Page 1

INSTRUCTION MANUAL

FOR

VOLTAGE BALANCE RELAY

BE1-60

Publication: 9170700990

Revision: D 09/07

Page 2

Page 3

INTRODUCTION

This instruction manual provides information about the operation and installation of the BE1-60 Voltage

Balance Relay. To accomplish this, the following information is provided:

• General Information and Specifications

• Controls and Indicators

• Functional Description

• Installation

• Testing

WARNING!

To avoid personal injury or equipment damage, only qualified personnel should

perform the procedures in this manual.

NOTE

Be sure that the relay is hard-wired to earth ground with no smaller than 12 AWG

copper wire attached to the ground terminal on the rear of the unit case. When

the relay is configured in a system with other devices, it is recommended to use a

separate lead to the ground bus from each unit.

9170700990 Rev D BE1-60 Introduction i

Page 4

First Printing: May 1985

Printed in USA

© 1985, 1998, 2003, 2007 Basler Electric, Highland Illinois 62249 USA

All Rights Reserved

September 2007

CONFIDENTIAL INFORMATION

of Basler Electric, Highland Illinois, USA. It is loaned for confidential use, subject

to return on request, and with the mutual understanding that it will not be used in

any manner detrimental to the interest of Basler Electric.

It is not the intention of this manual to cover all details and variations in equipment, nor does this manual

provide data for every possible contingency regarding installation or operation. The availability and design

of all features and options are subject to modification without notice. Should further information be

required, contact Basler Electric.

BASLER ELECTRIC

ROUTE 143, BOX 269

HIGHLAND IL 62249 USA

http://www.basler.com, info@basler.com

PHONE +1 618.654.2341 FAX +1 618.654.2351

ii BE1-60 Introduction 9170700990 Rev D

Page 5

REVISION HISTORY

The following information provides a historical summary of the changes made to the BE1-60 instruction

manual (9170700990). Revisions are listed in reverse chronological order.

Manual

Revision and Date

D, 09/07

C, 06/03

B, 07/98

• Added manual part number and revision to all footers.

• Updated Power Supply Burden data in Section 1.

• Updated Output Contact ratings in Section 1.

• Updated Target Indicator description in Section 3.

• Changed unit of measure for single-phase sensing values from V

and V

• Corrected terminal number error in Figure 4-8.

• Updated all applicable drawings to show redesigned case cover and

revised front panel.

• Deleted reference to service manual (9170700620).

• Updated the dielectric test information.

• Corrected the timing specification.

• Changed input voltage range and burden data in Table 1-1.

• Corrected style chart.

• Added power supply information to Section 3.

• Updated the style of the manual.

to Vac.

L-L

Change

L-N

9170700990 Rev D BE1-60 Introduction iii

Page 6

This page intentionally left blank.

iv BE1-60 Introduction 9170700990 Rev D

Page 7

CONTENTS

SECTION 1 • GENERAL INFORMATION................................................................................................ 1-1

PURPOSE........................................................................................................................................... 1-1

APPLICATION .................................................................................................................................... 1-1

SETTING THE RELAY........................................................................................................................ 1-2

Setting Example for Sensing Input Types E and F....................................................................... 1-2

MODEL AND STYLE NUMBER.......................................................................................................... 1-3

Style Number Example................................................................................................................. 1-3

SPECIFICATIONS.............................................................................................................................. 1-3

Sensing......................................................................................................................................... 1-5

Pickup........................................................................................................................................... 1-5

Dropout......................................................................................................................................... 1-5

Timing........................................................................................................................................... 1-5

Power Supply................................................................................................................................ 1-5

Target Indicators........................................................................................................................... 1-5

Outputs......................................................................................................................................... 1-6

Shock............................................................................................................................................ 1-6

Vibration........................................................................................................................................ 1-6

Dielectric Strength........................................................................................................................ 1-6

Surge Withstand Capability..........................................................................................................1-6

Radio Frequency Interference (RFI)............................................................................................. 1-6

Fast Transient............................................................................................................................... 1-6

Impulse......................................................................................................................................... 1-6

Temperature................................................................................................................................. 1-6

UL Recognition............................................................................................................................. 1-6

GOST-R........................................................................................................................................ 1-6

Weight........................................................................................................................................... 1-6

Case Size ..................................................................................................................................... 1-6

SECTION 2 • CONTROLS AND INDICATORS ....................................................................................... 2-1

INTRODUCTION................................................................................................................................. 2-1

SECTION 3 • FUNCTIONAL DESCRIPTION........................................................................................... 3-1

INTRODUCTION................................................................................................................................. 3-1

STEP-DOWN TRANSFORMERS....................................................................................................... 3-1

FULL-WAVE RECTIFIERS AND INTEGRATORS............................................................................. 3-1

DIFFERENTIAL AMPLIFIERS............................................................................................................ 3-1

LIMIT SETTING .................................................................................................................................. 3-2

LIMIT COMPARATORS.............................................................................................................

OUTPUTS...........................................................................................................................................3-2

OUTPUT TEST PUSHBUTTONS ....................................................................................................... 3-2

AUXILIARY OUTPUTS.......................................................................................................................3-2

POWER SUPPLY ............................................................................................................................... 3-7

POWER SUPPLY STATUS OUTPUT................................................................................................ 3-2

TARGET INDICATORS ...................................................................................................................... 3-2

Internally Operated Targets.......................................................................................................... 3-2

Current Operated Targets ............................................................................................................ 3-2

SECTION 4 • INSTALLATION.................................................................................................................. 4-1

INTRODUCTION................................................................................................................................. 4-1

RELAY OPERATING GUIDELINES AND PRECAUTIONS ............................................................... 4-1

MOUNTING......................................................................................................................................... 4-1

CONNECTIONS.................................................................................................................................. 4-6

MAINTENANCE.................................................................................................................................. 4-7

STORAGE........................................................................................................................................... 4-7

SECTION 5 • TESTING ............................................................................................................................ 5-1

OPERATIONAL TEST PROCEDURE................................................................................................ 5-1

......... 3-2

9170700990 Rev D BE1-60 Introduction v

Page 8

This page intentionally left blank.

vi BE1-60 Introduction 9170700990 Rev D

Page 9

SECTION 1 • GENERAL INFORMATION

INTRODUCTION

The BE1-60 Voltage Balance Relay provides a high-speed response to block other devices from incorrect

operation resulting from a blown fuse or other fault in a potential transformer circuit. The BE1-60 detects

these conditions, initiates corrective action, and indicates the problem and location.

Equipment benefiting from BE1-60 protection includes overcurrent relays (voltage controlled or voltage

restrained types), impedance measuring relays, synchronizing relays, voltage regulators, and static

excitation systems.

APPLICATION

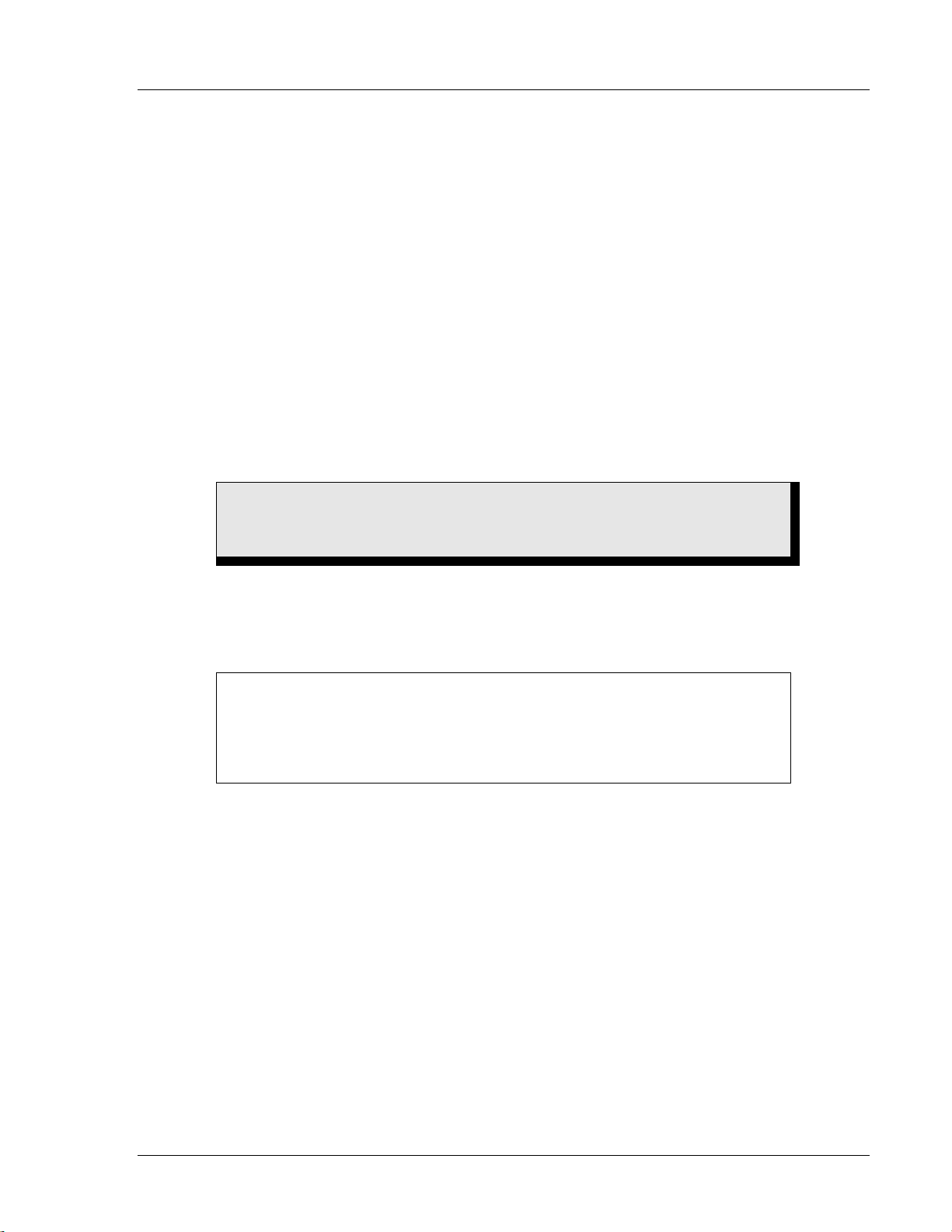

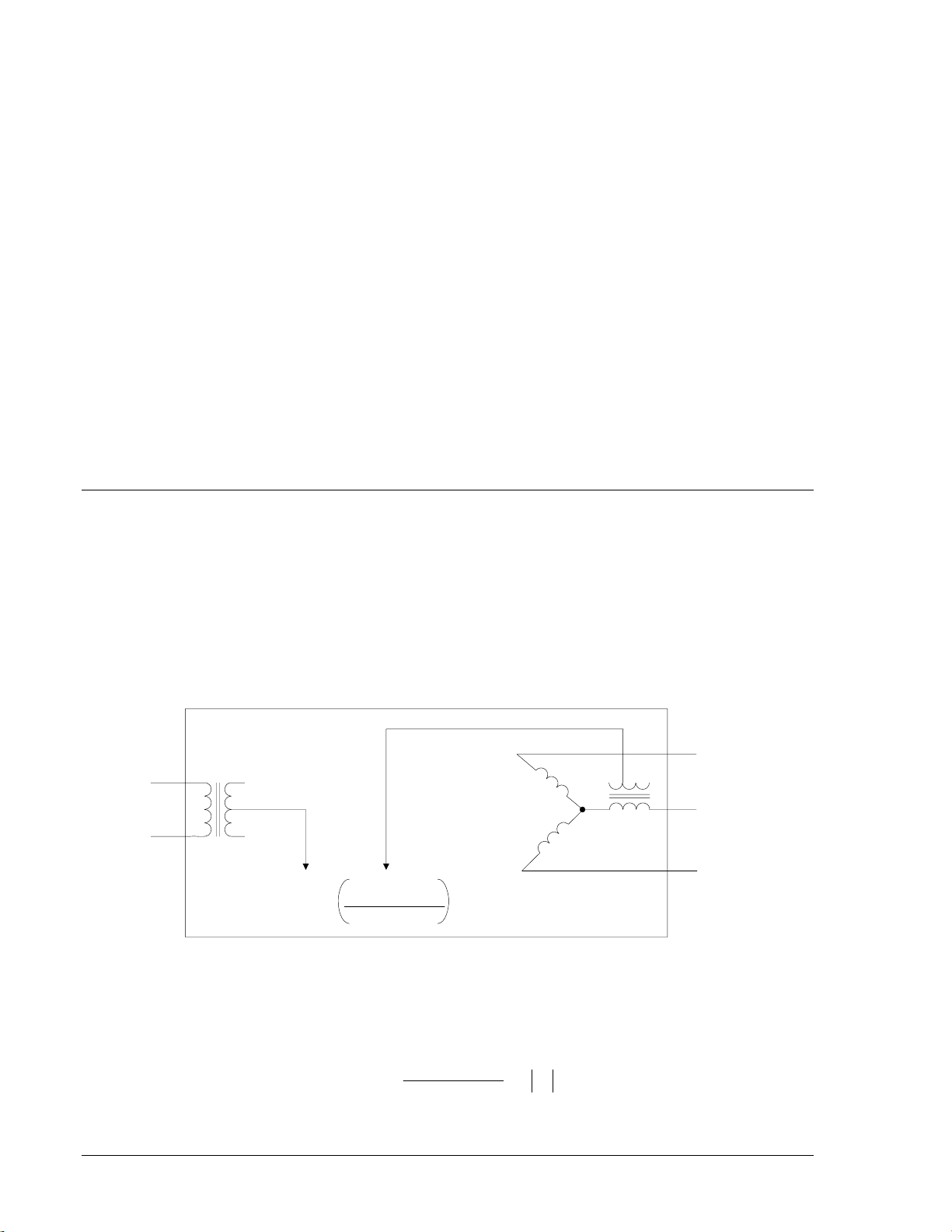

In the typical application shown in Figure 1-1, a generator is equipped with a static exciter and is

protected by voltage controlled or voltage restrained time-overcurrent relays and other devices.

52

POWER

POTENTIAL

TRANSFORMER

SHUTDOWN

CONTACTOR

POWER

INPUT

GEN

FIELD

SENSING

POTENTIAL

TRANSFORMER

CKT 1

BE1-60

CKT 2

60

BE1-51/27C

OR

BE1-51/27R

D2817-15

07-14-98

STATIC

EXCITER

SENSING

INPUT

Figure 1-1. Typical Application of BE1-60 Relay

9170700990 Rev D BE1-60 General Information 1-1

Page 10

If a power potential transformer fuse opens, the resulting unbalanced condition may cause excessive

heating in the power stage of the static exciter. This condition would warrant an alarm indication and an

orderly shutdown of the unit. The BE1-60 Circuit 1 output would accomplish this task and the Circuit 1

target would indicate that an open power potential transformer fuse had initiated the correct shutdown

sequence.

If a sensing potential transformer fuse opens, the static exciter (with three-phase sensing) output would

increase to maximum in an attempt to restore the sensed voltage to the proper level. For this condition,

the BE1-60 would initiate an emergency shutdown of the unit and issue an alarm. The BE1-60 Circuit 2

output would accomplish this task and the Circuit 2 target would indicate that an open sensing potential

transformer fuse had initiated the correct shutdown sequence.

1

Also, since the same potential source provides the control

relays, false tripping of the unit may result due to operation of the overcurrent relays. This is undesirable

because the overcurrent relay target would give a false indication of the reason for tripping. To prevent

this, the BE1-60 Circuit 2 output would be required to block operation of the overcurrent relays. This

would be accomplished by opening a normally-closed contact from the BE1-60, which is in series with the

tripping outputs of the overcurrent relays.

1

If the overcurrent functions were voltage controlled and the output current exceeded the relay

pickup setting, a loss of power potential would allow this overcurrent function to pick up and

start timing. Without the inhibit from the BE1-60, tripping would result.

2

If the overcurrent functions were voltage restrained, the loss of restraint potential would

increase the sensitivity of the relay (2½ times setting) and the relay would pick up and start

timing. Without the inhibit from the BE1-60, tripping would result.

or restraint2 input to the time-overcurrent

SETTING THE RELAY

When setting the relay, consideration should be given to the maximum voltage excursions permitted for

normal operating conditions. For example, if the power potential transformer output varies 5% from

machine no-load to machine full-load, the setting must accommodate this fluctuation.

Also note that since both BE1-60 inputs (Circuit 1 and Circuit 2) are monitoring essentially the same

voltage, BE1-60 tripping will not occur for system faults.

BE1-60 relays with sensing input type E (single-phase to three-phase wye) or F (single-phase to threephase delta) apply the three-phase input to an internal, Scott (T-connected) transformer. This transformer

produces a single-phase voltage that is proportional to the average of the three-phase voltages shown in

Figure 1-2. This decreases the relay’s sensitivity as illustrated by the following example.

A

CIRCUIT 1

INPUT

B

C

CIRCUIT 2

INPUT

(V1) - V2A+V2B+V2C = ΔV

3

Figure 1-2. Internal Voltage Sensing and Measurement for Sensing Types E and F

Setting Example for Sensing Input Types E and F

If a fuse blows in phase C of Circuit 2, an apparent difference of 40 volts is produced within the relay.

0120120

++

()

120 =

1-2 BE1-60 General Information 9170700990 Rev D

⎛

−

⎜

⎝

3

⎞

40

⎟

⎠

D2817-19

07-17-98

Page 11

Since Circuit 1 is nominally rated at 120 Vac, the three-phase voltages of Circuit 2 are defined as line-to-

==−

==−

neutral for a type E wye input or line-to-line for a type F delta input. This apparent voltage difference is not

sufficient to produce a response if the pickup setting is G, H, J, or K since these settings represent

voltage differences of 42, 48, 54, and 60 volts respectively. Therefore, it is recommended that the lower

pickup settings be used for relays with sensing input styles E or F.

OPERATIVE EXAMPLE

The following example details the effect that the BE1-60 would have on the system shown in Figure 1-1.

Given: Potential transformer secondary voltages are 120 Vac

BE1-51/27R pickup setting is 4.5 Aac

BE1-60 pickup setting is B (10%)

Assume that a fault causes the sensing potential transformer secondary voltage to dip 9% to 109.2 Vac.

Characteristically, the BE1-51/27R will pickup and start timing when the line current reaches 4.095 Aac

(instead of 4.5 Aac) as determined below.

A4.095(91%) A 4.59%)(100% A 4.5

This will result in the BE1-51/27R producing an undesired trip. The trip is undesired because the current

pickup level has been inadvertently lowered by the voltage dip seen on the secondary winding of the

sensing transformer—even though the line voltage has not changed.

Now assume that the fault causes the sensing potential transformer secondary voltage to dip 10% to 108

Vac. This will cause the BE1-51/27R to pick up and start timing at 4.05 Aac as shown below.

A4.05(90%) A 4.510%)(100% A 4.5

However, since the voltage dip seen on the secondary winding of the sensing potential transformer meets

the 10% pickup setting of the BE1-60 and the secondary voltage of the power potential transformer has

not changed, any undesired trip signal from the BE1-51/27R will be blocked by the BE1-60 Circuit 2

output contacts.

MODEL AND STYLE NUMBER

The electrical characteristics and operational features of the BE1-60 relay are defined by the model

number and style number. The model and style numbers appear on the relay front panel, draw-out cradle,

and inside the case. The model number BE1-60 identifies the relay as a Basler Electric Class 100 Voltage

Balance Relay. The style identification chart for the BE1-60 relay is shown in Figure 1-3.

Sample Style Number

The style number identification chart of Figure 1-3 illustrates how the BE1-60 relay’s operating

characteristics are determined. For example, if the style number were D1H-A1R-C0C2F, the BE1-60 relay

would have the following features.

D---------- three-phase wye to three-phase delta sensing input

1---------- sensing range of 60 to 125% of nominal

H---------- two normally-closed output relays (one per monitored circuit)

A1-------- instantaneous timing

R---------- operating power derived from 24 Vdc source

C---------- two internally operated targets (one per circuit)

0---------- no power supply status output

C---------- push-to-test outputs (pushbuttons)

2---------- normally-closed auxiliary output contacts (one per circuit)

F---------- semi-flush case mounting

9170700990 Rev D BE1-60 General Information 1-3

Page 12

Figure 1-3. BE1-60 Style Chart

1-4 BE1-60 General Information 9170700990 Rev D

Page 13

SPECIFICATIONS

BE1-60 electrical and physical specifications are listed in the following paragraphs. Specifications are

subject to change without notice.

Sensing

Frequency

Nominal: 60 Hz

Range: 45 to 65 Hz

Burden: 1 VA per phase, maximum

Voltage

Nominal Rating

3-Phase Wye: 208 V

3-Phase Delta: 120 V

1-Phase: 120 Vac

Range: 60 to 125% of nominal

Maximum Continuous: 160% of nominal

Pickup

Range: 5 to 50% of nominal

Accuracy: 1 V or 5% of setting, whichever is greater

Increment: 5%

Dropout

90% of pickup or greater

L-L

L-L

Timing

150 milliseconds or less for voltage differences greater than three times the setting

Power Supply

The five power supply types available for the BE1-60 are summarized in Table 1-1.

Table 1-1. Power Supply Types and Specifications

Type

Input Voltage

Nominal Range

Burden at

Nominal

O (mid range) 48 Vdc 24 to 150 Vdc 1.1 W

P (mid range)

R (low range)

S (mid range)

T (high range)

125 Vdc

120 Vac

24 Vdc

48 Vdc

125 Vdc

250 Vdc

240 Vac

24 to 150 Vdc

90 to 132 Vac

12 to 32 Vdc ∗

24 to 150 Vdc

24 to 150 Vdc

62 to 280 Vdc

90 to 270 Vac

1.4 W

11.2 VA

1.2 W

1.1 W

1.4 W

1.6 W

18.8 VA

∗ The type R power supply initially requires 14 Vdc to begin operating. Once operating, the voltage may

be reduced and operation will continue.

Target Indicators

Targets may be specified as either internally operated or current operated by a minimum of 0.2 amperes

through the output trip circuit. When current operated, the output circuit must be limited to 30 amperes for

0.2 seconds, 7 amperes for 2 minutes, and 3 amperes continuously.

9170700990 Rev D BE1-60 General Information 1-5

Page 14

Outputs

Resistive Ratings

120 Vac: Make, break, and carry 7 Aac continuously

250 Vdc: Make and carry 30 Adc for 0.2 s, carry 7 Adc continuously,

and break 0.3 Adc

500 Vdc: Make and carry 15 Adc for 0.2 s, carry 7 Adc continuously, and break 0.3

Adc

Inductive Ratings

120 Vac, 125 Vdc, 250 Vdc: Break 0.3 A (L/R = 0.04)

Shock

Withstands 15 G in each of three mutually perpendicular planes.

Vibration

Withstands 2 G in each of three mutually perpendicular axes, swept over the range of 10 to 500 Hz for a

total of six sweeps, 15 minutes each sweep.

Dielectric Strength

Complies with IEC 60255-5 and IEEE C37.90 one-minute dielectric (high potential) tests as follows:

All circuits to ground: 2121 Vdc

Input to output circuits: 1500 Vac or 2121 Vdc

Surge Withstand Capability

Qualified to IEEE C37.90 (transient immunity and radiated susceptibility), IEC 60255-5 (impulse

requirements), and IEC60255-5/6 (surge requirements).

Radio Frequency Interference (RFI)

Type tested using a 5 W, hand-held transceiver in the ranges of 144 and 440 MHz with the antenna

placed within 6 inches (152 millimeters) of the relay.

Fast Transient

Qualified to IEEE C37.90.

Impulse

Qualified to IEC 60255-5.

Temperature

Operating: –40°C to 70°C (–40°F to 158°F)

Storage: –65°C to 100°C (–85°F to 212°F)

UL Recognition

Recognized per Standard 508, UL file number E97033. Note: Output contacts are not UL-recognized for

voltages greater than 250 V.

GOST-R

Gost-R certified No. POCC US.ME05.B03391; complies with the relevant standards of Gosstandart of

Russia. Issued by accredited certification body POCC RU.0001.11ME05.

Weight

14.25 lb (6.46 kg) maximum

Case Size

S1 (Refer to Section 4, Installation for case dimensions.)

1-6 BE1-60 General Information 9170700990 Rev D

Page 15

SECTION 2 • CONTROLS AND INDICATORS

INTRODUCTION

All BE1-60 controls and indicators are located on the relay front panel. The controls and indicators are

shown in Figure 2-1 and described in Table 2-1.

Figure 2-1. BE1-60 Controls and Indicators

9170700990 Rev D BE1-60 Controls and Indicators 2-1

Page 16

Table 2-1. BE1-60 Control and Indicator Descriptions

Locator Control or Indicator Description

A Differential Limit Switch This ten-position thumbwheel switch sets the maximum

allowable voltage difference between Circuit 1 and Circuit 2.

The switch letters (A through K, excluding I) correspond to the

percent of nominal circuit voltage as indicated by the chart on

the front panel. The Differential Limit Switch can be adjusted

from 5% to 50% of nominal in 5% increments.

B Target Indicators

(optional)

The BE1-60 may be equipped with two electronically latching

red indicators—one for Circuit 1 and one for Circuit 2. When a

fault occurs on Circuit 1 or Circuit 2 and the appropriate relay

output changes state, the corresponding target indicator

illuminates. Target indicators are manually reset by operating

the target reset switch (locator D).

C Output Test Pushbutton

(optional)

The BE1-60 may be equipped with two pushbuttons (Circuit 1

and Circuit 2) that can be used to verify operation of the relay

output contacts. The momentary-action pushbuttons are recessed behind the front panel and are operated by inserting a

slender, non-conducting rod through one of the two panel

openings.

D Target Reset Switch

(optional)

The target reset switch is provided on BE1-60 relays

equipped with target indicators.

E Power Indicator This LED (light-emitting diode) lights to indicate that the relay

power supply is operating.

2-2 BE1-60 Controls and Indicators 9170700990 Rev D

Page 17

SECTION 3 • FUNCTIONAL DESCRIPTION

INTRODUCTION

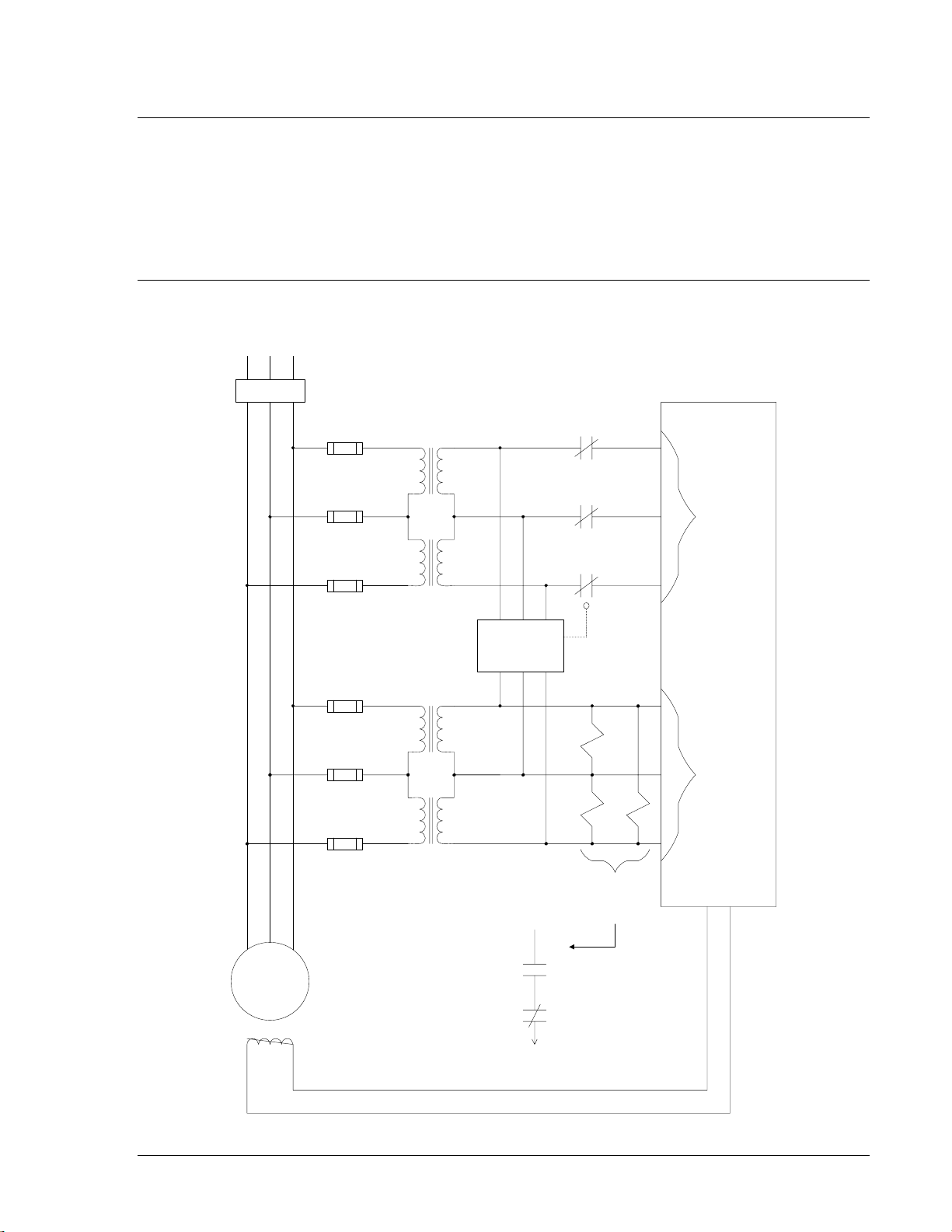

BE1-60 Voltage Balance Relay functions and operating features are illustrated in Figure 3-1 and

described in the following paragraphs.

LIMIT

SETTING

Δ

V > LIMIT SETTING

1A

2A

1B

2B

1C

2C

FULL-WAVE

RECTIFIER AND

INTEGRATOR

FULL-WAVE

RECTIFIER AND

INTEGRATOR

FULL-WAVE

RECTIFIER AND

INTEGRATOR

FULL-WAVE

RECTIFIER AND

INTEGRATOR

FULL-WAVE

RECTIFIER AND

INTEGRATOR

FULL-WAVE

RECTIFIER AND

INTEGRATOR

POWER

SUPPLY

DIFFERENTIAL

AMPLIFIER

DIFFERENTIAL

AMPLIFIER

DIFFERENTIAL

AMPLIFIER

DIFFERENTIAL

AMPLIFIER

DIFFERENTIAL

AMPLIFIER

DIFFERENTIAL

AMPLIFIER

POWER

V2A-V1A>0

Δ

V

V

1A-V2A

V

2B-V1B

V

1B-V2B

V

2C-V1C

V

1c-V2C

COMPARATOR

>0

COMPARATOR

>0

COMPARATOR

>0

COMPARATOR

>0

COMPARATOR

>0

COMPARATOR

TO INTERNAL CIRCUI TR Y

POWER

SUPPLY

SENSOR

LIMIT

LIMIT

LIMIT

LIMIT

LIMIT

LIMIT

Figure 3-1. BE1-60 Function Block Diagram

D2817-17

07-14-98

AUX.

CIRCUIT 1

0

0.75

0

0.75

TARGET

CIRCUIT 2

TARGET

AUX.

POWER

SUPPLY

STATUS

STEP-DOWN TRANSFORMERS

Voltage received from the power system potential transformers is applied to sensing transformers within

the BE1-60 relay. The voltage is stepped down to appropriate levels and supplied to full-wave rectifier

circuits within the relay.

FULL-WAVE RECTIFIERS AND INTEGRATORS

Outputs from the step-down transformers are full-wave rectified and then integrated. The integrator

circuits establish a dc voltage that represents the magnitude of the associated sensing input.

DIFFERENTIAL AMPLIFIERS

The representative dc voltage from each integrator is applied to a pair of differential amplifiers. Each

differential amplifier pair is dedicated to a particular phase of the monitored system. The pair determines

which monitored circuit has the lower voltage (for that phase) and the difference in magnitude. For

example, if phase A of Circuit 1 is lower than phase A of Circuit 2, then V

9170700990 Rev D BE1-60 Functional Description 3-1

– V1A = V.

2A

Page 18

LIMIT SETTING

The limit setting is controlled by the ten-position, front-panel, Differential Limit Switch. The limit setting

circuit establishes a reference voltage that represents the maximum permissible voltage difference.

LIMIT COMPARATORS

Reference voltage established by the limit setting circuit is compared to the output of each differential

amplifier. When the limit is exceeded by the voltage difference, a limit comparator generates a trip

command signal (V > limit setting).

OUTPUTS

Limit comparator outputs are ORed so that the appropriate output relay coil energizes during a fault

condition. In a fault condition, the relay coil that energizes corresponds to the circuit that senses the lower

of the two voltage levels.

When the lower of the two voltages increases, the voltage difference decreases below the limit setting

and the relay coil de-energizes after a fixed delay of 0.75 seconds.

OUTPUT TEST PUSHBUTTONS

Two momentary-action pushbuttons, accessible through the front panel, are provided on BE1-60 relays

with a style number of X1X A1X XXC

operation and external control/protective system wiring. The pushbuttons are operated by inserting a thin,

non-conducting rod through the appropriate front panel opening. The lower pushbutton energizes the

Circuit 1 output relay(s) and the upper pushbutton energizes the Circuit 2 output relay(s).

XX. The output test pushbuttons are useful for testing output relay

AUXILIARY OUTPUTS

Two sets of optional, auxiliary outputs are available on the BE1-60 relay. One auxiliary output changes

state when the Circuit 1 output relay energizes; the other auxiliary output changes state when the Circuit

2 output relay energizes. Auxiliary outputs may be specified as normally-open (style X1X A1X XXX1

normally-closed (style X1X A1X XXX2

X), or single-pole, double-throw (SPDT) (style X1X A1X XXX3X).

X),

POWER SUPPLY

Operating power for the relay circuitry is supplied by a wide range, electrically isolated, low-burden power

supply. Power supply operating power is not polarity sensitive. The front panel power LED and power

supply status output indicate when the power supply is operating. Power supply specifications are listed

in Table 1-1.

POWER SUPPLY STATUS OUTPUT

When the relay power supply is operating normally, the optional power supply status relay energizes and

opens the normally-closed power supply status contacts. If the power supply output falls below the proper

level or if operating power is removed from the relay, the power supply status relay de-energizes and the

power supply status output contacts close.

When the relay is equipped with a power supply status output (style X1X A1X X1

outputs (style X1X A1X XXX1

contacts are dedicated as the power supply status output. The Circuit 1 auxiliary output contacts will

operate when the Circuit 1 or Circuit 2 main output contacts operate.

X, X1X A1X XXX2X, or X1X A1X SSS3X), the Circuit 2 auxiliary output

XXX) and auxiliary

TARGET INDICATORS

Target indicators are optional components selected when a relay is ordered. The electronically latched

and reset targets consist of red LED indicators located on the relay front panel. A latched target is reset

by operating the target reset switch on the front panel. If relay operating power is lost, any illuminated

(latched) targets are extinguished. When relay operating power is restored, the previously latched targets

are restored to their latched state.

A relay can be equipped with either internally operated targets or current operated targets.

3-2 BE1-60 Functional Description 9170700990 Rev D

Page 19

Internally Operated Targets

The relay trip outputs are directly applied to drive the appropriate target indicator. Each indicator is

illuminated regardless of the current level in the trip circuit.

Current Operated Targets

A current operated target is triggered by closure of the corresponding output contact and

at least 200 milliamperes of current flowing in the trip circuit.

Prior to September 2007, BE1-60 target indicators consisted of magnetically

latched, disc indicators. These mechanically latched target indicators have been

replaced by the electronically latched LED targets in use today.

NOTE

the presence of

9170700990 Rev D BE1-60 Functional Description 3-3

Page 20

This page intentionally left blank.

3-4 BE1-60 Functional Description 9170700990 Rev D

Page 21

SECTION 4 • INSTALLATION

INTRODUCTION

BE1-60 relays are shipped in sturdy cartons to prevent damage during transit. Upon receipt of a relay,

check the model and style number against the requisition and packing list to see that they agree. Inspect

the relay for shipping damage. If there is evidence of damage, file a claim with the carrier, and notify the

regional sales office or Basler Electric.

If the relay will not be installed immediately, place the relay in its original shipping carton and store in a

moisture- and dust-free environment.

RELAY OPERATING GUIDELINES AND PRECAUTIONS

Before installing or operating the relay, not the following guidelines and precautions.

• For proper current operated target operation, a minimum current of 200 milliamperes must flow

through the output trip circuit.

• If a wiring insulation test is required, remove the connection plugs and withdraw the relay from its

case.

CAUTION

When the connection plugs are removed, the relay is disconnected from the

operating circuit and will not provide system protection. Always be sure that

external operating (monitored) conditions are stable before removing a relay for

inspection, test, or service.

NOTE

Be sure that the relay is hard-wired to earth ground with no smaller than 12 AWG

copper wire attached to the ground terminal on the rear of the case. When the

relay is configured in a system with other devices, it is recommended to use a

separate lead to the ground bus from each device.

MOUNTING

Because the relay is of solid-state design, it may be mounted at any convenient angle. Relay case

dimension drawings and panel cutting and drilling diagrams are provided in Figures 4-1 through 4-6.

9170700990 Rev D BE1-60 Installation 4-1

Page 22

Figure 4-1. S1 Cover, Outline Dimensions, Front View

Figure 4-2. S1 Case, Double-Ended, Semi-Flush Mounting, Outline Dimensions, Side View

4-2 BE1-60 Installation 9170700990 Rev D

Page 23

Figure 4-3. S1 Case, Double-Ended, Projection Mounting, Outline Dimensions, Side View

9170700990 Rev D BE1-60 Installation 4-3

Page 24

Figure 4-4. S1 Case, Double-Ended, Projection Mounting, Panel Drilling Diagram, Rear View

4-4 BE1-60 Installation 9170700990 Rev D

Page 25

Figure 4-5. S1 Case, Semi-Flush Mounting, Panel Cutting Diagram

Figure 4-6. S1 Case, Double-Ended, Projection Mounting, Outline Dimensions, Rear View

9170700990 Rev D BE1-60 Installation 4-5

Page 26

CONNECTIONS

Be sure to check the model and style number of a relay before connecting and energizing the relay.

Incorrect wiring may result in damage to the relay. Except where noted, connections should be made with

wire no smaller than 14 AWG.

Connections for each of the six sensing types are shown in Figure 4-7. Typical output connections are

shown in Figure 4-8.

Figure 4-7. Sensing Input Connections

4-6 BE1-60 Installation 9170700990 Rev D

Page 27

Figure 4-8. Typical Output Connections

MAINTENANCE

BE1-60 relays require no preventative maintenance other than a periodic operational check. If the relay

fails to function properly, contact Technical Sales Support at Basler Electric to coordinate repairs.

STORAGE

This protective relay contains aluminum electrolytic capacitors which generally have a life expectancy in

excess of 10 years at storage temperatures less than 40°C (104°F). Typically, the life expectancy of a

capacitor is cut in half for every 10°C rise in temperature. Storage life can be extended if, at one year

intervals, power is applied to the relay for a period of 30 minutes.

9170700990 Rev D BE1-60 Installation 4-7

Page 28

This page intentionally left blank.

4-8 BE1-60 Installation 9170700990 Rev D

Page 29

SECTION 5 • TESTING

OPERATIONAL TEST PROCEDURE

The following procedure verifies operation of the BE1-60 Voltage Balance Relay. Stated voltages refer to

line-to-neutral for single-phase and wye inputs, and line-to-line for delta inputs. Terminal numbers may be

found in Section 4, Installation. Target indicators, if present, should operate in conjunction with their

corresponding output.

1. Set the differential limit control to the “A” position.

2. Apply 120 Vac +0.1% to Circuit 1 and Circuit 2 inputs. After allowing conditions to stabilize, both

outputs should be in their normal states. If present, reset the target indicators.

3. Slowly increase the Circuit 1A input until the Circuit 2 output changes states. Circuit 1A input should

be between 125 and 127 Vac.

4. Decrease the Circuit 1A input to 120 Vac. Circuit 2 output should return to its normal state in

approximately 0.75 seconds. Reset the target indicator.

5. Set the differential limit control to the “K” position.

6. Slowly decrease the Circuit 1A input until the Circuit 1 output changes states. Circuit 1A input should

be between 57 and 63 Vac.

7. Increase the Circuit 1A input to 120 Vac. Circuit 1 output should return to its normal state in

approximately 0.75 seconds. Reset the target indicator.

8. For units with Sensing Input Types B, C, or D, repeat steps 3 through 7 accordingly for phase B and

C inputs.

9. For units with push-to-energize outputs, actuate pushbuttons. Observe output contacts.

9170700990 Rev D BE1-60 Testing 5-1

Page 30

This page intentionally left blank.

5-2 BE1-60 Testing 9170700990 Rev D

Page 31

ROUTE 143, BOX 269

HIGHLAND, IL 62249 USA

http://www.basler.c om, info@basler.c om

PHONE +1 618-654-2341 FAX +1 618-654-2351

Loading...

Loading...