1-79M Functional Description 9170100990 Rev N

Page 33

RECLOSE INITIATED SEQUENCE

RESET

IF

ITEC

S1E

{

1ST

ITEC

IF

S2E

TD1

TRIP RECL.

{

2ND

S3E

IF

ITEC

TRIP RECL.

TD2

{

3RD

S4E

ITEC

IF

TD3

RECL.

{

4TH

TRIP

TRIP

ITEC

IF

S5E

5TH

IF

ITEC

S1E

LOCKOUT

BREAKER

CLOSED

BREAKER

OPEN

OPEN

BREAKER

CLOSED

BREAKER

S1E

ITEC

IF

RESET

4TH

S5E

IF

ITEC

TRIP

TRIP

3RD

{

RECL.

TD3

IF

ITEC

S4E

2ND

{

TD2

RECL.TRIP

ITEC

IF

S3E

1ST

{

RECL.TRIP

TD1

LOCKOUT

S1E

ITEC

IF

RECLOSE INITIATE SEQUENCE W ITH INSTANTANEOUS RECLOSE BYPASS SIGNAL

OPEN

BREAKER

CLOSED

BREAKER

S2E

IF

ITEC

1ST

{

S1E

ITEC

IF

RESET

S1E

ITEC

IF

S5E

IF

ITEC

TRIP

TRIP

3RD

{

RECL.

TD3

IF

ITEC

S4E

2ND

TD2

RECL.

LOCKOUT

TRIP

{

INST.

4TH

PILOT INITIATED SEQUENCE

6-19-91

D741-008

BE1-79M

1

1

1

1

IF CONTROL OUTPUT IS "F" OR "G", ITEC W ILL BE OPEN.

TRIP RECL.

TRIP RECL.

ITEC = INSTANTANEOUS TRIP ENABLE OUTPUT CONTACT S CLOSED.

S_E =

INST.

TD_

= INSTANTANEOUS RECLOSURE (NO INTENTIONAL DELAY).

= RECLOSURE TIME DELAY SETTING.

= UNKNOWN TIME INTERVAL < RESET TIME SETTING.

INSTANTANEOUS TRIP SW ITCH

NOTES:

INST.

2

2

IF RECLOSE TIME DELAY OPTION IS A8, THEN THIS IS PILOT TIME DELAY.

Figure 3-5. Reclosing Sequences

9170100990 Rev N BE1-79M Functional Description 3-9

Page 34

Figure 3-6. Reclosing Flow Chart

3-10 BE1-79M Functional Description 9170100990 Rev N

Page 35

Control Outputs and Special Contact Assignments

Control output contacts and special contact assignments are options controlled by software. The functions

of these contacts are as follows:

I.T.E. Cold Load, Normally Open Option

•

in the LOCKOUT condition. Thus, when a breaker is manually closed from LOCKOUT, the output

will be open until the relay goes to reset. The normal I.T.E. option (NOT I.T.E. cold load) has the

instantaneous trip enable output closed immediately after the breaker is manually closed.

•

Pre-lockout Alarm Output, Normally Open Option

diately whenever the relay is attempting the last programmed reclose attempt. This output is

mutually exclusive with the pilot reclose output. This output will remain closed until the relay

reaches RESET.

•

Reset Inhibit Input Option

lights the RESET INHIBIT LED. When the input contact opens, the reset timer continues timing

from the point of interruption and the RESET INHIBIT LED extinguishes. The reset inhibit input is

mutually exclusive with the pilot initiate input, and the RESET INHIBIT LED is mutually exclusive

with the PILOT LED.

•

Reclose Wait Input Option

contacts remain in the previous state, unless the reclose or pilot outputs are energized prior to the

input closing. If the reclose or pilot outputs are energized when reclose wait is closed, the outputs

will open. When reclose wait input opens, reclosing will continue in the sequence to the next time

delay or LOCKOUT. The reclose wait input replaces the reclose initiate input and RI is not required to initiate the reclosing sequence. Closing the 52b input initiates the reclosing sequence.

•

Reclose Permissive Input Option

controlled delay timers and manual STATUS LED reset. The RESET LED flashes during this

condition. An energized reclose or pilot output is de-energized when the reclose permissive contact opens. When the reclose permissive input contact closes, reclosing continues in the

sequence to the next time delay or LOCKOUT.

A full reclose sequence (one instantaneous, followed by up to three time reclosures is enabled when the

reclose permissive contact is closed and the 52b input contact is closed. The reclose initiate input is

replaced by the reclose permissive input.

IRB and PI are latching inputs with this option. IRB and PI latch if closed when 52b input is closed and

reclose permissive input contact is open. A reclose permissive input is required for a reclose sequence.

- A closed reset inhibit input inhibits the reset timer from timing and

- A closed reclose wait input inhibits all timers from timing. All output

- An open reclose permissive contact inhibits all front-panel-

- The instantaneous trip enable output will remain open

- The pre-lockout alarm output will close imme-

Reclosing Event Memory

Purpose

In the normal service mode, the reclosing event memory (REM) increments software counters to record

significant events of the reclosing sequence. When the relay is reset, the accumulated data is transferred

to and stored in a nonvolatile memory. The data is retained even though power is lost. Only data accumulated prior to the last reset is retained in the non-volatile memory. If the relay loses power during a

reclosing sequence, the data accumulated during this uncompleted sequence will not be saved.

The REM counts and stores the cumulative number of attempts made in the following categories.

• Instantaneous reclosures

• First time-delayed reclosures

• Second time-delayed reclosures

• Third time-delayed reclosures

• Pilot reclosures

• Unsuccessful reclosures

Maximum count is 999 attempts per event type. Drive-to-Lockout events are not counted. REM is not

affected when the relay is in the test mode or by the position of the logic switch, S23, (reclose sequence

memory save enable).

9170100990 Rev N BE1-79M Functional Description 3-11

Page 36

Data Retrieval

In order to retrieve data from REM, the relay must first be taken out of service and placed in the test

mode. Do this by setting the logic board NORMAL/TEST switch (see Figure 2-1) to the TEST position.

Then set the front panel RESET thumbwheel switch to 00. The relay is now ready for data retrieval.

Before proceeding, notice that the following controls and indicators are re-defined whenever the REM

function is in use.

RECLOSE TIME thumbwheel #3 (least significant digit only)

is to be retrieved. Refer to for event and switch positions.

STATUS LEDs (INST., #1 and #2)

is correct. The STATUS LEDs will be ON as shown in .

RECLOSE TIME thumbwheel #1 (3 digits)

nually rotated so that RESET LED and STATUS #3 LED are both ON.

STATUS LED #3

RESET LED

To retrieve REM data, complete the following procedure.

• Remove relay from service and position NORMAL/TEST switch to TEST.

• Position RESET thumbwheel switch to 00.

• Select the type of event (MODE) desired by setting RECLOSE TIME thumbwheel #3 as indicated

in Table 3-4.

• Verify that the desired mode is selected by observing the INST., #1, and #2 STATUS LEDs.

• Observe the STATUS LED #3 and RESET LED. These indicators identify whether the number

selected on RECLOSE TIME #1 thumbwheel is less (STATUS LED #3 ON) or greater (RESET

LED ON) than the number stored in memory.

• Position RECLOSE TIME #1 thumbwheel until both STATUS LED and RESET LED are ON.

When both indicators are ON, the selected number on RECLOSE TIME #l thumbwheel setting is

equal to the stored number.

- Means "<" (less than).

- Means ">" (greater than).

Table 3-4

- Verify that the digit selected on RECLOSE TIME thumbwheel #3

- Indicates the number of accumulated events when ma-

Table 3-4. REM Data Retrieval Modes

- Selects the type of event for which data

Table 3-4

RECLOSE TIME

Type of Event

Instantaneous 0 0 0 0

1st time delayed 1 0 0 1

2nd time delayed 2 0 1 0

3rd time delayed 3 0 1 1

Pilot reclosure 4 1 0 0

Unsuccessful reclosures 5 1 0 1

None Any other 1 1 1

NOTE: A "1" in the STATUS Indication column indicates LED is ON.

#3 Thumbwheel

(Least Significant Digit)

Data Retention

To retain data stored in memory and resume the event count,

• Position the NORMAL/TEST switch on the logic board to NORMAL.

• Return front panel controls to their regular settings.

• Place the relay back in service.

STATUS LED

INST #1 #2

3-12 BE1-79M Functional Description 9170100990 Rev N

Page 37

Clearing Stored Data

To clear the data from memory,

• Toggle the RESET lever once

• Position the NORMAL/TEST switch on the logic board to NORMAL.

• Return front panel controls to their regular settings.

• Place the relay back in service.

It is a good practice to verify that the memory is cleared by repeating the data retrieval procedure and

observing the results.

9170100990 Rev N BE1-79M Functional Description 3-13

Page 38

3-14 BE1-79M Functional Description 9170100990 Rev N

Page 39

SECTION 4 • INSTALLATION

TABLE OF CONTENTS

SECTION 4 • INSTALLATION .................................................................................................................. 4-1

General .................................................................................................................................................. 4-1

Relay Operating Precautions ................................................................................................................. 4-1

Dielectric Test ........................................................................................................................................ 4-1

Mounting ................................................................................................................................................ 4-1

Connections ........................................................................................................................................... 4-9

Figures

Figure 4-1. Panel Cutting/Drilling, Semi-Flush, S1 Case .......................................................................... 4-2

Figure 4-2. S1 Case Dimensions, Rear View, Double Ended, Semi-Flush Mount

Figure 4-3. S1 Case Dimensions, Side View, Double Ended, Semi-Flush Mount

Figure 4-4. Panel Cutting/Drilling, Double Ended, Projection Mount, S1 Case

Figure 4-5. S1 Case Dimensions, Rear View, Double Ended, Projection Mount

Figure 4-6. S1 Case Dimensions, Side View, Double Ended, Projection Mount

Figure 4-7. S1 Case Cover Dimensions, Front View

Figure 4-8. Sensing Input Connections

Figure 4-9. External Terminal Connections

Figure 4-10. Typical Output Connections

Figure 4-11. Typical Internal Connections

................................... 4-3

.................................... 4-4

........................................ 4-5

...................................... 4-6

...................................... 4-7

................................................................................. 4-8

..................................................................................................... 4-9

............................................................................................. 4-10

................................................................................................ 4-11

............................................................................................... 4-12

9170100990 Rev N BE1-79M Installation i

Page 40

ii BE1-79M Installation 9170100990 Rev N

Page 41

SECTION 4 • INSTALLATION

General

When not shipped as part of a control or switchgear panel, the relays are shipped in sturdy cartons to

prevent damage during transit. Immediately upon receipt of a relay, check the model and style number

against the requisition and packing list to see that they agree. Visually inspect the relay for damage that

may have occurred during shipment. If there is evidence of damage, immediately file a claim with the

carrier and notify the Regional Sales Office, or contact the Sales Representative at Basler Electric, Highland, Illinois.

In the event the relay is not to be installed immediately, store the relay in its original shipping carton in a

moisture and dust free environment. When the relay is to be placed in service, it is recommended that the

operational test procedure (Section 5) be performed prior to installation.

Relay Operating Precautions

Before installation or operation of the relay, note the following precautions:

1. The relay is a solid-state device. If a wiring insulation test is required, remove the connection

plugs and withdraw the cradle from its case.

2. When the connection plugs are removed, the relay is disconnected from the operating circuit and

will not provide system protection. Always be sure that external operating (monitored) conditions

are stable before removing a relay for inspection, test, or service.

3. Be sure the relay case is hard wired to earth ground using the ground terminal on the rear of the

unit. It is recommended to use a separate ground lead to the ground bus for each relay.

Dielectric Test

In accordance with IEC 255-5 and ANSI/IEEE C37.90-1989, one-minute dielectric (high potential) tests up

to 2500 Vac (45-65 Hz) may be performed except across open contacts, which may be tested up to 1,500

Vac. Note that this device employs decoupling capacitors to ground from terminals 3, 4, 5, 6, 7, 8, 9, and

10. At 2500 Vac, a leakage current of approximately 5 mA per terminal is to be expected.

Mounting

Because the relay is of solid-state design, it does not have to be mounted vertically. Any convenient

mounting angle may be chosen. Relay outline dimensions and panel drilling diagrams are shown in

Figures 4-1 through 4-7.

9170100990 Rev N BE1-79M Installation 4-1

Page 42

Figure 4-1. Panel Cutting/Drilling, Semi-Flush, S1 Case

4-2 BE1-79M Installation 9170100990 Rev N

Page 43

Figure 4-2. S1 Case Dimensions, Rear View, Double Ended, Semi-Flush Mount

9170100990 Rev N BE1-79M Installation 4-3

Page 44

.75

(19.1)

(157.2)

6.19

(49.53)

1.95

10-32 SCREWS

(7.9)

.31

10-32 SCREWS

(102.4)

4.03

4.03

(102.4)

(7.9)

.31

MOUNTING PANEL

(55.75)

2.195

P0066-64

Figure 4-3. S1 Case Dimensions, Side View, Double Ended, Semi-Flush Mount

4-4 BE1-79M Installation 9170100990 Rev N

Page 45

Figure 4-4. Panel Cutting/Drilling, Double Ended, Projection Mount, S1 Case

9170100990 Rev N BE1-79M Installation 4-5

Page 46

Figure 4-5. S1 Case Dimensions, Rear View, Double Ended, Projection Mount

4-6 BE1-79M Installation 9170100990 Rev N

Page 47

.75

(19.1)

(157.2)

6.19

(49.53)

1.95

10-32 SCREWS

(7.9)

.31

10-32 SCREWS

(102.4)

4.03

4.03

(102.4)

(7.9)

.31

(55.75)

2.195

P0066-67

TERMINAL EXTENSION (TYP.)

FOR DETAILED INSTRUCITONS,

SEE THE TERMINAL PROJECTION

MOUNTING KIT SUPPLIED.

.25

(6.4)

5/16-18 STUD

2 PLACES

MOUNTING PANEL

Figure 4-6. S1 Case Dimensions, Side View, Double Ended, Projection Mount

9170100990 Rev N BE1-79M Installation 4-7

Page 48

P0066-68

Figure 4-7. S1 Case Cover Dimensions, Front View

4-8 BE1-79M Installation 9170100990 Rev N

Page 49

Connections

BE1-79M

4

3

OPERATING

POWER

8 5 7 6 10 9

PI RI DTL 52b IRB

-

+

SENSING

POWER

NON-ISOLATED SENSING

1 1

11

ISOLATED SENSING

IRB52bDTLRIPI

9106758

POWER

3

4

BE1-79M

OPERATING

LEGEND:

RI RECLOSE INITIATE SENSING INPUT CONTACTS

DTL DRIVE-TO-LOCKOUT SENSING INPUT CONTACTS

52b CIRCUIT BREAKER SENSING INPUT CONTACTS

IRB INSTANTANEOUS RECLOSE BYPASS SENSING INPUT CONTACTS

PI PILOT INITIATE SENSING INPUT CONTACTS (OPTIONAL)

RST INH RESET INHIBIT SENSING INPYT CONTACTS (OPTIONAL)

REC WAIT RECLOSE WAIT SENSING INPUT CONTACTS (OPTIONAL)

RP RECLOSE PERMISSIVE SENSING INPUT CONTACTS (OPTIONAL)

IF OPTION 1 IS 1

PI IS REPLACED WITH RST INH.

IF OPTION 1 IS 2

RI IS REPLACED WITH REC WAIT.

IF OPTION 1 IS 4

RI IS REPLACED BY RP.

1

11-14-91

D729-006

BE1-79M

Incorrect wiring may result in damage to the relay. Be sure to check model and style number against the

options listed in the Style Number Identification Chart before connecting and energizing a particular relay.

NOTE

Be sure the relay case is hard-wired to earth ground with no smaller than 12

AWG copper wire attached to the ground terminal on the rear of the relay

case. When the relay is configured in a system with other protective devices, it

is recommended to use a separate lead to the ground bus from each relay.

Connections should be made with minimum wire size of 14 AWG except as noted for the ground wire.

Typical external connections are shown in Figures 4-8 through 4-10. Internal connections are shown in

Figure 4-11.

Figure 4-8. Sensing Input Connections

9170100990 Rev N BE1-79M Installation 4-9

Page 50

#1 AND #2

19

20

17

18

15

16

13

14

11

12

9

10 8

7

6

5

4

3

2

1

SOLID-STATE PROTECTIVE RELAY

Reclosing

}

OUTPUT CONTACT

EXTERNAL CONNECTIONS

}

OUTPUT CONTACT

EXTERNAL CONNECTIONS

11-16-95

D772-004

GND

CASE GROUND

Figure 4-9. External Terminal Connections

4-10 BE1-79M Installation 9170100990 Rev N

Page 51

51

50

K4

K1

K7

K2

79M

15

79M

14

79M

19

79M

16

79M

20

79M

17

18

79M

52

TC

52

CC

LOCKOUT

ALARM

RELAY

FAIL

ALARM

RECLOSE

FAIL

ALARM

79M

11

K6

79M

13

K3

79M

1

K5

2

79M

CHANGER

TAP

LOAD

79M

12

52a 52b

+

-

1

1

LEGEND:

79M MULTIPLE SHOT RECLOSING RELAY

50 INSTANTANEOUS OVERCURRENT RELAY

51 TIME OVERCURRENT RELAY

52 CIRCUIT BREAKER

52a CIRCUIT BREAKER AUXILIARY CONTACTS

52b CIRCUIT BREAKER AUXILIARY CONTACTS

K1 RECLOSING OUTPUT CONTACTS

K7 PILOT RECLOSING OUTPUT CONTACTS

(LOCKOUT AND RESET-3, 5, 7, 8)

K2 LOCKOUT ALARM OUTPUT CONTACTS

K3 RECLOSE FAIL ALARM OUTPUT CONTACTS

(LOCKOUT AND RESET-2, 5, 6, 8)

K5 BLOCK LOAD TAP CHANGER OUTPUT CONTACTS

(CONTROL OUTPUT-B, C)

K4 INSTANTANEOUS TRIP ENABLE OUTPUT CONTACTS

(CONTROL OUTPUT-A, C)

TC TRIP COIL

CC CLOSING COIL

CONTROL CIRCUIT FUSING (IF USED)

MAY BE NO OR NC

1

5-13-91

D729-007

BE1-79M

K6 RELAY FAIL ALARM OUTPUT CONTACTS

9170100990 Rev N BE1-79M Installation 4-11

Figure 4-10. Typical Output Connections

Page 52

Figure 4-11. Typical Internal Connections

4-12 BE1-79M Installation 9170100990 Rev N

Page 53

SECTION 5 • TESTS AND ADJUSTMENTS

TABLE OF CONTENTS

SECTION 5 • TESTS AND ADJUSTMENTS ............................................................................................ 5-1

General .................................................................................................................................................. 5-1

Required Test Equipment ...................................................................................................................... 5-1

Operational Test .................................................................................................................................... 5-1

Reclosing Event Memory (REM)............................................................................................................ 5-6

Data Retrieval ..................................................................................................................................... 5-6

Data Retention ................................................................................................................................... 5-6

Clearing Stored Data .......................................................................................................................... 5-6

Figures

Figure 5-1. Operational Test Setup ........................................................................................................... 5-2

9170100990 Rev N BE1-79M Tests and Adjustments i

Page 54

ii BE1-79M Tests and Adjustments 9170100990 Rev N

Page 55

SECTION 5 • TESTS AND ADJUSTMENTS

General

Procedures in this section are for use in testing and adjusting a relay for the desired operation in a protective scheme. If a relay fails an operational test, or if an adjustment discloses a faulty relay, refer to Section

6, Maintenance.

Required Test Equipment

Minimum test equipment required for relay testing and adjustment is listed below. Refer to Figure 5-1 for

the test setup.

NOTE

Commercially available frequency relay test sets with frequency and time

generating accuracies exceeding those of the relay, and including electronic

switching, may be used.

• Appropriate ac or dc power source for relay operation.

• Appropriate ac source for frequency sensing. (A source with frequency stability of 0.00002 Hz must

exhibit phase noise of less than 90 db for accurate measurement. The accuracy and stability of this

source is necessary as the relay precisely measures the period between positive going zerocrossings of the applied waveform and responds instantaneously to the sensed condition.)

• Hardware (battery, and lamp, multimeter, etc.) or method of determining that the output contacts

close.

Operational Test

The following procedure verifies operation of the relay.

CAUTION

Performing the Operational Test Procedure with the relay in the NORMAL

Mode will increment the reclosing event memory. Prior to initiating the Operational Test Procedure, record the contents of the reclosing event memory.

Care must be taken not to exceed output contact ratings.

STEP 1. Connect the circuit as shown in Figure 5-1. K1 is a latching relay with a set of Form B aux-

iliary contacts to simulate a controlled breaker. If the Pilot Initiate option is not present, S4

and the connections to terminals 8 and 14 are not needed.

STEP 2. Press and release switch S7 (K1 reset) to assure that K1-auxiliary contacts are open (breaker

closed). Set thumbwheel switches as indicated below.

RESET (Note 1) 60.0 seconds (06 setting)

RECLOSE TIME (Note 2 and Note 3)

1 05.0 seconds (050 setting)

2 10.0 seconds (100 setting)

3 15.0 seconds (150 setting)

RECLOSE FAIL Inhibited (00 setting)

MAX. Cycle 1000.0 seconds (000 setting)

NOTES:

1. If reset timer option is D, set RESET to 60.

2. If reclose time delay option is A7, set RECLOSE TIME 2 to 010 and RECLOSE TIME 3 to

015.

3. If reclose time delay option is A8, set PILOT TIME to 99.

9170100990 Rev N BE1-79M Tests and Adjustments 5-1

Page 56

Figure 5-1. Operational Test Setup

STEP 3. If Instantaneous Trip Enable option is present in your unit, place all INSTANTANEOUS TRIP

toggle switches in the Block position. Apply relay operating power. POWER LED and RELAY

FAIL LED should light. In 60 seconds, RELAY FAIL LED should go out and RESET LED