Page 1

Users Manual

Snap 700 Linear Knife

Addendum

AVERY DENNISON

Manual Edition 2.2

7 February 2014

Manual Part Number 621395

Page 2

WARNING

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions:

1) this device may not cause harmful interference, and

2) this device must accept any interference that may cause undesired operations.

This Class A digital apparatus meets all requirements of the Canadian Interference

Causing Equipment Regulations. Cet appareil numerique de la classe A respecte toutes les exigences du

Reglement sur le material broilleur du Canada

ii Snap Linear Knife

Page 3

Contents

Scope 5

Introduction ................................................................................................................................ 5

Safety Issues / Warnings 5

Cautions ..................................................................................................................................... 5

Warranty Information 6

Warranty Policy ......................................................................................................................... 6

Description / Specifications 8

Linear Knife Description ........................................................................................................... 8

Linear Knife Specifications ....................................................................................................... 8

Installing Linear Knife – See Appendix A 9

Threading 9

Maintenance 10

Service ......................................................................................................................... 7

Cleaning Feed / Nip Rollers ..................................................................................................... 10

Knife Blade Replacement ........................................................................................................ 11

Knife Blade Cleaning ............................................................................................................... 15

Adjustments 18

Web Tracking in Center of Printer ........................................................................................... 18

Setting the Web Tracking .......................................................................................... 18

Setting the Web Guide ............................................................................................... 19

Knife Cam Adjustment ............................................................................................................ 20

Web Tracking Adjustment ....................................................................................................... 21

Adjusting the Sensor ................................................................................................................ 23

Positioning the Sensor .............................................................................................................. 26

Centering the Knife to the Web ............................................................................................... 29

Trouble Shooting 33

Appendix A 35

Removing the Stacker .............................................................................................................. 35

Removing the Nip Assembly ................................................................................................... 36

Removing the Knife Assembly ................................................................................................ 37

Removing the Rear Cover ........................................................................................................ 39

Installing the Linear Knife - Electrical Updates ....................................................................... 40

Snap Linear Knife iii

Page 4

Replace the Motherboard Entry ................................................................................. 40

Install Internal Harnesses ........................................................................................... 44

Installing the Linear Knife – Mechanical Updates................................................................... 46

Installing the Lower Frame Support for the Linear Knife ......................................... 46

Installing Linear Knife onto the Lower Frame Support ............................................. 47

Making Electrical Connections .................................................................................. 49

Installing the Nip Assembly ..................................................................................................... 50

Installing the Stacker on the Linear Knife ............................................................................... 52

Assembly Drawings 55

Linear Knife Assembly Drawing ............................................................................................. 56

Nip Roller Assembly Drawing ................................................................................................. 57

Drive Train Assembly Drawing ............................................................................................... 58

Feed Roller Assembly Drawing ............................................................................................... 59

Sensor Assembly Drawing ....................................................................................................... 60

Mounting Assembly Drawing .................................................................................................. 61

Cover Assembly Drawing ........................................................................................................ 62

Cover Assembly Drawing ........................................................................................................ 63

Harnesses ................................................................................................................................. 64

Linear Knife Parts List ............................................................................................................. 67

Linear Knife Parts List ............................................................................................................. 68

Linear Knife Parts List ............................................................................................................. 69

iv Snap Linear Knife

Page 5

Scope

Introduction

This manual details the installation, operation, and maintenance of the AVERY

DENNISON Model SNAPTM700 Linear Knife. Use this manual together with the

SNAPTM700 User Manual for other operational questions regarding the SNAP 700

printer itself.

Safety Issues / Warnings

Cautions

The Linear Knife uses very sharp cutting blades that are spring-loaded together. The

knife also has a well-guarded pinch points. The guarded covers provided with the

knife are for operator protection. Under no circumstance should the covers be

removed during operation.

Covers provide other functions beside safety. They affect cut quality and provide

strength to the knife assembly.

Snap Linear Knife Scope 5

Page 6

Warranty Information

Warranty Policy

Avery Dennison Retail Branding & Information Solutions provides the following warranty policy.

Scope

Warranties against defects from workmanship for equipment and parts manufactured and sold from

Miamisburg, OH. Includes time and material except as otherwise noted below.

Time

New equipment and parts: 1 year return to depot

Refurbished equipment and parts: 90 days

Warranty period starts when equipment ships from selling location.

General Conditions

Avery Dennison extends warranty coverage under the following conditions.

Equipment and parts will perform within published specifications. Promised or implied statements by

any Avery Dennison employee or representative will not be deemed to vary the terms of the warranty.

Equipment and parts must be installed and operated according to recommended procedures and

operating conditions.

Consumable elements are not covered. Consumable elements are those that show normal wear

from typical equipment usage including, without limitation, print heads, knives, rollers in contact with

the web, and sonic units. Avery Dennison reserves the right to determine which elements are defined

as “consumable.”

No customer maintenance may be performed except as directed by qualified Avery Dennison

personnel.

Equipment and parts damaged by negligence or abuse are not covered.

Avery Dennison US reserves the right in its sole Linearretion to incorporate any modifications or

improvements in the machine system and machine specifications which it considers necessary but

does not assume any obligation to make said changes in equipment previously sold.

Equipment Purchased In US and Shipped In US

Avery Dennison US covers warranty for equipment and parts installed and operated in the Americas

(United States, Canada, Mexico, Central America, Caribbean Region, and South America excluding

Brazil).

Outside the US, the local Avery Dennison office is responsible for equipment and parts warranty.

Customers must ensure coverage during machine purchase.

6 Warranty Information Snap Linear Knife

Page 7

Equipment purchased and exported to regions outside local Avery Dennison office coverage are not

covered by warranty. The purchasing agent must acquire a service contract from the Avery Dennison

office where the equipment or parts are operated to ensure machine coverage. For example, if an

agent purchases a printer in the US, exports to Brazil, and then needs warranty coverage, Avery

Dennison Brazil has no obligation to provide warranty coverage. The agent must purchase services

from Avery Dennison Brazil.

THE WARRANTIES PROVIDED HEREIN ARE EXCLUSIVE AND ARE IN LIEU OF ANY IMPLIED

WARRANTY OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR OTHER

WARRANTY OF QUALITY OR PERFORMANCE, WHETHER EXPRESS OR IMPLIED. EXCEPT THE

WARRANTY OF TITLE, IN NO EVENT SHALL AVERY DENNISON BE LIABLE FOR ANY INDIRECT,

INCIDENTAL OR CONSEQUENTIAL DAMAGES, EVEN IF AVERY DENNISON HAS BEEN ADVISED

OF THE POSSIBILITY OF SUCH DAMAGES.

Service

When ordering machines and supplies in the U.S.A., reference all correspondence to the address

below.

AVERY DENNISON Corporation

170 Monarch Lane

Miamisburg, OH 45342

Call: 1-800-214-0872 or (937) 865-2123

For spare parts, requests for service or technical support, contact

AVERY DENNISON Corporation

170 Monarch Lane

Miamisburg, OH 45342

Call: 1-800-214-0872 or (937) 865-2123

For parts and service in other countries, please contact your local AVERY DENNISON supplier.

Snap Linear Knife Warranty Information 7

Page 8

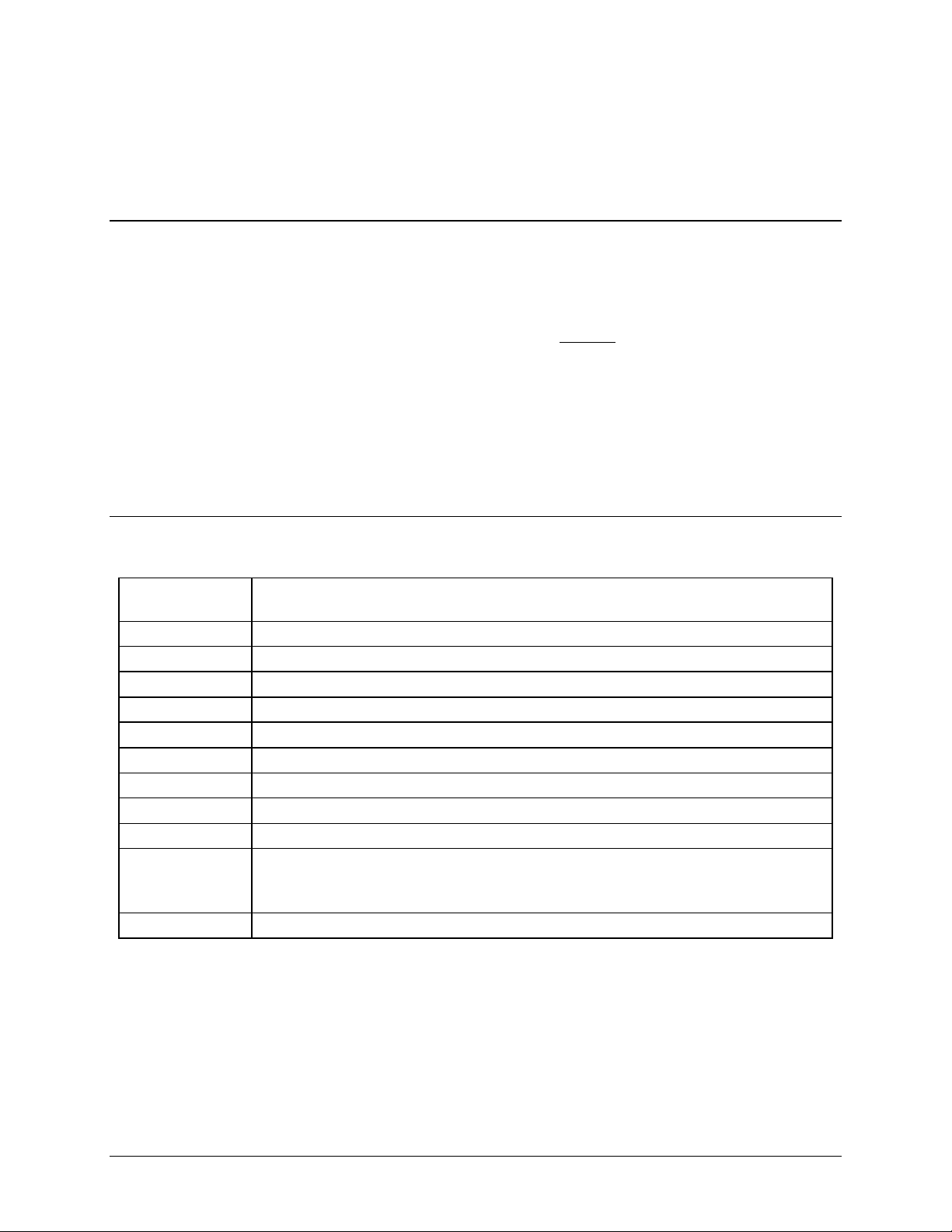

Label Size

Length: Min 1 1/2” (38.10mm) Max (See Printer Specs)

Width: Min: 1 1/2” (38.10 mm) TESTED, Max: 5 1/8" (130.18 mm) wide web

Print Speed

3ips, 4ips, 4.5ips, 5ips, 6ips, (RFID 2ips and 3ips) TESTED

Web Justification

Center

Stock

Coated and uncoated Tag Stock and RFID tag stock 10 point to 15 point TESTED

Cleaning

RFID supplies require knife blade cleaning every 25,000 cuts based on supply adhesive construction

Dimensions

11.00" (279.40 mm) wide x 17.25" (438.15 mm) deep x 18.00" (457.20 mm) high

Weight

34 Lbs. (15.5Kg.)

Electrical

DC Power, source is from the SNAP 700 Printer

Temperature

55°F - 95°F (12.7°C to 35°C)

Humidity

5% - 90% non-condensing without corrosion to finish

Registration

System

Blank stock, 1/16”(1.5mm) to 1/8” (3mm) hole, notch 1/16”(1.5mm) min., top reflective,

bottom reflective (80% contrast).

Hole or reflective mark can be any were across the web.

Options

N/A

Description / Specifications

Linear Knife Description

The SNAP Linear Knife is an add-on accessory for the SNAP 700 printer. It

mounts in place of the down stacker and in turn provides a mounting for the

down stacker.

The Linear Knife is designed to cut tag stock and stack into the down stacker. It

does not work with flimsy material such as care label tapes or pressure sensitive

materials.

The Linear Knife is removable if the other materials need to be processed on the

printer using the rotary knife. A training technician is required because the entry

into the printer electronics is required.

Linear Knife Specifications

8 Description / Specifications Snap Linear Knife

Page 9

Installing Linear Knife – See Appendix A

See Appendix A for Linear Knife Installation Instructions.

Threading

To thread the stock through the SNAP 700 Linear Knife, bring the stock up

to the entry point of the knife. Once the stock comes in contact between the

upper and lower rollers, turn the feed knob clockwise. The stock will

traverse through the knife and exit out the nip assembly.

You will need to rotate both the printer feed knob and the linear knife feed

knob. The feed on the linear knife will not pull the material through the

printer. The feed in the linear knife is for take-up tension only.

Snap Linear Knife Installing Linear Knife – See Appendix A 9

Page 10

Maintenance

Cleaning Feed / Nip Rollers

The Linear Knife has a set of feed rollers that keep web tension between the

printer feed and the accessory knife. These rollers will need cleaning daily or

more often based on the materials being run,

1. Clean the rollers with isopropyl rubbing alcohol 70%. Do not use other

cleaning products as they may have a long term effect to roller life.

2. Turn off the power to the printer to clean any moving part to avoid

injury or damage to the printer

3. Apply the alcohol to a clean cloth and rub the rollers to remove any

surface build up. The rubber roller may become stained for contact

with the materials running through the printer. This should not harm

the roller or the material.

4. The rubber roller should be replaced at least once a year or before due

to ware or if the rubber starts to harden from age or UV lighting.

10 Maintenance Snap Linear Knife

Page 11

Knife Blade Replacement

1. Turn off power to the printer.

2.

Remove the feed knob and the sensor

adjust knob.

Warning: Follow knife adjustment procedure exactly

or damage will occur.

Warning: Turn off power to the printer to avoid

personal injury when adjusting, removing, or

replacing the knife assembly.

Replace the wheel blade when it becomes dull or nicked. The knife has a life

expectancy of 3 million cuts. Monitor the number of cuts through PCMate since

the printer does not have a cut counter. Stock both the wheel and stationary

blades to avoid down time in case of blade damage or jams.

Note: Replace both the wheel blade and the stationary blade as a set only.

Replacing only one can cause early failure of the blades.

When following the instructions below, use extreme caution as the blades are

very sharp.

Snap Linear Knife Maintenance 11

Page 12

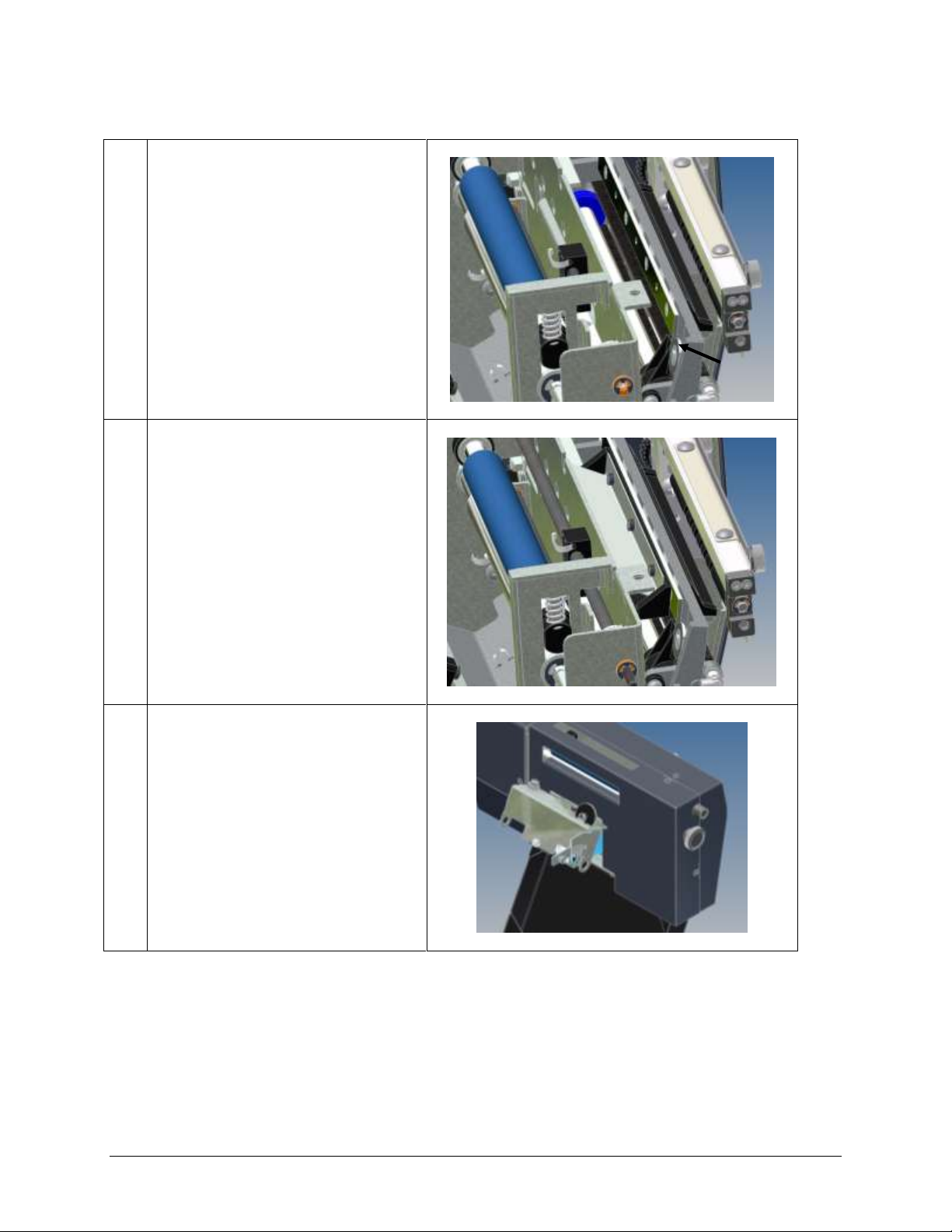

3. Remove the six 8-32 Button Head Screws

and remove the left and right side covers.

4.

Remove the entry guide and deflector

bracket by swinging the carriage assembly

out and inserting a 2.5mm Allen Key or

ball driver through the holes in the frame

to gain access to the screws.

Note: The upper sensor shaft is not shown

for clarity purposes.

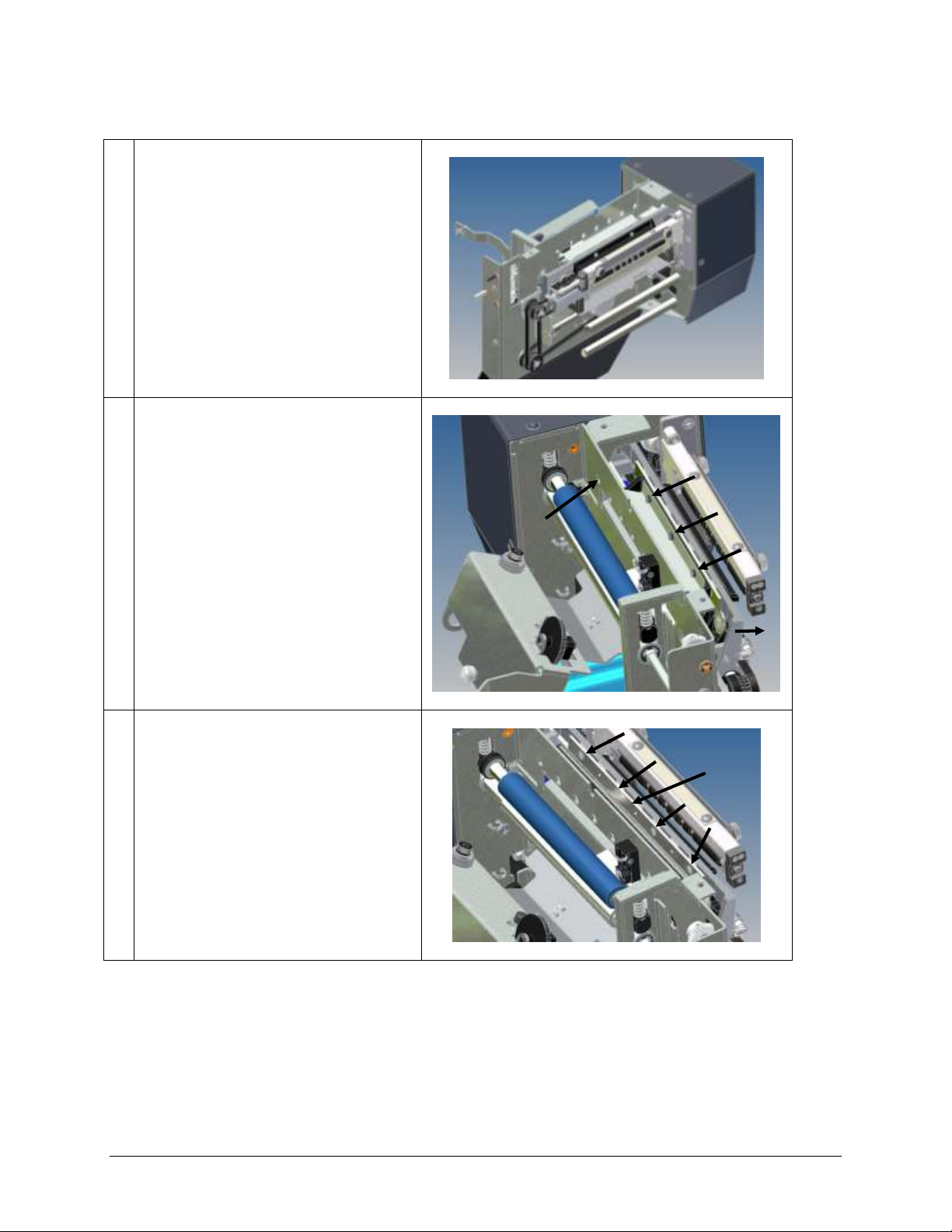

5.

With the entry guide removed, see the four

exposed Phillips flat head screws holding

the upper stationary blade. Remove

screws and blade with a #2 Phillips head

screw driver.

12 Maintenance Snap Linear Knife

Page 13

6. Removing the upper stationary blade

allows access to the wheel blade.

Remove the wheel blade, bearing, and

spacer. Replace the new parts in same

order as removed and shown.

Note: Be careful not to move the carriage

assembly too much as the wheel blade

will fall off.

7.

Re-install the upper stationary blade with

the four flat head screws removed from

step 5.

Be sure the wheel blade is behind the

Stationary Blade and that the stationary

blade is oriented so that the cutter edge is

down.

8.

Re-install the deflector bracket and entry

guide.

Snap Linear Knife Maintenance 13

Page 14

9.

Re-install the covers and knobs.

14 Maintenance Snap Linear Knife

Page 15

Knife Blade Cleaning

1. Turn off power to the printer.

2.

Remove the feed knob and the sensor

adjust knob.

Warning: Follow knife adjustment procedure exactly

or damage will occur.

Warning: Turn off power to the printer to avoid

personal injury when adjusting, removing, or

replacing the knife assembly.

When the material starts to have poor cut along all or part of the cut edge, the

knife blades will need to be removed and cleaned.

Note: When cutting RFID tag stock the knife may need to be cleaned every

25,000 cuts depending on the adhesive layer used to construct the tag material.

This may vary in frequency base on the supplies. The knife blades will need to

be taken apart as surface cleaning is insufficient.

When following the instructions below, use extreme caution as the blades are

very sharp.

Snap Linear Knife Maintenance 15

Page 16

3. Remove the six 8-32 Button Head Screws

and remove the left and right side covers.

4.

Remove the entry guide and deflector

bracket by swinging the carriage assembly

out and inserting a 2.5mm Allen Key or

ball driver through the holes in the frame

to gain access to the screws.

Note: The upper sensor shaft is not shown

for clarity purposes.

5.

With the entry guide removed, see the four

exposed Phillips flat head screws holding

the upper stationary blade. Remove

screws and blade with a #2 Phillips head

screw driver.

Clean the blade with Isopropyl Alcohol.

The blades are very sharp. Cut resistant

gloves should be worn to avoid injury.

6. With the upper stationary blade removed

there is access to the disc blade. Remove

the disc blade. The bearing and spacer can

stay on the carriage assembly.

Clean the disc blade with isopropyl

alcohol.

Replace blade in same order as removed.

Note: Be careful not to move the carriage

assembly too much as the disc blade will

fall off.

16 Maintenance Snap Linear Knife

Page 17

7.

Re-install the upper stationary blade with

the four Phillips flat head screws removed

from step 5.

Be sure the wheel blade is behind the

stationary blade and that the stationary

blade is oriented so that angle is down.

8.

Re-install the deflector bracket and entry

guide.

9.

Re-install the covers and knobs.

Snap Linear Knife Maintenance 17

Page 18

Adjustments

Web Tracking in Center of Printer

NOTE: Cut quality and straightness requires the stock to track down the center of the printer because the Linear

Knife cuts across the web from both sides. Two settings adjust web tracking. The first setting is moving the web

front to back as controlled by the Feed Roller Assembly. The second setting is the position of the Web Guide

Assembly.

The Linear Knife makes one pass across the web for each tag cut. This means that if the knife starts its cut from

the near side of the web and the next cut starts from the far side of the web. The cut is done while the web is

moving through the printer. The knife has been designed when properly installed to be located in the center of the

feed roller assembly and the print head assemblies. If one or both of these setting are not correct the cut will vary

in width every other cut.

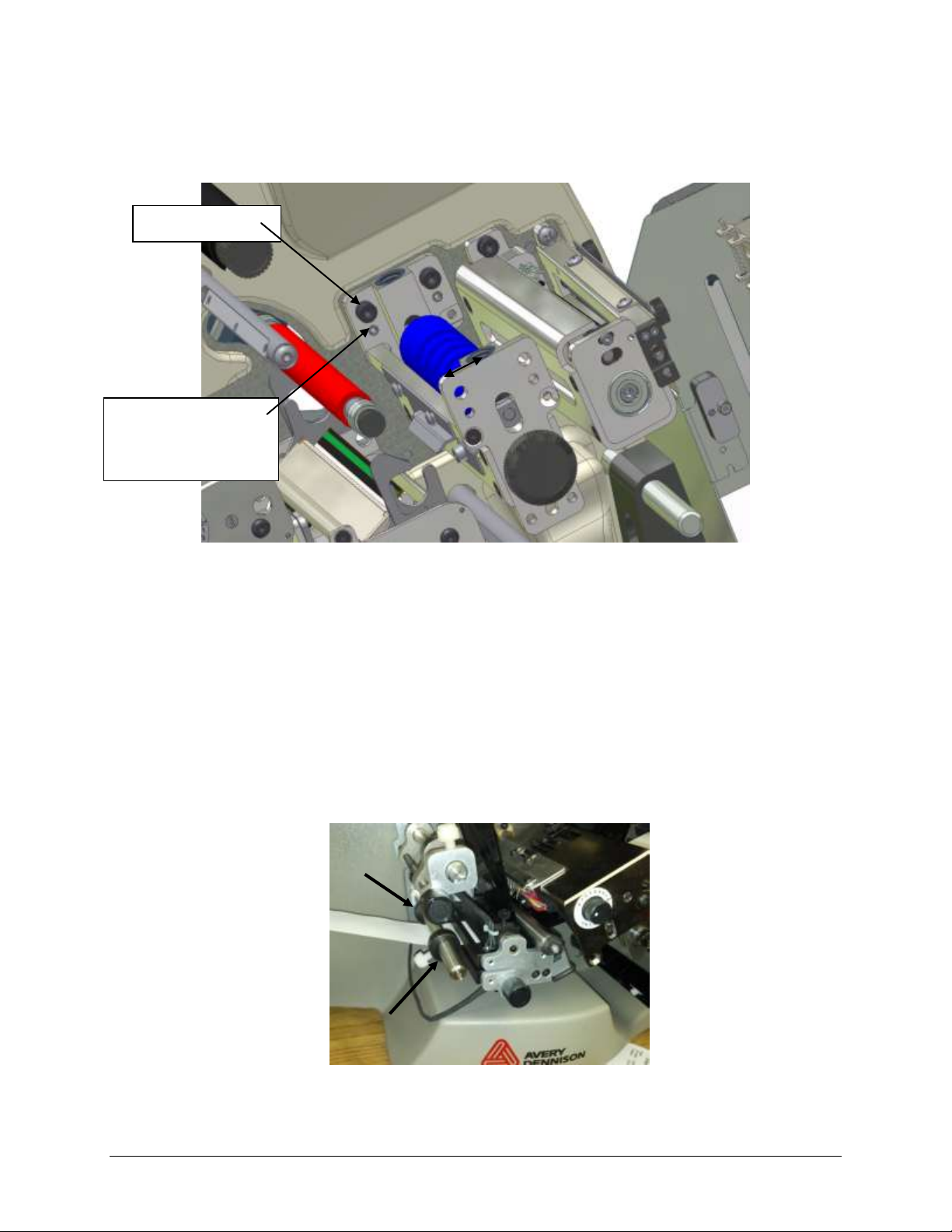

Setting the Web Tracking

Web tracking is the movement of the tag stock front to back in the Feed Assembly. To correct for this movement

there are four “Jack” Set Screws located on the inner mount bracket on the Feed Assembly. These will be adjusted

accordingly once the printer has been loaded with stock and run.

1. Load the printer with supplies (Stock & Ink) Make sure the tag stock supply roll is tight and the sides of the

roll are flat. If the roll is not flat it will track off the center of the print heads.

2. Leave the web guide open so the guides do not control the material moving through the printer.

3. Load the internal test format (see SNAP 700 user manual). The wide test format image will look like this.

The line running left to right should be in the center of the tag. The center of the line to the metal frame is

4” (101.6mm).

4. Start the printer, if the stock is walking toward the back of the printer, the outboard end of the Feed

Assembly needs to move toward the stacker. (Don’t worry if the knife cut is out of square, this will be

corrected later)

5. Loosen the three ¼-20 cap screws and turn the two left set screws 1/8 of a turn so that it will force the outer

end to move toward the stacker.

6. Snug the ¼-20 cap screws starting with the Upper right, then the lower, then the upper left.

7. Once all are snug, tighten the cap screws in the same order.

18 Adjustments Snap Linear Knife

Page 19

8. Run the printer again and see if there is a walking issue, if so repeat steps 4-6.

Loosen Screws

Use “Jack” Set

Screws to position

the Feed Assembly

one way or the other.

9. If the stock wants to walk toward the front of the printer, then position the feed assembly so that the outer

edge move slightly away from the stacker side, and reverse steps as previously stated.

10. Once the stock is tracking through the printer without walking, the feed assembly can be secured.

11. The Printer is now ready for the latest Operating System Installation. Download and install Operating

System Version 3.32.07.05 or later.

Setting the Web Guide

The web guide is located between the tag stock supply roll and the first print station in the web path. To set the

web guide correctly, get the tracking of the printer centered first. There are two set collars with thumbs screws

that will rest just off the material. Position these collars to steer the web correctly through the printer. Do not

try and force the stock more then 1/4” (5mm) as it can damage the edge of the tag stock.

Snap Linear Knife Adjustments 19

Page 20

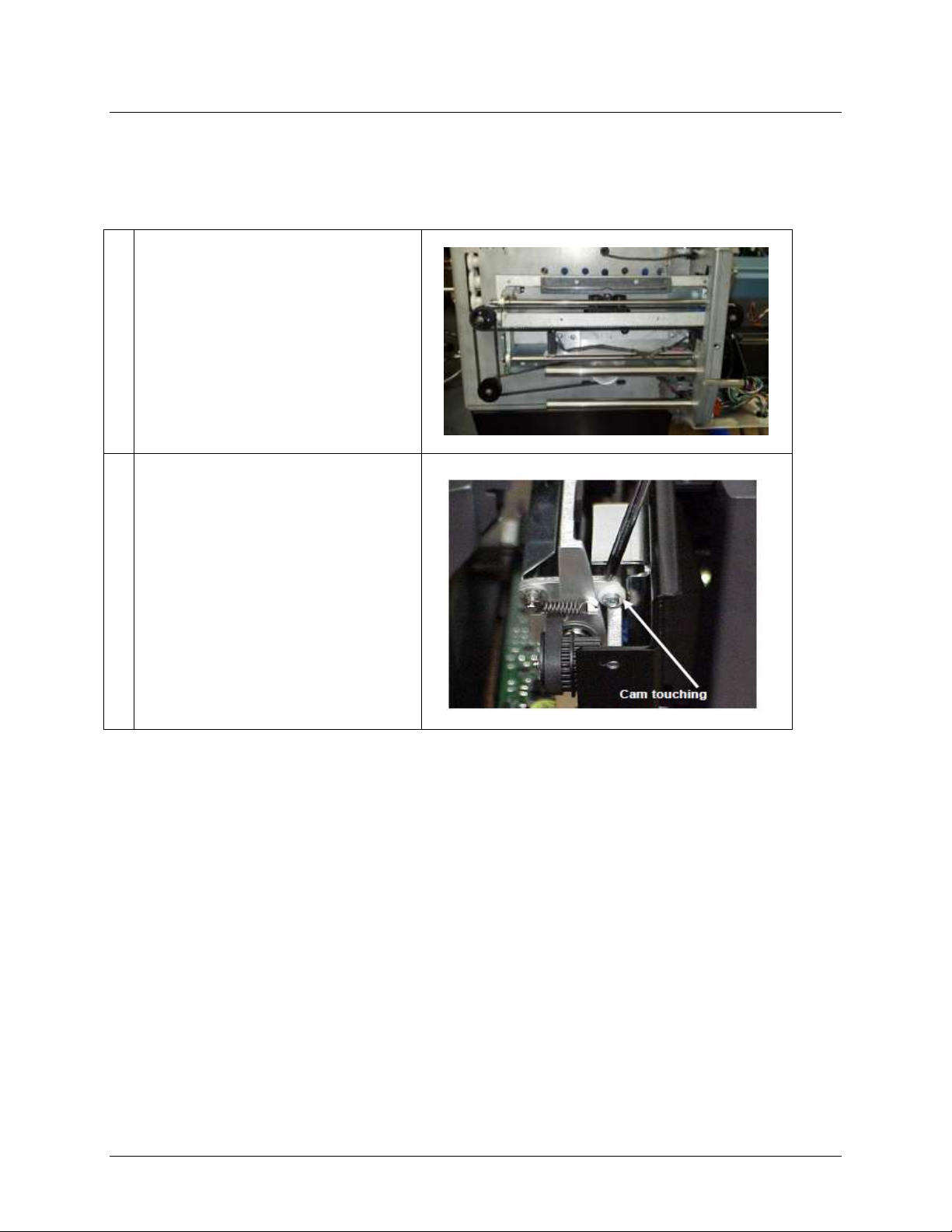

1. Move the rotary knife carriage to the

center of the stationary knife.

2.

Adjust the inboard and outboard cam to

just barely touch the frame. Hold the came

in the desired position while tightening the

screws.

Knife Cam Adjustment

The cam adjustment keeps the frame from distorting during operation and

affects the cut angle slightly.

20 Adjustments Snap Linear Knife

Page 21

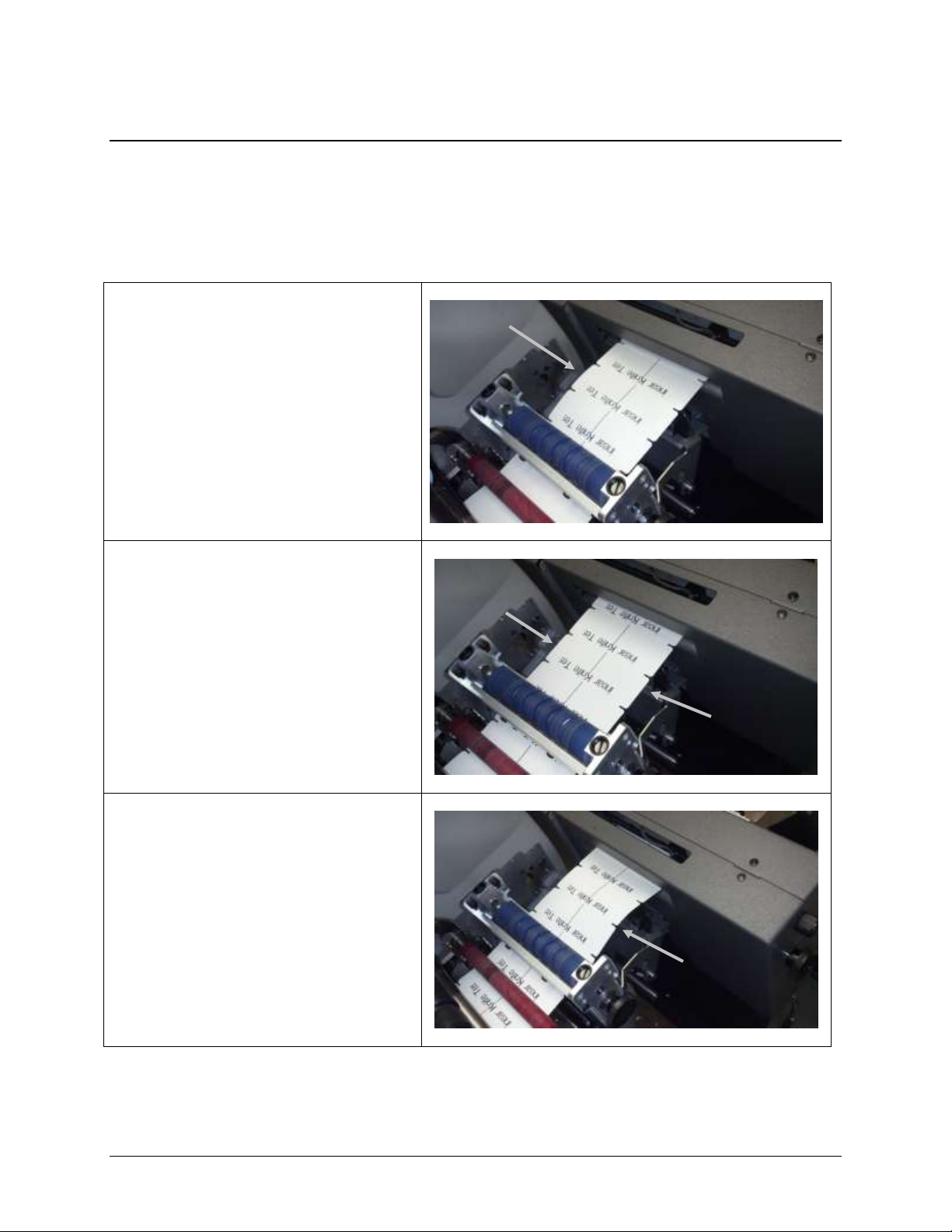

Web Tracking Adjustment

Buckle in Rear of Knife

(Needs to be adjusted, cut will not be

square.)

Web tracking straight

(No buckle)

Ready to move to the next step

Buckle in Front of Knife

(Needs to be adjusted, cut will not be

square.)

If the web is tracking through the SNAP 700 printer but is not tracking into the

Knife square, there will be a buckle in the web. The tracking can be adjusted by

rotating the thumb wheel on the Linear Knife located on the inboard side of the

Knife.

Snap Linear Knife Adjustments 21

Page 22

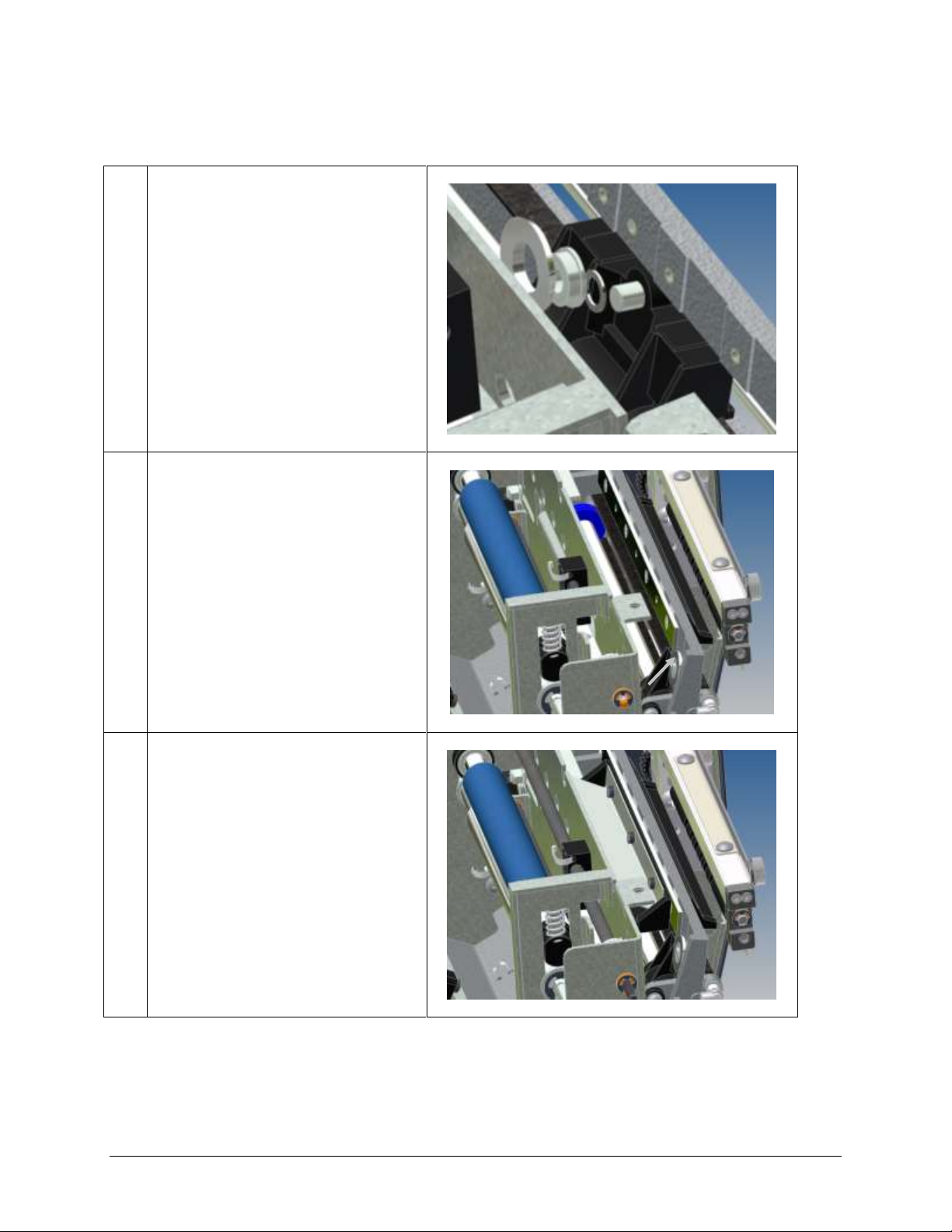

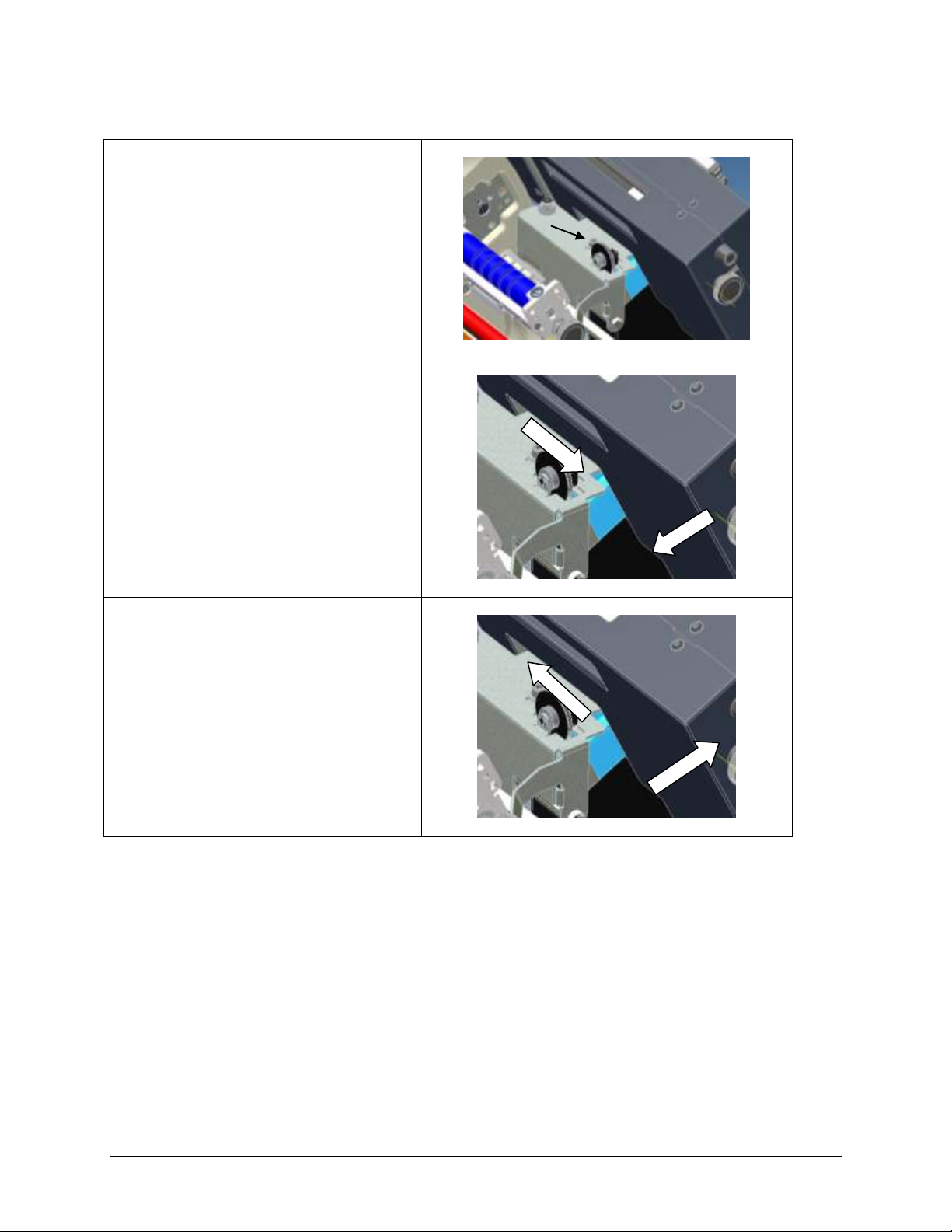

1.

Loosen the ¼-20 cap screw shown.

Rotating the thumb wheel will rotate the

knife in one direction or the other.

2.

Rotate the thumb wheel toward the

operator to move the outer edge of the

knife to the left.

3.

Rotate the thumb wheel away from the

operator to move the outer edge of the

knife to the right.

After the knife is in the desired location,

tighten the ¼-20 cap screw.

22 Adjustments Snap Linear Knife

Page 23

Adjusting the Sensor

1.

Remove the feed knob and the sensor

adjust knob.

2.

Remove three 8-32 button head screws and

the left side cover

3.

Temporarily re-install the sensor adjust

knob.

The SNAP 700 Linear Knife has the capability to sense through hole, slot,

top reflective, or bottom reflective sense marks. The sensors are assembled

so that the sender and receiver are opposite each other. See instructions

below to line up the sensors if they need to be re-aligned.

Snap Linear Knife Adjustments 23

Page 24

4.

Remove the Phillips head screw securing

the idler gear standoff shown and remove

the standoff with gear so that the top and

bottom sensor do not traverse together.

5.

Rotate the sensor adjust knob so that the

upper sensor travels directly over the lower

sensor. This will ensure the sensors are in

the correct location with each other.

6.

After the sensors are directly over each

other, remove the sensor adjust knob from

the end of the shaft.

24 Adjustments Snap Linear Knife

Page 25

7.

Re-install the idler gear removed from

Step 4.

8.

Re-install the left side cover and secure

with the three 8-32 button head screws.

9.

Re-install the sensor adjust knob and the

feed knob.

Snap Linear Knife Adjustments 25

Page 26

1. Load

supplies on

and

through the

printer and

knife and

be sure the

web is

tracking

correctly.

Move the

sensor in

the

proximity

of the hole

that is in

the web.

2.

Download

a format

that has a

thru-hole

sense mark.

The printer

will need to

be hooked

up to

PCMate

and a

format

created

with the

size stock

that is

being run.

Start the

printer, the

printer will

say

“calibrating

Screw

Sense Hole

Sense-Hole

Positioning the Sensor

To position the sensor correctly for a thru-hole format, the web must be tracking

through the printer and knife correctly. If not, see the section in this manual on

web tracking. The center of the sensor block will need to be slightly off center

to the hole that is being sensed.

26 Adjustments Snap Linear Knife

Page 27

sensors”

and begin

to run. If

the sensor

is not in the

correct

position,

the printer

will stop.

Traverse

the sensor

over the

hole so that

the screw

on the

sensor is

just to the

left of the

hole in the

stock.

Snap Linear Knife Adjustments 27

Page 28

3. Start the printer back up, as the stock

passes through the knife, the supply

light on the 700 should light up each

time the sensor senses a hole.

If the printer stops and gives another

sense mark error, repeat step 2 to move

the sensor slightly.

28 Adjustments Snap Linear Knife

Page 29

Centering the Knife to the Web

1. Turn off power to the printer.

Unplug the stacker and remove it from the

linear knife.

Unplug the Linear Knife from the Snap

700 printer.

2.

Remove the feed knob and the sensor

adjust knob.

For clarity purposes the knife if shown not

attached to the printer. These instructions

are stepped as if the knife was attached to a

printer.

3.

Remove three 8-32 button head screws and

the left side cover

After the web is tracking through the printer and into the knife straight, it may

still need to be centered going into the knife.

Snap Linear Knife Adjustments 29

Page 30

4. Loosen the thumb screw holding the upper

and lower halves of the Linear Knife

together.

Loosen the lower right 10-32 E-S Nut

mounting the knife pivot bracket to the

main frame. The other three nuts are just

tight enough to be able to slide with a

Belleville washer.

5.

Insert a flat blade screwdriver into the

triangle and rotate left or right depending

on which way the knife wants to move.

6.

With the hex nuts loose, the bracket will

now slide front to back. Depending on

where the stock was running through the

knife will determine which way the

bracket needs to move.

If the stock was running more on the

outside of the knife, the bracket will need

to move right.

If the stock was running more on the inside

of the knife, the bracket will need to move

left.

30 Adjustments Snap Linear Knife

Page 31

7.

Tighten the E-S Nut and the thumbscrew.

8.

Feed the web through the knife and run

some sample labels to see if the web is

centered through the knife.

9.

If web is not centered, repeat steps to take

off upper half of knife and move

mounting bracket to a more desired

location.

Repeat until there is the same amount of

distance between the edge of the rollers

and the sides of the web.

Equal distance

Snap Linear Knife Adjustments 31

Page 32

10.

Once the web is centered, remove the

web from the Linear Knife and remove

the feed knob.

11.

Install the left cover and reinstall the feed

knob and the sensor adjust knob.

12.

Thread the Linear Knife and run samples

to check centering of the web.

32 Adjustments Snap Linear Knife

Page 33

Trouble Shooting

Problem

Probable Cause

Corrective Action

Cut is out of square

1. Web not centered in printer

1. Adjust printer feed assembly

1. Incorrect cam adjustment

1. Re-calibrate Cam.

1. Knife is not square

1. Rotate thumbwheel to remove web buckle.

1. Knife is not centered to web

1. Center knife to web

Blade(s) are not cutting

clean edges.

1. Incorrect adjustment of blade

1. Check the blade is touching the upper blade.

2. Check that the extension springs on each side

of slide shaft are engaged.

1. Dull or nicked blades

1. Replace both upper and lower blades as a set.

Do not replace only one as that will shorten

the life of both blades.

1. Blades need cleaning

1. Remove blades from mounting and clean.

Cutting blade is not

rotating

1. Bearing in cutting blade is

jammed or gummed up

1. Replace cutting blade bearing

Knife won’t cut or tags not

the same width

1. Bad C-Sensor

1. Replace C Sensor(s)

1. Linear knife not connected to

the printer

1. Check the harness connection to the printer

both outside and inside

1. Web is tracking off center

1. Re-set tracking of web on the Printer

Cut edge of tag looks

ragged

1. Blades need cleaning

1. Remove blades and clean

1. Blades are dull

1. Replace blades as a set

1. Wheel knife bearing is dirty or

damaged

1. Replace ball bearing

Tag are dirty

1. In feed rollers are dirty

1. Clean rollers

1. Adhesive on tag

1. Clean knife blades

Missed sensor error

1. Sensor not aligned with hole

1. Move sensor over hole or slot to register

2. Top and bottom sensor not over each other see

section on Adjusting the Sensor.

1. Registration hole is below spec

1. Re-place stock with material to spec

1. Three registration holes in a row

blocked

1. Restart printer or replace stock

1. Web is not tracking straight

1. Check printer feed, unwind back tension,

Snap Linear Knife Trouble Shooting 33

Page 34

1. Damaged sensor

1. Replace sensor harness assembly.

Reflective sensor error

1. Sensor not aligned with mark

1. Move senor in align with registration mark

1. Sensor mark to small

1. Registration mark spec is 1/8” wide in the feed

direction and 3/8” wide across the web.

1. Sense mark contrast range to

close

1. Supplies not compatible with sensor

Knife did not home

1. Carriage may be out of sensor

range

1. Place carriage between front and back sensors.

1. Knife pulley may have become

loose missing.

1. Tighten or replace set screws on the knife

pulley.

34 Snap Linear Knife

Page 35

Appendix A

1.

Unplug the stacker cable from the printer.

There is an outer ring in the stacker

connector that will slide back to release the

cable connection.

2.

Loosen the thumb screw that clamps the

stacker to the mount shafts.

Slide stacker off the mount shafts and set

aside to be installed later.

Note: The two mount shafts are used to

mount the Linear Knife.

The SNAP 700 Printer will need minor alterations to have a Linear Knife

installed. These alterations apply to both a new printer and a field installation.

For new printer installation, see instruction “Installing the Linear Knife” and

“Installing the Stacker on the Linear Knife”.

For field installation, replace the original equipment rotary knife by beginning

below.

NOTE: Avoid personal injury or damage to the electronics in the printer by

turning off the printer and disconnect the power cord.

Removing the Stacker

Remove the stacker as shown. It will be installed later on the Linear Knife.

Snap Linear Knife Appendix A 35

Page 36

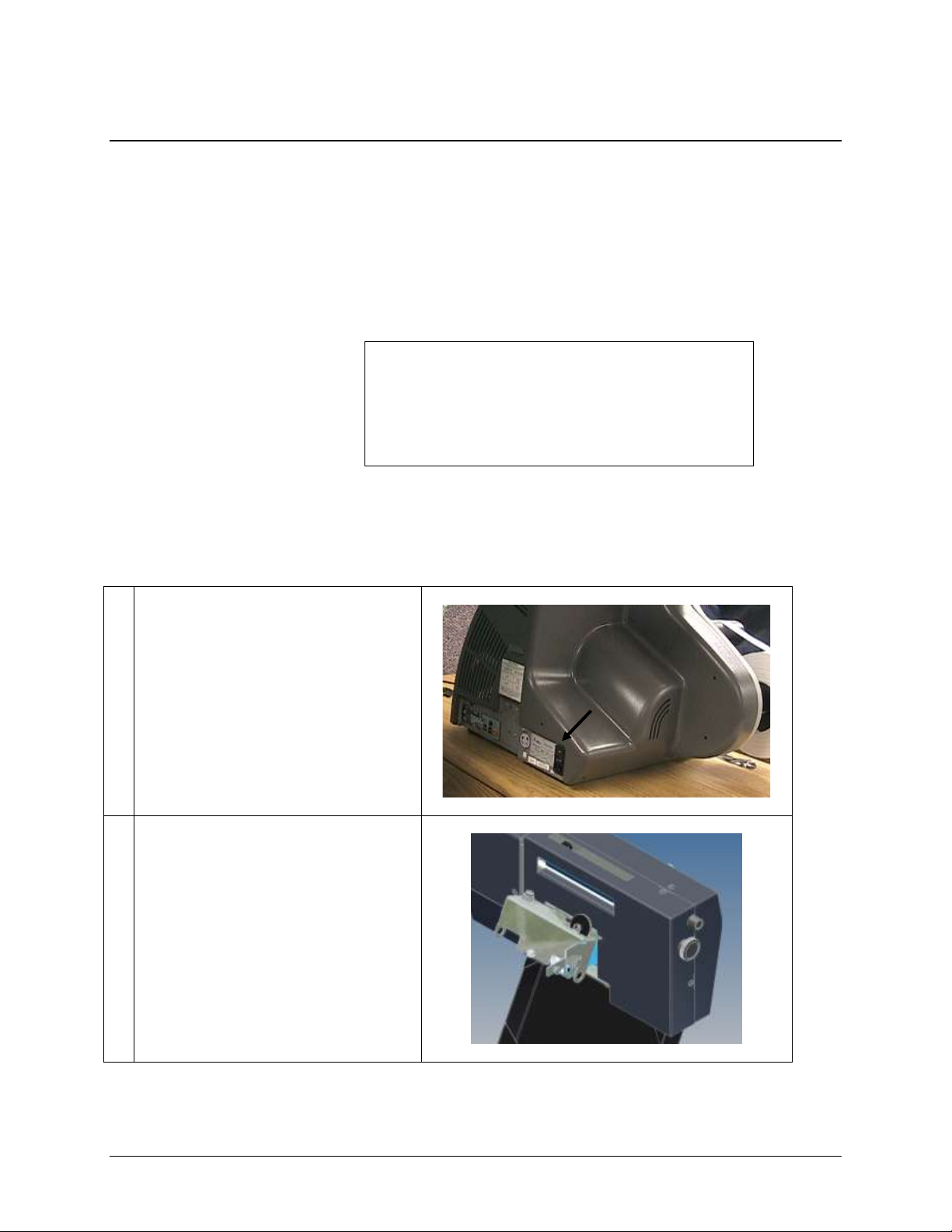

1.

The nip assembly is removed with a long

#2 Phillips screw driver. Loosen the two

10-32 X ¾” Phillips head screws that

mount the assembly to the frame and then

remove the two screws.

2.

Save the nip assembly and the two screws.

They will be used to remount the assembly

to the new linear knife.

Removing the Nip Assembly

The Linear Knife will use the existing nip assembly and mount hardware from

the printer.

36 Appendix A Snap Linear Knife

Page 37

Removing the Knife Assembly

1.

To remove the knife loosen the two ¼”-20

x ½” cap screws using a 3/16” hex tool.

2.

Retain the knife and screws for any future

needs. These are not part of the new knife

accessory.

The Linear Knife has its own feed and will reuse the existing printer nip

assemblies. The standard rotary knife assembly needs to be removed from the

printer. Save this unit to convert back to a standard printer in the future.

Snap Linear Knife Appendix A 37

Page 38

3.

Remove the feed / knife tie bracket. There

are two 10-32 x1/4” Button head screws to

removed using a 1/8” hex tool.

4.

Printer is ready for the new knife to be

installed.

38 Appendix A Snap Linear Knife

Page 39

Removing the Rear Cover

1.

Turn off the power to the printer at the end of a

batch so not to lose downloaded data and

disconnect power cord.

2.

Unplug all peripherals such as stacker, remote

display, verifier, etc.

Unplug power cord from wall outlet.

Remove the stock and ink.

Remove the back cover of the printer by removing

(10) button head cap screws using a 3/32 Allen Key

or T-Handle.

Snap Linear Knife Appendix A 39

Page 40

1.

Label each connector to the MCB with the

appropriate plug name printed on the

board.

Remove the connector from the board after

labeling it.

2.

Remove the two 6-32 Phillips head

screws from the rear of the upright bracket

holding it to the printer housing.

3.

Remove the two Phillips head screws

mounting the upright bracket to the main

rear frame.

With all of the connectors disconnected

from the MCB, the entire bracket can be

removed from the printer. This will allow

access to the mother board screws.

Installing the Linear Knife - Electrical Updates

Replace the Motherboard Entry

On field upgrades to the SNAP 700 printer, the motherboard entry bracket may need to be replaced. See the

steps below to replace the entry bracket. A new SNAP 700 printer with the Linear Knife installed will

already have the motherboard entry bracket installed onto the Snap 700 frame.

40 Appendix A Snap Linear Knife

Page 41

4.

Remove the six screws holding down the

motherboard.

5.

Slide the motherboard back and out of the

way to expose the three screws mounting

the motherboard entry bracket.

Remove the three screws.

.

6.

Pop out the motherboard plate from the

opening and save to re-install into the new

entry bracket.

Snap Linear Knife Appendix A 41

Page 42

7.

Remove the last two screws holding the

motherboard entry bracket to the base

frame.

Remove motherboard entry bracket.

8.

With the motherboard entry bracket

removed the printer should look something

like this…

.

9.

Install the new motherboard entry bracket

(with the 5 existing screws) back into the

same place the old one was removed.

Notice the new bracket now has three

accessory openings for mounting harness

connectors.

Remove PCI bracket from existing

motherboard entry bracket and place onto

the new bracket with the same screw.

10.

Install the existing motherboard plate into

the opening on the new mother board entry

bracket.

Slide the motherboard back into place and

secure with the screws from step 4.

42 Snap Linear Knife

Page 43

11.

Slide the MCB upright back into the slot

on the motherboard.

12.

Install the screws mounting the upright

bracket to the motherboard entry tray.

.

13.

Secure the upright bracket to the rear

frame with the existing hardware as

shown.

14.

Reinstall all connectors to the MCB from

the labels attached to each harness applied

in step 1.

* DO NOT RECONNECT THE SENSORS

FROM THE SNAP 700 LOCATED AT

J26 TOP REFLECTIVE OPTION HOLE

J27 KNIFE HOME

J28 OPTIONAL BOTTOM REFLECTIVE

THE LINEAR KNIFE SENSORS WILL GET

PLUGGED BACK INTO THESE THREE

CONNECTOR HOUSINGS.

Snap Linear Knife 43

Page 44

1.

Remove the two connector plates covering

the large slot and hole as shown.

2.

Find the Power Harness (05621139) and

remove the nut.

Slide one connector at a time through the

nut.

3.

Insert the two connectors from the power

harness through hole in the motherboard

entry bracket.

4.

Once the harness is inserted into the hole,

insert the nut over the connectors and

secure the harness body to the

motherboard entry tray.

Be sure to line up the tang on the round

harness connector and the key slot in the

motherboard tray.

5.

Install connectors to the corresponding

connectors on the daughterboard and

MCB.

Note: If the Snap 700 printer has the RFID

upgraded knife motor, be sure to

disconnect the motor connector from the

daughterboard. Having both knife motors

plugged in to the daughterboard will make

the Linear Knife motor fail.

Install Internal Harnesses

44 Snap Linear Knife

Page 45

6.

Find the other internal harness (05621138)

and remove the hardware mount kits and

install onto the motherboard entry bracket

from the back.

7.

With all hardware removed, install the

connector from the back of the

motherboard entry bracket.

Place one washer onto the standoff, insert

through the hole of both the bracket and

connector. Secure, with another washer,

lock washer and nut.

8.

Route harness between the upright frame

and the rear frame.

Install connectors to the corresponding

connectors on the MCB.

Snap Linear Knife 45

Page 46

1.

Remove the upper mount shaft for ease of

installing the Linear Knife. It will be reassembled a little later.

Locate the lower frame support and Install

it on the end of the SNAP 700

2.

Lift the end of the SNAP 700 and place

the bracket with the two large holes over

the corresponding feet of the SNAP 700.

3.

Place the SNAP 700 back onto table.

Installing the Linear Knife – Mechanical Updates

The Linear Knife is ready to install on the printer. Position the printer where

you want to use the system. Relocating the printer with Linear Knife installed is

not advised as they are too heavy and not stable enough to move without

damage.

Installing the Lower Frame Support for the Linear Knife

46 Snap Linear Knife

Page 47

Installing Linear Knife onto the Lower Frame Support

4.

Position the knife unit so that it rests onto

the lower frame support. Position it so

that the extended bracket sits behind the

Feed of the SNAP 700.

The rear end of the mounting bracket

should be resting against the front cover.

NOTE: The knife will be centered to the

web path when the bracket is in contact

with the back cover. This is critical to

knife cut registration

5.

Install a ¼-20 x ½ Phillips Head Screw

through the SNAP 700 Feed and into the

Extended Bracket of the Linear Knife.

Be sure that the Knife is still resting on the

lower frame support.

6.

Line up the upper knife unit and the lower

frame support and secure with the

thumbscrew provided.

Extended Bracket

Feed

Lower Frame Support

Thumb Screw

Line up holes

Snap Linear Knife 47

Page 48

7.

Install the stacker mount shaft removed

earlier through both holes of the knife

mounting bracket.

8.

Secure stacker mount shaft with existing

¼-20 x ½ Screw.

9.

Reinstall the rear cover.

Note: All but one cover mount screw will

be re-used. The screw that sits behind the

Linear Knife may be too hard to reach and

thus will be left out.

48 Snap Linear Knife

Page 49

Making Electrical Connections

1.

Plug the D-Shell connector from the

Linear Knife into mating receptacle on the

printer.

Tighten thumbs screws on connector.

2.

Plug the round connector from the Linear

Knife into the mating connector on the

Printer.

Screw the outer housing to secure the

connector to the printer.

3.

Plug power cord into the AC Entry. Do

not plug into wall at this time.

Connect any other cables that need to be

connected to the printer.

Snap Linear Knife 49

Page 50

1.

The nip assembly will be installed using

the same screws that mounted it to the

Printer.

2.

Place the top screw back through the

original mount hole and install the screw

but leave it loose by approx 3/8” (9mm).

Start the bottom screw but do not tighten

that screw as well.

3.

Push the nip assembly towards the frame

that it’s being mounted to and turn the

shaft to engage the drive with the driven

roller.

Installing the Nip Assembly

The nip assembly that was removed from the printer to make room for the new

knife will be installed on the Linear knife. Skip this section if the Linear Knife

already has a Nip Roller Assembly.

50 Snap Linear Knife

Page 51

4.

The nip assembly will be installed using

the same screws that mounted it to the

printer.

5.

Holding the nip assemble tight to the frame

with the drive engaged tighten the two

mount screws.

6.

Finished installed assembly.

Snap Linear Knife 51

Page 52

1.

Remove the stacker mount on the back of

the stacker and replace it with the Stacker

Mount Block supplied with the Linear

Knife (P/N: 05627843).

2.

Slide the stacker onto the two shafts of the

knife assembly. The back of the stacker

must be in back of the nip assembly

stripper plate. This allows the cut tags to

fall into the stacker and not catch on the

stacker frame.

3.

Move the stacker’s back until the stacker

upright is approx 1/8” past the back edge

of the web.

Installing the Stacker on the Linear Knife

The stacker that was removed from the printer will be used on the accessory

knife.

52 Snap Linear Knife

Page 53

4.

Set the stacker platform angle with the

right end set as high as possible to begin

with. Once the stacker starts to fill with

tags a more desirable angle can be found to

provide a stack that can be handled to

unload.

The stacker may not be able to hold a full

stack of tags based on the tag being

stacked. RFID tags have a chip imbedded

in them so the tag is not uniform in

thickness. This will cause the tags to tip or

rock around. The number of tags cut and

stacked can be controlled by PCMate in

the format with a stop between batch

configurations.

5.

Plug the Stacker connector into the side of

the printer.

Plug power cord into wall and turn on

Printer. Note: The stacker will not work if

the Stacker Harness is not connected to the

Printer prior to turning on the printer.

Snap Linear Knife 53

Page 54

Page 55

Assembly Drawings

Snap Linear Knife Assembly Drawings 55

Page 56

18

27

131

133

139

133

139

136

129

14

31

33

32

11

11

19

3

12

16

6

15

15

16

6

8

13

28

5

24

5

136

129

14

133

139

30

9

1374

17

29

22

23

23

2

2

17

1

4

2

2

22

23

23

137

137

137

111

41

68

135

135

111

111

67

21

77

135

41

140

10

20

135

33

85

121

121

121

86

150

19

150

148

66

158

160

159

103

103

159

160

159

103

24

Linear Knife Assembly Drawing

56 Assembly Drawings Snap Linear Knife

Page 57

Nip Roller Assembly Drawing

117

117

39

51

112

112

56

116

43

116

69

116

103

126

124

126

103

49

48

103

128

103

106

106

120

44

114

114

47

Snap Linear Knife Assembly Drawings 57

Page 58

Drive Train Assembly Drawing

58 Assembly Drawings Snap Linear Knife

Page 59

Feed Roller Assembly Drawing

127

103

123

60

103

58

61

26

26

60

123

119

25

105

105

127

Snap Linear Knife Assembly Drawings 59

Page 60

91

94

93

54

94

93

138

130

7

125

103

127

35

103

127

115

37

64

104

37

130

132

138

138

132

130

62

65

115

53

73

105

108

107

36

91

91

88

107

107

79

107

107

59

99

45

132

88

147

149

45

149

63

89

Sensor Assembly Drawing

60 Assembly Drawings Snap Linear Knife

Page 61

Mounting Assembly Drawing

75

97

95

107

38

111

103

76

113

101

101

101

101

100

98

80

Snap Linear Knife Assembly Drawings 61

Page 62

Cover Assembly Drawing

62 Assembly Drawings Snap Linear Knife

Page 63

Cover Assembly Drawing

Snap Linear Knife Assembly Drawings 63

Page 64

MCB J27MCB J23 MCB J28MCB J26

MCB J29

MCB J35

Part Number: 05621138

Harnesses

64 Assembly Drawings Snap Linear Knife

Page 65

DB J4

MCB J15

Part Number: 05621139

Part Number: 05621140

Snap Linear Knife Assembly Drawings 65

Page 66

REAR KNIFE SENSOR

CONTRAST SENSOR

FRONT KNIFE SENSOR

TOP REG SENSOR

BOTTOM REG SENSOR

Part Number: 05621141A

Part Number: 05621142

Part Number: 05621146

66 Assembly Drawings Snap Linear Knife

Page 67

Linear Knife Parts List

ITEM

PART NO.

DESCRIPTION

QTY

ITEM

PART NO.

DESCRIPTION

QTY

1

010107

O-RING

1 27

124387

BELT - PULLEY/BLADES

1 2 093986

SCREW - TAPTITE

4 28

124391

SHAFT-UPPER

1

3

099875

WASHER -CUTTER

1 29

124392

BRACKET-KNIFE MOUNTING

1

4

099944

E-RING (E3)

2 30

124393

FRAME-KNIFE LOWER

1 5 099945

E-RING (E5)

2 31

125038

ROLLER - SLIDER

2 6 100256

E-RING (E8)

2 32

125039

SHAFT - ROLLER, SLIDER

2 7 105023

IMPRESSION ADJ. KNOB

1 33

125040

BEARING - SLIDER ROLLER

4

8

627845

FRAME, KNIFE UPPER

1 34

126578

PLATEN DRIVE MOTOR ASSY

1

9

110894

KNIFE-BLADE

1 35

196028

KNOB, BLACK (GLOSS) .187 SHAFT

HOLE BUSHING SOCKET SET SCREW

1

10

110895

WHEEL-KNIFE

1 36

245026

STEPPER MOTOR, HARNESSED

1

11

110902

WIPER

2 37

354009

GEAR, DRIVEN

2

12

110904

SHAFT, LOWER

1 38

375021

BLOCK, HEAD ADJUST

1

13

110905

SHAFT, PIVOT

1 39

448010

STATIC BRUSH

1

14

110911

ECCENTRIC

2 40

541110

GROMMET, PLASTIC CLAMP

3

15

110916

WASHER - DAMPENING

2 41

621146

HARNESS, KNIFE SENSOR

2

16

110917

BEARING, UPPER PIVOT

4 42

584027

GEAR, IDLER 22T, 32P

2

17

627844

BEARING, LOWER PIVOT

2 43

584028

GEAR, NIP, 26T 32P

1

18

110923

BELT-TIMING SLIDER

1 44

584033

BRACKET, NIP ROLLER, OUTER

1

19

110924

BEARING - LINEAR

2 45

621142

SENSOR, REFLECTIVE HARNESSED

2

20

110925

SLIDER ASSEMBLY

1 46

624009

SHAFT, WEB TURN, STACKER MOUNT

2

21

111386

RING-PRONG LOCK EXTERNAL

1 47

624023

BRACKET, NIP ROLLER MOUNT

1

22

111418

BRACKET - DAMPENING

2 48

624024

ROLLER, NIP DRIVE, MOLDED

1

23

111419

GROMMET - DAMPENING

4 49

624025

ROLLER, NIP IDLER

1

24

111884

SPRING-EXTENSION

2 50

624037

GEAR, NIP IDLER, ALTERED

2

25

117902

GEAR, PLATEN

1 51

624038

BRACKET, STRIPPER

1

26

117903

BALL BEARING

2 52

627029

STANDOFF, KNIFE MOTOR

2

Snap Linear Knife Assembly Drawings 67

Page 68

ITEM

PART NO.

DESCRIPTION

QTY

ITEM

PART NO.

DESCRIPTION

QTY

53

627801

FRAME, LINEAR KNIFE

1 79

627835

BRIDGE BLADE, LOWER SENSOR

1

54

627802

BRACKET, KNIFE MOTOR MOUNT

1 80

627836

KNOB, HEAD ADJUST

1

55

627804

BRACKET, FEED MOTOR MOUNT

1 81

627837

BLOCK, SENSOR ADJUST, BOTTOM

1

56

627805

ASSY, BRACKET, NIP MOUNT

1 82

627838

BRACKET, KNIFE PIVOT LOWER

1

57

627806

BRACKET, LOWER SUPPORT FRAME

1 83

627839

BRACKET, 700 FOOT

1

58

627807

SHAFT, FEED

1 84

627840

BRACKET, LOWER REAR

1

59

627808

SHAFT, FEED EXTENSION

1 85

627841

GUIDE, ENTRY

1

60

627809

HOLDER, BEARING CUP

2 86

627842

GUIDE, EXIT

1

61

627810

SHAFT, UPPER FEED, MOLDED

1 87

989978

#8 STAR WASHER

1

62

627812

SHAFT, SENSOR ADJUST UPPER

1 88

989985

WASHER, #2 SAE

2

63

627813

SHAFT, SENSOR ADJUST LOWER

1 89

990003

4-40 X 1/4 FHCS

2

64

627814

SHAFT, SENSOR ADJUST IDLER POST

1 90

990006

4-40 X 1/4" SOCKET HD CAP SCR

1

65

627815

BLOCK, SENSOR ADJUST

1 91

990080

10-32 X 3/8 CAP SCREW

8

66

627816

PULLEY, KNIFE MOTOR

1 92

990081

10-32 X 1/2 CAP SCREW

1

67

627817

BELT, KNIFE MOTOR

1 93

990102

WASHER, #10 SAE

8

68

627818

BRACKET, SLIDE SENSOR MOUNT

1 94

990104

10-32 E-S NUT

6

69

627820

SHAFT, NIP ROLLER DRIVE

1 95

990119

1/4-20 x 3/8 SHCS

1

70

627821

COVER, REAR

1 96

990146

1/4:20 HEX NUT

2

71

627822

COVER, LEFT

1 97

990167

1/4 SAE WASHER

1

72

627823

COVER, RIGHT

1 98

990232

5/16 X 3/8 SLDR SCREW

1

73

627824

GEAR, IDLER, 36T

1 99

990262

SNAP RING, 1/4

1

74

627825

STANDOFF, IDLER GEAR

2 100

990275

WASHER, 5/16 HARDENED

1

75

627826

BRACKET, KNIFE PIVOT

1 101

990277

WASHER, BELLEVILLE .750 x .330 x .025

4

76

627827

BRACKET, KNIFE MOUNT

1 102

990313

KNOB, SZ 10 THUMB SCREW

1

77

627829

BRACKET, DEFLECTOR

1 103

990325

SNAP RING, 3/16 "E" RING

12

78

627831

GEAR, FEED DRIVE

1 104

990326

SNAP RING, 1/4" E-RING

5

Linear Knife Parts List

68 Assembly Drawings Snap Linear Knife

Page 69

Linear Knife Parts List

ITEM

PART NO.

DESCRIPTION

QTY

ITEM

PART NO.

DESCRIPTION

QTY

105

990327

E-RING, 5/16

5 130

PB00500555

WASHER-PLAIN M01460

6

106

990424

4-40 X 3/8 SHCS

2 131

PB00500557

WASHER-PLAIN (6mm)

1

107

990513

TIE WRAP, TY523M SMALL

8 132

PB00520505

WASHER-EXT. LOCK

6

108

990533

MOUNT, ABMM-A

1 133

PB00520508

WASHER-EXT. LOCK M01460

3

109

990821

.300" ROUND CABLE STRAIN RELIEF

2 134

PB00720611

SCREW/LOCKWASHER (8-32 X 3/8)

1

110

990920

STRAIN RELIEF BUSHING

2 135

PB00735148

SCREW-M3-0.5X5 PHIL PAN HD

4

111

991372

6 SCREW, 6-32 X 1/4 PAN PHILLIPS

5 136

PB00735150

SCREW-M3-0.5X8 PHIL PAN HD

2

112

991373

8 SCREW, 8-32 X 1/4 PAN PHILLIPS

6 137

PB00745149

SCREW-PHILLIPS FLAT HEAD (M3 X 6)

4

113

991374

1/4 SCREW, 1/4-20 X 1/2 PAN PHILLIPS

3 138

PB00800525

NUT-HEX M01460

6

114

991377

10-32 X 3/4 PHILLIPS PAN HEAD SCREW

2 139

PB00800527

NUT-HEX M01460

3

115

991379

10-32 X 3/8 PHILLIPS PAN HEAD SCREW

6 140

PB05910666

BEARING, BALL, SHIELDED (ROHS

COMPLIANT)

1

116

991442

SCREW, 8-32 X 3/8 PHILLIPS FLAT HEAD

3 141

621138

HARNESS, SNAP SIGNAL OUTPUT ROLLER

KNIFE

1

117

991454

8-32 X 1/4" THUMB SCREW

2 142

621139

HARNESS, SNAP POWER OUTPUT, ROLLER

KNIFE

1

118

991508

8-32 X 1/2 FLANGED BUTTON HEAD

SCREW

10 143

621140

HARNESS, SNAP / ROLLER KNIFE POWER

1

119

991510

BALL BEARING , 16mm O.D. x 8mm I.D.

FLG

2 144

621141A

HARNESS, SNAP / ROLLER KNIFE SIGNAL

PROGRAMMED

1

120

991523

SPRING, COMP 500/600 NIP ASSEMBLY

2 145

627834

ASSEMBLY, BRACKET, MOTHER BOARD

ENTRY

1

121

991646

M3 X 8 SHCS

4 146

627843

BLOCK, STACKER MOUNT

1

122

991648

LEVELING MOUNT, 1/4-20 X 1

2 147

990273

WASHER, #10 BELLEVILLE

4

123

991649

COMPRESSION SPRING

2 148

627847

PLATE, EXIT GUIDE

1

124

999076

BUSHING, 3/16 X 1/4 X 5/8

1 149

PB00730008

SCREW-PHILLIPS PAN HEAD (2-56 X 1/2)

2

125

999097

BUSHING, FL 1/4 X 3/8 X 3/16

1 150

991515

4-40 X 3/8 PHILLIPS HEAD SELF-TAPPING

SCREW

2

126

999098

BUSHING, 3/16 X 1/4 X 3/8

2 151

70030

CARTON, SHIPPING

1

127

999100

BUSHING, FL 3/16X5/16X1/8

4 152

70031

CARTON

1

128

999165

BUSHING, 3/16ID X 1/4OD X 1/4L

1 153

00054401

POLY BAG

1

129

PB00500554

WASHER-PLAIN

2 154

50038

BAG POLY 11 X 4 X 17 S

4

Snap Linear Knife Assembly Drawings 69

Page 70

ITEM

PART NO.

DESCRIPTION

QTY

ITEM

PART NO.

DESCRIPTION

QTY

155

627848

GUARD, COVER

1

156

989984

4-40 X 3/8 BHCS

2 157

989986

4-40 ES NUT

2 158

627850

SHAFT, IDLER, LOWER

1 159

627851

PULLEY, OUTBOARD

3

160

627849

SHAFT, IDLER, UPPER

2

161

990994

WIRE TIE, 8"

1

162

627853

LABEL, SERIAL NUMBER, LINEAR KNIFE

1

70 Assembly Drawings Snap Linear Knife

Page 71

Revision Date Description

2.1 11/18/2013 Initial release for part number 05621395 under ECN 3009741

2.2 02/07/2014 Add pictures of wire harnesses, ECN 3009839

Snap Linear Knife Assembly Drawings 71

Loading...

Loading...