Page 1

Gas red condensing wall hung

combination boilers

G.C.N : 47-116 - 62 (24 kW)

G.C.N : 47-116 - 63 (30 kW)

G.C.N : 47-116 - 64 (38 kW)

E-COMBI 24

E-COMBI 30

E-COMBI 38

Country of destination GB, IE

Page 2

2

overview

INDEX

Overview

General Information ........................................................... 3

Advice for the Installer ....................................................... 4

CE Labelling ........................................................................... 4

Data Plate Symbols ............................................................. 4

Safety Regulations ..............................................................5

Product description

Control Panel.........................................................................6

Overall View ........................................................................... 7

Overall Dimension .............................................................. 8

Minimum Clearances .........................................................8

Technical Information ........................................................ 9

Installation

Reference Standards ........................................................10

Condensate Discharge ....................................................13

Installing the Boiler ........................................................... 14

Gas Connection ..................................................................15

Water Connection .............................................................15

Instructions for Opening the Casing and Performing

an Internal Inspection ...................................................... 15

Connecting the Flue .........................................................17

Fitting the Coaxial Flue (Ø 60/100 Horizontal) ........18

Fitting the 5” Flue (Ø 80/125 Horizontal / Vertical) 19

Fitting the Coaxial Flue (Ø 60/100 Vertical) .............. 20

Fitting the Twin Pipe (Ø 80/80) .....................................21

Electrical Connections .....................................................25

Peripheral Unit Connection ...........................................25

Room Thermostat Connection .....................................26

Outdoor Sensor Connection .........................................26

Electrical Diagram .............................................................27

Commissioning

Initial Preparation .............................................................. 28

Electricity Supply ...............................................................28

Filling the Heating System .............................................28

Filling of the DHW System ..............................................28

Gas Supply ...........................................................................28

Water Treatment ................................................................28

First Igniton Operation .................................................... 29

Ignition procedure ............................................................ 30

Test Function and Combustion Analysis ...................32

Boiler Protection Devices

Boiler Protection Devices ...............................................33

Anti-Frost Device ...............................................................33

Table summarising error codes ....................................33

Maintenance

General Comments ...........................................................34

General Access ...................................................................36

Electrical Unit ......................................................................37

Hydraulic Unit ..................................................................... 39

Burner Unit ..........................................................................47

Fan Unit .................................................................................50

Gas Valve ...............................................................................51

Annual Maintenance ........................................................ 52

Benchmark Commissioning Checklist .......................53

Benchmark Service Interval Record ............................54

Spare Parts Short List .......................................................55

Page 3

3

overview

These instructions are suitable for E-COMBI boilers :

Do not forget the Log Book!

MTS supports Benchmark, the heating industry code to ensure the correct installation,

commissioning and servicing of domestic central heating systems.

To The Householder

Make sure you have a completed Log Book for your boiler. This provides a record of the

commissioning of your boiler.

It contains important information about your particular installation that may be required by service

engineers. The Log Book will also provide contact details for the installer should you need guidance

in the use of this appliance or if there are any problems.

As with your car, your boiler will work more reliably and eciently if regularly serviced. We recommend

an annual service check. The service history of the appliance will be recorded on the Log Book.

In the unlikely event of any problems with your boiler or system you should rst contact your

installer. If your installer cannot resolve the problem he should telephone our national service

helpline.

A charge may be made if MTS Service is called out to resolve a non-product related fault.

Your statutory rights are not aected.

To The Installer

As part of the commissioning of this appliance it is vital that the Log Book is completed and given to the

Householder. Please ensure that your customer is aware of the importance of keeping the Log Book safe as a

record of the installation and the appliance service history.

Please ensure that your customer is aware of the correct operation of the system, boiler and controls.

MTS recommend the use of protective clothing, when installing and working on the appliance i.e. gloves.

CUSTOMER CARE

MTS, as a leading manufacturer of domestic and commercial water heating appliances is committed to

providing high quality products and a high quality after sales service.

Advice on installation or servicing can also be obtained by contacting the MTS Technical and Customer

Service Departments at High Wycombe.

TECHNICAL DEPARTMENT CUSTOMER SERVICE

DEPARTMENT

Tel: 0870 241 8180 Tel: 0870 600 9888

Fax: 01494 459775 Fax: 01494 459775

GUARANTEE

The manufacturer’s guarantee is for 2 years from the date of purchase. The guarantee is invalidated if

the appliance is not installed in accordance with the recommendations made herein or in a manner not

approved by the manufacturer. To assist us in providing you with an ecient after sales service, please

return the guarantee registration card enclosed with the boiler without delay.

CAUTION

In the United Kingdom, installation, start-up, adjustments and maintenance, must be performed by a

competent person only, in accordance with the current Gas Safety (Installation & Use) Regulations and the

instructions provided.

In the Republic of Ireland, the installation and initial start up of the appliance must be carried out by a

Competent Person in accordance with the current edition of I.S.813 “Domestic Gas Installations”, the current

Buidling Regulations, reference should also be made to the current ETCI rules for electrical installation.

All CORGI registered installers carry a CORGI ID card, and have a registration number. Both should be

recorded in your boiler Log Book. You can check your installer is CORGI registered by calling CORGI

direct on:- (01256) 372300.

Improper installation may cause damage or injury to individuals, animals and personal property for which

the manufacturer will not be held liable. To ensure ecient and safe operation it is recommended that the

boiler is serviced annually by a competent person.

If it is known that a fault exists on the appliance, it must not be used until the fault has been corrected by a

competent person.

This instruction booklet is especially designed for appliances installed in the UK and the Republic of Ireland

Page 4

4

overview

Advice for the installer

The installation and rst ignition of the

boiler must be performed by qualied personnel

in compliance with current national regulations

regarding installation, and in conformity with

any requirements established by local authorities

and public health organisations.

After the boiler has been installed, the installer

must ensure that the end user receives the

declaration of conformity and the operating

manual, and should provide all necessary

information as to how the boiler and the safety

devices should be handled.

This appliance is designed to produce hot water for

domestic use.

It should be connected to a heating system and a

distribution network for domestic hot water, both of

which must be compatible with its performance and

power levels.

The use of the appliance for purposes other than

those specied is strictly forbidden. The manufacturer

cannot be held responsible for any damage caused

by improper, incorrect and unreasonable use of

the appliance or by the failure to comply with the

instructions given in this manual.

Installation, maintenance and all other interventions

must be carried out in full conformity with the

governing legal regulations and the instructions

provided by the manufacturer. Incorrect installation

can harm persons, animals and possessions;

the manufacturing company shall not be held

responsible for any damage caused as a result.

The boiler is delivered in a carton. Once you have

removed all the packaging, make sure the appliance

is intact and that no parts are missing. If this is not

the case, please contact your supplier.

Keep all packaging material (clips, plastic bags,

polystyrene foam, etc.) out of reach of children as it may

present a potential hazard.

In the event of a fault and/or malfunction, turn

the appliance o, turn o the gas cock and do not

attempt to repair it yourself. Contact a qualied

professional instead.

Before any maintenance or repair work is performed

on the boiler, make sure you have disconnected it

from the electricity supply by switching the external

bipolar switch to the “OFF” position and removing

the fuse.

All repairs, which should only be performed using

original spare parts, should be carried out by a

qualied professional. Failure to comply with the

above instructions could compromise the safety of

the appliance and invalidate all liability on the part

of the manufacturer.

In the event of any maintenance or other structural

work in the immediate vicinity of the ducts or ue

gas exhaust devices and their accessories, switch

the appliance o by switching the external bipolar

switch to the “OFF” position and shutting o the gas

control valve. When the work has been completed,

ask a qualied technician to check the eciency of

the ducting and the devices.

Turn the boiler o and turn the external switch “OFF”

to clean the exterior parts of the appliance.

Clean using a cloth dampened with soapy water. Do

not use aggressive detergents, insecticides or toxic

products. If the appliance is used in full compliance

with current legislation, it will operate in a safe,

environmentally-friendly and cost-ecient manner.

If using kits or optional extras, make sure they are

authentic.

CE labelling

The CE mark guarantees that the appliance conforms

to the following directives:

-

90/396/CEE

relating to gas appliances

-

2004/108/CEE

relating to electromagnetic compatibility

-

92/42/CEE

relating to energy eciency

-

2006/95/CEE

relating to electrical safety

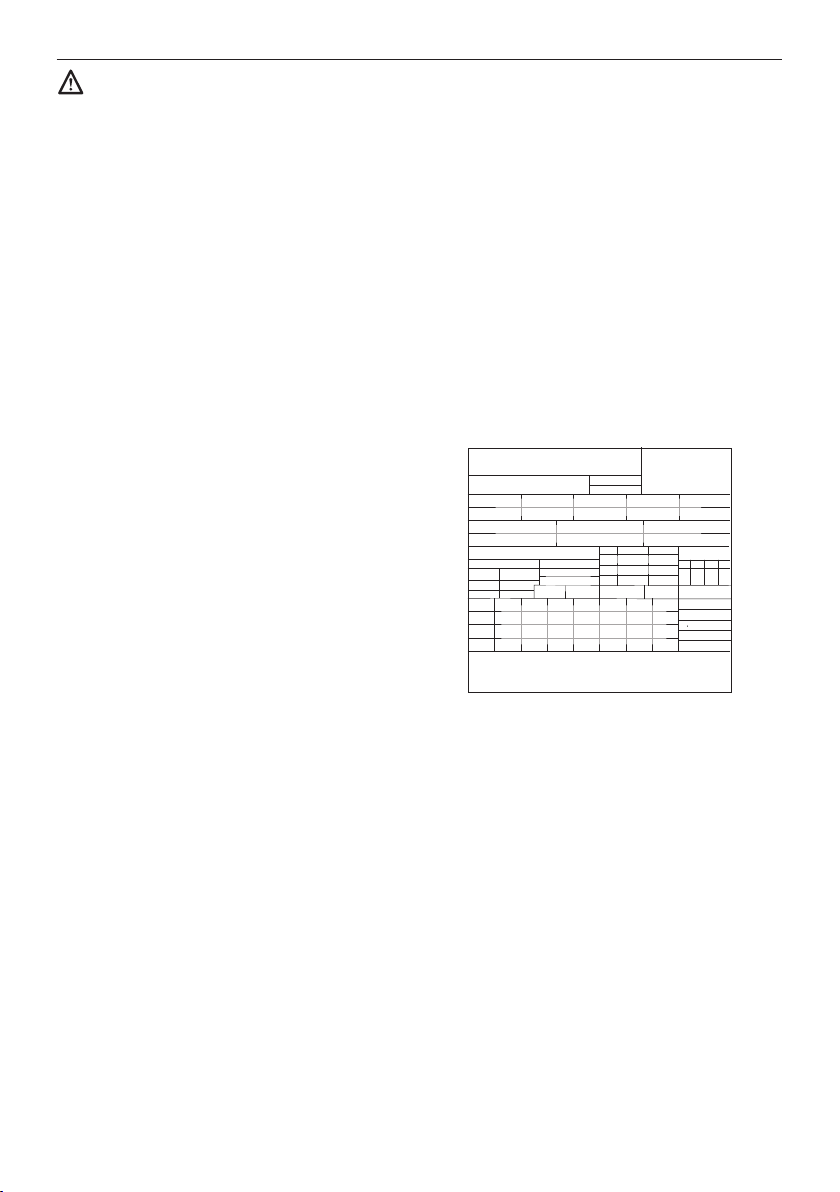

Symbols used on the data plate

Gas

MAX

MIN

Gas

mbar

mbar

1

2

5

4

3

6

7

19

8

9

10

11

12

14

15

16

17

18

13

20

21

22

Légende :

1.

Brand

2. Manufacturer

3. Boiler model - Serial number

4. Commercial reference

5. certication number

6. Destination country - gas category

7. Gas setting

8. Installation

type

9. Electrical data

10. Maximum domestic hot water pressure

11. Maximum heating pressure

12. Boiler type

13. NOx class / Eciency

14. Input rating nominal heating

15. Power ouput

heating

16. DHW specic ow rate

17. Boiler output eciency

18. Input rating nominal DHW

19. Gases which may be used

20. Température ambiante de fonctionnement

21. Max. central heating temperature

22. Max. Domestic Hot Water temperature

Page 5

5

overview

Safety regulations

Key to symbols:

Failure to comply with this warning implies the risk of

personal injury, in some circumstances even fatal

Failure to comply with this warning implies the risk

of damage, in some circumstances even serious, to

property, plants or animals.

Install the appliance on a solid wall which is not

subject to vibration.

Noisiness during operation.

When drilling holes in the wall for installation

purposes, take care not to damage any electrical

wiring or existing piping.

Electrocution caused by contact with live wires.

Explosions, res or intoxication caused by gas

leaking from damaged piping. Damage to existing

installations. Flooding caused by water leaking from

damaged piping.

Perform all electrical connections using wires

which have a suitable section.

Fire caused by overheating due to electrical current

passing through undersized cables.

Protect all connection pipes and wires in order to

prevent them from being damaged.

Electrocution caused by contact with live wires.

Explosions, res or intoxication caused by gas leaking

from damaged piping. Flooding caused by water

leaking from damaged piping.

Make sure the installation site and any systems to

which the appliance must be connected comply

with the applicable norms in force.

Electrocution caused by contact with live wires

which have been installed incorrectly. Damage to the

appliance caused by improper operating conditions.

Use suitable manual tools and equipment (make

sure in particular that the tool is not worn out

and that its handle is xed properly); use them

correctly and make sure they do not fall from

a height. Replace them once you have nished

using them.

Personal injury from the falling splinters or fragments,

inhalation of dust, shocks, cuts, pricks and abrasions.

Damage to the appliance or surrounding objects

caused by falling splinters, knocks and incisions.

Use electrical equipment suitable for its intended

use (in particular, make sure that the power

supply cable and plug are intact and that the parts

featuring rotary or reciprocating motions are

fastened correctly); use this equipment correctly;

do not obstruct passageways with the power

supply cable, make sure no equipment could fall

from a height. Disconnect it and replace it safely

after use.

Personal injury caused by falling splinters or

fragments, inhalation of dust, knocks, cuts, puncture

wounds, abrasions, noise and vibration. Damage

to the appliance or surrounding objects caused by

falling splinters, knocks and incisions.

Make sure any portable ladders are positioned

securely, that they are suitably strong and that

the steps are intact and not slippery and do not

wobble when someone climbs them. Ensure

someone provides supervision at all times.

Personal injury caused by falling from a height or cuts

(stepladders shutting accidentally).

Make sure any rolling ladders are positioned

securely, that they are suitably strong, that the

steps are intact and not slippery and that the

ladders are tted with handrails on either side of

the ladder and parapets on the landing.

Personal injury caused by falling from a height.

During all work carried out at a certain height

(generally with a dierence in height of more

than two metres), make sure that parapets are

used to surround the work area or that individual

harnesses are used to prevent falls. The space

where any accidental fall may occur should be

free from dangerous obstacles, and any impact

upon falling should be cushioned by semi-rigid or

deformable surfaces.

Personal injury caused by falling from a height.

Make sure the workplace has suitable hygiene and

sanitary conditions in terms of lighting, ventilation

and solidity of the structures.

Personal injury caused by knocks, stumbling etc.

Protect the appliance and all areas in the vicinity

of the work place using suitable material.

Damage to the appliance or surrounding objects

caused by falling splinters, knocks and incisions.

Handle the appliance with suitable protection and

with care.

Damage to the appliance or surrounding objects

from shocks, knocks, incisions and squashing.

During all work procedures, wear individual

protective clothing and equipment.

Personal injury caused by electrocution, falling

splinters or fragments, inhalation of dust, shocks, cuts,

puncture wounds, abrasions, noise and vibration.

Place all debris and equipment in such a way

as to make movement easy and safe, avoiding

the formation of any piles which could yield or

collapse.

Damage to the appliance or surrounding objects

from shocks, knocks, incisions and squashing.

All operations inside the appliance must be

performed with the necessary caution in order to

avoid abrupt contact with sharp parts.

Personal injury caused by cuts, puncture wounds and

abrasions.

Reset all the safety and control functions aected

by any work performed on the appliance and make

sure they operate correctly before restarting the

appliance.

Explosions, res or intoxication caused by gas leaks or

an incorrect ue gas exhaust. Damage or shutdown

of the appliance caused by out-of-control operation.

Before handling, empty all components that may

contain hot water, carrying out any bleeding if

necessary.

Personal injury caused by burns.

Descale the components, in accordance with

the instructions provided on the safety data

sheet of the product used, airing the room,

wearing protective clothing, avoid mixing

dierent products, and protect the appliance and

surrounding objects.

Personal injury caused by acidic substances coming

into contact with skin or eyes; inhaling or swallowing

harmful chemical agents. Damage to the appliance

or surrounding objects due to corrosion caused by

acidic substances.

If you detect a smell of burning or smoke, keep

clear of the appliance, disconnect it from the

electricity supply, open all windows and contact

the technician.

Personal injury caused by burns, smoke inhalation,

intoxication.

Page 6

6

product description

90°40°

50°

60° 70°

80°

on/o

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

9

6

12

I

1

2

3

4

5

8

9

10

6

7

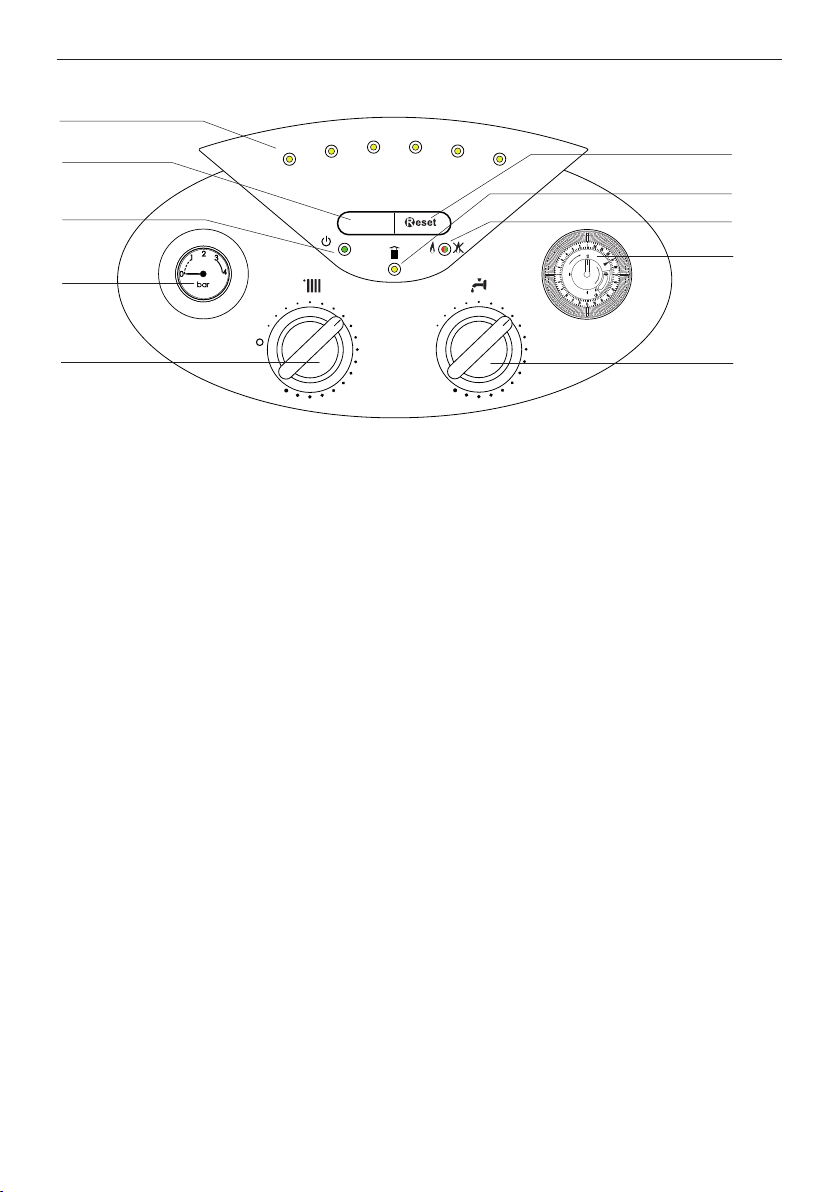

Control panel

Legend :

1. Green indicator CH temperarure and errors indicator

2. ON/OFF button

3. Green indicator ON/OFF

4.

Pressure gauge

5. Winter / Summer switch - Heating temperature regulation knob

6. Domestic Hot Water adjustment knob

7. Time clock

8. Green indicator : ame ON

Red indicator : locking light

9. Yellow

indicator : fumes exhaust malfunction

10. R

ESET button

Page 7

7

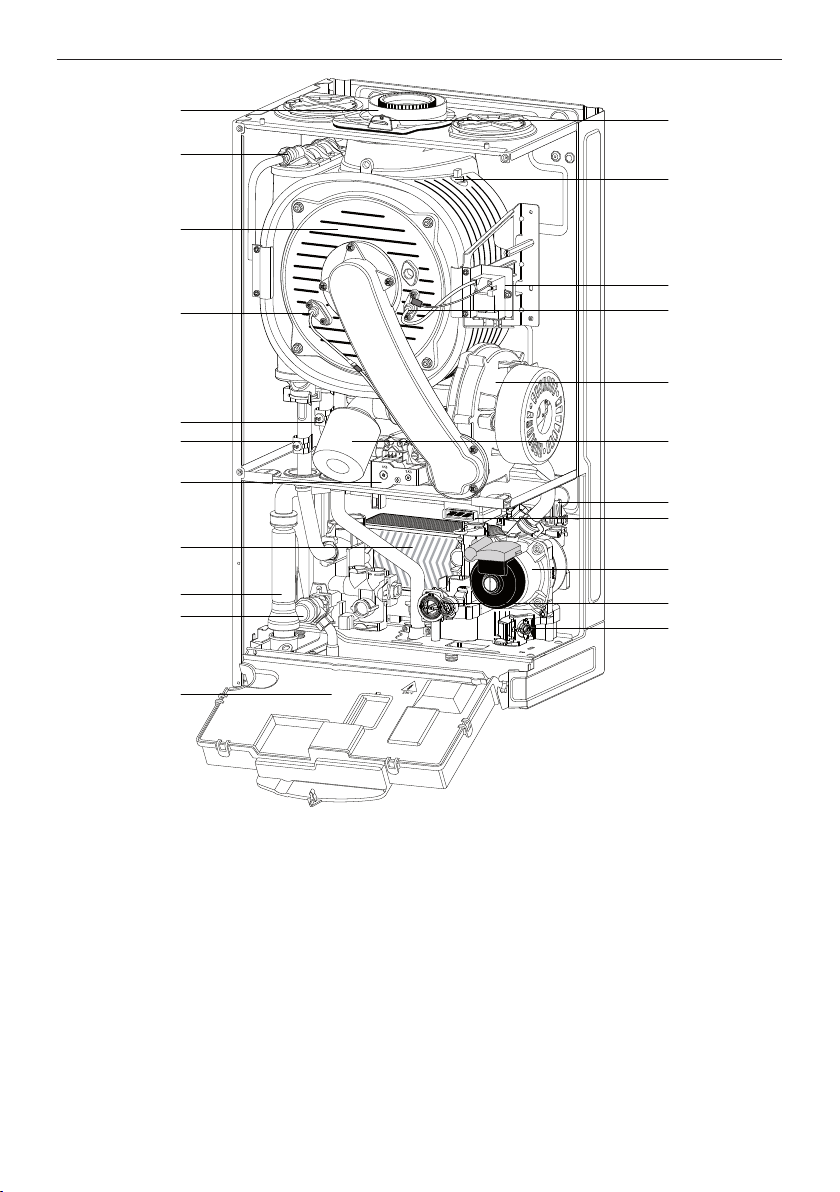

product description

1. ue connector

2.

air pressure switch

3. burner

4.

detection Electrode

6.

C.H. Return temperature probe

7.

C.H. Flow temperature probe

8.

gas valve

9.

secondary heat exchanger

11. siphon

12. C.H. pressure relief valve

13. electrical box

15.

C.H. circuit lter

16.

D.H.W. Flow switch

17.

circulation Pump with air release valve

18.

diverter valve

19.

switch On-O

20. silencer

21.

modulating Fan

22.

ignition electrodes

23. ignitor

24. thermal fuse

25.

combustion Analysis Test Point

Overall view

1

2

3

4

6

7

8

9

11

12

13

25

24

23

22

21

20

18

19

17

15

16

Page 8

8

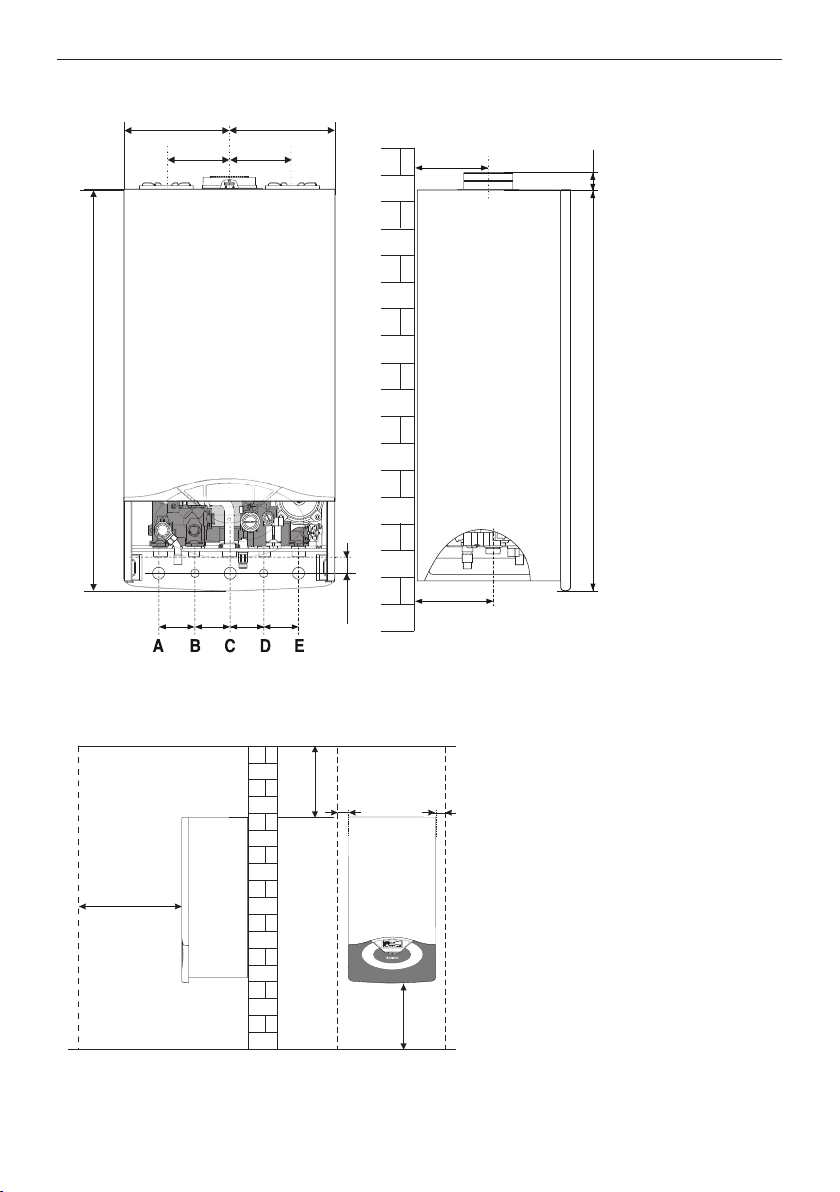

product description

28

770

200

150

120 120

200

180

65 6567 67

25770

Overall Dimensions

24/30/38

A. Central Heating Flow

B. Domestic Hot Water Outlet

C. Gas Inlet

D. Domestic Cold Water Inlet

E. Central Heating Return

450

003

003

50 50

Minimum clearances

In order to allow easy

access to the boiler for

maintenance operations,

The boiler must be installed

in accordance with the

clearances stated below.

5

5

Page 9

9

product description

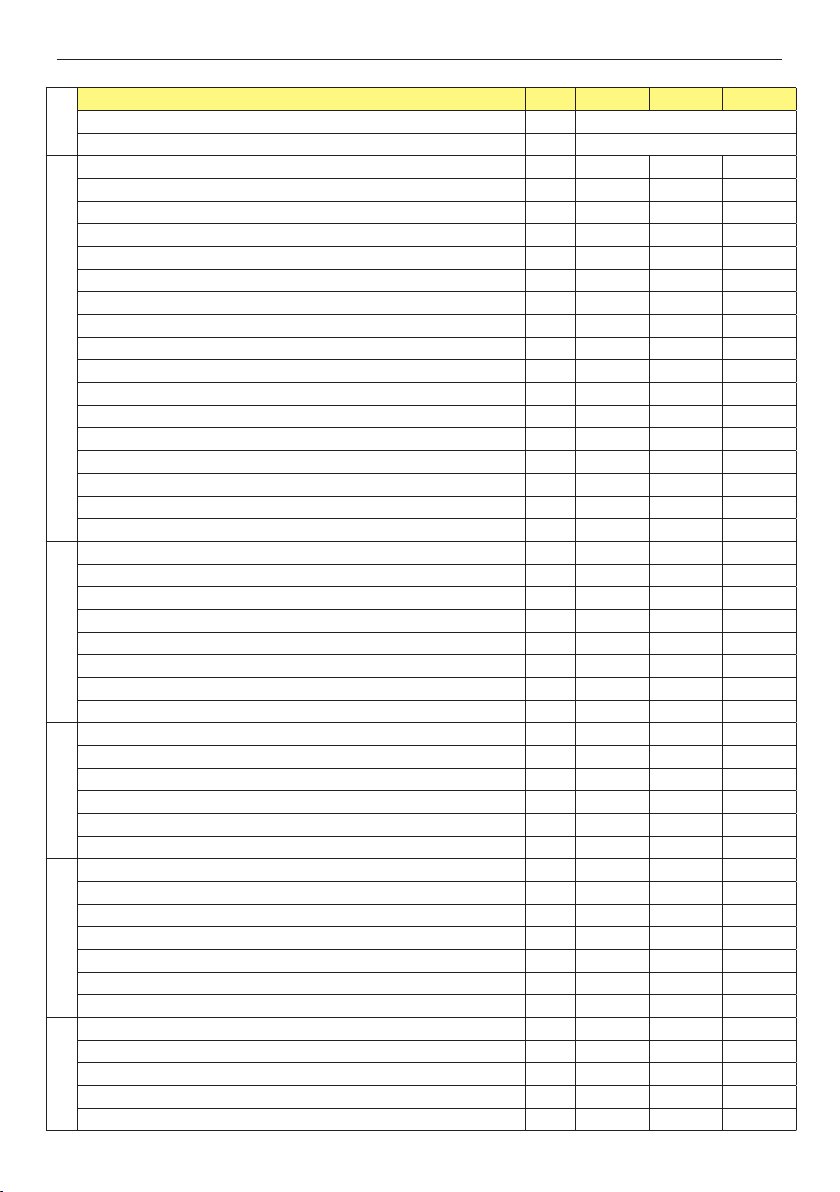

Technical Data

GENERAL

NOTE

Model E-COMBI

243038

CE Certication (pin)

0085BR0347

Boiler type

B23-C13-C33-C43-C53-C83

POWER SPECIFICATIONS

Max/min nominal caloric ow rate (Pci) Qn

KW

22,0/5,5

28,0/6,5

31,0/7,5

Max/min nominal caloric ow rate (Pcs) Qn

KW

24,4/6,1

31,1/7,2

34,4/8,3

Domestic hot water max/min nominal caloric ow rate (Pci) Qn

KW

25,0/5,5

30,0/6,5

38,0/7,5

Domestic hot water max/min nominal caloric ow rate (Pcs) Qn

KW

27,8/6,1

33,3/7,2

42,2/8,3

Max/min power output (80°C-60°C) Pn

KW

21,6/5,2

27,4/6,2

30,3/7,3

Max/min power output (50°C-30°C) Pn

KW

23,5/5,8

29,5/6,9

33,1/8,0

Domestic hot water max/min power output Pn

KW

25,0/5,0

30,0/6,0

38,9/7,1

Combustion eciency (of ue gas)

%

97,9

97,9

98,0

Nominal caloric ow rate eciency (60/80°C) Hi/Hs

%

98,0/88,2

98,0/88,2

97,6/87,9

Nominal caloric ow rate eciency (30/50°C) (condensation) Hi/Hs

%

107,0/96,4

105,3/94,8

106,9/96,3

Eciency at 30% at 30°C (condensation) Hi/Hs

%

108,0/97,3

110,3/99,3

107,2/96,5

Eciency at 30% at 47°C Hi/Hs

%

101,0/90,9

98,2/88,4

103,1/92,8

Minimum caloric ow rate eciency (60/80°C) Hi/Hs

%

95,0/85,5

95,6/86,1

96,8/87,2

Eciency rating (dir. 92/42/EEC)

stars

****

****

****

Sedbuk class

class

A / 90,3

A / 90,1

A / 90,1

Loss when stopped (∆T = 50°C)

%

0,2

0,1

0,1

Loss of burner gas when operating

%

2,1

2,1

2,0

EMISSIONS

Available air pressure

Pa

137

141

132

NoX class

class555Flue gas temperature (G20) (80°C-60°C)

°C636363CO2 content (G20) (80°C-60°C)

%

9,0

9,0

9,6

CO content (0%O2) (80°C-60°C)

ppm

< 100

< 100

< 125

O2 content (G20) (80°C-60°C)

%

4,5

4,5

3,5

Maximum ue gas ow (G20) (80°C-60°C)

Kg/h

41,2

49,4

59,2

Excess air (80°C-60°C)

%2727

20

HEATING CIRCUIT

Expansion chamber ination pressure

bar11

1

Maximum heating pressure

bar33

3

Expansion chamber capacity

L

6,5

6,5

6,5

Maximum water capacity with in the appliance (75°C-35°C)

L

100/300

100/300

100/300

Min/max heating temperature (high temperature range)

°C

35/82

35/82

35/82

Min/max heating temperature (low temperature range)

°C

20/45

20/45

20/45

DOMESTIC HOT WATER

CIRCUIT

Domestic hot water max/min temperature

°C

36/60

36/60

36/60

Specic ow rate of domestic hot water (∆T=30°C)

l/mn

12,0

15,0

18,2

Quantity of hot water ∆T=25°C

l/mn

14,4

18,0

21,8

Quantity of hot water ∆T=35°C

l/mn

10,3

12,9

15,6

Hot water comfort rating (EN13203)

stars

***

***

***

Hot water minimum ow rate

l/mn

< 2

< 2

< 2

Domestic hot water max/min pressure

bar

7/0,3

7/0,3

7/0,3

ELECTRICAL

Power supply frequency/voltage

V/Hz

230/50

230/50

230/50

Total electrical power absorbed

W

114

115

150

Minimum ambient temperature for use

°C+5+5

+5

Protection level for the electrical appliance

PI

X5D

X5D

X5D

Weightkg323535,5

Page 10

10

installation

Reference Standards

In the United Kingdom, the installation and initial

start-up of the boiler must be by a CORGI registered

installer in accordance with the installation standards

currently in eect, as well as with any and all local

health and safety standards i.e. CORGI.

In the Republic of Ireland the installation and initial

start-up of the appliance must be carried out by a

Competent Person in accordance with the current

edition of I.S.813 “Domestic Gas Installations” and

the current Building Regulations, reference should

also be made to the current ETCI rules for electrical

installation.

The installation of this appliance must be in

accordance with the relevant requirements of the

Local Building Regulations, the current I.E.E. Wiring

Regulations, the by-laws of the local authority, in

Scotland, in accordance with the Building Standards

(Scotland) Regulation and Health and Safety

document No. 635, “Electricity at Work Regulations

1989” and in the Republic of Ireland with the current

edition of I.S. 813 and the Local Building Regulations

(IE).

C.O.S.H.H.

Materials used in the manufacture of this appliance

are non-hazardous and no special precautions are

required when servicing.

Codes of Practive

Installation should also comply with the following

British Standards Code of Practice:

BS 7593:1992 Treatment of water in domestic

hot water central heating

systems

BS 5546:1990 Installation of hot water supplies

for domestic purposes

BS 5440-1:2000 Flues

BS 5440-2:2000 Air supply

BS 5449:1990 Forced cicrulation hot water

systems

BS 6798:2000 Installation of gas red hot

water boilers of rated input not

exceeding 70kW

BS 6891:1989 Installation of low pressure gas

pipes up to 28mm

BS 7671:2001 IEE Wiring Regulations

BS 4814:1990 Specication for expansion

vessels

BS 5482:1994 Installation of L.P.G.

and in the Republic of Ireland in accordancce with

the following codes of practice:

I.S. 813 Domestic Gas Installations

Avoid installing the boiler where the air inlet can

be polluted by checmical products such as chlorine

(swimming pool area), or ammonia (hair dresser), or

alkalin products (launderette).

Flue

Detailed information on ue assembly can be found

in the “Connecting the Flue” section.

The boiler must be installed so that the ue terminal

is exposed to the free passage of external air at all

times and must not be installed in a place likely to

cause nuisance. It must not be allowed to discharge

into another room or space such as an outhouse or

closed lean-to.

Condensing boilers have a tendency to form a plume

of water vapour from the ue terminal due to the low

temperature of the ue gasses. The terminal should

therefore be located with due regard for the damage

or discolouration that may occur to building within

the vicinity and consideration must also be given to

adjacent boundaries, openable windows should also

be taken into consideration when siting the ue.

Page 11

11

installation

NOTE: THE FLUE MUST NOT BE INSTALLED IN A PLACE LIKELY TO

CAUSE A NUISANCE AND POSITIONED TO ENSURE THAT PRODUCTS

OF COMBUSTION DO NOT DISCHARGE ACROSS A BOUNDARY

It may be necessary to protect the terminal with

a guard, if this is the case it will be necessary to

purchase a stainless steel terminal guard. Reference

should be made to the Building Regulations for

guidance.

Ventilation

The room in which the boiler is installed does not

require specic ventilation. If the boiler is installed

in a cupboard or compartment ventillation is not

required for cooling purposes.

Gas Supply

The gas installation and tightness testing must be

in accordance with the requirements of BS6891.

Ensure that the pipe size is adequate for demand

including other gas appliances on the same supply.

Electrical Supply

The appliance requires an earthed 230V - 50 Hz

supply and must be in accordance with current

I.E.E. regulations. It must also be possible to be

able to completely isolate the appliance electrically.

Connection should be via a 3 amp douple pole

fused isolating switch with contact separation of

at least 3mm on both poles. Alternatively, a fused

3 Amp, 3 pin plug and unswitched socket may be

used, provided it is not used in a room containing

a bath or shower, it. It shoild only supply the

appliance.

Water Supply

The boiler is suitable for sealed systems only. The

maximum working pressure for the appliance is

6 bar. All ttings and pipework for the appliance

should be of the same standard. If there is

a possibility of the incoming mains pressure

exceeding 6 bar, particularly at night, then a suitable

pressure limiting valve must be tted.

The boiler is designed to provide hot water on

demand to multiple outlets within the property.

If there is a requirement for greater demands, for

example if the boiler has several bathrooms and

cloakrooms, a vented or unvented hot water storage

system may be used.

Showers

Any shower valves used with the appliance should

be of a thermostatic or pressure balanced type.

Refer to the shower manufacturer for performance

guidance and suitability.

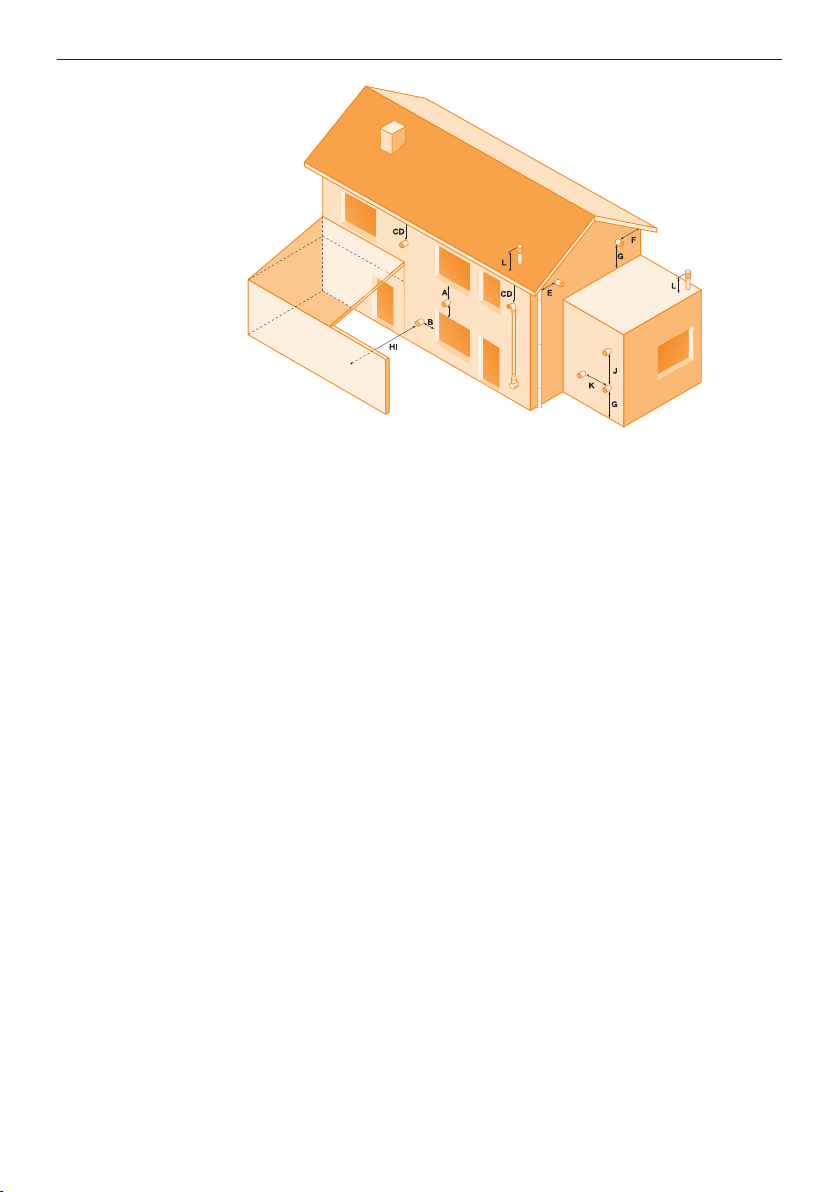

- A Directly below an opening, window, etc 300 mm

- B Horizontally to an opening, window, etc 300 mm

- C Below gutters, soils pipes or drain pipes 75 mm

- D Below eaves 200 mm

- E From vertical drain pipe or soil pipe 75 mm

- F From internal or external corner 300 mm

- G Above ground, roof or balcony level 300 mm

- H From a surface facing the terminal 2500 mm

- I From a terminal facing a terminal 2500 mm

- J Vertically from a terminal on the same wall 1500 mm

- K Horizontally from an terminal on the same wall 300 mm

- L Fixed by vertical ue terminal

The minimum acceptable clearances are shown below:

Page 12

12

installation

Flushing and Water Treatment

The boiler is equipped with a stainless steel heat

exchanger.

The detailed recommendations for water treatment

are given in BS 7593:1992 (Treatment of water in

domestic hot water central heating systems); the

following notes are givent for general guidance;

If the boiler is installed on an existing system, any

unsuitable additives must be removed.

Under no circumstances should the boiler be red

before the system has been thoroughly ushed;

the ushing procedure must be in line with BS

7593:1992.

We highly recommend the use of a ushing

detergent appropriate for the metals used in the

circuit. These include cleansers produced by Fernox

BetzDearbon, whose function is to disolve any

foreign matter that may be in the system;

In hard water areas or where large quantities of

water are in the system the treatment of water to

prevent premature scaling of the main exchanger is

necessary.

The formation of scale strongly compromises

the eciency of the thermic exchanger because

small areas of scale cause a high increase of the

temperature of the metallic walls and therefore add

to the thermal stress of the heat exchanger.

Demineralised water is more aggressive so in this

situation it is necessary to treat the water with an

appropriate corrosion inhibitor.

Any treatment of water by additives in the system

for frost protection or for corrosion inhibition has

to be absolutely suitable for all metals used in the

circuit.

The use of a corrosion inhibitor in the sysem such

as Fernox MB-1, BetzDearborn Sentinel X100 or

Fernox System Inhibitor is recommended to prevent

corrosion (sludge) damaging the boiler and system;

If anti-freeze substances are to be used in the

system, check carefully that they are compatible

with the metals used in the circuit.

MTS suggests the use of suitable anti-freeze

products such as Fernox ALPHI 11, which will

prevent rust and incrustation taking place.

Preiodically check the pH balance of the water/antifreeze mixture of the boiler circuit and replace it

when the amount measured is out of the range

stipulated by the manufacturer (7 < pH < 8).

DO NOT MIX DIFFERENT TYPES OF ANTI-FREEZE

In under-oor systems, the use of plastic pipes

without protection against penetration of oxygen

through the walls can cause corrosion of the

systems metal parts (metal piping, boiler etc),

through the formation of oxides and bacterial

agents.

To prevent this problem it is necessary to use pipes

with an “oxygen proof barrier”, in accordance with

standards DIN 4726/4729. If pipes of this kind are

not used, keep the system separate by installing

heat exchangers of those with a specic system

water treatment.

IMPORTANT

Failire to carry out the water treatment procedure

will invalidate the appliance guarantee.

System Controls

The boiler is electrically controlled and is suitable

for most modern electronic time and temperature

controls. The addition of such external controls

can be benecial to the ecient operation of the

system. The boiler connections for external contols

are 12V DC and so only controls of 12V DC that have

voltage free contacts should be used. (page 26).

MTS supply a range of wired and wireless system

controls. Contact your supplier for more details.

Location

The boiler can be installed on any suitable internal

wall (suitable sound proong may be required when

installing onto a stud partition wall). Provision

must be made to allow for the correct routing of

the ue and siting of the terminal to allow the

safe and ecient removal of the ue products. A

compartment or cupbaord may be used provided

that it has been built or modied for this purpose. It

is not necessary to provide permanent ventillation

for cooling purposes. Detailed recommendations

are given in BS 5440 Part 2. If it is proposed that it

is to be installed in a timber framed building then

reference should be made to British Gas Document

DM2, IGE/UP/7 or advice sought from CORGI.

Where a room sealed appliance is installed in a

room containing a bath or shower, the appliance

and any electrical switch or appliance control,

utilising mains electricity should be situated

specically in accordance with current IEE Wiring

Regulations.

For unusual locations, special procedures may be

necessary. BS 6798:2000 gives detailed guidance

on this aspect.

Page 13

13

installation

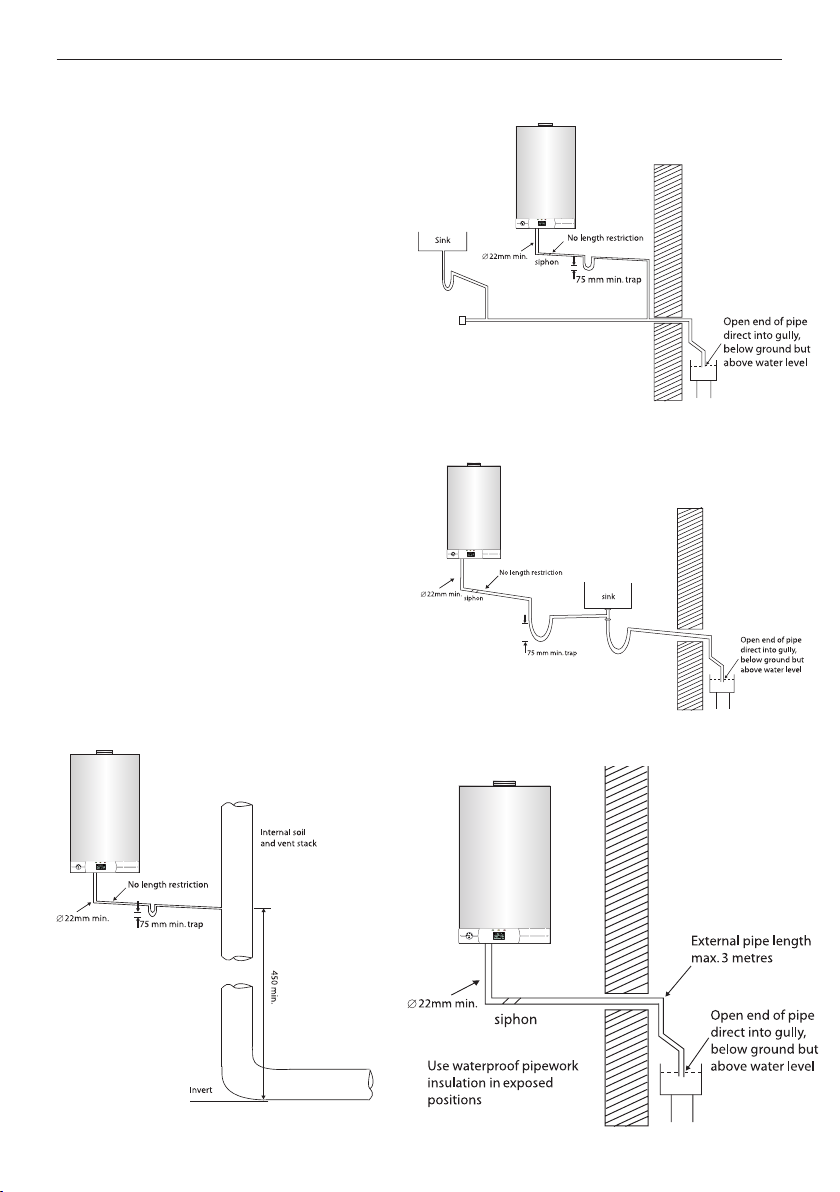

Condensate Discharge

The condensate discharge hose from the boiler

must have a continuous fall of 2.5o and must be

inserted by at least 50mm into a suitable acid

resistant pipe - e.g. plastic waste or overow

pipe. The condensate discharge pipe must have

a minimum diameter of 22mm, must have a

continuous fall and preferably be installed and

terminated to prevent freezing.

The discharge pipe must be terminated in a suitable

position:

i) Connecting into an internal soil stack (at least

450mm above the invert of the stack). A trap giving

a water seal of at least 75mm must be incorporated

into the pipe run, there also must be an air beak

upstream of the trap.

ii) Connecting into the waste system of the

building such as a washing maching or sink trap.

The connection must be upstream of the washing

machine/sink. If the connection is down stream of

if the waste trap then an additional trap giving a

minimum water seal of 75mm and an air break must

be incorporated in the pipe run, as above.

iii) Terminating into a gully, below the grid level

but above the water level

iv) Into a soakaway

Note: If any condensate pipework is to be installed

externally then it should be kept to a minimum and

be insulated with a waterproof insulation and have

a continuous fall. The total length of external pipe

used should not exceed 3 metres.

Some examples of the type of condensate

terminations can be found below.

1. Internal termination of codensate drainage pipe

to internal stack.

2. External terminaton of condensate drainage pipe

via internal discharge branch (e.g. sink waste) and

condensate siphon.

3. External termination of condensate drainage

pipe via internal discharge branch (e.g. sink waste

- proprietary tting).

4. External termination of condensate drainage pipe

via condensate siphon

Page 14

14

installation

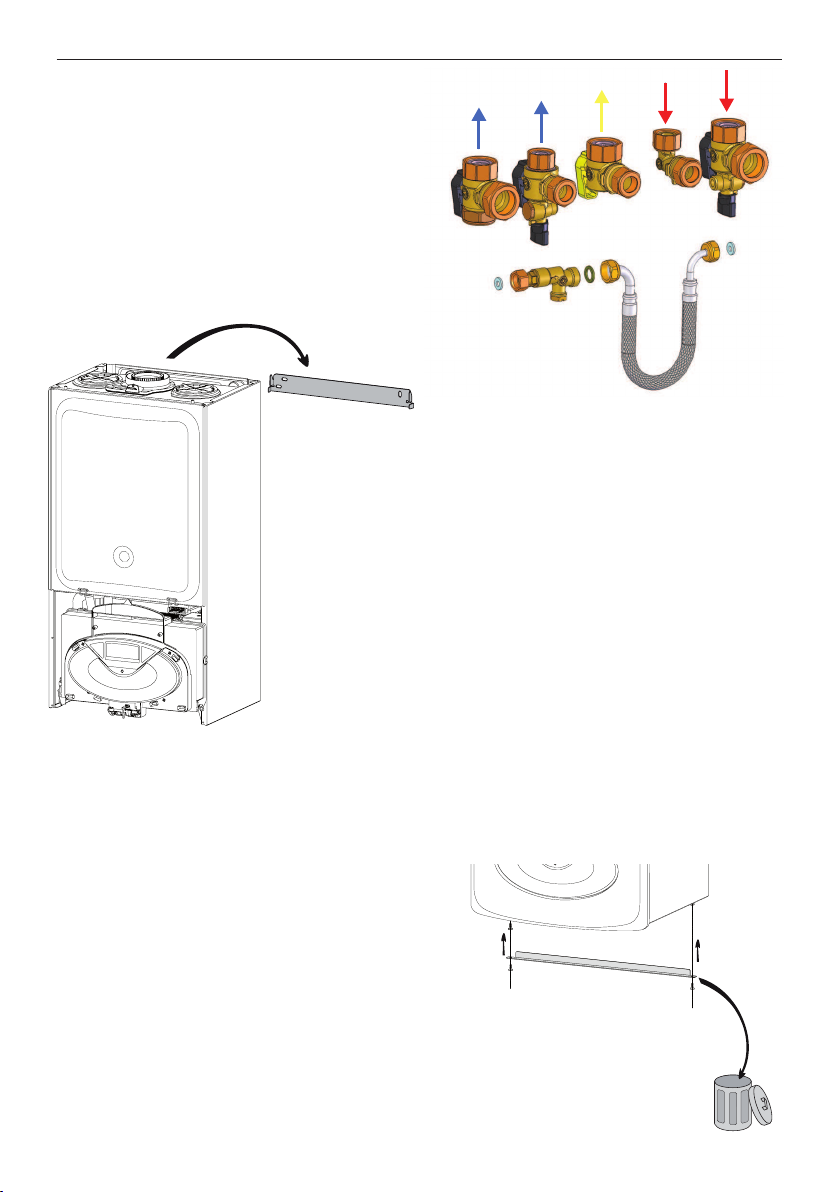

Installing the Boiler

Please check that you are familiar with the

installation requirement before commencing work

(pages 7 - 13).

The installation accessories described in the

following list are included in the boiler packaging:

- Hanging bracket

- A paper template (showing the dimensions of

the boiler with 5 mm side clearances)

- Connection valves (Compression)

- Screws and washers

- Filling loop

- Installation, Servicing and Operating Instructions

- Flue gasket

Method of positioning the boiler on the wall

The paper template can be used to ensure the

correct positioning of kitchen cabinets etc.

The paper template has to be xed to the wall and

used to locate the position of the hanging bracket

and the centre for the ue hole.

Drill and plug the wall and secure the hanging

bracket using the screws provided. Remove the

boiler from it’s packaging and remove the front

casing panel.

Place the boiler on the hanging bracket.

N

OTE: THE APPLIANCE MUST NOT BE FITTED ON A COMBUSTIBLE

WALL SURFACE.

Connecting the Boiler to the System

- Remove the boiler casing as described on page 15

- Remove the caps and connect the valves to the

boiler using the washers provided;

- 4 x bre washers for the CH ow and return, cold

water inlet and hot water outlet connections;

Safety Valve Discharge and Condense Outlet

The pressure relief valve tube is made of copper. It

should terminate below the boiler safely outside

the premises. Care should be taken that it does

not terminate over an entrance or window or

where a discharge of heated water could endanger

occupants or passers by.

Fill the central heating and DHW system and

bleed air from the system as described in the

Commissioning instructions (page 26).

The system should be carefully checked for

leaks, as frequent relling could cause premature

system corrosion or unnecessary scaling of the

heat exchanger. The pipe from the trap should be

connected to a drain as described in the relevant

regulations.

Pay special attention not to bend the condensate

silicone drain pipe is such a way as to interrupt the

ow. Please only use drain pipe material compatible

with condensate products (refer to BS 6798:2000).

The condensate ow can reach 2 litres/hour because

of the acidity of the condensate products (Ph close

to 2), take care before operation.

See page 13 for condensate discharge possibiities.

Note: Connections viewed from behind boiler

A

A

- remove the 2 screws A from

the transport bar

- dispose of the transport bar

and reassemble the xing

screws.

Page 15

15

installation

Gas connection

Make sure, using the labels on the packaging and the

data plate on the appliance itself, that the boiler is

in the correct country and that the gas category for

which the boiler was designed corresponds to one of

the categories available in the country where it will

be used.

The gas supply piping must be created and measured

out in compliance with specic legal requirements

and in accordance with the maximum power of the

boiler; you should also make sure that the shuto valve is the right size and that it is connected

correctly.

Check that the supplied gas corresponds to the type

of gas for which the boiler was designed (see the

data plate located on the appliance itself).

It is also important to check that the pressure of

the gas (methane or LPG) you will be using to feed

the boiler is suitable, because if it is insucient the

power may be reduced, causing inconvenience for

the user.

Water connection

The illustration shows the connections for the

water and gas attachments of the boiler. See valves

conguration on page 14.

Check that the maximum water mains pressure does

not exceed 6 bar; if it does, a pressure reducing valve

must be installed.

For the measuring of the pipes and of the heating

bodies in the heating system, the residual head value

should be calculated as a function of the requested

ow rate, in accordance with the values shown in the

circulation pump graph.

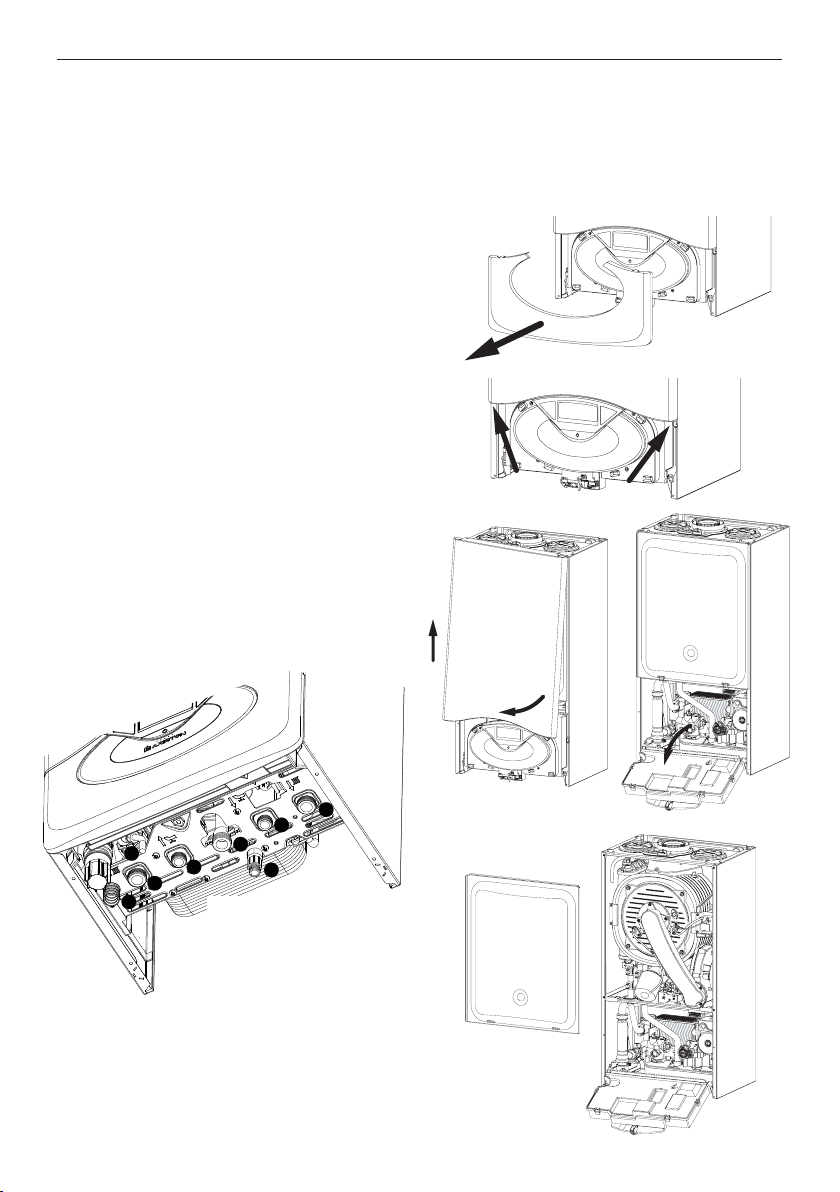

Instructions for opening the casing and performing

an internal inspection

Before performing any work on the boiler, rst

disconnect it from the electrical power supply using the

external bipolar switch removing the fuse and shutting

o the gas valve.

To access the inside of the boiler, the following is

necessary:

1.

Remove the casing by unhooking it from the control

panel (a)

2. Loosen the two screws on the front casing (b), pull it

forwards and unhook it from the upper pins (c)

3. Lower the control panel (d)

4. Unhook the two clips on the combustion chamber

panel and lift o (e).

A

B

C

D

E

I

H

F

A. Central heating Flow

B. Domestic Hot Water Outlet

C. Gas Inlet

D.

Domestic Cold Water Inlet

E. Central Heating Return

F. Safety Valve Discharge

H. Drain Valve

I. Drain condensate

(b)

(d)

(a)

(e)

(c)

Page 16

16

installation

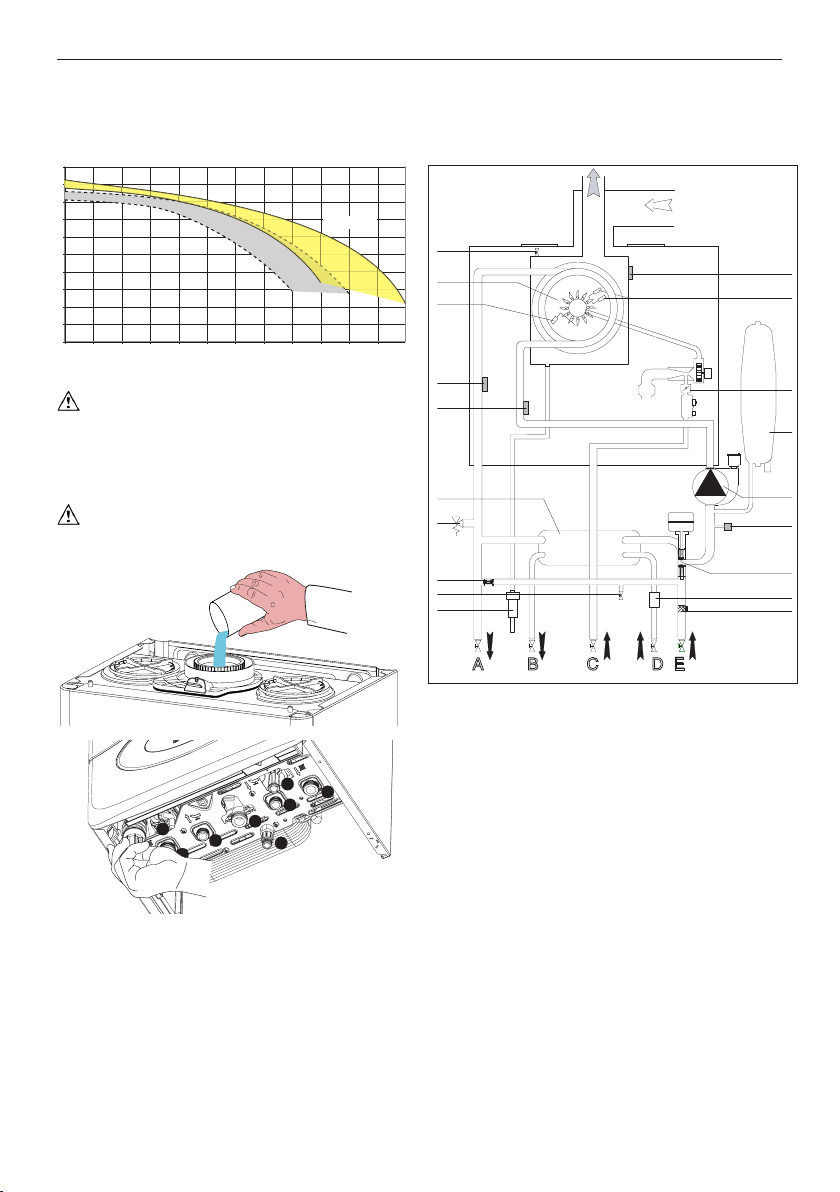

To calculate the size of the heating installation, refer

to the "Available pressure" graph below.

Graph representing the available circulation pump

pressure T20oC

Before the rst time the equipment is used,

the trap must be lled with water. To do this,

add approximately 1/4 litre of water via the

ue outlet before tting the ue system, or

unscrew the cap on the trap positioned underneath the boiler, ll it with water and ret it

Warning! insucient water in the trap can

temporarily cause the ue gas to be expelled

into the surrounding ambient air

Underoor heating

For appliances with underoor heating, t a safety

thermostat onto the underoor heating outlet. For

the electrical connection of the thermostat see the

section on “Electrical connections - page 26”.

If the outlet temperature is too high, the boiler will

stop both domestic hot water and the heating pro-

duction and the error code 116 “oor thermostat

contact open” will appear on the display. The boiler

will restart when the thermostat is closed during

automatic resetting.

If the thermostat cannot be installed, the underoor

heating equipment must be protected by a thermostatic valve, or by a by-pass to prevent the oor from

reaching too high a temperature.

Water circuit diagram

A

B

C

D

E

I

G

H

F

1

4

3

11

8

10

12

14

15

16

17

18

19

20

21

22

7

6

5

A B C D E

1. Manual air vent

3.

Burner

4.

Detection electrode

5.

C.H. ow temperature probe

6.

C.H. return temperature probe

7.

Secondary heat exchanger

8. C.H. pressure relief valve

10. By-pass

11.

Drain valve

12. Condensate trap

14.

C.H. circuit lter

15.

D.H.W. Flow switch

16.

diverter valve

17.

water pressure sensor

18.

circulation Pump

19. expansion vessel

20.

modulating Fan

21.

ignition electrodes

22. thermal fuse

0

50

100

150

200

250

300

350

400

450

500

0 100 200 300 400 500 600 700 800 900 1000 1100 1200

mbar

l/h

24 kW

30-35 kW

30-38 kW

Page 17

17

installation

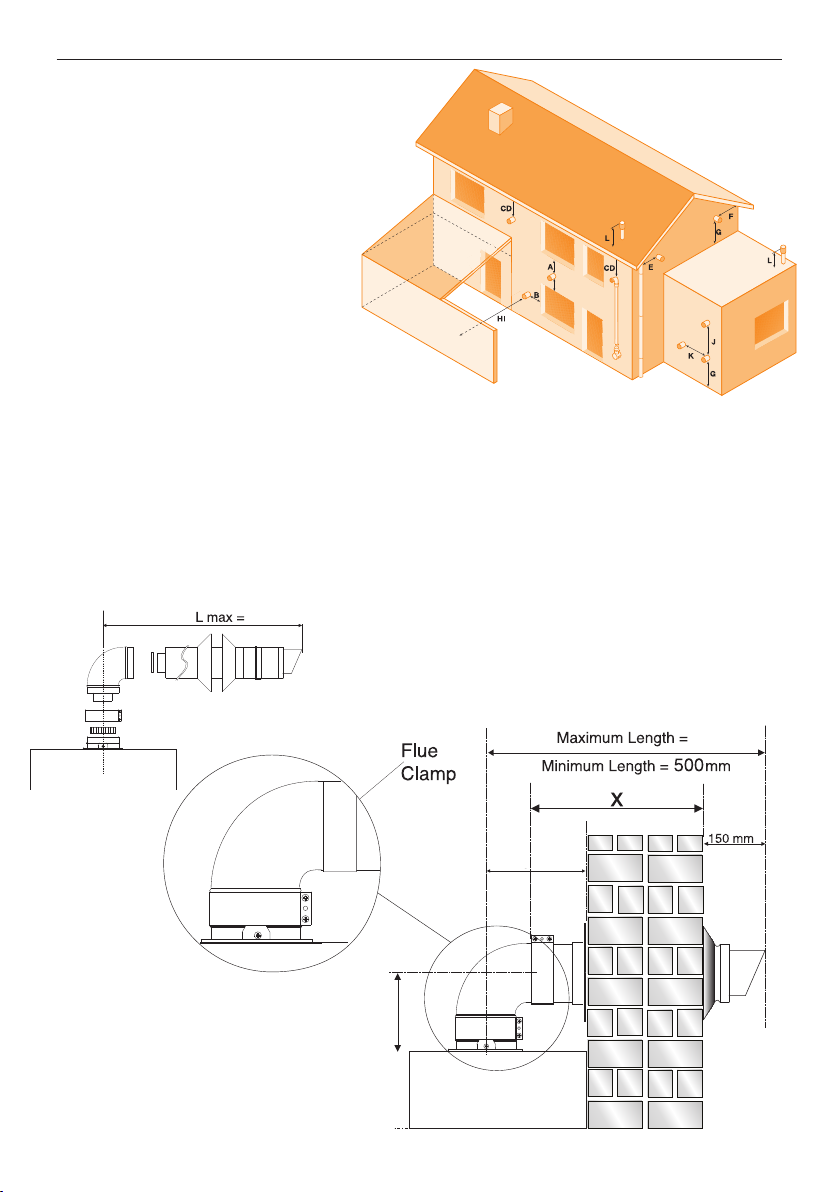

Connecting the Flue

Flue System

The provision for satisfactory ue termination must be made as described in BS

5440-1.

The appliance must be installed so that the

ue terminal is exposed to outdoor air.

The terminal must not discharge into

another room or space such as an outhouse

or lean-to.

It is important that the position of the

terminal allows a free passage of air across it

at all times.

The terminal should be located with due

regard for the damage or discolouration that

might occur on buildings in the vicinity, it

must also be located in a place not likely to

cause nuisance.

In cold or humid weather water vapour may

condense on leaving the ue terminal.

The eect of such “steaming” must be considered.

If the terminal is less than 2 metres above a

balcony, above ground or above a at roof to

which people have access, then a suitable stainless steel terminal guard must be tted.

The minimum acceptable spacing from the terminal to obstructions and ventilation openings

are specied in Fig. 1.

Fig. 1

- A Directly below an opening, window, etc 300 mm

- B Horizontally to an opening, window, etc 300 mm

- C Below gutters, soils pipes or drain pipes 75 mm

- D Below eaves 200 mm

- E From vertical drain pipe or soil pipe 75 mm

- F From internal or external corner 300 mm

- G Above ground, roof or balcony level 300 mm

- H From a surface facing the terminal 2500 mm

- I From a terminal facing a terminal 2500 mm

- J Vertically from a terminal on the same wall 1500 mm

- K Horizontally from an terminal on the same wall 300 mm

- L Fixed by vertical ue terminal

118 mm

See table

118 mm

4

See table on page 23

180

Fig. 2

Page 18

18

installation

Warning

The exhaust gas ducts must not be in contact with or close to inammable material and must not pass through building structures or walls made of inammable material.

When replacing an old appliance, the ue system must be changed.

Important

Ensure that the ue is not blocked.

Ensure that the ue is supported and assembled in accordance with these instructions.

150 mm

118

* pente 5 mm par mètre

150 mm

* pente

Installation without extension

Installation with extension

slope 5 mm per metre

Level

Level

slope

Fig. 3

Fitting the Coaxial Flue

(Ø 60 / 100 Horizontal)

Contents:

1x Silicone O-Ring (60mm)

1x Elbow (90°)

2x Wall Seals (Internal & External)

1x Flue Pipe including Terminal (1 metre - 60/100)

2x Flue Clamps

4x Screws

2x Seals

Once the boiler has been positioned on the wall, t

the rubber ue seal into the internal ue turret (see

diagram opposite),

insert the elbow into the socket and rotate to the

required position. note: It is possible to rotate the

elbow 360° on its vertical axis.

Using the ue clamp, seals and screws supplied (Fig

4) secure the elbow to the boiler.

The 1 metre horizontal ue kit (3318073) supplied is

suitable for an exact X dimension of 753mm.

Measure the distance from the face of the external

wall to the face of the ue elbow (X - Fig 2), this

gure must now be subtracted from 753mm, you

now have the total amount to be cut from the plain

end of the ue.

Draw a circle around the outer ue and cut the ue

to the required length taking care not to cut the

inner ue, next cut the inner ue ensuring that the

length between the inner and outer ue is maintained. (Fig 4).

e.g.

X = 555mm

753-555 = 198mm (Length to be cut from the

plain end of the ue).

Once cut to the required length, ensure that the ue

is free from burrs and reassemble the ue. If tting

the ue from inside of the building attach the grey

outer wall seal to the ue terminal and push the

ue through the hole, once the wall seal has passed

through the hole, pull the ue back until the seal

is ush with the wall. Alternatively, the ue can be

installed from outside of the building, the grey outer

seal being tted last.

Should the ue require extending, the ue connections are push t, however, one ue bracket should

be used to secure each metre of ue.

Note: See table for maximum and minimum ue

runs.

Page 19

19

installation

Clamp

Seal

Screws

Once the boiler has been positioned on the wall, it is necessary to insert the Ø80/125 adaptor (Fig. 5) for both

horizontal and vertical ue runs into the boiler ue socket (not supplied with ue kit - Part No 3318095).

Push the adaptor onto the boilers ue connection,

grease the seals then add extensions or elbows as required, secure the adaptor, using the clamp and screws

provided.

To t extensions or elbows it is rst necessary to ensure that the lip seal is tted correctly into the inner

ue, once veried, it is simply necessary to push them

together, no clamps are necessary to secure the ue

components.

Before proceeding to t the ue, ensure that the maximum ue length has not been exceeded (See the

tables) and that all elbows and bends have been taken

into consideration, the maximum ue length is 10 metres, for each additional 90° elbow 1 metre must be subtracted from the total ue length, and for each 45° 0.5

metres must be subtracted from the total ue length

(the height of the vertical adaptor and a 45° bend can

be seen in Fig.6 and a 90° bend in Fig. 7).

Note: DO NOT cut the vertical ue kit.

180 mm

Fig. 4

Fig. 5

Fig. 6

Fig. 7

Fitting the 5” Flue (Ø 80 / 125 Horizontal/vertical)

Page 20

20

installation

Fitting the Coaxial Flue (Ø 60 / 100 Vertical)

Note: See table for maximum and minimum ue

runs.

Contents:

1x Silicone O-Ring (60mm)

1x Conical Adaptor (60/100mm)

1x Vertical Flue Kit (80/125mm)

3x Screws

The vertical ue kit is supplied with a specially designed weather proof terminal tted, it can be used

either with a at roof or a pitched roof.

The Vertical ue kits useable lengths with the

pitched roof ashings are indicated in Fig. 7.

Before proceeding to t the ue, ensure that the

maximum ue length has not been exceeded (See

the tables) and that all elbows and bends have been

taken into consideration, the maximum ue length

is see table, for each additional 90° elbow 1 metre

must be subtracted from the total ue length, and

for each 45° 0.5 metres must be subtracted from the

total ue length (the height of the vertical adaptor

and a 45° bend can be seen in Fig. 8).

Mark the position of the ue hole in the ceiling

and/or roof (see Fig. 7 for distance from wall to the

centre of the ue).

Cut a 130mm diameter hole through the ceiling

and/or roof and t the ashing plate to the roof.

DO NOT cut the vertical ue kit.

To connect the vertical ue kit directly to the boiler,

place the vertical starter kit (Part No. 3318079) (see

Fig. 7) onto the exhaust manifold and secure with

the clamp, t the vertical adaptor onto the vertical

starter kit (note: there is no need to use a clamp to

secure this as it is a push t connection), the vertical

ue kit must then be inserted through the roof

ashing, this will ensure that the correct clearance

above the roof is provided as the terminal is a xed

height.

Should extensions be required, they are available in 1 metre (Part No. 3318077), 500mm (Part

No. 3318078) and 160mm lengths, they must be

connected directly to the vertical starter kit before

connecting the adaptor to allow the vertical ue kit

to be tted. In the event that extension pieces need

to be shortened, they must only be cut at the male

end and it must be ensured that the inner and outer

ue remain ush.

When utilising the vertical ue system, action

must be taken to ensure that the ue is supported

adequately to prevent the weight being transferred

to the appliance ue connection by using 1 ue

bracket per extension.

When the ue passes through a ceiling or wooden

oor, there must be an air gap of 25mm between

any part of the ue system and any combustible

material. The use of a ceiling plate will facilitate this.

Also when the ue passes from one room to another

a re stop must be tted to prevent the passage of

smoke or re, irrespective of the structural material

through which the ue passes.

180 mm

Fig. 7

Fig. 8

Page 21

21

installation

Fitting the Twin Pipe (Ø80 / 80)

Note: See table for maximum and minimum ue

runs.

Where it is not possible to terminate the ue within

the distance permitted for coaxial ues, the twin

ue pipe can be used by tting a special adaptor to

the ue connector and using the aperture for the air

intake located on top of the combustion chamber.

Always ensure that the ue is adequately supported,

using one ue bracket per extension and avoiding

low points. (MTS supply suitable clamps as Part No.

705778).

To utilise the air intake it is necessary to:

1) Take the air intake cover o the top of the appliance

2) Assemble the ange on the header supplied with

the boiler

3) Insert the header on the tube or the elbow up

until the lower stop (you do not have to use the

washer).

4) Insert the elbow/header in the boiler air intake

hole and fasten it with screws.

The twin ue pipes can be tted with or without additional elbows and need no clamps, simply ensure

that the red o-ring is inserted in the female end of

the ue pipe and push the extension piece fully into

the previous section of ue pipe or elbow, check

that the o-ring is not dislodged when assembling

the ue (greasing the seal will aid assembly).

Twin pipe can also be converted back to Coaxial ue

to enable vertical termination with a coaxial kit by

using the pipe bridge (Twin - Coaxial Adaptor - Part

No. 3318089). When running the twin ue pipe

vertically.

It is not possible to terminate concentrically horizontally. Termination is only possible with separate

air and exhaust terminals.

When siting the twin ue pipe, the air intake and

exhaust terminals must terminate on the same wall,

the centres of the terminals must be a minimum of

280 mm apart and the air intake must not be sited

above the exhaust terminal (refer to Fig. 10). The

air intake pipe can be run horizontally, however,

the terminal and the nal 1 metre of ue must be

installed either horizontally or with a slight fall away

from the boiler to avoid rain ingress.

It is also strongly recommended that the air intake

pipe run be constructed of insulated pipe to prevent

condense forming on the outside of the tube.

The maximum permissible ue length for twin ue

is dependent on the type of run used (see table on

page 23).

For further information relating to ue runs not

illustrated, please contact the Technical Department

on 0870 241 8180.

Page 22

22

installation

For coaxial systems, the maximum development

value, mentioned in the table below also takes into

account an elbow.

For twin ue systems the maximum development

value, mentioned in the table includes the exhaust

gas/air intake terminal.

Type 5 outlets should respect the following instructions:

1- Use the same ø 80 mm ue pipes for the air

intakes and exhaust gas ducts.

2- If you need to insert elbows in the air intake and

exhaust gas ducts, you should consider for each

one the equivalent length to be included in the

calculation of developed length.

3- The exhaust gas duct should jut above the roof by

at least 0.5 m.

4- The intake and exhaust gas ducts in Type C13 +

C53 must be installed on the same wall, or where

the exhaust is vertical and the air intake horizontal, the terminals must be on the same side of the

building.

EXHAUS T

AIR IN TAKE

AIR IN TAKE

AIR IN TAKE MUS T NO T BE

FITTED ABOVE THE EXHAUS T

195

105

120

180

Fig. 9

Fig. 10

Page 23

23

installation

Table of ue gas exhaust duct lengths

COAXIAL SYSTEM

FLUE TYPE

MAX

LENGTH

DIAMETER of

PIPE

C13

Flue gas exhaust and air suction

duct through external wall in the

same range of pressure

24

12 m

36 m

60/100

80/125

30

10 m

30 m

60/100

80/125

38

6 m

18 m

60/100

80/125

C 33

Flue gas exhaust and air suction

duct from outside with roof

terminal in the same range of

pressure

24

12 m

42 m

60/100

80/125

30

10 m

35 m

60/100

80/125

38

8 m

21 m

60/100

80/125

C43

Individual or shared ue gas

exhaust and air suction through

ue ducting built into the building

24

12 m

0 m

60/100

80/125

30

10 m

0 m

60/100

80/125

38

8 m

0 m

60/100

80/125

Page 24

24

installation

TWIN-PIPE SYSTEM

FLUE TYPE

MAX

LENGTH

DIAMETER of

PIPE

C13

Flue gas exhaust and air suction

duct through external wall in the

same range of pressure

24

36 m

(S1=S2)

80/80

30

30 m

(S1=S2)

38

18 m

(S1=S2)

C 33

Flue gas exhaust andair suction

duct from outsidewithroof

terminalin the same range of

pressure

24

60 m

(S1=S2)

80/80

30

50 m

(S1=S2)

38

21 m

(S1=S2)

C53

Flue gas exhaust leading outside

and air suction duct through

external wall not in the same range

of pressure

24

84 m

(S1+S2)

80/80

30

70 m

(S1+S2)

38

42 m

(S1+S2)

S1 = Air intake S2 = Flue gas exhaust

S1 = S2 - Air intake and ue gas exhaust equal lengths

S1 + S2 - Air intake and ue gas exhaust unequal lengths

Page 25

25

installation

WARNING

Before performing any work on the boiler,

rst disconnect it from the electrical power

supply using the external bipolar switch and

remove the fuse.

Electrical connections

For increased safety, ask a qualied technician to

perform a thorough check of the electrical system.

The manufacturer is not responsible for any damage

caused by the lack of a suitable earthing system or by

the malfunctioning of the electricity mains supply.

Make sure that the system is able to withstand the

maximum power absorbed by the boiler (this is

indicated on the appliance data plate). Check that

the section of the wires is suitable and is not less 0,75

mm2

The appliance must be connected to an eecient

earthing system if it is to operate correctly.

The power supply cable must be connected to a

230V-50Hz network, where the L-N poles and the

earth connection are all respected.

Important!

In the event that the power supply cable must

be changed, replace it with one with the same

specications.

Power supply cable

Important!

The appliance is supplied with a y-lead

already connected, this must be connected

to a 240V supply fused at 3 Amp and must

facilitate completed electrical isolation of

the appliance, by use od a fused double

pole isolator having a contact separation

of at least 3mm in all poles or alternatively

by means of a 3A fused three pin plug and

unswitched shuttered socket outlet both

complying with BS1363.

The use of multiplugs, extension leads or adaptors is

strictly prohibited.

It is strictly forbidden to use the piping from the

hydraulic, heating and gas systems for the appliance

earthing connection.

The boiler is not protected against the eects caused by

lightning. If the mains fuses need to be replaced, use 2A

rapid fuses.

Peripheral unit connection

To access peripheral unit connections carry out the

following steps:

- Disconnect the boiler from the power supply

- Remove the casing by unhooking it from the

instrument panel

- Rotate the control panel while pulling it forwards

- Unscrew the three screws on the back cover of

the instrument panel

- Unhook the right side clip and the right front clip;

then lift the ap

The terminal board (see gure) may be accessed in order

to connect:

Outdoor sensor

Room thermostat 1

Optional P.C.B.s can also be installed for further

accessories:

BUS P.C.B. Clima Manager

Modulating Room Sensor

Programmable Room Thermostat

Outdoor Sensor

- other plugs: for managing multi-zones

multitemperatures, Solar kit,

etc...

Caution!

For the connection and positioning of the

wires belonging to optional peripheral

units, please refer to the installation manuals of these units.

H05V2V2-F

120

140

Page 26

26

installation

Room Thermostat / Remote Clock Connection

To connect a room thermostat, it is necessary to:

1. Open the control panel

2. Loosen the cable clamp using a screwdriver

and insert the wires leading from the room

thermostat

3. Connect the wires to the terminals as indicated in

the gure below, removing the link

4. If a remote time clock is to be tted, using a volt

free switching time clock connect the switching

wires from the time clock following points 1 - 3

above

5. If using an external time clock and room

thermostat, these must be connected in series as

shown in diagram C,

6. Ensure that they are well connected and not

subject to stress when the control panel is closed

NOTE: WHEN CONNECTING THE BOILER TO EXTERNAL CONTROLS,

DO NOT RUN 240V CABLES AND CABLES FOR SWITCHING

CIRCUITS (WHICH ARE LOW VOLTAGE) TOGETHER, USE SEPERATE

CABLES TO PREVENT INDUCED VOLTAGE ON THE LOW VOLTAGE

CIRCUITS.

CARTE CHAUDIERE

ACO-GAL1

Transmetteur BUS

(Optionnel)

Emplacement

carte optionnelle

SE

TA

TP/

Connector TA on PCB

(low voltage switching)

Connector TA on PCB

(low voltage switching)

Connector TA on PCB

(low voltage switching)

Page 27

27

installation

Electrical diagram

For increased safety, ask a qualied technician to perform a thorough check of the electrical system.

The manufacturer is not responsible for any damage caused by the lack of a suitable earthing system or by the

malfunctioning of the electricity mains supply.

8

1

Connessione

sonda solare

5

1

ON

Display

Display

1 8

Flussimetro

sanitario

Elettrodo

Rilevazione

Ventilatore

AccenditoreValvola gas

Valvola dev.

motorizzata

L N

FAN

VALVOLA

GAS

ACCENDITORE

EARTH

FLAME

FLOW

PUMP

ZONE1

FILLING

PUMP

SPEED

1

1

FUSE 2AT

1 2 3 4 1 2 3 45 6

Circolatore

6

1

1

234

Termostato

Ambiente

Sonda NTC

mandata risc.

CN04

CN04

CN07

CN22

CN22

Pressostato

di minima

Sonda NTC

ritorno risc.

Term. protezione

scambiatore

P

13 12 11 10 9 8 7 6 5 4 3 2 1

12 11 10 9 8 7 6 5 4 3 2 1

11 10 9 8 7 6 5 4 3 2 1

11 10 9 8 7 6 5 4 3 2 1

2

1

8 7 6 5 4 3 2 1

Termostato

sovratemperatura

ignitor

detection

electrode

gas

valve

display

room

thermostat

circulation

pump

diverter valve

C.H. ow temp.

probe

thermal fuse

modulating fan

C.H. return temp.

probe

D.H.W ow

switch

Switch on/o

Page 28

28

commissioning

Initial preparation

MT S (G B) L imi ted sup por t the ben chm ark

initiative. On pages pages 65 and 66 of this

manual the Benchmark Commissioning Checklist

and Service interval Record can be found. It is

important that this is completed in the presence

of your customer, they are shown how to use it,

and it is signed by them. Please instruct your

customer that they must have this manual with

them whenever they contact a service engineer

or us.

Preliminary electrical system checks to ensure

elec trical sa fety m ust be car ried o ut b y a

competent person i.e. polarity, earth continuity,

resistance to earth and short circuit.

Electricity supply

- Check that the voltage and frequency of the

electricity supply correspond to the data shown

on the boiler data plate;

- Make sure that the earthing connection is

ecient.

Filling the Heating System:

Switch the electrical supply to the boiler on in

order to view the system pressure on the display;

Remove the front casing panel and lower the

control panel as described on page 13).

Open the central heating flow and return cocks

supplied with the connection kit;

Lift the cap on the automatic air release valve

and leave open permanently;

Close all air release valves on the central heating

system;

Gradually open the valves at the filling point

(filling loop) until water is heard to flow, do not

open fully;

Open ea ch air rele ase tap startin g with the

lowest point and close them only when clear

water free of air is visible;

Purge the air from the pump by unscrewing the

pump plug anti-clockwise, also manually rotate

the pump shaft in the direction indicated by the

pump label to ensure the pump is free;

Refit the pump plug;

Continue filling the system until at least 1.5 bar

registers on the pressure gauge;

Inspect the system for water tightn ess and

remedy any leaks discovered.

IMPORTANT!

MANUALLY VENT THE HEAT EXCHANGER AT THE MANUAL AIR

VENT. FAILURE TO VE NT ADEQ UATELY MAY DAMAGE THE

HEAT EXCHANGER (PAGE 7, LEGEND 2).

Filling of the DHW System:

Close all hot water draw off taps;

Open the cold water inlet cock supplied with the

connection kit;

Slowly open each draw off tap and close them

only when clear water, free of bubbles, is visible.

Gas Supply:

Inspect the entire installation inc ludin g the

gas meter and test for tightness. The entire

installation should be in accordance with the

relevant standards. In GB this is BS 6891 and in

IE this is the current edition of I.S.813.

The connection on the the appliance is a 15mm

nut and olive located at the rear of the gas

service cock.

If the gas supply serves other appliances, ensure

that an adequate supply is available both to the

boiler and the other appliances when they are in

use at the same time.

Pipe work must be of an adequate size. Pipes

of less than 22mm should not be used, final

connection being 15mm.

Open the gas cock (supplied with the connection

kit ) to the app lia nce and che ck the gas

connection on the appliance for leaks.

Water Treatment:

The boiler is equipped with a stainless steel heat

exchanger.

Th e d eta ile d r ecomm end ati ons fo r w ate r

treatment are given in BS 7593:1992 (Treatment

of water in domestic hot water central heating

syste ms); the followi ng notes are gi ven fo r

general guidance;

If the boiler is installed on an existing system, any

unsuitable additives must be removed;

Under no circumstances should the boiler be

fired before the system has been thoroughly

flushed; the flushing procedure must be in line

with BS7593:1992.

Fir stly fil l th e central heat in g system with

the power off, and flush through cold, fill the

central heating system again, adding a flushing

detergent, run the boi ler on central heating

until it reaches its operating temperature and

flush the system, refill the system with a suitable

corrosion inhibitor,

NOTE: FAILURE TO CARRY OUT THE FLUSHING PROCEDURE WILL

RESULT IN THE WARRANTY BECOMING VOID.

Page 29

29

commissioning

FIRST IGNITION OPERATION

1. Check the electrical supply.

Complete . . . . . . . . . . . . . . . . . . .

Date . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installer . . . . . . . . . . . . . . . . . . . . . . . . . .

2. Check the type of gas and

change the gas if necessary.

Complete . . . . . . . . . . . . . . . . . . .

3. Check the gas tightness.

Complete . . . . . . . . . . . . . . . . . . .

4. Measure the gas inlet.

Complete . . . . . . . . . . . . . . . . . . .

5. Check the exhaust fume.

See section….

Complete . . . . . . . . . . . . . . . . . . .

6. Fill the installation. See

section….

Complete . . . . . . . . . . . . . . . . . . .

7. Check the hydraulic water

tightness.

Complete . . . . . . . . . . . . . . . . . . .

8. Spin the pump.

Complete . . . . . . . . . . . . . . . . . . .

9. Set the heating power. See

section….

Complete . . . . . . . . . . . . . . . . . . .

10. Adapt the regulation at

the heating installation.

Complete . . . . . . . . . . . . . . . . . . .

11. Balance the central

heating circuit.

Complete . . . . . . . . . . . . . . . . . . .

12. Check the working in DHW

mode.

Complete . . . . . . . . . . . . . . . . . . .

13. Adjust DHW ow rate on

the boiler (if necessary).

Complete . . . . . . . . . . . . . . . . . . .

14. Make a combustion rate

with once pressing on

RESET button during 5 sec.

Complete . . . . . . . . . . . . . . . . . . .

15. Check the ionisation

current.

Complete . . . . . . . . . . . . . . . . . . .

6. Explain to the end user the

working of the boiler.

Complete . . . . . . . . . . . . . . . . . . .

Page 30

30

commissioning

Ignition procedure

Press the ON/OFF button on the control panel to

switch on the boiler.

Electricity supply

- Check that the voltage and frequency of the

electricity supply correspond to the data shown

on the boiler data plate;

- Make sure that the earthing connection is

ecient.

First ignition

1. Make sure that:

- The gas valve is closed;

- The electrical connection has been properly

carried out. Make sure that, in any case, the

green/yellow earthing wire is connected to an

ecient earthing system;

- Use a screwdriver to lift the cap on the automatic

air relief valve;

- Switch on the boiler (by pressing the ON/OFF

button), the green led 3 will illuminate indicating

that the boiler is ready to operate. Turn the CH

buttton 5 between min. and max position. The

pump will start and the burner will atemp to light,

after 7 seconds the boiler will look out because

there is no gas; the red Led 8 illuminates.

- Bleed the air from the radiators;

- The exhaust duct for combustion products should

be suitable and free from any obstructions;

- Any necessary ventilation inlets in the room

should be open (type B installation).

2. Open the gas cock and check the connection

seals, including the boiler connection joints,

making sure that the meter does not detect any

passage of gas. Eliminate any leaks.

3. Unlock the boiler by pushing on thr reset button.

The burner light, if the rst start fail, repend the

operation until the burner light.

90°40°

50°

60° 70°

80°

on/o

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

9

6

12

I

Page 31

31

commissioning

SETTING

Maximum CH power and soft ignition

setting

1. Push ON/OFF button for 10 secondes, the

led red 8 blinks.

2. Adjusting with the CH knob 5 the maxi

CH power between 0 and 99 % (see table)

3. Adjusting with the DHW knob 6 the soft

ignition between 0 and 99 % (see table)

The percentage level is visualized by the

green led 1

4. To store the new values of settings, it’s