Page 1

User Manual

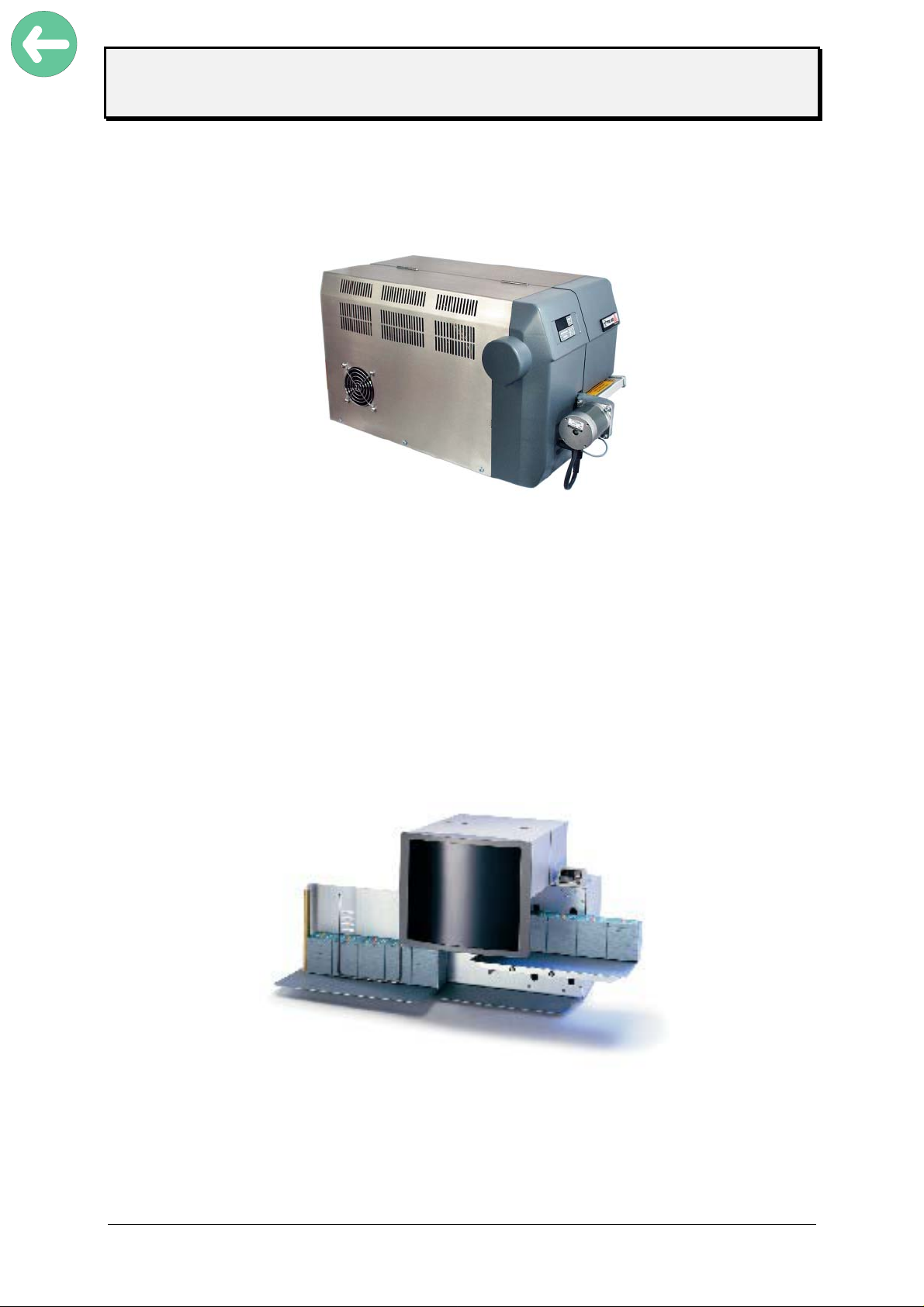

TTX 450/650/950/1050 – Puma/Lion/Tiger/Tiger XXL – TDI/STDI/XXtreme –

S45/65/95/105

User Manual

TTX 450/650/674/675/950/

1050 – Puma/Puma plus/Lion/

Lion plus/Tiger/TigerXXL –

S 45/65/95/105

TDI/XXtreme/S TDI

05/08 Rev. 2.14 1

Page 2

User Manual

TTX 450/650/950/1050 – Puma/Lion/Tiger/Tiger XXL – TDI/STDI/XXtreme –

S45/65/95/105

CONTENTS

General.................................................................................................................................4

Copyright..........................................................................................................................................4

IMPORTANT OPERATING INSTRUCTIONS..................................................................................4

Initiation................................................................................................................................5

Unpacking of Printer.........................................................................................................................5

Set - Up and Connection of Printer.................................................................................................6

Connections TTX: ..................................................................................................................... 6

Connections -TDI:.....................................................................................................................6

Connection of External Units............................................................................................................7

Card Plug in Modules.......................................................................................................................7

SLOTS TTX............................................................................................................................... 7

SLOTS TDI................................................................................................................................ 8

Card hardware..................................................................................................................................8

PCMCIA card pin assignment................................................................................................... 9

Memory types............................................................................................................................ 9

PROM card (Programmable Read Only Memory)....................................................................... 9

EPROM card (Erasable Programmable Read Only Memory).....................................................9

EEPROM or E²PROM (Electric Erasable Programmable Read Only Memory).......................... 9

FLASH RAM / PROM card........................................................................................................10

RAM card (Random Access Memory)....................................................................................... 10

Card use.........................................................................................................................................10

Card type........................................................................................................................................10

Set up mode.......................................................................................................................11

Winding Diagrams..........................................................................................................................11

TTX x50 / Wildcats.................................................................................................................. 11

TDI / XXtreme ......................................................................................................................... 11

Insertion of Document Material ......................................................................................................13

Material exchange..........................................................................................................................15

Insertion of fan folded material.......................................................................................................15

Insertion of Thermal Transfer Ribbon ............................................................................................15

Adjustment of ribbon unwind rewind tension..................................................................................17

Positioning of gap sensor...............................................................................................................18

Adjust position of printhead............................................................................................................19

Adjust pressure of printhead ..........................................................................................................19

Adjustment to thickness of material ...............................................................................................20

Installation of option .......................................................................................................................21

Short Tag Option................................................................................................................22

Fonts...............................................................................................................................................22

Modes of operation - operation...........................................................................................23

New Start of Printer.......................................................................................................................23

Restart of Printer............................................................................................................................23

Call of Program Version.................................................................................................................23

Modes of operation - OFFLINE......................................................................................................23

Modes of operation - OFFLINE......................................................................................................24

Modes of operation - ONLINE........................................................................................................25

05/08 Rev. 2.14 2

Page 3

User Manual

TTX 450/650/950/1050 – Puma/Lion/Tiger/Tiger XXL – TDI/STDI/XXtreme –

S45/65/95/105

Maintenance and cleaning..................................................................................................26

Cleaning the printhead...................................................................................................................26

Exchanging the printhead / TTX x50..............................................................................................27

Exchanging the printhead / TTX 67x..............................................................................................28

Cleaning of Print Roller ..................................................................................................................29

Clean feed roller for single tags -..................................................................................................30

TDI / XXTREME / S TDI only-........................................................................................................30

Clean Short Tag Option - TDI / XXTREME / S TDI only-..............................................................30

Cleaning of Punch-Recognition Sensor.........................................................................................30

Cleaning of ribbon guiding parts ....................................................................................................31

Cleaning of knifes - TTX 650 / LION / S 65 only -.....................................................................31

Other...................................................................................................................................32

MATERIAL AND RIBBON..............................................................................................................32

Material....................................................................................................................................32

Ribbons...................................................................................................................................32

Printer layout..................................................................................................................................33

Layout TTX.............................................................................................................................. 33

Layout TDI............................................................................................................................... 34

Technical Specification TDI............................................................................................................35

Label Stock Specifications......................................................................................................36

Ribbon specifications..............................................................................................................37

Fonts, Bar Codes....................................................................................................................37

Operating Features.................................................................................................................37

Connection, Device Data ........................................................................................................ 37

Certificates ..............................................................................................................................38

CE conformity.......................................................................................................................... 38

Service Data...................................................................................................................................38

INDEX.................................................................................................................................39

05/08 Rev. 2.14 3

Page 4

User Manual

TTX 450/650/950/1050 – Puma/Lion/Tiger/Tiger XXL – TDI/STDI/XXtreme –

S45/65/95/105

General

Copyright

This User Manual and its contents are subject to copyrightThe publisher’s prior written

consent must be obtained for reproduction of the manual as a whole or part thereof.

Names are generally given without any reference to existing patents, registered patterns or

designs, or trademarks. The omission of a corresponding note does not imply that the names

can be used freely. All trademarks are acknowledged.

The manufacturer reserves the right to technical and other alterations without prior notice.

The publisher cannot warrant the accuracy of the content of this manual.

Note: Please follow the notes shown in this text - it will help to cover all

situations and keep your engine working.

IMPORTANT OPERATING INSTRUCTIONS

The following warning hints and precautions contained in these Operating

Instructions must be strictly observed. This will considerable contribute to the safe

and expert operation of your printer.

Warnings: Exclusively original parts and accessories available from the manufacturer are to

be used to maintain the service life of your printer. The use of parts not in

compliance with the exacting demands made by the manufacturer may result in

unnecessary sources of danger.

The housing of the unit must exclusively be opened by authorised technical

personal.

Insertion/Exchange of foil and material should be carried out only by especially

instructed personnel (Set Up Mode!)

On operation with open cover, fingers, hair, clothes jewellery, et. may be caught

by and get into the unit in the foil-feed section . Do not expose or operate the

unit to moisture nor wet conditions.

Hazard of injury in the initialisation process and during cutting because of

moving knife

Remove printhead not until 3 minutes after disconnection of unit.

Re connect unit not until 10 seconds after disconnection’s.

Remove, insert or exchange Plug in Card not until 60 seconds after

disconnection of unit.

05/08 Rev. 2.14 4

Page 5

User Manual

TTX 450/650/950/1050 – Puma/Lion/Tiger/Tiger XXL – TDI/STDI/XXtreme –

S45/65/95/105

Initiation

Unpacking of Printer

• Remove top foamed packing.

• For removing the printer off the box, take it at the base plate only and lift.

A second person should assist by removing the cardboard box downwards.

Note: Front cover, motor of optional knife must not be used as carrying

handles.

• Set unit to a plain and stabile desk.

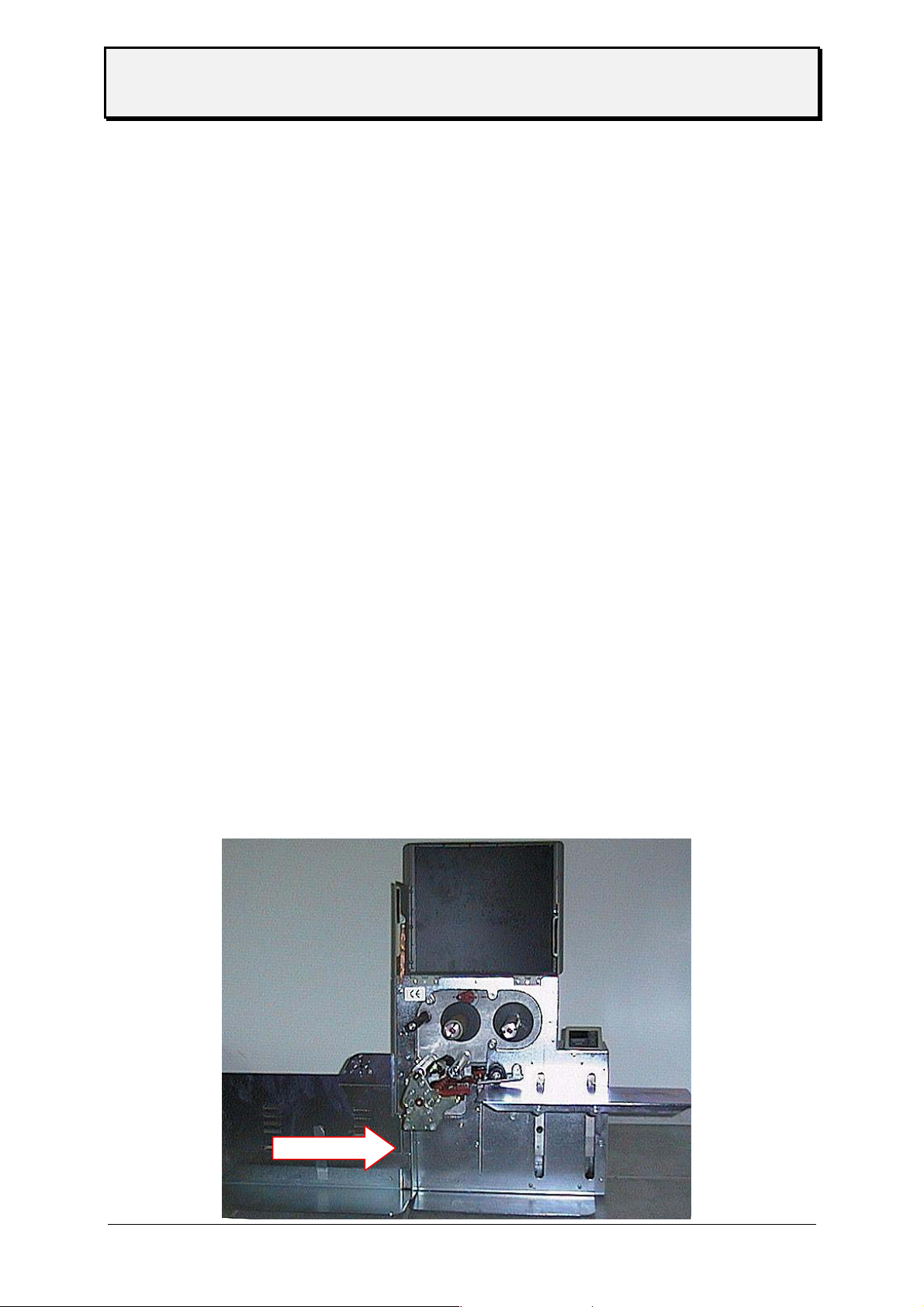

• -TDI / EXXTREME / S TDI only-

• Mount paper tray in and out, bow and length position stick according to picture

below

• Carry unit only by taking it at the base plate

Note: Front cover, motor of optional knife must not be used as carrying

handles.

05/08 Rev. 2.14 5

Page 6

User Manual

TTX 450/650/950/1050 – Puma/Lion/Tiger/Tiger XXL – TDI/STDI/XXtreme –

S45/65/95/105

Set - Up and Connection of Printer

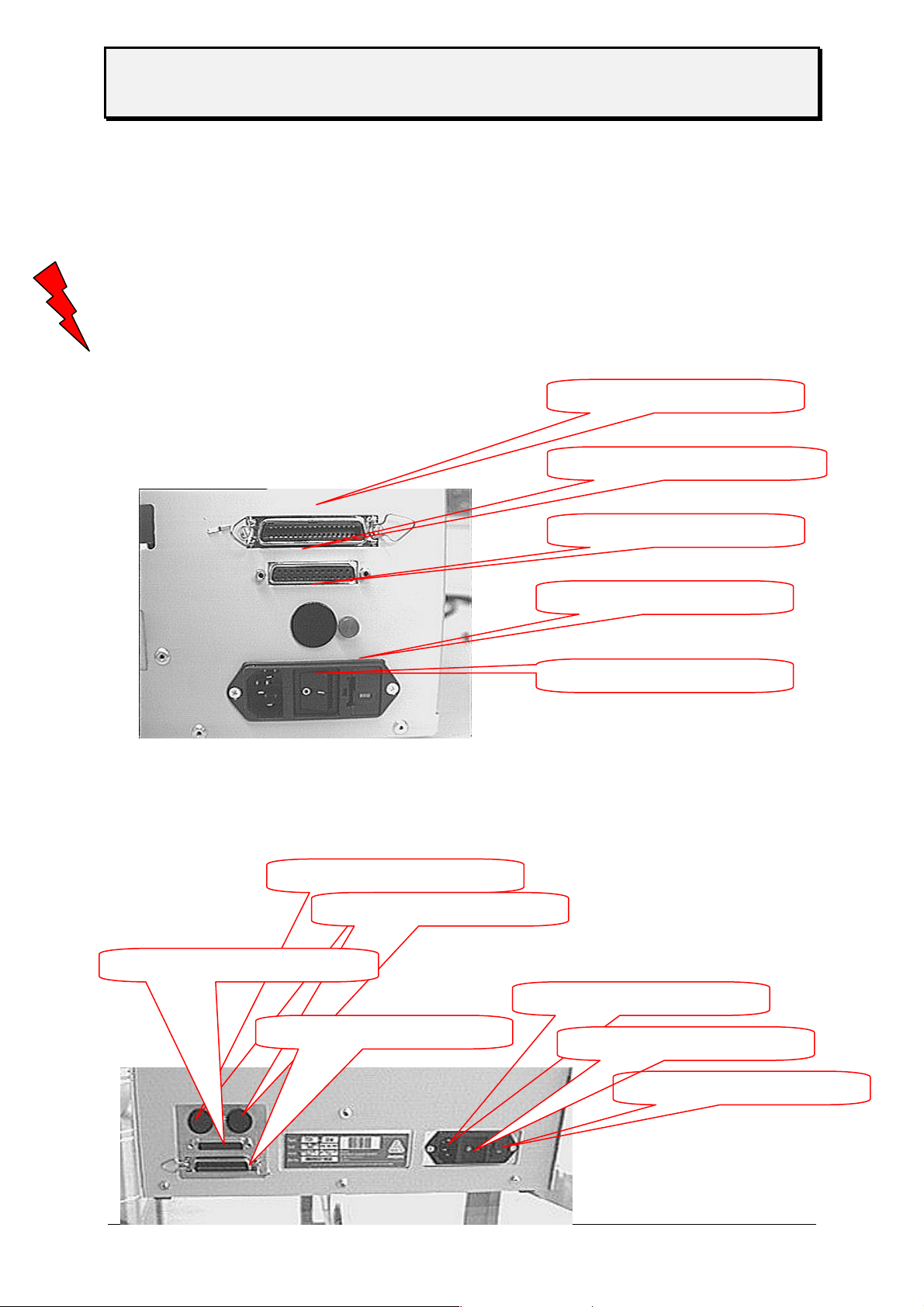

• Check mains voltage setting and fuses.

• The fuses can be replaced by turning the inserts .

Attention: Unplug mains power plug before checking/changing mains voltage or fuses!

Centronics (parallel)

Connections TTX:

serial Inteface (RS 232 / RS

optionale connector

power select

power ON/OFF switch

Connections -TDI:

serial Inteface (RS 232 / RS

0

optionale connector 1

optionale connector 2

Centronics (parallel)

main power inlet

power ON/OFF switch

power select

05/08 Rev. 2.14 6

Page 7

User Manual

TTX 450/650/950/1050 – Puma/Lion/Tiger/Tiger XXL – TDI/STDI/XXtreme –

S45/65/95/105

Connection of External Units

A serial interface V.24/DB25 (RS232) and a parallel interface (Centronics) are

integrated as standard for connection of the printer to the computer.

Optional there is a RS 485 interface available - the RS 232 can be (factory

installed) removed and changed to a RS 485 interface. Be aware that the RS

232 interface then is removed !

The rear side of the unit is, in addition, equipped with one ore two sockets for the

connection of an external unit.

Attention: Turn off unit prior to plugging/unplugging interface cable/stacker connector

Exclusively units tested in accordance with IEC 950 and VDE 0805-which are in

compliance with these standards according to SELV- must be connected to

interface and stacker socket.

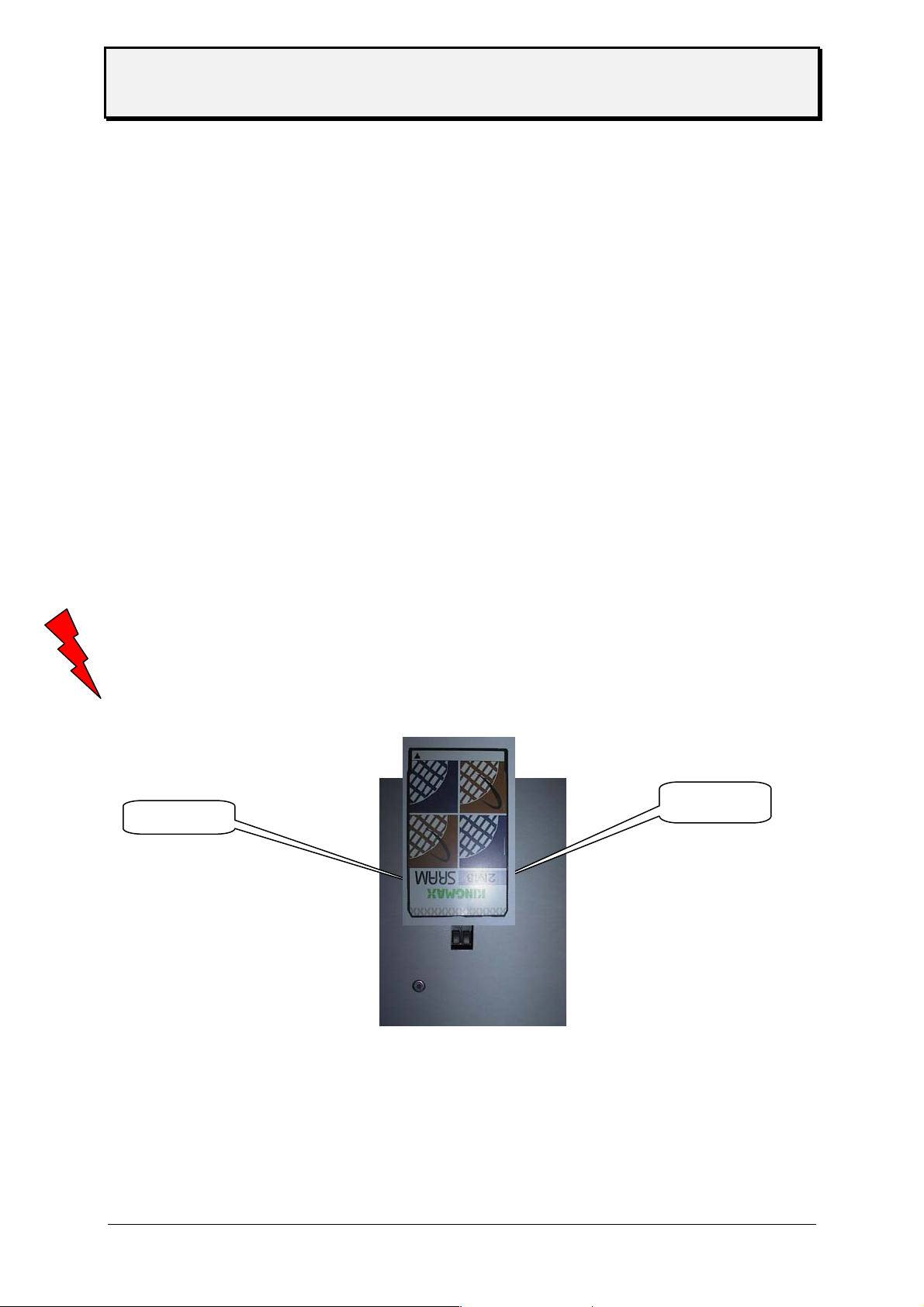

Card Plug in Modules

These plug in modules are provided for the optional font and logo cards. Use

PCMCIA cards up to a size of 2 MB only. There is a maximum of 1 logo card

alone or together with a font card – as well one or two font cards are possible.

Logo Cards and data bank cards are formatted by the printer itself.

Font cards are to be programmed by supplier only.

Attention: Exclusively plug in cards approved by the manufacturer must be used Insert,

remove, or exchange card not until 60 seconds after disconnection of unit.

SLOT 0

SLOT 1

SLOTS TTX

05/08 Rev. 2.14 7

Page 8

User Manual

TTX 450/650/950/1050 – Puma/Lion/Tiger/Tiger XXL – TDI/STDI/XXtreme –

S45/65/95/105

SLOTS TDI

Card hardware

printer

type

card

type

quantity

card

memory

of card

PROM

card

S-RAM

card

Flash

card

SLOT 1

TTX 450/650/950/1050/Puma/Lion/

Tiger/Tiger XXL

TDI PCMCIA 2 2 MB - yes yes

PCMCIA 2 2 MB - yes yes

SLOT 0

05/08 Rev. 2.14 8

Page 9

User Manual

TTX 450/650/950/1050 – Puma/Lion/Tiger/Tiger XXL – TDI/STDI/XXtreme –

S45/65/95/105

PCMCIA card pin assignment

Pin 34

Pin 1

Pin 68

Pin 35

Memory types

PROM card (Programmable Read Only Memory)

Programmable only with a special program unit (EPROM burner) – it is a on time card,

normally used to store fonts and logos witch are used again and again in the same shape

size or look like. The card will be programmed in the factory due to the customer wishes.

Memory size and capacity depends to the printer.

EPROM card (Erasable Programmable Read Only Memory)

Programmable only with a special program unit (EPROM burner) – it is a on time card,

normally used to store fonts and logos witch are used again and again in the same shape

size or look like. The card will be programmed in the factory due to the customer wishes. The

difference between EPROM and PROM card is that the EPROM card can be cleared by

using ultra violet light.

Is not used in our printer.

EEPROM or E²PROM (Electric Erasable Programmable Read Only Memory)

The function is similar to an EPROM card – to clear the memory there is no light used, it

works with electric power. The clear procedure is very slow. The data are hold in the memory

after power down – without battery !

Is not used in our printer.

05/08 Rev. 2.14 9

Page 10

User Manual

TTX 450/650/950/1050 – Puma/Lion/Tiger/Tiger XXL – TDI/STDI/XXtreme –

S45/65/95/105

FLASH RAM / PROM card

A name used and defined by the company INTEL witch has used this technology first. The

memory is build similar to the EEPROM but can be cleared in single sectors. A low voltage

(5V) is enough to clear the memory and this voltage is available in the most places

(PC/printer). The clear procedure is very fast, the data’s are stored in the memory after

power down – without battery.

This card is re programmable and can be programmed in a PC with the data’s. Stored on this

card type can be fonts and logos – same as on the EPROM card. In difference it is possible

to store as well formats.

Memory size is different depending on card type and printer.

RAM card (Random Access Memory)

Very fast, volatile memory. Each single memory cell is programmable and readable. Using

RAM card means that a battery is used to make the memory non volatile- the data’s are still

in the memory after power is switched off, reasoned by the power of the battery.

The card type is re programmable and depending on the printer type the card can be

programmed in the printer (via down load) or at the PC. It is possible to store – similar to the

EPROM card, as well logos fonts but different to the EPROM card as well formats.

Memory size is different depending on card type and printer.

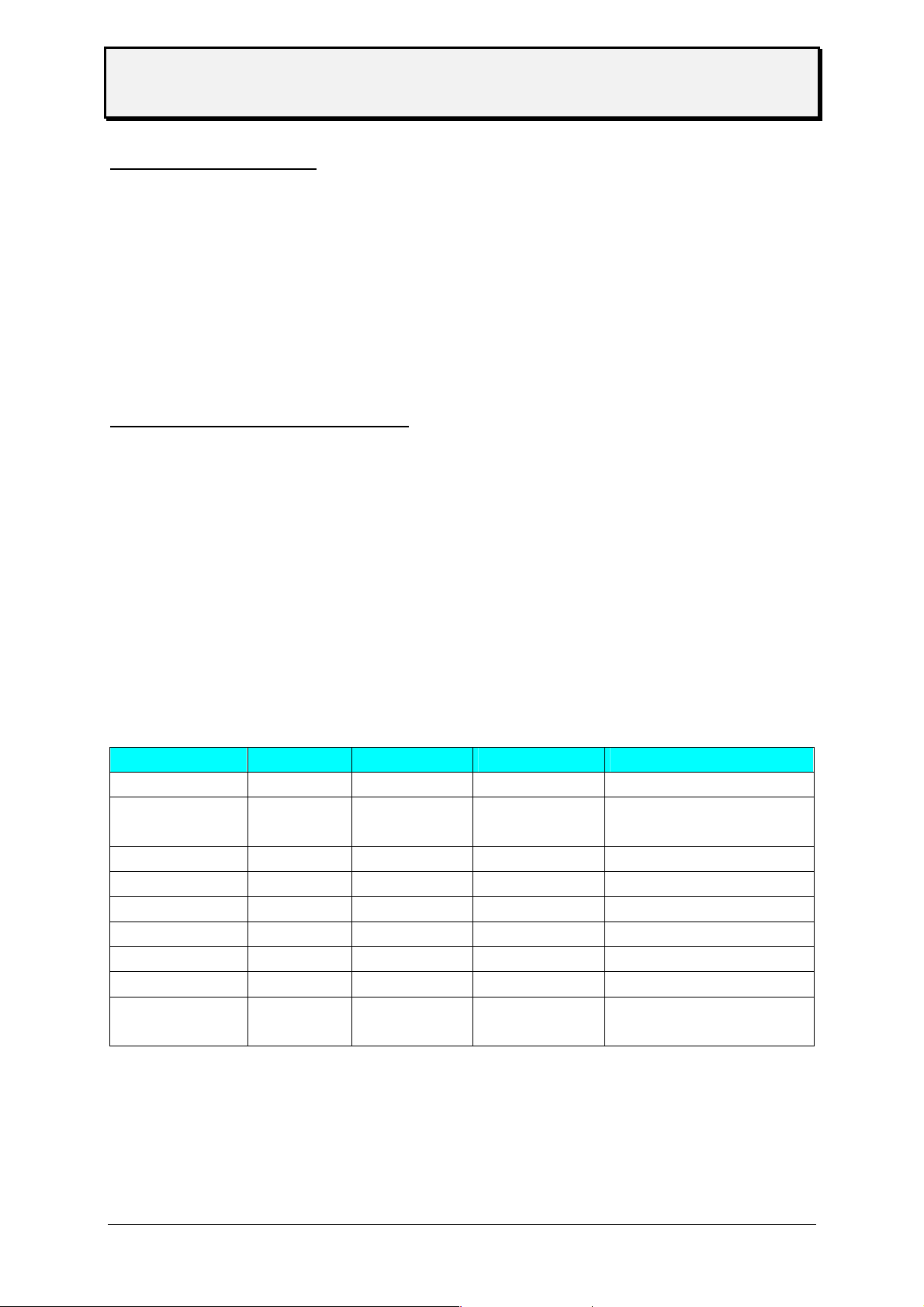

Card use

Depending on the printer type the cards can be used different. Attached you will find a table

showing card type, menu point to clear the card – where the card has to be formatted – and

as well the quantity of files.

card type menu point formatting formatting quantity of files

Easy Card

Format Card

Logo Card LCLR intern --Font Card DOWN intern DOS one, „V55_CARD.BIN“

Speedo Card DOWN intern DOS one, „PROMFILE.BIN“

DOS Card --- DOS as much as you want

Database Card DOWN intern one & Index

Barcode Card --- intern --Image Card ICLR intern ---

--- DOS as much as you want

(max. memory)

Card type

Note: For more information please refer to the card manual.

05/08 Rev. 2.14 10

Page 11

User Manual

TTX 450/650/950/1050 – Puma/Lion/Tiger/Tiger XXL – TDI/STDI/XXtreme –

S45/65/95/105

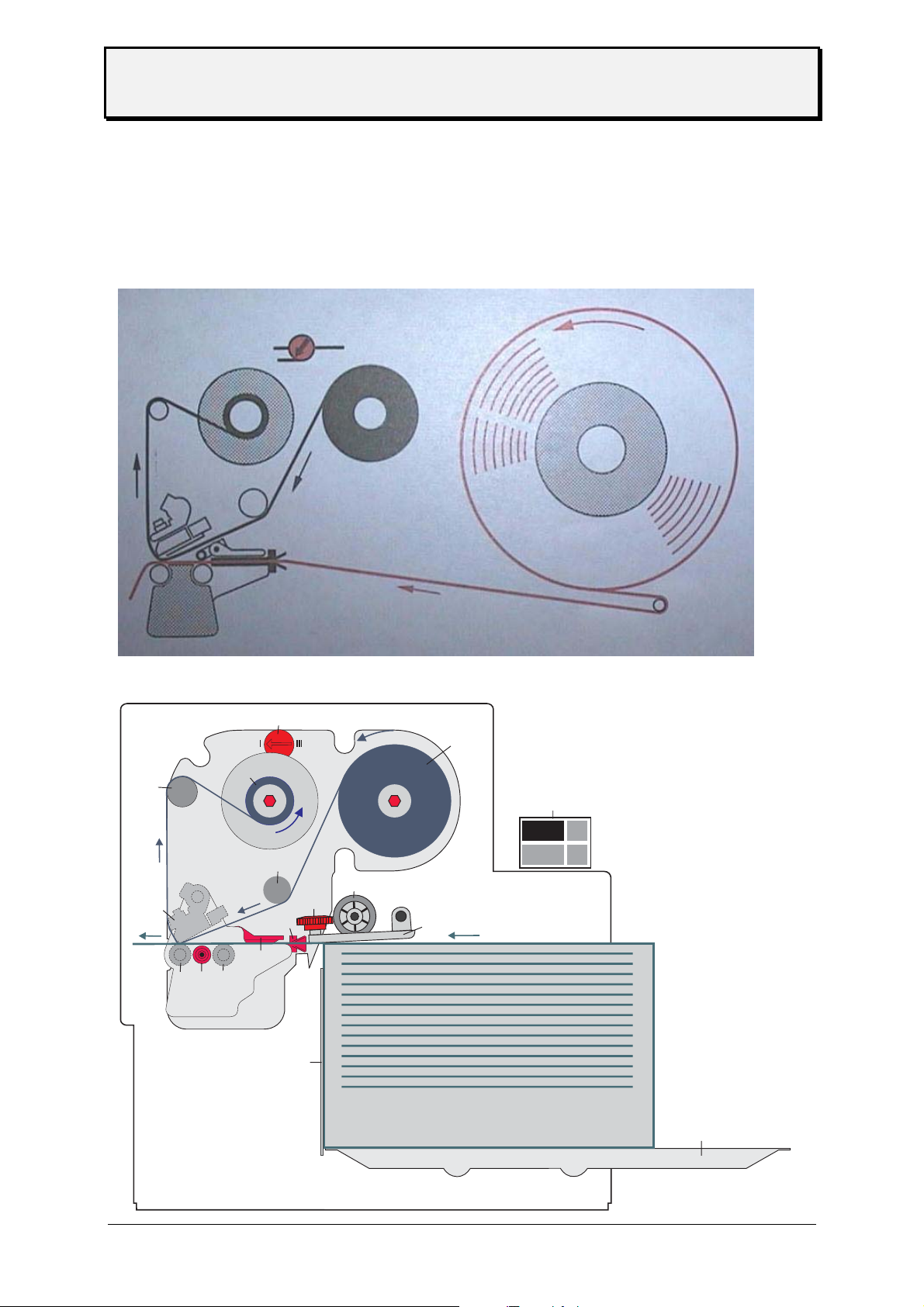

Set up mode

Winding Diagrams

TTX x50 / Wildcats

TDI / XXtreme

4

3

10

15

5

9

16

17

1

14

2

7

11

8

13

12

6

Z0133.cdr

05/08 Rev. 2.14 11

Page 12

User Manual

TTX 450/650/950/1050 – Puma/Lion/Tiger/Tiger XXL – TDI/STDI/XXtreme –

S45/65/95/105

Please follow during media / ribbon change the upper diagrams ! This is showing

the used directions of ribbon and media ( insert ribbon – insert media)

Attention : Sometimes it is helpful to release the head and rotate the head to insert ribbon

into the printer (esp. For TTX 450 / Puma / S 45) ! As well rotating the head

means that the wires connected to the head can be to short – then please

disconnect the wires – only if the printer is switched OFF ! Do not forget to

connect again – and check if the connectors are properly mounted !

This is shown in the following chapters as well.

05/08 Rev. 2.14 12

Page 13

User Manual

TTX 450/650/950/1050 – Puma/Lion/Tiger/Tiger XXL – TDI/STDI/XXtreme –

S45/65/95/105

Insertion of Document Material

Attention: Insertion/exchange of foil and material should be carried out only by especially

instructed personal.

• Open front over

• -TTX 650 / LION / S65 only-

Hang document material in reel holder in a way to ensure anticlockwise

unwinding. Put outer guide disk onto mandrel.

Guide material around the dancer.

05/08 Rev. 2.14 13

Page 14

User Manual

TTX 450/650/950/1050 – Puma/Lion/Tiger/Tiger XXL – TDI/STDI/XXtreme –

S45/65/95/105

• - only for TTX 1050

there is a special support which has to be opened before media can be loaded

or removed.

After removal or change of media – please close the support again.

-TDI/ EXXTREME/S TDI onlyMove paper tray down by means of simultaneously pressing ON/OFFLINE and

CUT key. Insert material to the left/rear corner of tray. Move paper tray up by

means of simultaneously pressing ON/OFFLINE and FEED key.

• Adjust lateral material guides (red) that the material may move easily.

-TTX 650/ LION / S 65 onlyPress the red lift lever at the right, outer end of the print module in order to lift the

pressure rolls of the feed roller and insert material below the printhead.

• Adjust both pressure roll units symmetric to material with so that material moves

smoothly.

• On printer versions with installed knife a straight cut edge is required for perfect

material insertion.

Attention: Do not touch feed unit with your free hand. The optional knife may cause

injuries with wrong key manipulations! On operation with open cover, fingers,

hair, clothes, jewellery, etc. may be caught by and get into the unit in the ribbon

feed section.

05/08 Rev. 2.14 14

Page 15

User Manual

TTX 450/650/950/1050 – Puma/Lion/Tiger/Tiger XXL – TDI/STDI/XXtreme –

S45/65/95/105

Material exchange

• Switch printer to OFFLINE mode and lift printhead by brief pressing of the

(FF)-key.

• Remove material by pressing the red lift lever and drawing the material

backward.

• -TTX 650 / LION / S 65 only-

By pressing the ON/OFFLINE and CUT key simultaneously the material will be

transported backward.

• -TDI / EXXTREME / S TDI only-

Move paper tray down by means of simultaneously the material will be

transported backwards automatically.

• Remove material off the mandrel or paper tray.

• For continuing steps see description above.

Insertion of fan folded material

• -TTX 650 / LION / S 65 only-

• Remove blade at rear side of unit.

• Set outer material guide disk according to width of material.

• Insert material with imprint side up.

• For continuing steps see description: Insertion of material.

Insertion of Thermal Transfer Ribbon

• Attach ribbon reel onto foil mandrel on the right-hand side for anticlockwise unwinding of

ribbon. Attach empty ribbon core onto mandrel on left-hand side.

• Insert ribbon end diagonally from the front under print-head holder or between knife cover

and printhead holder with open hinge drive mechanism. If foil is changed during a print job,

lift print head by short depression of the FF key.

05/08 Rev. 2.14 15

Page 16

User Manual

TTX 450/650/950/1050 – Puma/Lion/Tiger/Tiger XXL – TDI/STDI/XXtreme –

S45/65/95/105

• Pull ribbon upward and simultaneously move it towards printer.

• Guide ribbon around feed roller and attach it to ribbon core in anticlockwise direction

(ribbon may be folded so that adhesive part at start of ribbon can be used).

• -TTX 650/ LION / S 65 only-

By simultaneous depression of the (ON/OFFLINE)-and (FF)-keys, material and ribbon can

be advanced until perfect unwinding of ribbon is warranted.

• -TDI/XXTREME / S TDI only-

By pressing 2x the CUT key at OFFLINE mode at the display appears FOIL.

Subsequently by depressing the ON/OFFLINE key, the ribbon may be fed. Leave operation

by pressing FFED key 2 times back to OFFLINE mode.

Attention: Fingers, hair, clothing, jewellery, etc. may be caught by and get into the unit in

the ribbon feed section!

05/08 Rev. 2.14 16

Page 17

User Manual

TTX 450/650/950/1050 – Puma/Lion/Tiger/Tiger XXL – TDI/STDI/XXtreme –

S45/65/95/105

• - only for TTX 1050

Similar to the media unwind – the ribbon mechanic is supported as well. Open the handle to

remove / change ribbon and close the support again.

Adjustment of ribbon unwind rewind tension

The torque of ribbon unwind and rewind mandrels are adjustable by means of the red

hexagon pin .

The ribbon should run free of wrinkles respectively should not be stretched (especially at

drum section) over the whole run from roll to roll.

Increase of torque at unwind rewind mandrel Ribbon must not be stretched

Decrease of torque at unwind rewind mandrel Ribbon must not have wrinkle

The factory adjustment covers a wide range of ribbon width which is the main factor for

the torque. Use of very narrow and very wide ribbon however may need a readjustment.

05/08 Rev. 2.14 17

Page 18

User Manual

TTX 450/650/950/1050 – Puma/Lion/Tiger/Tiger XXL – TDI/STDI/XXtreme –

S45/65/95/105

Positioning of gap sensor

Depending on the printer different sensor are possible. Using the TDI two sensor are

available – through light and reflective. Using the TTX three sensor are possible (through

light, reflective and full size).

Between trough light and reflective there is a difference of 11 mm (adding). The optional full

size sensor is behind the standard sensor. The sensor can be moved across the web – and

the gap can be sensed . The minimum label width is extended to 38 mm.

Adapt sensor to the position of the gap by means of the adjusting knob located at the front

side of the print module. Adjustment range: 2-15mm across the web.

• A scale is marked around the knob

• Calculate position as follows. Measure distance between center of gap and left

edge of material reduce value. by 2 the results matches the adjustment value at

the scale

Sample :

Distance between center of gap and left edge of material 11mm

Reduction - 2mm

Adjustment value 9mm

With round labels punch - offset pre adjustment is possible at the printer (parameter

PUNO) or via Easy Plug command in order to correctly catch the label edge.

05/08 Rev. 2.14 18

Page 19

User Manual

TTX 450/650/950/1050 – Puma/Lion/Tiger/Tiger XXL – TDI/STDI/XXtreme –

S45/65/95/105

Adjust position of printhead

The zero line of the printhead can be varied from 2 - 13 mm of the left material edge

(this is only true for TTX 650, 950, 1050, TDI – not for the TTX 450)

• Loosen screw at center of printhead axle and set printhead to required

position.

Attention: Printhead must not be plugged off !

• Fix screw

• Loosen black plastic disk at ribbon rewind and unwind mandrell by means of 2

mm

allen key

• Adapt them both to position of printhead zero line and tighten again

Adjust pressure of printhead

Different material width may require different pressure of printhead to material in order to

optimise the print quality.

• 3 grades are available.

• Rotate the adjustment disk by means of a coin or screwdriver to the required

position.

Note: Select pressure only as high as necessary for the best print quality. Too

high pressure may lead to damages at the printhead.

thin media / small media

thick media / wide media

05/08 Rev. 2.14 19

medium media / medium

Page 20

User Manual

TTX 450/650/950/1050 – Puma/Lion/Tiger/Tiger XXL – TDI/STDI/XXtreme –

S45/65/95/105

Adjustment to thickness of material

• -TDI/EXXTREME / S TDI only-

The function of separating / transport roll at the paper tray has to be adapted to different

thickness off materials in order to ensure a correct label run.

The adjustment wheel is located between paper tray and lateral material guide, a bit offset in

the base plate of the print module. It carries a red, a yellow and a green arrow.

Adjust following:

• When using thin material 2 and/or more Rotate wheel clockwise

tags are drawn in

• When using thick material, Rotate wheel anticlockwise

none tag will be drawn in

The coloured arrows may be positioned at the wheel in order to set marks for different types

of tags.

Clip

05/08 Rev. 2.14 20

Page 21

User Manual

TTX 450/650/950/1050 – Puma/Lion/Tiger/Tiger XXL – TDI/STDI/XXtreme –

S45/65/95/105

Installation of option

for TTX 650 / LION / S 65

Attention: Some of the options – like the dispenser module can only be mounted by service

personal ! Sometimes it is necessary that a module can be imbedded only from a

defines series number – see option manual.

Unplug main power supply!

• Plug light-barrier connector and motor connector in. Both sockets are

located at front side of housing.

• Fasten unit by means of 2 hexagon socket screws at vertical base plate

of printer.

• Reconnect power supply and switch unit on.

Attention: Hazard of injury in the initialisation process and during cutting because of moving

knife!

• to activate the option go the parameter ‘PEPH’ and select the option with the

necessary parameter

• follow the steps in the option manual

A special case is the color option – therefore you have to install a separat firmware

and add an additional sensor. For more details refer to the color manual.

connecting

05/08 Rev. 2.14 21

Page 22

User Manual

TTX 450/650/950/1050 – Puma/Lion/Tiger/Tiger XXL – TDI/STDI/XXtreme –

S45/65/95/105

Short Tag Option

- for TDI / XXTREME / S TDI-

This option is used to handle short label (between 50 mm and 105 mm). The short tag option

is a second feed system driven by the main feed roller. A belt is connecting the main feed

roller with the short tag option. The label is transported from the separator to the short tag

option and from there to the feed section of the printer.

Attention: The option can be mounted to a printer by a service technician from a defined

serial number on ! From serial number SN 6800131605 on you can upgrade the

unit definitely ! This can only be done by a service technician.

Activate the shot tag option under menu point SECF (select YES)

OFF

INFO PRTP IFAC SYSP

EMUL

NACH

SENS

PUNS

FMOD

OMOD

SMOD

MMOD

LPOS

SECF

YES?

Fonts

Most the fonts used in the printer firmware are proportional – only the OCR fonts are non

proportional. This is given by the specs of this fonts.

Proportional font this means that all characters have a specific width

Non proportional font all characters have the same width

05/08 Rev. 2.14 22

Page 23

User Manual

TTX 450/650/950/1050 – Puma/Lion/Tiger/Tiger XXL – TDI/STDI/XXtreme –

S45/65/95/105

Modes of operation - operation

New Start of Printer

Connect printer to main power

Connect printer to computer

Switch on printer Display: OFF

Switch located at rear side of unit

Acknowledge by ON/OFFLINE key Display: ON

The printer is ready to receive data via the selected interface

Restart of Printer

Restart of printer without disconnection of unit by simultaneous operation of all three keys.

Note: All data stored in the printer will be deleted.

Call of Program Version

The program version is displayed during Reset – example 1H34

05/08 Rev. 2.14 23

Page 24

User Manual

TTX 450/650/950/1050 – Puma/Lion/Tiger/Tiger XXL – TDI/STDI/XXtreme –

S45/65/95/105

Modes of operation - OFFLINE

‘FEED’ and ‘CUT’ simultaneously = program or ‘ESC’

‘FEED’ -’CUT’ and ON/Offline simultaneously = Reset

OFFLINE MODE TTX 450, 650, 950 - S 45, 65, 95 - Puma, Lion, Tiger

Display Key Display function

OFF ON/OFFLINE ON ready to receive

OFF ON/OFFLINE FEED <-- slow media and ribbon movement

OFF ON/OFFLINE CUT cut and media backwards

OFF FEED FEED feed of media

OFF CUT CUT cut ( if the optional cutter is available)

OFF FEED CUT INFO enter the parameter menu

OFFLINE MODE TDI, XXTREME, S TDI

OFF ON/OFFLINE ON printer is ready to receive data

OFF ON/OFFLINE FEED UP move magazine up, if parameter MMOD = TAG

OFF ON/OFFLINE CUT DOWN move magazine down, if parameter MMOD = TAG

OFF FEED FEED feed of media

OFF CUT FOIL slow ribbon feed, to stop press CUT

ON/OFFLINE

OFF FEED CUT INFO enter parameter menu

status message

ST .. ON/OFFLINE press key to cancel the status

FEED turn off acoustic signal

CUT leave status message to OFFLINE mode

05/08 Rev. 2.14 24

Page 25

User Manual

TTX 450/650/950/1050 – Puma/Lion/Tiger/Tiger XXL – TDI/STDI/XXtreme –

S45/65/95/105

Modes of operation - ONLINE

‘FEED’ and ‘CUT’ simultaneously = program or ‘ESC’

‘FEED’ - ‘CUT’ and ON/OFFLINE simultaneously

= RESET

ONLINE MODE

Display Key Display function

ON FEED CUT HV.. energy

changing with FEED - (less)

changing with CUT + (more)

WAIT not possible WAIT image built up

XXXX display quantity of printable label including the one in

process

XXXX ON/OFFLINE STOP the label in process will be finished then the display starts

flashing

XXXX

STOP ON/OFFLINE OFF change to OFFLINE mode (quantity unchanged)

XXXX

OFF ON/OFFLINE STOP OFFLINE Mode – printout is stopped

XXXX

STOP FEED XXXX print job start again

XXXX

Parameter menu coming from OFFLINE Modus

Display key display function

OFF FEED CUT INFO enter parameter menu

INFO FEED CUT OFF leave parameter menu

INFO FEED selection

INFO CUT selection

05/08 Rev. 2.14 25

Page 26

User Manual

TTX 450/650/950/1050 – Puma/Lion/Tiger/Tiger XXL – TDI/STDI/XXtreme –

S45/65/95/105

Maintenance and cleaning

Clean printhead and feeding roller with cleaning liquor from paper, adhesive

and ink deposits at regular intervals.

Cleaning the printhead

• Disconnect unit

Attention: Pull off mains plug!.

•.Remove material and ribbon.

• Loosen hexagon socket screw at center of printhead axle by means of a

2mm allen key, until the printhead can be rotated clockwise.

Attention: The printhead is an electronic module and highly sensitive to static impacts. For

that reason discharge your static potential before going in contact with the

printhead by gripping the base plate of the printer. Do not remove plugs from the

printhead. If printhead is readjusted at axle mark ist position accordingly.

• Clean print roller with dust-free cloth and cleansing liquor only.

Attention: Never use knives or objects with sharp edges for cleaning. Metal objects must

never get in contact with the dot line.

• Put printhead to former position and fix screw again.

Note: The screw enters a non visible gap at the axle, which ensure the correct

position of the printhead. Factory adjustment is flash with the inner black

plastic bushing.

• Before switch on the unit, check that both connectors of printhead are still

plugged on correctly. Reconnect if necessary.

05/08 Rev. 2.14 26

Page 27

User Manual

TTX 450/650/950/1050 – Puma/Lion/Tiger/Tiger XXL – TDI/STDI/XXtreme –

S45/65/95/105

Exchanging the printhead / TTX x50

1. Disconnect unit

Attention: Pull out the mains plug!

2. Remove material and ribbon.

3. Remove plugs from printhead in horizontal direction.

Note: Remove printhead cable from printhead not until 3 minutes from

disconnection of unit.

4. Loosen the 2 red marked screws at fixation of printhead.

5. Loosen screw at center of printhead axle - until the printhead fixation can be

rotated clockwise.

Attention: The printhead is an electronic module and highly sensitive to static impacts. For

that reason discharge your static potential before going in contact with printhead

by gripping the base plate of the printer. If printhead is readjusted at axle mark

its position accordingly.

6. Let the printhead down to print roller and rotate the fixation clockwise.

7. Draw printhead carefully out of the print module.

Attention: Metal objects must never get in contact with the dot line. Do not touch printhead

at dot line or connectors.

8. For reassembling putt the printhead on the 180° rotated fixation, positioning is

done by means of the 2 upright bolts.

Note: Before mounting notice the resistor value of the printhead-noted at

printhead. Special care is to be taken that printhead is supported flush on

mounting plate.

9. Keep printhead and fixation together with fingers, rotate anticlockwise to print

roller.

10. Refix printhead by means of the 2 red marked screws at fixation bar.

11. Put printhead on axle to former position and fix screw again.

Note: The screw enters a non visible gap at the axle, which ensures the correct

position of the printhead. Factory adjustment is flash with the inner black

plastic bushing.

12. Plug on the 2 connectors to printhead.

13. When exchanging the printhead the value of the head resistor has to be keyed in

after restart.

Attention: Entry of an incorrect value may damage the printhead!

14. Repositioning of printhead to print roller

05/08 Rev. 2.14 27

Page 28

User Manual

TTX 450/650/950/1050 – Puma/Lion/Tiger/Tiger XXL – TDI/STDI/XXtreme –

S45/65/95/105

Production tolerances at printhead may cause to move the printhead in or versus

print direction. This is performed by twisting the little screws at the guiding tooth

when fixing screws are loose (tools are supported with printer)

Note: The optimal position can be found by print only !

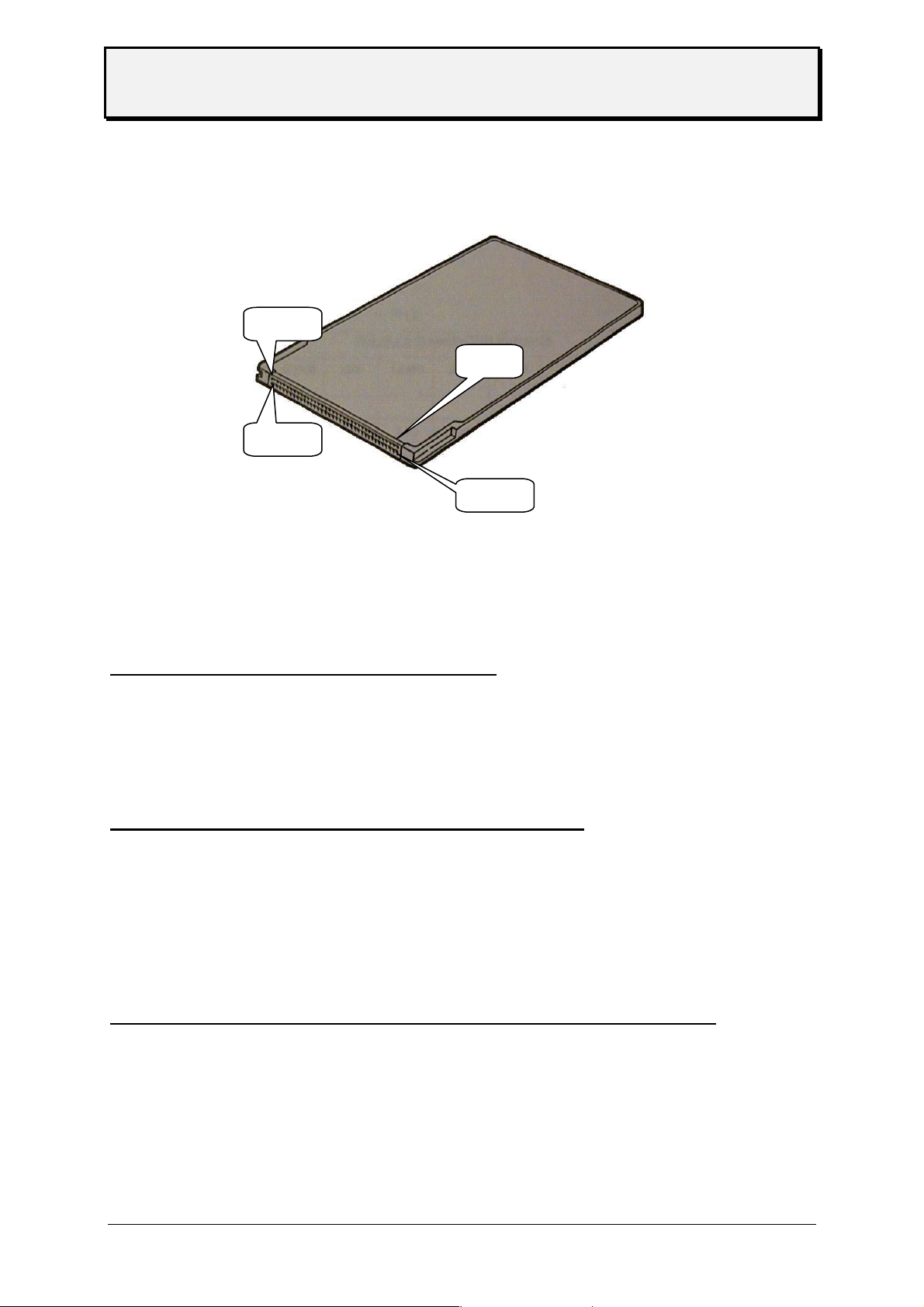

Exchanging the printhead / TTX 67x

The print head is adjusted to the print head mounting during manufacture. As a

result the print head can only be replaced in conjunction with the print head

mounting.

1. Switch off the device.

2. Pull out the mains plug.

3. Remove material and ribbon.

4. Pull out both plugs in a horizontal direction from the print head.

Note: Wait at least 3 minutes after switching off the device before removing the

print head cable from the print head. Mark the position of an axially

adjusted print head.

6. Unscrew the two thumb screws on the print head mounting until the entire print

head mounting can be removed from the contact shaft (see Fig. 1:).

Fig. 1: Take care not to touch the connector contacts (1) or

the thermal edge (2) when removing the printhead!

1

2

Attention: The print head is a sensitive electronic component and can be damaged by

electrostatic charges. Therefore, discharge any bodily static electricity before

coming into contact with the print head by touching the base plate of the printer.

The print head may not be touched on the print bar or on the plug-in contacts.

8. To install, move the new print head mounting to the old position and tighten the

thumb screws.

Note: Before doing this make a note of the resistance value of the print head

(read off from the print head). When placing the print head on the print

head mounting, ensure that the print head is lying flat.

05/08 Rev. 2.14 28

Page 29

User Manual

TTX 450/650/950/1050 – Puma/Lion/Tiger/Tiger XXL – TDI/STDI/XXtreme –

S45/65/95/105

Note: Press the thumb screw on the tapered edge of the square axle and

ensure the exact positioning of the print head mounting on the axle. Also

pay attention to the position of the print head in relation to the edge of the

label.

Basic factory settings: Flush against the inner black plastic plug.

9. Plug the print head cable back into the print head.

10. The resistance value of the print head must be entered after putting the printer

into operation using the parameter "SYSTEM PARAMETERS/ Head resistance".

Attention: Entering a false value can damage the print head!

Note: Please also read the Service Manual, topic section "Service print

module", paragraph "Exchanging the printhead".

Cleaning of Print Roller

• Disconnect unit

Attention: Pull off mains plug!

• Remove material and ribbon.

Loosen screw at center of printhead axle - until the printhead fixation can

be rotated clockwise.

Attention: Do not remove plugs form the printhead. If printhead is readjusted at axle mark

its position accordingly.

• After performance of this step, the feed roller as well as the print roller is

accessible from above.

• Clean print roller with dust-free cloth and cleansing liquor only.

• Rotate roller stepwise for complete cleaning.

Attention: Never use knives or objects with sharp edges for cleaning.

The feed roller and the friction rollers are also to be cleaning from time to time.

Performance of the printer and particularly the printhead is generally increased

by avoiding any type of contamination in the printing area.

In addition, neat printing results are preferable to poor ones in any case.

• Put printhead to former position and fix screw again.

05/08 Rev. 2.14 29

Page 30

User Manual

TTX 450/650/950/1050 – Puma/Lion/Tiger/Tiger XXL – TDI/STDI/XXtreme –

S45/65/95/105

Note: The screw enters a non visible gap at the axle, which ensures the correct

position of the printhead. Factory adjustment is flash with the inner black

plastic bushing.

• Before switch on the unit, check that both connectors of printhead are still

plugged on correctly. Reconnect if necessary.

Clean feed roller for single tags -

TDI / XXTREME / S TDI only-

• switch off device

Attention: Pull off mains plug!

• the feed roller should be cleaned with a dust free towel together with the

Avery roller cleaner

From time to time the separation edge and the bearings should be cleaned

Cleaning will help to extend the runtime of your device !

Attention: Cleaning of that roll on a regular basis is influencing the accuracy of the imprint

of your device. Please clean at least two times a day !

Clean Short Tag Option - TDI / XXTREME / S TDI only-

• switch off device

Attention: Pull off mains plug!

• if the Short Tag Option is built in, you have to clean the additional feed roller

as well – use a dust free towel ad the Avery roller cleaner.

• please clean as well the pressure roller

Cleaning of Punch-Recognition Sensor

According to the materials applied, the light barriers is to be cleaned from

material residues and dust by means of compressed air.

• Disconnect unit

Attention: Pull off mains plug!

05/08 Rev. 2.14 30

Page 31

User Manual

TTX 450/650/950/1050 – Puma/Lion/Tiger/Tiger XXL – TDI/STDI/XXtreme –

S45/65/95/105

• Remove material and ribbon.

• Loosen screw at center of printhead axle - until the printhead fixation can

be rotated clockwise.

Attention: Do not remove plugs from the printhead. If printhead is readjusted at axle mark

its position accordingly.

• After performance of this step, the sensor are accessible from above.

• Clean sensor with air pressure only.

With heavy contamination additional cleaning using a dust-free cloth and

cleansing liquor is recommended.

• Put printhead to former position and fix screw again.

Note: The screw enters a non visible gap at the axle, which ensure the correct

Position of the printhead. Factory adjustment is flash with the inner black

plastic bushing.

• Before switch on the unit, check that both connectors of printhead are still

plugged on correct. Reconnect if necessary.

Cleaning of ribbon guiding parts

Adhesive residues are to be removed at regular intervals upon processing

of self-adhesive material to ensure perfect print quality.

Clean parts with dust-free cloth and cleansing liquor only.

Contaminated parts affect the feed of the ribbon and will reduce the print

quality.

Cleaning of knifes - TTX 650 / LION / S 65 only -

Adhesive residues are to be removed at regular intervals upon processing

of self-adhesive material to ensure perfect material cut and unwinding.

Attention: Pull of mains plug

Be aware of sharp edge of knife which could cause injury.

Remove adhesive residues from upper and lower knife; in case slightly

swivel knives for better access to the entire edge.

Clean parts with dust-free cloth and cleansing liquor only.

05/08 Rev. 2.14 31

Page 32

User Manual

TTX 450/650/950/1050 – Puma/Lion/Tiger/Tiger XXL – TDI/STDI/XXtreme –

S45/65/95/105

Other

MATERIAL AND RIBBON

Material

The printer is equally suitable for thermal and thermal transfer printing. Three

factors are to be taken into account when choosing the material:

• Abrasive behaviour of the surface structure

• Properties with respect to chemical reaction on print-colour transfer

• Temperature required for colour- transfer

If the material is extremely abrasive, the printhead is faster worn as usual.

This criterion is particularly to be considered with thermal printing. It is not so

critical with thermal transfer printing, as for this process a ribbon of a width

exceeding the width of the material can be used. In this way the printhead is

protected over the entire material width.

Similar conditions prevail with a high printhead temperature. Material and foil

require a longer cooling down period, the printing quality is more critical and

the printhead is faster worn as on a normal rate.

Printing on materials with a higher specific weight than 240gr/sqm, slight

corrections of printhead pressure and position of printhead may be

necessary.

Ribbons

Ribbons are recommended to be:

• the rear side has to be coated with an anti static and friction reducing

media (back coating)

• suitable for print speeds up to 12 inches/second

• specified to „Near edge type printhead“

• wider as the material, i. e. the ribbon overlap the edges of the material by

appr. 1-2 mm each side.

Ribbons without these features may reduce printer performance and

printing quality, in some cases even the printhead may become defect.

05/08 Rev. 2.14 32

Page 33

User Manual

TTX 450/650/950/1050 – Puma/Lion/Tiger/Tiger XXL – TDI/STDI/XXtreme –

S45/65/95/105

Printer layout

Note: The printhead zero line may be repositioned in a range of 2-13mm in relation to

the label zero line.

This affects also the horizontal position of the print image

Also the ribbon zero line may be varied in relation to the label zero line.

Layout TTX

05/08 Rev. 2.14 33

Page 34

User Manual

TTX 450/650/950/1050 – Puma/Lion/Tiger/Tiger XXL – TDI/STDI/XXtreme –

S45/65/95/105

Layout TDI

05/08 Rev. 2.14 34

Page 35

User Manual

TTX 450/650/950/1050 – Puma/Lion/Tiger/Tiger XXL – TDI/STDI/XXtreme –

S45/65/95/105

Technical Specification TDI

Print technology Thermal-and Thermal Transfer Print

Print head „Near Edge Type“ print head, high resolution, fast, with integrated

temperature control.

Print speed 100 up to 250 mm/s in steps of 25,4 mm/s (1 “/s)

Resolution 12 Dots/mm (300 dpi)

Effective print width 128 mm

Imprint exactness Up to 100 mm label length: +/- 1 mm in X and Y direction

More than 100 mm label length: 1% of the label length

Label size Width: 25,2 (short tag 50mm) up to 154 mm

Length: 105 mm (short tag 50mm) up to ca. 350mm

Label length 105 mm up to max. printing length (standard device)

50 mm up to max. printing length (Short Tag option)

The max. printing length depends on the following points:

– Firmware intalled to the printer (standard or extended, furthermore of

the version of the respective firmware)

– Use of bar code cards

– Use of image cards

Depending on the combination of firmware, bar code card and image

card results a different maximum print length.

none 301 mm (324 mm*)

none 245 mm

1 x 1 MB S-RAM 339 mm

1 x 2 MB S-RAM 679 mm

2 x 2 MB S-RAM 1359 mm

Firmware Plug-in card

Standard (1H..)

Bar code card 242 mm

Extended (1X..)

Bar code card 197 mm

Tab. 1: The max. printing length can be extended by aid of S-RAM cards; assuming

that the special "extended firmware" (code 1X..) is installed. This firmware

takes more memory space than the standard firmware, that´s why the max.

printing length with extended firmware and without plugged-in S-RAM card

is even lower than with standard firmware.

*) with spooler set to 8 KB (standard: 65 KB)

Max. printing

length

P For detailed information on the different firmware versions refer to the

P For details about applying plug-in cards refer to the cards manual.

05/08 Rev. 2.14 35

Be aware, that the max. printing length may vary from one firmware

¯

version to the next. Adding features to the printer means often taking

away some millimeters of printing length from the image buffer!

service manual, topic section "Firmware", "Firmware Versions".

Page 36

User Manual

TTX 450/650/950/1050 – Puma/Lion/Tiger/Tiger XXL – TDI/STDI/XXtreme –

S45/65/95/105

Output mode 1:1 at 100% imprintable label area with or without cut.

Not imprintable area: 2 mm from lower side and 1 mm from left

(inner) side (fig.)!

Feed direction

1 mm not printable

Gap sensor Self initializing infrared gap sensor with adjustment range 2-17mm,

correction of gap offset possible; length of gap: 0,8 up to 14mm,

width: min. 4mm; optional reflex mark sensor

Interpreter Easy Plug, Line Printer, Hex Dump

Label Stock Specifications

Label stock Fan folded, single sheet or strip

Width 25.4 up to 154 mm (standard device)

50.0 up to 154 mm (Short Tag option)

Special case for Short Tag Option: Suitable tag stock can be used

¯

without the outer material guiding. In those cases, the minimum width

is 30.0 mm.

2 mm not printable

Type of stock Self-adhesive, tag or plastic label material

Thickness 0.1 to 0.5 mm

Weight 100 to 240 g/m

Crucial for the function is also the separability of the label stock:

P Continued overleaf.

05/08 Rev. 2.14 36

Not suitable is:

¯

Label stock with static charging surface

•

Label stock with adhesive surface

•

The label stock must generally be easy to separate, what means:

¯

it must not be talcum-powdered.

•

it must be free of punching burrs.

•

Label stock with sharp cutting edges must be processed so that the

¯

cutting edge faces the print roller! (otherwise printhead service life will

be decreased considerably)

2

Page 37

User Manual

TTX 450/650/950/1050 – Puma/Lion/Tiger/Tiger XXL – TDI/STDI/XXtreme –

S45/65/95/105

P See “Service Manual TTX 67x”, topic section “Service print module”,

Label stock which is thicker than 0.25 mm and/or heavier than

¯

240 g/m

done with a sufficiently large number of labels. Given a poor print

result, the printhead position must possibly be changed.

chapter “Adjusting the print head position”.

2

must be tested regarding printability. The testing must be

Ribbon specifications

Ribbon roll Roll max. outer ∅ 90mm, inner ∅ 1“ (25,4 mm)

Width 30 up to 132mm

Auto Economy Mode Starting up from > 10 mm imprint free length (on the last 32 mm of a

label only if SYSP/FMOD/SAVE is set to LEHU)

Fonts, Bar Codes

Fonts 17 Fonts inclusive OCR-A and OCR-B; 2 scaleable fonts

Character modification Margination in X/Yup to factor 8, rotation: 90,180,270 degrees

Barcodes EAN 8 and 13 with Add-On 2 and 5, UPC-A, UPC-E, Code 93,

Code 39 (Ratio 1:2, 1:2,5 and 1:3), Code ITF, Codabar, Code 128,

Code 2/5, Code 2/5 lnterleaved (Ration 1:2 and 1:3), Code 2/5 5,

Code 2/5 Matrix (Ratio 1:2, 1:2,5 and 1:3), Code MSI, Code EAN 128,

Postcode (Lead-and Identcode), UPS-Code 128

All bar codes in 16 widths, unlimited in height.

Operating Features

Operation 3 key panel with 4 digit display.

Adjustments Definition of parameters via menu or Easy Plug commands.

Test print outs of parameter adjustments, downloaded logos, font, line, and barcode

library.

Test functions Print tests with cut, Test routines to memory and sensors

Error messages Shows error messages on the display; continution of print jobs

without label loss

Connection, Device Data

Mains voltage 115/230/240 V +/- 10%, switchable

Mains frequency 50/60 Hz

Power consuption 336 VA

Current approx. 3 A at 115 V and 1,5 A at 230/240 V

Fuses 8 A at 115V, 6,3 A at 230 V and 6,3 A at 240 V

Ambient conditions Operation temperature: +5 up to +35 degree C

Storage temperature: -20 up to + 70 degree C

Humidity: 45 to 75%, non condensing

Dimensions WxHxD 840x420x380mm

05/08 Rev. 2.14 37

Page 38

User Manual

TTX 450/650/950/1050 – Puma/Lion/Tiger/Tiger XXL – TDI/STDI/XXtreme –

S45/65/95/105

Weight Approx. 25kg - without stock

Interfaces Standard: serial (RS 232) and parallel (Centronics) optional RS 485 -

in exchange against RS 232

Memory 1MB dynamic RAM

Cards 2 Slots for PCMCIA cards, 2 MB each

Certificates

TÜV GS Approved security (according to EN 60950:97)

CE conformity

The devices are marked with the CE label. The manufacturer

declares that the device conforms with the relevant European

guidelines.

EMC The EMC tests were performed according to the following norms:

EN 55022:98

EN 55024:98

EN 61000-3-2:95

EN 61000-3-3:95

EN 61000-6-2:99

Service Data

The data shown in STA3 can have a maximum value – shown in the table below. After that

value is reached the counter is set to zero and counts up again.

Number of service operations 255

Number of heads / rolls / knives 255

Head / roll run length 131 km

Cuts on knife 4.300.000.000

Total material length 430.000 km

Total foil length 430.000 km

Total number of cuts 4.300.000.000

Head moves 4.300.000.000

Head strobes 4.300.000.000

Operation time 8.800 years

05/08 Rev. 2.14 38

Page 39

User Manual

TTX 450/650/950/1050 – Puma/Lion/Tiger/Tiger XXL – TDI/STDI/XXtreme –

S45/65/95/105

INDEX

C

Card.......................................................7

Changing the print head......................28

Charges, electrostatic..........................28

Cleaning of Print Roller........................ 29

Cleaning of ribbon guiding parts..........31

Cleaning Printhead.............................. 26

Connections

TDI.................................................6

TTX................................................6

CONTENTS...........................................2

Copyright...............................................4

E

EMC..................................................... 38

Exchanging the Printhead ...................27

External Units........................................7

F

Fanfolded material...............................15

Font cards.............................................. 7

G

Gap sensor.................................... 18, 36

General..................................................4

I

INFO.................................................... 24

Initiation.................................................5

Insertion of Document Material............ 13

Interpreter............................................ 36

K

Knife option, installing.......................... 21

O

OFFLINE ............................................. 25

ONLINE MODE ................................... 25

Operating instructions

Printhead.......................................4

operation............................4, 23, 24, 25

Other.................................................... 32

P

parallel interface....................................7

parameter............................................24

PCMCIA card, pin assignment .............. 9

Plug-in cards

FLASH RAM / PPROM card .......10

PROM card ................................... 9

RAM card.................................... 10

use .............................................. 10

printhead............................ 19, 26, 30, 32

Printhead

adjust position of......................... 19

adjust pressure............................ 19

Program Version.................................. 23

PROMFILE.BIN...................................10

Putting into operation........................... 29

R

Resistance value thermal bar.............. 28

Restart................................................. 23

rewind.................................................. 19

Ribbon...........................................15, 32

Ribbon mandrels, setting torque.......... 17

Ribbon roll dimensions........................37

RS 232............................................. 7, 37

RS 485............................................. 7, 37

L

S

Layout............................................33, 34

M

Maintenance and cleaning................... 26

Memory types........................................9

MMOD .................................................24

05/08 Rev. 2.14 39

SECF................................................... 22

Sensor.................................................30

Set up mode........................................11

Short Tag Option.................................22

status message ................................... 24

Page 40

User Manual

TTX 450/650/950/1050 – Puma/Lion/Tiger/Tiger XXL – TDI/STDI/XXtreme –

S45/65/95/105

T

thickness of material............................20

Torque adjustment of ribbon mandrels 17

U

Unpacking printer .................................. 5

unwind.................................................19

05/08 Rev. 2.14 40

Loading...

Loading...