Page 1

MODEL

MS4782A/MS4782D

TEST SET FOR

POWER AMPLIFIER TEST SYSTEM

MAINTENANCE MANUAL

490 JARVIS DRIVE l MORGANHILL,CA95037-2809

P/N: 10410-00238

REVISION: A

PRINTED: JANUARY 2001

COPYRIGHT 2001 ANRITSU CO.

Page 2

WARRANTY

The ANRITSU product(s) listed on the title page is (are) warranted against defects in materials and

workmanship for three years from the date of shipment.

ANRITSU’s obligation covers repairing or replacing products which prove to be defective during the

warranty period. Buyers shall prepay transportation charges for equipment returned to ANRITSU

for warranty repairs. Obligation is limited to the original purchaser. ANRITSU is not liable for con

sequential damages.

LIMITATION OF WARRANTY

The foregoing warranty does not apply to ANRITSU connectors that have failed dueto normal wear.

Also, the warranty does not apply to defects resulting from improper or inadequate maintenance by

the Buyer, unauthorized modification or misuse, or operation outside of the environmental specifications of the product. No other warranty is expressed or implied, and the remedies provided herein

are the Buyer’s sole and exclusive remedies.

TRADEMARK ACKNOWLEDGEMENTS

V Connector and K Connector are registered trademarks of ANRITSU Company.

ANACAT is a registered trademark of EEsof, Inc.

Ink Jet and Think Jet are registered trademarks of Hewlett-Packard Co.

MS-DOS is a registered trademark of Microsoft Corporation.

NOTICE

-

ANRITSU Company has prepared this manual for use by ANRITSU Company personnel and cus

tomers as a guide for the proper installation, operation and maintenance of ANRITSU Company

equipment and computer programs. The drawings, specifications, and information contained herein

are the property of ANRITSU Company, and any unauthorized use or disclosure of these drawings,

specifications, and information is prohibited; they shall not be reproduced, copied, or used in whole

or in part as the basis for manufacture or sale of the equipment or software programs without the

prior written consent of ANRITSU Company.

-

Page 3

Table of Contents, Narrative

Chapter 1 — General Service Information

This chapter provides a general description of the Model MS4782X Test Set for the ME7840A Power

Amplifier Test System. It explains the level of maintenance covered in this manual and the service

strategy used throughout this manual. It also contains static-sensitive component handling precau

tions and a list of recommended test equipment.

Chapter 2 — Replaceable Parts

This chapter lists all replaceable subassemblies and components for the MS4782A and MS4782D

models. It explains the ANRITSU exchange assembly program and provides parts ordering informa

tion.

Chapter 3 — Performance Verification Procedures

This chapter provides detailed procedures for verifying that the performance of the MS4782X meets

minimum performance standards.

Chapter 4 — Troubleshooting

This chapter provides information for troubleshooting the MS4782X Test Set. The troubleshooting

procedures contained in this chapter support fault isolation down to a replaceable subassembly.

Chapter 5 — Removal and Replacement Procedures

This chapter describes how to gain access to all of the major assemblies and major parts for troubleshooting and/or replacement.

-

-

Appendix A — Connector Maintenance Check Procedures

This appendix contains procedures and information needed to perform maintenance checks (includ

ing pin-depth measurements) for the connectors on all ANRITSU supplied Calibration/Verification

Kit components, Through-cables, and other associated RF/microwave components.

Index

-

MS4782X MM i/ii

Page 4

Page 5

Chapter 1 General Information

Table of Contents

1-1 SCOPE OF MANUAL .......................1-3

1-2 INTRODUCTION .........................1-3

1-3 IDENTIFICATION NUMBER ..................1-3

1-4 ONLINE MANUAL ........................1-3

1-5 SYSTEM DESCRIPTION .....................1-4

1-6 RELATED MANUALS ......................1-4

1-7 STANDARD OPTIONS ......................1-4

1-8 SERVICE STRATEGY.......................1-5

Functional Assembly Level Troubleshooting ···········1-5

Internal Hardware Adjustments and Calibrations········1-5

Internal Service Log ························1-5

System Test/Certification ·····················1-6

Preventive Service ·························1-6

Servicing Specially Modified Instruments ············1-6

1-9 SERVICE SUPPORT .......................1-6

Technical Support ·························1-7

Field Service Kits ·························1-7

Service Software ··························1-7

Verification Kits ··························1-8

Test Fixtures/ Aids·························1-8

Failed Assembly Exchange Program ···············1-8

1-10 PERFORMANCE SPECIFICATIONS ..............1-9

1-11 SERVICE CENTERS .......................1-9

1-12 STATIC SENSITIVE COMPONENT HANDLING

PROCEDURES ..........................1-9

1-13 RECOMMENDED TEST EQUIPMENT ·············1-9

Page 6

Figure 1-1. Typical MS4782X Test Set

Page 7

Chapter 1

General Information

1-1 SCOPE OF MANUAL This manual provides general service and preventive maintenance in

formation for the ANRITSU MS4782A and MS4782D Test Set for the

ME7840A Power Amplifier Test System. It contains procedures for:

Testing the instrument for proper operation.

q

Verifying measurement accuracy and traceability to National In

q

stitute of Standards and Technology (NIST).

Troubleshooting a failed instrument to the exchange subassem

q

bly level or the subsystem requiring adjustment.

Locating and replacing failed parts.

q

Throughout this manual, the terms “MS4782X” and “Test Set” will be

used interchangeably to refer to both Models of MS4782X Test Set,

unless otherwise noted.

1-2 INTRODUCTION This chapter provides a general description of PowerAmplifier Test

System serial numbers, frequency ranges, and related manuals. It also

includes service strategy, available service facilities, and static-sensitive

component handling precautions, and a list of recommended test equip

ment.

1-3 IDENTIFICATION

NUMBER

All ANRITSU instruments are assigned a six-digit ID number, such as

“401001”. This number appears on a decal affixed to the rear panel.

Please use this identification number during any correspondence with

ANRITSU Customer Service about this instrument.

-

-

-

-

1-4 ONLINE MANUAL This manual is available on CD ROM as an Adobe Acrobat™ (*.pdf)

file. The file can be viewed using Acrobat Reader™, a free program

that is also available on the CD ROM. This file is “linked” such that

the viewer can choose a topic to view from the displayed “bookmark”

list and “jump” to the manual page on which the topic resides. The

text can also be word-searched. A copy of this CD ROM, part number

10920-00035, is provided free of charge with this manual.

1-5 PATS SYSTEM

OVERVIEW

The ANRITSU ME7840A Power Amplifier Test System (PATS) is in

tended for the measurement and real-time graphical display of the fol

lowing parameters of a power amplifier in the frequency range of 800

MHz to 2.4 GHz:

MS4782X MM 1-3

-

-

Page 8

HARDWARE DESCRIPTION GENERAL INFORMATION

S-Parameters including Hot S

q

K Factor

q

Gain Compression and Phase Distortion

q

Intermodulation Distortion

q

Harmonics

q

Drain Current and Power Added Efficiency (PAE)

q

PATS is designed to facilitate alignment, tuning and pass/fail testing

of the components, modules and subassemblies of a power amplifier as

well as the completed amplifier.

22

1-6 HARDWARE

DESCRIPTION

The ME7840A hardware (below) consists of a MS462XC, Direct Re

ceiver Access (DRA) Scorpion, a MS4782X Test Set, a customer sup

-

plied Personal Computer (PC), and an optional current probe. The

MS462XC is available in two frequency ranges: 10 MHz to 3 GHz or 10

MHz to 6 GHz.

The Test Set is available in two configurations, as described in Table

1-1 The MS4782D is standard, and the MS4782A is Option 2. A block

diagram of the PATS is shown in Figure 1-2 and the Option 2 system

in Figure 1-1.

1-4 372XXC/373XXC MM

Page 9

GENERAL INFORMATION HARDWARE DESCRIPTION

SOURCE 2 SOURCE 1

ACCESS

SCORPION

DIRECT RECEIVER

OPTIONAL

EXTERNAL

PREAMPLIFIERS

ATTENUATORS

70dB, 10dB/step

RF3

N

N

COMBINER

STEP

RF1

REVERSE

FORWAR

D

TRANSFER SWITCH

GPIB

ANALOG IN

SYSTEM

CONTROLLER

(PC)

GPIB

RECEIVERS

EXT I/O

a

b

1

1

N

KKKN

K

a

b

2

K

KKN

RF2

2

CONTROL

LINES

NK

-30dB

LIMITER

ER

POW

OPTIONAL

SPECTRUM

ANALYZER

POWER

METER

POWER

SUPPLY

MS478A Test Set

NK

OPTIONAL

MODULATION

SYNTHESIZER

OPTIONAL

EXTERNAL

PRE-AMP

HIGH

STEP

ATTENUATOR

-30dB

-30dB

N

K

70dB, 10dB/step

-30dB

N

TERMINATION

N

AUT

CURRENT PROBE

Indicates coaxjumper in the as-shipped configuration

Figure 1-1. Overall Functional Block Diagram of the Option 2 Power Amplifier Test System (PATS) with MS4782A

Test Set

MS4782X MM 1-5

Page 10

HARDWARE DESCRIPTION GENERAL INFORMATION

SOURCE 2 SOURCE 1

MS4782D Test Set

ACCESS

SCORPION

DIRECT RECEIVER

OPTIONAL

EXTERNAL

PREAMPLIFIERS

ATTENUATORS

70dB, 10dB/step

RF3

N

N

COMBINER

-30dB

STEP

RF1

REVERSE

FORWAR

D

TRANSFER SWITCH

GPIB

ANALOG IN

SYSTEM

CONTROLLER

(PC)

GPIB

RECEIVERS

EXT I/O

a

b

1

1

N

KKKN

K

LIMITER

STEP

ATTENUATOR

70dB, 10dB/step

a

b

2

2

K

KKN

RF2

-30dB

CONTROL

LINES

NK

K

C3

K

C2

EXTERNAL

100 W

TERMINATION

K

C1

CIRCULATOR

OPTIONAL

SPECTRUM

ANALYZER

NK

OPTIONAL

MODULATION

SYNTHESIZER

OPTIONAL

EXTERNAL

PRE-AMP

-30dB

N

K

-30dB

N

N

AUT

POWER

METER

POWER

SUPPLY

CURRENT PROBE

Indicates coaxjumper in the as-shipped configuration

Figure 1-2. Overall Functional Block Diagram of the Basic Power Amplifier Test System (PATS) with MS4782D Test

Set

1-6 MS4782X MM

Page 11

GENERAL INFORMATION SYSTEM DESCRIPTION

Table 1-1. Test Set Configurations

Model

MS4782A 800 to 1000 50 Yes Internal

MS4782D 800 to 2400

Notes:

1. This frequency range does not account for any restricting effects caused by use of external circulator.

2. This Max AUT power assumes a minimum isolation of 23 dB provided by external circulator(s). Two circulators may

have to be used to provide the required isolation.

Frequency Range

(MHz)

(Note 1)

Max AUT Power Output

(Watts)

100

(Note 2)

Reverse Measurements

, Hot S22,S12Possible)

(S

22

Yes External

Circulator

(at AUT Output Path)

1-7 SYSTEM DESCRIPTION Brief descriptions of the DRA Scorpion (MS462XC) and MS4782X

Test Set are given below.

DRA Scorpion The Scorpion Direct Receiver Access (DRA) version Vector Network

Measurement System (VNMS) (Figure 1-2) functions under control of

the software residing in the PC through GPIB commands. The software supports tuning and alignment operations by generating real

time graphic displays of the measured data on the PC screen.

Under software control, 3

sured and displayed. Also, the Upper and Lower Side Band (USB &

LSB) components of the IMD products are measured and displayed

separately.

rd,5th

and 7thorder IMD products can be mea-

The DRA Scorpion includes the following capabilities:

q

Two internal, independent RF sources. Each source has a range

of –15 dBm to +10 dBm. A 0dB to 70dB step attenuator (10 dB /

step) is provided for each source resulting in a Power Output

range of –85 dBm to +10 dBm from each source.

q

Complete built-in capability for IMD measurements. A combiner

is provided in the Test Set.

q

Internal Transfer Switch enabling S22and Hot S22measure

-

ments. The reflectometer set-up is provided in the Test Set.

q

Direct access to each of the four receiver channels (two reference

channels and two test channels) for maximum flexibility in mea

suring forward and reverse S-parameters over a wide range of

AUT output power. The Test Set provides incident and reflected

signal separation.

MS4782X Test Set The Series MS4782X Test Set contains a Wilkinson type combiner

that combines the two RF signals from Ports 1 and 3 (RF1 & RF3) of

the Scorpion. External preamplifiers can optionally be provided at the

MS4782X MM 1-7

Page 12

SYSTEM DESCRIPTION GENERAL INFORMATION

combiner input to boost the input RF power to the amplifier-undertest (AUT). The combiner has power input rating of 30-Watts maxi

mum when terminated with a VSWR of 1.2:1. For an open or short at

the combiner output, the combiner input power rating is 0.5 Watts

maximum.

-

The output of the combiner is fed to a source selection switch that en

ables one of the following to be applied to the AUT:

The combined signal from the Scorpion sources.

q

A modulated signal from an optional external modulation synthe

q

sizer.

A provision for the insertion of an optional external pre-amplifier (af

ter the combiner and source selection switch) is also provided. Refer to

Chapter 7, “Preamplifier Operations,” for details.

The test set includes a bi-directional coupler at the input of the AUT

that separates the incident signal from the reflected signal. The power

rating of this bi-directional coupler is 100 watts average. The –30 dB

portion of the incident and reflected signals are applied to the Scorpion reference port a

ment. The S

measurement determined by the DRA Scorpion is sim-

11

and test port b1, respectively, for S11measure-

1

ply the ratio of the reflected signal to the incident signal.

The amplified output of the AUT is fed to a high power coupler in the

test set. The power rating of this coupler is also 100-watts average.

The –30 dB coupled arm of this coupler is routed to the test port b

of

2

the Scorpion througha6dBresistive divider and a 0-dB to 70-dB step

attenuator (10dB/step). A limiter is also provided in this path provide

added protection for the Scorpion reference channel .

-

-

The divider enables the connections of a power meter or Spectrum An

alyzer, when desired, to measure the AUT b

output.

2

The through arm of the 100-W coupler is routed to a high power

(100-Watt) termination through a circulator. In the MS4782A Test

Set, the circulator is internal and has a rating of 100 watts average.

This circulator has an isolation specification of 20-dB minimum. This

means that the AUT output power is attenuated by 20 dB (plus other

losses) before reaching the Scorpion port 2. Since the maximum

(no-damage) power level for this port is 27 dBm (0.5 watt), this estab

-

lishes the maximum AUT output power at 50 watts.

In the MS4782D Test Set, the circulator is external as shown in Fig

ure 1-2. In selecting an external circulator, the following criteria

should be used.

1-8 MS4782X MM

-

Page 13

GENERAL INFORMATION SYSTEM DESCRIPTION

Power rating: Should be no less than the power output of the am

q

plifier-under-test (AUT). It should be noted that a 100 watt ter

mination is provided in the Test Set for the termination port of

the external circulator.

Bandwidth: Should be sufficiently wide to cover the frequency

q

band of the AUT.

Isolation: Should be no less than (Po-27 dB), where Pois the

q

power output in dBm of the AUT. Thus for Po = 47 dBm (50

watts), a 20 dB isolation is required. For a P

greater than 47

o

dBm up to 50 dBm (100 watts), two circulators in series can be

used.

Where S

or Hot S22measurements are not required, power amplifiers

22

with up to 100 watts average output power can be tested with the

MS4782D Test Set without any circulator by connecting the through

arm of the output coupler directly to the 100 watt termination (Port

C1 connected to Port C2 on the rear. The unit is shipped from the fac

tory with this loop jumper.)

For S

measurements, the transfer switch located within the Scorpion

22

routes the source 1 output signal to the output port of the AUT via

Port 2 (RF2) of the Scorpion. A separate 100-watt coupler in the test

set applies the –30 dB portion of this incident signal to the Scorpion

reference port a

AUT output port is applied to the Scorpion test port b

. The –30 dB portion of the signal reflected from the

2

by means of the

2

AUT output coupler.

-

-

-

The PATS calibration is performed with the test set in place, at the

connectors where AUT will be connected directly. Therefore, the test

set components and cables are included in the calibration loop and

their effects are calibrated out, resulting in correct and accurate mea

surements of the AUT.

The software supplied by ANRITSU supports operator control of the

source selection switch and step attenuator in the test set. This control

is achieved through the parallel TTL control lines available at the

Scorpion rear panel “External I/O” connector. The GPIB commands

from the PC to the Scorpion set the TTL control lines to the desired

states.

Connectors and Ports On the front panel of the Model MS4622/3C DRA Scorpion three Type

N (female) connectors are provided for Ports 1, 2 and 3.

Port 1 provides RF source 1 when the transfer switch is in the forward

position, and is terminated in 50 ohms to ground when the transfer

switch is in the reverse position.

-

MS4782X MM 1-9

Page 14

SERVICE CENTERS GENERAL INFORMATION

Port 2 provides RF source 1 when the transfer switch is in the reverse

position, and is terminated in 50 ohms to ground when the transfer

switch is in the forward position.

Port 3 is allocated to RF source 2. Under independent control, port 3

provides RF source 2, or is terminated in 50 ohms to ground.

On the rear of the unit, four SMA connectors (Figure 1-) are provided

for Reference ports a

unit as well as all other mechanical specifications is the same as the

model MS4623B.

On the MS4782D Test Set, three additional SMA connectors provide

for connecting an external circulator. If reverse measurements (S

Hot S

through line should be connected between connectors C1 and C2 (Fig

ure 1-). The MS4782A is shipped from the factory with this through

line in place.

) are not desired, then a circulator is not required. Instead, a

22

and a2and Test Ports b1and b2. The front of the

1

22

and

-

1-8 SERVICE CENTERS ANRITSU Company offers a full range of repair and calibration services

at fully staffed and equipped service centers throughout the world. Table

2-1, located on page 2-2, lists all ANRITSU services centers.

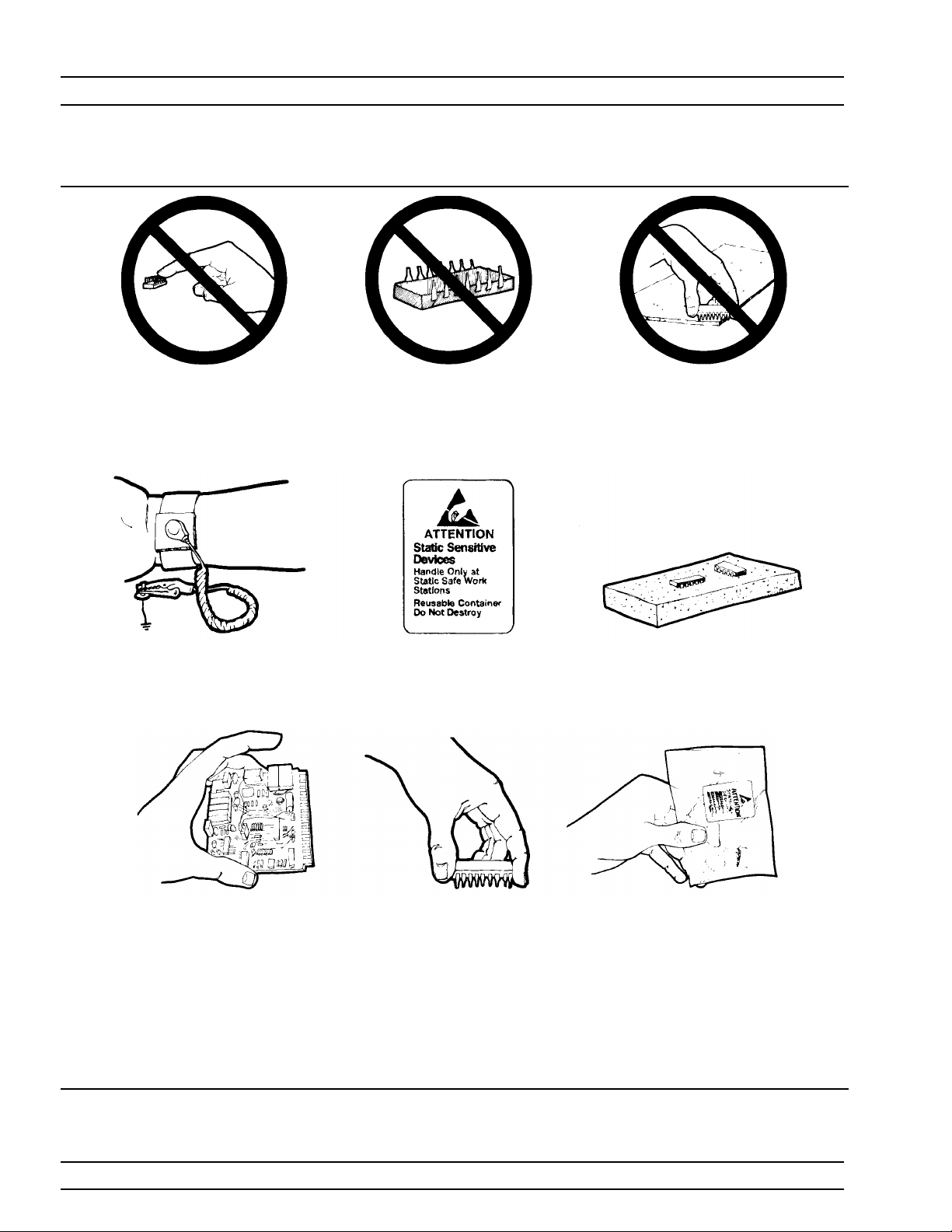

1-9 STATIC SENSITIVE

COMPONENT HANDLING

PROCEDURES

1-10 RECOMMENDED TEST

EQUIPMENT

The Test Set contains components that can be damaged by static electricity. Figure 1-2 illustrates the precautions that should be followed when

handling static-sensitive subassemblies and components. If followed,

these precautions will minimize the possibilities of static-shock damage to

these items.

Table 1-2 lists the recommended test equipment to be used for all mainte

nance activities for the MS4782X models. Note the “Use” codes listed in

the right hand column of the table. These codes list the applicable

maintenance activities for the equipment listed.

-

1-10 MS4782X MM

Page 15

GENERAL INFORMATION RECOMMENDED TEST EQUIPMENT

Table 1-2. Recommended Test Equipment

INSTRUMENT

Power Meter ANRITSU ML2437A or MS2438A

Power Sensor ANRITSU MA2472A

GPIB Cable IEEE 488-2 compliant ANRITSU 2100-2, or equivalent

Offset Termination SC5237 6 dB Return Loss

SC5270 20 dB Return Loss

Termination Return Loss 35 dB, DC to 3 GHz ANRITSU 28L50LF

Power Divider ANRITSU 11N50B

Adapter ANRITSU 34NN50A

Adapter ANRITSU 34NFNF50

Thru Line ANRITSU 3670NN50-2 or

Thru Line Phase stable

Length: 4 feet (2 each)

Calibration Kit ANRITSU 3653 or 3753LF

** USE CODES:

A Adjustment / Internal Hardware Calibration

O Operational Testing

P Performance Verification

T Troubleshooting

CRITICAL

SPECIFICATION

ANRITSU SC5237

ANRITSU SC5270

ANRITSU 34SFSF50

ANRITSU 34NKF50

15NN50-0.6B

GORE PhaseFlex

Part number EJD01D010480

RECOMMENDED

MANUFACTURER/MODEL

TM

USE*

*

P

P

P

P

OT

P

P

O, T

P

O, T

P,O

MS4782X MM 1-11

Page 16

STATIC HANDLING GENERAL INFORMATION

Do not touch exposed contacts on

1.

any static sensitive component.

Wear a static-discharge wristband

4.

when working with static sensitive

components.

Do not slide static sensitive compo

2.

nent across any surface.

Label all static sensitive devices.

5.

Do not handle static sensitive com

-

3.

ponents in areas where the floor or

work surface covering is capable of

generating a static charge.

Keep component leads shorted to-

6.

gether whenever possible.

-

Handle PCBs only by their edges.

7.

Do not handle by the edge connec

tors.

-

Lift & handle solid state devices by

8.

their bodies – never by their leads.

Transport and store PCBs and

9.

other static sensitive devices in

static-shielded containers.

10. ADDITIONAL PRECAUTIONS:

·

Keep workspaces clean and free of any objects capable of holding or storing a static charge.

·

Connect soldering tools to an earth ground.

·

Use only special anti-static suction or wick-type desoldering tools.

Figure 1-2. Static Sensitive Component Handling Procedures

1-12 MS4782X MM

Page 17

Chapter 2 Replaceable Parts

Table of Contents

2-1 INTRODUCTION .........................2-3

2-2 EXCHANGE ASSEMBLY PROGRAM ..............2-3

2-3 REPLACEABLE SUBASSEMBLIES AND PARTS .......2-3

2-4 PARTS ORDERING INFORMATION ..............2-4

Page 18

Table 2-1. Anritsu Service Centers

UNITED STATES

ANRITSU COMPANY

490 Jarvis Drive

Morgan Hill, CA 95037-2809

Telephone: (408) 776-8300

1-800-ANRITSU

FAX: 408-776-1744

ANRITSU COMPANY

10 New Maple Ave., Unit 305

Pine Brook, NJ 07058

Telephone: (201) 227-8999, 1-800-ANRITSU

FAX: 201-575-0092

ANRITSU COMPANY

1155 E. Collins Blvd

Richardson, TX 75081

Telephone: 1-800-ANRITSU

FAX: 972-671-1877

AUSTRALIA

ANRITSU PTY. LTD.

Unit 3, 170 Foster Road

Mt Waverley, VIC 3149

Australia

Telephone: 03-9558-8177

FAX: 03-9558-8255

BRAZIL

ANRITSU ELECTRONICA LTDA.

Praia de Botafogo, 440, Sala 2401

CEP22250-040, Rio de Janeiro, RJ, Brasil

Telephone: 021-527-6922

FAX: 021-53-71-456

CANADA

ANRITSU INSTRUMENTS LTD.

215 Stafford Road, Unit 102

Nepean, Ontario K2H 9C1

Telephone: (613) 828-4090

FAX: (613) 828-5400

FRANCE

ANRITSU S.A

9 Avenue du Quebec

Zone de Courtaboeuf

91951 Les Ulis Cedex

Telephone: 016-09-21-550

FAX: 016-44-61-065

GERMANY

ANRITSU GmbH

Grafenberger Allee 54-56

D-40237 Dusseldorf, Germany

Telephone: 0211-968550

FAX: 0211-9685555

INDIA

MEERA AGENCIES (P) LTD.

A-23 Hauz Khas

New Delhi 110 016

Telephone: 011-685-3959

FAX: 011-685-2275

ISRAEL

TECH-CENT, LTD.

4 Raul Valenberg St

Tel-Aviv 69719

Telephone: (03) 64-78-563

FAX: (03) 64-78-334

ITALY

ANRITSU Sp.A

Roma Office

Via E. Vittorini, 129

00144 Roma EUR

Telephone: (06) 50-99-711

FAX: (06) 50-22-4252

KOREA

ANRITSU CORPORATION LTD.

14F, Hyunjuk Bldg

832-41 Yeoksam-Dong

Kangnam-Ku

Seoul South Korea 150 010

Telephone: 02-553-6603

FAX: 02-553-6604, 02-553-6605

JAPAN

ANRITSU CUSTOMER SERVICE LTD.

1800 Onna Atsugi-shi

Kanagawa-Prf. 243 Japan

Telephone: 0462-96-6688

FAX: 0462-25-8379

SINGAPORE

ANRITSU (SINGAPORE) PTE LTD.

6 New Industrial Road #06-01/02

Hoe Huat Industrial Bldg

Singapore 536199

Telephone: 282-2400

FAX: 282-2533

SOUTH AFRICA

ETECSA

12 Surrey Square Office Park

330 Surrey Avenue

Ferndale, Randburt, 2194

South Africa

Telephone: 011-27-11-787-7200

FAX: 011-27-11-787-0446

SWEDEN

ANRITSU AB

Botivid Center

Fittja Backe 1-3

S145 84 Stockholmn

Telephone: (08) 534-707-00

FAX: (08) 534-707-30

TAIWAN

ANRITSU CO., LTD.

6F, No. 96, Section 3

Chien Kuo N. Road

Taipei, Taiwan, R.O.C.

Telephone: (02) 515-6050

FAX: (02) 509-5519

UNITED KINGDOM

ANRITSU LTD.

200 Capability Green

Luton, Bedfordshire

LU1 3LU, England

Telephone: 015-82-4332003

FAX: 015-82-731303

Page 19

Chapter 2

Replaceable Parts

2-1 INTRODUCTION This chapter provides replaceable parts information for both MS4782X

models. The major replaceable Test Set assemblies and parts are

listed in Table 2-2 . The locations of these assemblies/parts are shown

in Figure 2-1.

2-2 EXCHANGE ASSEMBLY

PROGRAM

ANRITSU maintains a module exchange program for selected subassem

blies. If a malfunction occurs in one of these subassemblies, the defective

item can be exchanged. Upon receiving your request, ANRITSU will ship

the exchange subassembly to you, typically within 24 hours. You then

have 45 days in which to return the defective item. All exchange subassemblies or RF assemblies are warranted for 90 days from the date of

shipment, or for the balance of the original equipment warranty, whichever is longer.

NOTE

When sending a failed assembly to the factory for exchange, a copy of the Service Log must always accompany

the failed assembly. This copy may be a printout, or a

saved disk copy. Due to the importance of the service log

information to the ANRITSU factory Service Engineers,

the exchange prices are only valid if the service log data is

included with the failed assembly.

Please have the exact model number and serial number of your unit

available when requesting this service, as the information about your

unit is filed according to the instrument’s model and serial number.

For more information about the program, contact your local sales rep

resentative or call ANRITSU Customer Service direct (refer to para

graph 2-4.

-

-

-

2-3 REPLACEABLE

SUBASSEMBLIES AND

PARTS

Table 2-2 lists the major replaceable subassemblies and parts for the

MS4782X. These assemblies/parts are presently covered by the

ANRITSU exchange assembly program.

MS4782X MM 2-3

Page 20

PARTS ORDERING INFORMATION REPLACEABLE PARTS

Table 2-2. Replaceable Subassemblies

Part Number Description Where used

1000-50 A7 Circulator, 800 to 1000 MHz, 50W MS4782A internal, MS4782D external

1000-52 A7 Circulator, 1.8 to 2.5 GHz, 50W MS4782D external

1000-53 A7 Circulator, 1.8 to 2.5 GHz, 79W MS4782D external

1015-51 A8 High Power Termination MS4782A and MS4782D

ND55507 A10 SPDT Switch Assembly MS4782A and MS4782D

1091-305 A4 Combiner MS4782A and MS4782D

1091-307 A1 Coupler MS4782A and MS4782D

1091-307 A2 Coupler MS4782A and MS4782D

1091-307 A3 Coupler MS4782A and MS4782D

1091-308 Dual Coupler MS4782A and MS4782D

1K50A A5A2 RF Limiter MS4782A and MS4782D

339H40998A A5 Step Attenuator MS4782A and MS4782D

40-133 A6 Power Supply MS4782A and MS4782D

43045-3 A9 System Control PCB Assy MS4782A and MS4782D

K240B A5A1Power Divider MS4782A and MS4782D

ND55508 Fan Assembly MS4782A and MS4782D

2-4 PARTS ORDERING

INFORMATION

All parts listed in Table 2-2 may be ordered from your local ANRITSU

service center (Table 2-1, page 2-2). Or, they may be ordered directly

from the factory at the following address:

ANRITSU Company

ATTN: Customer Service

490 Jarvis Drive

Morgan Hill, CA 95037-2809

Telephone: (408)-778-2000

FAX: (408)-778-0239

2-4 MS4782X MM

Page 21

REPLACEABLE PARTS PARTS ORDERING INFORMATION

A

r

A6 Power

Supply

A10 SPDT

Switch

A8 High Power

Termination

7 Circulator

(MS4782A only)

A9 Control PCB

Assembly

A6

A8

A3 Coupler

A5A2 Limiter

A5A2

A9

A3

A5

A5 Step Attenuato

A5A1 Power Divider

A10

A7

A2

A1

A4

A2 Coupler

A4 Combiner

A1 Coupler

Figure 2-1. Major Assemblies Location Diagram (Top View)

MS4782X MM 2-5/2-6

Page 22

Page 23

Chapter 3 Performance Verification Procedure

Table of Contents

3-1 INTRODUCTION .........................3-3

3-2 CONVENTIONS..........................3-3

3-3 TEST EQUIPMENT .......................3-3

3-4 SOURCE OUTPUT ACCURACY .................3-5

3-5 RETURN LOSS CONFIDENCE TEST ..............3-6

Test Procedure: ··························3-7

3-6 SYSTEM DYNAMIC RANGE ..................3-9

3-7 RECEIVER DISPLAY LINEARITY ..............3-11

Page 24

Page 25

Chapter 3

Performance Verification

Procedure

3-1 INTRODUCTION The following are the specific tests that should be used to verify the

performance of the Power Amplifier Test System (PATS). This is the

same procedure that appears in the system OMM, ME7840A Opera

tion and Maintenance Manual.

Source Output Level Accuracy Test

q

Return Loss Measurement Confidence Test

q

System Dynamic Range Test

q

Receiver Magnitude Display Linearity Test

q

3-2 CONVENTIONS In the tests in this chapter, instructions will direct use front panel

hard keys and softkeys. The hard keys and softkeys will appear in a

different typeface. For example:

-

Step 1. Press the Utility key and select:

DIAGNOSTICS

TROUBLESHOOTING

MORE

VERIFY ALC CALIBRATON

The Utility key is a front panel hard key and DIAGNOSTICS, TROU

BLESHOOTING, MORE, and VERIFY ALS CALIBRATION are all

softkeys.

-

3-3 TEST EQUIPMENT The following equipment is required to perform the verification proce

dures.

q

ANRITSU Model ML243XA Power Meter

q

ANRITSU Model MA247XA Power Sensor

q

ANRITSU Model 3653 or 3753LF N connector Calibration Kit

q

ANRITSU Model SC5237 6 dB Offset Termination

q

ANRITSU Model SC5270 20 dB Offset Termination

q

ANRITSU Model 11N50B Power Divider

-

MS4782X MM 3-3

Page 26

TEST EQUIPMENT PERFORMANCE VERIFICATION

ANRITSU Model 3670NN50-2 Cable

q

ANRITSU Model 34NN50A Adapter

q

ANRITSU 2100-2 GPIB cable

q

3-4 MS4782X MM

Page 27

PERFORMANCE VERIFICATION SOURCE OUTPUT ACCURACY

3-4 SOURCE OUTPUT

ACCURACY

This test verifies the source output accuracy of the MS462XC. The test

procedure uses the Power ALC Verification built-in function of the

MS462XC Basic Measurement software.

Setup:

Step 1. Connect a GPIB cable between the power meter GPIB connector and

the MS462XC dedicated GPIB connector, as shown in Figure 3-1.

00000001

WARNING

NOOPERATORSERVICE-

ABLEPARTSINSIDE.

REFERSERVICINGTO

QUALIFIEDPERSONNEL.

N274

PARALLELPRINTER

RS232

B

IEEE488.2

GPIB

Dedicated

GPIB

Madei nUK

GPIB/ IEEE 488

WARNING

NOOPERATORSERVICE-

ABLEPARTSINSIDE.

A

CALIBRATOR

SerialPort

Ethernet

CAUTION

85-250VAC

DONOTOPERATE

47-440Hz

WITHUNGROUNDED

40VAMAX

POWERCORD.

OUTPUT1 OUTPUT 2 INPUT1

DIGITAL

SEEMANUAL FOR VOLTAGE RANGES ON BNC CONNECTORS

VGA

Ext

Analog

Output

INPUT2

12-24VDC

ANALOG

(1.3A)

SCSI-2

CAUTION

FORCONTINUED FIRE

PROTECTIONREPLACE

ONLYWITHSPECIFIED

TYPEAND RATEDFUSE.

CAUTION

DONOTOPERATE

WITHPOWERCORD

UNGROUNDED

ExtI/O

47-440Hz

85-264VAC

REPLACEFUSE ONLYWITH

SAMETYPEAND RATING

LPTLine Printer

Ext

Trigger

Port2

Port2

Noise

In

Noise

+28V

Port1

Bias

BiasFuse

Bias

Ext

Port1

BiasFuse

Ext10 MHz

ExtAnalog

Source

In

In

Figure 3-1. ML2430A Series Power Meter GPIB connection to the MS462XX Vector Network Measurement System

Step 2. Turn on the MS462XC VNMS and allow it to warm-up at least one

hour.

Test Procedure

Step 1. Disconnect cables between MS462XC Port 1 and Port 1 of MS4782 Test

Set and between Port 3 of MS462XC and Port 3 of MS4782 Test Set.

Step 2. Press Utility key and select:

DIAGNOSTICS

TROUBLESHOOTING

MORE

VERIFY ALC CALIBRATON

Step 3. Calibrate and zero the power sensor.

MS4782X MM 3-5

Page 28

RETURN LOSS CONFIDENCE TEST PERFORMANCE VERIFICATION

Step 4. Connect power sensor to MS462XC Port 1 and select START VERIFI

CATION softkey.

Step 5. Verify that Source 1 passes this test.

Note

The worst case test result will be displayed on the screen

when the instrument fails this test only. The failed test re

sult is also recorded in the Service Log.

Step 6. Press the SELECT SOURCE soft key to select 2

Step 7. Connect power sensor to MS462XC Port 3 and select START VERIFI

CATION soft key.

Caution

The TROUBLESHOOTING function must be properly ex

ited to restore normal measurement operation.

Step 8. Verify that Source 2 passes this test.

Step 9. Select the menu soft key as follows to exit the TROUBLESHOOTING

mode:

-

-

-

-

3-5 RETURN LOSS

CONFIDENCE TEST

RETURN

RETURN

FINISHED, RECOVER FROM TROUBLESHOOTING

Step 10. Reconnect cables between MS462XC Port 1 and Port 1 of MS4782 Test

Set and between Port 3 of MS462XC and Port 3 of MS4782 Test Set.

This test verifies the accuracy of return loss measurements.

Setup: Set up the Test Set as described below.

Step 1. Turn on the MS462XC VNMS and MS4782X Test Set and allow them

to warm up for 30 minutes.

Step 2. Press Default key then 0 key.

Step 3. Press Seq key and select:

TTL I/O.

PARALLEL OUT SETUP

SET PARALLEL OUT PORT (0-255)

Step 4. Change the value from 0 to 8.

3-6 MS4782X MM

Page 29

PERFORMANCE VERIFICATION RETURN LOSS CONFIDENCE TEST

Step 5. Select:

RETURN

RETURN

Step 6. Press Display key and select:

DISPLAY MODE

SINGLE CHANNEL

RETURN

Step 7. Press Ch 4 key and then Display key.

Step 8. Select:

GRAPH TYPE

LOG MAGNITUDE

Step 9. Press Ch 1 key and select LOG MAGNITUDE.

Test Procedure: Insert the Calibration Component Coefficients disk into the MS462XC

floppy disk drive.

Step 1. Press Cal key and select:

COMPONENT UTILTIES

INSTALL KIT INFO FROM FLOPPY DISK

RETURN

Step 2. Follow the prompts and select:

PERFORM CAL: 2 PORT

CAL METHOD: STANDARD

LINE TYPE: COAXIAL

SELECT CALIBRATION TYPE: REFLECTION ONLY – PORT 1 ONLY

FREQUENCY RANGE OF CALIBRATION: 800 MHz TO 2400 MHz

SELECT CALIBRATION DATA POINTS: NORMAL

DATA POINTS: 401 POINTS

PORT 1 CONNECTOR TYPE: N (F)

LOAD TYPE: BROADBAND LOAD

Step 3. Select START CAL soft key to begin calibration.

Step 4. Install calibration device per instruction on the display. Select the ap

propriate soft key to measure the calibration device.

-

Step 5. When the “CALIBRATION SEQUENCE COMPLETED” message is

displayed, press the Enter key to continue.

MS4782X MM 3-7

Page 30

RETURN LOSS CONFIDENCE TEST PERFORMANCE VERIFICATION

Step 6. Connect SC5237 6 dB Offset Termination to Test Port 1 of MS4782

Test Set. Record the measured value in Table 3-3 and verify the mea

sured S

Step 7. Connect SC5270 20 dB Offset Termination to Test Port 1 of MS4782

Test Set. Record the measured value in Table 3-3 and verify the mea

sured S

Step 8. For MS4782D with no circulator installed, skip steps 8 to 15.

Step 9. Press Cal key.

Step 10. Follow the prompts and select:

PERFORM CAL: 2 PORT

CAL METHOD: STANDARD

LINE TYPE: COAXIAL

SELECT CALIBRATION TYPE: REFLECTION ONLY – PORT 2 ONLY

FREQUENCY RANGE OF CALIBRATION: See below:

value is 6 ±0.4 dB. Remove SC5237 Termination.

11

value is 20 ± 1.0 dB. Remove SC5270 Termination.

11

-

-

Model Frequency Range

MS4782A 800 MHz to 1000 MHz

MS4782D w/1000-50 Circulator 800 MHz to 1000 MHz

MS4782D w/1000-52 Circulator

or 1000-53 Circulator

1.8 GHz to 2.4 GHz

SELECT CALIBRATION DATA POINTS: NORMAL

DATA POINTS: 401 POINTS

PORT 2 CONNECTOR TYPE: N (F)

LOAD TYPE: BROADBAND LOAD

Step 11. Select START CAL soft key to begin calibration.

Step 12. Install calibration device per instruction on the display. Select the ap

propriate soft key to measure the calibration device.

Step 13. When the “CALIBRATION SEQUENCE COMPLETED” message is

displayed, press the Enter key to continue.

Step 14. Connect SC5237 6 dB Offset Termination toTest Port 2 of MS4782

Test Set. Record the measured value in Table 3-3 and verify the mea

sured S

value is 6 ± 0.4 dB. Remove SC5237 Termination.

22

-

-

Step 15. Connect SC5270 20 dB Offset Termination to Test Port 2 of MS4782

3-8 MS4782X MM

Page 31

PERFORMANCE VERIFICATION SYSTEM DYNAMIC RANGE

3-6 SYSTEM DYNAMIC

RANGE

Test Procedure:

Test Set. Record the measured value in Table 3-3 and verify the mea

sured S

Table 3-3. Offset Terminator Specifications

Offset

Termination

SC5237 6 ±0.4 dB

SC5270 20 ±1.0 dB

* Do not apply to MS4782D with no circulator installed

value is 20 ± 1.0 dB. Remove SC5270 Termination.

22

Measured S

Value

11

Measured S

Value*

22

Specification

This test verifies the PATS system dynamic range.

Step 1. Press Default key then 0 key of MS462XC to reset the system.

Step 2. Press Seq key.

Step 3. Select:

TTL I/O.

PARALLEL OUT SETUP

SET PARALLEL OUT PORT (0-255)

-

Step 4. Change the value from 0 to 8.

Step 5. Select:

RETURN

RETURN

Step 6. Press Ch 3 key.

Step 7. Press Display key and select:

DISPLAY MODE

SINGLE CHANNEL

RETURN

GRAPH TYPE

LOG MAGNITUDE

RETURN

Step 8. Press Cal key.

MS4782X MM 3-9

Page 32

SYSTEM DYNAMIC RANGE PERFORMANCE VERIFICATION

Step 9. Follow the prompts and select::

PERFORM CAL: 2 PORT

CAL METHOD: STANDARD

LINE TYPE: COAXIAL

SELECT CALIBRATION TYPE: TRANSMISSION FREQUENCY RE

SPONSE

PATH: FORWARD PATH (S

USE OF ISOLATION IN CALIBRATION: INCLUDE

FREQUENCY RANGE: 800 MHz TO 2400 MHz

SELECT CALIBRATION DATA POINTS: NORMAL

DATA POINTS: 401 POINTS

TEST SIGNAL/PORT 1 POWER: 10 dBm

)

21

-

Step 10. After the selections are complete, press the START CAL soft key to be

gin calibration.

Step 11. Install calibration device per instruction on the display. Select the ap

propriate soft key to measure. Connect a cable between Test Port 1 and

Test Port 2 of MS4782X Test Set when the software prompts for a

throughline on the display.

Step 12. When the “CALIBRATION SEQUENCE COMPLETED” message is

displayed, press the Enter key to continue.

Step 13. Press Avg key and select:

SELECT I.F. BANDWIDTH

I.F. BW 10 Hz

Step 14. Remove the through cable between Test Port 1 and Test Port 2 of

MS4782X Test Set and connect terminations to both ports.

Step 15. Press Display key and then select SCALE.

Step 16. Set REFERENCE VALUE to -80.

Step 17. Verify that the trace is less than -80 dB.

-

-

3-10 MS4782X MM

Page 33

PERFORMANCE VERIFICATION RECEIVER DISPLAY LINEARITY

3-7 RECEIVER DISPLAY

LINEARITY

Step 1. Set up the test equipment as shown in Figure 3-2

ML243XA

Power Meter

PowerMeter

ML2408A

8

9

7

4

5

6

1

0

ON/ OFF

Power Meter

3

2

+/-

CLR

Channel

Sensor

This test verifies the magnitude display linearity of the receiver.

NOTE

Zero and calibrate Power Sensor prior to connecting to the

power divider.

Setup: Set up the test equipment as described below.

MS462X3C

GPIB

CALIBRATOR

A

B

System

Trigger

Cal/ Zero

Port 3

50 Ohm Terminations

Port 1 Port 2

Port 1 Port 2Port 3

Test

Test

Port 2

Port 1

34NN50A

DRA Scorpion

MS4782A

Test Set

POWER SENSOR

Figure 3-2. Receiver Magnitude Display Linearity Test Setup

Step 2. Allow the system to warm up for at least one hour.

Step 3. Press Default key then 0 key.

Step 4. Press Seq key and select:

TTL I/O

PARALLEL OUT SETUP

SET PARALLEL OUT PORT (0-255)

Step 5. Change the value from 0 to 8.

Step 6. Select:

RETURN

RETURN

11N50B

POWER DIVIDER

MS4782X MM 3-11

Page 34

RECEIVER DISPLAY LINEARITY PERFORMANCE VERIFICATION

Step 7. Press Freq key.

Step 8. Change START FREQUENCY to 800 MHz and STOP FREQUENCY to

1 GHz.

Step 9. Toggle C.W. MODE OFF soft key to C.W. MODE ON.

Step 10. Change C.W. Frequency to 1 GHz.

Step 11. Press Config key and select:

DATA POINTS

POINTS DRAW IN C.W. – 51 POINT(S)

Step 12. Press Avg key and select:

SELECT I.F. BANDWIDTH

I. F. BW 10 Hz

Step 13. Press Power key and select SOURCE 1 SETUP.

Note

Ensure that the Power Sensor Cal Factor is set for 1 GHz.

Refer to the ML24XXA Operational Manual.

Step 14. Adjust SOURCE 1 POWER so that the power meter readout is 0 dBm

± 0.1 dB.

Step 15. Press Ch 3 key.

Step 16. Press Meas key and select USER DEFINED.

Step 17. Change RATIO to b2/1.

Step 18. Select S21/USER 1 soft key to use user defined parameter.

Step 19. Press Display key and select:

GRAPH TYPE

LOG MAGNITUDE

RETURN

TRACE MEMORY

Step 20. Allow the trace to sweep twice. Select:

STORE DATA TO MEMORY

VIEW DATE (/) MEMORY

Step 21. Press Marker key and select MARKER READOUT.

3-12 MS4782X MM

Page 35

PERFORMANCE VERIFICATION RECEIVER DISPLAY LINEARITY

Step 22. Use the soft key to turn on Marker 1. Then use the numeric data en

try key to change POINT to 25.

Step 23. Press Marker key again.

Step 24. Use the soft key to SCREEN DISPLAY ON.

Step 25. Press Power key and select SOURCE 1 SETUP.

Step 26. Set PORT 1 ATTN to 10 dB. Record the Power Meter Readout and the

Marker 1 Readout to the table on next page. Repeat this step for other

PORT 1 ATTN setting listed in the table.

Step 27. Verify if the difference of the two measured values are within specifi

cations (Table 3-4).

Table 3-4. Receiver Magnitude Display Linearity Specifications

PORT 1 ATTN

Setting (dB)

10

20

30

Power Meter

Reading

MS462XC Marker 1 Reading

Difference Between Two

Readings

-

-

Specification

£0.3 dB

£0.3 dB

£0.3 dB

40

50

60

£0.3 dB

£0.3 dB

£0.3 dB

MS4782X MM 3-13/3-14

Page 36

Page 37

Chapter 4 Troubleshooting

Table of Contents

4-1 INTRODUCTION ............................4-3

4-2 OPERATIONAL CHECK .....................4-3

4-3 COMBINER CHECK .......................4-3

Equipment Required: ·······················4-3

Setup:································4-3

Test Procedure: ··························4-6

4-4 COUPLER CHECK ........................4-9

Equipment Required: ·······················4-9

Setup:································4-9

Test Procedure: ··························4-11

4-5 TEST CHANNEL STEP ATTEN. CHECK ...........4-12

Setup: ·······························4-12

Test Procedure: ··························4-13

4-6 INT. TERM. RESISTANCE CHECK ................4-14

Test Procedure: ··························4-14

4-7 TROUBLESHOOTING......................4-14

If Test Set Does Not Power Up··················4-14

Line Source And Interface Checks················4-14

Power Supply

Voltage Check···························4-15

If The Pats System Fails Return Loss Confidence Tests ····4-15

If The Pats System Fails System Dynamic Range Test·····4-16

If The Pats System Fails Receiver Display Linearity Test · · · 4-16

Page 38

Page 39

Chapter 4

Troubleshooting

4-1 INTRODUCTION The tests in this section provide a method of testing the MS4782X

Test Set for proper operation. These tests are intended to be used as a

troubleshooting tools for checking the operational functionality of the

components in the MS4782X.

4-2 OPERATIONAL CHECK Operational Tests for the MS4782X consists of the following:

Combiner Check

q

Coupler Check

q

Test Channel Step Attenuator Check

q

Internal Termination Resistance Check

q

Caution

Prior to performing these tests, the MS462XC must be verified to be in good condition.

4-3 COMBINER CHECK This test checks whether the Combiner functions properly.

Equipment Required: Anritsu ML243XA Power Meter

Anritsu MA2472A Power Sensor

Anritsu 2100-2 GPIB Interface Cable

Anritsu 34NFNF50 Adapter

Anritsu 3670NN50-2 Through cable or Anritsu 15NN50-0.6B cable

Setup: Set up the equipment as shown in Figure-4-1

Step 1. Turn on the ML243XA Power Meter, MS462XC Vector Network Mea

surement System and the MS4782X Power Amplifier Test Set. Allow

warm up 30 minutes.

Step 2. Press Default key and then 0 key to reset the MS462XC.

Step 3. Change the START frequency to 800 MHz.

Step 4. Change the STOP frequency to 2400 MHz.

Step 5. Press Seq key.

-

MS4782X MM 4-3

Page 40

COMBINER CHECK TROUBLESHOOTING

00000001

PARALLELPRINTER

MadeinUK

CAUTION

85-250VAC

DONOTOPERATE

47-440Hz

WITHUNGROUNDED

40VAMAX

GPIB/IEEE 488

WARNING

NOOPERATORSERVICE-

ABLEPARTSINSIDE.

Ethernet

POWERCORD.

OUTPUT1 OUTPUT2 INPUT1

DIGITAL

SEEMANUALFOR VOLTAGERANGESON BNC CONNECTORS

VGA

Ext

Analog

Output

Port2

Bias

INPUT2

12-24VDC

ANALOG

(1.3A)

SCSI-2

ExtI/O

LPTLinePrinter

Ext

Trigger

Port1

Bias

47-440Hz

85-264VAC

REPLACEFUSEONLYWITH

SAMETYPEAND RATING

CAUTION

FORCONTINUEDFIRE

PROTECTIONREPLACE

ONLYWITHSPECIFIED

TYPEANDRATEDFUSE.

CAUTION

DONOTOPERATE

WITHPOWERCORD

UNGROUNDED

Port2

Port1

Ext

Ext10MHz

ExtAnalog

BiasFuse

BiasFuse

Source

In

In

RS232

B

A

CALIBRATOR

SerialPort

IEEE488.2

GPIB

Dedicated

GPIB

WARNING

NOOPERATORSERVICE-

ABLEPARTSINSIDE.

REFERSERVICINGTO

QUALIFIEDPERSONNEL.

N274

Noise

Noise

+28V

In

Rear panel power meter GPIB connection

GPIB

ML243XA

Power Meter

ML2408A

7

4

1

0

ON/ OFF

PowerMeter

8

5

2

9

6

Power Meter

3

+/-

CLR

Trigger

Channel

Sensor

CALIBRATOR

A

System

B

Cal/ Zero

POWER SENSOR

Figure 4-1. Test Equipment Setup for Combiner Check

Port 3

Port 3

50 Ohm Terminations

Port 1

Port 1

Test

Port 1

Port 2

Port 2

Test

Port 2

Connect as directed by procedure

MS462X3C

DRA Scorpion

MS4782X

Test Set

4-4 MS4782X MM

Page 41

TROUBLESHOOTING COMBINER CHECK

Step 6. Select:

TTL I/O

PARALLEL OUT SETUP

SET PARALLEL OUT PORT (0-255)

Step 7. Change the value from 0 to 8.

Step 8. Select:

RETURN

RETURN

Step 9. Press Display key.

Step 10. Select:

DISPLAY MODE

SINGLE CHANNEL

RETURN

GRAPH TYPE

LOG MAGNITUDE

RETURN

Step 11. Press Meas key.

Step 12. Select:

MORE

S23

MORE

USER DEFINED

CHANGE RATIO

b2 (Tb)

1

S23/USER 6

RETURN

Step 13. Press Ch 3 key and then Display key.

Step 14. Select:

GRAPH TYPE

LOG MAGNITUDE

RETURN

Step 15. Press Meas key.

Step 16. Select:

MORE

S21

MORE

USER DEFINED

MS4782X MM 4-5

Page 42

COMBINER CHECK TROUBLESHOOTING

CHANGE RATIO

b2 (Tb)

1

S21/USER 1

RETURN

Step 17. Press Config key.

Step 18. Select:

DATA POINTS

201 MAX PTS

Step 19. Disconnect the N male connector of the interconnect RF cable from “To

Port 1” front panel connector. Refer to Figure 4-1.

Step 20. Zero and calibrate the power sensor. Install the 34NFNF50 adapter to

the input of the Power Sensor.

Step 21. Connect the Power Sensor to the end of the RF cable.

Step 22. Press Power key.

Step 23. Select:

SOURCE 1 SETUP

FLAT TEST PORT POWER CAL

POWER TARGET 0.00 dBm

BEGIN CAL

Step 24. After the calibration is complete, remove the power sensor from the

RF cable and reconnect the cable to “To Port 1” front panel connector.

Step 25. Disconnect the N male connector of the interconnect RF cable from “To

Port 2” front panel connector. Refer to Figure 4-1.

Step 26. Connect the power sensor to the end of the RF cable.

Step 27. Press Power key.

Step 28. Select:

SOURCE 2 SETUP

FLAT TEST PORT POWER CAL

POWER TARGET 0.00 dBm

BEGIN CAL

Step 29. After the calibration is complete, remove the power sensor from the

RF cable and reconnect the cable to “To Port 2” front panel connector.

Test Procedure:

Step 1. Connect a through cable between Test Port 1 and Test Port 2 of the

MS4782X Test Set.

4-6 MS4782X MM

Page 43

TROUBLESHOOTING COMBINER CHECK

Step 2. Press Display key.

Step 3. Select:

TRACE MEMORY

Step 4. Allow the trace to sweep twice.

Step 5. Select:

STORE DATA TO MEMORY

DISK OPERATIONS

SAVE MEMORY TO HARD DISK

CREATE NEW FILE

Step 6. Enter “COMBTST” as file name and select DONE to save the data to

hard disk.

Step 7. Press CH1 key.

Step 8. Press Display key.

Step 9. Select:

TRACE MEMORY

DISK OPERATIONS

RECALL MEMORY FROM HARD DISK

COMBTST NRM

VIEW DATA (/) MEMORY

Step 10. Verify that the displayed trace is withina1dBwindow.

Step 11. If this test fails, replace the A4 combiner. Refer to Figure-4-2.

MS4782X MM 4-7

Page 44

COMBINER CHECK TROUBLESHOOTING

A

r

A6 Power

Supply

A10 SPDT

Switch

A8 High Power

Termination

7 Circulator

(MS4782A only)

A9 Control PCB

Assembly

A6

A8

A3 Coupler

A5A2 Limiter

A5A2

A9

A3

A5

A5 Step Attenuato

A5A1 Power Divider

A10

A7

A2

A1

A4

A2 Coupler

A4 Combiner

A1 Coupler

Figure 4-2. Major Assemblies Location Diagram (Top View)

4-8 MS4782X MM

Page 45

TROUBLESHOOTING COUPLER CHECK

4-4 COUPLER CHECK This test checks whether the Port 1 and Port 2 Couplers function prop

erly.

Equipment Required: Gore PhaseFlexTM cables (p/n EJD01D01048.0) or equivalent (2

each)

Anritsu 34SFSF50 Adapter or equivalent

Anritsu 34NKF50 Adapters (2 each) or equivalent

Anritsu 28N50LF Termination or equivalent

Anritsu 28L50LF Termination or equivalent

Setup: Setup the test equipment as described below.

Step 1. Disconnect all inter-connect RF cables between the MS462XC Vector

Network Measurement System and the MS4782X Power Amplifier

Test Set.

Note

Do not disconnect the cable connected between Ext I/O

port of the MS462XC and Control In port of the MS4782X.

Step 2. Connect the MS462XC as shown in Figure 4-3.

MS462XC Front Panel

VectorNetwork Measurement System

10MHz-6GHz

MS4623B

Port3

Keyboard

Power

DataEntry

G/ns/m

8

9

7

Enter

M/s/cm

m

6

4

5

k/ms/mm

3

1

2

Clr

.

X1

-

0

Local

Channels

Appl

Meas

Display

Marker

Hold

Port1

Enhancement

Ch2

Ch1

Ch3

Freq

Power

Cal

Seq

Ch4

Avg

Utility

System

Stimulus

Hard

Sweep

Print

Copy

Save/

Config

Default

Recall

Port2

ProbePower

MS462XC Rear Panel

SerialPort

IEEE488.2

GPIB

Dedicated

GPIB

WARNING

NOOPERATORSERVICE-

ABLEPARTSINSIDE.

REFERSERVICINGTO

QUALIFIEDPERSONNEL.

N274

Noise

Noise

In

+28V

VGA

Ethernet

Ext

Analog

Output

Port2

Bias

SCSI-2

ExtI/O

LPTLinePrinter

Ext

Trigger

Port1

Bias

47-440Hz

85-264VAC

REPLACEFUSEONLYWITH

SAMETYPEAND RATING

CAUTION

FORCONTINUEDFIRE

PROTECTIONREPLACE

ONLYWITHSPECIFIED

TYPEANDRATEDFUSE.

CAUTION

DONOTOPERATE

WITHPOWERCORD

UNGROUNDED

Port2

Port1

Ext

Ext10MHz

ExtAnalog

BiasFuse

BiasFuse

Source

In

In

-

Port 1

34SFSF50 Adapter

Cable A

4 foot Gore PhaseFlex

cable (part number EJD01D01048.0)

Cable B

4 foot Gore PhaseFlex

cable (part number EJD01D01048.0)

b2 input

Figure 4-3. Coupler Check Test Setup

Step 3. Connect a through cable between the C1 and C2 connector ports of the

MS4782X.

Step 4. Turn on the MS462XC Vector Network Measurement System and the

MS4782X Test Set. Allow warm up 30 minutes.

Step 5. Press Default key and then 0 key to reset the MS462XC.

Step 6. Change the START frequency to 800 MHz.

Step 7. Change the STOP frequency to 2400 MHz.

MS4782X MM 4-9

Page 46

COUPLER CHECK TROUBLESHOOTING

Step 8. Press Ch3 key and then Display key.

Step 9. Select:

DISPLAY MODE

SINGLE CHANNEL

RETURN

GRAPH TYPE

LOG MAGNITUDE

RETURN

Step 10. Press Meas key.

Step 11. Select:

MORE

S21

MORE

USER DEFINED

CHANGE RATIO

b2 (Tb)

1

S21/USER 1

RETURN

Step 12. Press Power key.

Step 13. Select:

Step 14. Verify the PORT 1 POWER is below –15 dBm. Adjust SOURCE 1

Step 15. Connect the two cables together with the 34SFSF50 Adapter.

Step 16. Press Display key.

Step 17. Select:

Step 18. Allow the trace to sweep twice. Select:

Step 19. Disconnect the connection between cable A and cable B at the adapter.

Test Procedure:

SOURCE 1 SETUP

PORT 1 ATTN 2*10 dB (0 – 70)

POWER control if necessary.

TRACE MEMORY

STORE DATA TO MEMORY

VIEW DATA (/) MEMORY

Step 1. Disconnect the Ext Pre-Amp RF loop cable between the Input and

Output connectors.

4-10 MS4782X MM

Page 47

TROUBLESHOOTING COUPLER CHECK

Step 2. Connect cable A, cable B and termination to the connector ports as

stated in Table 4-1.

Table 4-1. Troubleshooting Connections

Tests

(from Port 1 of MS462XC)

Cable A

A Ext Pre-Amp Output connector of

MS4782X

B Test Port 1 connector of

MS4782X

C Test Port 2 connector of

(to b1 Input of MS462XC)

a1 Output connector of

MS4782X

b1 Output connector of

MS4782X

Aux Out connector of MS4782X b2 Output connector

Cable B

MS4782X

D To Port 2 connector of MS4782X a2 Output connector of

MS4782X

Step 3. Refer to Figure 4-4 and Figure 4-5 for connector locations.

Port 1 Port 2Port 3

50 Ohm Terminations

Test

Port 1

Termination

Test Port 1 Connec

tor

Ext Pre-Amp Output

connector of

MS4782X

and To Port 2 Con

nector of MS4782X

C3 connector of

MS4782D

Test

Port 2

-

-

Insertion

Loss

£ 33 dB

£ 33 dB

£40 dB

£ 33 dB

Figure 4-4. Test Set Front Panel

Step 4. Verify that the insertion loss in the corresponding path is within the

tolerance as stated in Table 4-1.

N274

a

Control

In

1

WARNING

NOOPERATOR SERVICE-

ABLEPARTS INSIDE.

REFERSERVICING TO

QUALIFIEDPERSONNEL.

Output

ExtPreamp

CAUTION

DONOT OPERATE

WITHPOWER CORD

UNGROUNDED

a

2

Input

b

1

b2To

AUT

TestPort 2

b

2

External

Circulator

C3

C2C1

50dBm

50dBm

Max

27dBm

Max

Max

100W

a2To

VNMS

Port2

Termination

(Internal)

LINE INPUT

85-240VAC

47-63Hz

100VA max

FUSE250 V 1.6 A T

CAUTION

FORCONTINUED FIRE

PROTECTIONREPLACE

ONLYWITH SPECIFIED

TYPEAND RATED FUSE

Figure 4-5. Test Set Rear Panel

Step 5. Repeat the test for the rest of the signal paths stated in Table 4-1.

MS4782X MM 4-11

Page 48

TEST CHANNEL STEP ATTEN. CHECK TROUBLESHOOTING

Step 6. Reconnect all the inter-connect RF cables between the MS462XC Vec

Step 7. If Test A or Test B fails, replace A1 Port 1 Coupler (Figure 4-2).

Step 8. If Test C fails, replace:

Step 9. If Test D fails, replace A3 Coupler.

4-5 TEST CHANNEL STEP

ATTEN. CHECK

Setup: Turn on the MS462XC Vector Network Measurement System and the

Step 1. Press Default key and then 0 key.

Step 2. Press Seq key.

Step 3. Select:

tor Network Measurement System and MS4782X Test Set. Also

reconnect the Ext Pre Amp RF loop cable.

A2 Port 2 Coupler

q

A5A1 K240B Power Splitter

q

This test checks whether the Test Channel Step Attenuator functions

properly.

MS4782X Test Set and allow warm up 30 minutes.

-

TTL I/O

PARALLEL OUT SETUP

SET PARALLEL OUT PORT (0-255)

Step 4. Change the value from 0 to 8.

Step 5. Select:

RETURN

RETURN

Step 6. Press Display key.

Step 7. Select:

DISPLAY MODE

SINGLE CHANNEL

RETURN

Step 8. Press Ch 3 key and then Display key.

Step 9. Select:

GRAPH TYPE

LOG MAGNITUDE

RETURN

Step 10. Press Avg key.

4-12 MS4782X MM

Page 49

TROUBLESHOOTING TEST CHANNEL STEP ATTEN. CHECK

Step 11. Select:

SELECT I.F. BANDWIDTH

I. F. BW 10 Hz

Test Procedure:

Step 1. Connect a through cable between Test Port 1 and Test Port 2.

Step 2. Select:

TRACE MEMORY

Step 3. Allow the trace to sweep twice. Select:

STORE DATA TO MEMORY

VIEW DATA (/) MEMORY

RETURN

Step 4. Select:

SCALE

10 dB/DIV

Step 5. Press Seq key.

Step 6. Select:

TTL I/O

PARALLEL OUT SETUP

SET PARALLEL OUT PORT (0-255)

Step 7. Change the SET PARALLEL OUT PORT value to 9.

Step 8. Verify whether the displayed S21 trace is within the range specified in

Table 4-2.

Table 4-2. Step Attenuator Specifications

PARALLEL OUT PORT VALUE Corresponding Step Attenuator Setting Expected Range

9 10dB 10±1dB

10 20dB 20±1dB

12 40dB 40±2dB

Step 9. Repeat Steps 7 and step 8 for the other PARALLEL OUT PORT values

in Table-4-2.

MS4782X MM 4-13

Page 50

INT. TERM. RESISTANCE CHECK TROUBLESHOOTING

Step 10. If the test results are out of the expected range, replace:

Step Attenuator

q

Limiter

q

4-6 INT. TERM. RESISTANCE

CHECK

Test Procedure:

Step 1. For MS4782D, measure the DC resistance of the termination between

Step 2. Verify that the measured value is 50 ±5 ohms.

Step 3. If the measured value is out of the expected range, replace the termi-

This test checks whether the internal high power termination has

been overpowered.

the center conductor and the outer conductor of the Internal Termina

tion Input connector (C2) on the rear panel.

For the MS4782A:

Remove the cable between the termination and the internal circulator.

Measure the DC resistance between the center conductor and the

outer conductor of the termination connector.

nation (Figure 4-2).

4-7 TROUBLESHOOTING The following paragraphs provide suggestions for troubleshooting cer-

tain test set components.

If Test Set Does Not

Power Up

Check as follows:

-

Step 1. If the MS4782X Test Set does not power up when connected to an AC

power source and the Power key is pressed, perform the power supply

checks described below.

WARNING

Harzardous voltages are presented inside the instrument

when AC line power is connected. Turn off the instrument

and remove the line cord before removing any covers or

panels. Troubleshooting or repair procedures should only

be performed by service personnel who are fully aware of

the potential hazards.

Line Source And In

terface Checks

Step 1. Verify that AC power source is providing stable power at the correct

-

Check as follows:

line voltage.

4-14 MS4782X MM

Page 51

TROUBLESHOOTING TROUBLESHOOTING

Note

The MS4782X is designed to automatically sense and oper

ate with AC line voltage in the range of 85 – 264 VAC,

with a frequency of 47 – 63 Hz.

Step 2. Verify that power input cord is in good condition.

Step 3. Verify that the power line fuse is installed, that it is not blown (open),

and that it is the correct value (1.6A, Slow blow, part number 631-81).

-

Power Supply

Voltage Check

Step 1. Turn off the Test Set, and disconnect the power cord from the instru

Step 2. Remove the top cover.

Step 3. Reconnect the power cord to the Test Set and turn it on.

Step 4. Using DMM or oscilloscope, measure the DC power supply voltage

Step 5. Connect the DMM or oscilloscope to the TEST POINTS on the Control

Step 6. If any of the DC voltage tests fails, replace the A6 DC power supply.

Check as follows:

ment. Ensure all external cable connections to the Test Set front and

rear panel are also disconnected.

listed in Table 4-3.

Table 4-3. Power Supply Voltages

Measured Pin Common Pin DC Supply Voltage

TP2 TP1 +5 ± 0.05V

TP3 TP1 +24 ± 2.4 V

TP4 TP1 +15 ± 0.9 V

-

ler PCB assembly (Figure 4-1).

Refer to Figure-4-6 Part Location Diagram.

If the PATS Fails the

Return Loss

Confidence Tests

Step 1. Use a different Calibration Kit for measurement calibration and re

Step 2. Verify the performance of the MS462XC per Chapter 3 of the MS462XX Mainte

Check as follows:

peat the Return Loss Confidence Test. This step determines whether

the Calibration Kit is the cause of the failure.

nance Manual (part number 10410-00205). This step determines whether the

MS462XC is the cause of the failure.

MS4782X MM 4-15

-

Page 52

TROUBLESHOOTING TROUBLESHOOTING

Figure 4-6. A6 Power Supply Parts Location Diagram

Step 3. Perform Coupler Check (page 4-9).

4-16 MS4782X MM

Page 53

TROUBLESHOOTING TROUBLESHOOTING

If the PATS Fails the

System Dynamic Range

Test

Step 1. Verify the performance of the MS462XC per Chapter 3 of the

Step 2. Perform Test C of the Coupler Check (page 4-11).

If the PATS Fails the

Receiver Display Linearity

Test

Step 1. Verify the performance of the MS462XC per Chapter 3 of the

Step 2. Perform Test C of the Coupler Check (page 4-11).

Check as follows:

MS462XX Maintenance Manual (part number 10410-00205). This

step determines whether the MS462XC is the cause of the failure.

Check as follows:

MS462XX Maintenance Manual (part number 10410-00205). This

step determines whether the MS462XC is the cause of the failure.

MS4782X MM 4-17/4-18

Page 54

Page 55

Chapter 5 Remove and Replace Procedures

Table of Contents

5-1 INTRODUCTION .........................5-3

5-2 EQUIPMENT REQUIRED ....................5-3

5-3 A1, A2, A3 COUPLER .......................5-6

5-4 A4 COMBINER ..........................5-7

5-5 A5 STEP ATTENUATOR .....................5-8

5-6 A6 POWER SUPPLY .......................5-9

5-7 A7 CIRCULATOR (MS4782A)..................5-11

5-8 A8 HIGH POWER TERMINATION...............5-12

5-9 A9 SYSTEM CONTROL PCB .................5-13

5-10 FAN ASSEMBLY.........................5-14

Page 56

Page 57

Chapter 5

Remove and Replace

Procedures

5-1 INTRODUCTION This chapter provides procedures for removing and reinstalling the re

placeable subassemblies listed in Chapter 2, Table 2-2.

5-2 EQUIPMENT REQUIRED All procedures in this chapter require the use of either a #1 or #2 size

Phillips type screw driver. Most procedures require the use of a 5/16

inch wrench and the Anritsu 01-201 (8 in./pounds) Torque Wrench.

5-3 COVERS Troubleshooting operations require removal of the top cover. Replace-

ment of some Test Set assemblies and parts require removal of all covers. The following procedure describes this process.

NOTE

It is only necessary to loosen the Test Set handle assemblies to remove the top, bottom, or side covers. However, if

the front panel is to be removed, remove the handle assemblies at this time.

Preliminary:

q

Switch the Test Set power off and remove the power cord.

Procedure:

Step 1. Loosen (or remove) the right and left handle assemblies, as follows:

-

n

Place the Test Set on its top (bottom-side up).

n

Loosen/remove the screws at the sides of the handle as

semblies.

n

If removing handles, pull them away from unit and set

aside.

The green headed screws have Metric

threads.

Step 2. To remove the top cover:

n

Place the Test Set in normal (top-side up) position.

CAUTION

-

MS4782X MM 5-3

Page 58

COVERS REMOVE AND REPLACE

Remove the feet from the two top corners at the rear of

n

the Test Set (Figure 5-1).

Lift and slide cover back and

remove

Remove screw

from each side.

Remove

center screw

Figure 5-1. Top/Bottom Cover Removal

n Remove the center screw from rear of the top cover.

n Lift and slide the top cover away from the Test Set.

Step 3. To remove the bottom cover:

n

Place the Test Set on its top (bottom-side up).

n

Remove the feet from the two bottom corners at the rear

of the Test Set.

n

Remove the center screw from rear of the bottom cover.

n

Lift and slide the top cover away from the Test Set.

Remove green

screw from each

side.

5-4 MS4782X MM

Page 59

REMOVE AND REPLACE COVERS

Step 4. To remove the left cover:

Place the Test Set on its right side.

n

Remove the feet from the two left-side corners at the

n

rear of the Test Set.

Remove the center screw from the left cover (Figure 5-2).

n

Remove

center screw

Figure 5-2. Side Cover Removal

n

Lift and slide the side cover away from the Test Set.

Step 5. To remove the right cover:

n

Place the Test Set its left side.

n

Remove the feet from the two right-side corners at the

rear of the Test Set.

n

Remove the center screw from rear of the right side

cover.

n

Lift and slide the side cover away from the Test Set.

To replace the instrument covers, perform the steps above in the re

verse order.

Remove screw

from each foot.

Remove green

screw from each

foot.

-

MS4782X MM 5-5

Page 60

A1, A2, A3 COUPLER REMOVE AND REPLACE

5-4 A1, A2, A3 COUPLER This paragraph provides a procedure for removing and replacing the

A1, A2, or A3 Coupler.

Step 1. Remove top cover (paragraph 5-3).

Step 2. Disconnect the three connectors (Figure 5-3).

Step 3. Remove four screws.

Step 4. Remove coupler.

To replace coupler, reverse the order in the removal procedure.

A3Coupler

Figure 5-3. A1, A2, or A3 Coupler Removal

A3

Disconnect

Remove 4

screws

A1

A2

A1 Coupler

Disconnect

A2 Coupler

Disconnect

5-6 MS4782X MM

Page 61

REMOVE AND REPLACE A4 COMBINER

sconnec

5-5 A4 COMBINER This paragraph provides a procedure for removing and replacing the

A4 Combiner.

Step 1. Remove top cover (paragraph 5-3).

Step 2. Disconnect the three connectors (Figure 5-4).

Step 3. Remove four screws.

Step 4. Remove combiner.

Step 5. To replace combiner, reverse the order in the removal procedure.

A4 Combiner

Figure 5-4. A4 Combiner Removal

Disconnect

Di

Disconnect

A4

Remove 4

screws

t

MS4782X MM 5-7

Page 62

A5 STEP ATTENUATOR REMOVE AND REPLACE

5-6 A5 STEP ATTENUATOR This paragraph provides a procedure for removing and replacing the

A5 Step Attenuator and A5A2 RF Limiter.

Step 1. Remove top cover (paragraph 5-3).

Step 2. Disconnect the A5A2 RF Limiter from the step attenuator (Figure 5-5).

Step 3. Disconnect the fixed attenuator from the step attenuator.

Step 4. Disconnect the ribbon-cable connector from the step attenuator.

Step 5. Remove two screws.

Step 6. Remove step attenuator.

To replace step attenuator, reverse the order in the removal proce

dure.

A5 Step Attenuator

A5A2 RF Limiter

A5A2

A5

Disconnect

Remove 2

screws

Disconnect

Disconnect

Km

to Km

Adapter

A5A1 Power Divider

-

Figure 5-5. A5 Step Attenuator Removal

5-8 MS4782X MM

Page 63

REMOVE AND REPLACE A6 POWER SUPPLY

5-7 A6 POWER SUPPLY This paragraph provides a procedure for removing and replacing the

A6 Power Supply.

Step 1. Remove top cover and bottom covers (paragraph 5-3).

Step 2. Disconnect three wiring connectors from power supply (Figure 5-6).

Step 3. Set Test Set on its front handles.

Step 4. Grasp the the power supply to hold it in place while removing the four

screws from the underside (Figure 5-7).

Step 5. Remove power supply

To replace power supply, reverse the order in the removal procedure.

A6 Power Supply

Disconnect

Disconnect

A6

Disconnect

Figure 5-6. A6 Power Supply Removal (Bottom View)

MS4782X MM 5-9

Page 64

A6 POWER SUPPLY REMOVE AND REPLACE

F

l

rontPane

Remove 4

round-head

screws

Rear Panel

Figure 5-7. A6 Power Supply Removal (Bottom View)

5-10 MS4782X MM

Page 65

REMOVE AND REPLACE A7 CIRCULATOR (MS4782A)

5-8 A7 CIRCULATOR

(MS4782A)

This paragraph provides a procedure for removing and replacing the

A7 Circulator on the MS4782A Test Set.

Step 1. Remove top cover cover (paragraph 5-3).

Step 2. Disconnect semirigid cables in three places (Figure 5-8).

Step 3. Remove four mounting screws.

Step 4. Remove circulator and bracket.

Step 5. Remove circulator from bracket.

Step 6. To replace high power termination, reverse the order in the removal

procedure.

Remove 4

screws

Remove 3

connectors

Figure 5-8. A7 Circulator Removal

A7

MS4782X MM 5-11

Page 66

A8 HIGH POWER TERMINATION REMOVE AND REPLACE

screws

5-9 A8 HIGH POWER

TERMINATION

Disconnect

A8 High Power

Termination

This paragraph provides a procedure for removing and replacing the

A8 High Power Termination.

Step 1. Remove top cover (paragraph 5-3).

Step 2. Disconnect the cable connector from the termination (Figure 5-9).

Step 3. Remove the four screws, and remove the termination.

To replace high power termination, reverse the order in the removal

procedure.

A8

Remove 4

Figure 5-9. A8 High Power Termination Removal

5-12 MS4782X MM

Page 67

REMOVE AND REPLACE A9 SYSTEM CONTROL PCB

5-10 A9 SYSTEM CONTROL

PCB

Step 1. Remove top cover (paragraph 5-3).

Step 2. Disconnect six wiring connectors from the A9 PCB (Figure 5-10).

Step 3. Remove the four corner screws, and remove the A9 PCB.

To A10 SPDT

Remove 4 screws

To A6 Power Supply

Not Used

This paragraph provides a procedure for removing and replacing the

A9 System Control PCB.

To replace A9 PCB, reverse the order in the removal procedure.