Page 1

INSTRUCTION MANUA L

FOR

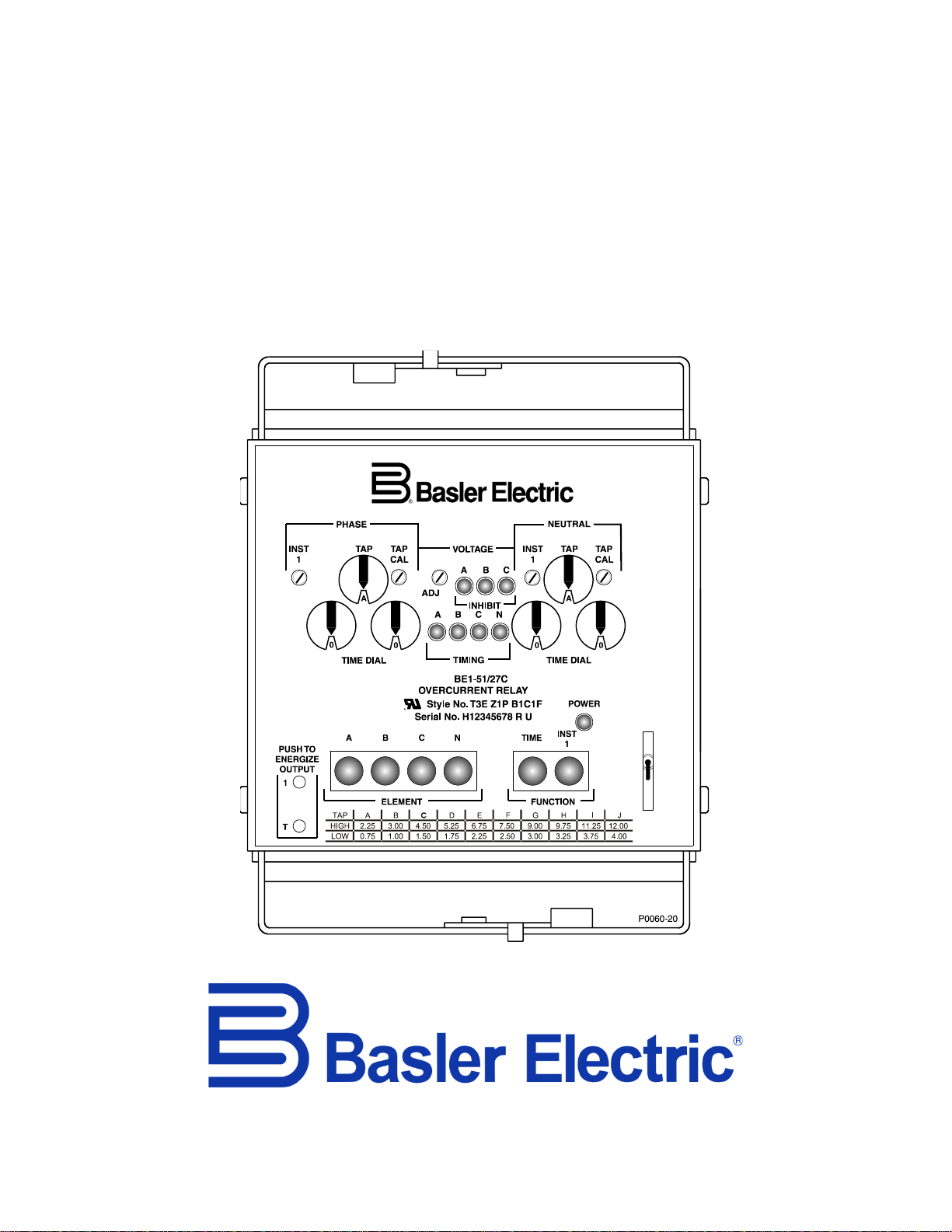

BE1-51/27C

Time Overcurrent Relay with Voltage Control

Publication: 9137200998

Revision: E Mar-15

Page 2

Page 3

9137200998 Rev E i

Caution

Note

Preface

This instruction manual provides information about the installation and operation of the BE1-51/27C Time

Overcurrent Relay with Voltage Control. To accomplish this, the following information is provided:

• General information

• Controls and indicators

• Functional description

• Installation

• Tests and adjustments

• Specifications

Conventions Used in this Ma nua l

Important safety and procedural information is emphasized and presented in this manual through

warning, caution, and note boxes. Each type is illustrated and defined as follows.

Warning!

Warning boxes call attention to conditions or actions that may cause

personal injury or death.

Caution boxes call attention to operating conditions that may lead to

equipment or property damage.

Note boxes emphasize important information pertaining to installation

or operation.

BE1-51/27C Preface

Page 4

ii 9137200998 Rev E

Basler Electric does not assume any responsibility to compliance or noncompliance with national code, local code,

For terms of service relating to this product and software, see the Commercial Terms of Products and Services

document available at www.basler.com/terms.

This publication contains confidential information of Basler Electric Company, an Illinois corporation. It is loaned for

manual.

The English-language versi on of this manu al ser ves as the only appr ove d manual version.

12570 State Route 143

Highland IL 62249-1074 USA

www.basler.com

info@basler.com

Tel: +1 618.654.2341

Fax: +1 618.654.2351

© 2015 by Basler Electric

All rights reserved

First printing: September 1993

Warning!

READ THIS MANUAL. Read this manual before installing, operating, or maintaining the BE1-51/27C.

Note all warnings, cautions, and notes in this manual as well as on the product. Keep this manual with

the product for reference. Only qualified personnel should install, operate, or service this system.

Failure to follow warning and cautionary labels may result in personal injury or property damage.

Exercise caution at all times.

or any other applicable code. This manual serves as reference material that must be well understood prior to

installation, operation, or maintenance.

confidential use, subject to return on request, and with the mutual understanding that it will not be used in any

manner detrimental to the interests of Basler Electric Company and used strictly for the purpose intended.

It is not the intention of this manual to cover all detai ls and var iatio ns in equi pm ent, nor does this manual provide

data for every possible contingency regarding installation or operation. The availability and design of all features

and options are subject to modification without notice. Over time, improvements and revisions may be made to this

publication. Before performing any of the following procedures, contact Basler Electric for the latest revision of this

Preface BE1-51/27C

Page 5

9137200998 Rev E iii

Contents

Introduction ................................................................................................................................................. 1

Standard Features ..................................................................................................................................... 1

Time Overcurrent Functions .................................................................................................................. 1

Non-Integrating Timing .......................................................................................................................... 2

Integrating Timing .................................................................................................................................. 3

Built-In Test ............................................................................................................................................ 3

Options ...................................................................................................................................................... 3

Timing .................................................................................................................................................... 3

Sensing Input Type ................................................................................................................................ 3

Sensing Input Range ............................................................................................................................. 3

Power Supply ......................................................................................................................................... 3

Targets ................................................................................................................................................... 4

Outputs .................................................................................................................................................. 4

Instantaneous Outputs ........................................................................................................................... 4

Packaging .............................................................................................................................................. 4

Model and Style Number Description ........................................................................................................ 4

Controls and Indicators .............................................................................................................................. 7

Functional Description ............................................................................................................................. 11

Block Diagram Analysis ........................................................................................................................... 11

Power Supply ....................................................................................................................................... 12

Current Sensing ................................................................................................................................... 12

Tap Select and Tap Cal ....................................................................................................................... 12

Voltage Sensing ................................................................................................................................... 12

Multiplexor ............................................................................................................................................ 12

Analog-To-Digital Converter and Level Detector ................................................................................. 12

Time Trip Comparator and Scaler ....................................................................................................... 12

Microprocessor (Not Shown) ............................................................................................................... 13

Voltage Inhibit ...................................................................................................................................... 13

Instantaneous Overcurrent (Options 1-1 and 1-2) ............................................................................... 13

Timed and Instantaneous Outputs....................................................................................................... 13

Auxiliary Outputs .................................................................................................................................. 13

Push-to-Energize Pushb utt ons ............................................................................................................ 13

Power Supply Status Output (Option 3-6) ........................................................................................... 13

Target Indicators .................................................................................................................................. 14

Installation ................................................................................................................................................. 15

Relay Operating Guidelines and Precautions ......................................................................................... 15

Mounting .................................................................................................................................................. 15

Connections ............................................................................................................................................. 28

Maintenance ............................................................................................................................................ 39

Storage .................................................................................................................................................... 39

Tests and Adjustments ............................................................................................................................. 41

Required Test Equipment ........................................................................................................................ 41

Operational Test ...................................................................................................................................... 41

Preliminary Instructions ....................................................................................................................... 41

Time Overcurrent Pickup Test ............................................................................................................. 45

Timed Output Test ............................................................................................................................... 47

Instantaneous Overcurrent Pickup Test .............................................................................................. 49

Voltage Control Test ............................................................................................................................ 50

Adjustments of Controls for Relay Operation .......................................................................................... 51

TAP and TAP (NEUTRAL) Selector Setting ........................................................................................ 51

Time Overcurrent Curve Selection (Timing Type Z1, Z2, and Z3 Only) .............................................. 53

Time Delay Selection ........................................................................................................................... 53

Neutral Time Delay Selection .............................................................................................................. 54

BE1-51/27C Contents

Page 6

iv 9137200998 Rev E

VOLTS INHIBIT ADJ or VO LT AGE I NH I BIT ADJ Se tti n g ................................................................... 54

INST 1 Control Setting ......................................................................................................................... 54

INST 2 Control Setting ......................................................................................................................... 55

Setting the Relay ..................................................................................................................................... 55

General ................................................................................................................................................ 55

Setting Example ................................................................................................................................... 56

Coordination with Feeder 51 Relay for Fault 1 .................................................................................... 57

Checking Coordination with Relay 67 for Fault 2 ................................................................................ 58

Checking Coordination with Relay 67 for Fault 3 ................................................................................ 59

Neutral Element Backup Settings ........................................................................................................ 60

Specifications ............................................................................................................................................ 61

Operational Specifications ....................................................................................................................... 61

Time Overcurrent Pickup Selection Range ......................................................................................... 61

Time Overcurrent Measuring Accuracy ............................................................................................... 61

Time Overcurrent Dropout Rati o .......................................................................................................... 61

Instantaneous Overcurrent Pickup Range ........................................................................................... 61

Instantaneous Overcur rent Meas ur ing Ac c urac y ................................................................................ 61

Instantaneous Overcurrent Dropout Ratio ........................................................................................... 61

Instantaneous Response ..................................................................................................................... 61

Time Delay Accuracy ........................................................................................................................... 62

General Specifications............................................................................................................................. 62

Voltage Sensing Inputs ........................................................................................................................ 62

Voltage Sensing Selection Rang e ....................................................................................................... 62

Voltage Sensing Accuracy ................................................................................................................... 62

Sensing Input Burden .......................................................................................................................... 62

Sensing Input Rating ........................................................................................................................... 62

Output Circuits ..................................................................................................................................... 62

Target Indicators .................................................................................................................................. 62

Power Supply ....................................................................................................................................... 62

Radio Frequency Interference (RFI) .................................................................................................... 63

Isolation ................................................................................................................................................ 63

Surge Withstand Capability ................................................................................................................. 63

UL Recognized .................................................................................................................................... 63

GOST-R ............................................................................................................................................... 63

Operating Temperature ....................................................................................................................... 63

Storage Temperature ........................................................................................................................... 63

Shock ................................................................................................................................................... 63

Vibration ............................................................................................................................................... 64

Weight .................................................................................................................................................. 64

Case Size ............................................................................................................................................. 64

Time Overcurrent Characteristic Curves ................................................................................................ 65

Revision History ...................................................................................................................................... 103

Contents BE1-51/27C

Page 7

9137200998 Rev E 1

Introduction

BE1-51/27C Time Overcurrent Relays are microprocessor-based devices that monitor the magnitude of

line current to provide accurate time-overcurrent protection with undervoltage control (when the voltage

drops below the set point, the timing circuit is enabled). Instantaneous overcurrent element(s) and the

neutral time overcurrent element, when supplied, operate independently of the undervoltage function.

Each relay is available with one, three, or four time overcurrent elements.

BE1-51/27C relays provide backup protection for generators or transformers. Voltage control provides

discrimination between load and fault conditions by allowing the time overcurrent pickup to be set below

the maximum load (or swing) current. For sustained fault conditions, the synchronous reactance, X

typically larger than for normal load, X

fault current will be less than the normal maximum load current. The relay pickup should be set below

rated maximum load current (e.g., 50 percent of rated) to ensure dependable backup. The BE1-51/27C

relay may also be used to provide primary phase fault protection for small generators or backup

protection for transformers.

When the BE1-51/27C is used to protect for faults on either side of a delta-wye power transformer, phase

overcurrent units should be supplied on all three phases (either three single-phase relays or one threephase relay). For this application, each phase time overcurrent element should be controlled by the

phase-to-ground voltage on its phase rather than by the phase-phase voltage.

Because the time overcurrent pickup of the phase element(s) does not vary with voltage level (the

element is either enabled or not depending upon voltage level), conventional time coordination

techniques apply.

. As a result, if the regulator is not in service, the three-phase

d(sat)

d(unsat)

, is

A neutral (ground) overcurrent element can be applied and connected residually to a set of three current

transformers on solidly grounded applications or on impedance grounded systems that provide ground

fault current approximating the generator rated current level. The neutral element can also be connected

to a 10:1 ampere, zero-sequence window current transformer to provide protection on systems producing

a minimum of about 20 amperes primary current. Still another alternative would be connecting this device

to a current transformer in the neutral of a generator or power transformer.

Instantaneous elements can be used for transformer back-up applications when connected on the source

side of the power transformer. Because the pickup of these elements can be set above the relay current

flowing in the low-side fault, coordination can be achieved. Instantaneous overcurrent elements would not

ordinarily be used for a generator back-up function because they would not operate correctly for faults

external to the generator zone.

Under normal operating conditions, the phase time overcurrent pickup will be less than the maximum load

or non-fault current. As long as the rated voltage is applied to the relay, no operation will occur. However,

if a fuse opens on the voltage transformer and interrupts the signal, the relay will see this as a fault

condition (i.e., current level above pickup and voltage level below minimum set point) and operate

accordingly. The Basler Electric BE1-60 Voltage Balance Relay can prevent such a misoperation where

two sources of signal voltage are available. This relay compares the output of two signal sources, to

detect an anomaly in one of these sources and block the operation of those devices connected to that

signal source. Therefore, for generator applications, the Basler BE1-60 Voltage Balance relay should be

used in conjunction with the BE1-51/27C to prevent misoperations due to loss of the voltage source.

Standard Features

Time Overcurrent Functions

Time overcurrent elements pick up over a range of 0.1 to 0.8 amperes, 0.3 to 2.4 amperes, 0.5 to 4.0

amperes, 1.5 to 12.0 amperes, 0.1 to 2.4 amperes, or 0.5 to 12.0 amperes and provide an adjustable time

delay that is proportional to the overcurrent. Time delay is initiated when the sensed current exceeds the

pickup point. When the current drops below the pickup point, the timing circuit is reset immediately. At

reset, the output contacts, if operated, are restored to normal.

BE1-51/27C Introduction

Page 8

2 9137200998 Rev E

Adjustment of the overcurrent pickup point is provided by controls on the relay front panel. Time delay is a

function of the characteristic curve that has been selected. Time delay is settable from 00 to 99 on the

TIME DIAL thumbwheel switch located on the front panel. Curve type is selected either as an option or, in

some models, is switch selectable.

Sixty-nine characteristic curves and three timing options are available:

Characteristic curves:

• Seven inverse time

• Nine I

• Seven inverse time with extended timing range

• Nine I

2

t

2

t with extended timing range

• Five British Standard 142 (E curves)

• Seven integrating inverse time

• Nine integrating I

• Seven integrating inverse time with extended timing range

• Nine integrating I

2

t

2

t with extended timing range

Timing option Z1 (switch-selectable, 16-position) B and C curves:

• Seven inverse time

• Nine I

2

t

Timing option Z1 with option 2-D or 2-E (switch-selectable, 16-position) B and C curves:

• Seven inverse time with extended timing range

• Nine I

2

t with extended timing range

Timing option Z2 (switch-selectable, 16-position) B and E (British Standard 142) curves:

• Seven inverse time

• One I

2

t

• Five British Standard (BS) 142 (E curves)

Timing option Z2 with option 2-D or 2-E (switch-selectable, 16-position) B and E (BS142) curves:

• Seven inverse time with extended timing range

• One I

2

t with extended timing range

• Five British Standard 142 (E curves)

Timing option Z3 (switch-selectable, 16-position) integrating B and C curves:

• Seven integrating inverse time

• Nine integrating I

2

t

Timing option Z3 with option 2-D or 2-E (switch-selectable, 16-posit ion) int egr at in g exten ded B and C

curves:

• Seven integrating inverse time with extended timing range

• Nine integrating I

2

t with extended timing range

Characteristic curves are shown by the graphs in the Time Overcurrent Characteristic Curves chapter.

Note that each graph (i.e. function) consists of a set of representative curves. Each curve (as well as any

between-curve interpolation) is selectable by the front panel TIME DIAL using a two-digit destination from

00 to 99. Because of space limitations, each graph shows only 14 of the 100 possible selections.

Non-Integrating Timing

Timing options Z1 and Z2 and the characteristic curves available with those options use non-integrating

timing. Non-integrat ing timi ng is acc ompl ished by timing at a gate that is not solely dependent on the

magnitude of the applied multiple of pickup current. The time-out value is calculated based on the type of

time curve characteristic selected, time dial setting, and the magnitude of the applied multiple of pickup

current. The time-out value is continuously updated during the timing cycle. When pickup is exceeded, a

timer is initiated. When the timer elapsed time exceeds the calculated time-out value, a time trip output

signal is generated.

Introduction BE1-51/27C

Page 9

9137200998 Rev E 3

This type of non-integrating time delay characteristic exhibits a dynamic characteristic that is immediately

responsive to changes of the applied multiple of pickup current.

Integrating Timing

Timing option Z3 and the characteristic curves available for that option uses integrating timing. Integrating

timing is accomplished by summing time increments that are based on the magnitude of the applied

multiple of pickup current, the time curve characteristic selected, and the time dial value. These time

increments are summed until a predetermined value is exceeded, then a time trip output signal is

generated.

This type of integrating time delay characteristic simulates the operating characteristics of an

electromechanical overcurrent relay.

Built-In Test

A built-in test (BIT) switch mounted on the Logic Board provides diagnostic troubleshooting and

calibration.

Options

Timing

An extended timing option multiplies by approximately 5.7, the standard time delays. The resulting curves

are shown following the standard curves in the Time Overcurrent Characteristic Curves chapter.

When timing option Z1, Z2, or Z3 is specified, a printed circuit board mounted selector switch allows a

choice of up to sixteen different time overcurrent functions. Timing option Z1 or Z3 may be further

specified as standard or extended time, depending upon option 2 selection.

Sensing Input Type

When single-phase, two-phase-and-neutral, three-phase, or three-phase-and-neutral sensing has been

specified, the front panel TAP selector and the front panel TAP CAL control set the pickup point for all

phases. An independent front panel TAP (NEUTRAL) selector and front panel CAL (NEUTRAL) control

set the neutral pickup point. In addition, for three-phase-and-neutral sensing units, one of the seven

sensing input range combinations must be specified.

Relay circuits inhibit the phase-element time overcurrent operation for a specific phase if the monitored ac

voltage exceeds a preselected level. The voltage level is established by a front panel VOLTS ADJ control

and all phases are inhibited at the same voltage level. Neutral overcurrent elements are not inhibited.

When the voltage inhibit level is exceeded, front panel INHIBIT LED is lit for the affected phase and the

front panel TIMING LED f or that particular phase extinguishes.

Sensing Input Range

For three-phase-and-neutral sensing units, input ranges are:

• 0.5 to 4.0 amperes (phas e and neutra l)

• 1.5 to 12 amperes (phase) and 0.5 to 4.0 amperes (neutral)

• 0.5 to 4 amperes (phase) and 1.5 to 12 amperes (neutral)

• 1.5 to 12 amperes (phase and neutral)

• 0.1 to 0.8 amperes (phase and neutral)

• 0.3 to 2.4 amperes (phase) and 0.1 to 0.8 amperes (neutral)

• 0.3 to 2.4 amperes (phase and neutral)

For all other units, two ranges are available: 0.5 to 12 amperes and 0.1 to 2.4 amperes.

Power Supply

Five power supply options are available:

BE1-51/27C Introduction

Page 10

4 9137200998 Rev E

• 24 Vdc

• 48 Vdc

• 125 Vdc and 100/125 Vac

• 48 Vdc or 125 Vdc and 100/125 Vac

• 250 Vdc and 240 Vac

Targets

Single-phase relays have two function targets that indicate when the time delay or instantaneous

element(s) have operated. On multiple phase relays, additional targets indicate which phase or neutral

element(s) operated.

Function targets may be specified as either internally operated or current operated by a minimum of 0.2

amperes through the output trip circuit. When current operated, the output circuit must be limited to 30

amperes for 0.2 seconds, 7 amperes for 2 minutes, and 3 amperes continuously.

Outputs

Optional normally opened, normally closed, or SPDT auxiliary output contacts may be selected. Contacts

actuate when the output relay is energized. Internally operated front panel mounted targets, and front

panel targets operated by the dc current in the output circuit are available for the time overcurrent and

instantaneous overcurrent functions. Optional front panel mounted PUSH-TO-ENERGIZE-OUTPUT

pushbuttons allow direct actuation of each output relay for external circuit testing.

Instantaneous Outputs

One or two instantaneous overcurrent outputs are optionally available. Each is adjustable up to 40 times

the time overcurrent pickup point. When the sensed current exceeds the instantaneous overcurrent

pickup point, an output relay is energized. An independent front panel control (INST 1 or INST 2) adjusts

the pickup point for each optional output. If more than one phase is applied to the relay, the instantaneous

pickup point will be the same for all phases. If neutral current is sensed, a front panel INST 1 (NEUTRAL)

provides adjustment of the neutral pickup point. Instantaneous overcurrent elements are not voltage

controlled.

Packaging

Each relay is mounted in a drawout cradle and enclosed in a standard utility style case with either semiflush or projection mounting (depending upon case style selected). An available test plug (Basler Electric

part number 10095) allows the relay to be tested in place without disturbing external control circuit wiring.

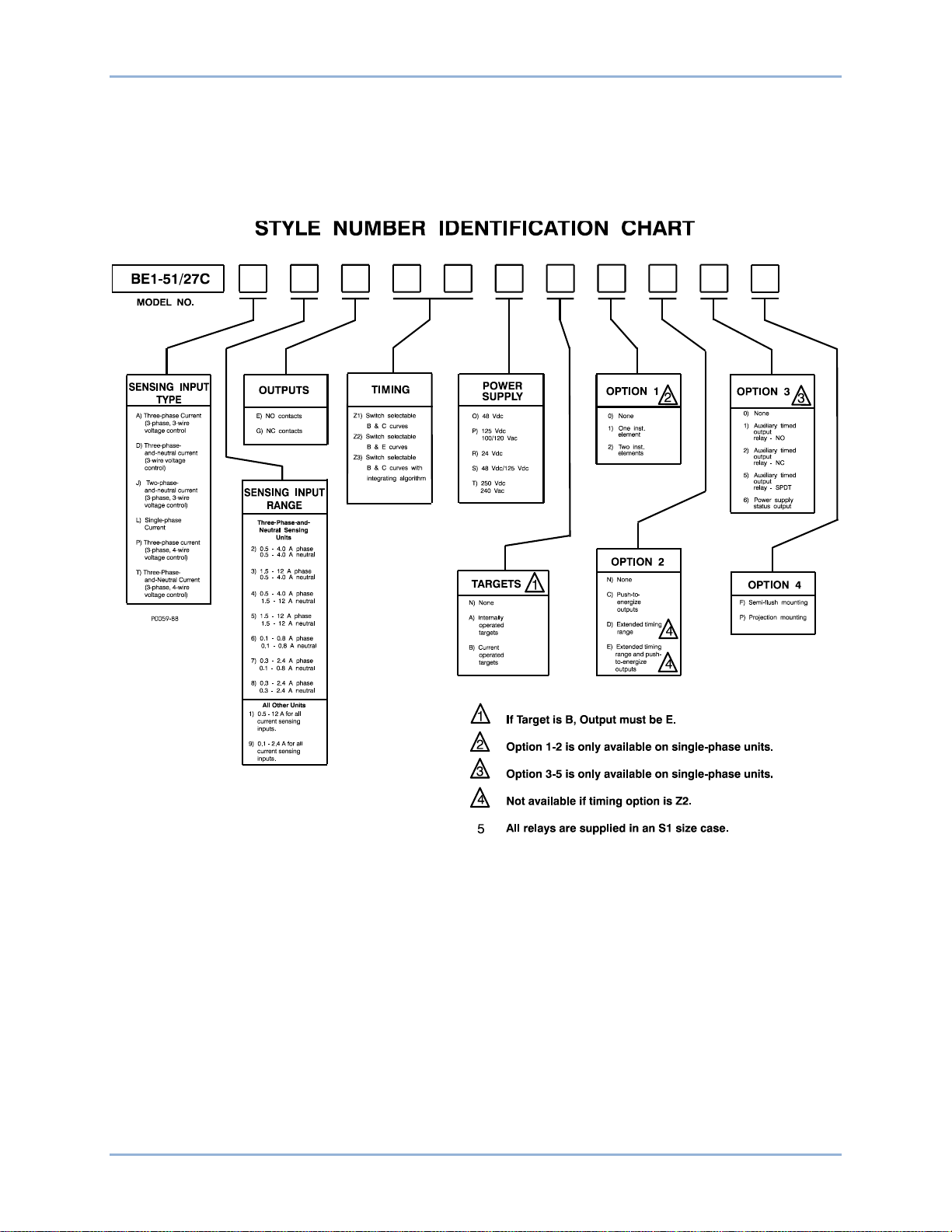

Model and Style Number Description

Electrical characteristics and operational features included in a particular style of the BE1-51/27C Time

Overcurrent Relay are defined by a combination of letters and numbers that make up its style number.

The model number, together with the style number, describes the options included in a specific device,

and appears on the front panel, drawout cradle, and inside the case assembly. Upon receipt of a relay, be

sure to check the style number against the requisition and the packing list to ensure that they agree.

The Style Number Identification Chart (Figure 1) illustrates the manner in which the relay style number is

determined. For example, if the style number were T3E-Z1P-B1C1F, the device would have the following

characteristics:

T - Three-Phase-and-Neutral sensing, 3-phas e, 4-wire voltage control

3 - Sensing input range of 1.5 to 12.0 amperes for phase and 0.5 to 4.0 amperes for neutral

E - Normally open outputs

Z1 - Switch selectable time curves

P - Operating power derived from 125 Vdc or 120 Vac

B - Current operated targets

Introduction BE1-51/27C

Page 11

9137200998 Rev E 5

1 - One instantaneous element

C - Push-to-energize outputs

1 - Normally open auxiliary timed output relay

F - Semi-flush mounting

Figure 1. Style Number Identification Chart

BE1-51/27C Introduction

Page 12

6 9137200998 Rev E

Introduction BE1-51/27C

Page 13

9137200998 Rev E 7

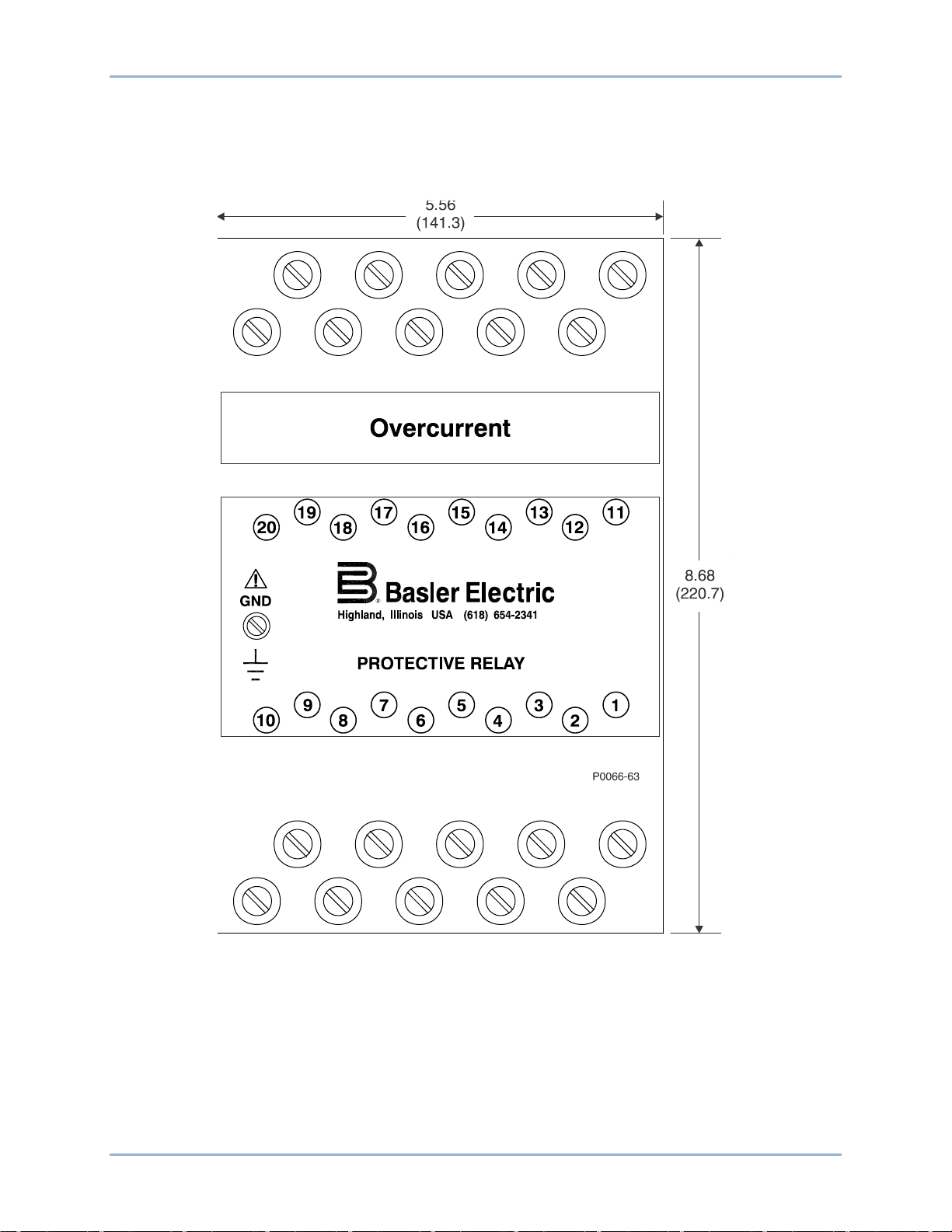

Controls and Indicators

BE1-51/27C controls and indicators are located on the front panel and left-side interior. The controls and

indicators are shown in Figure 2 and described in Table 1. Your relay may not have all of the controls and

indicators shown and described here.

BE1-51/27C Controls and Indicators

Figure 2. Location of Controls and Indicators

Page 14

8 9137200998 Rev E

Table 1. Controls and Indicators

A Phase Tap Calibration Control. This single-turn potentiometer adjusts the phase overcurrent pickup

threshold between the selected phase tap setting and the next lower tap setting.

B Phase Tap Selector. Selects the phase overcurrent pickup point in conjunction with the front panel

Phase Tap Calibration Control (locator A).

C Phase Instantaneous 1 Control. This four-turn potentiometer adjusts the phase instantaneous 1

element trip setting over the range of 1 to 40 times the selected Phase Tap Selector (locator B)

setting value. Your relay may be equipped with a Phase Instantaneous 2 Control which provides

similar adjustment of the phase instantaneous 2 element trip setting.

D Phase Time Dial Selector. These two knobs set the time delay between sensing of a phase

overcurrent condition and closing of the output contacts. See the Time Overcurrent Characteristic

Curves chapter for curve selection information.

E Target Indicators. LED indicators latch on when the corresponding output relay is energized by an

overcurrent condition. Target indicators are reset by the Target Reset Switch (locator H).

F Push-to-Energize Output Pushbuttons. These recessed pushbuttons are depressed to energize the

external trip circuits for testing purposes. A thin, non-conducting rod should be used to depress the

buttons. Do not use a screwdriver.

G Tap Selector Table. This front-panel reference lists the high and low setting limits for a particular tap

selection.

H Target Reset Switch. Operating this switch resets all active targets (locator E).

I Power Ind ic ator. This LED indicator lights when control power is applied and the relay power supply is

functioning.

J Timing Indicators. A Timing LED lights when the corresponding overcurrent pickup point is reached

and exceeded.

K Neutral Time Dial Selector. These two knobs set the time delay between sensing of a neutral

overcurrent condition and closing of the output contacts. See the Time Overcurrent Characteristic

Curves chapter for curve selection information.

L Neutral Tap Calibration Control. This single-turn pote n tiom eter adjus ts the phase ov erc urr ent pickup

threshold between the selected neutral tap setting and the next lower tap setting.

M Neutral Tap Selector. Selects the neutral overcurrent pickup point in conjunction with the front panel

Neutral Tap Calibration Control (locator L).

N Neutral Instantaneous 1 Control. This four-turn potentiometer adjusts the neutral instantaneous 1

element trip setting over the range of 1 to 40 times the selected Neutral Tap Selector (locator M)

setting value.

O Voltage Inhibit Indicators. A Voltage Inhibit indicator lights when the sensed input voltage level

exceeds the Voltage Inhibit control setting (locator P).

P Voltage Inhibit Control. This four-turn potentiometer adjusts the voltage inhibit level over the range of

40 to 120 Vac.

The time overcurrent characteristic curve selector (not shown) is located on the left-side interior. This

circuit board mounted switch selects the characteristic curve to be used.

Prior to August 2010, this switch was located behind the front panel.

The normal/test slide switch (not shown) is located on the left-side interior. This switch is only used for

factory testing and must be in the normal position (towards front of relay) for proper operation.

Prior to August 2010, this switch was located on the right-side interior.

The tap range plate (not shown) indicates the terminal connections (high or low) used to select the current

sensing input range. The sensing input ranges are listed in Table 2.

Controls and Indicators BE1-51/27C

Page 15

9137200998 Rev E 9

Table 2. Sensing Input Ranges

TAP

Range

Plate

or

Pickup

HIGH 2.25 3.00 4.50 5.25 6.75 7.50 9.00 9.75 11.25 12.00 8,7 — — —

LOW 0.75 1.00 1.50 1.75 2.25 2.50 3.00 3.25 3.75 4.00 9,7 — — —

HIGH 2.25 3.00 4.50 5.25 6.75 7.50 9.00 9.75 11.25 12.00 8,7 14,15 17,18 —

LOW 0.75 1.00 1.50 1.75 2.25 2.50 3.00 3.25 3.75 4.00 9,7 13,15 16,18 —

HIGH 2.25 3.00 4.50 5.25 6.75 7.50 9.00 9.75 11.25 12.00 8,7 — 14,15 17,18

LOW 0.75 1.00 1.50 1.75 2.25 2.50 3.00 3.25 3.75 4.00 9,7 — 13,15 16,18

Phase

or

Neutral

Phase 2.25 3.00 4.50 5.25 6.75 7.50 9.00 9.75 11.25 12.00 8,9 13,14 15,16 —

Neutral 0.75 1.00 1.50 1.75 2.25 2.50 3.00 3.25 3.75 4.00 — — — 17,18

A B C D E F G H I J ØA ØB ØC N

Sensing Input Range 1, Two-Phase-and-Neutral *

Sensing Input Range 2, Three-Phase-and-Neutral

0.75 1.00 1.50 1.75 2.25 2.50 3.00 3.25 3.75 4.00 8,9 13,14 15,16 17,18

Sensing Input Range 3, Three-Phase-and-Neutral

TAP Selector

Sensing Input Range 1, Single-Phase *

Sensing Input Range 1, Three-Phase *

Current Sensing

Terminals

Sensing Input Range 4, Three-Phase-and-Neutral

Phase 0.75 1.00 1.50 1.75 2.25 2.50 3.00 3.25 3.75 4.00 8,9 13,14 15,16 —

Neutral 2.25 3.00 4.50 5.25 6.75 7.50 9.00 9.75 11.25 12.00 — — — 17,18

Sensing Input Range 5, Three-Phase-and-Neutral

Phase or

Neutral

Phase or

Neutral

Phase 0.45 0.60 0.90 1.05 1.35 1.50 1.80 1.95 2.25 2.40 8,9 13,14 15,16 —

Neutral 0.15 0.20 0.30 0.35 0.45 0.50 0.60 0.65 0.75 0.80 — — — 17,18

Phase or

Neutral

HIGH 0.45 0.60 0.90 1.05 1.35 1.50 1.80 1.95 2.25 2.40 Same as Range 1

LOW 0.15 0.20 0.30 0.35 0.45 0.50 0.60 0.65 0.75 0.80 Same as Range 1

2.25 3.00 4.50 5.25 6.75 7.50 9.00 9.75 11.25 12.00 8,9 13,14 15,16 17,18

Sensing Input Range 6, Three-Phase-and-Neutral

0.15 0.20 0.30 0.35 0.45 0.50 0.60 0.65 0.75 0.80 8,9 13,14 15,16 17,18

Sensing Input Range 7, Three-Phase-and-Neutral

Sensing Input Range 8, Three-Phase-and-Neutral

0.45 0.60 0.90 1.05 1.35 1.50 1.80 1.95 2.25 2.40 8,9 13,14 15,16 17,18

Sensing Input Range 9 (All Other Sensing Types) *

* For relays with sensing input ranges 1 or 9, connect the system wiring to the current sensing terminals

for the desired range (HIGH or LOW).

BE1-51/27C Controls and Indicators

Page 16

10 9137200998 Rev E

Refer to Table 3 for target installation configurations.

Table 3. Target Installation Configurations

Number of Instantaneous Elements Targets Installed (Types A and B)

Sensing

Input Type

None One Two

X X

Element Function

A B C N TIME INST 1 INST 2

L

P

T

A

D

J

X X X

X X X X

X X X X

X X X X X X

X X X X X

X X X X X X X

X X X X

X X X X X X

X X X X X

X X X X X X X

X X X X

X X X X X X

Controls and Indicators BE1-51/27C

Page 17

9137200998 Rev E 11

Functional Description

BE1-51/27C Time Overcurrent Relays are microprocessor-based devices that provide protection for the

phase or phase and neutral time and instantaneous overcurrent functions.

Block Diagram Analysis

The following block diagram analysis is referenced to Figure 3. A microprocessor (not illustrated in Figure

3) processes signals, performs logic functions, and all of the time overcurrent computations.

Figure 3. Functional Block Diagram

BE1-51/27C Functional Description

Page 18

12 9137200998 Rev E

Power Supply

Operating power for the relay circuitry is supplied by a wide range, electrically isolated, low-burden power

supply. Power supply operating power is not polarity sensitive. The front panel power LED and power

supply status output indicate when the power supply is operating. Power supply specifications are listed in

the Specifications chapter.

Current Sensing

All relay models (except three-phase-and-neutral units) have two sensing ranges for each phase. Each

high/low sensing range has its own set of input terminal connections.

• Five ampere CTs have: LOW (0.5 A to 4.0 A) and HIGH (1.5 A to 12.0 A).

• One ampere CTs have: LOW (0.1 A to 0.8 A) and HIGH (0.3 A to 2.4 A).

Three-phase-and-neutral sensing units, however, have one of four possible combinations of input sensing

ranges with one range for neutral and one range for the phases.

• Five ampere CTs have: 0.5 A to 4.0 A and 1.5 A to 12.0 A.

• One ampere CTs have: 0.1 A to 0.8 A and 0.3 A to 2.4 A.

Tap Select and Tap Cal

Front panel TAP selectors and TAP CAL controls are provided for selection and precise adjustment of

the phase and neutral (if provided) time overcurrent pickup points. The front panel TAP selectors, tenposition BCD weighted rotary switches, select the desired current sensing pickup point, while the front

panel TAP CAL controls provide precise adjustment between the selected setting and the next lower

setting.

Voltage Sensing

Input voltage for each phase to be monitored is applied to the voltage sensing circuits. Each voltage

sensing circuit consists of an input transformer, rectifier, and filter Analog voltages from the voltage

sensing circuits are applied to the multiplexor. Note that neutral is not monitored for voltage.

Multiplexor

The multiplexor sequentially switches a voltage representing each of the sensed input currents to the

analog-to-digital converter and level detector.

Analog-To-Digital Converter and Level Detector

When the voltage representing the actual sensed inputs meets or exceeds the selected pickup point, this

circuit converts the level to a corresponding binary number and applies it to a time trip comparator and

scaler circuit and to a counter for calculation of the required time delay.

Time Trip Comparator and Scaler

This circuit accepts both the binary number representing the detected current level and the desired time

delay characteristic selected by the front panel TIME DIAL, then computes the required time delay before

the timed output relay will be energized. Time delay characteristics are shown in the curves located in the

Time Overcurrent Characteristic Curves chapter. If extended timing range options 2-D or 2-E is present,

the time delay characteristic curves are modified so that the time delay is approximately 5.7 times the

derived value.

Time delay computations are updated continuously so that changes in the overcurrent condition are

monitored and result in a corresponding change in the time delay. A software counter begins counting

when the initial binary number is received from the analog-to-digital converter and level detector. The

counter measures the elapsed time of the overcurrent condition, and resets if the current decreases

below the pickup point. This continuously increasing binary number is then passed to the comparator.

Functional Description BE1-51/27C

Page 19

9137200998 Rev E 13

Microprocessor (Not Shown)

Some of the circuitry already discussed is part of the microprocessor and no definite lines are drawn to

separate the functions. The microprocessor compares the desired time delay (from the time trip

comparator and scaler) with the actual elapsed time from the counter. When the elapsed time reaches the

intended delay, the timed output relay is energized. During the time delay period, the front panel TIMING

indicator (i.e. pickup) associated with the detected phase is illuminated.

If targets are present, the front panel TIME FUNCTION target wi ll be tripped, and t he A, B, C, or N

ELEMENT target associated with the detected phase will be tripped. See the Controls and Indicators

chapter for the types of targets that are present (depending upon relay configuration).

If option 3 is present, an auxiliary output relay (with N.O., N.C., or SPDT contacts) is also actuated when

the timed output relay energizes.

Voltage Inhibit

The output of the multiplexor is applied to the voltage inhibit circuit for comparison with a voltage limit set

by the front panel VOLTAGE INHIBIT ADJ control. If the (phase) input voltage exceeds this level, the

appropriate front panel VOLTAGE INHIBIT indicator will be illuminated and a voltage inhibit signal will

prevent the timed output relay and (if present) the auxiliary output relay from energizing. Instantaneous

overcurrent operation, if present , will not be affected.

Instantaneous Overcurrent (Options 1-1 and 1-2)

Input current levels applied to the time overcurrent circuitry are also passed to the instantaneous

overcurrent circuitry. These levels are compared to the setting of the front panel INST 1 adjust and the

front panel INST 1 (NEUTRAL) adjust (if present). If the input current level is above the setting, the output

driver energizes the instantaneous 1 output relay. If the instantaneous 2 option is present, the input level

is also compared with the setting of the front panel INST 2 adjust to energize the instantaneous 2 output

relay. Note that the current level settings for the instantaneous overcurrent element will always be from 1

to 40 times above the front panel TAP and TAP (NEUTRAL) settings of the time overcurrent element.

If target type A or B is present, the front panel INST 1 tar get and the fr ont pan el INST 2 targets are

tripped when their respective output relay is energized, along with the front panel A, B, C or N ELEMENT

targets (if present) associated with the detected phases. (See the Controls and Indicators chapter for the

types of targets that can be present depending upon the relay configuration.)

Timed and Instantaneous Outputs

Each output signal (representing either time overcurrent or instantaneous overcurrent) from each

monitored phase (or neutral) is applied to the respective output driver. Each output driver supplies

operating current to energize the associated output relay. Either normally open (output type E) or normally

closed (output type G) contacts may be specified. (The contact configurations of all output relays for a

given model will be the same.)

Auxiliary Outputs

In addition to the output relays, an auxiliary relay, having the same or a different contact configuration,

may be specified. Both the output and the auxiliary relays will remain energized for the duration of the

overcurrent condition.

Push-to-Energize Pushbuttons

If either option 2-C or 2-E is present, each individual output relay can be directly energized for test

purposes by the actuation of a front panel PUSH-TO-ENERGIZE OUTPUT pushbutton. The pushbutton is

actuated by the insertion of a thin, non-conducting rod through an access hole in the front panel.

Power Supply Status Output (Option 3-6)

Power supply status output relays have a set of normally closed contacts that are energized open during

power-up. If either or both power supply output legs (+12 Vdc or −12 Vdc) fails, the power supply status

BE1-51/27C Functional Description

Page 20

14 9137200998 Rev E

Note

output relay is de-energized and the output contacts close. Shorting bars across the output contacts are

held open by the installed connection plug. When the relay is removed from service by removing the

connection plug, the shorting bars are closed.

Target Indicators

Target indicators are optional components selected when a relay is ordered. The electronically latched

and reset targets consist of red LED indicators located on the relay front panel. A latched target is reset

by operating the target reset switch on the front panel. If relay operating power is lost, any illuminated

(latched) targets are extinguished. When relay operating power is restored, the previously latched targets

are restored to their latched state.

A relay can be equipped with either internally operated targets or current operated targets.

Internally Operated Targets

The relay trip outputs are directly applied to drive the appropriate target indicator. Each indicator is

illuminated regardless of the current level in the trip circuit.

Current Operated Targets

A current operated target is triggered by closure of the corresponding output contact and the presence of

at least 200 milliamperes of current flowing in the trip circuit.

Note that the front panel function targets (TIMED, INST 1, etc.) may be either internally or current

operated. Phase and neutral indicators are current operated only if the instantaneous options are not

included and if current operated targets are specified.

Prior to August 2007, BE1-51/27C target indic ator s co ns isted of

magnetically latched, disc indicators. These mechanically latch ed

target indicators have been replaced by the electronically latched LED

targets in use today.

Functional Description BE1-51/27C

Page 21

9137200998 Rev E 15

Caution

Note

Installation

BE1-51/27C relays are shipped in sturdy cartons to prevent damage during transit. Upon receipt of a

relay, check the model and style number against the requisition and packing list to see that they agree.

Inspect the relay for shipping damage. If there is evidence of damage, file a claim with the carrier, and

notify your sales representative or Basler Electric.

If the relay will not be installed immediately, store it in its original shipping carton in a moisture- and dustfree environment. Before placing the relay in service, it is recommended that the test procedures of the

Tests and Adjustments chapter be performed.

Relay Operating Guidel ines and Precautions

Before installing or operating the relay, note the following guidelines and precautions:

• For proper current operated target operation, a minimum current of 200 milliamperes must flow

through the output trip circuit.

• If a wiring insulation test is required, remove the connection plugs and withdraw the relay from its

case.

When the connection plugs are removed, the relay is disconnected

from the operating circuit and will not provide system protection.

Always be sure that external operating (monitored) conditions are

stable before removing a relay for inspection, test, or service.

Be sure that the BE1-51/27C is hard-wired to earth ground with no

smaller than 12 AWG copper wire attached to the ground terminal on

the rear of the case. When the BE1-51/27C is configured in a system

with other devices, it is recommended to use a separate lead to the

ground bus from each device.

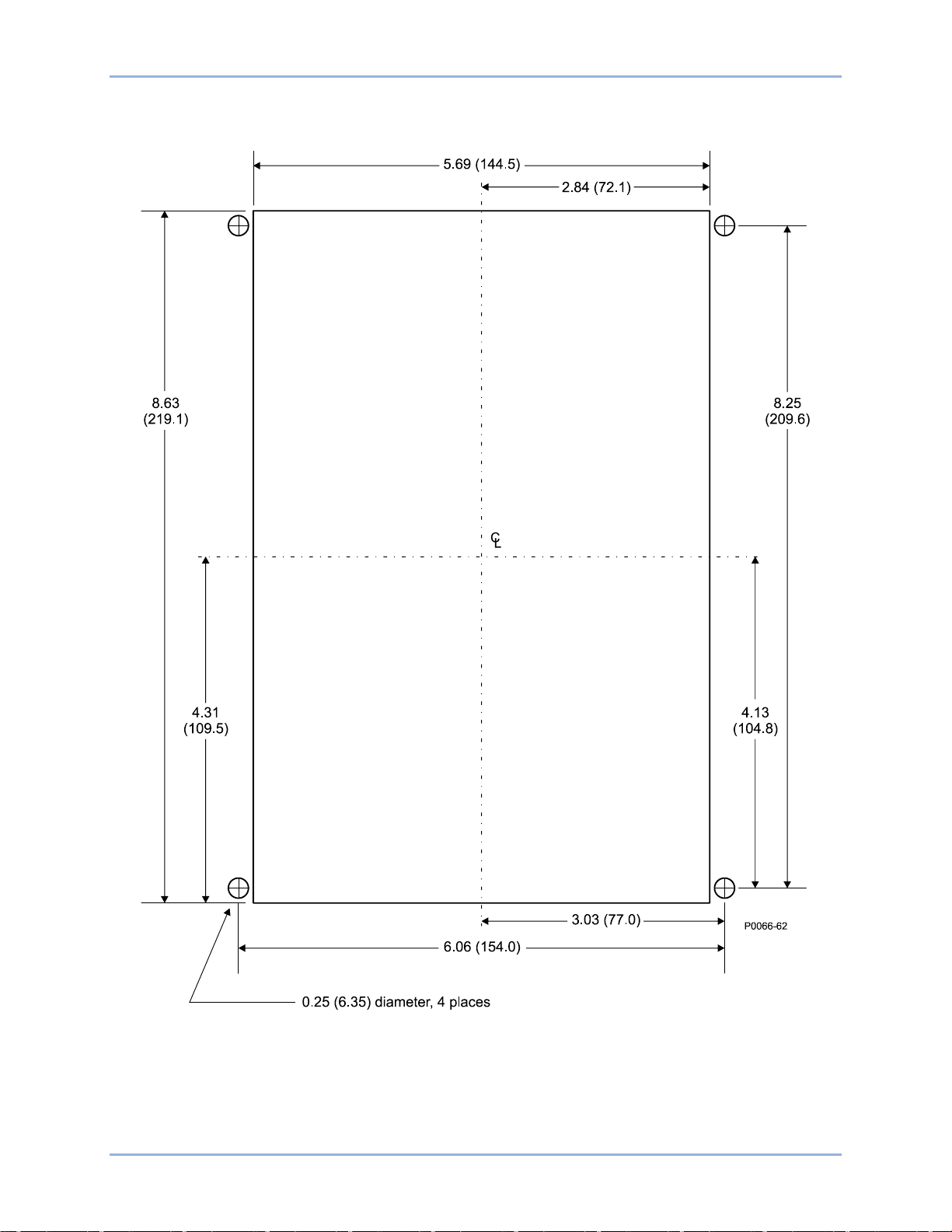

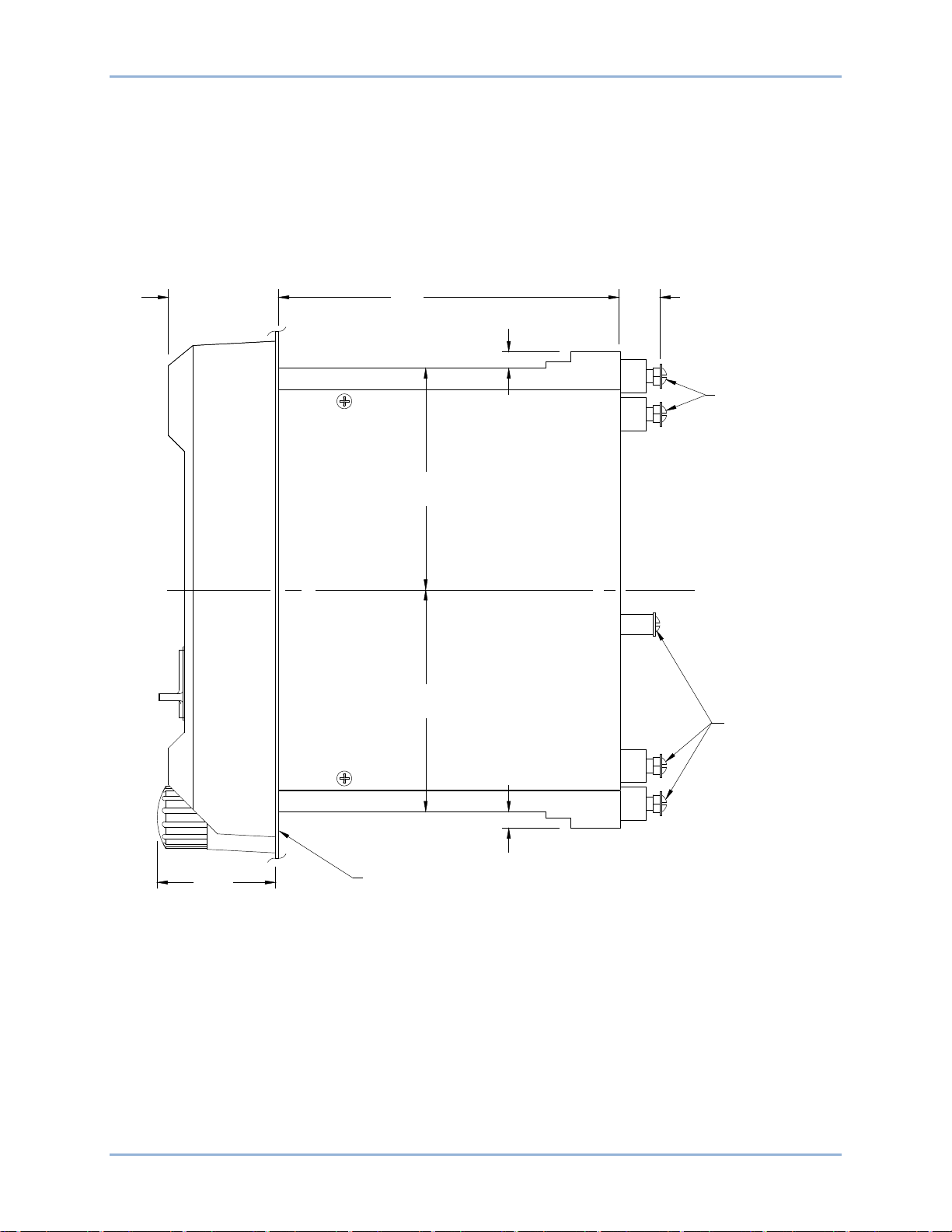

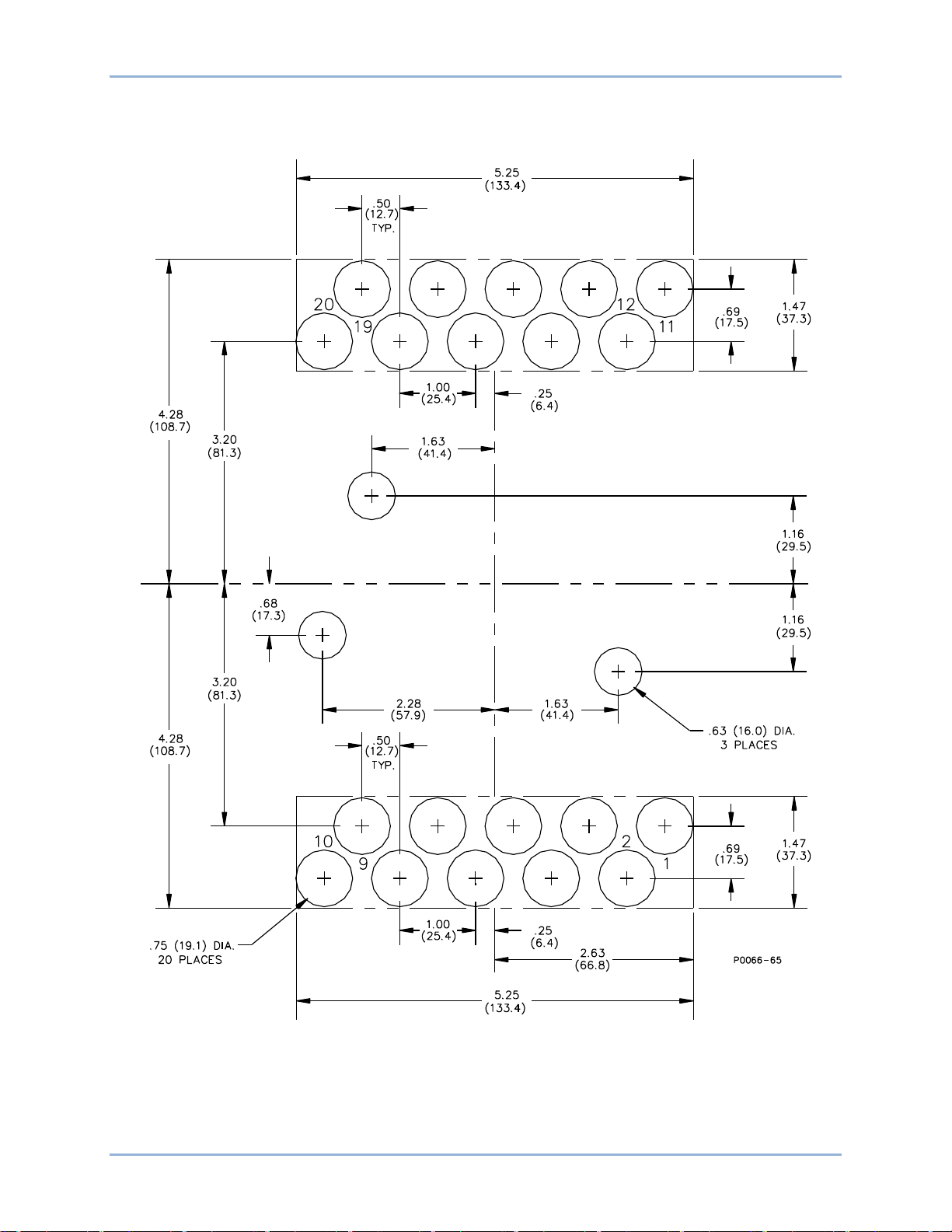

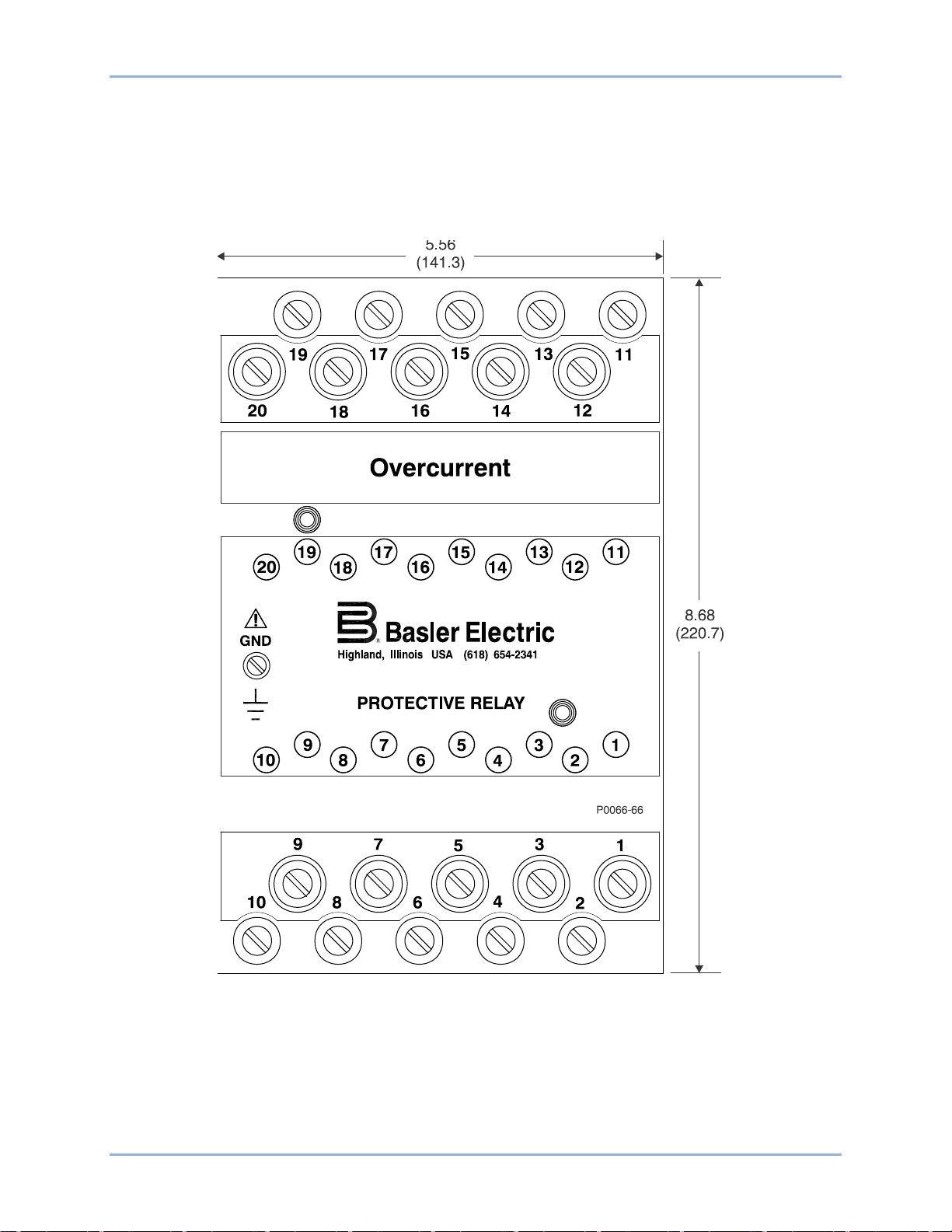

Mounting

Because the relay is of solid-state design, it does not have to be mounted vertically. Any convenient

mounting angle may be chosen. Refer to the following figures for relay outline dimensions and panel

drilling diagrams.

BE1-51/27C Installation

Page 22

16 9137200998 Rev E

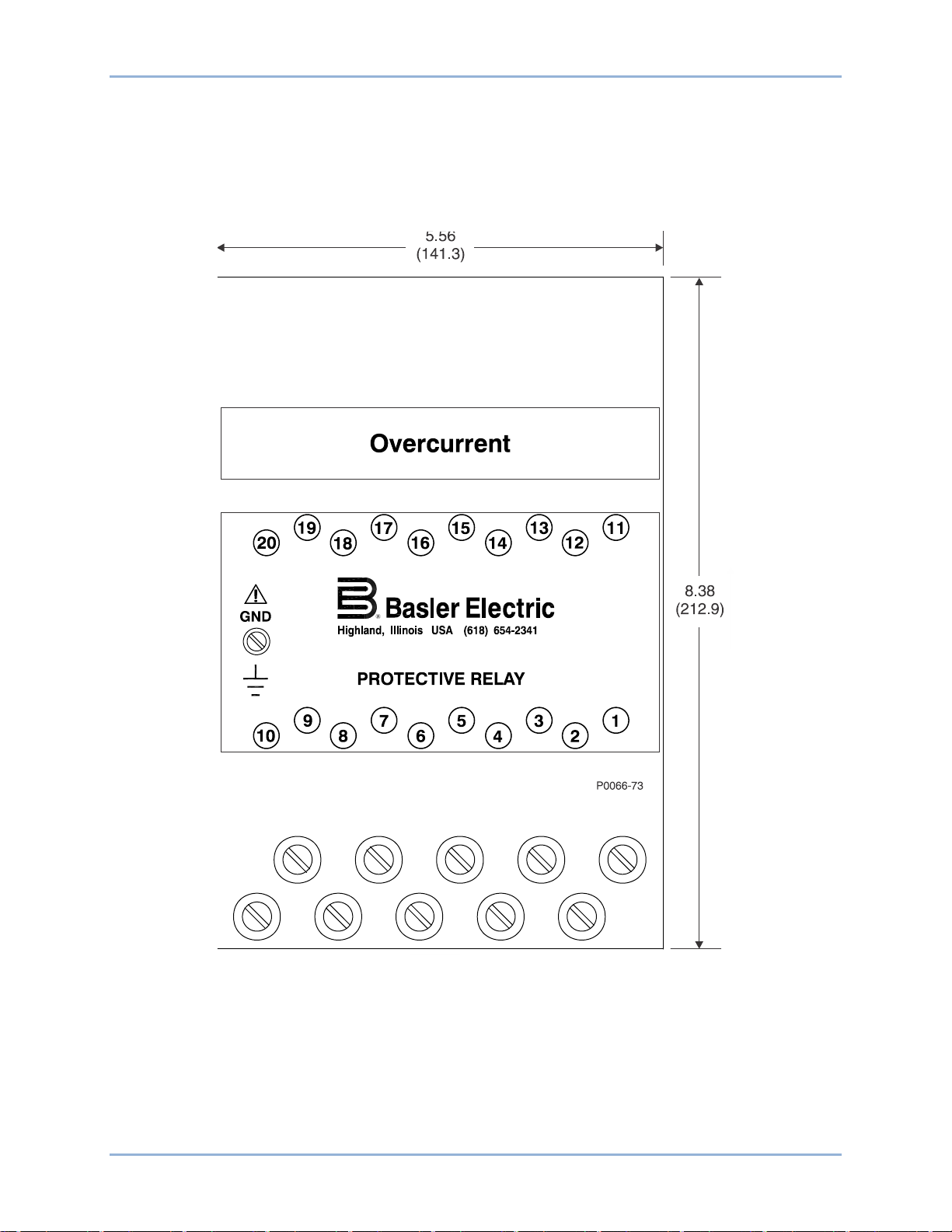

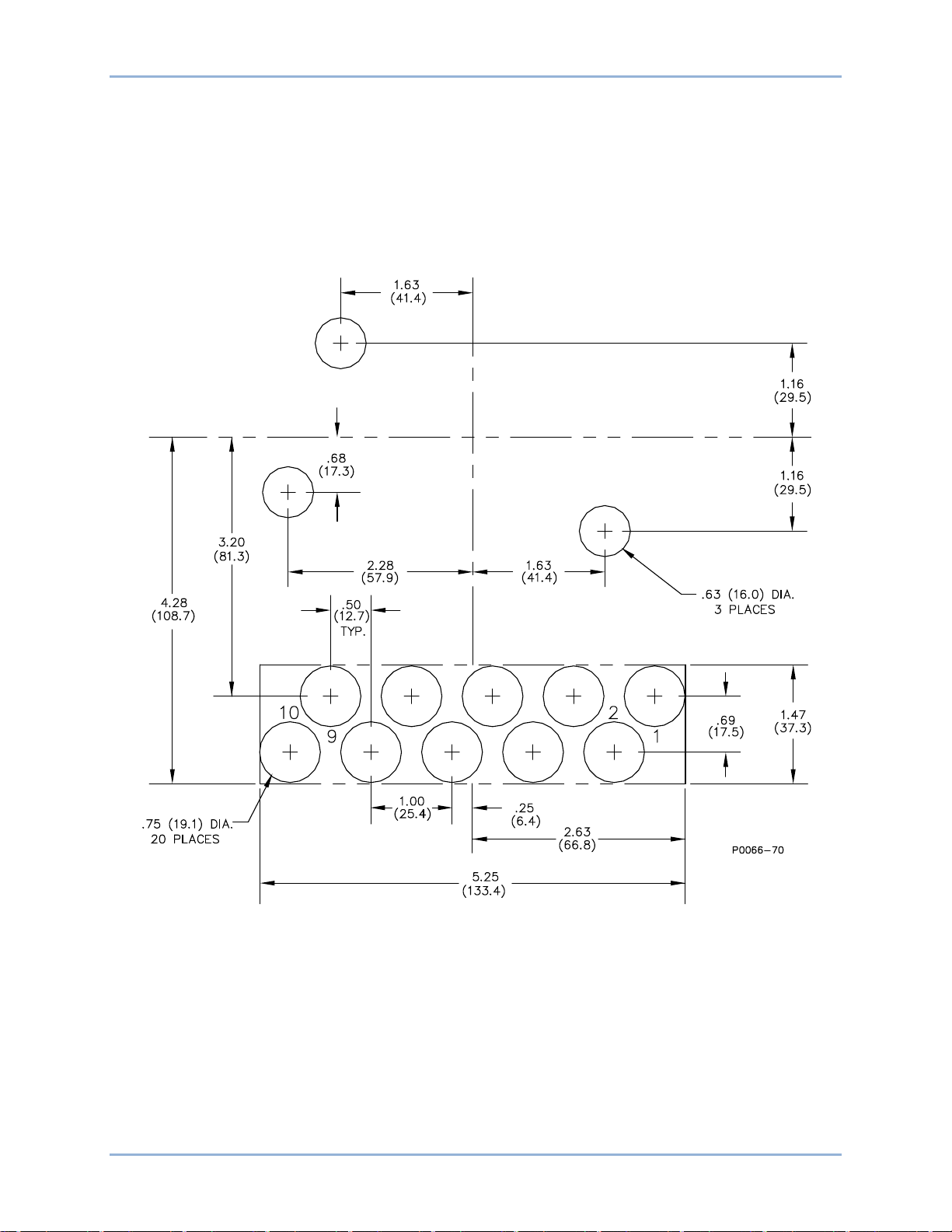

Figure 4. Panel Cutting/Drilling, Semi-Flush, S1 Case

Installation BE1-51/27C

Page 23

9137200998 Rev E 17

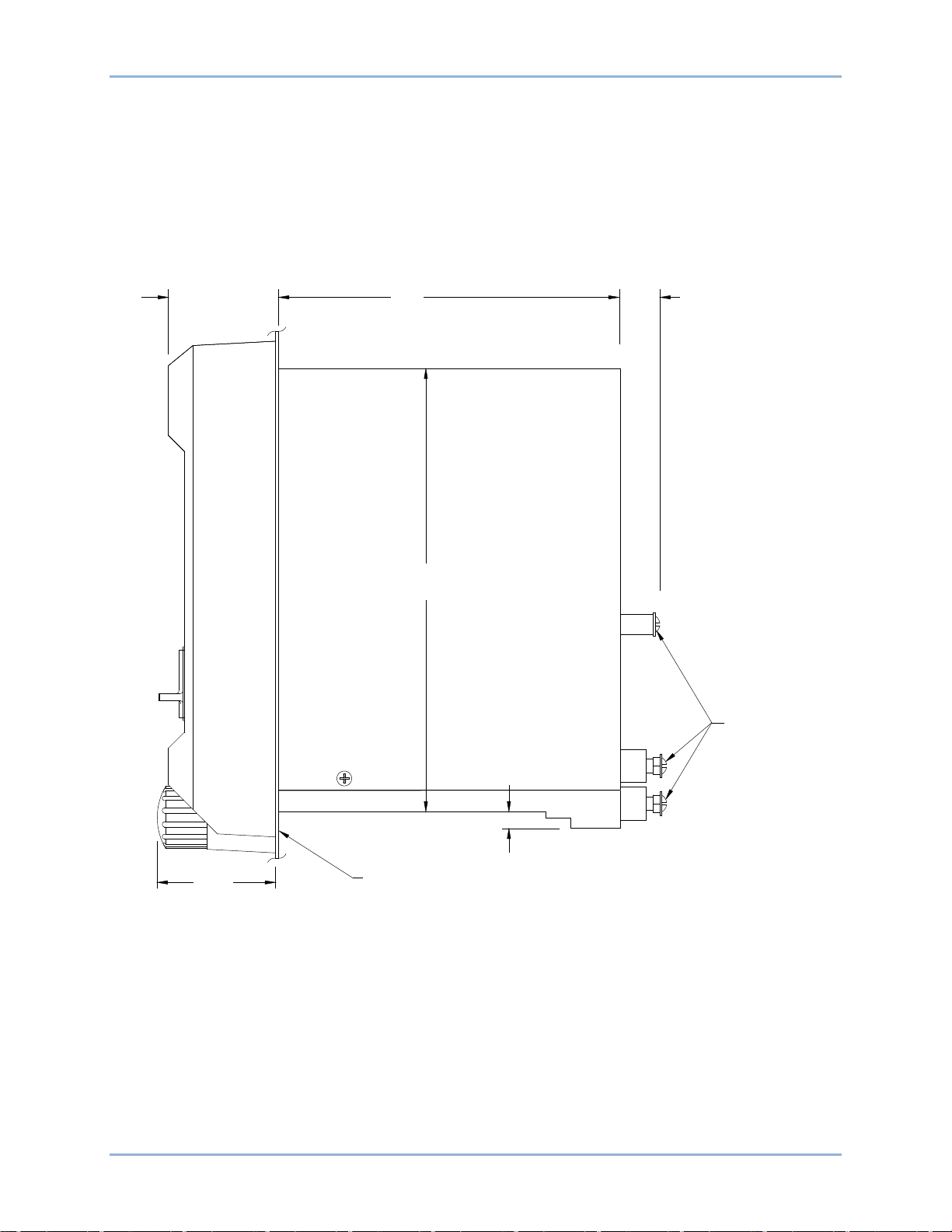

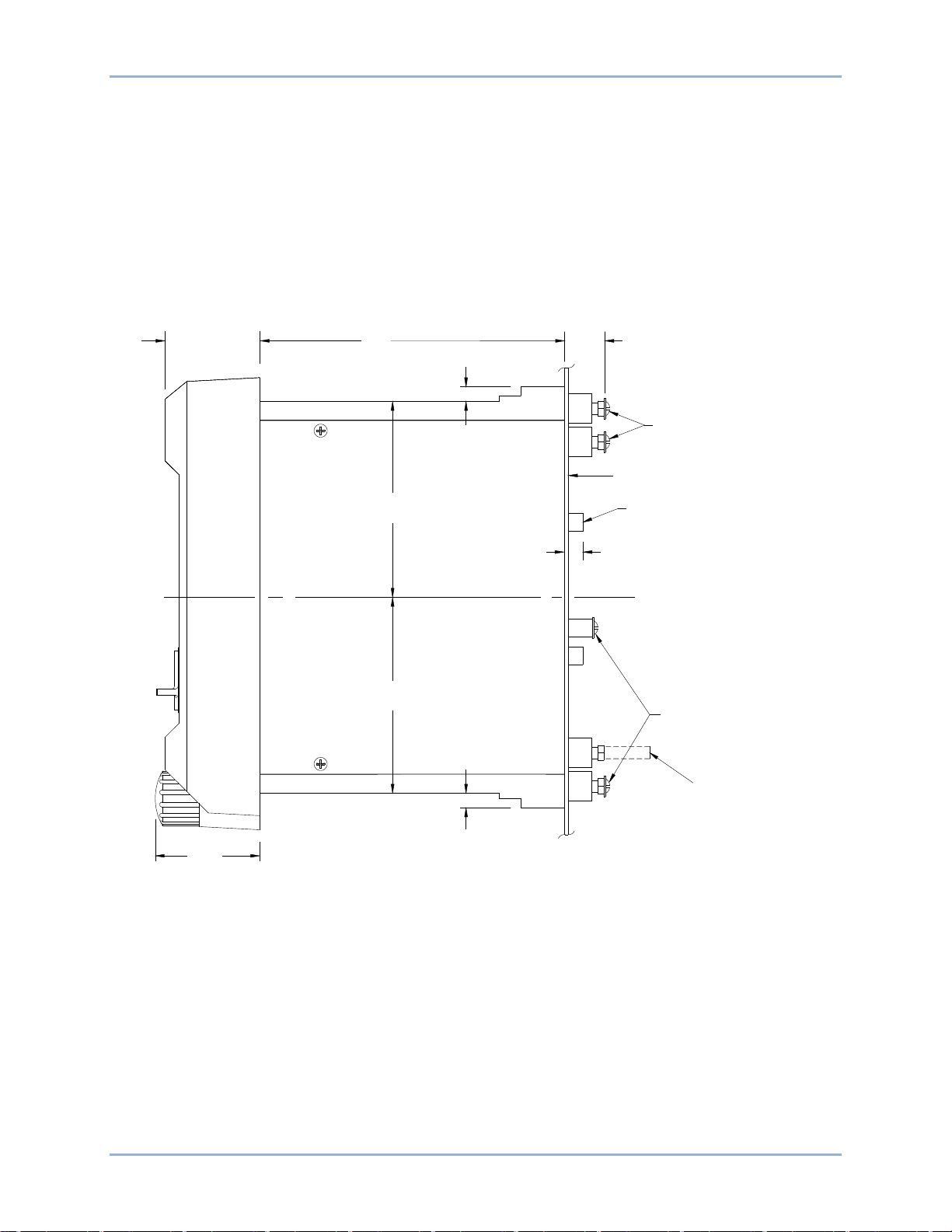

Figure 5. S1 Case Dimensions, Rear View, Double Ended, Semi-Flush Mount

BE1-51/27C Installation

Page 24

18 9137200998 Rev E

.75

(19.1)(157.2)

6.19

(49.53)

1.95

10-32 SCREWS

(7.9)

.31

10-32 SCREWS

(102.4)

4.03

4.03

(102.4)

(

7.9)

.31

MOUNTING PANEL

(55.75

)

2.195

P0066-64

Figure 6. S1 Case Dimensions, Side View, Double Ended, Semi-Flush Mount

Installation BE1-51/27C

Page 25

9137200998 Rev E 19

Figure 7. S1 Case Dimensions, Rear View, Single Ended, Semi-Flush Mount

BE1-51/27C Installation

Page 26

20 9137200998 Rev E

.75

(19.1)(157.2)

6.19

(49.53)

1.95

10-32 SCREWS

MOUNTING PANEL

(55.75)

2.195

P0066-69

8.06

(204.72)

(7.9)

.31

Figure 8. S1 Case Dimensions, Side View, Single Ended, Semi-Flush Mount

Installation BE1-51/27C

Page 27

9137200998 Rev E 21

Figure 9. Panel Cutting/Drilling, Double Ended, Projection Mount, S1 Case

BE1-51/27C Installation

Page 28

22 9137200998 Rev E

Figure 10. S1 Case Dimensions, Rear View, Double Ended, Projection Mount

Installation BE1-51/27C

Page 29

9137200998 Rev E 23

.

75

(

19

.1

)

(

157.

2)

6.

19

(

49

.53

)

1

.

95

10-

32 SCREWS

(

7.

9

)

.

31

10

-32 SCREWS

(

102.4)

4.

03

4.03

(102.

4)

(7.

9)

.

31

(55

.75

)

2.

195

P0066-

67

TERMINAL EXTENSION

(TYP.)

FOR DETAILED INSTRUCITONS,

SEE THE TERMINAL PROJECTION

MOUNTING KIT SUPPLIED.

.25

(6.

4)

5

/16-

18

STUD

2

PLACES

MOUNTING PANEL

Figure 11. S1 Case Dimensions, Side View, Double Ended, Projection Mount

BE1-51/27C Installation

Page 30

24 9137200998 Rev E

Figure 12. Panel Cutting/Drilling, Single Ended, Projection Mount, S1 Case

Installation BE1-51/27C

Page 31

9137200998 Rev E 25

Figure 13. S1 Case Dimensions, Rear View, Single Ended, Projection Mount

BE1-51/27C Installation

Page 32

26 9137200998 Rev E

(157.2)

6.19

(49.53)

1.95

10-32 SCREWS

MOUNTING PANEL

(55.75)

2.195

P0066-71

TERMINAL EXTENSION (TYP.)

FOR DETAILED INSTRUCITONS,

SEE THE TERMINAL PROJECTION

MOUNTING KIT SUPPLIED.

.25

(6.4)

5/16-18 STUD

2 PLACES

MOUNTING PANEL

8.06

(204.72)

(7.9)

.31

.75

(19.1)

Figure 14. S1 Case Dimensions, Side View, Single Ended, Projection Mount

Installation BE1-51/27C

Page 33

9137200998 Rev E 27

P

0066-68

Figure 15. S1 Case Cover Dimensions, Front View

BE1-51/27C Installation

Page 34

28 9137200998 Rev E

P

0050-03

Connections

Be sure to check the model and style number of a relay before connecting and energizing the relay.

Incorrect wiring may result in damage to the relay. Except where noted, connections should be made with

wire no smaller than 14 AWG.

Typical external and internal connections are shown in the following figures.

To prevent an inductive overload of the relay contacts, it is necessary to break the trip circuit extern a lly

through the 52a contacts.

Relay circuitry is connected to the case terminals by removable connection plugs (1 plug for 10-terminal

cases and 2 plugs for 20-terminal cases). Removal of the connection plug(s) opens the normally open trip

contact circuits and shorts the normally closed trip circuits before opening the power and sensing circuits.

Figure 16. Typical External Connections, Current Operated Targets, DC Powered

Installation BE1-51/27C

Page 35

9137200998 Rev E 29

P

0050-0

4

P0050-05

Figure 17. Typical Sensing External Connections, Sensing Input Type L

Figure 18. Typical Sensing External Connections, Sensing Input Type P

BE1-51/27C Installation

Page 36

30 9137200998 Rev E

P005

0-06

P0050-07

Figure 19. Typical Sensing External Connections, Sensing Input Type T

Figure 20. Typical External Connections, Sensing Input Type A

Installation BE1-51/27C

Page 37

9137200998 Rev E 31

P005

0-08

P0050-09

Figure 21. Typical Sensing External Connections, Sensing Input Type D

Figure 22. Typical Sensing External Connections, Sensing Input Type J

BE1-51/27C Installation

Page 38

32 9137200998 Rev E

P0050-10

Figure 23. Typical Sensing External Connections, Sensing Input Type P, Unit-Connected

Installation BE1-51/27C

Page 39

9137200998 Rev E 33

Figure 24. Typical Internal Diagram, Sensing Input Type L

BE1-51/27C Installation

Page 40

34 9137200998 Rev E

Figure 25. Typical Internal Diagram, Sensing Input Type J

Installation BE1-51/27C

Page 41

9137200998 Rev E 35

Figure 26. Typical Internal Diagram, Sensing Input Type A

BE1-51/27C Installation

Page 42

36 9137200998 Rev E

Figure 27. Typical Internal Diagram, Sensing Input Type P

Installation BE1-51/27C

Page 43

9137200998 Rev E 37

Figure 28. Typical Internal Diagram, Sensing Input Type D

BE1-51/27C Installation

Page 44

38 9137200998 Rev E

Figure 29. Typical Internal Diagram, Sensing Input Type T

Installation BE1-51/27C

Page 45

9137200998 Rev E 39

Maintenance

BE1-51/27C relays require no preventative maintenance other than a periodic operational check. If the

relay fails to function properly, contact Technical Sales Support at Basler Electric to coordinate repairs.

Storage

This device contains long-life aluminum electrolytic capacitors. For devices that are not in service (spares

in storage), the life of these capacitors can be maximized by energizing the device for 30 minutes once

per year.

BE1-51/27C Installation

Page 46

40 9137200998 Rev E

Installation BE1-51/27C

Page 47

9137200998 Rev E 41

Note

Note

Tests and Adjustments

Procedures in this section are for use in testing and adjusting a relay for the desired operation in a

protective scheme. If a relay fails an operational test, or if an adjustment discloses a faulty relay, contact

Basler Electric.

Required Test Equipment

Minimum test equipment required for relay testing and adjustment is listed below. Refer to the following

figures for test setups.

• Appropriate ac or dc power source for relay operation

• Appropriate ac source (50- or 60-hertz as appropr iat e) for volta ge and current testing

• Dc external power source for output relay(s) test setup and timer input

• Relay test set capable of delivering 40 amperes. A higher capability is needed for instantaneous

settings above 40 amperes

• Timer

• One shunt resistor for providing minimum target load

Operational Test

Preliminary Instructions

Perform the following steps before going on to any testing.

Step 1. Connect the relay test setup in accordance with Figures 30 through 35, depending upon the

sensing input type for your relay (see the style chart in the General Information chapter).

(a) Sensing Input Type L (Single-Phas e Sens i ng). Refer to Figure 30

For relays having the above sensing, only the from panel LOW range

current sense terminal(s) should be connected for a complete check of

the relay.

Ensure that timed output termina ls 1 and 10 are conn e cted.

(b) Sensing Input Type P (Three-Phase Sensing). Refer to Figure 31

For relays having the above sensing, only the from panel LOW range

current sense terminal(s) should be connected for a complete check of

the relay.

.

.

For all three-phase relays, the test signals must connect to both the

current and voltage terminals for the same phase.

BE1-51/27C Tests and Adjustments

Ensure that timed output termina ls 1 and 10 are conne c ted.

Page 48

42 9137200998 Rev E

(c) Sensing Input Type T (Three-Phase with Neutral Sensing). Refer to Figure 32.

Ensure that the timed output terminals 1 and 10 are connected. Also, verify that either A,

B, or C current sense terminals are connected initially (N terminals will be connected later

in the test).

(d) Sensing Input Type A (Three-Phase Sensing). Refer to Figure 33

.

Ensure that the timed output terminals 1 and 10 are connected. Also, verify that either A,

B, or C current sense terminals are connected initially (N terminals will be connected later

in the test). Ensure that the voltage sense terminals and the current sense terminals are

connected to the same phase.

(e) Sensing Input Type D (Three-Phase with Neutral Sensing). Refer to Figure 34

.

Ensure that the timed output terminals 1 and 10 are connected. Also, verify that either A,

B, or C current sense terminals are connected initially (N terminals will be connected later

in the test).

(f) Sensing Input Type J (Two-Phase with Neutral Sensing). Refer to Figure 35

.

Ensure that the timed output terminals 1 and 10 are connected. Also, verify that either A,

B, or C current sense terminals are connected initially (N terminals will be connected later

in the test).

Step 2. Remove the relay front cover.

Step 3. Set the front panel TIME DIAL selector and, if present, the front panel TIME DIAL (NEUTRAL)

selector to 99.

Step 4. Adjust the front panel INST 1 and INST 2 controls, if present, fully clockwise (CW).

Step 5. Adjust the front panel TAP CAL control, and if present, the front panel TAP (NEUTRAL) control

fully CW.

Step 6. Ensure that the relay front panel TARGETS, if present, are reset.

Step 7. Apply 100% of nominal voltage based on the sensing input type for your relay.

Figure 30. Test Setup for Sensing Input Type L (Single-Phase Sensing)

Tests and Adjustments BE1-51/27C

Page 49

9137200998 Rev E 43

Figure 31. Test Setup for Sensing Input Type P (Three-Phase Sensing)

Figure 32. Test Setup for Sensing Input Type T (Three-Phase with Neutral Sensing)

BE1-51/27C Tests and Adjustments

Page 50

44 9137200998 Rev E

Figure 33. Test Setup for Sensing Input Type A (Three-Phase, Delta Configuration)

Figure 34. Test Setup for Sensing Input Type D (Three-Phase with Neutral Sensing)

Tests and Adjustments BE1-51/27C

Page 51

9137200998 Rev E 45

Note

Figure 35. Test Setup for Sensing Input Type J (Two-Phase with Neutral Sensing)

Time Overcurrent Pickup Test

This test checks the minimum and maximum overcurrent pickup points of the time overcurrent element.

During this test, disregard any indication on the test setup timer.

Step 1. Perform the preliminary instructions.

Step 2. Set the front panel TAP selector to A.

Step 3. Adjust the test set, for an overcurrent threshold having one of the following values:

(a) 0.5 for relays with Sensing Input Range 1, 2, or 4.

(b) 1.5 A for relays with Sensing Input Range 3 or 5.

Step 4. Slowly adjust the front panel TAP CAL control CCW until the front panel TIMING indicator

illuminates.

RESULT: For the phase minimum overcurrent pickup point of 0.5 A (Step 3a, above) or 1.5 A

(Step 3b, above) the front panel TAP CAL control should be near its maximum CCW limit.

Step 5. Adjust the front panel TAP CAL control fully CW to allow measurement of the actual

overcurrent pickup point at the A setting of the front panel TAP selector. Note that the front

panel TIMING indicator wil l exting uis h. Do not disturb t his sett ing.

Step 6. Slowly increase the current toward the value of the front panel TAP selector A setting until the

front panel TIMING indicator illuminates. Do not disturb this setting.

Step 7. Record the current reading and remove input current.

RESULT: The recorded value should be within ±5% of the front panel TAP selector A setting

for the phase minimum overcurrent pickup point for the time overcurrent.

BE1-51/27C Tests and Adjustments

Page 52

46 9137200998 Rev E

Note

Step 8. Set the front panel TAP selector to J.

Step 9. Slowly adjust the test set, increasing the overcurrent threshold toward the value of the front

panel TAP selector J setting until the front panel TIMING indicator just illuminates. Do not

disturb this setting.

Step 10. Record the current reading and remove input current.

RESULT: The recorded value should be within ±5% of the front panel TAP selector J setting for

the phase maximum overcurrent pickup point for the time overcurrent element.

Step 11. Perform the following steps as appropriate for the correct sensing input types.

Ensure that the voltage sense terminals and current sense terminals

are connected to the same phase.

(a) Sensing Input Type L (Single-Phas e Sens i ng). This concludes the time overcurrent test.

Proceed to the timed output test.

(b) Sensing Input Type J (Two-Phase and Neutral Sensing) . Remove the power and

reconnect the input sensing to the remaining phases as shown in Figure 35, each time

repeating Steps 1 through 10. For neutral testing, continue with Step 12.

(c) Sensing Input Type A and P (Three-Phase Se ns ing). Remove the power and reconnect

the input sensing to each of the remaining phases as shown in Figures 33 and 35, each

time repeating Steps 1 through 10.

(d) Sensing Input Type D and U (Three-Phase with Neutral Sensing). Remove the power

and reconnect the input sensing to each of the remaining phases as shown in Figures 32

and 34, each time repeating Steps 1 through 10. For neutral testing, continue with Step

12.

Step 12. Perform the preliminary instructions.

For the neutral sensing (terminals 17 and 18), connect the relay as shown in Figures 32 and 34,

then perform the following steps (Steps 13 through 21).

Step 13. Set the front panel TAP (NEUTRAL) selector to A.

Step 14. Adjust the test set for an overcurrent threshold having one of the following values:

(a) 0.5 A for relays with Sensing Input Range 2 or 3.

(b) 1.5 A for relays with Sensing Input Range 4 or 5.

Step 15. Slowly adjust the front panel CAL (NEUTRAL) control CCW until the front panel TIMING

indicator illuminates.

RESULT: For the neutral minimum overcurrent pickup point of 0.5 A (Step 16a, above) or 1.5 A

(Step 16b, above) the front panel CAL (NEUTRAL) control should be near its maximum CCW

limit.

Step 16. Adjust the front panel CAL (NEUTRAL) control fully CW to allow measurement of the actual

overcurrent pickup point at the A setting of the front panel TAP (NEUTRAL) selector. Note that

the front panel TIMING (NEUTRAL) indicator will extinguish. Do not disturb this set ting.

Step 17. Slowly increase the current toward the value of the front panel TAP (NEUTRAL) selector A

setting until the front panel TIMING (NEUTRAL) indicator illuminates. Do not disturb this

setting.

Step 18. Record the current reading and remove input current.

Tests and Adjustments BE1-51/27C

Page 53

9137200998 Rev E 47

Note

Note

RESULT: The recorded value should be within ±5% of the front panel TAP (NEUTRAL)

selector A setting for the neutral minimum overcurrent pickup point for the time overcurrent.

Step 19. Set the front panel TAP (NEUTRAL) selector to J.

Step 20. Slowly adjust the test set, increasing the overcurrent threshold toward the value of the front

panel TAP (NEUTRAL) selector J setting until the front panel TIMING (NEUTRAL) indicator

just illuminates. Do not disturb this setting.

Step 21. Record the current reading and remove input current.

RESULT: The recorded value should be within ±5% of the front panel TAP (NEUTRAL)

selector J setting for the neutral maximum overcurrent pickup point for the time overcurrent

element.

Timed Output Test

This test checks the accuracy of the time overcurrent characteristic delay.

For relays having three-phase sensing (Sensing Input Type A or P)

only a single input phase needs to be connected, since this is

sufficient for a complete test of the Time Delay. For relays that include

neutral sensing (Sensing Input Type D, T, or J), this test includes

reconnecting the Test Output to the Neutral Sensing termina ls for

testing the Timed Output during neutral sensing.

Step 1. Verify that the preliminary instructions have been performed.

Step 2. (Timing type Z1, Z2, or Z3 only.) Select the desired time current characteristic curve.

Step 3. Set the front panel TAP selector to B.

Step 4. Adjust the front panel TIME DIAL to 20.

Step 5. Adjust the test set for an overcurrent threshold of precisely 5 times the front panel TAP selector

B setting.

Step 6. Apply input current to the relay and initiate the test setup timer.

Step 7. Observe that the appropriate front panel TIMING indicator illuminates and when the time delay

ends that the timed output relay is energized.

RESULTS: (1) The appropriate front panel TIMING indicator extin g uis hes .

(2) The test setup timer stops. (Record count for use in Step 9.)

(3) If target type A or B is present:

(a) The front panel FUNCTION-TIME target (if present) trips.

(b) The appropriate front panel ELEMENT target A, B, or C (if present)

trips.

Step 8. Remove input current and (if present) reset the relay front panel targets.

Due to delays inherent in the test equipment, the time delay for the

following test may appear to exceed these limits.

BE1-51/27C Tests and Adjustments

Page 54

48 9137200998 Rev E

Note

Step 9. On the appropriate time overcurrent curve chart (in the Time Overcurrent Characteristic Curves

chapter), locate the line representing 5 times the tap value (from Step 5) where it intersects the

particular curve representing the front panel TIME DIAL setting of 20 (from Step 4). The

resulting time delay value in seconds should be within ±5% of the timer reading [from Step

7(2)].

Step 10. Adjust the front panel TIME DIAL to 40, 60, and 99, each time repeating Steps 6 through 9.

For relays having two-phase-and-neutral, three-phase, or three-phaseand-neutral sensing (Sensing Input Types A, D, P, T, or J) it is not

necessary to repeat this test for the remaining phases.

For relays having two-phase-and-neutral, or three-phase-and-neutral

sensing (Sensing Input Types D, T, or J) perform Steps 11 through 20.

For relays having single-phase or three-phase sensing (Sensing Input

Types A or P) with instantaneous overcurrent option 1-1 or 1-2,

proceed to the instantaneous overcurrent test.

Step 11. Remove the power and reconnect the test output to the neutral current sensing input of the

relay as shown in Figures 32 and 34 (terminals 17 and 18).

Step 12. Set the front panel TAP (NEUTRAL) selector to B.

Step 13. Rotate the front panel CAL (NEUTRAL) control fully CW.

Step 14. Rotate the front panel TIME DIAL (NEUTRAL) to 20.

Step 15. Ensure that all relay targets have been reset.

Step 16. Adjust the test set for an overcurrent threshold of precisely 5 times the front panel TAP

(NEUTRAL) selector B setting as meas ur ed by the ammet er.

Step 17. Apply input current to the relay and initiate the test setup timer.

RESULTS: Observe that the appropriate front panel TIMING (NEUTRAL) indicator illuminates.

Step 18. When the time delay ends, the timed output relay is energized.

RESULTS: (1) The front panel TIMING (NEUTRAL) indicator extinguishes.

(2) The test setup timer stops. (Record count for use in Step 20.)

(3) If target Type A or B is present:

(a) Front panel FUNCTION-TIME target (if present) trips.

(b) Appropriate front panel ELEMENT target A, B, or C (if present) trips.

Step 19. Remove input current and (if present) reset the relay front panel targets.

Step 20. On the appropriate time overcurrent curve chart (in the Time Overcurrent Characteristic Curves

chapter), locate the line representing 5 times the tap value (from Step 5) where it intersects the

particular curve representing the front panel TIME DIAL (NEUTRAL) setting of 20 (from Step

14). The resulting time delay value in seconds should be within ±5% of the timer reading [from

step 18(2)].

Tests and Adjustments BE1-51/27C

Page 55

9137200998 Rev E 49

Note

Note

Due to delays inherent in the test equipment, the time delay may

appear to exceed these limits. This concludes the timed output test.

Relays having instantaneous overcurrent option 1-1 or 1-2 only

proceed to the Instantaneous Overcurrent Pickup Test.

Instantaneous Overcurrent Pickup Test

This test checks the minimum overcurrent pickup points for Instantaneous 1 and (if present)

Instantaneous 2 outputs.

For relays having three-phase sensing (Sensing Input Types A or P),

only a single input phase is connected since this is sufficient for a

complete test of the instantaneous overcurrent sensing and output.

For relays that include neutral sensing (Sensing Input Types D, T, or

J), this test includes reconnecting the test output to the neutral sensing

terminals for testing the instantaneous 1 output during neutral sensing.

Step 1. Perform the preliminary instructions.

Step 2. Reconnect the test setup to the INST 1 output terminals 2 and 10 as shown in Figures 30

through 35. Note that the timer may be removed from the test setup at this time.

Step 3. Set the TAP selector to A.

Step 4. Turn the front panel INST 1 control fully CCW to establish a pickup point of 1 times the TAP

selector A setting.

Step 5. Slowly adjust the test set, increasing the overcurrent threshold toward the value of the front

panel TAP selector A setting until the Instantaneous 1 output relay energizes.

RESULT: If target Type A or B is present:

(a) The front panel FUNCTION-INST 1 target (if present) will trip.

(b) The appropriate front panel ELEMENT target A, B, or C (if present) will trip.

Step 6. Remove input current. Record the test set current setting.

RESULT: The recorded value should be equal to or less than the front panel TAP selector A

setting for the minimum overcurrent pickup point for the instantaneous 1 overcurrent element.

Step 7. Reset the relay front panel targets (if present).

Step 8. Turn the front panel INST 1 control fully CW to establish a pickup point of 40 times the front

panel TAP selector A setting.

Step 9. Adjust the test set to approximately 35 times the front panel TAP selector A setting.

Step 10. Slowly adjust the test set further toward an overcurrent threshold of 40 times the front panel

TAP selector A setting until the instantaneous 1 output relay energizes. Do not disturb this

setting.

RESULT: If target Type A or B is present:

(a) The front panel FUNCTION-INST 1 target (if present) will trip.

(b) The appropriate front panel ELEMENT target A, B, or C (if present) will trip.

BE1-51/27C Tests and Adjustments

Page 56

50 9137200998 Rev E

Note

Note

Step 11. Record the current reading. Remove input current (the front panel TIMING indicator should

extinguish).

RESULT: The recorded value should be greater than 40 times the front panel TAP selector A

setting for the maximum overcurrent pickup point for the instantaneous 1 overcurrent element.

For relays having neutral sensing (Sensing Input Types D, T, or J)

perform Step 12. Otherwise, proceed to Step 13.

Step 12. For the neutral sensing, connect the relay as shown in Figures 32 and 34, then repeat Steps 2

through 11, substituting the following:

(a) The front panel TAP (NEUTRAL) selector instead of the front panel TAP selector (Step 3).

(b) The front panel INST 1 (NEUTRAL) control instead of the front panel INST 1 control

(Step 4)

For relays with Option 1-2 (Inst. 2 elements), perform Step 13.

Otherwise, the test ends here.

Step 13. Reconnect the test setup to the INST 2 output terminals (11 and 12) as shown in Figure 30,

then repeat Steps 4 through 11, substituting the following:

(a) Front panel INST 2 control instead of the front panel INST 1 control (Step 3).

(b) Front panel FUNCTION-INST 2 target instead of the front panel INST 1 target ( Step 4).

(c) Instantaneous 2 output relay instead of the instantaneous 1 output relay ( Step 2).

Voltage Control Test

This test checks the voltage control minimum and maximum limits for the voltage inhibit levels.

Step 1. Perform the Preliminary Instructions.

Step 2. Set the front panel TAP selector to B.

Step 3. Adjust the front panel TIME DIAL to 20.

Step 4. Adjust for an overcurrent threshold of 2 times the front panel TAP selector B setting.