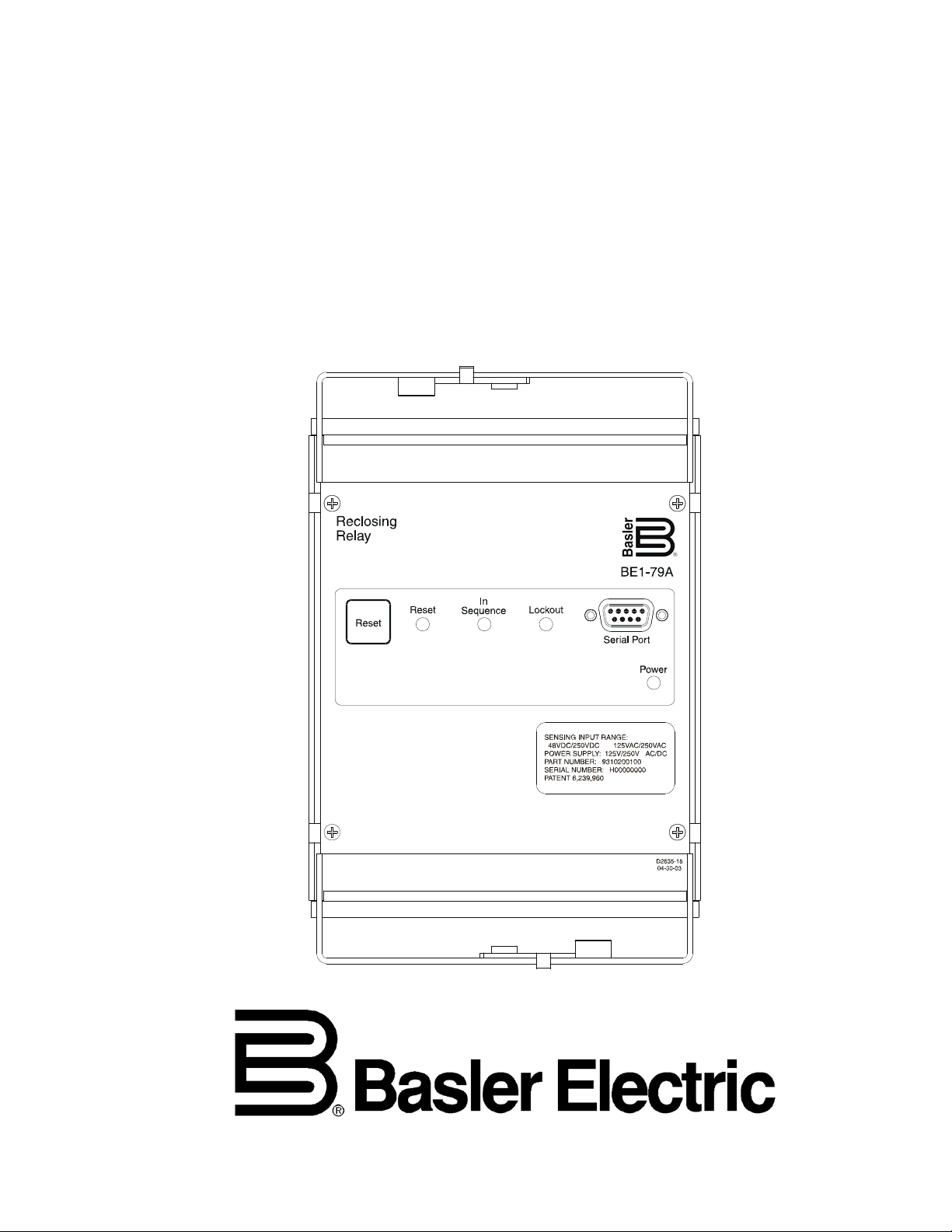

Page 1

INSTRUCTION MANUAL

FOR

RECLOSING RELAY

BE1-79A

Publication: 9310200990

Revision: J 12/11

Page 2

Page 3

INTRODUCTION

This instruction manual provides information about the operation and installation of the BE1-79A

Reclosing Relay. To accomplish this, the following information is provided:

General Information and Specifications

Controls and Indicators

Functional Description

Installation

Maintenance

WARNING!

To avoid personal injury or equipment damage, only qualified personnel should

perform the procedures in this manual.

9310200990 Rev J BE1-79A Introduction i

Page 4

First Printing: July 1997

Printed in USA

Copyright© 1997-2011 Basler Electric, Highland Illinois 62249 USA

All Rights Reserved

December 2011

CONFIDENTIAL INFORMATION

of Basler Electric, Highland Illinois, USA. It is loaned for confidential use,

subject to return on request, and with the mutual understanding that it will not

be used in any manner detrimental to the interest of Basler Electric.

It is not the intention of this manual to cover all details and variations in equipment, nor does this manual

provide data for every possible contingency regarding installation or operation. The availability and design

of all features and options are subject to modification without notice. Should further information be

required, contact Basler Electric.

BASLER ELECTRIC

12570 STATE ROUTE 143

HIGHLAND IL 62249 USA

http://www.basler.com, info@basler.com

PHONE +1 618.654.2341 FAX +1 618.654.2351

ii BE1-79A Introduction 9310200990 Rev J

Page 5

REVISION HISTORY

The following information provides a historical summary of the changes made to the BE1-79A hardware,

firmware, and software. The corresponding revisions made to this instruction manual (9310200990) are

also summarized. Revisions are listed in reverse chronological order.

Application Firmware

Version and Date Change

1.07, 02/08

1.05, 08/00

1.03.XX, 08/98

1.02.XX, 06/98

1.02.XX, 12/97

1.01.XX, 07/97

Hardware

Version and Date Change

M, 03/10

L, 02/08

K, 01/06

J, 09/04

H, 02/04

G, 05/03

F, 10/02

E, 09/00

D, 01/00

C, 10/98

B, 12/97

A, 07/97

Modified firmware so the relay will go to Lockout after the EXIT

command is entered through the RS-232 port or access has timed

out. If the breaker is closed, the relay will go to Reset after the

Lockout Timer expires.

SP-79ARS command mode parameters were changed from C

(closed) and O (open) to E (energized) and D (de-energized).

Coordinated open and close timing of outputs C5 and C6 to preserve

consistent operation of the anti-pump function.

Communication was made consistent with other Basler products by

adding line feeds to ASCII data returned by the relay.

Initial release of part number 9310200200.

Initial release of part numbers 9310200100 and 9310200101.

Production change to digital board.

Released firmware version 1.07

Improved digital board to prevent misoperation at high voltage and

high temperature.

Changed resistors used in power supply holdup module to improve

performance in surge applications.

Changed obsolete resonator on digital board.

Initial release of part number 9310200201.

Made changes to engineering documentation.

Added RS Contact Switch S5 for user-selection of normally-open or

normally-closed RS contacts.

Contact sensing jumpers added to the digital circuit board of relays

with part number 9310200101 gave inputs V1, V2, V3, and V4 three

specific ranges of operating voltage.

Changed serialization format to HXXXXXXXX.

Initial release of part number 9310200200.

Initial release of part numbers 9310200100 and 9310200101.

Manual

Revision and Date

J, 12/11

9310200990 Rev J BE1-79A Introduction iii

In Table 1-1, stated that connection plugs are included with all relays.

In Figures 3-2 and 3-3, added shorting bars between terminals 15 &

16 and removed shorting bars between terminals 1 & 2.

Change

Page 6

Manual

Revision and Date Change

H, 07/10

Expanded Table 1-1, BE1-79A Versions and Features.

Revised rating for output contacts under Specifications in Section 1.

Added GOST-R statement in Section 1.

G, 02/08

Added manual part number and revision to footers.

Updated Output Contact ratings in Section 1.

Updated Lockout description in Section 3 to support version 1.07

firmware.

Updated Command Descriptions in Section 4 to support version 1.07

firmware.

F, 10/05

Added switch S4 labels to Figure 2-3.

In Figures 3-1, 6-1, and 6-2, enhanced C8 function block illustration to

show NO or NC contact selectable by switch S5. Changed C10 from

NC to NO.

Added RS Mode Selector switch illustration and corrected shorting

bars placement in Figures 3-2 and 3-3.

Changed name of Section 4 from Communication to Communication

Commands.

Changed name of Section 5 from Installation to Installation and

Configuration.

Corrected and clarified connection drawings of Figures 5-4 and 5-5.

Added troubleshooting tips to Section 6.

Moved contents of Section 7 to Section 1 and deleted Section 7.

Added Appendix A, RS Contact Application.

Added Appendix B, Terminal Communication.

E, 04/03

Added information pertaining to part number 9310200201.

Clarified the weight specification in Section 1.

Corrected error in Figure 5-4.

D, 08/00

Covered addition of RS Contact Switch S5 and changes to SP-

79ARS command.

C, 01/00

Information pertaining to the jumper-selectable contact sensing

voltage ranges was added. Drawings in Figure 5-1 were changed to

show the revised relay case cover.

B, 05/98

Patent information was added to Section 1. Various errors in Sections

1, 3, and 6 were corrected.

A, 09/97

―, 07/97

Information pertaining to the power supply holdup feature was added.

Initial release

iv BE1-79A Introduction 9310200990 Rev J

Page 7

CONTENTS

SECTION 1 • GENERAL INFORMATION ................................................................................................ 1-1

SECTION 2 • CONTROLS AND INDICATORS ........................................................................................ 2-1

SECTION 3 • FUNCTIONAL DESCRIPTION ........................................................................................... 3-1

SECTION 4 • COMMUNICATION COMMANDS ...................................................................................... 4-1

SECTION 5 • INSTALLATION AND CONFIGURATION .......................................................................... 5-1

SECTION 6 • TESTING ............................................................................................................................ 6-1

APPENDIX A • RS CONTACT APPLICATION ......................................................................................... A-1

APPENDIX B • TERMINAL COMMUNICATION ....................................................................................... B-1

9310200990 Rev J BE1-79A Introduction v

Page 8

vi BE1-79A Introduction 9310200990 Rev J

Page 9

SECTION 1 • GENERAL INFORMATION

TABLE OF CONTENTS

SECTION 1 • GENERAL INFORMATION ................................................................................................ 1-1

Description ............................................................................................................................................. 1-1

Features ................................................................................................................................................. 1-2

Controls and Indicators ...................................................................................................................... 1-2

Communication .................................................................................................................................. 1-2

Power Holdup Circuit .......................................................................................................................... 1-2

Primary Application ................................................................................................................................ 1-2

Specifications ......................................................................................................................................... 1-2

Reclose Timers 1, 2, 3, and 4 ............................................................................................................ 1-2

Reset Timers 1, 2, 3, 4, and Final ...................................................................................................... 1-2

Lockout Timer ..................................................................................................................................... 1-3

RS Set and Reset Timers................................................................................................................... 1-3

Communication Port ........................................................................................................................... 1-3

Power Supply ..................................................................................................................................... 1-3

Contact Sensing Inputs ...................................................................................................................... 1-3

Output Contacts ................................................................................................................................. 1-3

Type Tests .......................................................................................................................................... 1-3

Environment ....................................................................................................................................... 1-4

GOST-R Certification ......................................................................................................................... 1-4

Weight ................................................................................................................................................ 1-4

Patent ................................................................................................................................................. 1-4

Maintenance........................................................................................................................................... 1-4

Tables

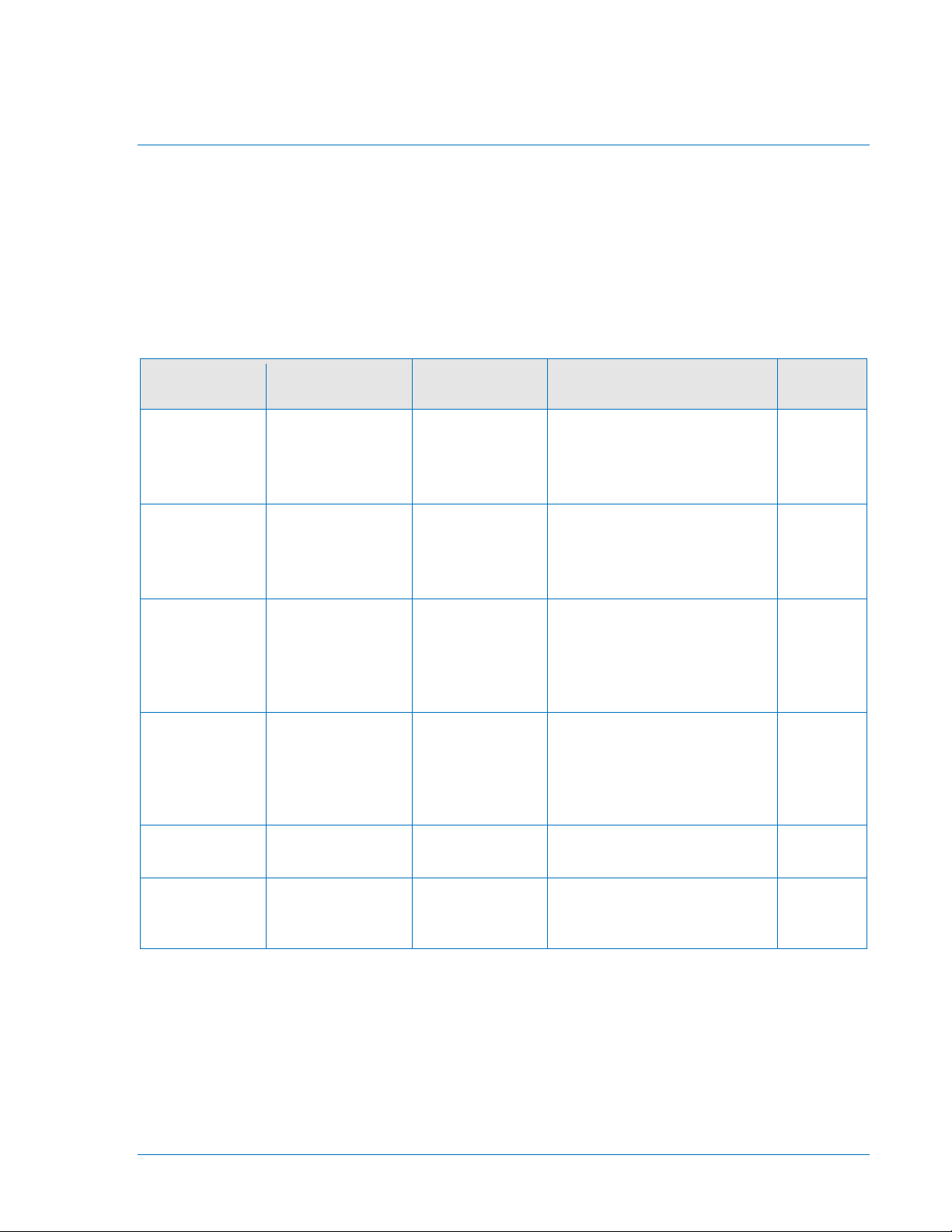

Table 1-1. BE1-79A Versions and Features .............................................................................................. 1-1

9310200990 Rev J BE1-79A General Information i

Page 10

ii BE1-79A General Information 9310200990 Rev J

Page 11

SECTION 1 • GENERAL INFORMATION

Description

The BE1-79A Reclosing Relay is an economical, microprocessor-based relay that automatically recloses

circuit breakers that have been tripped by protective relays or other devices in power transmission and

distribution systems. The BE1-79A offers true "plug and play" convenience; it can be installed in an

existing GE type S2 case with no wiring changes required. General Electric type ACR11A, ACR11B,

ACR11C, ACR11E, and ACR11F reclosing relays can be directly replaced by the BE1-79A-100 or BE179A-101. The BE1-79A-200 and BE1-79A-201 are available in a shorter cradle that fits in a Basler S1

case for new installations.

Table 1-1 lists the case style and special features of each version of the BE1-79A.

Table 1-1. BE1-79A Versions and Features

Catalog

Number

BE1-79A-100 9310200100

BE1-79A-101 9310200101

BE1-79A-109* 9310200109

BE1-79A-111*

Basler Relay

Part Number

9310200111

Retrofit for Options

None

GE 12ACR-11A

GE 12ACR-11B

GE 12ACR-11A

GE 12ACR-11B

GE 12NLR-21U

125 Vdc

GE 12NLR-21U

48 Vdc

Plugs into existing case.

Connection plugs included.

No rewiring required.

Power holdup circuit.

Plugs into existing case.

Connection plugs included.

No rewiring required.

None

Plugs into existing NLR case.

Connection plugs included.

Requires some rewiring on

back of case.

None

Plugs into existing NLR case.

Connection plugs included.

Requires some rewiring on

back of case.

Cradle

Style

S2

S2

S2

S2

BE1-79A-200 9310200200

BE1-79A-201 9310200201

* Refer to Instruction Manual for Modified BE1-79A, part number 9310200999.

9310200990 Rev J BE1-79A General Information 1-1

GE 12ACR-11A

GE 12ACR-11B

GE 12ACR-11A

GE 12ACR-11B

Mounting case and connection

plugs included.

Power holdup circuit.

Mounting case and connection

plugs included.

S1

S1

Page 12

Features

BE1-79A Multiple Shot Reclosing Relays have the following standard features:

• Rugged construction in a steel, draw-out case

• A maximum of four automatic reclosures

• A maximum of four automatic resets

• Lockout function

• Selectable instantaneous or delayed first reclosure

• Selectable internal or external instantaneous jumper

• Selectable normally closed or normally open RS output contact

• Selectable Relay Fail or Lockout and Relay Fail output contact

• Selectable contact sensing voltage range

Controls and Indicators

The front panel has indicators to verify relay power and recloser status. A Reset switch is provided to

restore the relay to the reset mode by clearing a reclosing sequence or a lockout condition. The left side

of the relay cradle has switches (S1, S2, and S3) to configure the relay for either ACR11A or ACR11B

operation. The right side of the cradle has a switch (S4) to select either an internal or an external jumper

for an instantaneous, first reclose. The right side of the cradle also has a switch (S5) to select either

normally open or normally closed operation of the RS contact.

Communication

All relay settings are read or changed through the serial port located on the front panel. The BE1-79A

uses ASCII protocol.

Power Holdup Circuit

The BE1-79A is available with an optional, internal, power holdup circuit. This circuitry maintains the

output contacts for a minimum of 40 cycles after nominal operating power is removed from relay terminals

5 and 6.

Primary Application

The BE1-79A automatically recloses circuit breakers that have been tripped by protective relays or other

devices in power transmission and distribution systems.

Over 90% of faults occurring on overhead lines may be cleared by momentarily de-energizing the line.

Once the circuit breaker has been opened to de-energize the line, the BE1-79A provides a reliable

automatic reclosure. The advantages are:

• Improved service continuity—returns the line to service quickly, preserving line integrity, and

minimizing outage effects on critical loads.

• System stability—prevents disjointing of the system grid.

• Higher line availability—decreases likelihood of permanent loss of line.

Specifications

BE1-79A relays have the following features and capabilities.

Reclose Timers 1, 2, 3, and 4

Range ........................................ 0 to 300 seconds

Increments ................................. 0.1 second

Accuracy .................................... ±20 milliseconds ±1%, typical

±50 milliseconds ±1%, maximum

Reset Timers 1, 2, 3, 4, and Final

Range ........................................ 0 to 300 seconds

Increments ................................. 0.1 seconds

Accuracy .................................... ±20 milliseconds ±1%, typical

±50 milliseconds ±1%, maximum

1-2 BE1-79A General Information 9310200990 Rev J

Page 13

Lockout Timer

Range ........................................ 0 to 300 seconds

Increments ................................. 0.1 seconds

Accuracy .................................... ±20 milliseconds ±1%, typical

±50 milliseconds ±1%, maximum

RS Set and Reset Timers

Range ........................................ 0 to 300 seconds

Increments ................................. 0.1 seconds

Accuracy .................................... ±20 milliseconds ±1%, typical

±50 milliseconds ±1%, maximum

Communication Port

Parameters ................................ 9600 baud, 8N1 half duplex

Protocol ...................................... ASCII

Power Supply

Operating Range ....................... 120 to 240 Vac

125 to 250 Vdc

Power Holdup Time* ................. 40 cycles (670 ms)

* BE1-79A-101, BE1-79A-201 only. Minimum holdup time after loss of nominal operating voltage.

Contact Sensing Inputs

Energizing Level ........................ 80% of nominal

Current Draw ............................. 1.5 mA maximum per input

Operating Range

48 Vdc, Nominal ........................ 38.4 to 275 Vdc

125 Vdc/120 Vac, Nominal ........ 100 to 275 Vdc, or 96 to 264 Vac

250 Vdc/240 Vac, Nominal ........ 200 to 275 Vdc, or 192 to 264 Vac

Recognition Time

Typical ....................................... 15 ms for dc, ac (45 to 65 Hz)

Maximum ................................... 25 ms for dc, ac (45-65 Hz)

Dropout Time

Typical ....................................... 15 ms for dc, ac (45-65 Hz)

Maximum ................................... 25 ms for dc, ac (45-65 Hz)

Output Contacts

Resistive Ratings

120 Vac ...................................... Make, break, and carry 7 Aac continuously

250 Vdc ...................................... Make and carry 30 Adc for 0.2 s, carry 7 Adc continuously,

break 0.3 Adc

Inductive Ratings

120 Vac, 125 Vdc, 250 Vdc ....... Break 0.3 A (L/R = 0.04)

Type Tests

Electrostatic Discharge (ESD)

8 kV contact discharges and 15 kV air discharges applied in accordance with IEC 801-2 ESD.

Dielectric Strength

1,500 Vac at 50/60 Hz in accordance with IEEE C37.90

The RS-232 serial communication port is intended only for periodic use and is not subject to the

requirements of IEEE C37.90.

9310200990 Rev J BE1-79A General Information 1-3

Page 14

Surge Withstand Capability—Oscillatory and Fast Transient

Qualified to IEEE C37.90.1-1989, Standard Surge Withstand Capability (SWC) Tests for Protective

Relays and Relay Systems. The RS-232 Serial Communication Port is intended only for periodic use and

is not subject to the requirements of IEEE C37.90.1.

Radio Frequency Interference (RFI)

Type tested using a 5 W, hand-held transceiver in the ranges of 144 and 440 MHz with the antenna

placed within 6 inches (152 millimeters) of the relay.

Shock

In standard tests, the relay has withstood 15 G in each of three mutually perpendicular planes without

structural damage or degradation of performance.

Vibration

In standard tests, the relay has withstood 2 G in each of three mutually perpendicular planes, swept over

the range of 10 to 500 Hz for six sweeps, 15 minutes each sweep, without structural damage or

degradation of performance.

Environment

Operating Temperature Range .. –40 to 70°C (–40 to 158°F)

Storage Temperature Range ..... –40 to 85°C (–40 to 185°F)

Humidity ..................................... Qualified to IEC 68-2-38, 1

Procedures, Part 2: Test Z/AD: Composite Temperature Humidity Cyclic

Test

st

Edition 1974, Basic Environmental Test

GOST-R Certification

GOST-R certified per the relevant standards of Gosstandart of Russia.

Weight

BE1-79A-100, -101 .................... 5 lb (2.3 kg)

BE1-79A-200, -201 .................... 13 lb (5.9 kg)

Patent

Number 6,239,960

Maintenance

BE1-79A relays require no preventative maintenance. However, testing should be performed according to

scheduled practices. If the relay fails to function properly, contact the Technical Support Services

department of Basler Electric for a return authorization number before returning the relay for service.

1-4 BE1-79A General Information 9310200990 Rev J

Page 15

SECTION 2 • CONTROLS AND INDICATORS

TABLE OF CONTENTS

SECTION 2 • CONTROLS AND INDICATORS ........................................................................................ 2-1

Front Panel............................................................................................................................................. 2-1

Style Configuration Switches ................................................................................................................. 2-2

Instantaneous Reclose Jumper Switch and RS Contact Switch ........................................................... 2-2

Figures

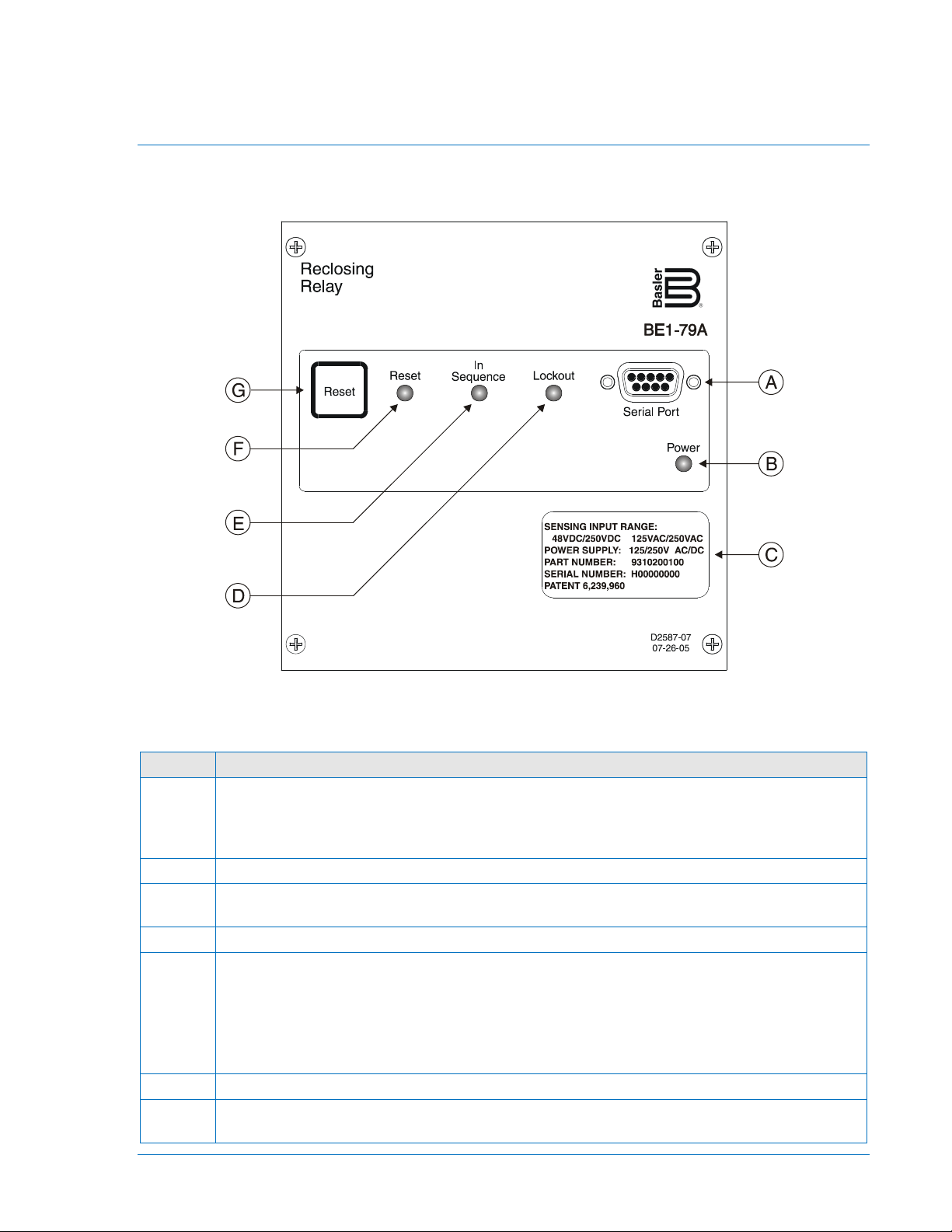

Figure 2-1. Front Panel Controls and Indicators ....................................................................................... 2-1

Figure 2-2. Style Configuration Switches .................................................................................................. 2-2

Figure 2-3. Instantaneous Reclose Jumper Switch and RS Contact Selection Switch ............................. 2-3

Tables

Table 2-1. Front Panel Control and Indicator Descriptions ....................................................................... 2-1

9310200990 Rev J BE1-79A Controls and Indicators i

Page 16

ii BE1-79A Controls and Indicators 9310200990 Rev J

Page 17

SECTION 2 • CONTROLS AND INDICATORS

Locator

Description

A

RS-232 Serial Communication Port. A PC or computer terminal running a terminal

ASCII command language.

B

Power LED. A lit Power LED indicates that operating power is applied to the relay.

C

Identification Label. Shows relay information such as the sensing input range, power supply

type, serial number, and part number.

D

Lockout LED. When lit, this LED indicates that the relay is in the lockout state.

E

In Sequence LED. A lit In Sequence LED indicates any one of the following states:

F

Reset LED. When lit, this LED indicates that the relay is in the reset state.

G

Reset Pushbutton. Pressing this momentary switch clears the In Sequence or Lockout LEDs

and restores the relay to the reset state.

Front Panel

Front panel controls and indicators are illustrated in Figure 2-1 and described in Table 2-1. The locators

and descriptions of Table 2-1 correspond to the locators shown in Figure 2-1.

Figure 2-1. Front Panel Controls and Indicators

Table 2-1. Front Panel Control and Indicator Descriptions

emulation program such as Windows® HyperTerminal can be connected to this port so that

relay settings can be read or changed. Communication with the BE1-79A uses a simple

• Timing to reclose

• Timing to reset

• Timing to lockout

• Attempting to reclose

• Attempting to reset

9310200990 Rev J BE1-79A Controls and Indicators 2-1

Page 18

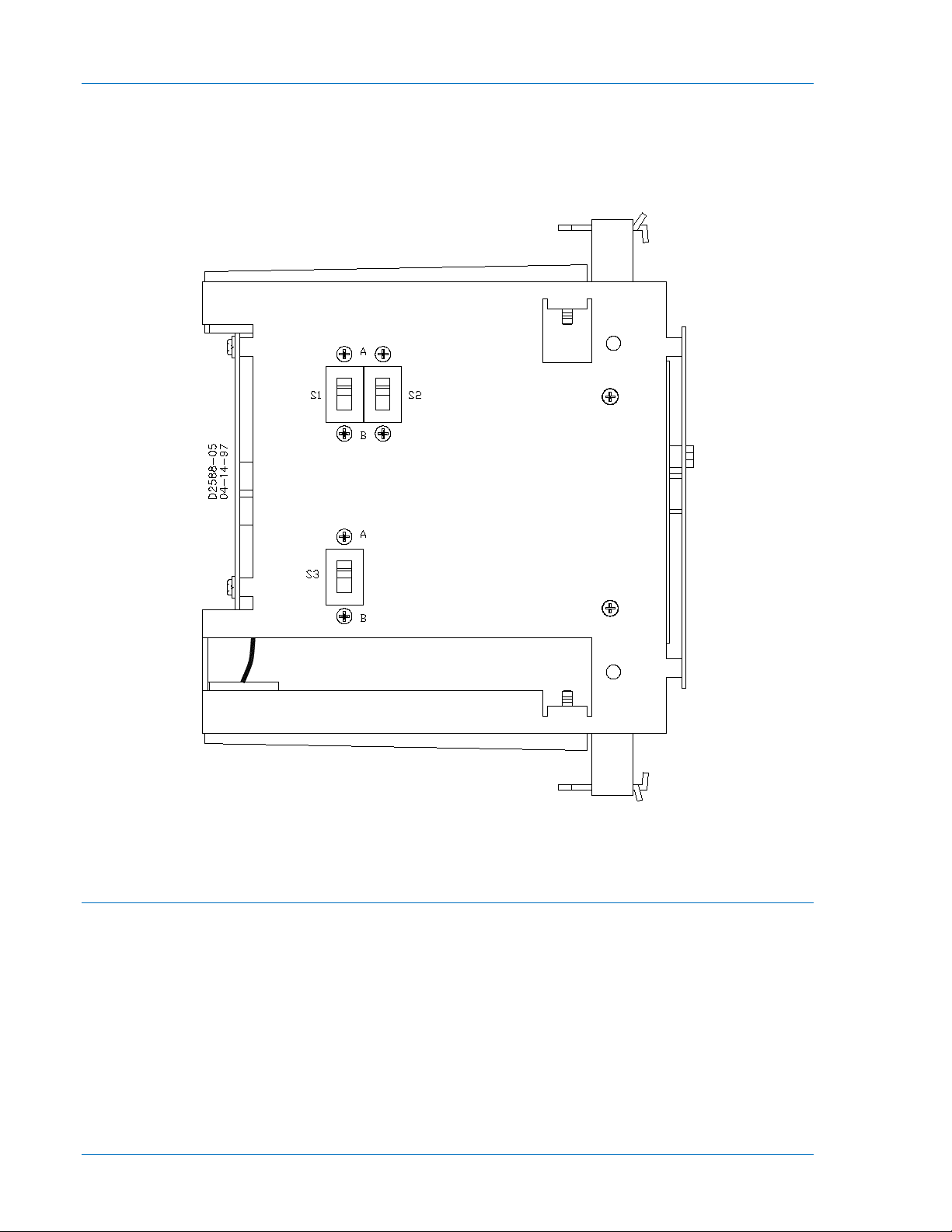

Style Configuration Switches

Three switches on the left side of the relay cradle are used to configure the BE1-79A for either ACR11A

or ACR11B operation. For simplicity, recloser styles ACR11B, ACR11C, ACR11D, ACR11E, and ACR11F

will be referred to as ACR11B throughout this manual. Figure 2-2 illustrates the location of the style

configuration switches. The BE1-79A is delivered with switches S1, S2, and S3 placed in the “A” position.

Figure 2-2. Style Configuration Switches

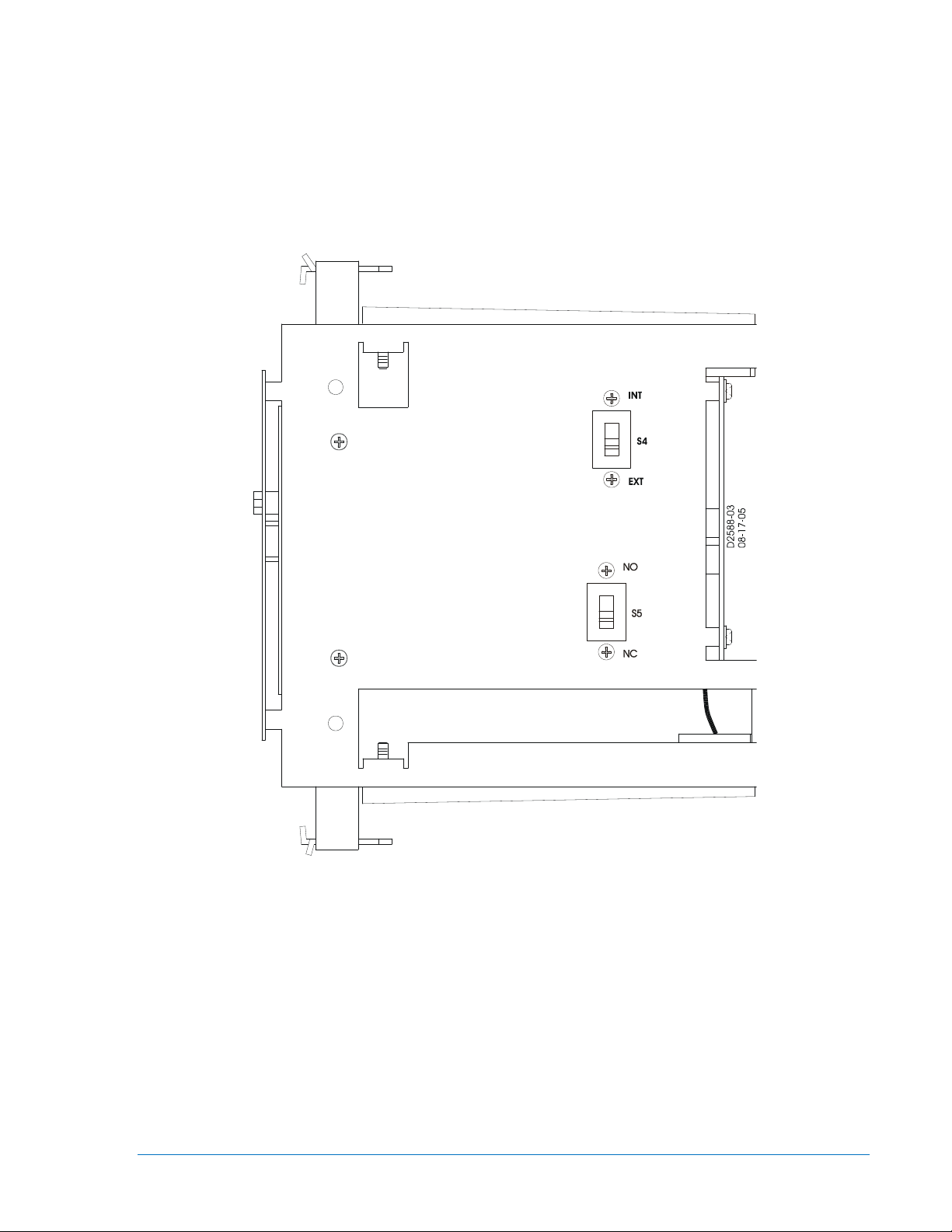

Instantaneous Reclose Jumper Switch and RS Contact Switch

Two switches on the right side of the relay cradle select either internal or external jumpering for an

instantaneous first reclosure and for selecting normally-closed or normally-open operation of the RS

contact. Switch S4 is used to select internal or external jumpering and switch S5 is used to select

normally-open or normally-closed operation of the RS contact. Figure 2-3 illustrates the location of

switches S4 and S5. The BE1-79A is delivered with switch S4 placed in the “EXT” position and switch S5

placed in the “NC” position.

2-2 BE1-79A Controls and Indicators 9310200990 Rev J

Page 19

Figure 2-3. Instantaneous Reclose Jumper Switch and RS Contact Selection Switch

9310200990 Rev J BE1-79A Controls and Indicators 2-3

Page 20

2-4 BE1-79A Controls and Indicators 9310200990 Rev J

Page 21

SECTION 3 • FUNCTIONAL DESCRIPTION

TABLE OF CONTENTS

SECTION 3 • FUNCTIONAL DESCRIPTION ........................................................................................... 3-1

Introduction ............................................................................................................................................ 3-1

Hardware ................................................................................................................................................ 3-1

100 Series Description ....................................................................................................................... 3-1

200 Series Description ....................................................................................................................... 3-1

Circuit Operation .................................................................................................................................... 3-1

Inputs .................................................................................................................................................. 3-1

Microprocessor ................................................................................................................................... 3-3

Outputs ............................................................................................................................................... 3-3

Interconnections ..................................................................................................................................... 3-5

Recloser Operation ................................................................................................................................ 3-7

Power-Up............................................................................................................................................ 3-7

Reset .................................................................................................................................................. 3-8

Lockout ............................................................................................................................................... 3-8

Reclosing Sequences ......................................................................................................................... 3-8

Figures

Figure 3-1. Function Block Diagram .......................................................................................................... 3-1

Figure 3-2. Relay Interconnections for ACR11A Applications

Figure 3-3. Relay Interconnections for ACR11B Applications

Figure 3-4. Power-Up Flow Chart

Figure 3-5. Reclose Settings Example

Figure 3-6. Reclosing Flow Chart

................................................................... 3-5

................................................................... 3-6

.............................................................................................................. 3-7

...................................................................................................... 3-9

............................................................................................................ 3-10

Tables

Table 3-1. Contact Sensing Jumpers ........................................................................................................ 3-2

Table 3-2. Contact Sensing Inputs Description for ACR11A Operation

Table 3-3. Contact Sensing Inputs Description for ACR11B Operation

Table 3-4. Outputs Description for ACR11A Operation

Table 3-5. Outputs Description for ACR11B Operation

.................................................... 3-2

.................................................... 3-3

............................................................................. 3-3

............................................................................. 3-4

9310200990 Rev J BE1-79A Functional Description i

Page 22

ii BE1-79A Functional Description 9310200990 Rev J

Page 23

SECTION 3 • FUNCTIONAL DESCRIPTION

V1

V3

V2

V4

V5

MICROPROCESSOR

C1 C3 C5 C7 C9

ISO

ISO

ISO

ISO

ISO

EEPROM

Settings and Status

Memory

RAM

Operating

Memory

ROM

Program

Memory

AC/DC

Power

Reset

Watchdog

Timer Circuit

Power Supply

RS-232

LED

Indicators

D2588-04

08-17-05

C2 C4 C6 C10

C8

S5

Introduction

BE1-79A relays are microprocessor-based devices that provide automatic reclosing of circuit breakers.

This section describes the hardware, circuitry, and software of the BE1-79A.

Hardware

The BE1-79A is supplied as an S1 cradle and case (200 series) or an S2 cradle without a case (100

series).

100 Series Description

The BE1-79A-100 and –101 consist of a draw-out cradle assembly that is intended for installation in an

existing S2 case. A case is not provided with the cradle assembly.

200 Series Description

The BE1-79A-200 and –201 consist of a draw-out cradle assembly with a steel and phenolic case. The

case has the same overall dimensions as a Basler Electric or General Electric S1 case.

Circuit Operation

This description of circuit operation is divided into Inputs, Microprocessor, and Outputs. BE1-79A circuit

functions are illustrated in Figure 3-1 and described in the following paragraphs.

Figure 3-1. Function Block Diagram

Inputs

The four types of BE1-79A inputs are:

• Operating power

• Contact sensing inputs

9310200990 Rev J BE1-79A Functional Description 3-1

• Reset switch

• Serial communication port

Page 24

Operating Power

Jumper Position

Nominal Voltage

1

125 Vdc or 120 Vac

2

48 Vdc

3

250 Vdc or 240 Vac

selectable voltage range should be

Input

Terminals

Description

lockout, a reset will be initiated anytime V1 senses voltage. (E Reset)

V2

7, 8

Connects to a 52b contact, which results in voltage being sensed when the

This prevents multiple reclose attempts for a single reclose setting. (Z)

V3

11, 12

Used to monitor the 52b contact while the relay is in a reset condition. When

V3 senses voltage, the relay initiates a reclose sequence. (E Operate)

V4

—

Not used in this application.

V5

5, 6

Internally connected to the relay power supply terminal. A loss of sensing

contacts to return to their de-energized or “in-the-box” state.

Operating power for the internal circuitry is applied to the internal, isolated, switching power supply. The

power supply operates over a range of 120 to 240 Vac or 125 to 250 Vdc with no connection changes or

jumpers required. The operating power input is not polarity sensitive and is not disrupted by variations in

the supply voltage or frequency over the power supply operating range. The power supply generates a 24

Vdc output.

BE1-79A-101 and BE1-79A-201 relays are equipped with holdup circuitry that maintains relay function for

a minimum of 40 cycles after nominal operating power is removed.

Contact Sensing Inputs

The contact sensing inputs are designated V1, V2, V3, V4, and V5. Each input is optically isolated to

electrically insulate the input from external power sources. Each contact sensing input is rated for 48 to

250 Vdc and 120 to 240 Vac at 45 to 65 hertz.

Inputs V1 through V4 can operate at any one of

three jumper-selectable voltage ranges. Table 3-1

lists the nominal operating voltage for each of the

three jumper positions. Each input has a dedicated

jumper that is located on the digital circuit board.

Jumper P3 controls the operating voltage for V1, P4

controls V2, P5 controls V3 and P6 controls V4.

Instructions for placing each jumper in the desired

position are provided in Section 5, Installation and

Configuration. Input V5 is dedicated to monitoring

the relay power supply input and is not jumper

selectable.

Table 3-1. Contact Sensing Jumpers

NOTE

In certain applications where 240 Vac control voltage is used, control circuit

feedback can occur through system inductive coupling. This feedback can

result in erroneous signals, causing relay operation. If there is potential for

control circuit feedback, the jumperchanged from the 48 Vdc, factory-default setting to a higher value. Selections

are listed in

The function of each input depends on the operating configuration of the relay. Tables 3-2 and 3-3

describe the function of each contact sensing input for each relay configuration. The GE nomenclature

used for each input is provided in parenthesis following each description.

Table 3-2. Contact Sensing Inputs Description for ACR11A Operation

V1 3, 4 Typically connects to a 52a contact, which results in voltage being sensed

Table 3-1.

when the breaker is closed. If V1 senses voltage within three seconds after the

Reset 1, 2, 3, or 4 timer expires, a reset will be initiated. If the relay is in

breaker is open. This input is typically used to provide an anti-pump feature. If

voltage is removed from V2 during a reclose attempt, the anti-pump feature

will prevent a further reclose attempt until the next reclose set time is reached.

voltage at this input causes all necessary data to be stored in memory and all

3-2 BE1-79A Functional Description 9310200990 Rev J

Page 25

Table 3-3. Contact Sensing Inputs Description for ACR11B Operation

Input

Terminals

Description

V1

3,4

Typically connects to a 52a contact, which results in voltage being sensed

lockout, a reset will be initiated anytime V1 senses voltage. (E Reset)

(Motor)

V3

11, 12

Used to monitor the 52b contact while the relay is in a reset condition. When

V3 senses voltage, the relay initiates a reclose sequence. (E Operate)

V4

11, 17

Connects to a 52b contact, which results in voltage being sensed when the

This prevents multiple reclose attempts for a single reclose setting. (Z)

V5

5, 6

Internally connected to the relay power supply terminal. A loss of sensing

Output

Terminals

Description

C1

—

Not used in this application.

reclose sequence, C2 will remain open until the relay returns to reset. (E1)

Descriptions, Alarm Output Command. (JK)

C4

17, 18

Used in conjunction with the anti-pump function. C4 is closed when voltage is

sensed at input V2. (Z2)

C5

19, 20

Used in conjunction with the anti-pump function. C5 is closed when voltage is

sensed at input V2. (Z3)

when the breaker is closed. If V1 senses voltage within three seconds after the

Reset 1, 2, 3, or 4 timer expires, a reset will be initiated. If the relay is in

V2 6, 7 Voltage sensed at this input causes the relay to start a reclose sequence.

breaker is open. This input is typically used to provide an anti-pump feature. If

voltage is removed from V4 during a reclose attempt, the anti-pump feature

will prevent a further reclose attempt until the next reclose set time is reached.

voltage at this input causes all necessary data to be stored in memory and all

contacts to return to their de-energized or “in-the-box” state.

Reset Switch

This momentary-action switch clears the front-panel In Sequence or Lockout LEDs and restores the relay

to a rest condition. The reset switch performs the same function as the manual clutch release on the

General Electric ACR11 relay. Operating power must be applied to terminals 5 and 6 in order for a reset

to occur.

Serial Communication Port

The communication port is a standard RS-232 (DB-9) female connector located on the front panel. This

port provides the means to read and configure BE1-79A settings.

Microprocessor

All reclosing and communication functions are coordinated by the microprocessor. The BE1-79A uses an

eight-bit microprocessor with integral ROM (read-only memory) and RAM (random access memory). The

microprocessor is monitored by a watchdog circuit that resets the microprocessor if a problem is detected.

Outputs

The BE1-79A has 10 outputs. The function of each output depends on the operating configuration of the

relay. Tables 3-4 and 3-5 provide a description of each output for each relay configuration.

Table 3-4. Outputs Description for ACR11A Operation

C2 13, 14 Closed during reset and open when voltage at input V3 is sensed. During a

C3 15, 16 Functions as a programmable alarm contact. It can be set to function as a

relay fail output or a combination relay fail/lockout output. a detailed

explanation is provided in Section 4, Communication Commands, Command

9310200990 Rev J BE1-79A Functional Description 3-3

Page 26

Output

Terminals

Description

C6

17, 20

This Anti-Pump output closes for the duration of reclose timing (time delay

reclosing) except when output C5 closes. If C5 closes, output C6 will only

in the reset position.

C7

15, 20

Anti-pump output. Closes for the duration of reclose timing except if output C6

sensing input V2. ((BC+Z1)∗KL)

Descriptions, RS Contact Setting Command.

C9

—

Not used in this application.

C10

1, 2

Closed during reset and open when a reclose time delay begins. (E4)

Output

Terminals

Description

C1

12, 17

Closes momentarily when voltage is sensed at input V4 and the relay is in a

reset condition. (Z2∗E6)

C2

13, 14

Closed during reset and open when voltage at input V3 is sensed. During a

reclose sequence, C2 remains open until the relay returns to reset. (E1)

C3

15, 16

Functions as a programmable alarm contact. Can be set to function as a relay

Alarm Output Command.

C4

18, 19

Closed any time that the unit is not in reset. (E5)

C5

17, 19

Closes for three seconds after a reclose timer expires. (AB)

sensing input V4. (BC∗Z1)

C7

8, 20

Closed when the relay is in a lockout state. (HI)

C8

9, 10

RS output. Can be configured as a normally open (NO) or normally closed

Application.

C9

5, 8

Closes when the relay is in reset and voltage is sensed at input V3. C9

timing begins or is running. (E4)

close when voltage is sensed at contact sensing input V4. (BC∗Z1) Note: At

reset, operational state of C6 (closed or open) is determined by the first time

delay reclose setting. If first reclose time delay setting is “0”, C6 is open in the

reset position. If first reclose time delay setting is greater than “0”, C6 is open

closes. If C6 closes, output C7 will close only if voltage is sensed at contact

C8 9, 10 RS output. Can be configured as a normally open (NO) or normally closed

(NC) contact. Can be set to energize for an adjustable duration after the start

of a reclose cycle. The interval between the start of the reclose sequence and

C8 energizing is also adjustable. A detailed explanation of programming the

RS output is provided in Section 4, Communication Commands, Command

Table 3-5. Outputs Description for ACR11B Operation

fail output or a combination relay fail/lockout output. a detailed explanation is

provided in Section 4, Communication Commands, Command Descriptions,

C6 14, 17 Anti-pump output. Closes for the duration of reclose timing except if output C5

closes. If C5 closes, output C6 will close only if voltage is sensed at contact

(NC) contact. Can be set to energize for an adjustable duration after the start

of a reclose cycle. The interval between the start of a reclose sequence and

C8 energizing is also adjustable. A detailed explanation of programming the

RS output is provided in Section 4, Communication Commands, Command

Descriptions, RS Contact Setting Command and Appendix A, RS Contact

remains closed until the relay reaches either a lockout or reset condition.

(GH+E3)

C10 1, 2 Closed only during a reset condition. Opens and stays open when a reclose

3-4 BE1-79A Functional Description 9310200990 Rev J

Page 27

Interconnections

11

12

13

14

15

16

17

18

19

20

1

2

3

4

5

6

7

8

9

10

C8

V1

V2

V3

C3

C10

C2

C4

C5

C7

C9

S3

S1

S1

S2

S2

S4

INT EXT

A B

B A

C6

B A

A

B

B A

D2633-06

NC

NO

S5

V5

Power

Supply

RS

D

E

1

1

RS mode electronic selector

switch (SP-79ARS command)

2

2

2

Case-mounted, paddle-operated

shorting bars

Figures 3-2 and 3-3 illustrate the interconnection of the contact sensing inputs, relay outputs, style

configuration switches, instantaneous reclose jumper switch, and RS contact configuration switch in the

BE1-79A relay. The state of all relay output contacts is shown with all power removed from the relay.

Figure 3-2 shows the relay configured for an ACR11A application. Figure 3-3 shows the relay configured

for an ACR11B application with an instantaneous recloser jumper.

9310200990 Rev J BE1-79A Functional Description 3-5

Figure 3-2. Relay Interconnections for ACR11A Applications

Page 28

11

12

13

14

15

16

17

18

19

20

1

2

3

4

5

6

7

8

9

10

C8

V1

V5

V2

V3

V4

C3

C10

C1

C2

C4 C5

C7

C9

S3

S1

S1

S2

S2

S4

INT EXT

A B

B A

C6

B A

A

B

B A

D2633-05

NC

NO

S5

Power

Supply

RS

D

E

1

RS mode electronic selector

switch (SP-79ARS command)

1

2

Case-mounted, paddle-operated

shorting bars

2

2

Figure 3-3. Relay Interconnections for ACR11B Applications

3-6 BE1-79A Functional Description 9310200990 Rev J

Page 29

Reclose

Power-Up

In Reset At

Power-Up

?

Style

Change Prior To

Power-Up?

Restore Power

Down State

Of Relay

Timing To

Lockout

?

Resetting

?

Reset

Timer Expired

?

52A

?

All

Reclose Attempts

Done?

Lockout

Time Reached

?

Lockout

Manual

Reclose

?

Reset

Time Reached

?

Reset

52B

?

Y

Y

Y

Y

N

N

Y

Y

N

Y

N

N

N

N

N

N

N

Y

N

N

Y

Y

Y

D2588-06

05-06-97

Reclose

Time Reached

?

Y

Recloser Operation

Information about the software-controlled features of the recloser is provided in the following paragraphs.

Power-Up

The flow chart of Figure 3-4 describes relay operation following the application of operating power.

Depending on conditions and the reset delay setting, the interval from power application to the resultant

state may be from 0 to 300 seconds.

Figure 3-4. Power-Up Flow Chart

9310200990 Rev J BE1-79A Functional Description 3-7

Page 30

Reset

A reclosing sequence may be initiated only when the relay is in the reset state. Reset is indicated by the

front panel Reset LED. In order for the relay to reach reset, the controlled breaker must be closed during

a three-second period when the reset timer expires. If the breaker opens prior to this time, the relay will

proceed to the next reclosing attempt. If the number of programmed reclosing attempts has been

exhausted, the relay will drive to lockout.

A reset time of zero is used if no reset is desired after a specific reclosing attempt. As an example, for a

first reclose/reset time delay setting of SP-79A1=10,0, the 0 indicates that the BE1-79A will not reset until

after the next non-zero reset time. If the second reclose/reset time delay setting is SP-79A2=30,40, then

the relay will reset at the 40 second point in the timing sequence.

Lockout

Lockout, a state inhibiting relay operation, may be produced by four conditions:

• Reclose failure

• Number of breaker openings exceeds the number of programmed reclosure attempts

• The EXIT command is entered to terminate RS-232 communication

• Communication access has timed out

Lockout is indicated by the front panel Lockout LED. The S-ALM command allows output C3 to be

programmed to close for a lockout condition. Lockout is terminated when the controlled breaker is closed

(manually or by other means) and remains closed for the duration of the final reset time delay setting.

Reclosing Sequences

A reclosing sequence is initiated by the closure of a 52b contact. A reclosing sequence is indicated by the

In Sequence LED located on the front panel. The BE1-79A provides up to four automatic reclosures.

Each reclose setting is adjustable and has a setting range of 0 to 300 seconds. The number of reclosing

attempts may be limited by adjusting any one of the reclose time delay settings (after the first reclose) to

zero. When a breaker trip occurs at this point in the reclosing sequence, the BE1-79A will time toward

lockout. An instantaneous first reclose is enabled on BE1-79A relays configured for ACR11B operation by

an external jumper connected across case terminals 13 and 17 or by switch S4 located on the right side

of the relay cradle.

Each of the four reclose settings has a corresponding reset timer. A final reset controls the time between

lockout and reset. Each reset setting is adjustable and has a setting range of 0 to 300 seconds. Pressing

the front panel Reset pushbutton will clear a reclosing sequence and return the relay to the reset state.

The numbering and labeling of reclose and reset timer settings of Basler reclosing relays such as the

BE1-79 and BE1-79M are based on the breaker opening that immediately precedes each reclose and

reset setting. This is not the case with the BE1-79A. Each reclose and reset timer setting begins at time

zero when the breaker opens the first time and initiates the first reclose timer. Typically, this makes the

first reclose setting the shortest time setting and the fourth reclose setting the longest time setting. Figure

3-5 illustrates a BE1-79A reclosing sequence and the relationship of each reclose setting to the breaker

openings.

The flow chart of Figure 3-6 is a simplified representation of reclosing sequence initiation and

progression.

If a reclosing sequence is interrupted by removing power supply voltage from terminal 5 or 6, this will

“freeze” the timing cycle at that point in the reclosing sequence. Freezing the timing sequence will result

in contact C10 and the RS contact returning to their de-energized state when the BE1-79A power supply

is de-energized. Once voltage is restored to the power supply, timing resumes from the point in the

reclosing sequence that the power supply was de-energized.

External restrictions such as “hot-bus, dead-line” should be connected between terminals 7 and 8 of the

BE1-79A to avoid de-energizing the power supply and “freezing” the timing sequence.

3-8 BE1-79A Functional Description 9310200990 Rev J

Page 31

Time zero begins at

1

st

breaker opening.

Final Reset

= 185 s or 5 s

after manual

close

Reclose 1

= 10 s

10 s

20 s 20 s 20 s

Lockout

= 180 s

180 s

185 s

P0034-01

09-20-05

2nd

Breaker

Opening

3rd

Breaker

Opening

4th

Breaker

Opening

5th

Breaker

Opening

Reclose 2

= 30 s

Reset 1

= 20 s

Reset 2

= 40 s

Reclose 3

= 50 s

Reset 3

= 60 s

Reclose 4

= 70 s

Reset 4

= 80 s

30 s

50 s

70 s

180 s - lockout

Relay Settings

SP-79A1=10,20 SP-79A3=50,60 SP-79ALO=180,185

SP-79A2=30,40 SP-79A4=70,80 SP-ALM=1

0

Figure 3-5. Reclose Settings Example

9310200990 Rev J BE1-79A Functional Description 3-9

Page 32

Reset 2

Time?

Reset

Rec 4

Time?

52B

?

Rec. 1

Time?

52B

?

Issue

Reclose

Signal

52B

?

Reclose

Complete?

Reset 1

Time?

52A

?

Reset

Reset

Complete?

Rec 2

=0?

Perform

Lockout

Rec 2

Time?

52B

?

Issue

Reclose

Signal

52B

?

Reclose

Complete?

52A

?

Reset

Reset

Complete?

Rec 3

=0?

Rec 3

Time?

52B

?

Issue

Reclose

Signal

52B

?

Reclose

Complete?

Reset 3

Time?

52A

?

Reset

Reset

Complete?

Rec 4

=0?

Perform

Lockout

52B

?

Issue

Reclose

Signal

52B

?

Reclose

Complete?

Reset 4

Time?

52A

?

Reset

Reset

Complete?

Perform

Lockout

Perform

Lockout

Lockout

52A

?

Final

Reset

Time?

Reset

Perform

Lockout

Lockout

Time?

Lockout

N

N

N

N

N

N

N

N

N

N

Y

Y

Y

Y

Y

Y

Y

Y

Y

Y

Y

N

Y

N

N

Y

N

Y

Y

N

N

Y

N

Y

N

Y

N

Y

N

Y

Y

N

Y

Y

N

N

Y

N

Y

N

Y

Y

N

Y

N

N

YY

N

N

Y

N

Y

Y

N

D2588-07

05-07-97

N

N

Y

Y

Figure 3-6. Reclosing Flow Chart

3-10 BE1-79A Functional Description 9310200990 Rev J

Page 33

SECTION 4 • COMMUNICATION COMMANDS

TABLE OF CONTENTS

SECTION 4 • COMMUNICATION COMMANDS ...................................................................................... 4-1

Introduction ............................................................................................................................................ 4-1

Communication Port Parameters ........................................................................................................... 4-1

ASCII Command Format ........................................................................................................................ 4-1

Command Format .............................................................................................................................. 4-1

Command Response Format ............................................................................................................. 4-1

Command Descriptions .......................................................................................................................... 4-2

Changing Settings through the Serial Port ......................................................................................... 4-2

Tables

Table 4-1. Internal Default Settings ........................................................................................................... 4-4

9310200990 Rev J BE1-79A Communication Commands i

Page 34

ii BE1-79A Communication Commands 9310200990 Rev J

Page 35

SECTION 4 • COMMUNICATION COMMANDS

Introduction

Communication commands are sent to the BE1-79A through a standard RS-232 (DB-9) connector located

on the front panel. The BE1-79A ASCII communication protocol is compatible with readily available

terminal/modem software such as the HyperTerminal application provided with the Windows® PC

operating system. Information about configuring HyperTerminal and Terminal for communication with the

BE1-79A is provided in Appendix B, Terminal Communication.

Communication Port Parameters

The following parameters apply to the BE1-79A communication port:

• Fixed baud rate of 9600

• Data bits fixed at 8

• Parity is fixed at NONE (N)

• Number of stop bits is fixed at 1

• Half duplex operation is supported

More information about BE1-79A communication interface requirements is provided in Section 5,

Installation and Configuration.

ASCII Command Format

Each communication command, <CMD>, consists of an ASCII string terminated by a carriage return,

<CR>. A line feed, <LF>, is optional.

Command Format

The BE1-79A uses a command format of <CMD>[<;>CMD…]<CR>[LF>]. Command components are

defined as follows.

[ ] Brackets identify optional parameters. The brackets are not part of the command.

< > Separators are used for clarity. The separators are not part of the command.

CMD <name>[n][<=><setting-x>…[<,><setting-x>]]

Where:

Name Command name. Refer to Command Descriptions for more information.

N Optional command object. If more than one object is available and n is omitted, the

command applies to all objects.

= Used to indicate that the command is to change data or settings.

Setting-x Command setting(s)

, Commas are used as setting separators

CR A carriage return is used to end a command and start command execution.

LF A line feed may be used for clarity. It is ignored by the relay.

Spaces One or more spaces may be added between entries for clarity if desired.

Command Response Format

The BE1-79A uses a command response format of [<response>][<ACK>]. Command components are

defined as follows.

response Determined by CMD.

ACK “>” is returned for a valid command, “?” is returned for an invalid command.

Commands received by the BE1-79A consist of two types: requests for information and changes to

operating parameters. Commands to change parameters are identified by and equal sign (=). The

operating parameters to the right of the equal sign are intended to replace the current operating

parameters related to the command.

Some commands may pertain to multiple items. In that case, a numeric identifier is used after the

command name to specify a single item. If the identifier is omitted, the command is applied to all possible

9310200990 Rev J BE1-79A Communication Commands 4-1

Page 36

items. For example, the SP-79A1 command could be used to read the first reclose setting or the

command S could be used to read all reclose settings.

Command Descriptions

BE1-79A command descriptions and examples are provided in the following paragraphs.

Changing Settings through the Serial Port

The ACCESS command is used to access write privileges while changing relay settings. Relay control

functions are disabled when access is granted. Changing the settings through the serial port requires that

the operator use the ACCESS command to obtain programming access. The operator enters ACCESS=

and the relay responds with an acknowledgement of ACCESS GRANTED if the command was received

and executed. Any time an invalid command is received, the relay will respond with a question mark (?).

The EXIT command is used to release write privileges while changing relay settings. After the changes

are made, the new data will be copied to the working settings and saved to nonvolatile memory when

EXIT is entered. The operator must confirm that the programming is completed and accepted before the

changes are actually made. It is important to make all changes to relay settings before executing the EXIT

command. This ensures that all intended settings are executed. The relay will go to the lockout state after

the EXIT command is entered. If voltage is sensed at V1, the relay will return to the reset state after the

lockout timer expires.

Changing settings through the serial port consists of the following sequence:

1. Enter ACCESS=<CR> or A=<CR>.

2. Enter the necessary commands to change the current settings.

3. Enter EXIT<CR> or E<CR> to clear access and save settings.

4. Enter Y (yes)<CR> to confirm save. Enter N (no) to continue using the old settings.

The <CR> characters placed after commands represent a carriage return or pressing the Enter key. For

simplicity, they will no longer be shown. However, each line entered by the operator must be terminated

with a carriage return <CR> or a carriage return–line feed <CR–LF>.

Access Command

ACCESS Command

Purpose: Read/set programming access in order to change user settings.

Syntax: ACCESS[=] or A[=]

Access must be changed by entering ACCESS= before any changes to the settings can be made. Relay

protection functions are disabled when access is granted. The ACCESS command is valid for a period of

five minutes if no new characters are entered. ACCESS by itself may be used to check if programming

access is active or disabled. The relay will respond with ACCESS GRANTED or ACCESS: NO. The

available access privilege is Privilege S: Setting Access. When exiting programming access, the relay will

go to the lockout state after the EXIT command is entered. If voltage is sensed at V1, the relay will return

to the reset state after the lockout timer expires.

Exit Command

EXIT Command

Purpose: Exit programming mode

Syntax: EXIT or E

Comments: Exits the programming mode and resets the programming access privilege to 0.

Changes are made to a scratchpad copy of the settings. After the changes are made, the new data will be

saved to nonvolatile memory and the new, working settings will be initialized when control to make

changes is released by entering the EXIT command. After entering EXIT, the user is prompted to confirm

that the new data should be saved. The user has three options (Y or N or C). If Y is entered, the data will

be saved. If N is entered, the changes will be cleared and the old settings will be restored. If C is entered,

the EXIT command will be aborted and programming may continue. It is important to make all changes to

relay parameters before executing the EXIT command. This ensures that all intended settings are

executed.

4-2 BE1-79A Communication Commands 9310200990 Rev J

Page 37

For clarity in the examples, relay responses are printed in the Courier typeface.

EXIT command example: exit after making setting changes.

EXIT

>SAVE CHANGES (Y/N/C)? Prompt to save (Y)es, discard changes (N)o, or (C)ontinue

>Y Confirmation to save changes

CHANGES SAVED Confirmation that changes were saved

Obtaining Help Information Through the Serial Port

The HELP or H command provides general help information on command syntax and functionality when

the manual is not available. Help is available only when the relay is in a reset state.

HELP Command

Purpose: Obtains help on using serial port commands.

Syntax: HELP or H

Comments: The HELP command returns a listing of all available commands along with the proper

syntax for each command.

Obtaining a Summary of All Settings

All relay settings may be listed using the S command.

S Command

Purpose: Read all relay settings back to user.

Syntax: SP-79A[n]

Comments: S by itself may be used to read all relay settings. SP-79A[n] is used to read a specific

setting. the S command can be used to make a record of the relay settings after they have

been set.

S command example: Obtain a report of the relay settings.

A=

S

SP-79A1 5,10

SP-79A2 15,20

SP-79A3 25,30

SP-79A4 35,40

SP-79ALO 45,50

SP-79ARS D,0,5

SP-ALM 2

>

Reclose and Reset Timer Setting Command

SP-79A Command

Purpose: Read or change the reclose and reset timer settings.

Syntax: S[-79a[n][=<reclose time delay>,<reset time delay>]

Comments: n: reclose number of LO for lockout. See Table 4-1 for setting defaults.

reclose time delay: adjustable from 0 to 300 seconds in 0.1 second steps. A Reclose 1

setting of zero will cause an instantaneous first reclosure. A setting of zero for any other

reclose time delay will disable the reclose shot.

reset time delay: adjustable from 0 to 300 seconds in 0.1 second steps. A reset time delay

setting of zero will cause the reset to be disabled. A reset time delay setting less than the

reclose time setting will cause an immediate reset following the reclose attempt.

SP-79A command example: Read the second reclose and reset timer settings.

A=

SP-79A2

15.0,20.0

>

9310200990 Rev J BE1-79A Communication Commands 4-3

Page 38

Lockout Timer Setting Command

Command

Default

SP-79A1

0.0,0.0

SP-79A2

0.0,0.0

SP-79A3

0.0,0.0

SP-79A4

0.0,0.0

SP-79ALO

0.0,15.0

SP-79ARS

E,1.5,15.0

SP-ALM

2

SP-79ALO Command

Purpose: Read or change the lockout timer settings.

Syntax: SP-79ALO[=<lockout time delay>,<final reset time delay>]

Comments: lockout time delay: adjustable from 0 to 300 seconds in 0.1 second increments. A lockout

time delay setting of zero will cause an instantaneous lockout when the breaker opens. A

lockout time delay setting that is shorter than a reclose time delay setting will take priority

and drive the relay to lockout.

Final reset time delay: adjustable from 0 to 300 seconds in 0.1 second increments. A final

reset time delay that is equal to zero or is less than the lockout time delay setting will give

an immediate reset following lockout and a manual reclose. See Table 4-1 for setting

defaults.

Table 4-1. Internal Default Settings

RS Contact Setting Command

SP-79ARS Command

Purpose: Read or change the RS contact settings.

Syntax: SP-79ARS[=<mode>,<apply time>,<remove time>]

Comments: mode: the state of the RS coil and contact, which can be D or E for the coil status.

D: de-energized RS coil. Second NO contact when terminals 5 and 6 are de-energized.

E: energized RS coil. Second NC contact when terminals 5 and 6 are energized.

apply time: time from the start of the reclose cycle until the RS contact is applied. The apply

time is adjustable from 0 to 300 seconds in 0.1 second increments.

remove time: time from the start of the reclose cycle until the RS contact is removed. The

remove time is adjustable from 0 to 300 seconds in 0.1 second increments. See Table 4-1

for setting defaults.

Refer to Appendix A for SP-79ARS command examples.

Alarm Output Command

SP-ALM Command

Purpose: Read or change the Lockout/Relay Fail output setting.

Syntax: SP-ALM[=<mode>]

Comments: mode: selects the operating mode of the alarm output, which can be 1 or 2.

1 selects Relay Fail

2 selects Relay Fail and Lockout (default setting)

Relay Information Command

RG-VER Command

Purpose: Read information about relay hardware/firmware configuration

Syntax: RG-VER

Comments: Transmitting the RG-VER command will cause the relay to respond with the relay model

number and the firmware version and date.

4-4 BE1-79A Communication Commands 9310200990 Rev J

Page 39

SECTION 5 • INSTALLATION AND

CONFIGURATION

TABLE OF CONTENTS

SECTION 5 • INSTALLATION AND CONFIGURATION .......................................................................... 5-1

General .................................................................................................................................................. 5-1

Mounting ................................................................................................................................................ 5-1

Connections ........................................................................................................................................... 5-1

Application.............................................................................................................................................. 5-1

Style Configuration Switches ............................................................................................................. 5-1

Instantaneous Reclose Jumper Switch .............................................................................................. 5-1

RS Switch ........................................................................................................................................... 5-1

Motor Voltage ..................................................................................................................................... 5-7

Contact Sensing Inputs ...................................................................................................................... 5-7

Timing Cams ...................................................................................................................................... 5-8

Fault Clearing ..................................................................................................................................... 5-8

RS Contact ......................................................................................................................................... 5-8

Alarm Output ...................................................................................................................................... 5-8

Reset Switch ...................................................................................................................................... 5-9

Relay Installation .................................................................................................................................... 5-9

Communication Connections and Settings ............................................................................................ 5-9

Communication Connector ................................................................................................................. 5-9

Communication Settings .................................................................................................................. 5-10

Figures

Figure 5-1. Overall Dimensions, S1 Case ................................................................................................. 5-2

Figure 5-2. Panel Cutout Dimensions, S1 Case

Figure 5-3. Terminal Connections, Rear View, S1 Case

Figure 5-4. Typical Connections for ACR11A Application

Figure 5-5. Typical Connections for ACR11B Application

Figure 5-6. Contact Sensing Jumpers ....................................................................................................... 5-7

Figure 5-7. Contact Sensing Jumper Locations

Figure 5-8. PC to BE1-79A Connections

Tables

Table 5-1. RS-232 Pin Functions .............................................................................................................. 5-9

........................................................................................ 5-3

........................................................................... 5-4

......................................................................... 5-5

......................................................................... 5-6

........................................................................................ 5-7

................................................................................................. 5-10

9310200990 Rev J BE1-79A Installation and Configuration i

Page 40

ii BE1-79A Installation and Configuration 9310200990 Rev J

Page 41

SECTION 5 • INSTALLATION AND

CONFIGURATION

General

BE1-79A Reclosing Relays are delivered in sturdy cartons to prevent shipping damage. Upon receipt of a

relay, check the model number against the requisition and packing list for agreement. Inspect for damage

and, if there is evidence of such, file a claim with the carrier and notify the Basler Electric regional sales

office, your sales representative, or the Technical Sales Support department of Basler Electric.

If the relay is not installed immediately, store it in the original shipping carton in a moisture- and dust-free

environment.

Mounting

Because the BE1-79A is of solid-state design, it does not have to be mounted vertically. Any convenient

mounting angle may be chosen. The BE1-79A is available in an S2 cradle or an S1 cradle with case. The

S2 cradle is intended for installation in an existing S2 case. Overall dimensions for the S1 case are shown

in Figure 5-1. S1 case cutout dimensions are shown in Figure 5-2.

Connections

Incorrect wiring may result in damage to the relay. Be sure to use the correct input power for the power

supply and the correct input voltage for the contact inputs. Connections should be made with a minimum

wire size of 14 AWG. Figure 5-3 illustrates the terminal connections of the S1 case. Figure 5-4 provides a

typical connection diagram for an application using an ACR11A style relay. Figure 5-5 shows typical

connections for an application using an ACR11B style relay.

Application

The intended function of the BE1-79A Reclosing Relay is to duplicate an ACR11 recloser with only minor

variations. To ensure that your BE1-79A relay functions properly, you should consider the adjustments

and settings described in the following paragraphs.

Style Configuration Switches

Switches S1, S2, and S3 must be set properly for your application. All three switches should be placed in

the A (up) position for ACR11A operation. All three switches should be placed in the B (down) position for

ACR11B, ACR11C, ACR11E, and ACR11F operation.

Instantaneous Reclose Jumper Switch

Use the following guidelines when setting Instantaneous Reclose Jumper Switch S4.

• For ACR11a operation, switch S4 should be placed in the EXT (down) position.

• An ACR relay has a red jumper from terminals 13 to 17 for an instantaneous first reclosure

(SP-79A1 0.0,X.X) is duplicated by placing BE1-79A switch S4 in the INT (up) position.

• A delayed first reclosure is achieved when S4 is placed in the EXT (down) position and the external

jumper is removed from terminals 13 and 17.

• If an external jumper is left in place at terminals 13 and 17 for an instantaneous first reclosure, S4

should be placed in the EXT (down) position.

• Neither an internal nor an external jumper is required at terminals 12 and 13 for a delayed first

reclosure. Switch S4 should be placed in the EXT (down) position for delayed reclosures.

RS Switch

RS switch S5 is used to control the RS contact for normally open or normally closed contact configuration.

Figure 2-2 and 2-3 should be consulted for the location and setting positions of the style and configuration

switches.

9310200990 Rev J BE1-79A Installation and Configuration 5-1

Page 42

Figure 5-1. Overall Dimensions, S1 Case

5-2 BE1-79A Installation and Configuration 9310200990 Rev J

Page 43

Figure 5-2. Panel Cutout Dimensions, S1 Case

9310200990 Rev J BE1-79A Installation and Configuration 5-3

Page 44

D2588-17

06-05-97

Figure 5-3. Terminal Connections, Rear View, S1 Case

5-4 BE1-79A Installation and Configuration 9310200990 Rev J

Page 45

Figure 5-4. Typical Connections for ACR11A Application

9310200990 Rev J BE1-79A Installation and Configuration 5-5

Page 46

Figure 5-5. Typical Connections for ACR11B Application

5-6 BE1-79A Installation and Configuration 9310200990 Rev J

Page 47

Motor Voltage

No adjustment is required for the motor voltage applied at terminals 5 and 6. The applied voltage can

range from 120 to 240 Vac or 125 to 250 Vdc. These terminals serve as the input to the BE1-79A power

supply and control functions.

Contact Sensing Inputs

Energizing levels for contact sensing inputs V1 through

V4 are jumper selectable for operation at three nominal

voltage levels. Jumper P3 controls the operating voltage

for V1, P4 controls V2, P5 controls V3, and P6 controls

V4. Nominal voltage levels of 125 Vdc/120 Vac, 48 Vdc,

or 250 Vdc/240 Vac may be selected. Figure 5-6

illustrates the three possible jumper positions for P3

through P6. Input V5 is dedicated to monitoring the relay

power supply input and is not jumper selectable.

Figure 5-6. Contact Sensing Jumpers

NOTE

In certain applications where 240 Vac control voltage is used, control circuit

feedback can occur through system inductive coupling. This feedback can

result in erroneous signals, causing relay operation. If there is a potential for

control circuit feedback, the jumper selectable voltage range should be

changed from the 48 Vdc factory default setting to a higher position. Selections

are provided in Table 3-1.

The following paragraphs describe how to locate and change the position of the contact-sensing jumpers.

1. Remove the four Phillips screws from the front panel and separate the front panel from the relay

chassis.

2. Carefully grasp and remove the Digital circuit board (top circuit board) from the relay chassis. Take

care not to damage any of the circuit board components. Observe all electrostatic discharge (ESD)

precautions when handling the circuit board. Place the circuit board on an ESD-safe surface.

3. Locate the four jumper terminal blocks (P3 through P6) on the circuit board. The jumper terminal

blocks are located on the component side of the circuit board near the rear contact fingers (see

Figure 5-7). Each terminal block has three pins and each jumper is factory installed on pins 2 and 3.

Figure 5-6 illustrates each of the three jumper positions.

Figure 5-7. Contact Sensing Jumper Locations

4. To select operation at 125 Vdc or 120 Vac, remove the jumper from pins 2 and 3 and position it on

pins 1 and 2. To select operation at 250 Vdc or 240 Vac, remove the jumper from pins 2 and 3 and

position it on pin 3 for storage. (Only pin 3 of the terminal block should be covered.)

9310200990 Rev J BE1-79A Installation and Configuration 5-7

Page 48

5. When all of the jumpers are positioned for operation in the desired sensing voltage range, prepare to

place the circuit board back in the relay chassis.

6. Align the circuit board edges with the white guide markings on the relay chassis. Once aligned, slide

the circuit board back into the chassis until the circuit board is seated in its connector. The front of the

circuit board should be flush with the front of the relay chassis. (The LEDs and serial port connector

will protrude past the front of the chassis.)