Page 1

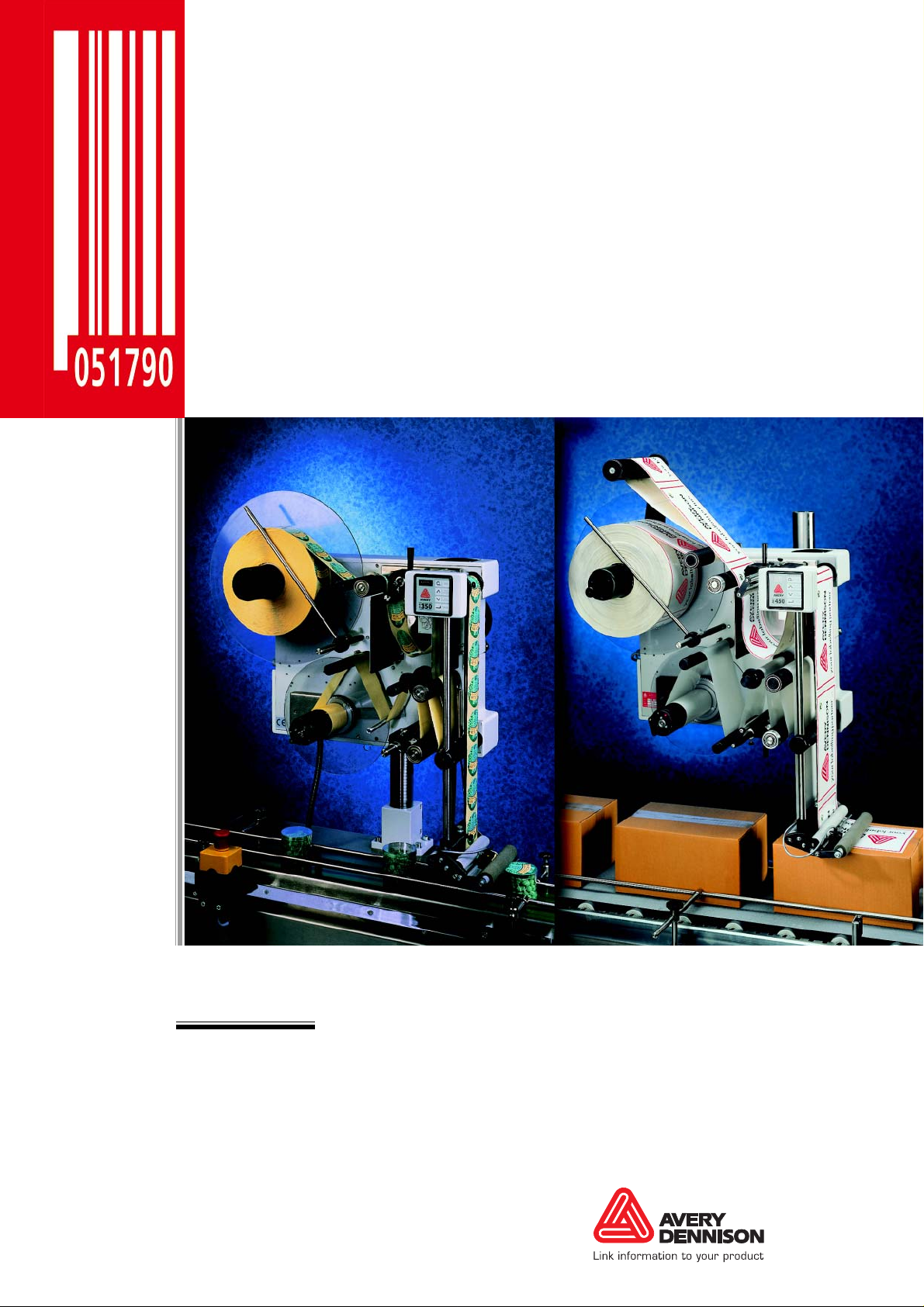

OPERATING MANUAL

Label Dispenser

ALS

350

450

Article number: A6432, Release 06.2005

Page 2

Page 3

CONTENTS

ALS

350

450

1 Please observe the following

1.1 General information. . . . . . . . . . . . . . 6

1.1.1 Validity and applicability of this manual . . . . . 6

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Technical State. . . . . . . . . . . . . . . . . . . . . . . . 6

Copyright notice . . . . . . . . . . . . . . . . . . . . . . . 6

Manufacturer. . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.1.2 Conventions and information . . . . . . . . . . . . . 7

Explanation of symbols. . . . . . . . . . . . . . . . . . 7

Warnings concerning dangers and risks. . . . . 7

Illustrations . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Supplemental information. . . . . . . . . . . . . . . . 7

Directional information . . . . . . . . . . . . . . . . . . 8

ALS 350 and ALS 450 . . . . . . . . . . . . . . . . . . 8

1.2 Safety instructions . . . . . . . . . . . . . . . 9

1.2.1 Information and qualifications. . . . . . . . . . . . . 9

Pay attention to the information . . . . . . . . . . . 9

Information must be made available. . . . . . . . 9

Ensure necessary qualifications . . . . . . . . . . . 9

1.2.2 Machine operating safety . . . . . . . . . . . . . . . 10

Appropriate use. . . . . . . . . . . . . . . . . . . . . . . 10

Protect against injuries that can result from elec-

trical current . . . . . . . . . . . . . . . . . . . . . . . . . 10

Protect against injuries that can result from me-

chanical actions . . . . . . . . . . . . . . . . . . . . . . 10

Protection against chemical injuries . . . . . . . 10

1.2.3 Before every production start . . . . . . . . . . . . 11

Operator's obligation and service personal to

exercise care. . . . . . . . . . . . . . . . . . . . . . . . . 11

Operating personnels' obligation to exercise

care. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2 Equipment description

2.1.4 Design versions . . . . . . . . . . . . . . . . . . . . . . 17

Right-hand version. . . . . . . . . . . . . . . . . . . . 17

Left-hand version . . . . . . . . . . . . . . . . . . . . . 17

2.2 Overview of the ALS 450 . . . . . . . . . 18

2.2.1 Structural elements . . . . . . . . . . . . . . . . . . . 18

2.2.2 Principle of operation . . . . . . . . . . . . . . . . . . 20

2.2.3 Technical data . . . . . . . . . . . . . . . . . . . . . . . 22

Characteristic values . . . . . . . . . . . . . . . . . . 22

Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Ambient conditions. . . . . . . . . . . . . . . . . . . . 22

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . 22

Casing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Electrical system . . . . . . . . . . . . . . . . . . . . . 22

Control system. . . . . . . . . . . . . . . . . . . . . . . 22

Emissions. . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.2.4 Design versions . . . . . . . . . . . . . . . . . . . . . . 23

Right-hand version. . . . . . . . . . . . . . . . . . . . 23

Left-hand version . . . . . . . . . . . . . . . . . . . . . 23

2.3 Options. . . . . . . . . . . . . . . . . . . . . . . 24

Serial interface. . . . . . . . . . . . . . . . . . . . . . . 24

Roll diameter control . . . . . . . . . . . . . . . . . . 24

Adjustable dispensing edge. . . . . . . . . . . . . 24

Spring-loaded dispensing edge . . . . . . . . . . 24

Pneumatic dispensing edge. . . . . . . . . . . . . 24

Printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Applicator. . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Water-resistant electronic control unit . . . . . 24

2.4 Operator controls . . . . . . . . . . . . . . . 25

2.4.1 Operator panel. . . . . . . . . . . . . . . . . . . . . . . 25

LED indicator . . . . . . . . . . . . . . . . . . . . . . . . 25

Keys. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2.4.2 Main switch . . . . . . . . . . . . . . . . . . . . . . . . . 26

2.1 Overview of the ALS 350. . . . . . . . . 12

2.1.1 Structural elements. . . . . . . . . . . . . . . . . . . . 12

2.1.2 Principle of operation . . . . . . . . . . . . . . . . . . 14

2.1.3 Technical data. . . . . . . . . . . . . . . . . . . . . . . . 16

Characteristic values. . . . . . . . . . . . . . . . . . . 16

Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Ambient conditions . . . . . . . . . . . . . . . . . . . . 16

Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . 16

Casing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Electrical system. . . . . . . . . . . . . . . . . . . . . . 16

Control system . . . . . . . . . . . . . . . . . . . . . . . 16

Emissions . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.5 Control system . . . . . . . . . . . . . . . . . 27

2.5.1 Brief description . . . . . . . . . . . . . . . . . . . . . . 27

2.5.2 Menus for operators and calibration technicians

28

2.5.3 Monitoring functions. . . . . . . . . . . . . . . . . . . 29

Dispensing a label to each product . . . . . . . 29

Label supply. . . . . . . . . . . . . . . . . . . . . . . . . 29

If errors occur. . . . . . . . . . . . . . . . . . . . . . . . 29

3 Prior to operating

3.1 Insert the labelling material – ALS 350.

3

Page 4

CONTENTS

ALS

350

450

30

3.1.1 Prerequisites. . . . . . . . . . . . . . . . . . . . . . . . . 30

3.1.2 Insert the label roller . . . . . . . . . . . . . . . . . . . 30

Remove the old backing material . . . . . . . . . 30

Remove adhesive residues. . . . . . . . . . . . . . 30

Insert new label roll. . . . . . . . . . . . . . . . . . . . 31

3.1.3 Threading the label ribbon . . . . . . . . . . . . . . 32

Overview of the threading path diagram. . . . 32

Thread the label ribbon at the unwind unit . . 33

Guide the label ribbon around the dispensing

edge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Thread the label ribbon at the rewind unit. . . 35

3.2 Insert the labelling material – ALS 450

36

3.2.1 Prerequisites. . . . . . . . . . . . . . . . . . . . . . . . . 36

3.2.2 Insert the label roller . . . . . . . . . . . . . . . . . . . 36

Remove the old backing material . . . . . . . . . 36

Remove adhesive residues. . . . . . . . . . . . . . 36

Insert new label roll. . . . . . . . . . . . . . . . . . . . 37

3.2.3 Threading the label ribbon . . . . . . . . . . . . . . 38

Overview of the threading path diagram. . . . 38

Thread the label ribbon at the unwind unit . . 39

Guide the label ribbon around the dispensing

edge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Thread the label ribbon at the rewind unit. . . 41

3.3 Mechanical settings. . . . . . . . . . . . . 42

3.3.1 Setting the ribbon guides . . . . . . . . . . . . . . . 42

Operator panel support. . . . . . . . . . . . . . . . . 42

Setting the ribbon guides on the disp enser head

42

Deflection roller on the rewind unit . . . . . . . . 42

3.3.2 Adjust pressure roller at the dispensing edge43

3.3.3 Adjust the pressure roller and the braking brush

44

Pressure roller. . . . . . . . . . . . . . . . . . . . . . . . 44

Braking brush . . . . . . . . . . . . . . . . . . . . . . . . 44

3.3.4 Adjust (optional) the position of the dispensing

edge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Adjusting vertically . . . . . . . . . . . . . . . . . . . . 45

Manually initialise the material. . . . . . . . . . . 47

4.1.2 Labelling. . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Prerequisites . . . . . . . . . . . . . . . . . . . . . . . . 48

Start dispensing labels. . . . . . . . . . . . . . . . . 49

Unwind unit . . . . . . . . . . . . . . . . . . . . . . . . . 50

Rewind unit . . . . . . . . . . . . . . . . . . . . . . . . . 50

4.1.3 Stop/end the label dispensing . . . . . . . . . . . 50

4.1.4 Tandem operation . . . . . . . . . . . . . . . . . . . . 51

Principle of operation . . . . . . . . . . . . . . . . . . 51

Prerequisites . . . . . . . . . . . . . . . . . . . . . . . . 52

Start dispensing labels. . . . . . . . . . . . . . . . . 52

Reloading label material. . . . . . . . . . . . . . . . 53

Switching off. . . . . . . . . . . . . . . . . . . . . . . . . 54

4.2 Setting and monitoring . . . . . . . . . . . 55

4.2.1 Settings in the standardmenu . . . . . . . . . . . 55

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Calling up menu. . . . . . . . . . . . . . . . . . . . . . 55

Call up function . . . . . . . . . . . . . . . . . . . . . . 55

4.2.2 Label stop position. . . . . . . . . . . . . . (STOD)56

4.2.3 Dispensing speed. . . . . . . . . . . . . . . (VELO)57

Automatic dispensing speed (optional) . . . . 57

4.2.4 Label position on the product

(POS). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

4.2.5 Automatic material initialisation . . . . . . (INIT)59

4.2.6 If errors occur. . . . . . . . . . . . . . . . . . . . . . . . 60

Warning messages . . . . . . . . . . . . . . . . . . . 60

Error messages . . . . . . . . . . . . . . . . . . . . . . 60

4.3 Product databanks . . . . . . . . . . . . . . 61

4.3.1 Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

4.3.2 Loading product data banks. . . . . . . . . . . . . 61

Please observe: . . . . . . . . . . . . . . . . . . . . . . 61

Activating product databanks at switch-on. . 62

Activating product databanks after switch-on .

62

4.3.3 Create/save product databank . . . . . . . . . . 63

Prerequisites . . . . . . . . . . . . . . . . . . . . . . . . 63

Saving the product databank . . . . . . . . . . . . 63

Documenting product databanks . . . . . . . . . 63

4.3.4 Delete the product databank . . . . . . . . . . . . 64

4 Operation

4.1 Activation and shut-down. . . . . . . . . 46

4.1.1 Starting the machine. . . . . . . . . . . . . . . . . . . 46

Automatic material initialisation. . . . . . . . . . . 46

4.4 Settings in the extended menu. . . . . 65

4.4.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

4.4.2 Activating an extended menu. . . . . . . . . . . . 67

Please observe: . . . . . . . . . . . . . . . . . . . . . . 67

Calling up menu. . . . . . . . . . . . . . . . . . . . . . 67

4

Page 5

CONTENTS

ALS

350

450

Call up function. . . . . . . . . . . . . . . . . . . . . . . 67

Exit the extended menu . . . . . . . . . . . . . . . . 67

4.4.3 Position of second label

(POS2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

4.4.4 Position of third label. . . . . . . . . . . . . (POS3)68

4.4.5 Speed ratio . . . . . . . . . . . . . . . . . . . . (VERT)69

4.4.6 Adjust the label stop sensor (CONT) . . . . . . 70

Technology . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Automatically adjusting the photoelectric sensor

70

Manually adjusting the sensor . . . . . . . . . . . 71

4.4.7 Label distance. . . . . . . . . . . . . . . . . . . (LPIT)72

Set distance . . . . . . . . . . . . . . . . . . . . . . . . . 72

Check setting . . . . . . . . . . . . . . . . . . . . . . . . 72

4.4.8 Distance from the label stop sensor to the dispensing edge

(E–SS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Set distance . . . . . . . . . . . . . . . . . . . . . . . . . 73

Check setting . . . . . . . . . . . . . . . . . . . . . . . . 74

4.4.9 Product length . . . . . . . . . . . . . . . . . (PRDL)75

4.4.10 Polarity of the product sensor

(P_S_). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

4.4.11 Polarity of the label stop sensor . . . . (S_S_)76

4.4.12 Number of unlabelled products

(MLAB) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

4.4.13 Electronic transmission ratio of the RPM trans-

mitter (EGRA) . . . . . . . . . . . . . . . . . . . . . . . . 77

4.4.14 Advance print start . . . . . . . . . . . . . . . (PDT)78

4.4.15 Printer dwell time . . . . . . . . . . . . . . .(PDWT)78

4.4.16 Tandem operation. . . . . . . . . . . . . . .(TMOD)79

4.4.17 Applicator type . . . . . . . . . . . . . . . . . (APPL)79

4.4.18 EP cylinder dwell time. . . . . . . . . . . . (APT1)79

4.4.19 Blowing time . . . . . . . . . . . . . . . . . . . (APT2)79

4.4.20 Delay time . . . . . . . . . . . . . . . . . . . . (APT3)79

4.4.21 Fine tuning of the dwell time

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . (APT4)79

4.4.22 Delete a product data bank

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . (LOAD)79

4.4.23 Create/save product data bank

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . (SAVE)79

4.4.24 Delete a product data bank

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . (DEL)79

4.5.2 Electronic transmission ratio of the RPM trans-

mitter . . . . . . . . . . . . . . . . . . . . . . . . (EGRA)81

Setting the compensation factor. . . . . . . . . . 81

Test the setting. . . . . . . . . . . . . . . . . . . . . . . 81

4.6 Applicator (optional) . . . . . . . . . . . . . 82

4.6.1 Principle of operation . . . . . . . . . . . . . . . . . . 82

4.6.2 Functions in the extended menu . . . . . . . . . 83

Please observe the following: . . . . . . . . . . . 83

Calling up the extended menu. . . . . . . . . . . 83

Applicator type . . . . . . . . . . . . . . . . . .(APPL)83

EP cylinder dwell time . . . . . . . . . . . .(APT1)84

Blowing time. . . . . . . . . . . . . . . . . . . .(APT2)84

Delay time . . . . . . . . . . . . . . . . . . . . .(APT3)84

Fine tuning of the dwell time . . . . . . .(APT4)85

5 After operation

5.1 Care and cleaning . . . . . . . . . . . . . . 86

5.1.1 Cleaning agents. . . . . . . . . . . . . . . . . . . . . . 86

5.1.2 Regular maintenance. . . . . . . . . . . . . . . . . . 86

Remove paper waste. . . . . . . . . . . . . . . . . . 87

Braking brush. . . . . . . . . . . . . . . . . . . . . . . . 87

Capacitive sensor at the dispenser head. . . 88

6 Operational malfunctions

6.1 Warning messages. . . . . . . . . . . . . . 89

6.1.1 Please observe: . . . . . . . . . . . . . . . . . . . . . . 89

6.1.2 If a problem occurs. . . . . . . . . . . . . . . . . . . . 89

6.1.3 Warning messages . . . . . . . . . . . . . . . . . . . 89

6.2 Error messages . . . . . . . . . . . . . . . . 91

6.2.1 If a malfunction occurs. . . . . . . . . . . . . . . . . 91

6.2.2 Error codes. . . . . . . . . . . . . . . . . . . . . . . . . . 91

7 Appendix

7.1 Factory settings . . . . . . . . . . . . . . . . 95

7.2 Product databanks . . . . . . . . . . . . . . 97

7.3 EC Declaration of Conformity. . . . . . 99

4.5 Automatic dispensing speed (APSF) 80

4.5.1 Principle of operation . . . . . . . . . . . . . . . . . . 80

5

Page 6

1PLEASE OBSERVE THE FOLLOWING

1.1 GENERAL INFORMATION

1 PLE ASE OBSERVE THE FOLLOWING

1.1 GENERAL INFORMATION

1.1.1 Validity and applicability of this manual

ALS

350

450

Contents

The present manual refers exclusively to the ALS 350

and ALS 450 labeller machines. The manual is to be

referred to for correct operation and ad ju stm e nt of the

machine.

The prerequisites for operation and adjustment are

proper installation and configuration of the machine.

For technical questions which are not addressed in this

operating manual:

£ Observe the instructions contained in the labeller

service guide

or

£ Request assistance from a service technician at our

sales partner.

– The customer se rvice at our sales partner is a t your

disposal and particularly helpful with configuration

settings and remedying malfunctions.

Technical State

Technical state as of: 06/200 5

Software version: 6.1

Copyright notice

All rights to this operating manual are assigned to Avery

Dennison. Transmission, reprinting or any other means

of reproduction of this manual, whether whole or in part,

are not allowed without prior written permission. Third

parties, in particular competitors, are not to be allowed

access to information derived from this manual.

Printed in Germany

Manufacturer

Avery Dennison Deutschland GmbH

Ohmstraße 3

D–85386 Eching

Phone: +49-8165-925-0

Fax: +49-8165-3143

http://www.machines.averydennison.com

Avery Dennison reserves the right to:

– implement modifications of structural parts, compo-

nents and software as well as to use equivalent

components that keep pace with the current state of

technology in lieu of the specified components.

– change information contained in this manual.

An obligation to extend these modifications to previously

delivered machines is excluded.

6

Page 7

1PLEASE OBSERVE THE FOLLOWING

1.1 GENERAL INFORMATION

1.1.2 Conventions and information

ALS

350

450

Explanation of symbols

In order to facilitate legibility and an overview, the various types of information used herein are categorised

and identified with certain symbols.

Sentences that are introduced by an arrow contain procedural instructions.

£ Carry out procedural instructions one after the other

in the prescribed order.

The following information is introduced with a dash:

– List items

– Descriptions of conditions

– Description of previous work steps

– Prerequisites for implementing actions described in

the following passage

Warnings concerning dangers and risks

Important text passages which must absolutely be followed are particularly marked for special attention:

DANGER!

A danger notice indicates an imminent

hazardous situation which, if not avoided,

could result in death or serious injury of the

personnel!

The notice contains instructions on how to

avoid or prevent the danger(s).

£ The instructions must be followed.

Illustrations

When required, text passages are accompanied by

illustrations. The reference to an illustration is indicated

by typesetting the [illustration number] in square brackets. Capital letters following an illustration number, e.g.

[12A], refer to the corresponding position indicated in

the illustration.

In general, the right-hand version of labeller ALS 350 is

depicted in the illustrations. The left-hand version or the

ALS 450 are only depicted if differentiation is necessary.

Supplemental information

The "Experts" symbol earmarks activities that

only to be performed by knowledgeable and

trained personnel.

The information symbol indicates notices and

recommendations as well as additional helpful

information.

Operating materials:

– Operating materials, e.g. lubricants or

cleaning agents

WARNING!

A warning notice indicates risks which could

result in death or serious injury of the

personnel! The notice contains safety

instructions on how to safeguard possibly

affected personnel.

£ The instructions must be followed.

CAUTION!

A caution notice indicates risks which, if

unheeded, could lead to material damage or

bodily injury (minor injuries). The notice

contains instructions on how to prevent

damage or injury.

£ The instructions must be followed.

7

Page 8

1PLEASE OBSERVE THE FOLLOWING

1.1 GENERAL INFORMATION

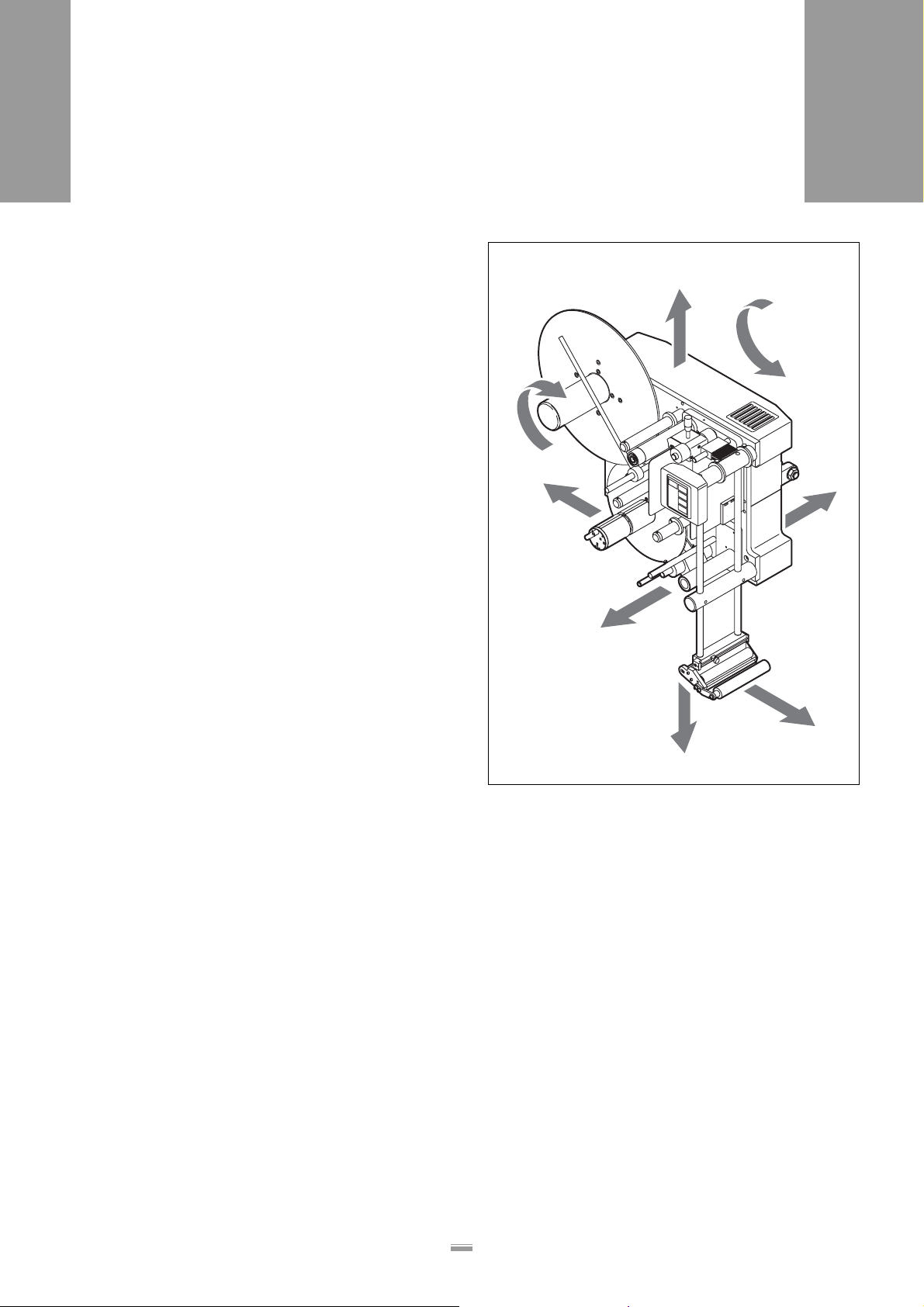

Directional information

Unless otherwise indicated, the directional information

mentioned in the text refers to the construction of the

right-hand version of Top Labeller. See Figure [1] for

the explanation of directional information.

ALS

350

450

C

H

ALS 350 and ALS 450

The operation of the two labellers described in this

operating manual is very similar. In general, the righthand version of labeller ALS 350 is described. The lefthand version or the ALS 450 are only discussed if the

descriptions deviate significantly.

In the header of each page, it is annotated whether the

respective page applies to the ALS 350 and ALS 450 or

to only one of the two types.

G

E

A

D

[1] Definition of directional information

A Front

B Rear

C Upward

D Downward

E Left

F Right

G Clockwise

H Counter-clockwise

B

F

8

Page 9

1PLEASE OBSERVE THE FOLLOWING

1.2 SAFETY INSTRUCTIONS

1.2 SAFETY INSTRUCTIONS

1.2.1 Information and qualifications

ALS

350

450

Pay attention to the information

WARNING!

Reliable and safe operation of the labeller is

only guaranteed if all necessary info rmation

is observed!

£ Read this operating manual thoroughly

and observe all notices prior to operation.

£ Observe all additional safety and warning

notices attached to the labeller.

£ Only allow qualified persons to operate

and adjust the labeller.

Information must be made available

This operating manual

£ is to stored at the machine operating location and

made accessible to the operator.

£ is to maintained in legible condition.

£ is to be made available to the new owner if the ma-

chine is sold.

£ Safety and warning notices attached to the machine

must be kept clean and legible. Missing or damaged

warning labels and plates are to be replaced.

Ensure necessary qualifications

£ Only allow the machine to be opera ted , ad ju ste d

and serviced by instructed and authorised personnel.

£ Adjustment tasks via the expanded menus as well

as programming and administration of product databases are only to be performed by qualified and a ppropriately trained personnel or the customer

service.

£ The responsibilities for operation, adjustment and

servicing of the machine must be clearly defined

and consistently maintained.

£ Moreover, personnel are to be regularly instructed

about work safety and environmental protection issues.

Operator qualifications

Instruction of the operating personnel must ensure:

– that operating personnel can use the machine inde-

pendently and without posing a danger.

– that operating personnel can remedy minor opera-

tional malfunctions themselves.

£ Train at least 2 person to operate the machine.

£ Make label materials for test purposes available in

sufficient quantities.

Qualifications for adjustment tasks

Settings in the expanded menus of the control

software require knowledge based on experience:

– The adjustment personnel must be familiar

with how the labeller functions.

– Adjustment personnel must be familiar with

the entire system into which the labeller is integrated.

– Adjustment personnel must be able to cor-

rectly apply the functions in the expanded

menu system to appropriately address the

order-specific requirements.

9

Page 10

1PLEASE OBSERVE THE FOLLOWING

1.2 SAFETY INSTRUCTIONS

1.2.2 Machine operating safety

ALS

350

450

Appropriate use

The labeller is a fully automatic machine for the application of self-adhesive labels to products or packages.

The machine is to be equipped by the operation planners with suitable safety devices so as to protect the

operating personnel from possible endangerment –

e.g. pinching or entrapment of body parts due to reaching between product and dispensing edge.

WARNING!

Improper usage of the machine can lead to

accidents, material damage and loss of production!

£ Only operate this machine in accordance

with information contained in this manual.

£ Do not put the machine into operation

without the required safety equipment in

place.

£ Only make adjustments to the machine in

accordance with this manual and with all

due care.

Protect against injuries that can result from electrical current

WARNING!

The machine is connected with the mains

supply! Contact with energised components

can result in life-endangering currents

through the body as well as burns.

£ Only put the machine into operation when

installed in a correctly installed housing.

– The housing may only be removed by

trained personnel when the machine is

de-energised.

£ Pull out the mains power connection plug

from the socket before cleaning and

maintenance.

The machine is not protected against

splashing water.

£ Maintain the machine in a dry condition.

£ In case fluids penetrate into the machine

interior, immediately switch off the machine and disconnect or plug out from the

mains power supply. Notify a service

technician.

Protect against injuries that can result from mechanical actions

WARNING!

Risk of injury due to moving or rapidly rota ting parts!

£ The following regulations always apply:

£ Keep a distance from running machines. Wear

snug-fitting clothing and, if necessary, hair nets.

£ Even when the machine is idle, maintain the area

clear of movable parts if the possibility exists that

the machine could start.

£ Never lay tools or loose parts on the machine if the

possibility exists that the machine could start.

£ Switch off the machine before performing mechani-

cal adjustment tasks.

£ Do not wear ties, loose garments, jewellery, watch-

es or similar articles on the body when in the machine vicinity.

CAUTION!

Danger of bodypart trapping and pinching at

the dispensing edge due to products moving

in the conveyor direction!

£ Never reach between the product and dis-

pensing edge of running or operationready machines.

£ During operation, never remove or defeat

the purpose of protective guards that prevent reaching into the machine.

Protection against chemical injuries

CAUTION!

Operational materials such as cleaning

agents or adhesive solvents may pose a

health risk.

£ Rules, work guidelines and safety regula-

tions issued by the manufacturer must

absolutely be followed!

10

Page 11

1PLEASE OBSERVE THE FOLLOWING

1.2 SAFETY INSTRUCTIONS

1.2.3 Before every production start

ALS

350

450

Operator's obligation and service personal to exercise care

£ Ensure the following prerequisites correspond to the

information of the operating manual:

– The machine is correctly installed and appropriately

configured for the requirements.

– All necessary safety equipment is installed.

– The machine has successfully completed at least

one test run.

– The machine is connected to the power supply.

£ The required per s ona l safe ty ge a r, e.g. hair nets,

must be provided. Make sure that the safety gear is

used in accordance with the regulations.

Operating personnels' obligation to exercise care

£ Verify flawless functioning of the safety equipment.

£ Check machine for visible damage. Any discovered

deficiency is to be reported immediately.

£ Use personal safety gear in accordance with the

regulations, e.g. wear hair nets.

£ Non-required materials and objects are to be re-

moved from the working area of the machine.

£ Make sure that only persons authorised to work on

the machine are within the working area of the machine.

£ Make sure that no one will be placed in a hazardous

situation as a result of the machine startup.

11

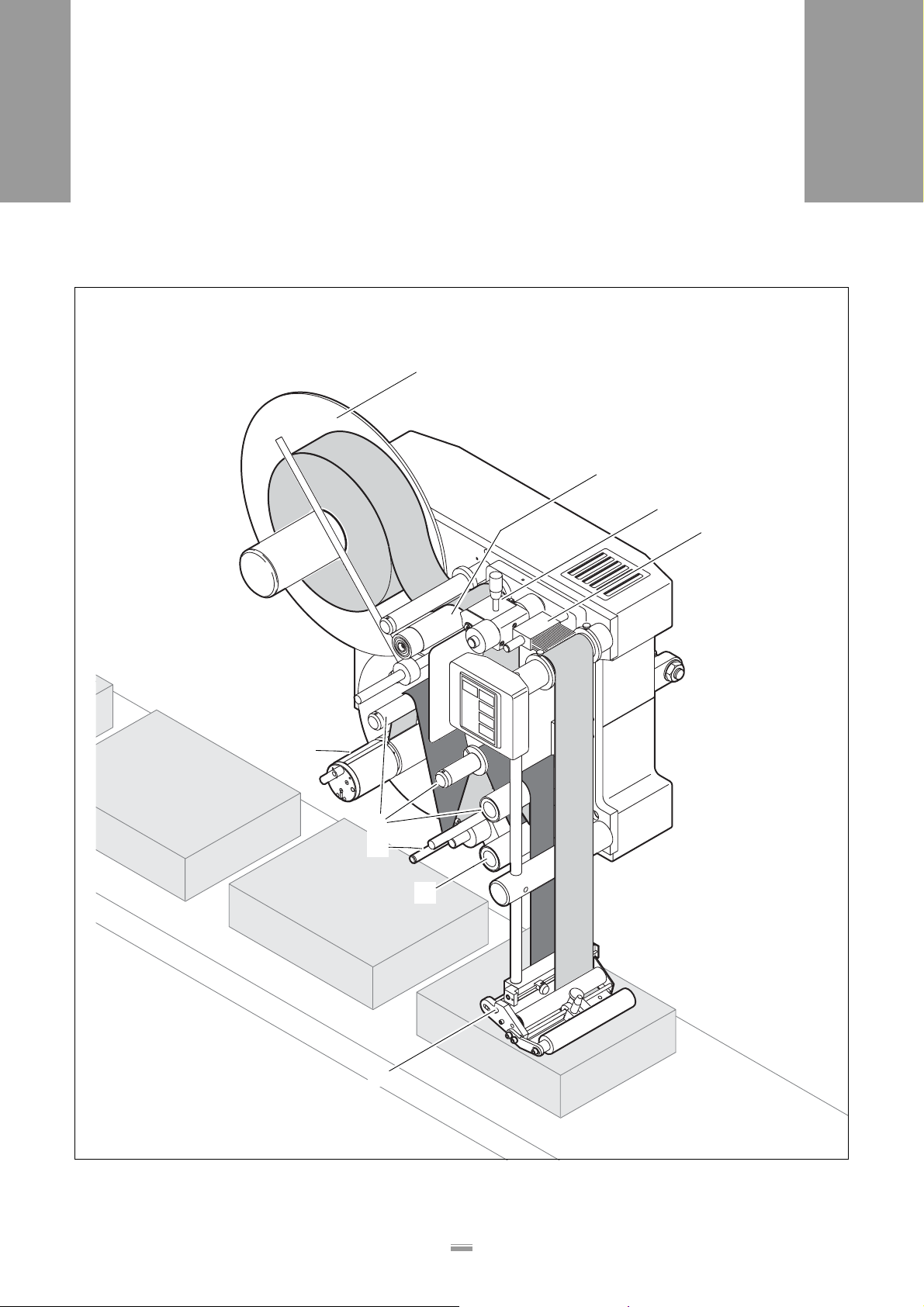

Page 12

2EQUIPMENT DESCRIPTION

2.1 OVERVIEW OF THE ALS 350

2 EQUIPMENT DESCRIPTION

2.1 OVERVIEW OF THE ALS 350

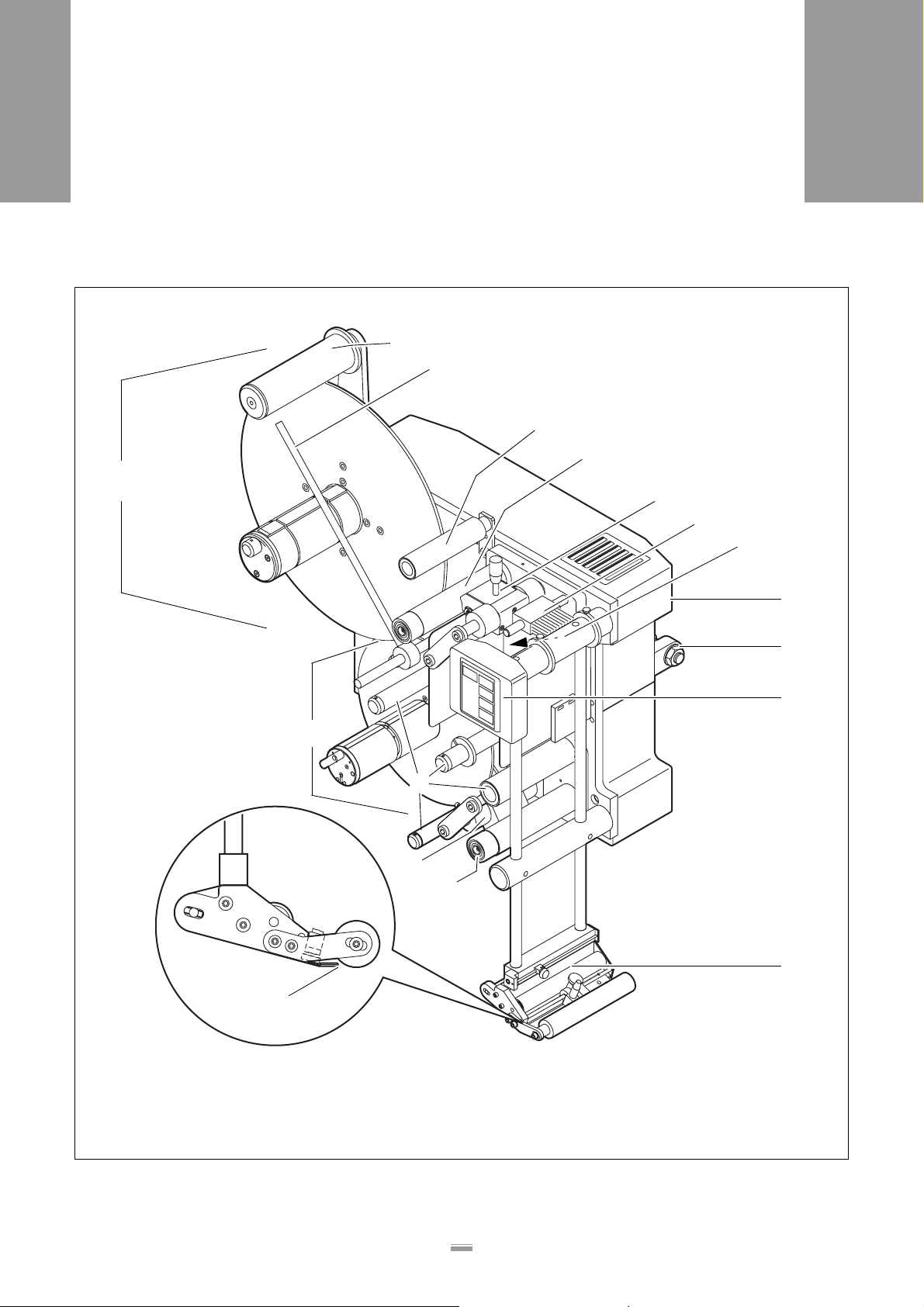

2.1.1 Structural elements

B

A

ALS

350

C

D

E

F

G

H

I

J

P

O

N

M

K

L

[2] Right-hand version of the ALS 350 Labeller

12

Page 13

2EQUIPMENT DESCRIPTION

2.1 OVERVIEW OF THE ALS 350

ALS

350

A Unwind unit

– The unwinding spindle holds the label roll.

B Guiding rod for unwind unit

– Secures the label roll on the unwinding spindle.

C Unwind unit deflection roller

D Drive roller unit of the unwind unit

– Pulls the label ribbon evenly from the label roll and

transports it into the loop space.

E Pres su re rolle r of th e un wind un it

– Presses the label ribbon against the drive roller unit.

F Braking brush

– Allows label ribbon to run smoothly, prevents flutter-

ing.

G Loop space

– Shaft located below the pressure roller and the brak-

ing brush.

– In this area the label ribbon forms a loop.

HCasing

– Houses the control electronics, drive electrical sys-

tem, main switch, and fuses.

– If equipped with optional water-resistant electronic

control unit: the electronic control unit, drive electri-

cal system, and electrical fuses are built into a sep-

arate switch cabinet.

I Mounting brackets

– For securing the machine in the system.

J Operator panel

– Used to enter commands into the machine and to

display operating states and error messages

– If equipped with optional water-resistant electronic

control unit: the operator panel is built into a separate switch cabinet.

K Dispenser head

– Optionally equipped with printer or applicator

L Dispensing edge

– The label separates from the backing material here.

M Drive roller unit of the label feed

– Pulls the label ribbon incrementally over the dis-

pensing edge. A label is dispensed with each incremental movement.

N Label feed pressure roller

– Presses the label ribbon against the drive roller unit.

O Rewind unit dancer arm and deflection rollers

– 3 fixed deflection rollers

– A spring-loaded, pivoting dancer arm

P Rewind unit

– An electrically driven rewinding roller takes up the

empty backing material.

– A spreader mechanism secures the backing material

roll.

13

Page 14

2EQUIPMENT DESCRIPTION

2.1 OVERVIEW OF THE ALS 350

2.1.2 Principle of operation

A

ALS

350

B

C

D

I

H

G

E

[3] Labeller ALS 350 operationally ready with label ribbon

F

14

Page 15

2EQUIPMENT DESCRIPTION

2.1 OVERVIEW OF THE ALS 350

In labelling mode, the drive roller unit [2B] transports

the label ribbon from the unwinding spool [2A]. A loop

is formed in the label ribbon below the pressure roller of

the unwind unit [2C] and the braking brush [2D]. The

feed roller unit [2F] behind the dispenser head [2E]

pulls the ribbon over the dispensing edge. The label

separates from the backing material at the dispensing

edge and is transferred onto the product.

The feed roller unit moves the respective ribbon for a

label and then stops until the next product is transported to the dispensing edge. Label ribbon is co ntinuously

unwound at the unwind unit. The loop acts as a buffer

between the continuously operating unwin d un it an d

the periodically operating label output. The braking

brushes keep the label ribbon taut.

ALS

350

From the dispensing head, the empty backing mate rial

runs over several deflection rollers [2H] and the springloaded, pivoting dancer arm [2G] to the motor-driven

spreader rewinding unit [2I]. The multiple deflections

with the spring-loaded dancer arm act as a buffer between the label output and the rewind unit. When in

operation, the dancer arm pivots back and forth constantly.

The entire operation of the labeller is electronically controlled and monitored. If a malfunction occurs, the control system sends a corresponding message to the

operator. If necessary, the labelling operation is automatically halted. An electronic signal is issued at the

same time. The signal can be picked up and evaluated

by an external control system.

15

Page 16

2EQUIPMENT DESCRIPTION

2.1 OVERVIEW OF THE ALS 350

2.1.3 Technical data

ALS

350

Characteristic values

Labelling speed: 0.2 m/min to 55 m/min

Labelling performance: Refer to the service guide

Stop accuracy (at the

dispensing edge): ± 0.5 mm

Unwind unit: Smooth unwinding spindle

Rewind unit: Spreader mechanism

Operation: Programmable, can be set

via the operator panel,

11 data bases available

Speed control: Automatic dispensing

speed, with RPMtransmitter

Labels

Label width

(incl. backing material): 10 mm to 155 mm

Label length maximum 350 mm

at maximum dispensing speed: 16 mm to 250 mm

Casing

Covering for the control

electronics:

Front plate: Aluminium, anodized,

Polyurethane (PUR),

10 mm thick

15 mm thick

Electrical system

Power consumption: 500 VA

Mains connection

Nominal voltage: 110 V/120 V/130 V/200 V/

220 V/230 V/240 V

Frequency: 50 Hz / 60 Hz

Type of protection

IP41: protected against vertically

falling drops of water, not

protected against sprayed

water

IP54 (optional): Protected against splash-

ing water and dust layers

Drive system

1)

1)

Label roll

Outer diameter: maximum 400 mm

Core diameter: 76.2 mm

Ambient conditions

Temperature

Operation:

Storage:

Relative humidity: 30 % to 80 %,

5 °C to 40 °C

5 °C to 70 °C

not condensing

Dimensions

Dimensions

Width:

Height:

Depth:

Weight 70 kg

735 mm

795 mm

400 mm

IP41: 2 stepper motors,

1 AC motor

IP54 (optional): 3 stepper motors

1) Customer options

Control system

Control electronics:

IP41: Integrated

IP54 (optional): The electronic control unit

and operator panel are

built into a separate switch

cabinet

Options: – Serial interface

– Roll diameter control

Emissions

Sound pressure level at

a distance of 1 m: 75 db (A)

16

Page 17

2EQUIPMENT DESCRIPTION

2.1 OVERVIEW OF THE ALS 350

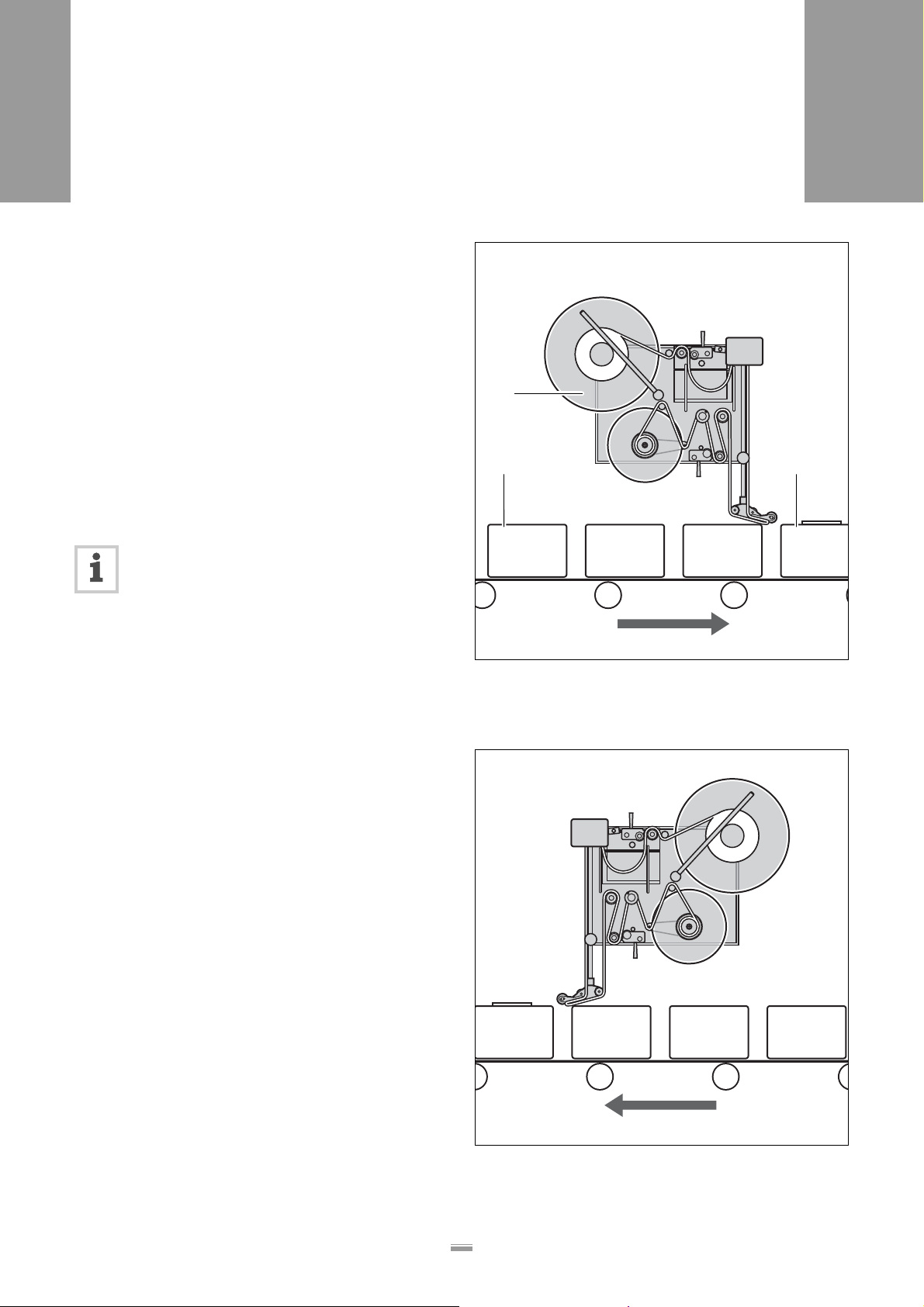

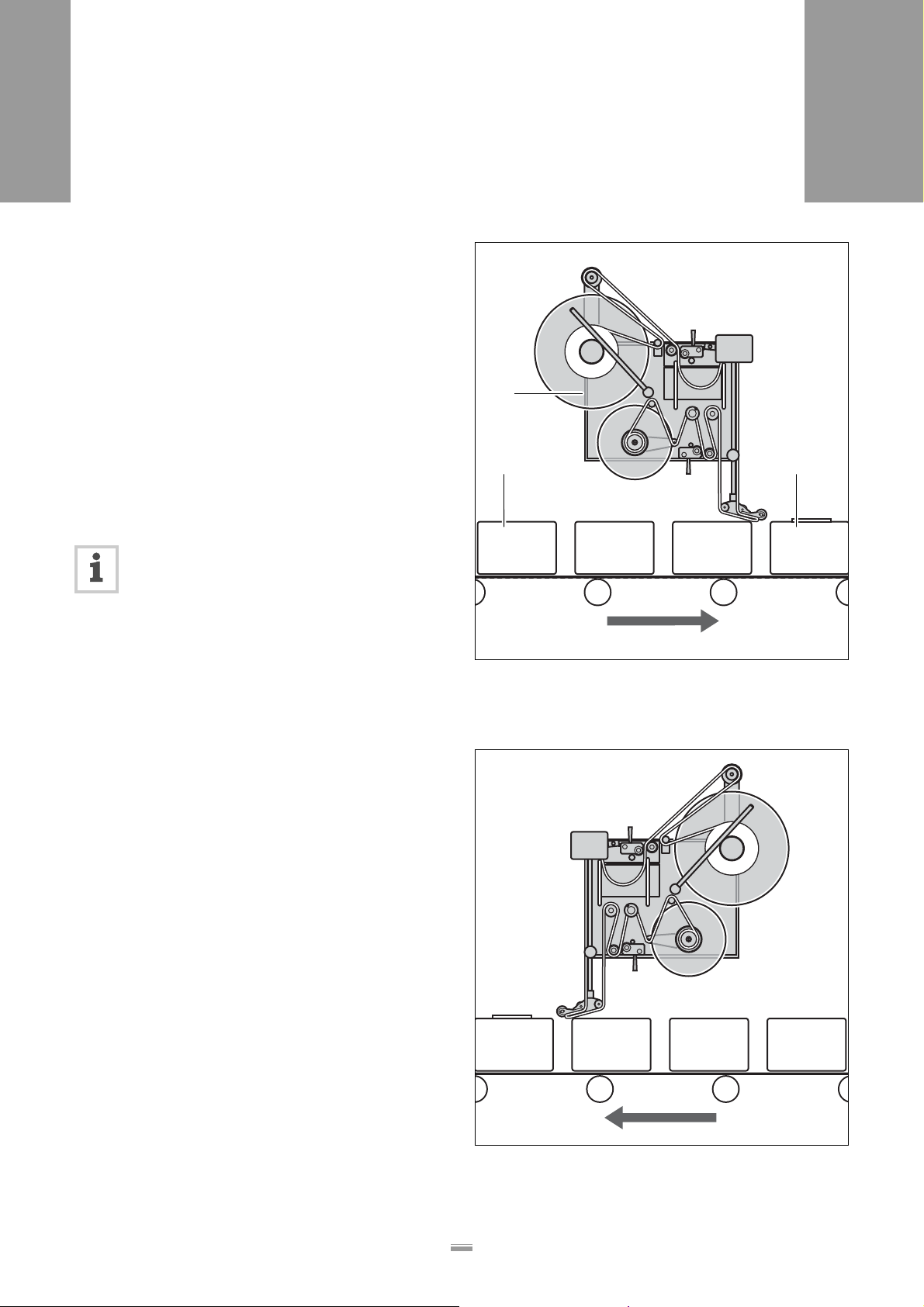

2.1.4 Design versions

The ALS 350 labeller is available in 2 different versions,

depending on the direction of the conveyor line:

Right-hand version

ALS

350

– The products are conveyed from left to right [4].

– The dispensing edge is located on the right side.

Left-hand version

– The products are conveyed from right to left [5].

– The dispensing edge is located on the left side.

Labeller operation is described in these instructions based on the right-hand design version.

The left-hand version is only considered if its

descriptions or illustrations differ significantly.

A

B C

[4] Right-hand version

A ALS 350 labeller

B Product on conveyor line

C Labelled product

[5] Left-hand version

17

Page 18

2EQUIPMENT DESCRIPTION

2.2 OVERVIEW OF THE ALS 450

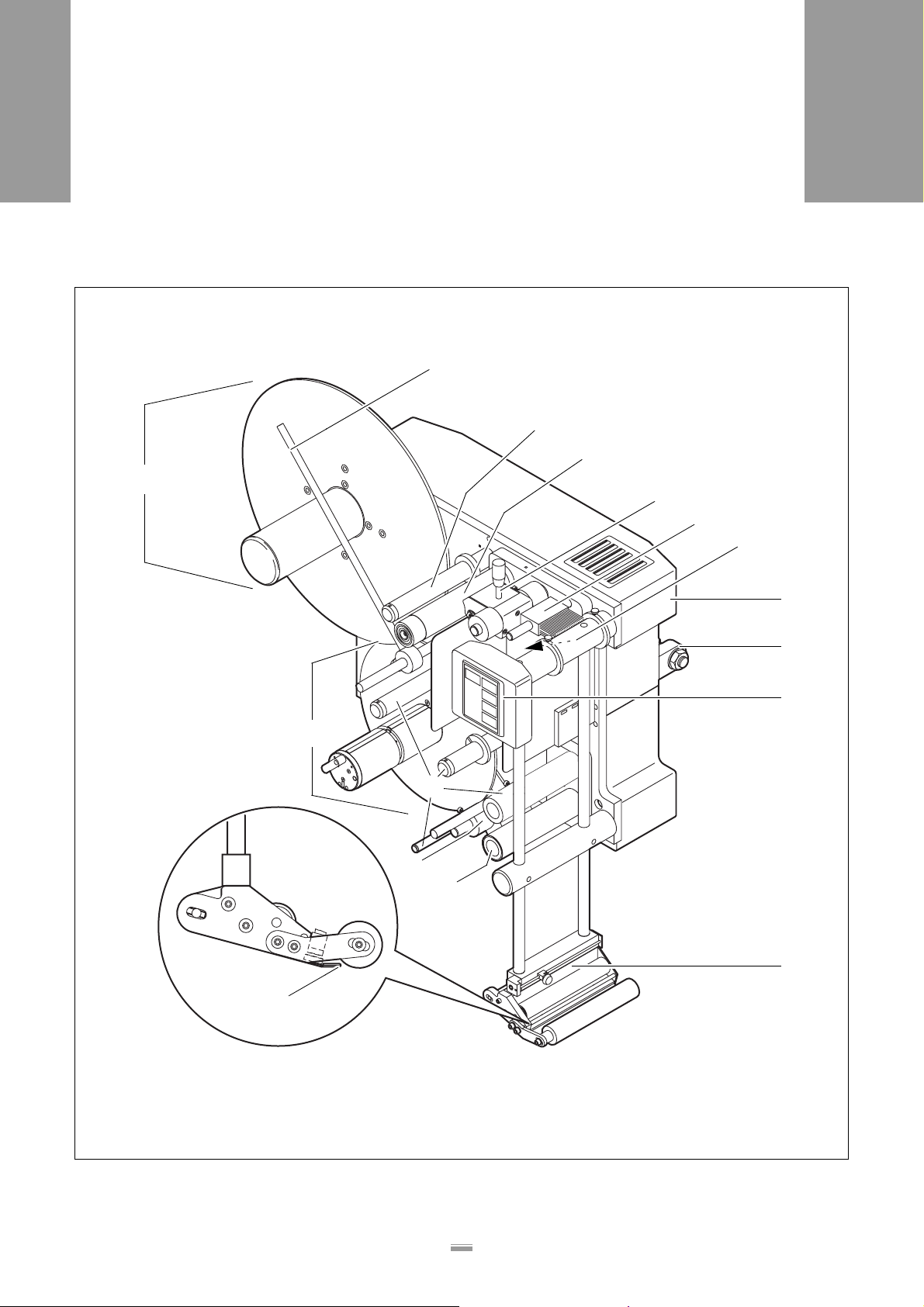

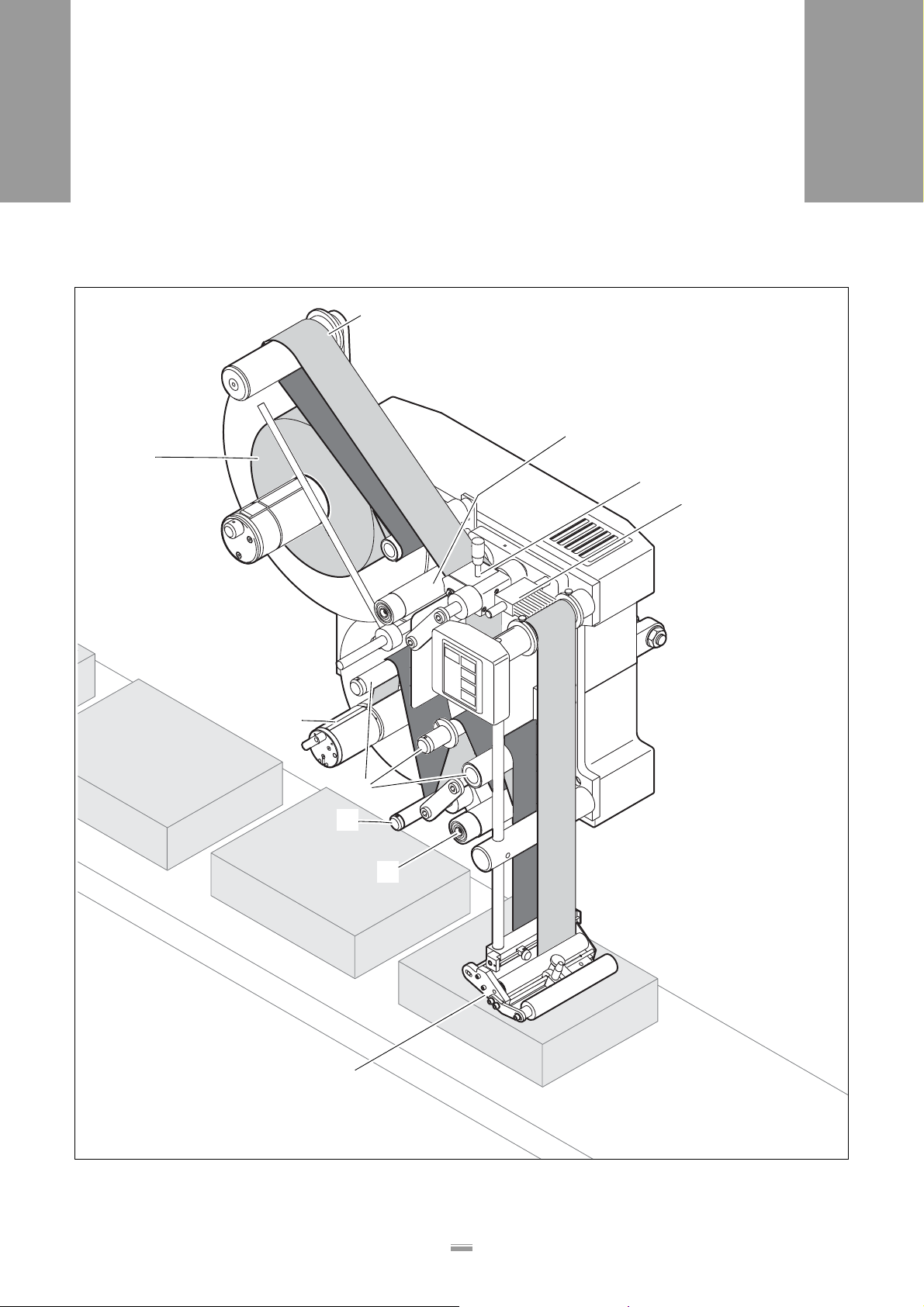

2.2 OVERVIEW OF THE ALS 450

2.2.1 Structural elements

B

C

A

ALS

450

D

E

F

G

H

M

I

J

K

Q

P

O

N

L

[6] Right-hand version of the ALS 450 Labeller

18

Page 19

2EQUIPMENT DESCRIPTION

2.2 OVERVIEW OF THE ALS 450

ALS

450

A Unwind unit

– The unwinding spindle holds the label roll.

– A spread er me ch an ism secures the label roll.

B Dan ce r arm of th e un wind un it

– Spring-loaded and rotatable

– Assists in the flawless unwinding of the label ribbon

from the unwinding spindle

C Guiding rod for unwind unit

– Secures the label roll on the unwinding spindle.

D Unwind unit deflection roller

E Drive roller unit of the unwind unit

– Pulls the label ribbon evenly from the label roll and

transports it into the loop space.

F Pressure roller of the unwind unit

– Presses the label ribbon against the drive roller unit.

G Braking brush

– Allows label ribbon to run smoothly, prevents flutter-

ing.

H Loop space

– Shaft located below the pressure roller and the

braking brush.

– In this area the label ribbon forms a loop.

ICasing

– Houses the control electronics, drive electrical sys-

tem, main switch, and fuses.

– If equipped with optional water-resistant electronic

control unit: the electronic control unit, drive electri-

cal system, and electrical fuses are built into a sep-

arate switch cabinet.

J Mounting brackets

– For securing the machine in the system.

K Operator panel

– Used to enter commands into the machine and to

display operating states and error messages

– If equipped with optional water-resistant electronic

control unit: the operator panel is built into a separate switch cabinet.

L Dispenser head

– Optionally equipped with printer or applicator

M Dispensing edge

– The label separates from the backing material here.

N Drive roller unit of the label feed

– Pulls the label ribbon incrementally over the dis-

pensing edge. A label is dispensed with each incremental movement.

O Label feed pressure roller

– Presses the label ribbon against the drive roller unit.

P Rewind unit dancer arm and deflection rollers

– 3 fixed deflection rollers

– A spring-loaded, pivoting dancer arm

Q Rewind unit

– An electrically driven rewinding roller takes up the

empty backing material.

– A spreader mechanism secures the backing material

roll.

19

Page 20

2EQUIPMENT DESCRIPTION

2.2 OVERVIEW OF THE ALS 450

2.2.2 Principle of operation

B

A

ALS

450

C

D

E

J

I

H

G

F

[7] Labeller ALS 450 operationally ready with label ribbon

20

Page 21

2EQUIPMENT DESCRIPTION

2.2 OVERVIEW OF THE ALS 450

In labelling mode, the drive roller unit [7C] transports

the label ribbon from the unwind mandrel [7A] around

the dancer arm [7B]. The dancer arm keeps the label

ribbon constantly taut and slightly under tension. A loop

is formed in the label ribbon below the pressure roller of

the unwind unit [7D] and the braking brush [7E]. The

feed roller unit [7G] behind the dispenser head [7F]

pulls the ribbon over the dispensing edge. The label

separates from the backing material at the dispensing

edge and is transferred onto the product.

The feed roller unit moves the respective ribbon for a label and then stops until the next product is transported

to the dispensing edge. Label ribbon is continuously

unwound at the unwind unit. The loop acts as a buffer

between the continuously operating unwin d un it an d

the periodically operating label output. The braking

brushes keep the label ribbon taut.

ALS

450

From the dispensing head, the empty backing mate rial

runs over several deflection rollers [7I] and the springloaded, pivoting dancer arm [7H] to the motor-driven

spreader rewinding unit [7J]. The multiple deflections

with the spring-loaded dancer arm act as a buffer between the label output and the rewind unit. When in operation, the dancer arm pivots back and forth

constantly.

The entire operation of the labeller is electronically controlled and monitored. If a malfunction occurs, the control system sends a corresponding message to the

operator. If necessary, the labelling operation is automatically halted. An electronic signal is issued at the

same time. The signal can be picked up and evaluated

by an external control system.

21

Page 22

2EQUIPMENT DESCRIPTION

2.2 OVERVIEW OF THE ALS 450

2.2.3 Technical data

ALS

450

Characteristic values

Labelling speed: 0.5 m/min to 55 m/min

Labelling performance: Refer to the service guide

Stop accuracy (at the

dispensing edge): ± 0.5 mm

Unwind unit: Unwinding spindle with

spreader mechanism

Rewind unit: Spreader mechanism

Operation: Programmable, can be set

via the operator panel,

11 data bases available

Speed control: Automatic dispensing

speed, with RPM-

transmitter

Labels

Label width

(incl. backing material): 10 mm to 230 mm

Label length

at maximum dispensing speed:

Label roll

Outer diameter:

Core diameter:

maximum 350 mm

16 mm to 250 mm

maximum 400 mm

76.2 mm

Casing

Covering for the controlelectronics:

Front plate: Aluminium, anodized,

Polyurethane (PUR),

10 mm thick

15 mm thick

Electrical system

Power consumption: 500 VA

Mains connection

Nominal voltage: 110 V/120 V/130 V/200 V/

220 V/230 V/240 V

Frequency: 50 Hz / 60 Hz

Type of protection

IP41: protected against vertically

falling drops of water, not

protected against sprayed

water

IP54 (optional): Protected against splash-

ing water and dust layers

Drive system

IP41: 2 stepping motors,

1 AC motor

IP54 (optional): 3 stepping motors

1)

1)

Ambient conditions

Temperature

Operation:

Storage:

Relative humidity: 30 % to 80 %,

5 °C to 40 °C

5 °C to 70 °C

not condensing

Dimensions

Dimensions

Width:

Height:

Depth:

Weight 85 kg

735 mm

795 mm

560 mm

1) Customer options

Control system

Control electronics:

IP41: Integrated

IP54 (optional): The electronic control unit

and operator panel are built

into a separate switch cabinet

Options: – Serial interface

– Roll diameter control

Emissions

Sound pressure level at

a distance of 1 m: 75 db (A)

22

Page 23

2EQUIPMENT DESCRIPTION

2.2 OVERVIEW OF THE ALS 450

2.2.4 Design versions

The ALS 450 labeller is available in 2 different versions,

depending on the direction of the conveyor line:

Right-hand version

ALS

450

– The products are conveyed from left to right [8].

– The dispensing edge is located on the right side.

Left-hand version

– The products are conveyed from right to left [9].

– The dispensing edge is located on the left side.

Labeller operation is described in these instructions based on the right-hand design version. In

general, the labeller ALS 350 (without dancer

arm on the unwind unit) is depicted in the illustrations. The left-hand version and the ALS 450

are only considered if their descriptions or illustrations differ significantly.

A

B C

[8] Right-hand version

A ALS 450 labeller

B Product on conveyor line

C Labelled product

[9] Left-hand version

23

Page 24

2EQUIPMENT DESCRIPTION

2.3 OPTIONS

2.3 OPTIONS

ALS

350

450

Serial interface

– Almost all of the setting values can be read out and

modified on an external device, the machine status

can be queried, and the machine can be controlled

via this interface.

– For further information, refer to the Service guide

Roll diameter control

– A sensor at the unwind unit monitors the diameter of

the label roll and, along with it, the supply of labels.

– The sensor sends a signal when the diameter of the

label roll reaches a set value.

– This sensor is required if two labellers are operating

in tandem mode (see chapter Operation – Activation

and shut-down, page 46)

Adjustable dispensing edge

– The position of the dispenser head can be adjusted

vertically.

– This allows adapting the position of the dispensing

edge to changing products.

– The machine does not have to be moved to adjust

the dispensing edge, the labelling head of the machine does not have to be released.

Spring-loaded dispensing edge

– The dispensing edge is pivotably mounted onto the

dispenser head. A torsion spring in the dispenser

head presses the dispensing edge downward onto

the surface of the product.

– Enables height differences between the products or

surface characteristics difference s to be com pen sated for.

Pneumatic dispensing edge

– The dispensing edge is pivotably mounted onto the

dispenser head. Compressed air presses the dispensing edge downward onto the surface of the

product.

– Enables height differences between the products or

surface characteristics differences to be compensated for.

Printer

– Inkjet or heat transfer printer at the dispenser head.

Applicator

If direct labelling from the dispensing edge is not possible, the labeller can be equipped with an applicator.

Various kinds of applicators are available depending on

the customer’s needs.

Water-resistant electronic control unit

– Protected against splashing water as per type of

protection IP54

– The control electronics, drive electrical system,

electrical fuses and operator panel are built into a

separate switch cabinet

– Driven exclusively by stepper motors

– Motors are protected against splashing water

24

Page 25

2EQUIPMENT DESCRIPTION

2.4 OPERATOR CONTROLS

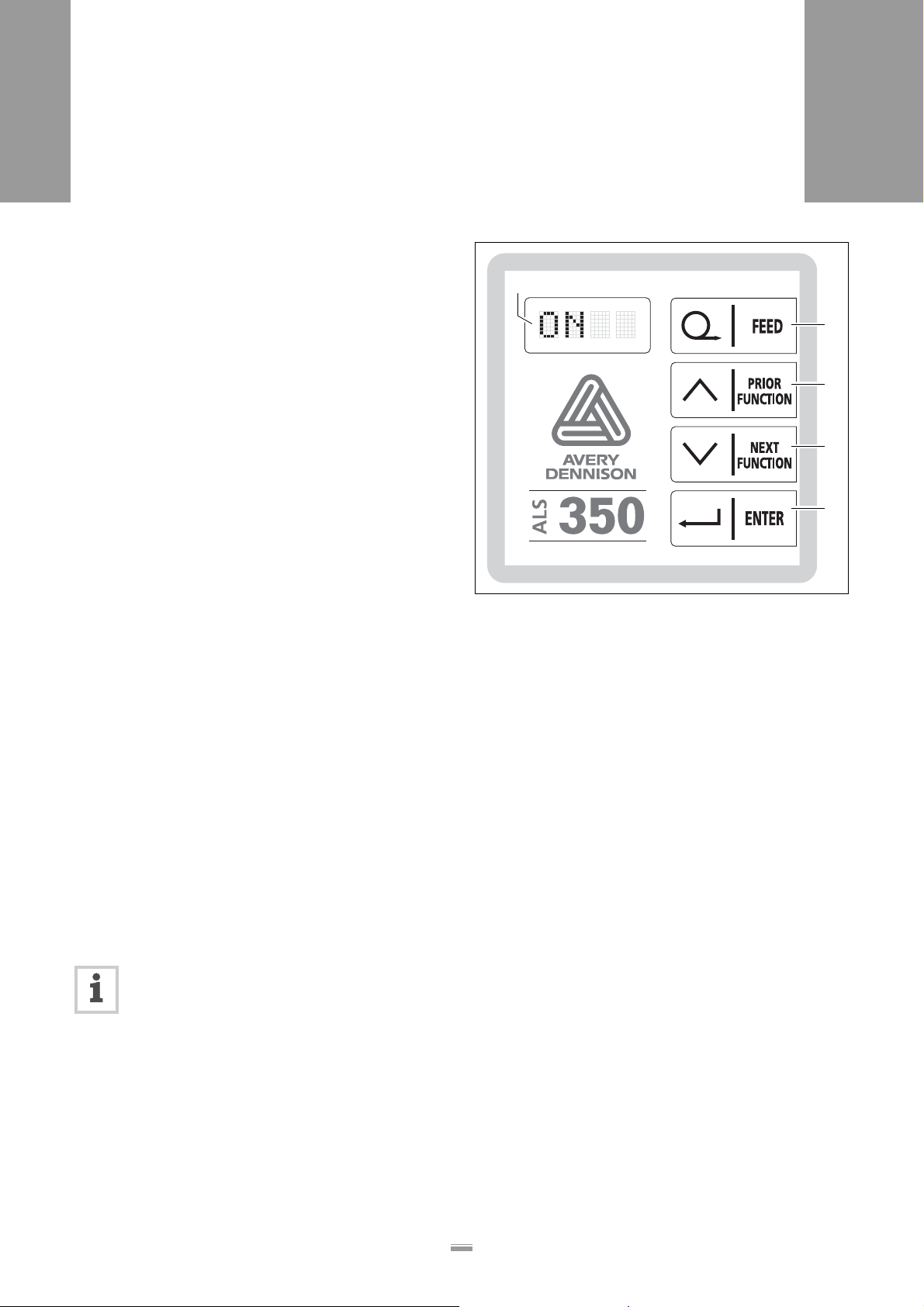

2.4 OPERATOR CONTROLS

2.4.1 Operator panel

ALS

350

450

LED indicator

– Display of functions, setting values, operating

states, error messages, and warning messages

If the LED indicator is ON:

– The machine is in labelling mode.

– Each time the product sensor is triggered, a label is

dispensed.

If the LED indicator is OFF:

– Labelling mode is switched off.

Keys

FEED

– When this key is pressed, the machine dispenses a

label.

PRIOR (previous function)

– Paging through the functions in the menu: to see the

previous function, page upward.

– Within a function: raise the current value, e.g. in-

crease dispensing speed.

A

B

C

D

E

[10] Operator panel of the ALS 350 (same design as ALS 450 oper-

ator panel)

A LED indicator

B FEED key

C PRIOR key

D NEXT key

E ENTER key

NEXT (next function)

– Paging through the functions in the menu: to see the

next function, page downward.

– Within a function: reduce the current value, e.g. de-

crease dispensing speed.

ENTER

– Activate or switch off labelling mode.

– Call up or end functions.

– Acknowledge error and warning messages.

Depending on the menu and the operating

state of the machine, special key functions are

also available. Where special functions are

available, they are described in the relevant

chapter.

25

Page 26

2EQUIPMENT DESCRIPTION

2.4 OPERATOR CONTROLS

2.4.2 Main switch

– The main switch [11] is located to the left on the

housing.

– The main switch is used to switch the machine on

and off.

ALS

350

450

WARNING!

Contact with energised components can result in life-endangering currents through the

body as well as burns. Voltage continues to

be present in the housing even when

switched off.

£ Only put the machine into operation when

installed in a correctly installed housing.

£ Maintain the machine in a dry condition.

A

[11] Main switch on the housing

26

Page 27

2EQUIPMENT DESCRIPTION

2.5 CONTROL SYSTEM

2.5 CONTROL SYSTEM

2.5.1 Brief description

ALS

350

450

All of the machine’s functions are electronically

controlled. Using the operator panel, the operators,

calibration technicians, or service personnel have

several options for adapting the machine's functions to

current requirements.

The LED indicator gives the operator feedback messages regarding the current operating state of the machine. Error messages or warning messages appear on

the display as necessary.

Before each operation, the operator must check and

adjust the occasionally changing settings such as the

label position on the product or the dispensing speed.

These settings can simply be input at any time by the

operator at the operator panel.

Task-specific data such as label distance or product

length are programmed at the beginning of a job. As a

rule, the settings are not modified as long as the job is

being processed. This data input require s in- de pt h

knowledge and may only be carried out by trained and

instructed personnel (calibration technicians).

Databanks are available for variable or frequently re curring task settings. The task-specific settings can be

saved in a databank. If the settings are need e d ag a in

after a product change, it is not necessary to re-input

the data. You only need to call up the corresponding

databank. In all, 11 databanks are available.

Only calibration technicians may administer the product

databanks.

It is also possible to modify the basic machine settings.

These are settings such as the motor’s direction of rotation. These settings are not to be changed in norma l

operation. They may only be changed by servicing personnel or the customer service.

To give the operator a better overview, the setting options for occasionally changing settings, task-specific

data, databanks, and basic settings are grouped together in menus: The standard menu, extended menu,

product databanks, and configuration menu. The following table provides an overview of the range of functions of the standard menu, extended menu, and

product databanks. The configuration menu is described in the service guide.

CAUTION!

Erroneous settings can lead to production

setbacks, damage to the machine and system, and can even cause work-related accidents!

– Only specially trained and instructed per-

sonnel may alter the settings in the extended menu or access the product

databanks.

27

Page 28

2EQUIPMENT DESCRIPTION

2.5 CONTROL SYSTEM

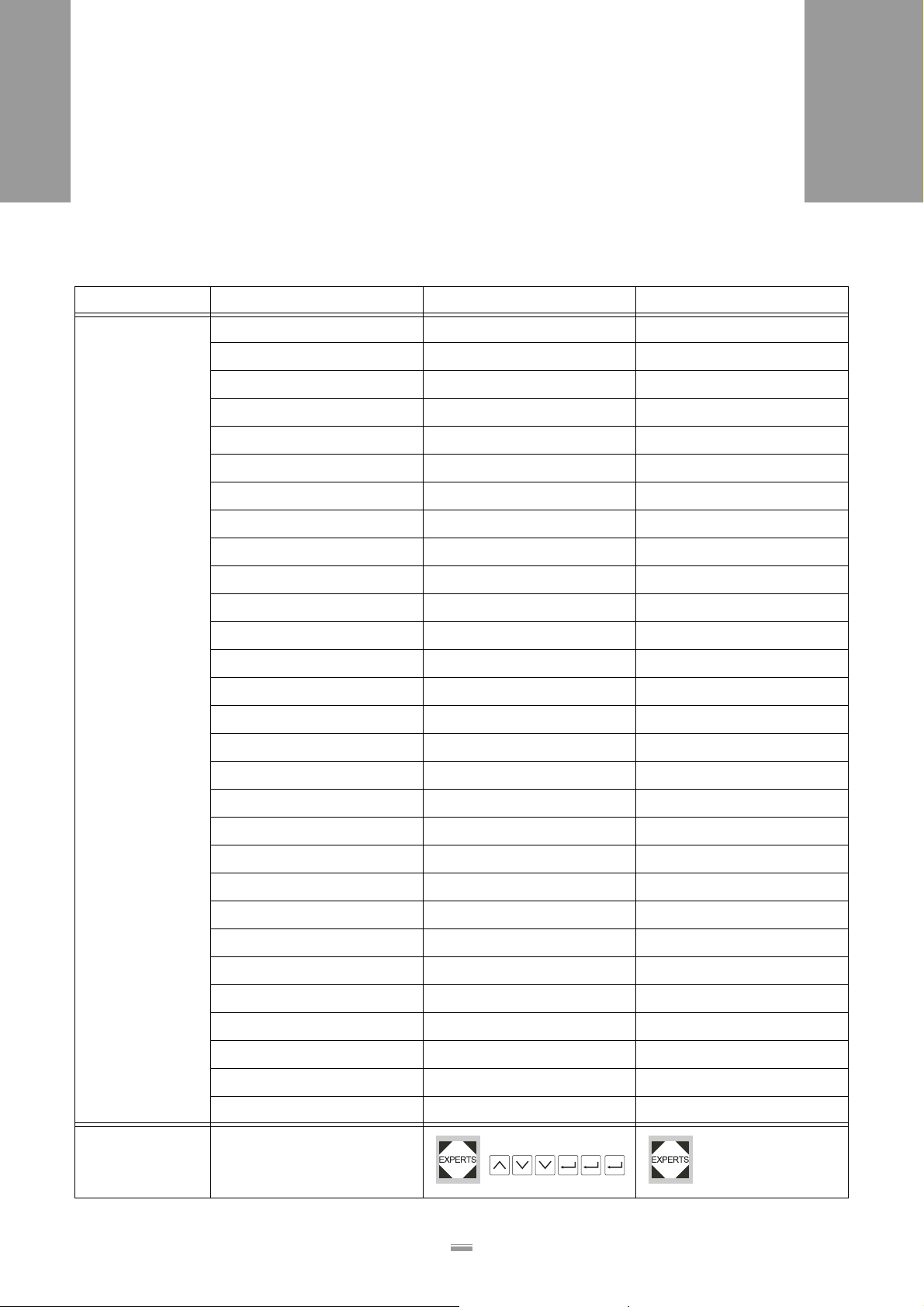

2.5.2 Menus for operators and calibration technicians

Menu Standard menu Extended menu Product databanks

Functions ON ON ON

OFF OFF OFF

INIT INIT PD01

VELO VELO PD02

STOD STOD PD03

POS POS PD04

POS 2 PD05

POS 3 PD06

ALS

350

450

VERT PD07

CONT PD08

E–SS PD09

LPIT PD10

PRDL PD11

P_S_

S_S_

MLAB

PDT

PDWT

EGRA

TMOD

APPL

APT1

APT2

APT3

APT4

Activating a

menu

LOAD

SAVE

DEL

QUIT

Main switch + NEXT PRIOR + NEXT Main switch +

PRIOR

28

Page 29

2EQUIPMENT DESCRIPTION

2.5 CONTROL SYSTEM

ALS

350

450

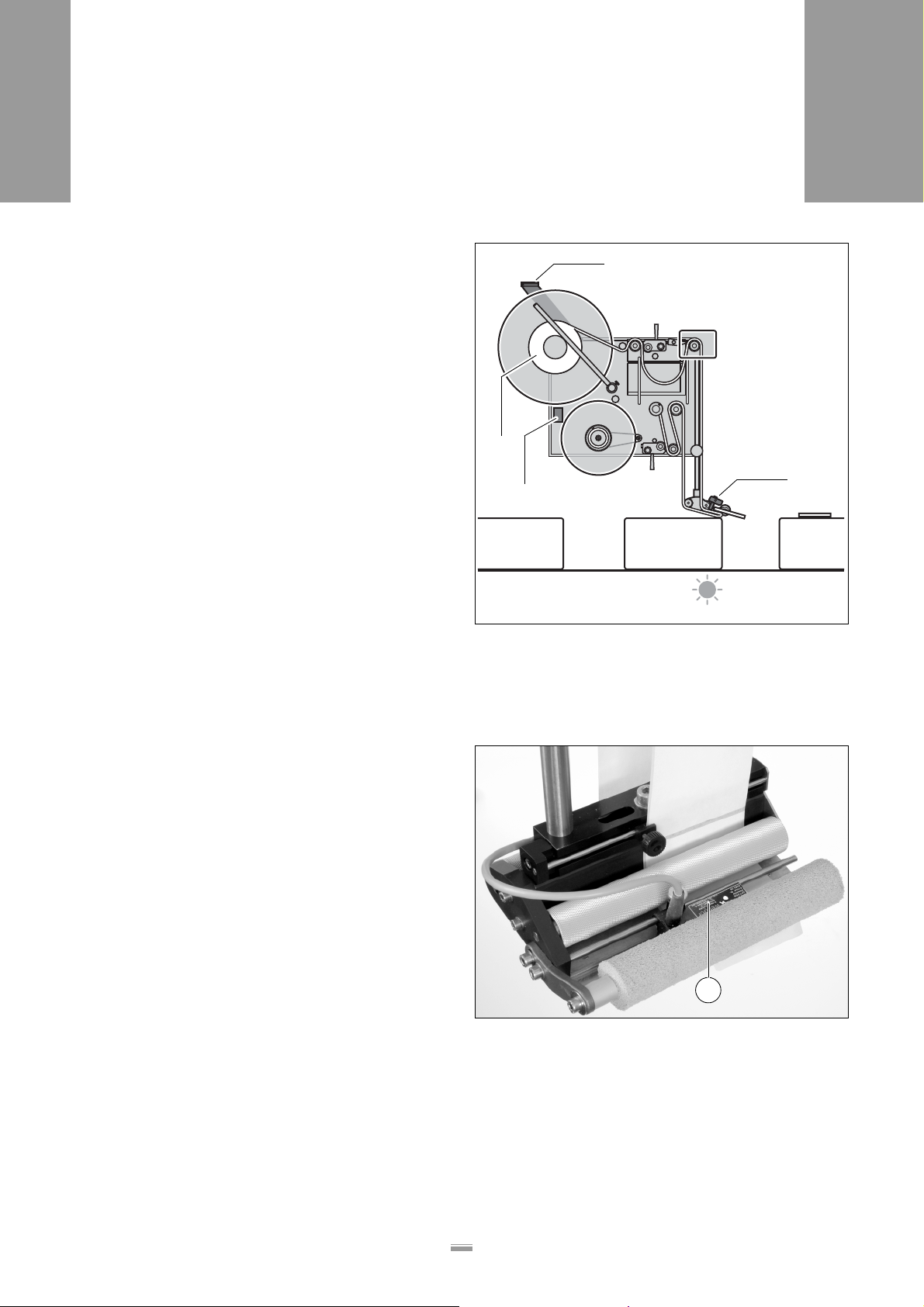

2.5.3 Monitoring functions

During labelling operation, the electronic control system and the sensors monitor the following functions.

Dispensing a label to each product

– A photoelectric sensor (product sensor) sends a sig-

nal when a product reaches the dispensing

edge [12B]. The signal from the product sensor trig-

gers the label feed for a single label.

– If individual labels are missing from the label ribbon,

the label feed compensates for this and advances

the label ribbon by one additional label distance (la-

bel compensation).

– If label compensation does not take place before the

next start signal of the product sensor, the product

does not get labelled. A warning message appears

at the operator panel.

– If the number of unlabelled products exceeds a cer-

tain value, the machine stops.

Label supply

– If no more labels arrive at the label stop

sensor [12A] [13A], the machine stops and sends a

signal to the output to the system controller.

– Roll diameter control (optional) [12D, E]:

If the diameter of the label roll on the unwinding

spool [12C] becomes too small, the control system

sends a warning message and a signal to the output

to the system controller. The diameter at which the

signal will be sent can be set by servicing techni-

cians.

E

C

A

D

B

[12] A Label stop sensor

B The product sensor sends a signal when the product has

reached the dispensing edge.

C Label roll on the unwinding spool

D Photoelectric sensor of the optional roll diameter control

E Reflector of the roll diameter control

If errors occur

If a malfunction occurs, the control system sends a corresponding message to the operator. If necessary, the

labelling operation is automatically halted. The machine simultaneously sends a signal to the system controller.

A

[13] Backing material with a label under the label stop sensor (A)

29

Page 30

3PRIOR TO OPERATING

3.1 INSERT THE LABELLING MATERIAL – ALS 350

3 PRI OR TO OPERATING

3.1 INSERT THE LABELLING MATERIAL – ALS 350

3.1.1 Prerequisites

£ Verify flawless functioning of the safety equipment.

£ Check machine for visible damage. Any discovered

deficiency is to be reported immediately.

£ Non-required materials and objects are to be re-

moved from the working area of the machine.

£ Make sure that only persons authorised to work on

the machine are within the working area of the ma-

chine.

£ Use required personal safety gear in accordance

with the regulations, e.g. wear hair ne ts, and protec-

tive eye-glasses.

– The label dispenser is switched off at the main

[14A] switch.

[14] Main switch on the housing

ALS

350

A

3.1.2 Insert the label roller

WARNING!

Risk of injury due to moving or rapidly rotating parts!

£ Before inserting the label roller, ensure

that the machine is switched off at the

main switch.

£ Never switch on the machine before the la-

bel ribbon has been completely threaded

into position.

Remove the old backing material

If backing material remains on the rewinding [15A]

roller:

£ Swing the lever [15C] at the rewinding roller over the

red [15B] point.

– The tension of the rewinding roller spreader mecha-

nism is relieved.

£ Remove the rewound backing material.

Remove adhesive residues

A

B

£ If necessary, clean the following components:

– Dispensing edge

– Deflection rollers

– Drive roller

– Rewinding roller

£ Observe the notices in chapter Care and cleaning,

Page 86.

C

[15] Remove the backing material from the rewinding roller

A Old backing material

B Red point on the rewinding roller

C Lever for the spreader mechanism of the rewinding roller

30

Page 31

3PRIOR TO OPERATING

3.1 INSERT THE LABELLING MATERIAL – ALS 350

Insert new label roll

£ Loosen the set-screw at the guiding rod [16A] and

swing the guiding rod to the side.

£ If there is still an old roll core on the unwinding spin-

dle: remove the old roll core.

£ Completely push on the new label roll. Make sure

the assembly is correctly positioned (see next page,

chapter Overview of the threading path diagram):

– Label material with labels positioned on the outside

of ribbon band: loose end to the right

– Label material with labels positioned on the inside of

ribbon band: loose end to the left

£ Allow the guiding rod to lightly rest against the label

roll and swing it approximately 1 cm over the un-

winding spindle.

£ Tighten the set-screw at the guiding rod.

ALS

350

A

[16] New label roll on the unwinding spindle with the guiding rod (A)

secured to the side

31

Page 32

3PRIOR TO OPERATING

3.1 INSERT THE LABELLING MATERIAL – ALS 350

3.1.3 Threading the label ribbon Overview of the threading path diagram

ALS

350

A B

[17] Threading path diagram for label ribbon with the labels on the outside

A Right-hand version B Left-hand version

A B

[18] Threading path diagram for label ribbon with the labels on the inside

A Right-hand version B Left-hand version

32

Page 33

3PRIOR TO OPERATING

3.1 INSERT THE LABELLING MATERIAL – ALS 350

Thread the label ribbon at the unwind unit

ALS

350

£ Swing up the pressur e ro ller [19A] and the braking

brush [19B].

£ Thread the label ribbon around the deflection

rollers [19C] and drive roller unit [19D].

£ Form a loop after the drive roller unit and guide the

label ribbon over the operator panel support [19E].

£ Swing the pressure roller and web brake back into

position.

– The pressure roller and braking brush click into op-

erating position.

A B

C

D

[19] Guides for the label ribbon in the unwinding section

A Pressure roller

B Braking brush

C Deflection roller

D Drive roller unit

E Operator panel support

E

33

Page 34

3PRIOR TO OPERATING

3.1 INSERT THE LABELLING MATERIAL – ALS 350

Guide the label ribbon around the dispensing edge

£ Unthread approximately 2 m of label ribbon from the

label roll.

£ Guide the label ribbon around the first deflection

roller [20A] and through the slot in the photoelectric

sensor [20C] [21A].

£ Guide the label ribbon under the pressure roller unit

[20B] to the dispensing edge [20D].

£ Guide the label ribbon around the dispensing edge

to the 2nd deflection roller [20E].

£ Thread the label ribbon around the upper deflection

roller [20F].

ALS

350

F

A

B

C

E

D

[20] Guides for the label ribbon in the dispenser head section

A 1st dispenser head deflection roller

B Pressure roller unit

C Label stop sensor

D Dispensing edge

E 2nd dispenser head deflection roller

F Upper deflection roller

[21] A Label stop sensor

34

A

Page 35

3PRIOR TO OPERATING

3.1 INSERT THE LABELLING MATERIAL – ALS 350

Thread the label ribbon at the rewind unit

£ Fold down lower pressure roller [22C].

£ Thread the label ribbon around the deflection roll-

ers, the feed roller unit and the dancer arm as

shown in figure [22].

£ Open the spreader mechanism of the rewinding roll-

er using the lever [22F].

– When the spreader mechanism is open, the red

point on the rewinding roller is not visible.

£ Insert the end of the label ribbon into the slot on the

rewinding roller.

£ Close the spreader mechanism of the rewinding roll-

er using the lever. The red point is now visible.

£ Rotate the rewinding roller counter-clo ckwis e until

the label ribbon is under tension.

£ Swing the pressure roller back into operating posi-

tion.

F

ALS

350

After a label roll is passed through, the backing

material roll rests firmly on the rewinding roller.

The spreader mechanism allows the diameter

of the rewinding roller to be decreased. The

backing material roll can then be easily removed.

£Only rewind the label ribbon on the rewinding

roller when the spreader mechanism is

closed (red point visible).

£ Do not open the spreader mechanism before

the backing material is removed from the rewinding roller

E

A

D B

[22] Guides for the label ribbon in the rewind unit section

A Deflection rollers

B Feed roller unit

C Pressure roller (in the open position)

D Dancer arm

E Rewinding roller

F Lever for the spreader mechanism of the rewinding roller

(in the open position)

C

35

Page 36

3PRIOR TO OPERATING

3.2 INSERT THE LABELLING MATERIAL – ALS 450

3.2 INSERT THE LABELLING MATERIAL – ALS 450

3.2.1 Prerequisites

£ Verify flawless functioning of the safety equipment.

£ Check machine for visible damage. Any discovered

deficiency is to be reported immediately.

£ Non-required materials and objects are to be re-

moved from the working area of the machine.

£ Make sure that only persons authorised to work on

the machine are within the working area of the ma-

chine.

£ Use required personal safety gear in accordance

with the regulations, e.g. wear hair ne ts, and protec-

tive eye-glasses.

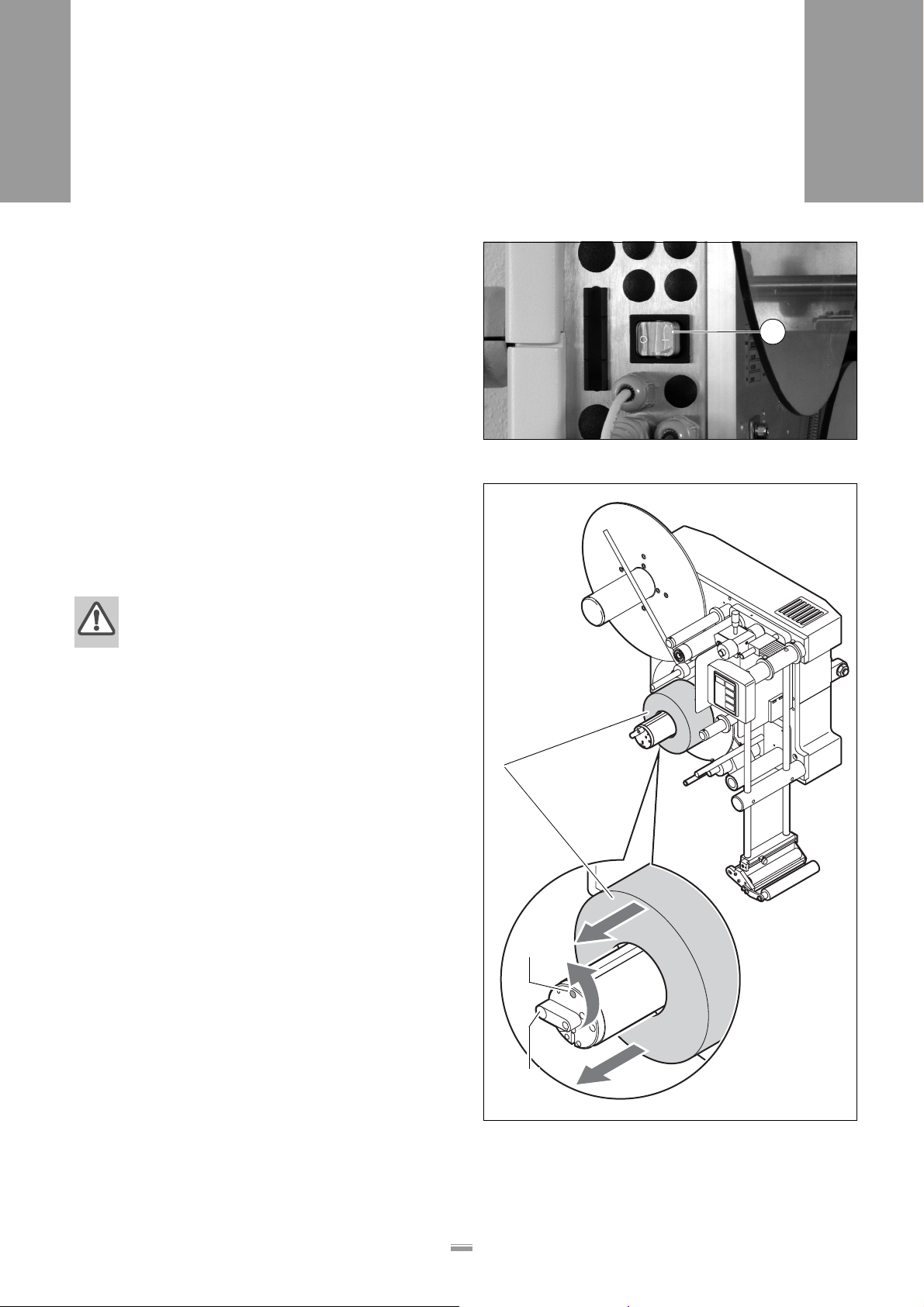

– The label dispenser is switched off at the main

[23A] switch.

[23] Main switch on the housing

ALS

450

A

3.2.2 Insert the label roller

WARNING!

Risk of injury due to moving or rapidly rotat-

ing parts!

£ Before inserting the label roller, ensure

that the machine is switched off at the

main switch.

£ Never switch on the machine before the

label ribbon has been completely threaded into position.

Remove the old backing material

If backing material remains on the rewinding [24A]

roller:

£ Swing the lever [24C] at the rewinding roller over the

red [24B] point.

– The tension of the rewinding roller spreader mecha-

nism is relieved.

£ Remove the rewound backing material.

Remove adhesive residues

A

B

£ If necessary, clean the following components:

– Dispensing edge

– Deflection rollers

– Drive roller

– Rewinding roller

£ Observe the notices in chapter Care and cleaning,

Page 86.

C

[24] Remove the backing material from the rewinding roller

A Old backing material

B Red point on the rewinding roller

C Lever for the spreader mechanism of the rewinding roller

36

Page 37

3PRIOR TO OPERATING

3.2 INSERT THE LABELLING MATERIAL – ALS 450

Insert new label roll

£ Loosen the set-screw at the guiding rod [25C] and

swing the guiding rod to the side.

£ Rotate the knurled knob [25B] clockwise, to retract

the chucking wedge [25A] in the unwinding spindle.

£ If there is still an old roll core on the unwinding spin-

dle: remove the old roll core.

£ Completely push on the new label roll. Make sure

the assembly is correctly positioned (see next page,

chapter Overview of the threading path diagram):

– Label material with labels positioned on the outside

of ribbon band: loose end to the right

– Label material with labels positioned on the inside of

ribbon band: loose end to the left

£ Rotate the knurled knob counter-clockwise to se-

cure the label roll on the unwinding spindle.

A

B

ALS

450

C

£ Allow the guiding rod to lightly rest against the label

roll and swing it approximately 1 cm over the un-

winding spindle.

£ Tighten the set-screw at the guiding rod.

[25] New label roll on the unwinding spindle, secured to the guiding

rod on the side

A Chucking wedge in the unwinding spindle

B Knurled knob on the unwinding spindle

C Guiding rod

37

Page 38

3PRIOR TO OPERATING

3.2 INSERT THE LABELLING MATERIAL – ALS 450

3.2.3 Threading the label ribbon Overview of the threading path diagram

ALS

450

A B

[26] Threading path diagram for label ribbon with the labels on the outside

A Right-hand version B Left-hand version

A B

[27] Threading path diagram for label ribbon with the labels on the inside

A Right-hand version B Left-hand version

38

Page 39

3PRIOR TO OPERATING

3.2 INSERT THE LABELLING MATERIAL – ALS 450

Thread the label ribbon at the unwind unit

£ Swing up the pressur e ro ller [28A] and the braking

brush [28B].

£ Thread the label ribbon around the deflection

rollers [28D], dancer arm roller [28C] and drive roller

unit [28E].

£ Form a loop after the drive roller unit and guide the

label ribbon over the operator panel support [28F].

£ Swing the pressure roller and web brake back into

position.

– The pressure roller and braking brush click into

operating position.

A

B

C

ALS

450

D

E

[28] Guides for the label ribbon in the unwinding section

A Pressure roller

B Braking brush

C Dancer arm

D Deflection roller

E Drive roller unit

F Operator panel support

F

39

Page 40

3PRIOR TO OPERATING

3.2 INSERT THE LABELLING MATERIAL – ALS 450

Guide the label ribbon around the dispensing edge

£ Unthread approximately 2 m of label ribbon from the

label roll.

£ Guide the label ribbon around the first deflection

roller [29A] and through the slot in the photoelectric

sensor [29B] [30A].

£ Guide the label ribbon under the pressure roller unit

[29C] to the dispensing edge [29D].

£ Guide the label ribbon around the dispensing edge

to the 2nd deflection roller [29E].

£ Thread the label ribbon around the upper deflection

roller [29F].

ALS

450

F

A

B

E

C

D

[29] Guides for the label ribbon in the dispenser head section

A 1st dispenser head deflection roller

B Label stop sensor

C Pressure roller unit

D Dispensing edge

E 2nd dispenser head deflection roller

F Upper deflection roller

A

[30] A Label stop sensor

40

Page 41

3PRIOR TO OPERATING

3.2 INSERT THE LABELLING MATERIAL – ALS 450

Thread the label ribbon at the rewind unit

£ Fold down lower pressure roller [31C].

£ Thread the label ribbon around the deflection roll-

ers, the feed roller unit and the dancer arm as

shown in figure [31].

£ Open the spreader mechanism of the rewinding roller

using the lever [31F].

– When the spreader mechanism is open, the red

point on the rewinding roller is not visible.

£ Insert the end of the label ribbon into the slot on the

rewinding roller.

£ Close the spreader mechanism of the rewinding roll-

er using the lever. The red point is now visible.

£ Rotate the rewinding roller counter-clo ckwis e until

the label ribbon is under tension.

£ Swing the pressure roller back into operating posi-

tion.

F

ALS

450

After a label roll is passed through, the backing

material roll rests firmly on the rewinding roller.

The spreader mechanism allows the diameter

of the rewinding roller to be decreased. The

backing material roll can then be easily removed.

£Only rewind the label ribbon on the rewinding

roller when the spreader mechanism is

closed (red point visible).

£ Do not open the spreader mechanism before

the backing material is removed from the rewinding roller

E

A

D B

[31] Guides for the label ribbon in the rewind unit section

A Deflection rollers

B Feed roller unit

C Pressure roller (in the open position)

D Dancer arm

E Rewinding roller

F Lever for the spreader mechanism of the rewinding roller (in

the open position)

C

41

Page 42

3PRIOR TO OPERATING

3.3 MECHANICAL SETTINGS

3.3 MECHANICAL SETTINGS

WARNING!

Risk of injury due to moving or rapidly rotating parts!

£ Before carrying out the mechanical set-

tings, ensure that the machine is

switched off at the main switch.

3.3.1 Setting the ribbon guides Operator panel support

£ Loosen the knurled thumb screws on the front-fac-

ing guide ring [32A].

£ To set the guide ring:

– The label ribbon must run between the two guide

rings with as little play as possible, but it must not be

pinched.

£ Tighten the knurled thumb screws.

ALS

350

450

Setting the ribbon guides on the dispenser head

£ Loosen the knurled thumb screws on the ribbon

guide [32B] and at the label stop sensor [32C].

£ Adjust the ribbon guide [32B] near the ribbon band

allowing as little play as possible, but it must not be

pinch the band. Tighten the knurled thumb screws.

£ In the same manner, adjust the position of the label

stop sensor [32C] and tighten the knurled thumb

screws.

Deflection roller on the rewind unit

£ Slide the guide bushes on to the def lec tion

rollers [32D] behind the feed drive :

– The label ribbon must not run from the side behind

the feed roller unit.

A

D

B

C

[32] Ribbon guides

42

Page 43

3PRIOR TO OPERATING

3.3 MECHANICAL SETTINGS

3.3.2 Adjust pressure roller at the

dispensing edge

The pressure roller [33A] on the dispensing edge enables the label ribbon to run smoothly around the dispensing edge and ensures that the labels separate

cleanly and in a controlled fashion from the backing

material.

The most favourable positioning of the pressure roller

unit may differ depending on the application.

For information on adjusting the pressure roller unit, the

customer service at our sales partner is at your disposal.

Only if necessary:

£ Loosen the fastening screws [33B].

£ Adjust the pressure roller

£ Tighten the fastening screws.

ALS

350

450

B

[33] A Pressure roller unit

B Fastening screws

A

43

Page 44

3PRIOR TO OPERATING

3.3 MECHANICAL SETTINGS

3.3.3 Adjust the pressure roller and the braking brush

A

ALS

350

450

C

B

[34] A Pressure roller, centrally aligned on the label ribbon

B Setting rings with knurled thumb screws

C Braking brush, centrally aligned on the label ribbon

Pressure roller

Mounting locations of the pressure rollers [34A]:

– On the drive roller unit of the unwind unit

– On the drive roller unit of the label feed

£ Loosen the knurled thumb screws on the setting

rings [34B].

£ Raise the pressure roller slightly and centrally align

it on the label ribbon.

£ Secure the pressure roller axially with the setting

rings. Tighten the knurled thumb screws.

Braking brush

£ Align the braking brush [34C] centrally on the label

ribbon.

44

Page 45

3PRIOR TO OPERATING

3.3 MECHANICAL SETTINGS

3.3.4 Adjust (optional) the position

of the dispensing edge

Adjusting vertically

Coarse adjustment:

£ Open the central lock [35B].

£ Hold the dispenser head firmly and open the lower

lock [35C].

£ Slide the dispenser head to the desired height and

tighten the lock [35C].

ALS

350

450

D

Fine adjustment:

£ Open the upper lock [35A].

£ Rotate the spindle [35D] clockwise to move the dis-

pensing edge downward or rotate the spindle co un -

ter-clockwise to move the dispensing edge upward.

£ Tighten the lock [35A]

£ Tighten the central lock [35B].

Forrecurring adjustments whe n pr od uc ts ar e

changed:

£Use the scales on the guide columns.

A

B

C

[35] Adjustable dispensing edge (optional)

45

Page 46

4OPERATION

4.1 ACTIVATION AND SHUT-DOWN

4 OPERATION

4.1 ACTIVATION AND SHUT-DOWN

4.1.1 Starting the machine

Before each use, the control system must be adapted

to the inserted label material. During this, the label distance is detected and the photoelectr ic sen so r at th e

dispenser head is adapted to the transparency of the

labels and of the backing material. This process is

called material initialisation.

Automatic material initialisation

Initialising material at switch-on:

£ Press and hold the FEED key [37A] and switch on

the machine at the main switch [36A].

– The message AUTO [37B] appears on the operator

panel.

– The machine slowly starts up and dispenses a label.

– The label distance is automatically measured.

– The photoelectric sensor is automatically adapted.

£ Release the FEED key once a label gap [38 arrow]

has passed the photoelectric sensor [38A] at the

dispenser head.

ALS

350

450

A

[36] Main switch on the housing

B A

If the initialisation was successful:

– „ON“ appears on the operator panel.

– When the FEED key is pressed, a label is dis-

pensed.

If the initialisation was unsuccessful:

– The message FAIL appears on the operator panel.

£ Switch off and automatically re-initialise the ma-

chine.

or:

£Manually initialise the material employing

qualified calibration technicians.

[37] Operator panel

A FEED key

B AUTO displayed

A

[38] Initialise the label material

46

Page 47

4OPERATION

4.1 ACTIVATION AND SHUT-DOWN

The machine can also be automatically initialised after switch-on by using the INIT function:

£ In the standard menu, press the NEXT or PRIOR key

until INIT [39] is displayed on the operator panel.

£ Call the INIT function by pressing the ENTER key.

£ Press and hold the FEED key.

– The message AUTO appears on the operator panel.

– The machine slowly starts up and dispenses a label.

£ Release the FEED key once a label gap has passed

the photoelectric sensor at the dispenser head.

– If the initialisation was successful, „ON“ appears on

the operator panel.

ALS

350

450

[39] INIT display on the operator panel

Manually initialise the material

If automatic initialisation is not possible, it does

not generally mean there is a malfunction. Manual initialisation is often required if:

– the proper label stop sensor is not installed.

– transparent labels are used.

– labels with only a slight difference of trans-

parency between label and backing material

are used.

– perforated or otherwise blocked out labels

are used [40].

Only by qualified calibration technicians:

£Calling up the extended menu.

£Input the label dis tan ce usin g th e LPI T

function

£Adjust the photoelectric sensor using the

CONT function.

£Refer to chapter Operation – Settings in the

extended menu.

BC C

A

[40] A Label distance

B Photoelectric sensor

C Labels with block outs (perforations)

47

Page 48

4OPERATION

4.1 ACTIVATION AND SHUT-DOWN

4.1.2 Labelling Prerequisites

– Label material is inserted.

– Machine is switched on.

– Material is initialised.

If „OFF“ appears on the operator panel:

£ Repeatedly press the NEXT or PRIOR key until

„ON“ [42A] is shown on the display.

If „ON“ appears on the operator panel [42A]:

£ Press the ENTER [41] key.

– The unwinding drive runs for a moment and fills the

loop space with label ribbon [42B].

– The unwinding drive runs for a moment until the

dancer arm points upward at an angle of approx.

30° [42C].

ALS

350