Bakemax BMCRS01, BMCR-FRS Installation Manual

REVERSIBLE SHEETERS

BMCRS01

BMCRS02

BMFRS01

BMFRS02

BMFRS03

INSTRUCTION MANUAL

1. GENERAL

l-l.PURPOSE

The most widely used reversible sheeter, design to code of baking industry standard,

suitable for sheeting and stretching various kinds of the dough, such as: puff pastry,

Danish, donut dough, croissant dough, pie dough, cookie dough, strudel, marzipan

and other special dough.

Please note: Dough must be at room temperature (21C or 70F) to operate with

sheeter properly

1-2.GENERAL FEATURE AND APPLICATION

* The machine used heavy duty and long life sanitary conveyor belts.

* Protective safety guards on both side of rollers, preventing hands to be caught by

rollers.

* Automatic overload protective prevents motor from damage.

* Both side conveyor table are easily folded up in seconds to save space.

* Open with a limit switch to shut off power immediately to protect operator.

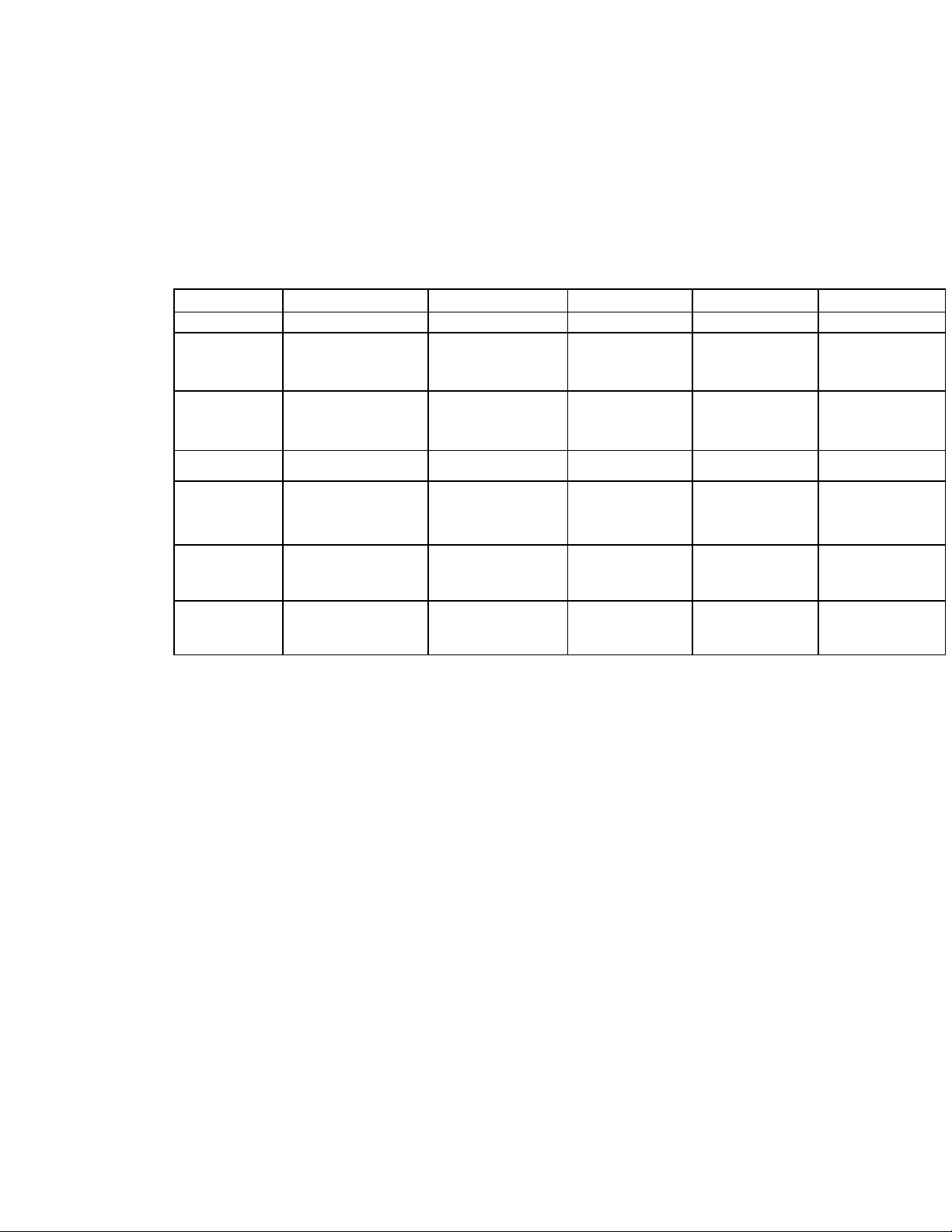

PACKING SIZE

WOODEN CASES SIZE

N.W

.

G.W.

TYPE

LxVVxH(cm)

LxWxH(cm)

(Kg)

(Kg)

BMFRS03

68x101x178

134x134x188

216

286

FLOOR TYPE

BMFRS02

68x91x158

80x110x106

176

216

FLOORTYPE

BMFRS01

68x81x158

80x100x106

156

192

FLOOR TYPE

BMCRS02

68x91x8S

80x110x100

124

150

BENCH TYPE

BMCRS01

68x81x88

80x100x100

118

140

BENC TYPE

1-3.WARNINGS

* To warn against risks inherent in use of the machine due to failure to observe the

safety regulations.

* Dough must be at room temperature to work with the sheeter.

* The machine must be used only for the purpose for which it has been designed. All

other uses are considered inappropriate and therefore unreasonable.

1-4.TRANSPORT INSTRUCTIONS

* Loading and unloading from the vehicle can be perfonned.

^ In particular the machine must not be placed on top of other materials and vice versa

either during transport or storage.

* During transport the machine must be positioned so that it cannot be knocked by

other materials loaded on the same vehicle.

sfc During unloading, place the machine carefully on the ground to prevent it being

knocked.

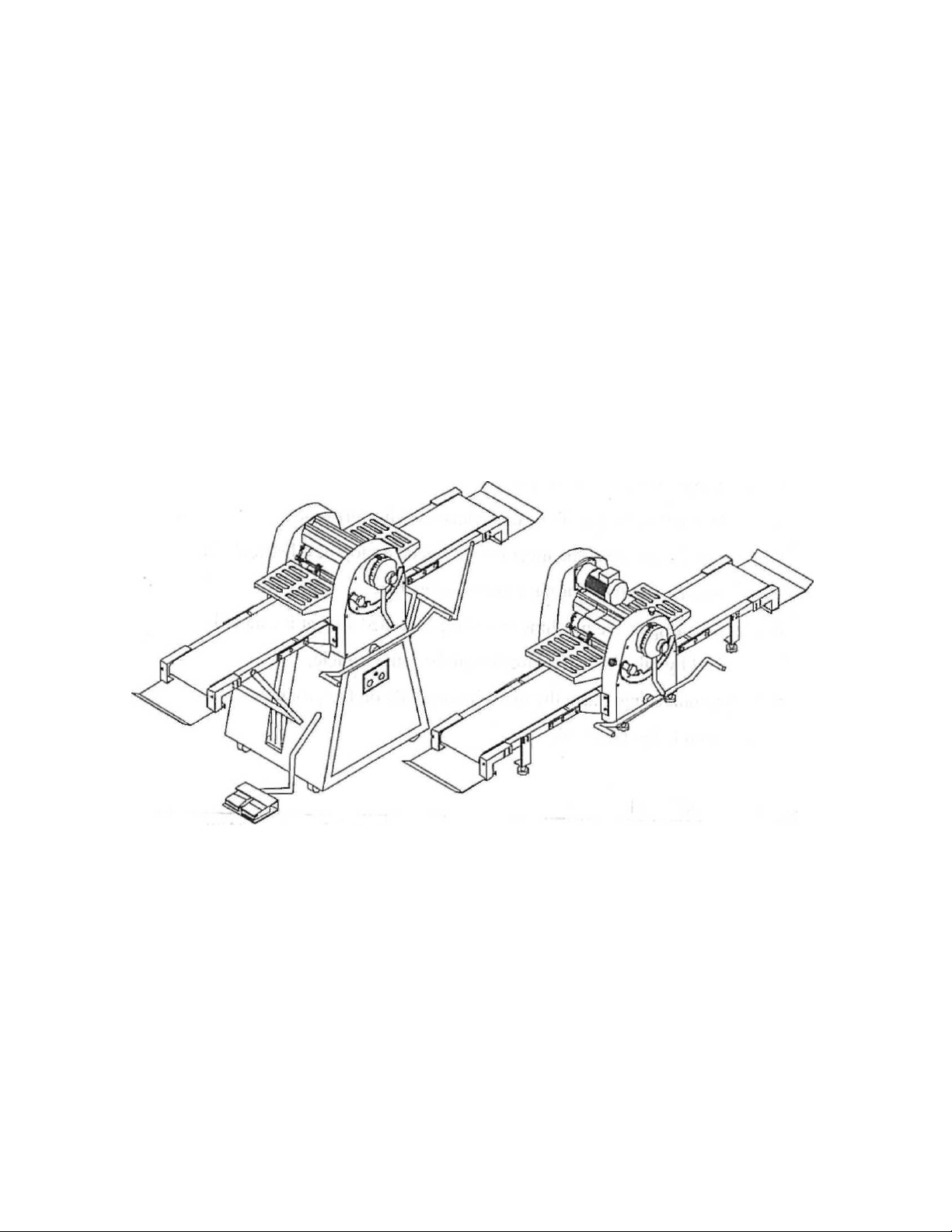

PACKAGING DATA :

ITEM

NAME

PURPOSE

1

Wheel

Move seat

2

Table strut

Support the conveyor

3

Extension catch pan

For protecting outflow sheet dough from falling

4

Conveyor belt

Transmission dough

5

Safety guard

protect operator in operating

6

Roller head housing

Protect of the roller

7

Movement control lever

Lever for rolling forth or back by hand control

8

Handle

Adjust the gap between upper and lower rollers

9

Indicate light

Light when switch on

10

Power switch

Start-slop switch

11

Stop switch

Emergency stop

12

Reversible running board

Switch for rolling forth or back by foot control

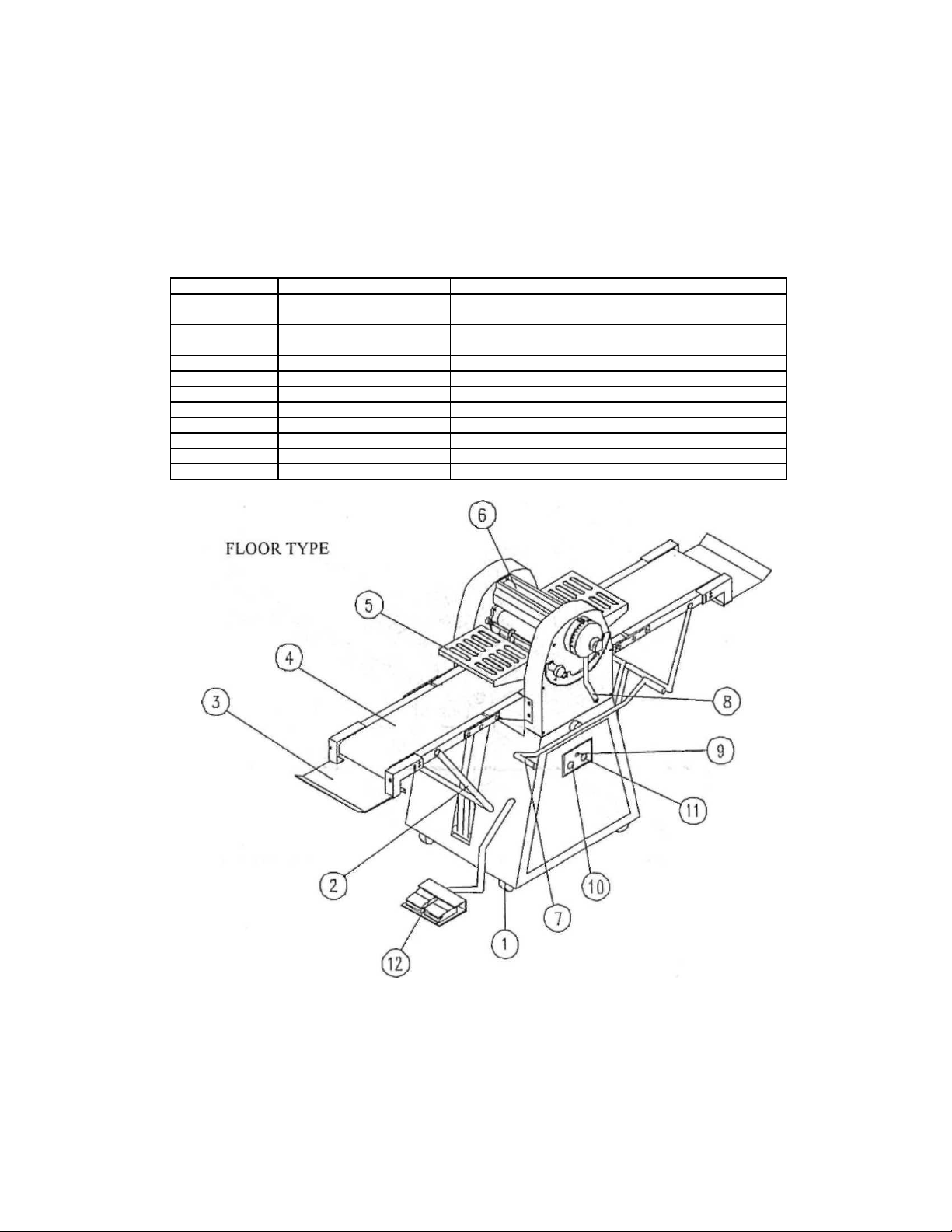

2. PARTS CHART OF MACHINE

2-l.MAIN DIMENSION AND NAMES OF MACHINE

ITEM

NAME

PURPOSE

1

Motor

Reducer motor

2

Table frame

Support the conveyor

3

Extension catch pan

For protecting outflow sheet dough from falling

4

Conveyor belt

Transmission dough

5

Safety guard

protect operator in operating

6

Roller head housing

Protect of the roller

7

Movement control lever

Lever for rolling foith or back by hand control

8

Handle

Adjust the gap between upper and lower rollers

9

Stop switch

Emergency stop

10

Power switch

Start-stop switch

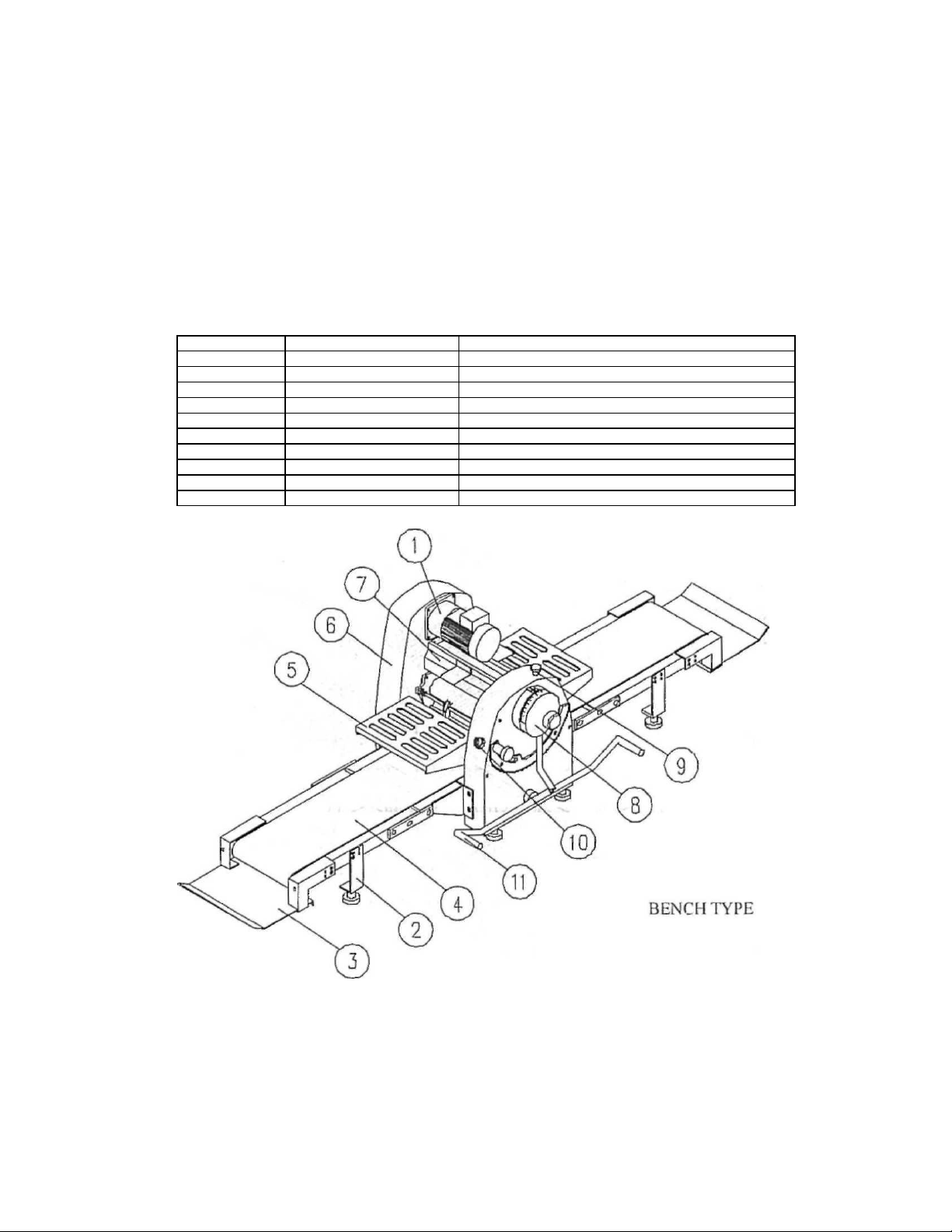

2. PAR CHART OF MACHINE

MODEL

BMFRS03

BMFRS02

BMFRS01

BMCRS02

BMCRS01

TYPE

FLOOR TYPE

FLOOR TYPE

FLOOR TYPE

BENCH TYPE

BENCI-I TYPE

Belt width

(mm)

650

520

450

520

450

Motor power

(HP)

1 1 1

1/2

1/2

Voltage (V)

220/380

220/380

220/380

220/380

220/380

N.W./GW.

(kg)

216/286

176/216

156/192

124/150

118/140

Machine size

LxWxH(mm)

2500x1010x1220

2100x910x1120

2100x810x1120

2100x910x600

2100x810x600

Fold size

~xWxY(mm)

700x1010x1900

700x910x1630

700x810x1630

700x910x800

700x810x800

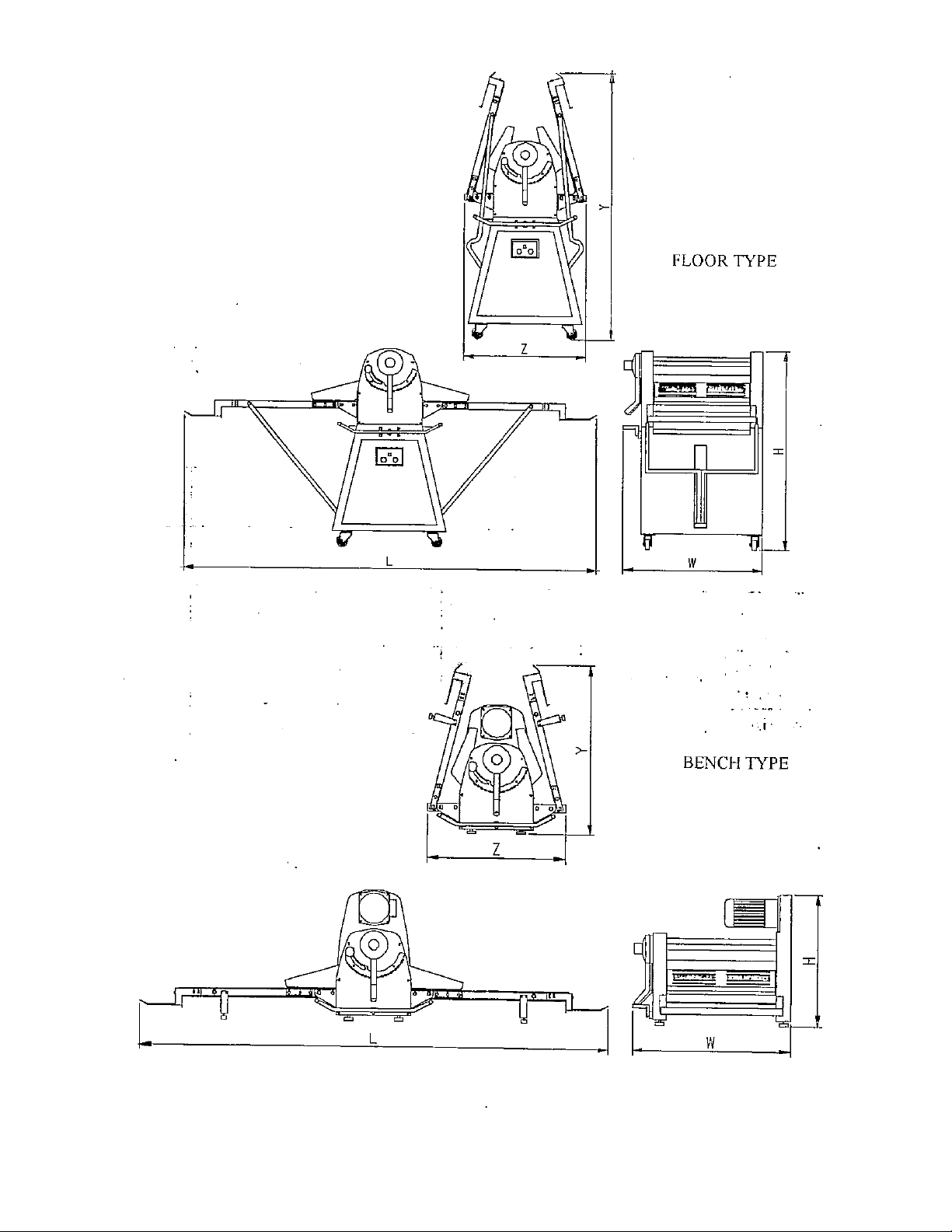

2-2. SPECIFICATIONS

8

3. MOUNTING OF MACHINE

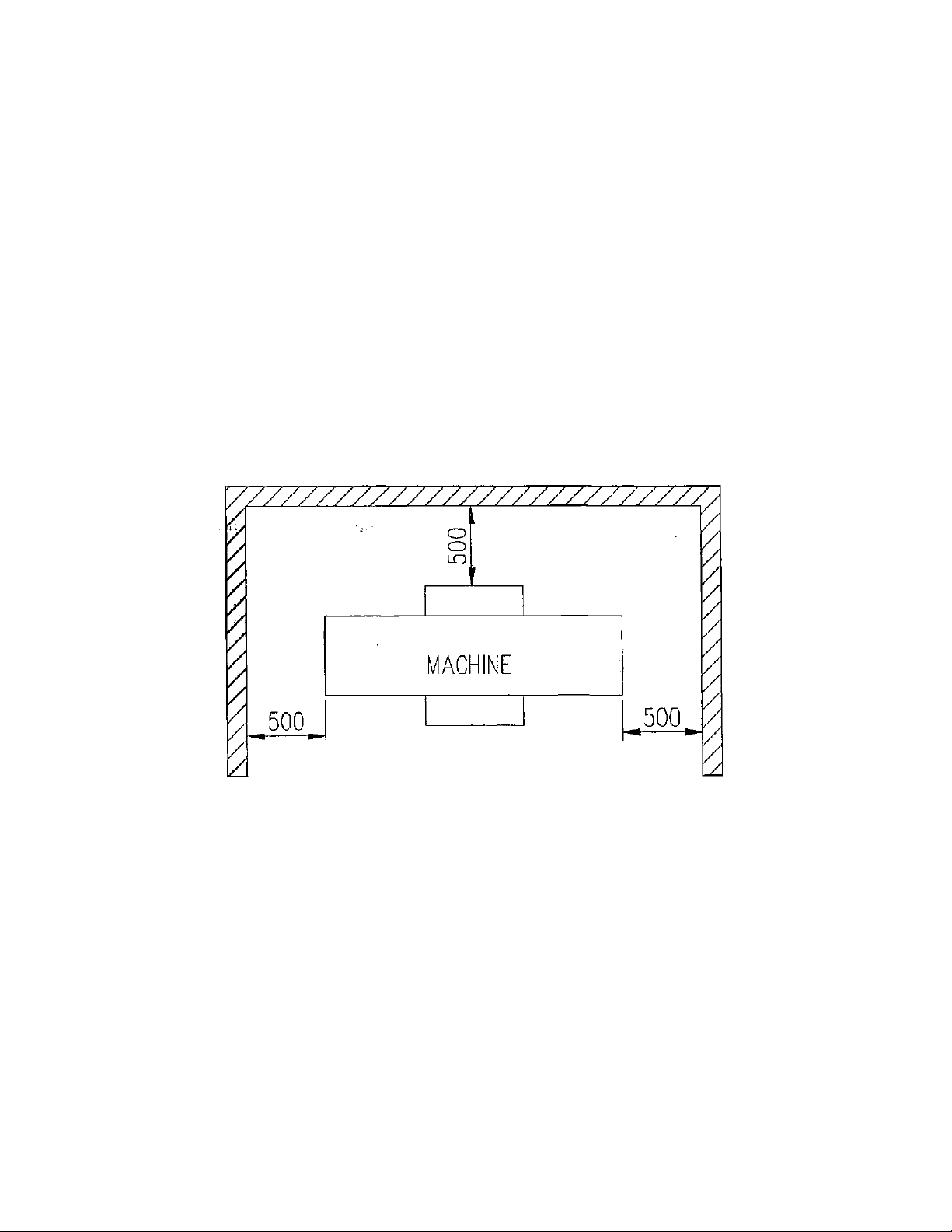

3-1. HOW TO MOUNT THE MACHINE

The machine must be installed on a horizontally-level floor. It should be pleased

in a location that is convenient for both operation and maintenance. The machine

safety features make it possible to stand close to the machine during operation.

Choose a suitable place for installing the machine, observing the minimum

distances from the walls as shown in the figure at the side. These spaces are

necessary for cleaning and routine maintenance operations and also ensure safe

operating conditions without the danger of dragging in and /or crushing.

The room must be provided with adequate lighting and ventilation.

Loading...

Loading...