Part Number:

3420210

Fitting Kit No:

6173022 (suits all year models)

Available Lower Panel Supplementary kits:

3520010 06-09 FJ Cruiser

3520020 2010 ON FJ Cruiser

3520030 Field fix kit is required for Australian

delivery vehicles in addition to the main bar kit.

Product Description:

Vehicle/s:

ARB WINCH BULL BAR

TOYOTA FJ CRUISER 2006 ON

WARNING

REGARDING VEHICLES EQUIPPED WITH SRS AIRBAG:

When installed in accordance with these instructions, the front protection bar does not affect operation of

the SRS airbag.

ALSO, NOTE THE FOLLOWING:

♦ This product must be installed exactly as per these instructions using only the hardware supplied.

♦ In the event of damage to any bull bar component, contact your nearest authorised ARB stockist.

Repairs or modifications to the impact absorption system must not be attempted.

♦ Do not use this product for any vehicle make or model, other than those specified by ARB.

♦ Do not remove labels from this bull bar.

♦ This product or its fixing must not be modified in any way.

♦ The installation of this product may require the use of specialized tools and/or techniques

♦ It is recommended that this product is only installed by trained personnel

♦ These instructions are correct as at the publication date. ARB Corporation Ltd. cannot be held

responsible for the impact of any changes subsequently made by the vehicle manufacturer

♦ During installation, it is the duty of the installer to check correct operation/clearances of all

components

♦ Work safely at all times

♦ Unless otherwise instructed, tighten fasteners to specified torque

ARB 4x4 ACCESSORIES

Corporate Head Office

42-44 Garden St Tel: +61 (3) 9761 6622

Kilsyth, Victoria Fax: +61 (3) 9761 6807

AUSTRALIA 3137

Australian enquiries sales@arb.com.au

North & South American enquiries sales@arbusa.com

Other international enquiries exports@arb.com.au

www.arb.com.au

Last Rev Date: 18/07/11 Page 1 of 15 Fitting instructions# 3787968

Copyright © 2005 by ARB Corporation Limited. All rights rese rved, t his document must not be reproduced without the express au thority of ARB Corporation Ltd

FITTING REQUIREMENTS

REQUIRED TOOLS FOR FITMENT OF PRODUCT:

Basic Tool Kit External Circlip pliers

17mm Tube Spanner Power Drill 13mm capacity

7mm, 10mm and 13mm drill bits Cold chisel

HAVE AVAILABLE THESE SAFETY ITEMS WHEN FITTING PRODUCT:

Protective eyewear

Hearing protection

NOTE: ‘WARNING’ notes in the fitting procedure relate to OHS situations, where to avoid a

potentially hazardous situation it is suggested that protective safety gear be worn or a safe work

procedure be employed. If these notes and warnings are not heeded, injury may result.

FASTENER TORQUE SETTINGS:

SIZE Torque Nm Torque lbft

M6 9Nm 7lbft

M8 22Nm 16lbft

M10 44Nm 32lbft

M12 77Nm 57lbft

OPTIONAL LIGHT SETS TO SUIT THIS PRODUCT:

♦ ARB 6821201 Fog Light Kit Suit 3163015

♦ Up to IPF 900 SERIES FOG OR DRIVING LIGHT SETS

Last Rev Date: 18/07/11 Page 2 of 15 Fitting instructions# 3787968

Copyright © 2005 by ARB Corporation Limited. All rights rese rved, t his document must not be reproduced without the express au thority of ARB Corporation Ltd

Fitting Kit 6172343 PARTS LISTING

APPLICATION. PART NO. QTY DESCRIPTION

Mount Assembly To Chassis

Bull Bar To Impact Absorber

Indicators To Bull Bar

Winch To Bull Bar

Number Plate To Bull Bar

Miscellaneous

Supplementary Kit:

3520010 06-09 Models:

Stone Tray

Supplementary Kit:

3520020 2010 ON Models:

Stone Tray and Wing Under Panels

3756848

3756851R

3756851L

3193741

6151306

6151255

6151189

6151094

4581049

4581050

5846401

6151357

4581040

6151026

3163015

6821152

6821151L

6821151R

EG50

3756499

6151021

4581044

6151132

BLB560

4581040

6151074

6821189

6151384

6781408

6821132

180302

3162152

3756857

6542088

6151300

6151213

4584310

4581287

6542111

6522795 R&L

6151300

6151213

4584310

4581082

4581287

6151132

6151234

4581307

4581047

3787825

1

1

1

2

2

8

6

2

18

10

4

10

10

10

1

2

1

1

1

1

2

2

2

2

4

2

2

2

1

2

8

2

1

1

4

4

4

4

1

1 pr

14

16

6

10

16

2

2

4

2

1

Bracket Mount Assembly

Bracket Mount Brace RHS

Bracket Mount Brace LHS

Captive Nut Plate

Nut Cage M12 x 1.75

Bolt M12 x 1.75 x 40mm

Nut M12 x 1.75

Bolt M12 x 1.25 x 30mm

Washer Flat M12

Washer Spring M12

Spacer 8mm

SEMS Bolt M10 x 1.5 x 30mm

Washer Flat M10 x 2mm

Nut M10 x 1.5

Combination Light Surround Kit

Turn signal / clearance light loom

Turn Signal / Clearance Light

Turn Signal / Clearance Light

Rubber Grommet

Bracket Control Box

Bolt M8 x 20mm

Washer Flat M8

Nut Flange M8

Cable Black 560mm

Washer Flat 3/8” x 1”

Bolt 1 ¾” x 3/8” UNC

Grommet Nylon Nut

Screw Pan Hd Phil 5x16mm

Tape Double sided

Rubber Grommet 3/8” ID

Cable Ties

Plastic Plug 16mm DIA

Bracket Bracing Lower Grille

Stone Tray 06-09

Nut Cage 6mm

Bolt M6 x 20mm BZ

Washer Flat M6 BZ

Washer Spring M6 BZ

Stone Tray 2010 ON

Wing under panels

Nut Cage 6mm

Bolt M6 x 20mm BZ

Washer Flat M6 THK BZ

Washer Flat M6 BZ

Washer Spring M6 BZ

Nut Flange 8mm

Bolt M8 x 25mm BZ

Washer Flat Panel M8 BZ

Washer Spring M8 BZ

Template drilling mount holes

Last Rev Date: 18/07/11 Page 3 of 15 Fitting instructions# 3787968

Copyright © 2005 by ARB Corporation Limited. All rights rese rved, t his document must not be reproduced without the express au thority of ARB Corporation Ltd

FITTING PROCEDURE

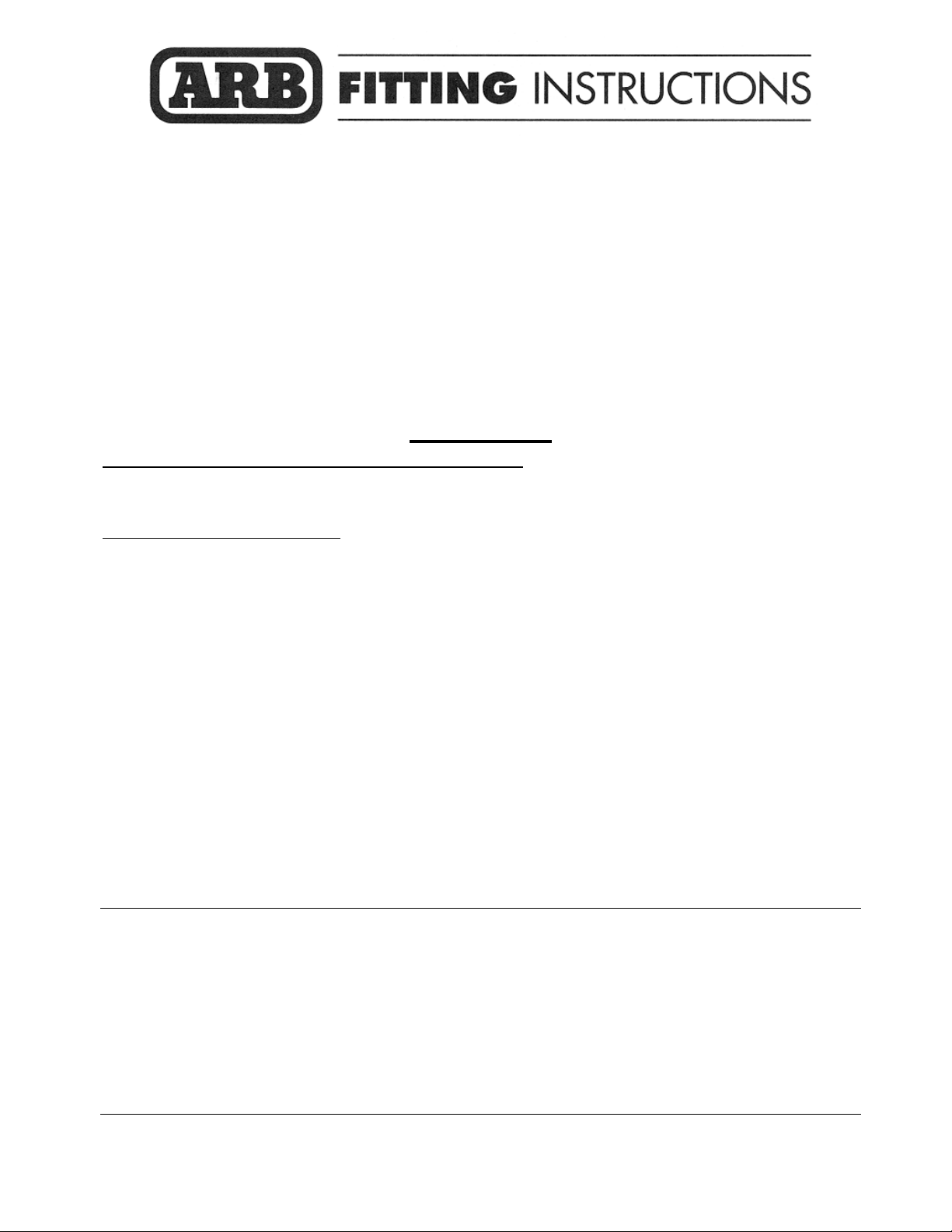

1. Remove protective plate if fitted

2. Remove front fasteners only from stone tray.

Retain fasteners for reuse.

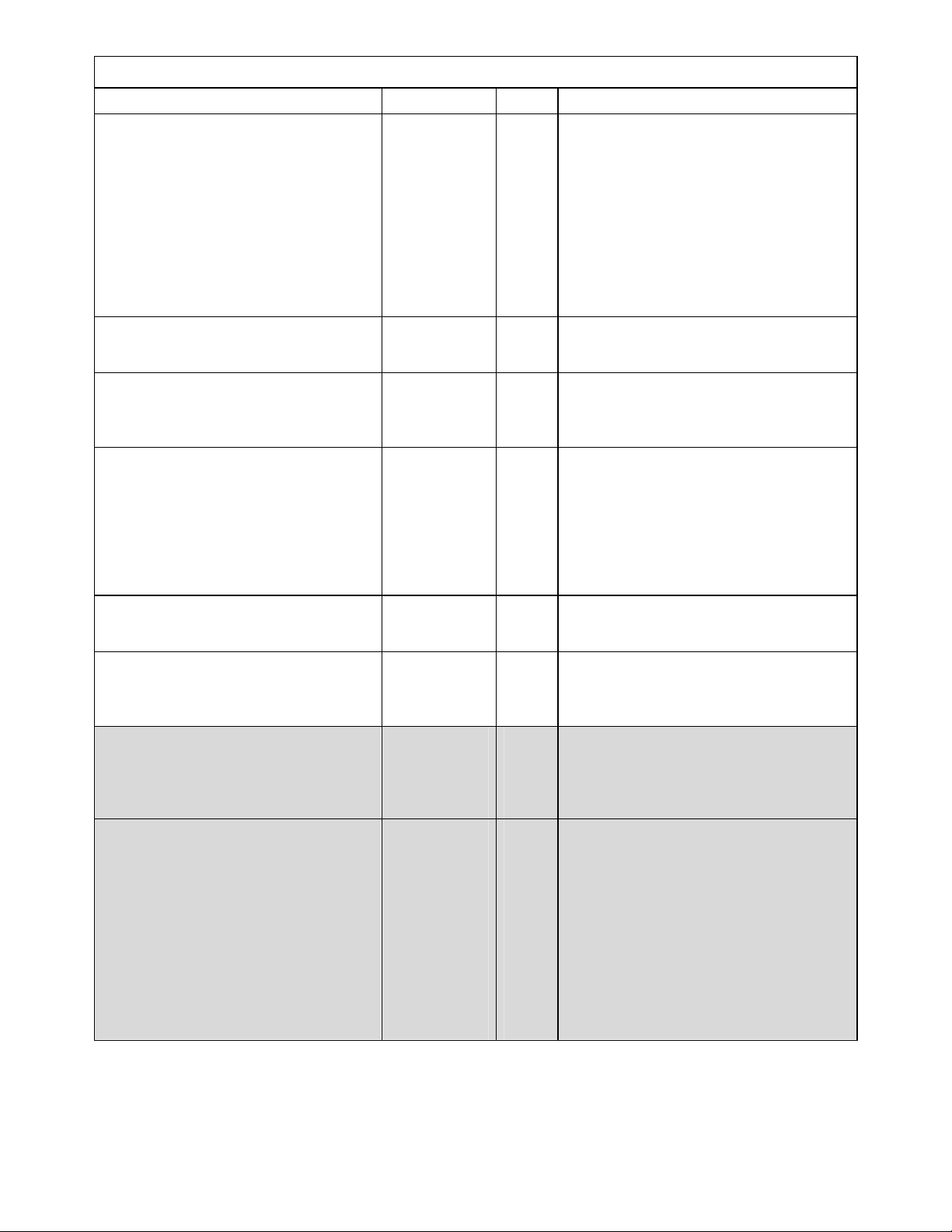

3. Remove lower bumper fixing screws and

screws in wheel arch area

4. Remove grille. Screws are located in tabs at

top of grille. Once these are removed

carefully release clips some are located along

the inside lower section.

Last Rev Date: 18/07/11 Page 4 of 15 Fitting instructions# 3787968

Copyright © 2005 by ARB Corporation Limited. All rights rese rved, t his document must not be reproduced without the express au thority of ARB Corporation Ltd

FITTING PROCEDURE

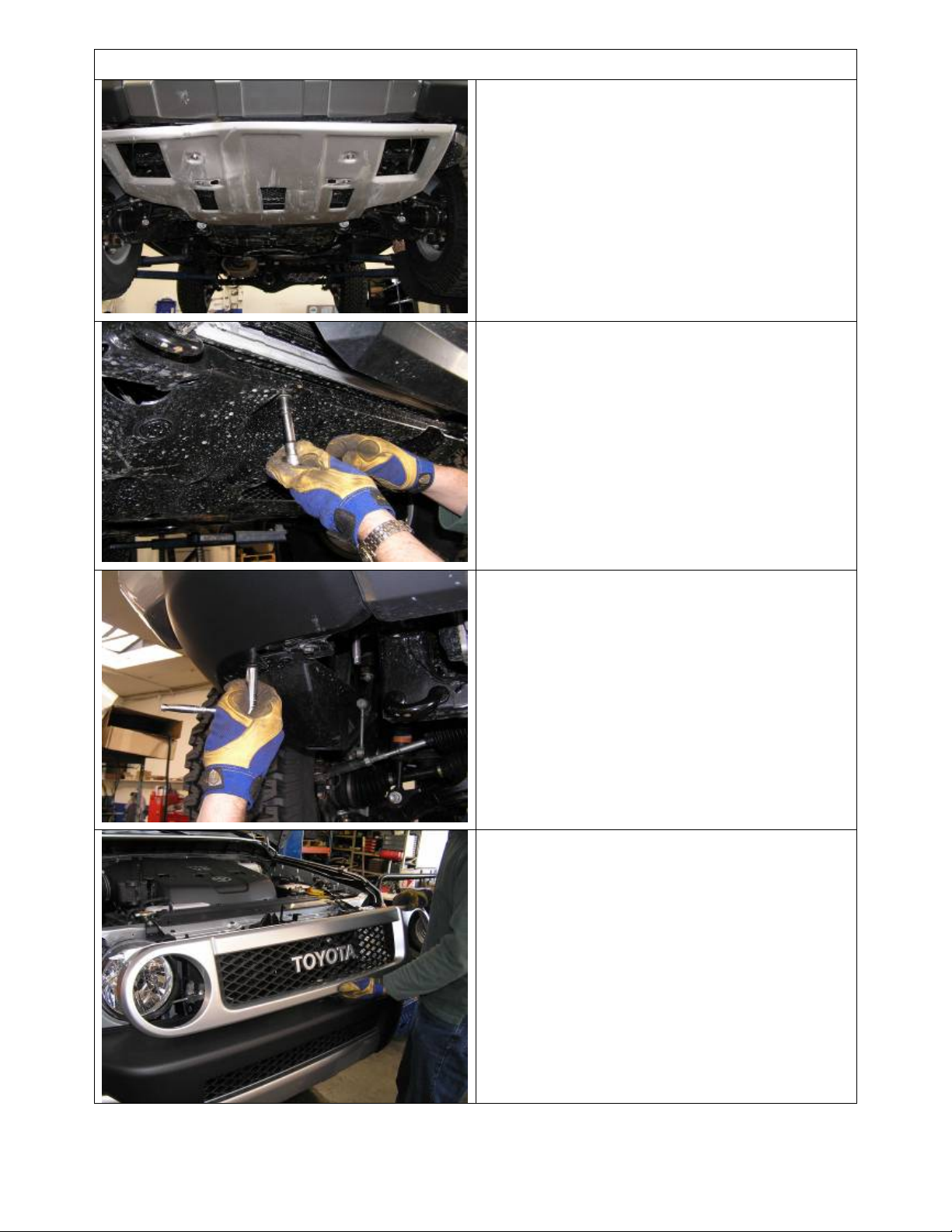

5. Remove plastic rivets along top of bumper

6. Remove screw then remove front bumper

cover from vehicle.

NOTE: Prise the rear lip of the bumper off the

retaining spigot where screw was located (as

shown with arrow) then pull bar wing outward

.

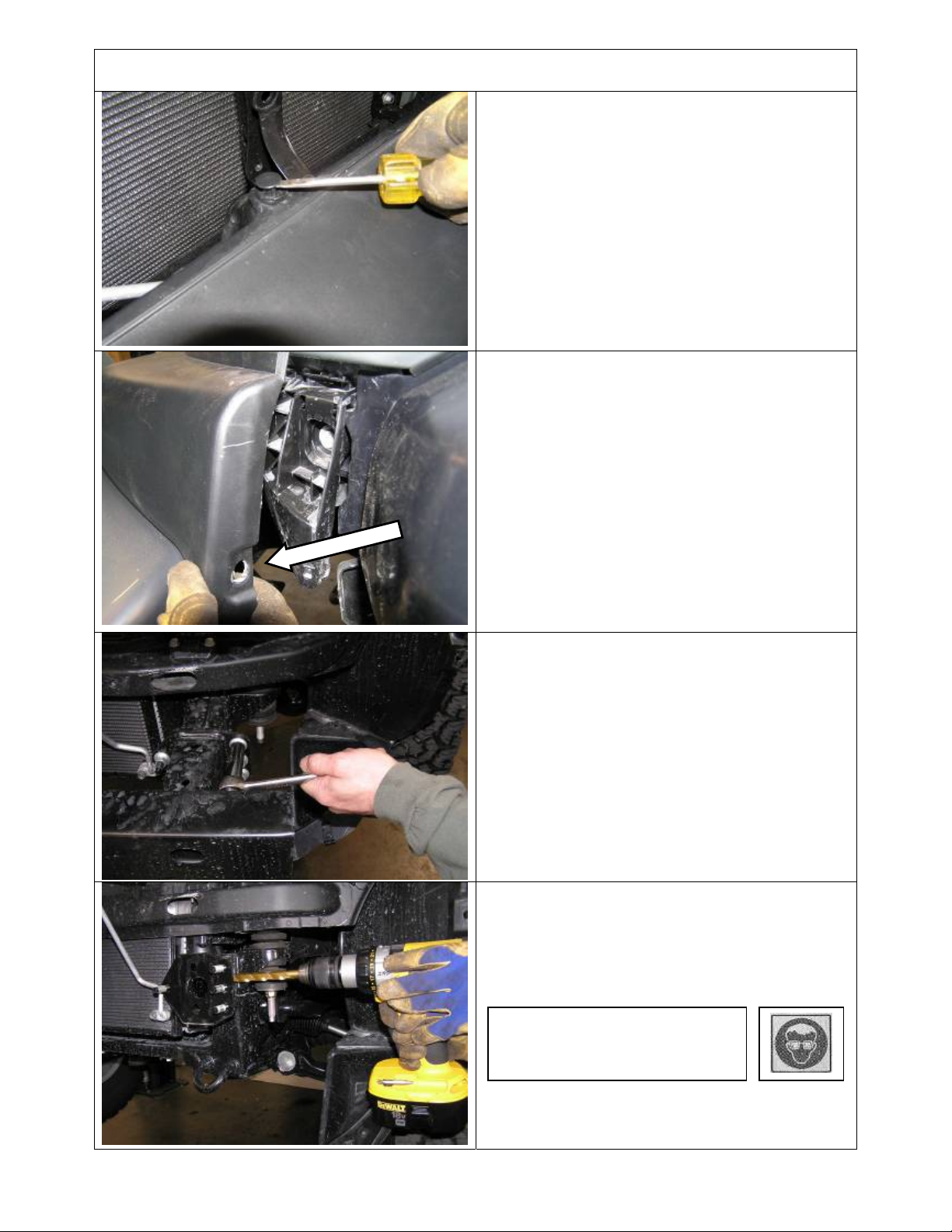

7. Remove front bumper reinforcing bar.

NOTE: Retain the 8 x flange nuts removed for

fitment of the bull bar chassis mount.

8. Using the 13mm drill bit and power drill, drill

out the M8 captive nut located at the outboard

side of the chassis as shown, on both sides of

the vehicle.

Warning: Drilling operations can

result in flying metal debris,

safety glasses should be worn.

Last Rev Date: 18/07/11 Page 5 of 15 Fitting instructions# 3787968

Copyright © 2005 by ARB Corporation Limited. All rights rese rved, t his document must not be reproduced without the express au thority of ARB Corporation Ltd

FITTING PROCEDURE

9. Check that the nut body is completely

removed, if it is not cleared, using a cold

chisel and hammer chisel the remainder off.

Warning: Hammering and

chiselling operations can result in

flying metal debris, safety glasses

should be worn.

10. Fit an M12 cage nut to each of the captive

nut plates 3193741.

Use a M12

flat washer

as a spacer

between

chassis and

bracket.

11. Fit the chassis mount braces to the vehicle

using the M12 x 30mm fine pitched bolt, M12

spring and flat washers supplied in the lower

hole. Use an M12 flat washer as a spacer

between the brace and the chassis at the

upper hole and fix with an M12 x 40mm bolt

M12 spring and flat washers and M12 x 1.75

nut. Do not tighten the bolts.

12. Insert the captive nut assembly through the

front of the chassis and line it up with the hole

at the end of the mount brace. Fix in place

with the M12 x 1.75 x 40mm bolt, M12 flat

and spring washers. Break off the end of the

captive nut plate. Do not tighten yet.

Last Rev Date: 18/07/11 Page 6 of 15 Fitting instructions# 3787968

Copyright © 2005 by ARB Corporation Limited. All rights rese rved, t his document must not be reproduced without the express au thority of ARB Corporation Ltd

FITTING PROCEDURE

Position brace so

spacer won’t protrude

from the chassis

13. Hold the 8mm spacer against the chassis

mount brace forward facing surface and

position the brace so that the spacers sit just

below the surface of the chassis front face.

Tighten the bolts.

14. If fitting the bar to an Australian delivered

vehicle, please refer now to fitting instructions

#3787967 to relocate the power steering

lines. If not proceed to the next step.

15. Fit the chassis mount bracket to the chassis

using the original flange nuts removed with

the bumper reinforcing bar. Centre the

chassis mount bracket and tighten.

CAUTION: When fitting the Chassis mounting

bracket carefully bend the air-conditioning pipe

out of the way.

16. If required, carefully bend A/C piping clear of

mount bracket assembly as shown, with a

minimum clearance of 20mm (3/4”).

CAUTION: Piping must not rub on

sharp edges, secure with cable tie

and protective sheath if required.

17. Fix the chassis mount bracket to the chassis

mount brace using M12 x 40mm bolts, M12

spring and flat washers, the 8mm spacers

and M12 x 1.75 nuts. Tighten bolts

Last Rev Date: 18/07/11 Page 7 of 15 Fitting instructions# 3787968

Copyright © 2005 by ARB Corporation Limited. All rights rese rved, t his document must not be reproduced without the express au thority of ARB Corporation Ltd

V

FITTING PROCEDURE

NOTE: If fitting winch continue

through step 17, if not skip to step 29

18. For ease of access the winch gearbox

handle needs to be rotated. To do this undo

all the cap screws, carefully lift the gearbox

clear of the winch body so as not to damage

the gasket. (Do not lift the gearbox more

than a couple of millimetres) Rotate the

gearbox anti-clockwise two hole spaces (72°).

Re-fit the cap screws.

iew on gearbox end

19. Using a 12mm (1/2”) drill bit, drill two new

holes in the roller fairlead 25mm below the

original holes.

Original hole.

New hole 25mm lower.

Warning: Drilling operations can result in

flying metal debris, safety glasses should be

20. Remove the three screws from the control

box and remove the cover.

21. Replace the two cables marked “A” and “F1”

and replace them with the two cables

(BLB560) supplied with the fitting kit. Label

the cables the same as the original to assist

in the wiring of the winch.

22. Place the winch on a table with the feet

facing up and using an assistant; carefully lift

the bull bar on top of the winch.

23. Attach the winch to the bull bar using two 1

½” x 3/8” bolts from the winch fitting kit, 3/8”

spring washer and 3/8” flat washers in the top

holes.

24. Fit the 4 x M6 cage nuts from inside of the

lower flange on the pan, where the stone tray

will bolt up.

NOTE: Access to this area for cage nut fitment

will be restricted once the RFL is fitted so it is

important to insert these now.

Last Rev Date: 18/07/11 Page 8 of 15 Fitting instructions# 3787968

Copyright © 2005 by ARB Corporation Limited. All rights rese rved, t his document must not be reproduced without the express au thority of ARB Corporation Ltd

FITTING PROCEDURE

25. Position the roller fairlead, and remove the

circlips from the lower of the vertical rollers

and push the pins up to give access to the

lower bolts.

26. Fix the roller fairlead to the bar using the 1

¾” x 3/8” bolts, spring and flat washers

27. Fit the control box bracket to the bull bar

using two M8 x 20mm bolts, M8 flat washers

and M8 flange nuts.

28. Fit the control box to the control box bracket

and connect the power cables to the winch as

per the winch instructions.

29. Connect the ground wire to the tension bar of

the winch.

CAUTION: Cable-tie all cables together and

keep all cables clear of sharp edges and all

moving parts.

30. Insert square grommets into holes in front of

bar for licence plate fixing. Place the doublesided tape along the top edge of the number

plate. Using supplied black Hi-lo screws,

attach the licence plate to the bull bar.

NOTE: If winch is not fitted, licence plate can

be located lower on bar front to cover RFL

opening.

Last Rev Date: 18/07/11 Page 9 of 15 Fitting instructions# 3787968

Copyright © 2005 by ARB Corporation Limited. All rights rese rved, t his document must not be reproduced without the express au thority of ARB Corporation Ltd

FITTING PROCEDURE

31. Remove original grille brace member. Retain

screws.

32. Fit supplied replacement brace and secure

with original fasteners

33. With the help of an assistant position the bull

bar on the chassis bracket and fix with six

M10 x 30mm bolts, M10 spring and flat

washers.

CAUTION: Nip up bolts, but do not tighten

them yet.

34. Position the bull bar so that there is an even

gap of approximately 5mm from the top face

of the bar to the underside of the body edge.

Then tighten all the bolts.

Last Rev Date: 18/07/11 Page 10 of 15 Fitting instructions# 3787968

Copyright © 2005 by ARB Corporation Limited. All rights rese rved, t his document must not be reproduced without the express au thority of ARB Corporation Ltd

FITTING PROCEDURE

35. With the bull bar in position drill Dia10mm

pinning holes, one though pilot hole in mount

bracket and one through hole in upright for

both sides of mounts.

Warning: Drilling operations can

result in flying metal debris,

safety glasses should be worn.

36. Fix in place using two M10 x 30mm SEMS

bolts, M10 Flat washers and M10 x 1.5 nuts

per side.

37. Assemble and install combination light

surrounds (P# 3163015) as per instructions

# 3786421 supplied with surround kit. Note:

Optional fog lamps can be installed at this

point as per fitting instruction #. 3783315

supplied with fog lamp kit # 6821201.

38. Wire the combination lamp to the vehicles

indicator and clearance lamps.

Caution: Cable tie all cables together and keep

all cables clear of sharp edges and moving

parts.

39. Wire up lights using loom extensions

supplied in fitting kit.

Wiring loom detail for flasher and clearance

lamps supplied standard with bullbar;

Red Clearance lamp

Green Flasher lamp

Black Ground

Wiring loom detail on FJ Cruiser;

LHS

Blue Flasher

Green Run

Wh/Blk Ground

RHS

Pink Flasher

Green Run

Wh/Blk Ground

NOTE: Other wiring detail supplied with

accessories.

Last Rev Date: 18/07/11 Page 11 of 15 Fitting instructions# 3787968

Copyright © 2005 by ARB Corporation Limited. All rights rese rved, t his document must not be reproduced without the express au thority of ARB Corporation Ltd

FITTING PROCEDURE

FROM SUPLEMENTARY KITS – 3520010 & 20

STONE TRAY

40. Fit the bull bar stone tray by sliding the tray

under the front of the vehicles original stone

tray

41. Fit the front of the stone tray to the bull bar

with four M6 x 20mm bolts, M6 large panel

washers and M6 spring washers.

ONLY FROM SUPLEMENTARY KIT - 3520020

WING UNDER PANELS

Check first, then if there are no holes in lower

flange of wing for fixing panels- follow the next

6 steps

42. Cut out the hole position paper template

Final shape of template

43. Locate on the RH wing lower flange and

align to the inner flange edge then tape in

position

44. Centre punch the hole positions onto the

wing lower flange

45. Remove template, apply to LH wing and

centre punch holes

46. Drill the holes to Dia 9mm (11/32”)

47. Deburr then touch up the bared steel with

rust preventing paint

Warning: Drilling operations can

result in flying metal debris,

safety glasses should be worn.

Last Rev Date: 18/07/11 Page 12 of 15 Fitting instructions# 3787968

Copyright © 2005 by ARB Corporation Limited. All rights rese rved, t his document must not be reproduced without the express au thority of ARB Corporation Ltd

FITTING PROCEDURE

FROM SUPPLEMENTARY KIT 3520020

48. Fit the cage nuts to the inside faces of the

wing under panels as shown

49. Fit the wing under panels as shown using M6

bolts and washer sets to bolt to wing

underside

If there is

brace lower flange to fix inside flange of the

sing under panels....

50. Use M8 x 25mm bolts, washer sets and

a corresponding hole in the chassis

flange nut to bolt to chassis brace lower

flange

If there is no corresponding hole in chassis

brace lower flange to fix inside flange of the

wing under panels....

51. On the RH side, lift the inner locating flange

up to the chassis reinforcing bracket lower

flange, position centrally then mark and drill a

Dia 7mm (11/32”) hole through the existing

reinforcing bracket flange. Repeat for LH side

52. Touch up holes with rust preventing paint

53. Use M8 x 25mm bolts, washer sets and

flange nut to bolt to chassis brace lower

flange

Warning: Drilling operations can

result in flying metal debris, safety

glasses should be worn.

If wing panels are fitted...

54. Drill 2 x Dia 7mm (5/16”) holes in each fender

liner lining up with the cage nuts in the rear

flanges of the wing under panels so the liners

can be fastened to the rear flange

55. Fix in place using 2 x M6 x 20 Bolts and

washer sets per side

Warning: Drilling operations can

result in flying metal debris, safety

glasses should be worn.

Last Rev Date: 18/07/11 Page 13 of 15 Fitting instructions# 3787968

Copyright © 2005 by ARB Corporation Limited. All rights rese rved, t his document must not be reproduced without the express au thority of ARB Corporation Ltd

FITTING PROCEDURE

56. Trim fender liner to coincide with the

underside of the wing under panel lower face

as shown

If no wing panels are fitted...

57. Trim fender liner horizontally with sharp knife

approximately 30mm (1 ¼”) below hole as

shown.

58. Trim corner as shown.

59. Drill 7mm securing holes in the liner and the

plastic bracket arm as shown.

Warning: Drilling operations can

result in flying metal debris,

safety glasses should be worn.

Last Rev Date: 18/07/11 Page 14 of 15 Fitting instructions# 3787968

Copyright © 2005 by ARB Corporation Limited. All rights rese rved, t his document must not be reproduced without the express au thority of ARB Corporation Ltd

FITTING PROCEDURE

60. Feed a cable tie through holes and secure.

61. The painted color coded area of vehicle

visible in the region around the trimmed

fender liner may be spray painted black to

hide this area.

NOTES: When finished make sure all bolts are tightened and that all wiring

is clear of hot, sharp and moving parts.

Also supplied in the kit are two 3/8” rubber grommets and two 16mm plugs.

The rubber grommets are for the two holes in the top pan if lights are being

fitted. The two plastic plugs are for the holes in the top surface of the wings

if no CB aerials are going to be connected.

CAUTION: If winch fitted, check that the air conditioner piping is clear of the

winch by at least 20mm (3/4”). Fit a sheath around tubing and secure with

cable tie to prevent chaffing which may lead to piping damage.

FITTED PRODUCT ON VEHICLE

Last Rev Date: 18/07/11 Page 15 of 15 Fitting instructions# 3787968

Copyright © 2005 by ARB Corporation Limited. All rights rese rved, t his document must not be reproduced without the express au thority of ARB Corporation Ltd

Loading...

Loading...