Page 1

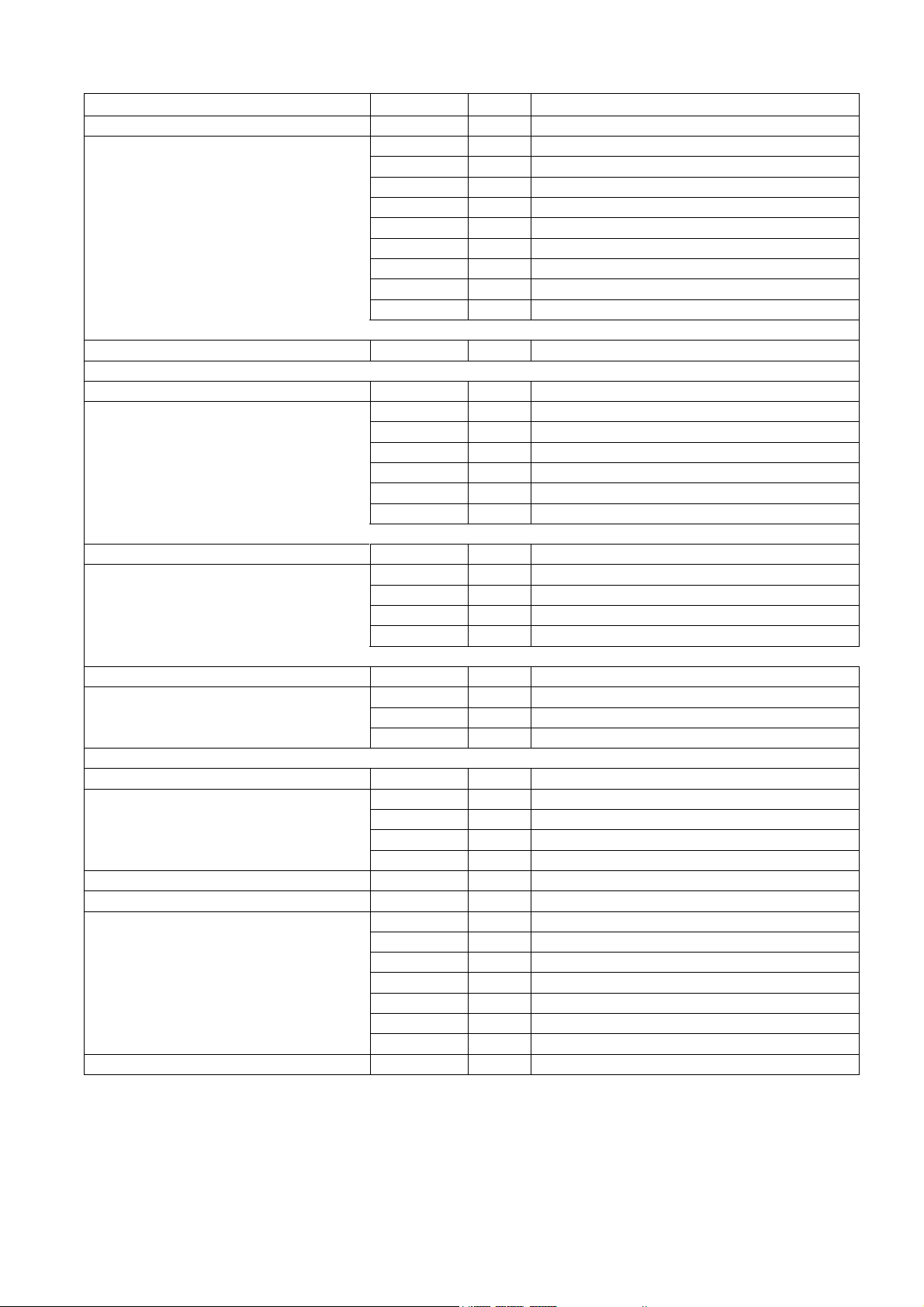

ARB COMBINATION WINCH, NON-WINCH BULL BAR TO SUIT

CHEVROLET SILVERADO 03 ON 1500 MODELS.

PRODUCT No. 3462020, WITH FITTING KIT 3562040

WARNING

FOR VEHICLES EQUIPPED WITH SRS AIRBAG

WHEN INSTALLED IN ACCORDANCE WITH THESE INSTRUCTIONS, THE FRONT

PROTECTION BAR DOES NOT AFFECT OPERATION OF THE SRS AIRBAG.

TAKE NOTE OF THE FOLLOWING:

• THIS PRODUCT MUST BE INSTALLED EXACTLY AS PER THESE

INSTRUCTIONS USING ONLY THE HARDWARE SUPPLIED.

• IN THE EVENT OF DAMAGE TO ANY BULL BAR COMPONENT,

CONTACT YOUR NEAREST AUTHORISED ARB STOCKIST. REPAIRS OR

MODIFICATIONS TO THE IMPACT ABSORPTION SYSTEM MUST NOT BE

ATTEMPED.

• DO NOT USE THIS PRODUCT FOR ANY VEHICLE MAKE OR MODEL,

OTHER THAN THOSE SPECIFIED BY ARB.

• DO NOT REMOVE LABELS FROM THIS BULL BAR.

• THIS PRODUCT OR ITS FIXING MUST NOT BE MODIFIED IN ANY WAY.

Note :

• This bull bar is suitable for Warn 9,500-16,500lb winches.

• Fog light provisions are in lower pan area of bull bar. IPF840FYS lights

are suitable for this location.

Tools Required

Metric Spanner and Socket set Allen key set

Phillips head screwdriver Dia 15/64”, 10.0 and 12.0mm drill bits

Electric drill 13mm chuck Sikaflex 227 adhesive, black color

11/10/05 Page 1 of 14 3783176

If you have any queries regarding the installation of this product please contact the distributor from whom it was purchased, or alternatively the ARB office in your state.

WA: (08) 9244 3553 NSW: (02) 9821 3633 ACT: (02) 6280 7475 SA: (08) 8244 5001 QLD: (07) 3872 3872 NT: (08) 8947 2262 TAS: (03) 6331 4190

Head Office – ARB Corporation Ltd VIC: 42-44 Garden Street, Kilsyth, Victoria, 3137 Tel: (03) 9761 6622 Fax: (03) 9761 6807

Page 2

USE PART No QTY DESCRIPTION

MOUNT BRACKETS TO VEHICLE 3756785L 1 BRACKET BAR MOUNT LHS

3756785R 1 BRACKET BAR MOUNT RHS

3199796 2 PLATE CAGE NUT

4581049 10 M12 WASHER FLAT

4581050 8 M12 WASHER SPRING

6151255 6 BOLT M12 X 40

6151244 2 BOLT M12X150

6151189 2 NUT M12x1.75

6151305 4 NUT M12 CAGE SUIT 4MM

5811037 2 SLEEVE

WINCH 180302 8 CABLE TIE

TOW HOOK RELOCATION 6151365 2 EYEBOLT M24 2.5 SWL

6151361 2 NUT M24 GR8 ZP

3756765 2 BRACKET NUT RETAINING

4581300 2 WASHER M24 EYEBOLT

6151046 2 WASHER M6

6151017 2 BOLT M6 X 16mm

6151128 2 NUT FLANGE M6

CONTROL BOX FITTMENT 4581291 2 WASHER M10 BZ

6151321 2 NUT FLANGED

6151364 2 SCREW CAP M10X30 ZP

3756775 1 BRACKET STD CONTROL BOX IN PAN

3199790 1 TRIM PLATE FOR 16500LB CONTROL

NUMBER PLATE FITTMENT 6151017 4 BOLT M6 X 16mm

6151128 4 NUT FLANGE M6

6151046 4 WASHER M6

3751384 1 BRACKET NO.PLATE

WINCH COVER FITTMENT 6151128 2 NUT FLANGE M6

6151256 2 SCREW M6 S/STEEL BUTTON HEAD

6151046 2 WASHER M6

6191013 1 EXTRUSION WINCH COVER @ 1757

6522048 1 PANEL WINCH COVER

WASHER BOTTLE PROTECTION 6131349 1 FRAME ASSY WASHR BOTTLE PROT

6151303 2 NUT CAGED M8 SUIT 1.6-3.2

6151022 2 BOLT M8X25

4581044 2 WASHER FLAT M8

4581046 2 WASHER SPR M8

6151232 2 BOLT M10X30

4581040 2 WASHER FLAT M10

4581048 2 WASHER SPR M10

11/10/05 Page 2 of 14 3783176

Page 3

BAR TO MOUNT ASSEMBLY 6151255 6 BOLT M12 X 40mm

4581050 6 WASHER SPRING M12

4581049 12 WASHER FLAT M12

4581048 2 WASHER SPRING M10

6151321 2 NUT M10 FLANGED

6151232 2 BOLT M10 X 30mm

4581040 2 WASHER FLAT 3/8”

6151189 6 NUT M12x1.75

INDICATOR ASSY 6821151R 1 INDICATOR ASSY RHS

6821151L 1 INDICATOR ASSY LHS

6151308 4 SCREW SELF TAPPING

6821116 4 NUT NYLON PLUG

6821152 2 LOOM

180701 6 SCOTCH LOCKS

180302 4 CABLE TIE

INNER GUARD RETAINER 3199787R 1 PLATE INNER GUARD

3199787L 1 PLATE INNER GUARD

6151128 4 NUT FLANGE M6

6151213 4 SCREW M6X20 BZ

4581082 4 WASHER M6X20 BZ

NOTE: Shipping brackets connecting

bull bar to pallet and associated

fasteners are not intended to be reused

in fitted bar assembly.

11/10/05 Page 3 of 14 3783176

Page 4

ASSEMBLY SEQUENCE FOR WINCH BUMPER.

1. FITTING MOUNTING BRACKETS

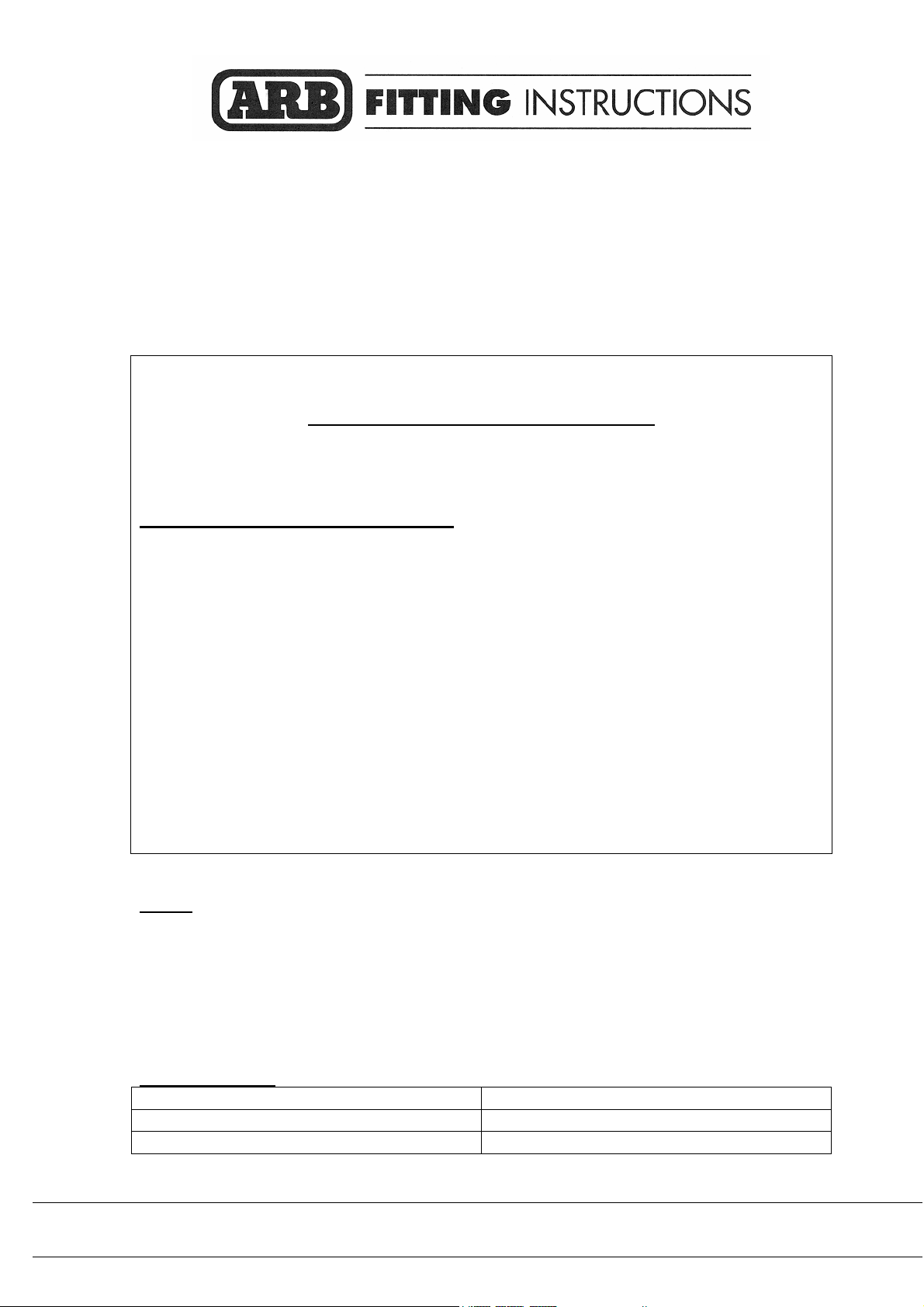

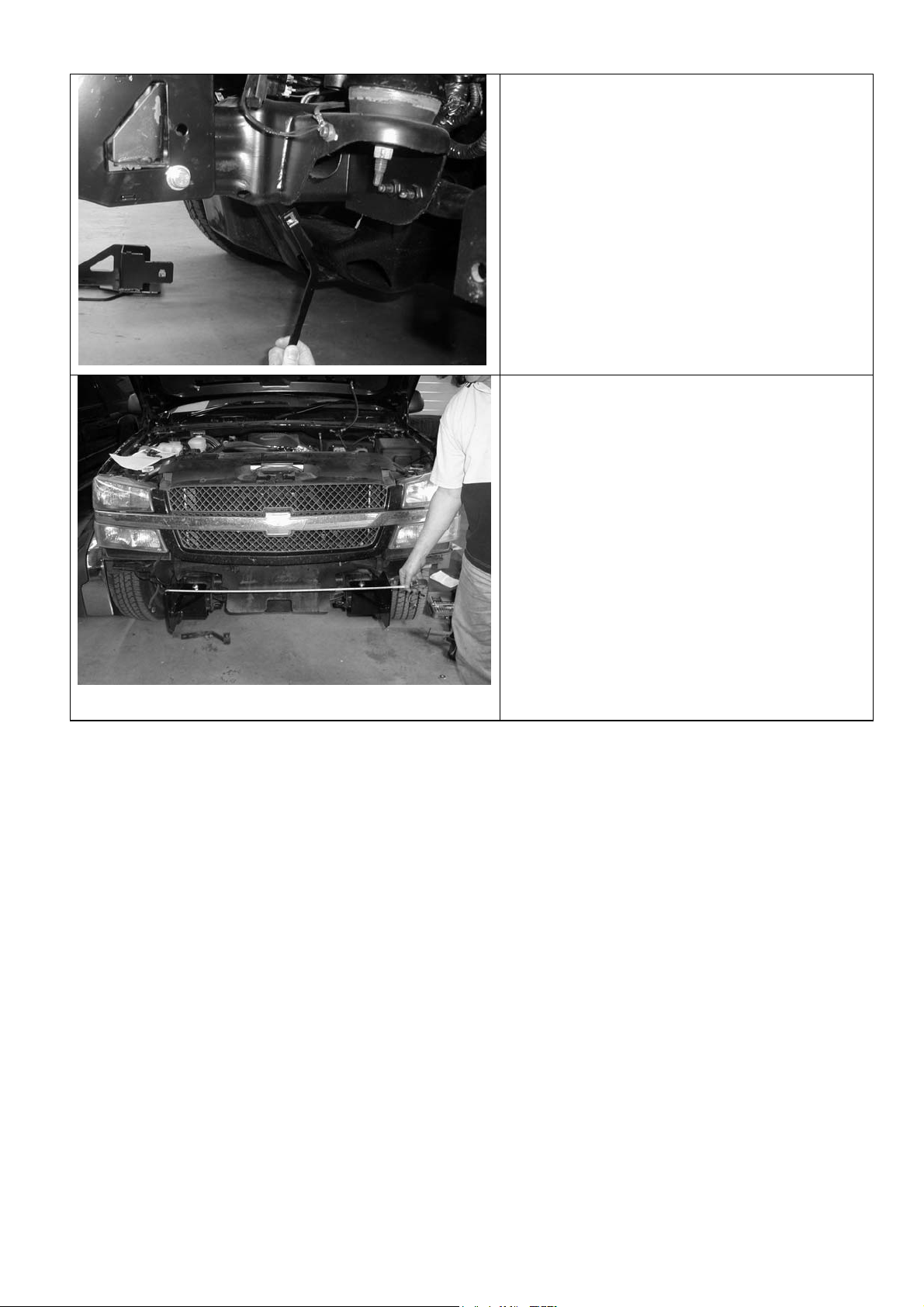

1.1 Remove the plastic shroud above the

radiator as shown, by releasing plastic

clips

1.2 To remove the grille, carefully push the

retainer spring clips back out in four

places behind grille. Pull outer bar from

between headlights forward to release

from clip into end of guard. NOTE: It may

be necessary to remove top headlights to

gain access to these clips if you cannot

release them easily.

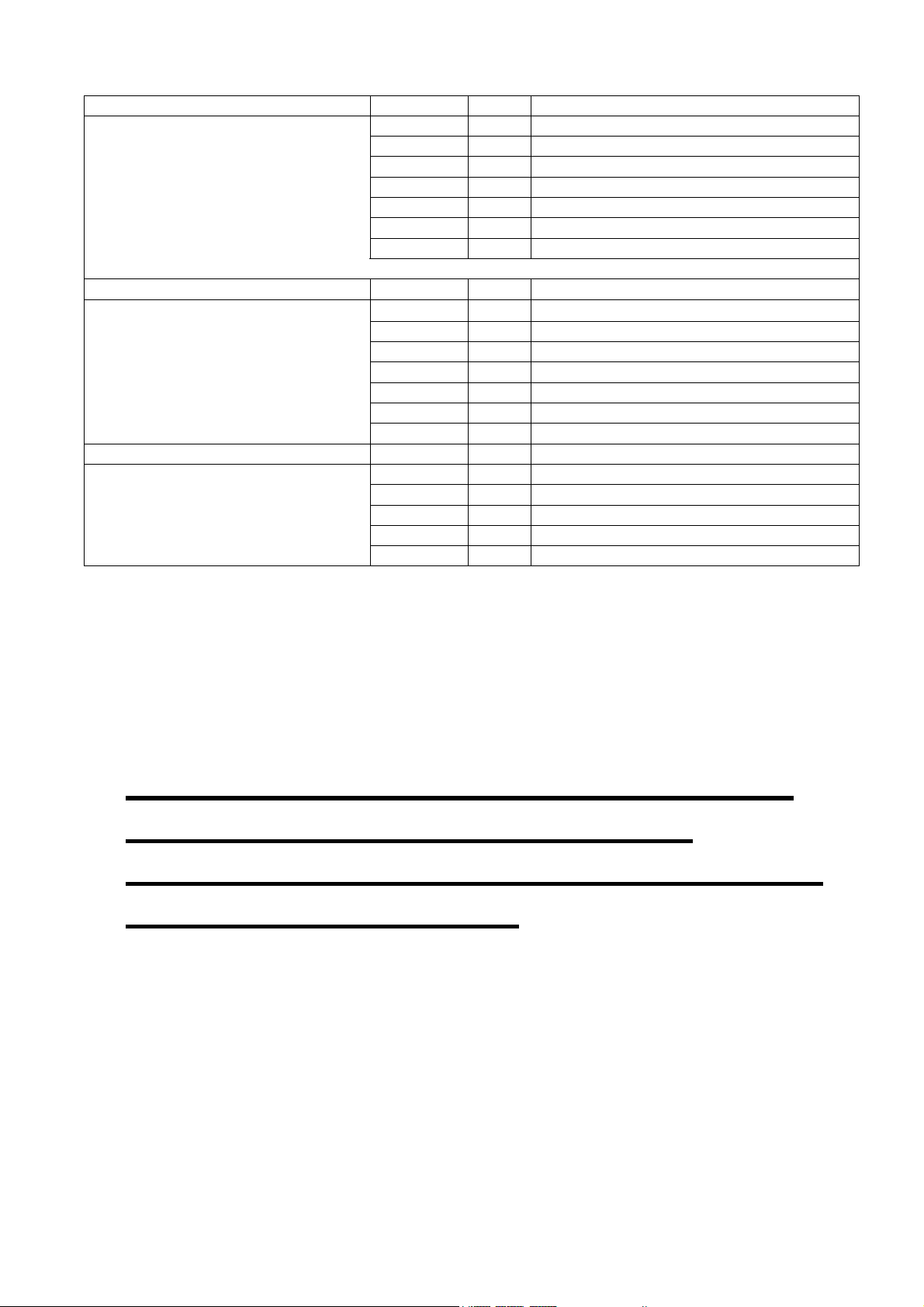

1.3 Remove bumper by undoing four bolts

from above and behind bumper then two

bolts securing bumper to wing support

braces from under and behind forward of

wheel arch area.

11/10/05 Page 4 of 14 3783176

Page 5

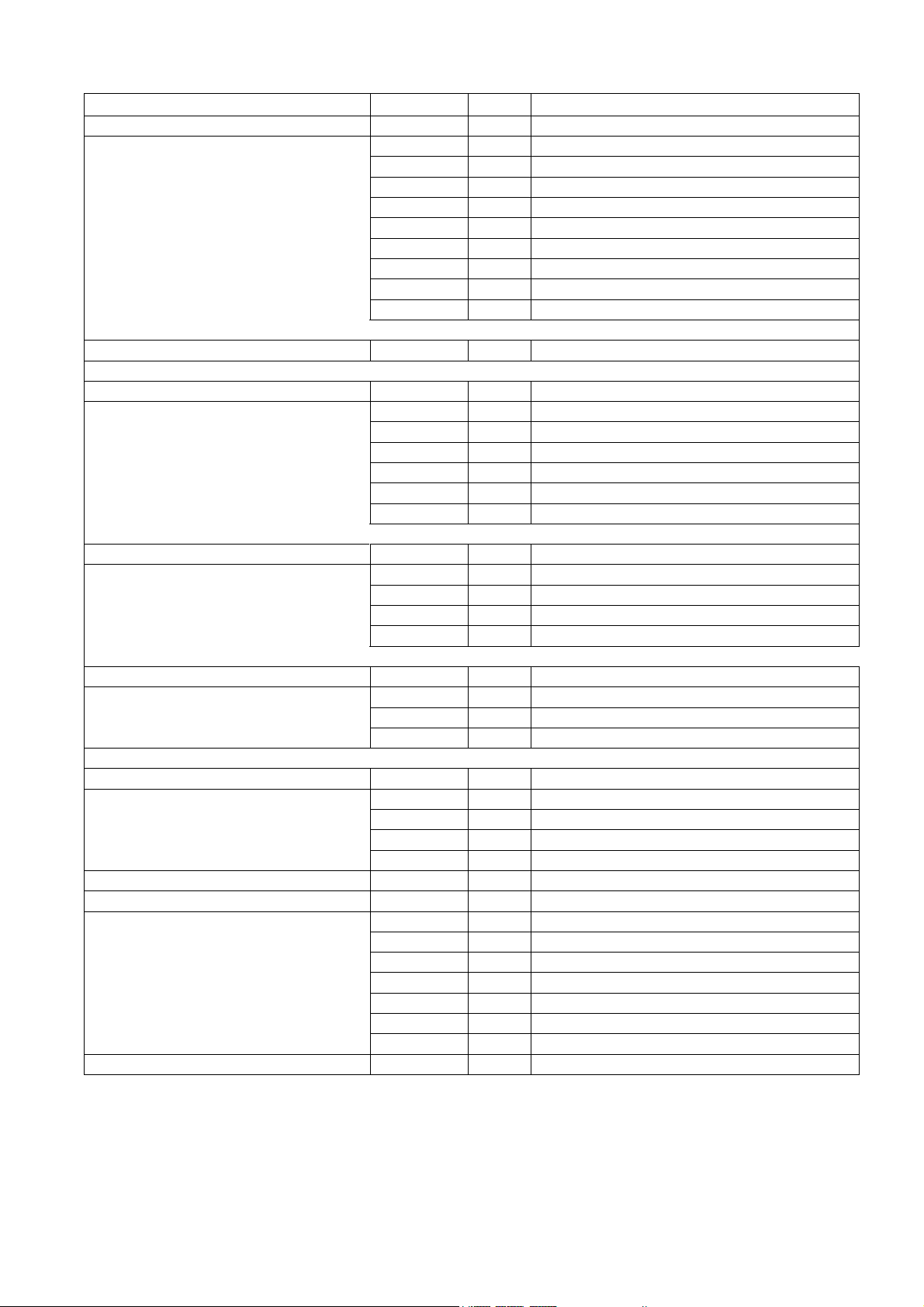

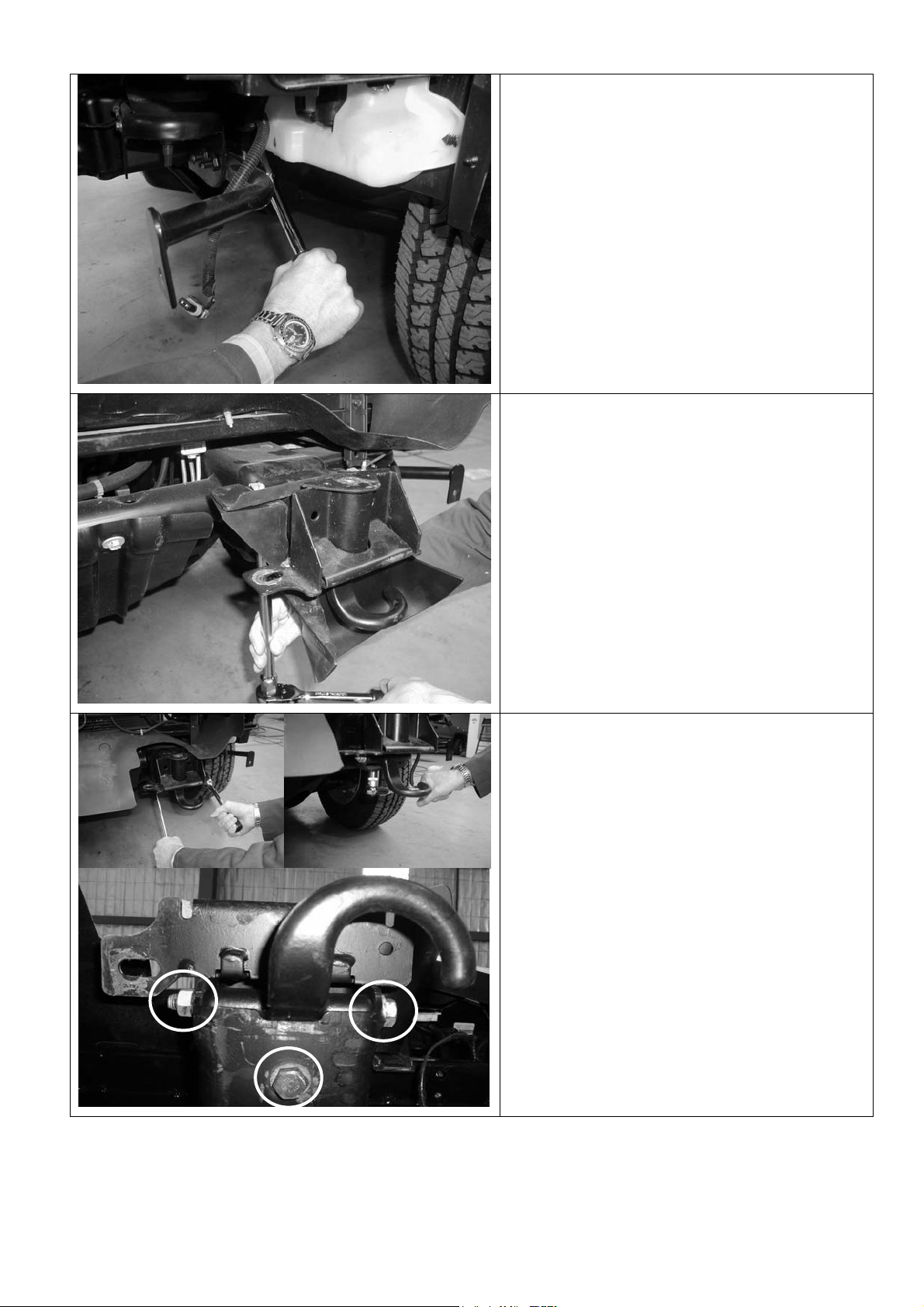

1.4 Remove stabilizer arms both sides

1.5 Remove plastic shrouds around chassis

1.6 Remove tow hooks

11/10/05 Page 5 of 14 3783176

Page 6

1.7 Fit cage nuts to bracket tangs as shown

1.8 Position the mount brackets as shown on

the ends of the chassis rails (LHS shown).

Loosely fit an M12 bolt and washer set to

top bolt position and lower position as

shown finger tight only.

Inserting sleeve

Sleeve in position

1.9 Partly withdraw M12 x 150 bolt and fit

crush sleeve over bolt body inside chassis

as shown. Fit flat and spring washers, and

nut. Do not tighten.

11/10/05 Page 6 of 14 3783176

Page 7

1.10 Fit M12 cage nuts to both bent plates, 1 x

LH and 1 x RH as assemblies are

opposite for each side of vehicle. Insert

nut assembly through large hole in

underside of chassis and up to meet

vacant hole above long bolt. Insert M12

bolt and washer set, do up finger tight.

1.14 Check that brackets are parallel to each

other, if not adjust. When parallel then

tighten all bolts (nominal outside

dimension across brackets is 898mm).

Fit grille and shroud back into

position.

11/10/05 Page 7 of 14 3783176

Page 8

2. PREPARING BULL BAR FOR FITTING

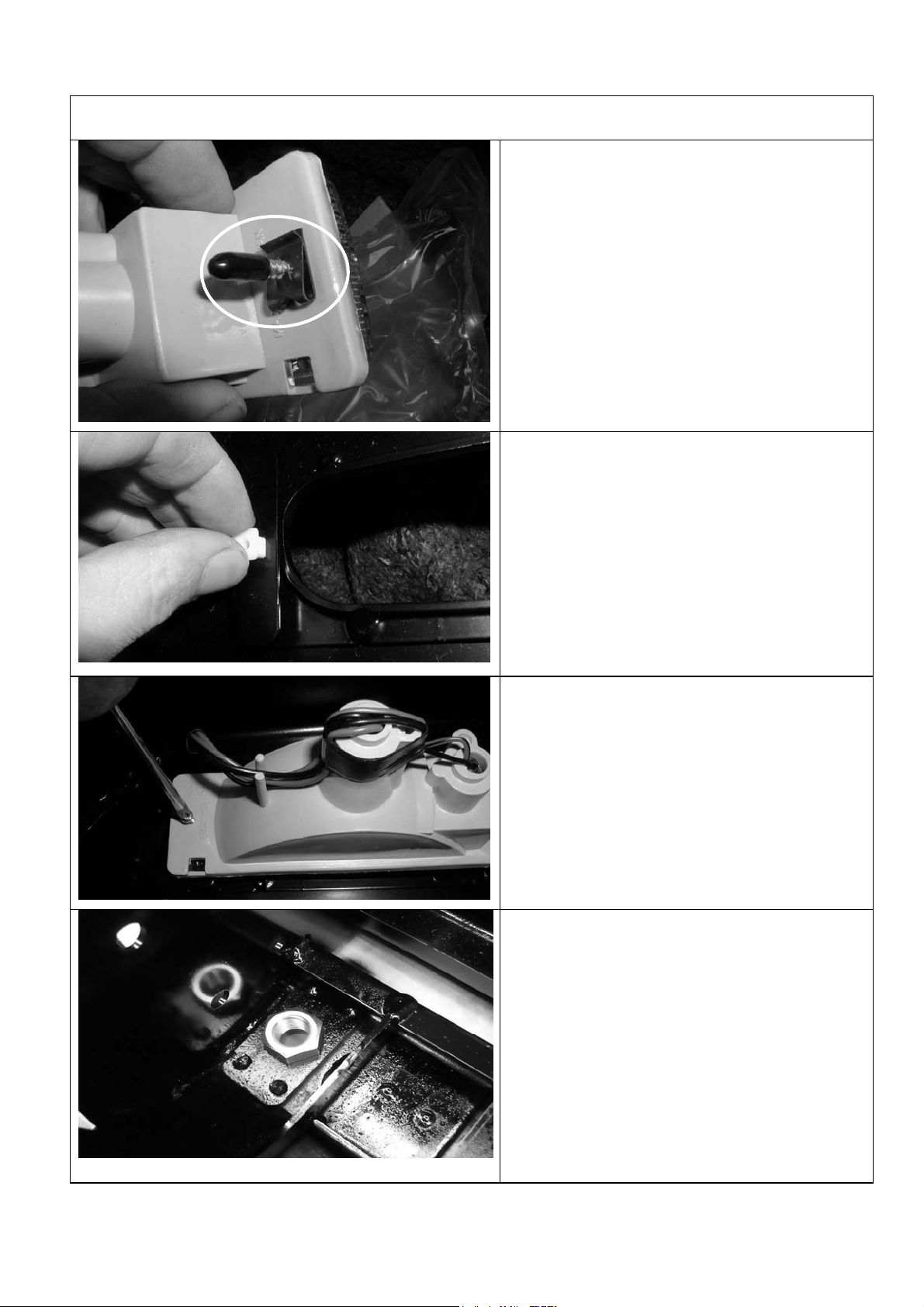

2.1 Remove lights from cartons and then

remove screws and speed nuts from each

light. These fasteners are not to be reused

– new screws are supplied in the fitting kit.

2.2 Insert nylon nuts into square holes in light

brackets inside wing area

2.3 Fit lights using screws supplied in fitting

kit, taking note of RH and LH light bodies,

they are different and must be placed on

the correct side of bull bar.

2.4 Fit large eyebolt nut into the plate on the

inside of the bar.

11/10/05 Page 8 of 14 3783176

Page 9

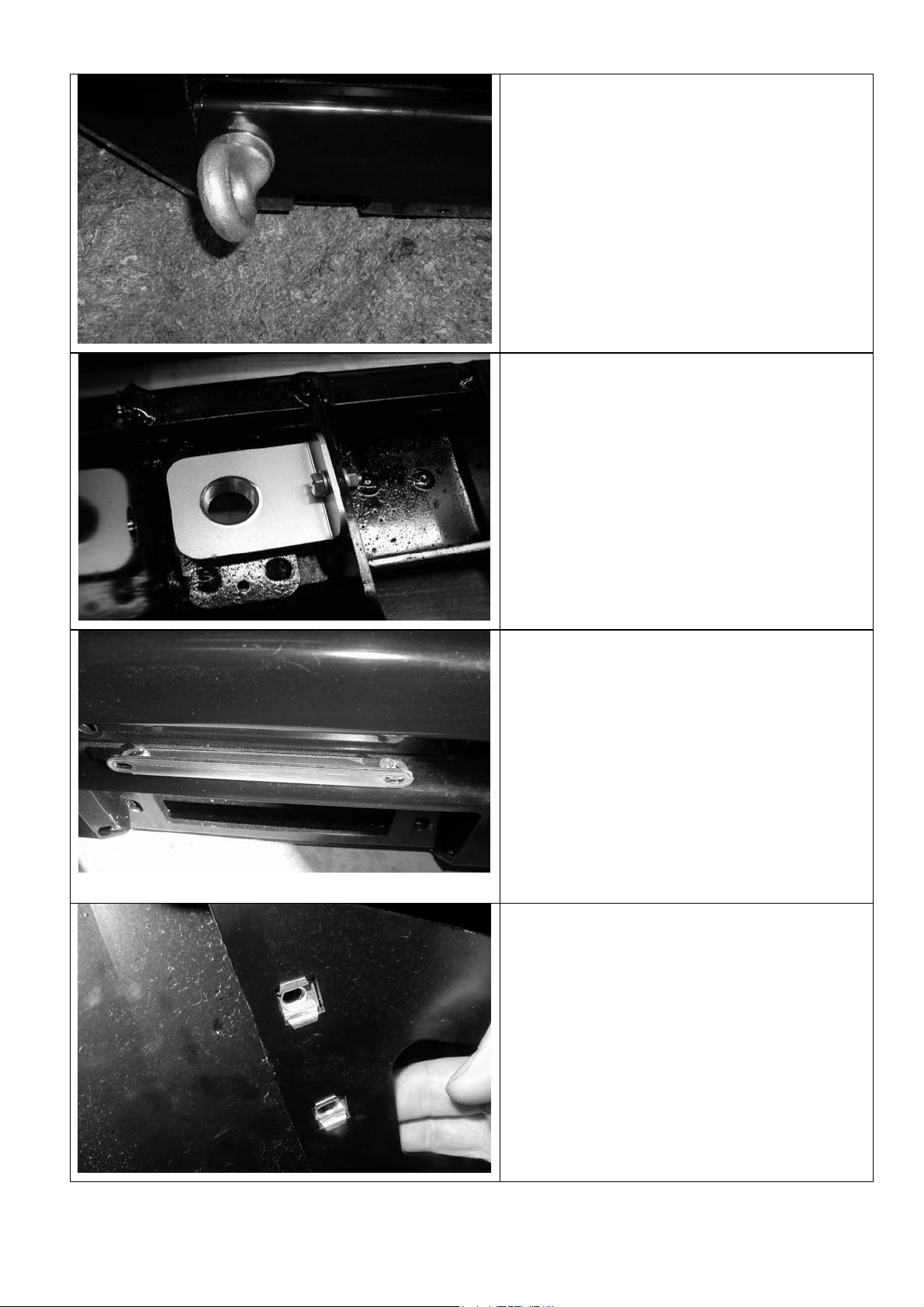

2.5 Screw in the eyebolt using the large

washer. Eyebolt can be positioned to sit

vertically by rotating the large nut to the

correct position.

NOTE: EYEBOLTS SHOULD BE REMOVED

FOR SAFETY REASONS WHEN

TRAVELLING ON PUBLIC ROADS.

2.6 When the large nut is in its final position,

secure with the nut retaining bracket using

an M6 bolt, washer and flange nut.

2.7 Secure the number plate bracket using M6

bolts, flat washers and flange nuts. Attach

the longer flange to the bullbar and the

shorter flange to the number plate.

2.8 Fit the M8 cage nuts to the square holes in

the wing brace on the LHS (washer bottle

side) of the bull bar. The body of the cage

nuts are to be on the inside of the brace.

These nuts are to be used to fasten the

washer bottle protection arm to the bull bar.

11/10/05 Page 9 of 14 3783176

Page 10

3. IF FITTING WINCH

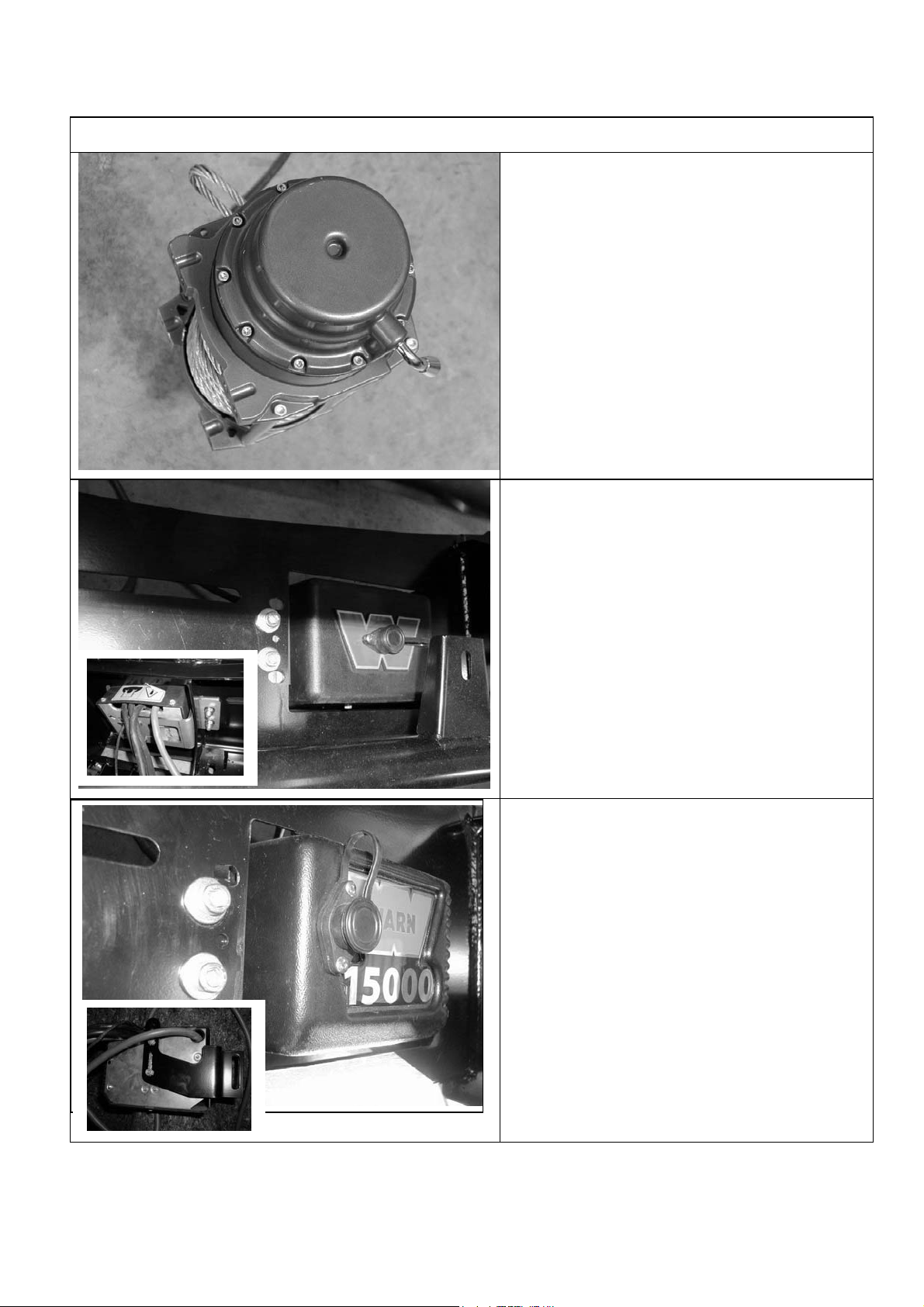

3.1 From the factory the winch handle should

be in the position as shown.

Remove cable retaining band and position

cable loop so it will go through roller

fairlead when it is placed in bull bar.

3.2 Fit control box to pan:

• For 9500-12000lb winches, use universal

control box bracket supplied, attaching to

rear of control box mount studs.

• Slide bracket flange under pan and align

with mount slots.

• Fasten in position with 2 x M10 cap

screws, black washers and flange nuts.

• For 15000lb winches, use Warn supplied

control box bracket, attaching to rear of

control box mount studs.

• Slide bracket flange under pan and align

with mount slots.

• Fasten in position with 2 x M10 cap

screws, black washers and flange nuts.

11/10/05 Page 10 of 14 3783176

Page 11

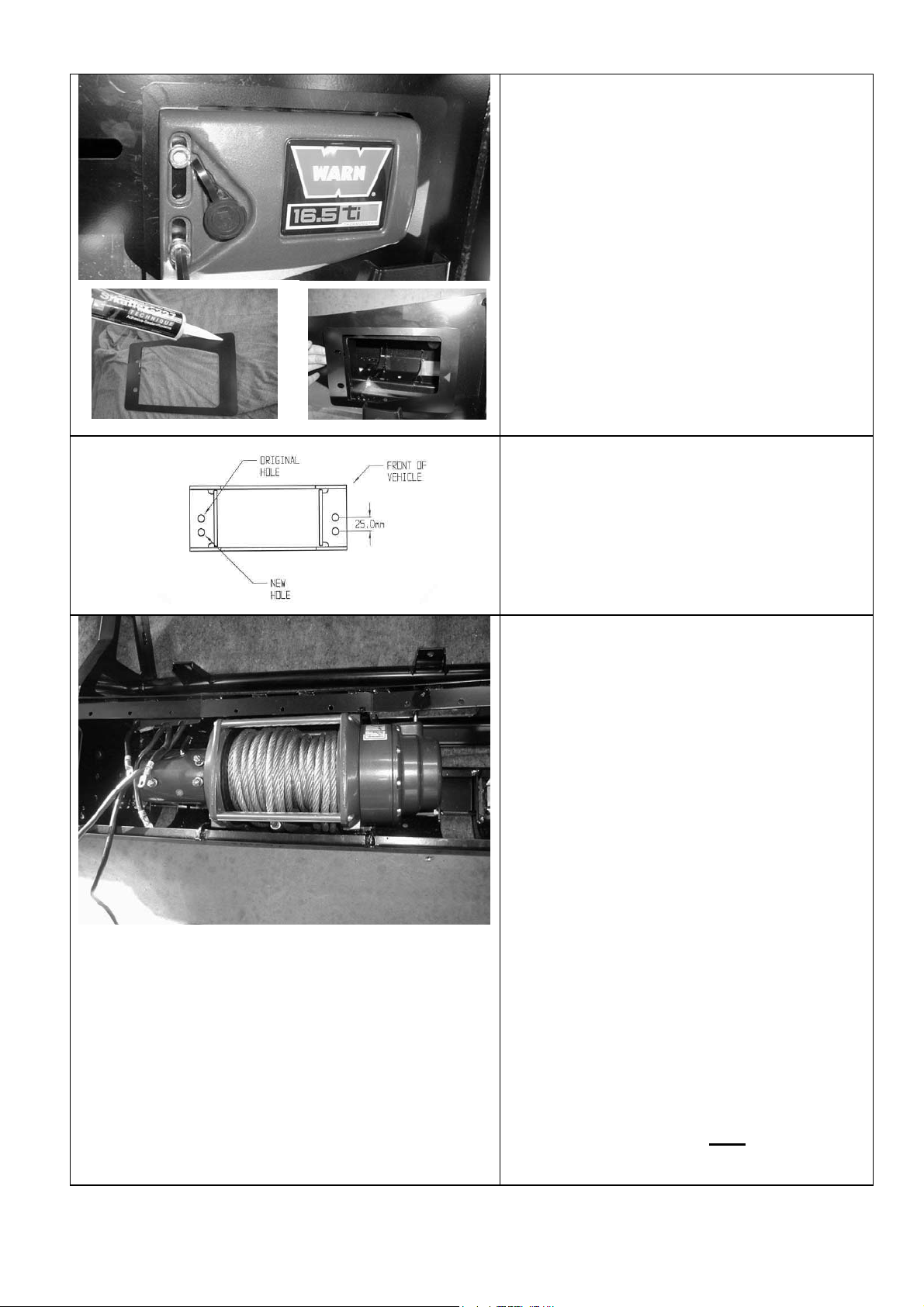

• For 16500lb winches, apply Sikaflex (or

similar product) to rear of control box trim

plate from fitting kit (note orientation critical

to suit final position with control box profile

in pan opening).

• Position trim plate on top of pan centrally

about control box opening and line up with

mount slots.

• Fasten in position with 2 x M10 cap screws

and flange nuts from fitting kit.

3.3 On some models, the roller fair lead must

be drilled prior to fitment.

Mark out as shown and using a 13.0 mm

drill bit, drill two holes as shown in

diagram.

3.4 Viewed from front of vehicle the winch

clutch (handle) must be positioned on the

LH side (same side as smaller square

access hole in pan). Cable must spool

from the bottom of winch. Draw off

enough cable so cable crimp can be

pulled through roller fairlead.

Hint: If crimp is too large to fit through, remove

a circlip from a horizontal roller, partially

remove the shaft so roller gap is increased and

feed cable and crimp through. Refit shaft and

circlip.

Bolt winch in position with the roller fair lead in

place.

Hint: To increase access to mount bolts in

front of roller fairlead, remove circlips from

bottom of each vertical roller shaft, push shaft

up so roller can be dislodged sideways. Do up

bolts in fairlead and winch, then refit circlip.

Connect the winch control box cables to the

winch motor. Refer to the Warn handbook for

additional information. Connect the long winch

+ & - cables to the vehicle after

installed. Refer to the Warn winch manual

for vehicle wiring instructions.

the bar is

11/10/05 Page 11 of 14 3783176

Page 12

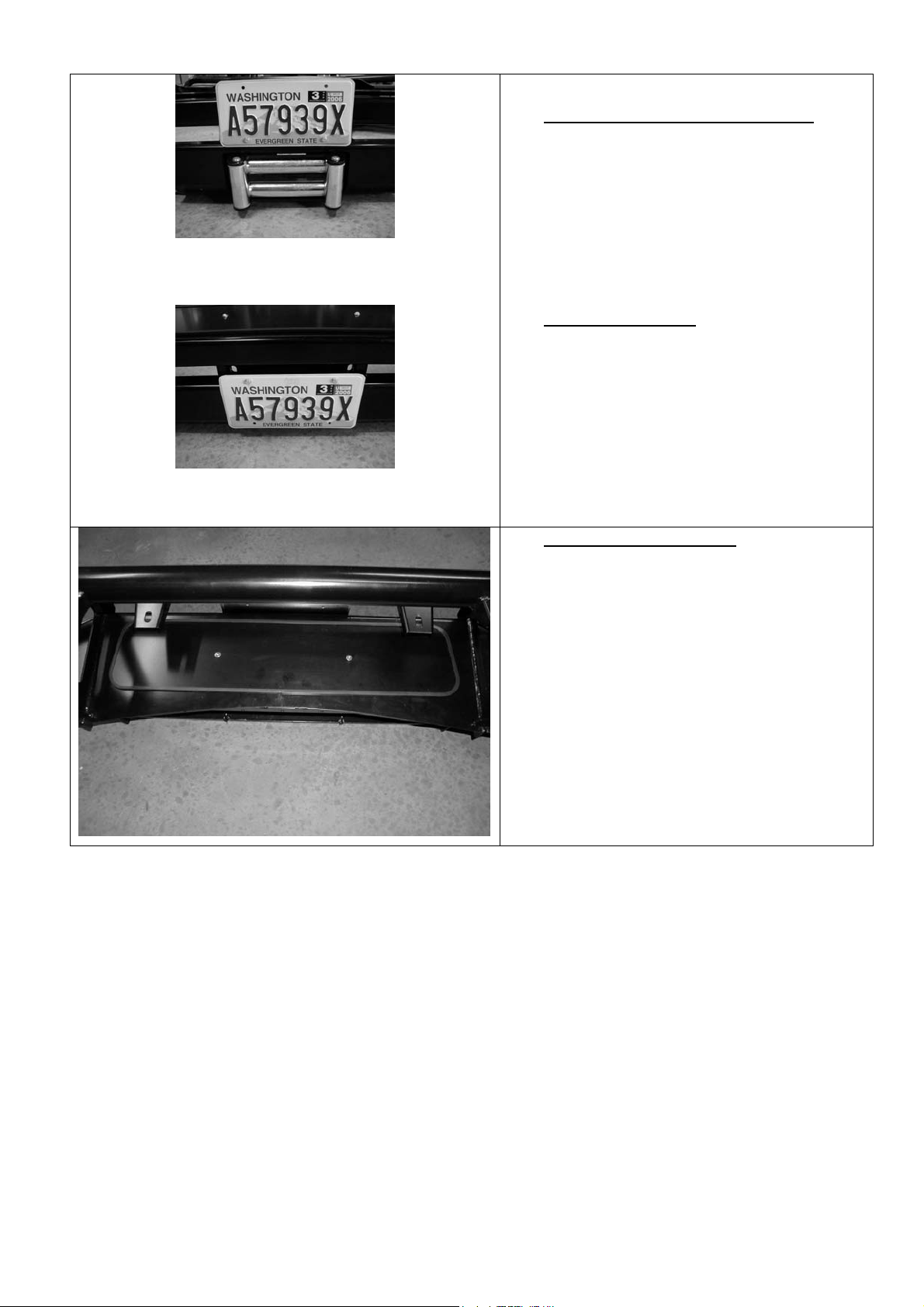

3.5

Fitting with winch, number plate above RFL

Fitting without winch, number plate covers RFL

opening

Fitting number plate – with winch

Bolt number plate to the bracket with the

M6 X 16mm bolts and M6 flange nuts

through the lower holes of the number

plate.

If not fitting winch.

Bolt the number plate through the top

holes using M6 X 16mm bolts and M6

flange nuts.

3.6 If not fitting winch cont.

Wrap rubber extrusion around winch

cover.

Place washers over the winch cover fixing

holes located on the top middle face of the

winch bumper.

Place the winch cover on top of the winch

bumper inline with the mount holes.

Bolt together using the M6 button head

stainless steel screws and M6 nuts.

11/10/05 Page 12 of 14 3783176

Page 13

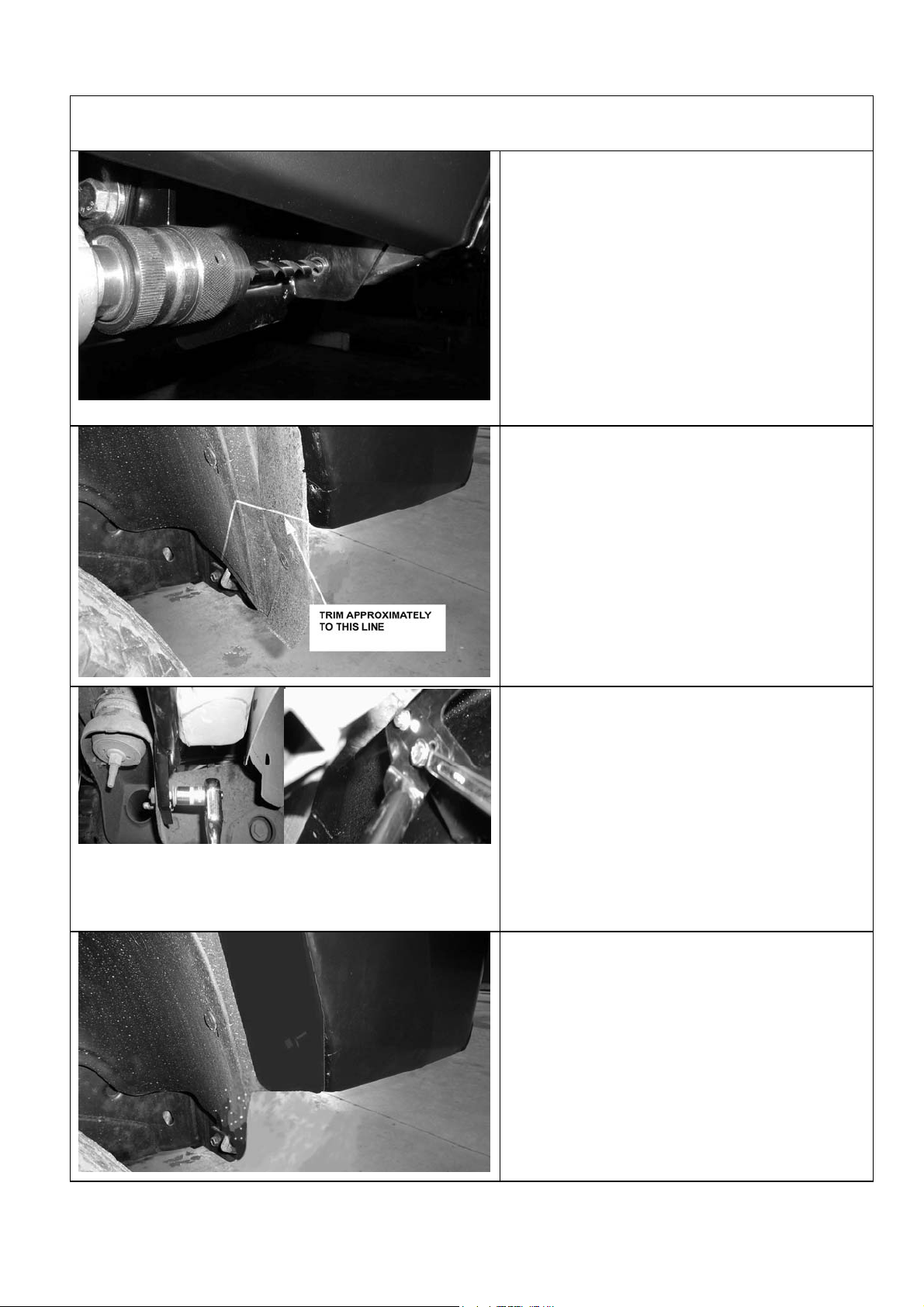

4. FITTING BULL BAR TO VEHICLE

4.1 Using two people, three if winch fitted,

position the bar assembly on the vehicle

mounts.

Bolt the bar to the mounts using M12

bolts, large flat washers and spring

washers. Align the bar to the profile of the

guards, grille and light profile and tighten

all bolts.

Using the M10 pilot holes in mount

brackets, drill pinning hole through

uprights on bull bar. Fit M10 screw,

washer set and flange nut and do up tight.

4.2 Trim excess plastic inner guard molding to

meet lower profile of bull bar wing. Note

the position of water bottle on LHS of

vehicle and trim neatly around it.

4.3 Fit washer bottle protection frame to

lower mounts where original bumper

stabiliser arms were located using 2 x

M10 x 30 bolt and washer sets. Fit off

the upper bracket to inner wing area of

bull bar as shown using M8 x 25 bolts

and washer sets.

NOTE: The 2 x M8 cage nuts should be in

place from step 2.7.

4.4 Fit inner guard plates to ends of bull bar

wings and fasten with M6 black screws

and washers.

11/10/05 Page 13 of 14 3783176

Page 14

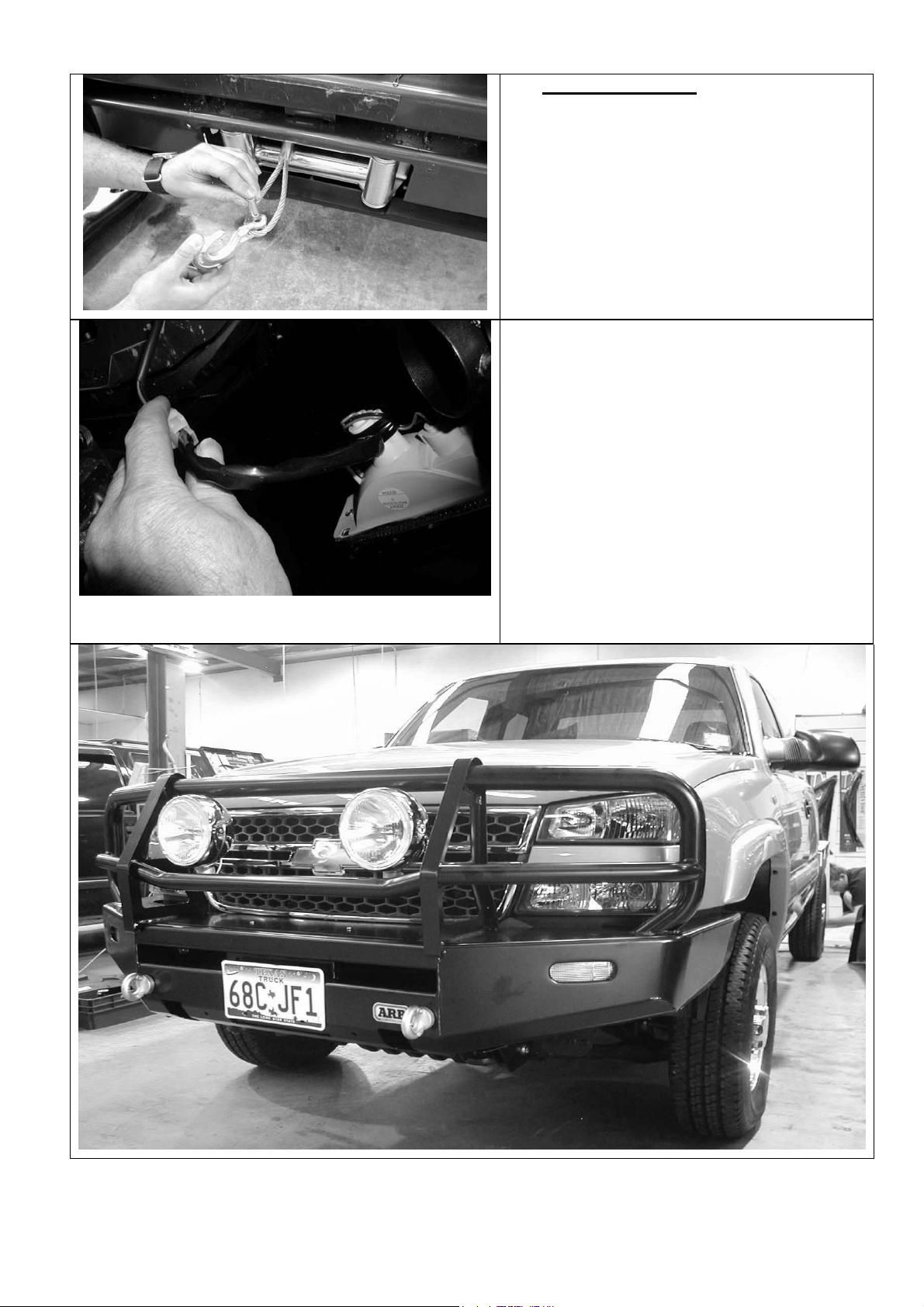

4.5 If fitting with winch

With the winch cable through the roller fair

lead. Mount the hook to the end of the

cable.

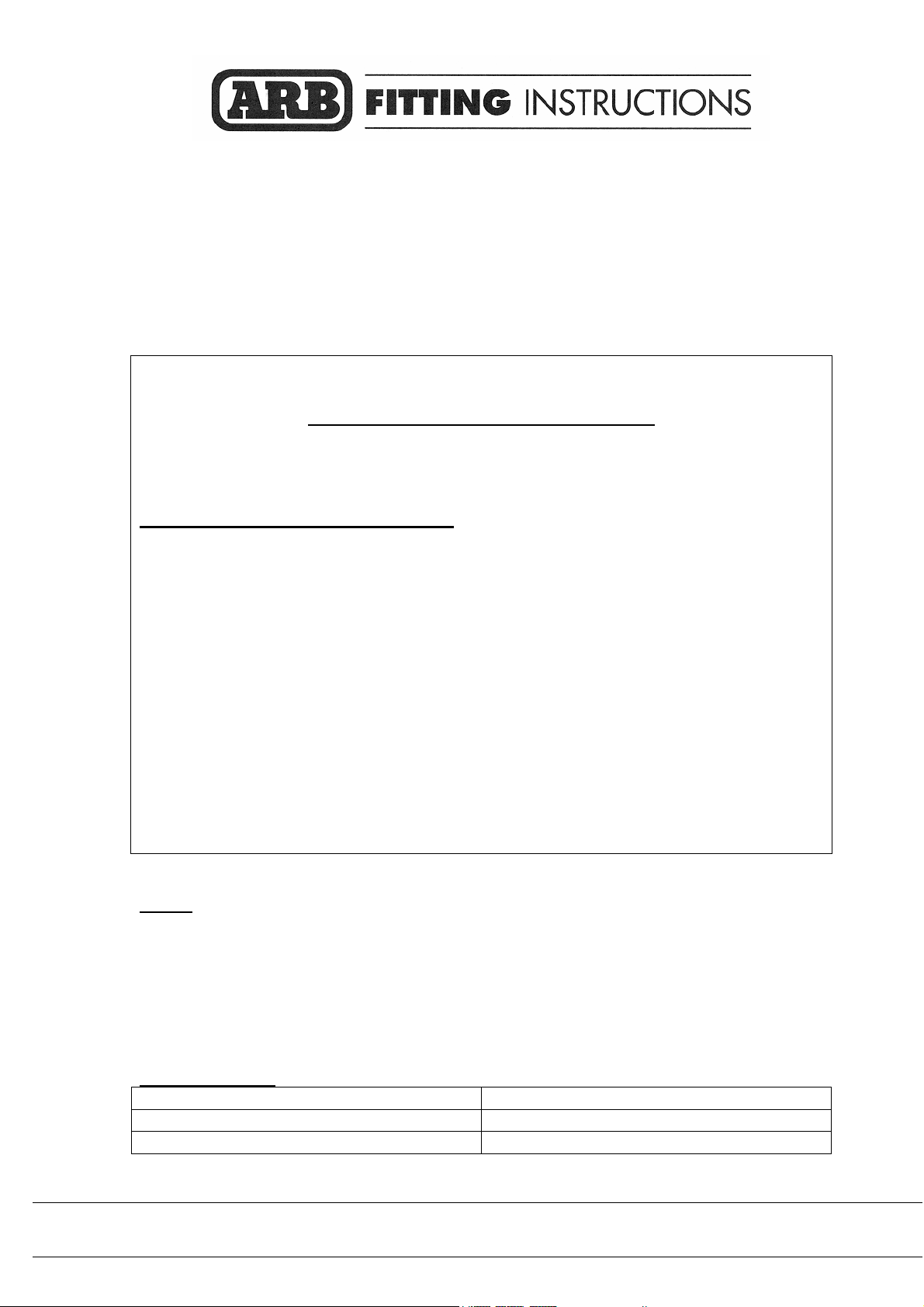

4.6 Wire up the indicator and clearance lamp

assemblies. Use scotch locks to splice

cables to existing indicator and clearance

lamp wiring and cable tie securely.

If fog lights are to be installed, mount

positions are on lower pan area between

winch opening and high lift jack position.

Refer to the Warn winch manual for

vehicle wiring instructions.

Ensure that electrical cables are installed

well clear of sharp, hot or moving objects.

Secure the winch cables to the vehicle

and winch bumper with the supplied cable

ties.

11/10/05 Page 14 of 14 3783176

Page 15

ARB COMBINATION WINCH, NON-WINCH BULL BAR TO SUIT

CHEVROLET SILVERADO 03 ON 1500 MODELS.

PRODUCT No. 3462020, WITH FITTING KIT 3562040

WARNING

FOR VEHICLES EQUIPPED WITH SRS AIRBAG

WHEN INSTALLED IN ACCORDANCE WITH THESE INSTRUCTIONS, THE FRONT

PROTECTION BAR DOES NOT AFFECT OPERATION OF THE SRS AIRBAG.

TAKE NOTE OF THE FOLLOWING:

• THIS PRODUCT MUST BE INSTALLED EXACTLY AS PER THESE

INSTRUCTIONS USING ONLY THE HARDWARE SUPPLIED.

• IN THE EVENT OF DAMAGE TO ANY BULL BAR COMPONENT,

CONTACT YOUR NEAREST AUTHORISED ARB STOCKIST. REPAIRS OR

MODIFICATIONS TO THE IMPACT ABSORPTION SYSTEM MUST NOT BE

ATTEMPED.

• DO NOT USE THIS PRODUCT FOR ANY VEHICLE MAKE OR MODEL,

OTHER THAN THOSE SPECIFIED BY ARB.

• DO NOT REMOVE LABELS FROM THIS BULL BAR.

• THIS PRODUCT OR ITS FIXING MUST NOT BE MODIFIED IN ANY WAY.

Note :

• This bull bar is suitable for Warn 9,500-16,500lb winches.

• Fog light provisions are in lower pan area of bull bar. IPF840FYS lights

are suitable for this location.

Tools Required

Metric Spanner and Socket set Allen key set

Phillips head screwdriver Dia 15/64”, 10.0 and 12.0mm drill bits

Electric drill 13mm chuck Sikaflex 227 adhesive, black color

11/10/05 Page 1 of 14 3783176

If you have any queries regarding the installation of this product please contact the distributor from whom it was purchased, or alternatively the ARB office in your state.

WA: (08) 9244 3553 NSW: (02) 9821 3633 ACT: (02) 6280 7475 SA: (08) 8244 5001 QLD: (07) 3872 3872 NT: (08) 8947 2262 TAS: (03) 6331 4190

Head Office – ARB Corporation Ltd VIC: 42-44 Garden Street, Kilsyth, Victoria, 3137 Tel: (03) 9761 6622 Fax: (03) 9761 6807

Page 16

USE PART No QTY DESCRIPTION

MOUNT BRACKETS TO VEHICLE 3756785L 1 BRACKET BAR MOUNT LHS

3756785R 1 BRACKET BAR MOUNT RHS

3199796 2 PLATE CAGE NUT

4581049 10 M12 WASHER FLAT

4581050 8 M12 WASHER SPRING

6151255 6 BOLT M12 X 40

6151244 2 BOLT M12X150

6151189 2 NUT M12x1.75

6151305 4 NUT M12 CAGE SUIT 4MM

5811037 2 SLEEVE

WINCH 180302 8 CABLE TIE

TOW HOOK RELOCATION 6151365 2 EYEBOLT M24 2.5 SWL

6151361 2 NUT M24 GR8 ZP

3756765 2 BRACKET NUT RETAINING

4581300 2 WASHER M24 EYEBOLT

6151046 2 WASHER M6

6151017 2 BOLT M6 X 16mm

6151128 2 NUT FLANGE M6

CONTROL BOX FITTMENT 4581291 2 WASHER M10 BZ

6151321 2 NUT FLANGED

6151364 2 SCREW CAP M10X30 ZP

3756775 1 BRACKET STD CONTROL BOX IN PAN

3199790 1 TRIM PLATE FOR 16500LB CONTROL

NUMBER PLATE FITTMENT 6151017 4 BOLT M6 X 16mm

6151128 4 NUT FLANGE M6

6151046 4 WASHER M6

3751384 1 BRACKET NO.PLATE

WINCH COVER FITTMENT 6151128 2 NUT FLANGE M6

6151256 2 SCREW M6 S/STEEL BUTTON HEAD

6151046 2 WASHER M6

6191013 1 EXTRUSION WINCH COVER @ 1757

6522048 1 PANEL WINCH COVER

WASHER BOTTLE PROTECTION 6131349 1 FRAME ASSY WASHR BOTTLE PROT

6151303 2 NUT CAGED M8 SUIT 1.6-3.2

6151022 2 BOLT M8X25

4581044 2 WASHER FLAT M8

4581046 2 WASHER SPR M8

6151232 2 BOLT M10X30

4581040 2 WASHER FLAT M10

4581048 2 WASHER SPR M10

11/10/05 Page 2 of 14 3783176

Page 17

BAR TO MOUNT ASSEMBLY 6151255 6 BOLT M12 X 40mm

4581050 6 WASHER SPRING M12

4581049 12 WASHER FLAT M12

4581048 2 WASHER SPRING M10

6151321 2 NUT M10 FLANGED

6151232 2 BOLT M10 X 30mm

4581040 2 WASHER FLAT 3/8”

6151189 6 NUT M12x1.75

INDICATOR ASSY 6821151R 1 INDICATOR ASSY RHS

6821151L 1 INDICATOR ASSY LHS

6151308 4 SCREW SELF TAPPING

6821116 4 NUT NYLON PLUG

6821152 2 LOOM

180701 6 SCOTCH LOCKS

180302 4 CABLE TIE

INNER GUARD RETAINER 3199787R 1 PLATE INNER GUARD

3199787L 1 PLATE INNER GUARD

6151128 4 NUT FLANGE M6

6151213 4 SCREW M6X20 BZ

4581082 4 WASHER M6X20 BZ

NOTE: Shipping brackets connecting

bull bar to pallet and associated

fasteners are not intended to be reused

in fitted bar assembly.

11/10/05 Page 3 of 14 3783176

Page 18

ASSEMBLY SEQUENCE FOR WINCH BUMPER.

1. FITTING MOUNTING BRACKETS

1.1 Remove the plastic shroud above the

radiator as shown, by releasing plastic

clips

1.2 To remove the grille, carefully push the

retainer spring clips back out in four

places behind grille. Pull outer bar from

between headlights forward to release

from clip into end of guard. NOTE: It may

be necessary to remove top headlights to

gain access to these clips if you cannot

release them easily.

1.3 Remove bumper by undoing four bolts

from above and behind bumper then two

bolts securing bumper to wing support

braces from under and behind forward of

wheel arch area.

11/10/05 Page 4 of 14 3783176

Page 19

1.4 Remove stabilizer arms both sides

1.5 Remove plastic shrouds around chassis

1.6 Remove tow hooks

11/10/05 Page 5 of 14 3783176

Page 20

1.7 Fit cage nuts to bracket tangs as shown

1.8 Position the mount brackets as shown on

the ends of the chassis rails (LHS shown).

Loosely fit an M12 bolt and washer set to

top bolt position and lower position as

shown finger tight only.

Inserting sleeve

Sleeve in position

1.9 Partly withdraw M12 x 150 bolt and fit

crush sleeve over bolt body inside chassis

as shown. Fit flat and spring washers, and

nut. Do not tighten.

11/10/05 Page 6 of 14 3783176

Page 21

1.10 Fit M12 cage nuts to both bent plates, 1 x

LH and 1 x RH as assemblies are

opposite for each side of vehicle. Insert

nut assembly through large hole in

underside of chassis and up to meet

vacant hole above long bolt. Insert M12

bolt and washer set, do up finger tight.

1.14 Check that brackets are parallel to each

other, if not adjust. When parallel then

tighten all bolts (nominal outside

dimension across brackets is 898mm).

Fit grille and shroud back into

position.

11/10/05 Page 7 of 14 3783176

Page 22

2. PREPARING BULL BAR FOR FITTING

2.1 Remove lights from cartons and then

remove screws and speed nuts from each

light. These fasteners are not to be reused

– new screws are supplied in the fitting kit.

2.2 Insert nylon nuts into square holes in light

brackets inside wing area

2.3 Fit lights using screws supplied in fitting

kit, taking note of RH and LH light bodies,

they are different and must be placed on

the correct side of bull bar.

2.4 Fit large eyebolt nut into the plate on the

inside of the bar.

11/10/05 Page 8 of 14 3783176

Page 23

2.5 Screw in the eyebolt using the large

washer. Eyebolt can be positioned to sit

vertically by rotating the large nut to the

correct position.

NOTE: EYEBOLTS SHOULD BE REMOVED

FOR SAFETY REASONS WHEN

TRAVELLING ON PUBLIC ROADS.

2.6 When the large nut is in its final position,

secure with the nut retaining bracket using

an M6 bolt, washer and flange nut.

2.7 Secure the number plate bracket using M6

bolts, flat washers and flange nuts. Attach

the longer flange to the bullbar and the

shorter flange to the number plate.

2.8 Fit the M8 cage nuts to the square holes in

the wing brace on the LHS (washer bottle

side) of the bull bar. The body of the cage

nuts are to be on the inside of the brace.

These nuts are to be used to fasten the

washer bottle protection arm to the bull bar.

11/10/05 Page 9 of 14 3783176

Page 24

3. IF FITTING WINCH

3.1 From the factory the winch handle should

be in the position as shown.

Remove cable retaining band and position

cable loop so it will go through roller

fairlead when it is placed in bull bar.

3.2 Fit control box to pan:

• For 9500-12000lb winches, use universal

control box bracket supplied, attaching to

rear of control box mount studs.

• Slide bracket flange under pan and align

with mount slots.

• Fasten in position with 2 x M10 cap

screws, black washers and flange nuts.

• For 15000lb winches, use Warn supplied

control box bracket, attaching to rear of

control box mount studs.

• Slide bracket flange under pan and align

with mount slots.

• Fasten in position with 2 x M10 cap

screws, black washers and flange nuts.

11/10/05 Page 10 of 14 3783176

Page 25

• For 16500lb winches, apply Sikaflex (or

similar product) to rear of control box trim

plate from fitting kit (note orientation critical

to suit final position with control box profile

in pan opening).

• Position trim plate on top of pan centrally

about control box opening and line up with

mount slots.

• Fasten in position with 2 x M10 cap screws

and flange nuts from fitting kit.

3.3 On some models, the roller fair lead must

be drilled prior to fitment.

Mark out as shown and using a 13.0 mm

drill bit, drill two holes as shown in

diagram.

3.4 Viewed from front of vehicle the winch

clutch (handle) must be positioned on the

LH side (same side as smaller square

access hole in pan). Cable must spool

from the bottom of winch. Draw off

enough cable so cable crimp can be

pulled through roller fairlead.

Hint: If crimp is too large to fit through, remove

a circlip from a horizontal roller, partially

remove the shaft so roller gap is increased and

feed cable and crimp through. Refit shaft and

circlip.

Bolt winch in position with the roller fair lead in

place.

Hint: To increase access to mount bolts in

front of roller fairlead, remove circlips from

bottom of each vertical roller shaft, push shaft

up so roller can be dislodged sideways. Do up

bolts in fairlead and winch, then refit circlip.

Connect the winch control box cables to the

winch motor. Refer to the Warn handbook for

additional information. Connect the long winch

+ & - cables to the vehicle after

installed. Refer to the Warn winch manual

for vehicle wiring instructions.

the bar is

11/10/05 Page 11 of 14 3783176

Page 26

3.5

Fitting with winch, number plate above RFL

Fitting without winch, number plate covers RFL

opening

Fitting number plate – with winch

Bolt number plate to the bracket with the

M6 X 16mm bolts and M6 flange nuts

through the lower holes of the number

plate.

If not fitting winch.

Bolt the number plate through the top

holes using M6 X 16mm bolts and M6

flange nuts.

3.6 If not fitting winch cont.

Wrap rubber extrusion around winch

cover.

Place washers over the winch cover fixing

holes located on the top middle face of the

winch bumper.

Place the winch cover on top of the winch

bumper inline with the mount holes.

Bolt together using the M6 button head

stainless steel screws and M6 nuts.

11/10/05 Page 12 of 14 3783176

Page 27

4. FITTING BULL BAR TO VEHICLE

4.1 Using two people, three if winch fitted,

position the bar assembly on the vehicle

mounts.

Bolt the bar to the mounts using M12

bolts, large flat washers and spring

washers. Align the bar to the profile of the

guards, grille and light profile and tighten

all bolts.

Using the M10 pilot holes in mount

brackets, drill pinning hole through

uprights on bull bar. Fit M10 screw,

washer set and flange nut and do up tight.

4.2 Trim excess plastic inner guard molding to

meet lower profile of bull bar wing. Note

the position of water bottle on LHS of

vehicle and trim neatly around it.

4.3 Fit washer bottle protection frame to

lower mounts where original bumper

stabiliser arms were located using 2 x

M10 x 30 bolt and washer sets. Fit off

the upper bracket to inner wing area of

bull bar as shown using M8 x 25 bolts

and washer sets.

NOTE: The 2 x M8 cage nuts should be in

place from step 2.7.

4.4 Fit inner guard plates to ends of bull bar

wings and fasten with M6 black screws

and washers.

11/10/05 Page 13 of 14 3783176

Page 28

4.5 If fitting with winch

With the winch cable through the roller fair

lead. Mount the hook to the end of the

cable.

4.6 Wire up the indicator and clearance lamp

assemblies. Use scotch locks to splice

cables to existing indicator and clearance

lamp wiring and cable tie securely.

If fog lights are to be installed, mount

positions are on lower pan area between

winch opening and high lift jack position.

Refer to the Warn winch manual for

vehicle wiring instructions.

Ensure that electrical cables are installed

well clear of sharp, hot or moving objects.

Secure the winch cables to the vehicle

and winch bumper with the supplied cable

ties.

11/10/05 Page 14 of 14 3783176

Page 29

ARB COMBINATION WINCH, NON-WINCH BULL BAR TO SUIT

CHEVROLET SILVERADO 03 ON 1500HD-2500 MODELS.

PRODUCT No. 3462020, WITH FITTING KIT 3562050

WARNING

FOR VEHICLES EQUIPPED WITH SRS AIRBAG

WHEN INSTALLED IN ACCORDANCE WITH THESE INSTRUCTIONS, THE FRONT

PROTECTION BAR DOES NOT AFFECT OPERATION OF THE SRS AIRBAG.

TAKE NOTE OF THE FOLLOWING:

• THIS PRODUCT MUST BE INSTALLED EXACTLY AS PER THESE

INSTRUCTIONS USING ONLY THE HARDWARE SUPPLIED.

• IN THE EVENT OF DAMAGE TO ANY BULL BAR COMPONENT,

CONTACT YOUR NEAREST AUTHORISED ARB STOCKIST. REPAIRS OR

MODIFICATIONS TO THE IMPACT ABSORPTION SYSTEM MUST NOT BE

ATTEMPED.

• DO NOT USE THIS PRODUCT FOR ANY VEHICLE MAKE OR MODEL,

OTHER THAN THOSE SPECIFIED BY ARB.

• DO NOT REMOVE LABELS FROM THIS BULL BAR.

• THIS PRODUCT OR ITS FIXING MUST NOT BE MODIFIED IN ANY WAY.

Note :

• This bull bar is suitable for Warn 9,500-16,500lb winches.

• Fog light provisions are in lower pan area of bull bar. IPF840FYS lights

are suitable for this location.

Tools Required

Metric Spanner and Socket set Allen key set

Phillips head screwdriver Dia 15/64”, 10.0 and 12.0mm drill bits

Electric drill 13mm chuck Sikaflex 227 adhesive, black color

11/10/05 Page 1 of 14 3783177

If you have any queries regarding the installation of this product please contact the distributor from whom it was purchased, or alternatively the ARB office in your state.

WA: (08) 9244 3553 NSW: (02) 9821 3633 ACT: (02) 6280 7475 SA: (08) 8244 5001 QLD: (07) 3872 3872 NT: (08) 8947 2262 TAS: (03) 6331 4190

Head Office – ARB Corporation Ltd VIC: 42-44 Garden Street, Kilsyth, Victoria, 3137 Tel: (03) 9761 6622 Fax: (03) 9761 6807

Page 30

USE PART No QTY DESCRIPTION

MOUNT BRACKETS TO VEHICLE 3756786L 1 BRACKET BAR MOUNT LHS

3756786R 1 BRACKET BAR MOUNT RHS

4581060 2 WASHER 13X30X3

4581049 12 M12 WASHER FLAT

4581050 8 M12 WASHER SPRING

6151255 8 BOLT M12 X 40

6151189 6 NUT M12x1.75

5848316 2 PACKER

WINCH 180302 8 CABLE TIE

TOW HOOK RELOCATION 6151365 2 EYEBOLT M24 2.5 SWL

6151361 2 NUT M24 GR8 ZP

3756765 2 BRACKET NUT RETAINING

4581300 2 WASHER M24 EYEBOLT

6151046 2 WASHER M6

6151017 2 BOLT M6 X 16mm

6151128 2 NUT FLANGE M6

CONTROL BOX FITTMENT 4581291 2 WASHER M10 BZ

6151321 2 NUT FLANGED

6151364 2 SCREW CAP M10X30 ZP

3756775 1 BRACKET STD CONTROL BOX IN PAN

3199790 1 TRIM PLATE FOR 16500LB CONTROL

NUMBER PLATE FITTMENT 6151017 4 BOLT M6 X 16mm

6151128 4 NUT FLANGE M6

6151046 4 WASHER M6

3751384 1 BRACKET NO.PLATE

WINCH COVER FITTMENT 6151128 2 NUT FLANGE M6

6151256 2 SCREW M6 S/STEEL BUTTON HEAD

6151046 2 WASHER M6

6191013 1 EXTRUSION WINCH COVER @ 1757

6522048 1 PANEL WINCH COVER

WASHER BOTTLE PROTECTION 6131349 1 FRAME ASSY WASHR BOTTLE PROT

6151303 2 NUT CAGED M8 SUIT 1.6-3.2

6151022 2 BOLT M8X25

4581044 2 WASHER FLAT M8

4581046 2 WASHER SPR M8

6151232 2 BOLT M10X30

4581040 2 WASHER FLAT M10

4581048 2 WASHER SPR M10

11/10/05 Page 2 of 14 3783177

Page 31

BAR TO MOUNT ASSEMBLY 6151255 6 BOLT M12 X 40mm

4581050 6 WASHER SPRING M12

4581049 12 WASHER FLAT M12

4581048 2 WASHER SPRING M10

6151321 2 NUT M10 FLANGED

6151232 2 BOLT M10 X 30mm

4581040 2 WASHER FLAT 3/8”

6151189 6 NUT M12x1.75

INDICATOR ASSY 6821151R 1 INDICATOR ASSY RHS

6821151L 1 INDICATOR ASSY LHS

6151308 4 SCREW SELF TAPPING

6821116 4 NUT NYLON PLUG

6821152 2 LOOM

180701 6 SCOTCH LOCKS

180302 4 CABLE TIE

INNER GUARD RETAINER 3199787R 1 PLATE INNER GUARD

3199787L 1 PLATE INNER GUARD

6151128 4 NUT FLANGE M6

6151213 4 SCREW M6X20 BZ

4581082 4 WASHER M6X20 BZ

NOTE: Shipping brackets connecting

bull bar to pallet and associated

fasteners are not intended to be reused

in fitted bar assembly.

11/10/05 Page 3 of 14 3783177

Page 32

ASSEMBLY SEQUENCE FOR WINCH BUMPER.

1. FITTING MOUNTING BRACKETS

1.1 Remove plastic shroud above radiator as

shown, by releasing plastic clips

1.2 To remove the grille, carefully push the

retainer spring clips back out in four

places behind grille. Pull outer bar from

between headlights forward to release

from clip into end of guard. NOTE: It may

be necessary to remove top headlights to

gain access to these clips if you cannot

release them easily.

1.3 Remove bumper by undoing four bolts

from above and behind bumper then two

bolts securing bumper to wing support

braces from under and behind forward of

wheel arch area.

11/10/05 Page 4 of 14 3783177

Page 33

1.4 Remove and replace tow hooks on

opposite chassis sides. Note, the hole

underneath the chassis may need to be

elongated to allow the bolt to fit into the

rear underside position. Leave the outer

bolt off.

1.5 Fit the mount brackets as shown, to the

end of the chassis rails, top M12 bolt and

washer set as shown finger tight only.

1.6 Slide in ‘L’ shaped packer oriented as

shown

1.7 Fit M12 bolt, spring washer and Dia

13.0x30x3 large washer into tow hook

thread, insert M12 bolt and washer set in

pinning hole to line up packer hole.

Tighten up lower bolt.

Remove loose bolt from pinning hole and

drill through using Dia12.0 drill. Then

insert and do up M12 bolt set.

11/10/05 Page 5 of 14 3783177

Page 34

1.8 Drill pinning hole in top position as shown

then insert and do up M12 bolt set.

1.9 Tighten up all bolts

1.10 Check that tops of brackets are

horizontal and that brackets are parallel to

each other. If not release bolts and make

necessary adjustments.

Refit grille and shroud.

11/10/05 Page 6 of 14 3783177

Page 35

2. PREPARING BULL BAR FOR FITTING

2.1 Remove lights from cartons and then

remove screws and speed nuts from each

light. These fasteners are not to be reused

– new screws are supplied in the fitting kit.

2.2 Insert nylon nuts into square holes in light

brackets inside wing area

2.3 Fit lights using screws supplied in fitting

kit, taking note of RH and LH light bodies,

they are different and must be placed on

the correct side of bull bar.

11/10/05 Page 7 of 14 3783177

Page 36

2.4 Fit large eyebolt nut into the plate on the

inside of the bar.

2.5 Screw in the eyebolt using the large

washer. Eyebolt can be positioned to sit

vertically by rotating the large nut to the

correct position.

NOTE: EYEBOLTS SHOULD BE REMOVED

FOR SAFETY REASONS WHEN

TRAVELLING ON PUBLIC ROADS.

2.6 When the large nut is in its final position,

secure with the nut retaining bracket using

an M6 bolt, washer and flange nut.

2.7 Secure the number plate bracket using M6

bolts, flat washers and flange nuts. Attach

the longer side to the bullbar and the

shorter side to the number plate.

11/10/05 Page 8 of 14 3783177

Page 37

3. IF FITTING WINCH

3.1 From the factory the winch handle should

be in the position as shown.

Remove cable retaining band and position

cable loop so it will go through roller

fairlead when it is placed in bull bar.

3.2 Fit control box to pan:

• For 9500-12000lb winches, use universal

control box bracket supplied, attaching to

rear of control box mount studs.

• Slide bracket flange under pan and align

with mount slots.

• Fasten in position with 2 x M10 cap

screws, black washers and flange nuts.

• For 15000lb winches, use Warn supplied

control box bracket, attaching to rear of

control box mount studs.

• Slide bracket flange under pan and align

with mount slots.

• Fasten in position with 2 x M10 cap

screws, black washers and flange nuts.

11/10/05 Page 9 of 14 3783177

Page 38

• For 16500lb winches, apply Sikaflex (or

similar product) to rear of control box trim

plate from fitting kit (note orientation critical

to suit final position with control box profile

in pan opening).

• Position trim plate on top of pan centrally

about control box opening and line up with

mount slots.

• Fasten in position with 2 x M10 cap screws

and flange nuts from fitting kit.

3.3 On some models, the roller fair lead must

be drilled prior to fitment.

Mark out as shown and using a 13.0 mm

drill bit, drill two holes as shown in

diagram.

3.4 Viewed from front of vehicle the winch

clutch (handle) must be positioned on the

LH side (same side as smaller square

access hole in pan). Cable must spool

from the bottom of winch. Draw off

enough cable so cable crimp can be

pulled through roller fairlead.

Hint: If crimp is too large to fit through, remove

a circlip from a horizontal roller, partially

remove the shaft so roller gap is increased

and feed cable and crimp through. Refit shaft

and circlip.

Bolt winch in position with the roller fair lead in

place.

Hint: To increase access to mount bolts in

front of roller fairlead, remove circlips from

bottom of each vertical roller shaft, push shaft

up so roller can be dislodged sideways. Do up

bolts in fairlead and winch, then refit circlip.

Connect the winch control box cables to the

winch motor. Refer to the Warn handbook for

additional information. Connect the long winch

+ & - cables to the vehicle after the bar is

installed. Refer to the Warn winch manual

for vehicle wiring instructions.

11/10/05 Page 10 of 14 3783177

Page 39

3.5

Fitting with winch, number plate above RFL

Fitting without winch, number plate covers RFL

opening

Fitting number plate – with winch

Bolt number plate to the bracket with the

M6 X 16mm bolts and M6 flange nuts

through the lower holes of the number

plate.

If not fitting winch.

Bolt the number plate through the top

holes using M6 X 16mm bolts and M6

flange nuts.

3.6 If not fitting winch cont.

View from above, rear of bull bar

Wrap rubber extrusion around winch

cover.

Place washers over the winch cover fixing

holes located on the top middle face of the

winch bumper.

Place the winch cover on top of the winch

bumper inline with the mount holes.

Bolt together using the M6 button head

stainless steel screws and M6 nuts.

3.7 Fit the M8 cage nuts to the square holes

in the wing brace on the LHS (washer

bottle side) of the bull bar. The body of

the cage nuts are to be on the inside of

the brace. These nuts are to be used to

fasten the washer bottle protection arm to

the bull bar.

11/10/05 Page 11 of 14 3783177

Page 40

4. FITTING BULL BAR TO VEHICLE

4.1 Using two people, three if winch fitted,

position the bar assembly on the vehicle

mounts.

Bolt the bar to the mounts using M12

bolts, large flat washers and spring

washers. Align the bar to the profile of the

guards, grille and light profile and tighten

all bolts.

Using the M10 pilot holes in mount

brackets, drill pinning hole through

uprights on bull bar. Fit M10 screw,

washer set and flange nut and do up tight.

4.2 Trim excess plastic inner guard molding to

meet lower profile of bull bar wing. Note

the position of water bottle on LHS of

vehicle and trim neatly around it.

4.3 Fit washer bottle protection frame to

lower mounts where original bumper

stabiliser arms were located using 2 x

M10 x 30 bolt and washer sets. Fit off

the upper bracket to inner wing area of

bull bar as shown using M8 x 25 bolts

and washer sets.

NOTE: The 2 x M8 cage nuts should be in

place from step 2.7.

11/10/05 Page 12 of 14 3783177

Page 41

4.4 Fit inner guard plates to ends of bull bar

wings and fasten with M6 black screws

and washers.

4.5 If fitting with winch

With the winch cable through the roller fair

lead. Mount the hook to the end of the

cable.

4.6 Wire up the indicator and clearance lamp

assemblies. Use scotch locks to splice

cables to existing indicator and clearance

lamp wiring and cable tie securely.

If fog lights are to be installed, mount

positions are on lower pan area between

winch opening and high lift jack position.

Refer to the Warn winch manual for

vehicle wiring instructions.

Ensure that electrical cables are installed

well clear of sharp, hot or moving objects.

Secure the winch cables to the vehicle

and winch bumper with the supplied cable

ties.

11/10/05 Page 13 of 14 3783177

Page 42

11/10/05 Page 14 of 14 3783177

Page 43

ARB COMBINATION WINCH, NON-WINCH BULL BAR TO SUIT

CHEVROLET SILVERADO 03 ON 2500HD-3500 MODELS.

PRODUCT No. 3462020, WITH FITTING KIT 3562060

WARNING

FOR VEHICLES EQUIPPED WITH SRS AIRBAG

WHEN INSTALLED IN ACCORDANCE WITH THESE INSTRUCTIONS, THE FRONT

PROTECTION BAR DOES NOT AFFECT OPERATION OF THE SRS AIRBAG.

TAKE NOTE OF THE FOLLOWING:

• THIS PRODUCT MUST BE INSTALLED EXACTLY AS PER THESE

INSTRUCTIONS USING ONLY THE HARDWARE SUPPLIED.

• IN THE EVENT OF DAMAGE TO ANY BULL BAR COMPONENT,

CONTACT YOUR NEAREST AUTHORISED ARB STOCKIST. REPAIRS OR

MODIFICATIONS TO THE IMPACT ABSORPTION SYSTEM MUST NOT BE

ATTEMPED.

• DO NOT USE THIS PRODUCT FOR ANY VEHICLE MAKE OR MODEL,

OTHER THAN THOSE SPECIFIED BY ARB.

• DO NOT REMOVE LABELS FROM THIS BULL BAR.

• THIS PRODUCT OR ITS FIXING MUST NOT BE MODIFIED IN ANY WAY.

Note :

• This bull bar is suitable for Warn 9,500-16,500lb winches.

• Fog light provisions are in lower pan area of bull bar. IPF840FYS lights

are suitable for this location.

Tools Required

Metric Spanner and Socket set Allen key set

Phillips head screwdriver Dia 5.5, 10.0 and 12.0mm drill bits

Electric drill 13mm chuck Sikaflex 227 adhesive, black color

11/10/05 Page 1 of 13 3783178

If you have any queries regarding the installation of this product please contact the distributor from whom it was purchased, or alternatively the ARB office in your state.

WA: (08) 9244 3553 NSW: (02) 9821 3633 ACT: (02) 6280 7475 SA: (08) 8244 5001 QLD: (07) 3872 3872 NT: (08) 8947 2262 TAS: (03) 6331 4190

Head Office – ARB Corporation Ltd VIC: 42-44 Garden Street, Kilsyth, Victoria, 3137 Tel: (03) 9761 6622 Fax: (03) 9761 6807

Page 44

USE PART No QTY DESCRIPTION

MOUNT BRACKETS TO VEHICLE 3756787L 1 BRACKET BAR MOUNT LHS

3756787R 1 BRACKET BAR MOUNT RHS

4581060 2 WASHER 13X30X3

4581049 14 M12 WASHER FLAT

4581050 8 M12 WASHER SPRING

6151255 8 BOLT M12 X 40

6151189 6 NUT M12x1.75

5848316 2 PACKER

WINCH 180302 8 CABLE TIE

TOW HOOK RELOCATION 6151365 2 EYEBOLT M24 2.5 SWL

6151361 2 NUT M24 GR8 ZP

3756765 2 BRACKET NUT RETAINING

4581300 2 WASHER M24 EYEBOLT

6151046 2 WASHER M6

6151017 2 BOLT M6 X 16mm

6151128 2 NUT FLANGE M6

CONTROL BOX FITTMENT 4581291 2 WASHER M10 BZ

6151321 2 NUT FLANGED

6151364 2 SCREW CAP M10X30 ZP

3756775 1 BRACKET STD CONTROL BOX IN PAN

3199790 1 TRIM PLATE FOR 16500LB CONTROL

NUMBER PLATE FITTMENT 6151017 4 BOLT M6 X 16mm

6151128 4 NUT FLANGE M6

6151046 4 WASHER M6

3751384 1 BRACKET NO.PLATE

WINCH COVER FITTMENT 6151128 2 NUT FLANGE M6

6151256 2 SCREW M6 S/STEEL BUTTON HEAD

6151046 2 WASHER M6

6191013 1 EXTRUSION WINCH COVER @ 1757

6522048 1 PANEL WINCH COVER

11/10/05 Page 2 of 13 3783177

Page 45

BAR TO MOUNT ASSEMBLY 6151255 6 BOLT M12 X 40mm

4581050 6 WASHER SPRING M12

4581049 12 WASHER FLAT M12

4581048 2 WASHER SPRING M10

6151321 2 NUT M10 FLANGED

6151232 2 BOLT M10 X 30mm

4581040 2 WASHER FLAT 3/8”

6151189 4 NUT M12x1.75

INDICATOR ASSY 6821151R 1 INDICATOR ASSY RHS

6821151L 1 INDICATOR ASSY LHS

6151308 4 SCREW SELF TAPPING

6821116 4 NUT NYLON PLUG

6821152 2 LOOM

180701 6 SCOTCH LOCKS

180302 4 CABLE TIE

INNER GUARD RETAINER 3199787R 1 PLATE INNER GUARD

3199787L 1 PLATE INNER GUARD

6151128 4 NUT FLANGE M6

6151213 4 SCREW M6X20 BZ

4581082 4 WASHER M6X20 BZ

NOTE: Shipping brackets connecting

bull bar to pallet and associated

fasteners are not intended to be reused

in fitted bar assembly.

11/10/05 Page 3 of 13 3783177

Page 46

ASSEMBLY SEQUENCE FOR WINCH BUMPER.

1. FITTING MOUNTING BRACKETS

1.1 Remove plastic shroud above radiator as

shown, by releasing plastic clips

1.2 To remove the grille, carefully push the

retainer spring clips back out in four

places behind grille. Pull outer bar from

between headlights forward to release

from clip into end of guard. NOTE: It may

be necessary to remove top headlights to

gain access to these clips if you cannot

release them easily

1.3 Remove bumper by undoing four bolts

from above and behind bumper then two

bolts securing bumper to wing support

braces from under and behind forward of

wheel arch area.

11/10/05 Page 4 of 13 3783177

Page 47

1.4 Remove and replace tow hooks on

opposite chassis sides. Note, the hole

underneath the chassis may need to be

elongated to allow the bolt to fit into the

rear underside position. Leave the outer

bolt off.

1.5 Fit the mount brackets as shown, to the

end of the chassis rails, top M12 bolt and

washer set as shown finger tight only.

1.6 Slide in ‘L’ shaped packer oriented as

shown

1.7 Fit M12 bolt, spring washer and Dia

13.0x30x3 large washer into tow hook

thread, insert M12 bolt and washer set in

pinning hole to line up packer hole.

Tighten up lower bolt.

Remove loose bolt from pinning hole and

drill through using Dia12.0 drill. Then

insert and do up M12 bolt set.

11/10/05 Page 5 of 13 3783177

Page 48

1.8 Remove loose bolt from pinning hole and

drill through using Dia12.0 drill. Then

insert and do up M12 bolt set.

1.9 Drill pinning hole in top position as shown

then insert and do up M12 bolt set.

1.10 Tighten up all bolts

11/10/05 Page 6 of 13 3783177

Page 49

2. PREPARING BULL BAR FOR FITTING

2.1 Remove lights from cartons and then

remove screws and speed nuts from each

light. These fasteners are not to be reused

– new screws are supplied in the fitting kit.

2.2 Insert nylon nuts into square holes in light

brackets inside wing area

2.3 Fit lights using screws supplied in fitting

kit, taking note of RH and LH light bodies,

they are different and must be placed on

the correct side of bull bar.

11/10/05 Page 7 of 13 3783177

Page 50

2.4 Fit large eyebolt nut into the plate on the

inside of the bar.

2.5 Screw in the eyebolt using the large

washer. Eyebolt can be positioned to sit

vertically by rotating the large nut to the

correct position.

NOTE: EYEBOLTS SHOULD BE REMOVED

FOR SAFETY REASONS WHEN

TRAVELLING ON PUBLIC ROADS.

2.6 When the large nut is in its final position,

secure with the nut retaining bracket using

an M6 bolt, washer and flange nut.

2.7 Secure the number plate bracket using M6

bolts, flat washers and flange nuts. Attach

the longer side to the bullbar and the

shorter side to the number plate.

11/10/05 Page 8 of 13 3783177

Page 51

3. IF FITTING WINCH

3.1 As supplied the winch handle should be in

the position as shown.

Remove cable retaining band and position

cable loop so it will go through roller

fairlead when it is placed in bull bar.

3.2 Fit control box to pan:

• For 9500-12000lb winches, use

universal control box bracket supplied,

attaching to rear of control box mount

studs.

• Slide bracket flange under pan and

align with mount slots.

• Fasten in position with 2 x M10 cap

screws, black washers and flange nuts.

• For 15000lb winches, use Warn

supplied control box bracket, attaching

to rear of control box mount studs.

• Slide bracket flange under pan and

align with mount slots.

• Fasten in position with 2 x M10 cap

screws, black washers and flange nuts.

11/10/05 Page 9 of 13 3783177

Page 52

• For 16500lb winches, apply Sikaflex (or

similar product) to rear of control box

trim plate from fitting kit (note

orientation critical to suit final position

with control box profile in pan opening).

• Position trim plate on top of pan

centrally about control box opening and

line up with mount slots.

• Fasten in position with 2 x M10 cap

screws and flange nuts from fitting kit.

3.3 On some models, the roller fair lead must

be drilled prior to fitment.

Mark out as shown and using a 13.0 mm

drill bit, drill two holes as shown in

diagram.

3.4 Viewed from front of vehicle the winch

clutch (handle) must be positioned on the

LH side (same side as smaller square

access hole in pan). Cable must spool

from the bottom of winch. Draw off

enough cable so cable crimp can be

pulled through roller fairlead.

Hint: If crimp is too large to fit through, remove

a circlip from a horizontal roller, partially

remove the shaft so roller gap is increased and

feed cable and crimp through. Refit shaft and

circlip.

Bolt winch in position with the roller fair lead in

place.

Hint: To increase access to mount bolts in

front of roller fairlead, remove circlips from

bottom of each vertical roller shaft, push shaft

up so roller can be dislodged sideways. Do up

bolts in fairlead and winch, then refit circlip.

Connect the winch control box cables to the

winch motor. Refer to the Warn handbook for

additional information. Connect the long winch

+ & - cables to the vehicle after the bar is

installed. Refer to the Warn winch manual

for vehicle wiring instructions.

11/10/05 Page 10 of 13 3783177

Page 53

3.5 Fitting number plate – with winch

Bolt number plate to the bracket with the

M6 X 16mm bolts and M6 flange nuts

through the lower holes of the number

plate.

Fitting with winch, number plate above RFL

Fitting without winch, number plate covers RFL

opening

If not fitting winch.

Bolt the number plate through the top

holes using M6 X 16mm bolts and M6

flange nuts.

3.6 If not fitting winch cont.

Wrap rubber extrusion around winch

cover.

Place washers over the winch cover fixing

holes located on the top middle face of the

winch bumper.

View from above, rear of bull bar

Place the winch cover on top of the winch

bumper inline with the mount holes.

Bolt together using the M6 button head

stainless steel screws and M6 nuts.

11/10/05 Page 11 of 13 3783177

Page 54

4. FITTING BULL BAR TO VEHICLE

4.1 Using two people, three if winch fitted,

position the bar assembly on the vehicle

mounts.

Bolt the bar to the mounts using M12

bolts, large flat washers and spring

washers. Align the bar to the profile of the

guards, grille and light profile and tighten

all bolts.

Using the M10 pilot holes in mount

brackets, drill pinning hole through

uprights on bull bar. Fit M10 screw,

washer set and flange nut and do up tight.

4.2 Trim excess plastic inner guard molding to

meet lower profile of bull bar wing. Note

the position of water bottle on LHS of

vehicle and trim neatly around it.

4.3 Fit inner guard plates to ends of bull bar

wings and fasten with M6 black screws

and washers.

4.4 If fitting with winch

With the winch cable through the roller fair

lead. Mount the hook to the end of the

cable.

11/10/05 Page 12 of 13 3783177

Page 55

4.5 Wire up the indicator and clearance lamp

assemblies. Use scotch locks to splice

cables to existing indicator and clearance

lamp wiring and cable tie securely.

If fog lights are to be installed, mount

positions are on lower pan area between

winch opening and high lift jack position.

Refer to the Warn winch manual for vehicle

wiring instructions.

Ensure that electrical cables are installed well

clear of sharp, hot or moving objects. Secure

the winch cables to the vehicle and winch

bumper with the supplied cable ties.

11/10/05 Page 13 of 13 3783177

Loading...

Loading...