Page 1

Service Manual Full Size Sensor

User / Service

Manual

Full Size Sensor

11/07 Rev. 1.03 1

Page 2

Service Manual Full Size Sensor

Chapter 0 General

11/07 Rev. 1.03 2

Page 3

Service Manual Full Size Sensor

Copyright

General notes:

This Service Manual and its contents are subject to copyright. The publisher’s prior written

consent must be obtained for reproduction of the manual as a whole or part thereof.

Names are generally given without any reference to existing patents, registered patterns or

designs, or trademarks. The ommision of a corresponding note does not imply that the

names can be used freely. All trademarks are acknowledged.

The manufacturer reserves the right to technical and other alterations without prior notice.

The publisher cannot warrent the accuracy of the content of this manual.

Note: Please follow the notes shown in this text - it will help to cover all

situations and keep your engine working.

If in the manual is used the name TTX 650 - it is as well meant the

TTX 450 and TTX 950 the Puma and Tiger or the S 45 and S 95 !

11/07 Rev. 1.03 3

Page 4

Service Manual Full Size Sensor

Contents

CHAPTER 0 GENERAL............................................................................................. 2

Copyright.........................................................................................................................3

General notes: ................................................................................................................3

Contents..........................................................................................................................4

CHAPTER 1 INITIATION ........................................................................................... 5

Media limitation...............................................................................................................6

Unpack............................................................................................................................6

Assemble Option.............................................................................................................7

Change position of pressure lever ..................................................................................7

Remove media guiding ...................................................................................................7

Mount full size sensor .....................................................................................................8

CHAPTER 2 SET UP MODE.................................................................................... 13

Adjustment of the sensor ..............................................................................................14

Initialise or activate option.............................................................................................15

Check Sensor ...............................................................................................................15

CHAPTER 3 INFORMATION PRINTOUT / PARAMETER...................................... 16

Parameter Menu ...........................................................................................................17

Status printout...............................................................................................................18

Status............................................................................................................................18

ST05 Media is not more in the gap sensor ...................................................................18

ST08 Media is not reaching the gap sensor.................................................................. 18

Status reports................................................................................................................19

CHAPTER 4 MAINTENANCE, CLEANING AND SERVICE .................................... 23

Maintenance and cleaning............................................................................................23

Service..........................................................................................................................23

CHAPTER 7 APPENDIX.......................................................................................... 23

Spare parts ...................................................................................................................24

INDEX...........................................................................................................................26

11/07 Rev. 1.03 4

Page 5

Service Manual Full Size Sensor

Chapter 1 Initiation

11/07 Rev. 1.03 5

Page 6

Service Manual Full Size Sensor

Media limitation

Please watch carefully, that the full size sensor can only be used with cardboard material

(notched) ! The sensor is a digital sensor – means only 0 and 1 – self adhesive media can

not be used.

The minimum media width – used with the full size sensor – has to be 36 mm ! If the full size

sensor is mounted to the unit – as well the standard sensor can not be used for smaller

material.

The optional full size sensor can be moved from

Printer can be moved from - to (mm)

TTX 450 16 – 93

TTX 650 16 – 134

TTX 950 16 – 165

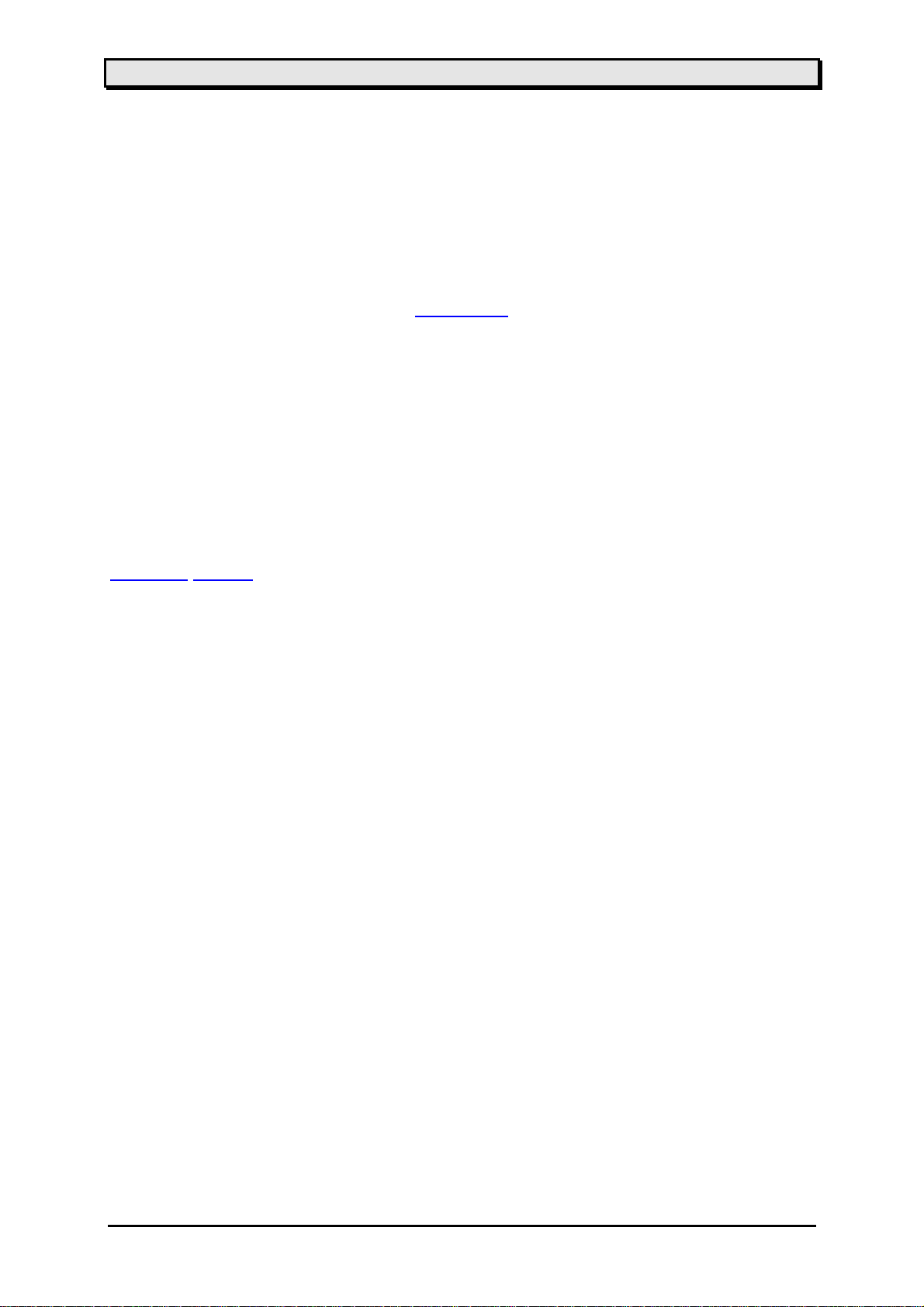

Unpack

Normally the full size sensor is supplied mounted to the printer (installed) ! If this is not the

case – the option can be retrofitted by a service technician !

Attention: To activate the sensor please follow the instruction shown in chapter set up

mode.

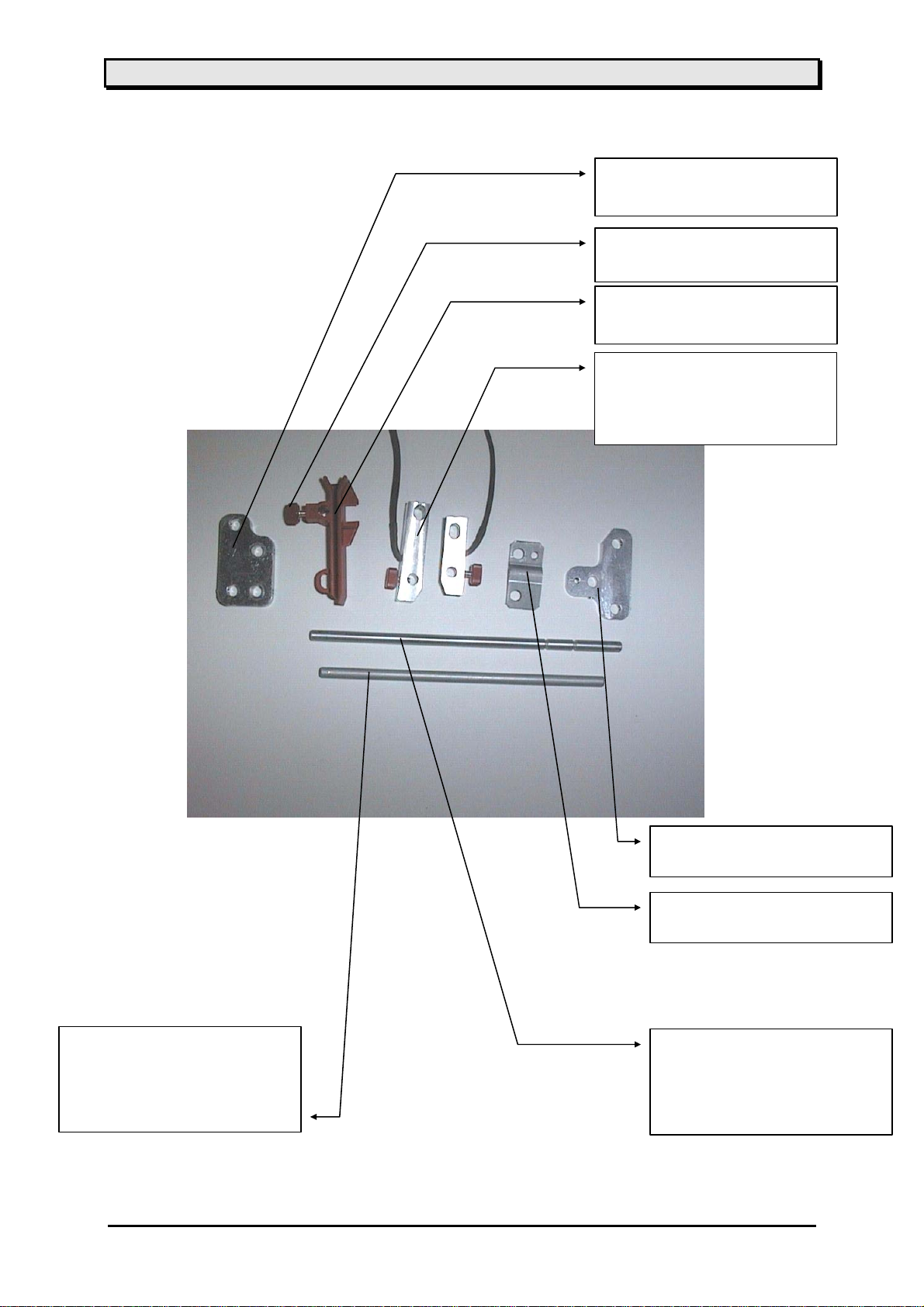

Please check if all parts are delivered

2 additional axle

1 outer side plate

1 inner side plate

1 steal part inner

1 sensor assy. ( 2 parts – 1 cable)

1 outer media guiding

11/07 Rev. 1.03 6

Page 7

Service Manual Full Size Sensor

Assemble Option

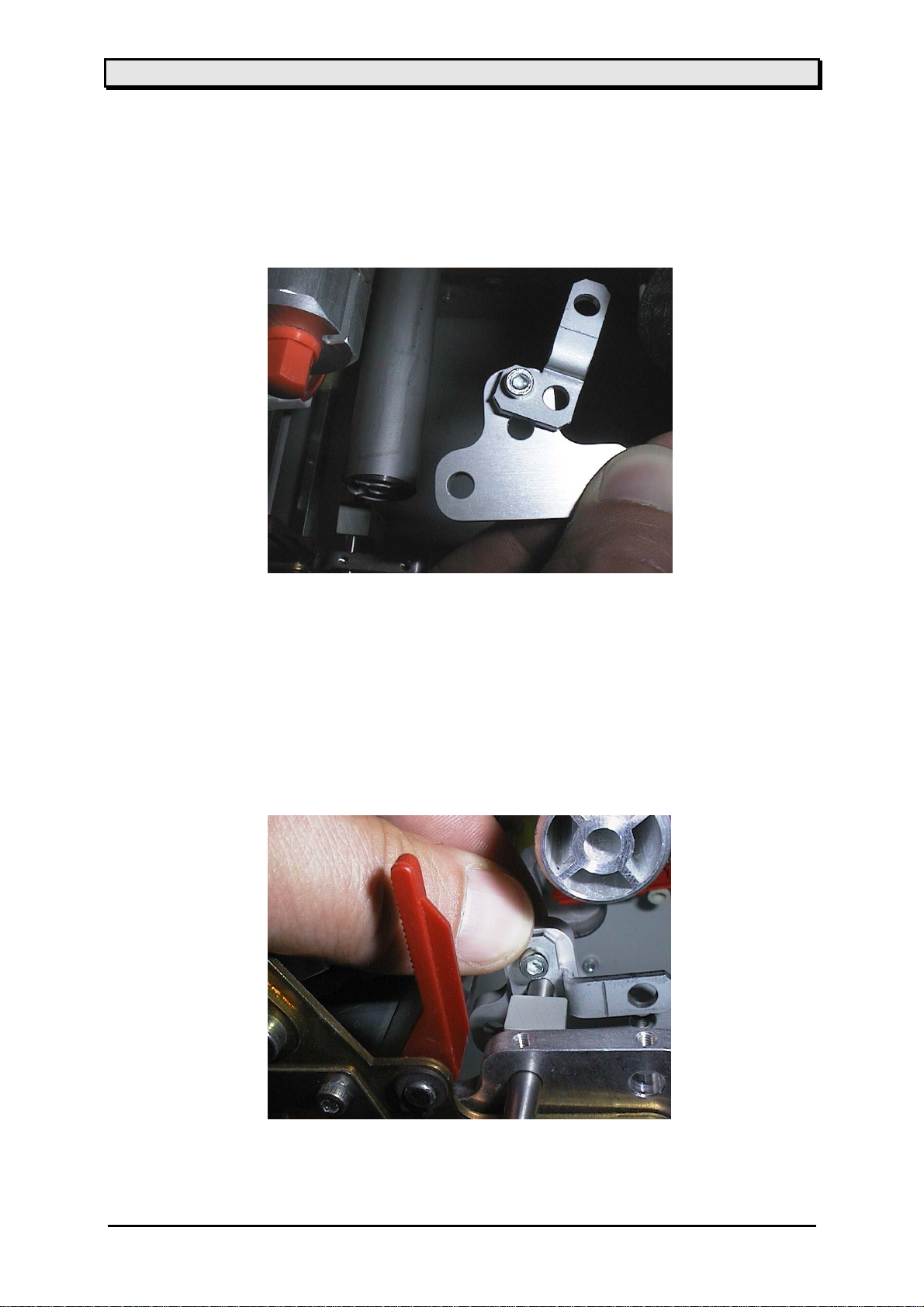

Change position of pressure lever

The lever position has to be changed from its normal position to a

position rotated 90 degrees (see photo).

Open the lock washer, push back the axle – remove the lever from the

axle – rotated the lever (90 degree) and pull the lever back to the axle.

Move the axle back into the hole of the metal plate and lock it with the

washer.

pressure lever

axle

lock washer

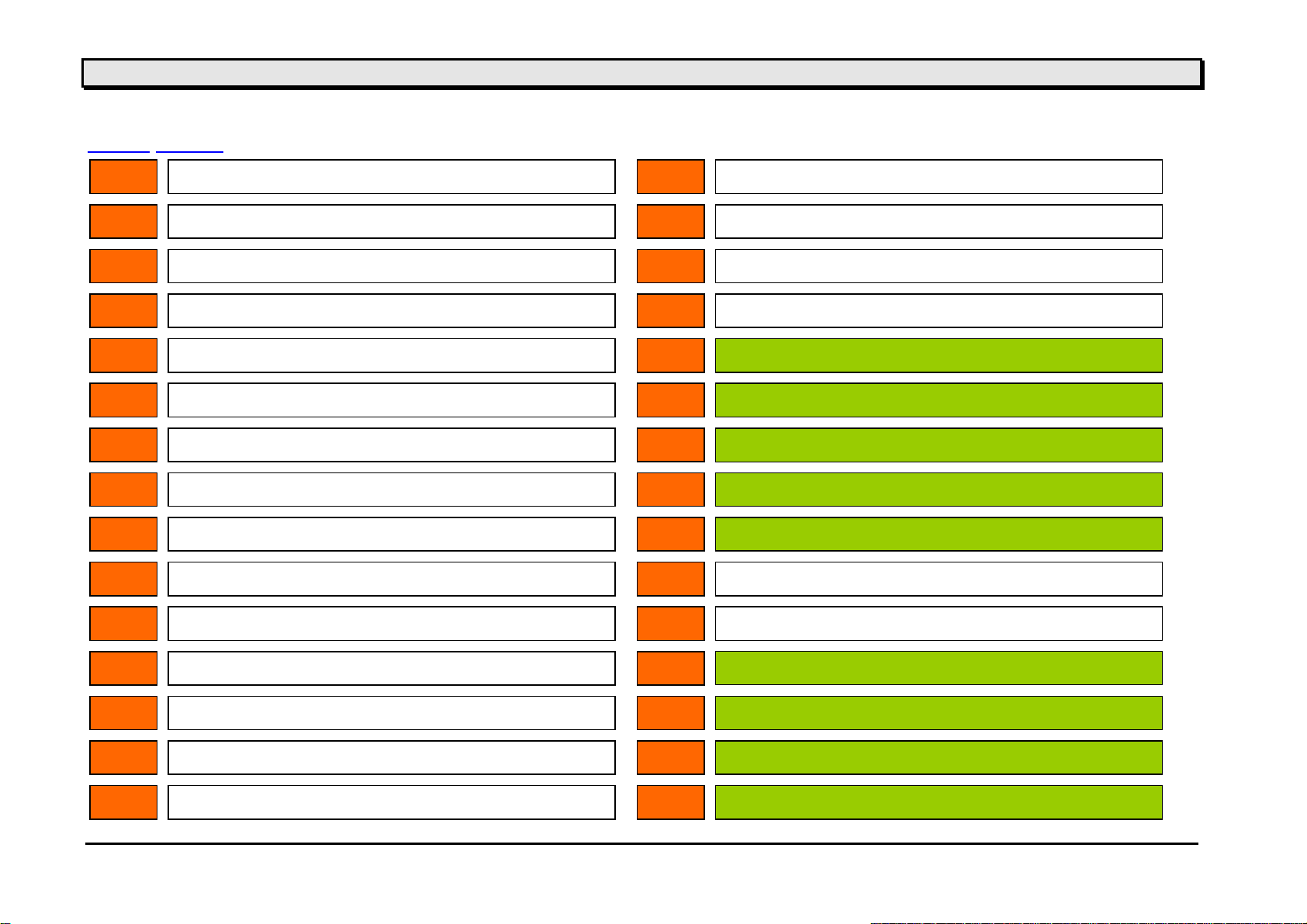

Remove media guiding

The old media guiding has to be removed from the unit. Therefore loosen the two

axles (locked with bushes) – open as well the hexagonal screws of the guiding (if

there) – and remove the axles to the front of the steel plate.

Attention: The inner guiding (with the sensor) will be used again – the outer

guiding can be thrown away . The new one (delivered with the sensor)

will be used.

11/07 Rev. 1.03 7

Page 8

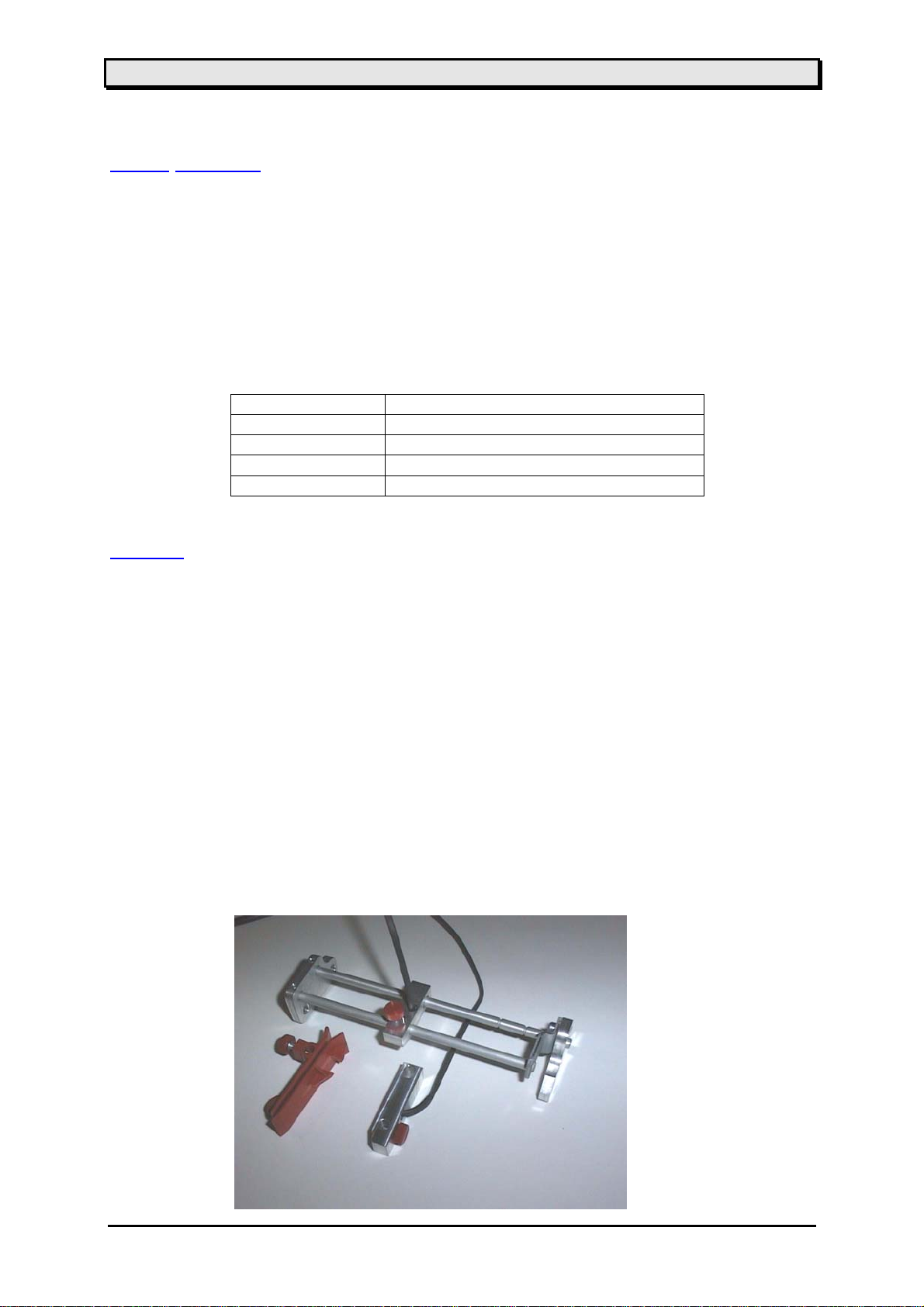

Mount full size sensor

Move the outer side plate from the inner side to the steel plate (see picture) and insert

the old axles into the drilled holes to lock the plate in this position. Take care that the

axles are inserted just 1 cm.

The upper – front axle has to be moved into the hole of the side plate (near print

head) – and the upper part of the full size sensor has to be slipped onto.

Service Manual Full Size Sensor

11/07 Rev. 1.03 8

Page 9

Service Manual Full Size Sensor

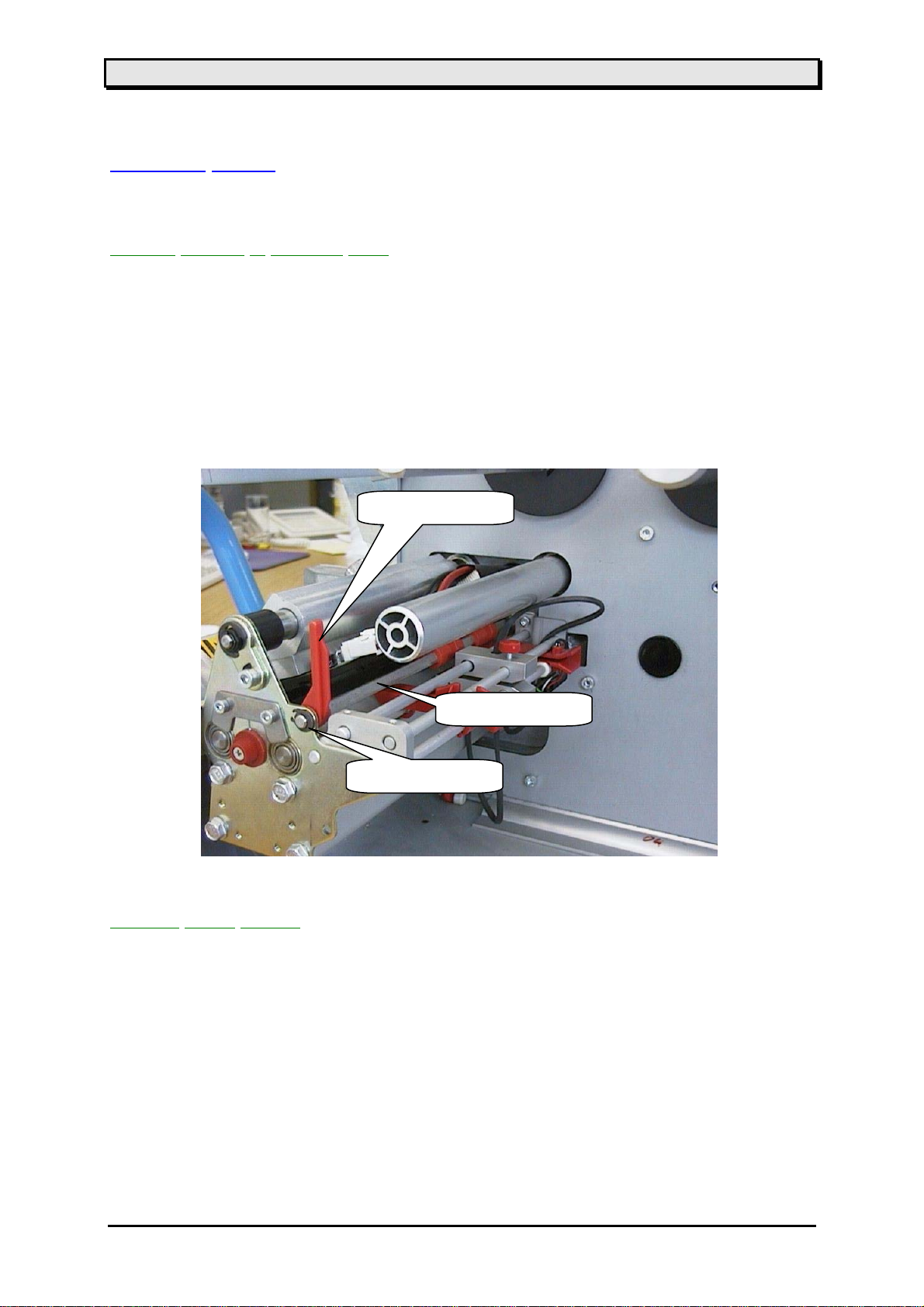

Screw the metal plate to the inner side plate

Attention: Take care that the screw is not tighten – both parts should be able to

move.

Slip the assemble to the upper – front axle. The end of the axle has to end with the

inner side of the plate (please take care about that) and fix the axle by using the

hexagonal screw in the plate.

Attention: Now you can tighten the screw fixing metal plate and inner side plate

together.

11/07 Rev. 1.03 9

Page 10

Service Manual Full Size Sensor

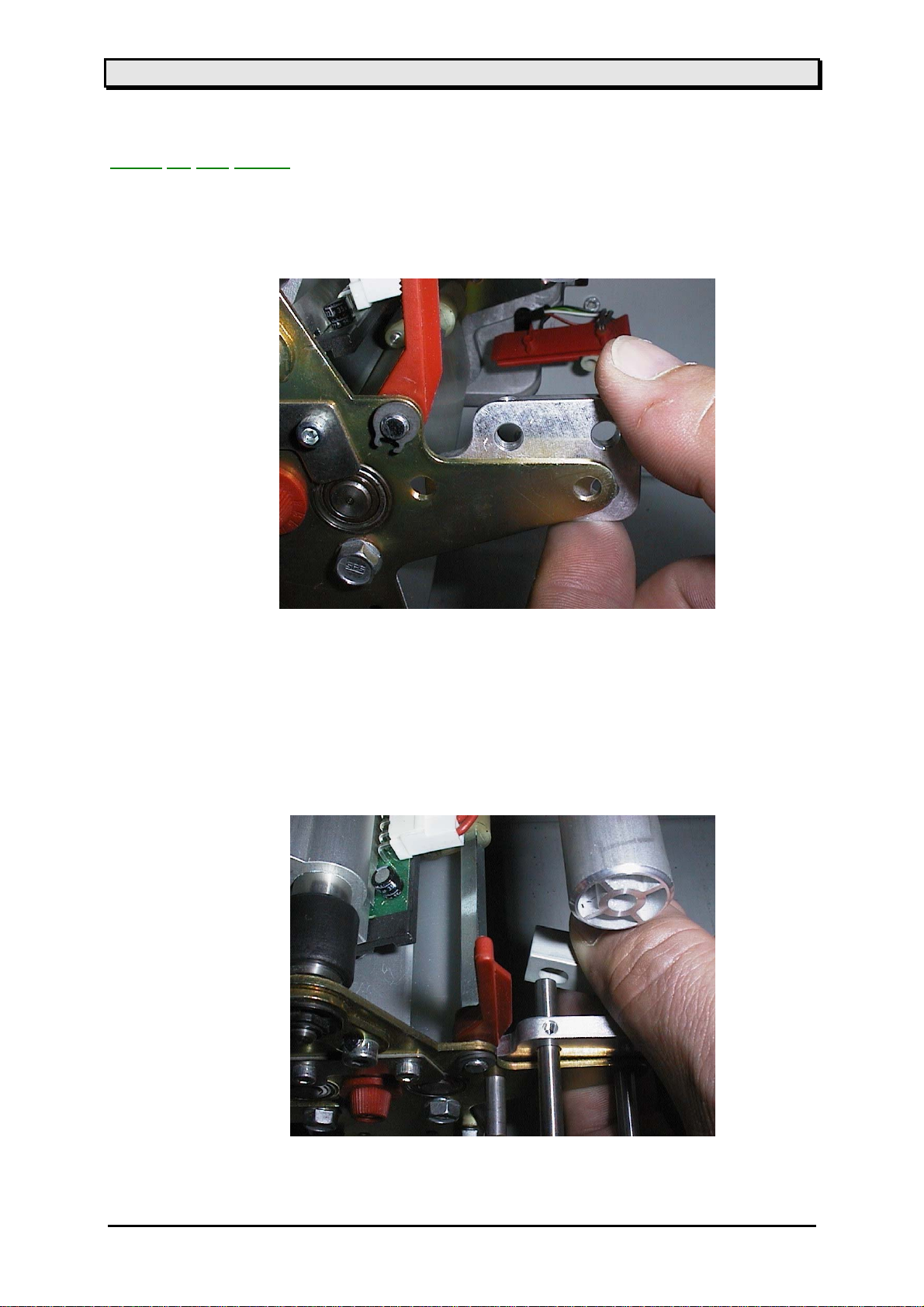

Now the other parts of the full size sensor can be mounted to the other axles – please

follow the shown sequence

outer media guiding

lower part of the sensor

inner media guiding

Then insert the upper – rear axle into the outer side plate – the upper part of the

full size sensor (rear hole) has to slide on the axle

The two lower axles slip into the holes of the inner side plate and have to be adjusted

in a way that 1,8 mm (+/- 0,1 mm) of the axles are looking out of the inner side plate

Fix the axles by use of the hexagonal screws.

1,8 mm

11/07 Rev. 1.03 10

Page 11

Service Manual Full Size Sensor

The upper – rear axle fits into the hole of the metal part

Guide the cable of the full size sensor the same way the other sensor cable is guided

into the printer (trough the metal casting)

Press the inner side plate against the metal casting – the two axles fit into the holes in

the metal casting

Press the outer side plate against the steel plate and fix it with the hexagonal screws

in a way that the whole assembly is fixed secure

Take care that the inner media guiding is fixed in the correct position to the axle (iiner

zero line)

11/07 Rev. 1.03 11

Page 12

Service Manual Full Size Sensor

Connect the connector of the sensor cable to CN 10 on the I/O board as shown on

the picture below

CN 10

11/07 Rev. 1.03 12

Page 13

Service Manual Full Size Sensor

Chapter 2 Set up mode

11/07 Rev. 1.03 13

Page 14

Service Manual Full Size Sensor

Adjustment of the sensor

After the sensor is mounted to the printer – it has to be adjusted to the position of the gap on

the media .

Both parts of the sensor are equipped with screws – used to fix the sensor on the axle. Both

parts have to be adjusted in the correct position ! Then activate the sensor and test it.

11/07 Rev. 1.03 14

Page 15

Service Manual Full Size Sensor

Initialise or activate option

After you have mounted the option correctly to the printer - and the necessary adjustment

the option can be activated

This can be done by changing the parameter in the Firmware.

• switch on the unit display shows OFF

• press FEED and CUT at the display shows INFO

same time

• press CUT until display shows SYSP

• press ENTER display shows EMUL

• press CUT until display shows SENS

• select until display shows FULL

• press ENTER to accept beep

• press FEED and CUT display shows SYSP

• press FEED and CUT display shows OFF

Attention: The option is now activated - all other option’s are deactivated!

Check Sensor

The sensor of the full size sensor – used to detect the presence of a label – can be

checked.

Select in the printer menu the function SCHK – go to menu point U xx and test the function

of the sensor.

Without media a shown in the display ‚U 0‘

with media is shown ‚U 15‘

11/07 Rev. 1.03 15

Page 16

Service Manual Full Size Sensor

Chapter 3 Information printout / parameter

11/07 Rev. 1.03 16

Page 17

Service Manual Full Size Sensor

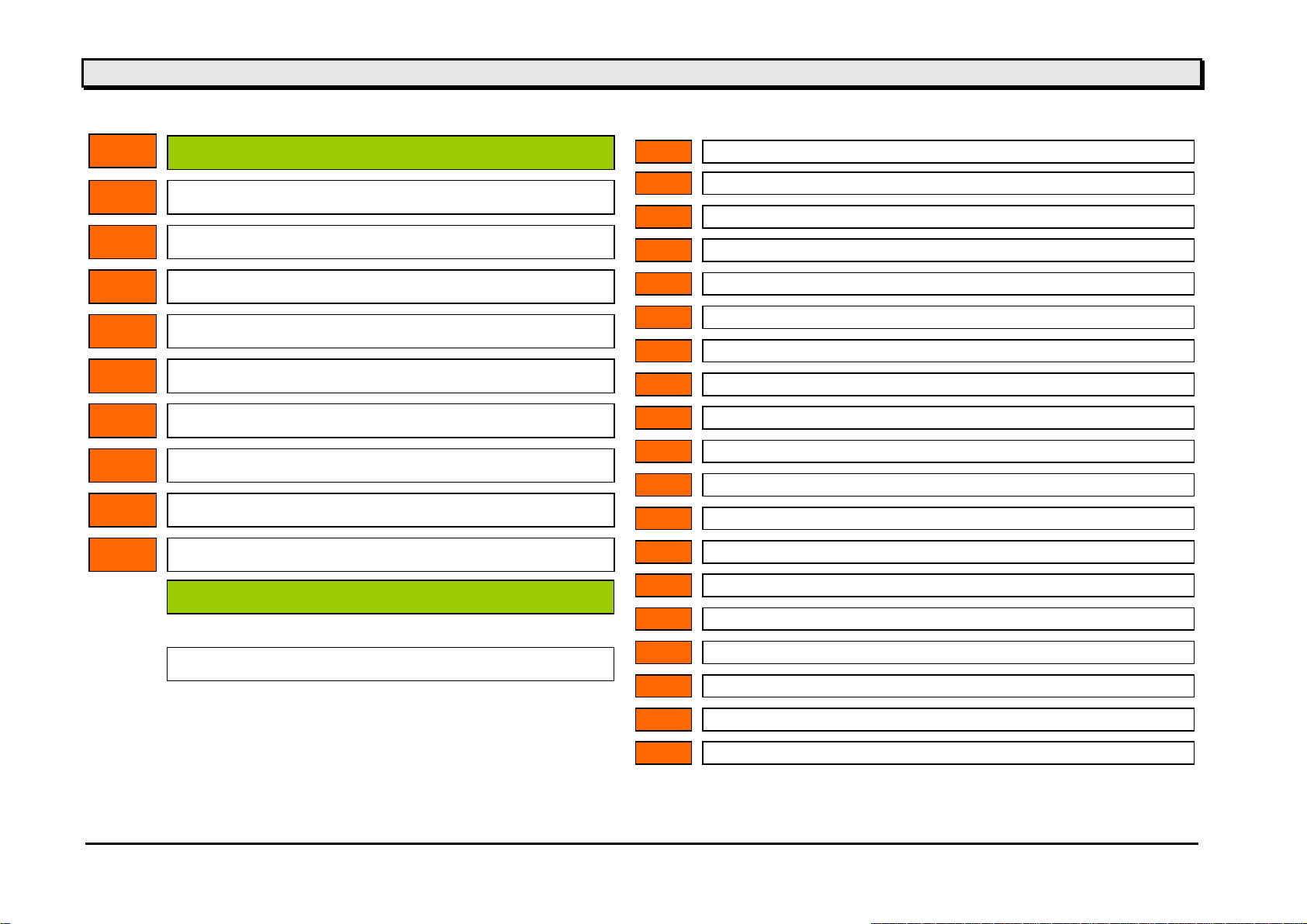

Parameter Menu

OFFLINE

INFO PRTP IFAC SYSP JCLR SCLR OTHR

STA0

STA1

STA2

STA3

DOT1

DOT2

PSPD

MTYP

MLEN

MWID

PUNO

BCHI

UPCA

CSPD

CPOS

CWID

CDIS

ASPD

ADIS

MPOS

PORT

SPOL

BMOD

<20H

BAUD

PARI

DBIT

SBIT

HAND

PRID

EMUL

NACH

SENS

PUNS

FMOD

OMOD

SMOD

EXTR

SGMO

CODE

HRES

HVOF

CLCK

USMD

DOWN

LCLR

CCLR

ICLR

ADJS

MCHK

SCHK

PCHK

FACT

SERV

NULL

HADJ

ACSC

XPOS

YPOS

SSPD

GAP

CMOD

DMOD

Nur mit Messer / cutter only

Spender mit Applikator / dispenser with applicator

Für Spender (MPOS – auch mit Abreißkante) / dispenser only (MPOS – tear off as well)

Nur mit Scanner / scanner only

Nur mit Color Option / with color option only

Nur für Service / for service only

LREP

CSET

MEND

SCAN

SERR

PEPH

Standard / standard

11/07 Rev. 1.03 17

Page 18

Service Manual Full Size Sensor

Status printout

Attention: Status printout is not available during infeed operation - there is no media to

print to!

Status

ST05 Media is not more in the gap sensor

from version 1.15 for TTX 650

1.00 for TTX 450/950

Action: Check the length inside your format

press ON/OFF to accept the message

ST08 Media is not reaching the gap sensor

Action: insert media (check the sensor)

press ON/OFF to accept the message

11/07 Rev. 1.03 18

Page 19

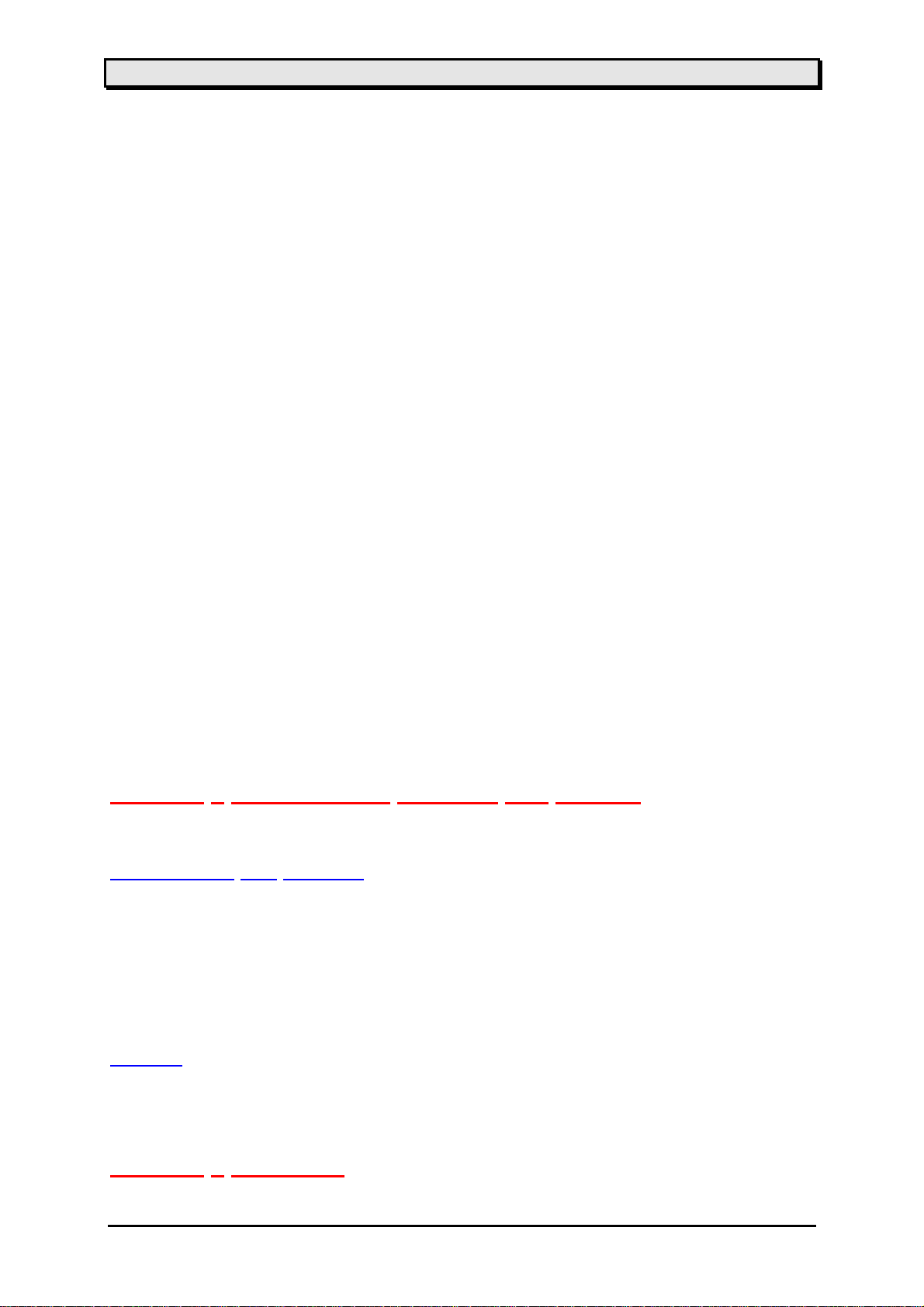

Status reports

ST 00

ST 01

ST 02

ST 03

ST 04

ST 05

ST 06

ST 07

ST 08

ST 09

ST 10

ST 11

ST 12

ST 13

ST 14

NOVRAM error (factory set)

NOVRAM write error

no material in SNGL sensor

stacker full

material end

printhead overheated

ribbon end

gap not found

ramcard error

ramcard error

barcode reading error or media broken for rewinder

cut sensor not found, dispenser second feeder, nothing

Service Manual Full Size Sensor

ST 15

ST 16

ST 17

ST 18

ST 19

ST 20

ST 21

ST 22

ST 23

ST 24

ST 25

ST 26

ST 27

ST 28

ST 29

head sensor not found (system will be locked)

applicator home position not found

dispenser pressure roller not closed

dispenser backing paper rewinder full

applicator – touch down not found

EASY PLUG wrong command (imedeate)

EASY PLUG wrong command between #ER and #Q

EASY PLUG command without #ER

EASY PLUG not known command

receive error RS 232

spooler overflow

EASY PLUG wrong size or print adjustment

EASY PLUG counter overflow

EASY PLUG field outside print area

EASY PLUG logo number doesn’t exist

11/07 Rev. 1.03 19

Page 20

ST 30

ST 31

ST 32

ST 33

ST 34

ST 35

ST 36

ST 37

ST 38

ST 39

ST 40

ST 41

ST 42

ST 43

ST 44

Service Manual Full Size Sensor

EASY PLUG logo buffer to small

EASY PLUG logo number error

EASY PLUG postbarcode not OK

EASY PLUG range command #PA to #IM wrong

COLOR PANEL color code not found

COLOR PANEL logo does not fit to the card

COLOR PANEL color card not found or programmable

EASY PLUG speedo error

receive error RS 232

receive error RS 232

ID matrix barcode error

ST 45

ST 46

ST 47

ST 48

ST 49

ST 50

ST 51

ST 52

ST 53

ST 54

ST 55

ST 56

ST 57

ST 58

ST 59

no read of scanner

scanner not programmable (system will be locked)

stacker full (standard)

acess denied for setting printer to zero

11/07 Rev. 1.03 20

Page 21

ST 60

ST 61

ST 62

ST 63

ST 64

ST 65

ST 66

ST 67

ST 68

ST 69

ST 70

ST 71

ST 72

ST 73

ST 74

Service Manual Full Size Sensor

memory allocation error (system will be locked)

font allocation error (system will be locked)

update or numberfield overflow

wrong board installed for selected peripherie option

interrupt error (system stands)

TDI stepper does not respond

headstrobe checksum wrong (system will be locked)

speedo system error

speedo scaling wrong

ST 75

ST 76

ST 77

ST 78

ST 79

ST 80

ST 81

ST 82

ST 83

ST 84

ST 85

ST 86

ST 87

ST 88

ST 89

EASY CARD wrong name of file in #FO command

EASY CARD field number not found

EASY CARD syntax of #YT or #YB command wrong

EASY CARD number of data field to big

EASY CARD quantity of variable characters = 0

EASY CARD no card found

DATA BASE not enough space for index file

DATA BASE no possibility to build index file

DATA BASE no possibility to sort index file

DATA BASE barcode onformation nor found in

11/07 Rev. 1.03 21

Page 22

K

A

–

p

p

p

p

p

p

p

p

p

p

pr

ST 90

ST 91

ST 92

ST 93

ST 94

ST 95

ST 96

ST 97

ST 98

ST 99

database contains identical records

barcode not readable

EASY CARD undefined error

EASY PLUG undefined error

INTERFACE undefined error

SYSTEM undefined derror

just warning – self confirming

must be confirmed by the user

Service Manual Full Size Sensor

POFF

FAIL

SCAN

OPEN

LOC

DAT

STOP

SNGL

WAIT

HOST

INIT

DOWN

UP

.LDR

.EMU

.SYS

SORT

----

LOAD

Power OFF

Image card could not be formatted

Scanner was unable to decode the information

cover open –switch is open

the printer is locked

data receive mode

rinter in STOP mode

rinter in single start mode

rinter in wait condition

rinter stopped by host

rinter is initialised

TDI table goes u

TDI table goes down

rinter in loader mode

rinter in interpretermode

rinter in system mode

data base information is sorted

inter was switched on to early after power down

barcodes loaded from card

rinter is switched OFF

11/07 Rev. 1.03 22

Page 23

Service Manual Full Size Sensor

Chapter 4 maintenance, cleaning and service

Maintenance and cleaning

Clean on a regular basis the feed roller of the infeed unit - as well of the printer - and the

metal parts from paper dust and glue!

If you are not cleaning regularly problem with the feed system can occur.

Service

No special service is needed !

Chapter 7 Appendix

11/07 Rev. 1.03 23

Page 24

Spare parts

Service Manual Full Size Sensor

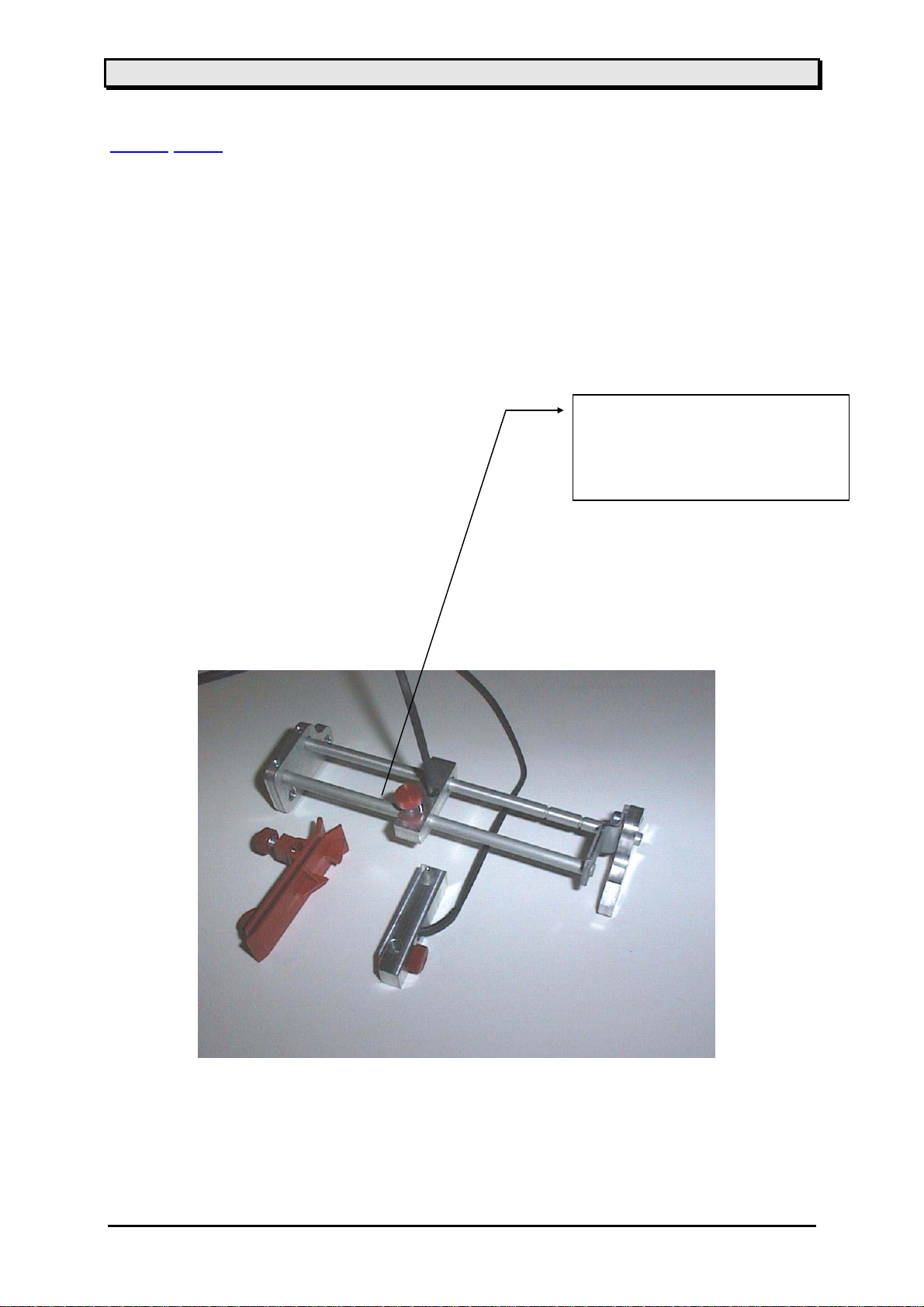

Part Number : 99904-xx-2 (450-Puma)

Part Number : 99984-xx-2 (650-Lion)

Part Number : 99985-xx-2 (950-Tiger)

Bezeichnung : Fullsize Lichtschranke ZSB

Identification : full size punch sensor assy.

11/07 Rev. 1.03 24

Page 25

Service Manual Full Size Sensor

g

g p

Part Number : 99908-xx-0

Bezeichnung : Flansch vorne

Identification : front flange

Part Number : A1679

Bezeichnung : ZSB Rändelschraube

Identification : Thumb screw assy.

Part Number : 99910-xx-0

Bezeichnung : Materialführung vorn

Identification : front media guiding

Part Number : A0216 (TTX x50 / TTX 67x

/ Wildcats (plus))

A1816 (64-xx / Chess x)

Bezeichnung : Lichtschranke ZSB

Identification : sensor assy.

Part Number : 99909-xx-0

Bezeichnung : Flansch hinten

Identification : rear flan

Part Number : 99979-xx-0

Bezeichnung : Halteblech

Identification : mountin

Part Number : 99907-xx-0 (450-Puma)

Part Number : 99986-xx-0 (650-Lion)

Part Number : 99987-xx-0 (950-Tiger)

Bezeichnung : Achse

Identification : axle

Part Number : 99926-xx-0 (450-Puma)

Part Number : 99927-xx-0 (650-Lion)

Part Number : 99925-xx-0 (950-Tiger)

Bezeichnung : Achse (mit Nut)

Identification : axle (with slot)

11/07 Rev. 1.03 25

e

art

Page 26

Service Manual Full Size Sensor

INDEX

A

activate Infeed............................................................................................................................. 15

Adjustment of the sensor ........................................................................................................4, 14

Appendix ..................................................................................................................................... 23

Assemble Option.......................................................................................................................4, 7

C

Change position of pressure lever ............................................................................................ 4, 7

Check Sensor..........................................................................................................................4, 15

cleaning....................................................................................................................................... 23

Contents........................................................................................................................................ 4

copyright........................................................................................................................................3

Copyright.......................................................................................................................................3

CUT............................................................................................................................................. 15

E

EMUL ..........................................................................................................................................15

Error ..............................................................................................................................................5

Error handling................................................................................................................................5

F

FEED...........................................................................................................................................15

G

General.................................................................................................................................. 2, 3, 4

General notes............................................................................................................................3, 4

I

INDEX ..................................................................................................................................... 4, 26

INFO............................................................................................................................................15

Information printout ..................................................................................................................... 16

Initialise or activate option.......................................................................................................4, 15

Initiation......................................................................................................................................... 5

M

maintenance................................................................................................................................23

Maintenance and cleaning...................................................................................................... 4, 23

Media limitation ......................................................................................................................... 4, 6

Mount full size sensor ...............................................................................................................4, 8

11/07 Rev. 1.03 26

Page 27

Service Manual Full Size Sensor

N

notes.............................................................................................................................................. 3

O

operation ..................................................................................................................................... 18

other........................................................................................................................................3, 15

P

parameter..............................................................................................................................15, 16

Parameter Menu......................................................................................................................4, 17

PEPH........................................................................................................................................... 15

R

Remove media guiding .............................................................................................................4, 7

S

Service ............................................................................................................................ 1, 3, 4, 23

Set up mode................................................................................................................................13

Spare parts..............................................................................................................................4, 24

ST05........................................................................................................................................4, 18

ST08........................................................................................................................................4, 18

Status................................................................................................................................4, 18, 19

Status printout......................................................................................................................... 4, 18

Status reports..............................................................................................................................19

SYSP...........................................................................................................................................15

U

Unpack......................................................................................................................................4, 6

11/07 Rev. 1.03 27

Loading...

Loading...