Page 1

HowToRFID

How to RFID

With printers from Avery Dennison

Revision: 13 Date: 31 August 2009

Page 1 of 53

Page 2

HowToRFID

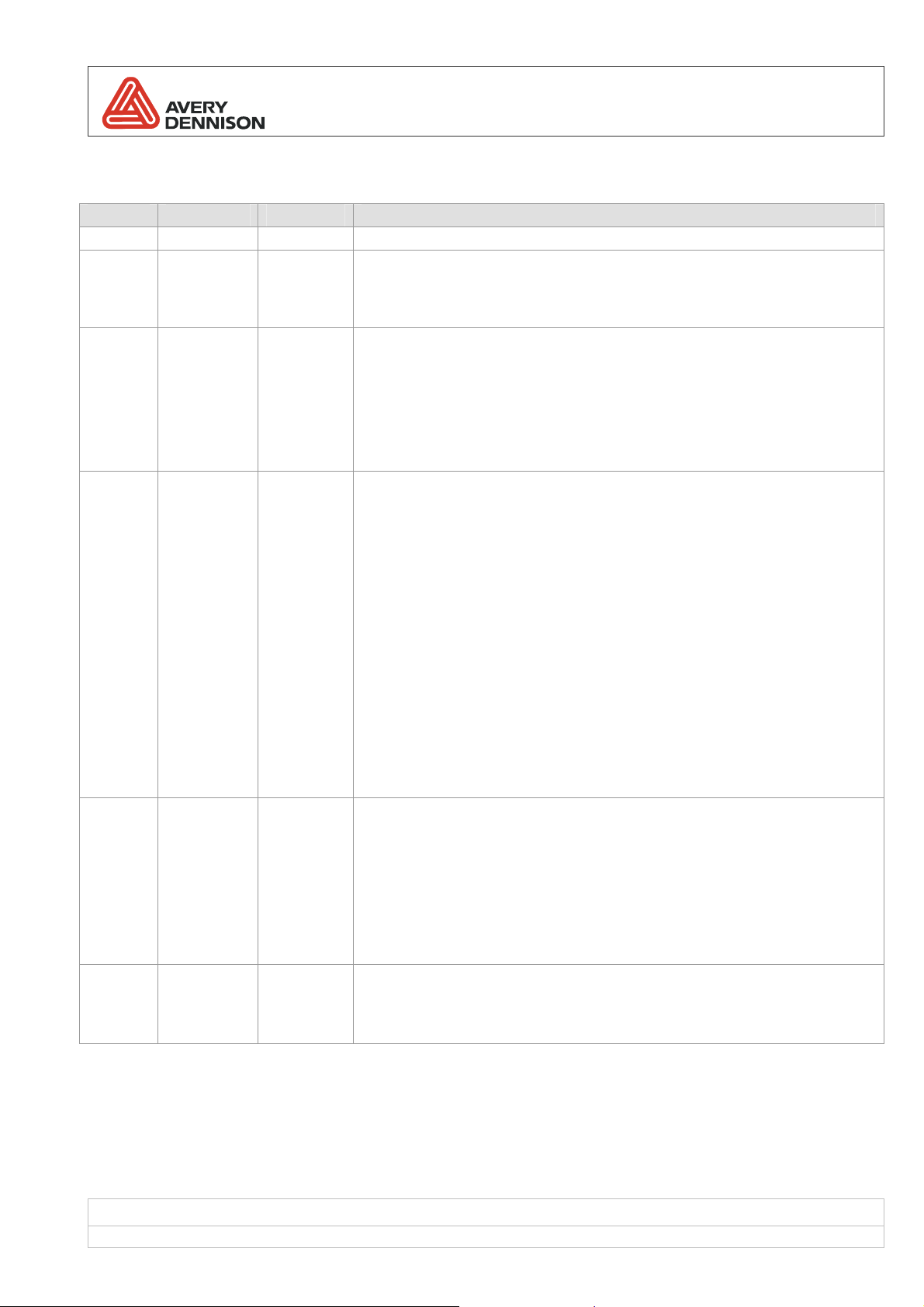

Revision history

Revision Date Author Changes

N/A Before 2007 M. Leiblich Changes have not been tracked in the past

7 2007-12-19 R. Boettcher Layout and document structure reworked

Section RFID basics removed

Section EasyPlug command description limited to commands not already

described in the EasyPlug manual (part of the printer documentation)

8 2008-05-30 R. Boettcher

9 2008-06-26 R. Boettcher Various changes indicating differences between standard printer firmware with

10 2008-08-21 R. Boettcher Adaptation of examples witch use PadLeft or PadRight functions to the syntax

11 2008-09-01 R. Boettcher

Section 3.1.2.1: Power level data updated (EU and US module data included)

Section 3.3.2.2: AWID Module identification clarified

Section 3.3.2.1: AWID Firmware compatibility list updated (EU Module => 4.10B)

Section: 4.1.1: HF Technology EAS bit added

Section 5.3.5.3: #RFC command description for modifying the EAS bit added

Section 6.2.7: Sample job for EPC/EAN128 4x6” shipping label added

Section 6.3 added an example for modifying the EAS bit of HF tags

RFID features and semi custom RFID firmware

New section 1 Summary of supported RFID features

New section 2.4.8 Processing failures (errors) – Bad tag signaling

Section 2.2: size limit of 224 bits user memory for NXP chip based tags removed

Section 3.3.2.1: size limit of 224 bits user memory for NXP chip based tags

removed

Section 3.1.2.1 Power level: power level tables and diagrams for AWID EU and

US RFID reader modules updated

Section 3.1.3 Parameters for error handling: description for parameter “Try

times” added

New section 3.1.5 Recommendations for web / material handling

New section 5.1.3 Operation / EasyPlug command matrix

Section 5: description of #SI command updated

Section 5: description of #RFL command added

Section 6: sample for usage of access password (EPC Gen 2 tags) updated

documented in the EasyPlug manual and implemented in firmware versions >=

x.33 (first standard release with RFID). The syntax was changed compared with

previous semi custom releases!

Affected examples:

Section 6.2.3: Write / Read / Print EPC with consecutive numbering

Section 6.2.6: Writing a SSCC-96 to tag

Section 6.2.7: EPC/EAN128 shipping label (SSCC + SSCC-96) + automatic

transfer from Barcode SSCC (NVE) to EPC using a scanner

Section 1.2: Correction of Korea Frequency Range

Section 2.3: table Table 2 – Available RFID kits updated, added 64-08 UHF kits,

HF kits for DPM/ALX removed

Revision: 13 Date: 31 August 2009

Page 2 of 53

Page 3

HowToRFID

Revision Date Author Changes

12 2008-09-22 R. Boettcher

13 2009-08-31 R. Boettcher

Section 3.3.2.1: List of approved AWID Firmware versions updated

Section 1.1: added “PEM” in the list of RFID enabled systems

Section 2.3: added part numbers for PEM / HF RFID kits

Section 2.4.4 “Using pre qualified supplies”: added a reference to the “RFID

Label Design & Printer Setup Guide” and the RFID inlay qualification process

Section 4.2 "Inlay qualification” added

Updated features list for printer firmware version Vx.34

Several sections: added transponder fields “AFI” and “DSFID” in field

descriptions; feature lists and command descriptions

Section 5.3.4.1: description of #SRF command; optional use of the size

parameter for reading the TID, MEMBANK field

Section 2.4.6: description of the new write based hotspot-/profile test of firmware

version >= X.34

Finalization of changes introduced in revision 12 (no significant changes of

content)

Revision: 13 Date: 31 August 2009

Page 3 of 53

Page 4

HowToRFID

Content

1

1.1

1.2

1.3

2

2.1

2.2

2.3

2.4

2.4.1

2.4.2

2.4.3

2.4.4

2.4.5

2.4.6

2.4.7

2.4.8

2.4.9

2.5

3

3.1

3.1.1

3.1.2

3.1.3

3.1.4

3.1.5

3.2

3.2.1

3.2.2

3.3

3.3.1

3.3.2

4

4.1

4.1.1

4.1.2

4.2

4.2.1

4.2.2

4.2.3

4.2.4

5

5.1

5.1.1

5.1.2

5.1.3

5.2

5.2.1

5.2.2

5.3

5.3.1

5.3.2

5.3.3

5.3.4

5.3.5

6 Applications / Examples ......................................................................................................................42

Summary of supported RFID features ...................................................................................................6

RFID in a printer ....................................................................................................................................8

Prepare the printer...............................................................................................................................20

RFID Transponder / tags / inlays.........................................................................................................28

Reading and writing RFID data using EasyPlug .................................................................................33

RFID enabled systems (machines)...........................................................................................6

UHF Technology .......................................................................................................................6

HF Technology..........................................................................................................................8

Introduction ...............................................................................................................................8

Supported Technologies ...........................................................................................................8

Hardware prerequisites .............................................................................................................9

Processing of RFID tags in the printer ....................................................................................10

General................................................................................................................................10

Mechanical specifications / restrictions ...............................................................................11

Inlay position / Tag antenna coupling..................................................................................12

Using pre qualified supplies ................................................................................................14

Finding and defining the optimum coupling position (the “Hotspot”)...................................14

Hotspot-/Profile test .............................................................................................................15

Processing failures (errors) – Invalidating labels ................................................................17

Processing failures (errors) – Bad tag signaling .................................................................18

Statistics ..............................................................................................................................18

Using a cutter ..........................................................................................................................19

Configuration...........................................................................................................................20

Activating the RFID-option ..................................................................................................20

Material depending RFID parameters .................................................................................20

Parameters for error handling .............................................................................................22

Chip protection ....................................................................................................................23

Recommendations for web / material handling ...................................................................23

Additional support functions ....................................................................................................24

Functions for testing purpose ..............................................................................................24

For information ....................................................................................................................24

AWID RFID module firmware update......................................................................................25

Update procedure................................................................................................................25

Dependencies .....................................................................................................................26

Memory layout (data fields) of RFID Tags ..............................................................................28

HF Technology ....................................................................................................................28

UHF Technology (EPC tags)...............................................................................................28

Inlay qualification.....................................................................................................................30

The inlay qualification process ............................................................................................30

RFID Label Design & Printer Setup Guide + RFID Suppy Specifications...........................31

Terms used in the inlay specifications and related documents...........................................31

Printer specific dimensions and restrictions ........................................................................32

Design an EASYPLUG job......................................................................................................33

The Basics...........................................................................................................................33

Concepts of data handling...................................................................................................33

Operation / EasyPlug command matrix...............................................................................33

Legacy EasyPlug commands..................................................................................................34

Read and Write operations..................................................................................................34

Other RFID operations ........................................................................................................35

Commands using the variable data handling mechanism ......................................................35

Definition of variables and data manipulation .....................................................................35

Data coding schemes / coding scheme conversion............................................................35

Functions .............................................................................................................................36

Read and Write operations..................................................................................................37

Sending data (read from tag) to an interface ......................................................................39

Revision: 13 Date: 31 August 2009

Page 4 of 53

Page 5

HowToRFID

6.1

6.2

6.2.1

6.2.2

6.2.3

6.2.4

45

6.2.5

6.2.6

6.2.7

(NVE) to EPC using a scanner .........................................................................................................................48

6.3

6.3.1

7

References ..........................................................................................................................................53

Hot spot test (UHF Technology) .............................................................................................42

EPC class1 Gen2 features......................................................................................................42

Write / Read / Print EPC with 96bit (using variable data handling approach).....................42

Write / Read / Print EPC with 96bit (using legacy commands) ...........................................43

Write / Read / Print EPC with consecutive numbering........................................................43

Write / Read / Print user data (NXP G2/G2XM, Alien Higgs 3 chips only) using legacy commands

Lock data fields (activating write protection + use of access password..............................46

Writing a SSCC-96 to tag ....................................................................................................47

EPC/EAN128 shipping label (SSCC + SSCC-96) + automatic transfer from Barcode SSCC

HF Technology Features ........................................................................................................51

Modifying the EAS bit of NXP I-Code based inlays ............................................................51

Revision: 13 Date: 31 August 2009

Page 5 of 53

Page 6

HowToRFID

1 Summary of supported RFID features

1.1 RFID enabled systems (machines)

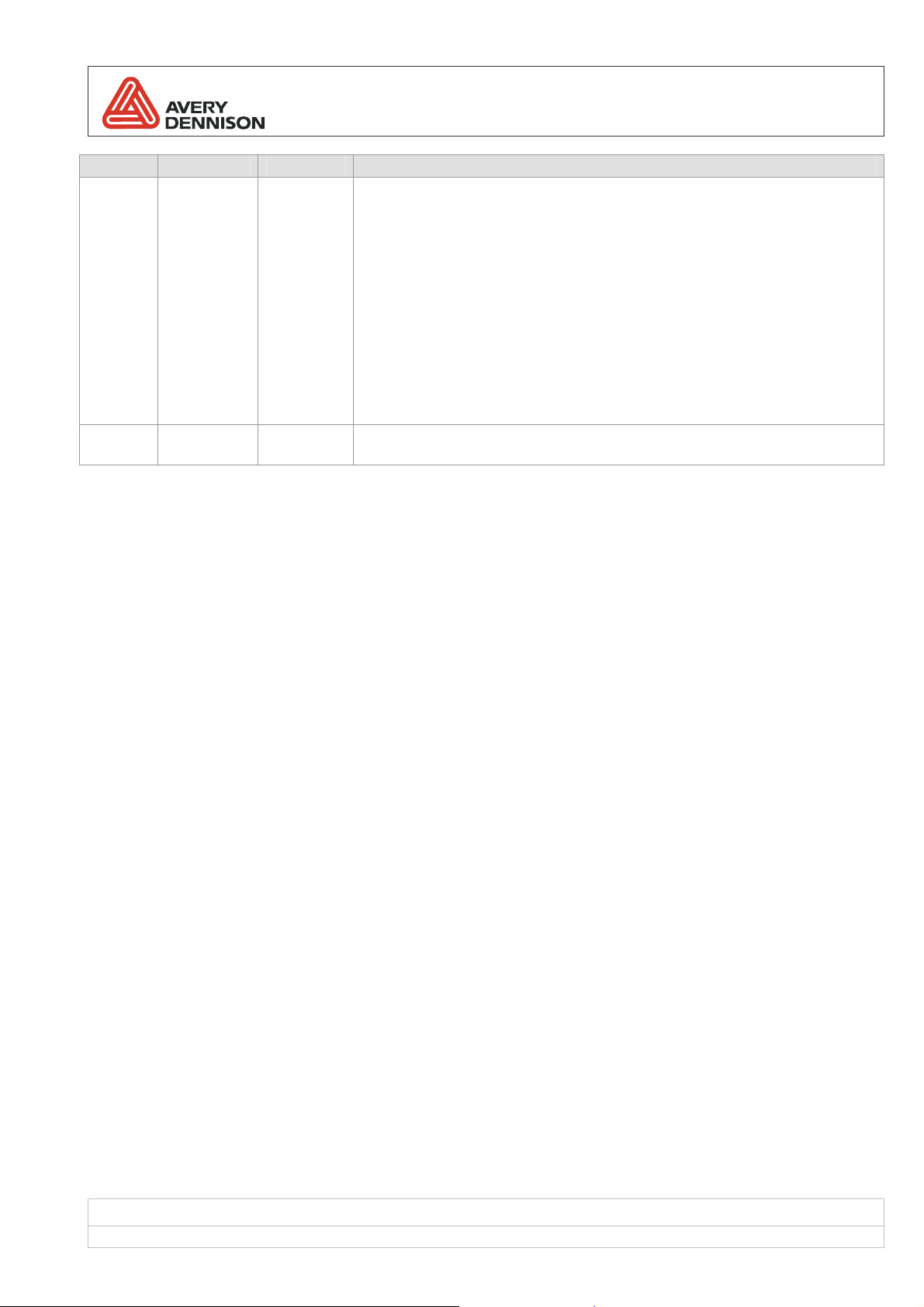

System UHF Technology

Region

AP 5.4 supported

EU / US / Korea

64-04 / 64-05 / 64-06 supported

EU / US / Korea

ALX 924 / ALX 926 supported

EU / US / Korea

PEM not supported supported

HF Technology

not supported

supported

not supported

For details please see section 2.2 and 2.3.

Limitations

− 64-0x printers: the combination of dispenser option and RFID option is not supported.

1.2 UHF Technology

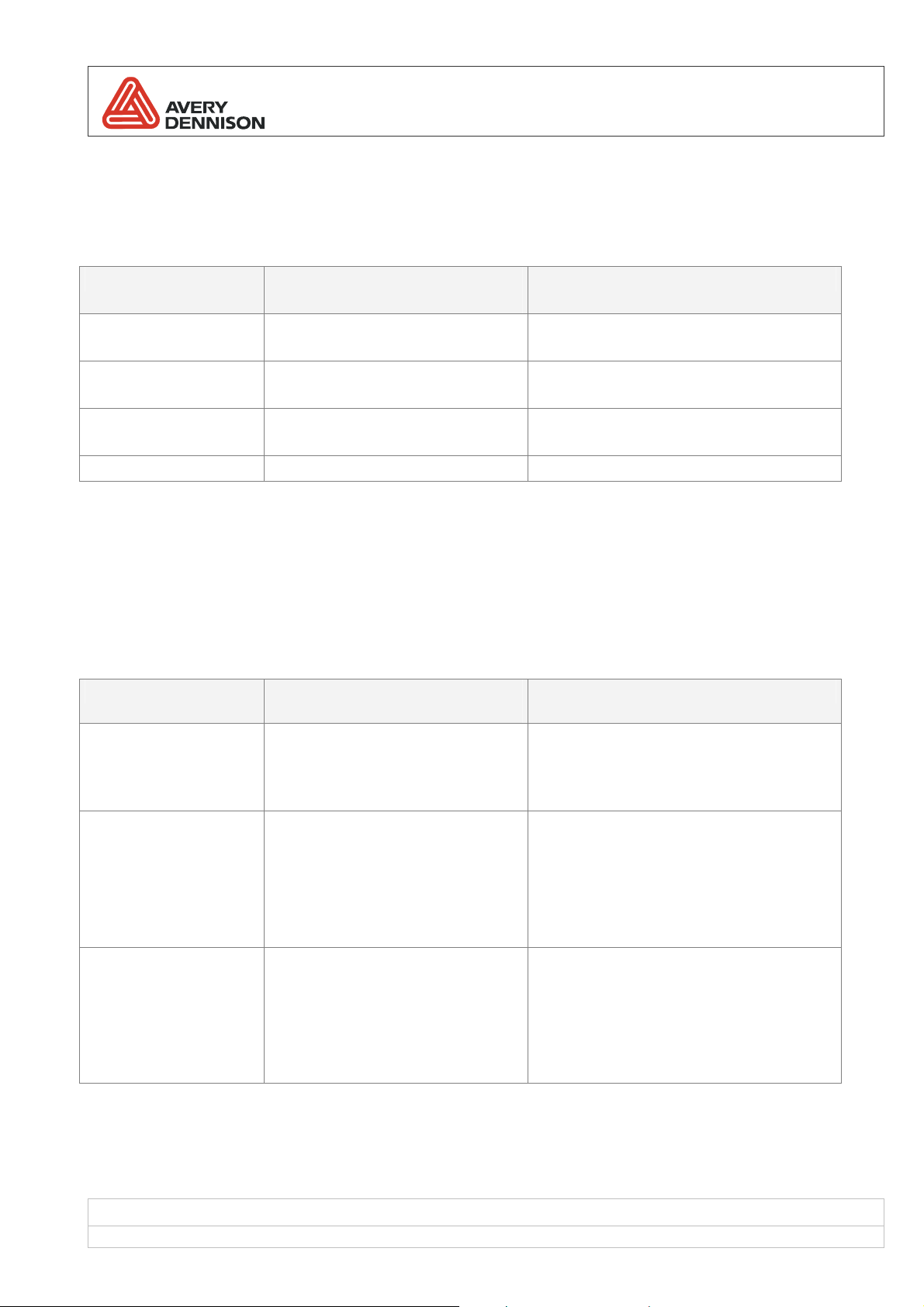

Feature / Classification Supported standards / variants /

options

Regions / Frequencies EU: 869.525 MHz

US: 902-928 MHz (Frequency hopping)

Korea: 910-914 MHz (Frequency

hopping)

UHF protocols / standards EPC Class 1 Gen 2

ISO / IEC 18000-6C

Addressable tag data tag

fields

EPC Class 1 Gen 2 tags:

EPC (64 / 96 Bit, up to 240 bit)

User memory (up to 512-Bit)

TID

Access password

Kill password

AFI

Notes

For each region a specific RFID reader module

is required.

protocols supported only by semi custom

releases of printer firmware:

EPC Class 1 (“Alien” protocol)

EPC C0 / C0+ (“Matrix” protocol)

EPC V1.19 Rev 2

Impinj Zuma

ISO 18000-6B (U-Code, HSL)

Please note the limitations for specific fields

Revision: 13 Date: 31 August 2009

Page 6 of 53

Page 7

HowToRFID

Feature / Classification Supported standards / variants /

options

Operations General

optional 2 pass verification of written

data

Data field specific

EPC: R / W / L / U

User memory: R / W / L / U

TID: R

Access password: W / L / U

Kill password: W / L / U

AFI field (*1): R / W

Tag data encoding

standards

Special features

All EPC global defined tag data standard

encodings are supported.

Chip protection feature (64-0x + ALX

only)

Bad tag signal: in case of tag

processing errors a “bad tag signal”

(BTS) is sent to the AI-board.

If not noticed otherwise all features are supported by the AP 5.4, the 64-0x printers and the ALX print and apply

system.

Notes

R = read content of data field

W= write / change content of data field

L = lock (write protect) data field (requires a nonzero access password)

U = unlock (remove write protection)

*1): printer firmware >= Vx.34

It’s preferred to generate the encoded data in

the host system in hex ascii encoding. If this is

not possible the printer can do various data

transformations on bit- and byte level to build

EPC conform data structures from basic

identifiers itself.

Direct transformations of EPC global defined

URI encodings are not supported.

The bad tag signal (BTS) signal can control a

bad tag removal unit (for example the bad tag

separator).

Limitations

AP 5.4 with cutter

− Inlay placement must be close to the inlay depending optimum position.

This is due to the limited back feeding capabilities in general (ribbon wrinkling!) and exceptionally for use of the

add-on cutter (possible loss of contact between material and feeding mechanism) and the need for additional

material movement to reach the RFID operating/coupling position.

− Minimum length of label >= 50 mm

This is due to the requirement to have the inlay in the optimum position and the position of the RFID antenna

inside the printer.

See section 2.5 for details.

AP 5.4 dispenser

− Inlay placement must be close to the inlay depending optimum position.

This is due to the limited back feeding capabilities (ribbon wrinkling!) and the need for additional material

movement to reach the RFID operating/coupling position.

Revision: 13 Date: 31 August 2009

Page 7 of 53

Page 8

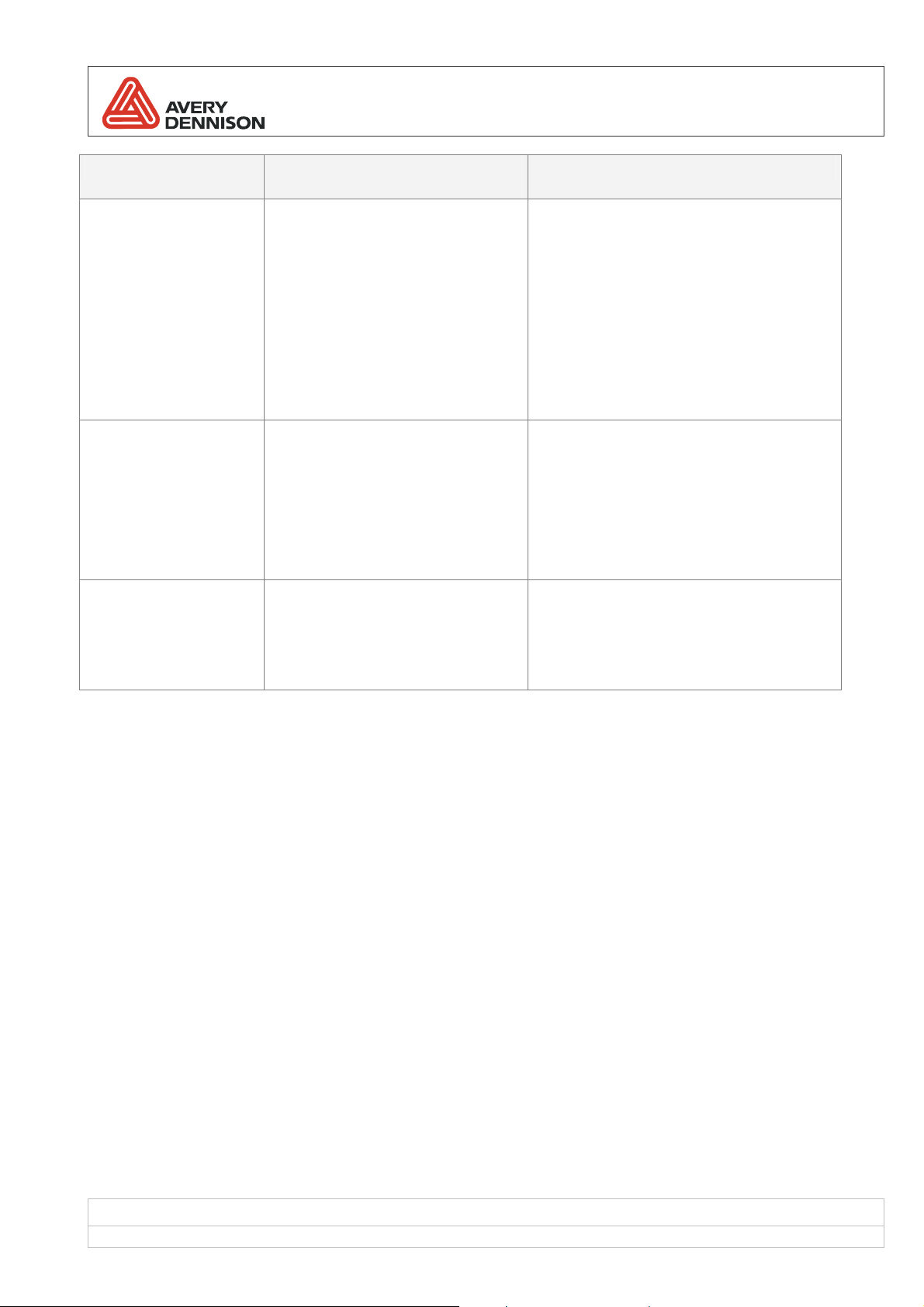

1.3 HF Technology

HowToRFID

Feature / Classification Supported standards / variants /

options

Regions / Frequencies global: 13.56 MHz

HF protocols / standards

Supported transponders

(tags / chips)

Addressable tag data tag

fields

Operations Data field specific

Tag data encoding

standards

Special features

ISO 15963

ISO 18000-3-Mode 1

Infineon my-d

NXP I-Code 1

NXP I-Code SLI

NXP I-Code EPC

NXP I-Code UID

TI Tag-it HF ISO

User data (block data)

UID

AFI (*1)

DSFID (*1)

EAS-Bit

User data (block data): R / W

AFI: W

DSFID: W (*1)

EAS-Bit: W / L (*1)

n/a

Chip protection feature (64-0x + ALX

only)

*1): printer firmware >= Vx.34

Notes

R = read content of data field

W= write / change content of data field

L = lock (write protect) data field

U = unlock (remove write protection)

2 RFID in a printer

2.1 Introduction

A RFID capable printer from Avery Dennison can be viewed as a normal label printer extended by RFID specific

parts (an RFID reader and an antenna). These parts are available as RFID-Kit for AVERY printer (compare table

1).

In addition to that you need smart labels. Smart labels are labels that are combined with an RFID tag. On the one

hand these labels can be used as normal labels to print human readable information on it and on the other hand as

RFID tags to read/write data in their memory.

2.2 Supported Technologies

Currently supported tags operate at either 13.56 MHz (HF) or 915/869 MHz (UHF). The following is a steady

growing list of supported tag types from different vendors.

Revision: 13 Date: 31 August 2009

Page 8 of 53

Page 9

HowToRFID

Manufacturer Tag type

Name ID

HF Technology

NXP (Philips)

I•CODE 1 (A) 2 512 bit 4 16 (11)1 proprietary

I•CODE SLI (A) 3 1024 bit 4 32 (28) 2 ISO 15693

I•CODE EPC (B) 7 96 bit EPC / no UID 1 17 proprietary

I•CODE UID (B) 8 192 bit / with UID 1 24 (12) proprietary

Tag-it HF * 256 bit 4 8 proprietary Texas Instruments

Tag-it HF ISO (A) 4 2048 bit 4 66 (64)3 ISO 15693

My-d (A) 1 10240 bit 10 (8)4 128 (125)5 ISO 15693 Infineon

My-d V2 (A) 1 10240 bit 4 256 (250) ISO 15693

UHF Technology

Matrics (1) EPC class 0 5 64 / 96 bit EPC na na proprietary

Alien (1) EPC class 1 6 64 / 96 bit EPC na na proprietary

U•CODE EPC 1.19 10 64/96 bit EPC + 256 bit user data 1 32 proprietary NXP (Phillips) (1)

U•CODE HSL 11 2048 bit 4 64 proprietary

Impinj (1) Zuma / EPC class 0+ 12 64/96 bit EPC + up to 64 bit user data 2 depending on

Various EPC class 1 Gen2 15 64..240 bit EPC (+ available user data) 2 0 / 14 / 326 EPC class 1

Table 1 – Supported transponder types

Memory Blocksize

in byte

Nr of blocks

(user data)

EPC size

Standard

proprietary

Gen2

Key: Text not longer supported

(option) (A) or (B) = different module options, one per module supported

(1) only supported by semi custom firmware (not standard firmware version X.33 and later)

2.3 Hardware prerequisites

For the different RFID technologies, printers and printer generations there are RFID upgrade options available. See the

following list of part numbers.

Application Country

HF WW (13.56 MHz)

UHF

EU (869.525 MHz)

US (915 MHz)

1

5 blocks are reserved internally. They are hidden from the user. There is an effective block range from 0 up to 10.

2

4 blocks are reserved internally. They are hidden from the user. There is an effective block range from 0 up to 27.

3

There is an effective block range from 0 up to 63.

4

There are 2 extra bytes for each block reserved for administration purposes. From an user point of view there are 8 bytes per block.

5

The first three blocks are reserved for internal purposes - for example ISO unique identification number (UID). These blocks are NOT hidden

from the user. These blocks cannot be written, but can be read. There is an effective block range from 0 up to 127. Block 0 contains UID.

6

NXP / Philips chips only

Description

Option for 64-04

Option for 64-05

Option for 64-06

Option for 64-04/05

Option for 64-06

Option for AP 5.4

Option for ALX/DPM 4/5"

Option for ALX/DPM 6"

Option for 64-04/05

Option for 64-06

Option for AP 5.4

Option for ALX/DPM 4/5"

Variant Part number

X1237

X1232

X1238

X1443

X1444

X1445

LH/RH X1446

LH/RH X1447

X1448

X1449

X1450

LH/RH X1451

Revision: 13 Date: 31 August 2009

Page 9 of 53

Page 10

HowToRFID

Application Country

64 bit series “High Performance” – RoHS compliant – Generation 3

HF WW (13.56 MHz)

UHF

Korea (910~914MHz)

EU (869.525 MHz)

US (915 MHz)

Korea (910~914MHz)

Description

Option for ALX/DPM 6"

Option for 64-04/05

Option for 64-06

Option for AP 5.4

Option for ALX/DPM 4/5"

Option for ALX/DPM 6"

Option for 64-04/05 HP

Option for 64-06 HP

Option for PEM 4/5”

Option for PEM 6”

Option for 64-04/05 HP

Option for 64-06 HP

Option for 64-08 HP

Option for ALX/DPM 4/5" HP

Option for ALX/DPM 6" HP

Option for 64-04/05 HP

Option for 64-06 HP

Option for 64-08 HP

Option for ALX/DPM 4/5" HP

Option for ALX/DPM 6" HP

Option for 64-04/05 HP

Option for 64-06 HP

Option for 64-08 HP

Option for ALX/DPM 4/5" HP

Option for ALX/DPM 6" HP

Variant Part number

LH/RH X1452

X1675

X1676

X1677

LH/RH X1678

LH/RH X1679

X1701

X1702

LH/RH X1716

LF/RH X1717

X1687

X1688

X1787

LH/RH X1689

LH/RH X1690

X1691

X1692

X1788

LH/RH X1693

LH/RH X1694

X1695

X1696

X1789

LH/RH X1697

LH/RH X1698

Table 2 – Available RFID kits

2.4 Processing of RFID tags in the printer

2.4.1

RFID operations are seamlessly integrated in the printing process of an AVERY printer. AVERY printers are

printing labels by means of EasyPlug commands. EasyPlug is a command oriented language for printer control.

There are some command extensions and several new commands to EasyPlug that handle RFID specific

operations. For the correct use of these commands it is necessary to understand process of printing first.

The basic RFID operations are READ data from tag and WRITE data to the tag. There is one more operation called

SELECT that is important for RFID communication. Because there can be more than one tag in the range of a

reader each tag has to be distinguished from another. This can be done by asking tags for their identification

number and select one tag because of this number. Once a tag is selected you can operate on a tag with

READ/WRITE operations. (The selection is an integrated part of each READ/WRITE operation, so there is no

special command the user needs to issue for this).

General

Revision: 13 Date: 31 August 2009

Page 10 of 53

Page 11

HowToRFID

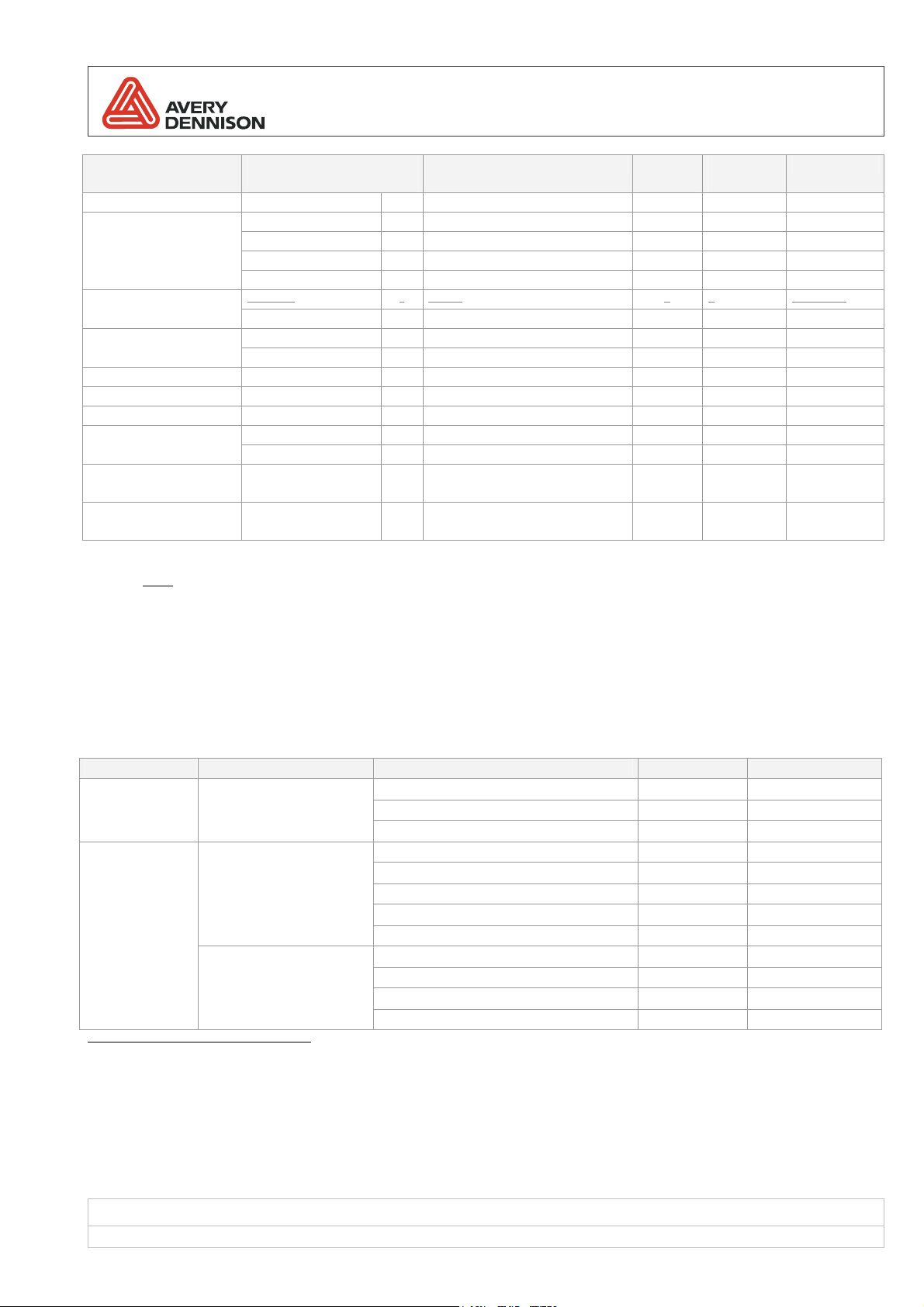

2.4.2

Definitions:

– Mechanical distances –

PH-CT: distance from print head (dot-line) to knife (cutting position)

PH-TB: distance from print head (dot-line) to tear bar (tear off edge)

PH-CA: distance from print head (dot-line) to center of printers RFID antenna

PH-DE: distance from print head (dot-line) to dispensing edge

– Mechanical restrictions –

MBF: maximum back-feed distance (without losing “grip” or ribbon wrinkling)

– Label/Inlay specific / depending distances –

LA: inlay / label specific distance from top of label to leading edge of inlay antenna

ILG: label specific inter label gap (distance between two subsequent inlays)

OPA: RFID operating point measured from leading edge of antenna of inlay

OPL: RFID operating point measured from leading edge of label (=> antenna offset)

Figure 1 shows a label web in the paper path of the printer with symbolic dimensions.

Mechanical specifications / restrictions

Figure 1: mechanical dimensions of the paper path (and label)

Revision: 13 Date: 31 August 2009

Page 11 of 53

Page 12

HowToRFID

Printer PH-CT [mm] PH-TB [mm] PH-CA [mm] PH-DE [mm] MBF [mm]

64-0X 17.13 10.50 62.00 48.50

AP 5.4 17.00 10.00 46.50 16

ALX 92x / DPM n/a n/a 50.00 24.20 (short

dispensing

edge)

39.80 (long

dispensing

edge)

Table 3 –Paper path dimensions of printer relevant for RFID

ca. 100

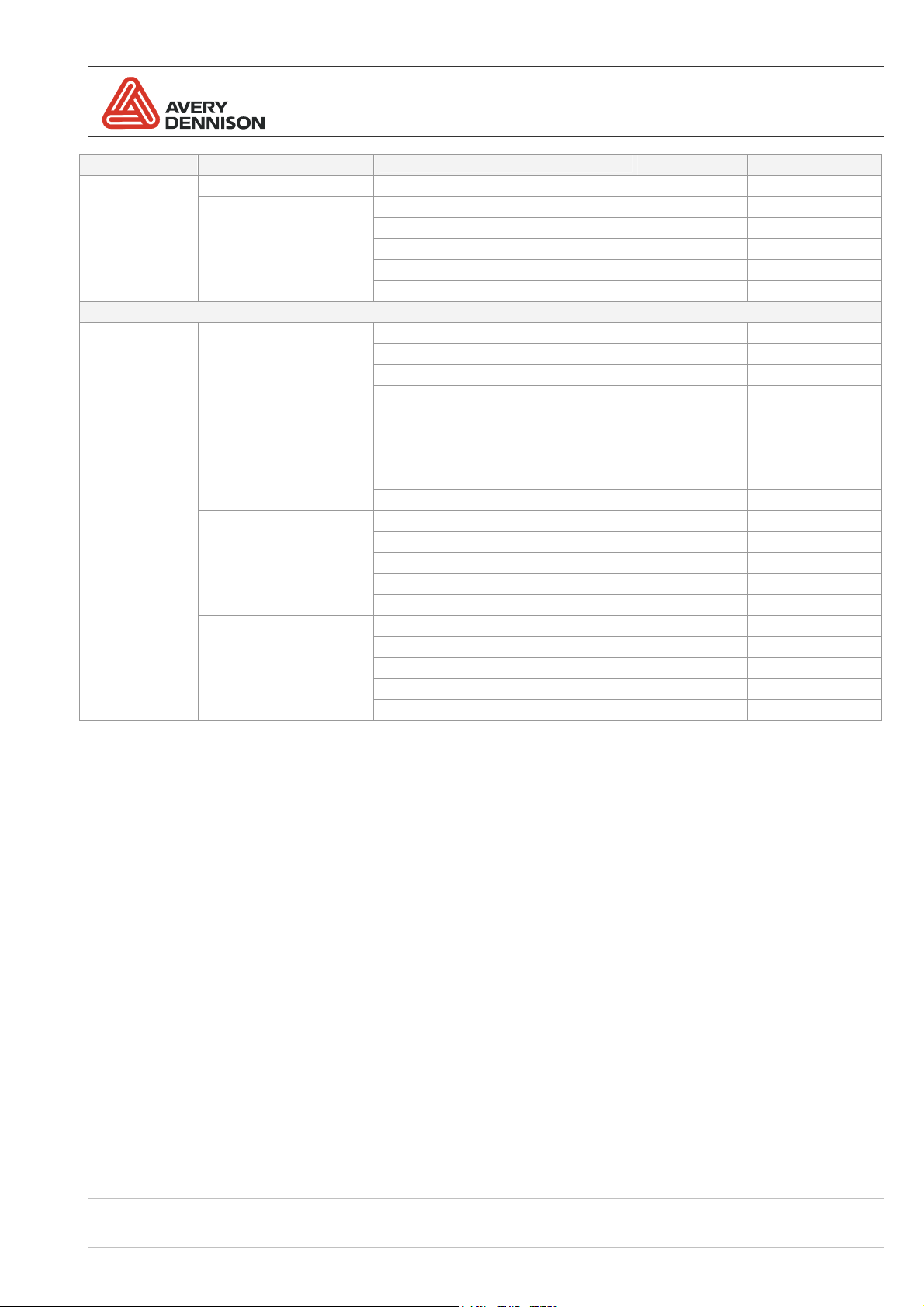

2.4.3

Inlay position / Tag antenna coupling

Smart labels with RFID functionality are treated by the printer in a two phase process. At first RFID functionality is

executed and afterwards the regular print processing is made. To communicate with an RFID transponder it has to

be in the range (RF field) of the built in reader antenna and it must be the only tag in range. For this purpose the

Easy Plug command #IM has been extended with a parameter called RFID antenna offset. It defines the distance

between label start and optimal coupling point position. In other words, it determines how much the label needs to

be back feed to bring the transponder in the right position near the printer’s antenna.

Figure 2: positioning at label start

Revision: 13 Date: 31 August 2009

Page 12 of 53

Page 13

HowToRFID

Material Feed Direction

Label X-1 Label X Label X+1

1

Label X-1 Label X Label X+1

2

Label X-1 Label X Label X+1

3

Label X-1 Label X Label X+1

0123456789

4

ABCD (1234)

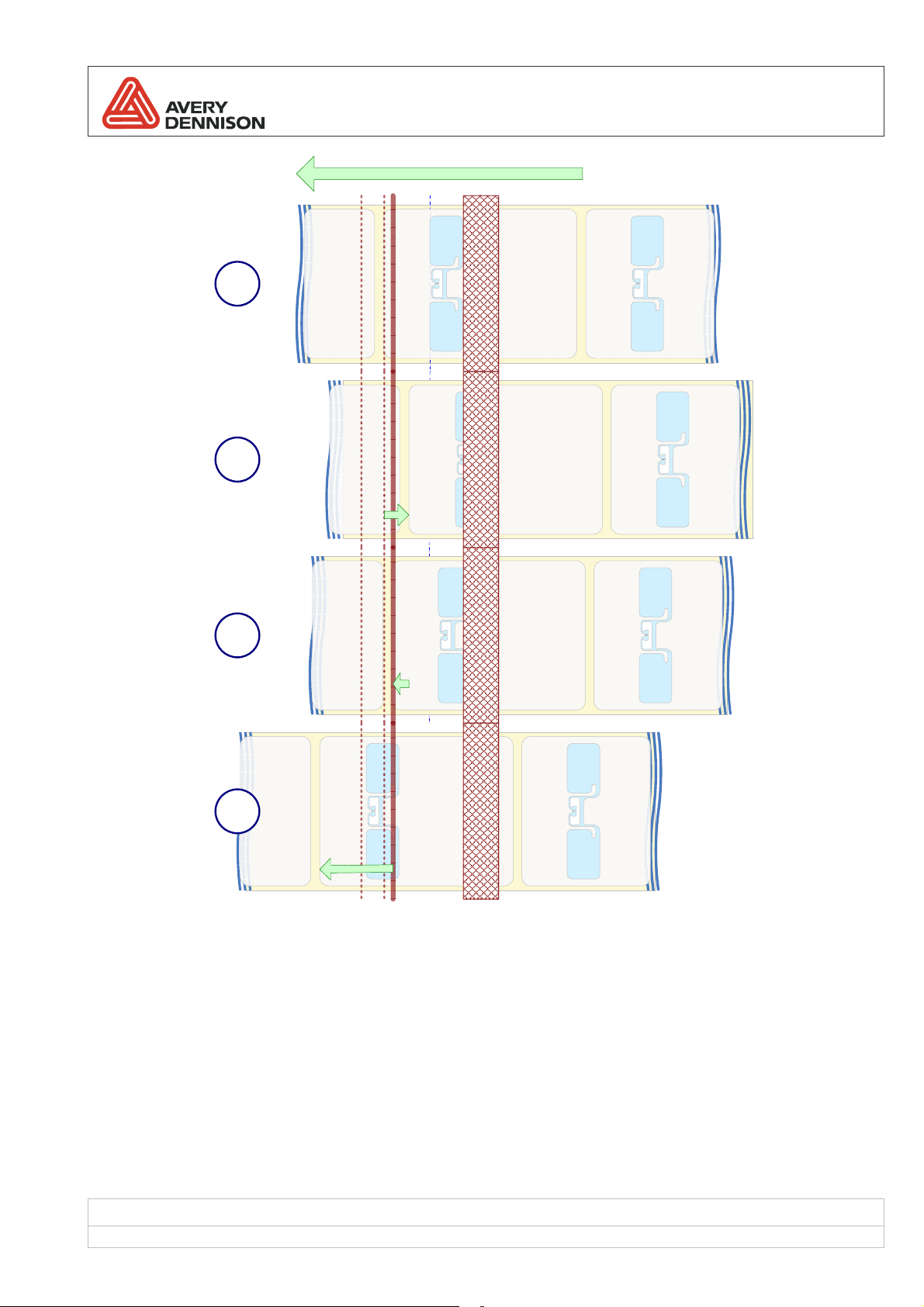

Figure 3: processing steps of RFID encoding and label printing:

(1) resting position before start of RFID processing / printing

(2) back-feeding of label to the RFID encoding position (move inlay antenna to best-match position with printer

antenna)

(3) forward-feeding to bring start of label to dot line again (after RFID encoding)

(4) label printing in progress

Label positioning is the first action that takes place when processing a RFID label. Afterwards all RFID commands

are executed. When this is finished the label is repositioned to the beginning and all other printing actions are

executed.

Revision: 13 Date: 31 August 2009

Page 13 of 53

Page 14

HowToRFID

2.4.4

RFID starter kits

Avery Dennison offers RFID starter kits for the RFID printers. The starter kit contains also RFID supplies (labels).

For those supplies a pre qualification was made and the parameters for adjusting the printer to this supply are

available on the supply data sheet. The supply is referenced by an Avery article number. If there is no data sheet

included in the supply package, please ask your reseller or the technical support team for the supply data sheets.

Application requires the use of another inlay?

Avery Dennison publishes a document called “RFID Label Design & Printer Setup Guide”. The content of this

document is the essential extract of an intensive inlay qualification process. Goal of that process is, to find the

optimum label design parameters and printer setup parameters for an “optimized” label.

It’s highly recommended to use the parameters determined in the RFID inlay qualification process for the

processing of inlays in the printer.

For further details see section 4.2…

Using pre qualified supplies

2.4.5

Finding and defining the optimum coupling position (the “Hotspot”)

If the position of the hotspot measured from the beginning of the label is close to the relative position of the

antenna, little or no material movement between RFID processing and printing is necessary. This leads to an

optimal performance (throughput).

But, due to shielding / coverage reasons this may be not the best position for coupling!

UHF Technology

Printer Position of the center-line of the

UHF antenna relative to print head

(dot-line)

64-0X 62.0 mm +/- 48 mm

AP 5.4 46.5 mm +/- 16 mm

ALX 92x / DPM 50.0 mm

PEM n/a n/a

Table 4 – Antenna position relative to print head

Inlay placement window (+/offset from ideal position)

TBD (depending on dispensing

mode, rewinder etc.)

HF Technology

Printer Position of the center-line of the HF antenna relative to

print head (dot-line)

64-0X 62 mm

AP 5.4 n/a

ALX 92x / DPM 80 mm

PEM n/a

Table 5 – Antenna position relative to print head

Revision: 13 Date: 31 August 2009

Page 14 of 53

Page 15

HowToRFID

2.4.6

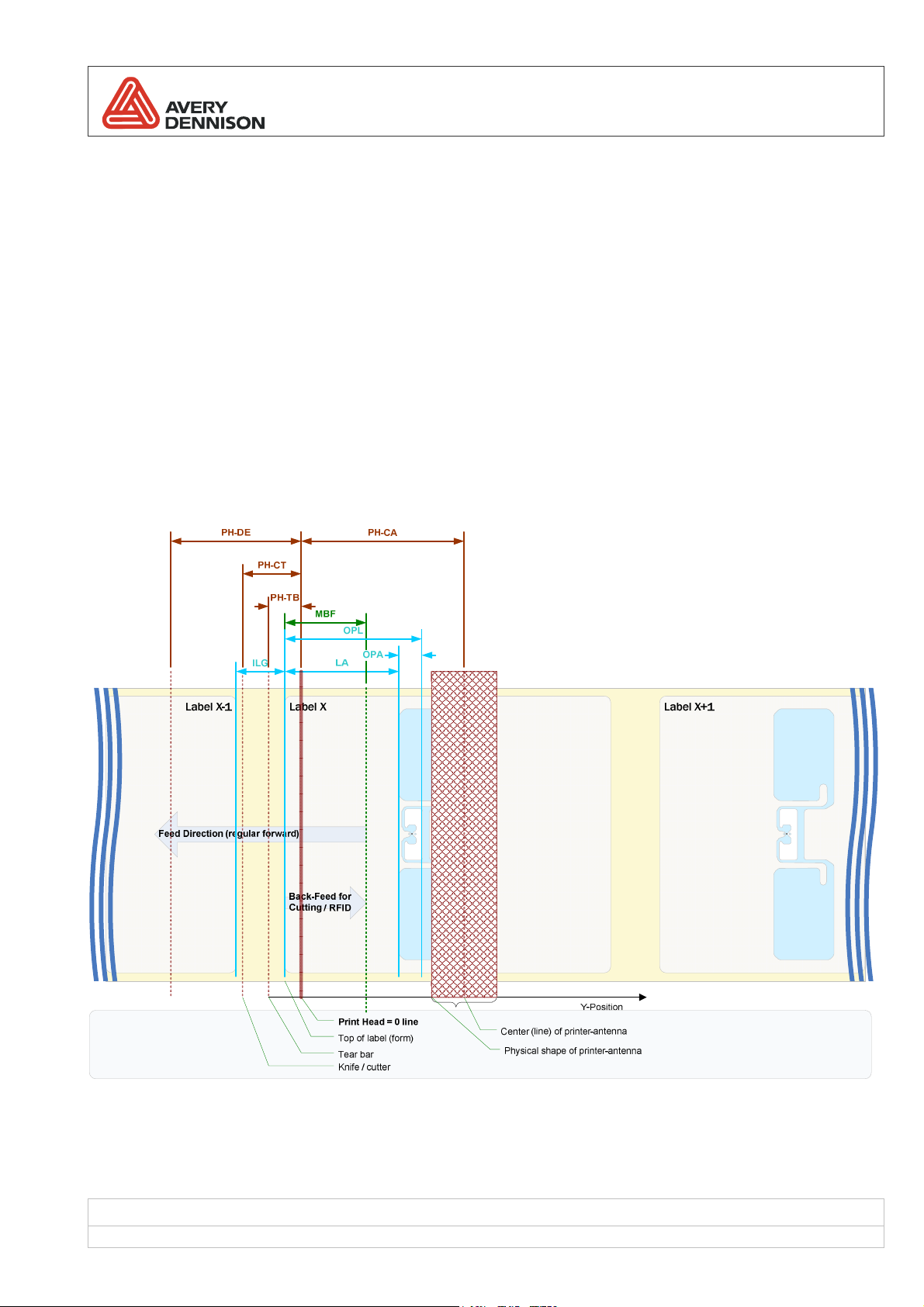

How to execute the hotspot-/profile test

To find an optimized antenna position, execute a “Hotspot test”. To execute a hotspot test use the menu item

“RFID Parameters / Hotspot test”.

Repeat the Hotspot test with different power level settings to find a combination of power level and antenna offset

which makes sure only the inlay in direct contact (located nearby) the antenna is processed and no adjacent read

or writes occur.

With attenuation power control (firmware version <= X.33):

Start with minimum power (high value, for example 245) and increase the power (decrease the power level value)

in steps of 5 or 10. Starting with low power identifies the most sensitive position.

With dBm power control (firmware version >= X.34):

Start with minimum power (low value, for example 5) and increase the power (increase the power level value) in

steps of 5. Starting with low power identifies the most sensitive position.

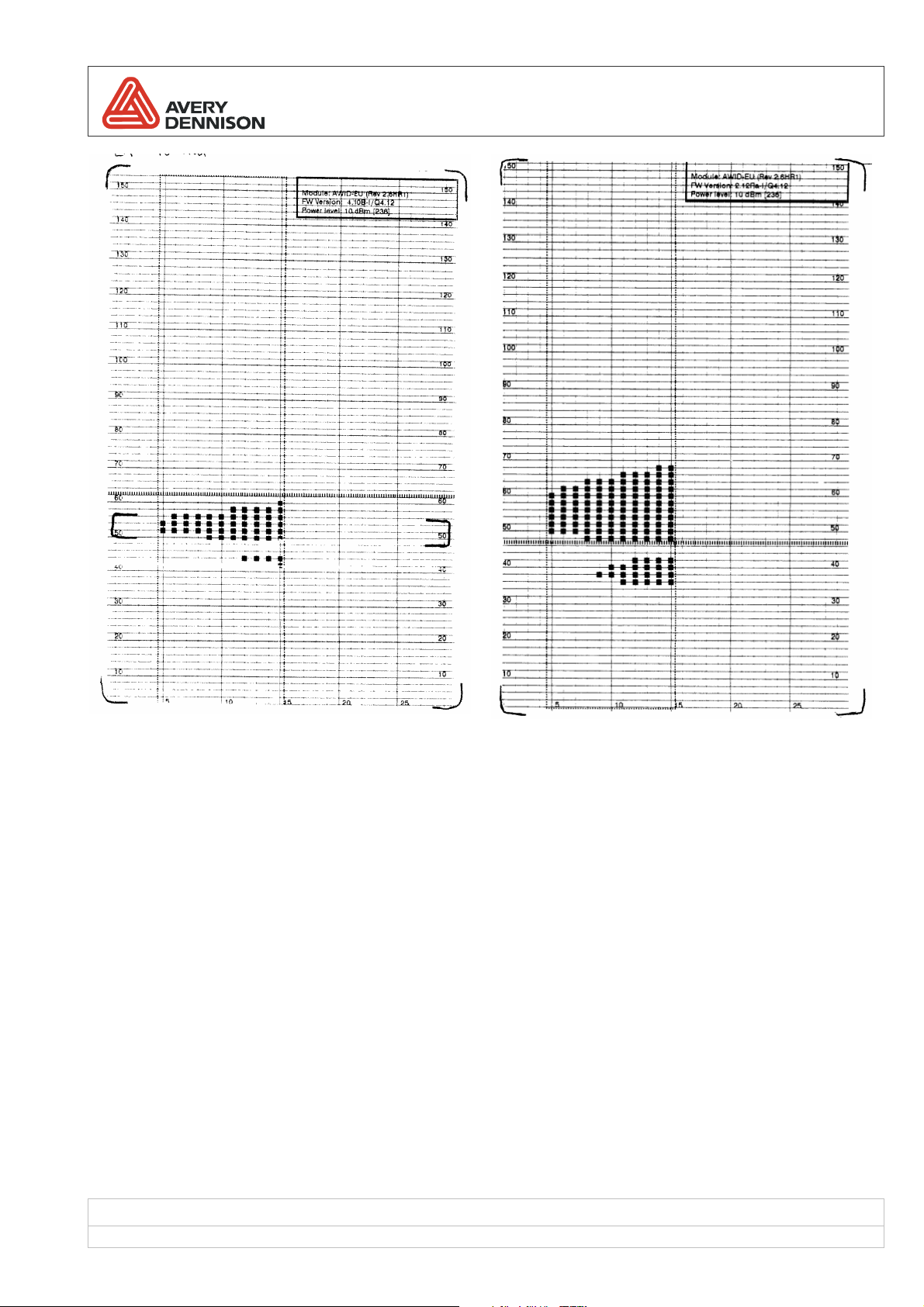

How to hotspot-/profile test works

Hotspot-/Profile test

At the beginning the printer positions the start of label (top of label) to the center of the printer’s antenna. During the

test the label gets feed stepwise by 2.0 mm until the end of the label reaches the position of the printers antenna.

The length of the label is determined by the current material length setting.

At each position the printer tries to write an EPC code to the tag with different power levels. The range of the power

level to be tested is determined by the current power level and ranges from current value -5 dBm ... current value +

5 dBm. At each test point (position / power level) a single write attempt is made and the result (success or failure)

gets recorded into the printer’s memory.

After the complete label has been processed, a test result graph is generated and printed to the same or a

following label. For short labels the printout can be printed to a following label due to slight slippage during feeding

and gap detection. If it’s required to print exactly to the same label, decreasing the material length by 1..3 mm may

help, especially if material length was adjusted with the auto-calibrate feature.

Hot to read the result printout

The Y-axis (feeding direction) direction shows the position (unit mm) of the “hotspot” relative to top of label (begin

of label = 0 mm). The position determined during analysis of the printout can be transferred 1:1 to the antennaoffset parameter of the EasyPlug #IM command.

The X-axis (across the label) shows the power level (unit dBm). Power level increases from left to right side (0 dBm

at the left side ca. 30 dBm on the right side). Possible range depends from the capabilities of the RFID reader

module.

A black dot (filled square) shows a successful encoding for the related position and power level. The complete

tested range (position and power level) is indicated by the dotted line rectangle.

Current settings of the RFID components (RFID reader module, firmware version, current power level) are shown in

the top right corner.

The thick dotted line across the label shows the position of the printer’s antenna (if TOL is at the print-head).

Revision: 13 Date: 31 August 2009

Page 15 of 53

Page 16

HowToRFID

AD 222 in 64-05 with AWID-EU reader module AD-222 in AP 5.4 AWID-EU reader module

How to select the antenna offset

Choose a region where at least 3 x 3 adjacent “dots” of the matrix show a successful writing. If there is more then

one region like this, choose one which is located near the center-line of the antenna in the printer (see 2.4.4). The

goal is to avoid unnecessary web movement to reach optimum throughput and to avoid problems from “loosing” the

material if a cutter or tearbar is used.

A note regarding the power level: please keep in mind “less is better”! Only use a high power level if there is no

large enough area in a low power level region for safe and reliable operation.

Revision: 13 Date: 31 August 2009

Page 16 of 53

Page 17

HowToRFID

Limitations of this test

The built-in hotspot-/profile test was designed to be a customer self-care instrument. It can not completely replace

the advanced and more detailed tests made during the inlay qualification process done by Avery Dennison. If

published printer settings are available for a specific inlay, it’s highly recommend to use that settings before making

several trials with self determined settings. During the inlay qualification process a lot more inlays are tested to

intercept possible performance decreases from placement and sensitivity tolerances. A test with a single RFID

label can never provide that level of reliability…

The following limitations apply:

1) The test can not determine write zones (sensitive zones) located before or after the label itself. For very short

labels where the inlay is located near top of label and / or near the end of the label (for example pure paper

faced inlays), the sensitive zones might be located in before or after the inlay.

2) The test can not determine whether crosstalk effects have an influence. Crosstalk effects: while trying to write

to the inlay nearest the printer’s antenna, the radio energy is reflected or otherwise forwarded to the adjacent

inlays (on the web) and those inlays respond to the write attempt to. For details about cross talk/adjacency

problems see section 4.2.

3) The material length must be adjusted to meet the real material length (+/-10%), otherwise the printout fails. If

the inlay is located near TOL in a (very) long label, it’s required to run the test for the whole label even if it’s

expectable to have a large “dead” zone at the end.

2.4.7

Processing failures (errors) – Invalidating labels

For HF technology the RFID command execution starts with selecting the tag under the antenna. When tag

selection fails, it is retried like every RFID command that can fail. After a defined number of retries (compare RFID

parameter „Number of CMD retries“) it is concluded that there is no transponder under the antenna or the

transponder is defective. This is documented by invalidating the label with printing a characteristic pattern

(diagonal bars) on the label.

Afterwards no more printing is done for this label and the next label is tried. This is repeated until a valid

transponder is found or a defined limit of invalid transponder in sequence is reached (defined in parameter „Max

tags to stop“).

When this maximum number of invalid labels in sequence is detected, job processing is stopped. It is assumed that

a certain number of invalid transponder is an indicator for a severe problem that has to be solved first. Afterwards

job processing can be continued.

Revision: 13 Date: 31 August 2009

Page 17 of 53

Page 18

HowToRFID

For UHF technology the step “selecting the tag” is skipped (not necessary). The RFID processing starts

immediately with the requested write or read operations. If one of the operations fails (is not successful) the label

gets invalidated in the same way is described for HF technology.

2.4.8

Processing failures (errors) – Bad tag signaling

As mentioned before if the RFID processing fails the label is invalidate. For automated processes this is not

sufficient because it must be made sure in not-encoded label is not released (forwarded) into a further process. As

a prerequisite for this requirement a print and apply system must signal RFID processing errors via a control

interface.

A mechanical unit for removal of invalid labels (also called bad tags) can be triggered by that signal and remove the

invalid label from the processing line.

BTS on the Applicator Interface

For the print and apply system ALX 924 / ALX 926 the bad tag signal is available on the applicator interface as

output signal “BTS”. For details see [AI-Manual].

An optional Bad Tag Separator can be attached to the ALX to remove the invalid labels by sticking them on a

waste roll.

Alternative solutions

Please note: the BTS is not available on the USI.

2.4.9

Statistics

There is information about RFID operations in a printable status. It tells you for example how many operations of

each type have been processed and how many of them have failed (compare).

RFID Status

System version V5.33

Printer type Avery 64-05

Nr. Cmd retries 3

Nr invalid tags 3

Statistics

Nr of tags 707

Nr invalid tags 72

Scrap rate 10.2 %

Total Nr SELECT 755

Invalid SELECT 17 %

Total Nr Read 730

Invalid Read 730

Total Nr WRITES 507

Invalid WRITE 29 %

…

Aug 01 2008

Figure 4: example of printable RFID information

Revision: 13 Date: 31 August 2009

Page 18 of 53

Page 19

HowToRFID

2.5 Using a cutter

There is a limitation by moving not more than 48 mm backwards for 64-0x and 17 mm for AP 5.4. For relevant

antenna positions in different machine/printer types see 2.4.4

This limitation must be considered if labels with a non-optimal inlay placement shall become processed. The inlay

must be placed behind the optimal position (away from top of label) to prevent additional back feeding for reaching

the RFID operation position. The optimal inlay position depends from the printer type and the inlay itself. Optimal

placement data for most common inlays is available on request.

Printer type Distance dotline / cutter

AP 5.4 17.00 mm

64 series 17.15 mm

Table 6 – Distances between dot line of print-head and cutter (cut line)

Revision: 13 Date: 31 August 2009

Page 19 of 53

Page 20

HowToRFID

3 Prepare the printer

3.1 Configuration

3.1.1

Activating the RFID-option

The very first thing to do for using RFID in an AVERY printer is to activate the RFID option. To activate RFID set

parameter „Interface Parameter / OPTIONS / RFID Option“ to the value of appropriate COM interface (internal

serial RS232 interface). After confirming the entry the printer reboots itself with appropriate settings for internal use

of COM.

Printer type RFID option (internal connection)

AP 5.4 (Marlin CPU board) Serial Com3

AP 5.4 (Redfin CPU board / Marlin MLK) Serial Com4

64 series / DPM / ALX 92x (Gen 2 CPU board) Serial Com2

64 series “High Performance” / DPM / ALX 92x (Gen 3 /

Dolphin CPU board)

Table 7 – Serial port for RFID option

3.1.2

Material depending RFID parameters

Serial Com4

3.1.2.1 Power level

The Power level setting is a very critical part of the whole setup of an RFID printer. The Power level setting controls

the output power of the radio module of the RFID reader. The output power must be adjusted an a way that the

inlay to be processed (in direct coupling with the antenna) gets enough “radio” energy to be able to respond to the

request from the RFID reader – but on the other side to avoid the activation of adjacent tags (resulting in unwanted

reads or writes from multiple transponders).

To find the right setting can be a tricky and time consuming process. It depends mainly from the dimensions of the

material especially the pitch between inlays and the type of inlay used.

To ease this process Avery Dennison has introduced a RFID inlay qualification process, were popular transponders

/ inlays get tested in the lab. See section 4.2 for details.

There is a simple rule of thumb: adjust to the lowest power level which gives constant success. Applying to much

power leads to problems caused by reflections and adjacent reads/writes.

Please note: the RF transmit power depends from the built-in RFID reader module, which is a different one for the

different regulatory regions (EU/ETSI, US/FCC, Korea).

Power control changing an “attenuation” value

Up to and including printer firmware versions Vx.33, the power level is adjusted by a numerical value which controls

the attenuation of the transmitted radio signal. Resultant in reverse logic: high numerical value => low power, low

numerical value => high power. The output power doesn’t follow a linear curve, especially in the range of 255 –

200. Therefore changes in small steps may result in very large differences in read / write success.

In most technical documents radio output power is measured in the unit of the physical power level mili watts (mW)

and is presented as logarithmic scaled value in dBm.

Revision: 13 Date: 31 August 2009

Page 20 of 53

Page 21

HowToRFID

The following table provides the correlation between the numerical setting and the physical value for the EU

module (C1616, hardware Rev A 2.6HR1) and the US module (C1184, hardware Rev E).

C1616 – EU Module (Rev A 2.6HR1) C1183 – US Module (Rev E)

Please note: range 0..30 dBm

Power dBm Attenuation Value

0 255

1 253

2 251

3 248

4 246

5 245

6 243

7 241

8 240

9 238

10 236

11 234

12 232

13 231

14 230

15 227

16 223

17 221

18 218

19 213

20 208

21 204

22 199

23 190

24 182

25 170

26 160

27 140

28 110

29 70

Please note: range 18..30 dBm

Power dBm Attenuation Value

18 255

19 230

20 200

21 160

22 140

23 110

24 90

25 70

26 55

27 40

28 25

29 10

30 0

Power Curve - AWID MPR 15xx EU, Rev A 2.6HR1, FW 4.07 I/Q4.06

35

30

25

20

15

Power Output (dBm)

10

5

0

0 25 50 75 1 00 125 150 175 200 225 250 275

-5

Power Setting (attenuation value)

Measured Power

35

30

25

20

15

Power Output (dBm)

10

5

0

0 25 50 75 100 125 150 175 200 225 250 275

Power Curve - AWID MPR 1510-AE RM Rev E (FCC) , FW 2.33B I/Q4.11

Measured Power

Power Setting (attenuation value)

Table 8 – Power level to attenuation mapping tables

As visible from the table and charts above there are big differences in the range of adjustable power for the

EU/ETSI and US/FCC modules. So a power level setting (attenuation value) for the EU module can not be simply

transferred to the US module.

Revision: 13 Date: 31 August 2009

Page 21 of 53

Page 22

HowToRFID

Power control by “dBm” scaled values

Starting with printer firmware version Vx.34 the direct control of the “attenuation” parameter was removed and a

new parameter “Power level in dBm” was introduced. The printer detects the built-in RFID reader module type +

hardware revision and uses an internal mapping table from the value in dBm to the attenuation value to be send to

the RFID reader module. To make it comparable with previously used settings the menu entry for power level

adjustment shows the resulting attenuation value from the selected dBm value.

The dBm value uses regular logic (low value = low power) and is in depended from the built-in module.

Please note: For applications using the EasyPlug #PC command for adjusting the power level as part of the printer

job an adaptation is needed. The parameter ID for the power level has changed and values need to be converted

to dBm. It’s not anymore possible to directly change the attenuation value.

Power control via EasyPlug

The RFID power level is adjustable via the EasyPlug #PC command. Changing the value shows immediate effect.

(Also during still running jobs, so be careful if working with different supplies.)

Parameter ID

− printer firmware version <= x.33: 5202 -> attenuation value

− printer firmware version >= x.34: 5208 -> dBm value

3.1.2.2 Antenna offset

The antenna offset is defined inside an EasyPlug job using the #IM command. Section 2.4 describes why you need

to set the offset and how to find the hotspot.

If you are using a label based on a qualified inlay, the value for the hotspot is mostly identical to the physical

antenna position in the printer (when label producer follows recommended inlay placement position). See section

4.2 for how to calculate the antenna offset for a deviating inlay placement.

3.1.3

Parameters for error handling

They can be found in the „RFID Parameter“ menu. Their meaning is

Parameter Effects

Max tags to stop Number of transponders (tags) that have to be invalid in sequence before a printing job is stopped.

This parameter exists because of the assumption that a certain number of invalid transponders in

sequence indicate a severe problem. After solving this problem the job can be continued.

Nr of CMD retries Number of internal RFID command retries (sending a command to the RFID reader module once

again of negative status is reported by the RFID reader module) before a fail is reported.

For HF technology especially SELECT retries are important when printer is used in noisy

environments.

Try Times UHF technology / AWID RFID reader module only:

This value controls how often the RFID reader module itself tries to perform a requested RFID

operation (read / write) until an error is reported. Setting a high value will result in lower throughput

in the case of bad tags or general non-matching RFID processing parameters (power level,

antenna offset).

The default value is set to 10 to get best throughput.

Increase this value if you have a poor yield rate resulting from a noisy environment.

Revision: 13 Date: 31 August 2009

Page 22 of 53

Page 23

HowToRFID

3.1.4

Another useful feature that can be activated on demand is “Chip protection”. Chips are part of the RFID inlay inside

a smart label. Most often they are much thicker than label material. Printing means putting pressure and heat to foil

and label. This might damage the chip. To prevent damage to the area where the chip resides, the print head can

be lifted in this area. Any printed output within the protected area is prevented.

Different implementations of chip protection

In printers without the capability for lifting the print head the chip protection features defines an unprintable area.

Any output in the chip protection area is suppressed so it stays blank. If you don’t use the chip protection keep in

mind that printing at the edges and on the inlay itself results in lower print quality due to the changes of thickness of

material.

Printer Effects

AP 5.4 Chip protection area is defined as unprintable area.

64-0x Chip protection area is defined as unprintable area.

DPM / ALX Same as 64-0x

PEM n/a

Chip protection

The head can’t be lifted.

The chip protection feature can be used to avoid printing inside the area of the inlay which may

result in lower printing quality because of the alternating thickness.

Additionally the head will be lifted before the start of the chip protection area to ensure the path is

open when the chip passes the print line. The area is enlarged by the way the head physically

needs to lift completely and go back down. The enlargement depends from the print speed (higher

speed – higher enlargement)

How to control the chip protection feature

EasyPlug: the #IM command gives full control over the chip protection feature. A value of 0 for the chip

position/offset disables the chip protection feature, a value greater than zero activates the chip protection feature.

Providing no value is identical to providing zero (which disables the feature).

Using the menu:

Parameter Effects

Chip protection Enable this parameter if you would like to activate chip protection. (See note below)

Chip size Visible if and only if parameter “Chip protection” is enabled. Defines size of area in regard to

printing direction that is excluded from printing.

For calculation of the protected area the chip size is centered around the the chip position (so the

size counts one times only) + a print speed depending offset for head up and down movement.

Chip offset Visible if and only if parameter “Chip protection” is enabled. The offset defines the beginning of the

chip protection area.

Note: The setting from the #IM command has highest priority. It activates (> 0) or deactivates (=0) the chip

protection feature depending from its value. After the #IM command was used in a job the menu reflects the last

setting from #IM command. De facto the menu setting “chip protection” can be seen as an informative / read only

parameter.

3.1.5

Recommendations for web / material handling

Adjusting the material pressure rollers

Please take care the pressure rollers don’t run over the RFID chip. Doing so will destroy the RFID inlays.

Revision: 13 Date: 31 August 2009

Page 23 of 53

Page 24

HowToRFID

Adjusting the punch level

The punch detection for RFID labels can be a little bit tricky due to the different “darkness” of the different zones of

in RFID label: liner only, liner + paper, liner + paper + RFID inlay plastics, liner + paper + RFID inlay antenna.

If it is not possible with the automatic punch detection mode to get reliable punch detection, the manual punch

detection might help.

Set the parameter “Punch mode” to “manual” and adjust the parameter “Punch level” to a value which is around 15

units higher then the measurement value when liner + paper (without inlay) is visible for the punch sensor.

For details about that please see the printer manual.

3.2 Additional support functions

3.2.1

Menu item Function

Tag type (*1) Choose tag type that is assumed as base for “Read EPC” / “Write EPC”

Read EPC Function to read and display EPC from smart label near printer antenna. Only smart labels with

Write EPC Function to write EPC to smart label near printer antenna. Only smart labels with chosen tag type

Hotspot tests Performs a test to find the sensitive write zones of the inlay (label). See 2.4.5 for details.

Functions for testing purpose

chosen tag type are considered.

The function stays in an endless loop until the user cancels with the “ESC” key. In each loop a

read attempt is made and if a tag could be read the EPC is displayed otherwise in line of “---“

chars.

are considered. The EPC that is written is created by printer firmware.

The function stays in an endless loop until the user cancels with the “ESC” key. In each loop a

write attempt is made and if the EPC could be written to an tag “OK” is displayed otherwise “fail”.

Each loop is signaled by a moving star in the progress bar.

The EPC which becomes written is fixed, but in every loop the first 16 bits are chosen randomly.

(*1) supported only in semi custom printer firmware. Standard printer firmware only supports EPC Gen2 protocol

(tag type) for UHF technology.

3.2.2

Menu item Function

Module Designator to identify RFID reader module that is mounted inside the printer.

FW Version Version number to identify firmware that is used by internal RFID reader module.

For information

Printer firmware version <= Vx.33:

This information is quasi static – it depends from the detected reader, but is not queried in a direct

way from the reader module. Unfortunately it doesn’t reflect the hardware revision which is an in

important for firmware updates.

Printer firmware version >= Vx.34:

During boot time the printer identifiers the built-in RFID reader module.

For the AWID reader (UHF technology) module The value shows the module type (“AWID”), the

regulatory region identifier (“EU”, “US”) and the hardware revision level (“Rev 2.6HR1”, “Rev E”).

For the HF technology it shows only the module type (“FEIG”).

Both values are also accessible via remote parameter query mechanisms and in the “setup” file.

Revision: 13 Date: 31 August 2009

Page 24 of 53

Page 25

HowToRFID

3.3 AWID RFID module firmware update

3.3.1

Update procedure

Note: firmware update for RFID reader module is handled like normal printer firmware update (compare printer

service manual), especially “*.ihb” files are treated like “*.s3b” files

4) Update printer firmware to appropriate version named in column “printer firmware”.

5) Update main reader firmware to version in same row (e.g. 4.10B for EU region and Gen2) - printer resets after

finishing update

6) Update I chip firmware to version in same row (e.g. 4.06) - printer resets after finishing update

7) Switch off/on printer

8) Update Q chip firmware to version in same row (e.g. 4.06) - printer resets after finishing update

9) Switch off/on printer

10) Check for function by activating “Read EPC” and “Write EPC” in menu RFID parameter

Caution

− Check hardware compatibility list (Never upgrade a module with FW 2.xxy to 4.xxy)

− Take care, do not switch off printer while updating

− main download takes about 15 minutes (on AP5.4)

− I/Q chip download takes about 5 minutes each (on AP5.4)

Revision: 13 Date: 31 August 2009

Page 25 of 53

Page 26

HowToRFID

3.3.2

3.3.2.1 Printer firmware / Reader module firmware

Applicable for UHF printer only (with RFID module from AWID). Bold highlighted versions are the most current

approved and recommended versions.

Main

2.05M ?? original version < V3.40 none

C1183 – US Versions (Rev E)

2.17M 2.10 split version US 915 MHz >= V3.40 >= V2.50

2.24M 4.03 adds EPC class 1 Gen2 US >= V4.00X1 >= V3.00X1

2.28M 4.03 Gen2 US with R/W user data

2.33M 4.11

C1616 – EU Versions (Rev 2.6HR1)

2.02Rd 4.06 Do not use – upgrade to 4.10B Not compatible Not compatible

2.05B 2.10 split version EU 869 MHz >= V3.40 >= V2.50

2.11B 4.03 adds EPC class 1 Gen2 EU >= V4.00X1 >= V3.00X1

4.07B 4.06 Gen2 EU with R/W user data >= V4.22X01 (Gen2)

4.10B 4.06 Data integrity issue for EPC Gen2 Monza 2

2.12Ra 4.12

C1674 – Korea Versions (Rev 2.6H2)

4.45Me 4.11 full support of 512 bit user memory of NXP

4.85Me 4.12

Dependencies

Version

I/Q

Purpose

Gen2 US

(recommend version for US)

chips corrected

Supports 240-bit EPC

Data integrity issue for NXP U-Code G2XL

/ G2XM chips corrected

(recommend version for EU)

U-Code G2XM chips

Supports 240-bit EPCs

Data integrity issue for NXP U-Code G2XL

/ G2XM chips corrected

(recommend version for EU)

Printer firmware Version

640x / ALX 92X / DPM AP5.4

>= V4.22X01 (Gen2)

>= V5.02X01 (Gen3)

Semi custom firmware

>= V4.22X01 (Gen2)

>= V5.02X01 (Gen3)

Standard firmware

>= V4.33 (Gen3)

>= V5.33 (Gen3)

>= V5.02X01 (Gen3)

Semi custom firmware

>= V4.22X01 (Gen2)

>= V5.02X01 (Gen3)

Standard firmware

>= V4.33 (Gen3)

>= V5.33 (Gen3)

Standard firmware

>= V4.33 (Gen3)

>= V5.33 (Gen3)

Semi custom firmware

>= V4.22X01 (Gen2)

>= V5.02X01 (Gen3)

Standard firmware

>= V4.33 (Gen3)

>= V5.33 (Gen3)

Standard firmware

>= V4.33 (Gen3)

>= V5.33 (Gen3)

>= V3.22X01

Semi custom firmware

>= V3.22X01

Standard firmware

>= V3.33 (Gen3)

>= V3.22X01

Semi custom firmware

>= V3.22X01

Standard firmware

>= V3.33 (Gen3)

Standard firmware

>= V3.33 (Gen3)

Semi custom firmware

>= V3.22X01

Standard firmware

>= V3.33 (Gen3)

Standard firmware

>= V3.33 (Gen3)

Table 9 – AWID firmware versions

Revision: 13 Date: 31 August 2009

Page 26 of 53

Page 27

HowToRFID

3.3.2.2 Hardware compatibility list (AWID reader modules only)

Region

Frequency

Article number

US

902-928MHz

C1183

EU

869.525MHz

C1616

Identifier on module Approved Firmware

UHF (902-928 MHz)

MPR 1510AE-RM REV: E

and/or

P/N: MPR1510AE-RM

UHF (869.525 MHz)

a) REV:H and/or P/N: MPR1580AH-RM

b) MPR1580A-RM REV: A and HW: 2.6HR1

c) 251060-001, Rev: A and HW 2.6HR1

2.33M + I/Q 4.11

2.12Ra + I/Q 4.12

4.10B + I/Q 4.06

4.07B + I/Q 4.06

Korea

910-914 MHz

C1674

Table 10 – AWID hardware compatibility list

UHF (902-928 MHz)

MPR-1510AH. RM

Rev H2

4.85Me + I/Q 4.12

Revision: 13 Date: 31 August 2009

Page 27 of 53

Page 28

HowToRFID

4 RFID Transponder / tags / inlays

4.1 Memory layout (data fields) of RFID Tags

4.1.1

HF Technology

HF Technology is based on a flat memory model without separation into specialized memory areas. All data is

organized as blocks of memory with equal size.

Note: a block of memory can only be written as a whole. Write operations where the length of data provided is not a

multiple of the size of a block are padded with 00 bytes.

The data type ID is used in commands for reading or writing data to select the field of tag where the operation

should work with.

Field

[data type id]

Block data (User

data) [0]

UID [1]

EAS Bit

AFI [6]

DSFID [8]

Table 11 – Data fields of HF tags

Contents / function Size in Bits (Bytes) Read / Write

access

− is organized in blocks of 4 bytes (depending from chip

type)

− size varies (depending from chip type)

− blocks can by access only as a whole

− called Unique Identifier

− is a tag identifier (contains a chip manufacturer ID, a chip

type ID and a serial number)

− is defined in [ISO15693]

− used in electronic article surveillance (EAS) applications

− it a single bit which can be set or cleared (not set)

− can be locked permanently which blocks any future

modification attempt

− AFI = Application Family Identifier

− can be used to filter out non application specific tags in

inventory operations

− is defined in [ISO15693]

− DSFID = Data Storage Format Identifier

− is defined in [ISO15693]

See Table 1 –

Supported

transponder types

64 (8)

1 Write / Lock

8 (1) Write

HF: 8 (1) Read / Write

Read / Write

Read only

4.1.2

UHF Technology (EPC tags)

The data type id is used in commands for reading or writing data to select the field of tag where the operation

should work with.

Field

[data type ID]

EPC [2]

TID [1]

Revision: 13 Date: 31 August 2009

Contents / function Size in Bits (Bytes) Read / Write

access

− called Electronic Product Code

− is a product identifier

− is defined in [EPC1]

− called Tag Identifier

− is a tag identifier (contains a chip manufacturer ID, a chip

type ID and optional a serial number)

− is defined in [ISO15693] + [EPC1]

96 (12)

64 (8)

up to 240 (30)

32 (4)

64 (8)

depending from

manufacturer

Read / Write

Read only

Page 28 of 53

Page 29

HowToRFID

Field

[data type ID]

User data [0]

Kill password [3]

Access password

[4]

Memory bank(s)

[5]

AFI [6]

Memory Block [7]

Table 12 – Data fields of UHF / EPC Gen 2 tags

Contents / function Size in Bits (Bytes) Read / Write

− also called user memory

− is organized in blocks of 2 bytes

− size varies (depending from chip type) from 0 to X

− this password must be referenced when using “Kill tag”

command

− must be 4 bytes

− is defined in [EPC3]

− this password must be used to authorize certain access to

tag memory e.g. locking and unlocking memory

− must be 4 bytes

− is defined in [EPC3]

− a memory bank presents the physical memory area of a

tag

− banks are defined as follows:

− 0: Access + Kill password

− 1: EPC

− 2: TID

− 3: User data

Direct access to a memory bank is depreciated since behavior

is undefined (behavior depends from size of memory bank

areas of different tags and additionally depends from RFID

reader firmware module.

A direct read or write access to a memory bank should only be

considered if there is no direct way to access a specific

information

Note: some memory banks may be unreadable due to security

restrictions

− AFI = Application Family Identifier

− is a part of PC (Protocol Control) bits in the EPC memory

bank (but not part of the EPC itself)

− possible range for values: 0..511 (0x00 … 0x1FF) where

the MSB is used as identifier for a not EPC global defined

identifier, and bits to lower 8 bits are named “NSI”

(Numbering System Identifier)

− is defined in [EPC3] for UHF technology

−

− There is no field “memory block” in EPC Gen 2

transponders!

− This field-identifier is only a helper to allow EasyPlug

commands the addressing of any memory area inside the

transponders memory without being limited to the

predefined field identifiers.

− see EasyPlug command description for details

access

0

224 (28): NXP G2

512 (64): NXP G2XM

32 (4) Write only

32 (4) Write only

Vary in size Read only

9 (2)

varying Read / (Write)

Read / Write

Read / Write

Revision: 13 Date: 31 August 2009

Page 29 of 53

Page 30

4.2 Inlay qualification

HowToRFID

4.2.1

The inlay qualification process

Using only the built-in functionality of the RFID enabled printer it’s more or less difficult to find out the best settings

for the RFID parameters to process a given RFID label in a safe manner.

Furthermore some of the very important parameters are already fixed (unchangeable) if a converted RFID label is

used. That’s mainly the placement of the inlay inside the label:

a) distance from top of label in feed direction,

b) placement from the left edge of the label,

c) the orientation of the inlay (typical forms: chip first or chip trailing), and

d) the distance (pitch) between two subsequent inlays (in subsequent labels).

All of those parameters have significant influence on the performance and throughput of the encoding (and printing)

process in the printer.

To get optimum performance and throughput it’s necessary to have the inlay placed in a printer- and inlay specific

optimum position in the label. This assures well coupling between the printers antenna and the (and only that) inlay

“near” the printers antenna.

On the other side it’s important to have the right minimum pitch (distance) between to subsequent inlays to avoid

the unwanted writing (and reading) to more than one inlay at once. These unwanted side-effects are also called

“crosstalk” or “adjacency” effects.

Please note: due to the EPC being “the” unique identifier of a EPC Gen 2 transponder, it’s not detectable whether

only one or multiple transponders have been “hit” by a write operation during the encoding. This would first be

possible after a unique EPC was written to each transponder – and what a bad luck – mostly the first and only

operation to be done is to write a unique EPC into the transponder.

So the only way to ensure individual programming of the transponders with a unique EPC is, to make sure it’s only

one transponder in coupling with the printer’s antenna. This can be attained by

a) using an antenna in the printer with a small “beam width” (restricted by physical limits),

b) using as less RF transmit (output) power as possible (but still enough to turn the transponder on),

c) use metal parts inside the printers paper path as shielding,

d) use a distance (pitch) between two inlays which avoids having two inlays at the same time in the RF field of

the printers antenna, and which additionally avoids energy transmission between subsequent inlays.

Another parameter having influence on the performance of an inlay is the RF regulatory region where the printer

shall operate. This is due to

a) varying sensitivity of the inlay itself for the different frequencies used,

b) different RFID reader modules used in the printer for the different regulatory regions (EU/ETSI, US/FCC,

Korea) => different RF output/transmit power and receive sensitivity

c) frequency depending RF field characteristics of the printers antenna

Because there are so many system- and transponder (inlay) specific parameters, it’s necessary to test a selected

transponder (inlay) in the target printer before designing and producing a label for a specific application.

To avoid this high burden for system setup, Avery Dennison makes the test of several well known transponders

(inlays) in advance. The results of the tests – the recommended parameters for each transponder and printer – are

published in several ways. This all together is called the “inlay qualification process”.

Revision: 13 Date: 31 August 2009

Page 30 of 53

Page 31

HowToRFID

4.2.2

RFID Label Design & Printer Setup Guide + RFID Suppy Specifications

Avery Dennison publishes documents called “RFID Label Design & Printer Setup Guide”. The content of this

document is the essential extract of the inlay qualification process required for system setup.

There are several “RFID Label Design & Printer Setup Guides”, one for each RFID enabled printer and RF

regulatory region. So care must be taken to use the right document as reference.

Having a specific requirement in an RFID application to use transponder (inlay) A from manufacturer B, it’s often a

question to find out what RFID enabled printer is the best to meet given requirements for label design.

In this case it’s a good idea to have a look inside another type of document. Additionally there is one document

called “RFID Supply Specification” for each transponder (inlay). This document contains some more details about

the transponder / inlay and the parameters for usage in the Avery Dennison printers. The parameters for all printers

are contained in the specification for that inlay and can be easily compared. Additionally the document contains

manufacturer’s part numbers, inlay dimensions, chip data etc.

4.2.3

Terms used in the inlay specifications and related documents

Transponder / inlay placement dimensions

Dim. Definition Explanation

LA Inlay position

from top of label

“offset”

This dimension is selected to ensure best operating throughput in the printer by having the inlay at the right

position for encoding, when the top of the label is at the dot line of the print head. This dimension is printer

model specific

Please note: the distance is always to the antenna leading edge, not the chip or transponder carrier (inlay base

material). This distance is generally given with a +/- 1.5 mm tolerance (otherwise see notes).

If required, a deviating inlay position is possible, but requires adaptation of the OPL dimension and leads to

decreased throughput.

For the system specific placement window see Table 13 below.

Revision: 13 Date: 31 August 2009

Page 31 of 53

Page 32

HowToRFID

Dim. Definition Explanation

LG Horizontal inlay

placement

“x-pos”

LF Minimum inlay

pitch / distance

“pitch”

LD Minimum label

length

OPL RFID operation

position relative

to top of label

OPA RFID operation

position relative

to start of inlay

antenna

Horizontal placement of inlay relative to the left edge of the liner – physically to the inside side of the paper path

in the printer. Dimension is given with a +/- 5mm tolerance.

Coupling with the transponder changes across the width of the printer paper path. An adjustment for optimal

coupling is possible by sliding the antenna of the printer. See Table 13 for the system specific limits). But, if inlay

width (distance across the web) is much smaller than the width of the printer’s antenna (100 mm), a preadjustment through proper placement of the inlay inside the label is required. Please note: especially for the

design of narrow size tags (e.g. hang tags) this can become a challenge.

This distance ensures coupling with the transponder in the current label only. Please note that the distance is

always to the antenna leading edge, not the chip or transponder carrier (inlay base material). Distance is

generally given with a +/-- 1.5 mm tolerance (otherwise see notes).

Minimum length of the label resulting from dimension LA (inlay placement relative to top of label) and the length

of the inlay carrier (base material). Additional backup might be required to ensure a valid label construction

(depending from label converting technology).

This distance identifies the “sensitive” area of the transponder which must be located in line with the center of

printer’s antenna for optimum coupling.

Distance is given relative to top of label, as printer requires it in that way.

If a deviating LA dimension is selected the corrected value for dimension OPL can be calculated by OPL = LA +

OPA.

Similar to distance OPL, but given relative to the leading edge of the transponder’s antenna.

This value is required to recalculate OPL if a deviating placement position of the inlay from top of label (LA

value) is used.

Printer settings

Dim. Definition Explanation

OPL RFID operation

OPL dimension = parameter “Antenna-Offset” of the EasyPlug #IM command

position relative

to top of label

n/a Power level

Power Level setting: up to firmware versions x.33 the printer’s power level was adjusted by

an attenuation value which results in reverse logic (high value = low power, low value = high

power)

Starting with firmware versions x.34 the printer’s power level is adjusted in dBm (a physical

unit for the power of RF fields)

See section 3.1.2.1

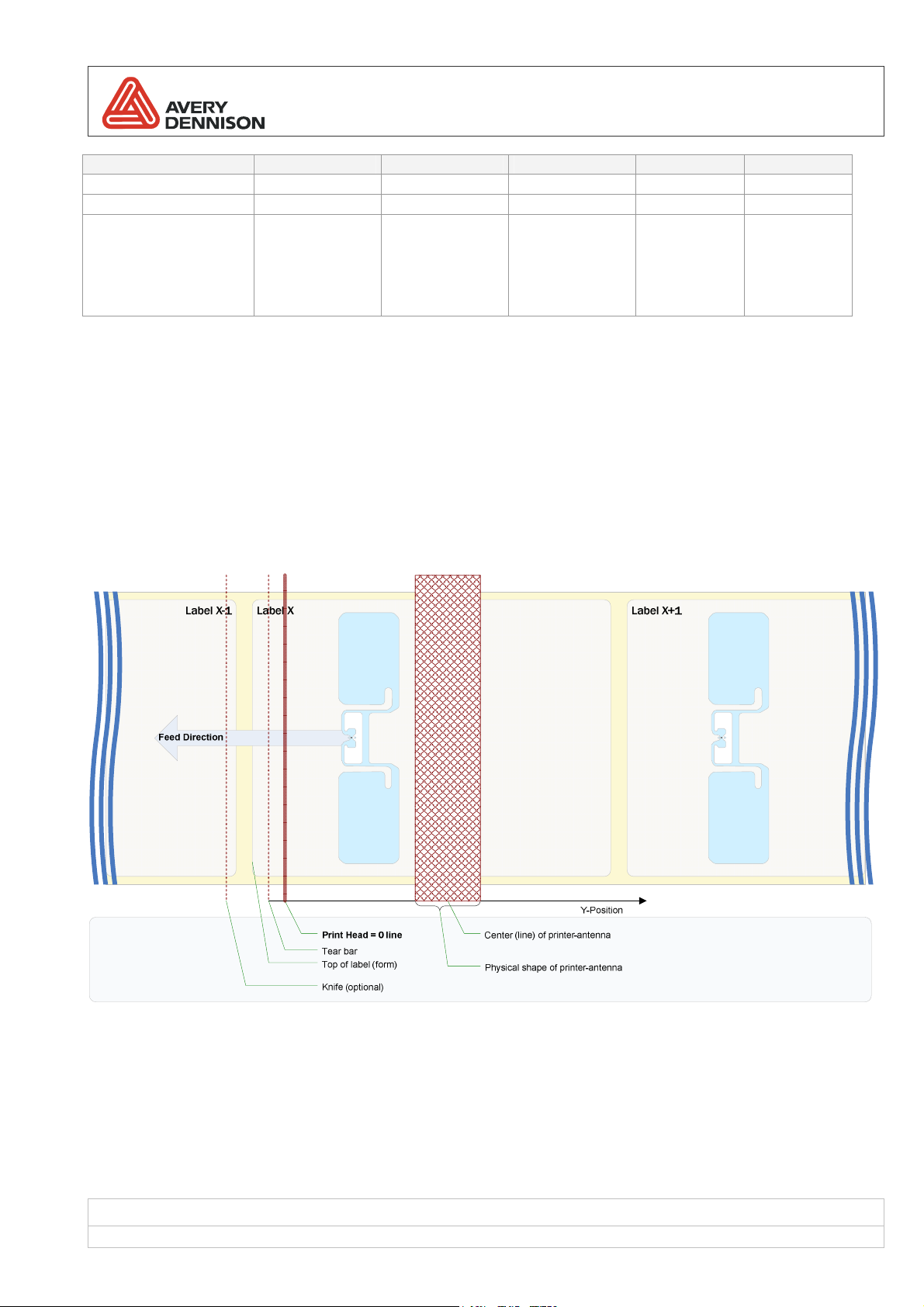

4.2.4

Printer specific dimensions and restrictions

Printer Position of the center-line

of the UHF antenna relative

to print head (dot-line)

64-04/05 62 mm +/- 48 mm + 25 mm

64-06 62 mm +/- 48 mm + 50 mm

AP 5.4 46.5 mm +/- 16 mm + 15 mm

ALX 924 / DPM 50 mm

ALX 926 / DPM 50 mm

PEM n/a n/a n/a

Inlay placement window

(+/- offset from ideal

position)

depending on dispensing

mode, rewinder etc.

depending on dispensing

mode, rewinder etc.

horizontal movement

restriction of the antenna

(across the web)

+ 25 mm

+ 50 mm

Table 13 – Antenna position relative to print head

Revision: 13 Date: 31 August 2009

Page 32 of 53

Page 33

HowToRFID

5 Reading and writing RFID data using EasyPlug

5.1 Design an EASYPLUG job

5.1.1

There are several specialized RFID commands and some extended commands. Some of these commands are

mandatory and some are optional depending on your application. (For example: the #IM command is extended with

antenna offset. This is mandatory information, because a non-zero offset indicates a RFID job.)

Like every EasyPlug job a RFID jobs needs at least a

Set the RFID parameters in #IM command based on settings you identified in a material setup phase.

Note: the power level setting can’t be controlled using the #IM command. It’s accessible only via the printer menu.

If there is a need to bind the power level setting directly into an EasyPlug job this can be done using the change

system parameter command #PC (#PC5202/<Power level setting>).

5.1.2

Resulting from the continuous enhancement of RFID functionality and improvement of RFID integration with regular

printing functionality there are two different approaches to perform RFID read and write operations have been

created.

The Basics

1) #IM command: defining material parameters and RFID processing parameters (chip type, antenna offset,

optional chip protection)

2) #ER / #Q sequence with contains the layout data and the RFID operations (and optional definitions of

variables for data handling)

Concepts of data handling

1) the legacy EasyPlug commands

2) the RFID parts of the mechanism for variable data handling

Note: Using approach 2) based on the variable data handling is the preferred (because more flexible and powerful)

way to design RFID jobs.

5.1.3

The following matrix shows which EasyPlug commands may be used for specific operations to be performed.

Commands which must be used in sequence are listed with a plus sign (+), alternative commands are separated by

lines.

Please note: the commands are not listed with complete syntax – only most important RFID specific parameters

are shown.

Operation / EasyPlug command matrix

Revision: 13 Date: 31 August 2009

Page 33 of 53

Page 34

HowToRFID

Technology /

Tag type

Data field EPC Code TID

Read data field #RT//2

Write data field #RFW2

Protect (Lock)

data field

Read data field

and send data to

host

Write data field

and send data to

host

UHF

Technology

#SRF2 +

#VR/T

#SRF2 +

#VW/T

(*1)

#RFL1/2

#RFR/2 +

#RFH

#SRF2 +

#VR/T +

#SI8 +

#VW/I

#SRF2 +

#VW/T +

#SI8 +

#VW/I

EPC Class

1 Gen 2

#RT//1

#SRF1 +

#VR/T

#RFW1

#SRF1 +

#VW/T

N/A (*1)

#RFR/1 +

#RFH

#SRF1 +

#VR/T +

#SI8 +

#VW/I

#SRF1 +

#VW/T +

#SI8 +

#VW/I

User

memory

#RT//0

#SRF0 +

#VR/T

#RFW0

#SRF0 +

#VW/T