Page 1

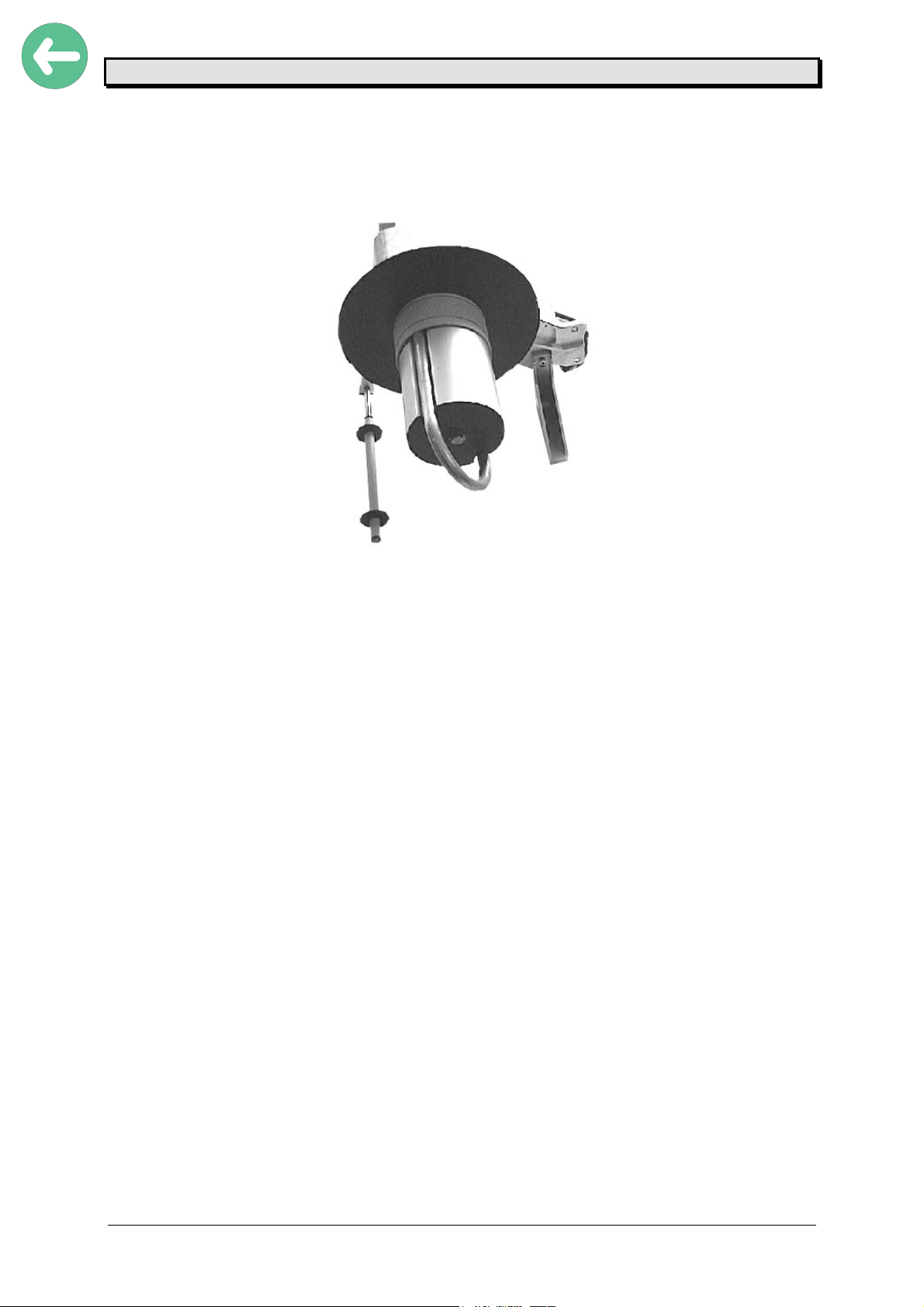

Manual Rewind Option

Manual Rewinder Option

06/01 Rev. 2.09 1

Page 2

Manual Rewind Option

Contents

Contents ...............................................................................................................................2

General.................................................................................................................................3

Copyright ..........................................................................................................................................3

Error handling and search ....................................................................................................4

Media fixation .......................................................................................................................5

Technical Specification.........................................................................................................7

Technical Service .................................................................................................................8

Mechanic ..........................................................................................................................................8

Rewinder complete ................................................................................................................... 8

Support foot............................................................................................................................... 9

Media guiding.......................................................................................................................... 10

Clamp handle .......................................................................................................................... 11

Roll profile ............................................................................................................................... 11

Guiding disc ............................................................................................................................ 12

Tooth belt tighten part ............................................................................................................. 13

Stepper motor ......................................................................................................................... 14

Tooth belt ................................................................................................................................ 15

Gear plate ............................................................................................................................... 16

Sensor wedge ......................................................................................................................... 17

Dancer arm spring................................................................................................................... 18

Dancer arm ............................................................................................................................. 19

Electronic........................................................................................................................................20

Sensor ..................................................................................................................................... 20

Activate rewinder..................................................................................................................... 21

Adjust rewinder sensor............................................................................................................ 22

Diagram, component, wiring............................................................................................... 24

Component peripherial board 99054-xx-6......................................................................................25

Diagram peripherial board99054-xx-6............................................................................................26

Adjustment peripherial board .........................................................................................................27

Wiring .............................................................................................................................................28

Appendix............................................................................................................................. 32

Tooling and work materials ............................................................................................................32

Parameter menu.............................................................................................................................33

INDEX................................................................................................................................. 35

06/01 Rev. 2.09 2

Page 3

Manual Rewind Option

General

Copyright

This User Manual and its contents are subject to copyright. The publisher’s prior written

consent must be obtained for reproduction of the manual as whole or part thereof.

Names are generally given without any reference to existing patents, registered patterns or

designs, or trademarks. The omission of a corresponding not does not imply that the names

can be used freely. All trademarks are acknowledged.

The manufacturer reserves the right to technical and other alterations without prior notice.

The publisher cannot warrant the accuracy of the content of this manual.

Note: Please follow the notes shown in this text - it will help to cover all

situations and keep your engine working.

06/01 Rev. 2.09 3

Page 4

Manual Rewind Option

Error handling and search

To verify functionality of mechanical and electronically functions - if there is not a evidently

defect - use status report ‘STA0 to STA3’ (see User Manual) - printout to check the unit.

06/01 Rev. 2.09 4

Page 5

Manual Rewind Option

Media fixation

characteristics possible reason solution

media moves on core forgotten clamp handle check and fix it

media sticks not to core fix media

core size to wide change core

media moves to inner dancer arm adjust dancer arm

or outer side bent

media guiding wrong adjust guiding

adjusted (ring)

rewind option not fix rewinder to

mounted properly printer

rewind unit is not stepper not plugged in plug in stepper

moving correctly motor

stepper motor defect check and change

stepper

sensor not plugged in check and plug in

characteristics possible reason solution

option board defect check and replace

or not there or insert

sensor wedge not check and adjust

mounted correctly

tooth belt defect check and change

belt tighten loose check and adjust

wrong direction direction programmed check and change

of movement wrong

stepper connection wrong check and change

06/01 Rev. 2.09 5

Page 6

Manual Rewind Option

(wiring)

printer falls to support not adjusted check and adjust

head side well

roll to heavy check and use

smaller roll

printer stand is not flat move printer to flat

surface

dancer arm is not moving spring is out of function check

guiding roll is not moving maybe dirty check and clean

06/01 Rev. 2.09 6

Page 7

Manual Rewind Option

Technical Specification

- drive stepper motor

- sense of position infra red sensor

- rewind speed self adjusting

- max. roll as used printer (see User Manual)

4250 g TTX 450/650 Puma/Lion

7250 g TTX 950 Tiger

- direction of movement user selectable

clock - counter clockwise

- used media self adhesive-, cardboard- and

plastic media up to 240 g/qm

- label size see printer manual

- electrical specification see printer manual

- environment specification operating temperature: +5 to +35 Grad C

storage temperature: -20 to +70 Grad C

humidity: 45 to 75% not condensing

- construction solid version build from strong aluminium

and stainless steal, all mobile axles pivoted

open assembly of parts and components for

easy, plain operating and service

06/01 Rev. 2.09 7

Page 8

Manual Rewind Option

Technical Service

Mechanic

Rewinder complete

Before mounting the rewinder option

an other option has to be disassembled

(like cutter, or infeed).

Assembly/Disassembly rewinder

- set printer to a flat surface

- the surface has to big enough

to hold as well the support foot

- mount the rewinder with two

hexagonal screws - use the defined

holes

- adjust the support foot in a way

that the weight of the rewound roll

is absorbed by the support

- small differences are regulated by the

rubber feet

- connect the sensor cable to the

responding connector at the front

of the printer

- select option on the display and

activate the option (PEPH)

- select direction at the display

(see User Manual)

Steppermoto

Sensor

- adjust sensor (as described under electronic)

Attention: The rewind option is now ready to operate - all other options are

deactivated!

06/01 Rev. 2.09 8

Page 9

Manual Rewind Option

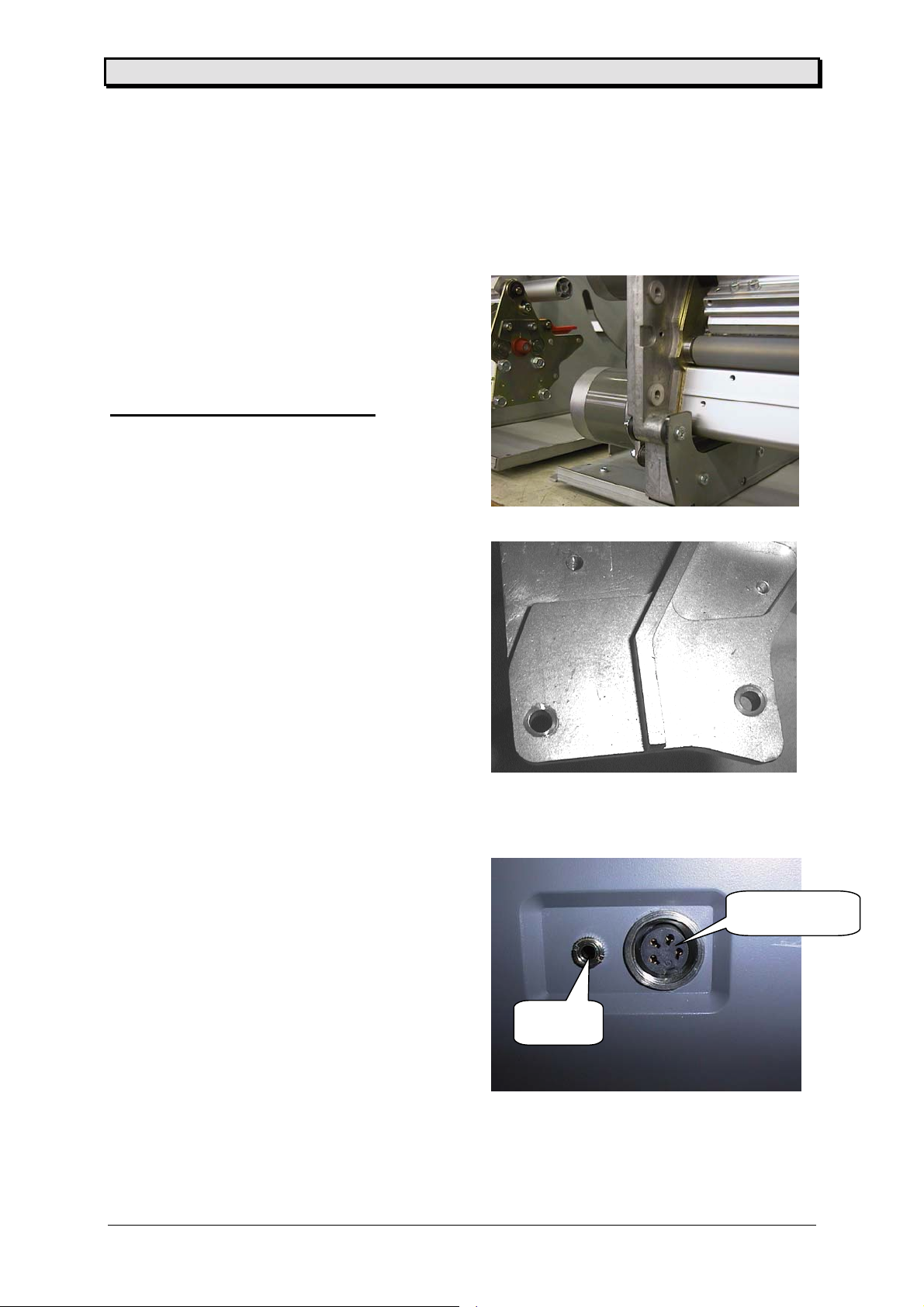

Support foot

The support foot is used to balance the weight of the printer and the rewound material on the

rewind roll. The maximum roll weight of the biggest printer is more than 7000 g - so you can

see that the function of this part is very important.

Assembly/Disassembly/Adjustment support foot

• set printer with the mounted rewind

option to a flat surface

• loose support foot by opening the

hexagonal screw

• press the rubber feet to the surface and

close the screw again

• adjust the support foot that it is parallel

to the metal casting

• tighten the screw very well

Tooling

hexagonal socket SW 4

06/01 Rev. 2.09 9

Page 10

Manual Rewind Option

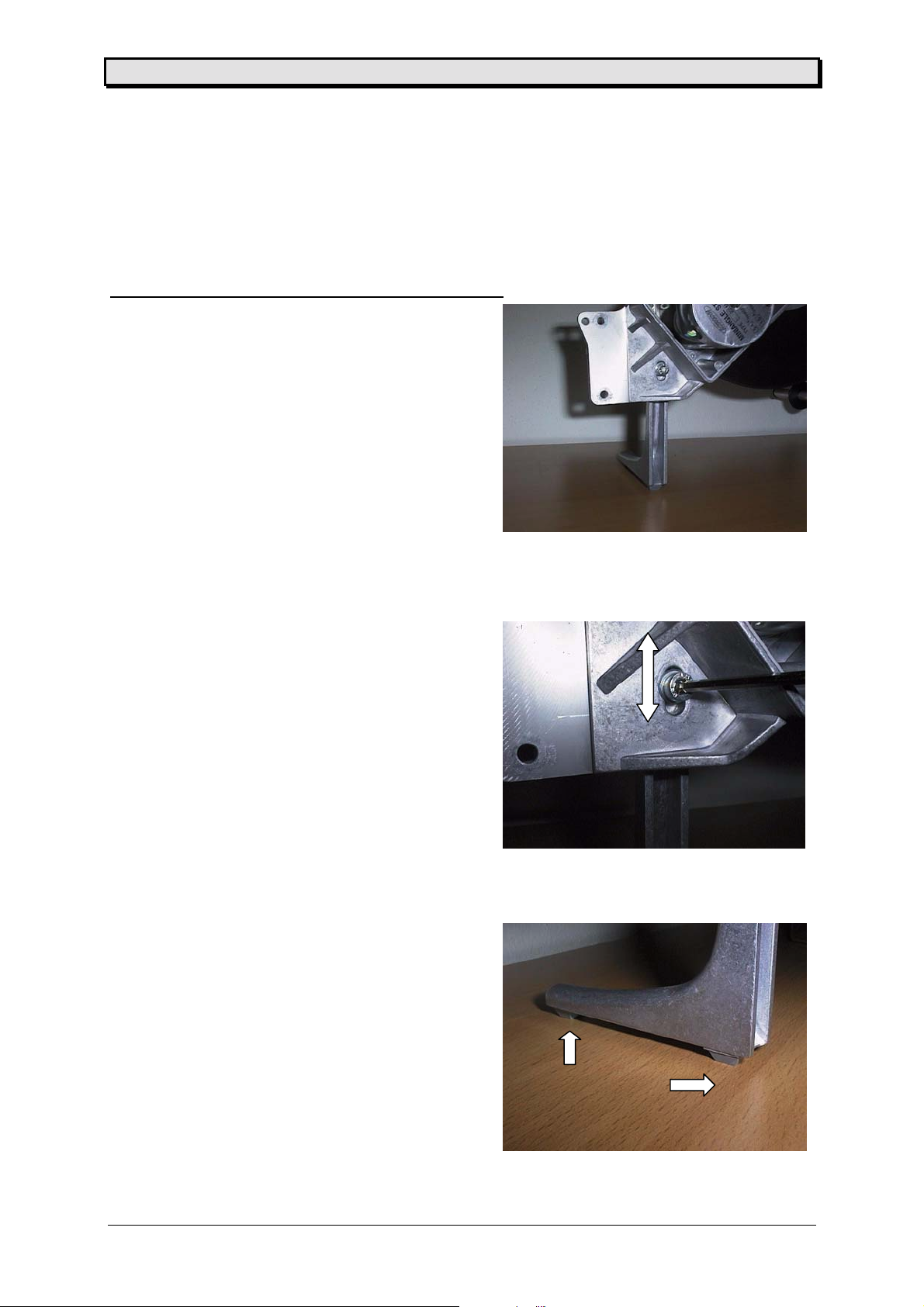

Media guiding

The media guiding of the rewind option is used to control the movement of the media before

the media is rewound. Otherwise the media will run outside or inside on the rewind core.

Assembly/Disassembly/Adjustment media guiding

• the roll can be disassembled complete

from the dancer arm (together with

the guiding rings)

• open the lock washer as shown on the

picture

• the roll can be removed from the axle

• sometimes it is possible that the roll has

collected glue or dust - then it is

necessary to clean the roll

• the plastic bearing can be replaced as well

if it is necessary

• the guiding rings can be adjusted by

moving the rings on the roll

• the roll is fixed to the lower position as

well with a lock washer

Sicherungsring

Tooling

screw driver small

06/01 Rev. 2.09 10

Page 11

Manual Rewind Option

Clamp handle

Using the clamp handle you will fix either a core or the media itself to the rewind core!

The core and the handle are available in 3“ and 4“ diameter.

Assembly/Disassembly clamp handle

• responding to the used method you will

use the handle with a core or without

• using the paper core you have to fix the

material (with a sticky label) to the core

• after fixing the media with the handle

to the profile it should not be possible

move the media on the core

Roll profile

Same as the handle the roll profile is available

in a diameter of 3“ and 4“ - at the rear side you

can see two fixation points and flat area of the

axle guiding. Mounting the profile to the disc

watch this points.

Assembly/Disassembly roll profile

• the roll profile is mounted to the

guiding disc and fixed to a axle in

the centre

• disassemble the profile by open the

lock washer by hand (see picture)

• the profile can be removed

• the guiding disc is fixed with a separate

lock washer to the axle

Tooling

screw driver small

06/01 Rev. 2.09 11

Page 12

Manual Rewind Option

Guiding disc

The guiding disc is used to control the movement of the rewound material during rewind

operation. The covered part of the guiding disc is as well the transport part (a gear wheel is

part of the disc). Fixed with a lock washer to the axle - the guiding disc shows two holes for

the roll profile to fix it there.

Assembly / Disassembly guiding disc

• before disassembling the disc - the

tooth belt should be relived (see tooth belt)

• after removing the lock washer the disc

can be removed

• now you can reach the tooth belt - the

tooth belt tighten part and the gear of

the stepper motor

• as well the sensor - the sensor, sensor

wedge, dancer arm spring can be

watched

Tooling

screw driver small

06/01 Rev. 2.09 12

Page 13

Manual Rewind Option

Tooth belt tighten part

The tooth belt tighten part is used to tighten the tooth belt in a proper way - this means

mechanical tolerances given by production and assembly can be controlled.

Assembly/Disassembly tooth belt tighten part

• open two cross recessed screws and

the back cover part can be removed

• remove cover carefully over the stepper

motor

• as well during assembly and

disassembly the wires should be

watched

• the two hexagonal screws of the

tighten part are now visible

• the screw in the long hole is used to

tighten the belt

• open the screw - move the part in the

direction you think of and close the

screw

• to remove the tighten part the roll profile

and the guiding disc have to be removed

before (see roll profile and guiding disc)

Tooling

cross recessed head size 1

hexagonal socket SW 3

06/01 Rev. 2.09 13

Page 14

Manual Rewind Option

Stepper motor

The stepper motor is the driving part of the unit. Driven and controlled by the printer - is the

only intelligent part on the rewinder the optical encoder of the dancer arm. Controlling speed

and position of the rewinder.

Assembly/Disassembly stepper motor

• open two cross recessed screws and

the back cover part can be removed

• remove cover carefully over the stepper

motor

• as well during assembly and

disassembly the wires should be

watched

• the two hexagonal screws of the

tighten part are now visible

• the fore hexagonal screws of the

stepper motor are now easy to reach

open them and the stepper can be r

removed

• the gear is pressed to the axle and

can not be removed

• during assembly watch the position

of the stepper - otherwise the motor

cable will block the cover

Tooling

cross recessed head size 1

hexagonal socket SW 3

06/01 Rev. 2.09 14

Page 15

Manual Rewind Option

Tooth belt

The tooth belt is transferring the power from the stepper motor to the guiding disc and has to

be controlled from time to time.

Assembly/Disassembly tooth belt

• remove roll profile and guiding disc

(see roll profile and guiding disc)

• the tooth belt can be removed c

controlled and maybe changed

• to insert the belt again follow

the steps below

• insert tooth belt around stepper gear

and tighten part (tighten part has to

be open)

• mount guiding disc to axle

• hold down the belt with a small screw

driver in the area of the motor gear

(see picture)

• moving guiding disc slow to slip the

belt over the gear

• secure guiding disc

Tooling

screw driver small

06/01 Rev. 2.09 15

Page 16

Manual Rewind Option

Gear plate

The gear plate is used to give more stability to the dancer arm mounting!

Assembly/Disassembly gear plate

• remove roll profile and guiding disc

(see roll profile and guiding disc)

• open the two hexagonal socket screws

• the gear plate can be removed

Tooling

hexagonal socket SW 3

screw driver small

06/01 Rev. 2.09 16

Page 17

Manual Rewind Option

Sensor wedge

This part is controlling position and speed of the stepper motor (controlled by the dancer

arm).

Assembly/Disassembly sensor wedge

• remove roll profile and guiding disc

(see roll profile and guiding disc)

• open the two hexagonal socket

screws

• the gear plate can be removed

•open lock washer on the axle

• pressure spring and wedge can

be removed

• the dancer arm axle is locked

with a second lock washer

Tooling

screw driver small

hexagonal socket SW 3

06/01 Rev. 2.09 17

Page 18

Manual Rewind Option

Dancer arm spring

The dancer arm spring gives a defined zero position to the dancer arm. If this position is not

working on your unit - maybe the spring is not working properly.

Assembly/Disassembly dancer arm spring

• remove roll profile and guiding disc

(see roll profile and guiding disc)

• open the two hexagonal socket screws

• the gear plate can be removed

• dancer arm spring can be removed

Tooling

screw driver small

hexagonal socket SW 3

06/01 Rev. 2.09 18

Page 19

Manual Rewind Option

Dancer arm

The dancer arm is a very important part - controlling more then one mission. First of all the

dancer arm is controlling that the media is always rolled up with the same friction. Second

the media is controlled and guided to the right position - the speed of the stepper motor is as

well controlled by the dancer arm.

Attention: It is clear that the dancer arm is very important for the correct

function of the unit. Never use the dancer to move the unit

or to carry it!

Assembly/Disassembly dancer arm

• remove roll profile and guiding disc

(see roll profile and guiding disc)

• open the two hexagonal socket

screws

• the gear plate can be removed

• remove lock washer from axle

• pressure spring and wedge can be

removed

• remove the second lock washer

from the axle - the axle can be

removed

Tooling

screw driver small

hexagonal socket SW 3

Attention: The dancer arm is an assembly and can not be disassembled!

06/01 Rev. 2.09 19

Page 20

Manual Rewind Option

Electronics

Sensor

The sensor (light transmission) is used to control the position together with the sensor

wedge. Different light sensibility is measured by the sensor and results in a different speed.

Assembly / Disassembly sensor

1. Remove roll profile and guiding disc (see Roll

profile and Guiding disc).

2. Remove back cover (1) (see back cover).

3. Unplug cable (2) from the connector on the light

sensor board (3).

4. Remove screw (4) and light sensor board.

Tooling

cross recessed head size 1

screw driver small

1

3

4

2

06/01 Rev. 2.09 20

Page 21

Manual Rewind Option

Activate rewinder

As an additional option the rewinder is a part of the TTX group Using the rewinder first time,

the software function has to be activated. Therefore use the printer menu.

1. Select SYSP

2. Select PEPH

3. Select RWND

4. Choose direction of rotation and select between DIRL (left – counter clockwise) and DIRR

(right –clockwise) – seen frontal towards the rewind core.

Fig. 1: Left side: Setting DIRL; Right side: Setting DIRR.

Attention: During OFFLINE Mode the rewinder is not moving. The rewinder is switched ON

and OFF using the CUT key !

Using the DIRR mode will result in not using the complete possible movement area of the

dancer arm. This is done via software (no additional adjustment necessary) – the reason for

is the angel of the dancer arm together with bigger outside diameter. So it is better to use

only a part of the movement area.

If there is no media in the media end sensor and is the sensor activated the rewinder is not

moving – as well not by pressing CUT.

The display is showing ST13 if the feed motor is not moving and the rewinder is not reaching

home position after 4 seconds of constant maximum speed.The rewinder will be switched

OFF.

Is the feed motor running and the rewinder is unable to reach the home position after 4

seconds of constant run – the rewinder will be re started ! Reason for – maybe the stepper

motor was blocked and has to be re started.

06/01 Rev. 2.09 21

Page 22

Manual Rewind Option

Adjusting the rewinder sensor

To adjust differences given by assembly and parts – we have given the possibility to adjust

the sensor via potentiometer.

PRINTER

home position (end1)

variabel speed

Fig. 2: End positions of the dancer.

home position (end2)

First please check the sensor by using the menu point SCHK.

The point Wxxx will show the value of the sensor depending on the position of the dancer

arm (between 0 ... 255).

!

The difference between the two end points must be bigger then 100!

If the difference between the two end points is not big enough, use the potentiometer on the

rewinders light sensor board (Fig. 3:) to set the current through the sensor. To do so,

proceed as follows:

Fig. 3: Left side: Pot. (arrows) on the light sensor board; Right side: Use the slot in

the housing to set the pot. from outside.

1. Turn the potentiometer at the rewinder (Fig. 3:, arrows) clockwise to its limit.

2. Activate the sensor check for sensor W.

3. Move the dancer in succession to both end positions. Keep an eye on the printer display:

The difference between both displayed values in the end positions must be greater than

110.

If the difference between the values is smaller, please check if the peripherals board is set

correctly.

06/01 Rev. 2.09 22

Page 23

Manual Rewind Option

30 mA

P1

Z0131.cdr

Fig. 4: Setting the peripheral board: disconnect the sensor, set the current by

means of P1 to 30 mA.

If the difference is big enough the sensor itself has to be adjusted now.

1. Select SYSP.

2. Select PEPH.

3. Select RWND.

4. Select RADJ (behind DIRL and DIRR) and select YES by using ENTER or leave the menu

by using ESC.

5. First adjust the home position of the dancer - RNUL. Acknowledge with ENTER – shown

is the momentary sensor value, by moving the dancer, the value is changing. By pressing

ENTER the value is overtaken by the program.

Attention: Do not set the value at the limit position but the position ~ 5 mm before!

6. Acknowledge the value by pressing ENTER. The display switches to REND.

7. Acknowledge by pressing ENTER – move the dancer arm to the opposite position (close

to the support foot, shown is the actual value of the sensor. Accept as well by pressing

ENTER – the value will be accepted.

Attention: Do not set the value at the limit position but the position ~ 5 mm before!

Watch carefully that the difference between the two shown values is bigger the

100 !

Is the program step broken by using the ESC key the printer is using default

values – maybe ending with mail functions.

06/01 Rev. 2.09 23

Page 24

Manual Rewind Option

Diagrams, components, wiring

06/01 Rev. 2.09 24

Page 25

Manual Rewind Option

Component peripherial board 99054-xx-6

06/01 Rev. 2.09 25

Page 26

Manual Rewind Option

06/01 Rev. 2.09 26

Diagram peripherial board99054-xx-6

Page 27

Adjustment peripherial board

g

Manual Rewind Option

CN 6 test point

CN 4 main stepper connector

JP 2 signal / power

connectin

to dispenser

Additional

information – this

board can be used

for:

- applicator option

- cutter option

- rewinder option

- infeed option

- cutter / stacker

option

CN5 signals :

touch down – digital signal

that the applicator base

plate get in contact with the

surface of He product !

Applicator moves back.

Peripherial board 99054

Poti P 1 infrared sensor

CN 5 touch down

home sensor

Poti R 41 label present sensor

CN 3 infrared sensor

30 mA

P1

Depending on the mounted option – this sensor is used in

different ways :

- cutter / stacker

- cutter

- infeed

- rewinder

-

for

no adjustment necessary

use Poti P1 to adjust the sensor

unplugged sensor as illustrated.

label present sensor

Poti R 41 to adjust between test point CN 6 and

ground a value of 2.5 Volt (no media in and cover

closed)

no adjustment necessary

set current to 30 mA by use of P1 with

Z0131.cdr

(manual application) use

06/01 Rev. 2.09 27

Page 28

Wiring

Manual Rewind Option

06/01 Rev. 2.09 28

Page 29

Manual Rewind Option

06/01 Rev. 2.09 29

Page 30

Manual Rewind Option

06/01 Rev. 2.09 30

Page 31

Manual Rewind Option

06/01 Rev. 2.09 31

Page 32

User / Service Manual Power Stacker

Appendix

Tooling and work materials

hexagonal socket SW 3

hexagonal socket SW 4

cross recessed head size 1

screw driver size 1

06/01 Rev. 2.09

32

Page 33

User / Service Manual Power Stacker

Parameter menu

OFFLINE

INFO PRTP IFAC SYSP JCLR SCLR OTHR

STA0

STA1

STA2

STA3

DOT1

DOT2

PSPD

MTYP

MLEN

MWID

PUNO

BCHI

UPCA

CSPD

CPOS

CWID

CDIS

ASPD

ADIS

MPOS

PORT

SPOL

BMOD

<20H

BAUD

PARI

DBIT

SBIT

HAND

PRID

EMUL

NACH

SENS

PUNS

FMOD

OMOD

SMOD

EXTR

SGMO

CODE

HRES

HVOF

CLCK

USMD

DOWN

LCLR

CCLR

ICLR

ADJS

MCHK

SCHK

PCHK

FACT

SERV

NULL

HADJ

ACSC

XPOS

YPOS

SSPD

GAP

CMOD

DMOD

Nur mit Messer / cutter only

Spender mit Applikator / dispenser with applicator

Für Spender (MPOS – auch mit Abreißkante) / dispenser only (MPOS – tear off as well)

Nur mit Scanner / scanner only

Nur mit Color Option / with color option only

Nur für Service / for service only

LREP

CSET

MEND

SCAN

SERR

PEPH

Standard / standard

06/01 Rev. 2.09

33

Page 34

User / Service Manual Power Stacker

OFFLINE

INFO PRTP IFAC SYSP JCLR SCLR OTHR

EMUL

NACH

SENS

PUNS

FMOD

OMOD

MMOD

SMOD

D_HD

EXTR

CODE

HRES

CLCK

USMD

LREP

CSET

MEND

SCAN

SERR

PEPH

RWND DIRL

DIRR

RADJ

06/01 Rev. 2.09

34

Page 35

INDEX

User / Service Manual Power Stacker

C

clamp handle ................................... 5, 11

construction ........................................... 7

Copyright.............................................. 3

D

dancer arm5, 6, 10, 12, 14, 16, 17, 18,

19

dancer arm spring.......................... 12, 18

drive....................................................... 7

E

electrical specification............................ 7

Electronics ........................................... 20

Error handling ........................................ 4

G

gear plate........................... 16, 17, 18, 19

General.................................................. 3

guiding disc11, 12, 13, 15, 16, 17, 18,

19, 20

L

label size................................................ 7

M

R

RADJ....................................................23

REND...................................................23

rewind speed..........................................7

Rewinder, activate ...............................21

RNUL ...................................................23

roll profile11, 12, 13, 15, 16, 17, 18, 19,

20

S

search ....................................................4

sense of position .................................... 7

sensor ..........................5, 7, 8, 12, 17, 20

sensor wedge.............................5, 17, 20

ST 13 ...................................................21

stepper motor.......5, 7, 12, 14, 15, 17, 19

support foot ........................................ 8, 9

T

Technical Service...................................8

Technical Specification ..........................7

Tooling9, 10, 11, 12, 13, 14, 15, 16, 17,

18, 19, 20, 32

tooth belt ..............................5, 12, 13, 15

Tooth belt tighten part .......................... 13

max. roll ................................................. 7

Mechanic ............................................... 8

Media fixation ........................................ 5

media guiding .................................. 5, 10

media moves ......................................... 5

U

W

N

notes ..................................................... 3

06/01 Rev. 2.09

used media ............................................7

wiring................................................6, 24

work material........................................32

wrong direction.......................................5

35

Loading...

Loading...