Page 1

Instructions for use

WASHING MACHINE

GB

English,1

CIS

Русский,43

BWMD 742

Contents

GB

Installation, 2-3-4-5

I

ES

Español,29Italiano,15

Unpacking and levelling

Connecting the electricity and water supplies

The first wash cycle

Technical data

Instructions for the fitter

Description of the washing machine, 6-7

Control panel

Display

Running a wash cycle, 8

Wash cycles and functions, 9

Table of wash cycles

Wash functions

Detergents and laundry, 10

Detergent dispenser drawer

Preparing the laundry

Special wash cycles

Load balancing system

Precautions and tips, 11

General safety

Disposal

Opening the porthole door manually

Care and maintenance, 12

Cutting off the water or electricity supply

Cleaning the washing machine

Cleaning the detergent dispenser drawer

Caring for the door and drum of your appliance

Cleaning the pump

Checking the water inlet hose

Troubleshooting, 13

Service, 14

1

Page 2

Installation

GB

! This instruction manual should be kept in a safe place for

future reference. If the washing machine is sold, transferred

or moved, make sure that the instruction manual remains

with the machine so that the new owner is able to familiarise himself/herself with its operation and features.

! Read these instructions carefully: they contain vital infor-

mation relating to the safe installation and operation of the

appliance.

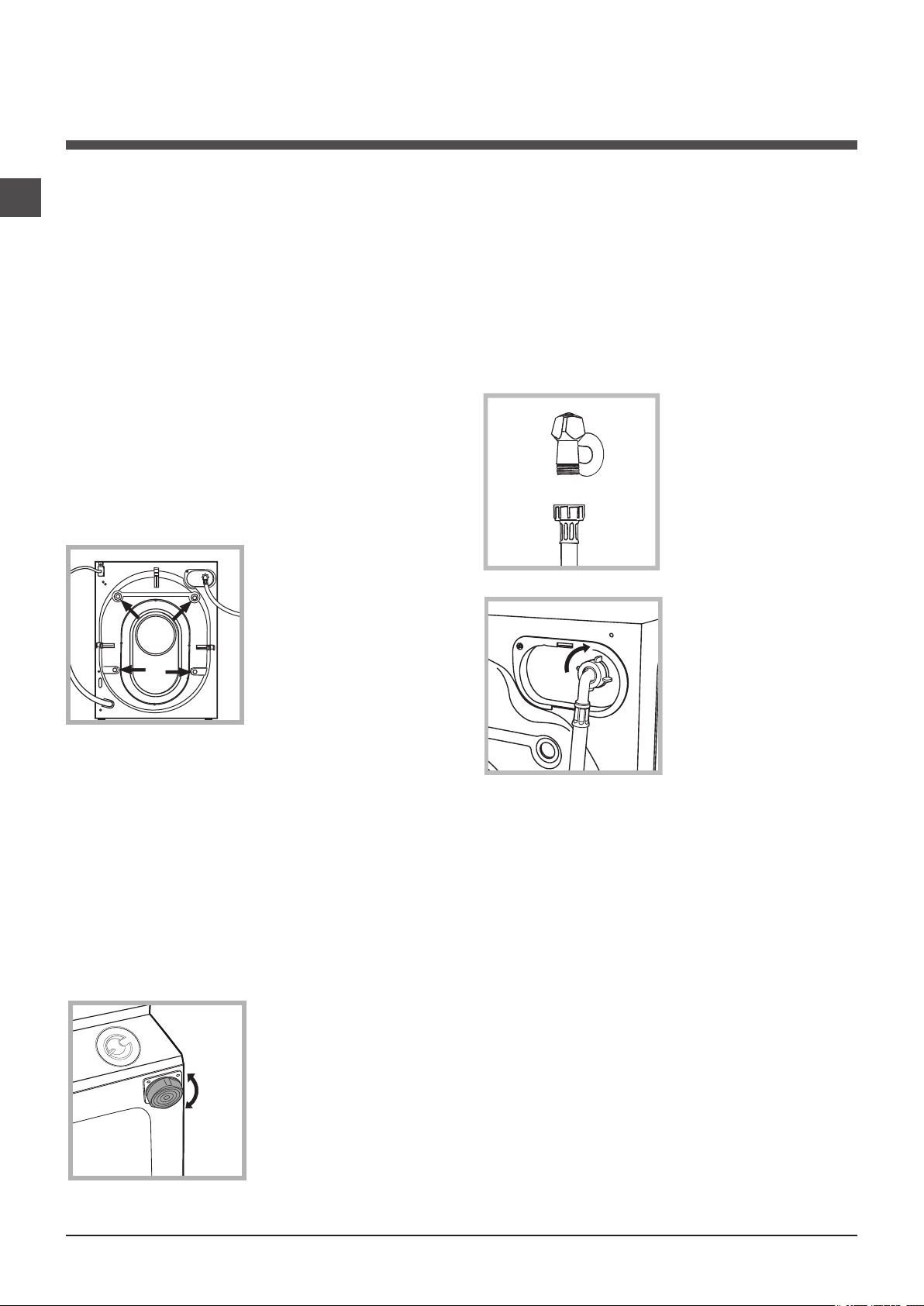

Unpacking and levelling

Unpacking

1. Remove the washing machine from its packaging.

2. Make sure that the washing machine has not been

damaged during the transportation process. If it has been

damaged, contact the retailer and do not proceed any

further with the installation process.

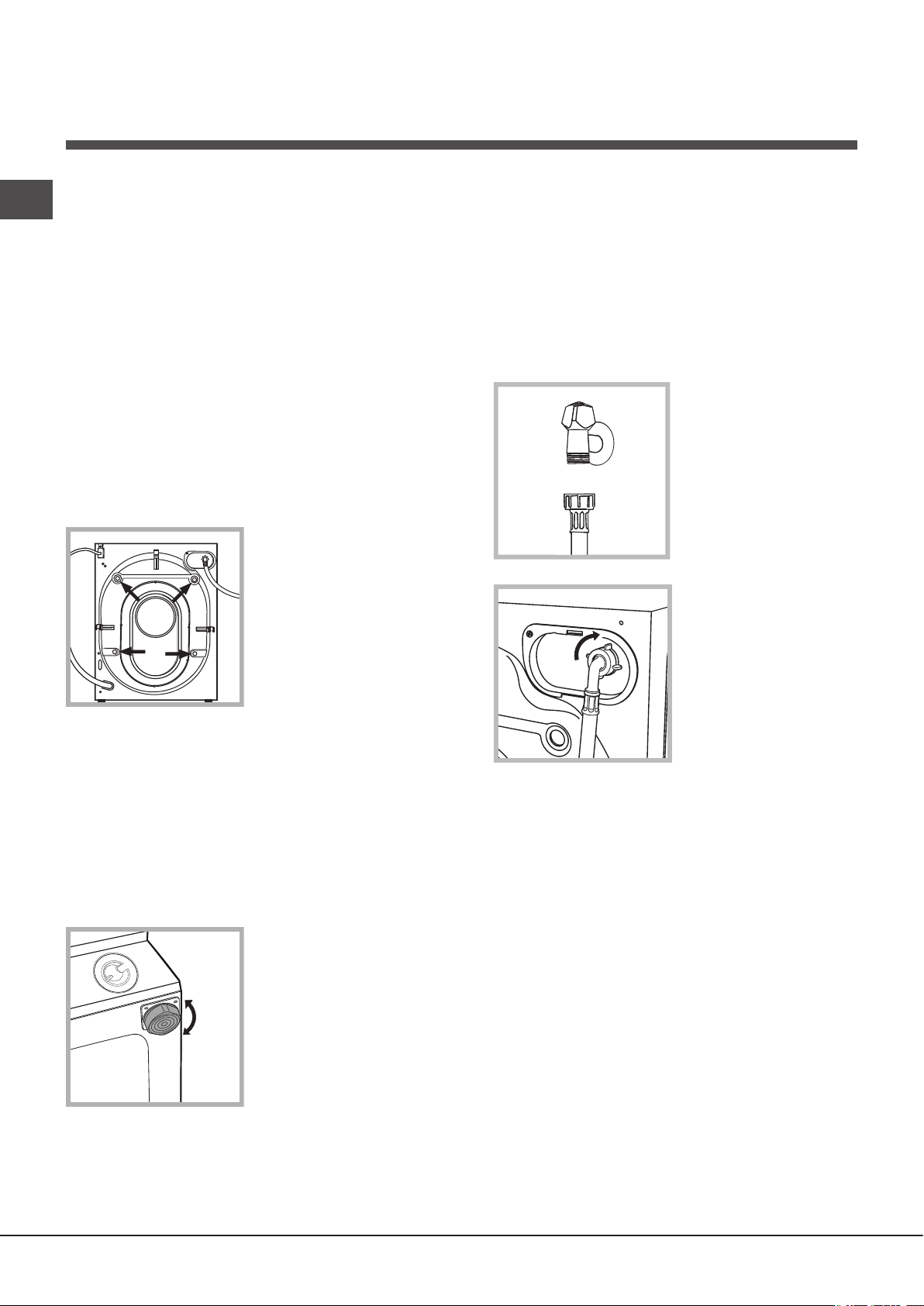

3. Remove the 4 protective

screws (used during transportation) and the rubber

washer with the corresponding spacer, located on the

rear part of the appliance

(see figure).

4. Close off the holes using the plastic plugs provided.

5. Keep all the parts in a safe place: you will need them

again if the washing machine needs to be moved to another location.

Levelling the machine correctly will provide it with stability,

help to avoid vibrations and excessive noise and prevent it

from shifting while it is operating. If it is placed on carpet or

a rug, adjust the feet in such a way as to allow a sufficient

ventilation space underneath the washing machine.

Connecting the electricity and water

supplies

Connecting the water inlet hose

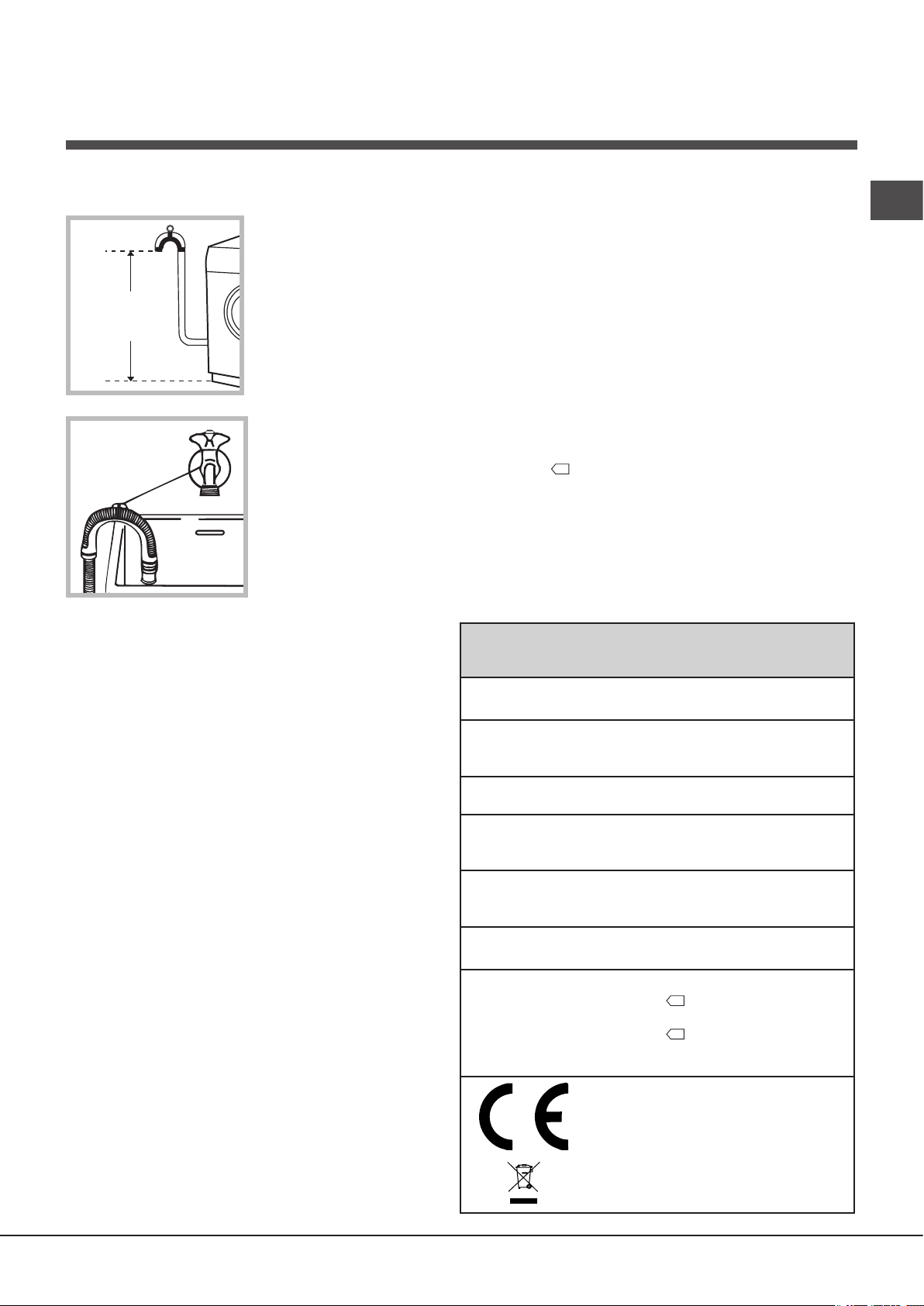

1. Connect the supply pipe

by screwing it to a cold

water tap using a ¾ gas

threaded connection (see

figure).

Before performing the connection, allow the water to

run freely until it is perfectly

clear.

2. Connect the inlet hose

to the washing machine by

screwing it onto the corresponding water inlet of the

appliance, which is situated on the top right-hand

side of the rear part of the

appliance (see figure).

3. Make sure that the hose is not folded over or bent.

! Packaging materials should not be used as toys for

children.

Levelling

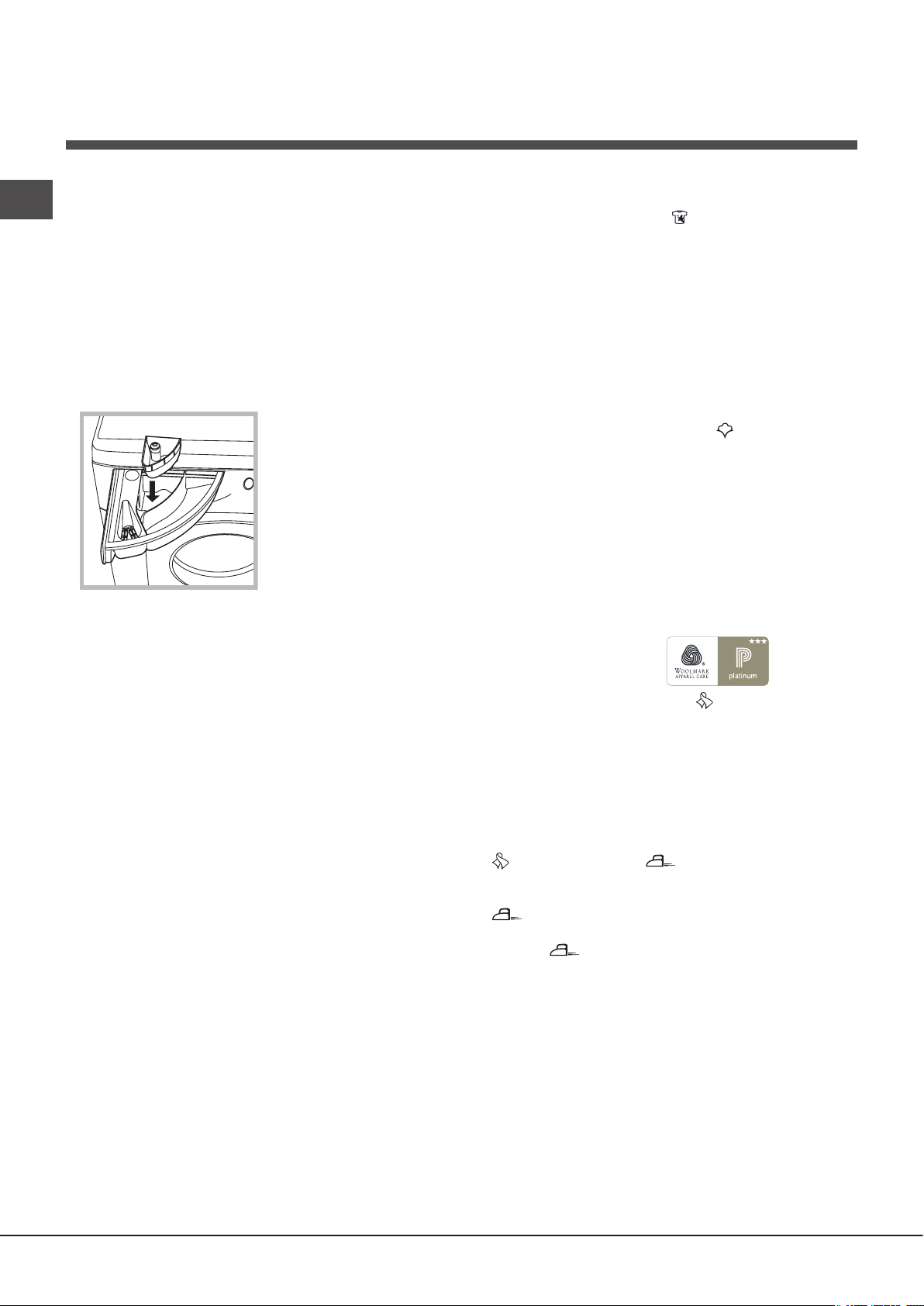

1. Install the washing machine on a flat sturdy floor, without

resting it up against walls, furniture cabinets or anything

else.

2. If the floor is not perfectly

level, compensate for any

unevenness by tightening

or loosening the adjustable front feet (see figure);

the angle of inclination,

measured in relation to the

worktop, must not exceed

2°.

2

! The water pressure at the tap must fall within the values

indicated in the Technical details table (see next page).

! If the inlet hose is not long enough, contact a specialised

shop or an authorised technician.

! Never use second-hand hoses.

! Use the ones supplied with the machine.

Page 3

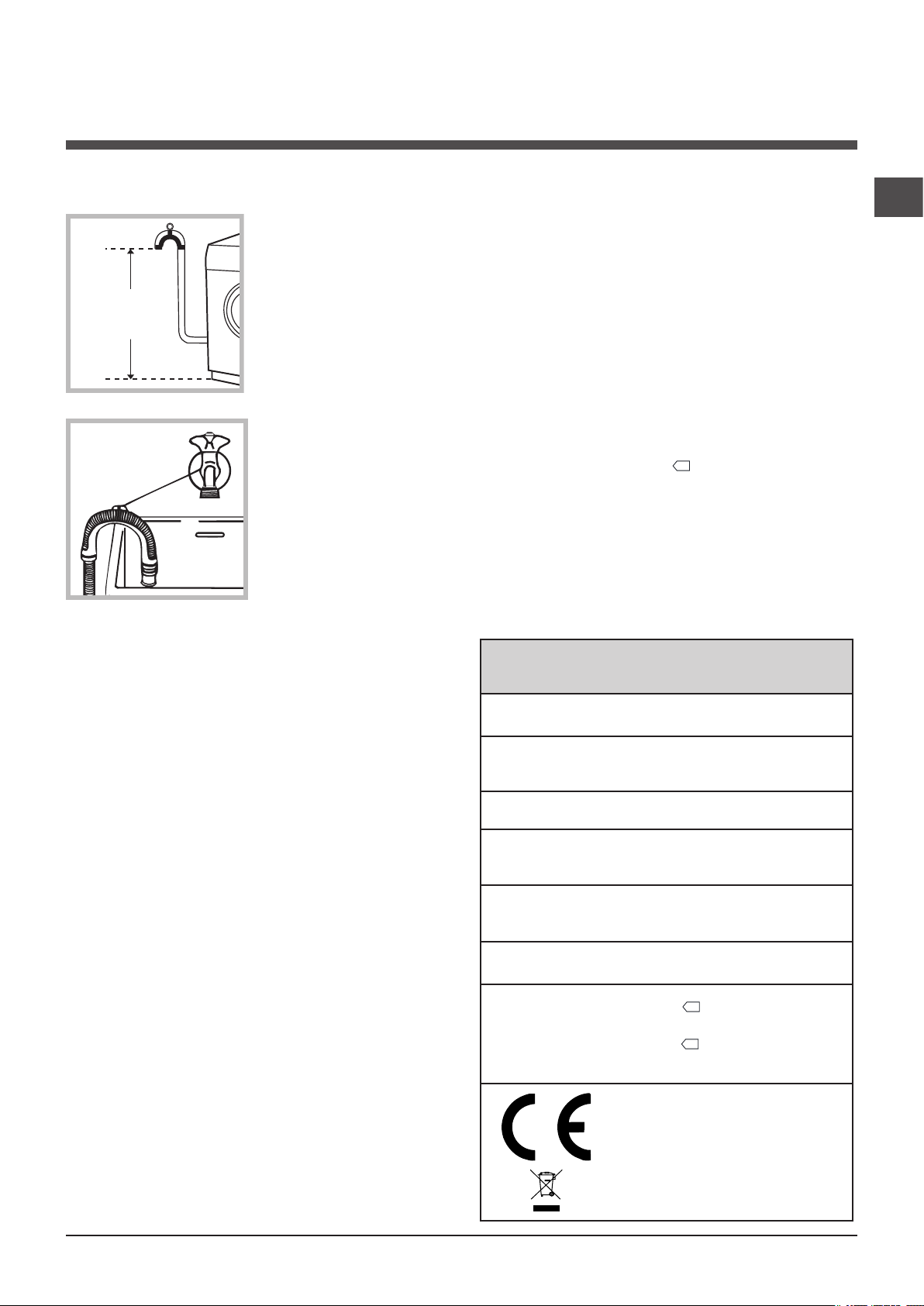

Connecting the drain hose

65 - 100 cm

- 2004/108/EC (Electromagnetic Compatibility)

Connect the drain hose,

without bending it, to a drainage duct or a wall drain

located at a height between

65 and 100 cm from the

floor;

! Do not use extension cords or multiple sockets.

! The cable should not be bent or compressed.

! The power supply cable must only be replaced by autho-

rised technicians.

Warning! The company shall not be held responsible in the

event that these regulations are not respected.

The first wash cycle

GB

alternatively, rest it on

the side of a washbasin

or bathtub, fastening the

duct supplied to the tap

(see figure). The free end

of the hose should not be

underwater.

! We advise against the use of hose extensions; if it is

absolutely necessary, the extension must have the same

diameter as the original hose and must not exceed 150 cm

in length.

Electrical connections

Before plugging the appliance into the electricity socket,

make sure that:

• the socket is earthed and complies with all applicable

laws;

• the socket is able to withstand the maximum power load

of the appliance as indicated in the Technical data table

(see opposite);

Once the appliance has been installed, and before you use

it for the first time, run a wash cycle with detergent and no

laundry, using the wash cycle (60°C).

Technical data

Model

Dimensions

Capacity

Electrical

connections

Water connections

BWMD 742

width 59.5 cm

height 81.5 cm

depth 54.5 cm

from 1 to 7 kg

please refer to the technical data plate

fixed to the machine

maximum pressure 1 MPa (10 bar)

minimum pressure 0.05 MPa (0.5 bar)

drum capacity 52 litres

• the power supply voltage falls within the values indicated

in the Technical data table (see opposite);

• the socket is compatible with the plug of the washing

machine. If this is not the case, replace the socket or the

plug.

! The washing machine must not be installed outdoors,

even in covered areas. It is extremely dangerous to leave

the appliance exposed to rain, storms and other weather

conditions.

! When the washing machine has been installed, the elec-

tricity socket must be within easy reach.

Spin speed

Test wash cycles

in accordance

with directives

1061/2010 and

1015/2010

up to 1400 rotations per minute

programme

Standard Cotton 60°C.

programme (40°) (2nd press of the button);

Standard Cotton 40°C.

This appliance conforms to the following

EC Directives:

- 2006/95/EC (Low Voltage)

- 2002/96/EC

(60°) (1st press of the button);

3

Page 4

GB

Tur seite

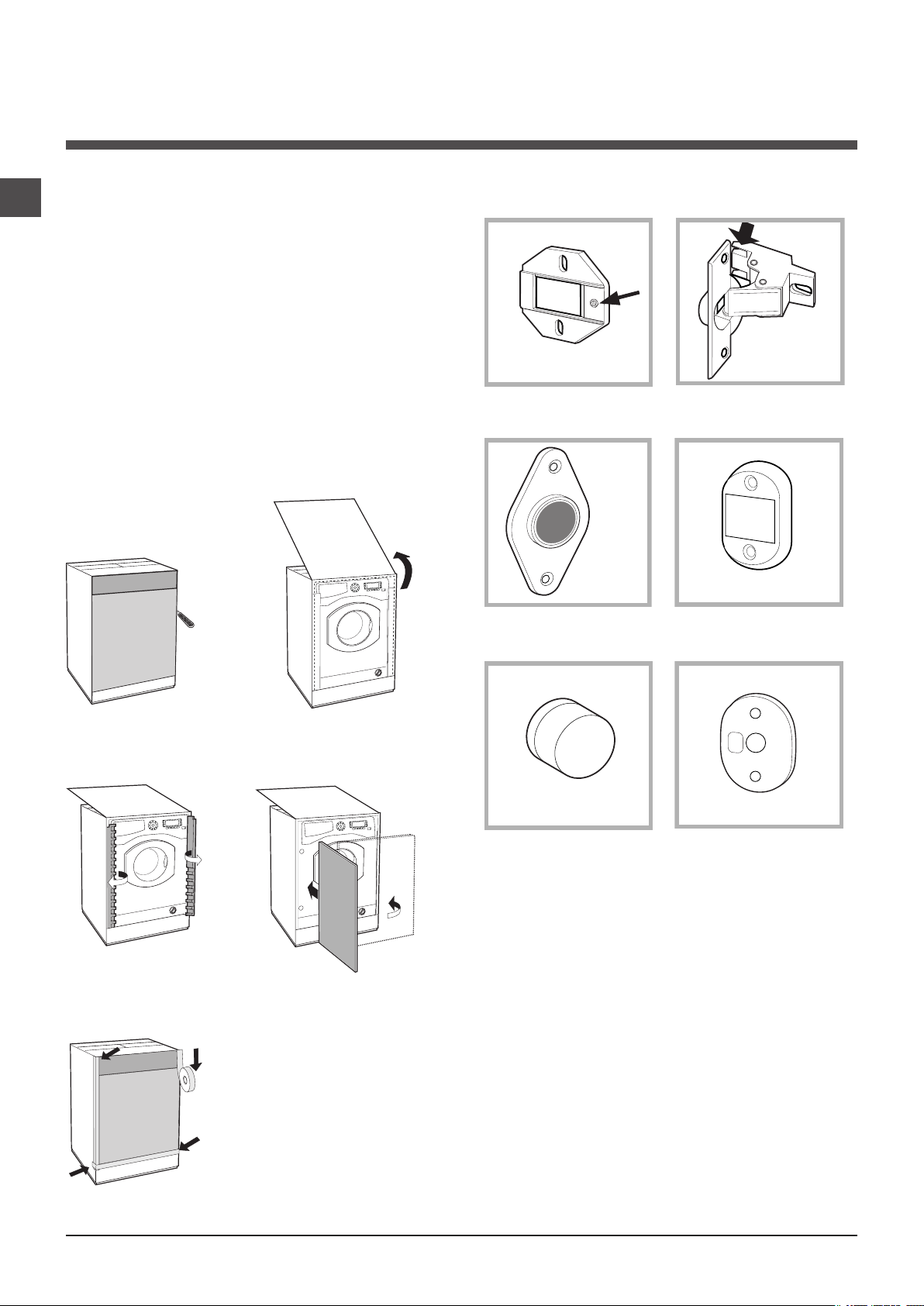

Instructions for the fitter

Mounting the wooden panel onto the door and inserting the machine into cabinets:

In the case where the machine must be shipped for final

installation after the wooden panel has been mounted, we

suggest leaving it in its original packaging. The packaging was

designed to make it possible to mount the wooden panel

onto the machine without removing it completely (see figures

below).

The wooden panel that covers the face of the machine must

not be less than 18 mm in thickness and can be hinged on

either the right or left. For the sake of practicality when using

the machine, we recommend that the panel be hinged on the

same side as the door for the machine itself - the left.

Door Mounting Accessories (Fig. 1-2-3-4-5).

N° 2 Hinge Supports

Fig. 1

N° 1 Magnet N° 1 Magnet plate

Fig. 3 Fig. 4

Fig. 2

N° 2 Hinges

A

C

E

B

D

N° 1 Rubber plug

Fig. 5

- No. 6 type A self-threading screws, l =13 mm.

- No. 2 type B metric, countersunk screws, l =25; for fastening the magnet plate to the cabinet.

- No. 4 type C metric screws, l =15 mm; for mounting the

hinge supports to the cabinet.

- No. 4 type D metric screws, l =7 mm; for mounting the

hinges on the supports.

Mounting the Parts onto the Face of the Machine.

- Fit the hinge supports to the appliance front panel, positioning

the hole marked with an arrow in fig. 1 so that it is on the inner

side of the front panel. Fit a spacer (fig. 4/B) between the

surfaces using type C screws.

- Fit the magnet plate at the top of the opposite side, using

type B screws to fix two spacers (fig. 4/B) between the plate

and the surface.

Fig. 4/B

N° 4 Spacers

4

Page 5

Using the Drilling Template.

570

min

815

540

595

820 ÷ 900

600 min

L

I

H

G

- To trace the positions of the holes on the left-hand side of

the panel, align the drilling template to the top left side of the

panel using the lines traced on the extremities as a reference.

- To trace the positions of the holes on the right-hand side of

the panel, align the drilling template to the top right side of the

panel.

- Use an appropriately sized router to mill the holes for the two

hinges, the rubber plug and the magnet.

Mounding the Parts onto the Wooden Panel (Door).

- Insert the hinges into the holes (the movable part of the hin-

ge must be positioned facing away from the panel) and fasten

them with the 4 type A screws.

- Insert the magnet into the top hole on the opposite side of

the hinges and fasten it with the two type B screws.

- Insert the rubber plug into the bottom hole.

The panel is now ready to be mounted onto the machine.

Mounting the Panel into the machine.

Insert the nib of the hinge (indicated by the arrow in fig. 2) into

the hole for the hinge and push the panel towards the front of

the machine. Fasten the two hinges with the type D screws.

GB

Fig. 8 Fig. 9

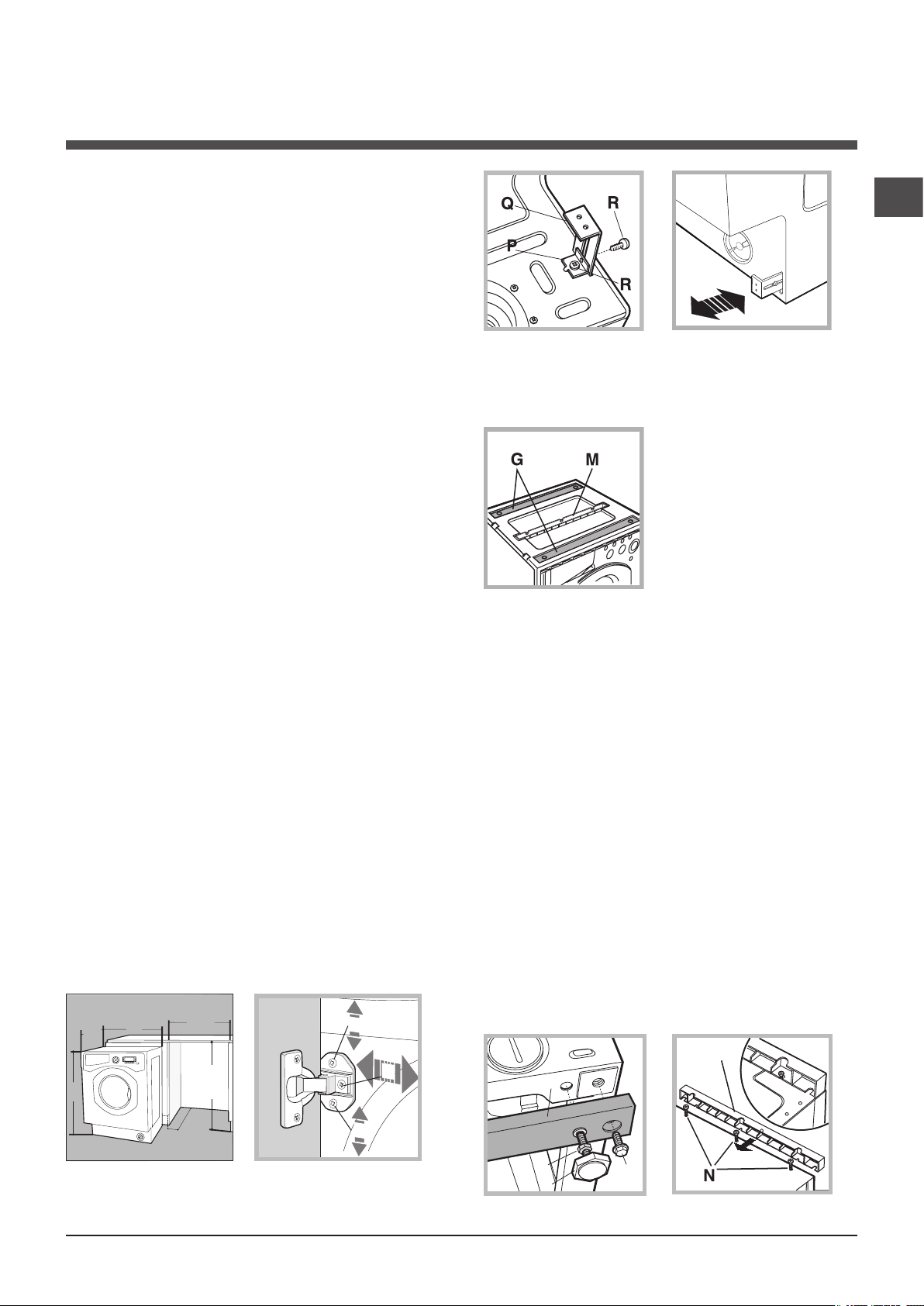

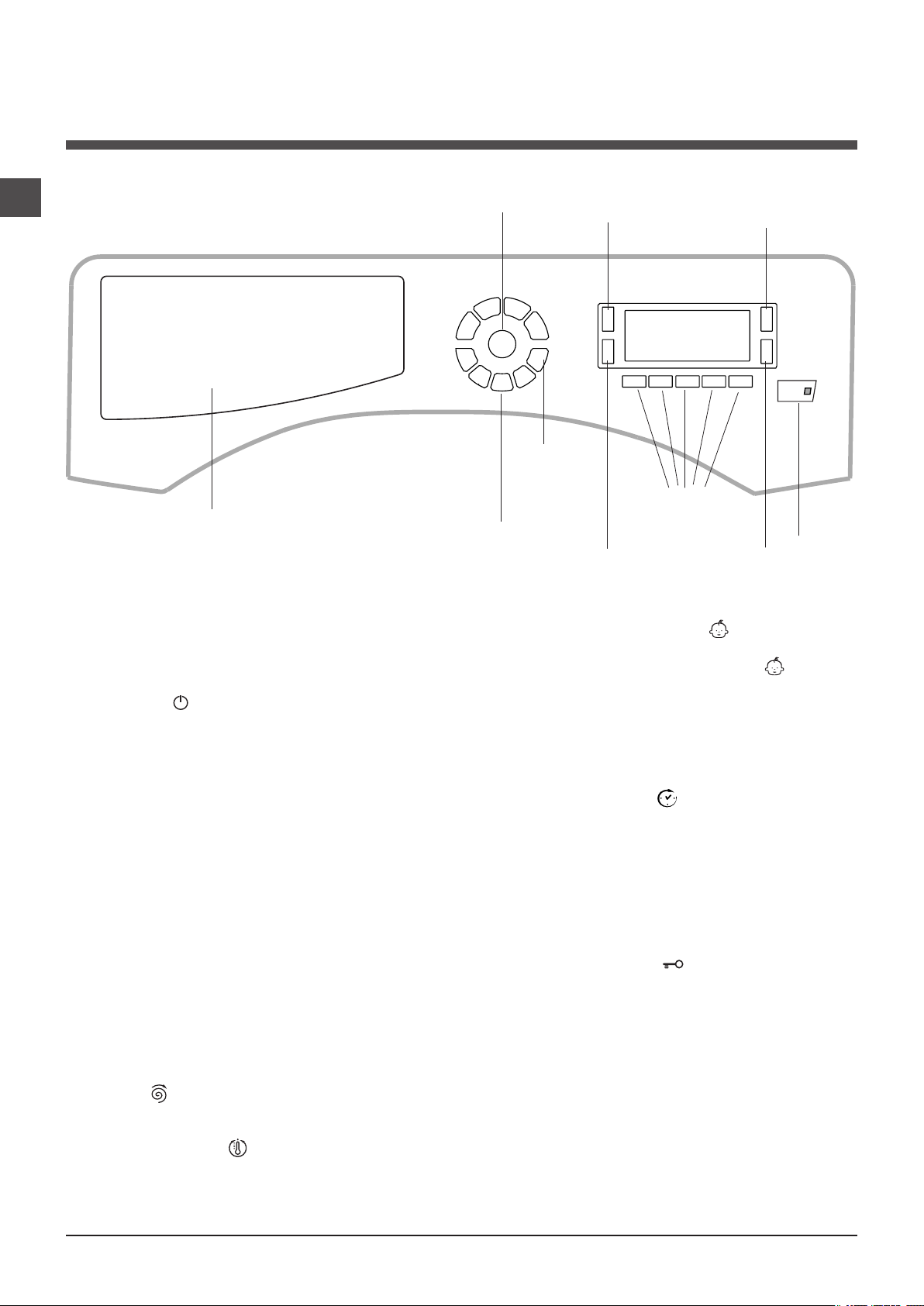

Accessories provided for the height adjustment.

The following can be found inside the polystyrene lid (fig. 10): 2

crossbars (G), 1 strip (M)

the following can be found inside

the appliance drum:

4 additional feet (H),

4 screws (I),

4 screws (R),

4 nuts (L),

2 plinth guides (Q)

Fastening the plinth guide.

If the machine is installed at the end of a set of modular

cabinets, mount either one or both of the guides for the base

molding (as shown in fig. 8). Adjust them for depth based on

the position of the base molding, and, if necessary, fasten the

base to the guides (fig. 9).

This is how to assemble the plinth guide (fig. 8):

Fasten angle P using screw R, insert plinth guide Q into the

special slot and once it is in the desired position, lock it in

place using angle P and screw R.

Inserting the machine into the Cabinet.

- Push the machine into the opening, aligning it with the cabi-

nets (fig. 6).

- Regulate the adjustable feet to raise the machine to the

appropriate height.

- To adjust the position of the wooden panel in both the

vertical and horizontal directions, use the C and D screws, as

shown in fig. 7.

Important: close the lower part of the appliance front by

ensuring that the plinth rests against the floor.

C

Fig. 10

Adjusting the appliance height.

The height of the appliance can be adjusted (from 815 mm to

835 mm), by turning the 4 feet.

Should you require the appliance to be placed higher than the

above height, you need to use the following accessories to

raise it to up to 870 mm:

the two crossbars (G); the 4 feet (H); the 4 screws (I); the 4

nuts (L) then perform the following operations (fig. 11):

remove the 4 original feet, place a crossbar G at the front of the

appliance, fastening it in place using screws I (screwing them in

where the original feet were) then insert the new feet H.

Repeat the same operation at the back of the appliance.

Now adjust feet H to raise or lower the appliance from 835 mm

to 870 mm.

Once you have reached the desired height, lock nuts L onto

crossbar G.

To adjust the appliance to a height between 870 mm and 900

mm, you need to mount strip M, adjusting feet H to the required height.

Insert the strip as follows:

loosen the three screws N situated at the front of the Top cover

of the appliance, insert strip M as shown in fig. 12, then fasten

screws N.

M

D

C

Fig. 6 Fig. 7

Fig. 11 Fig. 12

5

Page 6

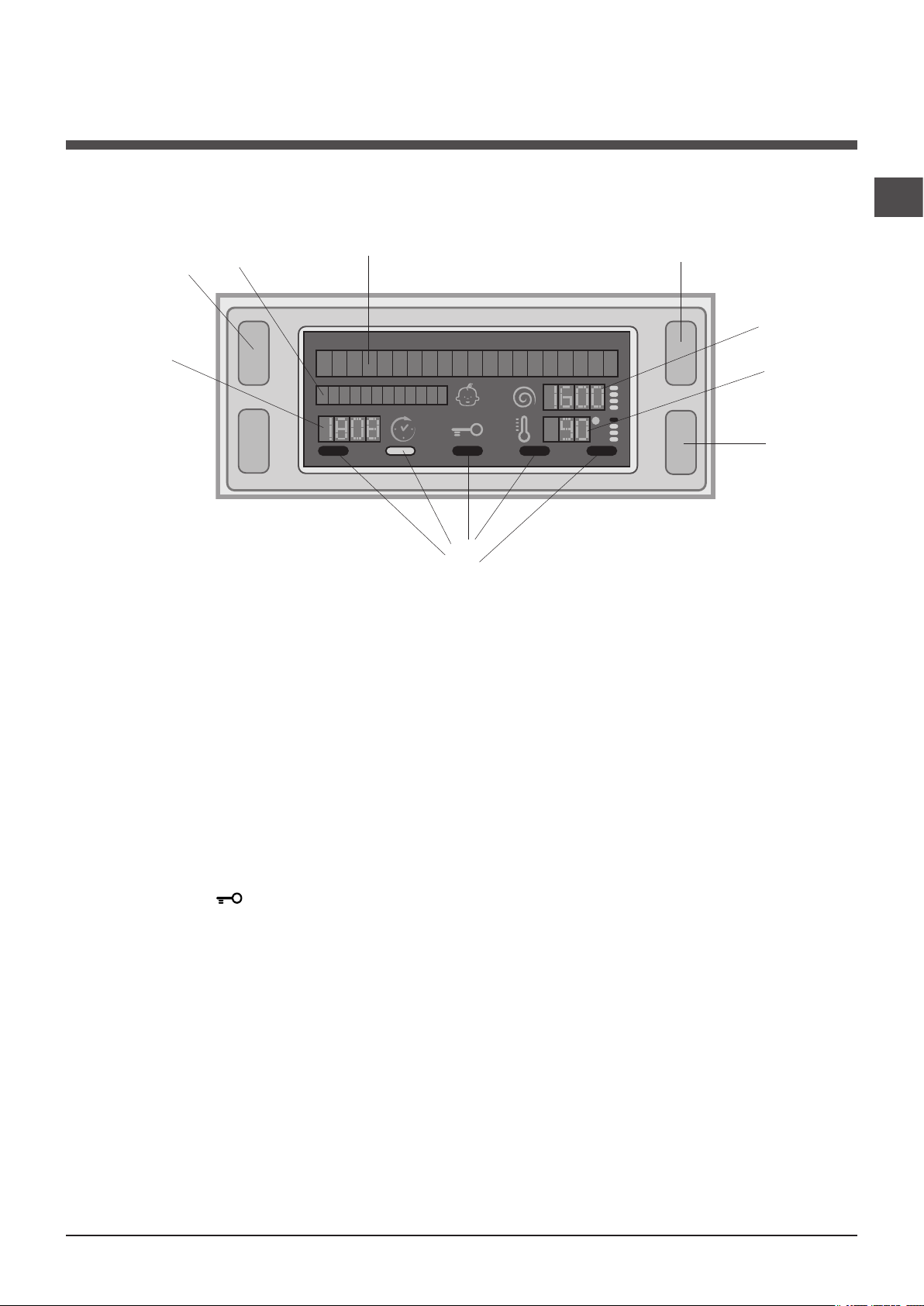

Description of the washing

machine

GB

Control panel

SELECTOR

Detergent dispenser drawer

Detergent dispenser drawer: used to dispense

detergents and washing additives (see “Detergents and

laundry”).

ON/OFF button : press this briefly to switch the machine on or off. The START/PAUSE indicator light, which

flashes slowly in a green colour shows that the machine is

switched on. To switch off the washing machine during the

wash cycle, press and hold the button for approximately 2

seconds; if the button is pressed briefly or accidentally the

machine will not switch off. If the machine is switched off

during a wash cycle, this wash cycle will be cancelled.

CONTROL PANEL

ON/OFF

button

WASH

CYCLE

Buttons

CONTROL PANEL LOCK button : to activate

the control panel lock, press and hold the button for

approximately 2 seconds. When the symbol is

illuminated, the control panel is locked. This means it

is possible to prevent wash cycles from being modified

accidentally, especially where there are children in the

home. To deactivate the control panel lock, press and

hold the button for approximately 2 seconds.

DELAYED START button : press to set a delayed start

time for the selected wash cycle. The delay time will be

shown on the display.

LOCK button

MEMORY

Button

DELAYED

START

Button

DISPLAY

FUNCTION

buttons

TEMPERATURE

Button

SPIN SPEED

Button

START/PAUSE

button with indicator

light

WASH CYCLE SELECTOR buttons: used to set the

desired wash cycle (see “Table of wash cycles”).

MEMORY button: press and hold the button to store a

cycle with your own set of preferences in the memory of

the machine. To recall a previously stored cycle, press the

MEMORY button.

FUNCTION buttons: press the button to select the

desired function. The corresponding indicator light on the

display will switch on.

SPIN button : press to reduce or completely exclude

the spin cycle - the value is indicated on the display.

TEMPERATURE button : press to decrease the temperature: the value will be shown on the display.

6

START/PAUSE button with indicator light: when the gre-

en indicator light flashes slowly, press the button to start a

wash cycle. Once the cycle has begun the indicator light

will remain lit in a fixed manner. To pause the wash cycle,

press the button again; the indicator light will flash in an

orange colour. If the symbol is not illuminated, the door

may be opened. To start the wash cycle from the point at

which it was interrupted, press the button again.

Standby mode

This washing machine, in compliance with new energy saving regulations, is fitted with an automatic standby system

which is enabled after about 30 minutes if no activity is

detected. Press the ON-OFF button briefly and wait for the

machine to start up again.

Consumption in off-mode: 0,5 W

Consumption in Left-on: 0,5 W

Page 7

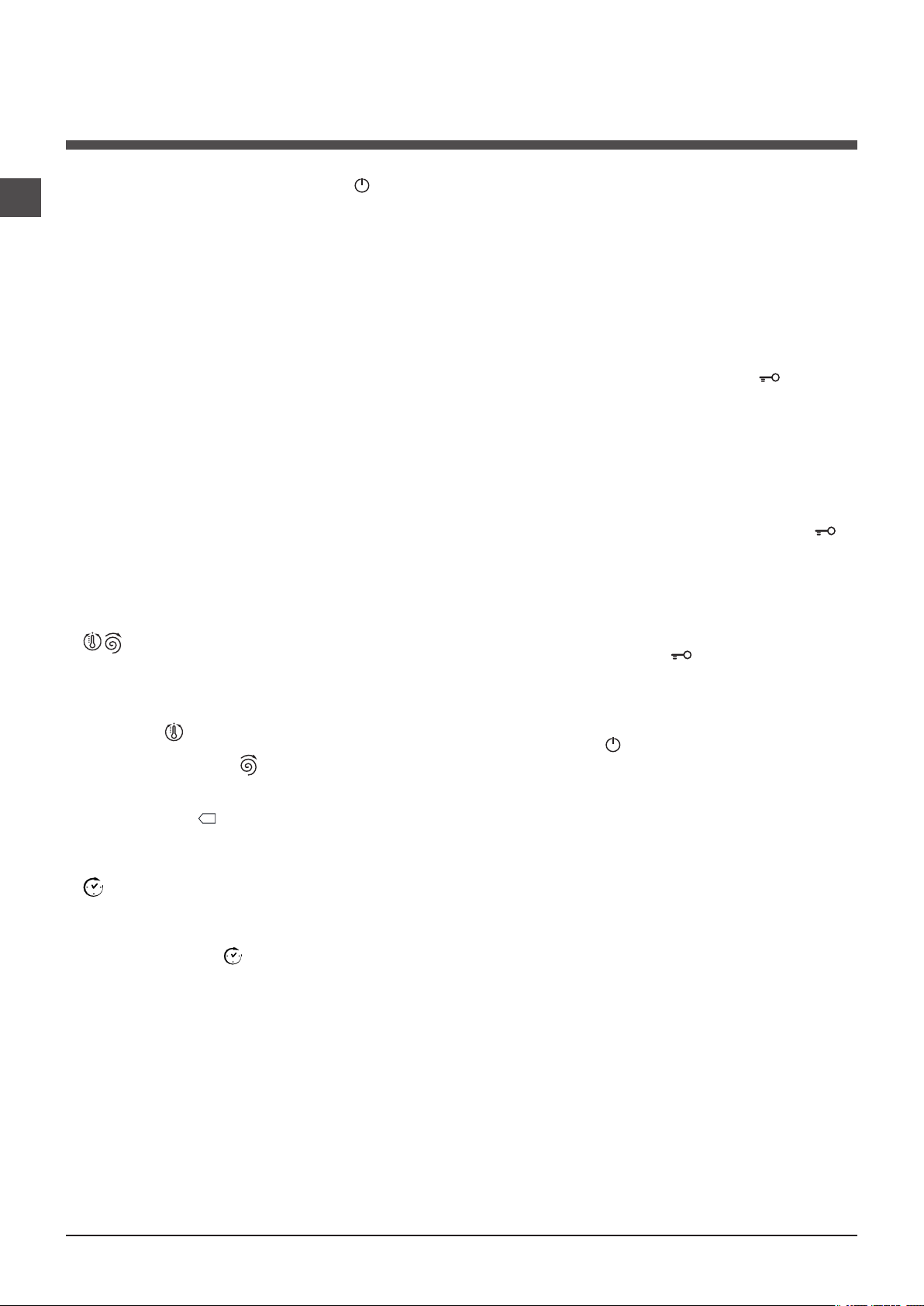

Display

GB

Z

B

A

X

D

C

E

Y

F

The display is useful when programming the machine and provides a great deal of information.

The two upper strings A and B provide details of the wash cycle selected, the wash cycle phase in progress and all information relating to the progress status of the wash cycle.

String C shows the time remaining until the end of the wash cycle in progress and, if a DELAYED START has been set, the

time remaining until the start of the selected wash cycle.

String D shows the maximum spin speed value (this depends on the selected wash cycle); if the wash cycle does not include

a spin cycle, the string remains unused.

String E shows the maximum temperature value which may be selected (this depends on the wash cycle used); if the temperature of the wash cycle cannot be modified, the string remains unused.

Indicator lights F correspond to the functions and light up when the selected function is compatible with the set wash cycle.

Door locked symbol

If the symbol is lit, this indicates that the washing machine door is blocked to prevent it from being opened accidentally. To

prevent any damage from occurring, wait for the symbol to switch itself off before opening the appliance door.

N.B.: if the DELAYED START function has been activated, the door cannot be opened; pauses the machine by pressing the

START/PAUSE button if you wish to open it.

! The first time the machine is switched on, you will be asked to select the language and the display will automatically show

the language selection menu.

To select the desired language press the X and Y buttons; to confirm the selection press the Z button.

To change the language switch off the machine and press buttons X, Y, Z simultaneously until an alarm is heard: the

language-selection menu will be displayed again.

7

Page 8

Running a wash cycle

GB

1. SWITCH THE MACHINE ON. Press the button;

the text HELLO will appear on the display and the

START/PAUSE indicator light will flash slowly in a green

colour.

2. LOAD THE LAUNDRY. Open the porthole door.

Load the laundry, making sure you do not exceed

the maximum load value indicated in the table of

programmes on the following page.

3. MEASURE OUT THE DETERGENT. Pull out the

detergent dispenser drawer and pour the detergent into

the relevant compartments as described in “Detergents

and laundry”.

4. CLOSE THE DOOR.

5. SELECT THE WASH CYCLE. Press one of the WASH

CYCLE SELECTOR buttons to select the required wash

cycle; the name of the wash cycle will appear on the

display. A temperature and spin speed is set for each

wash cycle; these may be adjusted. The duration of the

cycle will appear on the display.

6. CUSTOMISE THE WASH CYCLE. Use the relevant

buttons:

Modifying the temperature and/or spin

speed. The machine automatically selects the

maximum temperature and spin speed set for the

selected wash cycle; these values cannot therefore

be increased. The temperature can be decreased by

pressing the button, until the cold wash “OFF”

setting is reached. The spin speed may be progressively

reduced by pressing the button, until it is completely

excluded (the “OFF” setting). If these buttons are

pressed again, the maximum values are restored.

! Exception: if the (60°C)

programme is selected, the temperature can be

increased up to a value of 90°C.

(1st press of the button)

the indicator light corresponding to the first function

selected will flash and only the second function will

be activated; the indicator light corresponding to the

enabled function will remain lit.

! The functions may affect the recommended load value

and/or the duration of the cycle.

7. START THE PROGRAMME. Press the START/

PAUSE button. The corresponding indicator light will

become green, remaining lit in a fixed manner, and the

door will be locked (the DOOR LOCKED symbol will

be on). During the wash cycle, the name of the phase

in progress will appear on the display. To change a

wash cycle while it is in progress, pause the washing

machine using the START/PAUSE button (the START/

PAUSE indicator light will flash slowly in an orange

colour); then select the desired cycle and press the

START/PAUSE button again.

To open the door while a cycle is in progress, press

the START/PAUSE button; if the DOOR LOCKED

symbol is switched off the door may be opened. Press

the START/PAUSE button again to restart the wash

cycle from the point at which it was interrupted.

8. THE END OF THE WASH CYCLE. This will be

indicated by the text “END OF CYCLE” on the display;

when the DOOR LOCKED symbol switches off

the door may be opened. Open the door, unload the

laundry and switch off the machine.

! If you wish to cancel a cycle which has already begun,

press and hold the button. The cycle will be stopped

and the machine will switch off.

Setting a delayed start.

To set a delayed start for the selected programme,

press the corresponding button repeatedly until the

required delay period has been reached. When this

option is enabled, the symbol lights up on the

display. To remove the delayed start function press the

button until the text “OFF” appears on the display.

Modifying the cycle settings.

• Press the button to enable the function; the indicator

light corresponding to the button will switch on.

• Press the button again to disable the function; the

indicator light will switch off.

! If the selected function is not compatible with the

programmed wash cycle, the indicator light will flash

and the function will not be activated.

! If the selected function is not compatible with

another function which has been selected previously,

8

Page 9

Wash cycles and functions

M

AX

1

2

4

3

Table of wash cycles

Detergents

Description of the wash cycle

Wash cycles

Anti Stain

Standard Cotton 60° (1) (1st press of the button): heavily soiled whites and

delicate colours.

Standard Cotton 40° (2) (2nd press of the button): lightly soiled whites and

delicate colours.

Standard Cotton 20° (3rd press of the button): lightly soiled whites and

delicate colours.

Synthetics Resistant (1st press of the button): heavily soiled resistant colours. 60° 800

Synthetics Resistant (4) (1st press of the button): lightly soiled resistant colours. 40° 800

Synthetics Delicate (2nd press of the button): lightly soiled resistant colours. 40° 800

Fastwash 60' (1st press of the button): to refresh normal soiled garments quic-

kly (not suitable for wool, silk and clothes which require washing by hand).

Fastwash 30' (2nd press of the button): to refresh lightly soiled garments quic-

kly (not suitable for wool, silk and clothes which require washing by hand).

M

My Cycle: allows for any wash cycle to be stored.

Anti Allergy

Woolmark Platinum (Wool): for wool, cashmere, etc. 40° 800 -

Delicates

Spin (1st press of the button) - 1400 - - - - 7 - - - 16’

Rinse (2nd press of the button) - 1400 - -

Pump out (3rd press of the button) - 0 - - - - 7 - - - 2’

The length of cycle shown on the display or in this booklet is an estimation only and is calculated assuming standard working conditions. The actual duration can vary according to factors

such as water temperature and pressure, the amount of detergent used, the amount and type of load inserted, load balancing and any wash options selected.

1) Test wash cycle in compliance with directive 1061/2010: set wash cycle 60°C (1st press of the button).

This cycle is designed for cotton loads with a normal soil level and is the most efficient in terms of both electricity and water consumption; it should be used for garments which can be

washed at 60°C. The actual washing temperature may differ from the indicated value.

2) Test wash cycle in compliance with directive 1061/2010: set wash cycle 40°C (2nd press of the button).

This cycle is designed for cotton loads with a normal soil level and is the most efficient in terms of both electricity and water consumption; it should be used for garments which can be

washed at 40°C. The actual washing temperature may differ from the indicated value.

3) At 60 °C the “Prewash” function cannot be selected.

For all Test Institutes:

2) Long wash cycle for cottons: set wash cycle 40°C (2nd press of the button).

4) Long wash cycle for synthetics: set wash cycle 60°C (1st press of the button); temperature of 40°C (press TEMPERATURE button).

(°C)

Max. temp.

40° 1400

60°

(Max. 90°)

40° 1400 -

20° 1400 -

60° 1400 -

30° 800 -

60° 1400 -

30° 0 -

(rpm)

Max. speed

1400

(3)

Wash

Prewash

(kg)

pness %

Fabric

softener

Max. load

Bleach

4 - -

7 53 1,1 58 190’

7 53 0,99

7 - -

3 44 0,93 47 110’

3 44 0,57 46 95’

3 - - - 70’

- 3,5 53 0,81 40 60’

- 3 71 0,15 35 30’

- 4 - - - 195’

- 1,5 - - - 70’

- 1 - - - 80’

7 - - - 36’

Energy con-

Residual dam-

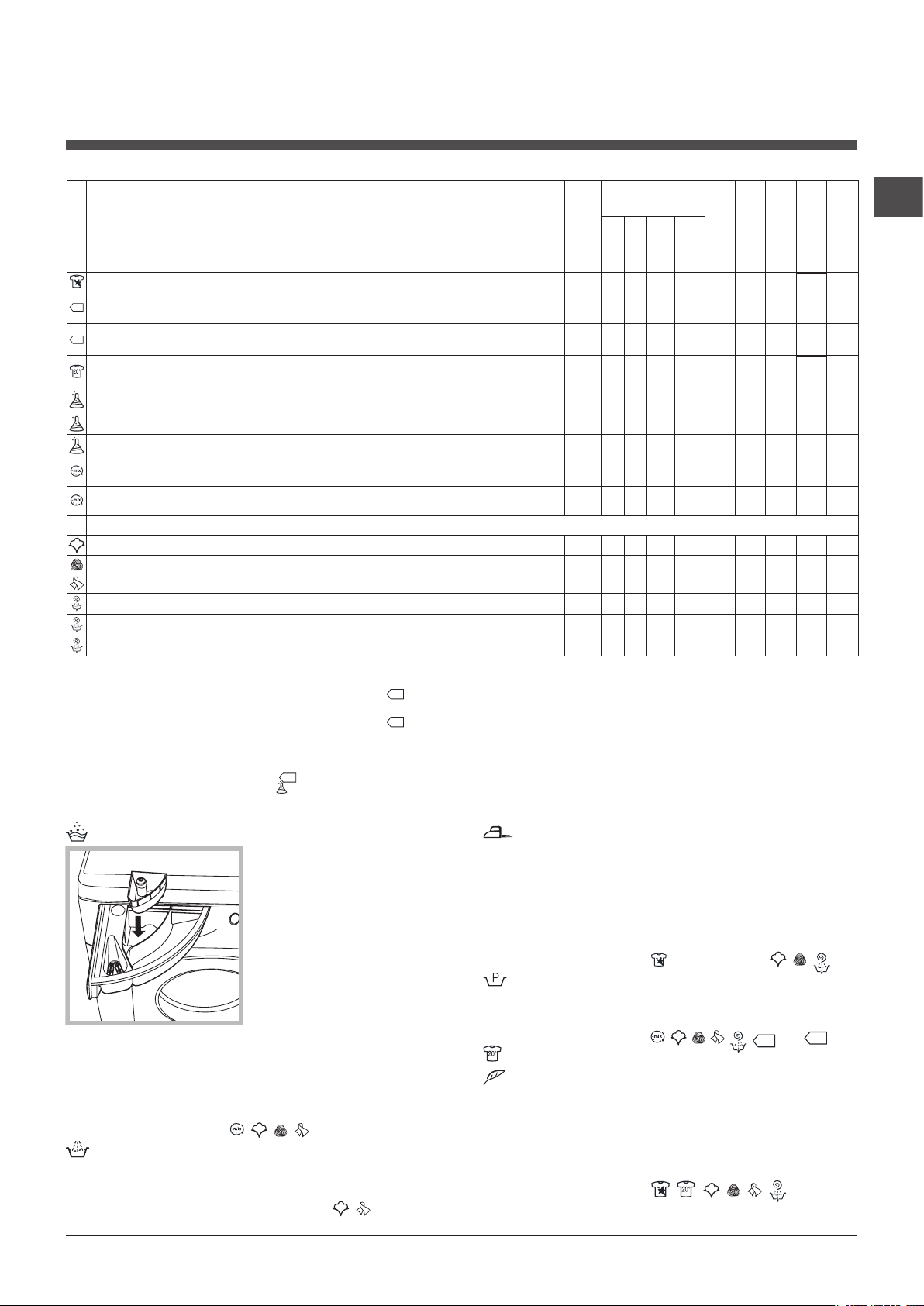

Wash functions

Super Wash

This option offers a highperformance wash due to the

greater quantity of water used

in the initial phase of the cycle,

and due to the increased wash

cycle duration, is particularly useful for the removal of

stubborn stains. It can be used

with or without bleach. If you

desire bleaching, insert the

extra tray compartment (4) into

compartment 1. When pouring

in the bleach, be careful not to

exceed the “max” level marked

on the central pivot (see figure). To bleach laundry without

carrying out a full wash cycle, pour the bleach into the extra

compartment 4, select the “Rinse” cycle and activate the

“Super Wash” option.

! The use of extra compartment 4 excludes the “Pre-wash”

function.

! It cannot be used with the , , , , “Spin”, “Pump out”.

Extra Rinse

By selecting this option, the efficiency of the rinse is increased

and optimal detergent removal is guaranteed. It is particularly

useful for sensitive skin.

! It cannot be used with the “Fastwash 30’”, , , “Spin”,

“Pump out”.

Easy Iron

By selecting this function, the wash and spin cycles will be modified

in order to reduce the formation of creases. At the end of the cycle

the washing machine will perform slow rotations of the drum; the

EASY IRON and START/PAUSE indicator lights will flash (orange)

and the text “END OF CYCLE” will appear on the display. To end

the cycle, press the START/PAUSE button or the EASY IRON

button. To drain the water so that the laundry may be removed,

press the START/PAUSE button or the EASY IRON button.

! It cannot be used with the , “Fastwash 30’”, , , .

Prewash

If this function is selected, the pre-wash cycle will run; this is

useful for removing stubborn stains.

N.B.: put the detergent in the relevant compartment.

! It cannot be used with the , , , , ,

(60°), (40°),

.

Eco Wash

The Eco Wash function saves energy by not heating the

water used to wash your laundry – an advantage both to the

environment and to your energy bill. Instead, intensified wash

action and water optimisation ensure great wash results in the

same average time of a standard cycle.

For the best washing results we recommend the usage of a

liquid detergent.

! It cannot be used with the , , , , , .

Total water lt

sumption kWh

82

180’

-

185’

170’

-

Cycle duration

GB

9

Page 10

Detergents and laundry

M

AX

1

2

4

3

GB

Detergent dispenser drawer

Good washing results also depend on the correct dose of

detergent: adding too much detergent will not necessarily result in a more efficient wash, and may in fact cause

build up on the inside of your appliance and contribute to

environmental pollution.

! Use powder detergent for white cotton garments, for

pre-washing, and for washing at temperatures over 60°C.

! Follow the instructions given on the detergent packaging.

! Do not use hand washing detergents because these

create too much foam.

Open the detergent dispenser drawer and pour

in the detergent or washing

additive, as follows.

compartment 1: Pre-wash detergent (powder)

Before pouring in the detergent, make sure that extra compartment 4 has been removed.

compartment 2: Detergent for the wash cycle

(powder or liquid)

Liquid detergent should only be poured in immediately

prior to the start of the wash cycle.

compartment 3: Additives (fabric softeners, etc.)

The fabric softener should not overflow the grid.

extra compartment 4: Bleach

Preparing the laundry

• Divide the laundry according to:

- the type of fabric/the symbol on the label

- the colours: separate coloured garments from whites

• Empty all garment pockets and check the buttons.

• Do not exceed the listed values, which refer to the weight

of the laundry when dry:

Durable fabrics: max. 7 kg

Synthetic fabrics: max. 3 kg

Wool: max. 1,5 kg

Silk: max. 1 kg

How much does your laundry weigh?

1 sheet 400-500 g

1 pillow case 150-200 g

1 tablecloth 400-500 g

1 bathrobe 900-1200 g

1 towel 150-250 g

Special wash cycles

Anti Stain : this programme is suitable to heavily-soiled

garments with resistant colours. It ensures a washing

class that is higher than the standard class (A class). When

running the programme, do not mix garments of different

colours. We recommend the use of powder detergent.

Pre-treatment with special additives is recommended if

there are obstinate stains.

Standard Cotton 20°: ideal for heavily soiled cotton

loads. The effective performance levels achieved at cold

temperatures, which are comparable to washing at 40°,

are guaranteed by a mechanical action which operates at

varying speed, with repeated and frequent peaks.

Anti Allergy: use programme to remove major allergens

such as pollen, mites, cat’s and dog’s hair.

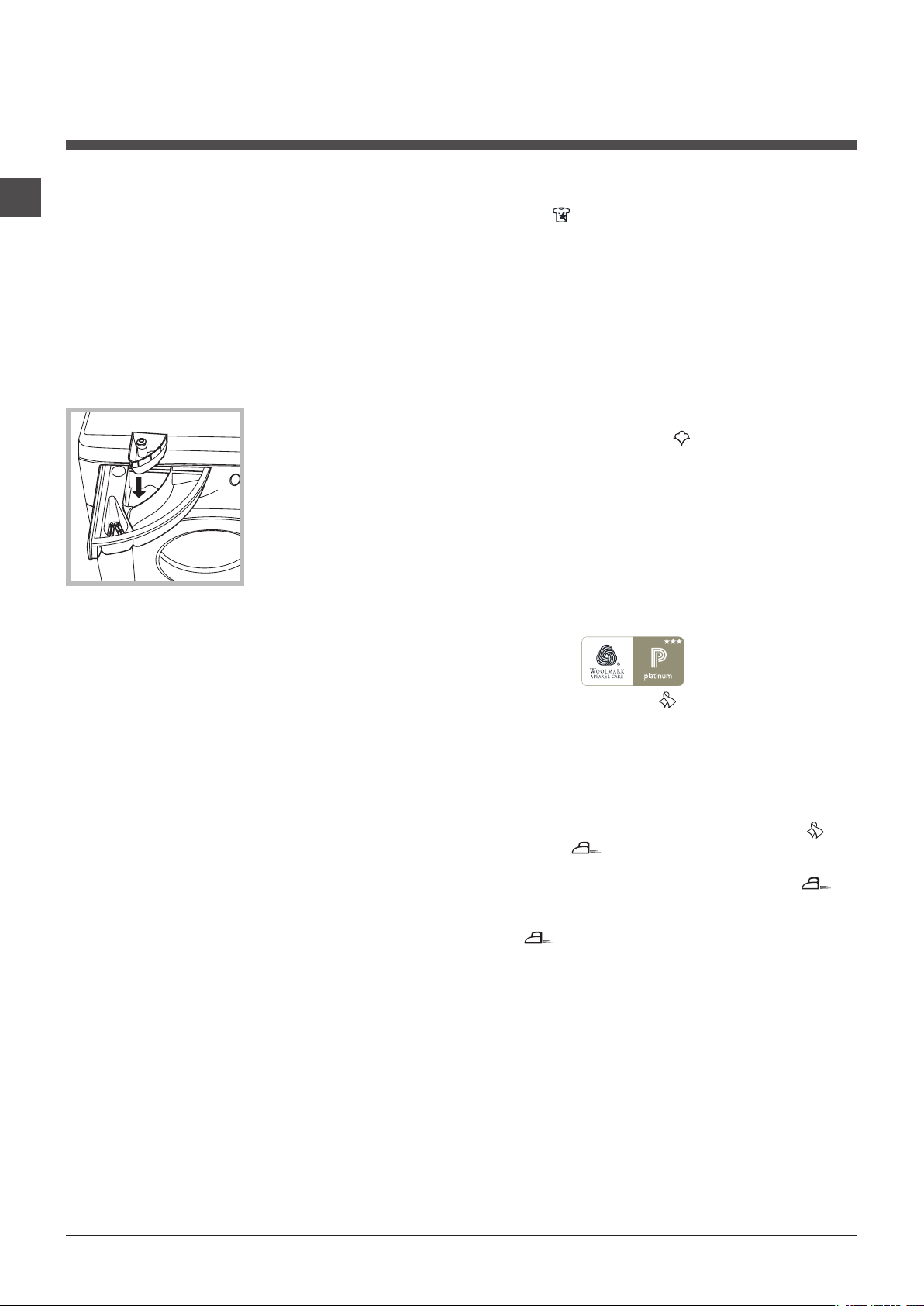

Wool: the wool wash cycle on this Hotpoint/Ariston machine has been tested and approved by The Woolmark

Company for washing wool garments labelled as hand washable provided that the garments are washed according

to the instructions on the garment label and those issued

by the manufacturer of this washing machine. Hotpoint/

Ariston is the first washing machine brand to be approved

by The Woolmark Company for Apparel Care- Platinum for

its washing performance and consumption of energy and

water. (M1126)

Delicates: use programme to wash very delicate

garments with decorative features, such as diamantes and

sequins.

We recommend turning the garments inside out before

washing and placing small items into the special bag

for washing delicates. Use liquid detergent on delicate

garments for best results.

To wash Silk garments and Curtains, select cycle and

then function (in this case it will also be possible

to enable the “Extra Rinse” function); the machine will

end the cycle while the laundry is soaking and the

indicator light will flash. To drain the water so that the

laundry may be removed, press the START/PAUSE button

or the button.

Load balancing system

Before every spin cycle, to avoid excessive vibrations and

to distribute the load in a uniform manner, the drum rotates

continuously at a speed which is slightly greater than the

washing rotation speed. If, after several attempts, the load

is not balanced correctly, the machine spins at a reduced

spin speed. If the load is excessively unbalanced, the

washing machine performs the distribution process instead

of spinning. To encourage improved load distribution and

balance, we recommend small and large garments are

mixed in the load.

10

Page 11

Precautions and tips

! This washing machine was designed and constructed in

accordance with international safety regulations. The following information is provided for safety reasons and must

therefore be read carefully.

General safety

• This appliance was designed for domestic use only.

• This appliance is not intended for use by persons (including children) with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge, unless

they have been given supervision or instruction concerning use of the appliance by a person responsible for

their safety. Children should be supervised to ensure that

they do not play with the appliance.

• Do not touch the machine when barefoot or with wet or

damp hands or feet.

• Do not pull on the power supply cable when unplugging

the appliance from the electricity socket. Hold the plug

and pull.

• Do not open the detergent dispenser drawer while the

machine is in operation.

• Do not touch the drained water as it may reach extremely high temperatures.

• Never force the porthole door. This could damage the safety

lock mechanism designed to prevent accidental opening.

• If the appliance breaks down, do not under any circumstances access the internal mechanisms in an attempt

to repair it yourself.

• Always keep children well away from the appliance while

it is operating.

• The door can become quite hot during the wash cycle.

• If the appliance has to be moved, work in a group of two

or three people and handle it with the utmost care. Never

try to do this alone, because the appliance is very heavy.

• Before loading laundry into the washing machine, make

sure the drum is empty.

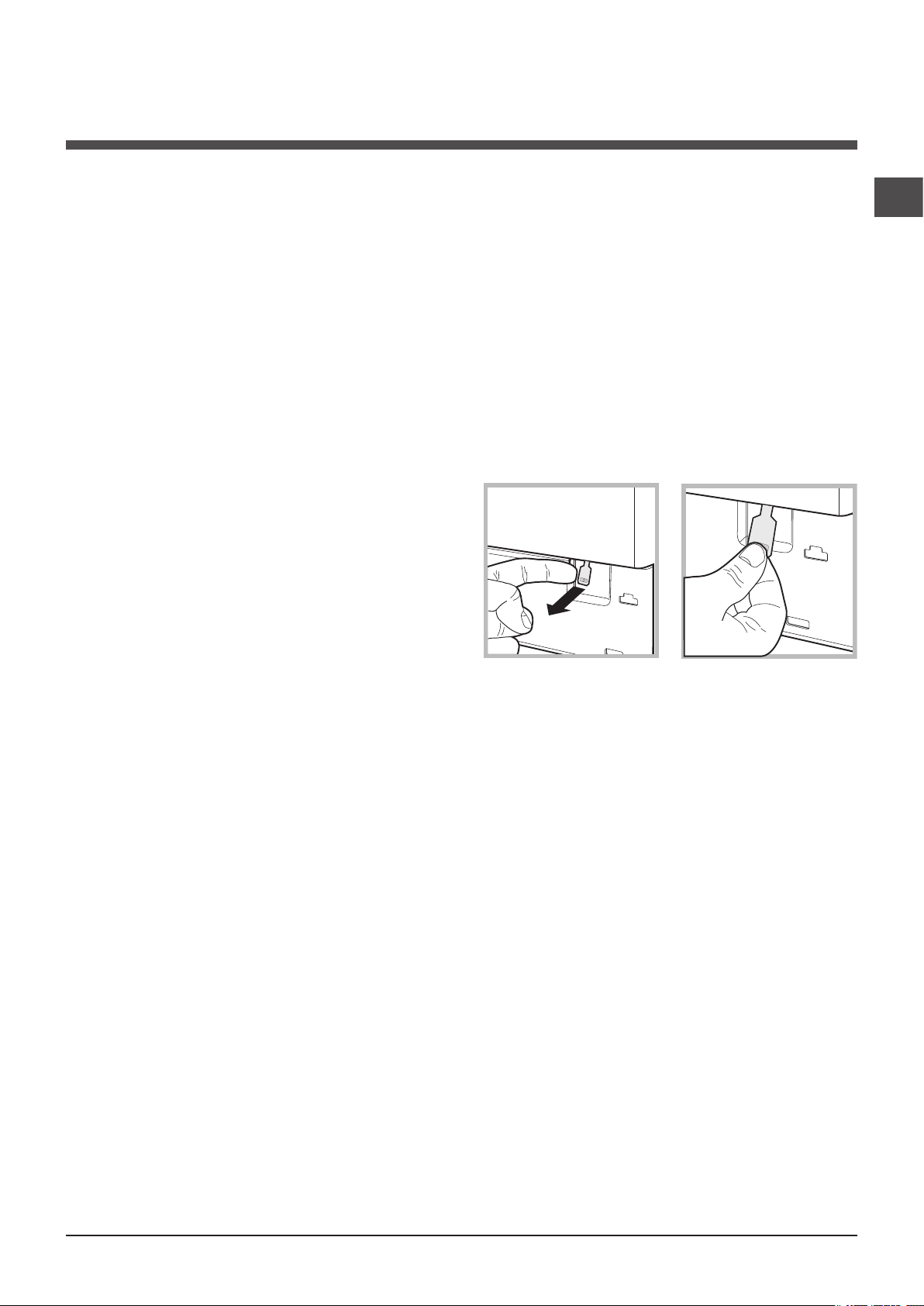

Opening the porthole door manually

In the event that it is not possible to open the porthole

door due to a powercut, and if you wish to remove the

laundry, proceed as follows:

1. remove the plug from the electrical socket.

2. make sure the water level inside the machine is lower

than the door opening; if it is not, remove excess water

using the drain hose, collecting it in a bucket as indicated

in the figure.

3. pull outwards using the tab as indicated in the figure,

until the plastic tie-rod is freed from its stop position; pull

downwards and open the door at the same time.

GB

Disposal

• Disposing of the packaging materials: observe local regu-

lations so that the packaging may be re-used.

• The European Directive 2002/96/EC on Waste Electrical

and Electronic Equipment, requires that old household

electrical appliances must not be disposed of in the normal

unsorted municipal waste stream. Old appliances must be

collected separately in order to optimise the recovery and

recycling of the materials they contain and reduce the impact on human health and the environment. The crossed

out “wheeled bin” symbol on the product reminds you of

your obligation, that when you dispose of the appliance it

must be separately collected. Consumers should contact

their local authority or retailer for information concerning the

correct disposal of their old appliance.

11

Page 12

Care and maintenance

1

2

GB

Cutting off the water and electricity

supplies

• Turn off the water tap after every wash cycle. This will limit

wear on the hydraulic system inside the washing machine

and help to prevent leaks.

• Unplug the washing machine when cleaning it and during all maintenance work.

Cleaning the washing machine

The outer parts and rubber components of the appliance

can be cleaned using a soft cloth soaked in lukewarm

soapy water. Do not use solvents or abrasives.

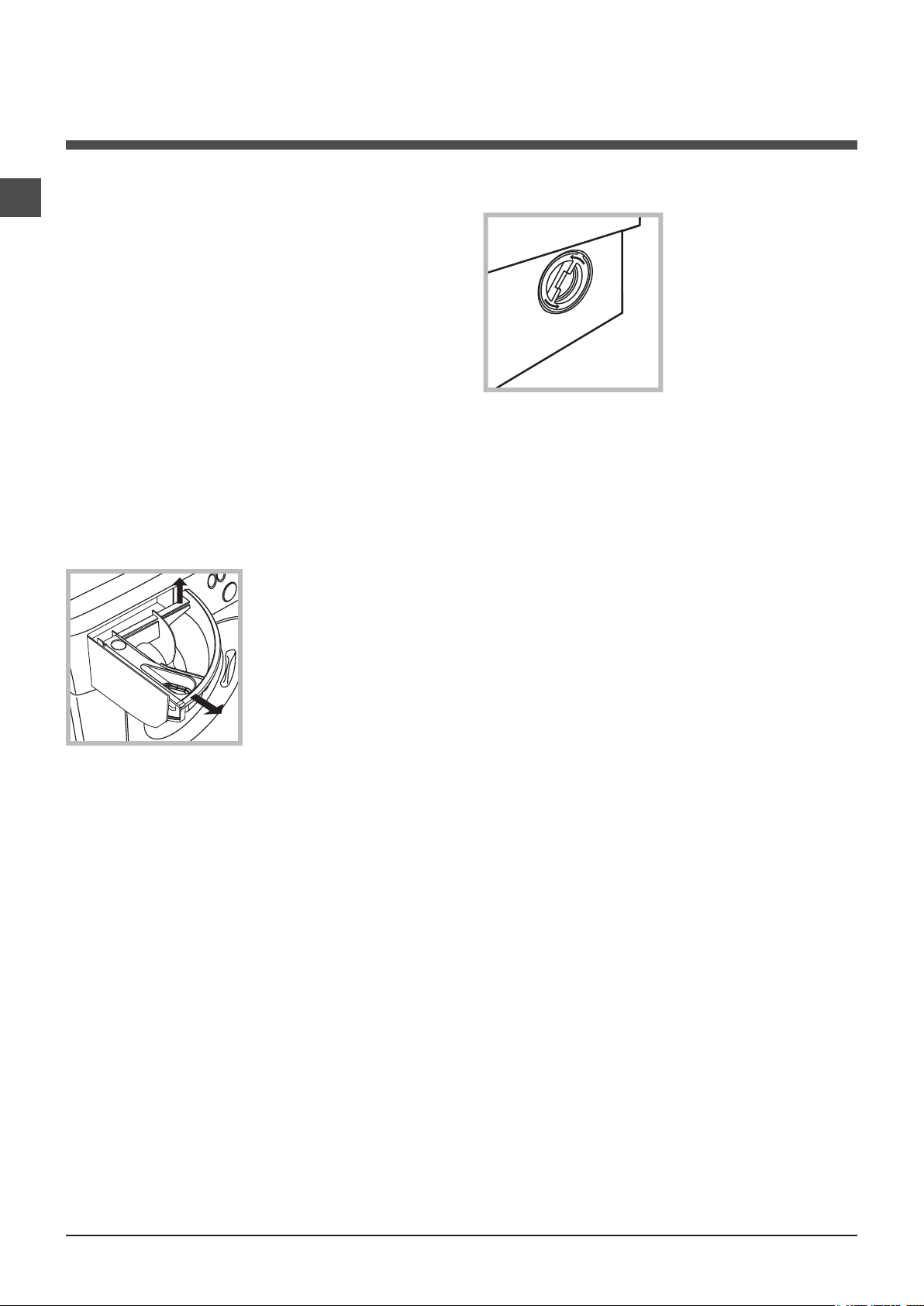

Cleaning the detergent dispenser drawer

Remove the dispenser by

raising it and pulling it out

(see figure).

Wash it under running water; this operation should be

repeated frequently.

To access the pre-chamber:

1. unscrew the lid by rotating it anti-clockwise (see

figure): a little water may

trickle out. This is perfectly

normal;

2. clean the inside thoroughly;

3. screw the lid back on;

Checking the water inlet hose

Check the inlet hose at least once a year. If there are any

cracks, it should be replaced immediately: during the wash

cycles, water pressure is very strong and a cracked hose

could easily split open.

! Never use second-hand hoses.

Caring for the door and drum of your

appliance

• Always leave the porthole door ajar in order to prevent

unpleasant odours from forming.

Cleaning the pump

The washing machine is fitted with a self-cleaning pump

which does not require any maintenance. Sometimes,

small items (such as coins or buttons) may fall into the prechamber which protects the pump, situated in its bottom

part.

! Make sure the wash cycle has finished and unplug the

appliance.

12

Page 13

Troubleshooting

Your washing machine could fail to work. Before contacting the Technical Assistance Centre (see “Assistance”), make sure

that the problem cannot be solved easily using the following list.

Problem:

The washing machine does not

switch on.

The wash cycle does not start.

The washing machine does not

take in water (the text “NO WATER,

CHECK SUPPLY” appears on the

display).

The washing machine continuously

takes in and

drains water.

Possible causes / Solutions:

• The appliance is not plugged into the socket fully, or is not making contact.

• There is no power in the house.

• The washing machine door is not closed properly.

• The ON/OFF button has not been pressed.

• The START/PAUSE button has not been pressed.

• The water tap has not been opened.

• A delayed start has been set (see “Running a wash cycle”).

• The water inlet hose is not connected to the tap.

• The hose is bent.

• The water tap has not been opened.

• There is no water supply in the house.

• The pressure is too low.

• The START/PAUSE button has not been pressed.

• The drain hose is not fitted at a height between 65 and 100 cm from the floor

(see “Installation”).

• The free end of the hose is under water (see “Installation”).

• The wall drainage system is not fitted with a breather pipe.

If the problem persists even after these checks, turn off the water tap, switch

the appliance off and contact the Assistance Service. If the dwelling is on one of

the upper floors of a building, there may be problems relating to water drainage,

causing the washing machine to fill with water and drain continuously. Special

anti-draining valves are available in shops and help to avoid this inconvenience.

GB

The washing machine does not

drain or spin.

The washing machine vibrates a lot

during the spin cycle.

The washing machine leaks.

The machine is locked and the display

flashes, indicating an error code (e.g.

F-01, F-..).

There is too much foam.

• The wash cycle does not include draining: some wash cycles require the drain

phase to be started manually (see “Wash cycles and functions”).

• The EASY IRON function has been activated: To complete the wash cycle,

press the START/PAUSE button (see “Wash cycles and functions”).

• The drain hose is bent (see “Installation”).

• The drainage duct is clogged.

• The drum was not unlocked correctly during installation (see “Installation”).

• The washing machine is not level (see “Installation”).

• The washing machine is trapped between cabinets and walls (see “Installation”).

• The water inlet hose is not screwed on properly (see “Installation”).

• The detergent dispenser drawer is blocked (for cleaning instructions, see

“Care and maintenance”).

• The drain hose is not fixed properly (see “Installation”).

• Switch off the machine and unplug it, wait for approximately 1 minute and

then switch it back on again.

If the problem persists, contact the Technical Assistance Service.

• The detergent is not suitable for machine washing (it should display the text

“for washing machines” or “hand and machine wash”, or the like).

• Too much detergent was used.

13

Page 14

Service

GB

Before calling for Assistance:

• Check whether you can solve the problem alone (see “Troubleshooting”);

• Restart the programme to check whether the problem has been solved;

• If this is not the case, contact an authorised Technical Assistance Centre using the telephone number provided on the

guarantee certificate.

! Always request the assistance of authorised technicians.

Have the following information to hand:

• the type of problem;

• the appliance model (Mod.);

• the serial number (S/N).

This information can be found on the data plate applied to the rear of the washing machine, and can also be found on the

front of the appliance by opening the door.

14

Page 15

Istruzioni per l’uso

LAVABIANCHERIA

I

Italiano

BWMD 742

Sommario

Installazione, 16-17-18-19

Disimballo e livellamento

Collegamenti idraulici ed elettrici

Primo ciclo di lavaggio

Dati tecnici

Istruzioni per l’installatore

Descrizione della lavabiancheria, 20-21

Pannello di controllo

Display

Come effettuare un ciclo di lavaggio, 22

Programmi e funzioni, 23

Tabella dei programmi

Funzioni di lavaggio

Detersivi e biancheria, 24

Cassetto dei detersivi

Preparare la biancheria

Programmi particolari

Sistema bilanciamento del carico

I

Precauzioni e consigli, 25

Sicurezza generale

Smaltimento

Apertura manuale della porta oblò

Manutenzione e cura, 26

Escludere acqua e corrente elettrica

Pulire la lavabiancheria

Pulire il cassetto dei detersivi

Curare oblò e cestello

Pulire la pompa

Controllare il tubo di alimentazione dell’acqua

Anomalie e rimedi, 27

Assistenza, 28

Assistenza Attiva 7 giorni su 7

15

Page 16

Installazione

! È importante conservare questo libretto per poterlo con-

I

sultare in ogni momento. In caso di vendita, di cessione o

di trasloco, assicurarsi che resti insieme alla lavabiancheria

per informare il nuovo proprietario sul funzionamento e sui

relativi avvertimenti.

! Leggere attentamente le istruzioni: ci sono importanti

informazioni sull’installazione, sull’uso e sulla sicurezza.

Disimballo e livellamento

Disimballo

1. Disimballare la lavabiancheria.

2. Controllare che la lavabiancheria non abbia

subìto danni nel trasporto. Se fosse danneggiata

non collegarla e contattare il rivenditore.

3. Rimuovere le 4 viti di

protezione per il trasporto

e il gommino con il relativo

distanziale, posti nella parte

posteriore (vedi figura).

Un accurato livellamento dà stabilità alla macchina ed

evita vibrazioni, rumori e spostamenti durante il funzionamento. In caso di moquette o di un tappeto, regolare i

piedini in modo da conservare sotto la lavabiancheria uno

spazio sufficiente per la ventilazione.

Collegamenti idraulici ed elettrici

Collegamento del tubo di alimentazione dell’acqua

1. Collegare il tubo di

alimentazione avvitandolo

a un rubinetto d’acqua

fredda con bocca filettata

da 3/4 gas (vedi figura).

Prima di allacciare, far

scorrere l’acqua finché

non sia limpida.

2. Collegare il tubo di alimentazione alla lavabiancheria avvitandolo all’apposita presa d’acqua,

nella parte posteriore in

alto a destra (vedi figura).

4. Chiudere i fori con i tappi di plastica in dotazione.

5. Conservare tutti i pezzi: qualora la lavabiancheria debba

essere trasportata, dovranno essere rimontati.

! Gli imballaggi non sono giocattoli per bambini.

Livellamento

1. Installare la lavabiancheria su un pavimento piano e rigi-

do, senza appoggiarla a muri, mobili o altro.

2. Se il pavimento non fosse

perfettamente orizzontale,

compensare le irregolarità

svitando o avvitando i piedini

anteriori (vedi figura); l’angolo di inclinazione, misurato

sul piano di lavoro, non deve

superare i 2°.

3. Fare attenzione che nel tubo non ci siano né pieghe né

strozzature.

! La pressione idrica del rubinetto deve essere compresa

nei valori della tabella Dati tecnici

(vedi pagina a fianco).

! Se la lunghezza del tubo di alimentazione non fosse

sufficiente, rivolgersi a un negozio specializzato o a un

tecnico autorizzato.

! Non utilizzare mai tubi già usati.

! Utilizzare quelli in dotazione alla macchina.

16

Page 17

Collegamento del tubo di scarico

65 - 100 cm

Collegare il tubo di scarico, senza piegarlo, a una

conduttura di scarico o a

uno scarico a muro posti

tra 65 e 100 cm da terra;

! Non usare prolunghe e multiple.

! Il cavo non deve subire piegature o compressioni.

! Il cavo di alimentazione deve essere sostituito solo da

tecnici autorizzati.

Attenzione! L’azienda declina ogni responsabilità qualora

queste norme non vengano rispettate.

Primo ciclo di lavaggio

I

oppure appoggiarlo al

bordo di un lavandino o

di una vasca, legando la

guida in dotazione al

rubinetto (vedi figura).

L’estremità libera del tubo

di scarico non deve rimanere immersa nell’acqua.

! È sconsigliato usare tubi di prolunga; se indispensabile,

la prolunga deve avere lo stesso diametro del tubo originale e non superare i 150 cm.

Collegamento elettrico

Prima di inserire la spina nella presa della corrente, accertarsi che:

• la presa abbia la messa a terra e sia a norma

di legge;

• la presa sia in grado di sopportare il carico

massimo di potenza della macchina, indicato nella

tabella Dati tecnici (vedi a fianco);

• la tensione di alimentazione sia compresa nei

valori indicati nella tabella Dati tecnici (vedi a

fianco);

• la presa sia compatibile con la spina della

lavabiancheria. In caso contrario sostituire la

presa o la spina.

! La lavabiancheria non va installata all’aperto, nemmeno

se lo spazio è riparato, perché è molto pericoloso lasciarla esposta a pioggia e temporali.

! A lavabiancheria installata, la presa della corrente deve

essere facilmente raggiungibile.

Dopo l’installazione, prima dell’uso, effettuare un ciclo di

lavaggio con detersivo e senza biancheria impostando il

programma (60° C).

Dati tecnici

Modello

Dimensioni

Capacità

Collegamenti

elettrici

Collegamenti

idrici

Velocità di centrifuga

Programmi di

prova

secondo la

direttive

1061/2010 e

1015/2010

BWMD 742

larghezza cm 59,5

altezza cm 81,5

profondità cm 54,5

da 1 a 7 kg

Vedi targhetta caratteristiche tecniche

applicata sulla macchina

pressione massima 1 MPa (10 bar)

pressione minima 0,05 MPa (0,5 bar)

capacità del cesto 52 litri

sino a 1400 giri al minuto

programma

Cotone standard 60°C.

programma

Cotone standard 40°C.

Questa apparecchiatura è conforme alle

seguenti Direttive Comunitarie:

- 2004/108/CE (Compatibilità

Elettromagnetica)

- 2006/95/CE (Bassa Tensione)

- 2002/96/CE

(60°) (1° pressione del tasto);

(40°) (2° pressione del tasto);

17

Page 18

I

Tur seite

Istruzioni per l’installatore

Applicazione del pannello in legno alla porta e inserimento della macchina nei mobili:

Nel caso in cui, dopo il montaggio del pannello in legno, sia

necessario spedire la macchina per l’installazione finale,

consigliamo di lasciarla nel suo imballo originale. A questo

scopo l’imballo è stato realizzato in modo da permettere il

montaggio del pannello di legno sulla macchina senza disimballare completamente il prodotto (vedi figure sottostanti).

Il pannello di legno che copre la facciata non deve essere di

spessore inferiore a 18 mm e può essere incernierato sia sul

lato destro che sinistro. Per ragioni di praticità d’uso della

macchina consigliamo lo stesso senso di apertura dell’oblò

con le cerniere applicate sul lato sinistro.

Accessori montaggio portina (Fig. 1-2-3-4-5).

N° 2 Supporti cerniera

Fig. 1

N° 1 Magnete N° 1 Riscontro magnete

Fig. 3 Fig. 4

Fig. 2

N° 2 cerniere

A

C

E

B

D

N° 1 Tassello in gomma

Fig. 5

- n° 6 viti autofilettanti l = 13 mm “tipo A”.

- n° 2 viti metriche testa svasata l = 25 mm “tipo B”; per il

fissaggio del riscontro magnete al mobile.

- n° 4 viti metriche l = 15 mm “tipo C”; per il montaggio dei

supporti cerniera al mobile.

- n° 4 viti metriche l = 7 mm “tipo D”; per il montaggio delle

cerniere ai supporti.

Montaggio dei particolari sulla facciata della macchina.

- Montare i supporti cerniera alla facciata posizionando il

foro indicato da una freccia nella fig. 1 verso l’interno della

facciata interponendo un distanziale (fig. 4/B), utilizzando le

viti tipo C.

- Montare il riscontro magnete dalla parte opposta in alto

interponendo due distanziali (fig. 4/B) utilizzando le due viti

tipo B.

N° 4 Distanziali

Fig. 4/B

18

Page 19

Uso della maschera di foratura.

570

min

815

540

595

820 ÷ 900

600 min

L

I

H

G

- Per tracciare le posizioni dei fori sul lato sinistro del pannello, allinerare la maschera di foratura al lato superiore e

sinistro del pannello facendo riferimento alle linee tracciate

alle estremità.

- Per tracciare le posizioni dei fori sul lato destro del pannello, allinerare la maschera di foratura al lato superiore e destro

del pannello.

- Con una fresa di adeguate dimensioni realizzare le quattro

sedi che dovranno alloggiare le due cerniere, il tassello di

gomma e il magnete.

Montaggio dei particolari sul pannello di legno (Antina).

- Inserire le cerniere nelle sedi predisposte (la parte mobile

della cerniera deve trovarsi verso l’esterno del pannello) e

fissarle con 4 viti del tipo A.

- Inserire il magnete nella sede in alto dalla parte opposta

alle cerniere e fissarlo con due viti tipo B.

- Inserire il tassello in gomma nella sede in basso.

Il pannello è ora pronto per essere montato sulla macchina.

Montaggio del pannello alla macchina.

Inserire il nasello della cerniera indicato dalla freccia nella fig.

2 nella sede del supporto cerniera spingere il pannello verso

la facciata della macchina e fissare le due cerniere con le

due viti tipo D.

Fissaggio della guida zoccolo.

Se la macchina è installata ad una estremità della cucina

componibile montare una o entrambe le guide zoccolo

come indicato in fig. 8, regolandone la profondità in funzione

della posizione dello zoccolo e se necessario fissarlo alle

stesse (fig. 9).

Per montare la guida zoccolo agire cone segue (fig. 8):

Fissare la squadretta P con la vite R, infilare la guida zoccolo

Q nell’apposita asola e una volta posizionata nel punto desiderato bloccarla alla squadretta P con la vite R.

Inserimento della macchina nei mobili.

- Spingere l’apparecchio nell’apertura allineandola con gli

altri mobili (fig. 6).

- Agire sui piedini di regolazione per portare la macchina

all’altezza desiderata.

- Per regolare la posizione del pannello in legno in senso

verticale ed orizzontale, agire sulle viti C e D come indicato

in fig. 7.

Importante: chiudere la parte inferiore della facciata con lo

zoccolo a battuta sul pavimento.

I

Fig. 8 Fig. 9

Accessori in dotazione per la regolazione in altezza.

Alloggiate nel coperchio di polistirolo (fig. 10) si trovano:

2 traverse (G); 1 listello (M)

all’interno del cestello si trovano:

4 piedini supplementari (H)

4 viti (I)

4 viti (R)

4 dadi (L)

2 guide zoccolo (Q)

Fig. 10

Regolazione in altezza della macchina.

La macchina può essere regolata in altezza (da 815 mm a 835

mm) agendo sui 4 piedini.

Se si desidera portarla ad un’altezza superiore a quella sopraindicata, arrivando fino a 870 mm, occorre utilizzare i seguenti

accessori:

le 2 traverse (G); i 4 piedini (H); le 4 viti (I); i 4 dadi (L), quindi

agire come segue (fig. 11):

togliere i 4 piedini originali, posizionare una traversa G nella parte anteriore della macchina, fissarla con le viti I (avvitandole nei

fori dove erano montati i piedini originali) quindi inserire i nuovi

pedini H.

Ripetere la stessa operazione nella parte posteriore della macchina.

A questo punto regolando i piedini H la macchina può essere

abbassata o alzata da 835 mm a 870 mm.

Una volta raggiunta l’altezza desiderata bloccare i dadi L alla

traversa G.

Per regolare la macchina ad un’altezza compresa tra 870 mm e

900 mm occorre montare il listello M regolando i piedini H fino

all’altezza desiderata. Per inserire il listello agire come segue:

allentare le tre viti N poste nella parte anteriore della copertura Top, inserire il listello M come indicato nella fig. 12, quindi

bloccare le viti N.

C

M

D

C

Fig. 6 Fig. 7

Fig. 11 Fig. 12

19

Page 20

Descrizione della lavabiancheria

Pannello di controllo

I

Tasto ON/OFF

Tasto

BLOCCO

TASTI

DISPLAY

Tasto

CENTRIFUGA

SELETTORE

PROGRAMMI

Cassetto dei detersivi

Cassetto dei detersivi: per caricare detersivi e additivi

(vedi “Detersivi e biancheria”).

Tasto ON/OFF : premere brevemente il tasto per accendere o spegnere la macchina. La spia START/PAUSE

che lampeggia lentamente di colore verde indica che la

macchina è accesa. Per spegnere la lavabiancheria durante il lavaggio è necessario tenere premuto il tasto più

a lungo, circa 2 sec.; una pressione breve o accidentale

non permetterà lo spegnimento della macchina.

Lo spegnimento della macchina durante un lavaggio in

corso annulla il lavaggio stesso.

Tasti SELETTORE PROGRAMMI: per impostare il programma desiderato (vedi “Tabella dei programmi”).

Tasto MEMO: tenere premuto il tasto per memorizzare

un ciclo e le proprie personalizzazioni preferite. Per richiamare un ciclo precedentemente memorizzato premere il

tasto MEMO.

Tasti FUNZIONE: premere il tasto per selezionare la funzione desiderata. Sul display si illuminerà la spia relativa.

Tasto CENTRIFUGA : premere per ridurre o escludere

del tutto la centrifuga; il valore viene indicato nel display.

Tasto TEMPERATURA : premere per ridurre la tem-

peratura; il valore viene indicato nel display.

Tasti

Tasto

MEMO

Tasti

Tasto

PARTENZA

RITARDATA

Tasto BLOCCO TASTI : per attivare il blocco del

pannello di controllo, tenere premuto il tasto per circa

2 secondi. Il simbolo acceso indica che il pannello

di controllo è bloccato. In questo modo si impediscono

modifiche accidentali dei programmi, soprattutto se in

casa ci sono dei bambini.

Per disattivare il blocco del pannello di controllo, tenere

premuto il tasto per circa 2 secondi.

Tasto PARTENZA RITARDATA : premere per impo-

stare una partenza ritardata del programma prescelto; il

ritardo viene indicato nel display.

Tasto con spia START/PAUSE: quando la spia verde

lampeggia lentamente, premere il tasto per avviare un

lavaggio. A ciclo avviato la spia diventa fissa. Per mettere

in pausa il lavaggio, premere nuovamente il tasto; la spia

lampeggerà con colore arancione. Se il simbolo non è

illuminato, si potrà aprire l’oblò. Per far ripartire il lavaggio

dal punto in cui è stato interrotto, premere nuovamente il

tasto.

Modalità di stand by

Questa lavatrice, in conformità alle nuove normative

legate al risparmio energetico, è dotata di un sistema

di autospegnimento (stand by) che entra in funzione

dopo circa 30 minuti nel caso di non utilizzo. Premere

brevemente il tasto ON/OFF e attendere che la macchina

si riattivi.

Consumo in off-mode: 0,5 W

Consumo in Left-on: 0,5 W

FUNZIONE

Tasto

TEMPERATURA

Tasto con spia

START/

PAUSE

20

Page 21

Display

I

Z

B

A

X

D

C

E

Y

F

Il display è utile per programmare la macchina e fornisce molteplici informazioni.

Nelle due stringhe superiori A e B vengono visualizzati il programma di lavaggio selezionato, la fase di lavaggio in corso e

tutte le indicazioni relative allo stato d’avanzamento del programma.

Nella stringa C viene visualizzato il tempo residuo alla fine del ciclo di lavaggio in corso e nel caso fosse stata impostata una

PARTENZA RITARDATA, il tempo mancante all’avvio del programma selezionato.

Nella stringa D viene visualizzato il valore massimo della velocità della centrifuga che la macchina può effettuare in base al

programma impostato; se il programma non prevede la centrifuga la stringa resta spenta.

Nella stringa E viene visualizzato il valore massimo della temperatura che si può selezionare in base al programma impostato;

se il programma non prevede l’impostazione della temperatura la stringa resta spenta.

Le spie F sono relative alle funzioni e si accendono quando la funzione selezionata è compatibile con il programma impostato.

Simbolo Oblò bloccato

Il simbolo acceso indica che l’oblò è bloccato per impedire aperture accidentali. Per evitare danni è necessario attendere che

il simbolo si spenga prima di aprire l’oblò.

N.B.: se è attiva la funzione PARTENZA RITARDATA l’oblo non si può aprire, per aprirlo mettere la macchina in pausa premendo il tasto START/PAUSE.

! Alla prima accensione verrà richiesto di selezionare la lingua ed il display entrerà automaticamente nel menu di selezione

lingua.

Per scegliere la lingua desiderata premere i tasti X e Y, per confermare la scelta premere il tasto Z.

Se si vuole cambiare lingua, spegnere la macchina, premere contemporaneamente i tasti X, Y, Z fino a sentire un segnale

acustico, verrà visualizzato di nuovo il menu di selezione lingua.

21

Page 22

Come effettuare un ciclo di

lavaggio

1. ACCENDERE LA MACCHINA. Premere il tasto , sul

I

display comparirà la scritta BENVENUTI; la spia START/

PAUSE lampeggerà lentamente di colore verde.

2. CARICARE LA BIANCHERIA. Aprire la porta oblò.

Caricare la biancheria facendo attenzione a non

superare la quantità di carico indicata nella tabella

programmi della pagina seguente.

3. DOSARE IL DETERSIVO. Estrarre il cassetto e

versare il detersivo nelle apposite vaschette come

spiegato in “Detersivi e biancheria”.

4. CHIUDERE L’OBLO’.

5. SCEGLIERE IL PROGRAMMA. Premere uno dei

tasti del SELETTORE PROGRAMMI per selezionare

il programma desiderato; il nome del programma

comparirà sul display; ad esso è associata una

temperatura e una velocità di centrifuga che possono

essere modificate. Sul display comparirà la durata del

ciclo.

6. PERSONALIZZARE IL CICLO DI LAVAGGIO.

Agire sugli appositi tasti:

Modificare la temperatura e/o la centrifuga. La

macchina seleziona automaticamente la temperatura

e la centrifuga massime previste per il programma

impostato e non possono pertanto essere aumentate.

Premendo il tasto si riduce progressivamente

la temperatura sino al lavaggio a freddo “OFF”.

Premendo il tasto si riduce progressivamente la

centrifuga sino alla sua esclusione “OFF”. Un’ulteriore

pressione dei tasti riporterà i valori a quelli massimi

previsti.

! Eccezione: selezionando il programma

(1° pressione del tasto) la temperatura può essere portata

sino a 90°.

attivata solo la seconda, la spia della funzione attivata

si illuminerà.

! Le funzioni possono variare il carico raccomandato

e/o la durata del ciclo.

7. AVVIARE IL PROGRAMMA. Premere il tasto

START/PAUSE. La spia relativa si illuminerà di

colore verde fisso e l’oblò si bloccherà (simbolo

OBLO’BLOCCATO acceso). Durante il lavaggio,

sul display comparirà il nome della fase in corso. Per

cambiare un programma mentre un ciclo è in corso,

mettere la lavabiancheria in pausa premendo il tasto

START/PAUSE (la spia START/PAUSE lampeggerà

lentamente di colore arancione); selezionare quindi il

ciclo desiderato e premere nuovamente il tasto START/

PAUSE.

Per aprire la porta mentre un ciclo è in corso premere il

tasto START/PAUSE; se il simbolo OBLO’BLOCCATO

è spenta sarà possibile aprire l’oblò. Premere

nuovamente il tasto START/PAUSE per far ripartire il

programma dal punto in cui era stato interrotto.

8. FINE DEL PROGRAMMA. Viene indicata dalla

scritta “FINE CICLO” sul display, quando il simbolo

OBLO’BLOCCATO si spegnerà sarà possibile

aprire l’oblò. Aprire l’oblò, scaricare la biancheria e

spegnere la macchina.

! Se si desidera annullare un ciclo già avviato, premere a

lungo il tasto . Il ciclo verrà interrotto e la macchina si

spegnerà.

(60°C)

Impostare una partenza ritardata.

Per impostare la partenza ritardata del programma

prescelto, premere il tasto relativo fino a raggiungere

il tempo di ritardo desiderato. Quando tale opzione

è attiva, sul display si illumina il simbolo . Per

rimuovere la partenza ritardata premere il tasto fino a

che sul display compare la scritta “OFF”.

Modificare le caratteristiche del ciclo.

• Premere il tasto per attivare la funzione; la spia

corrispondente al pulsante si accenderà.

• Premere nuovamente il tasto per disattivare la

funzione; la spia si spegnerà.

! Se la funzione selezionata non è compatibile con

il programma impostato, la spia lampeggerà e la

funzione non verrà attivata.

! Se la funzione selezionata non è compatibile con

un’altra precedentemente impostata, la spia relativa

alla prima funzione selezionata lampeggerà e verrà

22

Page 23

Programmi e funzioni

M

AX

1

2

4

3

Tabella dei programmi

Detersivi

Descrizione del Programma

Programmi

Antimacchia

Cotone standard 60° (1) (1° pressione del tasto): bianchi e colorati resi-

stenti molto sporchi.

Cotone standard 40° (2) (2° pressione del tasto): bianchi e colorati delicati

poco sporchi.

Cotone standard 20° (3° pressione del tasto): bianchi e colorati delicati

poco sporchi.

Sintetici Resistenti (1° pressione del tasto): colori resistenti molto sporchi. 60° 800

Sintetici Resistenti (4) (1° pressione del tasto): colori resistenti poco sporchi. 40° 800

Sintetici Delicati (2° pressione del tasto): colori resistenti poco sporchi. 40° 800

Rapido 60' (1° pressione del tasto): per rinfrescare rapidamente capi nor-

malmente (non indicato per lana, seta e capi da lavare a mano).

Rapido 30' (2° pressione del tasto): per rinfrescare rapidamente capi poco

(non indicato per lana, seta e capi da lavare a mano).

Memo: permette di memorizzare un qualsiasi ciclo di lavaggio.

M

Antiallergy

Woolmark Platinum (Lana): per lana, cachemire, ecc. 40° 800 -

Delicati

Centrifuga (1° pressione del tasto) - 1400 - - - - 7 - - - 16’

Risciacquo (2° pressione del tasto) - 1400 - Scarico (3° pressione del tasto) - 0 - - - - 7 - - - 2’

La durata del ciclo indicata sul display o sul libretto è una stima calcolata in base a condizioni standard. Il tempo effettivo può variare in base a numerosi fattori quali la temperatura e la pressione

dell’acqua in ingresso, la temperatura ambiente, la quantità di detersivo, la quantità ed il tipo di carico, il bilanciamento del carico, le opzioni aggiuntive selezionate.

1) Programma di controllo secondo la direttiva 1061/2010: impostare il programma a 60°C

Questo ciclo è adatto per pulire un carico di cotone normalmente sporco ed è il più efficiente in termini di consumo combinato di energia e di acqua, da usare su capi lavabili a 60°C. La

temperatura effettiva di lavaggio può differire da quella indicata.

2) Programma di controllo secondo la direttiva 1061/2010: impostare il programma a 40°C

Questo ciclo è adatto per pulire un carico di cotone normalmente sporco ed è il più efficiente in termini di consumo combinato di energia e di acqua, da usare su capi lavabili a 40°C. La

temperatura effettiva di lavaggio può differire da quella indicata.

3) Alla temperatura di 60 °C la funzione “Prelavaggio” non può essere attivata.

Per tutti Test Institutes:

2) Programma cotone lungo: impostare il programma a 40°C

4) Programma sintetico lungo: impostare il programma a 60°C

(2° pressione del tasto).

(1° pressione del tasto)

; temperaura di 40°C

(°C)

Temp. max.

40° 1400

60°

(Max. 90°)

40° 1400 -

20° 1400 -

60° 1400 -

30° 800 -

60° 1400 -

30° 0 -

(1° pressione del tasto)

(2° pressione del tasto).

1400

(premere il tasto TEMPERATURA).

Velocità max.

gio

(giri al minuto)

Prelavag-

(3)

.

dente

Lavaggio

Ammobi-

gina

Candeg-

- 3,5 53 0,81 40 60’

- 3 71 0,15 35 30’

- 4 - - - 195’

- 1,5 - - - 70’

- 1 - - - 80’

%

gia kWh

Acqua totale lt

Consumo ener-

Umidità residua

Carico max. (Kg)

4 - - - 180’

7 53 1,1 58 190’

7 53 0,99

7 - -

3 44 0,93 47 110’

3 44 0,57 46 95’

3 - - - 70’

7 - - - 36’

82

185’

170’

-

Durata ciclo

I

Funzioni di lavaggio

Super Wash

“max” indicato sul perno centrale (vedi figura). Se si desidera solo

candeggiare senza effettuare il lavaggio completo, versare la

candeggina nella vaschetta aggiuntiva 4, impostare il programma

“Risciacquo” e attivare l’opzione “Super Wash”.

! L’utilizzo della vaschetta aggiuntiva 4 esclude il prelavaggio.

! Non è attivabile sui programmi , , , , “Centrifuga”,

“Scarico”.

Extra Risciacquo

Selezionando questa opzione si aumenta l’efficacia del

risciacquo, e si assicura la massima rimozione del detersivo. E’

utile per pelli particolarmente sensibili.

! Non è attivabile sui programmi “Rapido 30’”, , ,

Centrifuga”, “Scarico”.

Questa opzione garantisce

un lavaggio di alte prestazioni

grazie all’utilizzo di una maggior

quantità d’ acqua nella fase

iniziale del ciclo e alla maggior

durata del programma ed è utile

per eliminare le macchie più

resistenti. Può essere utilizzata

con o senza candeggina. Se

si desidera effettuare anche il

candeggio inserire la vaschetta

aggiuntiva 4, in dotazione,

nella vaschetta 1. Nel dosare la

candeggina non superare il livello

Stira facile

Selezionando questa funzione, il lavaggio e la centrifuga saranno

opportunamente modificati per ridurre la formazione di pieghe. Al

temine del ciclo la lavabiancheria effettuerà delle lente rotazioni

del cestello; lla spia della funzione STIRA FACILE e quella di

START/PAUSE lampeggeranno (arancione) e la scritta “FINE

CICLO” apparirà su display. Per terminare il ciclo si dovrà

premere il tasto START/PAUSE o il tasto STIRA FACILE. Per

scaricare l’acqua e poter rimuovere il bucato sarà necessario

premere il tasto START/PAUSE o il tasto STIRA FACILE.

! Non è attivabile sui programmi , “Rapido 30’”, , , .

Prelavaggio

Selezionando questa funzione si effettua il prelavaggio, utile

per rimuovere macchie ostinate.

N.B.: Aggiungere il detersivo nell’apposito scomparto.

! Non è attivabile sui programmi , , , , ,

(40°),

.

(60°),

Eco wash

La funzione Eco Wash contribuisce al risparmio energetico

non riscaldando l’acqua utilizzata per lavare il bucato – un

vantaggio sia per l’ambiente, sia per la bolletta elettrica. Infatti,

l’azione rafforzata e il consumo ottimizzato dell’acqua garantiscono ottimi risultati nella stessa durata media di un ciclo

standard. Per ottenere i migliori risultati di lavaggio, si consiglia

l’uso di un detersivo liquido.

! Non è attivabile sui programmi , , , , , .

23

Page 24

Detersivi e biancheria

M

AX

1

2

4

3

Cassetto dei detersivi

I

Il buon risultato del lavaggio dipende anche dal corretto

dosaggio del detersivo: eccedendo non si lava in modo

più efficace e si contribuisce a incrostare le parti interne

della lavabiancheria e a inquinare l’ambiente.

! Usare detersivi in polvere per capi in cotone bianchi e per il

prelavaggio e per lavaggi con temperatura superiore a 60°C.

! Seguire le indicazioni riportate sulla confezione di deter-

sivo.

! Non usare detersivi per il lavaggio a mano, perché for-

mano troppa schiuma.

Estrarre il cassetto dei detersivi e inserire il detersivo

o l’additivo come segue.

vaschetta 1: Detersivo per prelavaggio

(in polvere)

Prima di versare il detersivo verificare che non sia inserita

la vaschetta aggiuntiva 4.

vaschetta 2: Detersivo per lavaggio

(in polvere o liquido)

Il detersivo liquido va versato solo prima dell’avvio.

vaschetta 3: Additivi (ammorbidente, ecc.)

L’ammorbidente non deve fuoriuscire dalla griglia.

vaschetta aggiuntiva 4: Candeggina

Preparare la biancheria

• Suddividere la biancheria secondo:

- il tipo di tessuto / il simbolo sull’etichetta.

- i colori: separare i capi colorati da quelli bianchi.

• Vuotare le tasche e controllare i bottoni.

• Non superare i valori indicati, riferiti al peso della

biancheria asciutta:

Tessuti resistenti: max 7 kg

Tessuti sintetici: max 3 kg

Lana: max 1,5 kg

Seta: max 1 kg

Quanto pesa la biancheria?

1 lenzuolo 400-500 gr.

1 federa 150-200 gr.

1 tovaglia 400-500 gr.

1 accappatoio 900-1200 gr.

1 asciugamano 150-250 gr.

Programmi particolari

Antimacchia: il programma è adatto al lavaggio di

capi molto sporchi, con colori resistenti. Il programma

garantisce una classe di lavaggio superiore alla classe

standard (classe A). Non eseguire il programma mescolando capi di colore diverso. Si consiglia l’utilizzo di

detersivo in polvere. Per macchie ostinate è consigliato il

pretrattamento con additivi specifici.

Cotone standard 20°: ideale per carichi in cotone

sporchi. Le buone performance anche a freddo, comparabili con un lavaggio a 40°, sono garantite da un’azione

meccanica che lavora con variazione di velocità a picchi

ripetuti e ravvicinati.

Antiallergy: utilizzare il programma per la rimozione dei

principali allergeni come polline, acari, peli del gatto e cane.

Lana: Il ciclo di lavaggio “Lana” di questa lavatrice

Hotpoint-Ariston è stato testato e approvato dalla

Woolmark Company per il lavaggio di capi in lana

classificati come “lavabili a mano”, purché il lavaggio

venga eseguito nel rispetto delle istruzioni riportate

sull’etichetta dell’indumento e delle indicazioni fornite dal

produttore dell’elettrodomestico. Hotpoint-Ariston è la

prima marca di lavatrici ad aver ottenuto dalla Woolmark

Company la certificazione Woolmark Apparel Care Platinum per le sue prestazioni di lavaggio e il consumo di

acqua ed energia. (M1126)

Delicati: utilizzare il programma per il lavaggio dei capi

molto delicati, che presentano applicazioni quali strass o

paillettes.

Si raccomanda di rovesciare i capi prima del lavaggio e di

inserire gli indumenti piccoli nell’apposito sacchetto per il

lavaggio dei capi delicati.

Per risultati migliori si raccomanda l’utilizzo del detersivo

liquido per capi delicati.

Per il lavaggio dei capi in seta e tende, selezionare il ciclo

e attivare la funzione (in questo caso la funzione

“Extra Risciacquo” sarà attiva); la macchina terminerà il

ciclo con la biancheria in ammollo e la spia della funzione

lampeggerà. Per scaricare l’acqua e poter rimuovere

il bucato sarà necessario premere il tasto START/PAUSE

o il tasto .

Sistema bilanciamento del carico

Prima di ogni centrifuga, per evitare vibrazioni eccessive

e per distribuire il carico in modo uniforme, il cestello

effettua delle rotazioni ad una velocità leggermente

superiore a quella del lavaggio. Se al termine di ripetuti

tentativi il carico non fosse ancora correttamente

bilanciato la macchina effettua la centrifuga ad una

velocità inferiore a quella prevista.

In presenza di eccessivo sbilanciamento la lavabiancheria

effettua la distribuzione anzichè la centrifuga. Per favorire

una migliore distribuzione del carico e il suo corretto

bilanciamento si consiglia di mescolare capi grandi e

piccoli.

24

Page 25

Precauzioni e consigli

! La lavabiancheria è stata progettata e costruita in

conformità alle norme internazionali di sicurezza. Queste

avvertenze sono fornite per ragioni di

sicurezza e devono essere lette attentamente.

Sicurezza generale

• Questo apparecchio è stato concepito esclusiva-

mente per un uso di tipo domestico.

• L’apparecchio non deve essere utilizzato da

persone (bambini compresi) con capacità fisiche,

sensoriali o mentali ridotte e con esperienze e

conoscenze insufficienti, a meno che tale utilizzo

non avvenga sotto la supervisione o le istruzioni di

una persona responsabile della loro sicurezza. I

bambini devono essere sorvegliati per garantire

che non giochino con l’apparecchio.

• Non toccare la macchina a piedi nudi o con le

mani o i piedi bagnati o umidi.

• Non staccare la spina dalla presa della corrente

tirando il cavo, bensì afferrando la spina.

• Non aprire il cassetto dei detersivi mentre la

macchina è in funzione.

• Non toccare l’acqua di scarico, che può

raggiungere temperature elevate.

• Non forzare in nessun caso l’oblò: potrebbe

danneggiarsi il meccanismo di sicurezza che

protegge da aperture accidentali.

• In caso di guasto, in nessun caso accedere ai

meccanismi interni per tentare una riparazione.

• Controllare sempre che i bambini non si avvicinino

alla macchina in funzione.

• Durante il lavaggio l’oblò tende a scaldarsi.

• Se dev’essere spostata, lavorare in due o tre

persone con la massima attenzione. Mai da soli

perché la macchina è molto pesante.

• Prima di introdurre la biancheria controlla che il

cestello sia vuoto.

degli elettrodomestici, i detentori potranno rivolgersi

al servizio pubblico preposto o ai rivenditori.

Apertura manuale dell’oblò

Nel caso non sia possibile aprire l’oblò a causa della

mancanza di energia elettrica e volete stendere il bucato,

procedere come segue:

1. togliere la spina dalla presa di corrente.

2. verificate che il livello dell’acqua all’interno della