Page 1

23 1 01

Page 1 of 16

3783013

If you have any queries regarding the installation of this product please contact the distributor from whom it was purchased, or alternatively the ARB office in your state.

Head Office – ARB Corporation Ltd VIC: 42-44 Garden Street, Kilsyth, Victoria, 3137 Tel: (03) 9761 6622 Fax: (03) 9761 6807

WA: (08) 9244 3553 NSW: (02) 9821 3633 ACT: (02) 6280 7475 SA: (08) 8244 5001 QLD: (07) 3872 3872 NT: (08) 8947 2262 TAS: (03) 6331 4190

KJ JEEP COMBINATION BULL BAR

PRODUCT NUMBER FITTING KIT NUMBER

3450110 6171745

WARNING

FOR VEHICLES EQUIPPED WITH SRS AIRBAG

WHEN INSTALLED IN ACCORDANCE WITH THESE INSTRUCTIONS, THE FRONT

PROTECTION BAR DOES NOT AFFECT OPERATION OF THE SRS AIRBAG.

TAKE NOTE OF THE FOLLOWING:

• THIS PRODUCT MUST BE INSTALLED EXACTLY AS PER THESE INSTRUCTIONS

USING ONLY THE HARDWARE SUPPLIED.

• DO NOT USE THIS PRODUCT FOR ANY VEHICLE MAKE OR MODEL, OTHER THAN

THOSE SPECIFIED BY ARB.

• DO NOT REMOVE LABELS FROM THIS BULL BAR.

• THIS PRODUCT OR ITS FIXING MUST NOT BE MODIFIED IN ANY WAY.

Page 2

31 10 02

Page 2 of 16

3783013

USE

PART No

QTY

DESCRIPTION

6151232

10

BOLT M10 x 30mm

IMPACT ABSORBER

4581040

10

WASHER FLAT M10

MOUNTING SYSTEM

4581048

10

WASHER SPRING M10

4601044

2

CHANNEL CAPTIVE NUT (INSIDE CHASSIS RAILS)

4601045

2

CHANNEL CAPTIVE NUT (INSIDE CROSSMEMBER)

3756449

1

MOUNTING SYSTEM

BULL BAR TO

6151232

6

BOLT M10 x 30mm

IMPACT ABSORBERS

4581048

6

WASHER SPRING M10

4581040

8

WASHER FLAT M10

6151026

2

NUT M10

6151021

2

BOLT M8 x 20mm

CONTROL BOX BRACKET

4581044

2

WASHER FLAT M8

3751564

1

CONTROL BOX BRACKET

6151132

2

NUT FLANGE M8

NUMBER PLATE BRACKET

6151080

2

BOLT M6 x 20mm (BRACKET TO BAR)

6151046

4

WASHER FLAT M6 x 13mm

6151128

4

NUT FLANGE M6

6151017

2

BOLT M6 x 16mm (NUMBER PLATE TO BRACKET)

3751370

1

NUMBER PLATE BRACKET

TO BOLT INDICATORS TO BAR

6151126

2

BOLT M4 x 30mm

4581037

2

WASHER FLAT M4

5848283

2

WASHER PACKER NYLON

6151127

2

NUT NYLOC M4

8-9000lb WINCH

4581040

4

WASHER FLAT 3/8” x 1"

6151074

2

BOLT 1 ¾” x 3/8” UNC

180302

10

CABLE TIES

6191007

1

EXTRUSION RUBBER

WINCH PAN COVER

6521031

1

PANEL WINCH COVER

6151256

2

SCREW BUTTON HEAD M6 x 16mm

6151128

2

NUT FLANGE M6

AIR DEFLECTOR

3314463

1

AIR DEFLECTOR

6151017

4

BOLT M6 X 16mm

6151128

4

NUT M6 - FLANGE

4581072

4

WASHER FLAT M6 x 20mm

WASHER BOTTLE COVER

3314462

1

WASHER BOTTLE COVER

3756446

1

BRACKET COVER

6151022

2

BOLT M8 x 25mm

4581044

2

WASHER FLAT M8

6151132

2

NUT FLANGE M8

6151017

5

BOLT M6 x 16mm

4581072

3

WASHER FLAT M6 x 20mm

6151046

2

WASHER FLAT M6 x 13mm

6151128

5

NUT FLANGE M6

FLARE MOULDING

6191009

1

FLARE MOULDING

FOG LIGHT HOUSING

3162457

1

PLASTIC HOUSING RHS

AND FITMENT

3162456

1

PLASTIC HOUSING LHS

4581040

4

WASHER

INNER GUARD TO BAR

6151017

2

BOLT M6 x 16mm

4581072

2

WASHER FLAT M6 x 20mm

6151128

2

NUT FLANGE M6

TOOLS REQUIRED.

BASIC TOOL KIT, KEY HOLE SAW, TORX KEY T-15

Page 3

31 10 02

Page 3 of 16

3783013

ASSEMBLY SEQUENCE FOR BULL BAR INSTALLATION.

PLEASE READ AND UNDERSTAND FITTING INSTRUCTIONS BEFORE

ATTEMPTING TO FIT BAR TO VEHICLE

1. Remove grille from vehicle using torx

keys.

2. Remove bumper from vehicle and

remove all lights and the wiring loom

from bumper.

3. Be careful when removing bumper from

the flares as the plastic clips are

awkward to undo.

4. When bumper is removed, cut the lower

plastic lug from grille panel to enable

bull bar mounting system to bolt up

against vehicle crossmember. Place either

thick cardboard or plywood either side of

lug to prevent paint damage.

Remove tow hook and crush cans

from vehicle

5. This is how it must look when it has been

cut.

Page 4

31 10 02

Page 4 of 16

3783013

6. Cut the lower section off the vehicle

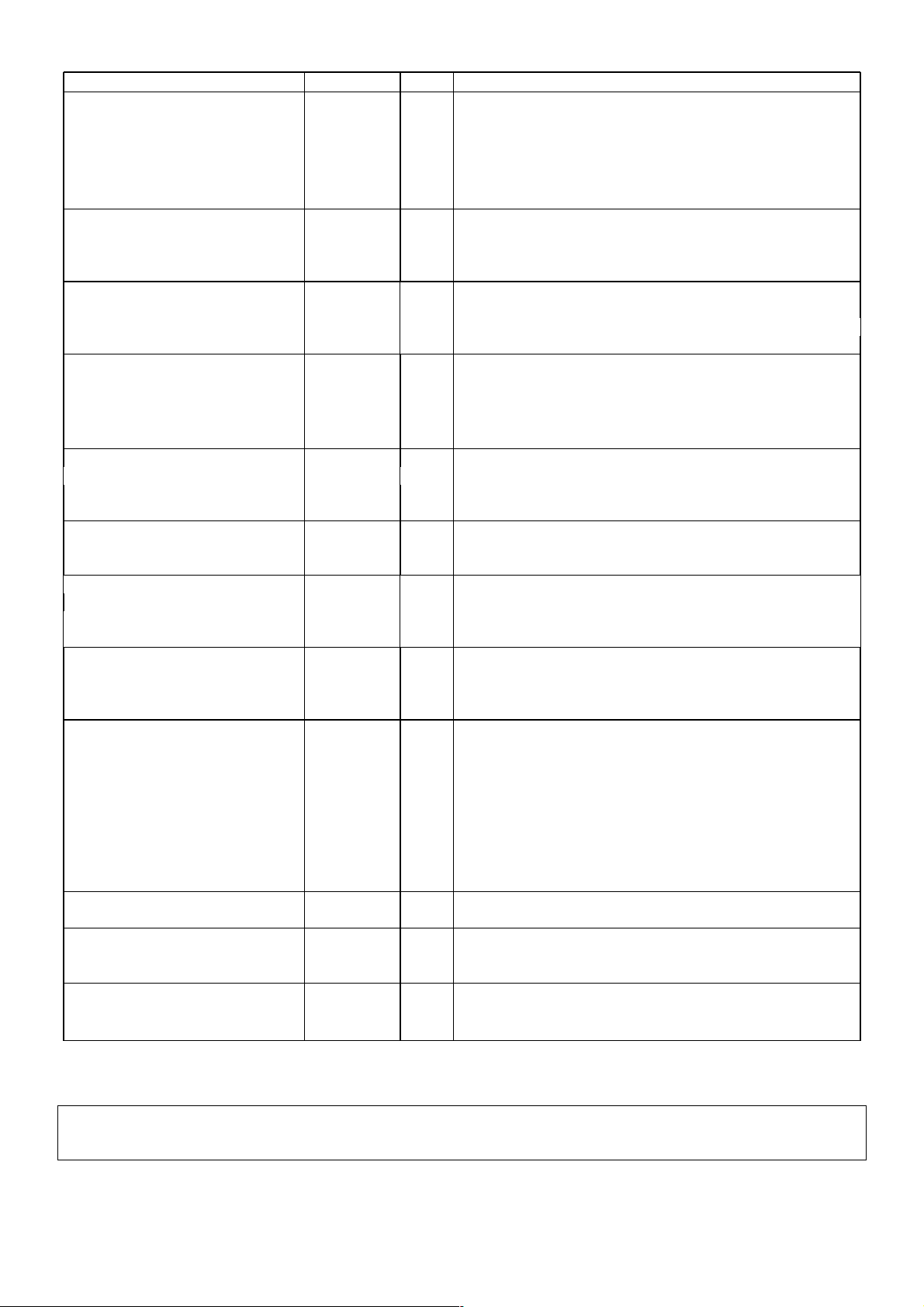

flares.

7. Mark a datum point by drawing a

horizontal line under the rivet inside the

inner guard. (Photo shows RHS of

vehicle)

8. Mark a second datum point where the

pencil is pointing, then using masking

tape join the two datum points together

making sure you have a level line.

9. Using a key hole saw, carefully cut below

the tape line.

Page 5

31 10 02

Page 5 of 16

3783013

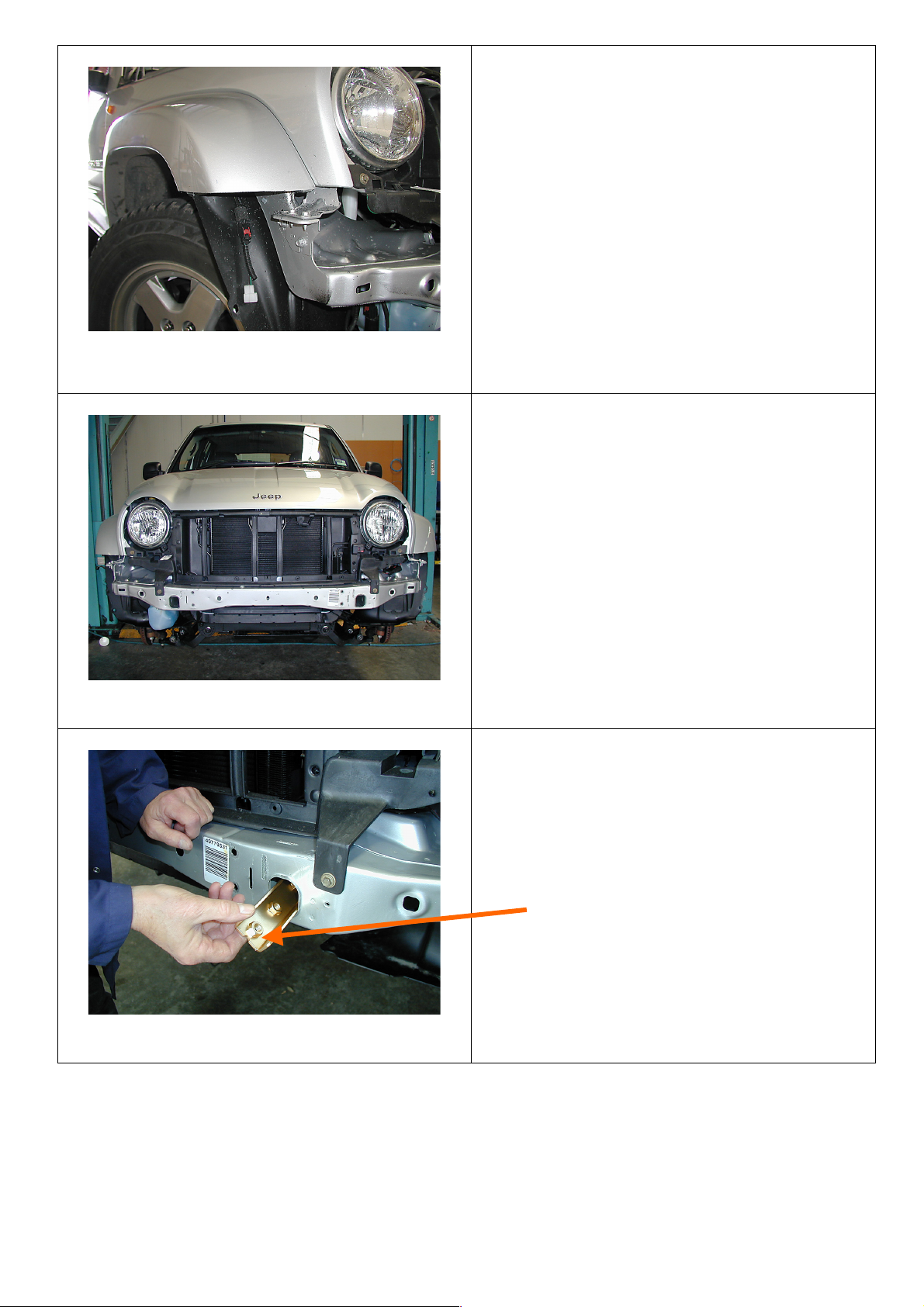

10. Photo shows a finished cut flare.

11. The vehicle is now ready to fit mounting

system and bar.

(Grille and bumper removed, flares cut and

grille lug cut.)

12. To fit mounting system to vehicle, fit

captive nut channel in through front

apertures in vehicle crossmember on both

sides.

(Notch in channel must face front of vehicle)

Page 6

31 10 02

Page 6 of 16

3783013

13. When both channels are inside of

crossmember, using your finger, align with

holes underneath of chassis rails.

14. Fit mounting system to front crossmember of

vehicle and centralized sideways.

15. Fit 10mm hardware to the two most forward

holes in lower brackets, to both sides of

vehicle, making sure mounting system is

hard up against vehicle crossmember,

tighten firmly.

16. Using 10mm drill bit, drill out holes in centre

of slots in front of crossmember.

Photo shows underside of mounting

system on LHS of vehicle.

Page 7

31 10 02

Page 7 of 16

3783013

17. Once holes have been drilled, fit captive nut

channels through lower aperture in vehicle

crossmember.

18. Secure using 10mm hardware and tighten

firmly making sure mounting system is hard

against vehicle crossmember.

NB. When step 19 is finished, slacken off

bolt tension to enable sideways movement if

needed when bar is fitted.

19. When front bolts are tighten, loosen off lower

bolts in chassis brackets. Using a 10mm drill

bit, drill out the most rearward hole in lower

chassis bracket being careful not to drill too

far into captive nut channel. When holes has

been drilled, realigned the rear hole with

rear nut in captive nut channel, and secure

using 10mm hardware, then lightly tighten

all bolts in lower chassis brackets.

MOUNTING SYSTEM MUST BE ABLE TO

BE MOVED SIDWAYS.

Page 8

31 10 02

Page 8 of 16

3783013

20. If bar is going to be a non winch bar, fit

number plate directly to front of bar using

6mm hardware.

21. To fit cover plate on top of bar winch cutout,

fit rubber extrusion around top cover panel,

trim to size and bolt to top of bar using M6

button head stainless steel screws and M6

flange nuts.

22. Indicator installation to bar , fit indicator

tang into slot of fog light bracket and under

outer bracket. Slide plastic packer between

bracket and indicator and fasten using 4mm

screw ,flat washer and 4mm nyloc nut.

PHOTO VEIWED FROM INSIDE OF BAR LHS

Page 9

31 10 02

Page 9 of 16

3783013

23. If bar is to have original fog lights fitted,

position light into the two lower holes in light

mounting bracket, place packer washer

over light locating boss and refit light screws

into all 3 holes, tighten firmly using torx key.

( If vehicle does not have fogs fitted, they can be

purchased. Part no. 05083895 - 05083896 and

screw kit to suit. )

24. Refit vehicle loom to mounting system using

cable ties and plug back into connector body.

25. If bar is to have a winch fitted, follow the

next steps.

26. Fit number plate bracket to bar using 6mm

hardware.( 20mm x 6mm bolts ) Fit number

plate to number plate bracket using 6mm

hardware when bar is fitted to vehicle.

27. Fit control box bracket to bar using 8mm

hardware.

VIEW OF THE CENTRE OF BAR

Page 10

31 10 02

Page 10 of 16

3783013

28. Drill 12mm holes under existing holes 25mm

lower down the same pitch as existing holes,

these will be the holes used to bolt to bar.

29. To fit winch into bar you must pack winch

up on a bench to enable you to lower bar

down on winch.

30. Line up top holes first and secure using 3/8”

hardware (1 ½”” x 3/8”bolts ) flat and spring

washers.

31. Place roller fairlead over lower holes and

again secure using 3/8” hardware ( 1 ¾”x

3/8” bolts ) flat and spring washers. When all

bolts are fitted tighten firmly.

NEW HOLES

Page 11

31 10 02

Page 11 of 16

3783013

32 . Fit control box to control box bracket using

original ¼” nuts from control box and

connect power cables to winch motor as per

winch instructions.

33. Cable tie power cables to bar keeping cables

clear from all moving parts.

Optional driving light fitted.

( Viewed from rear of bar )

34. Cable tie power leads to battery, to the left

side of the bar keeping clear of all moving

parts.

( Viewed from rear of bar )

Fasten control box earth to

winch tie rods.

Page 12

31 10 02

Page 12 of 16

3783013

35. Position bar in front of vehicle and connect

indicators, fog lights and fit winch cables

under grille into engine bay close to battery.

36. Slide bar onto vehicle mounting system and

secure using 10mm hardware. Align bar with

vehicle grille and flares, and tighten bolts

using socket, extension and uni joint

through fog light aperture in bar. Lastly

retighten mounting system bolts when bar

has been centralized sideways.

37. Once bar is secured to vehicle, using holes in

locking plates as a template, drill 10mm holes

through lower section of bar and bolt up

using 10mm hardware.

38. Fit washer bottle guard bracket to bar

mounting system using 8mm hardware.

.

Fit 6mm hardware to bracket

and guard

Finger tighten

Page 13

31 10 02

Page 13 of 16

3783013

39. Bolt washer bottle guard to lower bar wing

section using 6mm hardware. ( finger tighten

only )

40. On RHS of vehicle, using vice grips to hold

in place, drill a 6mm hole through washer

guard into under side of vehicle

crossmember and secure using 6mm

hardware. When all bolts are fitted, tighten

firmly. Cut plastic upward so you can tuck

plastic inner guard in behind washer

bottle guard.

41. Next step is to trim the plastic inner guards

that hang down passed the bar.

42. On the RHS of vehicle, tuck plastic inner

guard in behind bar wing section and secure

using 6mm hardware. Cut plastic level with

the bottom of bar wing section to washer

bottle guard.

Washer guard

Wing section

Bar wing section

Viewed from under vehicle

Page 14

31 10 02

Page 14 of 16

3783013

43. On the LHS of vehicle cut plastic inner

guard as per photo, tuck in behind bar wing,

secure to bar wing section using 6mm

hardware.

44. Fitting of AIR DEFLECTOR to underside of

bar.

45. Fit rear of air deflector to vehicle lower

crossmember using original screws and front

to bar using 6mm hardware. When all

hardware is fitted, tighten firmly.

46. When everything on bar is fitted and tighten,

the last part to fit if so desired, is the stick on

plastic molding that covers up where the

vehicle flare has been cut.

47. Molding in bolt kit is for both sides of

vehicle.

48. To fit molding to flare, cut molding on

matching angle of where flare meets guard,

remove backing tape and adhere to vehicle

about 3mm above the wing section of bar.

49. Cut off molding flush with wheel arch.

Photo of inside of LHS guard

New cut line of plastic inner guard

Photo of LHS of vehicle

Matching angle for molding

Page 15

31 10 02

Page 15 of 16

3783013

50. If no fog lights are not going to be fitted, fit

light surround to bar as is. If fog lights are

going to be fitted, cut out rear of surround using

a key hole saw and remove rough edges with a

file.

51. Fitting of fog light surround housings.

52. Apply a bead of silicon around the fog light

aperture, fit the surround into aperture and

hold to bar using masking tape until silicon

has set, then remove tape.

53. Position for Hi Lift jacking point.

Page 16

31 10 02

Page 16 of 16

3783013

PHOTO SHOWS COLOUR CODED BAR

Loading...

Loading...