Page 1

Part Number:

Product

Description:

Suited to

vehicle/s:

3452030

COMBAR DODGE RAM 2006 ON

F/KIT 6172164, 6172147

Models 1500 2006 ON ADD BRACKET KIT# 3552030

OR Models 2500/3500 2006 ON ADD BRACKET KIT# 3552040

WARNING

REGARDING VEHICLES EQUIPPED WITH SRS AIRBAG;

When installed in accordance with these instructions, the front protection bar does not affect operation of

the SRS airbag.

ALSO, NOTE THE FOLLOWING:

♦ This product must be installed exactly as per these instructions using only the hardware supplied.

♦ In the event of damage to any bull bar component, contact your nearest authorised ARB stockist.

Repairs or modifications to the impact absorption system must not be attempted.

♦ Do not use this product for any vehicle make or model, other than those specified by ARB.

♦ Do not remove labels from this bull bar.

♦ This product or its fixing must not be modified in any way.

♦ The installation of this product may require the use of specialized tools and/or techniques

♦ It is recommended that this product is only installed by trained personnel

♦ These instructions are correct as at the publication date. ARB Corporation Ltd. cannot be held

responsible for the impact of any changes subsequently made by the vehicle manufacturer

♦ During installation, it is the duty of the installer to check correct operation/clearances of all

components

♦ Work safely at all times

♦ Unless otherwise instructed, tighten fasteners to specified torque

ARB 4x4 ACCESSORIES

Corporate Head Office

42-44 Garden St Tel: +61 (3) 9761 6622

Kilsyth, Victoria Fax: +61 (3) 9761 6807

AUSTRALIA 3137

Australian enquiries sales@arb.com.au

North & South American enquiries sales@arbusa.com

Other international enquiries exports@arb.com.au

www.arb.com.au

Last Rev Date: 10-Feb-2007 Page 1 of 15 Fitting instructions# 3783246

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Page 2

GENERAL CARE AND MAINTENANCE

By choosing an ARB Bar, you have bought a product that is one of the most sought after 4WD products

in the world. Your bar is a properly engineered, reliable, quality accessory that represents excellent

value. To keep your bar in original condition it is important to care and maintain it following these

recommendations:

§ Prior to exposure to the weather your bar should be treated to a Canuba based polish on all exposed

surfaces. It is recommended that this is performed on a six monthly basis or following exposure to

salt, mud, sand or other contaminants.

§ As part of any Pre Trip Preparation, or on an annual basis, it is recommended that a thorough visual

inspection of the bar is carried out, making sure that all bolts and other components are torqued to

the correct specification. Also check that all wiring sheaths, connectors, and fittings are free of

damage. Replace any components as necessary. This service can be performed by your local

authorized ARB Stockist.

FITTING REQUIREMENTS

REQUIRED TOOLS FOR FITMENT OF PRODUCT:

METRIC SPANNER and SOCKET TOOL SET Sikaflex© Black

PHILIPS and FLAT BLADE SCREWDRIVERS DIA 19mm HOLESAW

POWER DRILL DIA 13mm CHUCK CAPACITY DRILL BITS, DIA 7.0 (@100mm min), 10.0mm

STEEL RULE 300mm SCRIBER

HAVE AVAILABLE THESE SAFETY ITEMS WHEN FITTING PRODUCT:

Protective eyewear

NOTE: ‘WARNING’ notes in the fitting procedure relate to OHS situations, where to avoid a

potentially hazardous situation it is suggested that protective safety gear be worn or a safe work

procedure be employed. If these notes and warnings are not heeded, injury may result.

Hearing protection

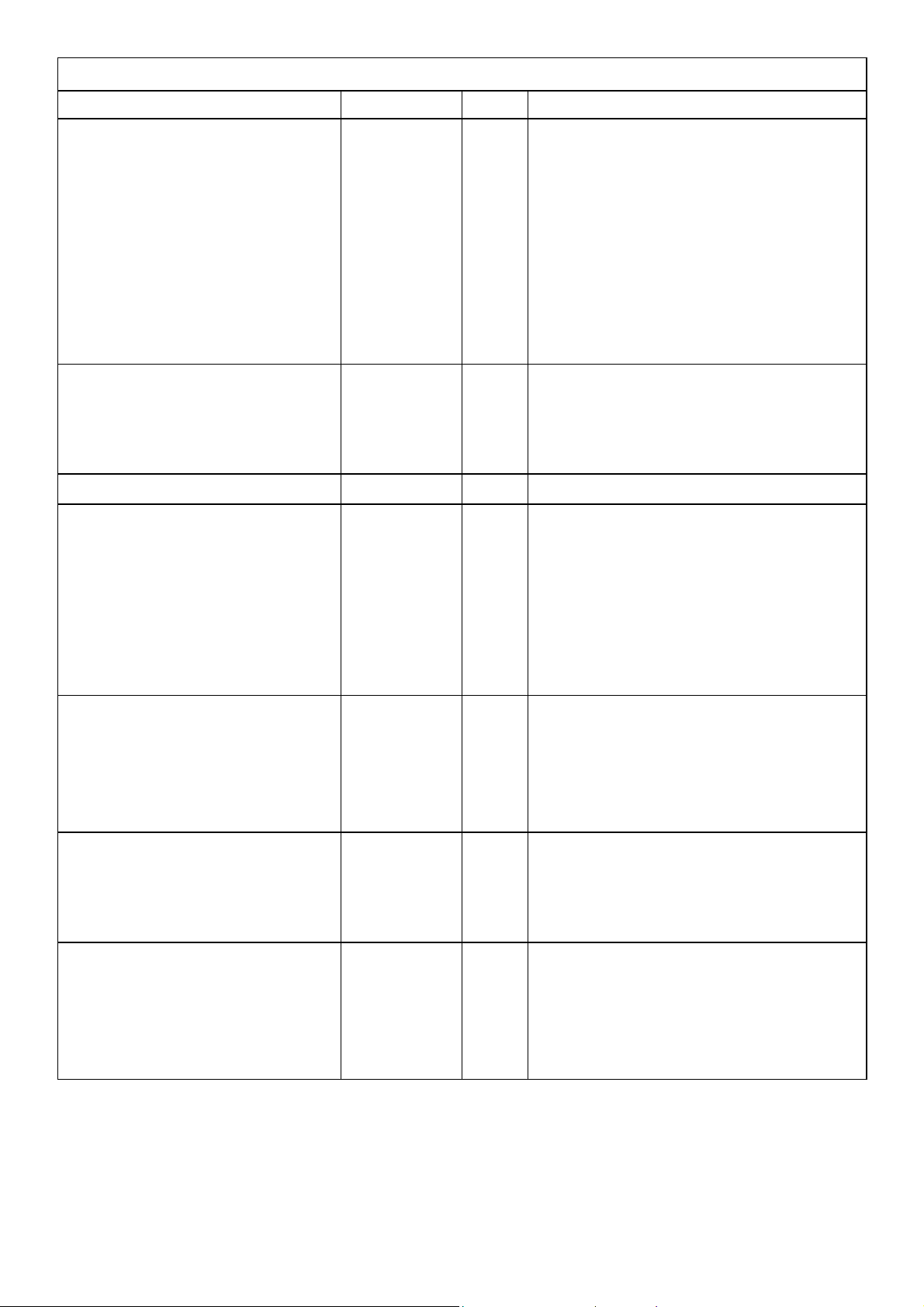

FASTENER TORQUE SETTINGS:

SIZE Torque Nm Torque lbft

M6 9Nm 4lbft

M8 22Nm 16lbft

M10 44Nm 32lbft

M12 77Nm 57lbft

Last Rev Date: 10-Feb-2007 Page 2 of 15 Fitting instructions# 3783246

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Page 3

PARTS LISTING

APPLICATION. PART NO. QTY DESCRIPTION

MOUNT BRACKETS TO VEHICLE

1500 MODEL ONLY

(INC. BRACKET SET 3552030)

MOUNT BRACKETS TO VEHICLE

2500/3500 MODELS ONLY

(INC. BRACKET SET 3552040)

WINCH

3756968R&L

3757018R&L

4581049

4581050

6151189

6151255

3199893

6151304

6151232

3756969R&L

6151299

6151321

4581040

1+1

1+1

20

10

10

10

2

2

2

1+1

2

2

2

BRACKET BAR MOUNT SET

BRACKET REINFORCING SET

M12 WASHER FLAT

M12 WASHER SPRING

NUT M12x1.75

BOLT M12 X 40

PLATE CAGE NUT

NUT CAGE M10

BOLT SEMS M10 X 30mm

BRACKET BAR MOUNT SET

BOLT M10 X 100

NUT M10 FLANGED

WASHER M10 X 3mm

180302 8 CABLE TIE

6151365

6151361

3756765

2

EYEBOLT M24 2.5T SWL

2

NUT M24 GR8 ZP

2

BRACKET NUT RETAINING

TOW HOOK RELOCATION

4581300

6151046

6151017

6151128

CONTROL BOX FITTMENT 4581291

6151321

6151364

3756775

3199790

6151017

6151128

NUMBER PLATE FITTMENT

6151046

3751313

6151128

6151256

WINCH COVER FITTMENT

6151046

6191013

2

WASHER M24 EYEBOLT

2

WASHER M6

2

BOLT M6 X 16mm

2

NUT FLANGE M6

2

WASHER M10 BZ

2

NUT FLANGED

2

SCREW CAP M10X30 ZP

1

BRACKET STD CONTROL BOX IN PAN

1

TRIM PLATE FOR 16500LB CONTROL

4

BOLT M6 X 16mm

4

NUT FLANGE M6

4

WASHER M6

1

BRACKET NO.PLATE

2

NUT FLANGE M6

2

SCREW M6 S/STEEL BUTTON HEAD

2

WASHER M6

1

EXTRUSION WINCH COVER @ 1757

6522048

Last Rev Date: 10-Feb-2007 Page 3 of 15 Fitting instructions# 3783246

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

1

PANEL WINCH COVER

Page 4

6151255

6

BOLT M12 X 40mm

BAR TO MOUNT ASSEMBLY

INDICATOR ASSY

RETAINER FENDER LINER

4581050

4581049

6151321

6151232

6151189

6821151R

6821151L

6151308

6821116

6821152

180701

180302

3756948R

3756948L

6151300

6151213

4581082

6

12

2

2

6

1

1

4

4

2

6

4

1

1

4

4

4

WASHER SPRING M12

WASHER FLAT M12

NUT M10 FLANGED

BOLT SEMS M10 X 30mm

NUT M12x1.75

INDICATOR ASSY RHS

INDICATOR ASSY LHS

SCREW SELF TAPPING

NUT NYLON PLUG

LOOM

SCOTCH LOCKS

CABLE TIE

PLATE RETAINER FENDER LINER

PLATE RETAINER FENDER LINER

NUT CAGED M6

SCREW M6X20 BZ

WASHER M6 BZ

3756949

6821189

6151300

FOG LAMPS

6151017

6151046

4581036

3162457

3162456

2

ADAPTER BRACKET

2

GROMMET

6

NUT CAGED M6

6

BOLT M6 X 16

6

WASHER M6

6

WASHER SPRING M6

1

LIGHT APERTURE MOLDING RH

1

LIGHT APERTURE MOLDING LH

*** NOTE:

Ø FOR IPF OPTIONAL FOG LAMPS, ORDER SUPPLIMENTARY KIT# 9381FCK.

Ø IF REFITTING OE FOG LAMPS, ADAPTER BRACKETS ARE SUPPLIED STANDARD WITH

THIS BULL BAR FITTING KIT TO MOUNT THESE LAMPS.

Last Rev Date: 10-Feb-2007 Page 4 of 15 Fitting instructions# 3783246

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Page 5

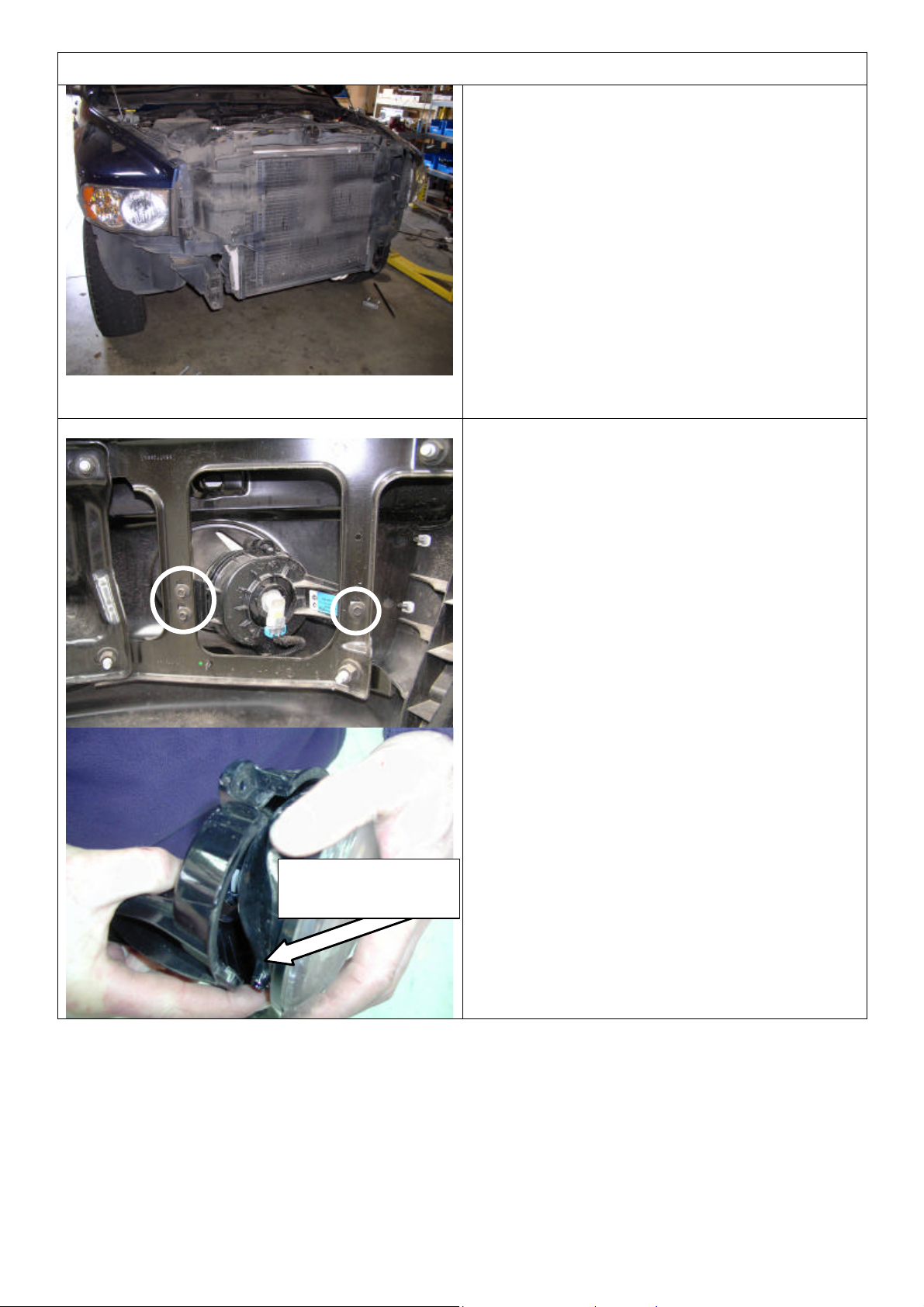

REMOVAL OF BUMPER

1. If fog lights fitted in bumper, undo fog light

loom connection (connection located on LHS

of bumper)

2. Remove bumper by undoing 4 x M12 nuts on

‘U’ bolts through chassis and withdrawing

bumper off chassis mount position, set aside.

Retain bumper retaining ‘U’ bolts and nuts.

Note: For 2500 turbo diesel shown (and 3500

TD), undo and remove intercooler top mount

bolts and rubber suspension blocks, this will

allow the intercooler to tip back at the top and

clear of the bumper U bolts allowing removal).

3. If OE fog lights fitted and are required for refitment into bull bar, remove each light and

bracket assembly and then remove lights as

shown by prising the lug each side from the

case and undoing the adjuster screw.

4. Also, if OE fog lamps are to be reused,

remove fog lamp loom fitted to bumper for reuse.

Prise open to

remove lug

Last Rev Date: 10-Feb-2007 Page 5 of 15 Fitting instructions# 3783246

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Page 6

showing location

bracket on RHS

FITTING PROCEDURE GENERAL

FOR 1500 MODEL VEHICLES

FOLLOW STEPS 5 - 11, FOR 2500

AND 3500 VEHICLES STEPS 12 – 18.

5. Fit mount brackets to chassis end plates, fit

reinforcing brackets behind flanges as

shown. Fasten using M12 x 40 bolts, washer

and nut sets, but only nip up hand tight at

this stage..

View from rear

of reinforcing

1008-1012mm

6. Align bracket set evenly on vehicle so that

the outside measurement across vertical

bracket plates is 1008-1012mm.

7. Do fasteners up tight, ensuring that

reinforcing bracket is sitting snugly against

chassis side face.

View showing layout of

mount brackets – note: set

distance outside of flanges

at 1008 and 1012mm.

8. Recheck 1008-1012mm pitch, readjust if

necessary.

NOTE: Distance between uprights in bull bar is

1013mm.

9. Drill 1 x M10 pinning hole in chassis using

existing hole in reinforcing bracket as a

guide.

Warning: Drilling operations can result in

flying metal debris, safety glasses should be

10. Fit the M10 cage nut to nut plate as shown.

Last Rev Date: 10-Feb-2007 Page 6 of 15 Fitting instructions# 3783246

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Page 7

FITTING PROCEDURE GENERAL

OF CHAS

SIS

BETWEEN FLANGES

Warning: Drilling operations can result in flying

metal debris, safety glasses should be worn.

Warning: Drilling operations can result in flying

metal debris, safety glasses should be worn.

11. For pinning bolt from outboard of reinforcing

bracket, fit cage nut plate assembly through

into chassis end aperture as shown, then

fasten in place through drilled pinning hole

with M10 x 30 SEMS bolt and washer set. Do

up tight. Repeat for other side of vehicle.

2500 AND 3500 ONLY STEPS 12 - 18

12. Fit chassis brackets as shown.

DRILL DIA

12.0mm

APPROX.

35mm FROM

UNDERSIDE

13. Insert original U bolts, entering from inboard

face of chassis (you may have to tilt

intercooler to gain sufficient clearance to

allow U bolt to enter this side).

14. Set brackets so front edge is vertical then do

bolts up tight.

15. Replace the intercooler suspension blocks

and bolts if removed for U bolt removal.

16. Mark the position for the pinning hole

centrally between the body mount bracket

flanges as shown on the outboard face of the

chassis rails.

17. Drill through both sides of chassis and mount

bracket flange Dia 10.0mm.

18. Fit M10 x 100 pinning bolt, M10 x 3MM

washer and flange nut set and do up tight.

LOCATE CENTRALLY

Last Rev Date: 10-Feb-2007 Page 7 of 15 Fitting instructions# 3783246

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Page 8

FITTING PROCEDURE GENERAL

19. Remove lights from cartons and then

remove screws and speed nuts from each

light. These fasteners are not to be reused –

new screws are supplied in the fitting kit

20. Insert nylon nuts into square holes in light

brackets inside wing area

21. Fit lights using screws supplied in fitting

kit, taking note of RH and LH light bodies,

they are different and must be placed on

the correct side of bull bar.

22. Fit large eyebolt nut into the plate on the

inside of the bar.

Last Rev Date: 10-Feb-2007 Page 8 of 15 Fitting instructions# 3783246

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Page 9

FITTING PROCEDURE GENERAL

23. Screw in the eyebolt using the large

washer. Eyebolt can be positioned to sit

vertically by rotating the large nut to the

correct position

NOTE: EYEBOLTS SHOULD BE REMOVED

FOR SAFETY REASONS WHEN

TRAVELLING ON PUBLIC ROADS.

24. When the large nut is in its final position,

secure with the nut retaining bracket

using an M6 bolt, washer and flange nut.

25. Secure the number plate bracket using

M6 bolts, flat washers and flange nuts.

Attach the longer side to the bullbar and

the shorter side to the number plate.

Note: As supplied from Warn, the winch handle

on 1500 and 16500lb winches should be in

the position as shown. This is correct

orientation for this bar.

26. Remove cable retaining band and position

cable loop so it will go through roller fairlead

when it is placed in bull bar.

Last Rev Date: 10-Feb-2007 Page 9 of 15 Fitting instructions# 3783246

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Page 10

FITTING PROCEDURE WINCH

Fit control box to pan:

• For 9500-12000lb winches, use universal

control box bracket supplied, attaching to

rear of control box mount studs.

• Slide bracket flange under pan and align

with mount slots.

27. Fasten in position with 2 x M10 cap screws,

black washers and flange nuts

• For 15000lb winches, use Warn supplied

control box bracket, attaching to rear of

control box mount studs.

• Slide bracket flange under pan and align

with mount slots.

28. Fasten in position with 2 x M10 cap screws,

black washers and flange nuts.

• For 16500lb winches, apply Sikaflex (or

similar product) to rear of control box trim

plate from fitting kit (note orientation critical

to suit final position with control box profile

in pan opening).

• Position trim plate on top of pan centrally

about control box opening and line up with

mount slots.

29. Fasten in position with 2 x M10 cap screws

and flange nuts from fitting kit.

30. In some cases, the roller fair lead bracket

must have a second set of holes drilled to line

up with holes in winch bracket. If required,

mark out as shown and using a 13.0 mm drill

bit, drill two holes as shown in diagram.

Last Rev Date: 10-Feb-2007 Page 10 of 15 Fitting instructions# 3783246

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Page 11

FITTING PROCEDURE WINCH

31. Viewed from front of vehicle the winch clutch

(handle) must be positioned on the LH side

(same side as smaller square access hole in

pan). Cable must spool from the bottom of

winch. Draw off enough cable so cable crimp

can be pulled through roller fairlead.

32. Bolt winch in position with the roller fair lead

in place.

Hint: To increase access to mount bolts in front of

roller fairlead, remove circlips from bottom of each

vertical roller shaft, push shaft up so roller can be

dislodged sideways. Do up bolts in fairlead and

winch, then refit circlip.

33. Connect the winch control box cables to the

winch motor. Refer to the Warn handbook for

additional information. Connect the long

winch + & - cables to the vehicle after the bar

is installed. Refer to the Warn winch

manual for vehicle wiring instructions.

34. Fitting number plate – with winch

Bolt number plate to the bracket with the M6 X

16mm bolts and M6 flange nuts through the

lower holes of the number plate.

If not fitting winch.

Bolt the number plate through the top holes

using M6 X 16mm bolts and M6 flange nuts.

35. If not fitting winch cont.

36. Wrap rubber extrusion around winch cover.

37. Place washers over the winch cover fixing

holes located on the top middle face of the

winch bumper.

38. Place the winch cover on top of the winch

bumper inline with the mount holes.

39. Bolt together using the M6 button head

stainless steel screws and M6 nuts.

View from above, rear of bull bar

Last Rev Date: 10-Feb-2007 Page 11 of 15 Fitting instructions# 3783246

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Page 12

Warning: Drilling operations can result in flying

metal debris, safety glasses should be worn.

25mm (3/4 to

FITTING PROCEDURE BAR ON VEHICLE

40. Using two people, three if winch fitted,

position the bar assembly on the vehicle

mounts.

Caution: This product is heavy, especially if a

winch is fitted. Do not attempt to lift it and fit it

by yourself. Have some assistants help you or

use a mechanical aid such as this hydraulic lift

table as shown.

40. Bolt the bar to the mounts using M12 bolts,

large flat washers and spring washers. Bolt

the bar to the mounts using M12 bolts, large

flat washers and spring washers. Align the

bar to the profile of the guards, grille and light

profile and tighten all bolts.

201”) gap

41. When bar is aligned, tighten bolts.

42. Using the M10 pilot holes in mount brackets,

drill pinning hole through uprights on bull bar.

Fit M10 screw, washer set and flange nut and

do up tight.

Last Rev Date: 10-Feb-2007 Page 12 of 15 Fitting instructions# 3783246

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Page 13

FITTING PROCEDURE BAR ON VEHICLE

If fitting optional accessory fog lamps kit

9381FCK follow fitting instructions supplied

with kit. If fitting OE fog lights follow steps 43 –

48.

43. Fit M6 cage nuts and grommet to adaptor

bracket as shown.

44. Fit light to adaptor bracket by locating mount

lugs in light body into holes in adaptor bracket

flanges.

45. Screw adjuster into grommet so that light is

approximately parallel to bracket.

46. Fit adapter bracket and fog lamp assembly

into brackets in bull bar wings, as shown.

47. Bolt in place with M6 x 16 bolt and washer

sets into cage nuts.

48. Route OE fog lamp loom and connect to

lamps.

Fitting plastic fog lamp aperture moldings.

49. If fog lamps are fitted, cut centre panel out of

light aperture moldings using a hack saw

blade.

50. If fog lamps are not fitted leave centre panel

in place.

Last Rev Date: 10-Feb-2007 Page 13 of 15 Fitting instructions# 3783246

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Page 14

FITTING PROCEDURE BAR ON VEHICLE

51. Note that the aperture moldings are handed

(RH or LH), select correct hand for each wing

aperture. Apply Sikaflex to recess in aperture

molding flange then fit to aperture in wing.

Use adhesive tape to secure plastic mold

while Sikaflex cures.

52. Use adhesive tape to secure plastic mold

while Sikaflex cures.

53. Wire up indicators and running lamps. Wire

loom extensions are supplied in fitting kit.

54. If winch fitted, fit off winch hook.

Last Rev Date: 10-Feb-2007 Page 14 of 15 Fitting instructions# 3783246

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Page 15

FITTING PROCEDURE BAR ON VEHICLE

55. Trim fender liner with air hacksaw or similar

tool along line as shown. Cut away the

outboard flap, which normally fits in the end

of the bumper wing. This is so the liner can

be held back easily by the retaining bracket at

step 56.

Cut along

this path

56. Fit liner retainer bracket with black M6 bolt

and washer sets into M6 cage nuts in wing

returns each side as shown.

FITTED PRODUCT ON 1500 MODEL

Last Rev Date: 10-Feb-2007 Page 15 of 15 Fitting instructions# 3783246

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Loading...

Loading...