Page 1

Part Number:

3462030

Product

Description:

Suited to

vehicle/s:

BULL BAR WINCH TYPE

CHEVROLET C/K 1500-3500 1988-1998 YEAR MODEL

RANGE AND Warn 9,500-15,000lb WINCHES

WARNING

REGARDING VEHICLES EQUIPPED WITH SRS AIRBAG;

When installed in accordance with these instructions, the front protection bar does not affect operation of

the SRS airbag.

ALSO, NOTE THE FOLLOWING:

♦ This product must be installed exactly as per these instructions using only the hardware supplied.

♦ In the event of damage to any bull bar component, contact your nearest authorised ARB stockist.

Repairs or modifications to the impact absorption system must not be attempted.

♦ Do not use this product for any vehicle make or model, other than those specified by ARB.

♦ Do not remove labels from this bull bar.

♦ This product or its fixing must not be modified in any way.

♦ The installation of this product may require the use of specialized tools and/or techniques

♦ It is recommended that this product is only installed by trained personnel

♦ These instructions are correct as at the publication date. ARB Corporation Ltd. cannot be held

responsible for the impact of any changes subsequently made by the vehicle manufacturer

♦ During installation, it is the duty of the installer to check correct operation/clearances of all

components

♦ Work safely at all times

♦ Unless otherwise instructed, tighten fasteners to specified torque

ARB 4x4 ACCESSORIES

Corporate Head Office

42-44 Garden St Tel: +61 (3) 9761 6622

Kilsyth, Victoria Fax: +61 (3) 9761 6807

AUSTRALIA 3137

Australian enquiries sales@arb.com.au

North & South American enquiries sales@arbusa.com

Other international enquiries exports@arb.com.au

www.arb.com.au

Last Rev Date: 27 Mar 2006 Page 1 of 12 Fitting instructions# 3783213

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Page 2

FITTING REQUIREMENTS

REQUIRED TOOLS FOR FITMENT OF PRODUCT:

Metric Spanner and Socket sets Allen key set

Phillips head screwdriver Dia 10.0 drill bit

Electric drill 13mm chuck

HAVE AVAILABLE THESE SAFETY ITEMS WHEN FITTING PRODUCT:

Protective eyewear

NOTE: ‘WARNING’ notes in the fitting procedure relate to OHS situations, where to avoid a

potentially hazardous situation it is suggested that protective safety gear be worn or a safe work

procedure be employed. If these notes and warnings are not heeded, injury may result.

Hearing protection

FASTENER TORQUE SETTINGS:

SIZE Torque Nm Torque lbft

M6 9Nm 4lbft

M8 22Nm 16lbft

M10 44Nm 32lbft

M12 77Nm 57lbft

NOTE: Shipping brackets connecting bull bar to pallet and

associated fasteners are not intended to be reused in fitted

bar assembly.

Last Rev Date: 27 Mar 2006 Page 2 of 12 Fitting instructions# 3783213

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Page 3

PARTS LISTING

APPLICATION PART NO. QTY DESCRIPTION

BRACKET BAR MOUNT LHS

3756825L

3756825R

3199815

3199813

1

BRACKET BAR MOUNT RHS

1

PLATE WELD NUT

2

PLATE WELD NUT TOW HOOK

2

MOUNT BRACKETS TO VEHICLE

WINCH

CONTROL BOX FITTMENT

4581049

4581050

6151255

3756897R

3756897L

6151357

6151321

180302

6151251

6151252

4581051

6151046

6151128

6151017

BLB 460

BLR 460

3756835

10

10

10

1

1

4

4

8

2

2

2

2

2

2

2

1

1

M12 WASHER FLAT

M12 WASHER SPRING

BOLT M12 X 40

REINFORCING BRACKET 2500

REINFORCING BRACKET 2500

BOLT SEMS M10X30

NUT FLANGE M10

CABLE TIE

BOLT M16 X 150

NUT NYLOC M16

WASHER M16

WASHER M6

NUT FLANGE M6

BOLT M6 X 16mm

CABLE EXTENSION NEGATIVE

CABLE EXTENSION POSITIVE

BRACKET STD CONTROL BOX

NUMBER PLATE FITTMENT

BAR TO MOUNT ASSEMBLY

INDICATOR ASSY

6151017

6151128

6151046

3751451

6151255

4581050

4581049

6151321

6151357

6151189

6821151R

6821151L

6151308

6821116

6821152

180701

180302

4

4

4

1

6

6

12

4

4

6

1

1

4

4

2

6

4

BOLT M6 X 16mm

NUT FLANGE M6

WASHER M6

BRACKET NO.PLATE

BOLT M12 X 40mm

WASHER SPRING M12

WASHER FLAT M12

NUT M10 FLANGED

BOLT SEMS M10 X 30mm

NUT M12x1.75

INDICATOR ASSY RHS

INDICATOR ASSY LHS

SCREW SELF TAPPING

NUT NYLON PLUG

LOOM

SCOTCH LOCKS

CABLE TIE

Last Rev Date: 3/4/06 Page 3 of 12 Fitting instructions# 3783194

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Page 4

FITTING PROCEDURE

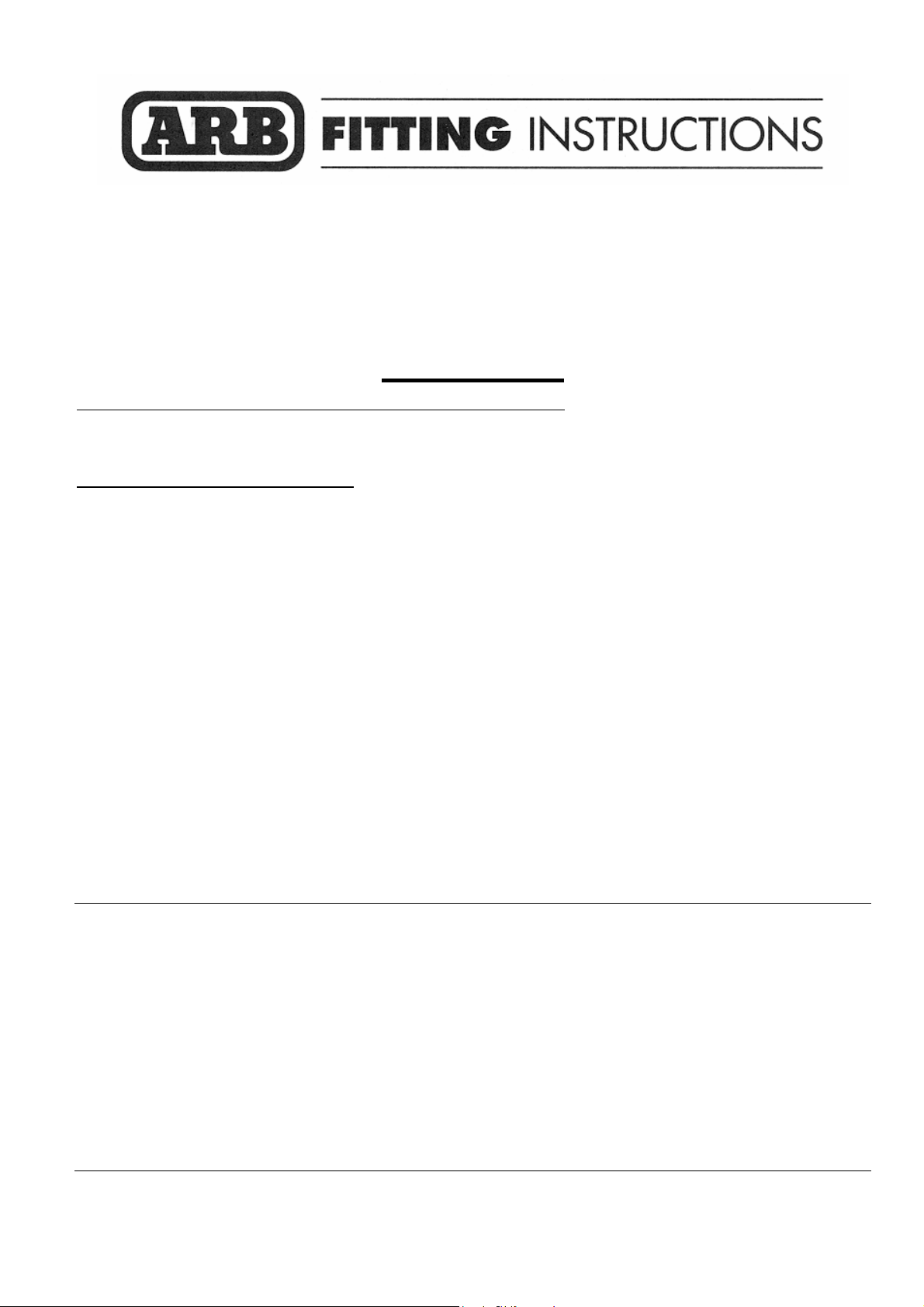

1. Remove the parker/indicator lights

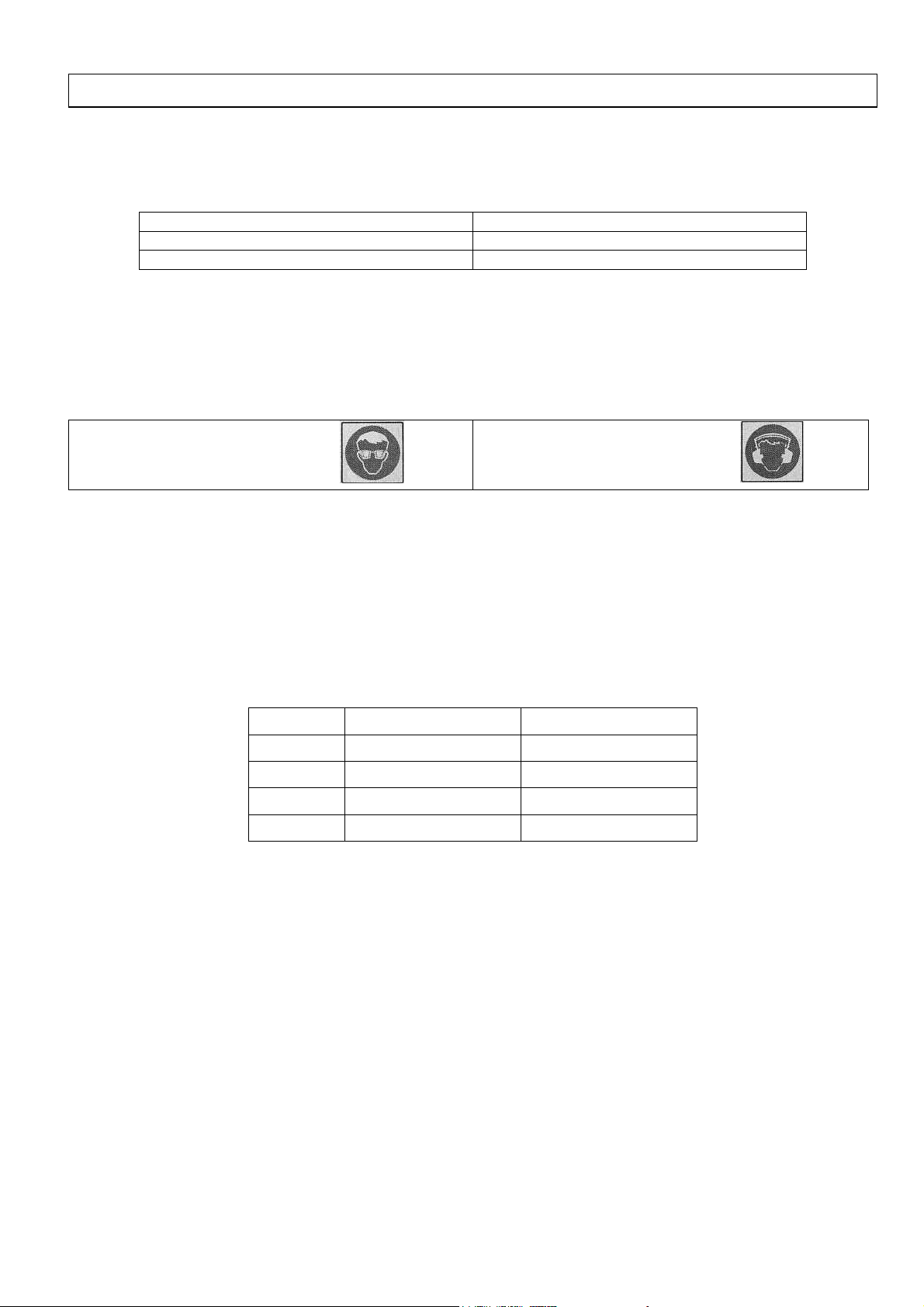

2. Undo and remove the grille. Undo the four

screws across the top and three clips into

lower plastic trim (locations as shown).

Depress clips to release tabs on grille (as

shown at Step 3). One clip is located in the

lower centre of the grille and two are located

outboard below the indicator light positions

located as shown.

Depress this

clip to release

grille tab.

Clip locations

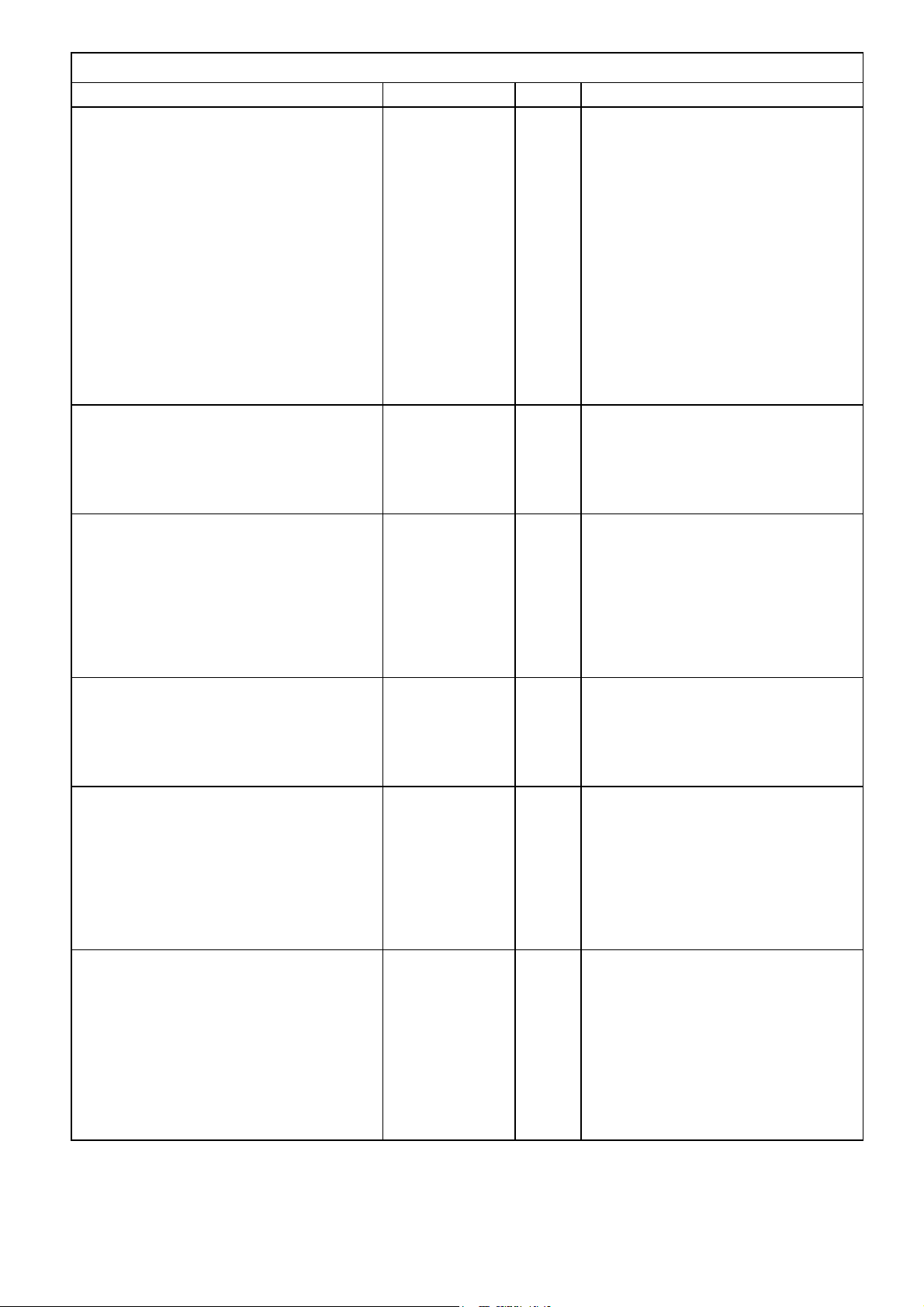

3. Showing clip detail, note that you may need a

large flat blade screwdriver to reach the

middle clip while reaching behind grille.

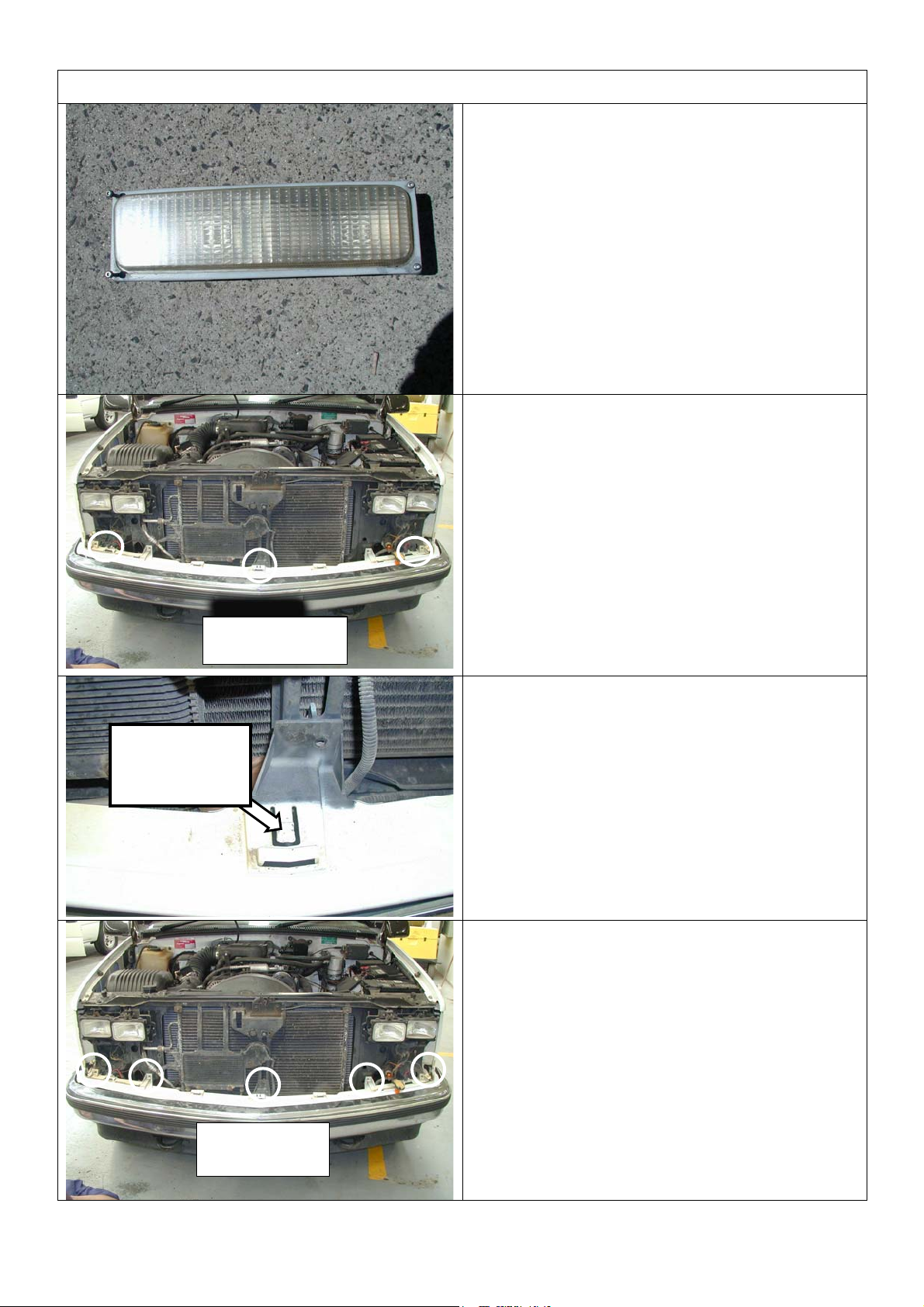

4. Remove plastic trim, this is secured by five

screws located as shown.

Screw

locations

Last Rev Date: 3/4/06 Page 4 of 12 Fitting instructions# 3783194

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Page 5

FITTING PROCEDURE

5. Remove bumper. Undo any electrical

connections to lights in bumper. Undo two

bolts per side retaining the bumper stabilising

bars to the chassis. Loosen only the two

bolts securing the stabiliser bars to the

bumper, the bars should now be able to

swing away from chassis. Undo the three

bolts per side securing the bumper mount

brackets to the chassis. Remove bumper.

6. Remove tow hooks, these will not need to be

refitted.

7. Remove plastic trims from lower front of

guards. At the indicated cut line (along the

moulded feature line approx. 23mm from top

face) cut and retain the lower section of these

trims. Deburr, if necessary touch up and refit

the trims.

NOTE: IF THE CHASSIS IS 2500/3500 THEN FIT

ADDITIONAL BRACKETS AS SHOWN IN STEPS

8 & 9, OTHERWISE PROCEED TO STEP 10.

8. Insert the brackets (note they are handed)

with the short end inside chassis first and the

large flange closest to the centre of the

vehicle.

9. Insert the nut plate and then insert M12 bolt

and washer sets but do not screw the front

NOTE: RHS bracket shown

Last Rev Date: 3/4/06 Page 5 of 12 Fitting instructions# 3783194

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

most bolt past the end of the nut. Leave

bolts loose.

Page 6

FITTING PROCEDURE

10. Slide mount brackets into chassis ends

oriented as shown with large flanges

outboard.

11. Position the nut plates with three M12 nuts

fitted into chassis brackets, so that all holes

line up with existing bumper mount holes in

outboard side of chassis. Fit three M12 x 40

bolt and washer sets per side. Do up finger

tight only

NOTE: THIS STEP FOR 1500 CHASSIS ONLY

12. Insert the nut plate with two nuts inside the

bracket and chassis to accept two M12 x 40

bolt sets in the tow hook position. Do up

finger tight only.

13. Nip up all bolts, check that the brackets are

parallel to each other and the front edge of

bracket flange is vertical, if not adjust and

retighten.

Last Rev Date: 3/4/06 Page 6 of 12 Fitting instructions# 3783194

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Page 7

FITTING PROCEDURE

NOTE: THIS STEP FOR 2500/3500 CHASSIS

ONLY

14. Drill with M10 drill bit and fit M10 bolt and

washer sets and flange nuts to pin the flange

of the reinforcing bracket to the side of the

mount bracket body.

Warning: Drilling operations can result in

Warning: Drilling operations can result in

flying metal debris, safety glasses should be

flying metal debris, safety glasses should be

15. Fit grille outboard anchoring brackets as

shown using existing screws.

16. Fit grille centre anchoring bracket as shown

using existing screw.

17. Re-fit grille, use 6mm bolts, panel washers and

flange nuts to secure tabs onto brackets in

three places.

18. Reconnect and refit lights.

Last Rev Date: 3/4/06 Page 7 of 12 Fitting instructions# 3783194

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Page 8

FITTING PROCEDURE

19. Remove lights from cartons and then remove

screws and speed nuts from each light.

These fasteners are not to be reused – new

screws are supplied in the fitting kit.

20. Insert nylon nuts into square holes in light

brackets inside wing area

21. Fit lights using screws supplied in fitting kit,

taking note of RH and LH light bodies, they

are different, marked LH or RH and must be

placed on the correct side of bull bar (drain

holes down).

22. Secure the number plate bracket using M6

bolts, flat washers and flange nuts. Attach the

shorter side to the bullbar and the longer side

to the number plate.

Last Rev Date: 3/4/06 Page 8 of 12 Fitting instructions# 3783194

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Page 9

FITTING PROCEDURE

IF FITTING WINCH, CONTINUE ON THOUGH

STEPS 23 TO 33, 35 & 37.

NOTE: From the factory the 15000lb winch

handle should be in the position shown,

allowing bottom spooling off of cable with the

gearbox handle on the LHS when in bull bar. If

your winch handle will not clear the bull bar

when installed, undo the gearbox end screws.

Lift the gearbox up to just clear locating lugs

and rotate to correct position then retighten,

checking that seals are undamaged and a

draining hole is at bottom centre.

23. Remove cable retaining band and position

cable loop so it will go through roller fairlead

when it is placed in bull bar.

24. Fit control box bracket supplied using M6

bolts and flange nuts as shown.

25. Remove vertical rollers from RFL and set

aside.

NOTE: On some models, the roller fair lead

must be drilled prior to fitment.

26. Mark out as shown then using a 13.0 mm drill

bit, drill two holes as shown in diagram.

Warning: Drilling operations can result in

flying metal debris, safety glasses should be

27. Lay winch on a suitable support table with

mount face up. With the help of an assistant,

lay the bull bar, face up, onto the winch.

28. Position the RFL bracket into position into

the viewer aperture and proceed to bolt up

the winch with original fasteners supplied with

winch.

29. Insert the vertical rollers into the RFL and fix

in position with M16 bolt and nyloc nut sets.

30. Tighten all winch mount bolts.

Last Rev Date: 3/4/06 Page 9 of 12 Fitting instructions# 3783194

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Page 10

A Red

F1

Black

F2

black

31. Fit control box to bracket.

32. Remove cover off control box. Supplied in

fitting kit are 2 x black and 1 x red 460mm

extended cables, mark these accordingly with

the F1, F2 (black) and A (red) markings from

original cables. Remove the 3 x shortest

original heavy duty cables and connect the

extended cables taking care that the

connections are per original configuration.

33. Route and connect the winch control box

cables to the winch motor, taking care that

the cables are connected to the

appropriate terminals. Refer to the Warn

handbook for additional information. Connect

the long winch + & - cables to the vehicle

after

the bar is installed. Refer to the Warn

winch manual for vehicle wiring instructions.

20mm gap

CAUTION: The next step is best achieved

using a safe lifting device or with the help of an

assistant. If a winch is fitted two assistants are

recommended.

34. Fit the bull bar to the vehicle mount brackets.

Use the M12 fasteners to secure it and make

adjustments so there is approximately 20mm

gap from under the grille to the top of the

wing.

35. Tighten the M12 fasteners.

34. Drill and pin the bar to the mounts in 2 x

places per side using M10 drill bit, as shown,

then bolt up using M10 x 30 SEMS bolts and

flange nuts.

Warning: Drilling operations can result in

flying metal debris, safety glasses should be

Last Rev Date: 3/4/06 Page 10 of 12 Fitting instructions# 3783194

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Page 11

If fitting with winch

35. With the winch cable through the roller fair

lead. Mount the hook to the end of the cable.

36. Wire up the indicator and clearance lamp

assemblies. Use scotch locks to splice

cables to existing indicator and clearance

lamp wiring and cable tie securely.

NOTE: Refer to the Warn winch manual for

vehicle wiring instructions.

37. Ensure that electrical cables are installed

well clear of sharp, hot or moving objects.

Secure the winch cables to the vehicle and

winch bumper with the supplied cable ties.

Last Rev Date: 3/4/06 Page 11 of 12 Fitting instructions# 3783194

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Page 12

FITTED PRODUCT

Last Rev Date: 3/4/06 Page 12 of 12 Fitting instructions# 3783194

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Loading...

Loading...