Atlas Air Compressor User Manual

Instruction book

Atlas Copco Stationary Air Compressors

Instruction book

SF1 - SF2 - SF4 Skid -Tank-mounted

SF6 - SF8 Twin

SF6 - SF8 - SF11 - SF15 Multi

Copyright 2003, Atlas Copco Airpower n.v, Antwerp, Belgium.

Any unauthorized use or copying of the contents or any part thereof is prohibited. This applies in particular to trademarks, model denominations, part numbers and drawings.

This instruction book meets the requirements for instructions specified by the machinery directive 98/37/EC and is valid for CE as well as non-CE labelled machines.

Note: The PED instructions for this machine are included at the end of the book.

No. 2920 1521 00

Registration code: APC SF / 38 / 980

2003-10 |

www.atlascopco.com |

2920 1521 00 |

1 |

Instruction book

This instruction book describes how to handle the machines to ensure safe operation, optimum efficiency and long service life.

Read this book before putting the machine into operation to ensure correct handling, operation and proper maintenance from the beginning. The maintenance schedule comprises measures for keeping the machine in good condition.

Keep the book available for the operator and make sure that the machine is operated and that maintenance is carried out according to the instructions. Record all operating data, maintenance performed, etc. in an operator's logbook available from Atlas Copco. Follow all relevant safety precautions, including those mentioned on the cover of this book.

Repairs must be carried out by trained personnel from Atlas Copco who can be contacted for any further information.

In all correspondence mention the type and the serial number, shown on the data plate.

For all data not mentioned in the text, see sections "Preventive maintenance schedule" and "Principal data".

The company reserves the right to make changes without prior notice.

2920 1521 00 |

2 |

Instruction book

1 LEADING PARTICULARS................................................................................................................... |

5 |

|

1.1 |

General description........................................................................................................................ |

5 |

1.1.1 Compressor variants ............................................................................................................... |

5 |

|

1.1.2 Compressor elements (Fig. 1.1).............................................................................................. |

5 |

|

1.2 |

Air flow ........................................................................................................................................... |

9 |

1.3 |

Cooling and condensate drain systems (Fig. 1.9) ......................................................................... |

9 |

1.4 |

Regulating system on SF Skid - Tank-mounted - Twin ............................................................... |

10 |

1.5 |

Regulating system on SF Multi .................................................................................................... |

11 |

1.5.1 Controlling the compressor ................................................................................................... |

11 |

|

1.5.2 Protecting the compressor .................................................................................................... |

11 |

|

1.5.3 Monitoring components subject to service............................................................................ |

11 |

|

1.5.4 Automatic restart after voltage failure ................................................................................... |

11 |

|

1.5.5 Control panel (Fig. 1.11) ....................................................................................................... |

12 |

|

1.5.6 Display – keys ....................................................................................................................... |

13 |

|

1.5.7 Function keys (5-Fig. 1.11) ................................................................................................... |

13 |

|

1.6 |

Electric cabinet on SF Multi ......................................................................................................... |

15 |

1.7 |

Air dryer on SF Full-Feature (Fig. 1.15)....................................................................................... |

16 |

2 INSTALLATION ................................................................................................................................. |

17 |

|

2.1 |

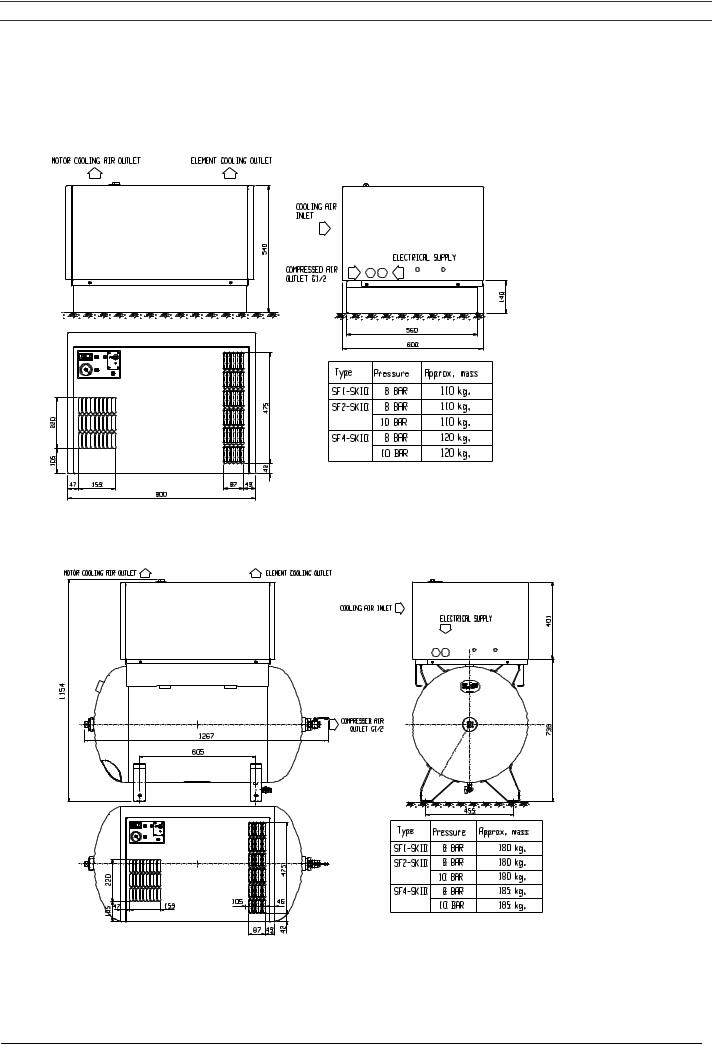

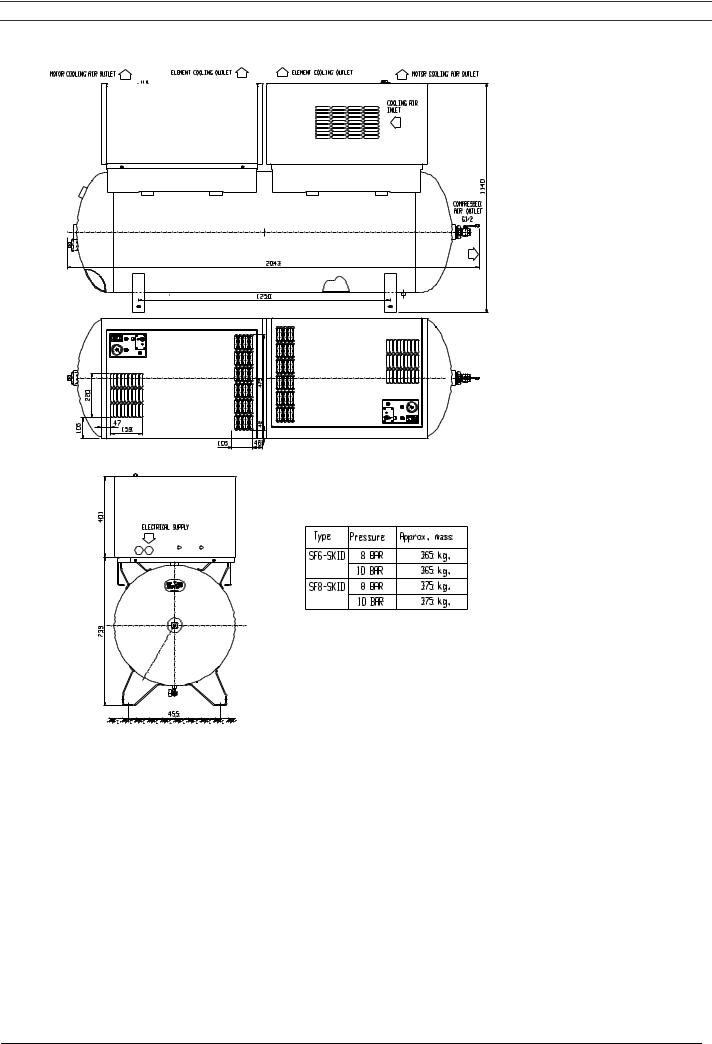

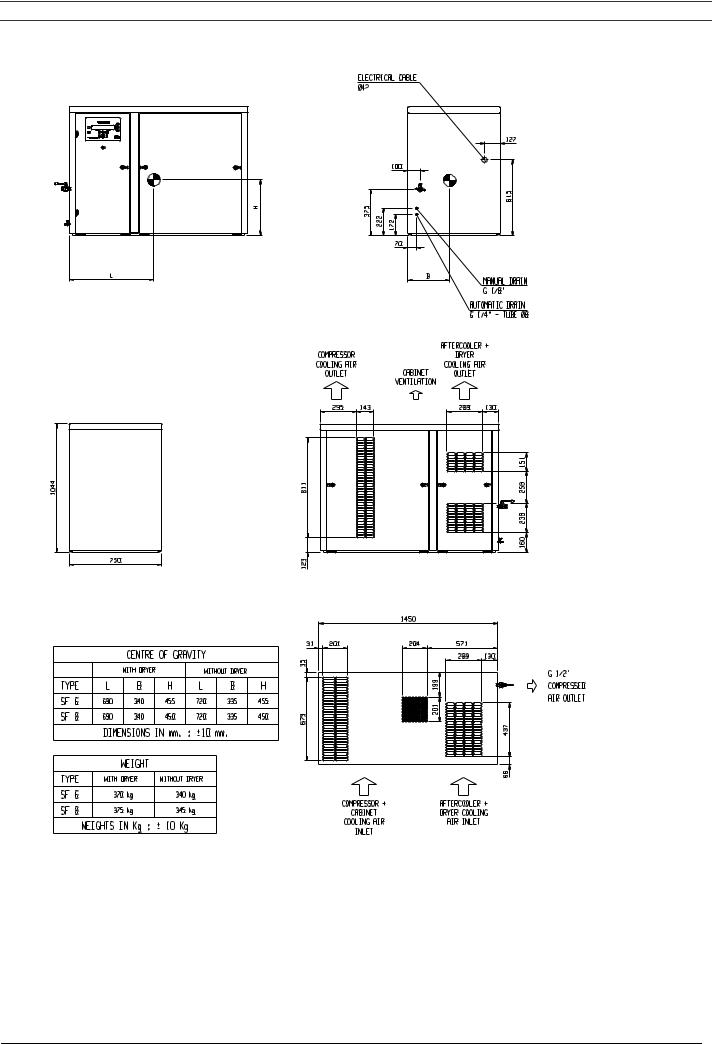

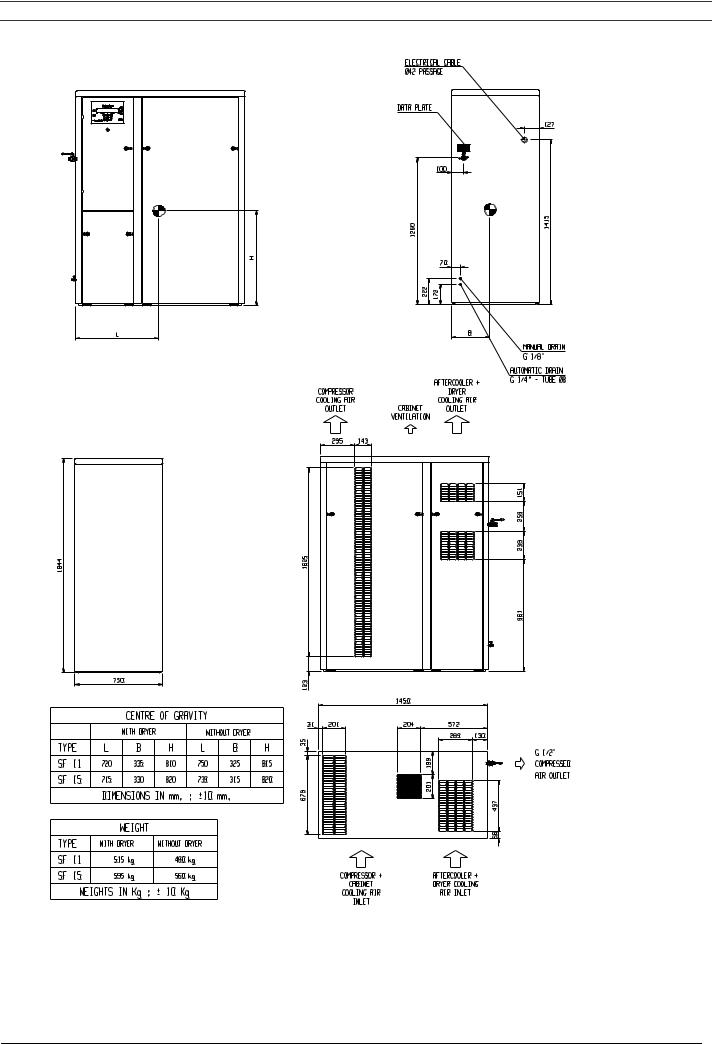

Dimension drawings (Figs. 2.1 up to 2.5) .................................................................................... |

17 |

2.2 |

Installation proposal (Fig. 2.6) ..................................................................................................... |

22 |

2.3 |

Electrical connections .................................................................................................................. |

24 |

2.4 |

Pictographs .................................................................................................................................. |

27 |

3 OPERATING INSTRUCTIONS .......................................................................................................... |

28 |

|

3.1 |

Initial start-up ............................................................................................................................... |

28 |

3.2 |

Starting......................................................................................................................................... |

28 |

3.2.1 Multi....................................................................................................................................... |

28 |

|

3.2.2 Skid - Tank-mounted - Twin .................................................................................................. |

28 |

|

3.3 |

During operation .......................................................................................................................... |

29 |

3.3.1 Multi....................................................................................................................................... |

29 |

|

3.3.2 Skid - Tank-mounted - Twin .................................................................................................. |

29 |

|

3.4 |

Stopping....................................................................................................................................... |

29 |

3.4.1 Multi....................................................................................................................................... |

29 |

|

3.4.2 Skid - Tank-mounted - Twin .................................................................................................. |

29 |

|

3.5 |

Taking out of operation at end of compressor service life........................................................... |

29 |

4 MAINTENANCE ................................................................................................................................. |

30 |

|

4.1 |

Compressor drive motors ............................................................................................................ |

30 |

4.2 |

Preventive maintenance schedule for the compressor................................................................ |

30 |

5 ADJUSTMENTS AND SERVICING PROCEDURES ........................................................................ |

32 |

|

5.1 |

Air filter (1-Figs. 1.7/1.8) .............................................................................................................. |

32 |

5.2 |

Belt exchange/tensioning (Fig. 5.1) ............................................................................................. |

32 |

5.3 |

Coolers......................................................................................................................................... |

32 |

5.4 |

Safety valve ................................................................................................................................. |

33 |

6 PROBLEM SOLVING ........................................................................................................................ |

34 |

|

7 PRINCIPAL DATA ............................................................................................................................. |

35 |

|

7.1 |

Electric cable size for SF1-8 ........................................................................................................ |

35 |

7.2 |

Electric cable size for SF 6-15 Multi ............................................................................................ |

35 |

7.3 |

Overload relays for SF1-8............................................................................................................ |

36 |

7.4 |

Overload relays for SF6-15 Multi ................................................................................................. |

36 |

7.5 |

Main fuses for SF1-8.................................................................................................................... |

37 |

7.6 |

Main fuses for SF6-15 Multi......................................................................................................... |

37 |

7.7 |

Reference conditions/limitations .................................................................................................. |

37 |

7.8 |

SF1-4 8bar 50 Hz 1) ................................................................................................................... |

38 |

7.9 |

SF2-4 10 bar 50 Hz 1) ................................................................................................................ |

38 |

7.10 SF1-4 100 psi 60 Hz 1)............................................................................................................. |

38 |

|

7.11 SF2-4 145 psi 60 Hz 1)............................................................................................................. |

38 |

|

7.12 SF6-15 Multi 8 bar 50 Hz 1)...................................................................................................... |

39 |

|

7.13 SF6-15 Multi 10 bar 50 Hz 1).................................................................................................... |

39 |

|

7.14 SF6-15 Multi 100 psi 60 Hz 1) .................................................................................................. |

39 |

|

7.15 SF6-15 Multi 125 psi 60 Hz 1) .................................................................................................. |

40 |

|

2920 1521 00 |

3 |

Instruction book

7.16 SF6-15 Multi 145 psi 60 Hz 1) .................................................................................................. |

40 |

|

8 REGULATOR FUNCTIONS FOR SF MULTI .................................................................................... |

41 |

|

8.1 |

Menu-driven control programs..................................................................................................... |

41 |

8.1.1 Function of control programs ................................................................................................ |

42 |

|

8.1.2 Main screen........................................................................................................................... |

42 |

|

8.1.3 Calling up other menus ......................................................................................................... |

44 |

|

8.2 |

Quick look at actual compressor status....................................................................................... |

44 |

8.3 |

Status data menu......................................................................................................................... |

45 |

8.3.1 No message exists................................................................................................................ |

45 |

|

8.3.2 A shut-down message exists ................................................................................................ |

45 |

|

8.3.3 A warning message exists .................................................................................................... |

46 |

|

8.3.4 A service warning message exists ........................................................................................ |

47 |

|

8.4 |

Measured data menu................................................................................................................... |

47 |

8.5 |

Counters menu ............................................................................................................................ |

48 |

8.6 |

Test menu .................................................................................................................................... |

48 |

8.7 |

Modify parameters menu ............................................................................................................. |

49 |

8.8 |

Modifying parameters .................................................................................................................. |

49 |

8.8.1 Modifying the pressure bands ............................................................................................... |

50 |

|

8.9 |

Modifying protection settings ....................................................................................................... |

51 |

8.9.1 Checking protections for compressor modules..................................................................... |

51 |

|

8.9.2 Modifying protections for Dryer LAT on Full-Feature machines ........................................... |

52 |

|

8.10 Modifying service plans ............................................................................................................. |

52 |

|

8.11 Programming Clock function...................................................................................................... |

54 |

|

8.11.1 Programming start/stop/pressure band commands ............................................................ |

54 |

|

8.11.2 To activate/deactivate the timer .......................................................................................... |

56 |

|

8.11.3 To modify a command......................................................................................................... |

56 |

|

8.11.4 To add a command ............................................................................................................. |

57 |

|

8.11.5 To delete commands........................................................................................................... |

58 |

|

8.12 Configuration menu.................................................................................................................... |

59 |

|

8.12.1 Programming compressor control modes ........................................................................... |

60 |

|

8.13 Service menu ............................................................................................................................. |

60 |

|

8.14 Saved data menu....................................................................................................................... |

63 |

|

8.15 Programmable settings.............................................................................................................. |

64 |

|

8.15.1 Regulation settings.............................................................................................................. |

64 |

|

8.15.2 Service settings................................................................................................................... |

65 |

|

9 CONVERSION LIST OF SI UNITS INTO US/BRITISH UNITS ......................................................... |

65 |

|

2920 1521 00 |

4 |

Instruction book

1 LEADING PARTICULARS

1.1 General description

SF1 up to SF15 are stationary, oil-free compressors driven by an electric motor.

1.1.1 Compressor variants

SF Skid (Fig. 1.2)

The components of the compressor are housed in a bodywork with removable front/top panel. The compressor is mounted on a frame designed to allow easy installation at the required spot.

SF Tank-mounted (Fig. 1.3)

The components of the compressor are housed in a bodywork with removable front/top panel. The compressor is mounted on an air receiver.

SF Twin (Fig. 1.4)

Two compressor modules are mounted on an air receiver. Each module is provided with its own control panel.

SF Multi Pack

The compressors have two up to four compressor modules enclosed in a sound-insulated bodywork. The front door comprises an Elektronikon regulator including the start and stop buttons. An emergency stop button is also provided. An electric cabinet comprising the motor starter is installed behind the front door.

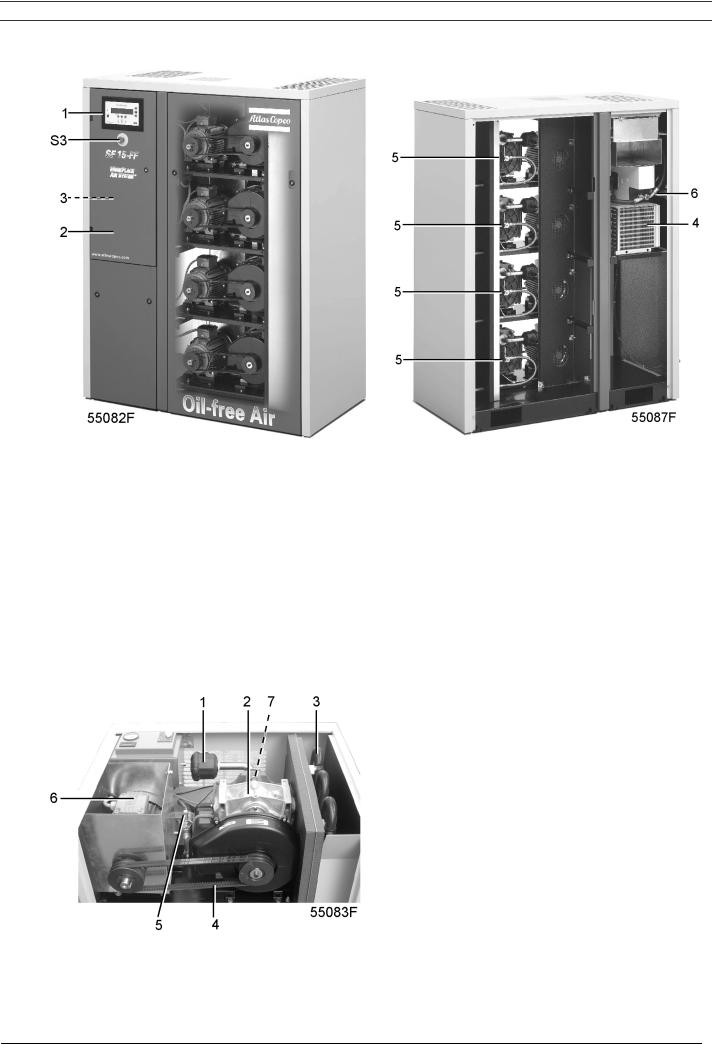

SF Multi Full-Feature (Figs. 1.5 and 1.6)

Full-Feature compressors are Pack compressors additionally provided with an air dryer integrated in the bodywork. The dryer removes moisture from compressed air by cooling the air to near freezing point and automatically draining the condensate. See section 1.7.

1.1.2 Compressor elements (Fig. 1.1)

Each compressor element consists of a fixed scroll-shaped housing and a scroll-shaped rotor. Air enters the compressor element through inlet opening (1). Once the air is drawn in, the orbiting scroll

(4) seals the inlet opening and forces the air into a continuously decreasing space. As scroll (4) keeps orbiting, this process of compression is constantly repeated, resulting in discharging of oil-free compressed air through outlet opening (3).

1 |

Air inlet |

2 |

Fixed scroll |

3 |

Compressed air outlet |

4 |

Orbiting scroll |

Fig. 1.1 Compressor element

2920 1521 00 |

5 |

Instruction book

1 Control panel

2 Air outlet valve

Fig. 1.2 SF4 Skid

1 Control panel

2 Air outlet valve

1.3 SF4 Tank-mounted

2920 1521 00 |

6 |

Instruction book

1 Control panels

2 Air outlet valve

Fig. 1.4 SF Twin

1Elektronikon regulator

2Electric cabinet

3Air outlet valve

4Dryer (on Full-Feature)

5Compressor modules S3 Emergency stop button

Fig. 1.5 SF8FF Multi

2920 1521 00 |

7 |

Instruction book

1Elektronikon regulator

2Electric cabinet

3Air outlet valve

4Dryer (on Full-Feature)

5Compressor modules

6Safety valve (ASME) S3 Emergency stop button

Fig. 1.6 SF15FF Multi

1 |

Air filter |

2 |

Compressor element |

3 |

Air cooler |

4 |

Belts |

5 |

Safety valve |

6 |

Drive motor |

7 |

Safety valve |

Fig. 1.7 Details of a compressor module on SF Tank-mounted

2920 1521 00 |

8 |

Instruction book

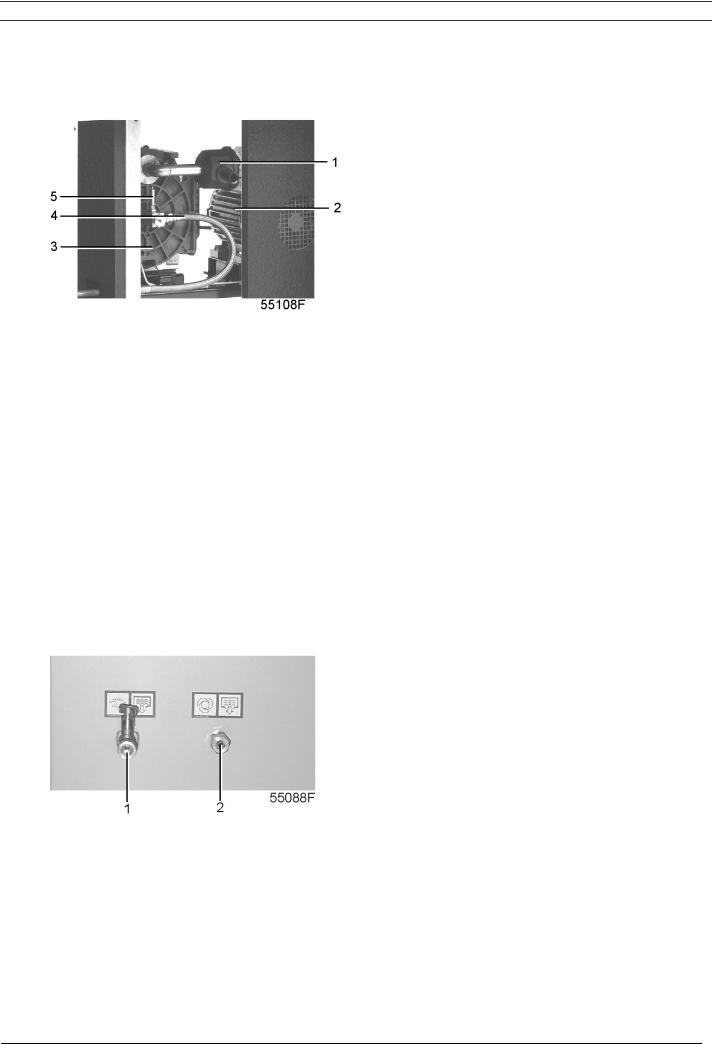

1 |

Air filter |

2 |

Drive motor |

3 |

Compressor element |

4 |

Compressed air outlet |

5 |

Safety valve (CE) |

Fig. 1.8 Details of a compressor module on SF Multi

1.2 Air flow

Air is drawn through the air filter into the compressor modules and is compressed. Compressed air is discharged through the check valve and air cooler towards the air net.

1.3 Cooling and condensate drain systems (Fig. 1.9)

Each compressor element is cooled by a fan. The fan is mounted on the drive shaft of the compressor element. The cooling air is blown over the compressor element and air cooler via a duct.

For SF Multi two fans, driven by electric motors, expel warm air from the bodywork.

SF Multi have a condensate trap, with an automatic condensate outlet (2) and a manual drain valve

(1).

1 Manual condensate drain valve

2 Automatic condensate outlet

Fig. 1.9 Condensate drains on SF Multi

2920 1521 00 |

9 |

Instruction book

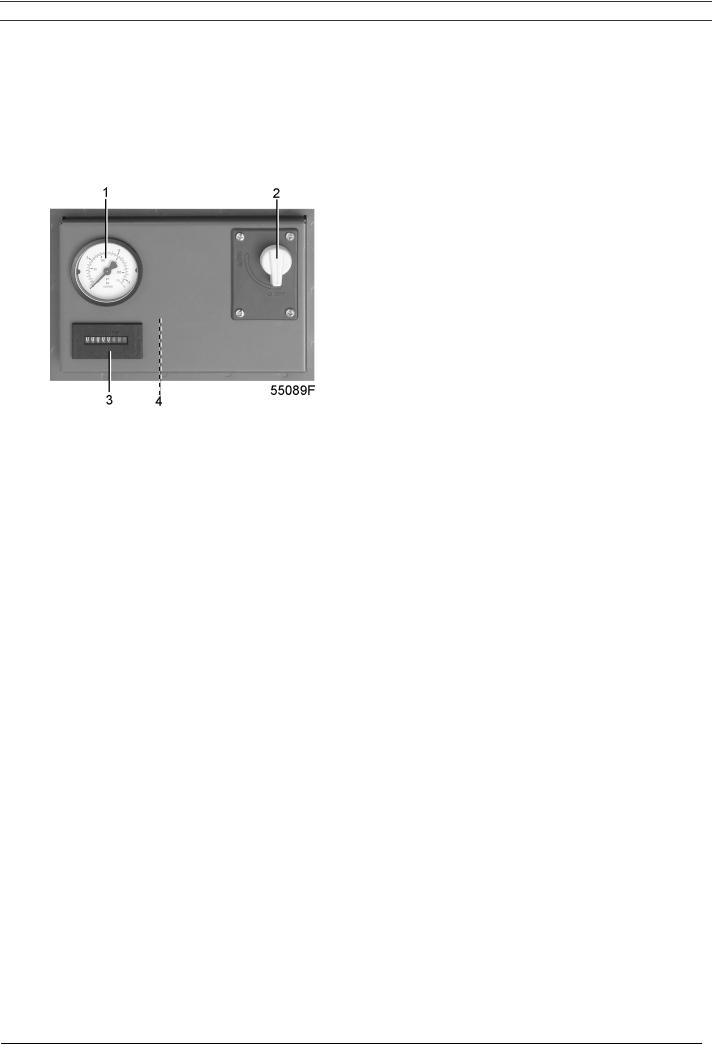

1.4 Regulating system on SF Skid - Tank-mounted - Twin

The air net pressure is kept within limits by a pressure switch mounted in the cabinet below the control panel (Fig. 1.10). The switch is connected to the air outlet and electrically connected in the circuit of the drive motor. The switch opens and closes its contacts at pre-set pressures.

1Pressure gauge

2On/off switch

3Hourmeter

4Air pressure switch/circuit breaker

Fig. 1.10 Control panel SF Skid - Tank-mounted - Twin

When the contacts are closed, the circuit to the drive motor is made: the compressor is operating. The air output is maximum.

When the pressure reaches the pre-set maximum, the circuit to the drive motor is broken, causing the compressor to stop. The air output is stopped.

Protecting the compressor

The compressor will be shut down in case temperature switch (TSHH11-Fig. 2.7) trips.

Warning

Before carrying out any inspection or repair, stop the compressor, switch off the voltage, open the isolating switch and depressurize the compressor.

2920 1521 00 |

10 |

Instruction book

1.5 Regulating system on SF Multi

SF Multi are provided with an Elektronikon® regulator (Fig. 1.11) to control the compressor.

The following is a short description of the main functions of the regulator. Consult section 8 for a detailed description of all functions.

1.5.1 Controlling the compressor

The Elektronikon regulator keeps the net pressure within programmable limits by starting and stopping the compressor modules, depending on the air consumption. The regulator distributes the running time among the compressor modules, taking into account the availability and number of running hours of each compressor module.

When the compressor has stopped automatically and the net pressure decreases, the regulator will start a compressor module before the net pressure has dropped to the starting pressure to prevent the net pressure from falling under the programmed minimum level.

1.5.2 Protecting the compressor

If one or more compressor modules are shut down due to a protection function a warning message will be shown on the display.

The compressor will be shut down in case temperature switch (TSHH20-Fig. 2.8) trips. See also section 8.3.2.

Warning

Before carrying out any inspection or repair, stop the compressor, switch off the voltage, open the isolating switch and depressurize the compressor.

After remedying, switch on the voltage and press the key “Reset” (F3).

1.5.3 Monitoring components subject to service

A number of service operations are grouped in plans (called Service plans I, A, B and D). Each Service plan has a programmed time interval. If a time interval is exceeded, a message will appear on the display to warn the operator to carry out the service actions belonging to that plan.

1.5.4 Automatic restart after voltage failure

The regulator has a built-in function to automatically restart the compressor if the voltage is restored after voltage failure. For compressors leaving the factory, this function is made inactive. If desired, the function can be activated. Consult Atlas Copco.

2920 1521 00 |

11 |

Instruction book

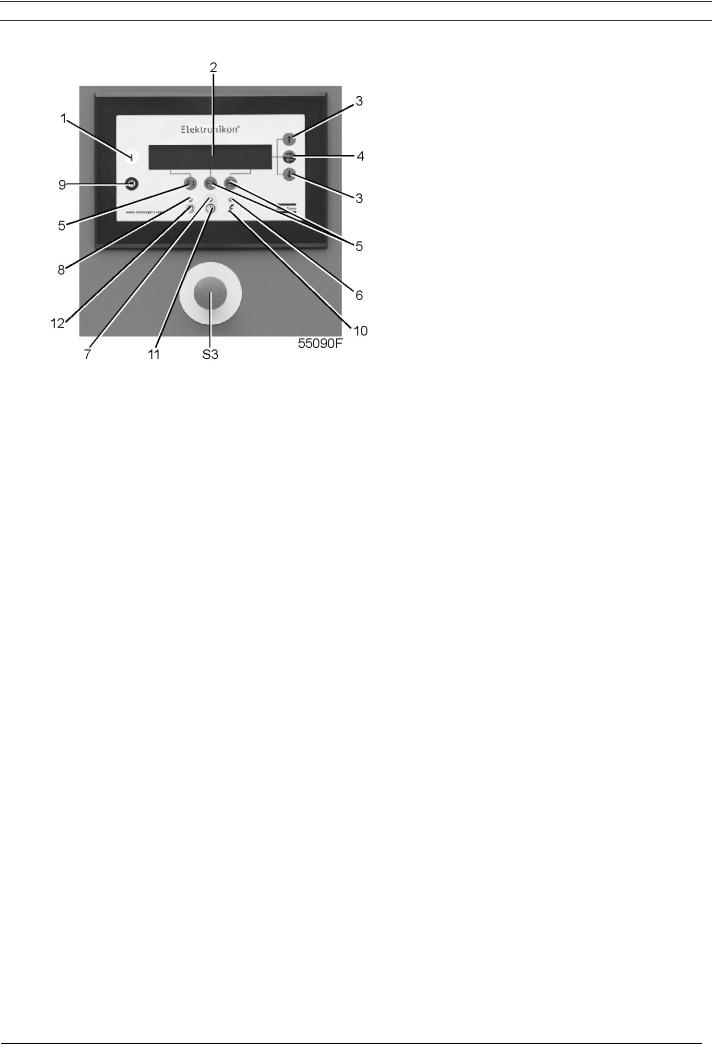

Fig. 1.11 Elektronikon regulator on SF Multi

1.5.5 Control panel (Fig. 1.11)

To control the compressor and to read and modify programmable parameters, the regulator is provided with a control panel including:

Ref |

Designation |

Function |

|

1 |

Start button |

Push button to start the compressor. LED (8) lights up indicating |

|

that the regulator is operative (in automatic operation). |

|||

|

|

||

2 |

Display |

Indicates messages concerning the compressor operating |

|

condition, a service need or a fault. |

|||

|

|

||

3 |

Scroll keys |

Keys to scroll through the display. |

|

4 |

Tabulator key |

Key to select the parameter indicated by a horizontal arrow. |

|

Only the parameters followed by an arrow pointing to the right |

|||

|

|

are accessible for modifying. |

|

5 |

Function keys |

Keys to control and program the compressor. |

|

6 |

Voltage on LED |

Indicates that the voltage is switched on. |

|

7 |

General alarm LED |

Is alight in case of a warning condition, see section 8.3. |

|

7 |

General alarm LED |

Blinks in case of shut-down condition, if a sensor with shut- |

|

down function is out of order or after an emergency stop. See |

|||

|

|

section 8.3. |

|

|

|

Indicates that the regulator is automatically controlling the |

|

8 |

Automatic operation LED |

compressor: the compressor is stopped and restarted |

|

depending on the air consumption and the limitations |

|||

|

|

||

|

|

programmed in the regulator. |

|

9 |

Stop button |

Push button to stop the compressor. LED (8) goes out. |

|

10 |

Pictograph |

Voltage on. |

|

11 |

Pictograph |

Alarm condition. |

|

12 |

Pictograph |

Automatic operation. |

|

S3 |

Emergency stop button |

Push button to stop the compressor immediately in case of |

|

emergency. After remedying the trouble, unlock the button by |

|||

|

|

pulling it out. |

2920 1521 00 |

12 |

Instruction book

1.5.6 Display – keys

Compressor Outlet |

|

7.0 bar |

Compressor Running |

|

↓ |

Menu |

|

- - - - |

F1 |

F2 |

F3 |

Fig. 1.12 Typical example of a display

Operating condition of a compressor module

The symbols shown above key F3 indicate the operating condition of each control module, see also section 8.1.2:

Symbol |

Indicates |

|

|

that the compressor module is available (ready to run), each |

|

- |

symbol stands for a compressor module (the left symbol stands for |

|

the lowest mounted module, the right symbol stands for the |

||

|

||

|

highest module) |

|

▄ |

that the compressor module is running |

|

- (blinking) |

that the compressor module is not available (due to minimum stop |

|

time or too many starts) |

||

|

||

* (blinking) |

that the compressor module is shut-down |

Scroll keys (3-Fig. 1.11)

These keys, labelled with vertical arrows, allow to scroll through the display.

As long as a downwards pointing arrow is shown at the utmost right position of the display, the key (3) with the same symbol can be used to see the next item.

As long as an upwards pointing arrow is shown at the utmost right position of the display, the key (3) with the same symbol can be used to see the previous item.

Tabulator key (4-Fig. 1.11)

This key, labelled with two horizontal arrows, allows the operator to go to the next field of the display, e.g. during modifying of programmable parameters.

1.5.7 Function keys (5-Fig. 1.11)

The keys are used:

-To call up or program settings

-To reset an active shut-down or service message, or an emergency stop

-To have access to all data collected by the regulator

The function keys allow to make the required selection from a menu of possibilities. The functions of the keys vary depending on the displayed menu. The actual function is abbreviated and indicated on the bottom line of the display just above the relevant key. Only the active and relevant functions at a moment are shown:

Designation |

Function |

Back |

To return to a previously shown option or menu |

Cancel |

To cancel a programmed setting when programming parameters |

Delete |

To delete compressor start/stop commands |

Extra |

To find the module configuration of the regulator |

Help |

To find the Atlas Copco internet address |

Limits |

To show limits for a programmable setting |

Mainscreen |

To return from a menu to the main screen |

2920 1521 00 |

13 |

Instruction book

Designation |

Function |

Menu |

Starting from the main screen, to have access to submenus |

Menu |

Starting from a submenu, to return to a previous menu |

Modify |

To modify programmable settings |

Program |

To program modified settings |

Reset |

To reset a timer or message |

Return |

To return to a previously shown option or menu |

Selecting a menu

To facilitate controlling the compressor, menu-driven programs are implemented in the electronic module. Use the function keys (5) to select the menus in order to program and monitor the compressor. See also section 8.

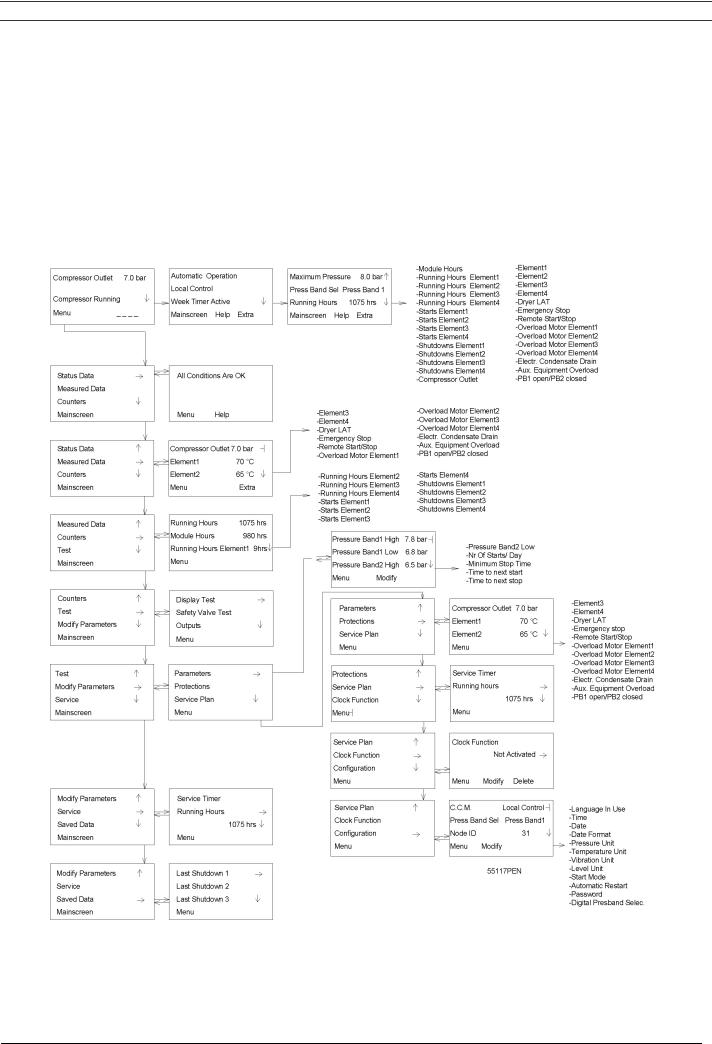

Fig. 1.13 Menu flow, SF Multi

2920 1521 00 |

14 |

Instruction book

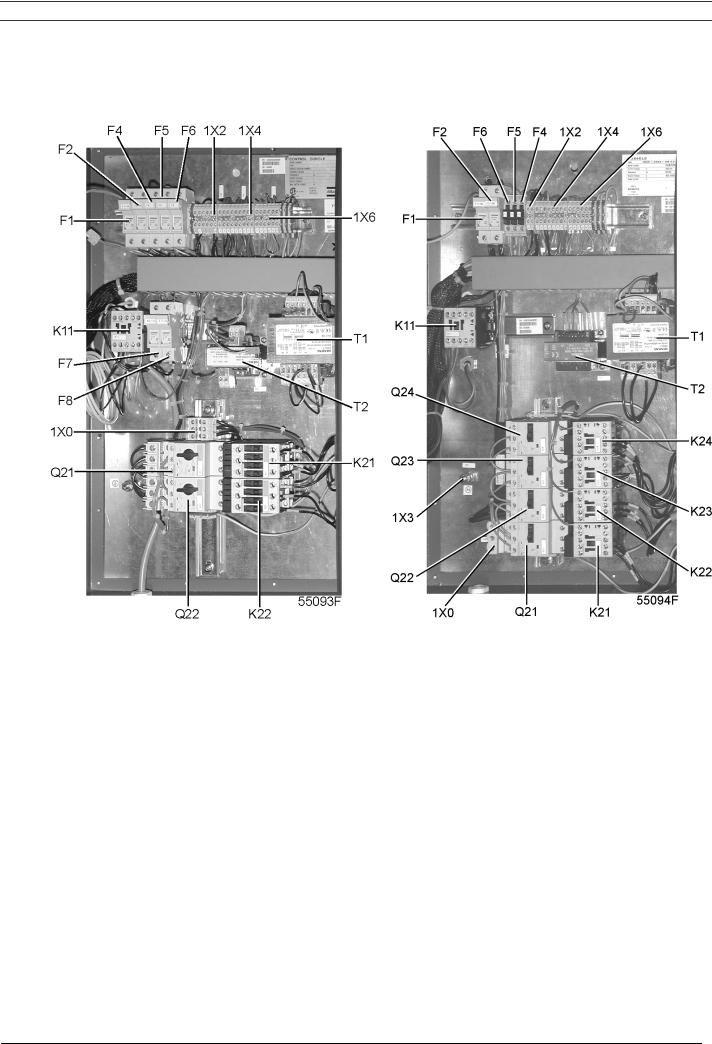

1.6 Electric cabinet on SF Multi

F1/8 |

Fuses |

K11 |

Auxiliary contactor, dryer |

K21/24 |

Contactors |

Q21/24 |

Circuit breakers |

T1/2 |

Transformers |

1X0 |

Terminal strip, mains supply |

1X2 |

Terminal strip, dryer |

1X3/6 |

Terminal strips |

Fig. 1.14 Electric cabinets, SF Multi

2920 1521 00 |

15 |

Instruction book

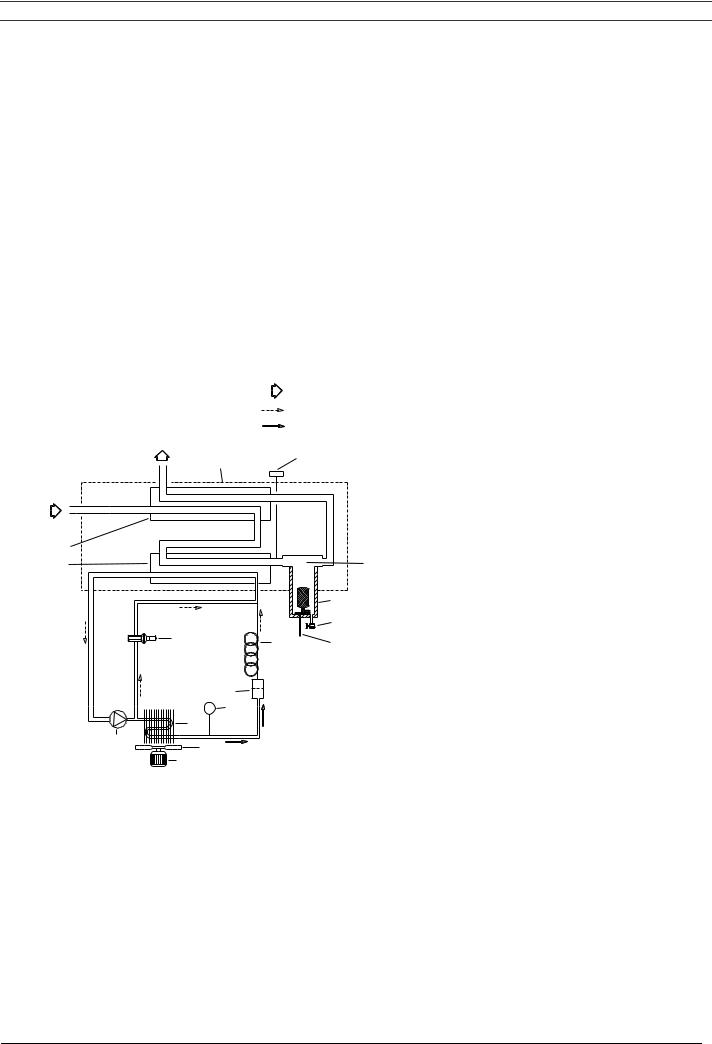

1.7 Air dryer on SF Full-Feature (Fig. 1.15)

Compressed air circuit

Wet compressed air enters heat exchanger (13) and is cooled by the outgoing, cold, dried air. Water in the incoming air starts to condense. The air then flows through heat exchanger (11) where the refrigerant evaporates and withdraws heat from the air. More water in the air condenses. The cold air then flows through condensate separator (3) where the condensate is separated from the air. The condensate is automatically drained through outlet (5). The cold, dried air then flows through heat exchanger (13), where it is warmed up by the incoming air.

Refrigerant circuit

Compressor (M1) delivers hot, high-pressure refrigerant gas which flows through condenser (9) where most of the refrigerant condenses.

The liquid flows through liquid refrigerant dryer/filter (12) to capillary tube (7). The refrigerant leaves the capillary tube at evaporating pressure.

The refrigerant enters evaporator (11) where it withdraws heat from the compressed air by further evaporation at constant pressure. The heated refrigerant leaves the evaporator and is sucked in by the compressor.

|

AIR (1) |

|

REFRIGERANT GAS (2) |

|

REFRIGERANT LIQUID (3) |

2 |

1 |

AO |

|

AI

13 |

|

|

|

Text on Fig. 1.15 |

|

11 |

|

|

|

3 |

|

|

|

|

|

(1) |

Air |

|

|

|

4 |

(2) |

Refrigerant gas |

|

|

|

6 |

(3) |

Refrigerant liquid |

|

|

|

|

|

|

|

10 |

7 |

5 |

|

|

|

12 |

|

|

|

|

|

S3 |

|

|

|

|

|

9 |

|

|

|

|

|

M1 |

|

|

|

|

|

8 |

|

|

|

|

|

M2 |

|

|

|

|

|

50972D |

|

|

|

|

AI |

Wet air inlet |

|

5 |

Automatic condensate drain |

|

AO |

Dry air outlet |

|

6 |

Manual condensate drain valve |

|

M1 |

Refrigerant compressor |

|

7 |

Capillary tube |

|

M2 |

Condenser fan motor |

|

8 |

Condenser cooling fan |

|

S3 |

Fan control switch |

|

9 |

Refrigerant condenser |

|

1 |

Pressure dewpoint sensor |

|

10 |

Hot gas by-pass valve |

|

2 |

Insulating block |

|

11 |

Air/refrigerant heat exchanger/evaporator |

|

3 |

Condensate separator |

|

12 |

Liquid refrigerant dryer/filter |

|

4 |

Condensate trap |

|

13 |

Air/air heat exchanger |

|

Fig. 1.15 Dryer on SF Full-Feature

2920 1521 00 |

16 |

Instruction book

2 INSTALLATION

2.1 Dimension drawings (Figs. 2.1 up to 2.5)

(1) |

(2) |

(3)

(5)

(4)

(6) |

(7) |

(8) |

9820 4052 00/1

55100D

Fig. 2.1 Dimension drawing, SF 1-4 Skid

(1) |

(2) |

(3)

(5)

(4)

(6) |

(7) |

(8) |

9820 4053 00/1

55101D

Fig. 2.2 Dimension drawing, SF 1-4 Tank-mounted

2920 1521 00 |

17 |

Instruction book

(1) |

|

(2) |

(2) |

(1) |

|

|

|

|

|

|

|

|

|

|

|

|

|

(3)

(4)

(5)

(6) |

(7) |

(8) |

|

|

|

9820 4054 00/1 |

|

|

|

55102D |

Fig. 2.3 |

Dimension drawing, SF 6-8 Twin |

|

|

Text on Figs.2.1/2.3 |

|

|

|

1 |

Motor cooling air outlet |

5 |

Electrical supply |

2 |

Element cooling outlet |

6 |

Type |

3 |

Cooling air inlet |

7 |

Pressure |

4 |

Compressed air outlet |

8 |

Mass, approx. |

2920 1521 00 |

18 |

Instruction book

(1)

(1)

(2)

(3)

(6)

(4)

(5)

(7)

(8) |

(9) |

(15)

(10)

(11)

(8) |

(9) |

(12)

(14)

(13)

9820 4027 00

55098D

Fig. 2.4 Dimension drawing, SF 6-8 Multi

2920 1521 00 |

19 |

Instruction book

(1)

(16)

|

|

(2) |

(4) |

(6) |

(3) |

|

||

|

|

|

|

(5) |

|

(7)

(8)(9)

(10) |

(15) |

|

(11)

(8)(9)

(12)

(14) |

9820 4026 00 |

(13) |

55099D |

Fig. 2.5 Dimension drawing, SF 11-15 Multi

2920 1521 00 |

20 |

Instruction book

Text on Figs. 2.4/2.5

(1)Electric cable

(2)Manual drain

(3)Automatic drain

(4)Compressor cooling air outlet

(5)Bodywork ventilation

(6)Aftercooler and dryer cooling air outlet

(7)Centre of gravity

(8)With dryer

(9)Without dryer

(10)Dimensions +/- 10 mm

(11)Weight

(12)Weight +/- 10 kg

(13)Compressor and bodywork cooling air inlet

(14)Aftercooler and dryer cooling air inlet

(15)Compressed air outlet

(16)Data plate

2920 1521 00 |

21 |

Loading...

Loading...