Page 1

Part Number: 3450210 F/KIT: 6172210

Product

JEEP ROCK CRAWLER BAR

Description:

Suited to

CHRYSLER WRANGLER JK JEEP 2006 ON

vehicle/s:

WARNING

♦ This product must be installed exactly as per these instructions us ing only the hardware supplied.

♦ In the event of damage to any bull bar component, contact your nearest authorised ARB stockist.

♦ Do not use this product for any vehicle make or model, other than those specified by ARB.

♦ Do not remove labels from this bull bar.

♦ This product or its fixing must not be modified in any way.

♦ The installation of this product may require the use of specialized tools and/or techniques

♦ It is recommended that this product is only installed by trained personnel

♦ These instructions are correct as at the publication date. ARB Corporation Ltd. cannot be held

responsible for the impact of any changes subsequently made by the vehicle manufacturer

♦ During installation, it is the duty of the installer to check correct operation/clearances of all

components

♦ Work safely at all times

♦ Unless otherwise instructed, tighten fasteners to specified torque

ARB 4x4 ACCESSORIES

Corporate Head Office

42-44 Garden St Tel: +61 (3) 9761 6622

Kilsyth, Victoria Fax: +61 (3) 9761 6807

AUSTRALIA 3137

Australian enquiries sales@arb.com.au

North & South American enquiries sales@arbusa.com

Other international enquiries exports@arb.com.au

www.arb.com.au

Last Rev Date: 25 01 08 Page 1 of 11 Fitting instructions# 3786376

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Page 2

GENERAL CARE AND MAINTENANCE

By choosing an ARB Bar, you have bought a product that is one of the most sought after 4WD products

in the world. Your bar is a properly engineered, reliable, quality accessory that represents excellent

value. To keep your bar in original condition it is important to care and maintain it following these

recommendations.

• Prior to exposure to the weather your bar should be treated to a Canuba based polish on all exposed

surfaces. It is recommended that this is performed on a six monthly basis or following exposure to

salt, mud, sand or other contaminants.

• As part of any Pre Trip Preparation, or on an annual basis, it is recommended that a thorough visual

inspection of the bar is carried out, making sure that all bolts and other components are torqued to the

correct specification. Also check that all wiring sheaths, connectors, and fittings are free of damage.

Replace any components as necessary.

• Please contact local Authorised ARB Stockist if you would like to have this service carried out on

your behalf.

HAVE AVAILABLE THESE SAFETY ITEMS WHEN FITTING PRODUCT:

BASIC TOOL KIT

Protective eyewear

NOTE: ‘WARNING’ notes in the fitting procedure relate to OHS situations, where to avoid a potentially

hazardous situation it is suggested that protective safety gear be worn or a safe work procedure be employed. If

these notes and warnings are not heeded, injury may result.

Hearing protection

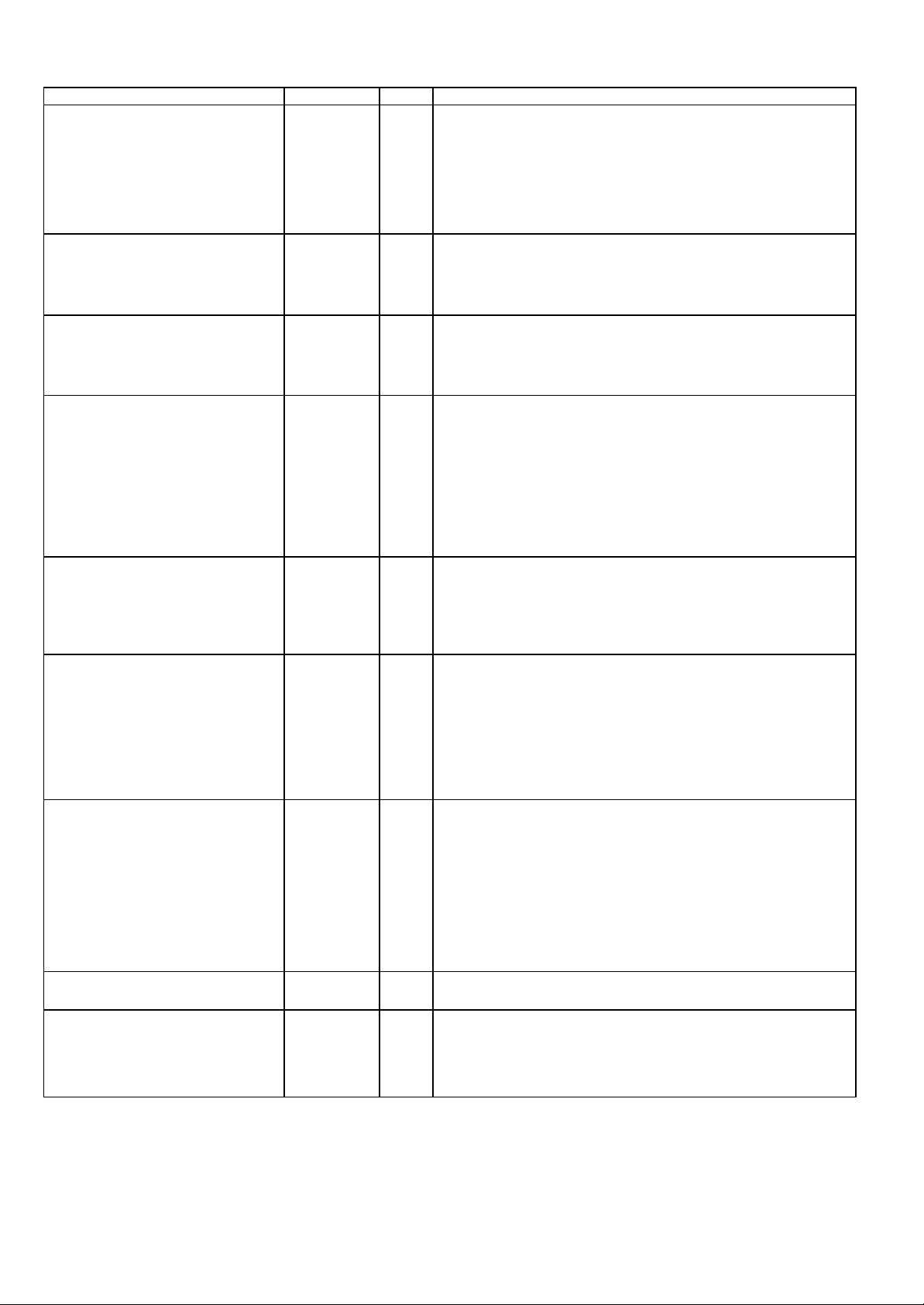

FASTENER TORQUE SETTINGS:

SIZE Torque Nm Torque lbft

M6 9Nm 4lbft

M8 22Nm 16lbft

M10 44Nm 32lbft

M12 77Nm 57lbft

OPTIONAL LIGHT SETS TO SUIT THIS PRODUCT:

Up to IPF 900 SERIES FOG OR DRIVING LIGHT SETS

WARN WINCHES TO FIT THIS PRODUCT

MID SIZE FRAME 6000LB – 9500LB

TI SERIES 9500LB

POWER PLANT 9500LB – 12000LB

RC SERIES 9000LB

Last Rev Date: 25 01 08 Page 2 of 11 Fitting instructions# 3786376

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Page 3

USE PART No QTY DESCRIPTION

6151357 8 BOLT M10 x 1.5 x 30mm SEMS ASSY

6151168 2 BOLT M12 X 1.75 X 80mm

TO FIT BAR TO 4581050 2 WASHER SPRING ½”

VEHICLE CHASSIS 4581049 2 WASHER FLAT ½”

3199848 2 NUT PLATE CAGED M12

6151305 2 NUT CAGED M12 X 1.75

5848342 2 PACKER

6151021 2 BOLT M8 x 20mm

CONTROL BOX BRACKET 4581044 2 WASHER FLAT M8

LIGHT BRACKETS 6151021 4 BOLT M8 X 25MM

NUMBER PLATE BRACKET 6151017 2 BOLT M6 X 16MM

WINCH FITMENT 6151073 2 BOLT 3/8” X 1 ½”

WING BRACE TO WINGS 4681011R 1 BRACE WING RHS

3756262 1 CONTROL BOX BRACKET

6151132 2 NUT FLANGE M8

3757047 2 BRACKETS LIGHT BOLT ON

4581063 8 WASHER FLAT M8 GOLD ZINC

6151212 4 NUT NYLOC M8

6151180 4 BOLT M6 x 20MM

ASSEMBLY 5848302 2 PACKER NYLON BLACK

4581072 4 WASHER FLAT M6 x 13mm

6151128 4 NUT FLANGE M6

6151162 2 NUT NYLOC M6

3757048 1 NUMBER PLATE MOUNT

3757049 1 NUMBER PLATE PIVOT

180302 10 CABLE TIES

4581040 6 WASHER FLAT M10

6151357 2 BOLT M10 x 1.5 x 30mm SEMS ASSY

6151321 2 NUT FLANGE M10

4681011L 1 BRACE WING LHS

6151021 8 BOLT M8 X 25MM

4581044 8 WASHER FLAT M8

4581046 8 WASHER SPRING M8

6151132 8 NUT FLANGE M8

Last Rev Date: 25 01 08 Page 3 of 11 Fitting instructions# 3786376

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Page 4

ASSEMBLY SEQUENCE FOR BULL BAR INSTALLATION.

PLEASE READ AND UNDERSTAND FITTING INSTRUCTIONS BEFORE

ATTEMPTING TO FIT BAR TO VEHICLE

1. To fit a bar to vehicle, the plastic

bumper and all hardware behind

bumper must be removed from

vehicle.

See photos below.

Last Rev Date: 25 01 08 Page 4 of 11 Fitting instructions# 3786376

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Page 5

SIDE MOUNTING

2. This is how the vehicle must be

prepared before fitting a bar to the

vehicle.

15MM IN

3. Arrows indicate which bolt holes to

use when fitting the bar to the

vehicle.

4. The set of mounting holes under

arrowed holes are for vehicles that

have been fitted with a body lift kit.

I.e. This set of mounting holes will

lift the bar 25mm.

5. If a winch is going to be fitted, the

right hand side mounting plate on

end of chassis has to be notched for

winch clearance.

6. Cut top flange up to chassis rail

and 15mm in.

Last Rev Date: 25 01 08 Page 5 of 11 Fitting instructions# 3786376

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

UP TO CHASSIS RAIL

VIEWED FROM RHS OF VEHICLE

Page 6

T

AIL OF

CAPTIVE NUT

YOU WILL HAVE TO BEND

-

6. With the help of a friend, lift bar

onto chassis and secure using 10mm

hardware, Finger tighten only.

4 BOLTS PER SIDE

VIEWED FROM LHS OF VEHICLE

7. This hardware is for side

mounting as per paragraph 3-4

Set up RHS of vehicle

VIEWED FROM UNDER RHS OF VEHICLE.

Caged nut fitted to nut plate

8. Packer fits in between inside of

chassis rail and bar in rear part of

captive slot

9. Pass 12mm bolt plus washers

through outside of bar, through packer

and just protruding into chassis rail.

10. Pass caged nut assembly into open

end of chassis rail and secure with

previously fitted 12mm bolt, see photo

on paragraph 11.

TAIL OF CAPTIVE NUT PLATE

TO FIT INTO CHASSIS RAILS.

Last Rev Date: 25 01 08 Page 6 of 11 Fitting instructions# 3786376

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Page 7

To assemble, using a 6mm x 25mm

11. Pass caged nut plate from top

through crossmember, then upwards

into open end of ch assis rails.

TOP VIEW LHS OF VEHICLE.

12. When all bolts are tighten to

correct torque, brake off the part of

the captive nut plate which hangs

through the hole in vehicle

crossmember with a pair of pliers.

13. If a number plate is to be fitted to

vehicle, you must assemble as per

photo opposite.

14.

bolt, flat washer, pass through

outer frame, fit black nylon packer

then pass through inner frame and

secure using a 6mm nyloc nut.

15. Tighten just enough so the

assembly can pivot.

16. The reason for a pivoting number

plate assembly is to allow the

number plate to pivot up when the

winch is being operated.

Last Rev Date: 25 01 08 Page 7 of 11 Fitting instructions# 3786376

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Page 8

17. When the number plate

assembly is assembled, fit to bar

using 6mm x 25mm bolt plus 6mm

hardware.

18. Tighten bolts to torque

specifications.

WINCH MOUNTING PLATFORM

19. As mentioned above, this bar

can be fitted with a series of

different Warn winches.

20. If a mid size frame type winch

is to be used, a control box bracket

has to be fitted to bar.

21. Lower winch onto mounting

platform of bar. Fit 3/8” square nuts

into winch retaining cavities.

22. Bolt up from under bar using

3/8” x 1 ½”bolts, spring and flat

washers

23. Fit control box bracket to bar

using M8 x 25mm bolts plus 8mm

hardware.

24. Fit control box to control box

bracket and wire up winch as per

Warn instructions.

25. Cable tie all power cables together

and keep clear of all moving

parts, hot parts and sharp edges.

26. If a RC Series winch is to be

fitted, the same as above applies

except the RC winch has its own

bolt on control box mount.

Last Rev Date: 25 01 08 Page 8 of 11 Fitting instructions# 3786376

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Page 9

Hold nylo

c nut

27. If a Power Plant 9500LB –

12000LB is going to be used. The top

compressor cover must be removed

by undoing the 4 capped head

screws.

27. Place protective cloths over top of

bar and lift winch onto winch

mounting platform.

28. Refit top cover.

29. Secure and wire up the same

method as paragraph 21- 22.

30. Winch has built in control box

feature, therefore no control box

bracket required.

31. Lastly, fitting a TI 9500LB winch,

is same as paragraph 21-22- 30.

32. If fitting lights to bar, the light

mounting brackets must be fitted

at this stage.

33. The brackets is bolted to bar

using 8mm hardware and secured

using a 8mm nyloc nuts.

34. The bracket faces towards the

winch so when the lights are fitted

the high lift jack, if used, does not

hit the light.

Using ¼” drive

Ratchet with

extension

35. If lights are going to be fitted to a

bar fitted with a power plant

winch, the brackets face

outwards, therefore a hi lift jack

cannot be used.

Last Rev Date: 25 01 08 Page 9 of 11 Fitting instructions# 3786376

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Page 10

36. The next part to fit to bar is the

roller fairlead. This is secured to bar

using 10mm hardware.

37. Pass 10mm bolt assembly through

front of roller fairlead, through bar

and secure from behind using a 10mm

flange nut.

ARROWS INDICATE 10MM FLANGE NUTS

38. Fit wing braces to bar using 8mm

hardware.

39. When all bolts are fitted, tighten to

torque specifications.

Last Rev Date: 25 01 08 Page 10 of 11 Fitting instructions# 3786376

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Page 11

Number Plate in up position during

Bolt number plate to number plate

bracket using 6mm hardware.

winching

PHOTO IS A OPTIONAL COLOURED BAR

Last Rev Date: 25 01 08 Page 11 of 11 Fitting instructions# 3786376

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Loading...

Loading...