Page 1

Users Manual

Model SNAP 700 Downstacker

Option

AVERY DENNISON

Manual Edition 1.0

04 Dec. 2012

Manual Part Number 628098

Page 2

WARNING

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions:

1) this device may not cause harmful interference, and

2) this device must accept any interference that may cause undesired operations.

This Class A digital apparatus meets all requirements of the Canadian Interference

Causing Equipment Regulations. Cet appareil numerique de la classe A respecte toutes les exigences du

Reglement sur le material broilleur du Canada

Users Manual Model 500 Downstacker

Page 3

Contents

Scope 4

Introduction................................................................................................................................ 4

Warranty Information 5

Warranty Policy ......................................................................................................................... 5

Description / Specifications 7

Stacker Description.................................................................................................................... 7

Optional Stacker Specification................................................................................................... 8

Customer Responsibility 9

Location of Stacker ....................................................................................................................9

AC Power Line ........................................................................................................................10

Unpacking / Installation 10

Unpacking................................................................................................................................ 10

Inventory of Components.........................................................................................................11

Down Stacker Option 12

Installation ............................................................................................................................... 12

Adjustments ............................................................................................................................. 13

Operation ................................................................................................................................. 14

Trouble Shooting 15

Installation Instructions for Stacker Option 580028 16

Installation Procedure .............................................................................................................. 16

Mechanical Assembly Drawings 19

Stacker Assembly Drawing...................................................................................................... 20

Stacker Parts List ..................................................................................................................... 23

Label Stop Assembly Drawing ................................................................................................ 24

Label Stop Parts List................................................................................................................ 25

Users Manual Model 500 Downstacker Scope •••• 3

Page 4

Scope

Introduction

This user manual was arranged for the person who is going to operate the machine.

The information is arranged in the order that is needed to install and operate the

machine. It starts with general information, then to unpacking, installing, stacker

operation and finally care and maintenance of the stacker.

We at AVERY DENNISON hope that you will come to appreciate the efforts and

quality that have gone into producing your AVERY DENNISON 500 Stacker and

wish to remind you that you are our number one priority. We welcome any

constructive comments or criticisms so that we may continue to offer you the best

products in the industry for years to come.

4 •••• Scope Users Manual Model 500 Downstacker

Page 5

Warranty Information

Warranty Policy

Avery Dennison Retail Information Systems, In-Plant Printing Solutions provides the following warranty policy.

Scope

Warranties against defects from workmanship for equipment and parts manufactured and sold from

Miamisburg, OH. Includes time and material except as otherwise noted below.

Time

− New equipment and parts: 6 months

− Refurbished equipment and parts: 90 days

− Warranty period starts when equipment ships from selling location.

General Conditions

Avery Dennison extends warranty coverage under the following conditions.

− Equipment and parts will perform within published specifications. Promised or implied statements by any

Avery Dennison employee or representative will not be deemed to vary the terms of the warranty.

− Equipment and parts must be installed and operated according to recommended procedures and

operating conditions.

− Consumable elements are not covered. Consumable elements are those that show normal wear from

typical equipment usage including, without limitation, printheads, knives, rollers in contact with the web,

and sonic units. Avery Dennison reserves the right to determine which elements are defined as

“consumable.”

− No customer maintenance may be performed except as directed by qualified Avery Dennison personnel.

− Equipment and parts damaged by negligence or abuse are not covered.

− Avery Dennison US reserves the right in its sole discretion to incorporate any modifications or

improvements in the machine system and machine specifications which it considers necessary but does

not assume any obligation to make said changes in equipment previously sold.

Equipment Purchased In US and Shipped In US

− Avery Dennison US covers warranty for equipment and parts installed and operated in the Americas

(United States, Canada, Mexico, Central America, Caribbean Region, and South America excluding

Brazil).

− Outside the US, the local Avery Dennison office is responsible for equipment and parts warranty.

Customers must ensure coverage during machine purchase.

Users Manual Model 500 Downstacker Warranty Information •••• 5

Page 6

− Equipment purchased and exported to regions outside local Avery Dennison office coverage are not

covered by warranty. The purchasing agent must acquire a service contract from the Avery Dennison

office where the equipment or parts are operated to ensure machine coverage. For example, if an agent

purchases a printer in the US, exports to Brazil, and then needs warranty coverage, Avery Dennison Brazil

has no obligation to provide warranty coverage. The agent must purchase services from Avery Dennison

Brazil.

THE WARRANTIES PROVIDED HEREIN ARE EXCLUSIVE AND ARE IN LIEU OF ANY IMPLIED

WARRANTY OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR OTHER WARRANTY

OF QUALITY OR PERFORMANCE, WHETHER EXPRESS OR IMPLIED. EXCEPT THE WARRANTY OF

TITLE, IN NO EVENT SHALL AVERY DENNISON BE LIABLE FOR ANY INDIRECT, INCIDENTAL OR

CONSEQUENTIAL DAMAGES, EVEN IF AVERY DENNISON HAS BEEN ADVISED OF THE POSSIBILITY

OF SUCH DAMAGES.

Service

When ordering machines and supplies in the U.S.A., reference all correspondence to the address below.

AVERY DENNISON Corporation

170 Monarch Lane

Miamisburg, OH 45342

Call: 1-800-214-0872 or (937) 865-2123

Fax: (000) 000-0000

For spare parts, requests for service or technical support, contact

AVERY DENNISON Corporation

170 Monarch Lane

Miamisburg, OH 45342

Call: 1-800-214-0872 or (937) 865-2123

Fax: (000) 000-0000

For parts and service in other countries, please contact your local AVERY DENNISON supplier.

6 •••• Warranty Information Users Manual Model 500 Downstacker

Page 7

Description / Specifications

Stacker Description

The Down Stacker Option is a low-end stacker for coated and woven fabric labels.

The stacker has several adjustments that can be made for the label size and material

to be printed and cut on the AVERY DENNISON 500 Printer or the Sonic Knife

when attached to an AVERY DENNISON 500 Printer. On most coated labels tested

to date, the finished stack is fairly even on the edges and the length may vary

dependent on stacker configuration adjustments, label material and size. The stack

for woven labels will not be quite as good as the coated tapes, but removal of the

labels and jogging them together on a table like a deck of cards is easily managed.

Figure 1 - AVERY DENNISON Model 500 Downstacker

Users Manual Model 500 Downstacker Description / Specifications •••• 7

Page 8

Optional Stacker Specification

Label Size Min: 1/2" (12.7mm) web x 7/8" (22.2mm) feed (standard stacker)

Max: 2 1/4" (57.2mm) web x 5" (127mm) feed (standard stacker)

5:1 web feed to width ratio

(Examples - ½”web = max feed 2 ½”

3/4”web = max feed 3 3/4”)

Label Capacity 4800TWT material = Approximately 2,000 labels for full stacker

Dimensions 12" (305mm) high x 7" (178mm) wide

Including stacker x 6.0" (152mm) deep

Weight 3.6 Lbs. (1.64 Kg.) Shipping weight 6 Lbs. (2.73Kg.)

Electrical Interface directly to the printer

Temperature

Humidity 5% to 90% non-condensing

41°F (5°C) to 104°F (40°C)

8 •••• Description / Specifications Users Manual Model 500 Downstacker

Page 9

Customer Responsibility

Location of Stacker

The printer w/Stacker weighs approximately 50 Lbs (23 Kg) and requires a table of

sufficient quality and strength to handle this load while the system is operating.

AVERY DENNISON recommends an industrial type worktable having the

approximate dimensions of 72" wide to 30" deep to 32" high. Refer to Figure 2.

Figure 2 - Recommended Workstation Layout.

The location of the AVERY DENNISON 500 Printer should be based on human

factors. The Stacker should be located in an area that maintains optimum flow of

your product while providing for the operator’s comfort. AVERY DENNISON has

taken significant steps to ensure that the operator controls and operations are easily

accessible. This goal can only be met, however, if the printer is also located with

human factors in mind. These include the height of the Stacker, the space around the

Stacker and the accessibility to the printer.

While AVERY DENNISON has designed the system to be reasonably quiet, it is

recommended to locate the printer in an area where printing and cutting repetitious

noise is acceptable.

Users Manual Model 500 Downstacker Customer Responsibility •••• 9

Page 10

AC Power Line

The AVERY DENNISON printer requires that the electric service be 10 Amps @

115VAC or 6 Amps @ 230VAC. This will allow the computer and any additional

support or service equipment to be plugged into the same service.

The AVERY DENNISON 500 downstacker option connects directly to the printer.

The printer controls all the functions of the downstacker option.

Any electrical service that is supplying a AVERY DENNISON printer or peripheral

equipment connected to a AVERY DENNISON printer should follow standard

electrical code practices including proper grounding and neutral requirements.

The AVERY DENNISON printer was designed to operate in an industrial setting for

extended periods of time; however, the printer is controlled by a microprocessor that

is very sensitive to brownouts or power spikes. For this reason as well as the

minimum recommended current supply, AVERY DENNISON recommends that a

separate “clean” service be installed or reserved for the exclusive use of the AVERY

DENNISON printer and its peripherals.

Unpacking / Installation

Unpacking

The AVERY DENNISON 500 stacker is shipped in a cardboard carton that may be

moved by hand.

DO NOT REMOVE THE STACKER FROM THE CARTON OR UNPACK IN

THE SHIPPING / RECEIVING DEPARTMENT.

Items may be lost. Also the carton should be saved for return of the stacker if

ever required. Return shipping damage in a poorly packed carton is the

responsibility of the customer.

Open the carton from the top by cutting the taped seam on the top of the carton.

Remove the foam packing layer. (See Figure 3).

Lift the stacker from the carton by the body of the stacker. Do not lift by the

interface cable or stacker platform.

Remove the plastic over the stacker.

10 •••• Unpacking / Installation Users Manual Model 500 Downstacker

Page 11

Inspect the stacker for shipping damage. If obvious damage is discovered, contact

AVERY DENNISON for further instructions - in the U.S.A. at (937) 865-2123. In

countries other than the U.S.A. please contact your local AVERY DENNISON

supplier.

TOP FOAM LAYER

POLY BAG COVERING

CARTON

Figure 3 - Shipping Carton

Save the shipping materials to return to the factory for service if ever required.

Shipping containers are specially made to protect the printer. Machines returned that

are not properly packed are the responsibility of the customer for any damage.

Inventory of Components

The following list shows the additional parts (pieces) that should be included in your

AVERY DENNISON 500 Stacker shipping carton. If anything is missing, notify

AVERY DENNISON immediately - in the U.S.A. at (937) 865-2123. In countries

other than the U.S.A. please contact your local AVERY DENNISON supplier.

- AVERY DENNISON 500 Optional Downstacker

- AVERY DENNISON 500 Optional Downstacker "User's Manual"

Users Manual Model 500 Downstacker Unpacking / Installation •••• 11

Page 12

Down Stacker Option

Installation

Note: Turn the power off to the printer to install or remove the stacker. While no

electrical failure will occur – the software must be initialized (on power up)

to automatically recognize what option has been connected to the printer.

There are two shafts on the printer located below the Auxiliary Feed and Knife

assembly. Loosen the thumbscrew in the mount bracket of the stacker and begin to

slides the stacker on the two shafts. The top of the stacker must slide behind the Nip

Roller stripper plate. Slide the stacker in until the backside of the stacker is beyond

the size web being run.

The interface cable that extends from the bottom of the stacker assembly plugs into

the larger connector on the right side of the printer. There is a sleeve on the

connector that will snap with the connector fully engaged with the mating connector.

The two cables will only slide into each other when the connectors are properly

aligned with each other. Rotating the connector and applying light pressure inward

will engage the connectors. To remove the connector - slide the outer sleeve out and

hold it while pulling the connector out.

12 •••• Down Stacker Option Users Manual Model 500 Downstacker

Page 13

Adjustments

There are several adjustments that improve the quality of stacking that can be made

to the stacker. There are no incorrect settings, just adjustments that stack the label

size and material the best.

Stacker Angle

The entire stacker can be tipped from a vertical position as shown below to 20° out at

the bottom. Coated tapes tested work well with the bottom tipped out when the feed

is 2” or longer. Woven tapes work best when the stacker is vertical or almost

vertical. There is no best angle for all label lengths and materials.

Platform Adjustments

The angle of the platform can be adjusted into indefinate different locations by

loosening the thumb screw and pivoting the platform. Woven labels tested worked

better in the lower position while coated labels worked the best with the outer end

elevated. Short feeds worked best with the outer end elevated.

The label stop helps get the first few labels in the stack when it’s completely empty.

Place a cut label on the platform and slide it into the back corner. Move the label

stop to within 1/8” to the end of the label. The label stop is spring-loaded and will

slide without loosening or adjusting the mount thumbscrew.

Static Brush

The static brush has been mounted with a thumbscrew for easy adjustment to help

guide and control labels into the stacker. The brush should contact the material as it

exits the nip rollers. The static brush should be maintained in good condition for the

best stacking.

In general – a light pressure is sufficient to stack well, but long feeds will require

slightly more pressure.

Keep the static brush parallel to the nip roller mount bracket.

Users Manual Model 500 Downstacker Down Stacker Option •••• 13

Page 14

(Under label platform)

(Shown Veritcal)

Operation

The platform is automatically adjusted to the sensor level hieght. The printer will

then begin to produce labels and deliver them into the stacker. As the labels begin to

build - the stacker platform will begin to descend. Once the stacker is full, a sensor

will stop the printer and light the supply LED on the control panel. Remove all the

labels from the stacker and press the Stop/Start button on the display. The platform

will return to the top and begin printing and stacking labels again.

Static Brush

Sensor Stacker Height

Stripper Bracket

Label Stop

Label Platform

Thumb Screw Adjustment

Stacker Angle

14 •••• Down Stacker Option Users Manual Model 500 Downstacker

Page 15

Trouble Shooting

Problem Probable Cause Corrective Action

Stacker fails to move up or

down when start button is

depressed.

Platform can not find home 1) Sensor unplugged 1) Remove back cover and check connections.

2) Sensor out of alignment 1) Outer bracket bent and needs to be reformed.

1) Interface cable 1) Not plugged in all the way.

2) Just installed and needs to be power cycled for

printer to identify option installed.

3) Printer has no batches to print.

2) Broken wire or damaged LED

Top of stack is blocking

incoming labels

Stack of labels falling over 2) Static brush position 1) Move static brush up or down

3) Platform angle 1) Move to other position

4) Tip stacker 1) Change angle

Label not entering stacker 1) Label jam in knife 1) Clean out label and debris

2) Nip roller not pulling 1) Worn rubber roller - Replace

3) Soft material / narrow web hitting

2) Sensor not operational 1) Check sensor alignment

2) Stacker not connected

3) Loose connection

2) Loose set screw or drive gear - Tighten

1) Adjust the height of the static brush

static brush

Users Manual Model 500 Downstacker Trouble Shooting •••• 15

Page 16

Installation Instructions for

Stacker Option 580028

(Use with Woven Edge Fabrics less than 1 inch wide & over 4 inches long)

Option consists of:

Part No. Description Qty

588048 Web Guide 1

588049 Long Stacker Mount Shaft 2

Installation Procedure

1. Remove (2) Stacker Mounting Shafts from the Sonic Knife and replace with

(2) 588049 long Stacker Mount Shafts.

BUTTON HEAD SCREWS MAY NEED

TO BE LOOSED AND THE MOUNT

ARM MAY NEED TO BE SWUNG IN

TOWARDS THE SONIC KNIFE TO

ALLOW THE STACKER TO PASS

FREELY WITHOUT INTERFERING

WITH THE OUTBOARD CONVEYOR

REMOVE STACKER MOUNTING

SHAFTS & REPLACE WITH LONG

STACKER MOUNTING SHAFTS (588049)

2. Adjust to allow Stacker to slide freely.

3. With Stacker installed, slide forward and tilt top back as far as possible

without blocking the Platform “Drop” Sensor.

16 •••• Installation Instructions for Stacker Option 580028 Users Manual Model 500 Downstacker

Page 17

4. Install Magnet backed Web Guide in position as shown below.

WEB GUIDE WITH

MAGNET

5. Slide Stacker horizontally until Label exiting Nip Roller slides across edge

of Web Guide as shown.

EDGE OF LABEL SHOULD

GLIDE ACROSS BENT EDGE

OF WEB GUIDE

Note: The single Web Guide creates a twist in the Label that gives it enough rigidity to be pushed

into the Stacker.

Users Manual Model 500 Downstacker Installation Instructions for Stacker Option 580028 •••• 17

Page 18

18 •••• Installation Instructions for Stacker Option 580028 Users Manual Model 500 Downstacker

Page 19

Mechanical Assembly Drawings

Users Manual Model 500 Downstacker Mechanical Assembly Drawings •••• 19

Page 20

Stacker Assembly Drawing

20 •••• Mechanical Assembly Drawings Users Manual Model 500 Downstacker

Page 21

Stacker Assembly Drawing

Users Manual Model 500 Downstacker Mechanical Assembly Drawings •••• 21

Page 22

22 •••• Mechanical Assembly Drawings Users Manual Model 500 Downstacker

Page 23

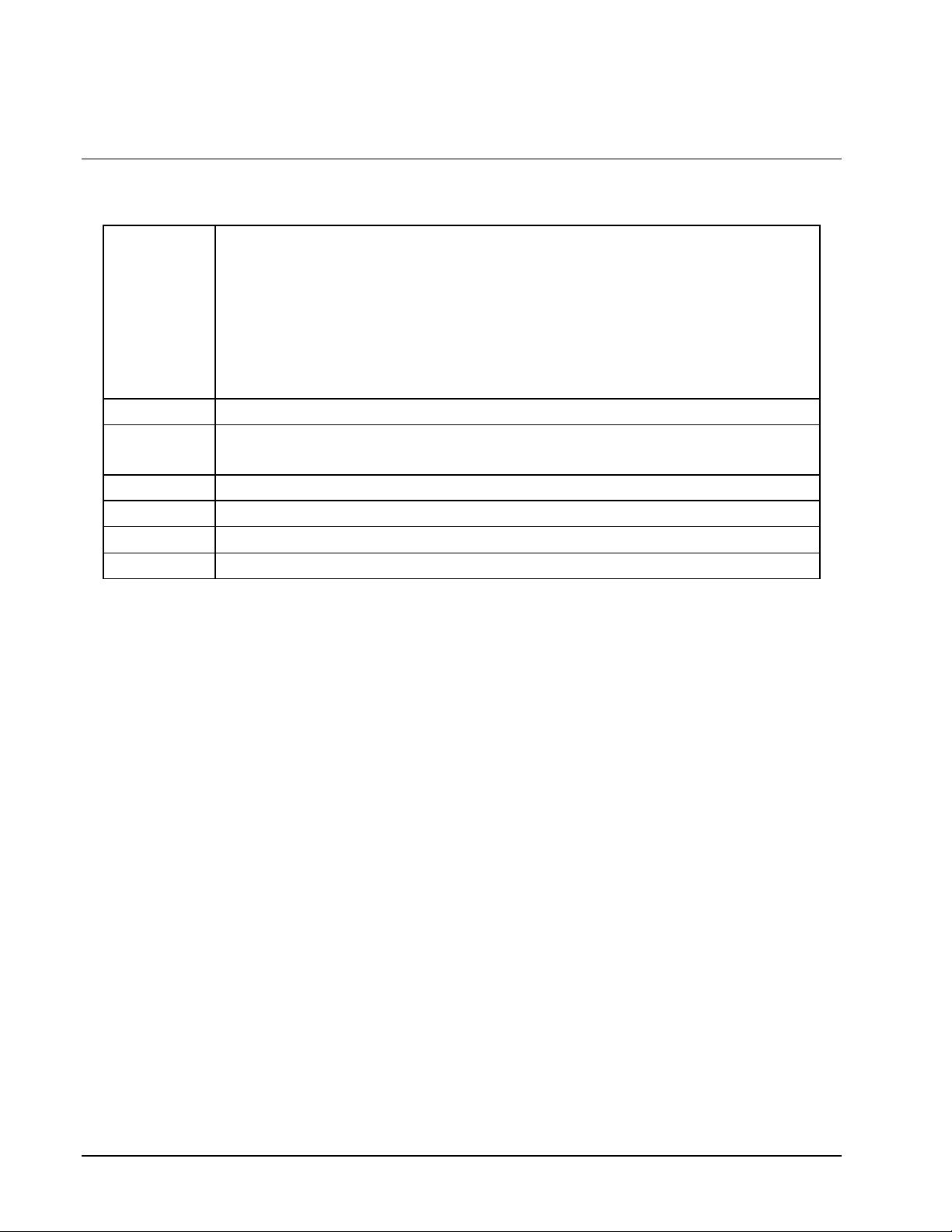

Stacker Parts List

ITEM PART NO.

1 638005 FRAME, STACKER 500 2/1 1 21 588080 BRACKET, LABEL PLATFORM 1

2 638004 BRACKET, MIDDLE SUPPORT 1 22 991182 10-32 X 3/8 SHCS w Nylon 1

3 638003 BRACKET, STACKER MOTOR 1 23 990081 10-32 x 1/2 SOC HD CAP SCR 1

4 588029 BRACKET, DIODE MOUNT, FRONT 1 24 990313 THUMB KNOB, #10 1

5 588028 BRACKET, DIODE MOUNT REAR 1 25 989966 #4 STAR WASHER 2

6 588031 COVER, LABEL SENSOR 2 26 990005 4-40 HEX NUT 2

7 638006 SHAFT, SPROCKET 2 27 990069 8-32 HEX NUT 5

8 638007 SHAFT, TENSIONER 1 28 990058 8-32 X 1/4 KNURLED CUP POINT 2

9 991640 SPROCKET, STACKER, 10T 3 29 989986 4-40 ES NUT 1

10 221117 STRAIN RELIEF .360 X .625" 1 30 638010 BRACKET, STACKER MOUNT 1

BALL BEARING , 16mm O.D. x 8mm I.D.

11 991510

12 638002 SHAFT, MAIN DRIVE 1 32 991455 10-32 X 5/8 THUMB SCREW 1

13 117954 GEAR-RIBBON 75T 1 33 588072 COVER, STACKER REAR VENTED 1

14 117955 GEAR-RIBBON 54T-15T 1 34 991508

15 991419A SPROCKET, STACKER 16T ALTERED 1 35 638008 CHAIN, STACKER DRIVE 1

16 588001A PLATFORM SLIDE, ALT 1 36 991335 E-RING, 3/32 1

17 990327 E-RING, 5/16 1

18 990329 E-RING, 7/32 3

19 991373 8 SCREW, 8-32 X 1/4 PAN PHILLIPS 3

20 581199A

FLG 2 31 990104 10-32 E-S NUT 2

HARNESS, DOWNSTACKER,

PROGRAMMED WITH GEAR 1

DESCRIPTION QTY ITEM PART NO.

DESCRIPTION QTY

8-32 X 1/2 FLANGED BUTTON HEAD

SCREW 3

Users Manual Model 500 Downstacker Mechanical Assembly Drawings •••• 23

Page 24

Label Stop Assembly Drawing

4

2

3

1

24 •••• Mechanical Assembly Drawings Users Manual Model 500 Downstacker

Page 25

Label Stop Parts List

Item Part # Description Qty

3 588043 Magnet, Label stop 1

1 588041 Bracket, Magnetic label stop 1

2 588042 Pin, Magnetic label stop 2

4 991356 Snap ring, 1/8 E-ring 2

Users Manual Model 500 Downstacker Mechanical Assembly Drawings •••• 25

Page 26

Revision Record

Revision Date

1.0 12/03/12 Removed CE mark from manual as not required

Update FCC ID and moved to page 2

Moved WEEE symbol to page 2

Description

26 •••• Mechanical Assembly Drawings Users Manual Model 500 Downstacker

Loading...

Loading...