Page 1

INSTRUCTION MANUA L

FOR

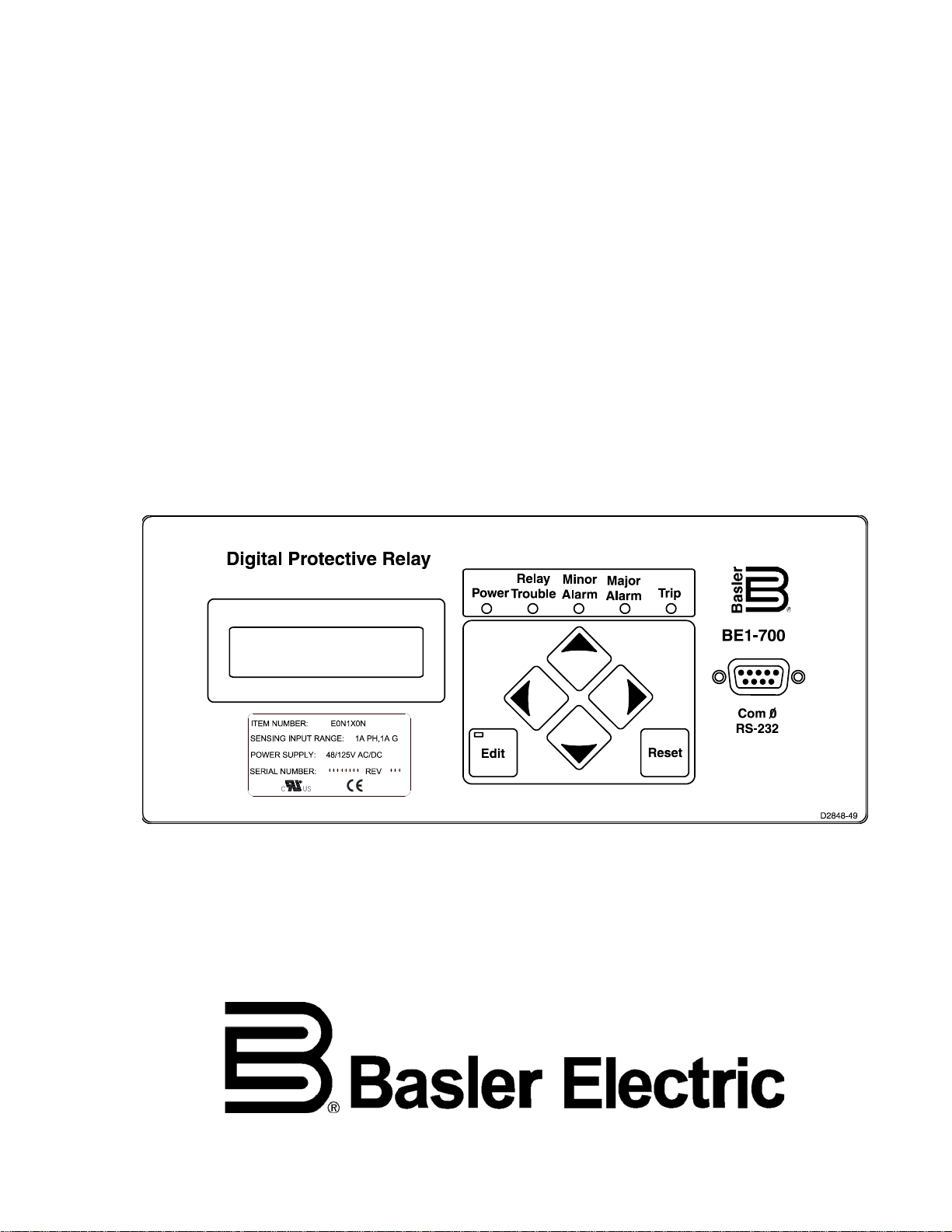

DIGITAL PROTECTIV E REL AY

BE1-700

Publication: 9376700990

Revision: M 08/14

Page 2

Page 3

INTRODUCTION

This instruction manua l provides information about t he operation and installation of t he BE1-700 Digital

Protective Relay. To accomplish this, the following information is provided:

• General information, specifications, and a Quick Start guide.

• Functional description and setting parameters for the inputs and outputs, protection and control

functions, metering functions, and reporting and alarm functions.

• BESTlogic programmable logic design and programming.

• Documentation of the preprogrammed logic schemes and application tips.

• Description of security and user interface setup including ASCII communication and the human-

machine interface (HMI).

• Installation procedures, dimension drawings, and connection diagrams.

• Description of the front panel HMI and the ASCII command interface with write access security

procedures.

• A summary of setting, metering, reporting, control, and miscellaneous commands.

• Testing and maintenance procedures.

• Description of BESTCOMS™ graphical user interface (GUI).

• Description of BESTNet Communication for the optional web page enabled relay.

• Appendices containing time overcurrent characteristic curves and an ASCII command-HMI cross-

reference, and overexcitation (24) inverse time curves.

Optional instruction manuals for the BE1-700 include:

• Modbus™ (9376700991).

WARNING!

To avoid personal inj ury or equipment damage, only qualified personnel should

perform the procedures in this manual.

NOTE

Be sure that the BE1-700 is hard-wired to e arth ground with no sma ller than 12

AWG copper wire attache d to the ground terminal on the rear of the unit case.

When the BE1-700 is configured in a system with other devices, it is

recommended to use a separate lead to the ground bus from each unit.

9376700990 Rev M BE1-700 Introduction i

Page 4

First Printing: July 2004

Basler Electric does not assume any responsibility to compliance or noncompliance with national code, local code,

For terms of service relating to this product and software, see the Commercial Terms of Products and Services

document available at www.basler.com/terms.

This publication contains confi dent i al inform at ion of Basler Electric Company, an Illinois corporation. It is loaned for

and options are subject to modification without notice. Over time, improvements and revisions may be made to this

manual.

The English-language version of this manual serves as the only approved manual version.

Printed in USA

© 2014 Basler Electric, Highland Illinois 62249 USA

All Rights Reserved

August 2014

or any other applicable code. This manual serves as reference material that must be well understood prior to

installation, operation, or maintenance.

confidential use, subject to return on request, and with the mutual understanding that it will not be used in any

manner detrimental to the interests of Basler Electric Company and used strictly for the purpose intended.

It is not the intention of this manual to cover all details and variations in equipment, nor does this manual provide

data for every possible contingency regarding installation or operation. The availability and design of all features

publication. Before performing any of the following procedures, contact Basler Electric for the latest revision of this

BASLER ELECTRIC

12570 STATE ROUTE 143

HIGHLAND IL 62249-1074 USA

http://www.basler.com, info@basler.com

PHONE +1 618.654.2341 FAX +1 618.654.2351

ii BE1-700 Introduction 9376700990 Rev M

Page 5

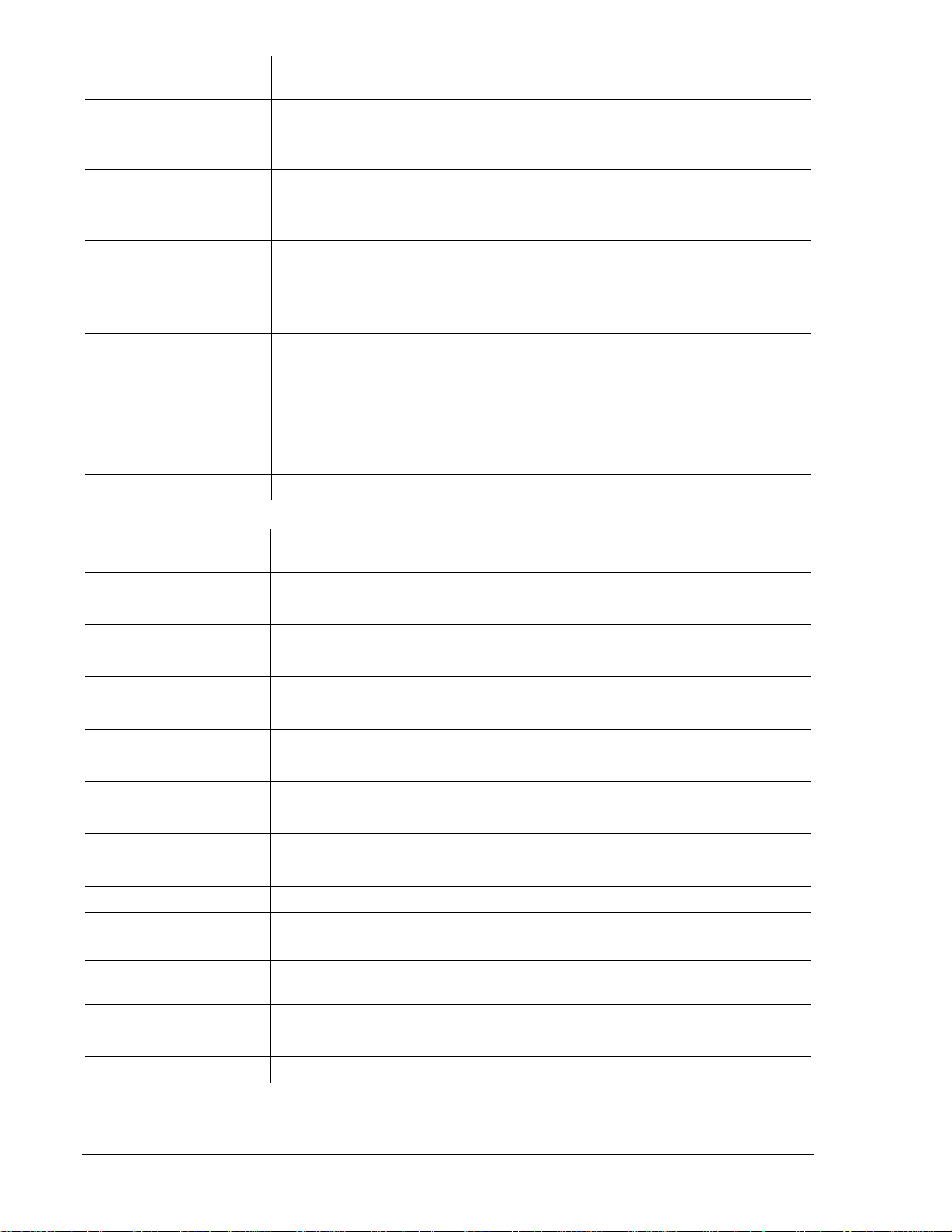

REVISION HISTORY

The following inform ation provides a h istorical summary of th e changes made to this instruction manual

(9376700990), BESTCOMS software, application firmware, and hardware of the BE1-700.

Manual

Revision and Date Change

M, 08/14

L, 02/14

K, 10/11

J, 12/10

H, 07/10

G, 10/09

F, 09/09

E, 02/09

D, 12/08

• Added serial number to fault reports and sequence of events in

Section 6 and replaced Figures 6-16, 6-20, and 14-41.

• Updated contact-sensing inputs specifications in Sections 1, 3, and

12.

• Added Storage statement in Section 13.

• Updated PC software requirements in Section 14.

• Changed Isolation specs in Section 1 to exclude Ethernet port.

• Updated 24 Vdc resistance, voltage, and current values in Table 6-9.

• Improved Figure 12-11.

• Re-organized Operation al Speci fic at ions and listed functions in

numerical order in Section 1.

• Moved Real-Time Clock from Operational Specifications to General

Specifications in Section 1.

• Corrected terminal numbering in Figure 12-22, RS-485 DB-37 to BE1-

700.

• Changed all instances of BESTWAVE to BESTWAVEPlus™.

• Added option “5” power supply type in style chart, power supply and

control inputs specifications in Section 1, General Information.

• Added option “5” power supply type under Co ntac t Se nsing Inp ut s in

Sections 3 and 12.

• Added CE Compliance in Section 1, General Information.

• Updated Figure 4-54, Overall Logic Diagram for Reclosing, to show

PI 0/100 ms and PI Stretched.

• Updated screen shots of BESTCOMS style chart screen.

• Added Republic of Belarus certification.

• Updated contact sense turn-on voltage range and burden values to

reflect new digital board.

• Added screens 5.1.2.2-5.1.2.4, 5.1.3.2-5.1.3.6, and 5.1.1.4 to Figure

10-8, Protection Menu Bran ch Struc ture. Removed screen 5.1.12.8.

• Changed Figure 12-5 to show OUTA as Normally Closed contact.

• Added 3-Phase VT 4-Wire Connection and 3-Phase VT 3-Wire

Connection to Figure 12-11.

9376700990 Rev M BE1-700 Introduction iii

Page 6

Manual

Revision and Date

Change

C, 10/08

B, 10/04

A, 07/04

• Added manual part number and revision to footers.

• Changed Appendix C, Overexcitation (24) Inverse Time Curves, to

Appendix D.

• Created Appendix C, T erminal Communication.

• Added GOST-R certification to Section 1.

• Combined BE1-700C and BE1-700V style charts into one style chart,

Figure 1-1.

• Changed 81 function pickup range from 40-70 to 20-70 Hz.

• Added Frequency Range to Power Supply specifications.

• Updated all BESTCOMS screenshots to Windows XP style.

• Added explanation of Inhibit setting for 27P/27X function in Section 4.

• Changed 25 function delta angle setting from 1-45 to 1-99.

• Added Figure 6-7, Breaker Monitoring Tab, and Figure 6-8,

BESTlogic Screen for Breaker Duty Monitoring.

• Added style number and firmware version display to fault reports

under Fault Reporting in Section 6.

• Added Settings Compare in Section 6.

• Added 127PPU and 127PT to Table 7-1, Logic Variable Names and

Descriptions.

• Added explanation of Figure 9-2, Show Passwords Screen.

• Added Figure 10-7 showing additional fault report screens.

• In Section 11, ASCII Command Interface, added descriptions for SA-

24, SG-DSP, SG-EM AIL, S G -VTP, SG-VTX, SL-27, S L-47, SL-59,

S<g>-24D, S<g>-25VM, S<g>-27, S<g>-47, S<g>-81, S<g>-81INH,

and SP-60FL.

• Added Figure 12-17, RS-232 Pin-outs.

• Added 27P/127P/27X Inhibit Pickup Test in Section 13.

• In Section 15, updated Configuration and Web Page screenshots

using Windows XP.

• Annotated each section, sub-section, figure, and tab le to indica te

applicability to a current (BE1-700C) or voltage (BE1-700V) relay, as

appropriate.

• Updated the discussion of the 24 element in Sect ion 4, Protection and

Control.

• Added Table 6-14, Targets as Displayed to Section 6, Reporting and

Alarm Functions.

• Updated Figure 10-7, Protection Menu Branch Struct ur e.

• Increased the number of figures in Section 14, BESTCOMS Software

from 16 to 42.

• Added a troubleshooting guide to Section 15, BESTNet

Communication.

• Added voltage ASCII commands to Appendix B, Command CrossReference.

• Added Appendix C, Overexcitation (24) Inverse Time Curves (BE1700V Only).

• Initial release

iv BE1-700 Introduction 9376700990 Rev M

Page 7

BESTCOMS™ Software

Version and Date

Change

Version and Date

2.05.00, 05/14

2.04.01, 10/11

2.04.00, 04/11

2.03.02, 09/09

2.03.01, 12/07

2.02.00, 09/04

2.01.00, 07/04

2.00.00, 06/04

Change

• Corrected settings file upload issue for 127P time delay.

• Added Windows 8 compatibility .

• Improved Settings Compare function.

• Added Windows® 7 32-/64-bit compatibility and removed Windows

2000 compatibility.

• Improved operation when regional parameters are set to French.

• Added option “5” power supply type to style chart.

• Improved Settings Compare function.

• “>” character can now be entered in setting name descriptions.

• Corrected overflow error when too many characters are entered for

time delays on the Voltage and Power Protection screens.

• Improved Modbus TCP Discovery program.

• Improved BESTCOMS metering func t ions .

• Changed pickup setting range of 81 function.

• Changed default nominal frequency range.

• Added support for the Modbus/TCP protocol.

• Added links on the Sys te m Sum mar y screen to jump to the Settings

screen for the selected setting.

• Revised the 47N Mode label to be Vpn always.

• Added the ability to double click a saved IP address to connect to it.

• Provided support for voltage relays (BE1-700V).

• Resolved a possible program crash when using the Discovery applet.

• Initial release

Application Firmware

2.03.02, 06/14

2.03.01, 09/09

• Added serial number to fault reports and sequence of events.

• Corrected access timeout operation.

• Corrected 62 logic timer operation when td2 is set less than 8 ms.

• Corrected 60FL operation that caused 60FL to be disabled when

power is cycled.

• Corrected password setting for Modbus over RS485.

• Corrected sample rate in Comtrade files.

• Made fault trigger logic input edge triggered.

• Corrected operation that caused intermittent loss of sync output.

• Changed 79 Pilot Reclose functionality so that if the recloser is in

reset, and if the time delay for the pilot reclose is non-zero, and if the

st

reclose time delay is set to zero, then upon a trip, a reclose initiate

1

will cause the relay to use the 2

nd

reclose time delay as the 1st reclose

time delay.

• Disabled recloser Timing Fail message to front panel HMI when the

recloser fail timer TD=0.

• Corrected 25VM logic “Live Phase/Dead Aux” for AB, BC, and CA

connections.

• Fixed invalid pointer so that screens are properly added to the screen

scroll list.

9376700990 Rev M BE1-700 Introduction v

Page 8

Application Firmware

Version and Date

Change

2.03.00, 07/09

1.03.01, 10/08

1.03.00, 11/07

1.02.02, 10/06

1.02.01, 01/05

1.02.00, 08/04

1.01.00, 07/04

Hardware

Revision and Date

S, 03/13

R ,11/11

Q

P, 11/10

N, 09/09

M, 07/09

L, 06/09

K, 06/09

J, 09/08

H, 09/08

G, 01/08

F, 03/07

E, 12/05

D, 04/05

C, 02/05

B, 01/05

A, 07/04

—, 06/04

• Increased immunity to noise when communicating via Modbus.

• Improved the SG-SCREEN command.

• Made firmware compatible with new digit al boar d.

• Improved Sync-check function.

• Increased immunity to noise on IRIG input.

• Improved web pages.

• Added additional fault report screens to front panel HMI.

• Changed pickup setting range of 81 function.

• Changed default nominal frequency range.

• Added capability for the 25 function to synchronize down to 25 Hz.

• Added style number and firmware version to fault reports and

sequence of events.

®

• Improved viewing of web pages using Firefox

browser.

• Expanded LCD contrast adjustment.

• Improved 60FL function.

• Added the Modbus/TCP option.

• Initial release

Change

• Improved watts and vars metering.

• Maintenance release.

• This revision letter not used.

• Improved communications circuit on digital board.

• Released BESTCOMS version 2.03.02 and firmware version 2.03.01.

• Added power supply option 5, “125 Vac/dc with extended holdup”.

• Standardized power supplies over several product lines.

• Improved contact sensing circuit on digital board.

• Released firmware version 1.03.01.

• EEPROM replacement.

• Added nylon washer on analog board to prevent hipotting.

• Changed rear label for only Ethernet options.

• Released new power supply boards.

• Re-designed terminal block to make it more reliable.

• Modified Ethernet cutout on back of case.

• Changed resistors on digital board to prevent input contacts on 24V

units from picking up too low.

• Added Modbus/TCP/IP prot ocol opti on.

• Added support for voltage relays (BE1-700V).

• Initial release

vi BE1-700 Introduction 9376700990 Rev M

Page 9

CONTENTS

SECTION 1 • GENERAL INFORMATION ................................................................................................ 1-1

SECTION 2 • QUICK START .................................................................................................................... 2-1

SECTION 3 • INPUT AND OUTPUT FUNCTIONS .................................................................................. 3-1

SECTION 4 • PROTECTION AND CONTROL ......................................................................................... 4-1

SECTION 5 • METERING ......................................................................................................................... 5-1

SECTION 6 • REPORTING AND ALARM FUNCTIONS .......................................................................... 6-1

SECTION 7 • BESTlogic PROGRAMMABLE LOGIC ............................................................................... 7-1

SECTION 8 • APPLICATION .................................................................................................................... 8-1

SECTION 9 • SECURITY .......................................................................................................................... 9-1

SECTION 10 • HUMAN-MACHINE INTERFACE ................................................................................... 10-1

SECTION 11 • ASCII COMMAND INTERFACE ..................................................................................... 11-1

SECTION 12 • INSTALLATION .............................................................................................................. 12-1

SECTION 13 • TESTING AND MAINTENANCE .................................................................................... 13-1

SECTION 14 • BESTCOMS SOFTWARE .............................................................................................. 14-1

SECTION 15 • BESTNet COMMUNICATION ........................................................................................ 15-1

APPENDIX A • TIME OVERCURRENT CHARACTERISTIC CURVES ................................................... A-1

APPENDIX B • COMMAND CROSS-REFERENCE ................................................................................. B-1

APPENDIX C • TERMINAL COMMUNICATION ...................................................................................... C-1

APPENDIX D • OVEREXCITATION (24) INVERSE TIME CURVES ....................................................... D-1

9376700990 Rev M BE1-700 Introduction vii

Page 10

This page intentionally left blank .

viii BE1-700 Introduction 9376700990 Rev M

Page 11

SECTION 1 • GENERAL INFORMATION

TABLE OF CONTENTS

SECTION 1 • GENERAL INFORMATION ................................................................................................ 1-1

DESCRIPTION....................................................................................................................................... 1-1

FEATURES ............................................................................................................................................ 1-1

Input and Output Functions ................................................................................................................ 1-1

Protection and Control Functions ....................................................................................................... 1-2

Metering Functions ............................................................................................................................. 1-3

Reporting and Alarm Functions .......................................................................................................... 1-3

BESTlogic Programmabl e Log ic ........................................................................................................ 1-4

Write Access Security ........................................................................................................................ 1-4

Human-Machine Interface (HMI) ........................................................................................................ 1-4

Communication .................................................................................................................................. 1-5

MODEL AND STYLE NUMBER DESCRIPTION ................................................................................... 1-5

General ............................................................................................................................................... 1-5

Sample Style Number ........................................................................................................................ 1-5

OPERATIONAL SP EC IF IC AT IO N S ...................................................................................................... 1-6

Metered Current Values and Accuracy (BE1-700C) .......................................................................... 1-6

Metered Voltage Values and Accuracy (BE1-700V) .......................................................................... 1-6

Metered Frequency Values and Accuracy (BE1-700V) ..................................................................... 1-6

Calculated Values and Accuracy ....................................................................................................... 1-6

24 Overexcitation Protection (BE1-700V) .......................................................................................... 1-7

25 Sync-Check Protection (BE1-700V, Optional) .............................................................................. 1-7

27P Phase Undervoltage Protection (BE1-700V) .............................................................................. 1-8

27X Auxiliary Undervoltage Protection (BE1-700V) ........................................................................... 1-8

47 Negative-Sequence Overvoltage Protection (BE1-700) ............................................................... 1-8

50T Instantaneous Overcurrent Protection (BE1-700C) .................................................................... 1-8

50BF Breaker Failure Protection (BE1-700C) .................................................................................... 1-9

51 Time Overcurrent Protection (BE1-700C) ..................................................................................... 1-9

59P Phase Overvoltage Protection (BE1-700V) ................................................................................ 1-9

59X Auxiliary Overvoltage Protection (BE1-700V) ........................................................................... 1-10

60FL Fuse Loss (BE1-700V) ............................................................................................................ 1-10

62 Logic Timers ................................................................................................................................ 1-10

79 Recloser Protection ..................................................................................................................... 1-10

81 Over/Under Frequency Protection (BE1-700V) .......................................................................... 1-10

Automatic Setting Group Characteristics ......................................................................................... 1-10

BESTlogic ......................................................................................................................................... 1-11

GENERAL SPECIF IC ATI ONS ............................................................................................................. 1-11

AC Current Inputs (BE1-700C)......................................................................................................... 1-11

Phase AC Voltage Inputs (BE1-700V) ............................................................................................. 1-11

Auxiliary AC Voltage Inputs .............................................................................................................. 1-11

Analog to Digital Converter .............................................................................................................. 1-11

Power Supply ................................................................................................................................... 1-11

Output Contacts ............................................................................................................................... 1-12

Contact-Sensing Inputs .................................................................................................................... 1-12

IRIG .................................................................................................................................................. 1-12

Real-Time Clock ............................................................................................................................... 1-13

Communication Ports ....................................................................................................................... 1-13

Display .............................................................................................................................................. 1-13

Isolation ............................................................................................................................................ 1-13

Surge Withstand Capability .............................................................................................................. 1-13

Radio Frequency Interference (RFI) ................................................................................................ 1-13

Electrostatic Discharge (ESD) .......................................................................................................... 1-13

Shock ................................................................................................................................................ 1-13

Vibration ........................................................................................................................................... 1-14

Environment ..................................................................................................................................... 1-14

CE Compliance ................................................................................................................................ 1-14

9376700990 Rev M BE1-700 General Information i

Page 12

UL Recognition for US and Canada ................................................................................................. 1-14

GOST-R Certification ....................................................................................................................... 1-14

Physical ............................................................................................................................................ 1-14

Figures

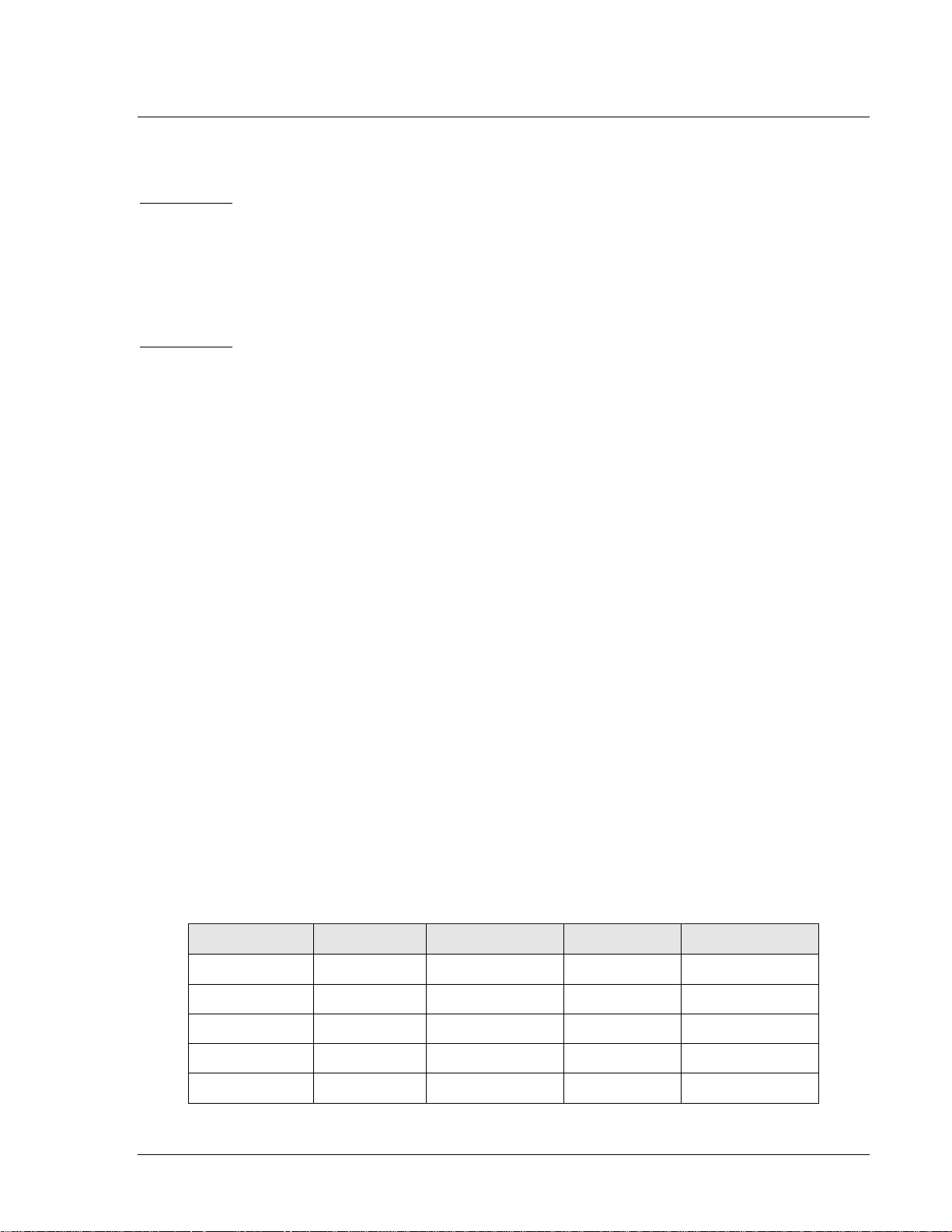

Figure 1-1. Style Number Identification Chart ........................................................................................... 1-6

Tables

Table 1-1. Power Supply Ranges and Holdup Times ............................................................................. 1-11

Table 1-2. Contact-Sensing Turn-On Voltages and Burdens .................................................................. 1-12

ii BE1-700 General Information 9376700990 Rev M

Page 13

SECTION 1 • GENERAL INFORMATION

DESCRIPTION

The BE1-700 Digital Pro tective R elay is an ec onomical, mic roprocessor b ased, mult ifunction sys tem that

is available in a panel mount, non-drawout case. The rela y can be purcha sed as a current relay (BE1-

700C) or as a voltage relay (BE1-700V). In this manual, function headings will note in parenthesis

whether it applies to a curr ent or v olta ge r elay . ( See F igures 1-1 and 1-2.) Depending on the ty p e of r elay,

the BE1-700 features inclu de the following. Functions are shown as C (current), V (voltage) or A (all -

either current or voltage).

• C Three-phase Overcurrent Protection

• C Ground Overcurrent Protection

• C Negative-Sequence Overcurrent Protection

• C Breaker Failure Protection

• V Voltage Protection

• V Frequency Protection

• A Control Protection

• A Communication

• A Breaker Monitoring

• A Metering Functions

• A Automatic Reclosing (optional)

BE1-700 relays have four programmable contact sensing inputs, five programmable outputs, and one

alarm output. Outputs can be assigned to perform protection, control, or indicator operations through

logical programming. For example, protection function s could be programmed to cause a protect ive trip.

Control functions could be programmed to cause a manual trip, manual close or automatic reclose.

Indicators could be configured to annunciate relay failure, a settings group change, and others.

Protection scheme des igners may select f rom a number of pre-programmed logic s chemes that perform

the most common protection and control requirements. Alternately, a custom scheme can be created

using BESTlogic™.

A simplified "How to Get Started" procedure for BE1-700 users is provided in Section 2, Quick Start.

FEATURES

The BE1-700 family inc ludes many features for the protection, monitor ing, and control of pow er system

equipment. These features include pr otec t ion an d c ont r ol func tio ns , m eter i ng functions, and reportin g a nd

alarm functions. A highly f lexible programmable logic sy stem called BESTlogic allows the user to apply

the available functions with complete flex ibility and c ustomize the sys tem to meet the requ irements of the

protected power sys tem. Programmable I/O, ex tensiv e c ommu nication features and an advanced humanmachine interface (HMI) provide easy access to the features provided.

The following information summarizes the capabilities of this multifunction device. Each feature, along

with how to set it up a nd h ow to use its out puts is des cribed in c omple te det ail in the lat er s ections of t his

manual.

Input and Output Functions

Input functions consist of p ower s ystem meas ure ment and contact sensing inputs . Pr ogramma ble con tact

outputs make up the output functions.

Power System Measurement Funct ions

Three-phase currents or voltages are digit ally sampled and the fundamenta l is extracted usin g a discrete

fourier transform (DFT) algorithm.

The voltage sensing circuits can be configured for single-phase, three wire or four wire voltage

transformer circuits. Voltage sensing circuitry provides voltage protection, frequency protection, and

metering. Neutral (res idual) and negat ive-sequence voltage magni tudes are deriv ed from t he thre e-phase

voltages. Digital sampling of the measured frequency provides high accuracy at off-nominal values.

An auxiliary voltage se nsing input pr ovides protecti on capabilities for over/underv oltage mon itoring of the

first and third harm onic of the VT source c onnected to the Vx input . This capability is useful for ground

fault protection or sync-check functions.

9376700990 Rev M BE1-700 General Information 1-1

Page 14

Each current sensing circ uit is low burd en and isolated . Neutral (res idual) and ne gative-sequence current

magnitudes are deriv ed from the three-ph ase currents. An indepen dent ground current i nput is included

for direct measurement of the c urrent in a transformer neutral, tertiary wind ing or flux balancing current

transformer.

Contact Sensing Inputs

Four programmable contact-sensing inputs (IN1, IN2, IN3, and IN4) with programmable signal

conditioning provide a b inary logic interface t o the prot ection and c ontrol sys tem. Each i nput funct ion and

label is programmab le using BESTlogic. A user-meaningful label ca n be assigned to each input and to

each state (open and closed) for use in reporting functions.

Contact Outputs

Five programmable g eneral-purpose contact outputs ( OUT1, OUT2, OUT 3, OUT4, and OU T5) provide a

binary logic interface to the protection and control sy stem. One programmable, fail-safe co ntact output

(OUTA) provides an a larm output. Each output function an d label is programmable using BESTlogic. A

user-meaningful name c an be assigned to each outp ut and to each state (open and c losed) for use in

reporting functions. Out put log ic c an be ov err id den to open , c lose, or pulse each output c ontac t for tes t ing

or control purposes. All output contacts are trip rated.

Protection and Control Functions

Protection functions, depending on the relay style ordered, may consist of overcurrent, voltage,

frequency, breaker rec losing, fuse loss and breaker failure protec tion and general purpose logic timer s.

Setting groups and virtual control switches make up the control functions. The following paragraphs

describe each protection and control function.

Overcurrent Protection (BE1-700C)

Overcurrent protection is provided by six instantaneo us overcurrent functions an d three time overcurrent

functions. Digital signal processing filters out unwanted harmonic components while providing fast

overcurrent response with limited transient overreach and overtravel.

Each instantaneous overcurrent function has a settable time delay. Phase elements inc lude 50TP and

150TP. Neutral elements include 50TN and 150TN. Negative-sequence elements include 50TQ and

150TQ.

Inverse time overcurr ent functions are provided for ph ase, neutral and negative-sequenc e protection. A

51P phase element, 51N and 151N neutral elements, and a 51Q negative-sequence element are

provided. Time overcurrent functions employ a dynamic integrating timing algorithm covering a range

from pickup to 40 times pickup with selectable instantaneous or integrated reset characteristics. Time

overcurrent curves conform to the IEEE PC37.112 document and include seven curves similar to

Westinghouse/ABB CO curves, five curves similar to GE IAC curves, a fixed time curve and a user

programmable curve.

Voltage Protection (BE1-700V)

One volts per hertz protective element (24) provides overexcitation protection for a generator and/or

transformer.

Two phase overvoltage an d tw o p hase undervoltage elements provide over/underv oltag e pr ot ec tio n (27 P,

59P). Phase overvoltage pr otection can be s et for one of thr ee, two of three or thr ee of three l ogic. When

a four-wire voltage transfor mer connect ion is used, over voltage protec tion can be set for eith er phase-tophase voltage or phase-to-neutral voltage.

Two auxiliary overvoltage and one auxiliary undervoltage e lement provides over/und ervoltage protection

(27X, 59X, 159X). Auxiliary voltage protection elem ents can be set to individually monitor the auxiliary

voltage fundamental, third harmonic or phase 3V

when the optional auxiliary voltage input is connected to a source of 3V

voltages. Ground unbalance protection is provided

0

such as a broken delta VT.

0

With the optional auxiliary voltage input connected to the bus, one sync-check function provides

synchronism protection (25). Sync-check protection checks for phase angle difference, magnitude

difference, frequency difference ( slip) and, op tionally, if the three-p hase VT freq uency is gr eater than t he

auxiliary VT frequency. One voltage monitor output (25VM1) provides independent dead/live voltage

closing logic.

One negative-sequence overvoltage element provides protection for phase unbalance or a reverse

system phase-sequence (47).

1-2 BE1-700 General Information 9376700990 Rev M

Page 15

Voltage transformer circuit monitoring adds security by detecting problems in the voltage transformer

sensing circuits and preventing mis-operations of the 27P/127P, 47, 59P/159P.

Frequency Protection (BE1-700V)

There are six independent frequency elements. Each can be set for overfrequency or underfrequency

operation. Each ca n be indiv idually s et to mon itor t he f requency on the ma in thr ee-phase voltage input or

the VX input.

Breaker Failure Protection (BE1-700C)

One breaker failure protection block (BF) provides programmable breaker failure protection.

Fuse Loss Protection (BE1-700V)

A fuse loss function protects against false tripping due to a loss of voltage sensing.

General Purpose Logic Timers

Two general purpose logic timers (62, 162) with six modes of operation are provided.

Setting Groups

Two setting groups all ow adaptive relaying to be impl emented to optimize BE1-700 sett ings for various

operating conditions. Automatic and external logic can be employed to select the active setting group.

Virtual Control Switches

BE1-700 virtual control switches include one virtual breaker control switch and two virtual 43 switches.

Trip and close contro l of a s elect ed break er ca n b e c o ntr ol led by the Virtual Breaker Contr o l Sw itch ( 101).

The virtual breaker contr ol s witch is ac cess ed locally f rom the fr ont pa nel hu man-machine interface (HMI)

or remotely from the communication ports.

Additional control is provided by the two virtual switches: 43 and 143. These virtual switches are

accessed locally from the front pane l HMI or r emote ly f rom the co mmunic atio n ports . Virtual s witc hes can

be used to trip and close additional switches or breakers, or enable and disable certain functions.

Metering Functions

Metering is provided for all measured currents, voltages and frequency, and all derived neutral and

negative-sequence currents and voltages.

Reporting and Alarm Functions

Several reporting and alarm fu nctions provi de fault re porting, dem and, breaker and trip cir cuit monitoring

as well as relay diagnostic and firmware information.

Relay Identification

Two free-form fields are pr ovided for the user to enter informa tion to identify the relay. These fi elds are

used by many of the repor ting functions to identify the relay that th e report is from. Examples of relay

identification field uses are station name, circuit number, relay system, purchase order, and others.

IRIG

A standard IRIG input is provided for receiving time synchronization signals from a master clock.

Automatic daylight sav in g t i me c om pens at io n can be enabled. Time reporting is settable for 12 or 24-hour

format. The date can be formatted as mm/dd/yy or dd/mm/yy.

General Status Reporting

The BE1-700 provides extensive general status reporting for monitoring, commissioning, and

troubleshooting. Status reports are available from the front panel HMI or communication ports.

Demand Reporting

Ampere demand registers monitor phase A, B, C, neutral and negative-sequenc e values. The demand

interval and demand calculation method are independently settable for phase, neutral and negativesequence measurements. Demand reporting records today's peak, yesterday's peak and peak since reset

with time stamps for each register.

Breaker Monitoring

Breaker statistics ar e recorded for a single break er. They includ e the number of operations, fault current

interruption duty and breaker time to trip. Each of these conditions can be set to trigger an alarm.

9376700990 Rev M BE1-700 General Information 1-3

Page 16

Trip Circuit Monitoring

A trip circuit monitor funct ion is provided to mon itor the trip circ uit of a breaker or loc kout relay for loss of

voltage (fuse blown) or loss of continuity (trip coil open). The monitoring input is internally connected

across OUT1. Addition al trip or close cir cuit monitors can be implemented in BE STlogic using addition al

inputs, logic timers, and programmable logic alarms.

Fault Reporting

Fault reports consist of simple target information, fault summary reports, and detailed oscillography

records to enable the user to retrieve informat ion abou t disturbanc es in as much detail as is d esired. The

relay records and r eports oscillography da ta in industry standard I EEE, Comtrade format to allow using

any fault analysis s oftware. Basl er Electric prov ides a Wi ndows® based program called BESTwave™ that

can read and plot binary or ASCII format files that are in the COMTRADE format.

Sequence of Events Recorder

A 255 event Sequence of Events Recorder (SER) is provided that records and time stamps all relay

inputs and outputs as well as all alarm condit ions monitored by the relay. Time s tamp resolution is to the

nearest half-cycle. I/O and Alarm reports can be extracted from the records as well as reports of events

recorded during the time span associated with a specific fault report.

Alarm Function

Extensive self-diagnostics will trigger a fatal relay trouble alarm if any of the relay core functions are

adversely affected. Fatal relay trouble alarms are not programmable and are dedicated to the Alarm

Output (OUTA) and the front panel Relay Tr oub le L E D. Ad dit ion al re lay tro ubl e alar ms a nd all other alarm

functions are programmab le for major or minor priority. Programmed al arms are indicated by major and

minor alarm LEDs on the front panel. Major and minor alarm points can also be programmed to any

output contact including OUTA. Over 20 alarm conditions are ava ilable to be monitored including user

definable logic conditions u sing BE STl ogic.

Active alarms can be read and reset from the front panel HMI or from the communication ports. A

historical sequence of events report with time stamps l ists when eac h al arm occ urr ed and c leared . Th ese

reports are available through the communication ports.

Version Report

The version of the embedded software (firmware) is available from the front panel HMI or the

communication ports. The unit serial number and style number is also available through the

communication port.

BESTlogic Programmable Logic

Each BE1-700 protec tion and control funct ion is implemented i n an independent functi on element. Every

function block is equivalen t to its single function, discrete device counterp art so it is immediately fami liar

to the protection engineer. Each independent function block has all of the inputs and outputs that the

discrete component cou nterpart might have. Program ming with BESTlogic is equivalent t o choosing the

devices required by your protec tion and contr ol sc heme and the n drawin g schem atic dia grams to c onnect

the inputs and outputs to obtain the desired operating logic.

Several preprogrammed logic schemes and a set of custom logic settings are provided. A

preprogrammed scheme c an be activate d by merely selecti ng it. Custom lo gic settings allow yo u to tailor

the relay functionality to match the needs of your operation's practices and power system requirements.

Write Access Security

Security can be defined fo r three distinct functional access areas: Settings, Reports, and Control. Eac h

access area can be as sign ed its ow n p as s wor d. A g lo bal pas s wor d prov id es acc es s to a ll thr ee fu nc tio nal

areas. Each of the four passwords can be unique or multiple access areas can share the same password.

A second dimension of sec urity is provided by allowin g the user to restrict access for any of the access

areas to only specific communication ports. For example, you could set up security to deny access to

control commands from the Ethernet port that is connected through a modem to a telephone line.

Security settings only affect write access.

Human-Machine Interface (HMI)

Each BE1-700 comes wi th a front panel display with f ive LED indicators for Pow er Supply Status, Relay

Trouble Alarm, Minor Alarm, Major Alarm, and Trip. The l ighted, liquid crystal display (LCD) allows the

1-4 BE1-700 General Information 9376700990 Rev M

Page 17

relay to replace loca l indication and control functions such as panel metering, alarm annunc iation and

control switches. Four s crolling pushbuttons on the front pan el provide a means to navigate thr ough the

menu tree. Edit and reset pus hbuttons provide access t o change parameters and reset targets , alarms,

and other registers. I n Edit mode, the scrolling pushb uttons provide data entry s elections. Edit mode is

indicated by an Edit LED on the Edit pushbutton.

The LCD has automat ic priority logic to govern what is being displayed on the scr een so that when an

operator approaches, the information of most interest is automatically displayed without having to

navigate the menu structure. The order of priorities is:

1. Recloser Active

2. Targets

3. Alarms

4. Programmable Automatic Scrolling List

Up to 16 screens can be defined in the programmable, automatic scroll list.

Communication

Three independent, isol ated communicatio n ports provide acces s to all functions in the r elay. COM0 is a

nine pin RS-232 port loc ated on the front of the cas e. COM2 is a two wire RS-485 port located on th e

back of the case. The optional rear Ethernet port is referred as Com1 in the BESTCOMS™ General

Operation screen, Security tab.

An ASCII command interface allows easy interaction with the relay using standard, off the shelf

communication software. The ASCII command interface is optimized to allow automation of the relay

setting process. Sett ings f iles c an be capt ured fr om th e relay and ed ited us ing a ny s oftware th at su pports

the ∗.txt file format. These ASCII text files can then be used to set the relay using the send text file

function of your communication software.

A Modbus™ protocol manual (9376700991) is optionally available for the RS-485 communication port.

Ethernet information can be found in Secti on 15, BESTnet™ Communication.

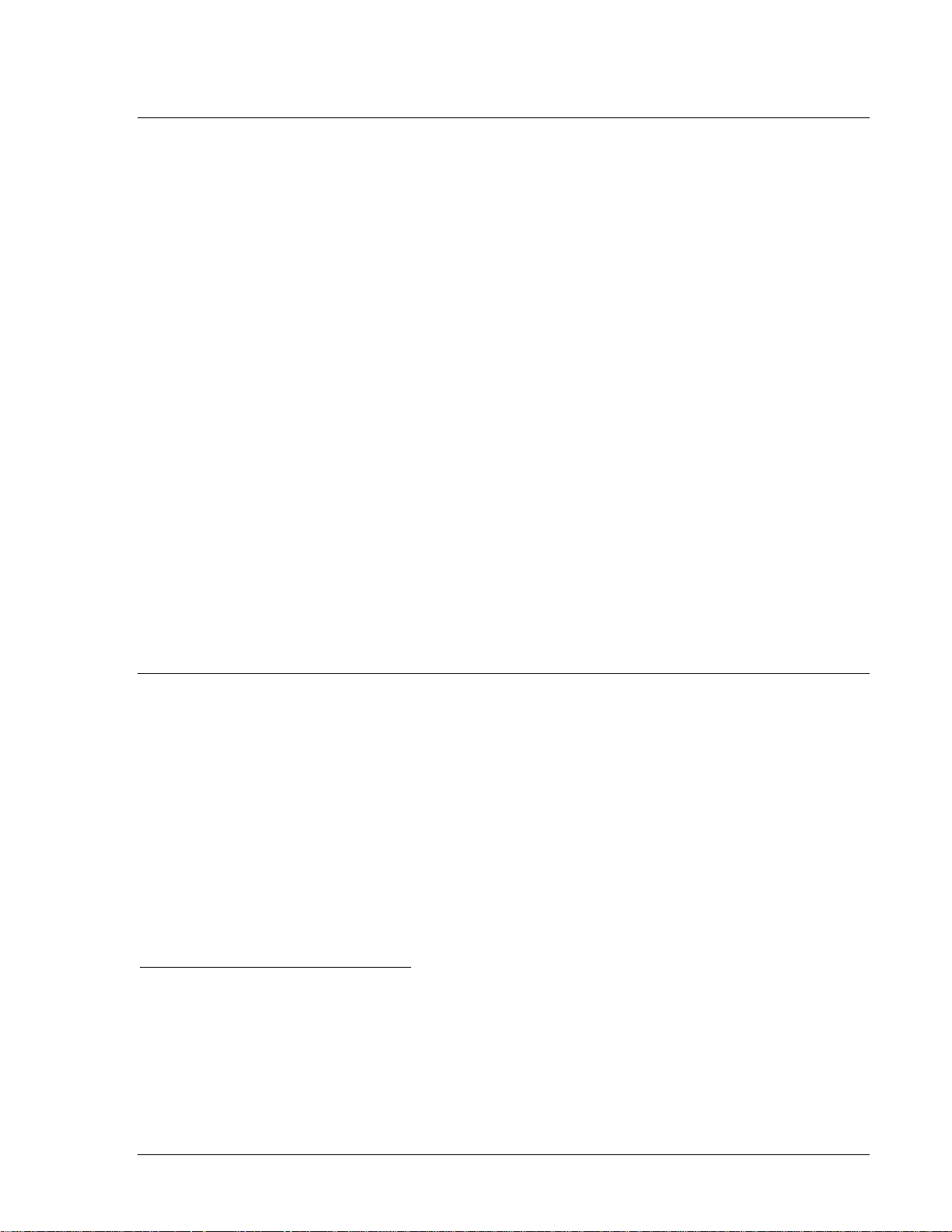

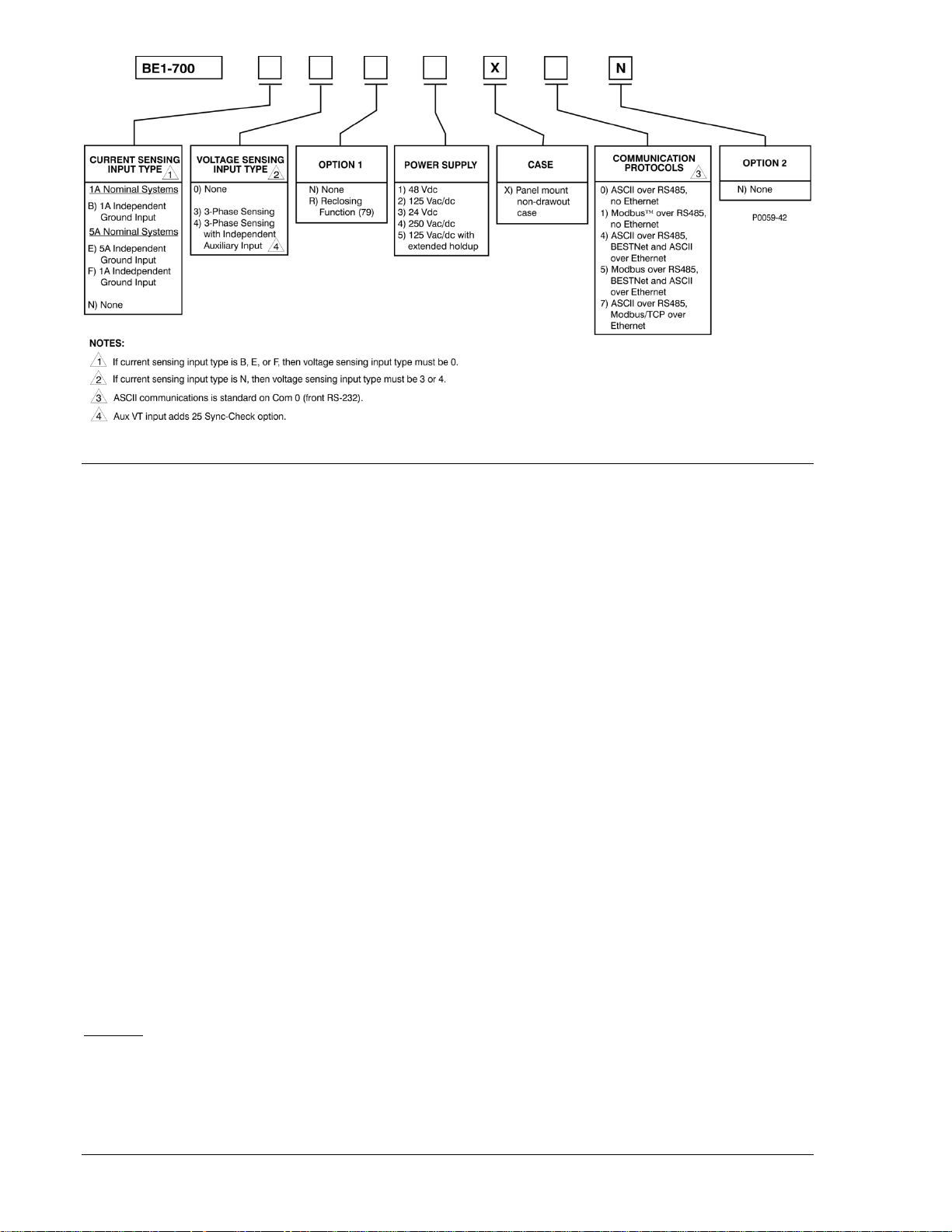

MODEL AND STYLE NUMBER DESCRIPTION

General

The BE1-700 relay electrical characteristics and operational features are defined by a combination of

letters and numbers that mak e up the style number. The model n umber, together with the sty le number,

describes the options included in a specific dev ice and appears on labels o n the front panel and i nside

the case. Upon receipt of a relay, be sure to check the style number against the requisition and the

packing list to ensure that they agree.

The style number id entification chart, Figures 1-1, defines the electrica l characteristics and operational

features included in BE1-700 c urrent and v oltage rela ys. In this manua l, the curr ent relay wil l be referred

to as a BE1-700C and the voltage relay as a BE1-700V.

Sample Style Number

If, for example, the style number were E0N1X0N, the device would be a current relay and have the

following characteristics and features:

BE1-700 —

(E) - 5 ampere phase and independent ground input

(0) - No voltage sensing input

(N) - No reclosing function option

(1) - 48 Vdc power supply

(X) - Pan el mou nt, non-drawout case

(0) - ASCII over RS-485, no Ethernet

(N) - No Option 2 is available

9376700990 Rev M BE1-700 General Information 1-5

Page 18

Figure 1-1. Style Number Identification Chart

OPERATIONAL SPECIFICATIONS

Depending on the style ordered, BE1-700 relays have the following features and capabilities:

Metered Current Values and Accuracy (BE1-700C)

Current Range

5 Aac Nominal: 0.5 to 15 Aac

1 Aac Nominal: 0.1 to 3.0 Aac

Accuracy: ±1% of reading, ±1 least si g nif icant dig it at 25°C

Temperature Dependence: ≤ ±0.02% per °C

Metered Voltage Values and Accuracy (BE1-700V)

Voltage Range

3-wire: 0 to 300 V

4-wire: 0 to 300 V

Accuracy (10 to 75 hertz)

50 V to 300 V: ±0.5% of reading, ±1 least significant digit at 25°C

Temperature Dependence: ≤ ±0.02% per °C

Metered Frequency Values and Accuracy (BE1-700V)

Frequency Range: 10 to 75 Hz

Accuracy: ±0.01 hertz, ±1 least significant digit at 25°C

Sensing Input

3-wire: Phase A – B

4-wire: Phase A – Neutral

Minimum Frequency Tracking Voltage: 10 V rms

L-L

L-L

Calculated Values and Accuracy

Demand

Range: 0.1 to 1.5 nominal

Type: Exponential

Accuracy: ±1% of reading ±1 digit at 25°C

Temperature Dependence: ≤ ±0.02% per °C

Interval: 1 to 60 min

1-6 BE1-700 General Information 9376700990 Rev M

Page 19

24 Overexcitation Protection (BE1-700V)

n

NOMINAL

MEASURED

T

1

HZ

V

HZ

V

DT

T

−

=

100*

FST

E

*DT

T

RR

=

Pickup

Setting Range: 0.5 to 6 V/Hz

Accuracy: ±2%

Integrating Time Delay

Time Dial: 0.0 to 9.9

Reset Dial: 0.0 to 9.9

Accuracy: 5% or 4 cycles, whichever is greater

Time to Trip

Time to Reset

where:

T

T

D

D

E

= Time to trip

T

= Time to reset

R

= Time dial trip

T

= Time dial, reset

R

= Elapsed time

T

n = Curve exponent (0.5, 1, 2)

FST = Full scale trip time (TT)

ET/FST = Fraction of total travel toward trip that integration had progressed to. (After a trip,

this value will be equal to one.)

Definite Time Delay

Time Delay: 0.050 to 600 s

Accuracy: 5% or 4 cycles, whichever is greater

25 Sync-Check Protection (BE1-700V, Optional)

Settings

Delta Phase Angle: 1 to 99°

Accuracy: ±0.5°

Delta Voltage Magnitude: 1 to 20 V

Accuracy: ±2% or ±1 V, whichever is greater

Delta Frequency: 0.01 to 0.50 Hz

Accuracy: ±0.01 Hz

Voltage Monitoring

Live/Dead voltage threshold: 10 to 150 V

Accuracy: ±2% or ±1 V

Dropout Time delay: 0.050 to 60 s

Accuracy: ±0.5% or ±2 cycles, whichever is greater

Logic: Dead Phase/Dead Aux

Dead Phase/ Live Aux

Live Phase/ Dead Aux

One independent output: 25VM1

9376700990 Rev M BE1-700 General Information 1-7

Page 20

27P Phase Undervoltage Protection (BE1-700V)

Pickup

Setting Range: 10 to 300 V

Accuracy: ±2% of setting or ±1 V, whichever is greater

Dropout/Pickup Ratio: 102%

Time Delay

Setting Range: 0.05 to 600 s

Accuracy: ±0.5% or ±2.5 cycles, whichever is greater

27X Auxiliary Undervoltage Protection (BE1-700V)

Pickup

Setting Range: 1 to 150 V

Accuracy: ±2% of setting or ±1 V, whichever is greater

Dropout/Pickup Ratio: 102%

Time Delay

Setting Range: 0.05 to 600 s

Accuracy: ±0.5% or ±2.5 cycles, whichever is greater

47 Negative-Sequence Overvoltage Protection (BE1-700)

Pickup

Setting Range: 1.0 to 300 V

L-N

Accuracy: ±2% of setting or ±1 V, whichever is greater

Dropout/Pickup Ratio: 98%

Time Delay

Setting Range: 0.050 to 600 s

Accuracy: ±0.5% or ±2.5 cycles, whichever is greater

50T Instantaneous Overcurrent Prote ction (BE1-700C)

Pickup

Setting Range

5 Ampere CT: 0.5 to 150 A

1 Ampere CT: 0.1 to 30 A

Accuracy (50TP, 50TN)

5 Ampere CT: ±2% or ±50 mA, whichever is greater

1 Ampere CT: ±2% or ±10 mA, whichever is greater

Accuracy (50TQ)

5 Ampere CT: ±3% or ±75 mA, whichever is greater

1 Ampere CT: ±3% or ±15 mA, whichever is greater

Dropout/Pickup Ratio: 95%

Time Delay

Setting Range: 0 to 60 s

Accuracy

50TP, 50TN: ±0.5% or ±½ cycle, whichever is gr eater, plus trip

time for instantaneous response (0.0 setting) *

50TQ: ±0.5% or ±1 cycle, whic hever is greater, plus trip

time for instantaneous response (0.0 setting) *

1-8 BE1-700 General Information 9376700990 Rev M

Page 21

∗ Trip Time for 0.0 Delay Setting

50TP, 50TN: 2¼ cycles maximum for currents ≥ 5 times the

pickup setting. Three cycles maximum for a

current of 1.5 times p ickup. Four c ycles maximu m

for a current of 1.05 times the pickup setting.

50TQ: 3¼ cycles maximum for currents 5 times the

pickup setting. Four cycles maximum for a current

of 1.5 times pickup. Five cycles maximum for a

current of 1.05 times the pickup setting

50BF Breaker Failure Protection (BE1-700C)

Pickup

Setting Range: Fixed at 0.5 A for 5 A unit, 0.1 A for 1 A unit

Accuracy: ±10%

Time Delay

Setting Range: 50 to 999 ms

Accuracy: ±0.5% or +1¼, –½ cycles, whichever is greater

Reset Time: Within 1¼ cycles of the current being removed

51 Time Overcurrent Protection (BE1-700C)

Pickup

Setting Range

5 Ampere CT: 0.5 to 16 A

1 Ampere CT: 0.1 to 3.2 A

Accuracy (51P, 51N)

5 Ampere CT: ±2% or ±50 mA, whichever is greater

1 Ampere CT: ±2% or ±10 mA, whichever is greater

Accuracy (51Q)

5 Ampere CT: ±3% or ±75 mA, whichever is greater

1 Ampere CT: ±3% or ±15 mA, whichever is greater

Dropout/Pickup Ratio: 95%

Time Current Characteristic Curves

Timing Accuracy (All 51 Functions): Within ±5% or ±1½ cycles, whichever is greater,

for time dial settings greater than 0.1 and

multiples of 2 to 40 times the pickup setting but

not over 150 A for 5 A CT units or 30 A for 1 A CT

units.

See Appendix A, Time Overcurrent Character istic

Curves, for information on available timing curves.

59P Phase Overvoltage Protection (BE1-700V)

Pickup

Setting Range: 10 to 300 V

Accuracy: ±2% of setting or ±1 V, whichever is greater

Dropout/Pickup Ratio: 98%

Time Delay

Setting Range: 0.050 to 600 s

Accuracy: ±0.5% or ±2.5 cycles, whichever is greater

9376700990 Rev M BE1-700 General Information 1-9

Page 22

59X Auxiliary Overvoltage Protection (BE1-700V)

Pickup

Setting Range: 1 to 150 V

Accuracy: ±2% of setting or ±1 V, whichever is greater

Dropout/Pickup Ratio: 98%

Time Delay

Setting Range: 0.050 to 600 s

Accuracy: ±0.5% or ±2.5 cycles, whichever is greater

60FL Fuse Loss (BE1-700V)

Time Delay: Fixed at 50 ms

62 Logic Timers

Modes: Pickup/Dropout, 1 Shot Nonretriggerable, 1 Shot

Retriggerable, Oscillator, Integrating, Latch

Setting Range: 0 to 9,999 s

Accuracy: ±0.5% or ±12 ms, whichever is greater

79 Recloser Protection

Reclose (791, 792, 793, 794), Reset (79R), Max Cycle (79M), Reclose Fail (79F), Pilot (79P)

Setting Range: 100 ms to 600 s

Accuracy: ±0.5% or +1¾, –0 cycles, whichever is greater

81 Over/Under Frequency Protection (BE1-700V)

Pickup

Setting Range: 20 to 70 Hz

Accuracy: ±0.01 Hz

Dropout : 0.02 Hz ±0.01 Hz of the actual pickup value

Time Delay

Setting Range: 0.00 to 600 s

Accuracy: ±0.5% or ±1 cycle, whichever is greater, plus 3

cycle recognition time

Voltage Inhibit

Setting Range: 15 to 300 V

Accuracy: ±2% or ±1 V, whichever is greater

Automatic Setting Group Character istics

Number of Setting Groups: 2

Control Modes

Automatic: Cold-Load Pickup, Dynamic Load or Unbalance,

Recloser Shot, or Unbalance (BE1-700C); Fuse

Loss (60FL) (BE1-700V)

External: Discrete Input Logic, Binary Input Logic

Switch Level

Setting Range: 0 to 150% of the Setting Group 0, monitored

element setting

Accuracy: ±2% or ±50 mA (5 A), ±2% or ±10 mA (1 A)

Switch Timer

Setting Range: 0 to 60 min with 1 min increments where 0 =

disabled

Accuracy: ±0.5% or ±2 s, whichever is greater

1-10 BE1-700 General Information 9376700990 Rev M

Page 23

BESTlogic™

Update Rate: ½ cycle

GENERAL SPECIFICATIONS

AC Current Inputs (BE1-700C)

5 Ampere CT

Continuous Rating: 20 A

One Second Rating: 400 A

For other current levels, use the formula: I= (K/t)

Begins to Clip (Saturate): 150 A

Burden: <0.01 Ω

1 Ampere CT

Continuous Rating: 4 A

One Second Rating: 80 A

For other current levels, us e the follow ing formu la: I = ( K/t)

mount, non-drawout case).

Begins to Clip (Saturate): 30 A

Burden: ≤0.01 Ω at 1 A

Phase AC Voltage Inputs (BE1-700V)

Continuous Rating: 300 V, Line to Line

One Second Rating: 600 V, Line to Line (3-wire sensing)

600 V, Line to Neutral (4-wire sensing)

Burden: <1 VA at 300 Vac

½

where t = time in seconds, K = 160,000.

½

where t = time in seconds, K = 9 0,000 (pane l

Auxiliary AC Voltage Inputs

Continuous Rating: 150 V, Line to Line

Fault Rating: 360 V, Line to Line

One Second Rating: 600 V, Line to Neutral

Burden: <1 VA at 150 Vac

Analog to Digital Converter

Type: 16-bit

Sampling Rate: 12 samples per cyc le, adjusted to input frequency

(10 to 75 Hz)

Power Supply

Power supply ranges and holdup times are listed in Table 1-1.

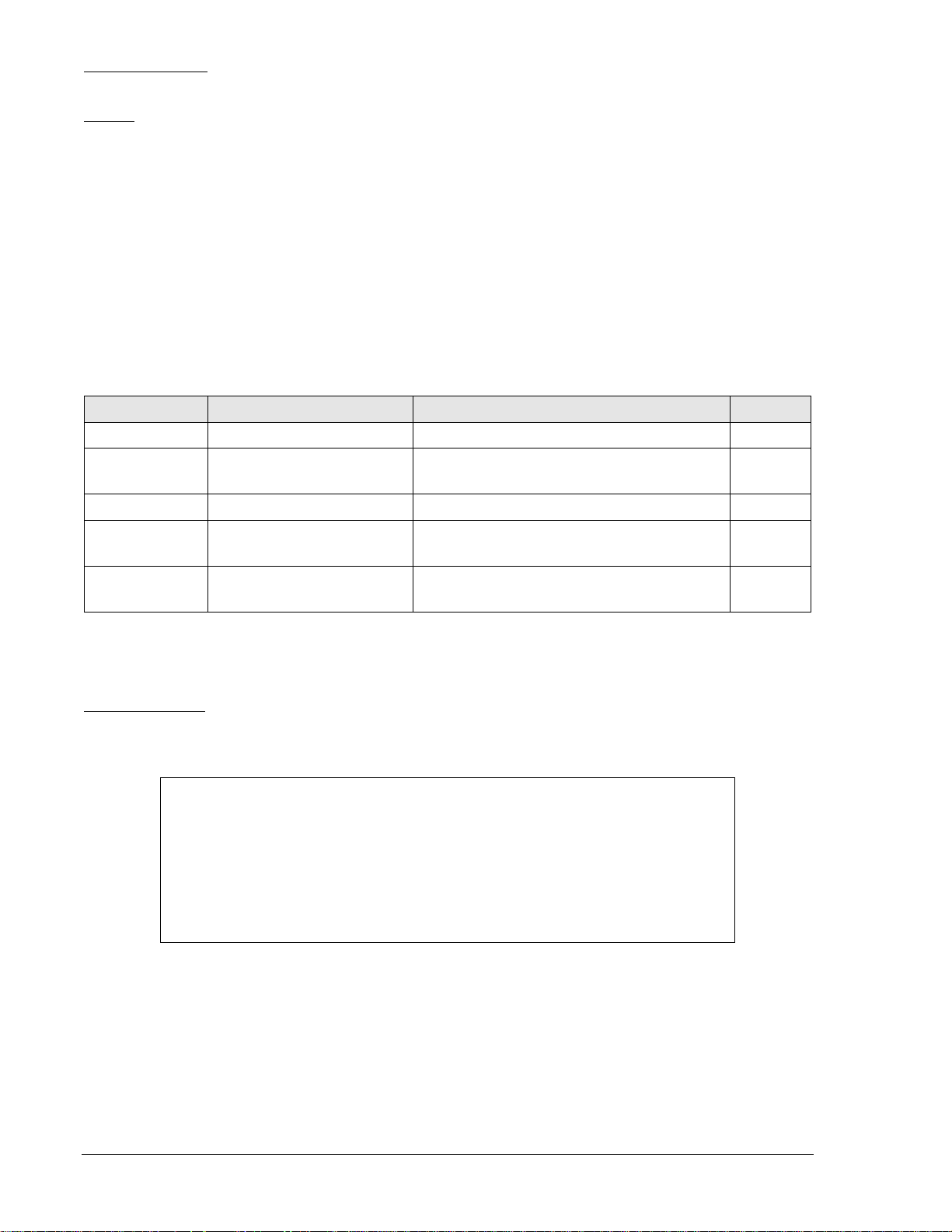

Table 1-1. Power Supply Ranges and Holdup Times

Style Option AC Range AC Holdup Time DC Range DC Holdup Time

1) 48 Vdc N/A N/A 35 to 150 Vdc 30 ms

2) 125 Vac/dc 90 to 270 Vac 70 ms 90 to 300 Vdc 50 ms

3) 24 Vdc N/A N/A 17 to 32 Vdc † 80 ms

4) 250 Vac/dc 90 to 270 Vac 280 ms 90 to 300 Vdc 170 ms

5) 125 Vac/dc *

55 to 135 Vac 280 ms 35 to 150 Vdc 170 ms

* Extended holdup option. See Style Chart in Figure 1-1.

† Operates down to 8 Vdc momentar ily.

9376700990 Rev M BE1-700 General Information 1-11

Page 24

Frequency Range

Options 1, 2, and 4 only: 40 to 70 Hz

Burden

Options 1, 2, 3, 4, 5: 8 W continuous, 11 W maximum w ith all outputs

energized

Output Contacts

Make and Carry for Tripping Duty: 30 A for 0.2 seconds per IEEE C37.90;

7 A continuous

Break Resistive or Inductive: 0.3 A at 125 or 250 Vdc (L/R = 0.04 maximum)

Contact-Sensing Inputs

Contact-sensing turn-on voltages and burdens are listed in Table 1-2. Burden values assume nominal

value of input voltage applied.

Table 1-2. Contact-Sensing Turn-On Voltages and Burdens

Style Option Nominal Input Voltage

xxx1xxx 48 Vdc 26 to 38 Vdc 23 kΩ

xxx2xxx 125 Vac/dc

xxx3xxx 24 Vdc Approx. 5 Vdc 6 kΩ

xxx4xxx 250 Vac/dc

xxx5xxx

* AC voltage ranges are calculated using the default recognition time (4 ms) and debounce time (16 ms).

† Extended holdup option. See Style Chart in Figure 1-1.

Recognition Time

Programmable ................................................................ 4 to 255 ms

All timing specifications are for the worst-case response. This includes output

contact operate times and standard BESTlogic operation timing but excludes

input debounce timing and non-standard logic configurations. If a non-standard

logic scheme involves feed back, then on e or more BESTlogic update rate d elays

must be included to calcul ate the worst-case delay. An example of feedbac k is

Virtual Outputs drivin g Function Block Inputs. For more informatio n, see Section

7, BESTlogic Programmable Logic.

125 Vac/dc †

Contact-Sensing Turn-On Voltage *

69 to 100 Vdc

56 to 97 Vac

138 to 200 Vdc

112 to 194 Vac

69 to 100 Vdc

56 to 97 Vac

NOTE

Burden

53 kΩ

123 kΩ

53 kΩ

IRIG

Supports IRIG Standard 200-98, Format B002

Input Signal: Demodulated (dc level-shifted digital signal)

Logic-High Voltage: 3.5 Vdc, minimum

Logic-Low Voltage: 0.5 Vdc, maximum

Input Voltage Range: ±20 Vdc, maximum

Resistance: Nonlinear, approximately 4 kΩ at 3.5 Vdc,

approximately 3 kΩ at 20 V dc

1-12 BE1-700 General Information 9376700990 Rev M

Page 25

Real-Time Clock

Accuracy: 1 second per day at 25°C (free running) or

±2 milliseconds (with IRIG synchronization)

Resolution: 1 millisecond

Date and Time Setting Provisions: Front panel, communications port, and IRIG. Leap

year and selectable daylight saving time

correction provided.

Communication Ports

Interface

Front RS-232: 300 to 19200 baud, 8N1 full duplex

Rear RS-485: 300 to 19200 baud, 8N1 half duplex

Rear Ethernet: IEEE 802.3 (10BaseT)

Response Time (RS-232): <100 ms for metering and control functions

Display

Type: Two line, 16 character alphanumeric LCD (liquid

crystal display) with LED (light emitting diode);

backlight

Operating Temperature: –40°C (–40°F) to +70°C (+158°F).

Display contrast may be impaired at temperatures

below –20°C (–4°F).

Isolation

Meets IEC 255-5 and exceeds IEEE C37.90 one minute dielectric test as follows:

All Circuits to Ground*: 2,000 Vac or 2,828 Vdc

Input Circuits to Output Circuits: 2,000 Vac or 2,828 Vdc

Communication Ports to Ground†: 700 Vdc for one minute

* Excludes communication ports.

† Ethernet port excluded from dielectric tests.

Surge Withstand Capability

Oscillatory

IEEE Std C37.90.1-2002 - IEEE Standard Surge Withs tand Capa bility (S WC) Test s for Relays and R elay

Systems Associated with Electric Power Apparatus (Excludes front panel RS-232 communication port.

Shielded RJ-45 cable is required for the Ethernet port.)

Fast Transient

Qualified to IEEE Std C37.90.1-2002 - IEEE Standard Surge Withstand Capability (SWC) Tests for

Relays and Relay Systems Associated with Electric Power Apparatus. (Due to surge suppression

components, excludes application across open output contacts. Excludes front panel RS-232

communication port. Shielded RJ-45 cable is required for the Ethernet port.)

Radio Frequency Interference (RFI)

Qualified to IEEE Std C37.90.2-2004 - IE EE Sta ndar d Withstand Capability of Relay Systems to R adi ate d

Electromagnetic Interference from Transceivers.

Electrostatic Discharge (ESD)

IEEE Std C37.90.3-2001 - IEEE Standa rd Electrostatic Discharge Test for Protective Relays.

Shock

Qualification: IEC 255-21-2, Class 1

9376700990 Rev M BE1-700 General Information 1-13

Page 26

Vibration

Qualification: IEC 255-21-1, Class 1

Environment

Temperature

Operating Range: –40°C to 70°C (–40°F to 158°F) *

Storage Range: –40°C to 70°C (–40°F to 158°F)

∗ Display is inoperative below –20°C

Humidity

Qualified to IEC 68-2-38, 1st Edition 1974, Basic Environmental Test Procedures, Part 2: Test Z/AD:

Composite Temperature Humidity Cyclic Test.

CE Compliance

This product meets or exceeds the standards required for distribution in the European Community.

UL Recognition for US and Canada

UL recognized per Standard 508 and Standard CAN/CSA-C22.2 Number 14-M91, UL File Number

E97033. Note: Output contacts are not recognized for voltages greater than 250 V.

GOST-R Certification

GOST-R certified per the relevant standards of Gosstandart of Russia.

Physical

Weight: 4.33 lb (1.96 kg) maximum

Case Size: See Section 12, Installation.

1-14 BE1-700 General Information 9376700990 Rev M

Page 27

SECTION 2 • QUICK START

TABLE OF CONTENTS

SECTION 2 • QUICK START .................................................................................................................... 2-1

GENERAL .............................................................................................................................................. 2-1

About This Manual ............................................................................................................................. 2-1

BESTlogic .............................................................................................................................................. 2-2

Characteristics of Protection and Control Function Blocks ................................................................ 2-2

Function Block Logic Settings ............................................................................................................ 2-2

Output Logic Settings ......................................................................................................................... 2-3

USER INTERFACES ............................................................................................................................. 2-3

Front Panel HMI ................................................................................................................................. 2-3

ASCII Command Communications .................................................................................................... 2-4

BESTCOMS™ for BE 1 -700, Graphical User Interface ....................................................................... 2-5

GETTING STARTED ............................................................................................................................. 2-6

Entering Test Settings ........................................................................................................................ 2-6

Checking the State of Inputs .............................................................................................................. 2-6

Testing ................................................................................................................................................ 2-7

FAQ/TROUBLESHOOTING .................................................................................................................. 2-7

Frequently Asked Questions (FAQs) ................................................................................................. 2-7

Figures

Figure 2-1. 51 Time Overcurrent Logic (BE1-700C) ................................................................................. 2-2

Figure 2-2. Menu Screens Numbering Example ....................................................................................... 2-4

Tables

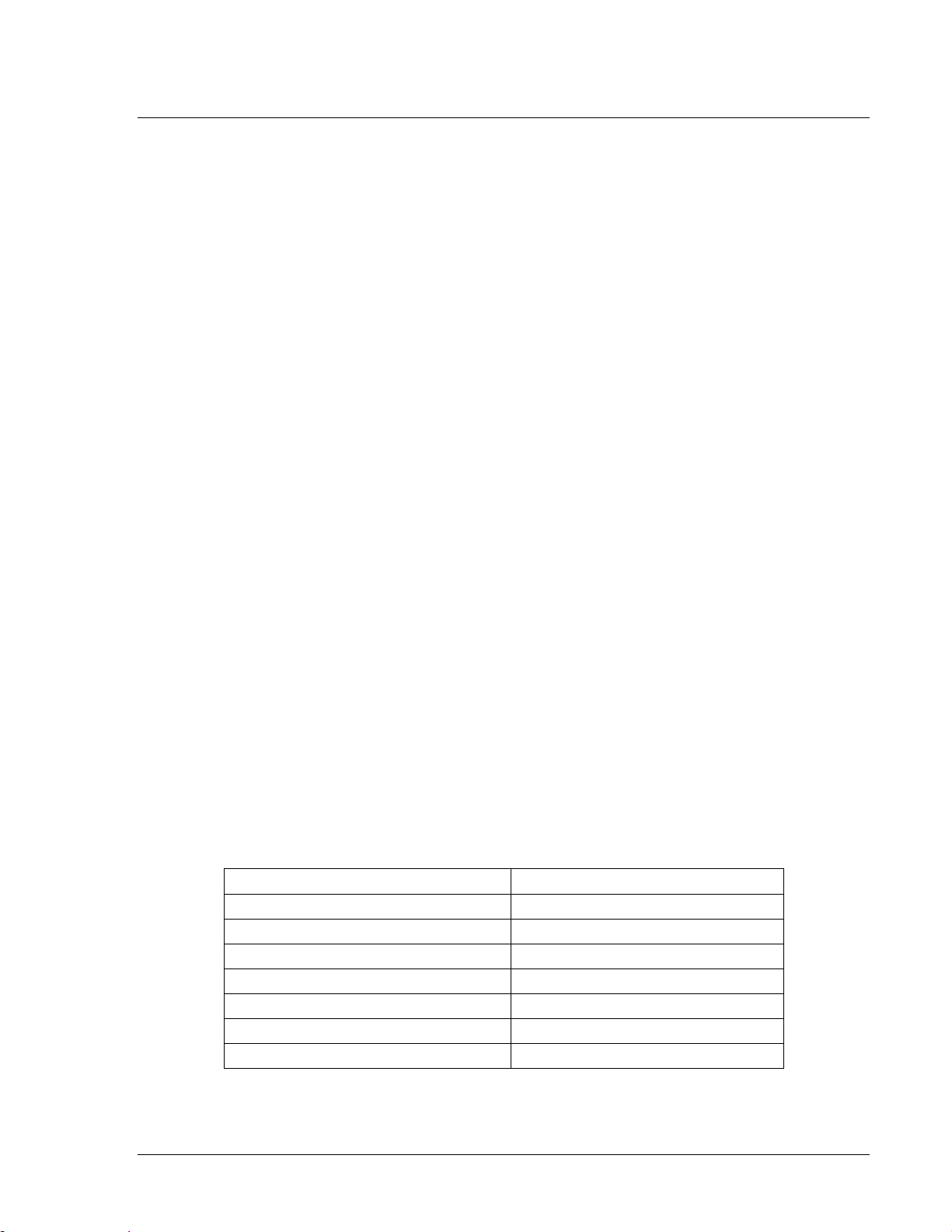

Table 2-1. Function Categories and Manual Sections Cross-Reference .................................................. 2-1

Table 2-2. Trip LED Truth Table ................................................................................................................ 2-9

9376700990 Rev M BE1-700 Quick Start i

Page 28

This page intentionally left blank .

ii BE1-700 Quick Start 9376700990 Rev M

Page 29

SECTION 2 • QUICK START

Section Title

Section

GENERAL

This section provides an overview of the BE1-700 Digital Protective Relay. You should be familiar with the

concepts behind the user inter faces and B ESTlo gic before y ou begin read ing ab out t he det ailed BE1-700

functions. Sections 3 through 6 in the instruction manual describe each function of the BE1-700 in detail.

The following information is intended to provide the reader with a basic understanding of the user

interfaces and the sec urity features pr ovided in the BE1-70 0 relay. Detailed information on th e operation

of the human-machin e interface (HMI) can be found i n Section 10, Human-Machine Inter face, and the

ASCII command commun ic atio ns in Sec t ion 11, ASCII Command Interface. BE ST COMS™ is a Wind ows

based software appl ication that enhances comm unication between the PC user and the BE1-700 re lay.

BESTCOMS for th e BE1-700 is prov ided free of char ge with the B E1-700. BESTCO MS operation is v ery

transparent, and does contain a Windows type help file for additional operational details.

Also covered in this section is an overview of BESTlogic, which is fundamental to how each of the

protection and control functions is set-up and used in the BE1-700 relay. Detailed i nformation on using

BESTlogic to design comp lete protection and control schemes for the prot ected circuit can be found in

Section 7, BESTlogic Programmable Logic, and Section 8, Application.

Sections 3 through 6 desc ribe each func tion provided in th e BE1-700 rel ay and include r eferences to the

following items. Note that not all items are appropriate for each function.

• Human-machine interface (HMI) screens for setting the operational parameters.

• BESTCOMS for setting the operational parameters.

• BESTCOMS for setting up the BESTlogic required for functions in your protection and control

scheme.

• Outputs from the function such as alarm and BESTlogic variables or data reports.

• HMI screens for operation or interrogation of the outputs and reports provided by each function.

• ASCII commands for operation or interrogation of the outputs and reports provided by each

function.

®

About This Manual

The various application functions provided by this multifunction relay are divided into four categories:

input/output functions, protection and control functions, metering functions, and reporting and alarm

functions. Detailed des criptions of each ind ividual func tion, s etup, and us e are cov ered in the sec tions as

shown in Table 2-1. Detailed informa tion on using progr ammable logic to create your own pr otection and

control scheme is described in Section 7, BESTlogic Programmable Logic. Section 15, BESTNet

Communication, provides information on all of the device Ethernet features and capabilities. Browser

screen shots of available web pages are illustrated and explained.

Table 2-1. Function Categories and Manual Sections Cross-Reference

Input and Output Functions Section 3

Protection and Control Section 4

Metering Section 5

Reporting and Alarm Functions Section 6

BESTlogic Programmabl e Log ic Section 7

Application Section 8

BESTNet Communication Section 15

9376700990 Rev M BE1-700 Quick Start 2-1

Page 30

BESTLOGIC

Each of the protection an d control functions in the BE1-70 0 is implemented as an independent f unction

block that is equivale nt to a s ingle functio n, discr ete dev ice counterpar t. Each independ ent function block

has all of the inputs and outputs that the discrete component counterpart might have. Programming

BESTlogic is equivalent to choosing the devices required by your protection and control scheme and

drawing schematic diagrams to connect the inputs and outputs to obtain the desired operational logic.

The concept is the sam e but the met hod is d ifferent i n that yo u choose eac h func tion block by enabling it

and use Boolean logic expr essions to c onnect the inputs and outputs. Th e result i s that in des igning your

system, you have even gr eater flexibility than you had using discrete dev ices. An added benefit is that

you are not constrained by the flexibility limitations inherent in many multifunction relays.

One user programmab le, custom logic scheme created by the user may be programmed and saved in

memory. To save you time, s everal preprogrammed logic schemes have also been pr ovided. Any of the

preprogrammed sche mes can be cop ied into the pr ogrammable log ic settings w ithout the user having to

make any BESTlogic programming.

There are two types of B ESTlogic settings: func tion block logic s ettings and output log ic settings. These

are described briefly in the following paragraphs. Detailed information on using BESTlogic to design

complete protection and co ntrol schemes for the protected circ uit can be found in Section 7, BESTlogic

Programmable Logic, and Section 8, Application.

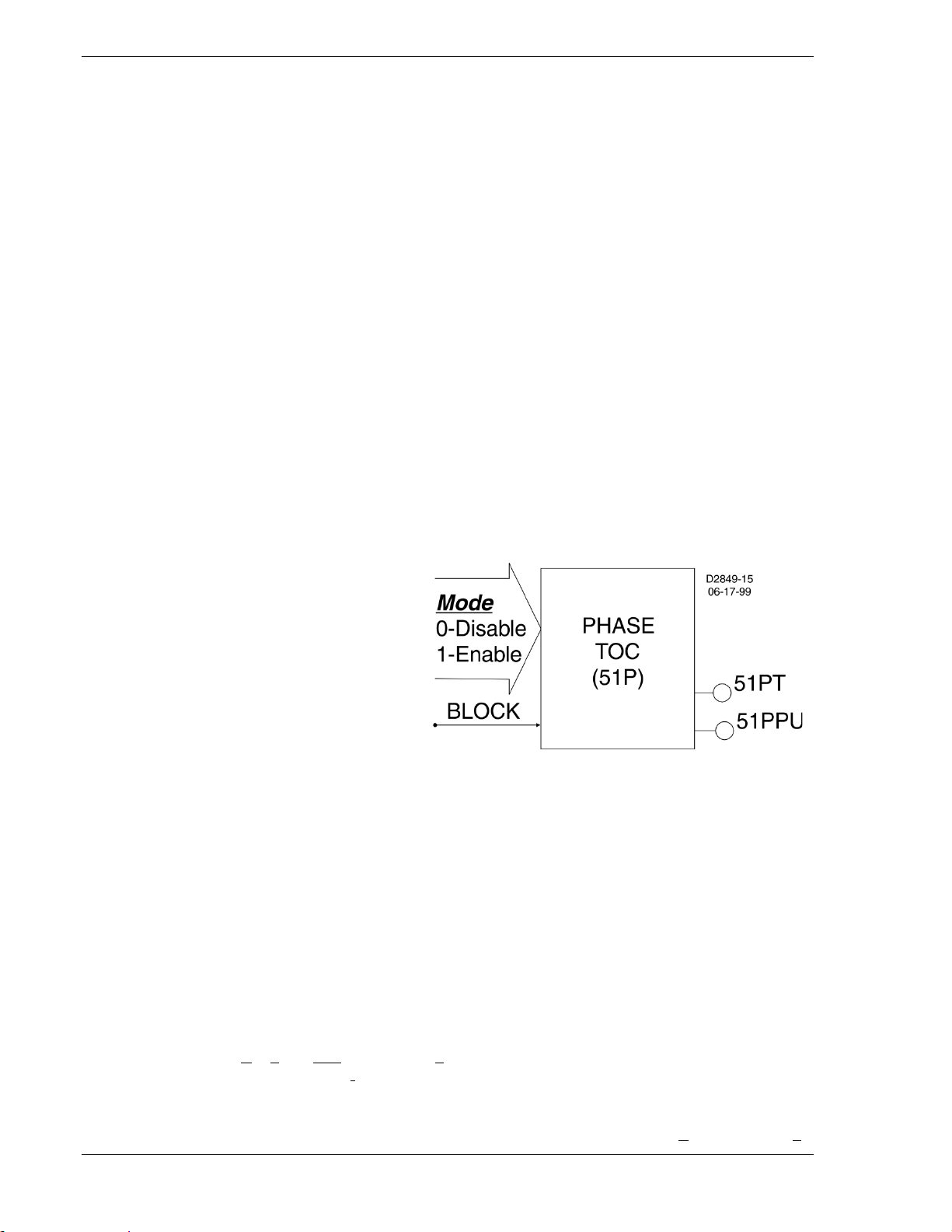

Characteristics of Protection and Control Function Blocks

As stated before, each function block is equivalent to a discrete device counterpart. For example, the

phase time-overcurr ent function block in the BE1-700 r elay has all of the characteristics of Bas ler BE1

relays with similar functionality. Figure 2-1 is a logic drawing showing the inputs and outputs.

One input:

• BLK (block 51P operation)

Two mode settings:

• Enable 51P operation

• Disable 51P operation

Two outputs:

• 51PT (51 Phase Trip)

• 51PPU (51 Phase Pickup)

Four operational settings:

• Pickup

• Time Delay

• Characteristic Curve

Of the above characteristic s, the four operational setti ngs are not included in the logic sett ings. They are

contained in the protection settings. This is an important distinction. Since changing logic settings is

similar to rewiring a pa nel, the logic s ettings are separ ate and distinct from t he operationa l settings such

as pickups and time delays.

Function Block Logic Settings

To use a protection or control function block, there ar e two items that need t o be set: Mode and Input

Logic. The mod e is equivalent t o deciding wh ich devic es you want to insta ll in your protec tion and contr ol

scheme. You then must set the logic variables that will be connected to the inputs.

For example, the 51N function block has three modes (disabled, three-phase summation (3Io), and

ground), and one input, block (torque control). To use this function block, the logic setting command might

be SL-51N=1,/IN2 for Set Logic-51N to be Mode 1 (three-phase and n eutral) with the funct ion blocked

when Contact Sensing Inp ut 2 is not (/) energized. Contact Sensing Inpu t 2 would be wired to a ground

relay enable switch.

As noted before, the pr otection settings for this funct ion block, pickup, time dia l, and curve must be set

separately in the settin g gr oup sett ings. T he sett ing m ight be S0-51N =6.5, 2.1,S1 R for Set ting in gr oup 0 -

Figure 2-1. 51 Time Overcurrent Logic (BE1-700C)

2-2 BE1-700 Quick Start 9376700990 Rev M

Page 31

the 51N function = pickup at 6.5 amps with a time dial of 2.1 using curve S1 with an integrating Reset

characteristic.

The 51N function block has two logic output variables, 51NT (Trip) and 51NPU (Picked Up). The

combination of the logic settings and the operational settings for the function block govern how these

variables respond to logic and current inputs.

Output Logic Settings

BESTlogic, as implemented in the BE1-700, supports up to 16 output expressions. The output

expressions are called virt ual outputs to distinguis h them from the physical out put relays. VOA and VO1

through VO5 drive phys ical outputs O UTA (failsafe a larm output) a nd OUT1 throu gh OUT5, respectively.

The rest of the virtual outputs can be used for intermediate logic expressions.

For example, OUT 1 is wir ed to the trip bus of th e circuit breaker . To set up the logic to trip the breaker,

the BESTlogic setting com mand might be SL-VO1=VO11+101T+BFPU for Set Logic - Virtual Output 1 =

to Virtual Output 11 (which is the intermediate logic expression for all of the function block tripping

outputs) or (+) 101T ( th e tr i p outp ut of t he v irtu al br eaker control switch) or ( +) BFPU (the pickup o utput of

the breaker failure function block that indicates that breaker failure has been initiated).

USER INTERFACES

Three user interfaces are provided for interacting with the BE1-700 relay: front panel HMI, ASCII

communications, and BESTC OMS for BE1-700. The fr ont panel HMI provides access to a subset of t he

total functionality of the de vice. ASCII communications provides access to all settings, controls, r eports,

and metering functions of the system. BESTCOMS for BE1-700 is software used to quickly develop

setting files, view metering data, and download reports in a user-friendly, Windows based enviro nme nt.

Front Panel HMI

The front panel HMI consis ts of a two line by 16 character LCD (liq uid crystal display) with four sc rolling

pushbuttons, an edit pushbutton, and a reset pushbutton. The EDIT pushbutton includes an LED to

indicate when edit mo de is active. There are five other LEDs for indicating power supply status, relay

trouble alarm status, programmable major and minor alarm status, and a multipurpose Trip LED that

flashes to indicate th at a protective element is pic ked up. The Trip LED lights continuously when the trip

output is energized a nd seals in when a protective tr ip has occurred to indicate that target informati on is

being displayed on the LCD. A complete description of the HMI is included in Section 10, Human-Machine

Interface.

The BE1-700 HMI is m enu dr iven and organized into a men u tr e e s truc tur e w ith s i x br anc hes. A com pl ete

menu tree description with display s is als o prov ided in Section 10, Human-Machine Inter face. A lis t of t he

menu branches and a brief description for scrolling through the menu is in the following paragraphs.

1. REPORT STATUS. Display and resetting of g eneral status information suc h as targets, alarms,

recloser status.

2. CONTROL. Operation of manual controls such as virtual switches, selection of active setting

group, etc.

3. METERING. Display of real-time metering values.

4. REPORTS. Display and re setting of report informatio n such as time an d date, deman d registers ,

breaker duty statistics, etc.

5. PROTECTION. Display and setting of protective function setting parameters such as logic

scheme, pickups, time delays, etc.

6. GENERAL SETTING S. D isplay and set ting of non-protective function setting parameters such as

communication, LCD contrast, and CT ratios.

Each screen is assigned a numb er in the HMI section. The number indicates the branch and leve l in the

menu tree structure. Sc reen numbering helps you to keep track of w here you are when you leave the

menu tree top level. You view each branch of the menu tree by using the RIGHT and LEFT scrolling

pushbuttons. To go to a level of greater detail, you use the DOWN scrolling pushbutton. Each time a

lower level in a menu branch is reached, the screen number changes to reflect the lower level. The

following paragraphs and Figure 2-2 illustrate how the display screens are numbered in the menu tree.

Viewing the 47 pickup and time delay settings of Setting Group 1 involves the following steps:

9376700990 Rev M BE1-700 Quick Start 2-3

Page 32

1. At the top level of the menu tree, use the LEFT or RIGHT scrolling pushbuttons to get to the

PROTECTION logic branch (Screen 5).

2. Press the DOWN scrolling pushbutton to reach the SETTING GROUP level (Screen 5.1).

3. Scroll RIGHT to SETTING GROUP 1 branch (Screen 5.2).

4. From Screen 5.2, scroll down to the next level of detail which is the 24 SETTINGS (Screen 5.2.1).

5. Scroll right to the 47 SETTINGS ( Screen 5.2.5) and then do wn to reach the 47 pickup an d time

delay settings (Screen 5.2.5.1).

Figure 2-2. Menu Screens Numbering Example

ASCII Command Communications

The BE1-700 relay has two independent communications ports for serial communications plus one

optional rear Ethernet port. A computer terminal or PC running a terminal emulation program such as

Windows HyperTerminal can be connected to any of the ports so that commands can be sent to the relay.

Communication with the rel ay uses a s imple ASCII comma nd language . When a c ommand is enter ed via