Page 1

MS2665C/MS2667C/MS2668C

Spectrum Analyzer

Service Manual

Third Edition

To ensure that this equipment is used safely, important safety items are explained in the

MS2665C/MS2667C/MS2668C Spectrum Analyzer

Operation Manual. This manual explains important service items related to service. Read both

the operation manual and this manual, and keep

both with the equipment.

Measuring Instruments Division

Measurement Group

ANRITSU CORPORATION

Document No.: M-W1335BE-3.0

i

Page 2

For Safety

For safety, do not open the equipment covers.

If repair is required, contact the sales representative, branch office, or agent at the

telephone number and address given in this document or in the equipment operation manual.

Although not recommended by Anritsu Corporation, if it is really imperative to

open the covers for emergency repair, take great care not to touch any dangerous

parts. Always request repair by a trained engineer who understands the hazards.

Anritsu Corporation will not accept liability for any injuries sustained as a result of

opening the equipment covers.

MS2665C/MS2667C/MS2668C

Spectrum Analyzer

Service Manual

15 April 1998 (First Edition)

2 March 1999 (Third Edition)

Copyright © 1998-1999, ANRITSU CORPORATION.

All rights reserved. No part of this manual may be reproduced without the prior written permission of the

publisher.

The contents of this manual may be changed without prior notice.

ii

Page 3

Part Names & Part Numbers

Please specify the part numbers shown in the parts list when making inquiries or when ordering

parts. There may be a difference between the names of parts used in this manual and the parts

actually used in the equipment or supplied for repair. This is because equivalent parts with the

same functions, performance and reliability as the parts specified in the circuit diagrams and

parts list have been used or supplied. Since the parts are equivalent, they have absolutely no

adverse effect on the equipment specified functions, performance or reliability.

iii

Page 4

iv

Page 5

Table of Contents

For Safety ...................................................... ii

Section 1 General......................................... 1-1

Section 2 MS2665C ...................................... 2-1

2.1 Overall Circuit description............................................... 2-2

2.2 Troubleshooting .............................................................. 2-9

2.3 Mechanical configuration ................................................ 2-31

Section 3 MS2667C ...................................... 3-1

3.1 Overall Circuit description............................................... 3-2

3.2 Troubleshooting .............................................................. 3-9

3.3 Mechanical configuration ................................................ 3-33

Section 4 MS2668C ...................................... 4-1

4.1 Overall Circuit description............................................... 4-2

4.2 Troubleshooting .............................................................. 4-9

4.3 Mechanical configuration ................................................ 4-27

Section 5 Firmware installation .................. 5-1

Section 6 Performance test system ........... 6-1

6.1 Required instruments...................................................... 6-2

6.2 Required software........................................................... 6-2

6.3 Test group 1.................................................................... 6-3

6.4 Test group 2.................................................................... 6-4

6.5 Test group 3.................................................................... 6-6

Section 7 Options ........................................ 7-1

7.1 Introduction ..................................................................... 7-2

7.2 Parts, PC board installation ............................................ 7-3

7.3 Software setting .............................................................. 7-7

7.4 Performance test ............................................................ 7-11

I

Page 6

II

.

Page 7

Section 1 General

This manual is for smooth maintenance and service work of the MS2665C/MS2667C/MS2668C Spectrum analyzer.

Refer to the separate operation manual for handling the instruments.

Our basic policy to the repair to the factory system, i.e. the defective instruments should be returned to Anritsu for repair.

However, it may be time consuming and some kinds of repairs can be easily done in the field.

Therefore, Anritsu allows only those who Anritsu has authorized to open the instrument and repair it.

As clearly stated in the WARRANTY statement, any unauthorized modification, repair, or attempt to repair will render the

warranty void.

This service manual is composed of the following sections:

SECTION 2 MS2665C

This section contains the following items of MS2665C.

(1) Overall circuit description, (2) Troubleshooting procedure, (3) Mechanical configuration.

SECTION 3 MS2667C

This section contains the following items of MS2667C.

(1) Overall circuit description, (2) Troubleshooting procedure, (3) Mechanical configuration.

SECTION 4 MS2668C

This section contains the following items of MS2668C.

(1) Overall circuit description, (2) Troubleshooting procedure, (3) Mechanical configuration.

SECTION 5 Firmware installation

This section describes Firmware installation procedure.

SECTION 6 Performance test system

This section describes performance test procedure after repairing modules.

SECTION 7 Options

This section describes option installation procedures and performance test.

1-1

Page 8

Section 1 General

1-2.

Page 9

Section 2 MS2665C

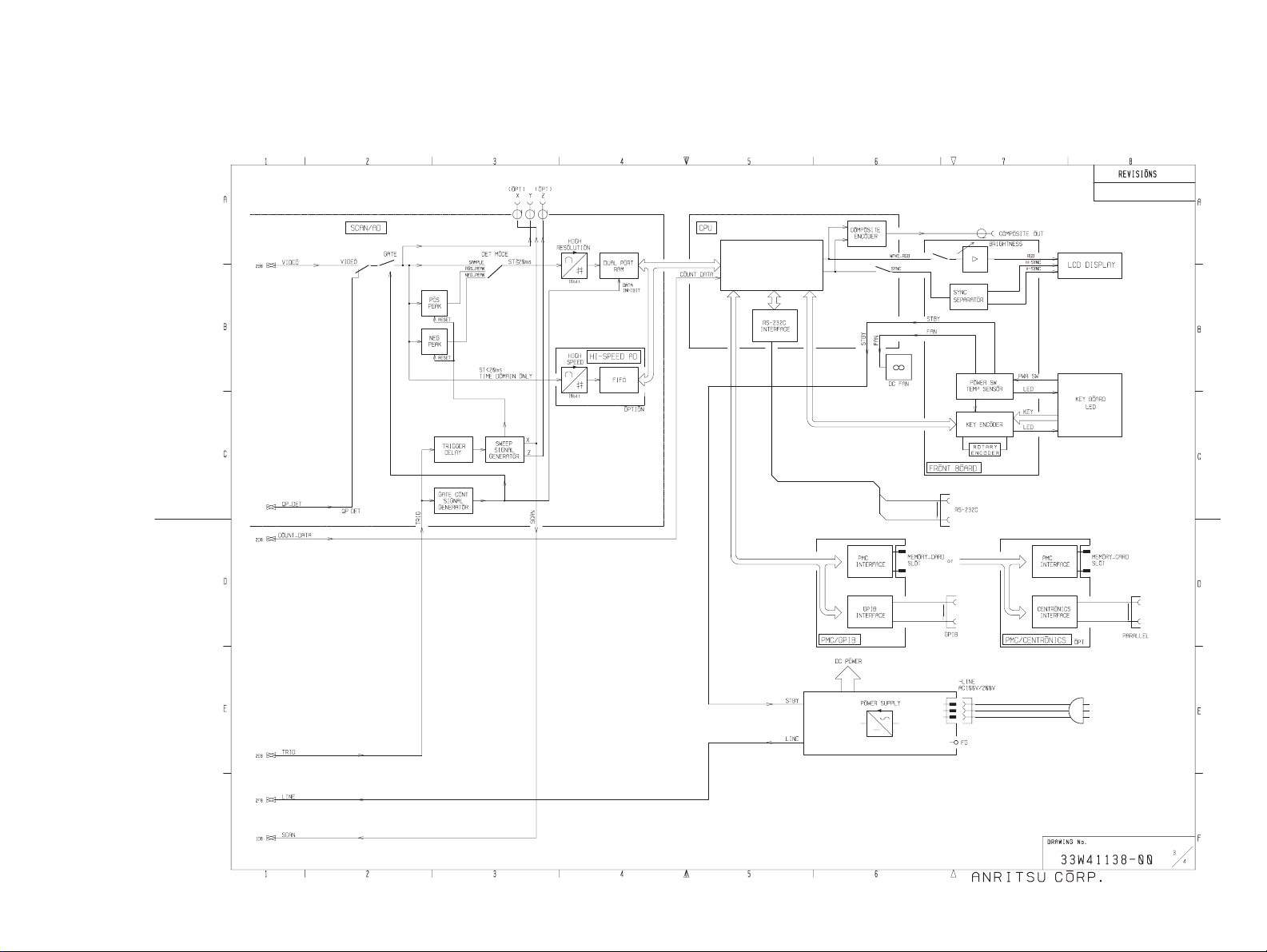

2.1 Overall Circuit description ......................................................... 2-2

2.2 Troubleshooting......................................................................... 2-9

2.2.1 Introduction .................................................................... 2-9

2.2.1.1 Service kit........................................................ 2-9

2.2.1.2 Required equipment........................................ 2-9

2.2.1.3 Circuit reference.............................................. 2-10

2.2.2 Detecting faulty module ................................................. 2-13

2.2.3 Disassembling cabinet................................................... 2-15

2.2.4 Replacement of faulty module ....................................... 2-15

2.2.5 Adjustment after module replacement ........................... 2-16

2.2.5.1 Reference crystal oscillator

(Option 01) adjustment.................................... 2-16

2.2.5.2 Sweep adjustment .......................................... 2-18

2.2.5.3 IF1 (ATT), IF2 (AMP) adjustment.................... 2-24

2.2.6 Assembling cabinet........................................................ 2-26

2.2.7 Checking items after assembling cabinet ...................... 2-26

2.2.8 Frequency response compensation .............................. 2-27

2.3 Mechanical configuration........................................................... 2-31

2.3.1 Disassembling/Assembling cabinet ............................... 2-31

2.3.2 Removing/Assembling units and PC boards ................. 2-35

2.3.3 Front unit disassembly/assembly................................... 2-39

2.3.4 A09 OPTION BASE disassembly/assembly .................. 2-43

2.3.5 Removing/Assembling

A0501 HI-SPEED AD from A05 SCAN/AD.................... 2-47

2-1

Page 10

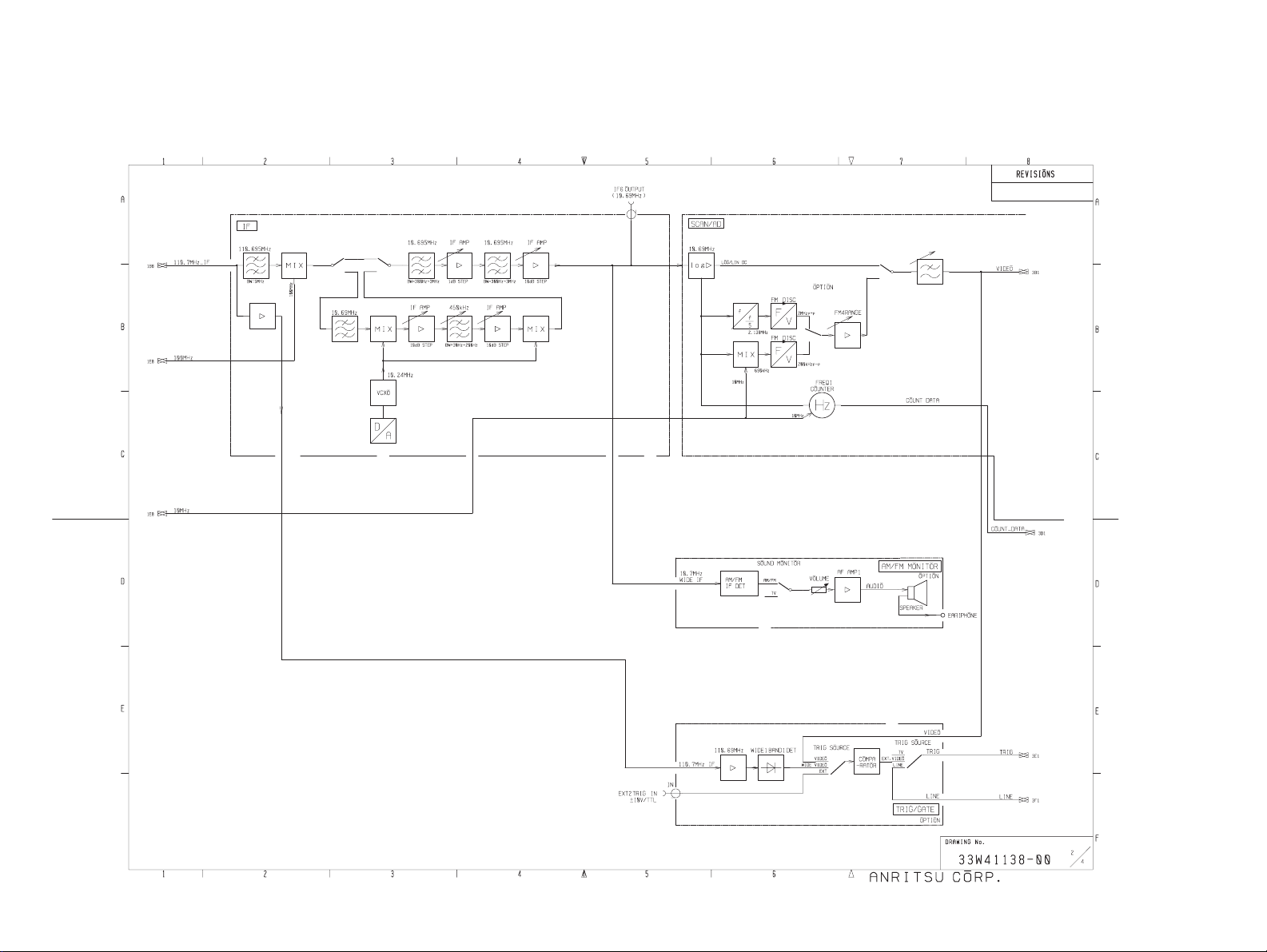

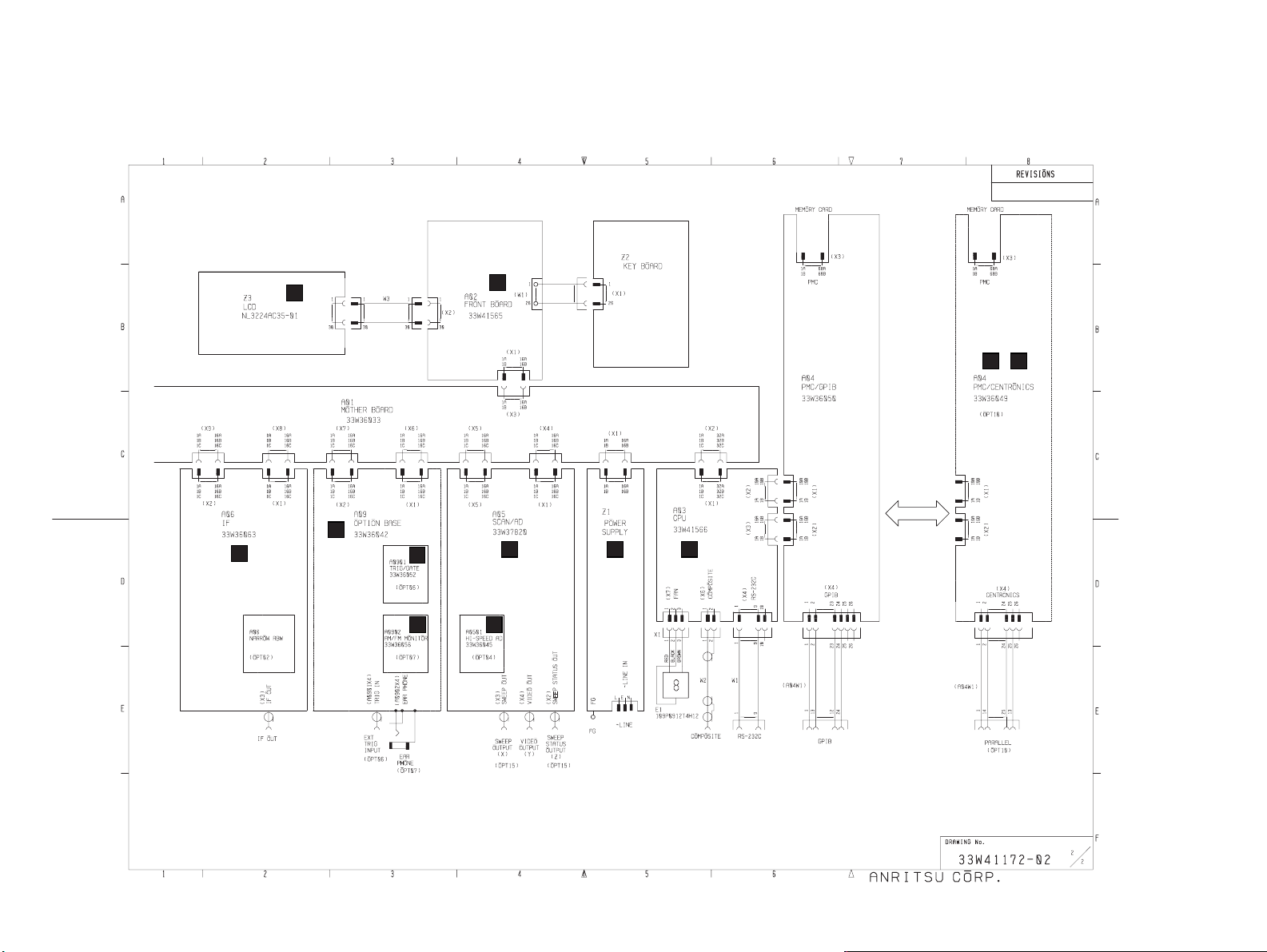

Section 2 MS2665C

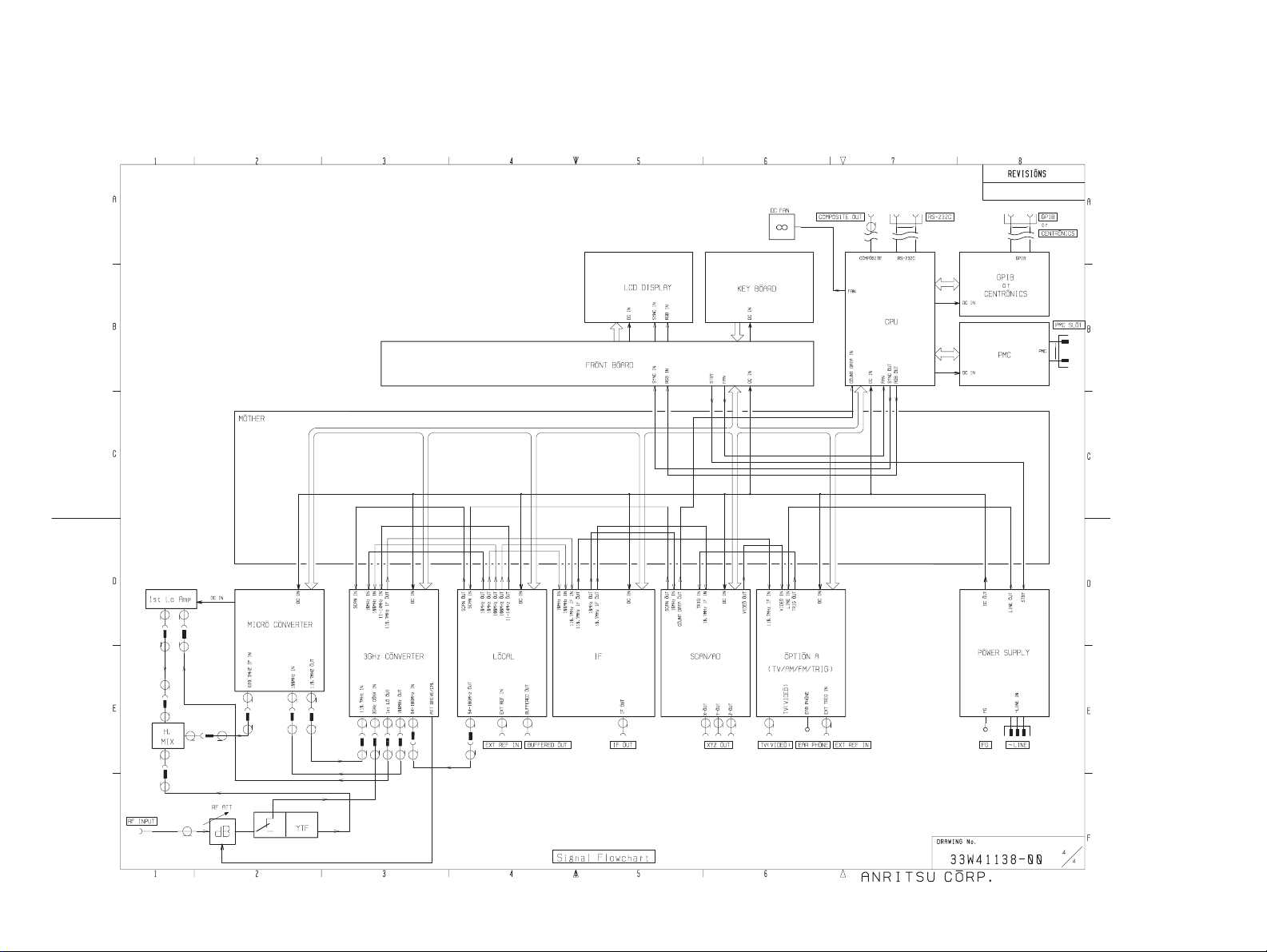

2.1 Overall Circuit description

MS2665C is a superheterodyne system scanning-type spectrum analyzer.

This section describes overall circuit of the MS2665C spectrum analyzer with its block diagram.

An RF input signal after passing through an RF switch and variable RF ATTN in 21 GHz S-ATT is switched by PIN diode

switch in 21 GHz YTF/SW to two different signal routes depending on input RF frequency.

For an RF input frequency of 9 kHz to 3.1 GHz (termed as band 0), the signal passes through 3.2 GHz LPF and then to 1st

mixer (1st MIX), where it is mixed with 1st local signal (4.1 GHz to 7.2 GHz) to generate 4110.69 MHz 1st IF signal.

The 1st IF signal is then passed through an amplifier and image rejection filters, and fed to 2nd mixer (2nd MIX), where it

is mixed with 4 GHz 2nd local signal to generate 110.69 MHz 2nd IF signal.

For an RF input frequency of 3.1 GHz to 21.2 GHz (band 1 to 3), the signal goes to YTF (YIG tuned filter) in 21 GHz YTF/

SW, and then to H. MIXER. In H. MIXER, the RF signal gets mixed with the 1st local signal (3.6 GHz to 7.5 GHz) to

generate 689.31 MHz 1st IF signal.

This 1st IF signal is passed through a series of amplifiers and image rejection filters before further mixing with 800 MHz

2nd local signal to convert the signal to 110.69 MHz 2nd IF signal.

Depending on the active band of RF input, one of the two above 2nd IF signal is sent to IF section for further processing.

The 1st local signal generated at YTO (YIG tuned oscillator) is frequency-swept by scan signal from SCAN/AD section

after phase-lock to reference signal (its frequency is 11 MHz to 14 MHz with the resolution of 1 Hz steps) generated on

LOCAL-A section at the center frequency of its sweeping range, in normal sweep condition.

The YTO output is passed through an amplifier, and then divided into three paths with directional couplers. One of divided

signal is fed to sampler circuit and the other are fed to the above mixers to frequency-convert.

In the sampler circuit, sampling signal (its frequency is 94 MHz to 106 MHz with the resolution of 1 MHz steps) generated

on LOCAL-A section is frequency-multiplied, and then mixed with the YTO output to generate sampler IF signal with a

frequency of 11 MHz to 14 MHz.

The sampler IF signal is compared with the reference signal of 11 MHz to 14 MHz at PFD.

The reference signal frequency (fREF) and the sampling signal frequency (fs) are controlled by CPU section according to

the measuring frequency of the instrument, and set so that the center frequency of 1st local signal is fs * N ± fREF (, where

N is an integer).

Meanwhile, the scan signal strength that is equivalent to frequency sweep width is controlled from LOCAL-A section.

The 2nd local signals of 4 GHz and 800 MHz are also phase-locked to 100 MHz VCXO signal, of which the frequency is

also phase-locked to 10 MHz crystal oscillator (option 01).

In the instrument, a high accuracy 625 kHz signal is present for level accuracy calibration. This signal is generated by

frequency-dividing the 10 MHz reference signal, and its power level is varied with 1 dB steps by CAL ATT.

Internal calibration operation being carried out, this calibrating signal is fed to the RF signal-route through the switch in 21

GHz S-ATT.

2-2

Page 11

2.1 Overall Circuit description

At the IF section the incoming signal is divided into two paths. The main route leads to image rejection filters while the

second, a highly attenuated feeler path signal is used for generation of wide band trigger signal in TRIG/GATE section (

option 06) situated on OPTION BASE board.

The main signal after passing through an image rejection filter is beat down to a 10.69 MHz signal using a 100 MHz

reference signal. This signal is then sent to various Resolution Band Width (RBW) setting circuits.

For RBW setting of 30 Hz to 200 Hz the signal is frequency converted to 450 kHz using 10.24 MHz signal. After passing

through the RBW circuits (Crystal filter circuits) the signal is up converted back to 10.69 MHz signal and passed through

wider RBW setting circuits.

For RBW setting of 300 Hz to 3 MHz the signal is sent directly to wide RBW setting circuits without any frequency

modifications.

The RBW processed signal is passed onto SCAN/AD section, where it passes through logarithmic amplifiers and then to a

linear detector. This linear detected signal is passed through smoothing filters called Video Band Width Filters (VBW).

This smoothed signal is then passed through Positive or Negative peak detection circuits and the output is converted to

digital signal by a Analog to Digital Convertor (ADC) circuit.

The results are then written (in digital word format) to a Dual Port RAM through one of the ports.

The CPU of the instrument on CPU section reads from the other port of Dual Port RAM and processes the data before

displaying on the LCD screen. The CPU also controls various interface functions such as reading the Key Inputs or remote

control commands received, and various outputs such as prints or plots of various data. The CPU also generates various

commands required for controlling or setting of all hardware units inside the instrument.

FRONT BOARD section generates the KEY and rotary-knob encoder data, drives the LEDs, detects the power switch

(PWR SW) setting, controls the power-supply On/Stby setting, and supplies power for the LCD backlight, etc.

2-3

Page 12

Section 2 MS2665C

2-4

Page 13

2.1 Overall Circuit description

2-5

Page 14

Section 2 MS2665C

2-6

Page 15

2.1 Overall Circuit description

2-7

Page 16

Section 2 MS2665C

2-8

Page 17

2.2 Troubleshooting

2.2.1 Introduction

2.2.1.1 Service kit

The ordering number of service kit is 34Y117630.

Table 2-2-1 Service kit

Name Quantity Drawing number Description

Adjustment driver

Adjustment driver

Torque wrench

HRM554S

HRM501

HRM519

1

1

1

2

2

2

34Z99432

34Z81433

34B35154

NO. 1305

NO. 1305

NO. 1305

2.2 Troubleshooting

NP-SMAJ adapter

SMAJ-SMAJ adapter

SMAP-BNCJ adapter

Extender cable

Extender cable

Extender cable

Extender cable

Extender cable

Extender cable

Extender cable

Extender cable

Extender cable

Extender cable

3

3

2

3

1

1

1

1

2

2

34J92837F

34J94207

S4J10001F

S4W10184C

349J109862

34Y109639

34Y109632

34Y109632B

34Y109632C

34Y109632D

BNC-PJ-1.5, 27DP-LP-1.5, 300 mm

27DP-BJ, 27DP-LP-1.5, 300 mm

BNC-P, 1000 mm

SMA-P-3T-NI (8), 300 mm

for A08 LOCAL-A

for 3 GHz CONVERTER

for A05 SCAN/AD

for A09 OPTION BASE

for A09 OPTION BASE

for A05 SCAN/AD

2.2.1.2 Required equipment

Table 2-2-2 shows the equipment to prepare for overall adjustment of the spectrum analyzer.

Table 2-2-2 Required equipment

ManufactureNomenclature

Anritsu

Anritsu

Anritsu

Anritsu

Anritsu

Anritsu

Hewlett Packard

National Instruments Corp.

Synthesized signal generator

Frequency counter

Swept frequency synthesizer

two Power meters

Power sensor

Power sensor

Digital multimeter

GPIB interface board

two 3 dB attenuators

IBM-PC/AT compatible

a printer

Model number

MG3633A

MF76A

6769B

ML4803A

MA4701A

MA4705A

HP3478A

GPIB-PC2/2A

2-9

Page 18

Section 2 MS2665C

2.2.1.3 Circuit reference

This paragraph supplies the exchangeable module list of the spectrum analyzer with its overall circuit diagram.

Table 2-2-3 Exchange modules of the MS2665C

Schematic number

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Options

17

18

19

20

Name Model number Ordering number Note

A01 MOTHER BOARD

A02 FRONT BOARD

A03 CPU

A04 PMC/GPIB

A05 SCAN/AD

A06 IF (B)

A08 LOCAL-A

3GHz CONVERTER

A13 MICRO CONVERTER

A14 1ST LO AMP

21GHz S-ATT

21GHz YTF/SW

H.MIXER

POWER SUPPLY UNIT

TFT LCD MODULE

A09 OPTION BASE

A0501 HI-SPEED AD

A0901 TRIG/GATE

A0902 AM/FM MONITOR

A04 PMC/CENTRONICS

322U12876

322U14223

322U14225

322U12853

34Y112923C

322U13830

322U12849

34Y108179B

34Z110446C

34Z110447

339H37752

329H13289

329H13290

34Z112975

NL3224AC35-01

322U12930

332U36333

322U12979

322U12981

34Y106692B

34Y106673

34Y118357

34Y118358

34Y106693

34Y112923C

34Y106718

34Y106679

34Y108179B

34Y110446C

34Y110447

339H37752

329H13289

329H13290

34Z112975

No1256

34Y106684

34Y106688

34Y106695

34Y106699

34Y106692B

Option 04

Option 06

Option 07

Option 10

To identify a exchange module, a label printed “Model number” is pasted on module.

2-10

Page 19

2.2 Troubleshooting

11

12

10

13

8

11

1

12

9

13

10

7

2-11

Page 20

Section 2 MS2665C

15

16

18

19

17

14

20

15

16

6

18

19

2

4 20

5

17

14

3

2-12

Page 21

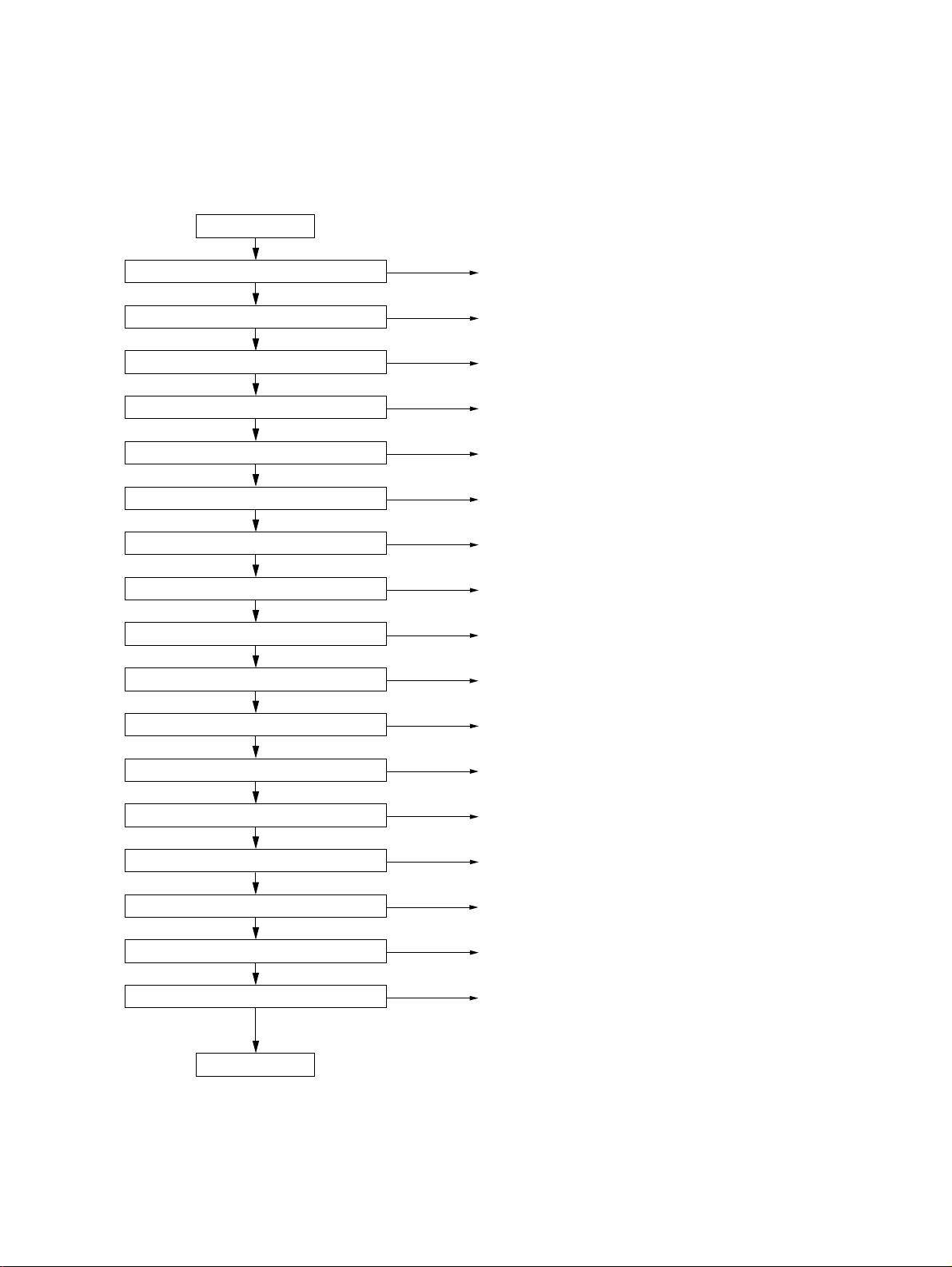

2.2.2 Detecting faulty module

The flowchart shows the way to locate the faulty module among them.

2.2 Troubleshooting

POWER ON

LEDs come on?

The LCD comes on?

Fan Movement?

Key, Rotary knob come on?

Sweeping?

Trace Displayd When signal input?

Freq Display correct?

Level Display correct?

RBW Setting?

VBW Setting?

No

No

No

No

No

No

No

No

No

No

[Location of faulty module]

Fuse, A02 FRONT BOARD, POWER SUPPLY UNIT

A03 CPU, TFT LCD MODULE, POWER SUPPLY UNIT

A02 FRONT BOARD, POWER SUPPLY UNIT

A02 FRONT BOARD, A03 CPU

A05 SCAN/AD, A08 LOCAL-A, A03 CPU

3GHz CONVERTER, A13 MICRO CONVERTER,

21GHz S-ATT, 21GHz YTF/SW, H. MIXER

A08 LOCAL-A, 3GHz CONVERTER

3GHz CONVERTER, A06 IF, A13 MICRO CONVERTER,

21GHz S-ATT, 21GHz YTF/SW, H. MIXER

A06 IF

A05 SCAN/AD

Input A TT Setting?

LOG/LIN Setting?

TRIG Setting?

Det mode Setting?

Display mode Setting?

Hardcopy possible?

Memory Backup?

(Yes)

Normal

No

No

No

No

No

No

No

3GHz CONVERTER

A05 SCAN/AD

A0902 TRIG/GA TE

A05 SCAN/AD

A03 CPU

A03 CPU

A03 CPU

2-13

Page 22

Section 2 MS2665C

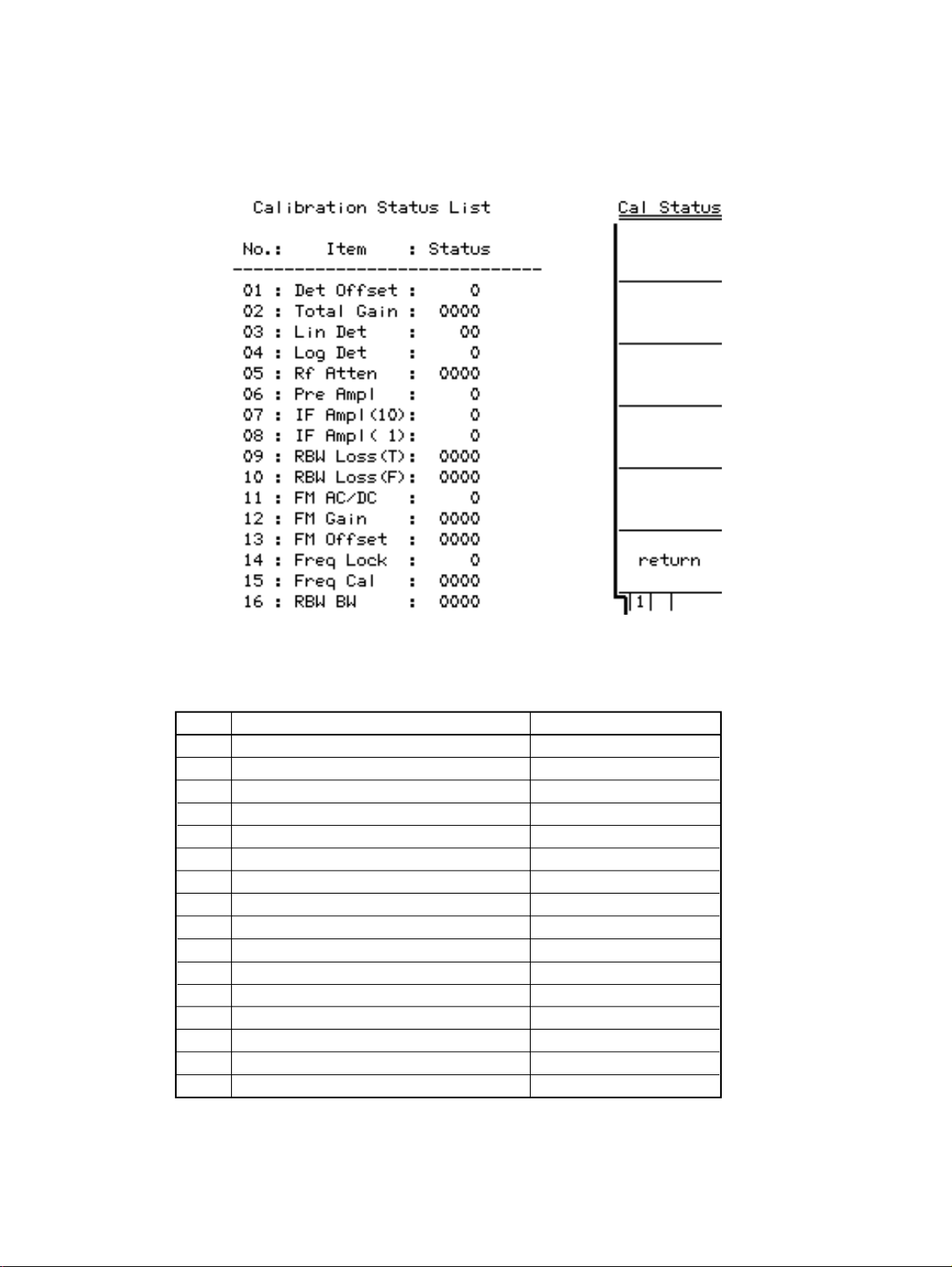

After executing internal calibration, you can locate the faulty module using “Cal Status” (as shown below). “Cal Status”

can be displayed by the key operation : open the second page of Cal menu with “More” key, and press “F5” key.

If error occurred (Status value is not zero), the faulty module corresponding to each item is shown below :

NO.

01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

16

Error item (at the status is not zero )

Det Offset

Total Gain

Lin Det

Log Det

RF Atten

Pre Ampl

IF Ampl (10)

IF Ampl (1)

RBW Loss (T)

RBW Loss (F)

FM DC/AC

FM Gain

FM Offset

Freq Lock

Freq Cal

RBW BW

Faulty module

A05 SCAN/AD

A06 IF

A05 SCAN/AD

A05 SCAN/AD

HR S-ATT

3 GHz PRE AMP

A06 IF

A06 IF

A06 IF

A06 IF

A0902 AM/FM MONITOR

A0902 AM/FM MONITOR

A0902 AM/FM MONITOR

A08 LOCAL-A

A08 LOCAL-A

A06 IF

2-14

Page 23

2.2.3 Disassembling cabinet

Refer to 2.3.1.

2.2.4 Replacement of faulty module

Refer to 2.3.2 to 2.3.5.

2.2 Troubleshooting

2-15

Page 24

Section 2 MS2665C

2.2.5 Adjustment after module replacement

This paragraph describes the overall adjustment required after replacement of any modules in following Table. Look for

modules which you replaced in Table. Please carry out work corresponding to module which you replaced. This adjustment is not necessary, if the module you replaced does not belong to the following Table.

Replaced module

A08 LOCAL-A Carry out 2.2.5.1 and 2.2.5.2.

3GHz CONVERTER Carry out 2.2.5.2 and 2.2.5.3.

A13 MICRO CONVERTER

21GHz YTF/SW

2.2.5.1 Reference crystal oscillator (option 01) adjustment

Remark :

Before this adjustment, leave the spectrum analyzer power-on at least for 6 to 7 hours. This adjustment needs a very high

accuracy frequency standard (10 MHz).

Required equipment :

(1) MG3633A Synthesized signal generator

(2) MF76A Frequency counter

Setup :

MG3633A

to Ref Input

on the rear

Output

to Ref Out

on the rear

MF76A

The spectrum analyzer

to 10 MHz In

on the rear

to 10 MHz

standard signal

2-16

Input

Fig. 2-2-1

Page 25

2.2 Troubleshooting

(1) Connect the spectrum analyzer Buff Out (on its rear panel) to MG3633A REF INPUT (on its rear panel).

(2) Connect the MG3633A OUTPUT to MF76A Input.

(3) Connect the MF76A EREQ STD 10 MHz IN (on its rear panel) to 10 MHz standard signal. And set the EXT/INT

selector switch to EXT.

Procedure :

(1) Set the MG3633A output to :

Center frequency, 1 GHz (CW)

Output level, 0 dBm

(2) Set the MF76A to resolution 1 Hz.

(3) Adjust the “Reference Adjust Screw (Multi-turn potentiometer)” visible through the hole provided on the rear panel

(refer to Fig. 2-2-2) to make the MF76A reading 1,000,000,000 Hz ±5 Hz.

Reference Adjust Screw

Fig. 2-2-2 The location of an adjuster of Reference crystal oscillator

2-17

Page 26

Section 2 MS2665C

2.2.5.2 Sweep adjustment

Required equipment :

(1) 6769B Swept frequency synthesizer,

(2) MG3633A Synthesized signal generator,

(3) HP3478A Digital multimeter.

Setup for the procedure (1), (2) :

MG3633A

Output

Fig. 2-2-3

Connect the spectrum analyzer RF Input to MG3633A OUTPUT.

Setup for the procedure (3) :

(1) Connect digital multimeter HI input to the TP4 terminal on A1306 MICRO DRIVER PC board attached to A13

MICRO CONVERTER.

(2) Connect digital multimeter LO input to the spectrum analyzer’s common.

Setup for the procedure (4), (5), (6) :

The spectrum analyzer

RF Input

6769B

RF Output

Fig. 2-2-4

(1) Connect the spectrum analyzer RF Input to 6769B RF OUTPUT.

The spectrum analyzer

2-18

RF Input

Page 27

Procedure :

(1) Local sweep adjustment

Initialize the spectrum analyzer and the MG3633A.

1) Set the spectrum analyzer to :

Center frequency, 100 MHz

Span, 100 kHz

Set the MG3633A output to :

LEVEL, -10 dBm

Frequency, 100 MHz (CW)

Press “→CF” key of the spectrum analyzer.

2) Set the MG3633A output frequency to 99.96 MHz (CW).

On the spectrum analyzer, press “Peak Search” key, and set the marker function to delta maker mode (Press

“Marker” key and press “F2” key).

3) Set the MG3633A output frequency to 100.04 MHz (CW).

On the spectrum analyzer, press “Peak Search” key, and read the frequency difference between 99.96 MHz input

and 100.04 MHz input.

2.2 Troubleshooting

4) Adjust the variable resistor R96 on A08 LOCAL-A (refer to Fig. 2-2-5) until the reading of frequency difference

becomes 80 kHz ±200 Hz, to repeat the procedure 2), 3).

(2) YTO FM sweep adjustment

Initialize the spectrum analyzer.

1) Set the spectrum analyzer to :

Center frequency, 1000 MHz

Span, 10 MHz

Set the MG3633A output to :

Frequency, 1000 MHz (CW)

Press “→CF” key of the spectrum analyzer.

2) Set the MG3633A output frequency to 996 MHz (CW).

On the spectrum analyzer, press “Peak Search” key, and set the marker function to delta maker mode (Press

“Marker” key and press “F2” key).

3) Set the MG3633A output frequency to 1004 MHz (CW).

On the spectrum analyzer, press “Peak Search” key, and read the frequency difference between 996 MHz input

and 1004 MHz input.

4) Adjust the variable resistor R53 on 3GHz CONVERTER (refer to Fig. 2-2-5) until the reading of frequency

difference becomes 8 MHz ±40 kHz, to repeat the procedure 2), 3).

2-19

Page 28

Section 2 MS2665C

(3) YTF tuning DAC adjustment

1) Turn the spectrum analyzer on, while pushing “0” key, and initialize the spectrum analyzer.

2) Set the spectrum analyzer to zero Span.

3) Enter Cal menu by pushing “Shift + 0” keys. Open the second page of the Cal menu, and enter Maintenance menu

with “F6” key. Enter RF/Micro converter maintenance menu with “F2” key, and open the 6th page of the menu

(Press “More” key 5 times).

4) Set YTF Pre-tuning value to 3600 by pushing “F2” key (assigned YTF Pre-tuning function) and data keys.

5) Adjust the variable resistor R60 on the A13 MICRO CONVERTER (refer to Fig. 2-2-6) to make multimeter

reading -3.600 ±0.005 Volts.

6) Set YTF Pre-tuning value to 7600 by pushing “F2” key.

7) Adjust the variable resistor R57 on the A13 MICRO CONVERTER (refer to Fig. 2-2-6) to make multimeter

reading -7.600 ±0.005 Volts.

8) Repeat the procedure 4), 5), 6), 7) until you get the required voltage corresponding to each YTF Pre-tuning value.

(4) YTF tuning adjustment

1) Initialize the spectrum analyzer (Press “Preset” key and press “F1” key).

2) After 5 seconds waiting, set the spectrum analyzer to :

Center frequency, 2.92 GHz

Zero Span

Set the 6769B output to :

Frequency, 2.92 GHz (CW)

RF LEVEL, -20 dBm

3) Enter Cal menu by pushing “Shift + 0” keys. Enter Pre-selector Tuning menu with “F6” key.

4) Press “F2” key and set Pre-selector bias value to 0, using the data keys or the knob on the front panel.

5) Adjust the variable resistor R22 on A13 MICRO CONVERTER (refer to Fig. 2-2-6) to make displayed signal

level maximum.

6) Set the spectrum analyzer to :

Center frequency, 6.4 GHz

Zero Span

Set the 6769B output to :

Frequency, 6.4 GHz (CW)

RF LEVEL, -20 dBm

2-20

Page 29

2.2 Troubleshooting

7) Enter Cal menu by pushing “Shift + 0” keys. Enter Pre-selector Tuning menu with “F6” key.

8) Press “F2” key and set Pre-selector bias value to 0, using the data keys or the knob on the front panel.

9) Adjust the variable resistor R31 on A13 MICRO CONVERTER (refer to Fig. 2-2-6) to make displayed signal

level maximum.

10) Put the screw of the variable resistor R68 on A13 MICRO CONVERTER (refer to Fig. 2-2-6) center in its rotation

range.

(5) YTO main sweep adjustment

Initialize the spectrum analyzer and the 6769B.

1) Set the spectrum analyzer to :

Center frequency, 1.5 GHz

Span, 3 GHz

Set the 6769B output to :

RF LEVEL, -10 dBm

Frequency, 1.5 GHz (CW)

Press “→CF” key of the spectrum analyzer.

2) Set the 6769B output frequency to 300 MHz.

On the spectrum analyzer, press “Peak Search” key, and set the marker function to delta marker mode (Press

“Marker” key and press “F2” key).

3) Set the 6769B output frequency to 2.7 GHz.

On the spectrum analyzer, press “Peak Search” key, and read the frequency difference between 300 MHz input

and 2.7 GHz input.

4) Adjust the variable resistor R57 on 3GHz CONVERTER (refer to Fig. 2-2-5) until the reading of frequency

difference becomes 2.4 GHz ±6 MHz, to repeat the procedure 2), 3).

5) Initialize the spectrum analyzer (Press “Preset” key and press “F1” key).

Set the 6769B to :

Frequency, 14.2 GHz (CW)

RF LEVEL, -20 dBm

6) Set Pre-selector bias value to 0, according to above-mentioned procedure.

7) Press “Peak Search” key to place marker indicator on the top of 14.2 GHz signal.

8) Adjust the variable resistors R63 and R64 on A13 MICRO CONVERTER (refer to Fig. 2-2-6) to make the signal

level maximum, i.e. increase the level roughly with R63, and then using R64, make it exactly maximum.

2-21

Page 30

Section 2 MS2665C

(6) Confirmation of YTF tuning

Initialize the spectrum analyzer and the 6769B.

1) Set the spectrum analyzer to :

Start frequency, 3 GHz

Stop frequency, 21 GHz

Log Scale, 2 dB

Storage Max Hold (Press “A, B” key, press “F5” key and “F2” key).

2) Set the 6769B to :

F1 frequency, 3 GHz

F2 frequency, 21 GHz

RF LEVEL, -10 dBm

Analog sweep ON

Sweep time, 50 seconds

3) Confirm that the waveform on the analyzer’s display is flat, after the 6769B finishes its 50-second sweeping.

R53, R57

R96

Fig. 2-2-5 The location of adjusters on A08 LOCAL-A and 3GHz CONVERTER

2-22

Page 31

R22, R31, R57, R60, R68

Jumper pin X12

2.2 Troubleshooting

Fig. 2-2-6 The location of adjusters on A13 MICRO CONVERTER

2-23

Page 32

Section 2 MS2665C

2.2.5.3 IF1 (ATT), IF2 (AMP) adjustment

Required equipment :

(1) 6769B swept frequency synthesizer

(2) ML4803A Power meter

(3) MA4705A Power sensor

(4) IBM PC/AT compatible

Setup :

(1) Connect the spectrum analyzer RF Input to 6769B RF OUTPUT

(2) Connect the spectrum analyzer and the personal computer with RS-232C interface

Procedure :

(1) Turn the spectrum analyzer on, while pushing “0” key.

(2) Initialize the spectrum analyzer :

1) Enter Preset menu with “Preset” key,

2) Initialize the spectrum analyzer completely with “F1” key.

(3) Calibrate the spectrum analyzer using its internal calibration function :

1) Enter Cal menu with “Shift” key and “0” key,

2) Calibrate the spectrum analyzer by pushing “F1” key.

[ Mixer harmonic order 1 ]

(4) Set mixing mode to Band 1- :

1) Enter Frequency menu by pressing “Frequency” key, and open its second page with “More” key,

2) Enter Band menu with “F1” key,

3) Set mixing mode to Band 1- by pushing “F3” key.

(5) Set the spectrum analyzer to :

Center frequency, 5.00 GHz

Span, 1 MHz

Set the 6769B output frequency to 5.00 GHz (CW).

(6) Adjust the 6769B output level to make power meter reading -10 dBm at the end of cable feeding the signal to the

spectrum analyzer, and then connect the cable to the spectrum analyzer’s RF Input.

(7) Tune the spectrum analyzer’s pre-selector, using its pre-selector auto tune function :

1) Enter Cal menu with “Shift + 0” key,

2) Enter Pre-selector Tuning menu with “F6” key,

3) Tune the pre-selector by pushing “F1” key.

(8) Read marker level using peak search function (Press “Peak Search” key), and if maker reading is within -10 dBm ±0.2

dB, skip next procedure.

2-24

Page 33

2.2 Troubleshooting

(9) Enter RF/MICRO CONVERTER maintenance menu, and open its 6th page :

1) Enter Cal menu by pushing “Shift + 0” key. Open the second page of the Cal menu,

2) Enter maintenance menu with “F6” key,

3) Enter RF/Micro Converter maintenance menu with “F2” key. Open the 6th page of the RF/Micro Converter

maintenance menu (Press “More” key 5 times).

Adjust IF-Gain 1 and IF-Gain 2 so that the maker reading becomes -10 dBm ±0.2 dB.

[ Mixer harmonic order 2 ]

(10) Set mixing mode to Band 2+ (refer to the procedure (4)).

(11) Set the spectrum analyzer to :

Center frequency, 12.01 GHz

Span, 1 MHz

Set the 6769B output frequency to 12.01 GHz (CW).

(12) Adjust the 6769B output level to make power meter reading -10 dBm at the end of cable, and then connect the cable

to the spectrum analyzer’s RF Input.

(13) Tune the spectrum analyzer’s pre-selector (refer to the procedure (7)).

(14) Read marker level with “Peak Search” key, and if marker reading is not within -10 dBm ±0.2 dB, adjust IF-Gain 1 and

2 to make the reading -10 dBm ±0.2 dB (refer to the procedure (9)).

[ Mixer harmonic order 3 ]

(15) Set mixing mode to Band 3+ (refer to the procedure (4)).

(16) Set the spectrum analyzer to :

Center frequency, 18.201 GHz

Span, 1 MHz

Set the 6769B output frequency to 18.201 GHz.

(17) Adjust the 6769B output level to make -10 dBm with power meter at the end of cable, and then connect the cable to the

spectrum analyzer’s RF Input.

(18) Tune the spectrum analyzer’s pre-selector (refer to the procedure (7)).

(19) Read the marker level with “Peak Search” key, and if marker reading is not within -10 dBm ±0.2 dB, adjust IF-Gain

1 and 2 to make the reading -10 dBm ±0.2 dB (refer to the procedure (9)).

2-25

Page 34

Section 2 MS2665C

(20) Write the compensation value of adjusted IF-Gain 1 and IF-Gain 2 to the spectrum analyzer’s Flash Memory with

Flash Memory writing command “CDW” from personal computer. For example :

CMD > MENTE P2110 ON

CMD > CD40 1, 0

CMD > CD41 1, 3

CMD > CD40 2, 0

CMD > CD41 2, 17

CMD > CD40 3, 0

CMD > CD41 3, 30

CMD > CDW

, where

line 1 makes the spectrum analyzer maintenance mode ON.

<CD40 n, m> is IF-Gain 1 setting statement. “n” is a mixer harmonic order number. “m” is a compensation value in

procedure (9), (14), (19) (0 to 255 integer).

Similarly, <CD41 n, l> is IF-Gain 2 setting statement. “l” is the compensation value (0 to 255 integer).

2.2.6 Assembling cabinet

Refer to 2.3.1.

2.2.7 Checking items after assembling cabinet

After switching the power on, check for the following faults.

(1) No burning smell and/or smoke.

(2) Fan rotates

(3) No strange sounds.

After checking the above items, make sure the original defect has been repaired.

2-26

Page 35

2.2 Troubleshooting

2.2.8 Frequency response compensation

Perform Frequency response compensation, when one of the following modules is replaced. This Frequency response

compensation is not necessary, if the module you replaced does not belong to the following modules.

• A03 CPU • 21GHz S-ATT

• 3GHz CONVERTER • 21GHz YTF/SW

• A13 MICRO CONVERTER • H. MIXER

• A14 1st LO AMP

Frequency response caused by front-end components such as step attenuator, low pass filter and mixer is corrected by

measuring the response and storing the data in instrument’s memory.

Frequency response compensation process consists of four steps that are performed semi-automatically with “Frequency

Response Compensation” software. The four steps are as follows :

1. DUT (Device Under Test) check,

2. Signal source power output calibration with power meter,

3. Frequency response measurement using the calibrated power output,

4. Compensation data updating.

Required instrument :

(1) 6769B Swept Frequency Synthesizer

(2) MG3633A Synthesized Signal Generator

(3) two ML4803A Power Meters

(4) MA4705A Power Sensor

(5) MA4601A Power Sensor

(6) two 3 dB attenuators

(7) IBM-PC/AT compatible for controller

(8) GPIB-PC2/2A

(9) ML2437A Power Meter (for MS2667C and MS2668C)

(10) MA2444A Power Meter (for MS2667C and MS2668C)

Required software :

(1) MS-DOS Ver. 5.0 or later and Windows 3.1, or Windows 95

(2) Frequency Response Compensation software.

2-27

Page 36

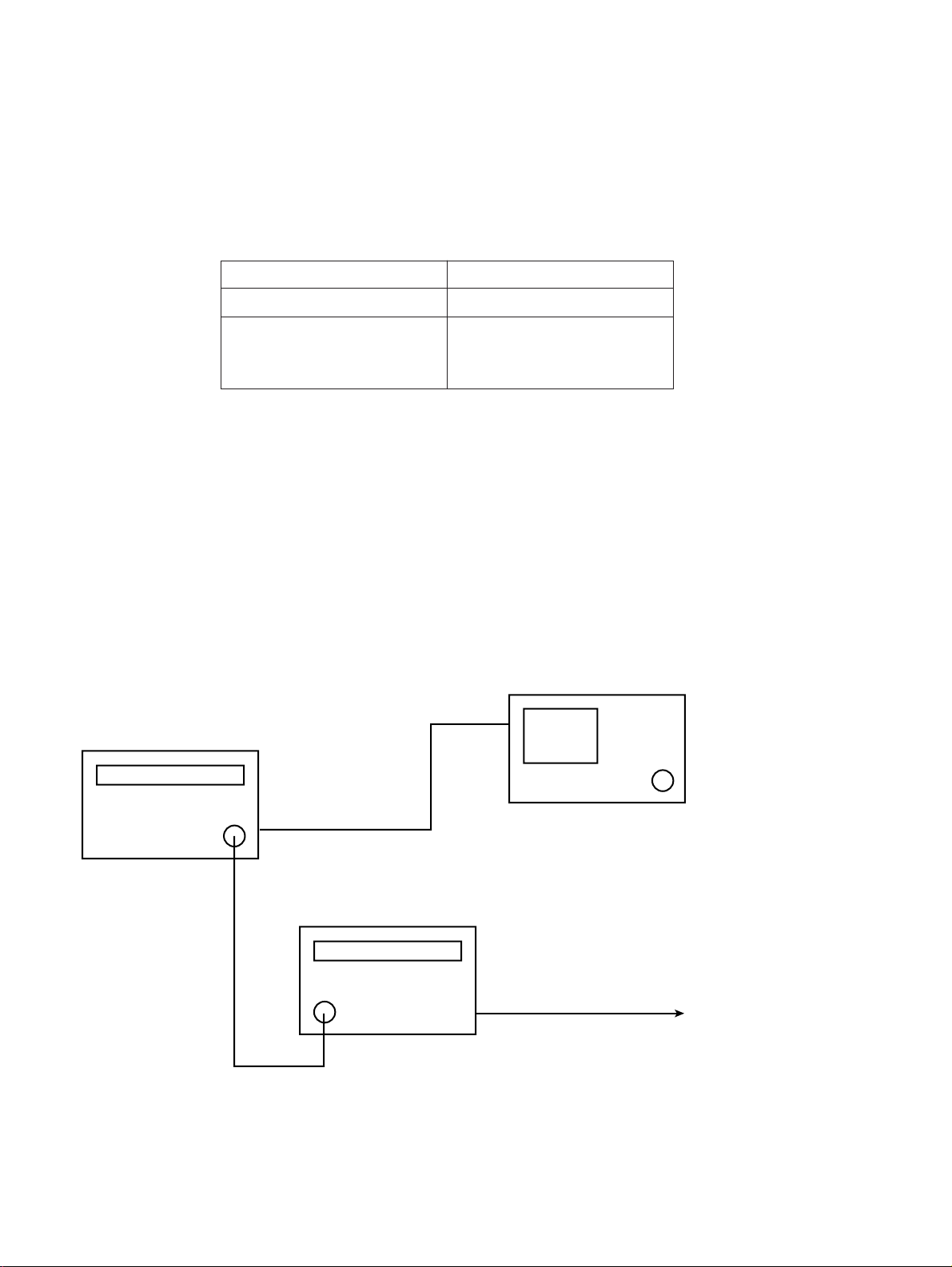

Section 2 MS2665C

Setup :

IBM-PC/AT Compatible

GP-IB control

The spectrum analyzer

6769B

3 dB

attenuator

MG3633A

RF Output

RF Input

Power meter :

ML4803A (for MS2665C)

ML2437A (for MS2667/68C)

3 dB

attenuator

Power sensor :

MA4705A (for MS2665C)

MA2444A (for MS2667/68C)

OUTPUT

ML4803A

2-28

Power sensor : MA4601A

Fig. 2-2-7

Page 37

2.2 Troubleshooting

(1) At the measurement of frequency response, connect the spectrum analyzer’s RF Input to 6769B RF OUTPUT through

a signal feeder. The signal feeder consists of a coaxial cable (e.g. SUCOFLEX) less than 1 m length and two 3 dB

attenuators attached to each end of the cable.

(2) At the calibration of power output, connect the end of the feeder to power sensor.

Note that 1) the coaxial cable and 3 dB attenuators must be with a frequency range over the spectrum analyzer’s range,

2) use a torque wrench for tightening each connection, 3) do not disconnect the connections of the 6769B and the

signal feeder after the power calibration in order to keep the measured data valid.

Procedure :

Note that the spectrum analyzer (DUT) and the measuring instruments must be warmed up at least for an hour, before the

compensation process.

(1) Run the Frequency Response Compensation program, and then confirm that 6769B output is set to 10 MHz (CW).

(2) After 5 minutes waiting or more, input the serial number of the spectrum analyzer to the personal computer.

(3) Execute “DUT Check” by pushing the button on the PC display.

(4) After internal calibration of the spectrum analyzer, confirm that the spectrum analyzer’s “Cal Status” is all zero.

(5) Carry out zero adjustment and sensor sensitivity adjustment on the power meter, and then connect the MA4601A

power sensor to the end of the cable from MG3633A OUTPUT.

(6) Set MG3633A output to 625 kHz (CW), and adjust the output level so that power meter reading becomes 0 dBm at the

end of the cable, and then connect this end to the spectrum analyzer RF Input.

(7) After “Preset All”, set the spectrum analyzer to :

Center frequency, 625 kHz

Span, 50 kHz

RBW, 10 kHz

VBW, 1 kHz

Atten, 10 dB

Reference Level, 0 dBm

(8) On the spectrum analyzer’s display, read the marker level of 625 kHz signal, and input the reading to “625 kHz CAL

OSC Level” space on the PC display. For example: when marker reading is 0.30 dBm, input “0.30” to the space.

2-29

Page 38

Section 2 MS2665C

(9) Measure the 6769B power output with “6769B output calibration” program.

1) Connect the 6769B RF OUTPUT to the MA4601A (for MS2665C) or MA2444A (for MS2667/68C) through a

signal feeder. The signal feeder consists of a coaxial cable (e.g. SUCOFLEX) less than 1 m length and two 3 dB

attenuators attached to each end of the cable. Note : Use a torque wrench for tightening each connection.

2) Run the “6769B output calibration” program by pushing the button on the PC display.

3) Change the power sensor for the MA4705A according to PC message. (for MS2665C only)

4) Before going to next step, leave the 6769B at least for 5 minutes after the program stopping.

Note that 1) The connections of the 6769B and the signal feeder must not be disconnected after the measurement

in order to keep the measured data valid, 2) this measurement is needed once a day, as long as the 6769B is power

on.

(10) Connect the end of the signal feeder to the spectrum analyzer RF Input.

(11) Run “Frequency Response Measurement” program with the button on the PC display.

(12) Write frequency response compensation data into the spectrum analyzer’s memory with the button on the PC display.

2-30

Page 39

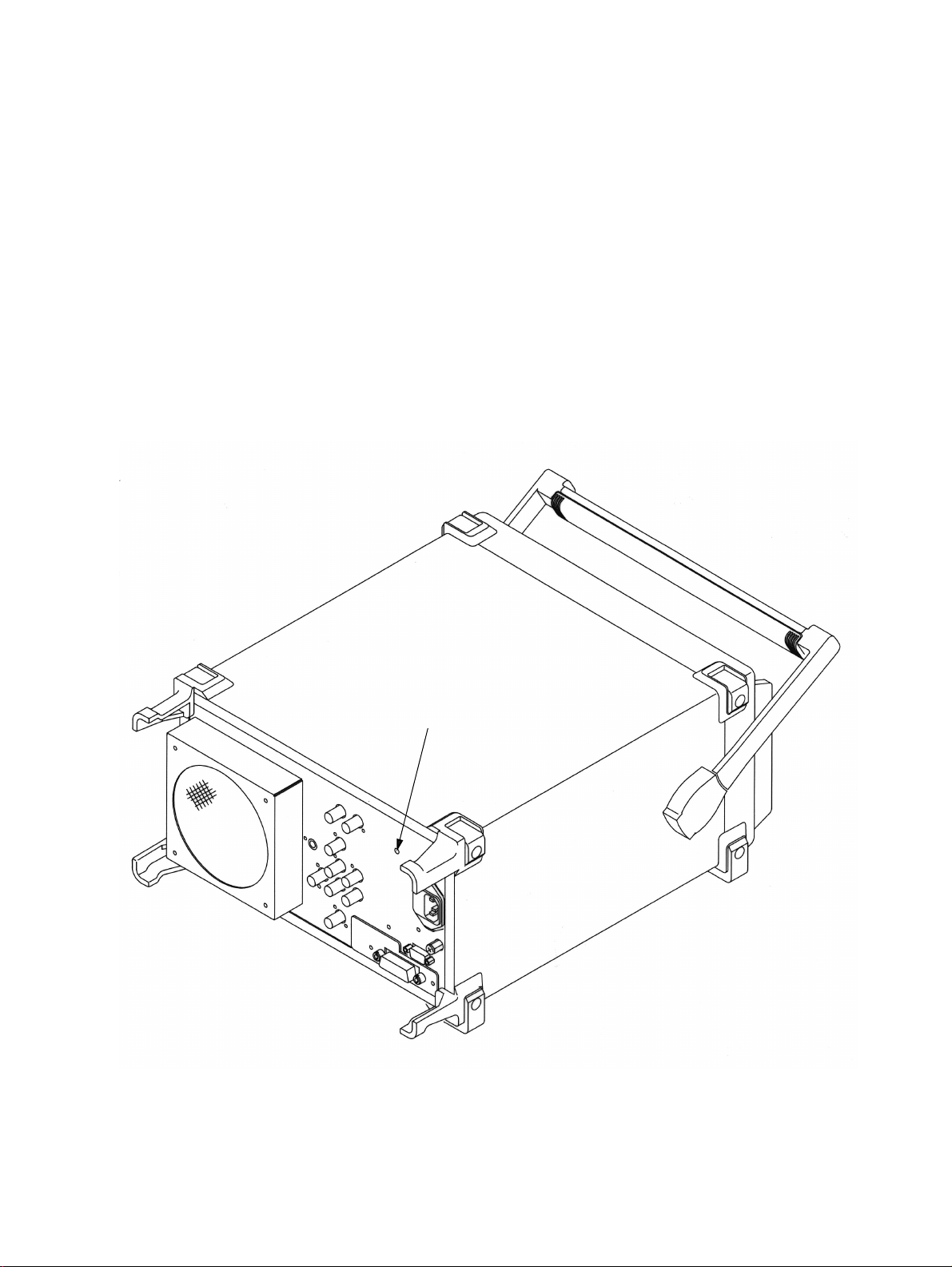

2.3 Mechanical configuration

2.3.1 Disassembling/Assembling cabinet

(1) Removing Feet (1 to 8)

Remove the S1/S2/S3 screws and remove the S3 screw of the rear.

(2) Removing around cover

Remove the four S1 screws (1 to 4) and remove the S3 screw of the rear.

Remove the around cover 10 to pull backward.

(3) Removing Front Frame

After (1) removing procedure, remove the 11 to pull forward.

To assemble, perform inversely.

Parts List

1

32E11805A Front foot

2

32E11805B Front foot

3

32E11806A Front foot Receiver

4

32E11806B Front foot Receiver

5

32E11807A Rear foot

6

32E11807B Rear foot

7

32E11808A Rear foot Receiver

8

32E11808B Rear foot Receiver

9

34Y107601 Tilt handle 3/4MW

10

333B35279 Around cover assembly

11

32E13058 Front frame

10

11

2.3 Mechanical configuration

2-31

Page 40

Section 2 MS2665C

2-32

Page 41

2.3 Mechanical configuration

Fig. 2-3-1

2-33

Page 42

Section 2 MS2665C

2-34

Page 43

2.3.2 Removing/Assembling units and PC boards

2.3 Mechanical configuration

(1) Removing MICRO CONVERTER 4 and 1ST LO AMP

5

After removing the screws and each cables, remove the 4 5 to pull backward.

(2) Removing Step Attenuator 3 Band ATT Angle

2

After removing the S1/S2 screws, remove the 2 3.

(3) Removing 21 GHz YTF/SW

After removing the Angle 8, remove the

(4) Removing PMC/GPIB 18 and CPU board

7

7

17

After removing the S3 screw, remove the 17 18 to pull backward.

To assemble, perform inversely.

Parts List

1

34J107713 N-J SMA-P Adapter

2

332B36744B ATT Angle

3

339H37752 21GHz Step Attenuator

4

34Y110446C A13 MICRO CONVERTER

5

34Y110447 A14 1ST LO AMP

6

329H13290 H.MIXER

7

329H13289 21GHz YTF/SW

8

34B111361 Angle

9

33B38019 Plate

10

34J110924 Semi-rigid cable

11

439H32078 SMA-Attenuator

12

34J117955 Semi-rigid cable

13

33J41281 Semi-rigid cable

14

33J41282 Semi-rigid cable

15

34J110713 Semi-rigid cable

16

34J117700 Semi-rigid cable

17

34Y106690 A03 CPU

18

34Y106693 A04 PMC/GPIB

or 34Y106692B or A04 PMC/CENTRONICS

2-35

Page 44

Section 2 MS2665C

2-36

Page 45

2.3 Mechanical configuration

Fig. 2-3-2

2-37

Page 46

Section 2 MS2665C

5

15

4

S2

2

10

7

13

11

6

12

18

9

16

17

1

S1

S3

2-38

Fig. 2-3-3

Page 47

2.3.3 Front unit disassembly/assembly

Removing TFT LCD MODULE

(1) After removing the S1, S2 screws and encoder knob 5, remove the front panel 1.

(2) After removing the S3 screw, remove the 2, 3 and 4 to pull forward.

(3) After removing the S4 screw and each cables, remove the LCD 2.

To assemble, perform inversely.

Parts List

1

322B13049 Front panel

2

No1256 TFT LCD MODULE

3

332B40222 LCD panel

4

322B13048 Front cover

5

33E32858 Encoder knob

6

34Y106676 A02 FRONT BOARD

7

34Y106673 A01 MOTHER BOARD

2.3 Mechanical configuration

2-39

Page 48

Section 2 MS2665C

2-40

Page 49

S1

2.3 Mechanical configuration

7

4

S4

3

S3

2

1

6

5

S2

Fig. 2-3-4

2-41

Page 50

Section 2 MS2665C

2-42

Page 51

2.3.4 A09 OPTION BASE disassembly/assembly

Parts List

1

34Y106684 A09 OPTION BASE

2

34Y106695 A0901 TRIG/GATE

3

34Y106699 A0902 AM/FM MONITOR

4

34Y106697 A0903 TV MONITOR

5

34Y113473 A0904 QP DETECTOR

or 34Y117105

2.3 Mechanical configuration

2-43

Page 52

Section 2 MS2665C

2-44

Page 53

2.3 Mechanical configuration

3

2

4

1

5

Fig. 2-3-5

2-45

Page 54

Section 2 MS2665C

2-46

Page 55

2.3 Mechanical configuration

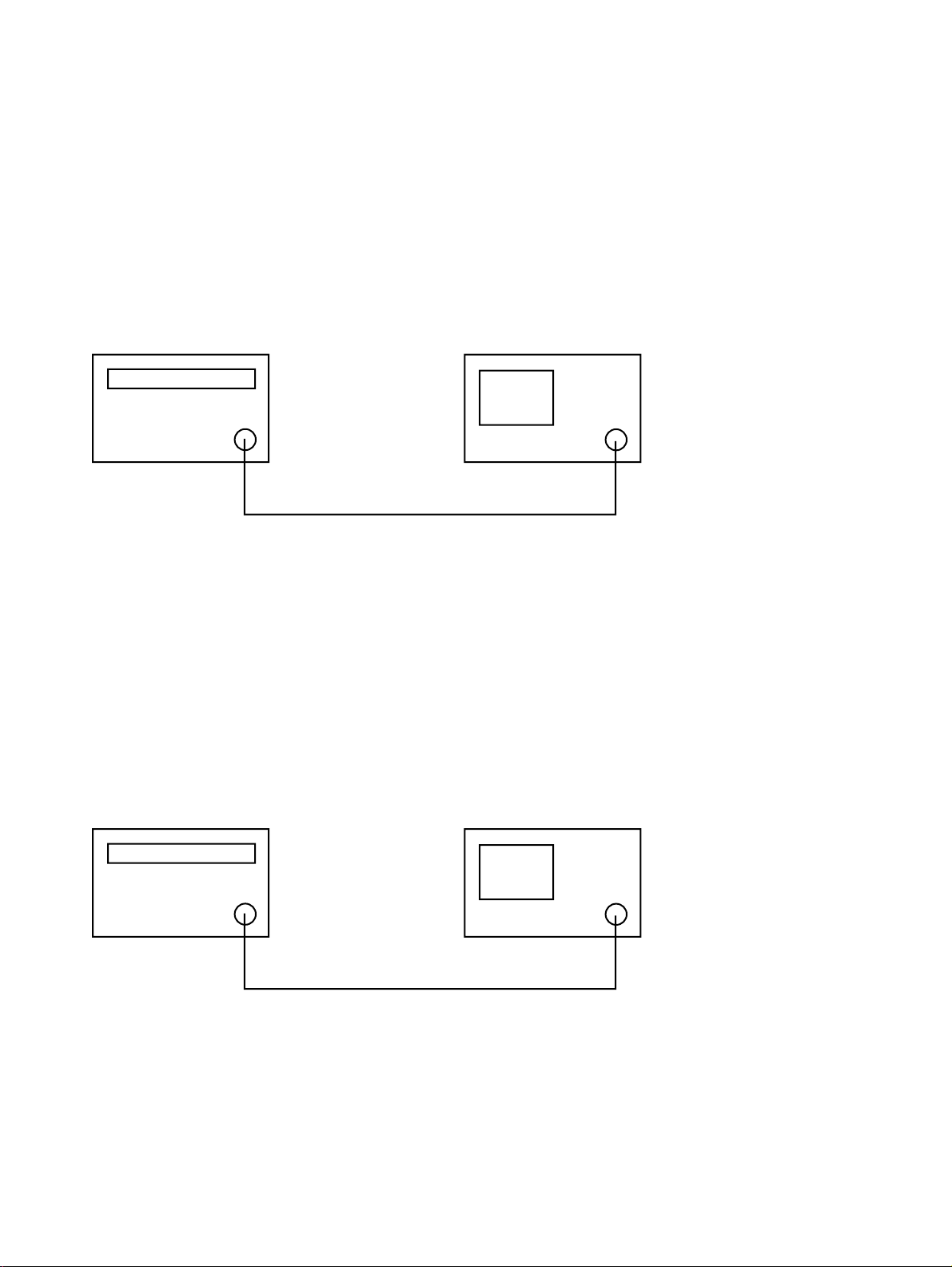

2.3.5 Removing/Assembling A0501 HI-SPEED AD from A05 SCAN/AD

Parts List

1

34Y112923A A05 SCAN/AD

or 34Y112923C

2

34Y106688 A0501 HI-SPEED AD

2

1

Fig. 2-3-6

2-47

Page 56

Section 2 MS2665C

2-48

.

Page 57

Section 3 MS2667C

3.1 Overall Circuit description ......................................................... 3-2

3.2 Troubleshooting......................................................................... 3-9

3.2.1 Introduction .................................................................... 3-9

3.2.1.1 Service kit ......................................................... 3-9

3.2.1.2 Required equipment ......................................... 3-9

3.2.1.3 Circuit reference ............................................... 3-10

3.2.2 Detecting faulty module ................................................. 3-15

3.2.3 Disassembling cabinet................................................... 3-16

3.2.4 Replacement of faulty module ....................................... 3-16

3.2.5 Adjustment after module replacement ........................... 3-16

3.2.5.1 Reference crystal oscillator adjustment .......... 3-16

3.2.5.2 Sweep adjustment .......................................... 3-16

3.2.5.3 IF Gain-1 (ATT), IF Gain-2 (AMP) of Internal

Mixer Band adjustment.................................... 3-26

3.2.5.4 IF Gain-1 (ATT), IF Gain-2 (AMP) of External

Mixer Band adjustment.................................... 3-30

3.2.6 Assembling cabinet........................................................ 3-32

3.2.7 Checking items after assembling cabinet ...................... 3-32

3.2.8 Frequency response compensation .............................. 3-32

3.3 Mechanical configuration........................................................... 3-33

3.3.1 Disassembling/Assembling cabinet ............................... 3-33

3.3.2 Removing/Assembling units and PC boards ................. 3-37

3.3.3

3.3.4 Disassembling/Assembling Units and Components on

3.3.5 Front unit disassembly/assembly................................... 3-51

3.3.6 OPTION BASE disassembly/assembly ......................... 3-55

3.3.7 Removing/Assembling A0501 HI-SPEED AD

3.3.8 Connecting the cable to Diplexing Bandswitch

Disassembling/Assembling Components around RF Input .....

lower surface ................................................................. 3-45

from SCAN/AD............................................................... 3-59

and F2626 (YTF) ........................................................... 3-60

3-41

3-1

Page 58

Section 3 MS2667C

3.1 Overall Circuit description

MS2667C is a superheterodyne system scanning-type spectrum analyzer.

This section describes overall circuit of the MS2667C spectrum analyzer with its block diagram.

An RF input signal after passing through an RF switch and variable RF ATTN in Switched Attenuator is switched by

Diplexing Bandswitch to two different signal routes depending on input RF frequency.

For an RF input frequency of 9 kHz to 3.1 GHz (termed as band 0), the signal passes through 3.2 GHz LPF and then to 1st

mixer (1st MIX), where it is mixed with 1st local signal (4.1 GHz to 7.2 GHz) to generate 4110.69 MHz 1st IF signal.

The 1st IF signal is then passed through an amplifier and image rejection filters, and fed to 2nd mixer (2nd MIX), where it

is mixed with 4 GHz 2nd local signal to generate 110.690 MHz 2nd IF signal.

For an RF input frequency of 3.1 GHz to 30 GHz (band 1 to 5), the signal goes to YTF (YIG tuned filter), and then to 30

GHz H.MIXER. In 30 GHz H.MIXER, the RF signal gets mixed with the 1st local signal (3.6 GHz to 7.5 GHz) to generate

689.31 MHz 1st IF signal.

This 1st IF signal is passed through a series of amplifiers and image rejection filters before further mixing with 800 MHz

2nd local signal to convert the signal to the 110.690 MHz 2nd IF signal.

Depending on the active band of RF input, one of the two above 2nd IF signal is sent to IF section for further processing.

The 1st local signal generated at YTO (YIG tuned oscillator) is frequency-swept by scan signal from SCAN/AD section

after phase-lock to reference signal (its frequency is 11 MHz to 14 MHz with the resolution of 1 Hz steps) generated on

LOCAL-SP1, 2 section at the center frequency of its sweeping range, in normal sweep condition.

The YTO output is passed through an amplifier, and then divided into three paths with directional couplers. One of divided

signal is fed to sampler circuit and the other are fed to the above mixers to frequency-convert.

In the sampler circuit, sampling signal (its frequency is 94 MHz to 106 MHz with the resolution of 1 MHz steps) generated

on LOCAL-SP1, 2 section is frequency-multiplied, and then mixed with the YTO output to generate sampler IF signal with

a frequency of 11 MHz to 14 MHz.

The sampler IF signal is compared with the reference signal of 11 MHz to 14 MHz at PFD.

The reference signal frequency (fREF) and the sampling signal frequency (fs) are controlled by CPU section according to

the measuring frequency of the instrument, and set so that the center frequency of 1st local signal is fs * N ± fREF (, where

N is an integer).

Meanwhile, the scan signal strength that is equivalent to frequency sweep width is controlled from LOCAL-SP1, 2 section.

The 2nd local signals of 4 GHz and 800 MHz are also phase-locked to 100 MHz VCXO signal, of which the frequency is

also phase-locked to 10 MHz crystal oscillator.

In the instrument, a high accuracy 625 kHz signal is present for level accuracy calibration. This signal is generated by

frequency-dividing the 10 MHz reference signal, and its power level is varied with 1 dB steps by CAL ATT.

Internal calibration operation being carried out, this calibrating signal is fed to the RF signal-route through the switch in

Switched Attenuator.

3-2

Page 59

3.1 Overall Circuit description

At the IF section the incoming signal is divided into two paths. The main route leads to image rejection filters while the

second, a highly attenuated feeler path signal is used for generation of wide band trigger signal in TRIG/GATE section

(option 06) situated on OPTION BASE board.

The main signal after passing through an image rejection filter is beat down to a 10.69 MHz signal using a 100 MHz

reference signal. This signal is then sent to various Resolution Band Width (RBW) setting circuits.

For RBW setting of 30 Hz to 200 Hz the signal is frequency converted to 450 kHz using 10.24 MHz signal. After passing

through the RBW circuits (Crystal filter circuits) the signal is up converted back to 10.690 MHz signal and passed through

wider RBW setting circuits. For RBW setting of 300 Hz to 3 MHz the signal is sent directly to wide RBW setting circuits

without any frequency modifications.

The RBW processed signal is passed onto SCAN/AD section, where it passes through logarithmic amplifiers and then to a

linear detector. This linear detected signal is passed through smoothing filters called Video Band Width Filters (VBW).

This smoothed signal is then passed through Positive or Negative peak detection circuits and the output is converted to

digital signal by a Analog to Digital Converter (ADC) circuit.

The results are then written (in digital word format) to a Dual Port RAM through one of the ports.

The CPU of the instrument on CPU section reads from the other port of Dual Port RAM and processes the data before

displaying on the LCD screen. The CPU also controls various interface functions such as reading the Key Inputs or remote

control commands received, and various outputs such as prints or plots of various data. The CPU also generates various

commands required for controlling or setting of all hardware units inside the instrument.

FRONT BOARD section generates the KEY and rotary-knob encoder data, drives the LEDs, detects the power switch

(PWR SW) setting, controls the power-supply On/Stby setting, and supplies power for the LCD backlight, etc.

3-3

Page 60

Section 3 MS2667C

3-4

Page 61

3.1 Overall Circuit description

3-5

Page 62

Section 3 MS2667C

3-6

Page 63

3.1 Overall Circuit description

3-7

Page 64

Section 3 MS2667C

3-8

Page 65

3.2 Troubleshooting

3.2.1 Introduction

This section describes how to troubleshoot the MS2667C.

3.2.1.1 Service kit

Refer to 2.2.1.1.

3.2.1.2 Required equipment

Table 3-2-1 shows the equipment to prepare for overall adjustment of the spectrum analyzer.

Table 3-2-1 Required equipment

3.2 Troubleshooting

Synthesized signal generator

Frequency counter

Swept frequency synthesizer

Power meter

Power sensor

Power meter

Power sensor

Adapter (K female to K female)

Digital multimeter

GPIB interface board

two 3 dB attenuators

IBM-PC/AT compatible

a printer

Model number

MG3633A

MF76A

6769B

ML4803A

MA4601A

ML2437A

MA2444A

K222B

HP3478A

GPIB-PC2/2A

41KC-3

ManufactureNomenclature

Anritsu

Anritsu

Anritsu

Anritsu

Anritsu

Anritsu

Anritsu

Anritsu

Hewlett Packard

National Instruments Corp.

Anritsu

3-9

Page 66

Section 3 MS2667C

3.2.1.3 Circuit reference

This paragraph supplies the exchange module list of the spectrum analyzer with its overall circuit diagram.

Table 3-2-2 Exchange Modules of MS2667C

Schematic number Name Model name

10

11

12

13

14

15

16

17

18

1

2

3

4

5

6

7

8

9

MOTHER BOARD

A02 FRONT BOARD

A03 CPU

A04 PMC/GPIB

SCAN/AD

IF(B)

LOCAL-SP2

LOCAL-SP1

RF CONVERTER

2nd CONVERTER

1ST LO AMP

AK-AKF PANEL CONNECTOR

Switched Attenuator

Diplexing Bandswitch

OPEN LOOP YIG FILTER

30GHz YTF

30GHz H.MIXER

POWER SUPPLY UNIT

TFT LCD MODULE

OPTION BASE

MM200013A

322U14223

322U14225

322U12853

MM200014A

MM200015A

MM200016A

MM200017A

MM200019A

MM200020A

MM200022B

MM200021A

B46790

D29638

D29870

F2626

MM200001A

339H41184B

34Z114508

NL3224AC35-01

MM200018A

Ordering number

34Y115415

34Y118357

34Y118358

34Y106693

34Y112923D

34Y106718B

34Y111112B

34Y111111B

34Y117226

34Y117228

34Y117228B

34Y118007

B46790

D29638

D29870

34Y117225

339H41853

339H41184B

34Z114508

No1256

34Y106684B

Note

Order both

numbers

*pair 1

*pair 2

*pair 1

*pair 2

Options

19

20

21

22

To identify a exchange module, a label printed “Model number” is pasted on module.

Remark :

1. MS2667C has two kinds of YTF as exchange module. When you replace a YTF, check YTF model according to

following procedure.

(1) Keep key “0” depressed while switching on the spectrum analyzer.

(2) Enter RF/Micro Conv maintenance menu.

1) Enter Cal menu by pushing “Shift” + “0” keys. Open second page of Cal menu by pushing “more”.

2) Enter maintenance menu with “F6” (Maintenance) key.

(3) Press “F1” (Version & options) keys.

A0501 HI-SPEED AD

A0901 TRIG/GATE

A0902 AM/FM MONITORA

A04 PMC/CENTRONICS

332U36333

34Y106695B

34Y106699B

34Y106692B

34Y106688

34Y106695B

34Y106699B

34Y106692B

Option 04

Option 06

Option 07

Option 10

3-10

Page 67

3.2 Troubleshooting

(4) Press Key “more” 3 times. MAINTENANCE (4/4) page appears. Check YTF model. If “09 : YTF MODEL” is

not indicated, order “F2626”.

If “09 : YTF MODEL” is indicated, order same model which is indicated.

YTF Model

2. 2nd Converter (Schematic number 9) and YTF (Schematic number 14) forms a pair.

*pair 1 : MM200020A (34Y117228) and F2626 (34Y117225)

*pair 2 : MM200022B (34Y117228B) and MM200001A (339H41853)

When you replace a YTF, make sure to order the same model number.

When you replace 2nd Converter, Check model number of YTF (easily visible) and make sure to order it’s matching

pair.

3. When you replace a A02 FRONT BOARD or A03 CPU, check circuit board number (322U******) of A03 CPU.

If circuit board number of A03 CPU is 322U13903, make sure to order A02 FRONT BOARD (322U14223) and A03

CPU (322U14225).

If circuit board number of A03 CPU is 322U14225, make sure to order one module which you replace.

3-11

Page 68

Section 3 MS2667C

3-12

Page 69

3.2 Troubleshooting

13

10

14

15

12

11

12

13

14

15

8

1

9

7

7

10

3-13

Page 70

Section 3 MS2667C

17

19

20

18

16

21

2

17

6

18

20

21

19

5

16

3

4

3-14

Page 71

3.2.2 Detecting faulty module

The flowchart shows the way to locate the faulty module among them.

3.2 Troubleshooting

POWER ON

LEDs come on?

The LCD comes on?

Fan Movement?

Key, Rotary knob come on?

Sweeping?

Trace Displayd When signal input?

Freq Display correct?

Level Display correct?

RBW Setting?

VBW Setting?

No

No

No

No

No

No

No

No

No

No

[Location of faulty module]

Fuse, A02 FRONT BOARD, POWER SUPPLY UNIT

A03 CPU, TFT LCD MODULE, POWER SUPPLY UNIT

POWER SUPPLY UNIT

A02 FRONT BOARD, A03 CPU

SCAN/AD, LOCAL-SP2, LOCAL-SP1, A03 CPU

RF CONVERTER, 2nd CONVERTER,

Switched Attenuator, Diplexing Bandswitch, YTF, 30GHz H.MIXER

LOCAL-SP2, LOCAL-SP1, RF CONVERTER

RF CONVERTER, IF, 2nd CONVERTER,

Switched Attenuator, Diplexing Bandswitch, YTF, 30GHz H.MIXER

IF

SCAN/AD

Input A TT Setting?

LOG/LIN Setting?

TRIG Setting?

Det mode Setting?

Display mode Setting?

Hardcopy possible?

Memory Backup?

(Yes)

Normal

No

No

No

No

No

No

No

RF CONVERTER, Switched Attenuator

SCAN/AD

A0902 TRIG/GA TE

SCAN/AD

A03 CPU

A03 CPU

A03 CPU

3-15

Page 72

Section 3 MS2667C

3.2.3 Disassembling cabinet

Refer to 3.3.1.

3.2.4 Replacement of faulty module

Refer to 3.3.2 to 3.3.8.

3.2.5 Adjustment after module replacement

This paragraph describes the overall adjustment required after replacement of any modules in following Table. Look for

modules which you replaced in Table. Please carry out work corresponding to module which you replaced. This adjustment is not necessary, if the module you replaced does not belong to the following Table.

Replaced module

LOCAL-SP2 and LOCAL-SP1 Carry out 3.2.5.1 and 3.2.5.2.

RF CONVERTER Carry out 3.2.5.2 and 3.2.5.3.

OPEN LOOP YIG FILTER (F2626)

30GHz YTF

2nd CONVERTER Carry out 3.2.5.2 to 3.2.5.4.

30GHz H.MIXER Carry out 3.2.5.3.

A03 CPU Carry out 3.2.5.3 and 3.2.5.4.

3.2.5.1 Reference crystal oscillator adjustment

Refer to 2.2.5.1.

3.2.5.2 Sweep adjustment

Required equipment :

(1) 6769B Swept frequency synthesizer

(2) MG3633A Synthesized signal generator

(3) HP3478A Digital multimeter

3-16

Page 73

Setup for the procedure (1), (2) :

3.2 Troubleshooting

MG3633A

Output

Fig. 3-2-1

Connect the spectrum analyzer RF Input to MG3633A OUTPUT.

Setup for the procedure (3) :

(1) Connect digital multimeter HI input to the X3 terminal on LOCAL-SP2 PC board. (Refer to Fig. 3-2-4)

(2) Connect digital multimeter LO input to the spectrum analyzer’s common.

Setup for the procedure (4) :

(1) Connect digital multimeter HI input to the X21 terminal on LOCAL-SP2 PC board. (Refer to Fig. 3-2-4)

(2) Connect digital multimeter LO input to the spectrum analyzer’s common.

The spectrum analyzer

RF Input

Setup for the procedure (5) :

(1) Connect digital multimeter HI input to the X3 terminal on A1307 YTF DRIVER PC board attached to 2nd CON-

VERTER. (Refer to Fig. 3-2-5)

(2) Connect digital multimeter LO input to the spectrum analyzer’s common.

Setup for the procedure (6), (7) :

(1) Check model of YTF on lower surface.

(2) Set jumper pins, X10 and X12 on A1307 YTF DRIVER PC board attached to 2nd CONVERTER, to YTF model side

which you checked at (1). (Refer to Fig. 3-2-5 )

Example : When YTF model is “F2626”, jumper pins are set as follows.

F2626

F2626

MM200001A

X10

1313

(X11) (X13)

MLFP1312

(F2726)

MLFP-1312

(F2726)

Jumper pins

X12

MM200001A

Fig.3-2-2

3-17

Page 74

Section 3 MS2667C

(3) Connect the spectrum analyzer RF Input to 6769B RF OUTPUT.

6769B

RF Output

The spectrum analyzer

RF Input

Fig. 3-2-3

3-18

Page 75

Procedure :

(1) Local sweep adjustment

Initialize the spectrum analyzer and the MG3633A.

1) Set the spectrum analyzer to :

Center frequency, 100 MHz

Span, 100 kHz

Set the MG3633A output to :

LEVEL, -10 dBm

Frequency, 100 MHz (CW)

Press “→CF” key of the spectrum analyzer.

2) Set the MG3633A output frequency to 99.96 MHz (CW).

On the spectrum analyzer, press “Peak Search” key, and set the marker function to delta maker mode (Press

“Marker” key and press “F2” key).

3) Set the MG3633A output frequency to 100.04 MHz (CW).

On the spectrum analyzer, press “Peak Search” key, and read the frequency difference between 99.96 MHz input

and 100.04 MHz input.

3.2 Troubleshooting

4) Adjust the variable resistor R123 on LOCAL-SP2 (refer to Fig. 3-2-4) until the reading of frequency difference

becomes 80 kHz ±200 Hz, to repeat the procedure 2), 3).

(2) YTO FM sweep adjustment

Initialize the spectrum analyzer.

1) Set the spectrum analyzer to :

Center frequency, 1000 MHz

Span, 10 MHz

Set the MG3633A output to :

Frequency, 1000 MHz (CW)

Press “→CF” key of the spectrum analyzer.

2) Set the MG3633A output frequency to 996 MHz (CW).

On the spectrum analyzer, press “Peak Search” key, and set the marker function to delta maker mode (Press

“Marker” key and press “F2” key).

3) Set the MG3633A output frequency to 1004 MHz (CW).

On the spectrum analyzer, press “Peak Search” key, and read the frequency difference between 996 MHz input

and 1004 MHz input.

4) Adjust the variable resistor R53 on RF CONVERTER (refer to Fig. 3-2-4) until the reading of frequency difference becomes 8 MHz ±40 kHz, to repeat the procedure 2), 3).

3-19

Page 76

Section 3 MS2667C

(3) YTF offset voltage adjustment 1

1) Set the spectrum analyzer.

Center frequency : 4 GHz

Span : 400 MHz

2) On the spectrum analyzer, press “single” key.

3) After sweep of the spectrum analyzer is finished, check the X3 voltage (multimeter indicated). This voltage value

is V1.

4) Set the spectrum analyzer’s span to 401 MHz.

5) On the spectrum analyzer, press “single” key.

6) After sweep of the spectrum analyzer is finished, check the X3 voltage (multimeter indicated). This voltage value

is V2.

7) Adjust R287 on the LOCAL-SP2 (refer to Fig. 3-2-4) until the difference voltage between V1 and V2 is below ±1

mV, to repeat the procedure 1) to 6).

(4) YTF offset voltage adjustment 2

1) Set the spectrum analyzer.

Center frequency : 4 GHz

Span : 4 GHz

2) On the spectrum analyzer, press “single” key.

3) After sweep of the spectrum analyzer is finished, check the X21 voltage (multimeter indicated). This voltage

value is V1.

4) Set the spectrum analyzer’s span to 4.01 GHz.

5) On the spectrum analyzer, press “single” key.

6) After sweep of the spectrum analyzer is finished, check the X21 voltage (multimeter indicated). This voltage

value is V2.

7) Adjust R280 on the LOCAL-SP2 (refer to Fig. 3-2-4) until the difference voltage between V1 and V2 is below ±1

mV, to repeat the procedure 1) to 6).

3-20

Page 77

3.2 Troubleshooting

R287

X3

X21

R280

R53, R57

R123

Fig. 3-2-4 The location of adjusters on LOCAL-SP2 and RF CONVERTER

3-21

Page 78

Section 3 MS2667C

(5) YTF tuning DAC adjustment

1) Turn the spectrum analyzer on, while pushing “0” key, and initialize the spectrum analyzer.

2) Set the spectrum analyzer to zero Span.

3) Enter Cal menu by pushing “Shift + 0” keys. Open the second page of the Cal menu, and enter Maintenance menu

with “F6” key. Enter RF/Micro converter maintenance menu with “F2” key, and open the 6th page of the menu

(Press “More” key 5 times).

4) Set YTF Pre-tuning value to 3600 by pushing “F2” key (assigned YTF Pre-tuning function) and data keys. (Press

keys “3”+“6”+“0”+“0”+“Enter”)

5) Adjust the variable resistor R27 on the 2nd CONVERTER (refer to Fig. 3-2-5) to make multimeter reading -3.600

±0.005 Volts.

6) Set YTF Pre-tuning value to 7600 by pushing “F2” key. (Press keys “7”+”6”+“0”+“0”+“Enter”)

7) Adjust the variable resistor R30 on the 2nd CONVERTER (refer to Fig. 3-2-5) to make multimeter reading -7.600

±0.005 Volts.

8) Repeat the procedure 4), 5), 6), 7) until you get the required voltage corresponding to each YTF Pre-tuning value.

(6) YTF tuning adjustment

1) Keep key “Preset” depressed while Switching ON the spectrum analyzer.

2) Wait till sweep of the spectrum analyzer starts and after that Switch OFF the power supply of the spectrum

analyzer.

3) Now once again keep key “0” depressed while switching on the spectrum analyzer.

4) Initialize the spectrum analyzer (Press key “preset”, followed by Key “F1”).

5) Set the spectrum analyzer to :

Center frequency : 3.2 GHz

Span : 200 MHz

6) Set 6769B Signal generator output to :

Frequency : 3.2 GHz

RF level : -10 dBm

7) Enter Cal menu by pushing “Shift” + “0” keys. Open the second page of Cal menu (press the key “more”), and

enter Maintenance menu with “F6” key.

3-22

Page 79

3.2 Troubleshooting

8) Select key “Mainte RF/Micro Conv” (F2), and press the key “more”.

9) Press the key “Main Swp → off” (F2). At this point YTF filter shape appears on the display of the spectrum

analyzer.

10) Adjust R79 on the 2nd Converter (refer to Fig. 3-2-5) so as to shift the center of filter display about 5 MHz below

the center frequency of the display.

5 MHz

AB

10 dB down point

A=B

The center of filter

Center frequency

(3.2 GHz)

11) Set the spectrum analyzer to :

Center frequency : 20 GHz

12) Set 6769B Signal generator output to :

Frequency : 20 GHz

RF level : -10 dBm

13) Enter Cal menu by pushing “Shift” + “0” keys. Open the second page of Cal menu (press the key “more”), and

enter Maintenance menu with “F6” key.

14) Select key “Mainte RF/Micro Conv” (F2), and press the key “more”.

15) Press the key “Main Swp → off” (F2). At this point YTF filter shape appears on the display of the spectrum

analyzer.

16) Wait 1 minuets.

17) Adjust R70 on the 2nd Converter (refer to Fig. 3-2-5) so as to shift the center of filter display to the center

frequency of the display.

3-23

Page 80

Section 3 MS2667C

AB

Center frequency

(20 GHz)

(7) YTF Sweep adjustment

1) Initialize the spectrum analyzer (Press key “preset”, followed by Key “F1”).

10 dB down point

A=B

2) Set 6769B Signal generator output to :

Frequency : 22.2 GHz

RF level : -10 dBm

3) Set Marker of the spectrum analyzer to 22.2 GHz (Press keys “Marker” + “2”+“2”+“.”+“2”+“GHz”) and adjust

R41 on the 2nd Converter (refer to Fig. 3-2-5) to make Marker read maximum.

4) Set Pre-selector bias value to 0 by pressing keys “frequency” + “F5” (Pre-selector Tuning) + “F2” (Manual).

5) Set the marker function to delta marker mode (Press keys “Marker” + “F2”).

6) Change Pre-selector bias value to negative value by the knob on the front panel as to read the level of delta marker

to -6 dB ±1 dB. Now read Pre-selector bias value (P1).

7) Change Pre-selector bias value to positive value by the knob on the front panel as to read the level of delta marker

to -6 dB ±1 dB. Now read Pre-selector bias value (P2).

8) Adjust R41 (rough adjustment) or R42 (close adjustment) on the 2nd Converter (refer to Fig. 3-2-5) until P1 + P2

become below ±8, to repeat the procedure 4) to 8).

3-24

Page 81

3.2 Troubleshooting

Jumper pin X12

R27, R30, R41, R42

R70, R79, X3, X10,

X12

Fig. 3-2-5 The location of adjusters on 2nd CONVERTER

3-25

Page 82

Section 3 MS2667C

3.2.5.3 IF Gain-1 (ATT), IF Gain-2 (AMP) of Internal Mixer Band adjustment

Required equipment :

(1) 6769B swept frequency synthesizer

(2) ML2437A Power sensor

(3) MA2444A Power sensor

Setup :

(1) Connect RF Input of the spectrum analyzer to RF OUTPUT of 6769B.

Procedure :

(1) Keep key “0” depressed while switching on the spectrum analyzer.

(2) Initialize the spectrum analyzer :

1) Enter Preset menu with “preset” key.

2) Initialize the spectrum analyzer completely with “F1” key.

(3) Calibrate the spectrum analyzer using its internal calibration function :

1) Enter Cal menu with “Shift” key and “0” key.

2) Calibrate the spectrum analyzer by pushing “F1” key.

[ Band 1- ]

(4) Set Manual Band to Band 1- :

1) Enter Frequency menu by pushing “Frequency” key, and open its second page with “more” key.

2) Enter Internal mixer Band menu with “F1” (Internal Mix) key.

3) Set manual band to Band 1- by pushing “F3” (Manual Band 1-) key.

(5) Set the spectrum analyzer to :

Center frequency : 4.8 GHz

Span : 200 MHz

Set the 6769B output frequency to 4.8 GHz (CW).

(6) Adjust the 6769B output level to make power meter reading -10 dBm at end of cable feeding the signal to the spectrum

analyzer, and then connect the cable to the spectrum analyzer’s RF Input.

(7) Tune the spectrum analyzer’s pre-selector, using its pre-selector auto tune function :

1) Press “frequency” key.

2) Carry out pre-selector Auto Tune function by pushing “F4” (Pre-selector Auto Tune) key.

(8) Take the marker to signal peak by pushing “Peak Search” key.

3-26

Page 83

3.2 Troubleshooting

(9) Enter RF/Micro Conv maintenance menu, and open its 6th page :

1) Enter Cal menu by pushing “Shift” + “0” keys. Open second page of Cal menu by pushing “more”.

2) Enter maintenance menu with “F6” (Maintenance) key.

3) Enter RF/Micro Converter maintenance menu with “F2” (Mainte RF/Micro conv) key. Open the 6th page of RF/

Micro converter maintenance menu (Press “more” key 5 times).

(10) Set IF Gain-1 and IF Gain-2 values to 0.

1) Press “F4” (IF Gain-1) + “0” + “enter” keys and on display appears a writing “IF Gain1 set to 0”.

2) Press “F5” (IF Gain-2) + “0” + “enter” keys and on display appears a writing “IF Gain2 set to 0”.

(11) Adjust IF Gain 1 and IF Gain 2 so that marker reading becomes -12 dBm ±0.5 dB.

• If the level is lesser than this, the level can be raised by increasing the Number of IF Gain-2 (F5) from 0 to 255 in

single whole numbers.

Press “F5” + “number (0 to 255)” + “enter” keys.

• If the level is greater than this, the level can be lowered by increasing the Number of IF Gain-1 (F4) from 0 to 255

in single whole numbers.

Press “F4” + “number (0 to 255)” + “enter” keys.

[ Band 1+ ]

(12) Set Manual Band to Band 1+ :

1) Enter Frequency menu by pushing “Frequency” key, and open its second page with “more” key.

2) Enter Internal mixer Band menu with “F1” (Internal Mix) key.

3) Set manual band to Band 1+ by pushing “F4” (Manual Band 1+) key.

(13) Set the spectrum analyzer to :

Center frequency : 7.25 GHz

Span : 200 MHz

Set the 6769B output frequency to 7.25 GHz (CW).

(14) Adjust the 6769B output level to make power meter reading -10 dBm at end of cable feeding the signal to the spectrum

analyzer, and then connect the cable to the spectrum analyzer’s RF Input.

(15) Tune the spectrum analyzer’s pre-selector (refer to procedure (7)).

(16) Enter RF/Micro Conv maintenance menu, and open its 6th page (refer to procedure (9)).

(17) Set IF Gain-1 and IF Gain-2 values to 0 (refer to procedure (10)).

(18) Adjust IF Gain 1 and IF Gain 2 so that marker reading becomes -12 dBm ±0.5 dB (refer to procedure (11)).

3-27

Page 84

Section 3 MS2667C

[ Band 2+ ]

(19) Set Manual Band to Band 2+ :

1) Enter Frequency menu by pushing “Frequency” key, and open its second page with “more” key.

2) Enter Internal mixer Band menu with “F1” (Internal Mix) key and open its second page with “more” key.

3) Set manual band to Band 2+ by pushing “F2” (Manual Band 2+) key.

(20) Set the spectrum analyzer to :

Center frequency : 11.65 GHz

Span : 200 MHz

Set the 6769B output frequency to 11.65 GHz (CW).

(21) Adjust the 6769B output level to make power meter reading -10 dBm at end of cable feeding the signal to the spectrum

analyzer, and then connect the cable to the spectrum analyzer’s RF Input.

(22) Tune the spectrum analyzer’s pre-selector (refer to procedure (7)).

(23) Enter RF/Micro Conv maintenance menu, and open its 6th page (refer to procedure (9)).

(24) Set IF Gain-1 and IF Gain-2 values to 0 (refer to procedure (10)).

(25) Adjust IF Gain 1 and IF Gain 2 so that marker reading becomes -12 dBm ±0.5 dB (refer to procedure (11)).

[ Band 3+ ]

(26) Set Manual Band to Band 3+ :

1) Enter Frequency menu by pushing “Frequency” key, and open its second page with “more” key.

2) Enter Internal mixer Band menu with “F1” (Internal Mix) key and open its second page with “more” key.

3) Set manual band to Band 3+ by pushing “F3” (Manual Band 3+) key.

(27) Set the spectrum analyzer to :

Center frequency : 18.8 GHz

Span : 200 MHz

Set the 6769B output frequency to 18.8 GHz (CW).

(28) Adjust the 6769B output level to make power meter reading -10 dBm at end of cable feeding the signal to the spectrum

analyzer, and then connect the cable to the spectrum analyzer’s RF Input.

(29) Tune the spectrum analyzer’s pre-selector (refer to procedure (7)).

(30) Enter RF/Micro Conv maintenance menu, and open its 6th page (refer to procedure (9)).

(31) Set IF Gain-1 and IF Gain-2 values to 0 (refer to procedure (10)).

(32) Adjust IF Gain 1 and IF Gain 2 so that marker reading becomes -12 dBm ±0.5 dB (refer to procedure (11)).

3-28

Page 85

3.2 Troubleshooting

[ Band 4+ ]

(33) Set Manual Band to Band 4+ :

1) Enter Frequency menu by pushing “Frequency” key, and open its second page with “more” key.

2) Enter Internal mixer Band menu with “F1” (Internal Mix) key and open its second page with “more” key.

3) Set manual band to Band 4+ by pushing “F4” (Manual Band 4+) key.

(34) Set the spectrum analyzer to :

Center frequency : 26.15 GHz

Span : 200 MHz

Set the 6769B output frequency to 26.15 GHz (CW).

(35) Adjust the 6769B output level to make power meter reading -10 dBm at end of cable feeding the signal to the spectrum

analyzer, and then connect the cable to the spectrum analyzer’s RF Input.